SERVICE MANUAL

CS-02-01.10

(Replaces CS-02-01.9)

January - 2013

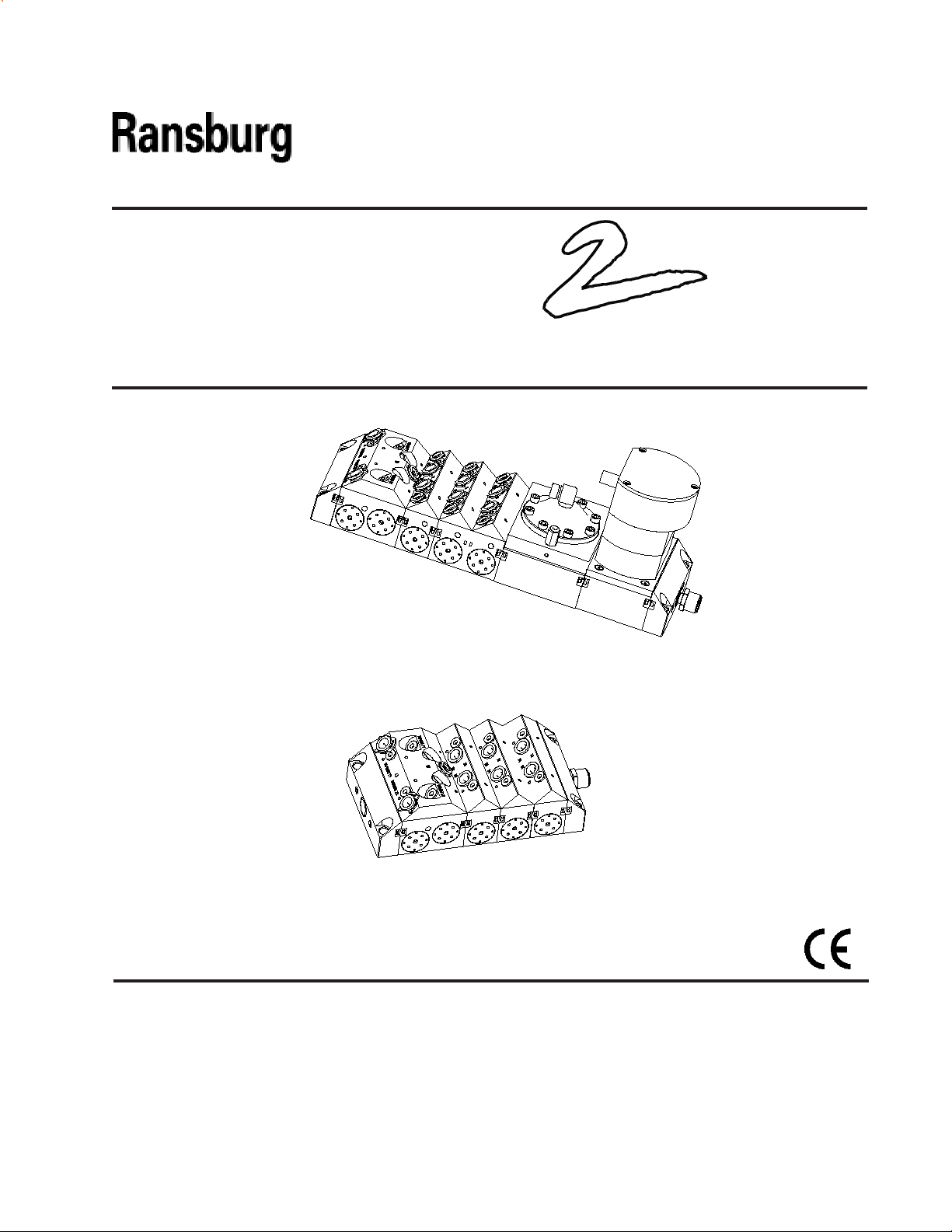

MCV

COLLET SERIES

MODULAR COLOR CHANGER

MODELS: A10800XX Metric

A11077-XX - English

IMPORTANT: Before using this equipment, carefully

read SAFETY PRECAUTIONS, starting on page 1, and all

instructions in this manual. Keep this Service Manual

for future reference.

Service Manual Price: $30.00 (U.S.)

NOTE: This manual has been changed from CS-02-01.9 to revision CS-02-01.10. Reasons for

this change are noted under “Manual Change Summary” inside the back cover of this

manual.

CONTENTS

MCV 2 Collet Series Color Changer - Contents

PAGE

SAFETY:

SAFETY PRECAUTIONS...........................................................................................................

HAZARDS / SAFEGUARDS.......................................................................................................

INTRODUCTION:

DESCRIPTIONS.........................................................................................................................

SPECIFICATIONS......................................................................................................................

REGULATOR PERFORMANCE.................................................................................................

MCV 2 PRE-ENGINEERED COLOR CHANGER

ASSEMBLIES / PARTS LIST ..... ...............................................................................................

MCV 2 PRE-ENGINEERED COLOR CHANGER

MODEL IDENTIFICATION (METRIC) / PARTS LIST................................................................

MCV 2 PRE-ENGINEERED COLOR CHANGER

ASSEMBLIES - PARTS LIST (ENGLISH)..................................................................................

MCV 2 PRE-ENGINEERED COLOR CHANGER

MODEL IDENTIFICATION (ENGLISH) / PARTS LIST..............................................................

INSTALLATION:

MCV 2 INSTALLATION PROCEDURES....................................................................................

1-4

1

2-3

5-14

5

5

6

7-8

8-10

11

11-13

15-16

15

OPERATION:

OPERATING.............................................................................................................................

DIMENSIONS - METRIC (FRACTION) AND PROPOSED

HOOK-UP FOR 8-COLORS......................................................................................................

MAINTENANCE:

GENERAL MAINTENANCE........................................................................................................

REMOVING AND REINSTALLING A VALVE BLOCK

FROM A STACK.........................................................................................................................

REGULATOR DISASSEMBLY / REASSEMBLY

PROCEDURE.............................................................................................................................

TEST AND CHECKOUT PROCEDURE FOR

COLOR CHANGER....................................................................................................................

(Continued On Next Page)

17-18

17

18

19-26

19-21

21

22-23

24-25

MCV 2 Collet Series Color Changer - Contents

CONTENTS (Cont.)

PARTS IDENTIFICATION :

A10800 (METRIC) AND A11077 (ENGLISH) MCV 2

COLOR CHANGER ASSEMBLIES / PARTS LIST....................................................................

A10717 (METRIC) AND A11080 (ENGLISH) BELL /

BLOCK WASH ASSEMBLIES / PARTS LIST............................................................................

A11788 BELL / BLOCK WASH ASSEMBLY (METRIC) PARTS LIST.......................................

A11080 BELL / BLOCK WASH ASSEMBLY (ENGLISH) PARTS LIST.....................................

A10727 (METRIC) AND A10953 (ENGLISH) 2-COLOR

VALVE - CIRCULATING ASSEMBLY / PARTS LIST................................................................

A10726 (METRIC) AND A10954 (ENGLISH) 2-COLOR

VALVE - DAISY CHAIN / PARTS LIST......................................................................................

A10733 (METRIC) AND A10955 (ENGLISH) 2-COLOR

VALVE - DEAD HEAD / PARTS LIST........................................................................................

A10729 (METRIC) AND A10960 (ENGLISH) 4-COLOR

VALVE CIRCULATING ASSEMBLY / PARTS LIST..................................................................

A10728 (METRIC) AND A10961 (ENGLISH) 4-COLOR

VALVE - DAISY CHAIN ASSEMBLY / PARTS LIST..................................................................

A10732 (METRIC) AND A10962 (ENGLISH) 4-COLOR

VALVE - DEAD HEAD ASSEMBLY / PARTS LIST....................................................................

A10725 REGULATOR ASSEMBLY / PARTS LIST....................................................................

A10720-01/02 FLOW METER BLOCK ASSEMBLY / PARTS LIST...........................................

A10826-XX STAND ALONE BELL / BLOCK WASH ASSEMBLY

(METRIC & ENGLISH) / PARTS LIST.......................................................................................

A10827-00 STAND ALONE REGULATOR ASSEMBLY / PARTS LIST....................................

A10828-XX STAND ALONE FLOW METER ASSEMBLY

(RF-1 FIBER OPTIC) / PARTS LIST..........................................................................................

A10999-00 STAND ALONE FLOW METER ASSEMBLY

(AW) / PARTS LIST....................................................................................................................

78949-00 VALVE AND 77367-00 SEAT REPLACEMENT PARTS...........................................

77620-00 VALVE PLUG KIT (OPTIONAL).................................................................................

RECOMMENDED SPARE PARTS ...........................................................................................

PAGE

27-57

27-31

32-33

34

35

37-28

39-40

41-42

43-44

45-46

47-48

49-50

51

52

53

54

55

56

56

57

WARRANTY POLICIES:

LIMITED WARRANTY.................................................................................................................

59

59

MCV 2 Collet Series Color Changer - Contents

MCV 2 Collet Series Color Changer - Safety

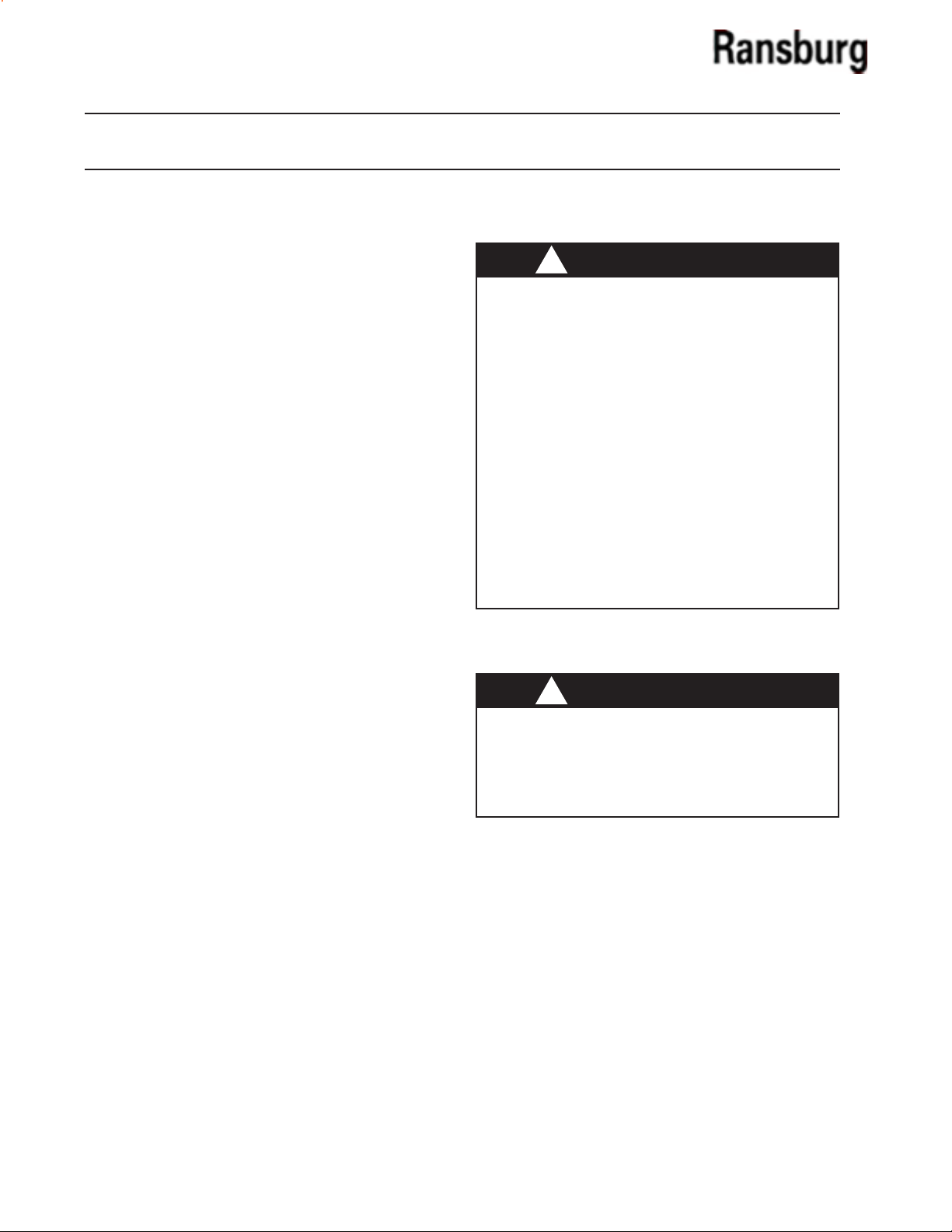

SAFETY

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any Ransburg electrostatic coating system, read and understand all of the technical and safety literature for your

Ransburg products. This manual contains information

that is important for you to know and understand. This

information relates to USER SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this

information, we use the following symbols. Please

pay particular attention to these sections.

A WARNING! states information to alert you to a situation that might cause serious injury if instructions

are not followed.

A CAUTION! states information that tells how to

prevent damage to equipment or how to avoid a

situation that might cause minor injury.

A NOTE is information relevant to the procedure in

progress.

While this manual lists standard specications and

service procedures, some minor deviations may be

found between this literature and your equipment.

Dierences in local codes and plant requirements,

material delivery requirements, etc., make such

variations inevitable. Compare this manual with

your system installation drawings and appropriate

Ransburg equipment manuals to reconcile such

dierences.

!

> The user MUST read and be familiar with the

Safety Section in this manual and the Ransburg

safety literature therein identied.

> This manual MUST be read and thoroughly

understood by ALL personnel who operate,

clean or maintain this equipment! Special care

should be taken to ensure that the WARNINGS

and safety requirements for operating and

servicing the equipment are followed. The

user should be aware of and adhere to ALL

local building and re codes and ordinances

as well as NFPA-33 SAFETY STANDARD, prior

to installing, operating, and/or servicing this

equipment.

!

> The hazards shown on the following page

may occur during the normal use of this equipment. Please read the hazard chart beginning

on page 2.

W A R N I N G

W A R N I N G

Careful study and continued use of this manual will

provide a better understanding of the equipment and

process, resulting in more ecient operation, longer

trouble-free service and faster, easier troubleshooting.

If you do not have the manuals and safety literature

for your Ransburg system, contact your local Ransburg

representative or Ransburg.

1 CS-02-01.10

MCV 2 Collet Series Color Changer - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate operation and maintenance procedures

will cause a re hazard.

Protection against inadvertent

arcing that is capable of causing

re or explosion is lost if any safety

interlocks are disabled during

operation. Frequent power supply

shutdown indicates a problem in

the system requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

spray area and tested periodically.

