Page 1

E

OPERATING, SERVICE AND

MAINTENANCE MANUAL

MODEL RPH 8000T

PLANETARY WINCH

INTENDED PURPOSE for RAMSEY RPH 8000T:

Vehicle Recovery and Pulling of Loads

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFOR

INSTALLATION AND OPERATION OF WINCH. SEE WARNINGS!

Page 2

RAMSEY HYDRAULIC PLANETARY WINCH MODEL RPH-8000T

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most efficient operation from your Ramsey Winch, and safety

procedures one needs to know before operating a Ramsey Winch. Do not operate this winch until you have

carefully read and understand the “WARNING” and “OPERATION” sections of this manual.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great care and skill go into every winch we

make. If the need should arise, warranty procedure is outlined on the back of your self-addressed postage paid

warranty card. Please read and fill out the enclosed warranty card and send it to Ramsey Winch Company. If you

have any problems with our winch, please follow instructions for prompt service on all warranty claims. Refer to

back page for limited warranty.

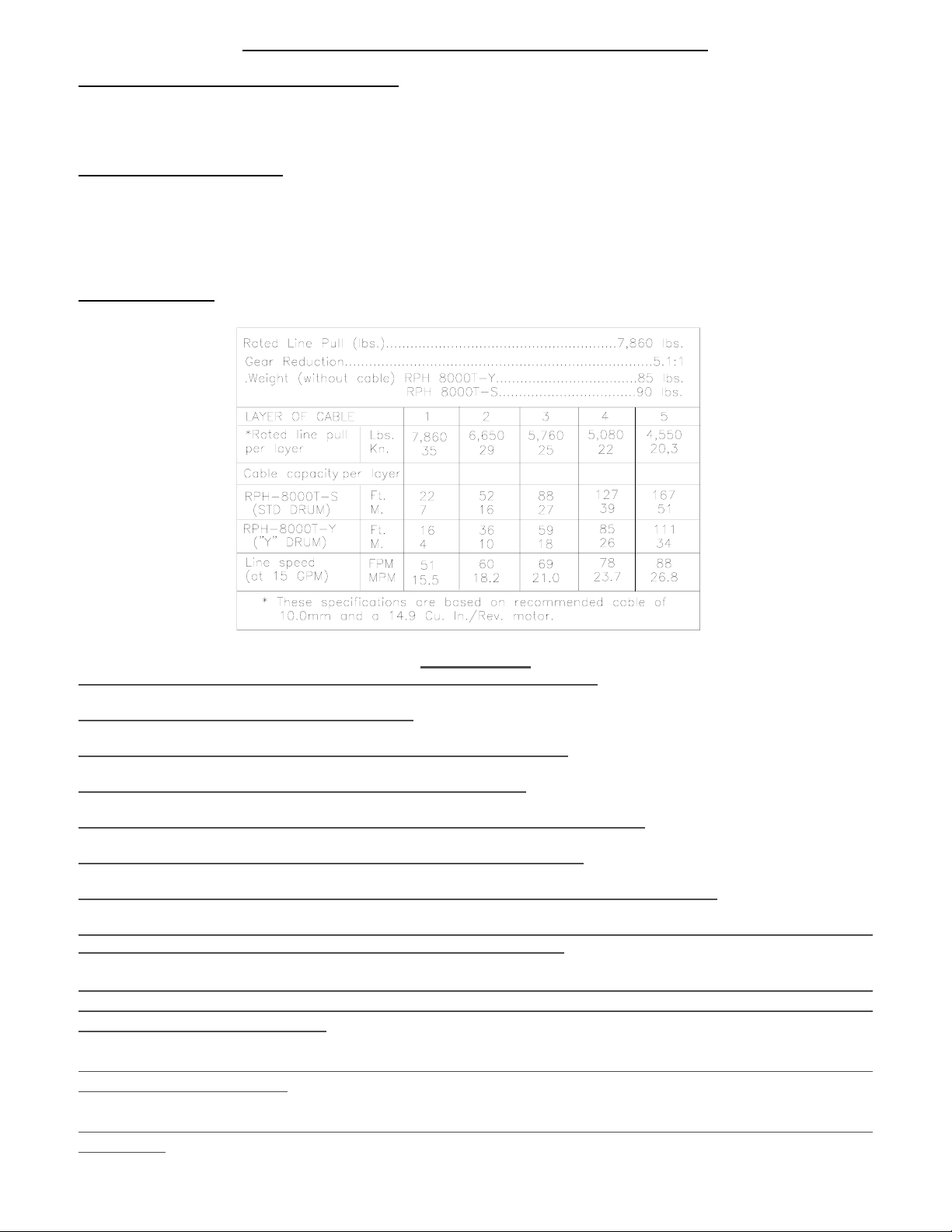

SPECIFICATIONS*

Noise level 79 dB (A)

NOTE: The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for wire rope ratings.

WARNINGS:

CLUTCH MUST BE FULLY ENGAGED BEFORE STARTING THE WINCH.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

DO NOT LEAVE CLUTCH ENGAGED WHEN WINCH IS NOT IN USE.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PERSONNEL.

A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD.

CABLE CLAMP (SETSCREW) IS NOT DESIGNED TO HOLD LOAD.

IN CAR CARRIER APPLICATIONS, AFTER PULLING VEHICLE ON CARRIER, BE SURE TO SECURE VEHICLE

TO CARRIER BED. DO NOT MAINTAIN LOAD ON WINCH CABLE WHILE TRANSPORTING VEHICLE. DO

NOT USE WINCH AS A TIE DOWN

WHEN PULLING A HEAVY LOAD PLACE A BLANKET, JACKET, OR TARPAULIN OVER THE CABLE FIVE OR

SIX FEET FROM THE HOOK.

AVOID CONDITIONS WHERE LOAD SHIFTS OR JERKS OCCUR, AS THEY MAY INDICATE A DANGEROUS

SITUATION.

