Ransburg 80102-31X Quick Start Guide

CUSTOMER /TECHNICAL SUPPORT CALL 800-233-3366

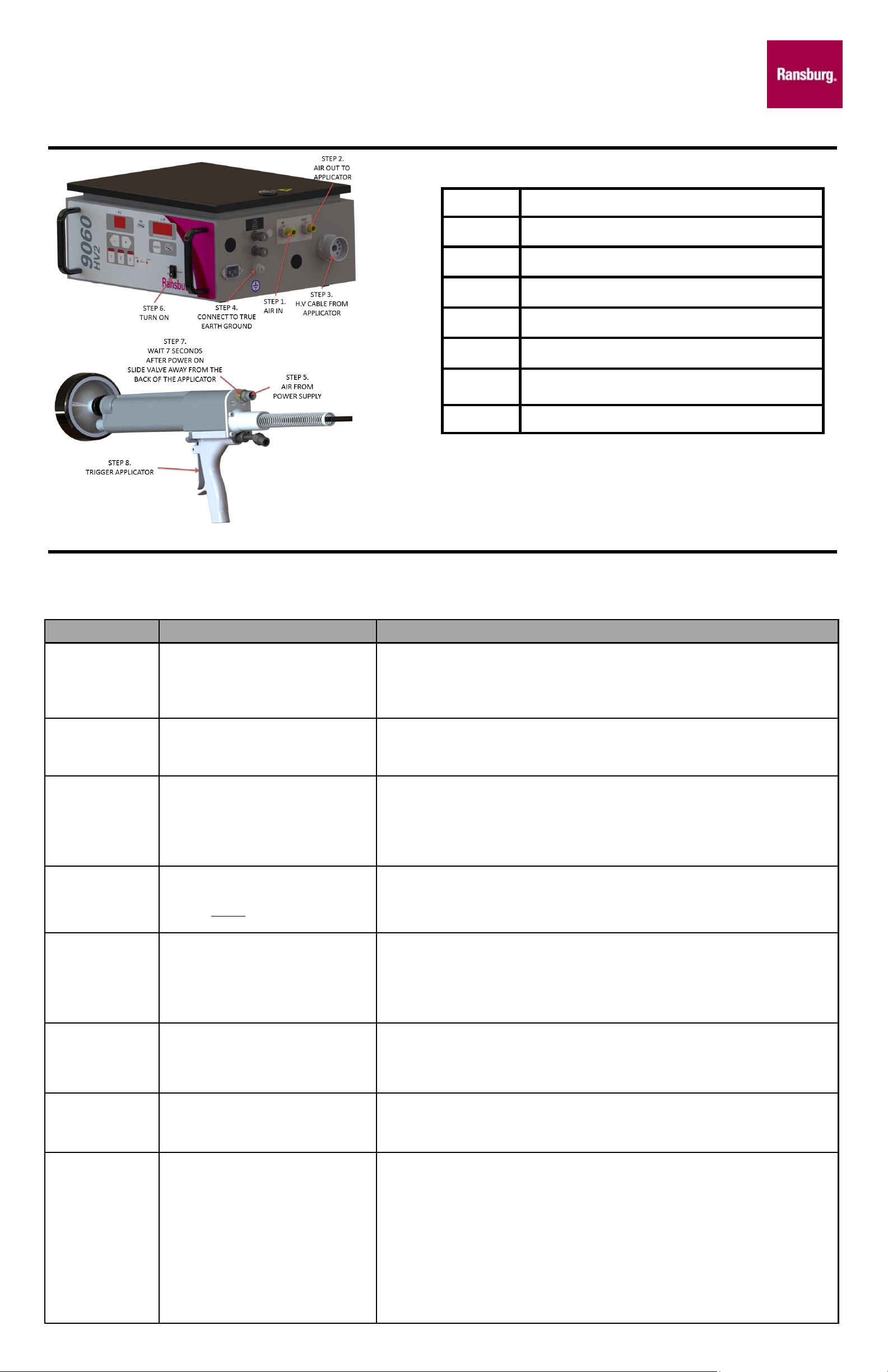

QUICK START GUIDE

MODEL 80102-31X AIR MOTOR NO.2 SPRAYGUN

END USER MUST READ AND UNDERSTAND THE SERVICE MANUAL PROVIDED WITH THIS PRODUCT.

QUICK START INSTRUCTIONS

STEP #1

STEP #2

STEP #3

STEP #4

STEP #5

STEP #6

STEP #7

CONNECT AIR IN.

CONNECT AIR OUT TO APPLICATOR.

CONNECT HV CABLE FROM APPLICATOR.