Spray areas must be kept clean to prevent the accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must

be turned o prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

Those used for equipment ushing should have ash

points equal to or higher than those of the coating

material.

Those used for general cleaning must have ash

points above 100oF (37.8oC).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, and local codes. In

addition, ventilation must be maintained during

cleaning operations using ammable or combustible

solvents.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only

as instructed.

Non-factory replacement parts or unauthorized

equipment modications may cause re or injury.

If used, the key switch bypass is intended for use only

during setup operations. Production should never

be done with safety interlocks disabled.

Never use equipment intended for use in waterborne installations to spray solvent based materials.

The paint process and equipment should be set up

and operated in accordance with NFPA-33, NEC,

and OSHA requirements.

CS-02-01.10

2

MCV 2 Collet Series Color Changer - Safety

AREA

Tells where hazards

may occur.

Ge ne r al Us e an d

Maintenance

Electrical

Equipment

HAZARD

Tells what the hazard is.

Improper operation or mainte nance may create a hazard.

Personnel must be properly trained

in the use of this equipment.

High voltage equipment is utilized.

Arcing in areas of flammable or

combustible materials may occur.

Personnel are exposed to high

voltage during operation and maintenance.

Protection against inadver tent

arcing that may cause a re or explosion is lost if safety circuits are

disabled during operation.

Frequent power supply shut-down

indicates a problem in the system

which requires correction.

An electrical arc can ignite coating materials and cause a fire or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Personnel must be given training in accordance with

the requirements of NFPA-33.

Instructions and safety precautions must be read

and understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, re protection, operation maintenance, and housekeeping. Reference

OSHA, NFPA-33, and your insurance company

requirements.

The power supply, optional remote control

cabinet, and all other electrical equipment must

be located outside Class I or II, Division 1 and 2

hazardous areas. Refer to NFPA-33.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of ammable or combustible material.

Testing may require high voltage to be on, but

only as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Explosion Hazard /

Incompatible

Materials

3

Halogenated hydrocarbon solvents for example: methylene

chloride and 1,1,1,-Trichloroethane are not chemically compatible with the aluminum that

might be used in many system

components. The chemical reaction caused by these solvents

reacting with aluminum can

become violent and lead to an

equipment explosion.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum equipment during spraying, ushing, or cleaning. Read

the label or data sheet for the material you intend

to spray. If in doubt as to whether or not a coating

or cleaning material is compatible, contact your

material supplier. Any other type of solvent may

be used with aluminum equipment.

CS-02-01.10

NOTES

MCV 2 Collet Series Color Changer - Safety

CS-02-01.10

4

MCV 2 Collet Series Color Changer - Introduction

INTRODUCTION

DESCRIPTIONS

The MCV 2 Collet Series Modular Color Changer is a

material valve stack used to control material ow to

an applicator or other material supply equipment.

The stack assembly is made up of several sub-assembled stacks which are then connected together.

The assemblies are available in both Metric and

English tube sizes.

A description of stacks are as follows:

• Bell Wash Module - This may be attached

to the main stack.

• Stand-Alone Bell Wash Module - These may

be mounted separately away from the stack

assembly. An external outlet port is included

to provide a connection to an applicator or

other such device.

• Two and Four Color Block Modules. Both

available in 3 styles: Circulating, Daisy

Chain, and Dead Head.

• Inline DR-2 Regulator with performance

matching the industry standard

Ransburg DR-1 Regulator.

• Flow Meter Module for use with bottom

ported uid ow meters.

SPECIFICATIONS

Electrical / Physical

Operating Pressure:

Fluid: 300 psi maximum

(20.68 bar)

Air: 100 psi maximum

(7 bar)

Fluid Tube Metric:

(Inlet) 10mm ODT

(Circulation) 8mm ODT

(Bell wash) 6mm & 8mm ODT

Fluid Tube Fraction:

(Inlet) 3/8-inch ODT

(Circulation) 5/16-inch ODT

(Bell wash) 5/16-inch ODT

Air Tube Fraction Metric:

(Actuation) 5/32-inch

(4mm) ODT Inlet

Air Actuating Pressure: 75-120 psi

(5.2-8.3 bar)

Maximum Number of Colors: 32

Construction Materials:

Stainless Steel

UHMW

DR-2 Regulator

The 78949-00 microvalve was designed to trigger

up to 2-million cycles. The uid and air sections are

separated by a weep port to prevent contamination

between air and uid.

5

Air Pressures: Variable by Control

(Manual or Automatic)

100 psi (7 bar max.)

Fluid Input: 300 psi (20.7 bar max.)

(10 psi min. above output

pressure)

Fluid Output: Variable by Ratio

Pneumatic Connections

Air Pilot: 1/8-inch NPT (F) Thread

(Cap)

#10-32 (F) Thread (Plate)

Volume of Paint Held

Within Regulator: 5 cc

CS-02-01.10

MCV 2 Collet Series Color Changer - Introduction

0

200

400

600

800

1000

1200

1400

1600

1800

2000

0 10 20 30 40 50 60 70 80 90 100

Flow Rate (cc/min)

Pilot Pressure (psig)

Adjustment Sensitivity-DR-2 Regulator

Pilot Pressure vs. Flow Rate100 psig inlet

22 Sec Ford #4 Viscosity

1/8 Orifice

3/32 orifice

1/16 Orifice

0

200

400

600

800

1000

1200

0 10 20 30 40 50 60 70 80 90 100

Flow Rate (cc/min)

Pilot Pressure (psig)

Adjustment Sensitivity-DR-2 Regulator

.093 Feed Tube

22 Sec. Ford #4 Viscosity

100 psig inlet

200 psig inlet

300 psig inlet

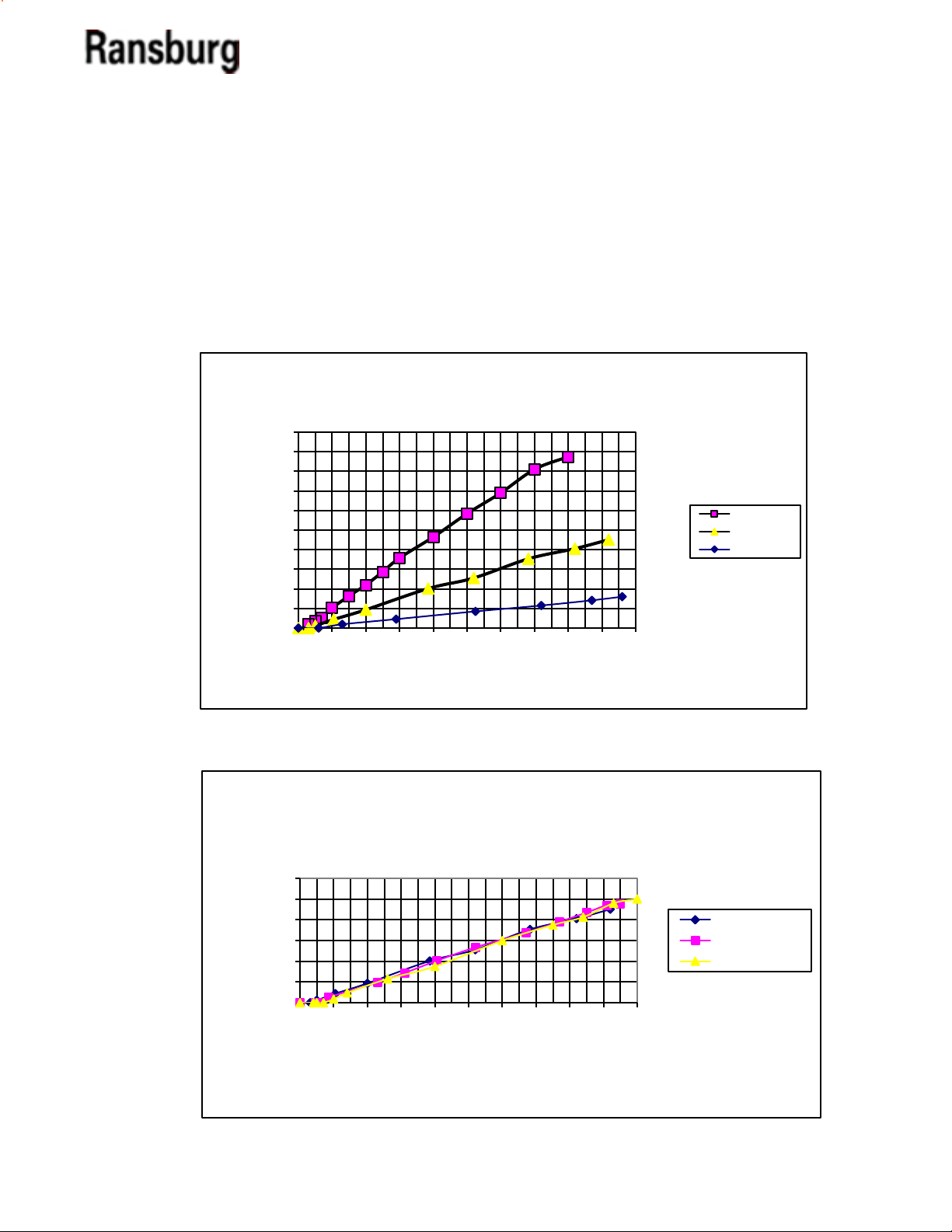

REGULATOR PERFORMANCE

The A10725 regulator performance matches that

of the stand-alone DR-1. Figures X and Y show the

performance curves associated with the A10725

regulator.

CS-02-01.10

Figure X

Figure Y

6

MCV 2 Collet Series Color Changer - Introduction

O-RINGS INCLUDED WITH EACH BLOCK ASY.

