Ransburg 80086-XX User Manual

SERVICE MANUAL

SERVICE MANUAL

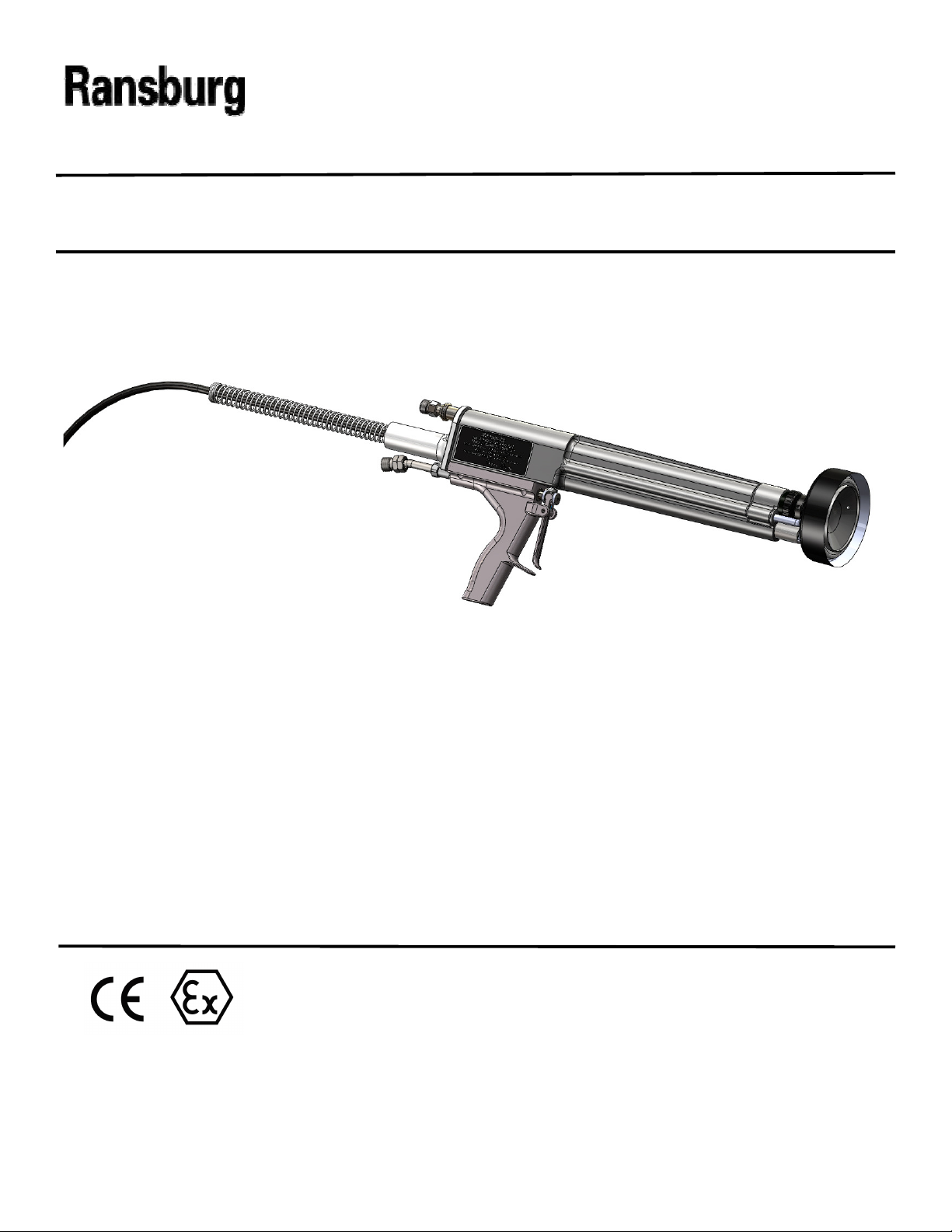

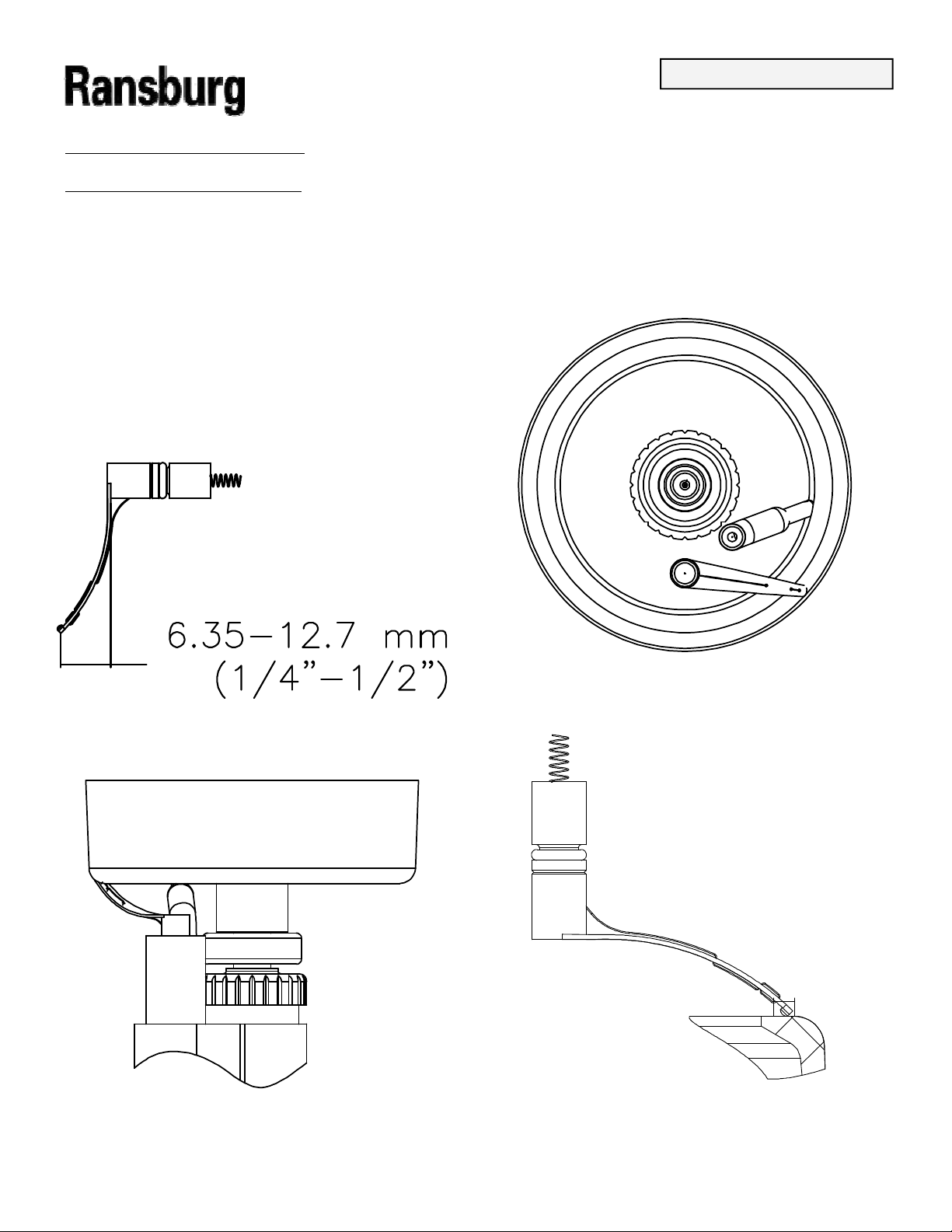

NO. 2 PROCESS HANDGUN UNIT

NO. 2 PROCESS HANDGUN UNIT

NO. 2 PROCESS HANDGUN UNITNO. 2 PROCESS HANDGUN UNIT

SERVICE MANUALSERVICE MANUAL

AH

AH----12

12----01.03

1212

01.03

01.0301.03

AHAH

AIR MOTOR DRIVEN

AIR MOTOR DRIVEN----ATEX APPROVED

AIR MOTOR DRIVENAIR MOTOR DRIVEN

MODEL: 80086

MODEL: 80086----XX

MODEL: 80086MODEL: 80086

IMPORTANT: Before using this equipment, carefully read

SAFETY PRECAUTIONS, starting on page 1, and all instructions

in this manual. Keep this Service Manual for future reference.

Service Manual Price: $30.00 (U.S.)

AH

ATEX APPROVED

ATEX APPROVEDATEX APPROVED

XX

XXXX

IMPORTANT: Before using this equipment, carefully read

IMPORTANT: Before using this equipment, carefully read IMPORTANT: Before using this equipment, carefully read

SAFETY PRECAUTIONS, starting on page 1, and all instructions

SAFETY PRECAUTIONS, starting on page 1, and all instructions SAFETY PRECAUTIONS, starting on page 1, and all instructions

in this manual. Keep this Service Manual for future reference.

in this manual. Keep this Service Manual for future reference.in this manual. Keep this Service Manual for future reference.

Service Manual Price: $30.00 (U.S.)

Service Manual Price: $30.00 (U.S.)Service Manual Price: $30.00 (U.S.)

AH----12

12----01.03 No. 2 Air Motor Handgun

AHAH

01.03 No. 2 Air Motor Handgun

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

NOTE:

NOTE: This is a release with some changes of this manual. Any future revisions will be listed in the rear

NOTE:NOTE:

appendix of this manual.

appendix of this manual.

appendix of this manual. appendix of this manual.

