Page 1

OPERATING, SERVICE AND

MAINTENANCE MANUAL

English............................1

Français........................15

Deutsch.........................29

Espanol.........................43

MODEL RPH-20,000 INDUSTRIAL

PLANETARY WINCH

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION AND OPERATION OF

WINCH. SEE WARNINGS!

RAMSEY WINCH COMPANY

PO Box 581510 Tulsa, Oklahoma 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688

Visit us at http://www.ramsey.com

OM-914198-0309-C

Page 2

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................ 3

WARRANTY INFORMATION .......................................................................................................3

SPECIFICATIONS...................................................................................................................... 3

WARNINGS............................................................................................................................... 3

WINCH FRAME MOUNTING....................................................................................................... 3

CABLE INSTALLATION............................................................................................................... 4

CLUTCH OPERATION ................................................................................................................4

WINCH OPERATION.................................................................................................................. 4

MAINTENANCE......................................................................................................................... 4

HYDRAULIC SYSTEM REQUIREMENTS....................................................................................... 5

PERFORMANCE CHARTS .......................................................................................................... 5

TROUBLE SHOOTING GUIDE...................................................................................................... 6

MOUNTING CONFIGURATIONS ..................................................................................................6

INSTRUCTIONS FOR OVERHAUL...........................................................................................7-11

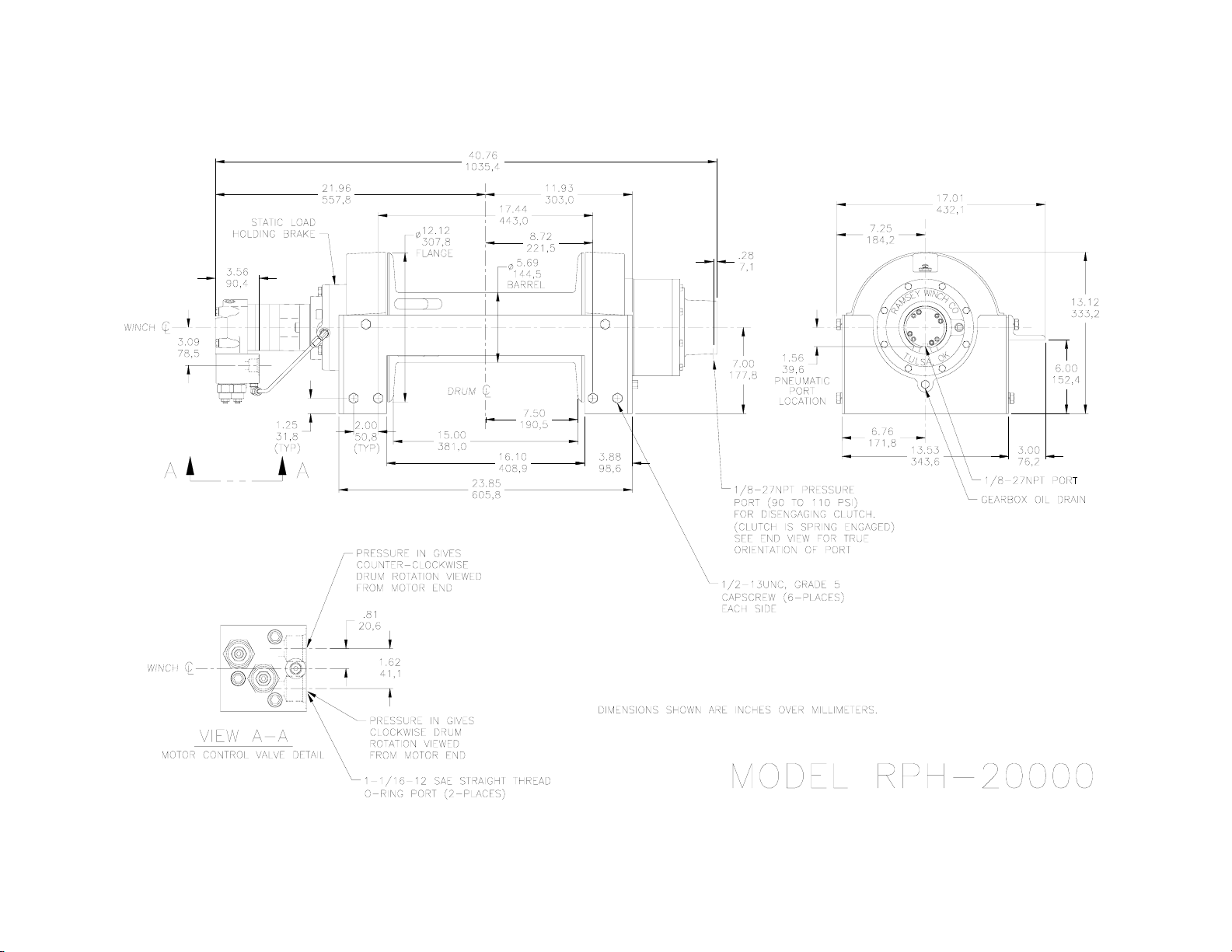

DIMENSIONAL DRAWING ........................................................................................................ 12

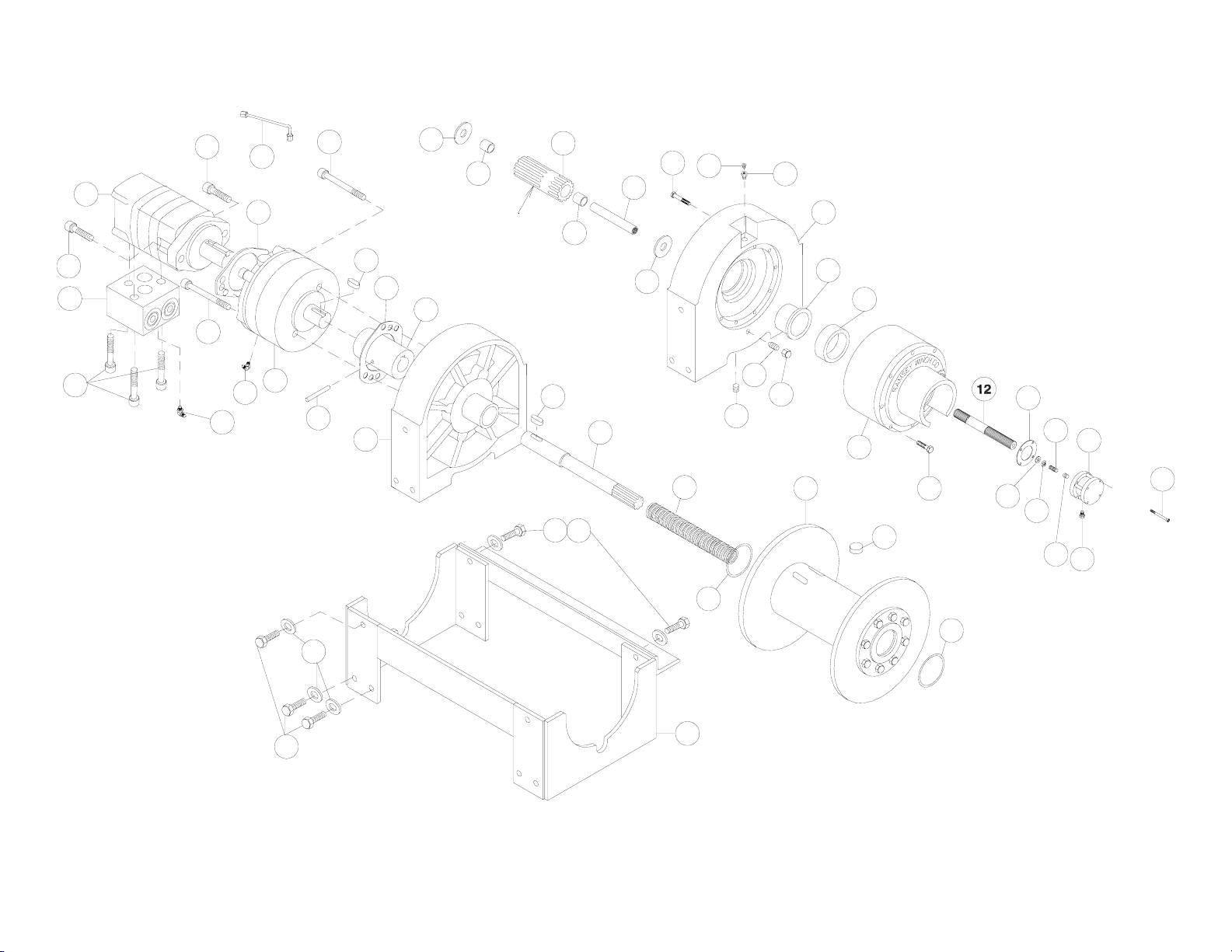

PARTS LIST AND PART DRAWING.......................................................................................13-14

LIMITED WARRANTY

RAMSEY WINCH warrants each new RAMSEY WINCH to be free from defects in material and

workmanship for a period of one (1) year from date of purchase.

The obligation under this warranty, statutory or otherwise, is limited to the replacement or repair

at the Manufacturer's factory, or at a point designated by the Manufacturer, of such part that shall

appear to the Manufacturer, upon inspection of such part, to have been defective in material or

workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost of labor or transportation

charges in connection with the replacement or repair of defective parts, nor shall it apply to a

product upon which repair or alterations have been made, unless authorized by Manufacturer, or

for equipment misused, neglected or which has not been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential damages. RAMSEY

WINCH makes no warranty in respect to accessories such as being subject to the warranties of

their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the right to improve

its products through changes in design or materials as it may deem desirable without being

obligated to incorporate such changes in products of prior manufacture.

If field service at the request of the Buyer is rendered and the fault is found not to be with

RAMSEY WINCH's product, the Buyer shall pay the time and expense to the field representative.

Bills for service, labor or other expenses that have been incurred by the Buyer without approval or

authorization by RAMSEY WINCH will not be accepted.

See warranty card for details.

Page 3

…

…

…

RAMSEY HYDRAULIC PLANETARY WINCH MODEL RPH 20,000

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most efficient operation from your Ramsey Winch, and safety procedures one needs to

know before operating a Ramsey Winch. Do not operate this winch until you have carefully read and understand the "WARNINGS" and

"OPERATION" sections of this manual.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great care and skill go into every winch we make. If the need should

arise, warranty procedure is outlined on the back of your self-addressed postage paid warranty card. Please read and fill out the enclosed

warranty card and send it to Ramsey Winch Company. If you have any problems with our winch, please follow instructions for prompt service

on all warranty claims. Refer to back page for limited warranty.