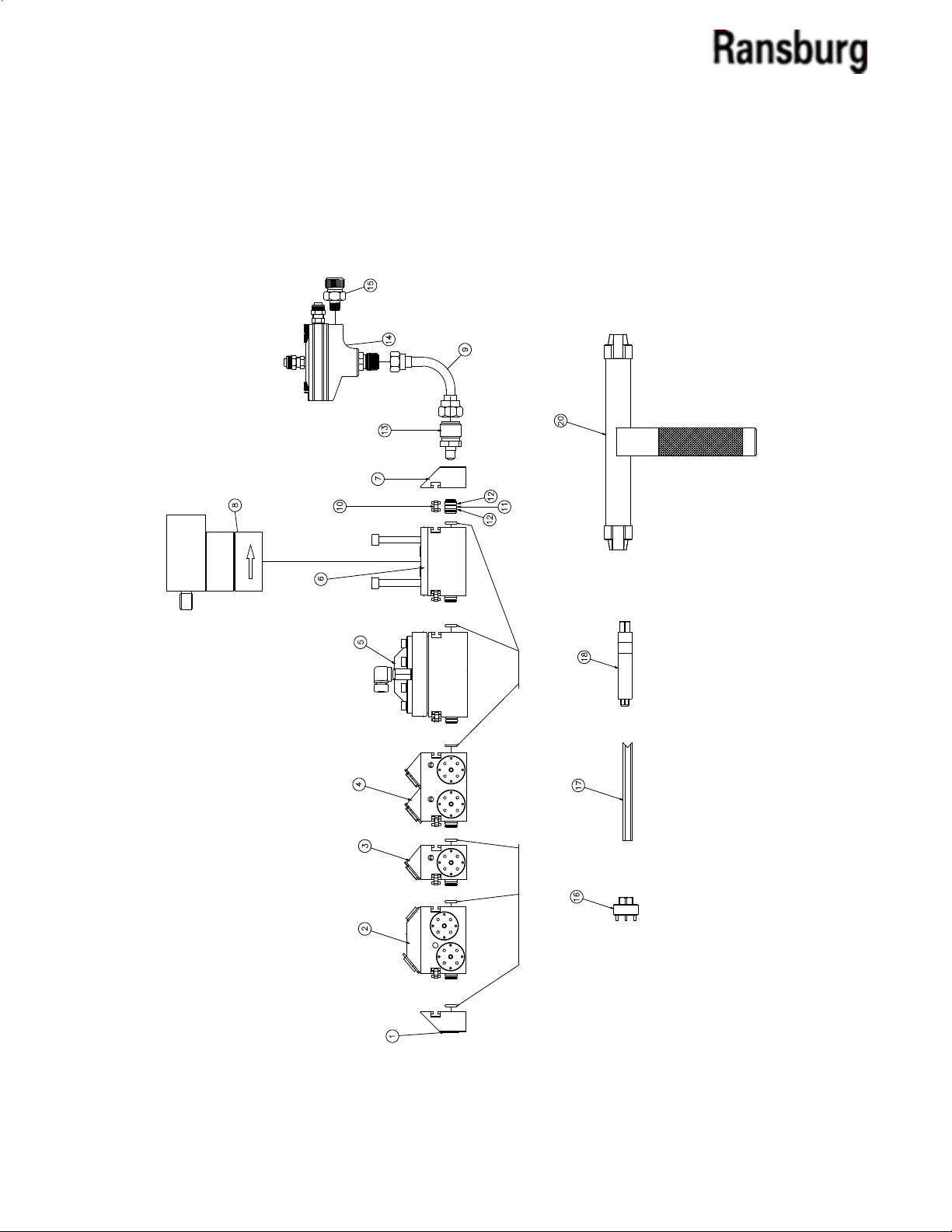

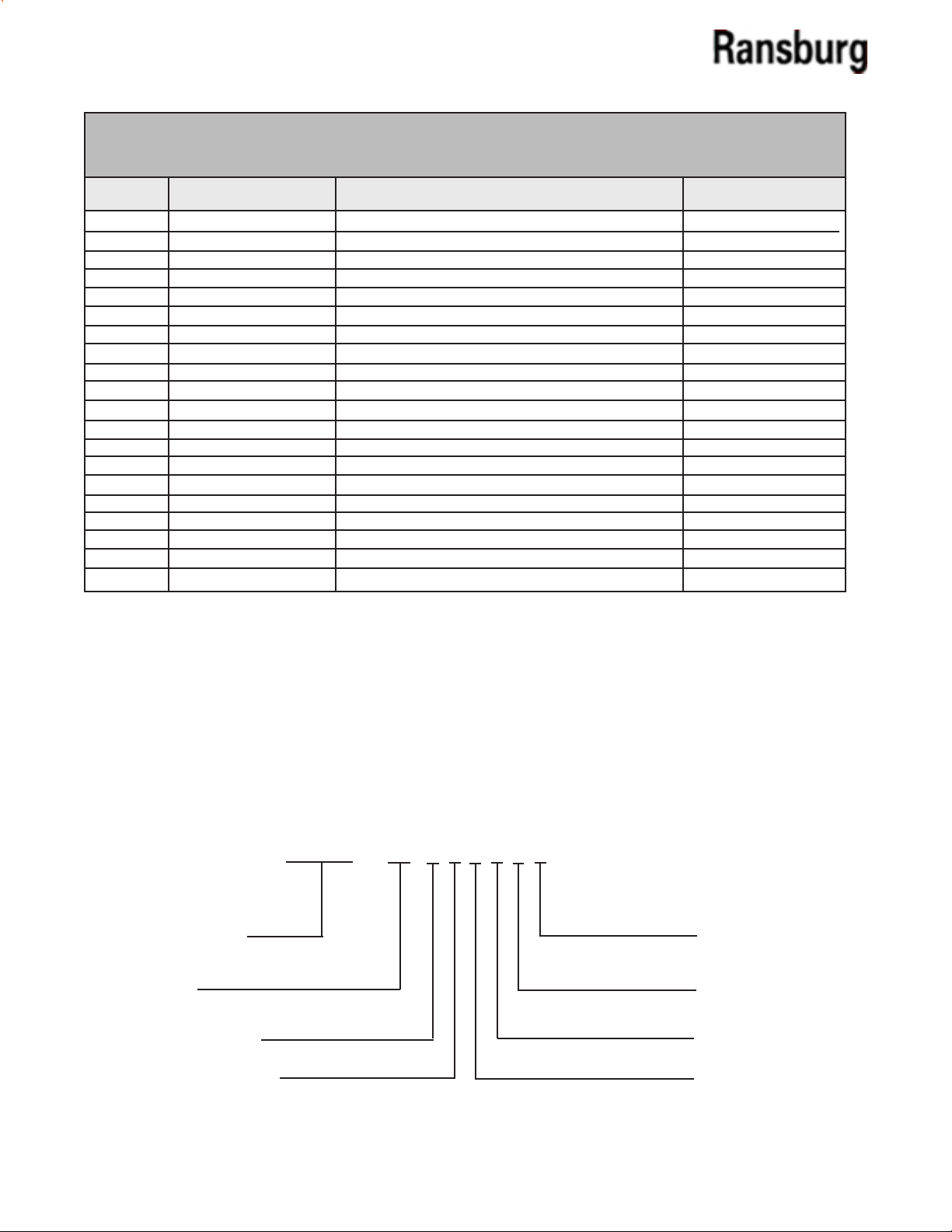

MCV 2 PREENGINEEREDCOLOR CHANGER ASSEMBLIES

The following is for “pre-engineered” color changer assemblies. Please reference selection chart for the

changer assembly number.

Figure 1: Pre-Engineered Color Changer Assemblies

7

CS-02-01.10

MCV 2 Collet Series Color Changer - Introduction

MCV 2 PRE-ENGINEERED COLOR CHANGER ASSEMBLIES PARTS LIST (METRIC) (Figure 1)

Item #

1 A10711-00 Assembly, Plate, Closed End 1

2 See Table C - “Z” Assembly, Bell/Block Wash (Metric) See Table C - “E”

3 See Table B - “R” Assembly, 2-Color Valve Circulating (Metric) See Table AA - “F”

4 See Table B - “S” Assembly, 4-Color Valve Circulating (Metric) See Table AA - “G”

5 See Table V - “X” Assembly, Regulator See Table V - “T”

6 See Table D - “Y” Assembly, Flow Meter Block See Table D - “H”

7 A10712-00 Assembly, Plate Fitting End 1

8 See Table D - “K” Flow Meter See Table D - “J”

9 78069-00 Fluid Regulator Inlet Tube See Table W - “N”

10 77957-00 Retaining Clip, Color Changer 1

11 A10714-00 Fitting, End 1

12 79001-06 O-Ring, Solvent Proof 2

13 78079-00 Fitting, Outlet 1

14 See Table W - “L” Fluid Regulator See Table W - “M”

15 78098-00 Adapter 1/8” NPT (M) X 3/8” NPS (M) See Table W - “P”

16 A10756-00 Tool, Valve Removal 1

17 78078-00 Tool, Retaining Clip Removal 1

18 A10766-00 Tool, Valve Seat Removal 1

19 (Not Used) ---- -20 A10758-00 Tool, Hose Removal 1

(Tool Items #16, 17, 18, and 20 are included with each assembly.)

Part # Description

Qty

MCV 2 PREENGINEERED COLOR CHANGER ASSEMBLIES

MODEL IDENTIFICATION Metric)

When ordering, use A10800-AA, B, C, D, V, W, or BB as indicated by the Tables AA, B, C, D, V, W, and BB.

Seven characters must follow the basic part number, for example:

A10800 - 06 3 0 2 1 2 1

Fiber Optic

Basic Part Number

Quantity of

Color Valves

Style of Color Valves

Bell/Block Wash Option

(Table AA)

(Table B)

(Table C)

(Table D)

(Table BB)

(Table W)

(Table V)

Cable Length

Outlet - Fluid

Regulator Ratio

Inline - Fluid

Regulator Option

Flow Meter Type

CS-02-01.10

8

MCV 2 Collet Series Color Changer - Introduction

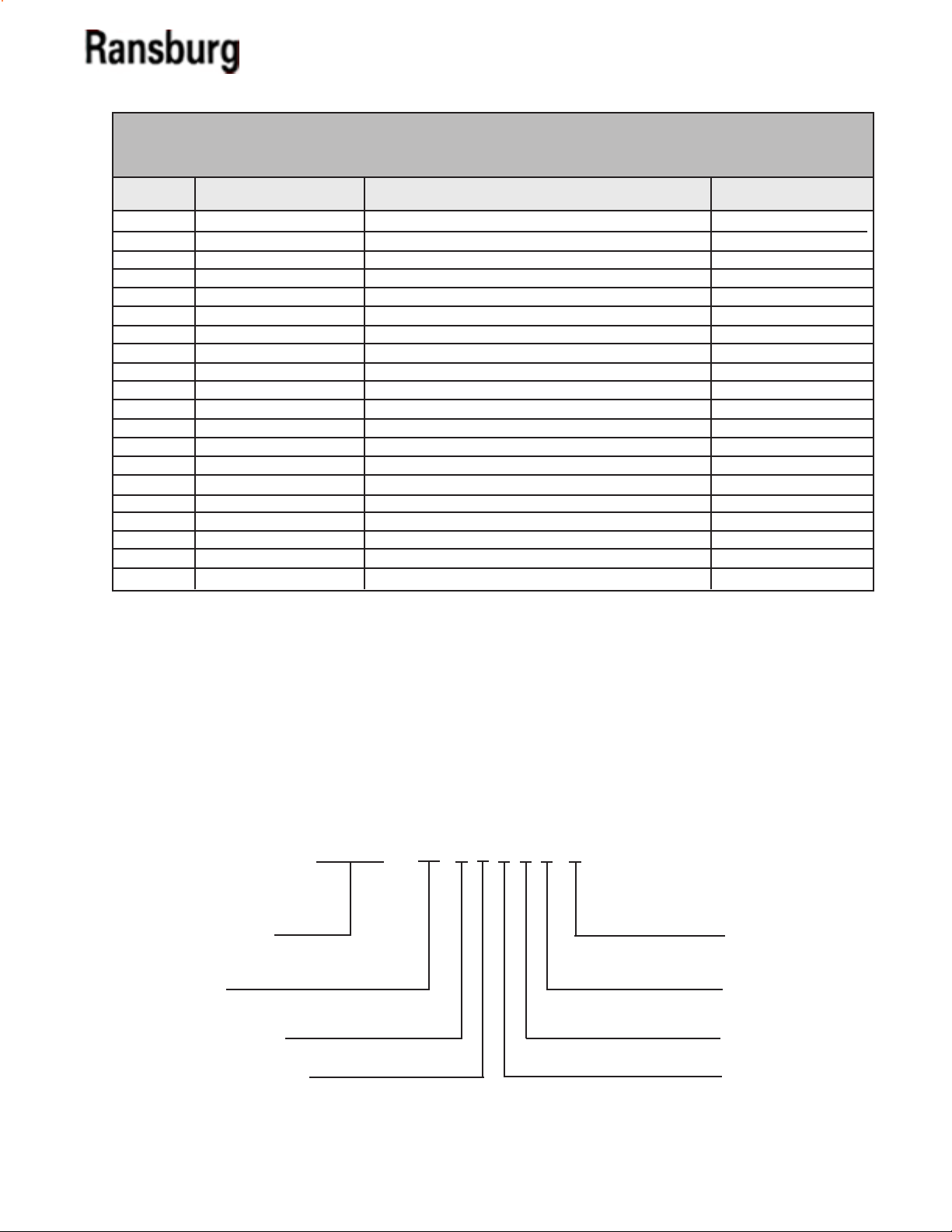

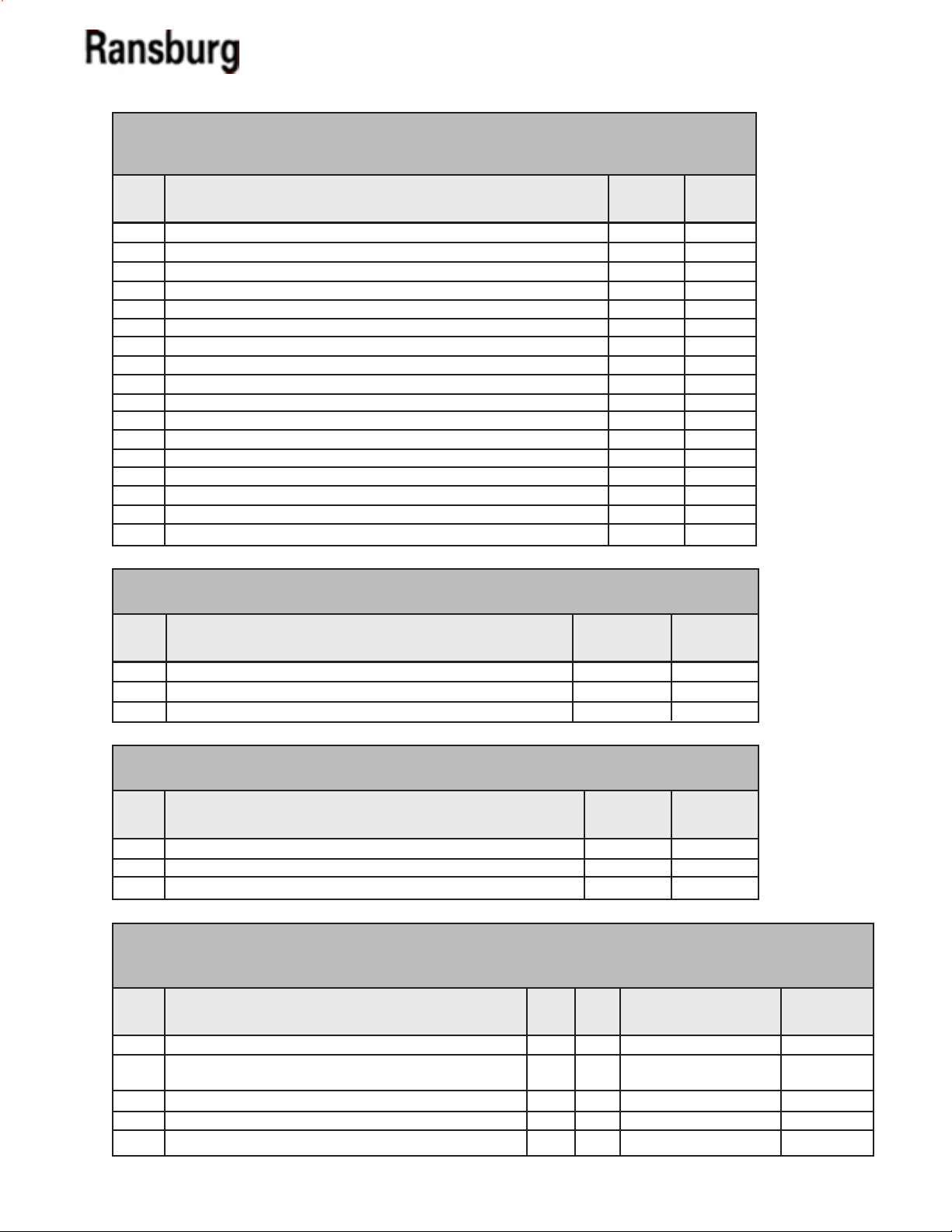

TABLE AA - QUANTITY OF COLOR VALVES (METRIC)

Dash

No.

Description

0-Color - Color Changer

00

2-Color - Color Changer

02

4-Color - Color Changer

04

6-Color - Color Changer

06

8-Color - Color Changer

08

10-Color - Color Changer

10

12-Color - Color Changer

12

14-Color - Color Changer

14

16-Color - Color Changer

16

18-Color - Color Changer

18

20-Color - Color Changer

20

22-Color - Color Changer

22

24-Color - Color Changer

24

26-Color - Color Changer

26

28-Color - Color Changer

28

30-Color - Color Changer

30

32-Color - Color Changer

32

“F”

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

“G”

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

TABLE B - STYLE OF COLOR VALVES (METRIC)

Dash

No.

Description

Circulating (Metric)

1

Daisy Chain (Metric)

2

Dead Head (Metric)

3

TABLE C - BELL / BLOCK WASH OPTION (METRIC)

Dash

No.

Description

0

No Bell / Block Wash

1

With Both Bell / Block Wash, 8mm Bell Wash

2

With Purge Block Only, 8mm Bell Wash

3

With Both Bell/Block Wash, 6mm Bell Wash

4

With Purge Block Only, 6mm Bell Wash

“R”

A10727-00

A10726-00

A10733-00

“E”

0

1

1

1

1

“S”

A10729-00

A10728-00

A10732-00

“Z”

0

A10717-02

A10717-01

A11788-02

A11788-01

9

CS-02-01.10

MCV 2 Collet Series Color Changer - Introduction

TABLE D - FLOW METER TYPE (METRIC & ENGLISH)

Dash

No.

Description

No Flow Meter

0

Block W/AW Flow Meter Attached -

1

Consult your Sales Rep. for Pick-Up

Block W/RF-1 Fiber Optic Flow Meter Attached

2

AW Block W/No Flow Meter

3

RF-1 Fiber Optic Block W/No Flow Meter

4

“H”

“J”

0

1

1

1

1

0

1

1

0

0

See Table BB - “CC”

“K”

0

75955-06

0

0

TABLE V - INLINE - FLUID REGULATOR OPTION (METRIC & ENGLISH)

Dash

No.

