Ransburg A11925-00 User Manual

SERVICE MANUAL

LN-9256-07.4LN-9256-07.4

LN-9256-07.4

LN-9256-07.4LN-9256-07.4

(Replaces LN-9256-07.3)

July-2012

SERIALSERIAL

SERIAL

SERIALSERIAL

A A

TT

A

T

A A

TT

OMIZER MODULEOMIZER MODULE

OMIZER MODULE

OMIZER MODULEOMIZER MODULE

MODEL: A1MODEL: A1

MODEL: A1

MODEL: A1MODEL: A1

1925-001925-00

1925-00

1925-001925-00

IMPORIMPOR

IMPOR

IMPORIMPOR

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,

carefully read SAFETY PRECAUTIONS,carefully read SAFETY PRECAUTIONS,

starting on page 1, and all instructions in thisstarting on page 1, and all instructions in this

starting on page 1, and all instructions in this

starting on page 1, and all instructions in thisstarting on page 1, and all instructions in this

manual. Keep this Service Manual for futuremanual. Keep this Service Manual for future

manual. Keep this Service Manual for future

manual. Keep this Service Manual for futuremanual. Keep this Service Manual for future

reference.reference.

reference.

reference.reference.

TT

ANTANT

T

ANT

TT

ANTANT

: Before using this equipment,: Before using this equipment,

: Before using this equipment,

: Before using this equipment,: Before using this equipment,

Service Manual Price:Service Manual Price:

Service Manual Price: €

Service Manual Price:Service Manual Price:

15.00 (Euro)15.00 (Euro)

15.00 (Euro)

15.00 (Euro)15.00 (Euro)

$20.00 (U.S.)$20.00 (U.S.)

$20.00 (U.S.)

$20.00 (U.S.)$20.00 (U.S.)

NOTE:NOTE:

NOTE: This service manual has been superceded from service manual number

NOTE:NOTE:

manual number

the back cover of this manual.

LN-9256-07.4LN-9256-07.4

LN-9256-07.4. Reasons for this change are noted under “Manual Change Summary” inside

LN-9256-07.4LN-9256-07.4

LN-9256-07.3 LN-9256-07.3

LN-9256-07.3 to service

LN-9256-07.3 LN-9256-07.3

LN-9256-07.4

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

SAFETY:SAFETY:

SAFETY:

SAFETY:SAFETY:

Serial Atomizer Module - Contents

PAGEPAGE

PAGE

PAGEPAGE

1-61-6

1-6

1-61-6

SAFETY PRECAUTIONS..........................................................................................................

HAZARDS / SAFEGUARDS......................................................................................................

INTRODUCTION:INTRODUCTION:

INTRODUCTION:

INTRODUCTION:INTRODUCTION:

GENERAL DESCRIPTION........................................................................................................

SPECIFICATIONS......................................................................................................................

INSTALLATION:INSTALLATION:

INSTALLATION:

INSTALLATION:INSTALLATION:

LOCATION..................................................................................................................................

CONNECTIONS.........................................................................................................................

OPERATION:OPERATION:

OPERATION:

OPERATION:OPERATION:

SPEED CONTROL.....................................................................................................................

79128-00 SERIAL ATOMIZER SPEED SELECT .....................................................................

AUTOMATIC SHUTDOWN........................................................................................................

OTHER MODES.........................................................................................................................

SIGNAL I/O.................................................................................................................................

MOTHERBOARDS.....................................................................................................................

SPEED CONTROL SYSTEM.....................................................................................................