1

Page 3

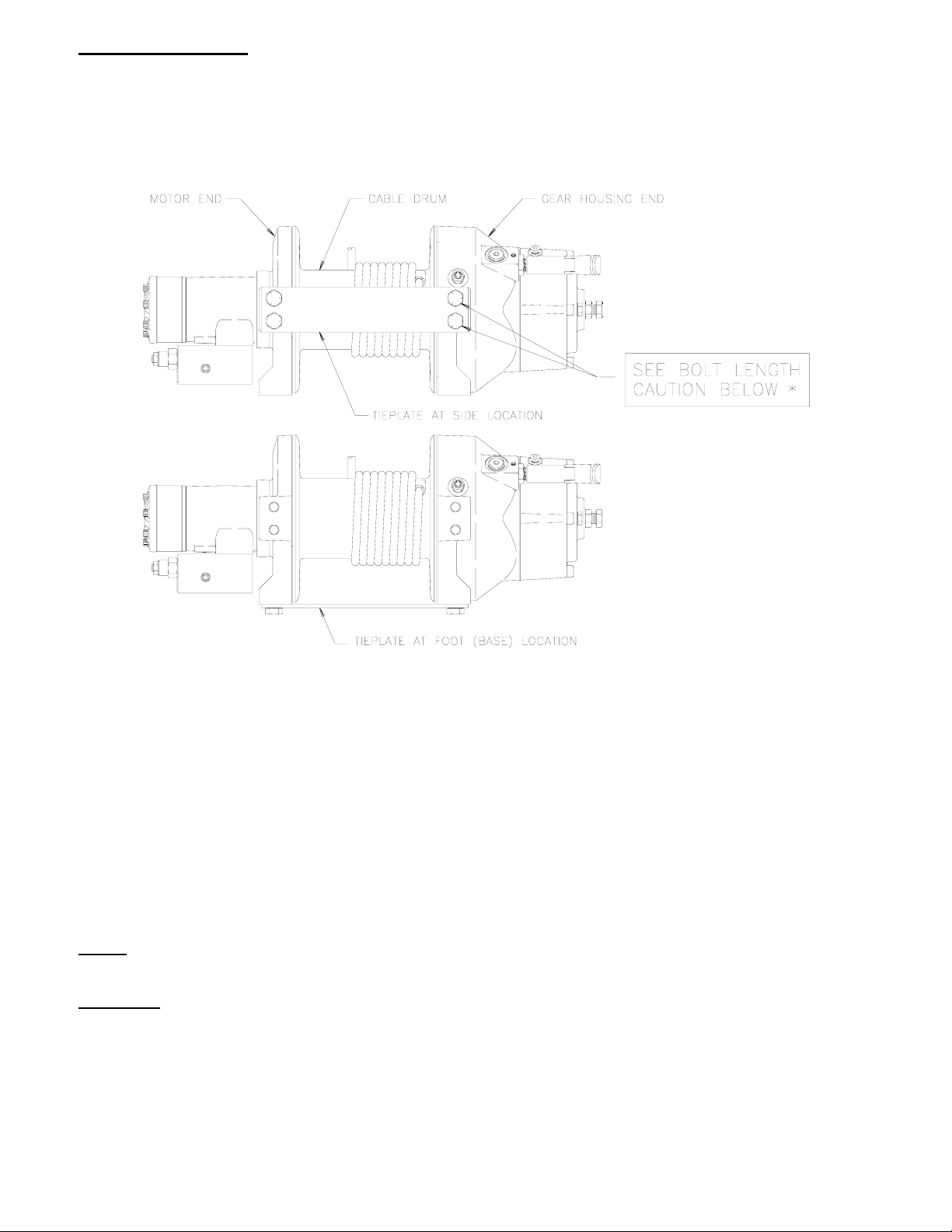

WINCH MOUNTING

ESSENTIAL MOUNTING INSTRUCTIONS TO MAINTAIN ALIGNMENT OF PLANETARY WINCH

COMPONENTS

It is most important that this winch be mounted securely so the three major sections (the motor end, the cable

drum and the gear-housing end) are properly aligned. Excessive bushing wear and difficulty in freespooling are

usually symptoms of misalignment.

In the as-installed condition, if the winch is mid mounted then at least one tie plate must be attached to the

mounting feet at the bottom of the winch to maintain alignment. NOTE: If the winch is foot mounted then at least

one tie plate must remain mounted at mid point of winch to maintain alignment. It is always desirable to use both

tie plates in the final installed configuration.

Angle Mounting Kit, #251006 (“STD.” drum) and #251007 (“Y” drum), is recommended for maximum ease in

mounting the winch. The angle kit will allow the winch to be mounted in upright or midmount applications and will

meet the criteria of serving as a solid and true mounting surface.

When mounting the winch with other than the recommended Ramsey Angle Kit, the mounting hole patterns

described on page 14 must be used. The mounting surface must be flat within .015 inch and sufficiently stiff to

resist flexing. If a steel plate is used for foot mounting it should be .750 inch thick. For this mounting application

eight (8) ½-13NC x 1-1/2 Lg. Gr. 5 capscrews with lockwashers will be needed to mount winch. Capscrews should

be torqued to 85-ft. lb. (115 Nm.).

NOTE:

the remaining mounting pads, whether they be side or foot.

*CAUTION:

side mount pads, bolt length must be such as to allow a maximum of .50 inch thread length engagement in the

tapped holes in sides of each end bearing. Refer to page 15. Use of excessive length bolts will damage the winch

and prevent free spool of the drum. Torque bolts to 55-ft. lb. (75 Nm).

If angles or a steel plate are used in mounting winch, tie plates provided with winch are to be attached to

If longer bolts (minimum Grade 5) are substituted to mount winch or to mount a roller guide at the