Description

No Outlet Regulator

0

DR-2 - 1:1 Ratio

1

DR-2 - 1:2 Ratio

2

DR-2 - 1:3 Ratio

3

DR-2 - 1:4 Ratio

4

DR-2 - 1:6 Ratio

5

DR-2 - 1:8 Ratio

6

DR-2 - 1:10 Ratio

7

“X”

A10725-01

A10725-02

A10725-03

A10725-04

A10725-06

A10725-06

A10725-08

A10725-10

“Y”

0

A10720-01

A10720-02

A10720-01

A10720-02

“T”

0

1

1

1

1

1

1

1

TABLE W - OUTLET - FLUID REGULATOR RATIO (METRIC & ENGLISH)

Dash

No.

0

1

2

3

4

5

6

7

Description

No Outlet Regulator

DR-1 - 1:1 Ratio

DR-1 - 1:2 Ratio

DR-1 - 1:3 Ratio

DR-1 - 1:4 Ratio

DR-1 - 1:6 Ratio

DR-1 - 1:8 Ratio

DR-1 - 1:10 Ratio

“L”

---74151-11

74151-01

74151-06

74151-02

74151-03

74151-04

74151-05

“M”

0

1

1

1

1

1

1

1

TABLE BB - RF-1 FLOW METER KIT/FIBER OPTIC CABLE LENGTH

(METRIC & ENGLISH)

Dash

No.

Description

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

1

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

2

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

3

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

5

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

4

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

6

“CC”

A11516-15

A11516-25

A11516-50

A11516-65

A11516-75

A11516-100

“N”

0

1

1

1

1

1

1

1

“P”

0

1

1

1

1

1

1

1

“Fiber Optic Cable

Length”

15 Ft.

25 Ft.

50 Ft.

65 Ft.

75 Ft.

100 Ft.

CS-02-01.10

10

MCV 2 Collet Series Color Changer - Introduction

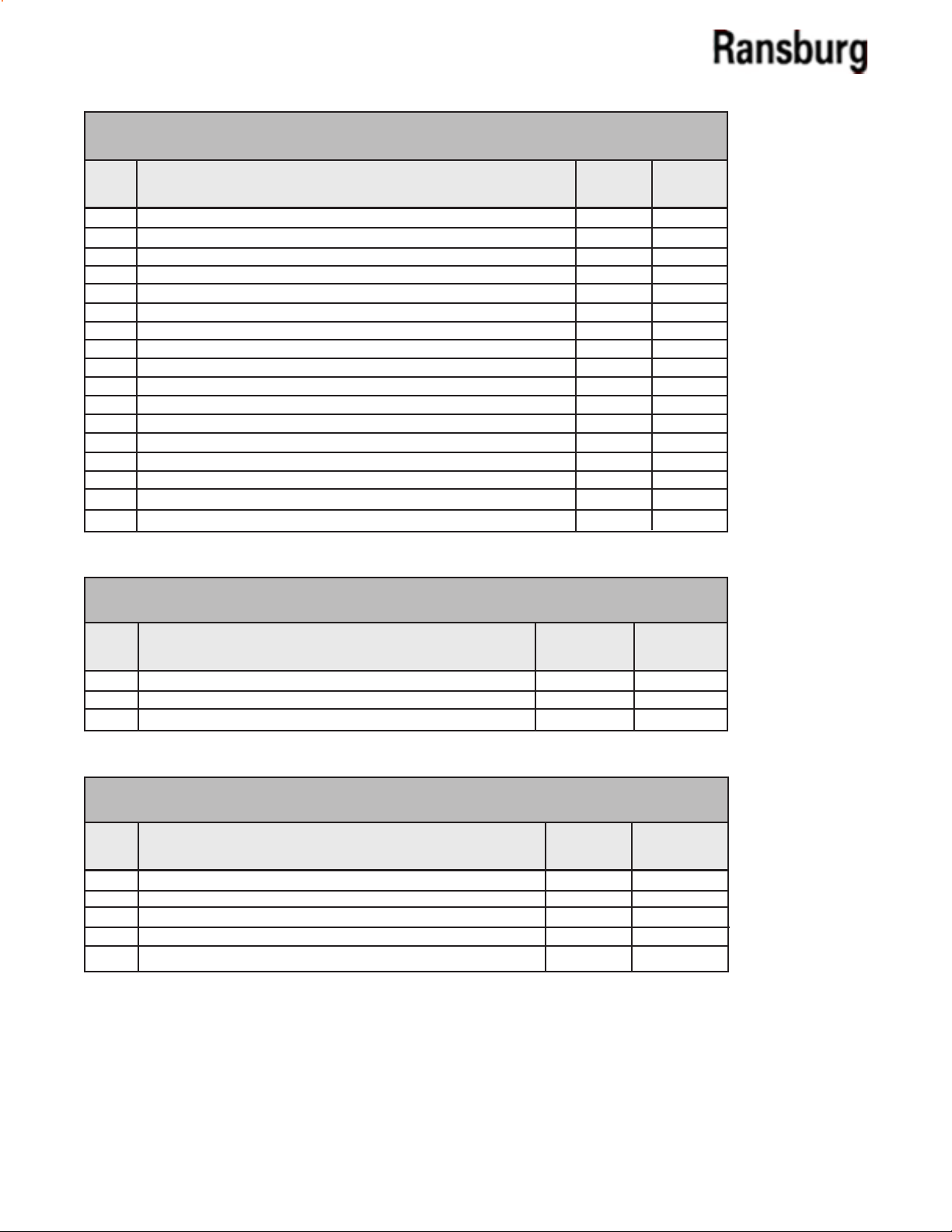

MCV 2 PRE-ENGINEERED COLOR CHANGER ASSEMBLIES PARTS LIST (ENGLISH) (Figure 1)

Item #

1 A10711-00 Assembly, Plate, Closed End 1

2 See Table C - “Z” Assembly, Bell/Block Wash (Metric) See Table C - “E”

3 See Table B - “R” Assembly, 2-Color Valve Circulating (Metric) See Table AA - “F”

4 See Table B - “S” Assembly, 4-Color Valve Circulating (Metric) See Table AA - “G”

5 See Table V - “X” Assembly, Regulator See Table V - “T”

6 See Table D - “Y” Assembly, Flow Meter Block See Table D - “H”

7 A10712-00 Assembly, Plate Fitting End 1

8 See Table D - “K” Flow Meter See Table D - “J”

9 78069-00 Fluid Regulator Inlet Tube See Table W - “N”

10 77957-00 Retaining Clip, Color Changer 1

11 A10714-00 Fitting, End 1

12 79001-06 O-Ring, Solvent Proof 2

13 78079-00 Fitting, Outlet 1

14 See Table W - “L” Fluid Regulator See Table W - “M”

15 78098-00 Adapter 1/8” NPT (M) X 3/8” NPS (M) See Table W - “P”

16 A10756-00 Tool, Valve Removal 1

17 78078-00 Tool, Retaining Clip Removal 1

18 A10766-00 Tool, Valve Seat Removal 1

19 (Not Used) ---- -20 A10758-00 Tool, Hose Removal 1

(Tool Items #16, 17, 18, and 20 are included with each assembly.)

Part # Description

Qty

MCV 2 PREENGINEERED COLOR CHANGER ASSEMBLIES

MODEL IDENTIFICATION English)

When ordering, use A11077-AA, B, C, D, V, W, or BB as indicated by the Tables AA, B, C, D, V, W, and BB.

Seven characters must follow the basic part number, for example:

A11077 - 06 3 0 2 1 2 1

Fiber Optic

Basic Part Number

Quantity of

Color Valves

Style of Color Valves

Bell/Block Wash Option

(Table AA)

(Table B)

(Table C)

(Table BB)

(Table W)

(Table V)

(Table D)

Cable Length

Outlet - Fluid

Regulator Ratio

Inline - Fluid

Regulator Option

Flow Meter Type

11

CS-02-01.10

MCV 2 Collet Series Color Changer - Introduction

TABLE AA - QUANTITY OF COLOR VALVES (ENGLISH)

Dash

No.

Description

00

0 Color - Color Changer

02

2 Color - Color Changer

04

4 Color - Color Changer

06

6 Color - Color Changer

08

8 Color - Color Changer

10

10 Color - Color Changer

12

12 Color - Color Changer

14

14 Color - Color Changer

16

16 Color - Color Changer

18

18 Color - Color Changer

20

20 Color - Color Changer

22

22 Color - Color Changer

24

24 Color - Color Changer

26

26 Color - Color Changer

28

28 Color - Color Changer

30

30 Color - Color Changer

32

32 Color - Color Changer

“F”

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

“G”

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

TABLE B - STYLE OF COLOR VALVES (ENGLISH)

Dash

No.

1

2

3

Description

Circulating (English)

Daisy Chain (English)

Dead Head (English)

“R”

A10953-00

A10954-00

A10955-00

TABLE C - BELL / BLOCK WASH OPTION - (ENGLISH)

Dash

No.

0

1

2

Description

No Bell / Block Wash

W/Both Bell / Block Wash

W/Block Wash Only

“E”

0

1

1

TABLE D - FLOW METER TYPE / FIBER OPTIC CABLE LENGTH

(METRIC & ENGLISH)

Dash

No.

Description

No Flow Meter

0

Block W/AW Flow Meter Attached -

1

Consult your Sales Rep. for Pick-Up

Block W/RF-1 Fiber Optic Flow Meter Attached

2

AW Block W/No Flow Meter

3

RF-1 Fiber Optic Block W/No Flow Meter

4

“H”

“J”

0

1

1

1

1

0

1

1

See Table BB - “CC”

0

0

“S”

A10960-00

A10961-00

A10962-00

“Z”

0

A11080-02

A11080-01

“K”

0

75955-06

0

0

“Y”