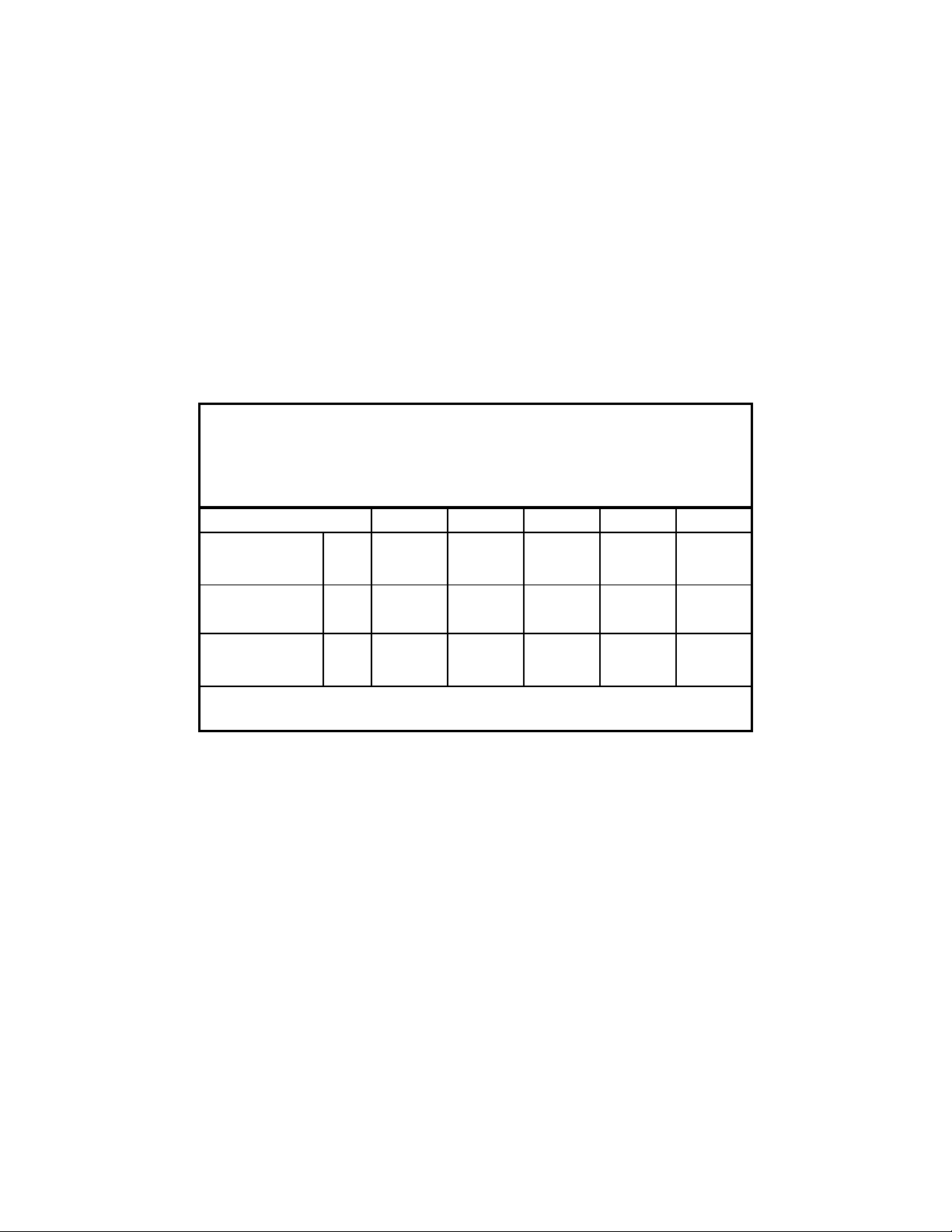

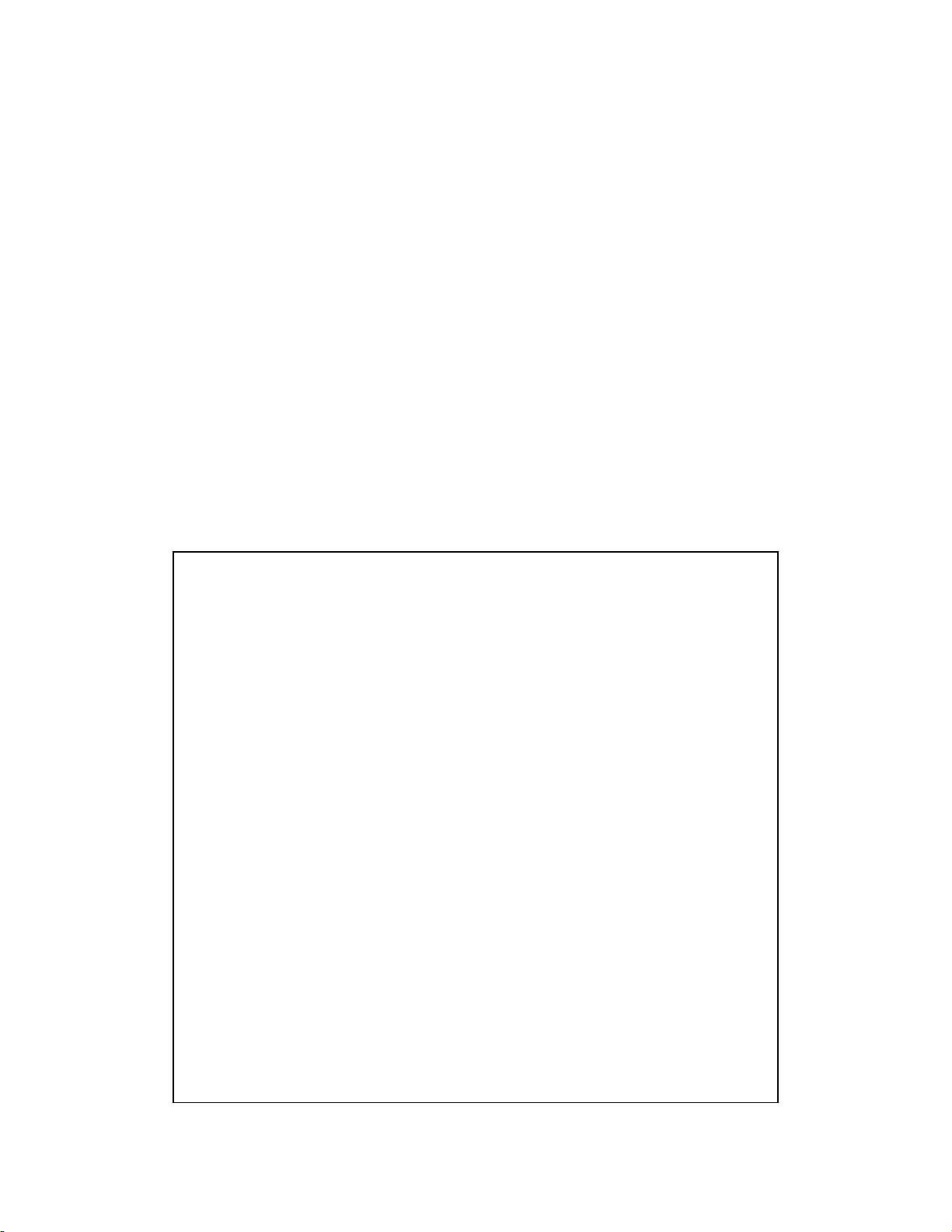

SPECIFICATIONS*

Rated Line Pull (lbs.) …………………………………………………

(Kg.) …………………………………………………

Gear Reduction 25.53:1

Weight (without cable)

LAYER OF CABLE

*Rated line pull

per layer

Cable Capacity

per Layer

* Line Speed (at

15 GPM)

* These specifications are based on recommended .56" (14 mm) wire rope and

a 8.0 cu.in./Rev. motor.

NOTE: The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for wire rope ratings.

…………………………………………………………

……………………………………… 375 lb. 170,0 Kg

12345

lbs. 20,000 16,900 14,700 13,000 11,600

Kg. 9,070 7,660 6,660 5,890 5,260

ft. 35 85 135 195 265

m1025415980

FPM2630353944

MPM 7,9 9,1 10,6 11,8 13,4

20,000

9,070

WARNINGS:

CLUTCH MUST BE TOTALLY ENGAGED BEFORE STARTING THE WINCHING OPERATION.

DO NOT START WINCH MOTOR BEFORE ENGAGING CLUTCH.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PEOPLE.

A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD.

CABLE ANCHOR IS NOT DESIGNED TO HOLD LOAD.

WINCH FRAME MOUNTING

Use (8) 1/2" diameter grade 5 or better bolts to attach mounting frame to the wrecker.

3

Page 4

CABLE INSTALLATION

The RPH-20000 winch has two tapered pockets cast into the drum. One pocket is for installations with the wire rope wound over

the drum. The other pocket is for an underwound wire rope. When properly used, the wedge pocket design is one of the most

secure anchoring methods available.

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of wire rope, opposite hook, with

plastic or similar tape to prevent fraying.

2. Slide the wire rope through narrow end of pocket against the drum flange and wrap the wire rope around the anchor “puck”

and pull the wire rope and anchor back into the wide end of the pocket. Use a soft hammer to drive the back side of the wire

rope, firmly seating the wire rope and anchor, into the pocket.

3. Carefully run the winch in the “reel-in” direction. Keeping tension on end of cable, spool all the cable onto the cable drum,

taking care to form neatly wrapped layers.

The wire rope can easily be removed from the drum by driving the anchor out the wide end of the pocket.

CLUTCH OPERATION

To engage clutch:

1. Move the clutch control valve to the “clutch engaged” position.

2. Anytime the temperature is below freezing, run the motor in the “cable out” direction only until the drum starts to turn. In

extreme cold temperatures (below 0o F/-18o C), pull out on the cable by hand only until the drum starts to turn.

3. Wait at least 3 seconds for the clutch to fully engage, after which the winch is ready to winch in the cable.

WARNING: Do not attempt to engage the clutch by first running the winch motor and then moving the clutch control valve to the

"clutch-engaged" position while the motor is running. Do not start picking up the load at the same time the clutch is being

engaged.

To disengage clutch:

1. Run the winch in the "cable out" direction until the load is off the cable.

2. Move the clutch control valve to the "clutch-disengaged" position.

The cable may now be pulled off by hand.

WINCH OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you use it. Plan your test in

advance. Remember, you hear your winch, as well as see it operate; learn to recognize the sounds of a light steady

pull, a heavy pull, and sounds caused by load jerking or shifting. Gain confidence in operating your winch and its use

will become second nature with you.

The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable pileup on one end of drum.

If this happens reverse the winch to relieve the load and move your anchor point further to the center of the vehicle.

After the job is done you can unspool and rewind for a neat lay of the cable.

MAINTENANCE

Adhering to the following maintenance schedule will keep your winch in top condition and performing as it should with

a minimum of repair.

A. WEEKLY

Check the oil level and maintain it to the oil level plug. If oil is leaking out, determine location and repair.

1.

2. Check the pressure relief plug in top of the gear housing. Be sure that it is not plugged. Lubricate cable with light oil.

B. MONTHLY

1.

Check the winch mounting bolts. If any are missing, replace them and securely tighten any that are loose. Use grade 5

or better bolts.

2. Inspect the cable. If the cable has become frayed with broken strands, replace immediately.

C. ANNUALLY

1. Drain the oil from the winch annually or more often if winch is used frequently.

2. Fill the winch to the oil level plug with clean kerosene. Run the winch a few seconds with no load in the reel in direction.

Drain the kerosene from the winch.

3. Refill the winch to the oil level plug with all purpose SAE 80W-140 gear oil.

4. Inspect frame and surrounding structure for cracks or deformation.

4

Page 5

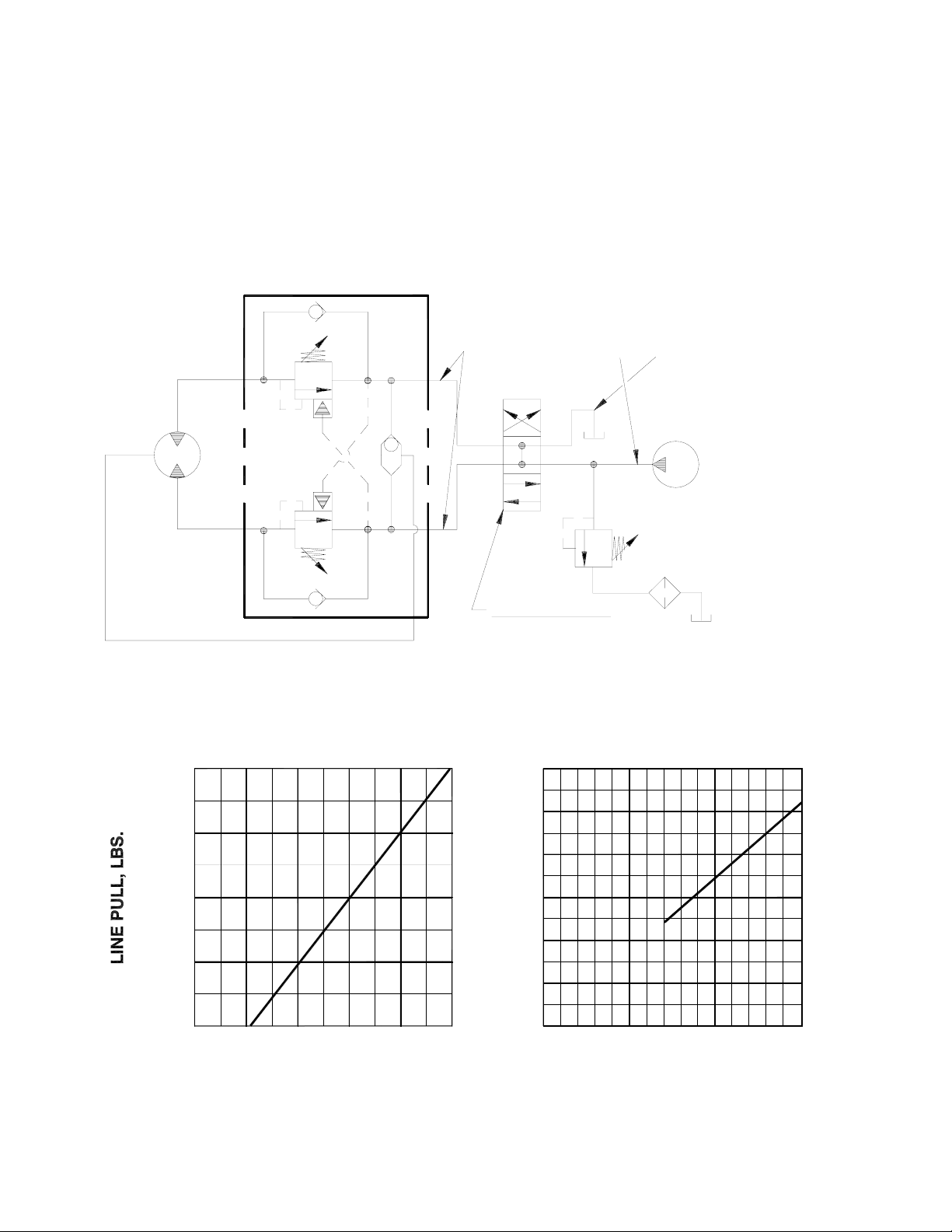

HYDRAULIC SYSTEM REQUIREMENTS

Refer to the performance charts, below, to properly match your hydraulic system to RPH-20000 winch performance. The charts

consist of:

(1) Line pull (lb.) first layer vs. working pressure (PSI) and

(2) Line speed, first layer (FPM) vs. gallons per minute (GPM).

TYPICAL LAYOUT

DUAL-A & B PORT CONTROL

WITH BRAKE RELEASE SHUTTLE

MOTOR

BRAKE

PORT

A

B

PERFORMANCE CHARTS

20000

HIGH PRESSURE LINE

CONTROL VALVE

3 POSITION

4 WAY VALVE

(MOTOR SPOOL)

30

LOW PRESSURE LINE

PUMP

25

N

15000

R

E

Y

A

L

10000

T

S

R

I

F

5000

0

0 500

WORKING PRESSURE, PSI

200015001000 2500

I

M

/

T

F

,

D

E

E

P

S

E

N

I

L

20

R

E

Y

A

15

L

T

S

R

10

I

F

5

0

0

5

10

15

GALLONS PER MINUTE

BASED ON 8.0 CU. IN/REV. MOTOR

5

Page 6

TROUBLE SHOOTING GUIDE

CONDITIONS POSSIBLE CAUSE CORRECTION

OIL LEAKS FROM WINCH

2. Too much oil. 2. Drain excess oil. Refer to

3. Damaged gaskets. 3. Replace gaskets.

WINCH RUNS TOO SLOW

2. Hydraulic motor worn out. 2. Replace motor.

CABLE DRUM WILL NOT

FREESPOOL

BRAKE WILL NOT RELEASE

1. Seals damaged or worn. 1. Replace seal.

OPERATION.

1. Low flow rate 1. Check flow rate. Refer to

Hydraulic Systems requirements,

page 5

1. Clutch not disengaged 1. Check air pressure to clutch

cylinder 90 PSI minimum

required-Refer to page 12.

1. Air in hydraulic system 1. Bleed air from brake. Refer to

page 11.