2

Page 4

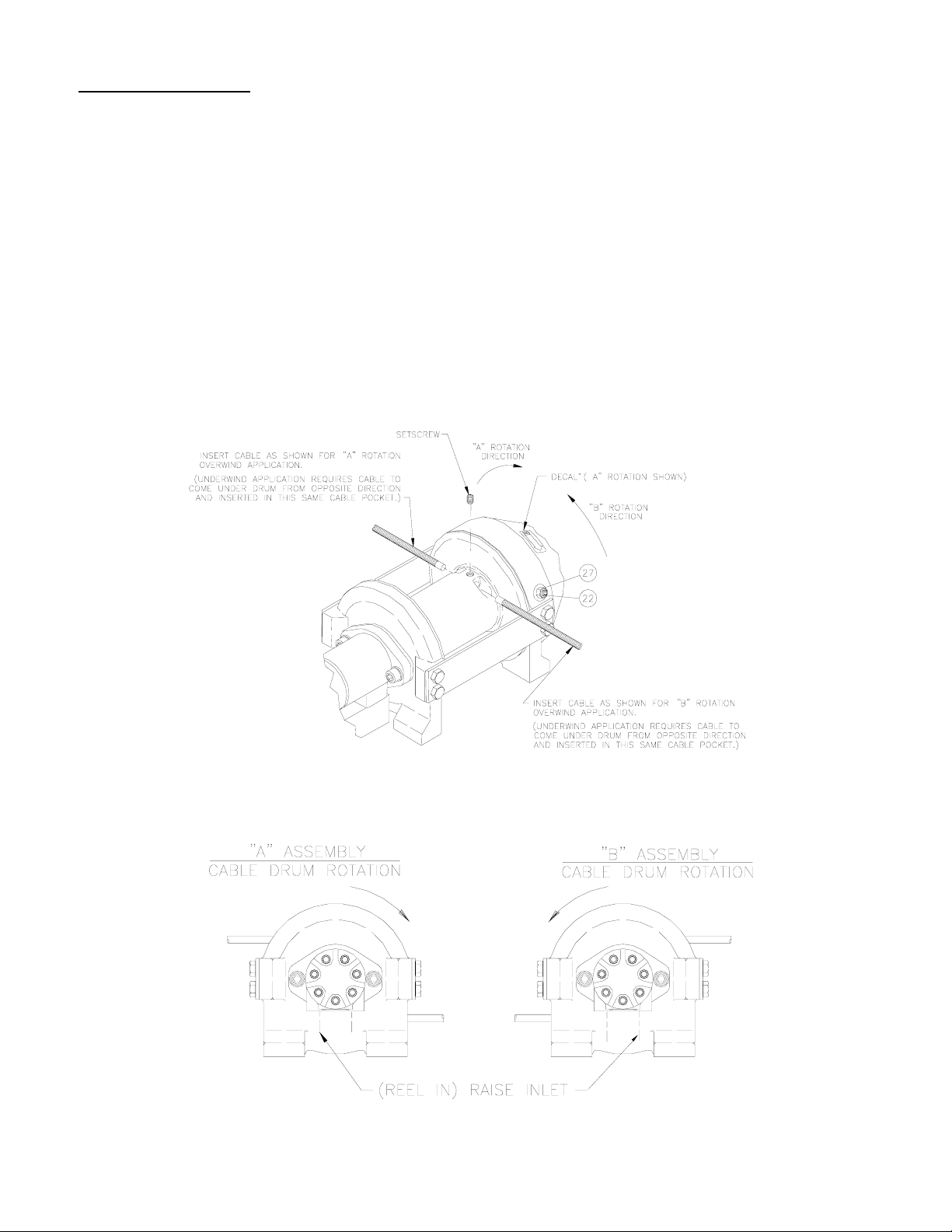

CABLE INSTALLATION

A decal on the top of the end bearing indicates the spooling direction of the cable. Also, a letter “A” or “B” is

stamped in the end bearing on the brake end indicating rotation. If the decal is damaged or unreadable, contact

Customer Service for additional instructions to determine proper direction.

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of cable, opposite

hook, with plastic or similar tape to prevent fraying.

2. Place taped end of cable into hole in cable drum, as shown below. Use 3/8-16NC x ½ lg. Hex. Soc. drive

setscrew (part of 234165 “Y” drum assembly. & 234166 “STD.” drum assembly.) to secure cable to drum.

3. Carefully run winch in the “reel-in” direction. Keeping tension on end of cable, spool all the cable onto the

cable drum, taking care to form neatly wrapped layers.

After installing cable, check freespool operation. Disengage clutch and pull on cable at a walking speed. If cable

“Birdnests”, loosen jam nut (item #27) and turn nylon screw (item #22)

cable pull is excessive loosen nylon setscrew by turning counterclockwise. Tighten jam nut when proper setting is

obtained. CAUTION: Over-tightening of jam nut may strip nylon setscrew.

clockwise to increase drag on drum. If

3

Page 5

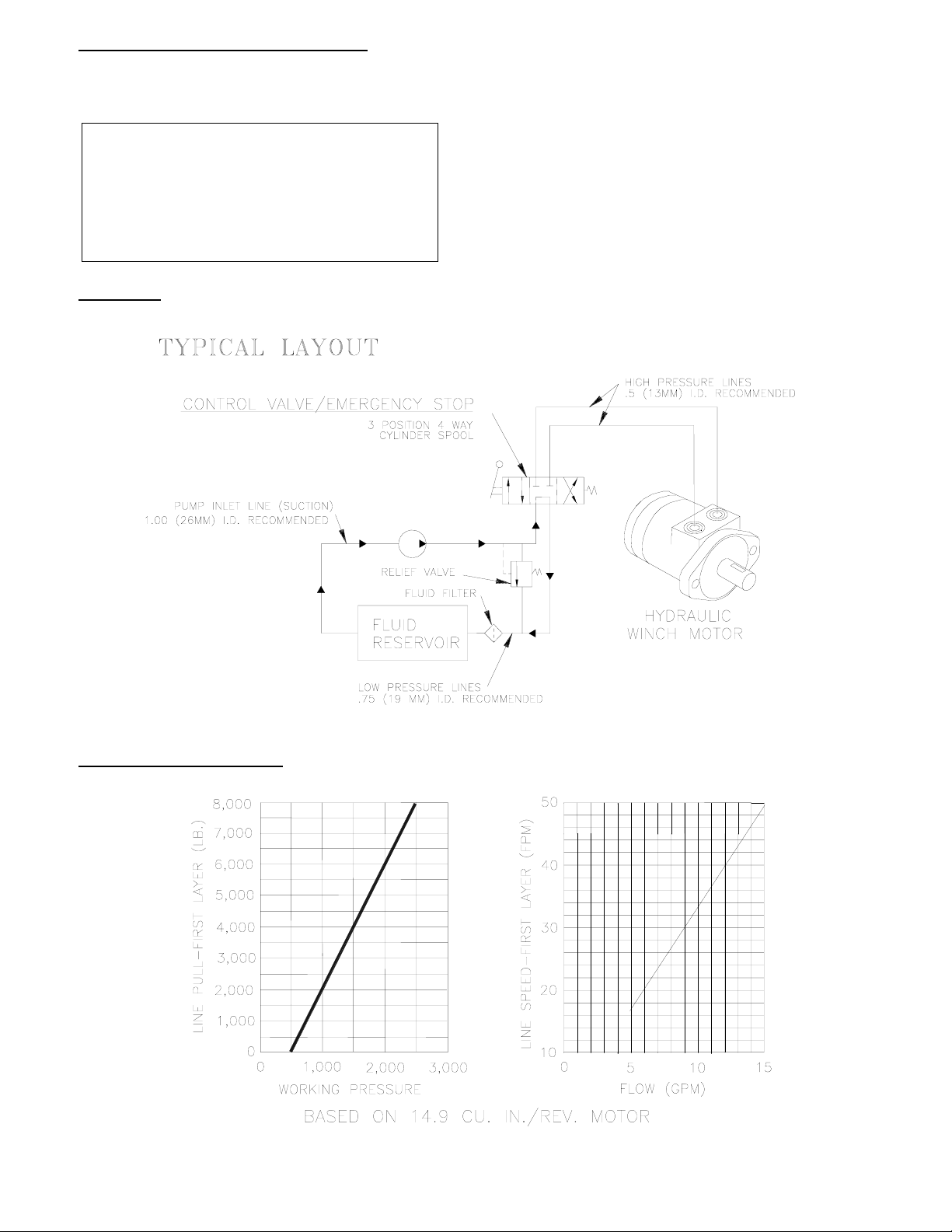

HYDRAULIC SYSTEM REQUIREMENTS

A

Refer to the performance charts below to properly match your hydraulic system to the winch performance. The

charts consist of: (1) line pull (LB) first layer vs. working pressure (PSI), and (2) line speed, first layer (FPM) vs. flow

(GPM). A cylinder spool directional control valve is recommended.

