Page 1

OPERATING, SERVICE AND

MAINTENANCE MANUAL

MODEL SCH 2900

MODEL SCH 3600

MODEL SCH 4900

PLANETARY WINCHES

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION AND

OPERATION OF WINCH. SEE WARNINGS!

Page 2

TABLE OF CONTENTS

INTRODUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

WINCH MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

HYDRAULIC SYSTEM REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

PERFORMANCE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

CABLE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

TROUBLE SHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

DIMENSIONAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PARTS LIST AND PARTS DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BACK COVER

Page 3

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas for obtaining the most efficient operation from your Ramsey Winch, and safety

procedures one needs to know before operating a Ramsey Winch. Do not operate this winch until you have carefully

read and understand the "WARNING" and "OPERATION" sections of this manual.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great care and skill go into every winch we

make. If the need should arise, warranty procedure is outlined on the back of your self-addressed postage paid warranty card. Please read and fill out the enclosed warranty card and send it to Ramsey Winch Company. If you have

any problems with your winch, please follow instructions for prompt service on all warranty claims. Refer to back

page for limited warranty.

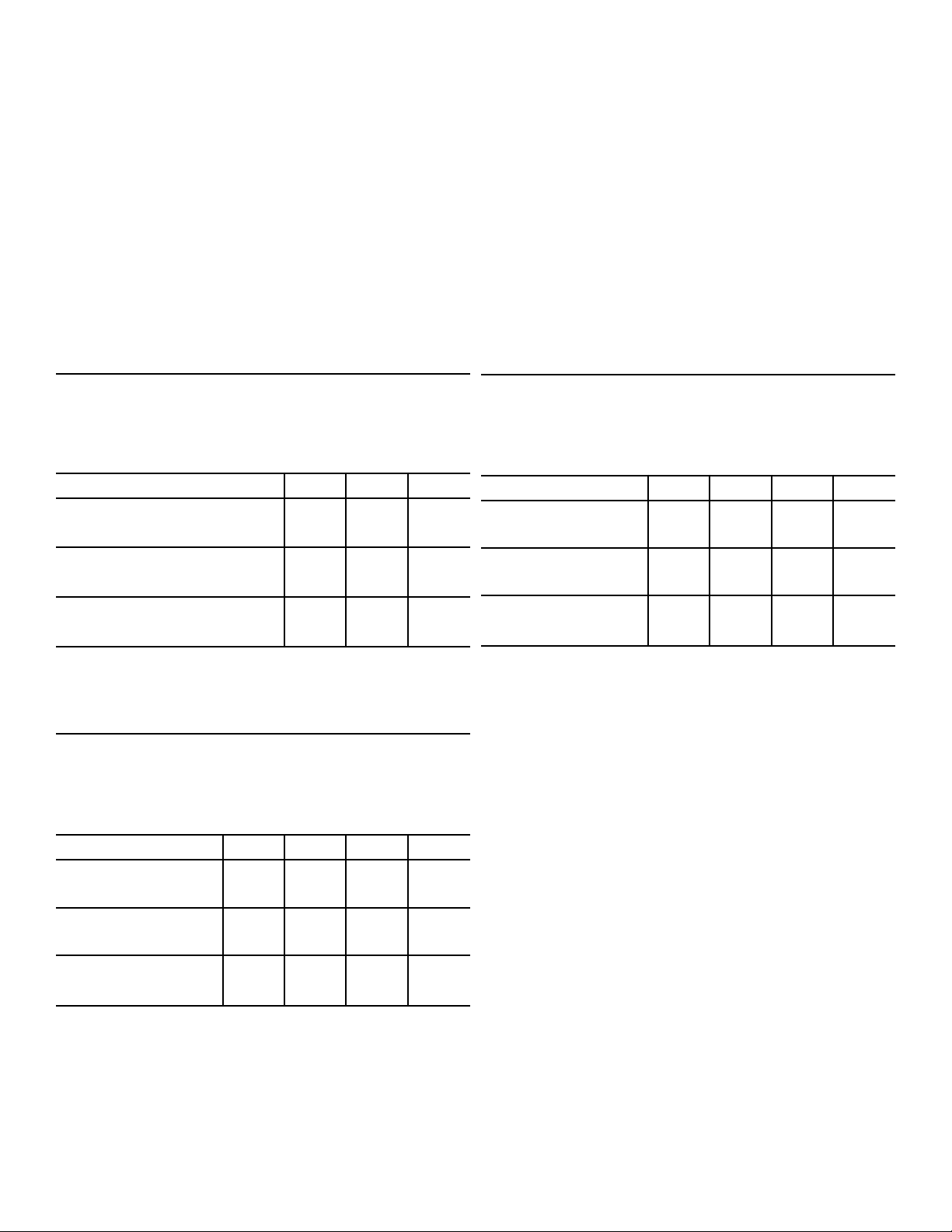

SPECIFICATIONS*

NOTE: The rated line pulls shown are for the winch only. Consult the

wire rope manufacturer for wire rope ratings.

SCH 2900

Rated Line Pull (lbs) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,900

(kg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,310

Gear Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.1:1

Weight (without cable) . . . . . . . . . . . . . . . . . . . .118 lbs. (54 kg)

LAYER OF CABLE 1 2 3

Rated Line Pull per Layer lbs 2900 2600 2400

kg 1310 1170 1080

Line Speed at 8 GPM fpm 59 63 68

mpm 17.9 19.1 20.6

Cable Capacity ft 30 65 100

m 9 19 30

* These specifications are based on recommended 5/16 in. (8 mm)