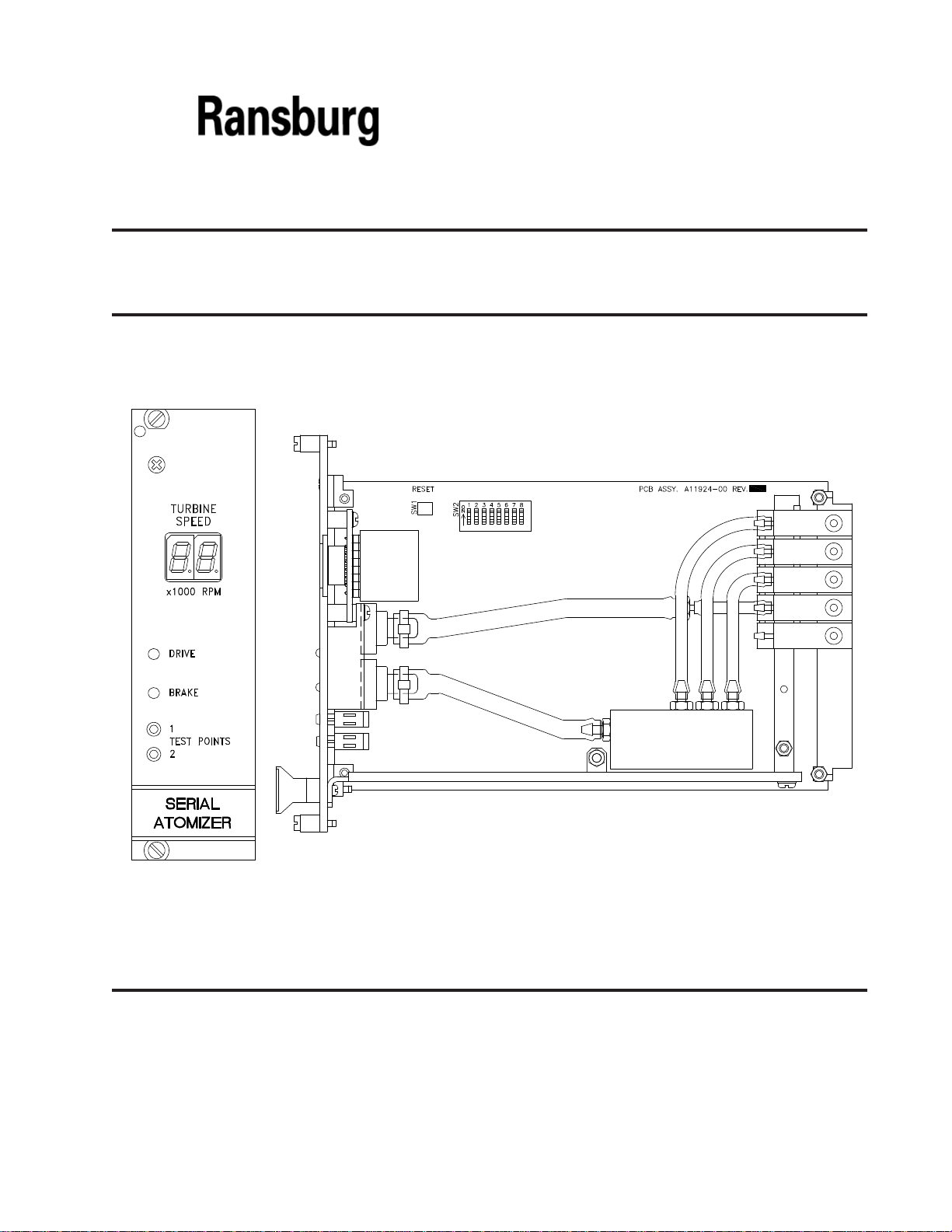

SIDE VIEW..................................................................................................................................

DIP SWITCH SETTINGS...........................................................................................................

1

2-5

77

7

77

7

7

88

8

88

8

8

9-159-15

9-15

9-159-15

9

10

11

11

11-12

13

14

14

15

MAINTENANCE:MAINTENANCE:

MAINTENANCE:

MAINTENANCE:MAINTENANCE:

SERIAL ATOMIZER MODULE...................................................................................................

STATUS CODE DISPLAY..........................................................................................................

TROUBLESHOOTING / TROUBLESHOOTING GUIDE CHART...........................................

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

PARTS IDENTIFICATION:

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

PARTS LIST................................................................................................................................

POWER CONNECTIONS TO MOTHERBOARD TB1.............................................................

TRANSCEIVER CONNECTIONS TO MOTHERBOARD TB(X)..............................................

WARRANTY POLICIES:WARRANTY POLICIES:

WARRANTY POLICIES:

WARRANTY POLICIES:WARRANTY POLICIES:

LIMITED WARRANTY................................................................................................................

LN-9256-07.4

16-1816-18

16-18

16-1816-18

16

16

17-18

19-2019-20

19-20

19-2019-20

19

19

19-20

2121

21

2121

21

Serial Atomizer Module - Safety

SAFETY

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature

for your Ransburg products. This manual contains

information that is important for you to know and

understand. This information relates to USER

SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this

information, we use the following symbols. Please

pay particular attention to these sections.