This is a release with some changes of this manual. Any future revisions will be listed in the rear

This is a release with some changes of this manual. Any future revisions will be listed in the rear This is a release with some changes of this manual. Any future revisions will be listed in the rear

AH

AH----12

12----01.03 No. 2 Air Motor Handgun

AHAH

01.03 No. 2 Air Motor Handgun 2222

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

CONTENTS

CONTENTS

CONTENTSCONTENTS

SAFETY:

SAFETY: 4

SAFETY:SAFETY:

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS ........ ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... .4

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

HAZARDS / SAFEGUARDS

HAZARDS / SAFEGUARDS ... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... .... 5

HAZARDS / SAFEGUARDSHAZARDS / SAFEGUARDS

INTRODUCTION:

INTRODUCTION: 7

INTRODUCTION:INTRODUCTION:

THE PROCESS

THE PROCESS ........ ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ... 8

THE PROCESSTHE PROCESS

EUROPEAN ATEX DIRECTIVE 94/9/EC ……………………………………………………………………..9

EUROPEAN ATEX DIRECTIVE 94/9/EC ……………………………………………………………………..9----10

EUROPEAN ATEX DIRECTIVE 94/9/EC ……………………………………………………………………..9EUROPEAN ATEX DIRECTIVE 94/9/EC ……………………………………………………………………..9

SPECIFICATIONS

SPECIFICATIONS .. ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ..... 11

SPECIFICATIONSSPECIFICATIONS

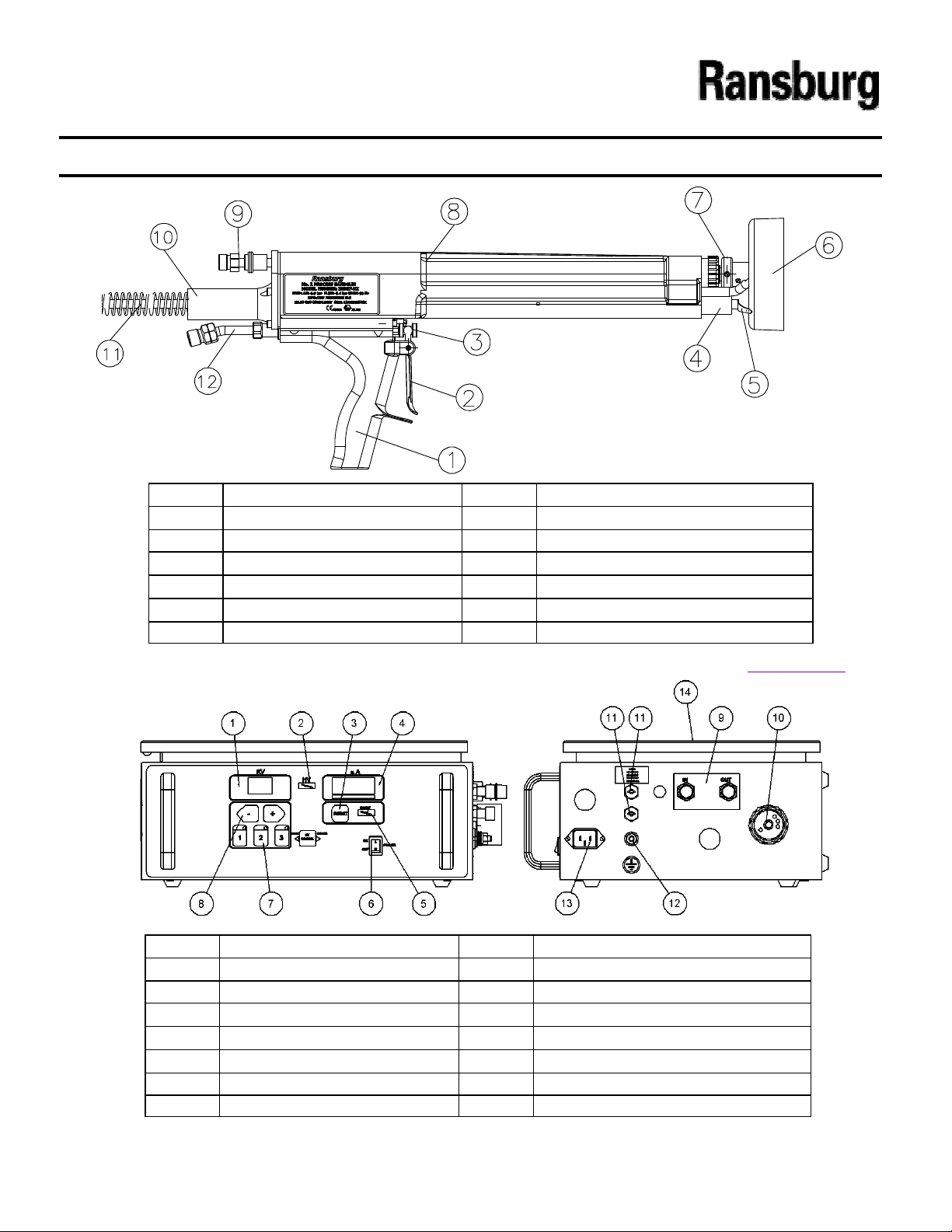

GUN FEATURES

GUN FEATURES .. ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... . 12

GUN FEATURESGUN FEATURES

INSTALLATION:

INSTALLATION: 9

INSTALLATION:INSTALLATION:

PRE

PRE----INSTALLATION REQUIREMENTS

INSTALLATION REQUIREMENTS.......... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..13

PREPRE

INSTALLATION REQUIREMENTSINSTALLATION REQUIREMENTS

SAFEGUARDS

SAFEGUARDS . ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... .13

SAFEGUARDSSAFEGUARDS

EQUIPMENT INSTALLATION

EQUIPMENT INSTALLATION ......... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... 13

EQUIPMENT INSTALLATIONEQUIPMENT INSTALLATION

OPERATION:

OPERATION: 21

OPERATION:OPERATION:

PROCEDURES

PROCEDURES ........ ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ... 21

PROCEDURESPROCEDURES

GUN ELECTRICAL OUTPUT

GUN ELECTRICAL OUTPUT ... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... . 26

GUN ELECTRICAL OUTPUTGUN ELECTRICAL OUTPUT

MAINTENANCE:

MAINTENANCE: 28

MAINTENANCE:MAINTENANCE:

EFFECTS OF SOLVENTS

EFFECTS OF SOLVENTS ....... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... .28

EFFECTS OF SOLVENTSEFFECTS OF SOLVENTS

SCHEDULES

SCHEDULES ....... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...30

SCHEDULESSCHEDULES

TEST PROCEDURES

TEST PROCEDURES ... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... 30

TEST PROCEDURESTEST PROCEDURES

FILTER CLEANING……………………………………………………………………………………………… 32

FILTER CLEANING……………………………………………………………………………………………… 32

FILTER CLEANING……………………………………………………………………………………………… 32FILTER CLEANING……………………………………………………………………………………………… 32

REPAIR PROCEDURES

REPAIR PROCEDURES . ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ..... 32

REPAIR PROCEDURESREPAIR PROCEDURES

CABLE / MOTOR ASSEMBLY

CABLE / MOTOR ASSEMBLY .......... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ..... 34

CABLE / MOTOR ASSEMBLYCABLE / MOTOR ASSEMBLY

HANDLE ASSEMBLY

HANDLE ASSEMBLY...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... .... 35

HANDLE ASSEMBLYHANDLE ASSEMBLY

BARREL ASSEMBLY

BARREL ASSEMBLY . ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ... 40

BARREL ASSEMBLYBARREL ASSEMBLY

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE ......... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ..... 45

TROUBLESHOOTING GUIDETROUBLESHOOTING GUIDE

PARTS IDENTIFICATION:

PARTS IDENTIFICATION: 49

PARTS IDENTIFICATION:PARTS IDENTIFICATION:

No. 2 APPLICATOR PARTS

No. 2 APPLICATOR PARTS .. ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... .... 49

No. 2 APPLICATOR PARTSNo. 2 APPLICATOR PARTS

CABLE/MOTOR PARTS LIST…………………………………………………………………………………. 50

CABLE/MOTOR PARTS LIST…………………………………………………………………………………. 50

CABLE/MOTOR PARTS LIST…………………………………………………………………………………. 50CABLE/MOTOR PARTS LIST…………………………………………………………………………………. 50

HANDLE ASSEMBLY

HANDLE ASSEMBLY ... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... .51

HANDLE ASSEMBLYHANDLE ASSEMBLY

NEEDLE VALVE ASSEMBLY PARTS………………………………………………………………..……… 52

NEEDLE VALVE ASSEMBLY PARTS………………………………………………………………..……… 52

NEEDLE VALVE ASSEMBLY PARTS………………………………………………………………..……… 52NEEDLE VALVE ASSEMBLY PARTS………………………………………………………………..……… 52

BARREL ASSEMBLY

BARREL ASSEMBLY .... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ..... 53

BARREL ASSEMBLYBARREL ASSEMBLY

FLUID HOSE/AIR HOSE PARTS

FLUID HOSE/AIR HOSE PARTS .. ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...54

FLUID HOSE/AIR HOSE PARTSFLUID HOSE/AIR HOSE PARTS

FEED TUBE/BRUSH PARTS

FEED TUBE/BRUSH PARTS ......... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ..56

FEED TUBE/BRUSH PARTSFEED TUBE/BRUSH PARTS

FLUID FILTER SPARE PARTS

FLUID FILTER SPARE PARTS ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ..57

FLUID FILTER SPARE PARTSFLUID FILTER SPARE PARTS

BELL PARTS AND ASSEMBLIES

BELL PARTS AND ASSEMBLIES ......... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... 58

BELL PARTS AND ASSEMBLIESBELL PARTS AND ASSEMBLIES

9050 SPARE PARTS LIST

9050 SPARE PARTS LIST ......... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ..... 59

9050 SPARE PARTS LIST9050 SPARE PARTS LIST

RECOMMENDED SPARE PARTS

RECOMMENDED SPARE PARTS ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..52

RECOMMENDED SPARE PARTSRECOMMENDED SPARE PARTS

WARRANTY POLICIES:

WARRANTY POLICIES: 61

WARRANTY POLICIES:WARRANTY POLICIES:

LIMITED WARRANTY

LIMITED WARRANTY ....... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... ..... ...... ...... ..... ...... ...... ...... 61

LIMITED WARRANTYLIMITED WARRANTY

3333 AH

AH----12

AHAH

PAGE

PAGE

PAGEPAGE

7

444----777

4

44

7

555----777

-12

12

777---

1212

8

88

10

1010

11

1111

12

1212

-14

14

999---

1414

13

1313

13

1313

13----20

20

1313

2020

21----27

27

2121

2727

21----26

26

2121

2626

26----27

27

2626

2727

28----48

48

2828

4848

28----29

29

2828

2929

30

3030

30----31

31

3030

3131

32----34

34

3232

3434

34----35

35

3434

3535

35----39

39

3535

3939

40----43

43

4040

4343

45----48

48

4545

4848

49----60

60

4949

6060

49

4949

51

5151

53

5353

54----55

55

5454

5555

56

5656

57

5757

58

5858

59

5959

52

5252

61

6161

61

6161

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

Before operating, maintaining or servicing any

Before operating, maintaining or servicing any

Before operating, maintaining or servicing any Before operating, maintaining or servicing any

Ransburg coating system, read and understand all of

Ransburg coating system, read and understand all of

Ransburg coating system, read and understand all of Ransburg coating system, read and understand all of

the technical and safety literature for your Ransburg

the technical and safety literature for your Ransburg

the technical and safety literature for your Ransburg the technical and safety literature for your Ransburg

products. This manual contains information that is im-

products. This manual contains information that is im-

products. This manual contains information that is im-products. This manual contains information that is important for you to know and understand. This infor-

portant for you to know and understand. This infor-

portant for you to know and understand. This infor-portant for you to know and understand. This information relates to USER SAFETY and PREVENTING

mation relates to USER SAFETY and PREVENTING

mation relates to USER SAFETY and PREVENTING mation relates to USER SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this

EQUIPMENT PROBLEMS. To help you recognize this

EQUIPMENT PROBLEMS. To help you recognize this EQUIPMENT PROBLEMS. To help you recognize this

information, we use the following symbols. Please pay

information, we use the following symbols. Please pay

information, we use the following symbols. Please pay information, we use the following symbols. Please pay

particular attention to these sections.

particular attention to these sections.

particular attention to these sections.particular attention to these sections.