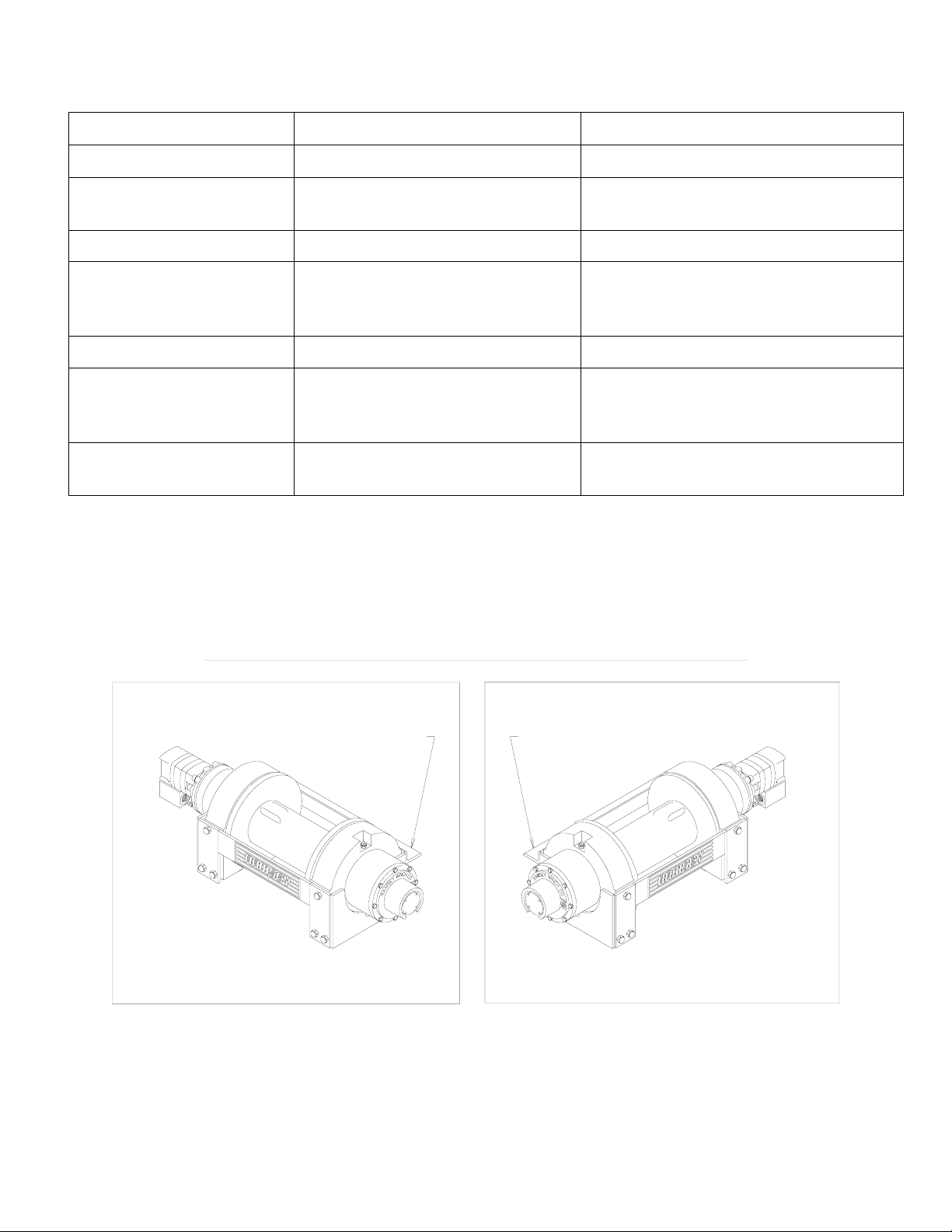

WINCH MOUNTING CONFIGURATIONS

ANGLE SIDE

R. H. MOUNTING

CONFIGURATION

ANGLE SIDE

L. H. MOUNTING

CONFIGURATION

6

Page 7

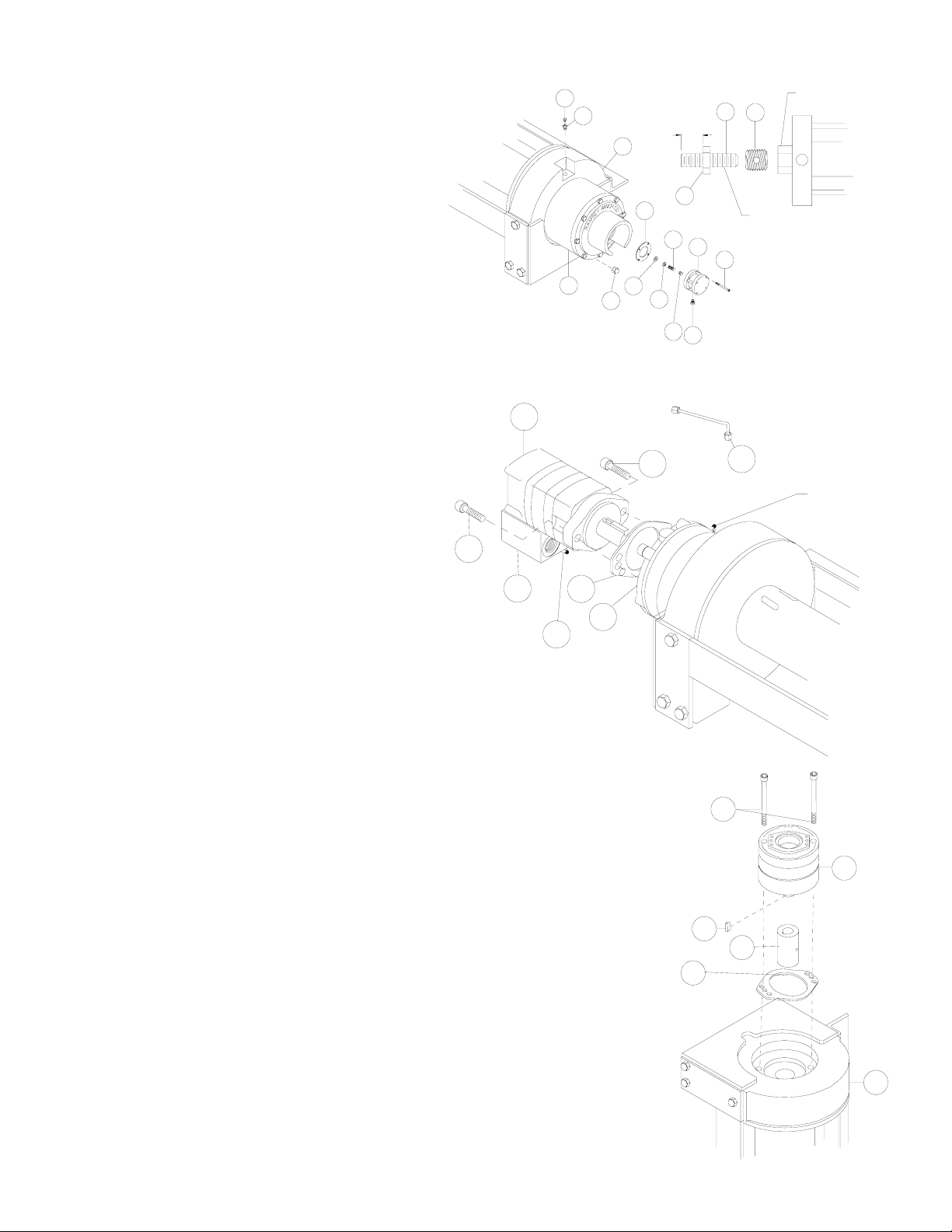

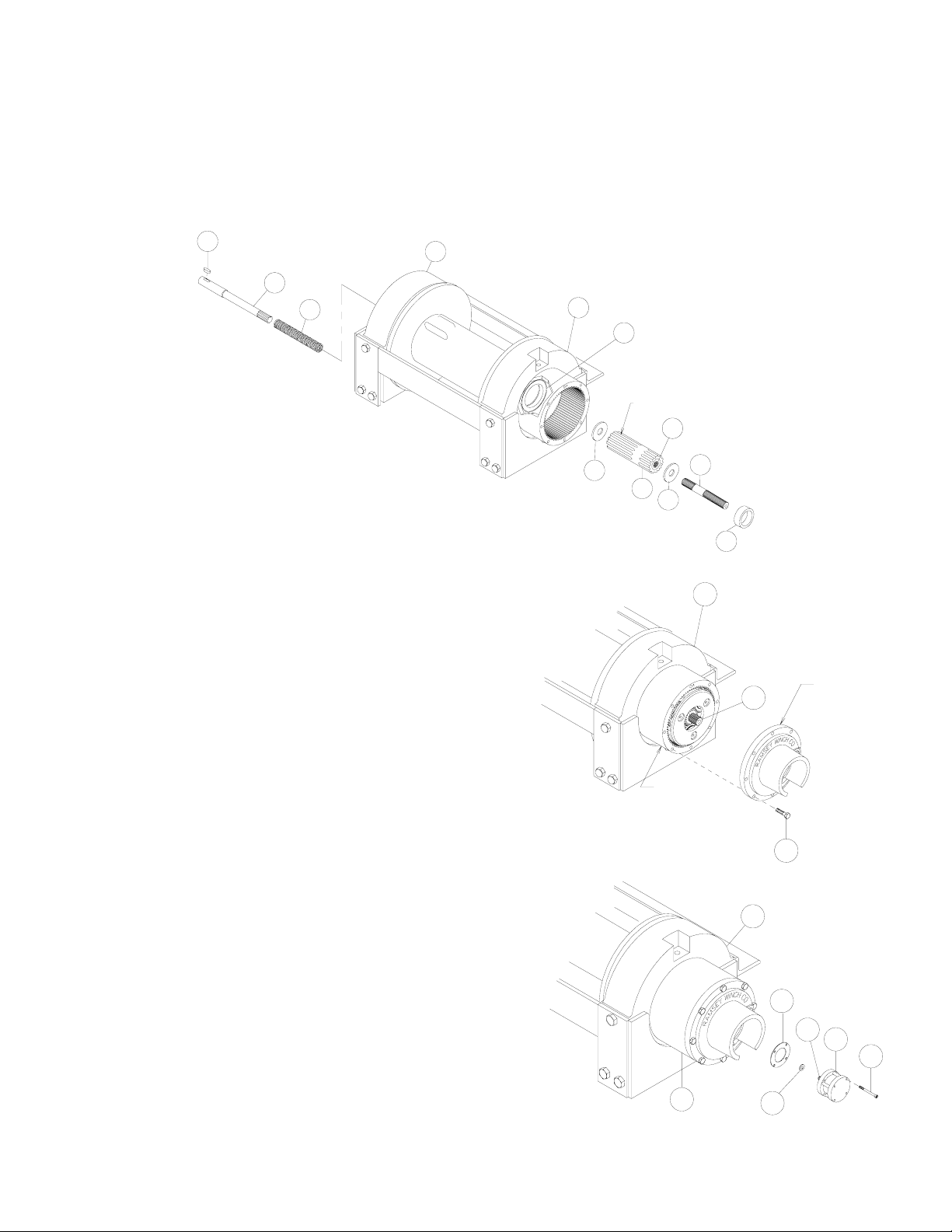

INSTRUCTIONS FOR OVERHAUL

1. Drain oil from gear housing #9 by removing pipe

cap #43 from pipe nipple in end bearing. Remove

reducer #41 and relief fitting #35. If new air

cylinder is required, remove air cylinder #30 from

36

42

3/8

9

cover by removing (4) capscrews #23.

Remove washer #25, nut #26, setscrew #22, and

insert #28 from end of air cylinder rod. Apply Loctite to threads of nut #26 and thread onto setscrew

27

34

23

31

#22 to 3/8” from drive end, as shown below.

Apply Loc-tite to threads of setscrew and thread

insert #28 over end of setscrew and against nut.

Use setscrew and nut to thread insert #28 into end

of air cylinder rod. Tighten nut against cylinder rod,

3

26

44

27

29

37

keeping 3/8” distance from drive end of setscrew to nut. If breather vent is damaged, remove and replace.

2. Disconnect tube #46 from elbows #29, as shown.

Remove motor #37 and gasket #32 by removing

(2) capscrews #20. Remove valve #47, if

needed, from motor by loosening (3) capscrews

#19, as shown on page 13.

38

19

19

48

33

30

30

3. Remove brake assembly (item #31) by removing (2) mounting screws (item #21)

attaching brake to end bearing (item #8). Remove coupling (item #5) and gasket (item

#34) from end bearing. Take note of mounting configuration for proper mounting of

parts during re-assembly.

AIR CYLINDER

23

29

APPLY LOC-TITE TO SETSCREW

24

47

ROD

BLEEDER

FITTING

20

32

10

5

35

8

7

Page 8

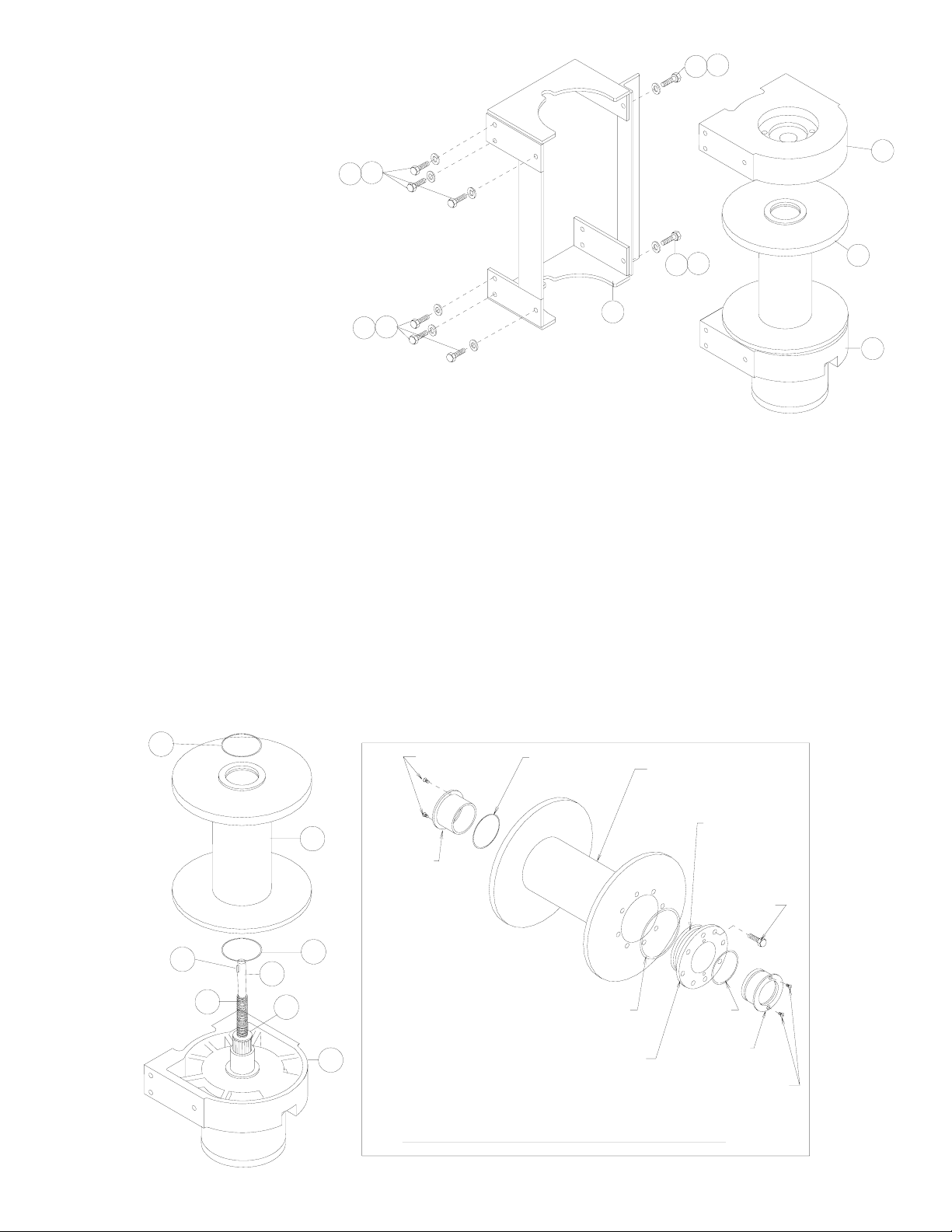

4. Remove winch from upright

mounting frame (item #1) by

17

25

removing (4) capscrews and

lockwashers. Pull motor end

bearing (item #8) from drum

assembly (item #2).