EIPS wire rope.

SCH 3600

Rated Line Pull (lbs) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,600

(kg) . . . . . . . . . . . . . . . . . . . . . . . . . . . .1,630

Gear Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.1:1

Weight (without cable) . . . . . . . . . . . . . . . . . . . .120 lbs. (55 kg)

LAYER OF CABLE 1 2 3 4

Rated Line Pull

per Layer

lbs 3600 3200 2900 2700

kg 1630 1450 1310 1220

Line Speed

at 8 GPM

fpm 48 52 56 60

mpm 14 15.8 17 18.2

Cable Capacity ft 25 55 85 120

m 7 16 25 36

* These specifications are based on recommended 3/8 in. (9.5 mm)

EIPS wire rope.

SCH 4900

Rated Line Pull (lbs) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,900

(kg) . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,220

Gear Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.1:1

Weight (without cable) . . . . . . . . . . . . . . . . . . . .125 lbs. (57 kg)

LAYER OF CABLE 1 2 3 4

Rated Line Pull

per Layer

lbs 4900 4400 4000 3600

kg 2220 1990 1810 1630

Line Speed

at 8 GPM

fpm 51 55 59 64

mpm 15.5 16.7 17.9 19.5

Cable Capacity ft 25 55 85 120

m 7 16 25 36

* These specifications are based on recommended 3/8 in. (9.5 mm)

EIPS wire rope.

1

Page 4

WARNINGS:

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PERSONNEL.

A MINIMUM OF 5 WRAPS OF WIRE ROPE AROUND DRUM BARREL IS REQUIRED TO HOLD THE LOAD.

WINCH MOUNTING

NOTE: The winch must be mounted so that the cable reels in in the required direction as noted on page 6.

NOTE: Remove and discard the (4) 1/2” capscrews from the foot mounting holes in the end bearings.

These capscrews hold on the foot mount spacers during shipping and should not be used for mounting.

It is most important that this winch be mounted securely so that the three major sections (the motor end, the cable

drum, and the gear-housing end) are properly aligned. Excessive bushing wear is a symptom of misalignment.

When installed mid-mounted, at least one tie plate should be attached to the mounting feet at the bottom of the winch

to maintain alignment. When installed foot-mounted, at least one tie plate should remain mounted at mid point of

winch to maintain alignment. It is always preferable to use both tie plates in the installed configuration.