SYSTEM REQUIREMENTS:

2500 PSI RELIEF VALVE SETTING

15 GPM FLOW RATE*

10 MICRON NORMAL FILTRATION

1000 PSI MAXIMUM BACK PRESSURE

EMERGENCY STOP VALVE

Installer must determine type of emergency

stop required.

manual control valve also

serves as an emergency stop valve. An

emergency stop valve may be required with

other types of control valves.

*CAUTION:

PERFORMANCE

DO NOT EXCEED 20 GPM. IF EXCEEDED, MOTOR AND WINCH MAY BE DAMAGED.

CHARTS*

4

Page 6

OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you actually use it. Plan

your test in advance. Remember that you hear your winch, as well as see it operate. Get to recognize the sounds

of a light steady pull, a heavy pull, and sounds caused by load jerking or shifting. Avoid conditions where load

shifts or jerks occur, as they may indicate a dangerous situation.

The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable pileup on one end of

drum. If this happens, reverse the winch to relieve the load and move your anchor point further to the center of the

vehicle. After the job is done you can unspool and rewind for a neat lay of the cable.

When pulling a heavy load, place a blanket, jacket or tarpaulin over the cable about five or six feet behind the hook.

In the event of a broken cable, this will slow the snap back of the cable and could prevent serious injury.

The winch clutch allows rapid unspooling of the cable, from cable drum, for hooking onto the load. The clutch is

operated by the clutch shifter lever or air shifter.

WARNING:

MANUAL CLUTCH SHIFTER

TO DISENGAGE CLUTCH: Run the winch in the reverse (reel out) direction until load is off the cable. Pull

handle out and rotate 90o. With handle in the “DISENGAGED” position cable may now be free-spooled from

drum.

TO ENGAGE CLUTCH: Pull handle out, rotate 90 o and release handle. Run the winch in reverse until the

clutch handle snaps fully into the “ENGAGED” position. DO NOT attempt to pull a load unless the handle is

fully at the “ENGAGED” position. If manual shift indicator light is present, the green light is lit when clutch is

fully “ENGAGED”. DO NOT attempt to pull a load unless the green light is lit. To hookup light to the vehicle

electrical system refer to the Electrical Schematic on page 15.

AIR CYLINDER CLUTCH SHIFTER

TO DISENGAGE CLUTCH: Run the winch in the reverse (reel out) direction until load is off the cable. Apply air

pressure to the .125-27 NPT port: 80 PSI (min.), 150 PSI (max.).

CAUTION:

TO ENGAGE CLUTCH:

winch in reverse until the clutch engagement indicator light (green light) is lit. DO NOT attempt to pull a load

unless the green light is lit. To hookup light to the vehicle electrical system refer to the Electrical Schematic on

page 15.

MAINTENANCE

Pressure must not exceed 150 PSI.

Remove air pressure from the cylinder (a return spring engages the plunger). Run

DO NOT DISENGAGE CLUTCH UNDER LOAD.

(Refer to page 14)

(Refer to page 15)

1. Inspect the cable for damage and lubricate frequently. If the cable becomes frayed with broken strands,

replace immediately. Cable and hook assembly P/N 524118 (“Y” drum) or P/N 524119 (“STD” drum) may be

purchased from a Ramsey distributor.

2. Check that the clutch is fully engaging. See OPERATION instructions, above, for the appropriate clutch shifter.

FOR MANUAL CLUTCH ONLY: Monthly disengage clutch, put several drops of oil on the shaft and work clutch

IN and OUT several times to lubricate inside of clutch cylinder.

3. Check brake for drift. Refer to page 7.

4. Check oil level of winch brake housing every month. Remove oil level plug (refer to pg.13). Oil level should be

kept up to oil level hole (plus or minus 1/8”). Replace oil annually or more often if winch is used frequently. Use

½ pint of Mobilfluid 424, Phillips HG Fluid, Texaco TDH, Shell Oil Co. Donax TD high performance tractor

transmission fluid or equivalent, and for quietest operation, add ¼ fl. oz. of an oil additive (available from the

factory).

5. Check to see that drum cable does not overrun (BIRDNEST) when freespooling. Refer to page 3.

6. Replace drum bushings and seals when seals begin to seep grease. Refer to OVERHAUL

INSTRUCTIONS, page 8.

Add additional lubricant, Mobilith SHC 007, to gears if required.

5

Page 7

TROUBLE SHOOTING GUIDE

CONDITIONS POSSIBLE CAUSE CORRECTION

DRUM WILL NOT ROTATE

AT NO LOAD

DRUM WILL NOT ROTATE

UNDER LOAD

WINCH RUNS TOO SLOW Low hydraulic system flow rate.

DRUM WILL NOT FREESPOOL Clutch not disengaged.

OIL LEAKAGE Damaged brake housing, gasket, or

OIL LEAKAGE FROM BREATHER PLUG Breather below oil level. Check oil level.

LOADS DRIFT Brake needs adjusting Adjust brake. Refer to page 7

CABLE BIRDNESTS WHEN CLUTCH IS

DISENGAGED

EXCESSIVE NOISE Brake torque too high.

DRUM CHATTERS IN “REEL IN” DIRECTION

Winch not mounted squarely,

causing end bearings to bind

up drum.

Brake damaged

Gears damaged

Load greater than rated

capacity of winch.

Low hydraulic system pressure.

Winch not mounted squarely, causing

end bearing to bind up drum.

Motor worn out.

Winch not mounted squarely, causing

end bearings to bind drum.

Side mount bolts (item #18 Page 17) too

long, causing binding of ring gear.

breather.

Damaged brake hub seal.

Drag screw improperly adjusted. Adjust nylon drag screw. Refer to page

Hydraulic system flow too high.

Brake oil level low.

Drum in bind, winch not mounted

squarely.

Low hydraulic system flow.

Low hydraulic system relief pressure

setting.

Check mounting. Refer to WINCH

MOUNTING page 2.

Inspect and replace brake.

Inspect and replace damaged gears.

Refer to SPECIFICATIONS page. 1 for

line pull rating.

Check pressure. Refer to HYDRAULIC

SYSTEMS performance charts page 4.

Check mounting. Refer to WINCH

MOUNTING page 2.

Check flow rate. Refer to HYDRAULIC

SYSTEMS flow chart page. 4.

Replace motor.

Check OPERATION. Refer to page. 5.

