Page 1

Ramsey Winch Company

OWNER’S MANUAL Front

Mount Electric Winches

Model RE 8,000

Model RE 10,000

Model RE 12,000

Model RE 12,000X

RE8000

RE1000

RE12000

RATED LINE PULL PER LAYER (LBS)

CABLE CAPACITY PER LAYER (FT)*

RATED LINE PULL PER LAYER (LBS)

CABLE CAPACITY PER LAYER (FT)*

RATED LINE LBS

PULL PER LAYER KGS

CUMULATIVE CABLE (ft.)*

CAPACITY PER LAYER (M) *

(3/8" DIA. WIRE ROPE)

CUMULATIVE CABLE (ft.)*

CAPACITY PER LAYER (M) *

(3/8" DIA. WIRE ROPE)

LINE PULL (LBS)

FIRST LAYER (KGS)

12V-LINE SPEED FPM

FIRST LAYER MPM

AMP DRAW 12V

24V-LINE SPEED FPM

FIRST LAYER MPM

AMP DRAW 24V

LAYER OF CABLE

12V-LINE SPEED FPM

24V-LINE SPEED FPM

LAYER OF CABLE

12V-LINE SPEED FPM

24V-LINE SPEED FPM

LAYER OF CABLE

(KGS)

5/16 DIA. (M)*

LINE PULL (LBS)

(KGS)

MPM

AMP DRAW 12V

MPM

AMP DRAW 24V

3/8 DIA. (M)*

LINE PULL (LBS)

AMP DRAW 12V

AMP DRAW 24V

(KGS)

MPM

MPM

RE 12,000/12,000X

RE 8000

1

8,000

3,620

20

6

0

0

20

6.1

90

15

4.5

36

RE 10,000

(KGS)

RE 12,000

RE 12,000X

0

0

16

4.9

80

14

4.2

30

0

0

16

4.9

80

14

4.2

30

2,000

900

8.6

2.6

150

2.1

50

2,000

900

9.5

2.9

170

10,000

4,530

12,000

5,430

7

7.5

2.2

2

6,800

3,080

50

15

75

1

20

6

1

20

25

2,000

900

8.6

2.6

150

2.1

50

6

7

4,000

1,810

5.5

2.0

200

1.5

85

7

5

3

6,000

2,710

80

24

4,000

1,810

7

2.1

235

5.5

1.6

105

2

8,300

3,750

40

12

4,000

1,810

6.5

2.0 1.6

200

5

1.5

85

2

10,000

4,530

40

12

60

18

6,000

2,710

5.3

1.6 1.3

250

4

1.2

110

4

5,300

2,400

120

36

6,000

2,710

5.3

1.6

305

4

1.2

140 170

3

7,200

3,260

70

21

6,000

2,710

5.3

250

4

1.2

110

3

8,600

3,890

70

21

95

28

10,000

8,000

3,620

4.4

290

3.5

1

135

8,000

3,620

4.4

1.3

290

3.5

135

4,530

3.8

1.2

335

2.5

0.7

160

5

4,800

2,170

150

45

8,000

3,620

4.3

1.3

370

3

0.9

4

6,300

2,850

100

30

10,000

4,530

3.8

1.2

335

2.5

0.7

1

160

4

7,500

3,390

100

30

125

38

12,000

5,430

3.3

1

380

2

0.6

190

CONGRATULATIONS

You have purchased the fi nest winch available in its

service class. It features a strong worm and gear

drive to provide load-reversing protection. An exclusive semi-automatic RAM-LOK clutch disengages

for free spooling and is spring loaded for positive

engagement. It was designed and manufactured

to provide you with the utmost in utility. As with any

device that combines power and movement in

its use, there are dangers if improper1y used. At

the same time, there are easier and faster ways

for getting the job done if certain precautions are

taken fi rst. Please read this manual carefully. It

contains useful ideas in obtaining the most effi cient

operation from your Ramsey Winch and safety procedures you need to know before beginning use.

CAUTION: Read and understand this manual before installation and operation of

winch. See safety precautions.

When you follow our guidelines for operation your Ramsey Winch will give you many

years of satisfying service. Thank you for

choosing Ramsey. You will be glad you have

one working for you.

Please Note: Ramsey RE 8000, RE 10,000

and RE 12,000 Series winches are designed

for front mount vehicle use. The winches are

not designed for and should not be used in

industrial applications (car haulers/carriers,

wreckers, hoisting,etc.), and Ramsey does

not warrant them to be suitable for such use.

Ramsey makes a separate, complete line

of winches for industrial/commercial use.

Please contact the factory for further information.