When mounting the winch, the mounting hole patterns described on page 6 should be used. The mounting surface

must be flat within 0.015 inch and sufficiently stiff to resist flexing. If a steel plate is used for foot mounting it should

be .750 inch thick. For this mounting application eight (8) 1/2-13NC x 2-1/4” Lg. Gr. 5 capscrews with lockwashers

will be needed to mount winch. Note that the supplied foot-mount spacers (.88” thick) must be installed between the

winch and the mounting plate. Capscrews should be torqued to 85 ft-lb. (115 Nm).

CAUTION: IF LONGER BOLTS ARE SUBSTITUTED TO MOUNT WINCH OR TO MOUNT A ROLLER GUIDE AT

THE SIDE MOUNT PADS, GRADE 5 OR BETTER BOLTS SHOULD ALWAYS BE USED, AND BOLT LENGTH

SHOULD BE SUCH THAT A MAXIMUM OF .56 INCH THREAD LENGTH ENGAGEMENT IS ACHIEVED IN THE

TAPPED HOLES IN THE SIDES OF EACH END BEARING.

2

Page 5

TYPICAL LAYOUT

PUMP

(.75 I.D. MINIMUM)

LOW PRESSURE LINE

(.50 I.D. MINIMUM)

HIGH PRESSURE LINE

SEE PERFORMANCE

RATED LOAD:

PRESSURE AT

MAX. FLOW &

(MOTOR SPOOL)

4 WAY VALVE

3 POSITION

RELIEF

SYSTEM

PORT

BRAKE

MOTOR

WITH BRAKE RELEASE SHUTTLE

DUAL-A & B PORT CONTROL

CHARTS BELOW

60

50

40

20

30

LINE PULL-FIRST LAYER (LB.)

LINE SPEED-FIRST LAYER (FPM)

WORKING PRESSURE, PSI

0

0

600

1,000

2,000

1,8001,200

10

3,000

FLOW (GPM)

5

0

10

SCH 2,900

10

0

5

FLOW (GPM)

4,000

3,000

10

1,200 1,800

2,000

1,000

600

0

0

WORKING PRESSURE, PSI

LINE SPEED-FIRST LAYER (FPM)

LINE PULL-FIRST LAYER (LB.)

30

20

40

50

SCH 3,600

50

40

45

5,000

1,600

15

10

0

5

FLOW (GPM)

4,000

3,000

5

800

1,200

2,000

1,000

400

0

0

WORKING PRESSURE, PSI

LINE SPEED-FIRST LAYER (FPM)

LINE PULL-FIRST LAYER (LB.)

15

10

35

20

25

30

SCH 4,900

9.6 cu.in. Motor 11.9 cu.in. Motor

18.7 cu.in. Motor

3

PERFORMANCE CHARTS

HYDRAULIC SYSTEM REQUIREMENTS

Refer to the performance charts below to properly match your hydraulic system to the winch performance. The

charts consist of: (1) first layer line pull (LB) vs. working pressure (PSI) and (2) first layer line speed (FPM) vs. flow

(GPM). A motor spool directional control valve is required.

Page 6

OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you actually use it. Plan

your test in advance. Remember, you hear your winch, as well as see it operate. Get to recognize the sounds of a

light steady pull, a heavy pull, and sounds caused by load jerking or shifting. Avoid conditions where load shifts or

jerks occur, as they may indicate a dangerous situation.

The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable pileup on one end of

drum. If this happens, reverse the winch to relieve the load and move your anchor point further to the center of the

load. After the job is done you can unspool and rewind for a neat lay of the cable.

MAINTENANCE

1. Inspect the cable for damage and lubricate frequently. If the cable becomes frayed with broken strands, replace

immediately.

2. Replace drum bushings and seals when seals begin to seep grease. Add additional lubricant, Mobilith SHC 007,

to gears if required.

CABLE INSTALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of cable, opposite hook,

with plastic or similar tape to prevent fraying.

2. Place taped end of cable into narrow side of pocket on the cable drum. Wrap end of cable around cable anchor

or puck and pull tight.

3. Carefully run winch in the "reel-in" direction. Keeping tension on end of cable, spool all the cable onto the cable

drum, taking care to form neatly wrapped layers.