Check mounting. Refer to WINCH

MOUNTING page. 2.

Check bolt length. Bolt thread MUST

NOT engage threaded holes in sides of

end bearing by more than the .50 inch

thread depth in the end bearing. Refer

to page 15.

Replace gasket. Check for plugged

breather. Refer to pages 8 & 10.

Replace seal. Refer to page 10.

3

Reduce torque. Refer to page 7.

Check flow rate. Refer to HYDRAULIC

SYSTEMS flow chart page 4.

Check oil level, add oil if necessary.

Check mounting. Refer to WINCH

MOUNTING page 2.

Check flow rate. Refer to HYDRAULIC

SYSTEMS flow chart page 4.

Check relief valve setting. Refer to

HYDRAULIC SYSTEMS page 4.

6

Page 8

ADJUSTING THE BRAKE

All parts of the oil-cooled automatic safety brake are bathed in oil. When the brake wears to the point that the load

begins to drift, the brake can be adjusted as follows:

1. Loosen the lock nut on the adjusting screw (see drawing on page 10).

2. Increase the brake torque by turning the adjusting screw clockwise. CAUTION: Only ¼ turn is

usually required to adjust the brake. Over-tightening can cause overheating, and damage to the

brake parts. Tighten the lock nut after adjustment is completed.

If the brake does not respond to adjustment, then a new flat spring (item #3) and/or brake discs (item #31) may be

needed.

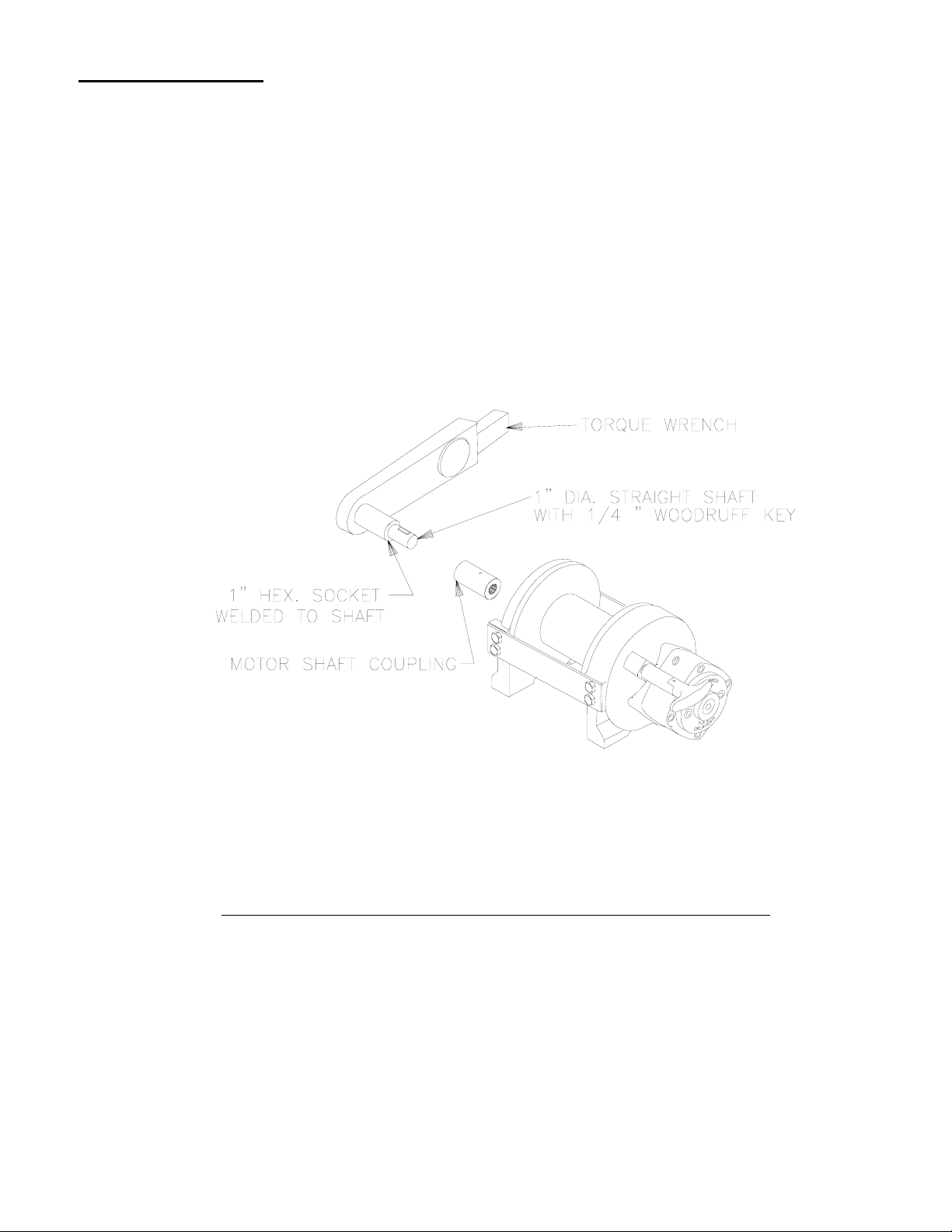

Brake torque can be checked/set as follows: A torque wrench can be equipped with a special adapter to fit the input

coupling of the winch. The adapter can be made by welding a 1” dia. straight motor shaft, with ¼” key, in a 1” hex.

socket, as shown in the following figure.

This special adapter will fit into the motor shaft coupling. Place coupling onto drum shaft in winch. Turn the

torque wrench so that the drum turns in the “CABLE OUT” direction (lowering direction). The torque setting for the

brake should be 155 to 160 ft. lbs. If the torque wrench does not show the proper torque value, the adjusting screw

should be adjusted ¼ turn (clockwise if torque is low or counter-clockwise if torque is high). Each time the adjusting

bolt is turned, check the torque reading. Continue this procedure until the proper torque reading is achieved. Then

tighten the lock nut. If proper adjustment cannot be made, follow overhaul instructions on page 10.

After the brake has been adjusted to the proper torque setting, as described above, disengage clutch. Start

vehicle engine and run winch in the “CABLE IN” (raise direction). Allow winch to run in this direction for one

minute.

Place your hand on the brake housing. If housing is not hot to the touch then run winch in the reverse direction

(cable out) for one minute. Brake housing should begin to heat.

When these conditions exist, proper installation has been made. If heating becomes noticeable when running the

winch in “CABLE IN” (raising direction), the brake should be again disassembled. When disassembled, place the

brake balls in the alternate set of slots in the cam plate (see View A-A page 10), then carefully follow the

instructions for re-assembling and checking the brake.