A WARNING! states information to alert you to a situation

A WARNING! states information to alert you to a situation

A WARNING! states information to alert you to a situation A WARNING! states information to alert you to a situation

that might cause serious injury if instructions are not fol-

that might cause serious injury if instructions are not fol-

that might cause serious injury if instructions are not fol-that might cause serious injury if instructions are not followed.

lowed.

lowed.lowed.

A CAUTION! states information that tells how to prevent

A CAUTION! states information that tells how to prevent

A CAUTION! states information that tells how to prevent A CAUTION! states information that tells how to prevent

damage to equipment or how to avoid a situation that

damage to equipment or how to avoid a situation that

damage to equipment or how to avoid a situation that damage to equipment or how to avoid a situation that

might cause minor injury.

might cause minor injury.

might cause minor injury.might cause minor injury.

A NOTE is information relevant to the procedure in pro-

A NOTE is information relevant to the procedure in pro-

A NOTE is information relevant to the procedure in pro-A NOTE is information relevant to the procedure in progress.

gress.

gress.gress.

While this manual lists standard specifications and

While this manual lists standard specifications and

While this manual lists standard specifications and While this manual lists standard specifications and

service procedures, some minor deviations may be

service procedures, some minor deviations may be

service procedures, some minor deviations may be service procedures, some minor deviations may be

found between this literature and your equipment. Dif-

found between this literature and your equipment. Dif-

found between this literature and your equipment. Dif-found between this literature and your equipment. Differences in local codes and plant requirements, mate-

ferences in local codes and plant requirements, mate-

ferences in local codes and plant requirements, mate-ferences in local codes and plant requirements, material delivery requirements, etc., make such variations

rial delivery requirements, etc., make such variations

rial delivery requirements, etc., make such variations rial delivery requirements, etc., make such variations

inevitable. Compare this manual with your system in-

inevitable. Compare this manual with your system in-

inevitable. Compare this manual with your system in-inevitable. Compare this manual with your system installation drawings and appropriate Ransburg equip-

stallation drawings and appropriate Ransburg equip-

stallation drawings and appropriate Ransburg equip-stallation drawings and appropriate Ransburg equipment manuals to reconcile such differences.

ment manuals to reconcile such differences.

ment manuals to reconcile such differences.ment manuals to reconcile such differences.

Careful study and continued use of this manual will pro-

Careful study and continued use of this manual will pro-

Careful study and continued use of this manual will pro-Careful study and continued use of this manual will provide a better understanding of the equipment and pro-

vide a better understanding of the equipment and pro-

vide a better understanding of the equipment and pro-vide a better understanding of the equipment and process, resulting in more efficient operation, longer trouble

cess, resulting in more efficient operation, longer trouble----

cess, resulting in more efficient operation, longer troublecess, resulting in more efficient operation, longer trouble

free service and faster, easier troubleshooting. If you do

free service and faster, easier troubleshooting. If you do

free service and faster, easier troubleshooting. If you do free service and faster, easier troubleshooting. If you do

not have the manuals and safety literature for your

not have the manuals and safety literature for your

not have the manuals and safety literature for your not have the manuals and safety literature for your

Ransburg system, contact your local Ransburg repre-

Ransburg system, contact your local Ransburg repre-

Ransburg system, contact your local Ransburg repre-Ransburg system, contact your local Ransburg representative or Ransburg.

sentative or Ransburg.

sentative or Ransburg.sentative or Ransburg.

The user MUST read and be familiar

The user MUST read and be familiar

The user MUST read and be familiar The user MUST read and be familiar

with the Safety Section in this manual and the Ransburg

with the Safety Section in this manual and the Ransburg

with the Safety Section in this manual and the Ransburg with the Safety Section in this manual and the Ransburg

safety literature therein identified.

safety literature therein identified.

safety literature therein identified.safety literature therein identified.

!!!!

Warning

Warning

WarningWarning

This manual

This manual MUST

This manualThis manual

derstood by ALL personnel who operate, clean

derstood by ALL personnel who operate, clean

derstood by ALL personnel who operate, clean derstood by ALL personnel who operate, clean

or maintain this equipment! Special care should

or maintain this equipment! Special care should

or maintain this equipment! Special care should or maintain this equipment! Special care should

be taken to ensure that the WARNINGS and

be taken to ensure that the WARNINGS and

be taken to ensure that the WARNINGS and be taken to ensure that the WARNINGS and

safety requirements for operating and servicing

safety requirements for operating and servicing

safety requirements for operating and servicing safety requirements for operating and servicing

the equipment are followed. The user should be

the equipment are followed. The user should be

the equipment are followed. The user should be the equipment are followed. The user should be

aware of and adhere to ALL local building and

aware of and adhere to ALL local building and

aware of and adhere to ALL local building and aware of and adhere to ALL local building and

fire codes and ordinances as well as NFPA

fire codes and ordinances as well as NFPA----33 ,

fire codes and ordinances as well as NFPAfire codes and ordinances as well as NFPA

EN 50 176 SAFETY STANDARDS, prior to in-

EN 50 176 SAFETY STANDARDS, prior to in-

EN 50 176 SAFETY STANDARDS, prior to in-EN 50 176 SAFETY STANDARDS, prior to installing, operating, and/or servicing this equip-

stalling, operating, and/or servicing this equip-

stalling, operating, and/or servicing this equip-stalling, operating, and/or servicing this equipment.

ment.

ment.ment.

W A R N I N G

W A R N I N G

W A R N I N G W A R N I N G

MUST be read and thoroughly un-

MUSTMUST

be read and thoroughly un-

be read and thoroughly un-be read and thoroughly un-

The hazards shown on t

The hazards shown on thhhhe following page may

The hazards shown on tThe hazards shown on t

occur during the normal use of this equipment.

occur during the normal use of this equipment.

occur during the normal use of this equipment. occur during the normal use of this equipment.

Please read the hazard chart beginning on page

Please read the hazard chart beginning on page

Please read the hazard chart beginning on page Please read the hazard chart beginning on page

5.

5.

5. 5.

!!!!

Warning

Warning

WarningWarning

e following page may

e following page may e following page may

33 ,

33 , 33 ,

AH

AH----12

12----01.03 No. 2 Air Motor Handgun

AHAH

01.03 No. 2 Air Motor Handgun 4444

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

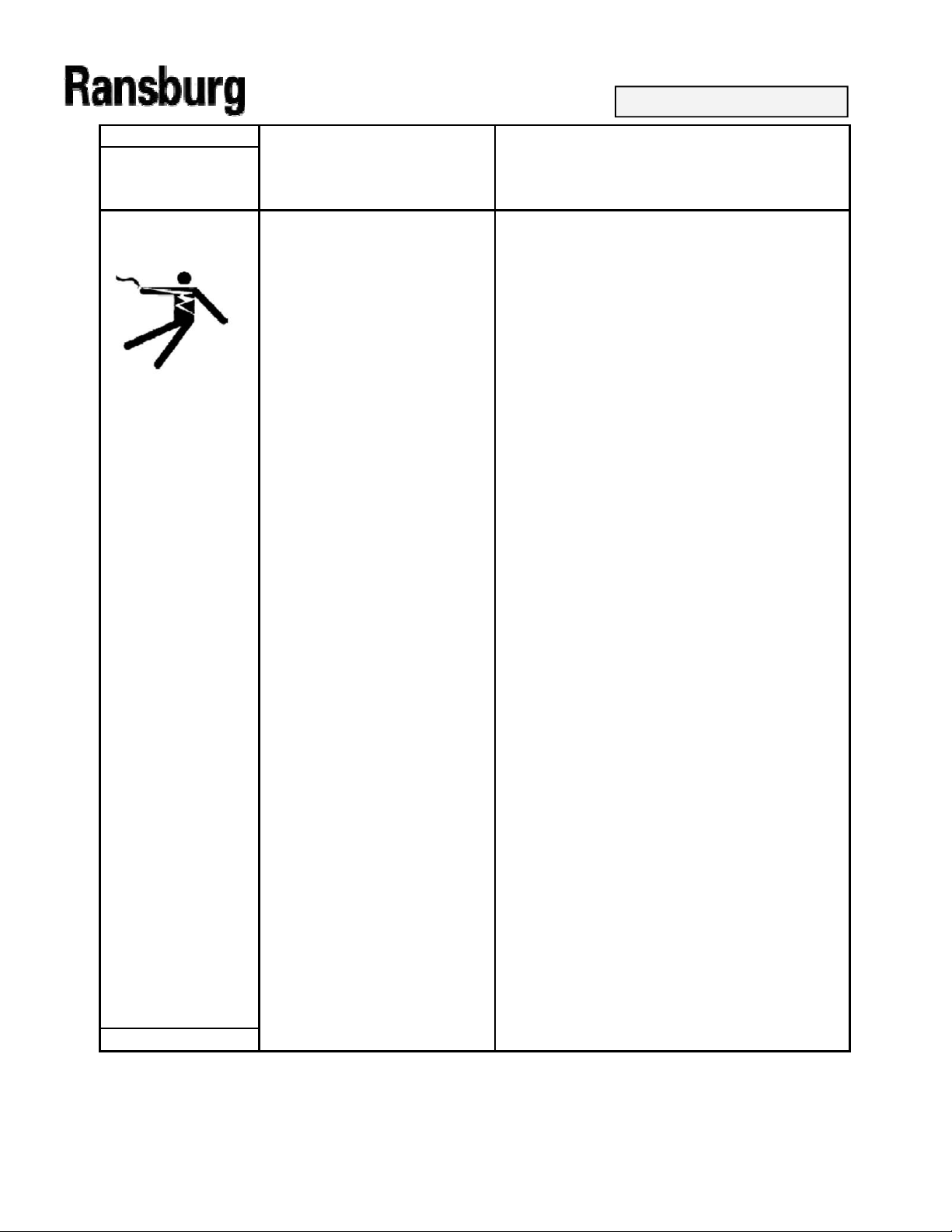

AREA

AREA

AREAAREA

Tells where hazards

Tells where hazards Tells what the hazard is.