4

Page 7

CONDITIONS POSSIBLE CAUSE CORRECTION/ACTION

DRUM WILL NOT ROTATE AT NO

LOAD

Brake damaged Inspect and replace brake

Gears damaged Inspect and replace damaged gears

Brake not releasing Brake damaged; inspect and replace.

DRUM WILL NOT ROTATE UNDER

LOAD

Load greater than rated capacity of

winch

Refer to Specifications page 1 for line

pull rating

Low hydraulic system pressure Check pressure. Refer to Hydraulic

Systems performance charts page 3

WINCH RUNS TOO SLOW Low hydraulic system flow rate Check flow rate. Refer to Typical

Layout page 3

Motor worn out Replace motor

BRAKE WILL NOT RELEASE Brake damaged Inspect and replace

EXCESSIVE NOISE Hydraulic system flow too high Check flow rate. Refer to Typical

Layout page 3

DRUM CHATTERS IN “REEL IN”

DIRECTION

Low hydraulic system flow rate Check flow rate. Refer to Typical

Layout page 3

Low hydraulic system relief pressure

setting

Check relief valve setting.

OIL SEEPAGE FROM BREATHER

VENT OF BRAKE HOUSING

Brake piston not sealing properly Replace o-ring and backup o-rings on

brake piston

TROUBLESHOOTING GUIDE

5

Page 8

PRESSURE IN GIVES CLOCKWISE DRUM

ROTATION VIEWED FROM MOTOR END

17,1

.675

PRESSURE IN GIVES COUNTER-CLOCKWISE DRUM

ROTATION VIEWED FROM MOTOR END

7/8-14 SAE STRAIGHT THREAD

O-RING PORT (2-PLACES)

19,8

.781

WINCH MOUNTING CAPSCREWS MUST MEET OR EXCEED SAE GRADE 5 SPECIFICATION

NOTE: THESE HOLE LOCATIONS MUST BE HELD WITHIN ±.03" (0,8 MM) OF

TRUE POSITION. RECOMMENDED MOUNTING HOLE DIAMETER IS .53" (13,5 MM).

REEL IN DIRECTION

4.50

114,3

9.00

228,6

5.25

133,3

B

C

1/2-13UNC x .75"(19,1mm) DEEP

TAPPED HOLE (4-PLACES EACH

END BEARING)

4.23

107,4

A

DIMENSIONS SHOWN ARE INCHES OVER MILLIMETERS

11.86

301,2

DRUM

6.50

165,1

BARREL DIA.

DIMENSION SCH-2900 SCH-3600 SCH-4900

A 8.34/211,7 8.46/214,8 9.27/235,4

B 12.82/325,6 12.94/328.6 13.75/349,3

C 20.99/533,1 21.11/536,1 21.92/556,8

A-A

MOTOR CONTROL VALVE DETAIL

WINCH

VIEW

(TYP)

.88

22,3

FOOT MOUNT SPACER

THICKNESS

6.20

157,4

FLANGE DIA.

10.62

269,8

3.10

78,7

1.12

28,4

(TYP)

4.50

114,3

2.25

57,2

10.81

274,5

5.50

139,7

5.94

150,8

SCH 2900, 3600, & 4900

6

Page 9

NOTES

Page 10

11

32

44

18

5

21

50

41

26

23

38

17

40

35

37

7

24

22

3

10

9

MODEL SCH-2900, 3600, & 4900

WITH BLOCKED CLUTCH

45

17

8

42

51

7

4

42

12

36

13

1

19

14

46

2

47

28

16

6

48

39

30

43

47

29

33

52

34

20

20

25

31

27

28

49

15

25

8

Page 11

Item Quantity Part No. Description Item Quantity Part No. Description

1 1 234189 DRUM ASSEM BLY 28 2 432018 FITTING

2 1 306042 PISTON-BRAKE 29 4 438022 DISC-BRAKE

3 1 315004 ANCHOR- CABLE 30 1 442220 GASKET-BRAKE HSG.