7

Page 9

INSTRUCTIONS FOR OVERHAUL OF RAMSEY WINCH

MODEL RPH-8,000T

DISASSEMBLY

Remove breather plug and reducer (item #34 & #39) from winch. Drain oil from winch by removing plug

(item # 40). Remove motor (item #35), and coupling (item #31) from winch by unscrewing capscrews (item

#24). If coupling is being replaced, be sure pin (item #41) is installed. Tap motor lightly to disengage.

Replace all o-rings and seals with new ones during re-assembly (order kit #246042). If necessary, remove

valve (item # 49) from motor by removing capscrews (item # 21).

8

Page 10

Remove tie plates (item #13) from end bearings (items #7 & #8) by unscrewing capscrews (item #18), as

shown. Slide motor end bearing (item #7) from drum (item #1) and drum from gear housing end bearing

(item #8). Remove input shaft (item #12) from end bearing. Inspect teeth of gear (item #5) for signs of wear.

If necessary replace gear by removing snap ring (item #47) and thrust washer (item #50). Slide new gear

over splines of shaft and against snap ring on shaft. Re-install thrust washer and place snap ring into groove

of shaft.

9

Page 11

Remove brake housing (item #9) from end bearing (item #8) by unscrewing (4) capscrews (item #23).

Remove plate (item #12) and light assembly, if present. Remove gasket (item #33), coil spring (item #48),

flat spring (item #3), retainer plate (item #11), composition brake discs (item #32) and cam plate (item #4).

Remove hub (item #10), and brake shaft (item #55) with plug (item #42)-which is press-fitted in the hub I.D.

Inspect the seal (item #37), inside of gear housing bore, and replace if necessary.

Inspect brake discs. Discs are 1/4" thick when new, replace if thinner than .200 in. thick or if surfaces are

glazed or burnt. Inspect the flat ground surfaces of the cam plate and retainer plate for glazing, warpage or

other damage. Glazing can be removed by scraping carefully. Inspect flat spring. It should be bowed at

least 1/8". Replace spring if bowed less than 1/8".

Replace all worn or damaged parts as needed. Reassemble all parts as shown. Be sure balls are secure

between cam plate and hub.

Install brake housing, making sure that ends of capscrews (item #17) go through notches in end of flat

springs and holes in the retainer plate. Secure brake housing and plate (item #12), if present, to end bearing

using capscrews (item #23). Tighten capscrews to 30-40 FT.LBS.

INDICATOR LIGHT ASSEMBLY

If light is not functioning, remove light (item #2) and apply 12v DC (+) to test. If necessary, remove the

switch (item #52). The terminals are normally closed. With ball depressed, the switch should be open.

Replace light and/or switch, as needed.

10

Page 12

Remove o-ring (item #36) and bushing (item #15) from motor end bearing (item #7). Press new bushing onto

end bearing and dip o-ring in oil and seat into groove of end bearing. Remove seal (item #45) from gear

housing end bearing (item #8). Loosen nut (item #27) and remove nylon setscrew (item #22) and remove ring

gear (item #6) from gear housing end bearing, if necessary. Remove bushing (item #16) from gear housing

end bearing (item #8). Press new bushing (item #16) into place in end bearing. Install ring gear and nylon

setscrew and nut. Ring gear must be fully seated in gear housing end bearing (item #8) and slot in ring gear

must NOT be aligned with clutch shifter hole. Install new seal in gear housing end bearing, with sharp edge of

seal outward.

11

Page 13

Generously apply grease (MOBILITH SHC 007) to teeth of ring gear (item #6), teeth of planet gears in drum

(item #1) and to bushing in end bearings (item #7 & #8). Apply grease to teeth of gear (item #5) and to

splines of shaft (item #12). Place splined end of shaft into splines of hub in brake housing end bearing (item

#8). Place drum over shaft and rotate drum to engage planet gears with output gear on shaft and ring gear in

end bearing.

Assemble end bearing to drum assembly and use tie plates (item #13) and capscrews (item #18) to hold both

end bearings together. Tighten capscrews to 106 Ft. Lbs. (144 Nm.). If necessary, remove and replace

appropriate shifter assembly (item #2 or #3), as follows:

MANUAL CLUTCH SHIFTER ASSEMBLY

Remove by loosening setscrew (item #25), jam nut and unscrewing clutch shifter. Be sure slot in ring gear is

NOT aligned with clutch shifter hole. Rotate drum, if necessary, to insure holes are not aligned. Reinstall

clutch shifter with plunger, jam nut and handle positioned in cylinder housing, as shown. Thread assembly

(with handle engaged in cylinder slot) into the end bearing. Pull drum toward the brake housing end bearing

to remove play. Hold drum in position and continue threading the shifter assembly in until the gap between

the end of the handle and cylinder is 7/16

NOTE: This gap will vary with drum endplay. With the drum pulled against the gear housing, the gap should

be 7/16 inch. Lightly tighten jam nut. Rotate drum until handle snaps fully into the engaged position. Pull

handle out and rotate 90o. Verify that drum can be rotated freely (at least one full revolution) with clutch

shifter at DISENGEGED position. Securely tighten jam nut while holding the handle. Tighten setscrew

securely. Re-check clutch operation as described on page 5.

AIR CYLINDER SHIFTER ASSEMBLY

Remove by loosening setscrew (item #25), jam nut and unscrewing clutch shifter. To reinstall, thread air

cylinder into housing. Install one or two shims (item #49) under cylinder head, if needed, to orient air cylinder

port for pneumatic connections. Tighten setscrew. Refer to page 5 and check for proper operation of the

clutch.

BLOCKED CLUTCH

Insert plunger assembly into gear housing bore so it engages into ring gear slot. Pull drum flange toward gear

housing and thread setscrew into housing until it bottoms out and drum starts to move. Back setscrew out 1/2

turn and lock in place with jam nut.

+0 -1/16”

and handle is in the horizontal position, as shown below.

12

Page 14

Before installing motor, check brake adjustment (refer to page 7 - ADJUSTING THE BRAKE).

Place splined end of coupling (item #31), with spirol pin (item #41) installed, inside of motor end bearing

housing (item #7) and slide over splines on end of input shaft. Place o-ring (item #38) around motor pilot.

Mount motor (item #35) to end bearing by aligning key on motor shaft with keyway in coupling. Be sure that

motor mounts flush to end bearing and that o-ring is set securely in place between motor and end bearing.

Secure motor to end bearing using two capscrews and lockwashers (items #24 & #30). Tighten capscrews to

49 ft.lbs. (66 Nm). Thread plug (item #40) into bottom of brake housing. Permatex can be added to threads of

plug to help in sealing. Pour a mixture of 8 oz. of high performance tractor transmission fluid, (Mobilfluid 424,

Phillips HG Fluid, Texaco TDH, Shell Oil Co. Donax TD, or equivalent) and 1/4 oz. of an additive (available

from the factory) into oil level hole. Oil level should be kept at oil level hole (plus or minus 1/8"). Thread plug

(item #40) into oil level hole. Insert reducer (item #39) into hole in top of brake housing and breather plug (item

#34) into reducer. Tighten plugs and reducer securely.