Tells where hazardsTells where hazards

may occur.

may occur.

may occur.may occur.

Spray Area

Spray Area Electrostatic Arcing

Spray AreaSpray Area

HAZARD

HAZARD SAFEGUARDS

HAZARDHAZARD

Tells what the hazard is. Tells how to avoid the hazard.

Tells what the hazard is.Tells what the hazard is.

Electrostatic Arcing Never operate the spray gun without properly

Electrostatic ArcingElectrostatic Arcing

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Tells how to avoid the hazard.Tells how to avoid the hazard.

Never operate the spray gun without properly

Never operate the spray gun without properlyNever operate the spray gun without properly

grounding the following.

insulating shoes should not be worn.

Grounding leg straps may be used.

handle of the gun. If work gloves are used, the

palm section should be cut out.

metal objects that are not grounded.

1 megohm.

area. This includes the booth, parts hangers,

fire extinguishers, conductive flooring, etc.

grounding the following.

grounding the following.grounding the following.

A. Operators

A. Operators

A. OperatorsA. Operators

Operators must be grounded. Rubber soled

Operators must be grounded. Rubber soled

Operators must be grounded. Rubber soledOperators must be grounded. Rubber soled

insulating shoes should not be worn.

insulating shoes should not be worn.insulating shoes should not be worn.

Grounding leg straps may be used.

Grounding leg straps may be used.Grounding leg straps may be used.

Operators must maintain contact with the

Operators must maintain contact with the

Operators must maintain contact with theOperators must maintain contact with the

handle of the gun. If work gloves are used, the

handle of the gun. If work gloves are used, thehandle of the gun. If work gloves are used, the

palm section should be cut out.

palm section should be cut out.palm section should be cut out.

Operators must remove from themselves all

Operators must remove from themselves all

Operators must remove from themselves allOperators must remove from themselves all

metal objects that are not grounded.

metal objects that are not grounded.metal objects that are not grounded.

NOTE: REFER TO NFPA

NOTE: REFER TO NFPA----33/EN 50 176 RE-

NOTE: REFER TO NFPANOTE: REFER TO NFPA

GARDING OPERATOR GROUNDING.

GARDING OPERATOR GROUNDING.

GARDING OPERATOR GROUNDING.GARDING OPERATOR GROUNDING.

B. Parts being sprayed. Resistance between the

B. Parts being sprayed. Resistance between the

B. Parts being sprayed. Resistance between theB. Parts being sprayed. Resistance between the

part and a grounded conveyor must not exceed

part and a grounded conveyor must not exceed

part and a grounded conveyor must not exceedpart and a grounded conveyor must not exceed

1 megohm.

1 megohm.1 megohm.

C. Every metal and conductive object in the spray

C. Every metal and conductive object in the spray

C. Every metal and conductive object in the sprayC. Every metal and conductive object in the spray

area. This includes the booth, parts hangers,

area. This includes the booth, parts hangers,area. This includes the booth, parts hangers,

fire extinguishers, conductive flooring, etc.

fire extinguishers, conductive flooring, etc.fire extinguishers, conductive flooring, etc.

33/EN 50 176 RE-

33/EN 50 176 RE-33/EN 50 176 RE-

the spray area.

out, cleaning, or removing any parts from the gun.

systems.

isolated solvent supply.

prior to servicing.

5555 AH

Grounded conductive flooring must be provided in

Grounded conductive flooring must be provided in

Grounded conductive flooring must be provided inGrounded conductive flooring must be provided in

the spray area.

the spray area.the spray area.

Turn off voltage at the power supply before flushing

Turn off voltage at the power supply before flushing

Turn off voltage at the power supply before flushingTurn off voltage at the power supply before flushing

out, cleaning, or removing any parts from the gun.

out, cleaning, or removing any parts from the gun.out, cleaning, or removing any parts from the gun.

Provide proper protection for waterborne supply

Provide proper protection for waterborne supply

Provide proper protection for waterborne supplyProvide proper protection for waterborne supply

systems.

systems.systems.

Never install a spray gun into a fluid system using an

Never install a spray gun into a fluid system using an

Never install a spray gun into a fluid system using anNever install a spray gun into a fluid system using an

isolated solvent supply.

isolated solvent supply.isolated solvent supply.

Always discharge Waterborne system capacitance

Always discharge Waterborne system capacitance

Always discharge Waterborne system capacitanceAlways discharge Waterborne system capacitance

prior to servicing.

prior to servicing.prior to servicing.

Do not touch gun electrode while gun is energized.

Do not touch gun electrode while gun is energized.

Do not touch gun electrode while gun is energized.Do not touch gun electrode while gun is energized.

AH----12

12----01.03 No. 2 Air Motor Handgun

AHAH

01.03 No. 2 Air Motor Handgun

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

AREA

AREA

AREAAREA

Tells where

Tells where Tells what the hazard is.

Tells whereTells where

hazards may occur.

hazards may occur.

hazards may occur.hazards may occur.

Spray Area

Spray Area Fire Hazard

Spray AreaSpray Area

HAZARD

HAZARD SAFEGUARDS

HAZARDHAZARD

Tells what the hazard is. Tells how to avoid the hazard.

Tells what the hazard is.Tells what the hazard is.

Fire Hazard

Fire HazardFire Hazard

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Tells how to avoid the hazard.Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

Fire extinguishing equipment must be present in the

Fire extinguishing equipment must be present in theFire extinguishing equipment must be present in the

spray area and tested periodically.

and maintenance procedures will

cause a fire hazard.

arcing that is capable of causing

interlocks are disabled during

shutdown indicates a problem in

the system requiring correction.

points equal to or higher than those of the coating

material.

Improper or inadequate operation

Improper or inadequate operation

Improper or inadequate operationImproper or inadequate operation

and maintenance procedures will Spray areas must be kept clean to prevent the

and maintenance procedures willand maintenance procedures will

cause a fire hazard. accumulation of combustible residues.

cause a fire hazard.cause a fire hazard.

Protection against inadvertent

Protection against inadvertent Smoking must never be allowed in the spray area.

Protection against inadvertentProtection against inadvertent

arcing that is capable of causing

arcing that is capable of causingarcing that is capable of causing

fire or explosion is lost if any safety

fire or explosion is lost if any safety

fire or explosion is lost if any safetyfire or explosion is lost if any safety

interlocks are disabled during

interlocks are disabled duringinterlocks are disabled during

operation. Frequent power supply

operation. Frequent power supply

operation. Frequent power supplyoperation. Frequent power supply

shutdown indicates a problem in When using solvents for cleaning:

shutdown indicates a problem inshutdown indicates a problem in

the system requiring correction.

the system requiring correction.the system requiring correction.

required by local codes and national codes. In

addition, ventilation must be maintained during

solvents.

spray area and tested periodically.

spray area and tested periodically.spray area and tested periodically.

Spray areas must be kept clean to prevent the

Spray areas must be kept clean to prevent theSpray areas must be kept clean to prevent the

accumulation of combustible residues.

accumulation of combustible residues.accumulation of combustible residues.

Smoking must never be allowed in the spray area.

Smoking must never be allowed in the spray area.Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

The high voltage supplied to the atomizer must be

The high voltage supplied to the atomizer must beThe high voltage supplied to the atomizer must be

turned off prior to cleaning, flushing, or maintenance.

turned off prior to cleaning, flushing, or maintenance.

turned off prior to cleaning, flushing, or maintenance.turned off prior to cleaning, flushing, or maintenance.

When using solvents for cleaning:

When using solvents for cleaning:When using solvents for cleaning:

Those used for equipment flushing should have flash

Those used for equipment flushing should have flash

Those used for equipment flushing should have flashThose used for equipment flushing should have flash

points equal to or higher than those of the coating

points equal to or higher than those of the coatingpoints equal to or higher than those of the coating

material.

material.material.

Those used for general cleaning must have flash

Those used for general cleaning must have flash

Those used for general cleaning must have flashThose used for general cleaning must have flash

points at least 5

points at least 5°C (9

points at least 5points at least 5

ture. It is the end users responsibility to insure this

ture. It is the end users responsibility to insure this

ture. It is the end users responsibility to insure this ture. It is the end users responsibility to insure this

condition is met.

condition is met.

condition is met. condition is met.

Spray booth ventilation must be kept at the rates

Spray booth ventilation must be kept at the rates

Spray booth ventilation must be kept at the ratesSpray booth ventilation must be kept at the rates

required by local codes and national codes. In

required by local codes and national codes. Inrequired by local codes and national codes. In

addition, ventilation must be maintained during

addition, ventilation must be maintained duringaddition, ventilation must be maintained during

cleaning operations using flammable or combustible

cleaning operations using flammable or combustible

cleaning operations using flammable or combustiblecleaning operations using flammable or combustible

solvents.

solvents.solvents.

C (9° F.) above ambient tempera-

F.) above ambient tempera-

C (9C (9

F.) above ambient tempera- F.) above ambient tempera-

instructed.

equipment modifications may cause fire or injury.

done with safety interlocks disabled.

installations to spray solvent based materials.

AH

AH----12

12----01.03 No. 2 Air Motor Handgun

AHAH

01.03 No. 2 Air Motor Handgun 6666

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

EN Health and Safety requirements.

Electrostatic arcing must be prevented.

Electrostatic arcing must be prevented.

Electrostatic arcing must be prevented.Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Test only in areas free of combustible material.

Test only in areas free of combustible material.Test only in areas free of combustible material.

Testing may require high voltage to be on, but only as

Testing may require high voltage to be on, but only as

Testing may require high voltage to be on, but only asTesting may require high voltage to be on, but only as

instructed.

instructed.instructed.

Non

Non----factory replacement parts or unauthorized

factory replacement parts or unauthorized

NonNon

factory replacement parts or unauthorizedfactory replacement parts or unauthorized

equipment modifications may cause fire or injury.

equipment modifications may cause fire or injury.equipment modifications may cause fire or injury.

If used, the key switch bypass is intended for use only

If used, the key switch bypass is intended for use only

If used, the key switch bypass is intended for use onlyIf used, the key switch bypass is intended for use only

during setup operations. Production should never be

during setup operations. Production should never be

during setup operations. Production should never beduring setup operations. Production should never be

done with safety interlocks disabled.

done with safety interlocks disabled.done with safety interlocks disabled.