0

A10720-01

A10720-02

A10720-01

A10720-02

CS-02-01.10

12

MCV 2 Collet Series Color Changer - Introduction

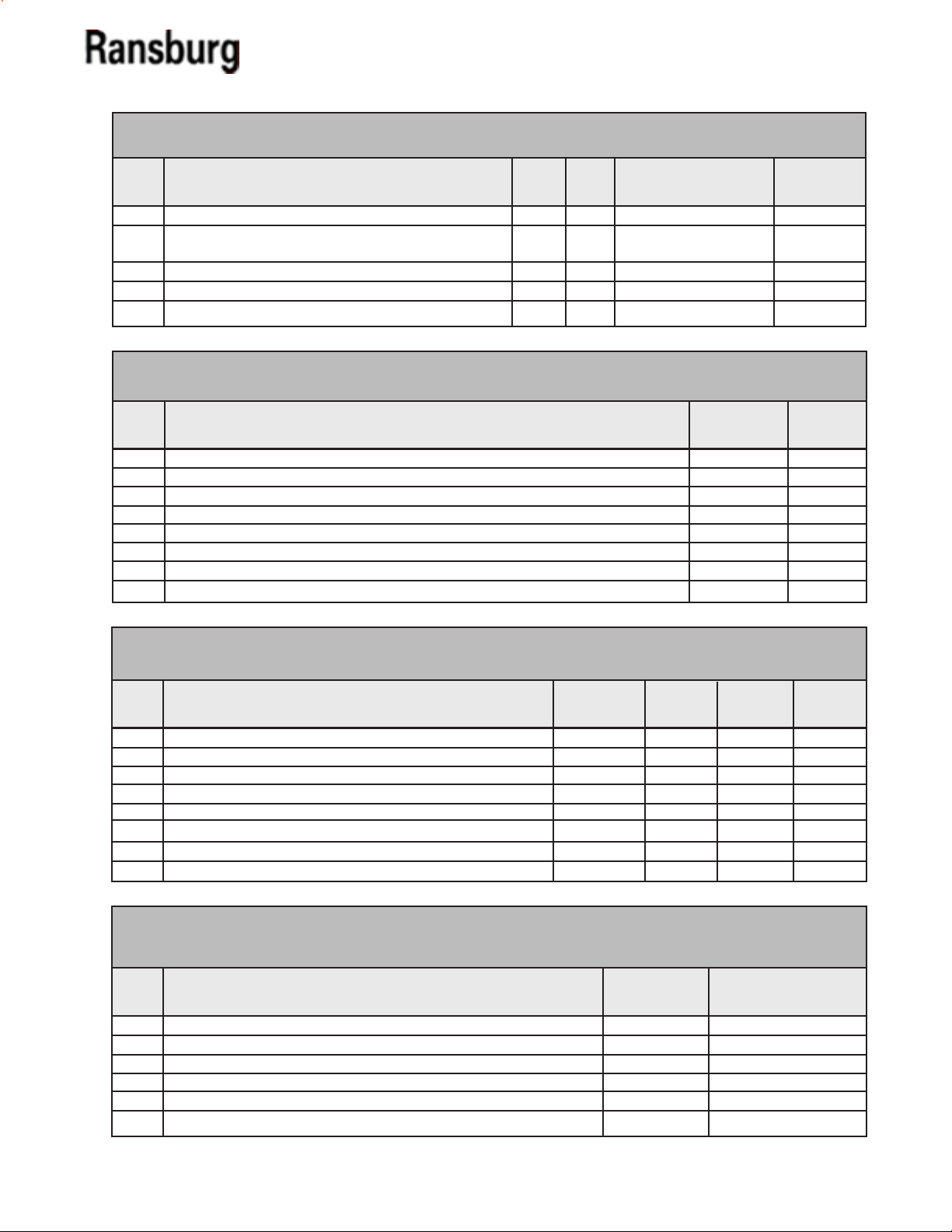

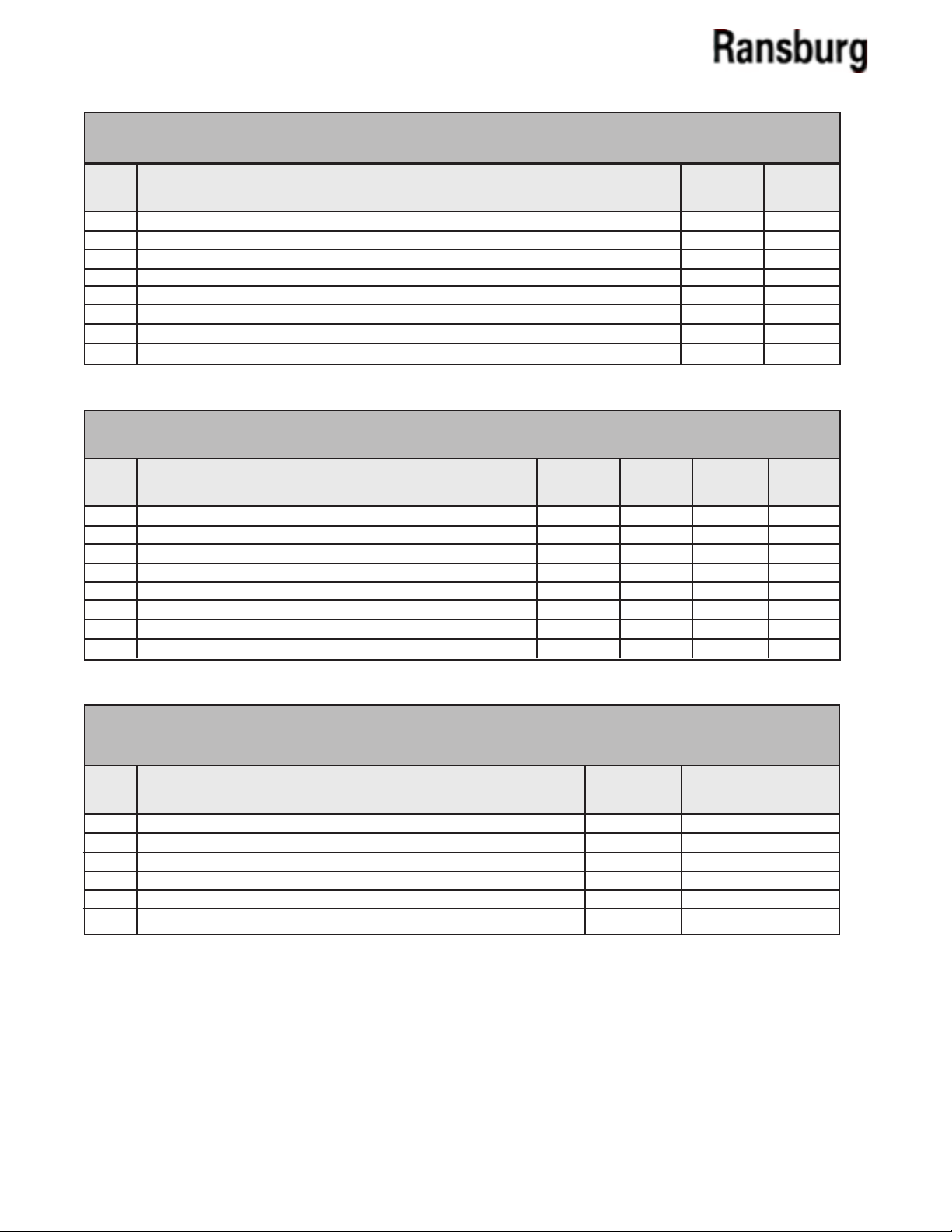

TABLE V - INLINE - FLUID REGULATOR OPTION (METRIC & ENGLISH)

Dash

No.

Description

No Outlet Regulator

0

DR-2 - 1:1 Ratio

1

DR-2 - 1:2 Ratio

2

DR-2 - 1:3 Ratio

3

DR-2 - 1:4 Ratio

4

DR-2 - 1:6 Ratio

5

DR-2 - 1:8 Ratio

6

DR-2 - 1:10 Ratio

7

TABLE W - OUTLET - FLUID REGULATOR OPTION (METRIC & ENGLISH)

Dash

No.

Description

No Outlet Regulator

0

DR-1 - 1:1 Ratio

1

DR-1 - 1:2 Ratio

2

DR-1 - 1:3 Ratio

3

DR-1 - 1:4 Ratio

4

DR-1 - 1:6 Ratio

5

DR-1 - 1:8 Ratio

6

DR-1 - 1:10 Ratio

7

“L”

---74151-11

74151-01

74151-06

74151-02

74151-03

74151-04

74151-05

“M”

0

1

1

1

1

1

1

1

“X”

A10725-01

A10725-02

A10725-03

A10725-04

A10725-06

A10725-06

A10725-08

A10725-10

“N”

0

1

1

1

1

1

1

1

“T”

0

1

1

1

1

1

1

1

“P”

0

1

1

1

1

1

1

1

TABLE BB - RF 1 FLOW METER KIT/FIBER OPTIC CABLE LENGTH (METRIC & ENGLISH)

Dash

No.

1

2

3

4

5

6

Description

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

“CC”

A11516-15

A11516-25

A11516-50

A11516-65

A11516-75

A11516-100

“Fiber Optic Cable

Length”

15 Ft.

25 Ft.

50 Ft.

65 Ft.

75 Ft.

100 Ft.

13

CS-02-01.10

MCV 2 Collet Series Color Changer - Introduction

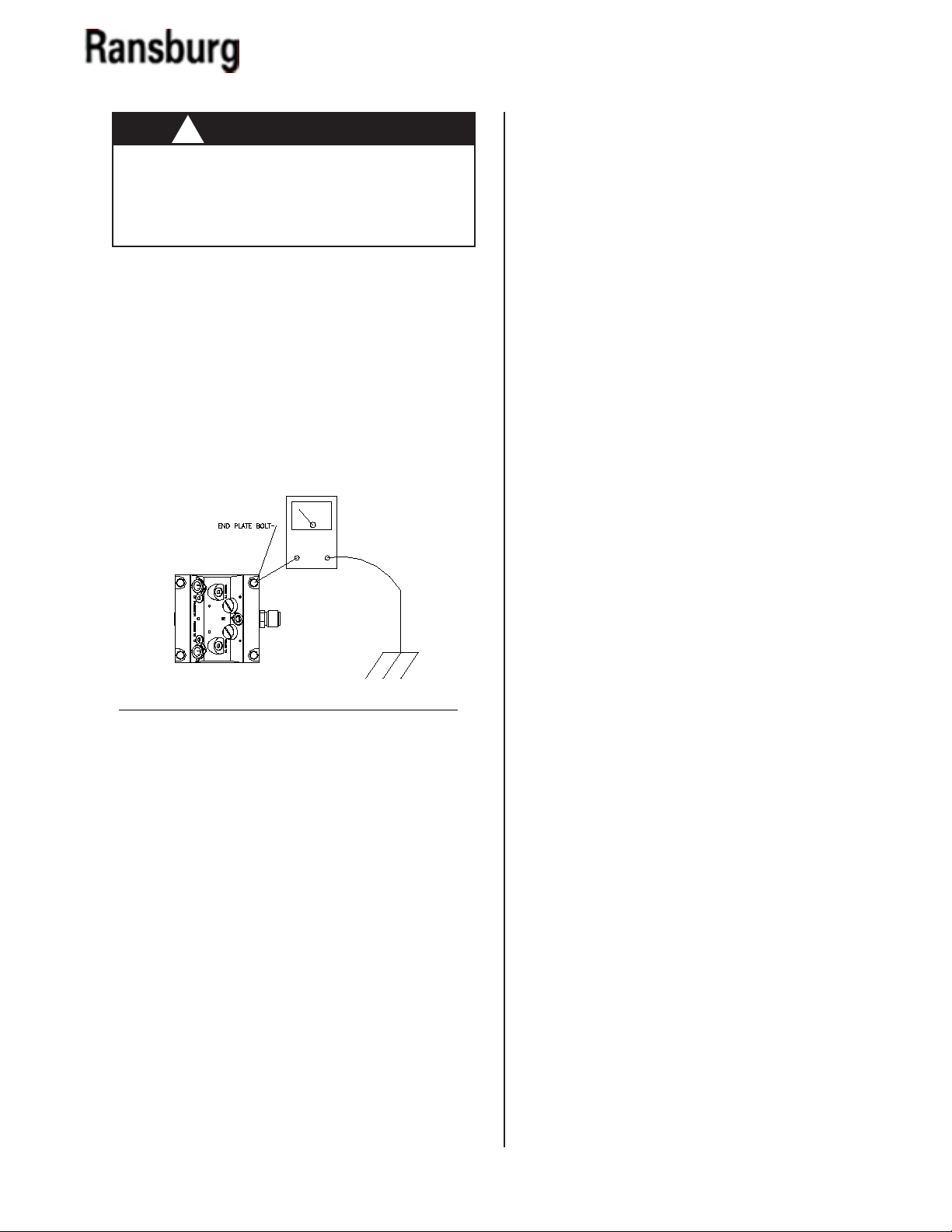

EARTH GROUND

(TRUE)

OHMS

10

0

!

W A R N I N G

> The color changer MUST be properly grounded. Proper grounding (as described below)

will prevent static charge buildup and possible

discharge from the color changer.

Grounding of the Color Changer

For safety, the color changer MUST be grounded.

Using a 12-gauge wire, ground the output plate

of the color changer to a true earth ground. Using

an ohmmeter, check for ground, testing the earth

ground to the outlet. The resistance should be 10

ohms or less.

NOTES

CS-02-01.10

Figure 2: Grounding the Color Changer

14

MCV 2 Collet Series Color Changer - Installation

INSTALLATION

MCV 2 INSTALLATION

PROCEDURES

Determine Location for Color Changer

The color changer should be located as close as

possible to the spray device in order to save paint

and solvent with a color changer. If possible, use an

enclosure to protect the color changer from airborne

paints and solvents.

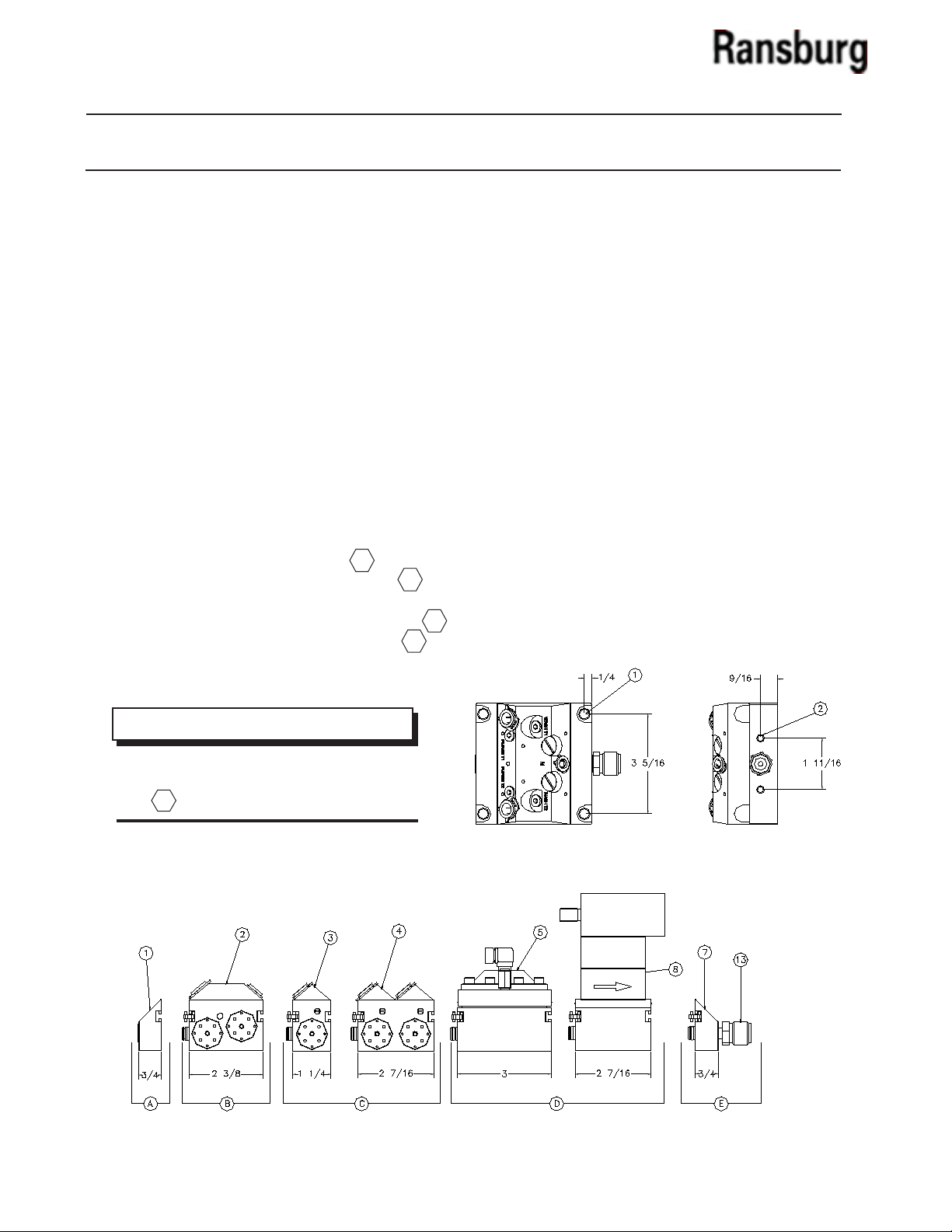

Calculate Footprint of Color Changer

(See Figure 3)

To calculate the footprint of the color changer add:

• The dimension of the end plate

• The dimension of the purge assembly

• The dimension(s) of the module(s) used to

create the desired number of color valves

• The dimension of the output assembly

A

B

C

E

NOTE

Example: To calculate the footprint of an 6-Color

MCV Assembly:

3/4” (End Plate) + 2-3/8” (purge assembly) +

3-11/16” (8-color valve assembly) + 3/4” (output

assembly) = 7-9/16”

Mounting the Color Changer

There are two mounting congurations as follows:

(Reference Figure 4)

1 5/16” clearance holes for ush mounting

to the booth wall.

2 1/4” x 20 threaded holes in the end blocks.

15

> If using the optional control devices (regulator and ow meter) include dimension in

D

calculation above.

Figure 3: Calculate Footprint

Figure 4: Mounting Congurations Footprint

CS-02-01.10

MCV 2 Collet Series Color Changer - Installation

NOTES

CS-02-01.10

16

MCV 2 Collet Series Color Changer - Operation

Solvent

Color 1 IN

Main Air

Flow Meter

Fluid

Regulator

MCV Color Selector

Spray

Device

Color 1 OUT

Color 2 IN

Color 2 OUT

OPERATION

OPERATING

Modules may be added or removed from the assembly as desired; the user need only purchase the

appropriately sized changer. If, for instance, the number of required materials increases, the changer can

be expanded by adding more modules. Also, each

module can be individually serviced. Recommended

for use with waterborne or solventborne paints.

Figure 5a shows “Typical Color Changer Schematics”

to prevent back ow of material. Figure 5b shows

“Typical Bell Wash or Stack Purge Flow Schematics.