Page 2

TABLE OF CONTENTS

Safety Precautions ............................ 1

Tips For Safe Operation ............................ 2

Techniques of Operation ............................ 3

Cable Installation ........................... 4

Operating Instructions ........................... 5

Electrical Connections and Operations ......... 6

Lubrication/ ......................... 6

Troubleshooting Guide ........................... 7

Winch Exploded Views and Parts List

RE 8,000 ............................ 8-9

RE 10,000 ............................ 10-11

RE 12,000/12,000X ............................ 12-13

Solenoid Parts LisVFairleads & Switch ......... 14

Accessory Information ........................... 15

Warranty ........................... Back Cover

Page 3

SAFETY PRECAUTIONS

Safety Precautions To Guard Against Possible Injury.....

A minimum of five wraps of cable around the drum barrel is necessary to hold

the rated load. Cable clamp is not designed to hold the load.

A. Keep yourself and others a safe dis-

tance to the side of the cable when

pulling under load.

B. Do not step over a cable, or near a

cable under load.

C. Use supplied hook strap when han-

dling hook for spooling wire rope.

D. Do not move the vehicle to pull a load

on the winch cable. This could result

in cable breakage and/or winch damage.

E. Use a heavy rag or gloves to protect

hands from burrs when handling winch

cable.

F. Apply blocks to wheels when vehicle

is on an incline.

G. Winch clutch should be disengaged

when winch is not in use and fully

engaged when in use.

H. Modification, alteration, or deviation

to the winch should only be made by

Ramsey Winch Company.

I. Keep the duration of your pulls

as short as possible. If the motor

becomes uncomfortably hot to the

touch, stop and let it cool for a few

minutes. Do not pull more than one

minute at or near the rated load. Do

not maintain power to the winch if the

motor stalls. Electric winches are for

intermittent usage and should not be

used in constant duty applications.

J. Disconnect the remote control

switch from the winch when not in

use. A Ramsey Part No. 282053

battery disconnect switch in your

vehicle is recommended.

K. Do Not use winch in hoisting appli-

cations due to required hoist safety

factors and features.

L. Do not exceed maximum line pull

ratings shown in tables. Shock

loads must not exceed these ratings.

M. To respool correctly, it is necessary

to keep a slight load on the cable.

This is accomplished by (wearing

gloves) holding the cable with one

hand and the remote control with

the other, starting as far back and

in the center as you can, walking up keeping load on the cable

as the winch is powered in. Do

not allow the cable to slip through

your hand and do not approach

the winch too closely. Turn off the

winch and repeat the procedure

until all the cable except a few feet

is in. Disconnect the remote control switch and finish spooling in

cable by rotating the drum by hand

with clutch disengaged. On hidden winches, spool in cable under

power using supplied hook strap.

1

Page 4

SAFE OPERATION TIPS

Tips for Safe Operation

Do not underestimate the potential danger in

winching operations. Neither should you fear

them. Do learn the basic dangers and avoid

them.

The uneven spooling of cable, while pulling a

load, is not a problem, unless there is a cable

pileup on one end of drum. If this happens,

reverse the winch to relieve the load and

move your anchor point further to the center of the vehicle. After the job is done you

can unspool and rewind for a neat lay of the

cable.

Store the remote control switch inside your

vehicle where it will not become damaged.

Inspect it before you plug it in.

When ready to begin spooling in, plug in

remote control switch with clutch disengaged.

Do not engage clutch with motor running.

Never connect the hook back to the cable.

This causes cable damage. Always use a

sling or chain of suitable strength as shown in

the illustration, page 3.

Observe your winch while winching, if possible, while standing at a safe distance. If you

use vehicle drive to assist, stop and get out

every few feet to assure the cable is not piling

up in one corner. Jamming cable can break

your winch.

Do not attach tow hooks to winch mounting apparatus. They must attach to vehicle

frame.

When double lining during stationary winching, the winch hook should be attached to the

chassis of the vehicle.

Since the greatest pulling power is

achieved on the innermost layer of

your winch, it is desirable to pull off as

much line as you can for heavy pulls.

Remember, a minimum of 5 wraps of

cable around the drum barrel is necessary to hold the rated load.

If this is not practical, use a snatch

block and double line arrangement as

shown in the illustration, page 3. Neat,

tight spooling avoids cable binding.

Cable binding occurs when a cable

under load pulls down into the layer

below, becoming pinched between two

other wraps of cable. If this happens,

alternately power the winch in and out

a few inches. Do not attempt to work a

bound cable under load; free by hand.

Since the greatest pulling power is

achieved on the innermost layer of your

winch, it is desirable to pull off as much line

as you can for heavy pulls. Remember, a

minimum of 5 wraps of cable around the

drum barrel is necessary to hold the rated

load.

If this is not practical, use a snatch block

and double line arrangement as shown in

the illustration, page 3. Neat, tight spooling

avoids cable binding. Cable binding occurs

when a cable under load pulls down into

the layer below, becoming pinched between

two other wraps of cable. If this happens,

alternately power the winch in and out

a few inches. Do not attempt to work a

bound cable under load; free by hand.