16

25

8

25

17

2

16

25

1

9

5. Pull drum assembly (item #2) upward from end bearing (item #9). Remove quad-rings (item #39 & #38) from grooves in

drum bushings. Remove input shaft (item #11), clutch spring (item #45) and washer (item #27) from end bearing (item

#9). Examine splined ends of input shaft for signs of wear, replace if damaged.

Examine drum assembly (item #2) for signs of wear. If splines inside of drum driver (332166) are damaged, drum driver

must be replaced. Remove drum driver by unscrewing (8) capscrews (414462). Place well-oiled o-ring (462053) into drum

driver groove and attach driver to drum (332165) using (8) capscrews (414462). Torque capscrews to 55 ft. lbs. each, in

criss-cross pattern.

Press old bushings from drum and drum driver. Remove o-rings (462055 & 462052) from grooves in drum and drum

driver-bushing (412092). Place well-oiled o-rings (462055 & 462052) into grooves in drum and outer diameter of drum

driver bushing (412092). Press new bushing (412091) into end of drum opposite drum driver and press bushing (412092)

into drum driver until flange of bushings are flush against drum and driver. Secure bushings to drum and drum driver using

(2) capscrews (414819).

39

2

10

46

40

11

28

9

412091

414819

462055

462053

332166

332165

DRUM DRIVER

GROOVE

414462

462052

412092

414819

DRUM ASSEMBLY 234170 (ITEM #2)

8

Page 9

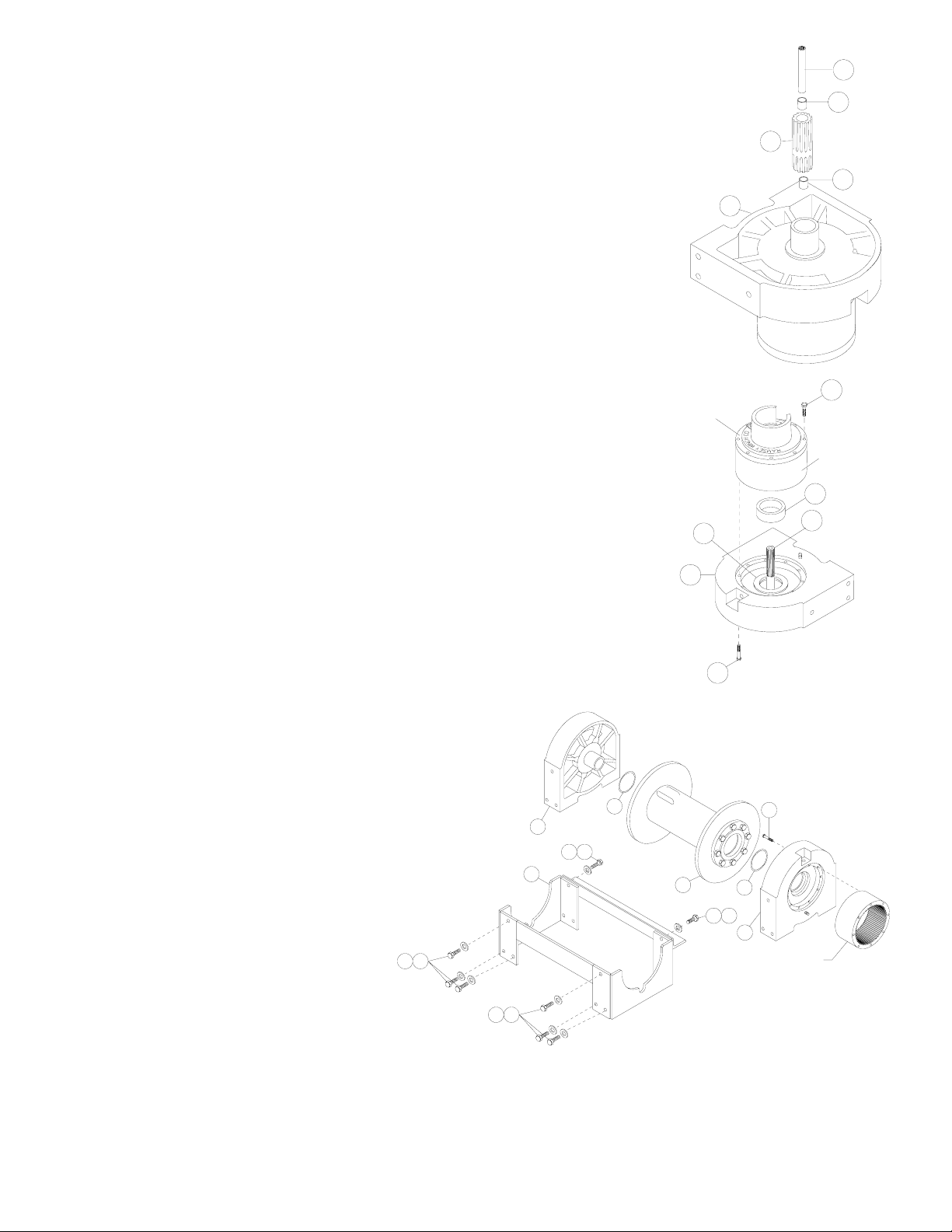

6. Remove output coupling (item #7) and coupling shaft (item #6) from end bearing (item

#9). Examine bearings (item #13), pressed in output coupling (item #7), for signs of

wear. Replace bearings, if necessary, by pressing old bearings from coupling and press

new bearings (item #13) into each end of output coupling (item #7). Place coupling

shaft (item #6) into bearings (item #13).

7. Remove (8) capscrews (item #15) to pull gear-housing cover from ring

gear. Remove input thrust washer, sun gear, carrier assemblies, and

GEAR HOUSING

COVER

spacer (item #13) from inside of ring gear. Examine splines of ring gear

and if necessary, remove ring gear from end bearing (item #9) by

removing (12) capscrews (item #16). Examine bushing (item #14) for

signs of wear. Replace bushing, if necessary, by pressing old bushing

from housing and pressing new bushing into place.

Apply RTV sealing compound to ring gear-mounting surface of end bearing

(item #9). Place ring gear onto end bearing, aligning holes in ring gear with

holes and gear housing end bearing. Secure ring gear to end bearing using

(12) capscrews (item #16). Torque to 40 ft-lbs, each in a criss-cross pattern.

Examine shifter shaft (item #12) for signs of wear, replace if necessary.

8. NOTE: DETERMINE MOUNTING CONFIG-

URATION OF WINCH (R.H. or L.H.

MOUNTED) BEFORE ATTACHING FRONT

AND REAR FRAME ASSEMBLY TO WINCH,

TO ASSURE PARTS ARE MOUNTED TO

PROPER SIDE, REFER TO WINCH

MOUNTING CONFIGURATIONS, PAGE 6.

Seat well-oiled quad-rings (item #38 &

#39) into groove of bushing in each end of

drum assembly (item #2), as shown.

Carefully set drum assembly (item #2)

down over motor end bearing (item #9). Lift

gear-housing end bearing (item #9) and set

into place on drum assembly. Install frame

assembly (item #1) using capscrews and

lockwashers shown below. Tighten (4)

capscrews securely, check rotation of cable

drum.

8

1

2516

16 25

39

17

25

6

14

7

14

9

21

RING GEAR

13

15

9

22

2

40

17

25

9

12

22

RING GEAR

9

Page 10

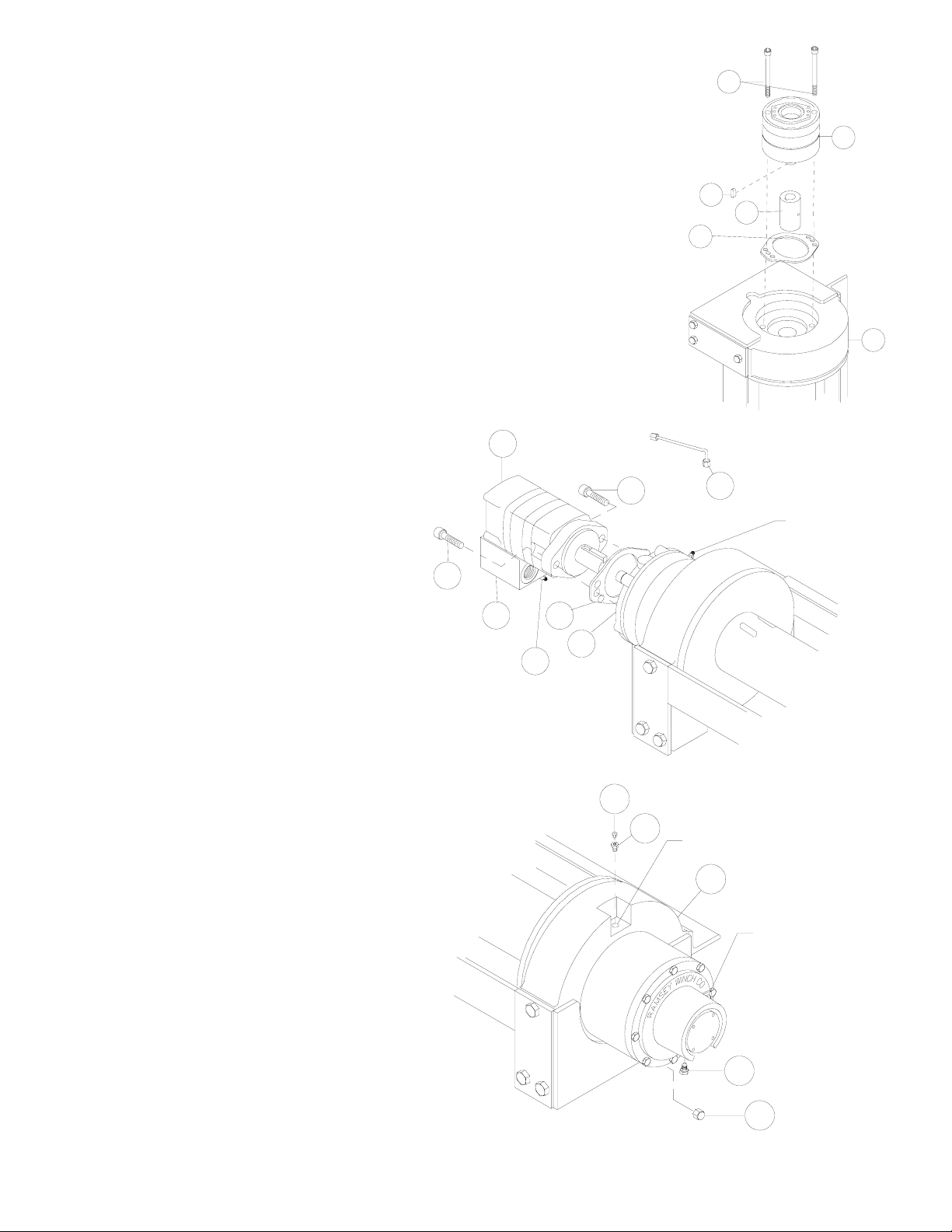

9. Liberally apply grease to shoulder of input shaft (item #11). Place spring (item #45) over longer splined end of shaft. Use

grease to hold spring in place against shoulder of shaft.

Place spring and shaft through motor end bearing (item #8) and drum until shaft extends through bushing (item #14) in end

bearing (item #9). Place clutch washer (item #27) over splined end of shaft and against spring. Place end of output

coupling assembly (item #7), with longest spline inward, through end bearing bushing (item #14) and mesh shaft coupling

spline with splined end of shaft. Place short splined end of shifter shaft (item #12) through washer (item #27) and into

shaft coupling (item #6), meshing splines of shifter shaft with splines in shaft coupling. Place spacer (item #13) over

output coupling assembly (item #7).

10

11

46

8

10. Place (2) gear carrier assemblies into ring gear meshing carrier

gears with ring gear. Make sure that ring gear and carrier

assemblies are securely against end bearing (item #9). Inspect

cover o-ring for damage and replace if necessary. Attach cover to

ring gear. Use (8) capscrews (item #15) to secure gearbox cover

to gear housing end bearing. Torque capscrews to 18 ft-lbs.

each, in criss-cross pattern.

11. Pull rod from air cylinder as far as possible. Slide washer (item

#25) over setscrew (item #22) and against nut attached to air

cylinder rod. Place setscrew into hole of shifter shaft (item #12).

Attach new air cylinder (item #30) and gasket (item #33) with

sealer, to adapter using (4) capscrews (item #23). Apply Loc-tite

PST thread sealer to threads of capscrews. Torque capscrews to

5 ft-lbs. each, in criss-cross pattern.

9

15

LONGEST SPLINES

6

28

7

12

28

13

9

GEAR HOUSING

COVER

RING

GEAR

12

21

9

34

23

31

24

10

3

26

Page 11

12. With pin (item #44) installed in coupling, slide coupling (item #5) over end of input shaft

below. Slide coupling over end of shaft (item #12). Place gasket (Item #34) into

position on motor mounting surface of end bearing (item #8). Insert brake shaft into

coupling. Use (2) screws (item #21) to attach brake assembly to motor end bearing.

Torque capscrews to 85 ft lbs each.

13. Attach motor (item #37) with well oiled gasket

(item #32) to brake (item #31). Use (2)

capscrews (item #20) and torque to 74 ft. lbs.

each. Securely connect tube (item #46) to elbow

(item #29), in valve (item #47), and brake (item

#31).

14. Apply Permatex to threads of pipe cap (item #43).

Thread pipe cap onto pipe nipple in bottom of gear

housing end bearing (item #9). Pour approx. 1.75

pints of SAE 80W-140 oil into end bearing. Check oil

level by removing oil plug noted below. Insert relief

fitting (item #35) and thread reducer (item #41)

into end bearing at oil fill hole.

Install winch and connect pressure lines. Apply at

least 230 PSI pressure to release brake and verify

that brake releases, by observing that the winch

drum rotates.

15. Check proper operation of clutch by applying air

pressure to clutch air cylinder to disengage clutch.

Verify that winch freespools. Re-engage clutch. A

loud noise should be heard when clutch engages.

Winch drum should not freespool.

16. Operate winch forward and reverse to verify that

drum rotates.