A WARNING!A WARNING!

A WARNING!

A WARNING!A WARNING!

you to a situation that might cause seri-you to a situation that might cause seri-

you to a situation that might cause seri-

you to a situation that might cause seri-you to a situation that might cause serious injury if instructions are not followed.ous injury if instructions are not followed.

ous injury if instructions are not followed.

ous injury if instructions are not followed.ous injury if instructions are not followed.

A CAUTION! states information that tellsA CAUTION! states information that tells

A CAUTION! states information that tells

A CAUTION! states information that tellsA CAUTION! states information that tells

how to prevent damage to equipment orhow to prevent damage to equipment or

how to prevent damage to equipment or

how to prevent damage to equipment orhow to prevent damage to equipment or

how to avoid a situation that might causehow to avoid a situation that might cause

how to avoid a situation that might cause

how to avoid a situation that might causehow to avoid a situation that might cause

minor injury.minor injury.

minor injury.

minor injury.minor injury.

A NOTE is information relevant to theA NOTE is information relevant to the

A NOTE is information relevant to the

A NOTE is information relevant to theA NOTE is information relevant to the

procedure in progress.procedure in progress.

procedure in progress.

procedure in progress.procedure in progress.

While this manual lists standard specifications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements, etc.,

make such variations inevitable. Compare this

manual with your system installation drawings

and appropriate Ransburg equipment manuals to

reconcile such differences.

states information to alertstates information to alert

states information to alert

states information to alertstates information to alert

> The user

with the Safety Section in this manual and

the Ransburg safety literature therein

identified.

> This manual

oughly understood by

operate, clean or maintain this equipment!

Special care should be taken to ensure that

WARNINGSWARNINGS

the

WARNINGS and safety requirements

WARNINGSWARNINGS

for operating and servicing the equipment

are followed. The user should be aware of

and adhere to

codes and ordinances as well as

33 SAFETY STANDARD, 33 SAFETY STANDARD,

33 SAFETY STANDARD, prior to

33 SAFETY STANDARD, 33 SAFETY STANDARD,

installing, operating, and/or servicing this

equipment.

MUSTMUST

MUST read and be familiar

MUSTMUST

MUSTMUST

MUST be read and thor-

MUSTMUST

ALLALL

ALL personnel who

ALLALL

ALLALL

ALL local building and fire

ALLALL

W A R N I N GW A R N I N G

W A R N I N G

W A R N I N GW A R N I N G

!!

!

!!

NFPA-NFPA-

NFPA-

NFPA-NFPA-

>The hazards shown on the following page

may occur during the normal use of this

equipment. Please read the hazard chart

beginning on page 2.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efficient operation,

longer trouble-free service and faster, easier

troubleshooting. If you do not have the manuals

and safety literature for your Ransburg system,

contact your local Ransburg representative or

Ransburg.