Never use equipment intended for use in waterborne

Never use equipment intended for use in waterborne

Never use equipment intended for use in waterborneNever use equipment intended for use in waterborne

installations to spray solvent based materials.

installations to spray solvent based materials.installations to spray solvent based materials.

The paint process and equipment should be set up

The paint process and equipment should be set up

The paint process and equipment should be set upThe paint process and equipment should be set up

and operated in accordance with NFPA

and operated in accordance with NFPA----33, NEC, and

and operated in accordance with NFPAand operated in accordance with NFPA

EN Health and Safety requirements.

EN Health and Safety requirements.EN Health and Safety requirements.

33, NEC, and

33, NEC, and33, NEC, and

AREA

AREA

AREAAREA

Tells where hazards

Tells where hazards Tells what the hazard is.

Tells where hazardsTells where hazards

may occur.

may occur.

may occur.may occur.

General Use and

General Use and

General Use andGeneral Use and

Maintenance

Maintenance

MaintenanceMaintenance

HAZARD

HAZARD SAFEGUARDS

HAZARDHAZARD

Tells what the hazard is. Tells how to avoid the hazard.

Tells what the hazard is.Tells what the hazard is.

Improper operation or mainte-

Improper operation or mainte-

Improper operation or mainte-Improper operation or maintenance

nance

nancenance

may create a hazard.

may create a hazard. the requirements of NFPA

may create a hazard.may create a hazard.

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFEGUARDS

SAFEGUARDSSAFEGUARDS

Tells how to avoid the hazard.

Tells how to avoid the hazard.Tells how to avoid the hazard.

Personnel must be given training in accordance with

Personnel must be given training in accordance with

Personnel must be given training in accordance withPersonnel must be given training in accordance with

the requirements of NFPA----33/EN 50 176.

the requirements of NFPAthe requirements of NFPA

33/EN 50 176.

33/EN 50 176.33/EN 50 176.

in the use of this equipment.

General Use and

General Use and Use of hand tools may cause

General Use andGeneral Use and

Maintenance

Maintenance cumulative trauma disorders

MaintenanceMaintenance

disorders, involve damage to the

neck and back. Carpal tunnel

tennis elbow or rotator cuff

them. Should you experience any such symptoms,

to affect the upper extremities.

Factors which may increase the

use of the arm, wrist and hand can lead to serious

1.

Personnel must be properly trained

Personnel must be properly trained Instructions and safety precautions must be read and

Personnel must be properly trainedPersonnel must be properly trained

in the use of this equipment. understood prior to using this equipment.

in the use of this equipment.in the use of this equipment.

Use of hand tools may cause Risk is reduced by avoiding or lessening the listed

Use of hand tools may causeUse of hand tools may cause

cumulative trauma disorders hazards.

cumulative trauma disorderscumulative trauma disorders

(CTD's). CTD's or musculoskeletal

(CTD's). CTD's or musculoskeletal

(CTD's). CTD's or musculoskeletal(CTD's). CTD's or musculoskeletal

disorders, involve damage to the CTD's can also be caused by such activities as

disorders, involve damage to thedisorders, involve damage to the

hands, wrists, elbows, shoulders,

hands, wrists, elbows, shoulders,

hands, wrists, elbows, shoulders,hands, wrists, elbows, shoulders,

neck and back. Carpal tunnel

neck and back. Carpal tunnelneck and back. Carpal tunnel

syndrome and tendinitis (such as

syndrome and tendinitis (such as Pain, tingling, or numbness in the shoulder, forearm,

syndrome and tendinitis (such assyndrome and tendinitis (such as

tennis elbow or rotator cuff

tennis elbow or rotator cufftennis elbow or rotator cuff

syndrome) are examples of CTD's.

syndrome) are examples of CTD's.

syndrome) are examples of CTD's.syndrome) are examples of CTD's.

CTD's when using hand tools,

CTD's when using hand tools,

CTD's when using hand tools, CTD's when using hand tools,

tend

tend

tendtend

to affect the upper extremities. may include vague discomfort in the hand, loss of

to affect the upper extremities.to affect the upper extremities.

Factors which may increase the manual dexterity, and non

Factors which may increase theFactors which may increase the

risk of developing a CTD include:

risk of developing a CTD include:

risk of developing a CTD include:risk of developing a CTD include:

1. High frequency of the activity.

High frequency of the activity. disability.

1.1.

High frequency of the activity.High frequency of the activity.

Instructions and safety precautions must be read and

Instructions and safety precautions must be read andInstructions and safety precautions must be read and

understood prior to using this equipment.

understood prior to using this equipment.understood prior to using this equipment.

Comply with appropriate local, state, and national

Comply with appropriate local, state, and national

Comply with appropriate local, state, and nationalComply with appropriate local, state, and national

codes governing ventilation, fire protection, operation

codes governing ventilation, fire protection, operation

codes governing ventilation, fire protection, operationcodes governing ventilation, fire protection, operation

maintenance, and housekeeping.

maintenance, and housekeeping.

maintenance, and housekeeping. maintenance, and housekeeping.

Risk is reduced by avoiding or lessening the listed

Risk is reduced by avoiding or lessening the listedRisk is reduced by avoiding or lessening the listed

hazards.

hazards.hazards.

CTD's can also be caused by such activities as

CTD's can also be caused by such activities asCTD's can also be caused by such activities as

sewing, golf, tennis and bowling, to name a few.

sewing, golf, tennis and bowling, to name a few.

sewing, golf, tennis and bowling, to name a few.sewing, golf, tennis and bowling, to name a few.

Pain, tingling, or numbness in the shoulder, forearm,

Pain, tingling, or numbness in the shoulder, forearm,Pain, tingling, or numbness in the shoulder, forearm,

wrists, hands, or fingers, especially during the night,

wrists, hands, or fingers, especially during the night,

wrists, hands, or fingers, especially during the night,wrists, hands, or fingers, especially during the night,

may be early symptoms of a CTD. Do not ignore

may be early symptoms of a CTD. Do not ignore

may be early symptoms of a CTD. Do not ignoremay be early symptoms of a CTD. Do not ignore

them. Should you experience any such symptoms,

them. Should you experience any such symptoms,them. Should you experience any such symptoms,

see a physician immediately. Other early symptoms

see a physician immediately. Other early symptoms

see a physician immediately. Other early symptomssee a physician immediately. Other early symptoms

may include vague discomfort in the hand, loss of

may include vague discomfort in the hand, loss ofmay include vague discomfort in the hand, loss of

manual dexterity, and non----specific pain in the arm.

manual dexterity, and nonmanual dexterity, and non

Ignoring early symptoms and continued repetitive

Ignoring early symptoms and continued repetitive

Ignoring early symptoms and continued repetitiveIgnoring early symptoms and continued repetitive

use of the arm, wrist and hand can lead to serious

use of the arm, wrist and hand can lead to serioususe of the arm, wrist and hand can lead to serious

disability.

disability.disability.

specific pain in the arm.

specific pain in the arm.specific pain in the arm.

gripping, pinching or pressing

with the hands and fingers.

wrist or arm positions.

activity.

body part.

7777 AH

2.

2. Excessive force, such as

Excessive force, such as

2.2.

Excessive force, such asExcessive force, such as

gripping, pinching or pressing

gripping, pinching or pressinggripping, pinching or pressing

with the hands and fingers.

with the hands and fingers.with the hands and fingers.

3. Extreme or awkward finger,

3. Extreme or awkward finger,

3. Extreme or awkward finger,3. Extreme or awkward finger,

wrist or arm positions.

wrist or arm positions.wrist or arm positions.

4. Excessive duration of the

4. Excessive duration of the

4. Excessive duration of the4. Excessive duration of the

activity.

activity.activity.

5.

5. Tool vibration.

Tool vibration.

5.5.

Tool vibration.Tool vibration.

6. Repeated pressure on a

6. Repeated pressure on a

6. Repeated pressure on a6. Repeated pressure on a

body part.

body part.body part.

7.

7.

Working in cold temperatures.

Working in cold temperatures.

7.7.

Working in cold temperatures.Working in cold temperatures.

AH----12

AHAH

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

INTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

This is a method of applying electrostatically at-

This is a method of applying electrostatically at-

This is a method of applying electrostatically at-This is a method of applying electrostatically atomized coating material. The

omized coating material. The

omized coating material. The omized coating material. The

Handgun

Handgun

Handgun Handgun

negative charge to the applicator bell, creating

negative charge to the applicator bell, creating

negative charge to the applicator bell, creating negative charge to the applicator bell, creating

an electrostatic field between the bell and the

an electrostatic field between the bell and the

an electrostatic field between the bell and the an electrostatic field between the bell and the

target object. The target is electrically grounded

target object. The target is electrically grounded

target object. The target is electrically grounded target object. The target is electrically grounded

through its support (which may be stationary or

through its support (which may be stationary or

through its support (which may be stationary or through its support (which may be stationary or

moving) or through an electrical connection to a

moving) or through an electrical connection to a

moving) or through an electrical connection to a moving) or through an electrical connection to a

known earth ground.

known earth ground.

known earth ground.known earth ground.

system applies a high voltage, DC

system applies a high voltage, DC

system applies a high voltage, DCsystem applies a high voltage, DC

No. 2 Process

No. 2 Process

No. 2 ProcessNo. 2 Process

A regulated pressure fluid system delivers coat-

A regulated pressure fluid system delivers coat-

A regulated pressure fluid system delivers coat-A regulated pressure fluid system delivers coating material to the air motor driven bell when the

ing material to the air motor driven bell when the

ing material to the air motor driven bell when the ing material to the air motor driven bell when the

gun is triggered. There, the fluid travels across

gun is triggered. There, the fluid travels across

gun is triggered. There, the fluid travels across gun is triggered. There, the fluid travels across

the face of the rotating bell and is charged. The

the face of the rotating bell and is charged. The

the face of the rotating bell and is charged. The the face of the rotating bell and is charged. The

fluid is atomized at the edge of the bell forming

fluid is atomized at the edge of the bell forming

fluid is atomized at the edge of the bell forming fluid is atomized at the edge of the bell forming

a fine mist, which under the influence of the

a fine mist, which under the influence of the

a fine mist, which under the influence of the a fine mist, which under the influence of the

electrostatic field is attracted to and deposited

electrostatic field is attracted to and deposited

electrostatic field is attracted to and deposited electrostatic field is attracted to and deposited

on the target object. The forces between the

on the target object. The forces between the

on the target object. The forces between the on the target object. The forces between the

charged particles and the grounded target are

charged particles and the grounded target are

charged particles and the grounded target are charged particles and the grounded target are

sufficient to turn most normal overspray around

sufficient to turn most normal overspray around

sufficient to turn most normal overspray around sufficient to turn most normal overspray around

and deposit it on the rear surface of the target.

and deposit it on the rear surface of the target.

and deposit it on the rear surface of the target. and deposit it on the rear surface of the target.