19

48

38

19

33

30

30

36

42

20

32

10

5

35

8

47

BLEEDER

FITTING

OIL FILL HOLE

9

OIL LEVEL HOLE

37

44

11

Page 12

12

Page 13

13

28

LONGEST SPLINE

35

5

14

10

17

7

22

36

6

14

28

41

11

46

25

39

43

44

42

9

15

13

34

23

29

31

24

37

3

2

21

4

40

26

27

19

48

18

38

19

20

30

30

47

20

33

10

32

45

8

25

RPH 20000

16

1

Page 14

14

PARTS LIST – RPH 20000

ITEM

1 1 242157 ASSY-FRAME 25 12 418218 LOCKWASHER 1/2 MED SECT

2 1 234170 DRUM ASSEMBLY 26 1 418432 WASHER – THRUST

3 1 296504 GEAR BOX 27 1 418433 NUT – 5/16-24 NF X 3/16 THK LOCK

4 1 314010 CABLE ANCHOR 28 2 418462 WASHER – CLUTCH

5 1 324290 COUPLING – BRAKE 29 1 426045 INSERT

6 1 324294 COUPLING – SHAFT 30 2 432018

7 1 324299 COUPLING – OUTPUT 31 1 433014 AIR CYLINDER

8 1 338294 END BEARING – MOTOR 32 1 438020 BRAKE

9 1 338315 END BEARING – GEAR 33 1 442215 GASKET – BRAKE & MOTOR END*

10 2 342194 KEY – RD END 34 1 442217 GASKET – AIR CYLINDER*

11 1 357496 SHAFT – INPUT 35 1 442224 GASKET – BRAKE OUTPUT FACE*

12 1 358073 SHIFTER SHAFT 36 1 456008 RELIEF FITTING

13 1 362269 SPACER 37 1 456038 BREATHER VENT

14 2 402119 BEARING 38 1 458081 MOTOR – HYDRAULIC

QTY. PART # DESCRIPTION ITEM QTY. PART

NO.

DESCRIPTION

FITTING – HYD 7/16-20 90° ELBOW

15 1 412090 BUSHING – THRUST 39 1 462012 QUAD. RING*

16 10 414561 CAPSCREW 1/2-13 NC X 1-1/4 LG HX HD GR 5 40 1 462050 QUAD. RING*

17 2 414551 CAPSCREW 1/2-13 NC X 1-1/2 LG HX HD GR 5 41 1 468017 PIPE PLUG

18 3 414935 CAPSCREW 3/8-16NC X 2-1/2 LG HX SOC HD 42 1 468024 REDUCER

19 2 414948 CAPSCREW 1/2-13NC X 1-1/4 LG SOC HD 43 1 468036 PIPE NIPPLE

20 2 414958 CAPSCREW 1/2-13NC X 4 LG SOC HD 44 1 468037 PIPE CAP

21 8 415152 BOLT – M8-1.25X30MM LG. HX HD GR 8.8 Z/P 45 1 470091 PIN

22 12 415207 BOLT – M10-1.25X60MM LG. HX HD GR 8.8 Z/P 46 1 494108 SPRING

23 1 416051 SETSCREW 5/16-24 NF X 1 LG SOC HD 47 1 509006 TUBE ASSEMBLY

24 4 416233 CAPSCREW #10-24NC X 2-1/2 LG HX SOC HD 48 1 516011 CONTROL VALVE

* THESE ITEMS ARE PART OF SEAL AND GASKET KIT #246047 WHICH ALSO INCLUDES (3) O-RINGS USED IN DRUM ASSEMBLY #234170 (SEE PAGE8) AND O-RING

USED ON GEAR BOX COVER (SEE PAGE 9).

Page 15

MANUEL D’UTILISATION, DE

DÉPANNAGE ET D’ENTRETIEN

TREUIL À PLANÉTAIRE

MODÈLE RPH-20000

MISE EN GARDE : ASSUREZ-VOUS DE LIRE ET DE COMPRENDRE CE MANUEL AVANT D’INSTALLER ET D’UTILISER

LE TREUIL. N’OUBLIEZ PAS LES AVERTISSEMENTS ET MISES EN GARDE.

RAMSEY WINCH COMPANY

PO Box 581510 Tulsa, Oklahoma 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688

Visit us at http://www.ramsey.com

Page 16

t

TABLE DES MATIÈRES

INTRODUCTIONS ...........................................................................................................17

INFORMATIONS DE GARANTIE ....................................................................................... 17

CARACTÉRISTIQUES TECHNIQUES.................................................................................17

AVERTISSEMENTS.........................................................................................................17

FIXATION DU TREUIL.....................................................................................................17

INSTALLATION DU CÂBLE .............................................................................................. 18

FONCTIONNEMENT DE L’EMBRAYAGE............................................................................18

FONCTIONNEMENT DE TREUIL.......................................................................................18

ENTRETIEN DU TREUIL ..................................................................................................18

SYSTÈMES HYDRAULIQUES ...........................................................................................19

DIAGRAMMES DE PERFORMANCES ...............................................................................19

GUIDE DE RÉSOLUTION DES PROBLÈMES ......................................................................20

CONFIGURATIONS DE MONTAGE....................................................................................20

INSTRUCTIONS DE RÉVISION DES TREUILS....................................................................21-25

PLAN COTÉ ...................................................................................................................26

LISTE ET SCHÉMA DES PIÈCES......................................................................................27-28

RAMSEY WINCH garantit chaque treuil RAMSEY neuf contre tout défaut de matériau et de

fabrication pendant une période d’un (1) an à partir de la date d’achat. L'obligation aux termes de

cette garantie, statutaire ou autre, est limitée au remplacement ou à la réparation à l’usine du

fabricant, ou à un endroit désigné par le fabricant, de la pièce qui semblera présenter un défaut de

fabrication ou de matériau, suite à l'inspection effectuée par le fabricant.

Cette garantie n’oblige pas RAMSEY WINCH à s’acquitter des frais de main-d'œuvre ou de

ransport liés au remplacement ou à la réparation des pièces défectueuses, et ne s'applique pas à

un produit ayant subi des réparations ou des modifications (sauf si elles ont été autorisées par le

fabricant), ou en cas de mauvaise utilisation de l’équipement, de négligence ou de matériel mal

installé.

RAMSEY WINCH ne pourra en aucun cas être tenue responsable des dommages particuliers et

indirects. RAMSEY WINCH n’émet aucune garantie au sujet des accessoires et portant par

exemple sur les garanties de leurs fabricants respectifs. RAMSEY WINCH s’efforce de poursuivre

une politique d’amélioration constante et se réserve par conséquent le droit d'améliorer ses

produits par le biais de modifications de leur conception ou des matériaux employés, selon les

besoins, et sans être obligée d'incorporer ces modifications aux produits fabriqués

précédemment.

En cas d’intervention sur le terrain à la demande de l’acquéreur, et si la défaillance s’avère ne pas

provenir du produit RAMSEY WINCH, l’acquéreur s’engage à s’acquitter auprès du représentant

des frais correspondant au temps et aux dépenses.

GARANTIE LIMITÉE

Les factures d'entretien, de main-d’œuvre et autres frais engagés par l’acquéreur sans l'accord ou

l'autorisation de RAMSEY WINCH ne seront pas acceptées.

Reportez-vous à la carte de garantie pour les détails.

Page 17

…

…

…

TREUIL À PLANÉTAIRE MODÈLE RPH-20000

VEUILLEZ LIRE ATTENTIVEMENT CE MANUEL

Ce manuel contient des conseils utiles pour l'utilisation efficace de votre treuil Ramsey ; il aborde aussi les procédures de sécurité à connaître

absolument avant l’utilisation d’un tel équipement.

INFORMATIONS DE GARANTIE

Les treuils Ramsey sont conçus et fabriqués selon des spécifications rigoureuses. Ils font tous l’objet d’un travail soigné et compétent. En cas

de besoin, la procédure de recours en garantie est détaillée au verso de votre carte de garantie préadressée à port payé. Veuillez lire et remplir

la carte de garantie ci-jointe, et l'envoyer à Ramsey Winch Company. En cas de problème avec votre treuil, suivez les instructions fournies afin

d’obtenir un service rapide de recours en garantie.

*CARACTÉRISTIQUES TECHNIQUES

Traction du câble

nominale

Démultiplication 25.53:1

Poids (sans le câble)

Couche de câble

*Traction Nominale

Par Couche De Câble

Capacité De Câble

Par Couche

* Vitesse du câble

(à 56 l/min)

*Ces caractéristiques techniques sont basées sur un câble de 14 mm et sur un

moteur de 131 cm³/tr.

Remarque : les tractions nominales indiquées sont uniquement pour le treuil. Consultez le fabricant du câble pour les caractéristiques

nominales de ce dernier.

(lbs.) …………………………………………………

(Kg.) …………………………………………………

…………………………………………………………

…………....…...……..…....……… 375 lb. 170,0 Kg

12345

lbs. 20,000 16,900 14,700 13,000 11,600

Kg. 9,070 7,660 6,660 5,890 5,260

ft. 35 85 135 195 265

m1025415980

FPM2630353944

MPM 7,9 9,1 10,6 11,8 13,4

20,000

9,070

AVERTISSEMENTS :

L’embrayage doit être entièrement enclenché avant de commencer tout treuillage.

Ne relâchez jamais l’embrayage en présence d’une charge.

Ne laissez pas l’embrayage enclenché lorsque le treuil n’est pas utilisé.

Ne vous placez jamais sous une charge soulevée ni à proximité.

Restez à l’écart du câble lors du treuillage. N’essayez pas de guider le câble.

Ne dépassez pas les caractéristiques de traction nominales maximales indiquées dans le tableau.

N’utilisez pas le treuil pour soulever, maintenir ou transporter des personnes.

Il convient de conserver au minimum cinq tours de câble autour du tambour pour maintenir la charge.

L’attache du câble n’est pas conçue pour assurer le maintien d’une charge.

Dans les applications de transport d’automobiles, veillez à bien fixer le véhicule sur le porte-voitures. La

charge imposée au câble du treuil ne doit pas être maintenue pendant le transport. N’utilisez pas le

treuil comme dispositif d’attache.

Lorsque vous treuillez une lourde charge, placez une couverture, une veste ou une bâche sur le câble à

environ 1,8 m du crochet.

Évitez tous risques de glissement de la charge ou d’à-coups à son niveau, car ils pourraient s’avérer

dangereux.

MONTAGE DU CADRE DU TREUIL

Utilisez huit boulons de 13 mm de diamètre de grade 5 ou plus pour fixer le cadre de montage sur la dépanneuse.

17

Page 18

INSTALLATION DU CÂBLE

Le treuil RPH-20000 comporte deux logements effilés, moulés dans le tambour. L’un d’eux s’emploie pour les installations requérant un

enroulement du câble par-dessus le tambour. L’autre pour un enroulement par-dessous le tambour. Lorsqu’elle est correctement utilisée, cette

conception représente la méthode d'ancrage la plus sûre actuellement disponible.

1. Déroulez le câble sur le sol pour éviter qu'il ne se torde. Recouvrez bien l’extrémité du câble opposée au crochet d’un ruban adhésif

plastique ou de type équivalent pour éviter qu’elle ne s’effiloche.

2. Insérez le câble dans la partie étroite du logement, contre la bride du tambour, enroulez-le autour du galet d’ancrage, puis retirez le câble

et l’ancrage dans la partie large du logement. Utilisez un marteau-caoutchouc pour acheminer l’arrière du câble, en le plaçant fermement

avec l’ancrage dans le logement.

3. Faites tourner avec précaution le treuil dans le sens de l’enroulement. Conservez une tension sur l’extrémité du câble et enroulez tout le

câble sur le tambour en veillant à former des couches régulières.

Le câble peut se retirer facilement du tambour en sortant l’ancrage de la partie large du logement.

FONCTIONNEMENT DE L’EMBRAYAGE

Enclenchement de l’embrayage

1. Déplacez la commande d'embrayage en position « embrayage enclenché ».

2. S’il gèle, faites uniquement tourner le moteur dans le sens de déroulement du câble jusqu’à ce que le tambour commence à tourner. S’il

fait extrêmement froid (au-dessous de -18 ºC), tirez le câble à la main jusqu’à ce que le tambour commence à tourner.

3. Attendez au moins trois secondes pour que l’embrayage s'enclenche complètement, après quoi le treuil est prêt à gérer le câble.

AVERTISSEMENT : n'essayez pas d'enclencher l'embrayage en commençant par faire tourner le moteur du treuil puis en

enclenchant la commande d’embrayage pendant le fonctionnement du moteur. Ne commencez pas à treuiller pendant

l’enclenchement de l’embrayage.

Désenclenchement de l’embrayage

1. Faites fonctionner le treuil dans le sens de déroulement jusqu'à ce que le câble ne tracte plus la charge.

2. Déplacez la commande de l'embrayage en position « embrayage désenclenché ».

Il est désormais possible de tirer le câble à la main.

FONCTIONNEMENT DU TREUIL

Pour vous familiariser avec votre treuil, il est vivement conseillé de l’essayer avant de vraiment l’utiliser. Préparez votre essai à l’avance.

N’oubliez pas que vous entendez votre treuil autant que vous le voyez fonctionner. Apprenez à reconnaître le son d'une traction légère et

régulière, celui d'une lourde charge ou encore celui provoqué par des à-coups ou une déviation de la charge. Prenez l’habitude de faire

fonctionner votre treuil et tout deviendra automatique.

L’enroulement irrégulier du câble lors de la traction d’une charge ne présente pas de problème sauf en cas d’accumulation du câble sur un

côté du tambour. Dans ce cas, inversez le fonctionnement du treuil afin de soulager la charge et déplacez votre point d’attache vers le centre

du véhicule. Une fois le travail terminé, vous pouvez dérouler le câble et l’enrouler à nouveau d’une manière régulière.

ENTRETIEN

L’observation du calendrier de maintenance suivant vous permettra de maintenir votre treuil en bon état et garantira un fonctionnement avec

un minimum de réparations.

A. HEBDOMADAIRE

1. Vérifiez le niveau d’huile et maintenez-le au niveau du bouchon. En cas de fuite d’huile, déterminez l’emplacement de la fuite et

réparez.

2. Vérifiez le bouchon d’échappement en haut de la boîte d’engrenages. Assurez-vous qu’il n’est pas bouché. Lubrifiez le câble avec de

l’huile légère.

B. MENSUEL

1. Vérifiez les boulons de fixation du treuil. Remplacez tout boulon manquant et serrez fermement les autres. Utilisez des boulons de

grade 5 ou de qualité supérieure.

2. Examinez le câble. Tout câble effiloché ou comportant des brins brisés doit être remplacé immédiatement.

C. ANNUEL

1. Le treuil doit être vidangé une fois par an ou plus souvent en cas d’usage fréquent.

2. Remplissez le treuil de kérosène propre jusqu’au niveau du bouchon de niveau d’huile. Faites fonctionner le treuil quelques secondes

sans charge dans le sens de l’enroulement. Éliminez le kérosène du treuil.

3. Remplissez le treuil d’huile pour engrenages SAE 80W-140 polyvalente jusqu’au bouchon de niveau d’huile.

4. Examinez le châssis et la structure afin de déceler toutes déformations ou fissures éventuelles.

18

Page 19

CARACTÉRISTIQUES DU SYSTÈME HYDRAULIQUE

Reportez-vous aux diagrammes de performances ci-dessous pour établir une correspondance entre votre système hydraulique et

le fonctionnement de votre treuil. Ces diagrammes sont constitués des éléments suivants :

(1) Traction du câble, première couche (lb) / Pression de fonctionnement (PSI)

(2) Vitesse du câble, première couche en pieds par minute (FPM) / débit en gallons par minute (GPM)

Disposition Type

Contrôle À Double Orifice A Et B

Avec Navette De Desserrage Du Frein

Moteur

Entrée

Frein

A

B

DIAGRAMMES DE PERFORMANCES

20000

)

.