CONNECT TO TRUE EARTH GROUND.

AIR FROM POWER SUPPLY.

TURN ON POWER SUPPLY.

WAIT 7 SECONDS AFTER POWER ON. SLIDE VALVE AWAY

FROM THE BACK OF THE APPLICATOR.

STEP #8

TRIGGER APPLICATOR.

NOTE:

IF POWER IS PROVIDED FROM AN ALTERNATE SOURCE SUCH AS PORTABLE

GENERATOR THE USER MUST INSURE THE EQUIPMENT IS CONNECTED TO TRUE

EARTH GROUND.

TROUBLESHOOTING GUIDE

WARNING: Before troubleshooting gun and control unit problems, flush the gun with solvent and purge with air.

Some of the tests will require high voltage to be applied to the gun, so the gun must be empty of paint and solvent.

FAULT CODE DESCRIPTION SOLUTION

CABLE FAULT

(CF)

PAGE #21

CURRENT LIMIT

FAULT (CL)

PAGE #21

GROUND FAULT

(GF)

PAGE #21

OVERLOAD FAULT

(OL)

PAGE #21

BOOT FAULT

(BF)

PAGE #22

The Cable Fault indicates the control unit does not

detect a high voltage section on the end of the cable. The fault typically occurs at a high voltage trigger.

The Current Limit Fault indicates the current output

of the gun has exceeded the maximum allowable

output current. It typically occurs with the high voltage on.

The Ground Fault is typically caused by a ground

connection problem, and can create a safety hazard.

It can occur without high voltage and will not reset.

The Over Load Fault indicates the current output

has exceeded the overload threshold. This fault is

only active if jumper 17 is shorted. The overload

threshold is normally set at 10 µA below the maximum output of the applicator.

The Boot Fault indicates that an active trigger signal

was detected during the start-up sequence.

1. Check for loose wiring between the pc board connector and the high voltage section by pulling on each wire.

Repair if necessary. Insure both connectors are secure and re-test for CF fault.

2. Replace high voltage section or send unit in for repair.

3. Send unit in for repair.

1. Clean outside of the applicator.

2. Replace barrel or applicator.

3. Send applicator in for repair.

1. Check for loose wiring between the pc board connector and the high voltage section by pulling on each wire.

Repair if necessary. Insure both connectors are secure and re-test for GF fault.

2. Adjust the set point to 20kV and turn on the high voltage. A GF fault indicates a faulty pc board - replace.

3. Replace high voltage section or send unit in for repair.

4. Send unit in for repair.

1. This may indicate the paint conductivity is too high (resistance too low) or the outside of the applicator is

contaminated with paint.

1. Turn off the voltage controller.

2. Ensure that the gun trigger is not pressed.

3. Turn on the voltage controller to verify that a trigger signal is not present and that the unit enters the ‘ready’

state..

FEEDBACK FAULT

(FF)

PAGE #22

OVER VOLTAGE

FAULT (OU)

PAGE #22

VOLTAGE CABLE

FAULT (UC)

PAGE #22

The Feedback Fault indicates there is no current

feedback or it is incorrect. It typically occurs with the

high voltage on.

The Over Voltage Fault indicates the output voltage

exceeds the design specifications. It typically occurs

during a high voltage trigger.

The Voltage Feedback Fault indicates the cascade

drive signal is not present. It typically occurs when

high voltage is triggered.

4. Send the voltage controller in for repair or contact technical support.

1. Securely attach a ground wire to the applicator electrode.

2. Set the high voltage to maximum and place a jumper across the flow switch.

3. The current reading on the control unit should rise up to the maximum current output. If it does not, send the

applicator in for repair.

1. Check connections using two finger pull test to ensure they are connected.

2. Replace the pc board.

3. Send unit in form repair.

1. Turn off the voltage controller and remove the high voltage cable from the voltage controller.

2. Turn on the power and place a jumper across the flow switch. If the fault occurs, send the voltage controller

in for repair. If no fault occurs, continue.

3. Either the high voltage cable or if using a hand gun, the gun resistor tube has failed.. If available, replace the

high voltage cable, or continue to test the resistor tube.

4. To test the resistor tube, remove the resistor tube from the gun and inspect for signs of burning or arcing.

Cracks or black marks indicate failure of the resistor tube, indicating the resistor tube must be replaced.

Measure the resistance using a tri-meter connected to the black end of the tube and screwdriver in the

other end. The measurement must be 150 to 170 Mega ohms. Replace resistor tube if the reading is not

correct.

5. Replace high voltage cable or send applicator unit in for repair.

IL-421-01

Loading...

Loading...