Therefore, most of the spray is deposited and

Therefore, most of the spray is deposited and

Therefore, most of the spray is deposited and Therefore, most of the spray is deposited and

overspray is controlled. This process makes the

overspray is controlled. This process makes the

overspray is controlled. This process makes the overspray is controlled. This process makes the

No. 2 Process Handgun one of the most effi-

No. 2 Process Handgun one of the most effi-

No. 2 Process Handgun one of the most effi-No. 2 Process Handgun one of the most efficient electrostatic spray products on the market.

cient electrostatic spray products on the market.

cient electrostatic spray products on the market.cient electrostatic spray products on the market.

The No. 2 Process Handgun applies a DC neg-

The No. 2 Process Handgun applies a DC neg-

The No. 2 Process Handgun applies a DC neg-The No. 2 Process Handgun applies a DC negaaaattttiiiivvvveeee cccchhhhaaaarrrrggggeeee ttttoooo tttthhhheeee ccccooooaaaattttiiiinnnngggg mmmmaaaatttteeeerrrriiiiaaaallllssss aaaatttt tttthhhheeee ppppooooiiiinnnntttt

of atomization. The electrostatic charge allows a

of atomization. The electrostatic charge allows a

of atomization. The electrostatic charge allows a of atomization. The electrostatic charge allows a

more efficient, uniform application of coating

more efficient, uniform application of coating

more efficient, uniform application of coating more efficient, uniform application of coating

material to the front, edges, sides, and back of

material to the front, edges, sides, and back of

material to the front, edges, sides, and back of material to the front, edges, sides, and back of

products, making it highly suitable for applying

products, making it highly suitable for applying

products, making it highly suitable for applying products, making it highly suitable for applying

coatings to a variety of surface configurations;

coatings to a variety of surface configurations;

coatings to a variety of surface configurations; coatings to a variety of surface configurations;

large targets, tubular products, small parts,

large targets, tubular products, small parts,

large targets, tubular products, small parts, large targets, tubular products, small parts,

fencing, etc. Because it is a grounded fluid sys-

fencing, etc. Because it is a grounded fluid sys-

fencing, etc. Because it is a grounded fluid sys-fencing, etc. Because it is a grounded fluid system, it is highly suitable for applying a wide

tem, it is highly suitable for applying a wide

tem, it is highly suitable for applying a wide tem, it is highly suitable for applying a wide

range of solvent reduced coatings such as

range of solvent reduced coatings such as

range of solvent reduced coatings such as range of solvent reduced coatings such as

enamels, epoxies, etc.

enamels, epoxies, etc.

enamels, epoxies, etc.enamels, epoxies, etc.

One of the many features of the No. 2 Process

One of the many features of the No. 2 Process

One of the many features of the No. 2 Process One of the many features of the No. 2 Process

Handgun is that the electrical discharge, which

Handgun is that the electrical discharge, which

Handgun is that the electrical discharge, which Handgun is that the electrical discharge, which

is available from the resistive charging brush, is

is available from the resistive charging brush, is

is available from the resistive charging brush, is is available from the resistive charging brush, is

limited to the optimum combination of safety

limited to the optimum combination of safety

limited to the optimum combination of safety limited to the optimum combination of safety

and efficiency. This discharge energy is con-

and efficiency. This discharge energy is con-

and efficiency. This discharge energy is con-and efficiency. This discharge energy is confirmed by Atex type testing found to be below

firmed by Atex type testing found to be below

firmed by Atex type testing found to be below firmed by Atex type testing found to be below

the .24 mJ energy level thus may be used safely

the .24 mJ energy level thus may be used safely

the .24 mJ energy level thus may be used safely the .24 mJ energy level thus may be used safely

in Zone 1 and Zone 2 applications.

in Zone 1 and Zone 2 applications.

in Zone 1 and Zone 2 applications. in Zone 1 and Zone 2 applications.

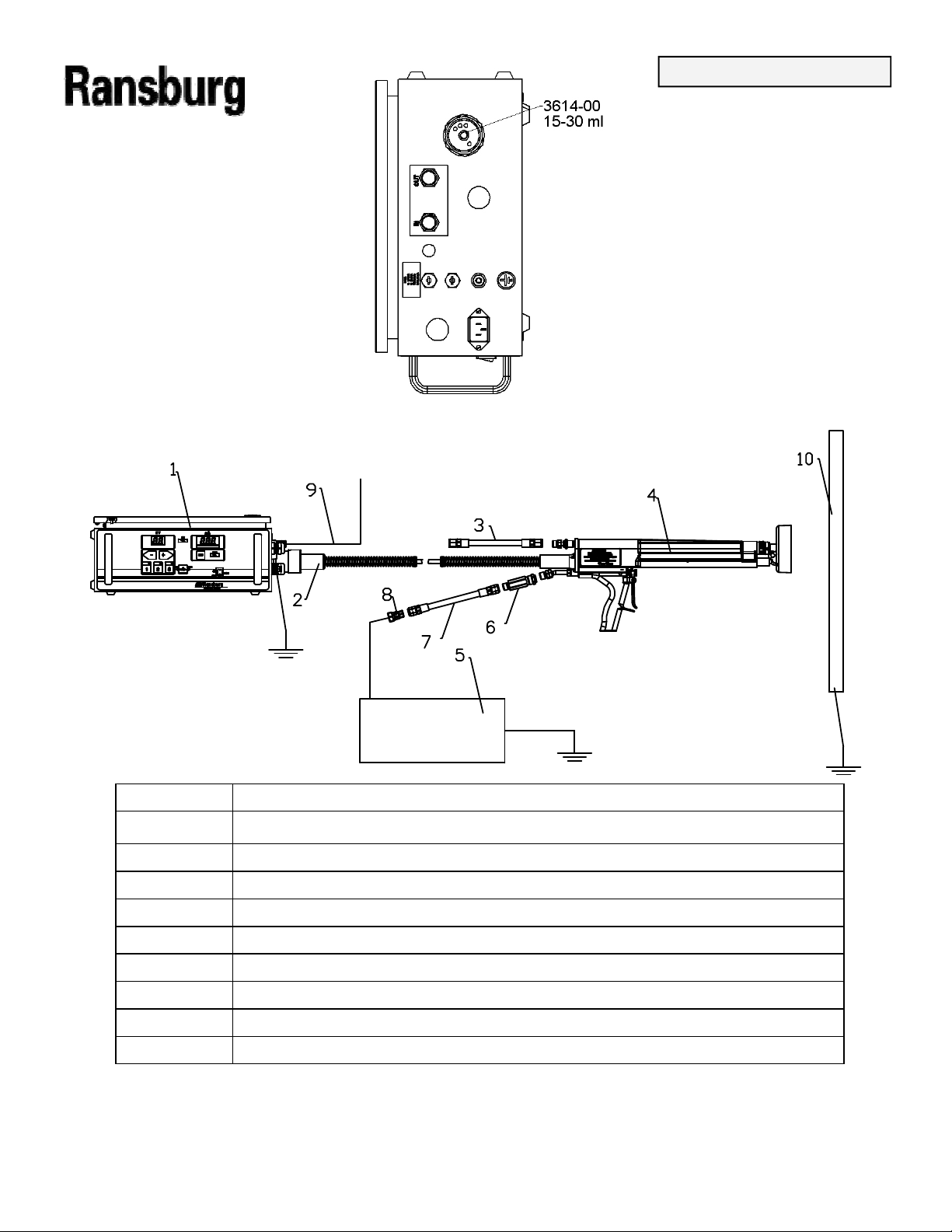

The No. 2 Process Handgun system includes

The No. 2 Process Handgun system includes

The No. 2 Process Handgun system includes The No. 2 Process Handgun system includes

the Hand Gun, the High Voltage Power Supply,

the Hand Gun, the High Voltage Power Supply,

the Hand Gun, the High Voltage Power Supply, the Hand Gun, the High Voltage Power Supply,

the High Voltage Cable, Air Hose and Fluid

the High Voltage Cable, Air Hose and Fluid

the High Voltage Cable, Air Hose and Fluid the High Voltage Cable, Air Hose and Fluid

Hose.

Hose.

Hose.Hose.

This unit contains the 20987

This unit contains the 20987----XX No. 2 handgun

This unit contains the 20987This unit contains the 20987

air motor version and the 80102

air motor version and the 80102----31X 9060 pow-

air motor version and the 80102air motor version and the 80102

er supply along with several required accesso-

er supply along with several required accesso-

er supply along with several required accesso-er supply along with several required accessories. Below illustrates the ordering matrix availa-

ries. Below illustrates the ordering matrix availa-

ries. Below illustrates the ordering matrix availa-ries. Below illustrates the ordering matrix available .

ble .

ble . ble .