B

,

L

15000

(

E

L

E

B

H

Â

C

C

U

10000

U

O

D

C

N

E

R

O

I

5000

È

T

I

C

M

A

E

R

R

T

P

0

0 500

PRESSION DE

FONCTIONNEMENT EN PSI

200015001000 2500

Conduite Haute Pression

Valve À 3

Positions Et 4 Voies

(Distributeur Moteur)

30

)

.

n

i

m

25

/

t

f

(

,

E

20

E

H

L

C

B

U

Â

15

O

C

C

U

E

D

10

R

E

È

I

S

S

5

M

E

E

T

I

R

V

P

0

DÉBIT (GPM)

Conduite Basse Pression

Pompe

5

10

150

CES PERFORMANCES SONT BASÉES SUR UNE CYLINDRÉE DU MOTEUR DE 131 CM

19

3

Page 20

GUIDE DE RÉSOLUTION DES PROBLÈMES

PROBLÈME CAUSE POSSIBLE SOLUTION

FUITE D’HUILE AU NIVEAU

DU CARTER

LE TREUIL FONCTIONNE

TROP LENTEMENT

LE TAMBOUR NE RELÂCHE

PAS LE REMBOBINAGE

BRAKE WILL NOT RELEASE 1. Air dans le système hydraulique 1. Purgez l’air du frein. Reportez-vous à la

1. Joint d’étanchéité endommagé ou

usé.

2. Trop d’huile. 2. Vidangez l’excédent d’huile. Reportez-

3. Joint statique endommagé. 3. Remplacez le joint statique.

1. Débit faible 1. Vérifiez le débit. Reportez-vous aux

2. Moteur hydraulique usé. 2. Remplacez le moteur.

1. Embrayage non désenclenché. 1. Vérifiez la pression d’air au cylindre

1. Remplacez le joint d’étanchéité.

vous aux TECHNIQUES D’UTILISATION.

diagrammes des SYSTÈMES

HYDRAULIQUES.

d’embrayage, 620 kPa (90 PSI)

minimum requis. Reportez-vous à la

page 13.

page 25.

WINCH MOUNTING CONFIGURATIONS

R. H. MOUNTING

CONFIGURATION

LA CONFIGURATION DE MONTAGE DU TREUIL

CÔTÉ DU CORNIÈRE

ANGLE SIDE

DROIT

CÔTÉ DU CORNIÈRE

ANGLE SIDE

L. H. MOUNTING

GAUCHE

CONFIGURATION

20

Page 21

INSTRUCTIONS DE RÉVISION

1. Vidangez l’huile de la boîte d’engrenage nº 9 en

retirant le bouchon femelle nº 44 du mamelon du

palier d’extrémité. Retirez le réducteur nº 42 et le

raccord de dégagement nº 36. S’il s'avère

36

42

9

23

29

3/8

LA TIGE DU

AIR CYLINDER

CYLINDRE

ROD

nécessaire de changer le cylindre pneumatique nº

31, retirez-le du couvercle en enlevant les quatre

vis d’assemblage nº 24.

Retirez la rondelle nº 26, l'écrou nº 27, la vis de

pression nº 23 et le raccord nº 29 de l'extrémité de

la tige du cylindre pneumatique. Appliquez du Loctite sur les filets de l’écrou nº 27 et enfilez ce

dernier sur la vis de pression nº 23, à 9,5 mm de

l'extrémité d'entraînement, comme indiqué ci-

3

26

44

27

34

23

31

27

29

37

APPLY LOC-TITE TO SETSCREW

APPLIQUER DU LOC-TITE SUR LES FILETS

24

dessous. Appliquer du Loc-tite sur les filets de la

vis de pression et enfilez le raccord nº 29 sur son

extrémité et contre l'écrou. Utilisez la vis de pression et l’écrou pour enfiler le raccord nº 29 sur l’extrémité de la tige du

cylindre pneumatique. Serrez l’écrou sur la tige du cylindre, en conservant 9,5 mm entre l’extrémité de l’entraînement de la

vis et l’écrou. Si le reniflard est endommagé, retirez-le et remplacez-le.

38

2. Débranchez le tube nº 47 des coudes nº 30, comme

indiqué sur le schéma. Pour retirer le moteur nº 38 et

19

47

le joint statique nº 33, enlevez les deux vis

d’assemblage nº 19. Le cas échéant, retirez la valve

nº 48 du moteur en desserrant les trois vis

d'assemblage nº 18, comme indiqué en page 27.

19

48

33

30

30

3. Pour retirer le frein (pièce nº 32), enlevez les deux vis d’assemblage (pièce nº 20) le

fixant au palier d’extrémité (pièce nº 8). Retirez le raccordement (pièce nº 5) et le joint

statique (pièce nº 35) du palier d’extrémité. Prenez note de l’aspect du montage pour

assembler correctement les pièces lors du remontage.

20

RACCORD

BLEEDER

PURGEUR

FITTING

32

10

5

35

8

21

Page 22

4. Retirez les quatre vis d'assemblage et

leurs rondelles de sécurité afin d'ôter le

17

25

treuil du cadre de fixation vertical (pièce

nº1). Retirez le palier d’extrémité du

moteur (pièce nº 8) du tambour (pièce

nº 2).

25

16

8

17

25

2

25

16

1

9

5. Tirez le tambour (pièce nº 2) vers le haut par le palier d'extrémité (pièce nº 9) Retirez les joints quad-ring (pièces nº 39 et 40) des

rainures des bagues du tambour. Retirez l’arbre d’entrée (pièce nº 11), le ressort d’embrayage (pièce nº 46) et la rondelle (pièce nº 28)

du palier d’extrémité (pièce nº 9). Examinez l’état des extrémités cannelées de l'arbre et remplacez-le si nécessaire.

Vérifiez le tambour (pièce nº 2) afin de déceler tout signe d’usure éventuel. Si les cannelures à l’intérieur de l’entraînement du tambour

(332166) sont endommagées, il convient alors de le remplacer. Dévissez les huit vis d'assemblage (414462) pour retirer l'entraînement

du tambour. Placez un joint torique bien huilé (462053) dans la rainure de l’entraînement et fixez ce dernier au tambour (332165) au

moyen des huit vis d’assemblage (414462). Serrez chaque vis à un couple de 74 Nm en alternant en croix.

Retirez les bagues usagées du tambour et de son entraînement. Retirez les joints toriques (462055 et 462052) des rainures des bagues

du tambour et de l'entraînement (412092). Placez des joints toriques (462055 et 462052) bien huilés dans les rainures du tambour et du

pourtour externe de la bague d'entraînement du tambour (412092). Insérez la bague (412091) neuve sur l’extrémité du tambour, à

l’opposé de l’entraînement du tambour, puis pressez la bague (412092) contre l’entraînement jusqu’à ce que les brides se trouvent tout

contre le tambour et l'entraînement. Fixez les bagues sur le tambour et sur son entraînement au moyen de deux vis d’assemblage

(414819).

39

2

10

46

40

11

28

9

414819

412091

DRUM ASSEMBLY 234170 (ITEM #2)

LE TAMBOUR 234170 (PIÈCE Nº 2)

462055

332165

462053

332166

LA RAINURE DE

DRUM DRIVER

L’ENTRAÎNEMENT

GROOVE

414462

462052

412092

414819

22

Page 23

A

6. Retirez le raccordement de sortie (pièce nº 7) et l’arbre du raccordement (pièce nº 6) du

palier d’extrémité (pièce nº 9). Examinez les paliers (pièce nº 14) dans le raccordement de

sortie (pièce nº 7) afin de déceler tout signe d'usure éventuel. Changez-les si besoin est en

les sortant et en les remplaçant par des neufs (pièce nº 14) dans chaque extrémité du

raccordement de sortie (pièce nº 7). Placez l’arbre de raccordement (pièce nº 6) dans les

7

paliers (pièce nº 14).

9

7. Retirez les huit vis d’assemblage (pièce nº 21) pour sortir le couvercle de la boîte

d'engrenages de la couronne. Retirez la rondelle de butée d’entrée, le planétaire,

les porte-pignons et l’entretoise (pièce nº 13) de l’intérieur de la couronne.

LE COUVERCLE DE L

GEAR HOUSING

BOÎTE D'ENGRENAGES

COVER

Examinez les cannelures de la couronne et, le cas échéant, retirez celle-ci du

palier d’extrémité (pièce nº 9) en retirant les douze vis d’assemblage (pièce

nº 22). Vérifiez la bague (pièce nº 15) pour déceler toute trace d’usure. Si

13

nécessaire, sortez la bague usagée et remplacez-la par une neuve.

Appliquez un mastic d’étanchéité de vulcanisation à la température ambiante sur

15

12

la surface de montage de la couronne du palier d’extrémité (pièce nº 9). Placez la

couronne sur le palier d’extrémité, en alignant les trous de la couronne sur les

9

trous du palier d'extrémité de la boîte d'engrenages. Fixez la couronne sur le

palier d’extrémité au moyen de douze vis d’assemblage (pièce nº 22). Serrez-les

chacune à un couple de 54 Nm en alternant en croix. Examinez l’arbre de

l'embrayeur (pièce nº 12) afin de déceler toute trace d'usure et remplacez-le si

nécessaire.

22

8. REMARQUE : DÉTERMINEZ LA CONFIGURATION

DE MONTAGE DU TREUIL (MONTAGE DROIT OU

GAUCHE) AVANT DE FIXER L'AVANT ET

L’ARRIÈRE DU CADRE, AFIN DE VOUS ASSURER

QUE LES PIÈCES SONT MONTÉES DU BON CÔTÉ.

RÉFÉREZ-VOUS AUX CONFIGURATIONS DE

8

MONTAGE DU TREUIL, DE LA PAGE 20.

Placez des joints quad-ring bien huilés (pièces

1

nº 38 et 39) dans la rainure de bague, à chaque

extrémité du tambour (pièce nº 2), comme indiqué

sur le schéma. Placez avec précaution le tambour

(pièce nº 2) sur le palier d'extrémité du moteur

2516

(pièce nº 9). Soulevez le palier d’extrémité de la

boîte d’engrenages (pièce nº 9) et mettez-le en

place sur le tambour. Installez le cadre (pièce

16 25

nº 1) au moyen des vis d’assemblage et des

rondelles de sécurité indiquées ci-dessous. Serrez fermement les quatre vis d’assemblage et vérifiez la rotation du tambour.

39

17

25

2

17

25

40

9

22

LA COURONNE

RING GEAR

6

14

14

21

LA COURONNE

RING GEAR

23

Page 24

9. Appliquez une quantité généreuse de graisse sur l’épaulement de l’arbre d’entrée (pièce nº 11). Placez le ressort (pièce nº

46) sur l’extrémité cannelée la plus longue de l’arbre. Utilisez de la graisse pour maintenir le ressort en place contre

l’épaulement de l’arbre.

Insérez le ressort et l’arbre dans le palier d’extrémité du moteur (pièce nº 8) et le tambour jusqu’à ce que l’arbre dépasse de

la bague (pièce nº 15) du palier d’extrémité (pièce nº 9). Placez la rondelle de l'embrayage (pièce nº 28) sur l'extrémité

cannelée de l'arbre et contre le ressort. Placez l’extrémité de raccordement de sortie (pièce nº 7), avec la cannelure la plus

longue vers l’intérieur, dans la bague du palier d’extrémité (pièce nº 15) et faites prendre la cannelure de raccordement de

l’arbre sur l’extrémité cannelée de l’arbre. Placez l’extrémité cannelée courte de l’arbre d’embrayage (pièce nº 12) dans la

rondelle (pièce nº 28) et dans le raccordement d’arbre (pièce nº 6), en faisant prendre les cannelures de l’arbre d’embrayage

sur celles du raccordement d’arbre. Placez l’entretoise (pièce nº 13) sur le raccordement de sortie (pièce nº 7).

10

11

46

8

9

15

LA PLUS LONGUE CANNELURE

LONGEST SPLINES

6

28

7

12

28

10. Placez deux porte-pignons dans la couronne en faisant

prendre les engrenages sur la couronne. Assurez-vous que

la couronne et les porte-pignons se trouvent bien contre le

palier d'extrémité (pièce nº 9). Examinez le joint torique du

couvercle et remplacez-le si besoin est. Fixez le couvercle

sur la couronne. Utilisez huit vis d’assemblage (pièce nº 21)

pour fixer le couvercle sur le palier d'extrémité de la boîte

d’engrenages. Serrez chaque vis selon un couple de 24 Nm

en alternant en croix.

11. Tirez la tige du cylindre pneumatique aussi loin que

possible. Faites glisser la rondelle (pièce nº 26) sur

la vis de pression (pièce nº 23) et contre l’écrou fixé

sur la tige du cylindre pneumatique. Placez la vis de

pression dans le trou de l’arbre d’embrayage (pièce

nº 12). Fixez le cylindre pneumatique neuf (pièce nº

30) et le joint statique (pièce nº 34) avec du produit

d’étanchéité, sur l’adaptateur au moyen de quatre vis

d’assemblage (pièce nº 24). Appliquez du produit

d’étanchéité PST Loc-tite sur les filets des vis

d'assemblage. Serrez chaque vis à un couple de

6 Nm en alternant en croix.

9

13

GEAR HOUSING

LE COUVERCLE DE LA

COVER

BOÎTE D'ENGRENAGES

LA COURONNE

RING

GEAR

12

21

9

34

23

31

24

3

26

24

Page 25

12. Avec la goupille (pièce nº 45) installée dans le raccordement, faites glisser ce dernier

(pièce nº 5) sur l’extrémité de l’arbre d’entrée au-dessous. Faites glisser le

raccordement sur l’extrémité de l’arbre (pièce nº 12). Placez le joint statique (pièce nº

35) sur la surface de montage du moteur du palier d'extrémité (pièce nº 8). Insérez

l’arbre du frein dans le raccordement. Utilisez deux vis (pièce nº 20) pour fixer le frein au

palier d’extrémité du moteur. Serrez chaque vis à un couple de 115 Nm.

13. Fixez le moteur (pièce nº 38) avec un joint statique

38

bien huilé (pièce nº 33) sur le frein (pièce nº 32).

Utilisez deux vis d’assemblage (pièce nº 19) et

serrez-les à un couple de 100 Nm. Raccordez

19

fermement le tube (pièce nº 47) sur le coude (pièce

nº 30) de la valve (pièce nº 48) et sur le frein (pièce

nº 32).