Figure 5b: Typical Bell Wash or Stack Purge Flow Sche-

matics

17

Figure 5a: Color Changer Schematics

CS-02-01.10

MCV 2 Collet Series Color Changer - Operation

WASH SOLVENT TRIGGER

(4 mm ODT) (5/32 in ODT)

SOLVENT SUPPLY

(10 mm ODT)

(3/8 in ODT)

WASH AIR TRIGGER

(4 mm ODT)

(5/32 in ODT)

AIR SUPPLY

(10 mm ODT) (3/8 in ODT)

BELL WASH OUTLET

(6mm & 8mm ODT)

(5/16 in ODT)

PURGE SOLVENT TRIGGEER

(4 mm ODT) (5/32 in ODT)

PURGE AIR TRIGGER

(4 mm ODT)

(5/32 in ODT)

COLOR IN

(10 mm ODT)

(3/8 in ODT)

COLOR OUT

(8 mm ODT)

(5/16 in ODT)

OUTLET

(3/8 NPSM (M))

GROUND TO EARTH

GROUND HERE

COLOR TRIGGER

(4 mm ODT)

(5/32 in ODT)

221.54 [8.722 in]

101.40 [3.992 in]

53.95 [2.124 in]

DIMENSIONS METRIC FRACTION & PROPOSED HOOKUP

FOR 8COLORS

CS-02-01.10

18

MCV 2 Collet Series Color Changer - Maintenance

MAINTENANCE

!

> Prior to servicing the unit, ensure that all uid

pressure is relieved to atmosphere. A solvent

purge should be performed if possible.

W A R N I N G

GENERAL MAINTENANCE

NOTE

> When replacing or repairing any components in this system, before reassembling,

apply a light coat of food grade

petroleum jelly to all o-rings.

NOTE

Figure 6: Valve Removal

To remove the seat, insert the seat removal tool

into the seat and turn counter-clockwise using a

3/8” socket, adjustable wrench, or combination box

open-end wrench.

> The following procedure allows valve

and/or seat removal without removing the

valve slice from the assembly.

Value and Seat Removal

To remove the valve for any reason, insert the four

(4) prongs from the tool into the holes on the top the

Microvalve. Using a 1/2” socket, adjustable wrench, or

a combination box open-end wrench, turn counterclockwise to remove the valve.

Figure 7: Seat Removal

19

CS-02-01.10

MCV 2 Collet Series Color Changer - Maintenance

To reinstall, tighten the valve seat rst using the

tool by hand. Then using a torque wrench with a

3/8’ socket, tighten the seat in place, clockwise in

direction to 15 to 20 lbs.•in torque.

NOTE

> Not using a torque wrench for seat installation may cause permanent damage to the

seat pocket of the valve block.

Figure 9: Microvalve Installation

Tube Insertion

Prior to inserting the tube, remove the red clip under

the collet. Insert the tube into the stack collet by

grasping the tube about 2-4-inches from the end.

Press the tube all the way down in the collet until it

cannot be pressed any further, the tube must pass

by both o-rings. Each tube must be inserted into its

mating collet to the proper depth as shown in the

chart below. With the tube inserted, pull the collet

up enough to slide the clip under the collet.

Figure 8: Reinstall Valve and Seat

To install the Microvalve, tighten the valve into the

pocket using the provided tool and a 1/2” wrench

or socket clockwise till the valve has just about

seated. Then using a torque wrench tighten to 1520 lbs.•in.

C A U T I O N

!

> Be careful not to cross thread the parts when

reassembling as this could cause permanent

damage to block.

Tube OD Tube Depth

10mm or 3/8” 3/4” or 19.0mm

8mm or 5/16” 11/16” or 17.5mm

6mm 25/32” or 19.8mm

4mm or 5/32” 5/8” or 16.0mm

CS-02-01.10

20

MCV 2 Collet Series Color Changer - Maintenance

TUBING

Tube Removal

The 4mm trigger line tubes may be removed by hand

by pushing on the collet while pulling out the tube. A

tool is required to remove both the 8mm and 10mm

tubes. To remove the 8mm tube, use the white end of

the tool, and for the 10mm tube use the black end.

First remove the red clips then press the tool against

the collet in the block. With the collet pushed in, pull

out the tube that is being removed (see Figure 10).

REMOVING AND

REINSTALLING A VALVE

BLOCK FROM A STACK

1. Ensure all pressure is bled o the system. If

possible, ush the block with appropriate solvent.

2. Using the clip removal tool (78078-00), push

on the installed locking clip with the “V” cut as

shown in Figure 11.

Figure 10: Tube Removal

!

> Prior to servicing the unit, ensure that all uid

pressure is relieved to atmosphere. A solvent

purge should be performed if possible.

W A R N I N G

Figure 11: 78078-00 Clip Removal Tool

3. Push the locking clips out of the locking slots.

4. Loosen and remove any mounting bolts holding the stack in place.

5. Carefully pull the stack assembly ends apart

and remove the valve block.

!

> Be careful of residual uid pressure or solvent

pressure in the line. Cover the area where the

valve slice is being removed to prevent any

solvent or paint from spraying on you.

6. Replace the valve slice, push the assembly

together and insert the locking clips.

W A R N I N G

21

CS-02-01.10

MCV 2 Collet Series Color Changer - Maintenance

16

3

6

13

2

8

9

4

5

11

7

12

1

15

10

14

Figure 12: Regulator Disassembly/Reassembly Procedure

CS-02-01.10

22

MCV 2 Collet Series Color Changer - Maintenance

REGULATOR DISASSEMBLY /

REASSEMBLY PROCEDURE

Disassembly

1. Remove eight (8) screws [16] using a 5/32” Allen

wrench.

2. Pull cap [14], upper diaphragm [6], and plate

[13] from the assembly.

3. Pull diaphragm assembly [2] from the assembly.

4. Using a 3/16” Allen wrench, remove the regulator insert [8]. By removing the insert, the seat

will be removed [5]. To remove the carbide seat from

the insert, blow compressed air in the hex end of the

insert and the carbide seat will come out.

Figure 13: Diaphragm Assembly Position

NOTE

> The seat and stem are matched sets of

parts, each having a serial number engraved

on them. Care must be taken not to mix nonmatching seats and stems or the regulator

will not perform properly.

Reassembly

1. Install all removed o-rings [9] and [4] on the

insert and the seat. Push the seat [5] into the insert

(straight in) using an arbor press if possible.

2. Insert spring [10], stem [5], and one o-ring [4]

into the regulator body [1].

3. Using a 3/16” Allen wrench, tighten the insert

down until it bottoms out.

5. Add plate [13], upper diaphragm [6], and lid

[14]. Tighten the eight (8) screws [16] in a cross

pattern to 10 lbs•in. Then follow by tightening

each screw in a circular pattern to 20 lbs•in.

4. Locate the dot on the diaphragm assembly [2]

and place it so it is 180° from the outlet hole of

the body.

23

CS-02-01.10

MCV 2 Collet Series Color Changer - Maintenance

TEST AND CHECKOUT

PROCEDURE FOR COLOR

CHANGER

Step 1:

1. Connect air line to a regulated air supply.

2. Attach the air line to a ball valve assembled to

the outlet of the color changer.

3. Adjust the air supply pressure to 100 psi (6.9

bar).

4. Open the ball valve at the outlet of the color

changer.

5. Apply a soap solution on the color changer

manifold.

6. Check the manifold assembly’s mating surfaces between color blocks for soap bubbles.

2. Connect the air supply hose with 100 psi

(6.9 bar) to color inlet valve. Connect a 2-way ball

valve to the matching return port on the color

changer manifold.

3. Turn the ball valve installed on the paint circulation tting to verify recirculation ability.

NOTE

> Ensure valve is closed when completed.

4. Connect the air supply with a 3-way valve

(normally closed) to the color valve cylinder.

5. Activate the 3-way valve to operate the color

valve.

NOTE

NOTE

> If bubbles are observed, dismantle color

changer manifold and repair as required.

7. If no bubbles are present, rinse manifold with

water and blow dry with air.

Step 2:

1. Attach two (2) regulated air supply hoses, one

with a 3-way valve (normally closed) for operating

the color valve cylinder on the color changer. (Set

the pressure to the 3-way valve at 75 psi

(5.8 bar) or more.)

The second hose will be used for supplying 100 psi

(6.9 bar) of air to the color inlet port of each color

changer valve.

> The piston rod on the top of the color valve

assembly should EXTEND and air should

blow out of the color changer outlet. Check

for a crisp and sharp actuation of the color

valve air cylinder.

6. Deactivate the 3-way valve and close the

color valves.

NOTE

> The piston rod on the top of the color

valve assembly should be RETRACTED, and

the air should have stopped blowing out of

the outlet of the color changer.

7. Connect a 1/4-inch (6.4cm) ID hose 3-ft.

(91.4cm) long to the outlet of the color changer.

CS-02-01.10

24

MCV 2 Collet Series Color Changer - Maintenance

EARTH GROUND

(TRUE)

OHMS

10

0

8. Acquire a container of water and ll it with

about 4-inches (10.6cm) of WATER. Position the

hose in the container lled with water.

9. There should be no more than 6 bubbles per

minute coming from the outlet of the hose that is

submerged.

10. If there are more than 6 bubbles per minute,

remove the color valve assembly, replace the

valve seat (77367-00) and reinstall color valve

assembly. If the new seat does not correct the

problem, either the manifold block or color valve

assembly is defective.

11. Proceed to the next color valve and repeat

Steps 2 thru 11.

12. When all the color valves are checked out,

then check the purge valve assembly repeating

Steps 2 thru 11.

!

W A R N I N G

> NEVER wrap the equipment in plastic to

keep it clean. A surface charge may build-up

on the plastic surface and discharge to the

nearest grounded object. Eciency of the

equipment will also be reduced and damage

or failure of the equipment’s components may

occur. WRAPPING THE EQUIPMENT in plastic

will void warranty.

13. Once all valves are operational, deactivate

the 3-way valve, and then disconnect the air

lines used for testing from the color changer.

!

W A R N I N G

> ALWAYS test color changer for conductivity

after assembly or repair. Proper conductivity is

required to assure entire color changer can be

properly grounded when installed.

14. With an ohmmeter, check for conductivity

between the output plate on the color changer

and earth ground. There should be 10 ohms or less

between the two points (see Figure 14).

Figure 14: Ground Test

25

CS-02-01.10

MCV 2 Collet Series Color Changer - Maintenance

NOTES

CS-02-01.10

26

MCV 2 Collet Series Color Changer - Parts Identication

O-RINGS INCLUDED WITH EACH BLOCK ASY.

PARTS IDENTIFICATION

27

Figure 15: A10800 (Metric) & A11077 (English) MCV 2 Color Changer Assemblies

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

A10800 MCV 2 COLOR CHANGER ASSEMBLY - PARTS LIST (METRIC) (Figure 15)

Item #

1 A10711-00 Assembly, Plate Closed End 1

2 See Table C - “Z” Assembly, Bell/Block Wash (Metric) See Table C - “E”

3 See Table B - “R” Assembly, 2-Color Valve Circulating (Metric) See Table AA - “F”

4 See Table B - “S” Assembly, 4-Color Valve Circulating (Metric) See Table AA - “G”

5 See Table V - “X” Assembly, Regulator See Table V - “T”

6 See Table D - “Y” Assembly, Flow Meter Block See Table D - “H”

7 A10712-00 Assembly, Plate Fitting End 1

8 See Table D - “K” Flow Meter See Table D - “J”

9 78069-00 Fluid Regulator Inlet Tube See Table W - “N”

10 77957-00 Retaining Cup, Color Changer 1

11 A10714-00 Fitting, End 1

12 79001-06 O-Ring, Solvent Proof 2

13 78079-00 Fitting, Outlet 1

14 See Table W - “L” Fluid Regulator See Table W - “M”

15 78098-00 Adapter 1/8” NPT (M) X 3/8” NPS (M) See Table W - “P”

Part # Description

TABLE B - STYLE OF COLOR VALVES (METRIC)

Dash

No.

1

2

3

Description

Circulating (Metric)

Daisy Chain (Metric)

Dead Head (Metric)

“R”

A10727-00

A10726-00

A10733-00

Qty

“S”

A10729-00

A10728-00

A10732-00

TABLE C - BELL / BLOCK WASH OPTION (METRIC)

Dash

No.

CS-02-01.10

Description

0

No Bell / Block Wash

1

W/Both Bell / Block Wash, 8mm Bell Wash

2

W/Block Wash Only, 8mm Bell Wash

3

W/Both Bell / Block Wash, 6mm Bell Wash

4

W/Purge Block Only, 6mm Bell Wash

“E”

0

1

1

1

1

“Z”

0

A10717-02

A10717-01

A11788-02

A11788-01

28

MCV 2 Collet Series Color Changer - Parts Identication

TABLE D - FLOW METER TYPE (METRIC & ENGLISH)

Dash

No.

Description

No Flow Meter

0

Block W/AW Flow Meter Attached -

1

Consult Your Sales Rep. for Pick-Up

Block W/RF-1 Fiber Optic Flow Meter Attached

2

AW Block W/No Flow Meter

3

RF-1 Fiber Optic Block W/No Flow Meter

4

“H”

0

1

1

1

1

TABLE V - INLINE - FLUID REGULATOR OPTION

Dash

No.

Description

No Outlet Regulator

0

DR-2 - 1:1 Ratio

1

DR-2 - 1:2 Ratio

2

DR-2 - 1:3 Ratio

3

DR-2 - 1:4 Ratio

4

DR-2 - 1:6 Ratio

5

DR-2 - 1:8 Ratio

6

DR-2 - 1:10 Ratio

7

“J”

0

1

1

0

0

“K”

0

75955-06

See Table BB - “CC”

0

0

“X”

A10725-01

A10725-02

A10725-03

A10725-04

A10725-06

A10725-06

A10725-08

A10725-10

“Y”

0

A10720-01

A10720-02

A10720-01

A10720-02

“T”

0

1

1

1

1

1

1

1

TABLE W - OUTLET - FLUID REGULATOR RATIO

Dash

No.

Description

No Outlet Regulator

0

DR-1 - 1:1 Ratio

1

DR-1 - 1:2 Ratio

2

DR-1 - 1:3 Ratio

3

DR-1 - 1:4 Ratio

4

DR-1 - 1:6 Ratio

5

DR-1 - 1:8 Ratio

6

DR-1 - 1:10 Ratio

7

“L”

---74151-11

74151-01

74151-06

74151-02

74151-03

74151-04

74151-05

“M”

0

1

1

1

1

1

1

1

“N”

0

1

1

1

1

1

1

1

“P”

0

1

1

1

1

1

1

1

29

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

TABLE BB - RF 1 FLOW METER KIT / FIBER OPTIC CABLE LENGTH

(METRIC & ENGLISH)

Dash

No.