13

Page 15

WITH MANUAL CLUTCH SHIFTER

14

MODEL RPH 8,000T

Page 16

15

WITH AIR-CYLINDER CLUTCH SHIFTER

MODEL RPH 8,000T

Page 17

PARTS LIST RPH-8000T WITH MANUAL CLUTCH SHIFTER

ITEM QTY. PART NO. DESCRIPTION

1 1 234165 DRUM ASS’Y. “Y”

1 234166 DRUM ASS’Y. “STD.”

2 1 276048 SHIFTER ASS’Y.

3 1 306035 SPRING-FLAT, BRK.

4 1 314017 CAM PLATE-BRAKE “A” ROTATION

1 314018 CAM PLATE-BRAKE “B” ROTATION

5 1 334174 GEAR-OUTPUT, SUN

6 1 444084 GEAR-RING

7 1 338296 END BEARING-MOTOR

8 1 338287 HOUSING-GEAR, END BEARING

9 1 338288 HOUSING-BRAKE

10 1 314019 HUB-PLATE

11 1 352021 RETAINER PLATE

12 1 357489 SHAFT-INPUT “Y”

1 357490 SHAFT-INPUT “STD.”

13 2 395163 TIE PLATE “Y”

2 395172 TIE PLATE “STD.”

14 3 400007 BALL

15 1 412084 BUSHING-DRUM, MOTOR END

16 1 412085 BUSHING-DRUM, GEAR

17 2 414273 BOLT-3/8-16NC X 1-3/4, HX, GR. 5

18 8 414581 CAPSCREW-1/2-13NC X ¾ LG. HX. HD., GR. 5, Z/P

19 1 414622 BOLT-1/2-13NC X 2-1/4, HX. HD., GR. 5, ALL-THD.

20 2 414836 CAPSCREW-1/4-20NC X ½, HX. SOC. HD.

21 4 414868 SCREW-5/16-18NC X 2-1/2, HX. SOC. HD. , NYLOCK

22 1 414926 SETSCREW-3/8-16NC X 1, SOCKET, NYLON

23 4 414934 CAPSCREW-3/8-16NC X 2-3/4, HX. SOC. HD.

24 2 414948 CAPSCREW-1/2-13NC X 1-1/4, SOC. HD.

25 1 416030 SETSCREW-1/4-20NC X 3/8 HX. SOC. HD. FULL DOG PT.

26 4 418034 NUT 3/8-16NC HEX.REG.

27 1 418036 NUT 3/8-16NC HEX. JAM

28 1 418061 NUT-1/2-13NC HEX. JAM

29 4 418184 WASHER-3/8 ID X 5/8 OD X 1/16 FLAT ALUM

30 2 418218 LOCKWASHER-1/2 ID MED. SECT.

31 1 431014 COUPLING-HYD. MOTOR

32 2 438018 PLATE-BRAKE

33 1 442212 GASKET-BRK. HSG.

34 1 456008 RELIEF FITTING

35 1 458074 MOTOR-HYDRAULIC

36 1 462046 O-RING

37 2 462047 QUAD-RING

38 1 462048 O-RING

39 1 468002 REDUCER

40 2 468018 PIPE PLUG

41 1 470033 SPIROL PIN

42 1 472051 PLUG

43 1 472052 PLUG

44 1 486076 SEAL

45 1 486080 SEAL-GEAR HSG.

46 1 518037 SHIM

47 2 490003 SNAP RING

48 1 494010 SPRING

49 1 516008 VALVE-COUNTERBALANCE (“A” ROTATION)

1 516009 VALVE-COUNTERBALANCE (“B” ROTATION)

50 1 518047 WASHER-THRUST

51 1 340077 SHAFT-BRAKE

52 1 416059 SETSCREW 3/8-16NC X ½ HX SOC HD CUP

EFFECTIVE S/N 2038147

16

Page 18

17

WITH MANUAL CLUTCH SHIFTER

MODEL RPH 8,000T

Page 19

PARTS LIST RPH-8000T WITH MANUAL CLUTCH SHIFTER AND CLUTCH ENGAGEMENT INDICATOR LIGHT

ITEM QTY. PART NO. DESCRIPTION

1 1 234165 DRUM ASS’Y. “Y”

1 234166 DRUM ASS’Y. “STD.”

2 1 236020 LIGHT ASS’Y.

3 1 276048 SHIFTER ASS’Y.

4 1 306035 SPRING-FLAT, BRK.

5 1 314017 CAM PLATE-BRAKE “A” ROTATION

1 314018 CAM PLATE-BRAKE “B” ROTATION

6 1 334174 GEAR-OUTPUT, SUN

7 1 444084 GEAR-RING

8 1 338296 END BEARING-MOTOR

9 1 338287 HOUSING-GEAR, END BEARING

10 1 338288 HOUSING-BRAKE

11 1 314019 HUB-PLATE

12 1 350598 PLATE-LIGHT MTG.

13 1 352021 RETAINER PLATE

14 1 357489 SHAFT-INPUT “Y”

1 357490 SHAFT-INPUT “STD.”

15 2 395163 TIE PLATE “Y”

2 395172 TIE PLATE “STD.”

16 3 400007 BALL

17 1 412084 BUSHING-DRUM, MOTOR END

18 1 412085 BUSHING-DRUM, GEAR

19 2 414273 BOLT-3/8-16NC X 1-3/4, HX, GR. 5

20 8 414581 CAPSCREW-1/2-13NC X ¾ LG. HX. HD., GR. 5, Z/P

21 1 414622 BOLT-1/2-13NC X 2-1/4, HX. HD., GR. 5, ALL-THD.

22 2 414836 CAPSCREW-1/4-20NC X ½, HX. SOC. HD.

23 4 414868 SCREW-5/16-18NC X 2-1/2, HX. SOC. HD., NYLOCK

24 1 414926 SETSCREW-3/8-16NC X 1, SOCKET, NYLON

25 4 414934 CAPSCREW-3/8-16NC X 2-3/4, HX. SOC. HD.

26 2 414948 CAPSCREW-1/2-13NC X 1-1/4, SOC. HD.

27 1 416030 SETSCREW-1/4-20NC X 3/8 HX. SOC. HD. FULL DOG PT.

28 4 418034 NUT 3/8-16NC HEX.REG.

29 1 418036 NUT 3/8-16NC HEX. JAM

30 1 418061 NUT-1/2-13NC HEX. JAM

31 4 418184 WASHER-3/8 ID X 5/8 OD X 1/16 FLAT ALUM

32 2 418218 LOCKWASHER-1/2 ID MED. SECT.