19

48

33

30

30

14. Appliquez du Permatex sur les filets du bouchon femelle

(pièce nº 44). Enfilez le bouchon femelle sur le mamelon au

bas du palier d’extrémité de la boîte d'engrenages (pièce nº

36

42

9). Versez environ 0,8 l d'huile SAE 80W-140 dans le palier

d’extrémité. Vérifiez le niveau d’huile en retirant le bouchon

d’huile indiqué ci-dessous. Insérez le raccord de

dégagement (pièce nº 36) et le réducteur de filet (pièce

nº 42) dans le palier d’extrémité au niveau de l’orifice de

remplissage d'huile.

Installez le treuil et connectez les conduites de pression.

Appliquez une pression d’au moins 1 580 kPa pour relâcher

le frein et vérifiez qu’il se relâche en observant si le tambour

tourne.

15. Vérifiez le fonctionnement de l’embrayage en appliquant une

pression pneumatique au cylindre d’embrayage afin de

désenclencher ce dernier. Vérifiez que le treuil tourne librement. Réenclenchez l’embrayage. Un bruit fort doit retentir lorsque

l’embrayage s'enclenche. Le tambour du treuil ne doit plus tourner librement.

16. Faites fonctionner le treuil en avant et en arrière pour vérifier que le tambour tourne.

20

10

5

35

47

L’ORIFICE DE

OIL FILL HOLE

REMPLISSAGE D'HUILE

9

37

RACCORD

BLEEDER

PURGEUR

FITTING

TROU DE NIVEAU D'HUILE

OIL LEVEL HOLE

44

32

8

25

Page 26

26

FREIN DE MAINTIEN

DE CHARGE STATIQUE

EMPLACEMENT

DE L’ORIFICE

PNEUMATIQUE

ORIFICE NPT DE 0,125-27 (RACCORDEZ

UNE PRESSION DE 620 À 750 KPA**

POUR DÉSENCLENCHER L’EMBRAYAGE)

L’EMBRAYAGE EST ENCLENCHÉ PAR RESSORT.

L'ENTRÉE DE PRESSION DONNE UNE

ROTATION DU TAMBOUR DANS LE SENS

CONTRAIRE DES AIGUILLES D’UNE

MONTRE VUE DE L'EXTRÉMITÉ MOTEUR

OBSERVEZ LA VUE DE L’EXTRÉMITÉ POUR

L’ORIENTATION RÉELLE DE L’ORIFICE.

VIS D’ASSEMBLAGE - 1/213NC, Gr. 5 (6 ENDROITS DE

CHAQUE CÔTÉ DU TREUIL)

ORIFICE NPT DE 0,125-27

VIDANGE DE L’HUILE DE LA BOÎTE

D’ENGRENAGES

L'ENTRÉE DE PRESSION DONNE UNE

DÉTAIL DE DISTRIBUTEUR DU MOTEUR

VUE A-A

ROTATION DU TAMBOUR DANS LE

SENS DES AIGUILLES D’UNE MONTRE

VUE DE L'EXTRÉMITÉ MOTEUR

ORIFICE DE JOINT TORIQUE À FILETAGE DROIT

1-1/6-12 SAE (2 ENDROITS)

MODELE RPH-20000

LES DIMENSIONS SONT INDIQUÉES EN POUCES PUIS EN MILLIMÈTRES.

Page 27

27

28

LA PLUS LONGUE CANNELURE

LONGEST SPLINE

35

5

14

10

17

7

22

36

6

14

28

41

11

46

25

39

43

44

42

9

15

13

34

23

29

31

24

37

3

2

21

4

40

26

27

19

48

18

38

19

20

30

30

47

20

33

10

32

45

8

25

RPH 20000

16

1

Page 28

28

PIÈCE QTÉ Nº RÉF.

1 1 242157

2 1 234170

3 1 296504

4 1 314010

5 1 324290

6 1 324294

7 1 324299

8 1 338294

9 1 338315

10 2 342194

11 1 357496

12 1 358073

13 1 362269

14 2 402119

15 1 412090

16 10 414561

DESCRIPTION

CADRE

TAMBOUR

BOÎTE D’ENGRENAGES

ANCRAGE DU CÂBLE

RACCORDEMENT - FREIN

RACCORDEMENT - ARBRE

RACCORDEMENT - SORTIE

PALIER D’EXTRÉMITÉ - MOTEUR

PALIER D’EXTRÉMITÉ - ENGRENAGES

CLAVETTE

ARBRE - ENTRÉE

ARBRE D’EMBRAYEUR

ENTRETOISE

PALIER

BAGUE DE BUTÉE

VIS D’ASSEMBLAGE 1/2-13 NC x 1,25 po (long), tête hex.,

LISTE DES PIÈCES – RPH 20000

PIÈCE QTÉ Nº RÉF.

25 12 418218

26 1 418432

27 1 418433

28 2 418462

29 1 426045

30 2 432018

31 1 433014

32 1 438020

33 1 442215

34 1 442217

35 1 442224

36 1 456008

37 1 456038

38 1 458081

39 1 462012

40 1 462050

DESCRIPTION

RONDELLE DE SÉCURITÉ 1/2 SECT. MOY.

RONDELLE DE BUTÉE

ÉCROU - 5/16-24 NF x 3/16 po d’épaisseur

RONDELLE D’EMBRAYAGE

RACCORD

RACCORD HYDRAULIQUE COUDÉ 7/16-20 90°

CYLINDRE PNEUMATIQUE

FREIN

JOINT STATIQUE - EXTRÉMITÉ FREIN ET MOTEUR*

JOINT STATIQUE - CYLINDRE PNEUMATIQUE*

JOINT STATIQUE - FACE DE SORTIE FREIN*

RACCORD DE DÉGAGEMENT

RENIFLARD

MOTEUR - HYDRAULIQUE

JOINT QUAD-RING*

JOINT QUAD-RING*

Gr. 5

17 2 414551

VIS D’ASSEMBLAGE 1/2-13 NC x 1,5 po (long), tête hex.,

41 1 468017

BOUCHON CYLINDRIQUE

Gr. 5

18 3 414935

VIS D'ASSEMBLAGE 3/8-16 NC x 2,5 po (long), tête hex. à

42 1 468024

RÉDUCTEUR

pans creux

19 2 414948

VIS D’ASSEMBLAGE 1/2-13 NC x 1,25 po (long), tête

43 1 468036

MAMELON

creuse

20 2 414958

21 8 415152

22 12 415207

VIS D’ASSEMBLAGE 1/2-13 NC x 4 po (long), tête creuse

BOULON - M8-1,25 x 30 mm (long), tête hex., gr. 8,8, zinc

BOULON - M10-1,25 x 60 mm (long), tête hex., gr. 8,8,

44 1 468037

45 1 470091

46 1 494108

BOUCHON FEMELLE

GOUPILLE

RESSORT

zinc

23 1 416051

24 4 416233

VIS D’ASSEMBLAGE 5/16-24 NF x 1 po (long), tête creuse

VIS D'ASSEMBLAGE 10-24 NC x 2,5 po (long), tête hex. à

47 1 509006

48 1 516011

TUBE

VALVE DE COMMANDE

pans creux

* CES ARTICLES FONT PARTIE DU KIT DE JOINTS D’ÉTANCHÉITÉ ET DE JOINTS STATIQUES Nº 246047 QUI COMPREND AUSSI 3 JOINTS TORIQUES UTILISÉS DANS L’ENSEMBLE DU TAMBOUR Nº

234170 (VOIR PAGE 22) ET UN JOINT TORIQUE UTILISÉ SUR LE COUVERCLE DE LA BOÎTE D’ENGRENAGES (VOIR PAGE 23).

Page 29

BETRIEBS-, INSTANDHALTUNGS-

UND WARTUNGSHANDBUCH

PLANETENWINDE

MODELL RPH 20000

ACHTUNG: VOR DER INSTALLATION UND INBETRIEBNAHME DER WINDE MUSS DIESES HANDBUCH

GELESEN UND VERSTANDEN WERDEN. ALLE SICHERHEITS- UND WARNHINWEISE LESEN!

RAMSEY WINCH COMPANY

PO Box 581510 Tulsa, Oklahoma 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688

Visit us at http://www.ramsey.com

Page 30

INHALTSVERZEICHNIS

EINFÜHRUNG ......................................................................................................................... 31

GARANTIEHINWEISE............................................................................................................... 31

TECHNISCHE DATEN............................................................................................................... 31

WARNHINWEISE..................................................................................................................... 31

MONTAGE DES WINDEN-ANBAURAHMENS.............................................................................. 31

INSTALLATION DES WINDENSEILS ..........................................................................................32

KUPPLUNGSBETRIEB.............................................................................................................. 32

WINDENBETRIEB.................................................................................................................... 32

WARTUNG.............................................................................................................................. 32

HYDRAULIKANFORDERUNGEN................................................................................................. 33

LEISTUNGSDIAGRAMME......................................................................................................... 33

FEHLERSUCHE....................................................................................................................... 34

MONTAGEKONFIGURATIONEN................................................................................................. 34

ANLEITUNG ZUM ÜBERHOLEN ...........................................................................................35-39

MASSZEICHNUNGEN .............................................................................................................. 40

TEILELISTE UND TEILEZEICHNUNGEN ................................................................................41-42

RAMSEY WINCH garantiert für ein (1) Jahr ab Kaufdatum, dass jede neue RAMSEY Winde frei von

Material- und Verarbeitungsfehlern ist. Die Verpflichtung unter dieser Garantie, ob im gesetzlichen

Umfang oder anderweitig, beschränkt sich auf den Ersatz oder die Reparatur des Teils, bei dem

vom Hersteller nach Inspektion ein Material- oder Verarbeitungsfehler bestätigt wird. Reparaturen

dürfen nur im Herstellerwerk oder an einer vom Hersteller bestimmten Stelle durchgeführt werden.

Aus dieser Garantie ausgeschlossen sind Teile, bei denen ohne die Genehmigung des Herstellers

Reparaturen oder Modifizierungen durchgeführt wurden oder Geräte, die missbraucht,

vernachlässigt oder falsch installiert wurden und RAMSEY WINCH übernimmt keine Arbeits- oder

Transportkosten in Verbindung mit dem Ersatz oder der Reparatur solcher defekter Teile.

RAMSEY WINCH haftet in keinem Fall für Sonder- oder Folgeschäden. RAMSEY WINCH gibt keine

Gewähr in Bezug auf Zubehör, das durch die Garantie der jeweiligen anderen Hersteller geschützt

ist. RAMSEY WINCH behält sich das Recht vor, im Rahmen seines kontinuierlichen

Verbesserungsprogramms Produkte durch Ausführungs- und Materialveränderungen zu

verbessern, ohne dass dem Hersteller dadurch irgendwelche Pflichten zur Änderung früherer

Produkte entstehen.

Wenn auf Anfrage des Käufers im Außendienst Reparaturen durchgeführt werden und es wird

festgestellt, dass es sich nicht um einen Defekt des RAMSEY WINCH Produkts handelt, muss der

Käufer den Außendienstvertreter für den anfallenden Zeit- und Kostenaufwand entschädigen.

Rechnungen des Käufers für Reparaturen, Arbeitsaufwand und andere Kosten, die nicht im Voraus

von RAMSEY WINCH genehmigt wurden, werden nicht akzeptiert.

BESCHRÄNKTE GARANTIE

Genauere Informationen sind der Garantiekarte zu entnehmen.

Page 31

…

…

…

RAMSEY HYDRAULISCHE PLANETENWINDE MODELL RPH -20000

DIESES HANDBUCH BITTE SORGFÄLTIG DURCHLESEN

Das Handbuch enthält nützliche Informationen für den effizienten Betrieb der Ramsey Winde sowie Sicherheitsmaßnahmen, mit denen sich der

Benutzer vor der Inbetriebnahme der Ramsey Winde vertraut machen muss. Die Winde darf erst in Betrieb genommen werden, wenn die

Abschnitte „WARNHINWEISE“ und „BETRIEB“ dieses Handbuchs gelesen und verstanden wurden.

GARANTIEHINWEISE

Ramsey Winden werden nach strengsten Spezifikationen konstruiert und gebaut. Jede Winde wird mit großer Sorgfalt und fachlichem Knowhow hergestellt. Sollte trotzdem ein Garantiefall eintreten, befolgen Sie bitte die Anweisungen auf der Rückseite der adressierten und

frankierten Garantiekarte. Lesen Sie die beiliegende Garantiekarte, füllen Sie diese aus und senden Sie sie an die Ramsey Winch Company.

Falls Sie mit Ihrer Winde Probleme haben, folgen Sie bitte den Anweisungen, um einen prompten Service bei allen Garantieansprüchen zu

gewährleisten. Die beschränkte Garantie ist auf der Rückseite des Handbuchs aufgeführt.

TECHNISCHE DATEN*

ANMERKUNG: Die aufgeführte nominale Zugkraft gilt nur für die Winde. Die Nennleistung des Seils muss vom Seilhersteller in Erfahrung gebracht werden.

Nominale Zugkraft (lbs.) …………………………………………………

(Kg.) …………………………………………………

Getriebeuntersetzung 25.53:1

Gewicht (ohne Seil) 375 lb. 170,0 Kg

Seillage

*Nominale Zugkraft

pro Lage

Seilaufnahme pro

Lage

*Seilgeschwindigkeit

(bei 56 l/min)

* Diese technischen Daten basieren auf dem empfohlenen Drahtseil (14 mm) dickes

verstärktes Stahlseil und einem 131 cm³/R Motor.

…………………………………………………………

……..……..…………..……..…....……….

12345

lbs. 20,000 16,900 14,700 13,000 11,600

Kg. 9,070 7,660 6,660 5,890 5,260

ft. 35 85 135 195 265

m1025415980

FPM2630353944

MPM 7,9 9,1 10,6 11,8 13,4

20,000

9,070

WARNHINWEISE:

VOR BEGINN DES WINDENBETRIEBS MUSS SICHERGESTELLT WERDEN, DASS DIE KUPPLUNG VOLLSTÄNDIG EINGERÜCKT IST.

DIE KUPPLUNG NICHT UNTER LAST AUSRÜCKEN.

DIE KUPPLUNG NICHT EINGERÜCKT LASSEN, WENN DIE WINDE NICHT GEBRAUCHT WIRD.

NIEMALS UNTER ODER NEBEN ANGEHOBENEN LASTEN STEHEN.

WÄHREND DES ZIEHENS EINEN SICHEREN ABSTAND ZUM SEIL EINHALTEN. NICHT VERSUCHEN, DAS SEIL ZU LENKEN.

DIE IN DER TABELLE ANGEFÜHRTE MAXIMALE ZUGKRAFT NICHT ÜBERSCHREITEN.

DIE WINDE NICHT ZUM HEBEN, TRAGEN ODER ANDERWEITIGEN TRANSPORT VON MENSCHEN VERWENDEN.

ZUM HALTEN DER LAST SIND MINDESTENS 5 SEILWICKLUNGEN UM DEN TROMMELZYLINDER NOTWENDIG. DIE SEILKLEMME IST

NICHT FÜR DAS HALTEN DER LAST AUSGELEGT.