80086

80086----AB No. 2 air motor unit

8008680086

A is

----2 for users with plug style 2

----3 for users with plug style 3

B is

----2 for 36’ (11 m) high voltage cable

----3 for 50’ (15.2 m) high voltage cable

AB No. 2 air motor unit

AB No. 2 air motor unitAB No. 2 air motor unit

A is ----1 for users with plug style 1

A isA is

B is ----1 for 25’ (7.6 m) high voltage cable

B is B is

1 for users with plug style 1

1 for users with plug style 11 for users with plug style 1

2 for users with plug style 2

2 for users with plug style 22 for users with plug style 2

3 for users with plug style 3

3 for users with plug style 33 for users with plug style 3

1 for 25’ (7.6 m) high voltage cable

1 for 25’ (7.6 m) high voltage cable1 for 25’ (7.6 m) high voltage cable

2 for 36’ (11 m) high voltage cable

2 for 36’ (11 m) high voltage cable2 for 36’ (11 m) high voltage cable

3 for 50’ (15.2 m) high voltage cable

3 for 50’ (15.2 m) high voltage cable3 for 50’ (15.2 m) high voltage cable

XX No. 2 handgun

XX No. 2 handgun XX No. 2 handgun

31X 9060 pow-

31X 9060 pow-31X 9060 pow-

-1 -2 -3

USA EUROPE CHINA

AH

AH----12

12----01.03 No. 2 Air Motor Handgun

AHAH

01.03 No. 2 Air Motor Handgun 8888

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

INTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

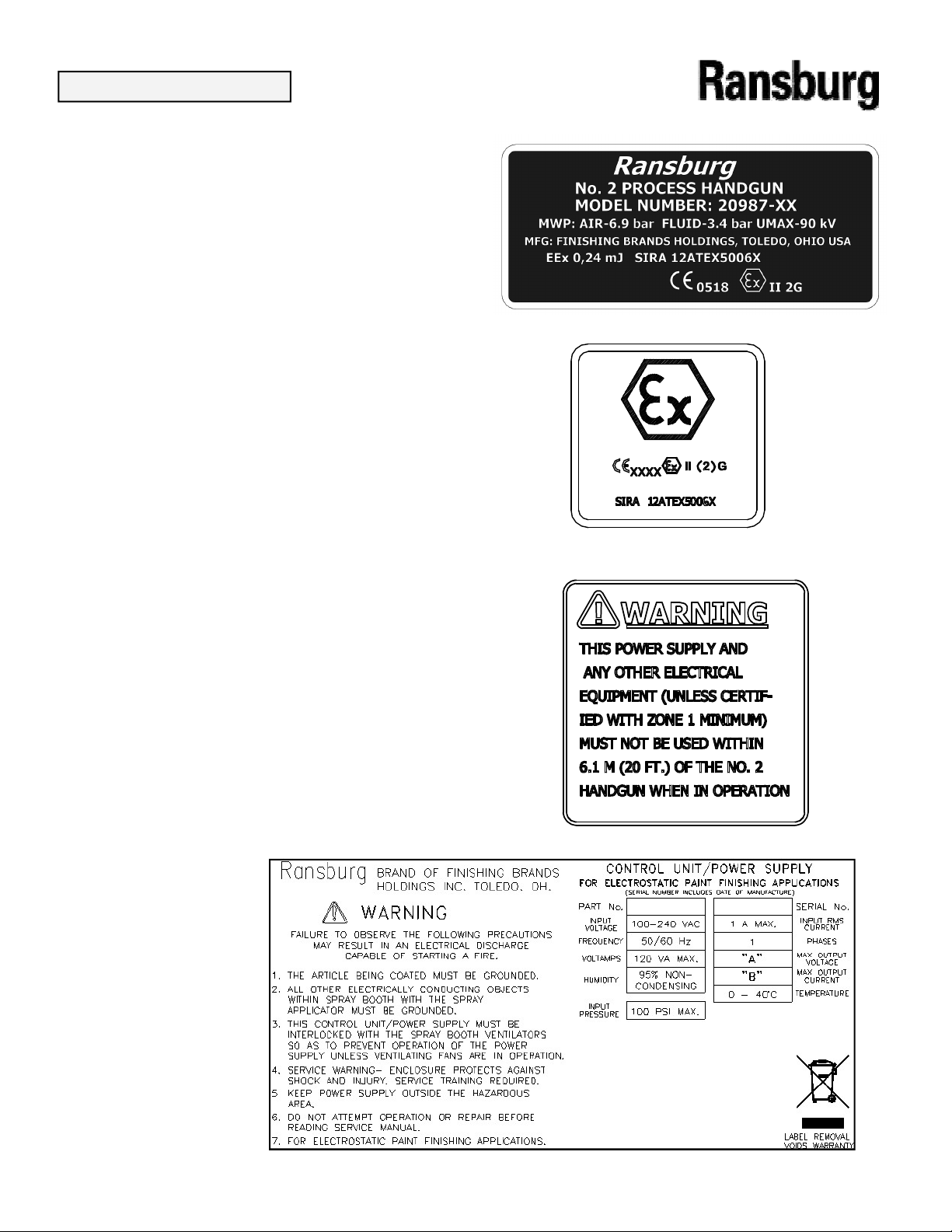

EUROPEAN ATEX DIRECTIVE 94/9/EC, ANNEX II, 1.0.6

The following instructions apply to equipment covered

The following instructions apply to equipment covered

The following instructions apply to equipment covered The following instructions apply to equipment covered

by certificate number Sira 12ATEX5006X:

by certificate number Sira 12ATEX5006X:

by certificate number Sira 12ATEX5006X:by certificate number Sira 12ATEX5006X:

The equipment may be used with flammable gases

The equipment may be used with flammable gases

The equipment may be used with flammable gases The equipment may be used with flammable gases

and vapors with apparatus groups II and with temper-

and vapors with apparatus groups II and with temper-

and vapors with apparatus groups II and with temper-and vapors with apparatus groups II and with temperature class T6.

ature class T6.

ature class T6. ature class T6.

The equipment is only certified for use in ambient

The equipment is only certified for use in ambient

The equipment is only certified for use in ambient The equipment is only certified for use in ambient

temperatures in the range 0

temperatures in the range 0 °C to +40

temperatures in the range 0 temperatures in the range 0

not be used outside this range.

not be used outside this range.

not be used outside this range. not be used outside this range.

Installation shall be carried out by suitably trained

Installation shall be carried out by suitably trained

Installation shall be carried out by suitably trained Installation shall be carried out by suitably trained

personnel in accordance with the applicable code of

personnel in accordance with the applicable code of

personnel in accordance with the applicable code of personnel in accordance with the applicable code of

practice e.g. EN 60079

practice e.g. EN 60079----14:1997.

practice e.g. EN 60079practice e.g. EN 60079

Special conditions of the certificate require the power

Special conditions of the certificate require the power

Special conditions of the certificate require the power Special conditions of the certificate require the power

supply to be located a minimum of 6.1 m (20’) out-

supply to be located a minimum of 6.1 m (20’) out-

supply to be located a minimum of 6.1 m (20’) out-supply to be located a minimum of 6.1 m (20’) outside or away from the target being sprayed. It is the

side or away from the target being sprayed. It is the

side or away from the target being sprayed. It is the side or away from the target being sprayed. It is the

end users’ responsibility to insure this products spe-

end users’ responsibility to insure this products spe-

end users’ responsibility to insure this products spe-end users’ responsibility to insure this products special condition are met when equipment is installed

cial condition are met when equipment is installed

cial condition are met when equipment is installed cial condition are met when equipment is installed

and used.

and used.

and used. and used.

Inspection and maintenance of this equipment shall

Inspection and maintenance of this equipment shall

Inspection and maintenance of this equipment shall Inspection and maintenance of this equipment shall

be carried out by suitably trained personnel in accord-

be carried out by suitably trained personnel in accord-

be carried out by suitably trained personnel in accord-be carried out by suitably trained personnel in accordance with the applicable code of practice e.g. EN

ance with the applicable code of practice e.g. EN

ance with the applicable code of practice e.g. EN ance with the applicable code of practice e.g. EN

60079

60079----17.

6007960079

Repair of this equipment shall be carried out by suita-

Repair of this equipment shall be carried out by suita-

Repair of this equipment shall be carried out by suita-Repair of this equipment shall be carried out by suitable trained personnel in accordance with the applica-

ble trained personnel in accordance with the applica-

ble trained personnel in accordance with the applica-ble trained personnel in accordance with the applicable code of practice e.g. EN 60079

ble code of practice e.g. EN 60079----19.

ble code of practice e.g. EN 60079ble code of practice e.g. EN 60079

Putting into service, use, assembling, and adjustment

Putting into service, use, assembling, and adjustment

Putting into service, use, assembling, and adjustment Putting into service, use, assembling, and adjustment

of the equipment shall be fitted by suitably trained

of the equipment shall be fitted by suitably trained

of the equipment shall be fitted by suitably trained of the equipment shall be fitted by suitably trained

personnel in accordance with the manufacturer's doc-

personnel in accordance with the manufacturer's doc-

personnel in accordance with the manufacturer's doc-personnel in accordance with the manufacturer's documentation.

umentation.

umentation. umentation.

Refer to the "Table of Contents" of this service manu-

Refer to the "Table of Contents" of this service manu-

Refer to the "Table of Contents" of this service manu-Refer to the "Table of Contents" of this service manual:

al:

al:al:

Components to be incorporated into or used as re-

Components to be incorporated into or used as re-

Components to be incorporated into or used as re-Components to be incorporated into or used as re-

17.

17. 17.

Installation

Installation

Installation Installation

Operation

Operation

Operation Operation

Maintenance

Maintenance

Maintenance Maintenance

Parts Identification

Parts Identification

Parts Identification Parts Identification

14:1997.

14:1997. 14:1997.

C to +40°C and should

C to +40C to +40

C and should

C and should C and should

19.

19. 19.

placement parts of the equipment shall be fitted by

placement parts of the equipment shall be fitted by

placement parts of the equipment shall be fitted by placement parts of the equipment shall be fitted by

suitably trained personnel in accordance with the

suitably trained personnel in accordance with the

suitably trained personnel in accordance with the suitably trained personnel in accordance with the

manufacturer's documentation.

manufacturer's documentation.

manufacturer's documentation. manufacturer's documentation.

The certification of this equipment relies upon the fol-

The certification of this equipment relies upon the fol-

The certification of this equipment relies upon the fol-The certification of this equipment relies upon the following materials used in its construction:

lowing materials used in its construction:

lowing materials used in its construction:lowing materials used in its construction:

If the equipment is likely to come into contact with

If the equipment is likely to come into contact with

If the equipment is likely to come into contact with If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility of

aggressive substances, then it is the responsibility of

aggressive substances, then it is the responsibility of aggressive substances, then it is the responsibility of

the user to take suitable precautions that prevent it

the user to take suitable precautions that prevent it

the user to take suitable precautions that prevent it the user to take suitable precautions that prevent it

from being adversely affected, thus ensuring that the

from being adversely affected, thus ensuring that the

from being adversely affected, thus ensuring that the from being adversely affected, thus ensuring that the

type of protection provided by the equipment is not

type of protection provided by the equipment is not

type of protection provided by the equipment is not type of protection provided by the equipment is not

compromised.

compromised.

compromised.compromised.

Aggressive substances: e.g. acidic liquids or gases

Aggressive substances: e.g. acidic liquids or gases

Aggressive substances: e.g. acidic liquids or gases Aggressive substances: e.g. acidic liquids or gases

that may attack metals, or solvents that may affect

that may attack metals, or solvents that may affect

that may attack metals, or solvents that may affect that may attack metals, or solvents that may affect

polymeric materials.

polymeric materials.

polymeric materials.polymeric materials.