33 1 431014 COUPLING-HYD. MOTOR

34 2 438018 PLATE-BRAKE

35 1 442212 GASKET-BRK. HSG.

36 1 456008 RELIEF FITTING

37 1 458074 MOTOR-HYDRAULIC

38 1 462046 O-RING

39 2 462047 QUAD-RING

40 1 462048 O-RING

41 1 468002 REDUCER

42 2 468018 PIPE PLUG

43 1 470033 SPIROL PIN

44 1 472051 PLUG

45 1 482013 GROMMET

46 1 482045 RUBBER BOOT

47 1 486076 SEAL

48 1 486080 SEAL-GEAR HSG.

49 2 490003 SNAP RING

50 1 494010 SPRING

51 1 504021 SWITCH ASS’Y.

52 1 516008 VALVE-COUNTERBALANCE (“A” ROTATION)

1 516009 VALVE-COUNTERBALANCE (“B” ROTATION)

53 1 518047 WASHER-THRUST

54 1 340077 SHAFT-BRAKE

55 1 416059 SETSCREW 3/8-16NC X ½ HX SOC HD CUP

EFFECTIVE S/N 2038147

18

Page 20

18

19

WITH MANUAL CLUTCH SHIFTER AND

MODEL RPH 8,000T

CLUTCH ENGAGEMENT INDICATOR LIGHT

Page 21

PARTS LIST RPH-8,000T WITH AIR-CYLINDER CLUTCH SHIFTER

ITEM QTY. PART NO. DESCRIPTION

1 1 234165 DRUM ASS'Y. "Y"

1 234166 DRUM ASS'Y. "STD."

2 1 236020 LIGHT ASS'Y.

3 1 276049 SHIFTER ASS'Y.-AIR

4 1 306035 SPRING-FLAT, BRK.

5 1 314017 CAM PLATE-BRAKE “A” ROTATION

1 314018 CAM PLATE-BRAKE “B” ROTATION

6 1 334174 GEAR-OUTPUT, SUN

7 1 444084 GEAR-RING

8 1 338296 END BEARING-MOTOR

9 1 338287 HOUSING-GEAR, END BEARING

10 1 338288 HOUSING-BRAKE

11 1 314019 HUB-PLATE

12 1 350598 PLATE-LIGHT MTG.

13 1 352021 RETAINER PLATE

14 1 357489 SHAFT-INPUT "Y"

1 357490 SHAFT-INPUT "STD."

15 2 395163 TIE PLATE "Y"

2 395172 TIE PLATE "STD."

16 3 400007 BALL

17 1 412084 BUSHING-DRUM, MOTOR END

18 1 412085 BUSHING-DRUM, GEAR

19 2 414273 BOLT-3/8-16NC X 1-3/4, HX, GR. 5

20 8 414581 CAPSCREW-1/2-13NC X 3/4 LG. HX. HD., GR. 5, Z/P

21 1 414622 BOLT-1/2-13NC X 2-1/4, HX. HD., GR. 5, ALL-THD.

22 2 414836 CAPSCREW-1/4-20NC X 1/2, HX. SOC. HD.

23 4 414868 SCREW-5/16-18NC X 2-1/2, HX. SOC. HD., NYLOCK

24 1 414926 SETSCREW-3/8-16NC X 1, SOCKET, NYLON

25 4 414934 CAPSCREW-3/8-16NC X 2-3/4, HX. SOC. HD.

26 2 414948 CAPSCREW-1/2-13NC X 1-1/4, SOC. HD.

27 1 416030 SETSCREW-1/4-20NC X 3/8 HX. SOC. HD. FULL DOG PT.

28 4 418034 NUT 3/8-16NC HEX.REG.

29 1 418036 NUT 3/8-16NC HEX. JAM

30 1 418061 NUT-1/2-13NC HEX. JAM

31 4 418184 WASHER-3/8 ID X 5/8 OD X 1/16 FLAT ALUM

32 2 418218 LOCKWASHER-1/2 ID MED. SECT.

33 1 431014 COUPLING-HYD. MOTOR

34 2 438018 PLATE-BRAKE

35 1 442212 GASKET-BRK. HSG.

36 1 456008 RELIEF FITTING

37 1 458074 MOTOR-HYDRAULIC

38 1 462046 O-RING

39 2 462047 QUAD-RING

40 1 462048 O-RING

41 1 468002 REDUCER

42 2 468018 PIPE PLUG

43 1 470033 SPIROL PIN

44 1 472051 PLUG

45 1 482013 GROMMET

46 1 482045 RUBBER BOOT

47 1 486076 SEAL

48 1 486080 SEAL-GEAR HSG.

49 2 488007 SHIM

50 2 490003 SNAP RING

51 1 494010 SPRING

52 1 504021 SWITCH ASS'Y.

53 1 516008 VALVE-COUNTERBALANCE (“A” ROTATION)

1 516009 VALVE-COUNTERBALANCE (“A” ROTATION)

54 1 518047 WASHER-THRUST

55 1 340077 SHAFT-BRAKE

56 1 416059 SETSCREW 3/8-16NC X ½ HX SOC HD CUP

EFFECTIVE S/N 2038147

20

Page 22

WITH AIR-CYLINDER CLUTCH SHIFTER

MODEL RPH 8,000T

21

Page 23

Page 24

LIMITED WARRANTY

RAMSEY WINCH warrants each new RAMSEY WINCH to be free from defects

in material and workmanship for a period of one (1) year from date of

purchase.

The obligation under this warranty, statutory or otherwise, is limited to the

replacement or repair at the Manufacturer's factory, or at a point designated

by the Manufacturer, of such part that shall appear to the Manufacturer, upon

inspection of such part, to have been defective in material or workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost of labor or

transportation charges in connection with the replacement or repair of

defective parts, nor shall it apply to a product upon which repair or alterations

have been made, unless authorized by Manufacturer, or for equipment

misused, neglected or which has not been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential

damages. RAMSEY WINCH makes no warranty in respect to accessories

such as being subject to the warranties of their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves

the right to improve its products through changes in design or materials as it

may deem desirable without being obligated to incorporate such changes in

products of prior manufacture.

If field service at the request of the Buyer is rendered and the fault is found

not to be with RAMSEY WINCH's product, the Buyer shall pay the time and

expense to the field representative. Bills for service, labor or other expenses

that have been incurred by the Buyer without approval or authorization by

RAMSEY WINCH will not be accepted.

See warranty card for details.

RAMSEY WINCH COMPANY

Post Office Box 581510 Tulsa, Oklahoma 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688 OM-912457-0404-H

Loading...

Loading...