DIE SEILKLEMME WURDE NICHT ZUM HALTEN DER LAST KONSTRUIERT.

MONTAGE DES WINDEN-ANBAURAHMENS

Für die Befestigung des Anbaurahmens am Bergungsfahrzeug müssen acht (8) Schrauben der Sorte 5 mit einem Mindestdurchmesser von 13

mm verwendet werden.

31

Page 32

INSTALLATION DES WINDENSEILS

Bei der RPH-20000 Winde sind zwei konische Taschen in die Seiltrommel gegossen. Eine Tasche wird für Installationen verwendet, bei denen

das Drahtseil über die Trommel gewickelt wird. Die andere Tasche wird verwendet, wenn das Seil unter der Trommel durchgeführt wird. Bei

richtiger Anwendung ist diese konische Taschenausführung eine der sichersten Verankerungsmethoden auf dem Markt.

1. Zum Abwickeln das Seil am Boden entlang auslegen, um ein Knicken zu vermeiden. Das dem Haken gegenüberliegende Seilende mit

Plastik- oder ähnlichem Klebeband umwickeln, um ein Ausfransen zu verhindern.

2. Das Drahtseil durch das schmale Ende der Tasche bis gegen den Trommelflansch schieben und um den Anker-Puck wickeln. Dann das

Drahtseil mit dem Anker in das weite Ende der Tasche ziehen. Mit einem Gummihammer auf die Rückseite des Drahtseils klopfen, bis

Drahtseil und Anker fest in der Tasche sitzen.

3. Die Winde langsam in Aufwickelrichtung in Bewegung setzen. Das Seilende gespannt halten und das Seil vollständig auf die Seiltrommel

aufwickeln. Darauf achten, dass sauber gewickelte Lagen entstehen.

Das Drahtseil lässt sich leicht von der Trommel entfernen, indem der Anker aus dem weiten Ende der Tasche herausgetrieben wird.

KUPPLUNGSBETRIEB

Einrücken der Kupplung:

1. Den Kupplungssteuerschieber in die eingerückte Position stellen.

2. Bei Temperaturen unter null Grad immer zuerst der Motor in Seilabrollrichtung laufen lassen, bis sich die Trommel zu drehen beginnt. Bei

extrem tiefen Temperaturen (unter -18 ºC) das Seil von Hand herausziehen, bis sich die Trommel zu drehen beginnt.

3. Mindestens 3 Sekunden warten, bis die Kupplung vollständig eingerückt ist. Danach ist die Winde zum Aufrollen des Seils bereit.

WARNUNG: Nicht versuchen, zum Einrücken der Kupplung zuerst den Windenmotor in Betrieb zu setzen und dann den

Kupplungssteuerschieber bei laufendem Motor in die Einrückstellung zu stellen. Niemals gleichzeitig mit dem Einrücken der Kupplung das

Aufnehmen der Last beginnen.

Ausrücken der Kupplung:

1. Die Winde in Abwickelrichtung laufen lassen, bis das Seil von der Last befreit ist.

2. Den Kupplungssteuerschieber in die ausgerückte Position stellen.

Anschließend kann das Seil von Hand abgezogen werden.

WINDENBETRIEB

Um mit der Funktion der Winde vertraut zu werden, sollte vor der tatsächlichen Verwendung ein Probelauf durchgeführt werden. Planen Sie

den Probelauf im Voraus. Werden Sie mit den Geräuschen vertraut, die bei einem leichten konstanten Zug, schweren Zug und bei ruckartigen

Bewegungen oder Verschiebungen der Last zu hören sind. Nachdem Sie sich mit allen Funktionen der Winde vertraut gemacht haben, ist deren

Bedienung sehr einfach.

Ein ungleichmäßiges Spulen des Seils beim Ziehen einer Last stellt kein Problem dar, außer wenn sich das Seil an einem Trommelende

anhäuft. In diesem Fall muss die Winde reversiert werden, um die Last vom Seil zu nehmen, und der Ankerpunkt weiter zur Fahrzeugmitte

verschoben werden. Nach Erledigung des Auftrags kann die Winde abgespult und das Seil in sauberen Lagen aufgewickelt werden.

WARTUNG

Bei Einhaltung der folgenden Wartungsintervalle bleibt die Winde stets im optimalen Zustand mit maximaler Leistung und minimalem

Reparaturaufwand.

A. WÖCHENTLICH

1. Ölstand prüfen und ggf. bis zur Ölstandsschraube auffüllen. Bei einem Ölleck dessen Lage ausfindig machen und reparieren.

2. Das Überdruckventil an der Oberseite des Getriebekastens überprüfen. Sicherstellen, dass es nicht verstopft ist. Das Seil mit einem

leichten Öl schmieren.

B. MONATLICH

1. Die Befestigungsschrauben der Winde überprüfen. Fehlende Schrauben ersetzen und lockere Schrauben festziehen. Nur Schrauben der

Sorte 5 oder besser verwenden.

2. Das Windenseil inspizieren. Ein ausgefranstes oder beschädigtes Seil muss sofort ersetzt werden.

C. JÄHRLICH

1. Das Öl mindestens jährlich wechseln, öfter bei häufigem Einsatz.

2. Die Winde bis zur Ölstandsschraube mit sauberem Kerosin auffüllen. Die Winde einige Sekunden lang ohne Last in Aufwickelrichtung

laufen lassen. Das Kerosin aus der Winde ablassen.

3. Die Winde bis zur Ölstandsschraube mit Allzweckgetriebeöl SAE 80W-140 auffüllen.

4. Den Rahmen und die den Rahmen umgebende Struktur auf Risse und Verformungen überprüfen.

32

Page 33

HYDRAULIKANFORDERUNGEN

Zur richtigen Wahl der Hydraulik für die Leistung der Winde ist auf die folgenden Leistungsdiagramme Bezug zu nehmen. Die Diagramme

zeigen:

(1) Seilzugkraft (Lb.) der ersten Lage im Vergleich zum Arbeitsdruck (PSI)

(2) Seilgeschwindigkeit, erste Lage (ft/min) im Vergleich zur Förderrate (GPM)

TYPISCHE ANORDNUNG

DOPPELANSCHLUSSREGLER (A UND B)

MIT BREMSENFREIGABEVENTIL

MOTOR

BREMSENAN-

SCHLUSS

LEISTUNGSDIAGRAMME

20000

15000

)

.

,

B

T

L

10000

(

F

A

E

R

G

K

A

G

L

5000

U

E

Z

T

L

I

S

E

R

S

E

0

0500

ARBEITSDRUCK (PSI)

HOCHDRUCKLEITUNG

A

B

4-WEGEVENTIL MIT

3 STELLUNGEN

(MOTORWICKLUNG)

30

25

,

T

I

E

20

)

K

n

i

G

I

m

D

/

15

t

N

f

I

(

W

E

10

H

G

C

A

S

L

E

5

E

G

T

L

S

I

R

E

0

E

200015001000 2500

S

NIEDERDRUCKLEITUNG

PUMPE

5

10

150

FÖRDERRATE (GPM)

LEISTUNG AUF BASIS EINES HUBRAUMS VON 131 CM

3

33

Page 34

FEHLERSUCHE

ZUSTAND MÖGLICHE URSACHE ABHILFE

ÖL LECKT AUS DEM

GEHÄUSE

DIE WINDE LÄUFT ZU

LANGSAM

KEIN FREILAUF AN DER

SEILTROMMEL

BREMSE KANN NICHT

GELÖST WERDEN

1. Dichtung beschädigt oder

verschlissen.

2. Zu viel Öl. 2. Überschüssiges Öl ablassen. Siehe

3. Beschädigter Dichtring. 3. Dichtring ersetzen.

1. Niedrige Förderrate. 1. Förderrate überprüfen. Siehe Hydraulik-

2. Hydraulikmotor ist abgenutzt 2. Motor ersetzen.

1. Kupplung nicht eingerückt 1. Druckluft zum Kupplungszylinder

1. Lufteinschluss in der Hydraulik 1. Bremse entlüften. Siehe Seite 39.

1. Dichtung ersetzen.

Hinweise zum Betrieb.

Flussdiagramm auf Seite 33.

prüfen; Mindestdruck: 620 kPa. Siehe

Seite 40.

WINCH MOUNTING CONFIGURATIONS

R. H. MOUNTING

RECHTSSEITIGE

CONFIGURATION

WINDE DIE MONTAGEKONFIGURATION

MONTAGE

ANGLE SIDE

WINKELSEITE

ANGLE SIDE

WINKELSEITE

L. H. MOUNTING

CONFIGURATION

LINKSSEITIGE

MONTAGE

34

Page 35

ANLEITUNG ZUM ÜBERHOLEN

1. Das Öl aus dem Getriebekasten (Nr. 9) ablassen. Dazu

die Rohrkappe (Nr. 43) vom Rohrnippel im Endlager

abnehmen. Das Reduzierstück (Nr. 41) und das

Überdruckventil (Nr. 35) entfernen. Wenn der

36

42

9

23

29

3/8

Luftzylinder ersetzt werden muss, die vier (4)

Kopfschrauben (Nr. 23) und den Luftzylinder (Nr. 30)

vom Deckel abnehmen.

Unterlegscheibe (Nr. 25), Mutter (Nr. 26), Stellschraube

(Nr. 22) und Einsatz (Nr. 28) vom Ende der

Luftzylinderstange abnehmen. Auf das Gewinde der

Mutter (Nr. 26) Loc-tite auftragen und die Mutter bis zu

10 mm vor dem Antriebsende auf das Gewinde der

Stellschraube (Nr. 22) aufschreiben (siehe unten). Auf

das Gewinde der Stellschraube Loc-tite auftragen und

3

26

44

27

34

23

31

27

29

37

Auf Gewinde Der Stellschraube

APPLY LOC-TITE TO SETSCREW

Loc-Tite Auftragen

24

den Einsatz (Nr. 28) auf die Stellschraube drehen und

gegen die Mutter festschrauben. Unter Verwendung der Stellschraube und Mutter den Einsatz (Nr. 28) in das Ende der

Luftzylinderstange schrauben. Die Mutter fest gegen die Zylinderstange festziehen, wobei zwischen dem Antriebsende der Stellschraube

und der Mutter ein Abstand von 10 mm aufrechterhalten werden muss. Wenn der Entlüfter beschädigt ist, diesen ausbauen und

ersetzen.

AIR CYLINDER

Luftzylinderstange

ROD

2. Das Rohr (Nr. 46) wie gezeigt von den Kniestücken (Nr.

29) trennen. Den Motor (Nr. 37) und den Dichtring (Nr.

32) durch Entfernen der 2 Kopfschrauben (Nr. 20)

ausbauen. Das Ventil (Nr. 47), falls notwendig, durch

Lösen der 3 Kopfschrauben (Nr. 19) (siehe Abbildung

auf Seite 41) vom Motor abnehmen.

38

19

47

19

LÜFTERSCHRAUBE

BLEEDER

FITTING

48

33

30

30

3. Die Bremsenbaugruppe (Nr. 31) durch Entfernen der 2 Befestigungsschrauben (Nr. 21), mit denen

die Bremse am Endlager (Nr. 8) befestigt ist, ausbauen. Kupplung (Nr. 5) und Dichtring (Nr. 34)

vom Endlager ausbauen. Auf die Zusammensetzung der Teile achten, damit diese wieder richtig

zusammengebaut werden.

20

32

10

5

35

8

35

Page 36

4. Die Winde aus dem stehenden

Anbaurahmen (Nr. 1) ausbauen. Dazu

17

25

die vier (4) Kopfschrauben und

Sicherungsscheiben entfernen. Das

Motorendlager (Nr. 8) aus der

Trommelbaugruppe (Nr. 2) ziehen.

16

25

8

17

25

2

25

16

1

9

5. Die Trommelbaugruppe (Nr. 2) nach oben aus dem Endlager (Nr. 9) ziehen. Die Vierlippendichtungen (Nr. 39 und 38) aus den Rillen in

den Seiltrommelbuchsen entfernen. Antriebswelle (Nr. 11), Kupplungsfeder (Nr. 45) und Unterlegscheibe (Nr. 27) aus dem Endlager (Nr.

9) entfernen. Die Keile der Antriebswelle auf Anzeichen von Verschleiß untersuchen und bei Bedarf ersetzen.

Die Seiltrommelbaugruppe (Nr. 2) auf Anzeichen von Verschleiß überprüfen. Wenn die Keile im Seiltrommelantrieb (3321660 beschädigt

sind, muss der Seiltrommelantrieb ersetzt werden. Zum Ausbauen des Seiltrommelantriebs die acht (8) Kopfschrauben (414462)

entfernen. Einen gut geölten O-Ring (462053) in die Rille des Seiltrommelantriebs legen und den Antrieb mit acht (8) Kopfschrauben

(414462) an der Seiltrommel (332165) befestigen. Die Kopfschrauben über Kreuz auf 74 Nm festziehen.

Die alten Buchsen aus der Seiltrommel und aus dem Trommelantrieb stemmen. Die O-Ringe (462055 und 462052) aus den Rillen der

Seiltrommel und der Trommelantriebsbuchse (412092) herausnehmen. Gut geölte O-Ringe (462055 und 462052) in die Rillen der

Seiltrommel und die Außenrillen der Trommelantriebsbuchse (412092) drücken. Eine neue Buchse (412091) in das dem

Trommelantrieb gegenüberliegende Ende der Seiltrommel pressen und die Buchse (412092) in den Trommelantrieb pressen, bis die

Flansche der Buchse gegen die Seiltrommel und den Antrieb anliegen. Die Buchsen mit zwei (2) Kopfschrauben (414819) an der

Seiltrommel und am Seiltrommelantrieb befestigen.

39

2

10

46

40

11

28

9

414819

412091

DRUM ASSEMBLY 234170 (ITEM #2)

TROMMELBAUGRUPPE 234170 (NR. 2)

462055

332165

462053

332166

RILLE DES

DRUM DRIVER

SEILTROMMELANT

GROOVE

414462

462052

412092

414819

36

Page 37

6. Die Abtriebskupplung (Nr. 7) und die Kupplungswelle (Nr. 6) vom Endlager (Nr. 9) ausbauen. Die in

die Abtriebskupplung (Nr. 7) gepressten Lager (Nr. 13) auf Anzeichen von Verschleiß untersuchen.

Die Lager bei Bedarf ersetzen. Dazu die alten Lager aus der Kupplung stemmen und neue Lager

(Nr. 13) an beiden Enden der Abtriebskupplung (Nr. 7) einpressen. Die Kupplungswelle (Nr. 6) in

die Lager (Nr. 13) stecken.

7. Acht (8) Kopfschrauben (Nr. 15) abnehmen und den Getriebekastendeckel aus dem

Hohlrad ziehen. Die antriebsseitige Anlaufscheibe, das Sonnenrad, die

Trägerbaugruppen und den Abstandhalter (Nr. 13) aus der Innenseite des Hohlrads