11

1

11

LN-9256-07.4

Serial Atomizer Module - Safety

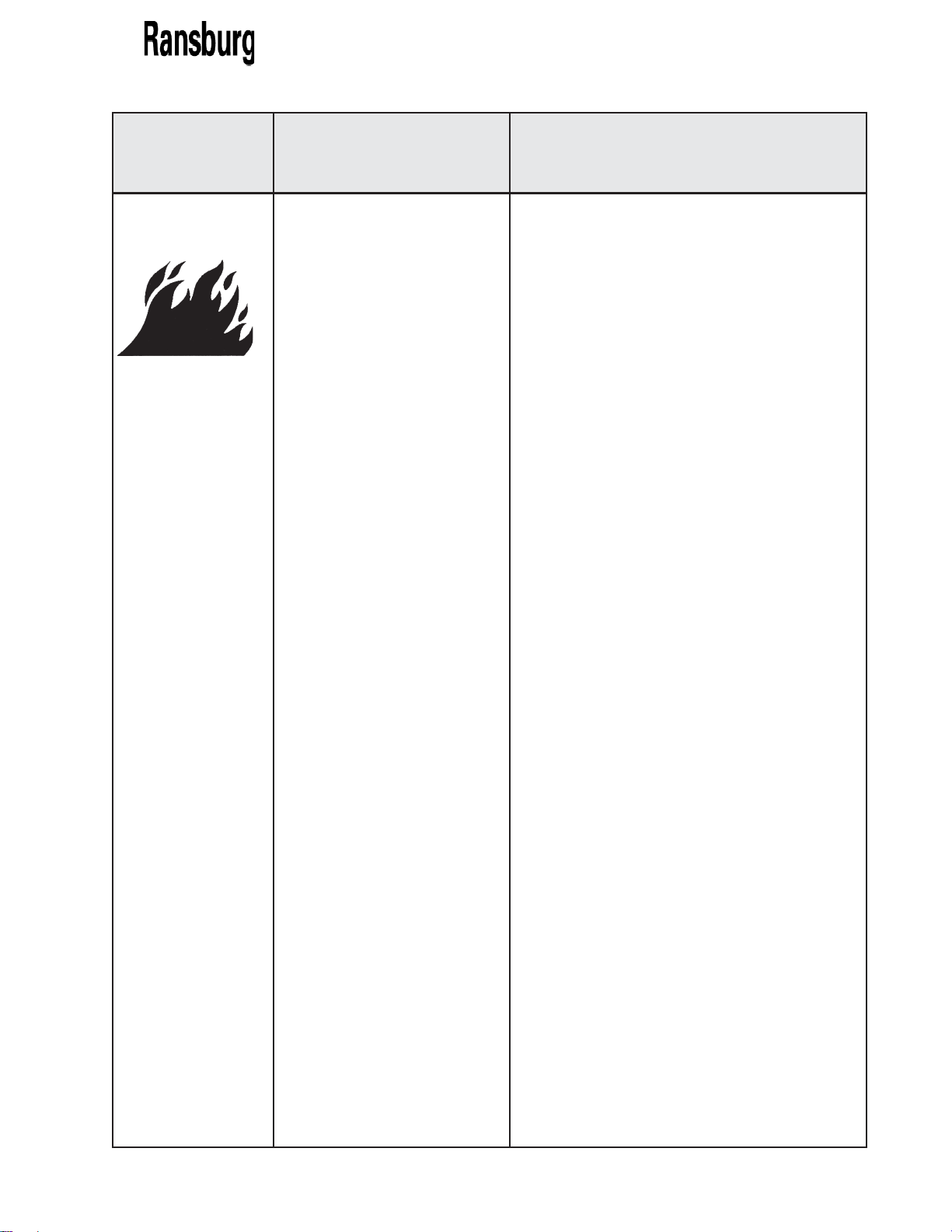

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Spray AreaSpray Area

Spray Area

Spray AreaSpray Area

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate operation

and maintenance procedures will

cause a fire hazard.

Protection against inadvertent

arcing that is capable of causing

fire or explosion is lost if any safety

interlocks are disabled during

operation. Frequent power supply

shutdown indicates a problem in

the system requiring correction.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, flushing or maintenance.

When using solvents for cleaning:

Those used for equipment flushing should have flash

points equal to or higher than those of the coating

material.

Those used for general cleaning must have flash

points above 100

o

F (37.8oC).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, and local codes. In

addition, ventilation must be maintained during

cleaning operations using flammable or combustible

solvents.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only as

instructed.

Non-factory replacement parts or unauthorized

equipment modifications may cause fire or injury.

If used, the key switch bypass is intended for use only

during setup operations. Production should never be

done with safety interlocks disabled.

Never use equipment intended for use in waterborne

installations to spray solvent based materials.

The paint process and equipment should be set up

and operated in accordance with NFPA-33, NEC, and

OSHA requirements.

LN-9256-07.4

22

2

22

Serial Atomizer Module - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

General Use andGeneral Use and

General Use and

General Use andGeneral Use and

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

ElectricalElectrical

Electrical

ElectricalElectrical

EquipmentEquipment

Equipment

EquipmentEquipment

Improper operation or maintenance

may create a hazard.

Personnel must be properly trained

in the use of this equipment.

High voltage equipment is utilized. Arcing in areas of flammable or combustible materials

may occur. Personnel are exposed to high voltage during

operation and maintenance.

Protection against inadvertent

arcing that may cause a fire or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shutdown indicates a problem in the

system which requires correction.