1

2

3

4

5

6

Description

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

“CC”

A11516-15

A11516-25

A11516-50

A11516-65

A11516-75

A11516-100

“Fiber Optic Cable

Length”

15 Ft.

25 Ft.

50 Ft.

65 Ft.

75 Ft.

100 Ft.

A11077 MCV 2 COLOR CHANGER ASSEMBLY - PARTS LIST

(ENGLISH) (Figure 15)

Item #

1 A10711-00 Assembly, Plate, Closed End 1

2 See Table C - “Z” Assembly, Bell/Block Wash (Metric) See Table C - “E”

3 See Table B - “R” Assembly, 2-Color Valve (Metric) See Table AA - “F”

4 See Table B - “S” Assembly, 4-Color Valve (Metric) See Table AA - “G”

5 See Table V - “X” Assembly, Regulator See Table V - “T”

6 See Table D - “Y” Assembly, Flow Meter Block See Table D - “H”

7 A10712-00 Assembly, Plate Fitting End 1

8 See Table D - “K” Flow Meter See Table D - “J”

9 78069-00 Fluid Regulator Inlet Tube See Table W - “N”

10 77957-00 Retaining Cup, Color Changer 1

11 A10714-00 Fitting, End 1

12 79001-06 O-Ring, Solvent Proof 2

13 78079-00 Fitting, Outlet 1

14 See Table W - “L” Fluid Regulator See Table W - “M”

15 78098-00 Adapter 1/8” NPT (M) X 3/8 “ NPS (M) See Table W - “P”

Part # Description

Qty

TABLE B - STYLE OF COLOR VALVES (ENGLISH)

Dash

No.

Description

Circulating (English)

1

Daisy Chain (English)

2

Dead Head (English)

3

TABLE C - BELL / BLOCK WASH OPTION - (ENGLISH)

Dash

No.

CS-02-01.10

Description

0

No Bell / Block Wash

1

W/Both Bell / Block Wash

2

W/Block Wash Only

“R”

A10953-00

A10954-00

A10955-00

“E”

0

1

1

“S”

A10960-00

A10961-00

A10962-00

“Z”

0

A11080-02

A11080-01

30

MCV 2 Collet Series Color Changer - Parts Identication

TABLE D - FLOW METER TYPE

Dash

No.

Description

No Flow Meter

0

Block W/AW Flow Meter Attached -

1

Consult Your Sales Rep. for Pick-Up

Block W/RF-1 Fiber Optic Flow Meter Attached

2

AW Block W/No Flow Meter

3

RF-1 Fiber Optic Block W/No Flow Meter

4

“H”

0

1

1

1

1

TABLE V - INLINE - FLUID REGULATOR OPTION

Dash

No.

Description

No Outlet Regulator

0

DR-2 - 1:1 Ratio

1

DR-2 - 1:2 Ratio

2

DR-2 - 1:3 Ratio

3

DR-2 - 1:4 Ratio

4

DR-2 - 1:6 Ratio

5

DR-2 - 1:8 Ratio

6

DR-2 - 1:10 Ratio

7

“J”

0

1

1

0

0

“K”

0

75955-06

See Table BB - “CC”

0

0

“X”

A10725-01

A10725-02

A10725-03

A10725-04

A10725-06

A10725-06

A10725-08

A10725-10

“Y”

0

A10720-01

A10720-02

A10720-01

A10720-02

“T”

0

1

1

1

1

1

1

1

TABLE W - OUTLET - FLUID REGULATOR RATIO

Dash

No.

0

1

2

3

4

5

6

7

Description

No Outlet Regulator

DR-1 - 1:1 Ratio

DR-1 - 1:2 Ratio

DR-1 - 1:3 Ratio

DR-1 - 1:4 Ratio

DR-1 - 1:6 Ratio

DR-1 - 1:8 Ratio

DR-1 - 1:10 Ratio

“L”

---74151-11

74151-01

74151-06

74151-02

74151-03

74151-04

74151-05

“M”

TABLE BB - RF-1 FLOW METER KIT/FIBER OPTIC CABLE LENGTH

(METRIC & ENGLISH)

Dash

No.

100

Description

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

15

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

25

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

35

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

65

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

75

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

“CC”

A11516-15

A11516-25

A11516-50

A11516-65

A11516-75

A11516-100

“N”

0

1

1

1

1

1

1

1

0

1

1

1

1

1

1

1

“P”

0

1

1

1

1

1

1

1

“Fiber Optic Cable

Length”

15 Ft.

25 Ft.

50 Ft.

65 Ft.

75 Ft.

100 Ft.

31

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

CS-02-01.10

Figure 16: A10717 (Metric) & A11080 (English) Bell/Block Wash Assembly

32

MCV 2 Collet Series Color Changer - Parts Identication

A10717 BELL /BLOCK WASH ASSEMBLY - PARTS LIST

(METRIC) (Figure 16)

Item #

1 78944-00 Assembly, Check Valve 2

2 See Table X - “A” Assembly, Valve Seat or Plug 2

3 See Table X - “B” Assembly, Valve or Plug 2

4 78947-00 Seal 2

5 78945-00 Plug, Check Valve 2

6 77516-04 Collet, 4mm 4

7 A10825-00 Red Locking Clip, 1/4” OD Tube 1

8 79001-30 O-Ring, Solvent Proof 4

9 79001-06 O-Ring, Solvent Proof 3

10 79001-05 O-Ring, Solvent Proof 1

11 79001-34 O-Ring, Solvent Proof 2

12 77762-02 Collet, 10mm 2

13 77762-04 Collet, 8mm 1

14 79001-31 O-Ring, Solvent Proof 4

15 A10824-00 Red Locking Clip, 3/8” OD Tube 2

16 A10968-00 Assembly, Bell Wash & Purge Block (Metric) 1

17 77957-00 Retaining Clip, Color Changer 1

18 77367-00 Assembly, Valve Seat 2

19 78949-00 Assemby, Valve 2

Part # Description

Qty

TABLE X - A10717 BELL / BLOCK WASH ASSEMBLY - PARTS LIST (METRIC)

Part #

A10717-01

A10717-02

Description

Purge Block Only

Bell Wash & Purge Block

“A”

Kit #77620-00

78949-00

“B”

77367-00

33

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

A11788 BELL /BLOCK WASH ASSEMBLY - PARTS LIST

(METRIC) (Figure 16)

Item #

1 78944-00 Assembly, Check Valve 2

2 See Table X - “A” Assembly, Valve Seat or Plug 2

3 See Table X - “B” Assembly, Valve or Plug 2

4 78947-00 Seal 2

5 78945-00 Plug, Check Valve 2

6 77516-04 Collet, 4mm 4

7 A10825-00 Red Locking Clip, 1/4” OD Tube 1

8 79001-30 O-Ring, Solvent Proof 4

9 79001-06 O-Ring, Solvent Proof 3

10 79001-05 O-Ring, Solvent Proof 1

11 79001-32 O-Ring, Solvent Proof 2

12 77762-02 Collet, 10mm 2

13 77762-01 Collet, 6mm 1

14 79001-31 O-Ring, Solvent Proof 4

15 A10824-00 Red Locking Clip, 3/8” OD Tube 2

16 A10968-00 Assembly, Bell Wash & Purge Block (Metric) 1

17 77957-00 Retaining Clip, Color Changer 1

18 77367-00 Assembly, Valve Seat 2

19 78949-00 Assemby, Valve 2

Part # Description

Qty

TABLE X - A11788 BELL/BLOCK WASH ASSEMBLY - PARTS LIST

Part #

A11788-01

A11788-02

Description

Purge Block Only

Bell Wash & Purge Block

“A”

Kit #77620-00

78949-00

“B”

77367-00

CS-02-01.10

34

MCV 2 Color Changer - Parts Identication

A11080 BELL / BLOCK WASH ASSEMBLY - PARTS LIST

(ENGLISH) (Figure 16)

Item #

1 78944-00 Assembly, Check Valve 2

2 See Table X - “A” Assembly, Valve Seat or Plug 2

3 See Table X - “B” Assembly, Valve or Plug 2

4 78947-00 Seal 2

5 78945-00 Plug, Check Valve 2

6 77516-04 Collet, 5/32” 4

7 A10825-00 Red Locking Clip, 1/4” OD Tube 1

8 79001-30 O-Ring, Solvent Proof 4

9 79001-06 O-Ring, Solvent Proof 3

10 79001-05 O-Ring, Solvent Proof 1

11 79001-34 O-Ring, Solvent Proof 2

12 77762-05 Collet, 3/8” 2

13 77762-04 Collet, 5/16” 1

14 79001-24 O-Ring, Solvent Proof 4

15 A10824-00 Red Locking Clip, 3/8” OD Tube 2

16 A10968-00 Assembly, Bell Wash & Purge Block (Metric) 1

17 77957-00 Retaining Clip, Color Changer 1

18 77367-00 Assembly, Valve Seat 2

19 78949-00 Assemby, Valve 2

Part # Description

TABLE X - A11080 BELL / BLOCK WASH ASSEMBLY PARTS LIST (ENGLISH)

Qty

Part #

A111080-1

A110880-2

Description

Purge Block Only

Bell Wash & Purge Block

“A”

Kit #77620-00

78949-00

“B”

77367-00

35

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

NOTES

CS-02-01.10

36

MCV 2 Collet Series Color Changer - Parts Identication

8

9

11

1

2

3

12

10

13

7

5

4

6

14

Figure 17: A10727 (Metric) & A10953 (English) 2-Color Valve Circulating Assembly

37

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

A10727 2-COLOR VALVE CIRCULATING ASSEMBLY PARTS LIST (METRIC) (Figure 17)

Item #

1 A10734-01 Assembly, 2-Color Valve Circulating 1

2 77367-00 Assembly, Valve Seat 2

3 78949-00 Assembly, Valve 2

4 77762-02 Collet, 10mm 2

5 79001-31 O-Ring, Solvent Proof 4

6 77762-04 Collet, 8mm 2

7 79001-34 O-Ring, Solvent Proof 4

8 77516-04 Collet, 4mm 2

9 79001-30 O-Ring, Solvent Proof 2

10 79001-06 O-Ring, Solvent Proof 1

11 76001-05 O-Ring, Solvent Proof 1

12 77957-00 Retaining Clip, Color Changer 1

13 A10824-00 Red Locking Clip, 3/8” OD Tube 2

14 A10825-00 Red Locking Clip, 1/4” OD Tube 2

Part # Description

A10953 2-COLOR VALVE CIRCULATING ASSEMBLY PARTS LIST (ENGLISH) (Figure 17)

Item #

1 A10956-01 Assembly, 2-Color Valve Circulating 1

2 77367-00 Assembly, Valve Seat 2

3 78949-00 Assembly, Valve 2

4 77762-05 Collet, 3/8” 2

5 79001-24 O-Ring, Solvent Proof 4

6 77762-04 Collet, 5/16” 2

7 79001-34 O-Ring, Solvent Proof 4

8 77516-04 Collet, 5/32” 2

9 79001-30 O-Ring, Solvent Proof 2

10 79001-06 O-Ring, Solvent Proof 1

11 76001-05 O-Ring, Solvent Proof 1

12 77957-00 Retaining Clip, Color Changer 1

13 A10824-00 Red Locking Clip, 3/8” OD Tube 2

14 A10825-00 Red Locking Clip, 1/4” OD Tube 2

Part # Description

Qty

Qty

CS-02-01.10

38

MCV 2 Collet Series Color Changer - Parts Identication

3

9

4

5

5

4

8

1

7

6

6

7

2

10

3

9

4

5

5

4

8

1

7

6

6

7

2

10

11

39

Figure 18: A10726 (Metric) & A10954 (English) 2-Color Valve - Daisy Chain

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

A10726 2-COLOR VALVE - DAISY CHAIN - PARTS LIST

(METRIC) (Figure 18)

Item #

1 A10734-03 Assembly, 2-Color Daisy Chain 1

2 77367-00 Assembly, Valve Seat 2

3 78949-00 Assembly, Valve 2

4 77762-02 Collet, 10mm 4

5 79001-31 O-Ring, Solvent Proof 8

6 77516-04 Collet, 4mm 2

7 79001-30 O-Ring, Solvent Proof 2

8 79001-06 O-Ring, Solvent Proof 1

9 79001-05 O-Ring, Solvent Proof 1

10 77957-00 Retaining Clip, Color Changer 1

11 A10824-00 Red Locking Clip, 3/8” OD Tube 4

Part # Description

A10954 2-COLOR VALVE - DAISY CHAIN - PARTS LIST

(ENGLISH) (Figure 18)

Item #

1 A10956-03 Assembly, 2-Color Daisy Chain 1

2 77367-00 Assembly, Valve Seat 2

3 78949-00 Assembly, Valve 2

4 77762-05 Collet, 3/8” 4

5 79001-24 O-Ring, Solvent Proof 8

6 77516-04 Collet, 5/32” 2

7 79001-30 O-Ring, Solvent Proof 2

8 79001-06 O-Ring, Solvent Proof 1

9 79001-05 O-Ring, Solvent Proof 1

10 77957-00 Retaining Clip, Color Changer 1

11 A10824-00 Red Locking Clip, 3/8” OD Tube 4

Part # Description

Qty

Qty

CS-02-01.10

40

MCV 2 Collet Series Color Changer - Parts Identication

11

8

1

10

3

2

6

7

5

5

4

4

5

5

6

7

2

1

9

3

41

Figure 19: A10733 (Metric) & A10955 (English) 2-Color Valve - Dead Head

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

A10733 2-COLOR VALVE - DEAD HEAD - PARTS LIST

(METRIC) (Figure 19)

Item #

1 A10734-02 Assembly, 2-Color Dead Head (Metric) 1

2 77367-00 Assembly, Valve Seat 2

3 78949-00 Assembly, Valve 2

4 77762-02 Collet, 10mm 2

5 79001-31 O-Ring, Solvent Proof 4

6 77516-04 Collet, 4mm 2

7 79001-30 O-Ring, Solvent Proof 2

8 79001-06 O-Ring, Solvent Proof 1

9 79001-05 O-Ring, Solvent Proof 1

10 77957-00 Retaining Clip, Color Changer 1

11 A10824-00 Red Locking Clip, 3/8” OD Tube 2

Part # Description

A10955 2-COLOR VALVE - DEAD HEAD - PARTS LIST

(ENGLISH) (Figure 19)

Item #

1 A10956-02 Assembly, 2-Color Dead Head (Metric) 1

2 77367-00 Assembly, Valve Seat 2

3 78949-00 Assembly, Valve 2

4 77762-05 Collet, 3/8” 2

5 79001-24 O-Ring, Solvent Proof 4

6 77516-04 Collet, 5/32” 2

7 79001-30 O-Ring, Solvent Proof 2

8 79001-06 O-Ring, Solvent Proof 1

9 79001-05 O-Ring, Solvent Proof 1

10 77957-00 Retaining Clip, Color Changer 1

11 A10824-00 Red Locking Clip, 3/8” OD Tube 2

Part # Description

Qty

Qty

CS-02-01.10

42

MCV 2 Collet Series Color Changer - Parts Identication

43

Figure 20: A10729 (Metric) & A10960 (English) 4-Color Valve Circulating Assembly

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

A10729 4-COLOR VALVE CIRCULATING ASSEMBLY PARTS LIST (METRIC) (Figure 20)