Suitable precautions: e.g. regular checks as part of

Suitable precautions: e.g. regular checks as part of

Suitable precautions: e.g. regular checks as part of Suitable precautions: e.g. regular checks as part of

routine inspections or establishing from the material's

routine inspections or establishing from the material's

routine inspections or establishing from the material's routine inspections or establishing from the material's

data sheets that it is resistant to specific chemicals.

data sheets that it is resistant to specific chemicals.

data sheets that it is resistant to specific chemicals.data sheets that it is resistant to specific chemicals.

Refer to "Specifications" in the "Introduction" section:

Refer to "Specifications" in the "Introduction" section:

Refer to "Specifications" in the "Introduction" section:Refer to "Specifications" in the "Introduction" section:

• All fluid passages contain stainless steel

All fluid passages contain stainless steel

All fluid passages contain stainless steel All fluid passages contain stainless steel

or nylon fittings.

or nylon fittings.

A recapitulation of the certification marking is detailed

A recapitulation of the certification marking is detailed

A recapitulation of the certification marking is detailed A recapitulation of the certification marking is detailed

in the "Atex" section, on the next page, drawing num-

in the "Atex" section, on the next page, drawing num-

in the "Atex" section, on the next page, drawing num-in the "Atex" section, on the next page, drawing numbers: 80108, 80082, 80083 and 80088.

bers: 80108, 80082, 80083 and 80088.

bers: 80108, 80082, 80083 and 80088. bers: 80108, 80082, 80083 and 80088.

The characteristics of the equipment shall be detailed

The characteristics of the equipment shall be detailed

The characteristics of the equipment shall be detailed The characteristics of the equipment shall be detailed

e.g. electrical, pressure, and voltage parameters.

e.g. electrical, pressure, and voltage parameters.

e.g. electrical, pressure, and voltage parameters. e.g. electrical, pressure, and voltage parameters.

The manufacturer should note that, on being put into

The manufacturer should note that, on being put into

The manufacturer should note that, on being put into The manufacturer should note that, on being put into

service, the equipment must be accompanied by a

service, the equipment must be accompanied by a

service, the equipment must be accompanied by a service, the equipment must be accompanied by a

translation of the instructions in the language or lan-

translation of the instructions in the language or lan-

translation of the instructions in the language or lan-translation of the instructions in the language or languages of the country in which the equipment is to be

guages of the country in which the equipment is to be

guages of the country in which the equipment is to be guages of the country in which the equipment is to be

used and by the instructions in the original language.

used and by the instructions in the original language.

used and by the instructions in the original language.used and by the instructions in the original language.

or nylon fittings. or nylon fittings.

• High voltage cascade is encapsulated with

High voltage cascade is encapsulated with

High voltage cascade is encapsulated with High voltage cascade is encapsulated with

a di

a di----electric oil.

electric oil.

a dia di

electric oil. electric oil.

9999 AH

AH----12

AHAH

12----01.03 No. 2 Air Motor Handgun

01.03 No. 2 Air Motor Handgun

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

INTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

No. 2 Air Motor Handgun with

No. 2 Air Motor Handgun with

No. 2 Air Motor Handgun withNo. 2 Air Motor Handgun with

9050 Control Unit

9050 Control Unit ————80086

9050 Control Unit 9050 Control Unit

Marking Definitions

Marking Definitions

Marking DefinitionsMarking Definitions

Ex Certificate Number: Sira 12ATEX5006X

Ex Certificate Number: Sira 12ATEX5006X

Ex Certificate Number: Sira 12ATEX5006XEx Certificate Number: Sira 12ATEX5006X

Sira = Notified Body performing EC

Sira = Notified Body performing EC----type exami-

Sira = Notified Body performing ECSira = Notified Body performing EC

nation

nation

nationnation

12 = Year of certification

12 = Year of certification

12 = Year of certification12 = Year of certification

ATEX = Reference to ATEX Directive

ATEX = Reference to ATEX Directive

ATEX = Reference to ATEX DirectiveATEX = Reference to ATEX Directive

5 = Protection Concept Code (code 5 is titled En-

5 = Protection Concept Code (code 5 is titled En-

5 = Protection Concept Code (code 5 is titled En-5 = Protection Concept Code (code 5 is titled Encapsulation)

capsulation)

capsulation)capsulation)

006= Document serial number

006= Document serial number

006= Document serial number006= Document serial number

X = Special conditions for safe use apply

X = Special conditions for safe use apply

X = Special conditions for safe use applyX = Special conditions for safe use apply

Ex = Specific marking of explosive protection

Ex = Specific marking of explosive protection

Ex = Specific marking of explosive protectionEx = Specific marking of explosive protection

II = Equipment Group hazardous area character-

II = Equipment Group hazardous area character-

II = Equipment Group hazardous area character-II = Equipment Group hazardous area characteristics

istics

isticsistics

2 = Equipment Category

2 = Equipment Category

2 = Equipment Category2 = Equipment Category

Note: (2) indicates that the equipment can be

Note: (2) indicates that the equipment can be

Note: (2) indicates that the equipment can be Note: (2) indicates that the equipment can be

connected to Group 2 equipment although only

connected to Group 2 equipment although only

connected to Group 2 equipment although only connected to Group 2 equipment although only

to be used/installed in a safe area only

to be used/installed in a safe area only

to be used/installed in a safe area onlyto be used/installed in a safe area only

G = Type of explosive atmosphere (gases, va-

G = Type of explosive atmosphere (gases, va-

G = Type of explosive atmosphere (gases, va-G = Type of explosive atmosphere (gases, vapors, or mists)

pors, or mists)

pors, or mists)pors, or mists)

EEx 0.24mJ.

EEx 0.24mJ.––––---- The No. 2 air motor handgun is

EEx 0.24mJ.EEx 0.24mJ.

suitable for use in electrostatic spraying installa-

suitable for use in electrostatic spraying installa-

suitable for use in electrostatic spraying installa-suitable for use in electrostatic spraying installations complying with EN 50 176 as they are a

tions complying with EN 50 176 as they are a

tions complying with EN 50 176 as they are a tions complying with EN 50 176 as they are a

Type A class with a discharge energy limit of

Type A class with a discharge energy limit of

Type A class with a discharge energy limit of Type A class with a discharge energy limit of

0.24mJ. The special conditions on the certificate

0.24mJ. The special conditions on the certificate

0.24mJ. The special conditions on the certificate 0.24mJ. The special conditions on the certificate

as noted by the “X” requires the end user locate

as noted by the “X” requires the end user locate

as noted by the “X” requires the end user locate as noted by the “X” requires the end user locate

the 9060 Control unit outside the hazardous area

the 9060 Control unit outside the hazardous area

the 9060 Control unit outside the hazardous area the 9060 Control unit outside the hazardous area

for safe usage.

for safe usage.

for safe usage. for safe usage.

The No. 2 air motor handgun is

The No. 2 air motor handgun is The No. 2 air motor handgun is

80086--

8008680086

--XX

XX

----

XXXX

type exami-

type exami-type exami-

80083

80083----00 No. 2 Air Motor Label

8008380083

80082

80082----00 9060 Supply Label

8008280082

80088

80088----00 9060 Supply Label

8008880088

00 No. 2 Air Motor Label

00 No. 2 Air Motor Label00 No. 2 Air Motor Label

00 9060 Supply Label

00 9060 Supply Label00 9060 Supply Label

00 9060 Supply Label

00 9060 Supply Label00 9060 Supply Label

AH

AH----12

12----01.03 No. 2 Air Motor Handgun

AHAH

01.03 No. 2 Air Motor Handgun 10

1212

01.03 No. 2 Air Motor Handgun01.03 No. 2 Air Motor Handgun

80108

80108----00 9060 Supply Label

8010880108

00 9060 Supply Label

00 9060 Supply Label00 9060 Supply Label

10

1010

SPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

Environmental

Environmental / Physical

EnvironmentalEnvironmental

Length:

Length: 508 cm (20 inches)

Length:Length:

Weight:

Weight: 1588 g (56 ounces)

Weight:Weight:

/ Physical Mechanical

/ Physical/ Physical

508 cm (20 inches)

508 cm (20 inches)508 cm (20 inches)

1588 g (56 ounces)

1588 g (56 ounces)1588 g (56 ounces)

2222----3/4" Bell

Electrical

Electrical

ElectricalElectrical

Input Voltage:

Input Voltage: 110 or 220 VAC

Input Voltage:Input Voltage:

110 or 220 VAC 4"

110 or 220 VAC110 or 220 VAC

50/60 Hertz

50/60 Hertz

50/60 Hertz50/60 Hertz

(4 fl oz/minute)

Output Voltage:

Output Voltage: 90 kV DC (negative)

Output Voltage:Output Voltage:

Current:

Current: 30

Current:Current:

SCI:(From Brush)

SCI:(From Brush)

SCI:(From Brush)SCI:(From Brush)

(maximum)

90 kV DC (negative)

90 kV DC (negative)90 kV DC (negative)

30----50 microamperes

50 microamperes Application Rate:

3030

50 microamperes50 microamperes

(operating)

(operating)

(operating)(operating)

(.46

115 microamperes

115 microamperes

115 microamperes115 microamperes

(maximum)

(maximum)(maximum)

Mechanical

MechanicalMechanical

Fluid

Fluid Input Pressure :

FluidFluid

Air

Air

Air Air

Fluid

Fluid Delivery

FluidFluid

Input Pressure : 3.45 bar (50 psig)

Input Pressure :Input Pressure :

Input Pressure:

Input Pressure:

Input Pressure:Input Pressure:

Delivery Rate:

DeliveryDelivery

3/4" Bell Size:

3/4" Bell3/4" Bell

Rate:

Rate:Rate:

Size: 75 cc/minute

Size: Size:

75 cc/minute

75 cc/minute75 cc/minute

(2.5 fl oz/minute)

(2.5 fl oz/minute)

(2.5 fl oz/minute)(2.5 fl oz/minute)

4" Bell:

Bell: 120 cc/minute

4"4"

Bell:Bell:

120 cc/minute

120 cc/minute120 cc/minute

(4 fl oz/minute)

(4 fl oz/minute)(4 fl oz/minute)

Application Rate: (maximum)

Application Rate: Application Rate:

2222----3/4" Bell:

3/4" Bell:

3/4" Bell:3/4" Bell:

4"

4" Bell:

Bell: 10

4"4"

Bell:Bell:

(maximum)

(maximum)(maximum)

5555----7 ft

7 ft

7 ft7 ft

(.46----.65 m

(.46(.46

10----12 ft

12 ft

1010

12 ft12 ft

(.93

(.93----1.11 m

1.11 m

(.93(.93

1.11 m1.11 m