Personnel must be given training in accordance with

the requirements of NFPA-33.

Instructions and safety precautions must be read

and understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, fire protection, operation

maintenance, and housekeeping. Reference OSHA,

NFPA-33, and your insurance company requirements.

The power supply, optional remote control cabinet,

and all other electrical equipment must be located

outside Class I or II, Division 1 and 2 hazardous

areas. Refer to NFPA-33.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of flammable or combustible material.

Testing may require high voltage to be on, but

only as instructed.

Production should never be done with the safety

circuits disabled.

ExplosionExplosion

Explosion

ExplosionExplosion

Hazard /Hazard /

Hazard /

Hazard /Hazard /

IncompatibleIncompatible

Incompatible

IncompatibleIncompatible

MaterialsMaterials

Materials

MaterialsMaterials

33

3

33

An electrical arc can ignite coating materials and cause a fire or

explosion.

Halogenated hydrocarbon solvents

for example: methylene chloride

and 1,1,1,-Trichloroethane are not

chemically compatible with the

aluminum that might be used in

many system components. The

chemical reaction caused by these

solvents reacting with aluminum

can become violent and lead to an

equipment explosion.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum equipment during spraying, flushing, or cleaning. Read

the label or data sheet for the material you intend

to spray. If in doubt as to whether or not a coating

or cleaning material is compatible, contact your

material supplier. Any other type of solvent may

be used with aluminum equipment.

LN-9256-07.4

Serial Atomizer Module - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Toxic SubstancesToxic Substances

Toxic Substances

Toxic SubstancesToxic Substances

Spray Area /Spray Area /

Spray Area /

Spray Area /Spray Area /

High VoltageHigh Voltage

High Voltage

High VoltageHigh Voltage

EquipmentEquipment

Equipment

EquipmentEquipment

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Certain material may be harmful if

inhaled, or if there is contact with

the skin.

This is a high voltage device that

can produce electrical arcs capable

of igniting coating materials.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air

free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance

of inhaling sprayed materials. The mask must be

compatible with the material being spray-ed and its

concentration. Equipment must be as prescribed by

an industrial hygienist or safety expert, and be

NIOSH approved.

Parts being sprayed must be supported on conveyors

or hangers and be grounded. The resistance between

the part and ground must not exceed 1 megohm.

(Reference NFPA-33)

A safe distance must be maintained between the

parts being coated and the atomizer bell. A distance

of at least 1-inch for each 10kV of power supply

output voltage is required at all times.

Personnel Safety/Personnel Safety/

Personnel Safety/

Personnel Safety/Personnel Safety/

MechanicalMechanical

Mechanical

MechanicalMechanical

HazardsHazards

Hazards

HazardsHazards

The disk atomizer can rotate at

speeds up to 40,000 rpm. At these

speeds, the edge of the applicator

can easily cut into skin. Loose

articles of clothing can also be

caught by the rotating bell.

Parts must be supported so that they will not swing

and reduce the clearance specified above.

All electrically conductive objects in the spray area,

with the exception of those objects required by the

process to be at high voltage, must be grounded.

Unless specifically approved for use in hazardous

locations, the power supply and other electrical

equipment must not be used in Class I, Division 1 or

2 locations.

Personnel must stay clear of the bell whenever it is

rotating.

Before touching the bell, the turbine air must be shut

off.

If the disk has been rotating, allow at least three

minutes for it to come to a complete stop before

touching it.

LN-9256-07.4

44

4

44

Serial Atomizer Module - Safety

AREAAREA

AREA

AREAAREA

Tells where hazards

may occur.

Personnel SafetyPersonnel Safety

Personnel Safety

Personnel SafetyPersonnel Safety

Intended UseIntended Use

Intended Use

Intended UseIntended Use

HAZARDHAZARD

HAZARD

HAZARDHAZARD

Tells what the hazard is.

Skin puncturing by sharp electrode. Take precautions to see that flesh is not punctured by

Using coating materials and/or

cleaning and flushing solvents

which have flash points below 100oF

(37.8oC) may cause a fire hazard.

SAFEGUARDSSAFEGUARDS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

sharp electrode.

This system is intended for use with waterborne

coating formulations only. As stated in this manual,

this system can also be used for solventborne coatings.

55

5

55

LN-9256-07.4

Loading...

Loading...