Item #

1 A10735-01 Assembly, Circulating 4-Color Stack 1

2 77367-00 Assembly, Valve Seat 4

3 78949-00 Assembly, Valve 4

4 77762-02 Collet, 10mm 4

5 79001-31 O-Ring, Solvent Proof 8

6 77762-04 Collet, 8mm 4

7 79001-34 O-Ring, Solvent Proof 8

8 77516-04 Collet, 4mm 4

9 79001-30 O-Ring, Solvent Proof 4

10 79001-06 O-Ring, Solvent Proof 1

11 79001-05 O-Ring, Solvent Proof 1

12 77957-00 Retaining Clip, Color Changer 1

13 A10824-00 Red Locking Clip, 3/8” OD Tube 4

14 A10825-00 Red Locking Clip, 1/4” OD Tube 4

Part # Description

A10960 4-COLOR VALVE CIRCULATING ASSEMBLY PARTS LIST (ENGLISH) (Figure 20)

Item #

1 A10960-00 Assembly, Circulating 4-Color Stack 1

2 77367-00 Assembly, Valve Seat 4

3 78949-00 Assembly, Valve 4

4 77762-05 Collet, 3/8” 4

5 79001-24 O-Ring, Solvent Proof 8

6 77762-04 Collet, 5/16” 4

7 79001-24 O-Ring, Solvent Proof 8

8 77516-04 Collet, 5/32” 4

9 79001-30 O-Ring, Solvent Proof 4

10 79001-06 O-Ring, Solvent Proof 1

11 79001-05 O-Ring, Solvent Proof 1

12 77957-00 Retaining Clip, Color Changer 1

13 A10824-00 Red Locking Clip, 3/8” OD Tube 4

14 A10825-00 Red Locking Clip, 1/4” OD Tube 4

Part # Description

Qty

Qty

CS-02-01.10

44

MCV 2 Collet Series Color Changer - Parts Identication

8

5

4

6

3

2

1

10

9

7

11

45

Figure 21: A10728 (Metric) & A10961 (English) 4-Color Valve - Daisy Chain Assembly

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

A10728 4-COLOR VALVE - DAISY CHAIN ASSEMBLY PARTS LIST (METRIC) (Figure 21)

Item #

1 A10735-03 Assembly, Body 4-Color - Daisy Chain 1

2 77367-00 Assembly, Valve Seat 4

3 78949-00 Assembly, Valve 4

4 77762-02 Collet, 10mm 8

5 79001-31 O-Ring, Solvent Proof 16

6 77516-04 Collet, 4mm 4

7 79001-30 O-Ring, Solvent Proof 4

8 79001-06 O-Ring, Solvent Proof 1

9 79001-05 O-Ring, Solvent Proof 1

10 77957-00 Retaining Clip, Color Changer 1

11 A10824-00 Red Locking Clip, 3/8” OD Tube 8

Part # Description

A10961 4-COLOR VALVE - DAISY CHAIN ASSEMBLY PARTS LIST (ENGLISH) (Figure 21)

Item #

1 A10963-03 Assembly, Body 4-Color - Daisy Chain 1

2 77367-00 Assembly, Valve Seat 4

3 78949-00 Assembly, Valve 4

4 77762-05 Collet, 3/8” 8

5 79001-24 O-Ring, Solvent Proof 16

6 77516-04 Collet, 5/32” 4

7 79001-30 O-Ring, Solvent Proof 4

8 79001-06 O-Ring, Solvent Proof 1

9 79001-05 O-Ring, Solvent Proof 1

10 77957-00 Retaining Clip, Color Changer 1

11 A10824-00 Red Locking Clip, 3/8” OD Tube 8

Part # Description

Qty

Qty

CS-02-01.10

46

MCV 2 Collet Series Color Changer - Parts Identication

3

2

9

1

8

7

6

5

5

4

11

10

47

Figure 22: A10732 (Metric) & A10962 (English) 4-Color Valve Dead Head Assembly

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

A10732 4-COLOR VALVE DEAD HEAD ASSEMBLY PARTS LIST (METRIC) (Figure 22)

Item #

1 A10735-02 Assembly, Block 4-Color Dead Head 1

2 77367-00 Assembly, Valve Seat 4

3 78949-00 Assembly, Valve 4

4 77762-02 Collet, 10mm 4

5 79001-31 O-Ring, Solvent Proof 8

6 77516-04 Collet, 4mm 4

7 79001-30 O-Ring, Solvent Proof 4

8 79001-06 O-Ring, Solvent Proof 1

9 79001-05 O-Ring, Solvent Proof 1

10 77957-00 Retaining Clip, Color Changer 1

11 A10824-00 Red Locking Clip, 3/8” OD Tube 4

Part # Description

A10962 4-COLOR VALVE DEAD HEAD ASSEMBLY PARTS LIST (ENGLISH) (Figure 22)

Item #

1 A10963-02 Assembly, Block 4-Color Dead Head 1

2 77367-00 Assembly, Valve Seat 4

3 78949-00 Assembly, Valve 4

4 77762-05 Collet, 3/8” 4

5 79001-24 O-Ring, Solvent Proof 8

6 77516-04 Collet, 5/32” 4

7 79001-30 O-Ring, Solvent Proof 4

8 79001-06 O-Ring, Solvent Proof 1

9 79001-05 O-Ring, Solvent Proof 1

10 77957-00 Retaining Clip, Color Changer 1

11 A10824-00 Red Locking Clip, 3/8” OD Tube 4

Part # Description

Qty

Qty

CS-02-01.10

48

MCV 2 Collet Series Color Changer - Parts Identication

16

3

6

13

2

8

9

4

5

11

7

12

1

15

10

14

Figure 23: A10725 Regulator Assembly

49

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

A10725 REGULATOR ASSEMBLY - PARTS LIST (Figure 23)

Item #

1 A10724-00 Assembly, Regulator Body 1

2 See Table A - “A” Assembly, Diaphragm DR-2 1

3 A11069-00 Fitting, Elbow, Push-In, 1/8” NPT X 4mm (5/32”) ODT 1

4 79001-08 O-Ring, Solvent Proof 2

5 74160-00 Assembly Matched Seat & Stem 1

6 74157-03 Diaphragm, Regulator 1

7 79001-05 O-Ring, Solvent Proof 1

8 79238-00 Insert, Regulator 1

9 79001-18 O-Ring, Solvent Proof 1

10 74161-00 Spring, Regulator 1

11 79001-06 O-Ring, Solvent Proof 1

12 77957-00 Retaining Clip, Color Changer 1

13 See Table A - “B” Ratio Spacer Ring, Fluid Regulator 1

14 79231-00 Cap, Fluid Regulator 1

15 77544-01 Fitting, Straight, Push-In, 1/8” NPT X 4mm (5/32”) ODT 2

16 LSFA-0006-40F Screw, Socket Head Cap, 10-32 X 1-1/4” Lg. 8

Part # Description

TABLE A - A10725 REGULATOR ASSEMBLY

Dash

No.

01

02

03

04

06

08

10

Description

Regulator Ratio 1:1

Regulator Ratio 1:2

Regulator Ratio 1:3

Regulator Ratio 1:4

Regulator Ratio 1:6

Regulator Ratio 1:8

Regulator Ratio 1:10

“A”

79235-01

79235-02

79235-03

79235-04

79235-06

79235-08

79235-10

A11067-01

A11067-02

A11067-03

A11067-04

A11067-06

A11067-08

A11067-10

Qty

“B”

CS-02-01.10

50

MCV 2 Collet Series Color Changer - Parts Identication

7

4

3

3

4

3

3

3

1

6

5

Figure 24: A10720-01/02 Flow Meter Block Assembly

A10720-01/02 FLOW METER BLOCK ASSEMBLY - PARTS LIST

(Figure 24)

Item #

1 A10719-00 Assembly, Flow Meter Block 1

2 A10467-00 Assembly, Flow Meter Plate 1

3 79001-05 O-Ring, Solvent Proof 5

4 78232-16C Screw, Counter Sunk Head 6

5 79001-06 O-Ring, Solvent Proof 1

6 77957-00 Retaining Clip, Color Changer 1

7 See Table Y - “A” Screw, SHC 4

TABLE Y - FLOW METER BLOCK ASSEMBLY OPTION

Part #

A10720-01

A10720-02

Part # Description

Description

AW Flow Meter Block

RF-1 Fiber Optic Flow Meter Block

Qty

“A”

A10468-45

A10468-50

51

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

Figure 25: A10826-XX Stand Alone Bell/Block Wash Assembly

A10826-XX STAND ALONE BELL / BLOCK WASH ASSEMBLY PARTS LIST (METRIC & ENGLISH) (Figure 25)

Item #

1 A10711-00 Assembly, Plate Closed End 1

2 See Table Z - “A” Assembly, Bell / Block Wash (Metric) 1

3 77957-00 Retaining Clip, Color Changer 1

4 79001-06 O-Ring, Solvent Proof 2

5 A10714-00 Fitting, End 1

6 A10712-00 Assembly, Plate Fitting, End 1

7 78079-00 Fitting, Outlet 1

Part # Description

TABLE Z - A10826 STAND ALONE BELL / BLOCK WASH ASSEMBLY

OPTIONS

Part #

A10826-01

A10826-02

A10826-03

A10826-04

A10826-06

A10826-06

Description

Purge Block Only, 8mm (Metric)

Bell Wash & Purge Block, 8mm (Metric)

Purge Block Only (English)

Bell Wash & Purge Block (English)

Purge Block Only, 6mm (Metric)

Bell Wash Purge Block, 6mm (Metric)

A10717-01

A10717-02

A10080-01

A11080-02

A11788-01

A11788-02

Qty

“A”

CS-02-01.10

52

MCV 2 Collet Series Color Changer - Parts Identication

Figure 26: A10827-00 Stand Alone Regulator Assembly

A10827-00 STAND ALONE REGULATOR ASSEMBLY PARTS LIST (Figure 26)

Item #

1 79001-05 O-Ring, Solvent Proof 1

2 See Table A Assembly, Regulator 1

3 77957-00 Retaining Clip, Color Changer 1

4 79001-06 O-Ring, Solvent Proof 2

5 A10714-00 Fitting, End 1

6 A10712-00 Assembly, Plate Fitting End 2

7 78079-00 Fitting, Outlet 2

Part # Description

TABLE A - A10827-00 REGULATOR ASSEMBLY

Part #

A10827-01

A10827-02

A10827-03

A10827-04

A10827-06

A10827-08

A10827-10

Description

Regulator- 1:1 Ratio

Regulator - 1:2 Ratio

Regulator - 1:3 Ratio

Regulator - 1:4 Ratio

Regulator - 1:6 Ratio

Regulator - 1:8 Ratio

Regulator - 1:10 Ratio

A10725-01

A10725-02

A10725-03

A10725-04

A10725-06

A10725-08

A10725-10

Qty

“A”

53

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

Figure 27: A10828-XX Stand Alone Flow Meter Assembly (RF-1 Fiber Optic)

A10828-XX STAND ALONE FLOW METER ASSEMBLY

(RF-1 FIBER OPTIC) - PARTS LIST (Figure 27)

Item #

1 79001-05 O-Ring, Solvent Proof 1

2 See Table BB - “CC” Flow Meter and Cable 1

3 77957-00 Retaining Clip, Color Changer 1

4 79001-06 O-Ring, Solvent Proof 2

5 A10714-00 Fitting, End 1

6 A10712-00 Assembly Plate, Fitting End 2

7 78079-00 Fitting, Outlet 2

8 A10720-02 Assembly Flow Meter Block 1

Part # Description

TABLE BB - RF -1 FLOW METER KIT/ FIBER OPTIC CABLE LENGTH

(METRIC & ENGLISH)

Dash

No.

15

25

50

65

75

100

Description

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

RF-1 Flow Meter, Receiver & Cable, Fiber Optic Cable

“CC”

A11516-15

A11516-25

A11516-50

A11516-65

A11516-75

A11516-100

“Fiber Optic Cable

Length”

15 Ft.

25 Ft.

50 Ft.

65 Ft.

75 Ft.

100 Ft.

Qty

CS-02-01.10

54

MCV 2 Collet Series Color Changer - Parts Identication

Figure 28: A10999-00 Stand Alone Flow Meter Assembly (AW)

A10999-00 STAND ALONE FLOW METER ASSEMBLY (AW) PARTS LIST (Figure 28)

Item #

1 79001-05 O-Ring, Solvent Proof 1

2 75955-06 Flow Meter, AW (Consult Your Sales Rep. for 1

Pick-Up)

3 77957-00 Retaining Clip, Color Changer 1

4 79001-06 O-Ring, Solvent Proof 2

5 A10714-00 Fitting, End 1

6 A10712-00 Assembly, Plate Fitting End 2

7 78079-00 Fitting, Outlet 2

8 A10720-01 Assembly, Flow Meter Block, AW 1

Part # Description

Qty

55

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

3

2

1

2

Figure 29a: 78949-00 Valve & 77367-00 Seat Replacement Parts

78949-00 VALVE & 77367-00 SEAT REPLACEMENT

PARTS (Figure 29a)

Item #

1 79244-00 Plug 1

2 79001-19 O-Ring, Solvent Proof 1

3 79001-14 O-Ring, Solvent Proof 1

4 77618-00 Plug, Seat 1

Part # Description

Figure 29b: 77620-00 Valve Plug Kit

77620-00 VALVE PLUG KIT (Use in Place of Valve & Seat)

(Optional) (Figure 29b)

Item #

1 79244-00 Plug 1

2 79001-19 O-Ring, Solvent Proof 1

3 79001-14 O-Ring, Solvent Proof 1

4 77618-00 Plug, Seat 1

Part # Description

Qty

Qty

CS-02-01.10

56

MCV 2 Collet Series Color Changer - Parts Identication

RECOMMENDED SPARE PARTS

Part #

74160-00

74161-00

77957-00

A10824-00

A10825-00

79001-05

79001-06

Description

Needle and Seat, Regulating

Spring

Retaining Clip

Locking Clip, 3/18”

Locking Clip, 1/4”

O-Ring, Solvent Proof

O-Ring, Solvent Proof

57

CS-02-01.10

MCV 2 Collet Series Color Changer - Parts Identication

NOTES

CS-02-01.10

58

MCV 2 Collet Series Color Changer - Warranty Policies

WARRANTY POLICIES

LIMITED WARRANTY

Ransburg will replace or repair without charge any

part and/or equipment that fails within the specied

time (see below) because of faulty workmanship or

material, provided that the equipment has been used

and maintained in accordance with Ransburg’s written safety and operating instructions, and has been