4 1 338300 END BRG-MOTOR END 31 1 442223 GASKET-MOTOR FLANGE

5 1 338301 END BRG-GEAR HSG. 32 1 444085 GEAR-RING

6 1 338302 HSG-BRAKE 33 1 456038 FITTING-VENT,BREATHER

7 4 346045 PIN-BRAKE 34 1 458119 MOTO R-HYDRAULIC (RPH-3600)

8 1 357513 SHAFT- INPUT 458121 MOTO R-HYDRAULIC (RPH-4900)

9 2 362291 SPACER - FOOT MOUNTING 458124 MOTO R-HYDRAULIC (RPH-2900)

10 4 362284 SPACER - TIE PLATE 35 1 462046 O-RING

11 1 402120 BEARING 36 1 462056 O-RING

12 1 402121 BEARING 37 1 462057 O-RING

13 1 412084 BUSHING-DRUM,MOTOR END 38 1 462058 O-RING

14 1 412085 BUSHING-DR UM,GEAR END 39 1 462059 O-RING-BACK-UP

15 4 414129 CAPSCREW 5/16-18NCX3 LG HX HD GR-5 40 1 462060 O-RING-BACK-UP

16 6 414303 BOLT-3/ 8-16N C X2 1/2,HXHD,GR-5, Z/P 41 1 472052 PLUG

17 8 414548 CAPSCREW-1/ 2-13N CX1 1/2,HXHD,Z/P,G5 42 2 474065 TIE PLATE

18 2 414854 SCREW-1/4-20N CX1/ 2LG,RDHD,SLOT,Z/PL 43 5 474111 PLATE-SEPARATOR, BRAKE

19 1 414926 SETSCREW-3/8-16NC X1,SOCKET,N YLON 44 1 486080 SEAL

20 2 414948 CAPSCREW-1/ 2-13N CX1 1/4LG,SOCKET HD 45 1 490037 SNAP RING

21 1 416016 SETSCREW1/4-20NCX1/4 HX SOCK HD CUP 46 6 494110 SPRING-BRAKE

22 1 416080 SETSCREW-5/8-18NF X1 LG,HXSOCHD,CUP 47 4 494112 SPRING

23 1 418036 NUT-3/8-16 NC,HEX JAM,Z/P 48 1 509009 TUBE ASSY

24 1 418088 NUT-JAM 5/8-18NF H EX HD,ZINC PLT 49 1 516033 VALVE-MO TOR CONTROL

25 2 418218 LOCKWASHER-1/2 ID MED SECT,ZINC PLT 50 1 518037 THRUST WASHER

26 1 426048 PLUNGER-CLUTCH,BLOCKED 51 1 518047 THRUST WASHER

27 1 431015 COUPLING-MO TOR 52 1 518052 THRUST WASHER

PARTS LIST

9

Page 12

LIMITED WARRANTY

RAMSEY WINCH warrants each new RAMSEY Winch to be free from defects in material and workmanship for a period of one (1) year from date of purchase.

The obligation under this warranty, statutory or otherwise, is limited to the replacement or repair at

the Manufacturer's factory, or at a point designated by the Manufacturer, of such part that shall

appear to the Manufacturer, upon inspection of such part, to have been defective in material or workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost of labor or transportation charges

in connection with the replacement or repair of defective parts, nor shall it apply to a product upon

which repair or alterations have been made, unless authorized by Manufacturer, or for equipment misused, neglected or which has not been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential damages. RAMSEY WINCH

makes no warranty in respect to accessories such as being subject to the warranties of their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the right to improve its

products through changes in design or materials as it may deem desirable without being obligated to

incorporate such changes in products of prior manufacture.

If field service at the request of the Buyer is rendered and the fault is found not to be with RAMSEY

WINCH's product, the Buyer shall pay the time and expense to the field representative. Bills for service, labor or other expenses that have been incurred by the Buyer without approval or authorization by

RAMSEY WINCH will not be accepted

See warranty card for details.

RAMSEY WINCH COMPANY

PO BOX 581510 Tulsa OK 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688

http://www.ramsey.com

914168-0207-C

Loading...

Loading...