2

Page 5

TECHNIQUES OF OPERATION

Techniques of Operation

The best way to get acquainted with how your

winch operates is to make a few test runs

before you actually need to use it. Plan your

test in advance. Remember

winch as well as see it operate. Get to recognize

the sound of a light steady pull, a heavy pull, and

sounds caused by load jerking or shifting. Soon

you will gain confidence in operating your winch

and its use will become second nature with you.

you hear your

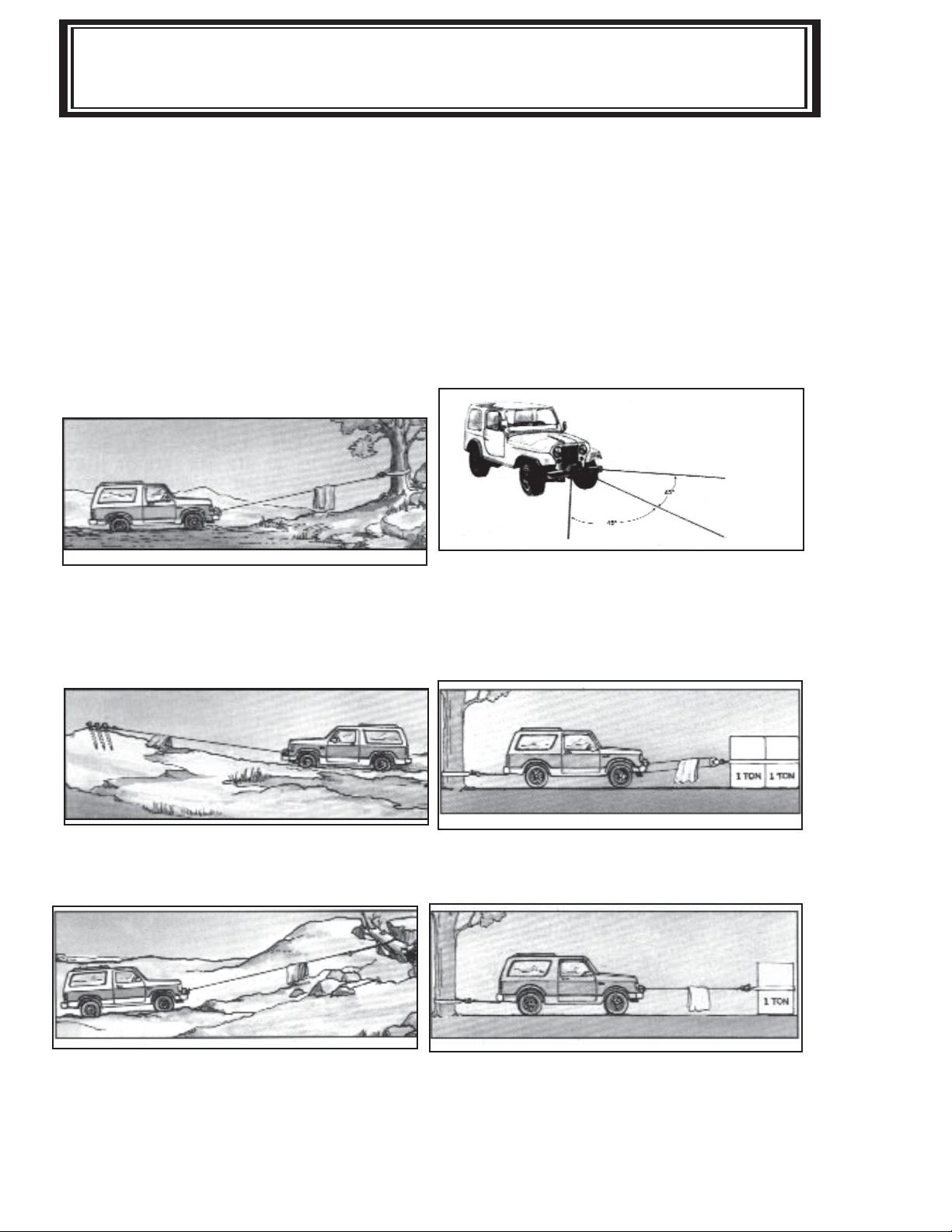

Your winch will not only pull you up or ease

you down a steep grade, it will also pull another

vehicle or a load while your vehicle is anchored in

a stationary position. The following illustrations

show a few basic winching techniques.

For basic self recovery, anchor to a tree or heavy rock. When

anchoring to a tree, always use a tree trunk protector.

Stakes driven in solid earth and chained together make a good

anchor point for self-recovery when no solid anchor point is

available.

Winches equipped with cable guide fairleads can pull from

several directions. Pull from an angle only to straighten up

the vehicle-otherwise you can damage structural members or

other parts of your vehicle and cause excess cable buildup on

one end of the winch drum.

To double the pull, use 2-part line with snatch block and tie

off to chassis. Take out of gear.

For a solid anchor, bury a log with earth or sand or place it in

a deep ravine

3

For a direct pull of 2,000 lbs., hitch truck to a tree or solid

anchor, and take out of gear.

Page 6

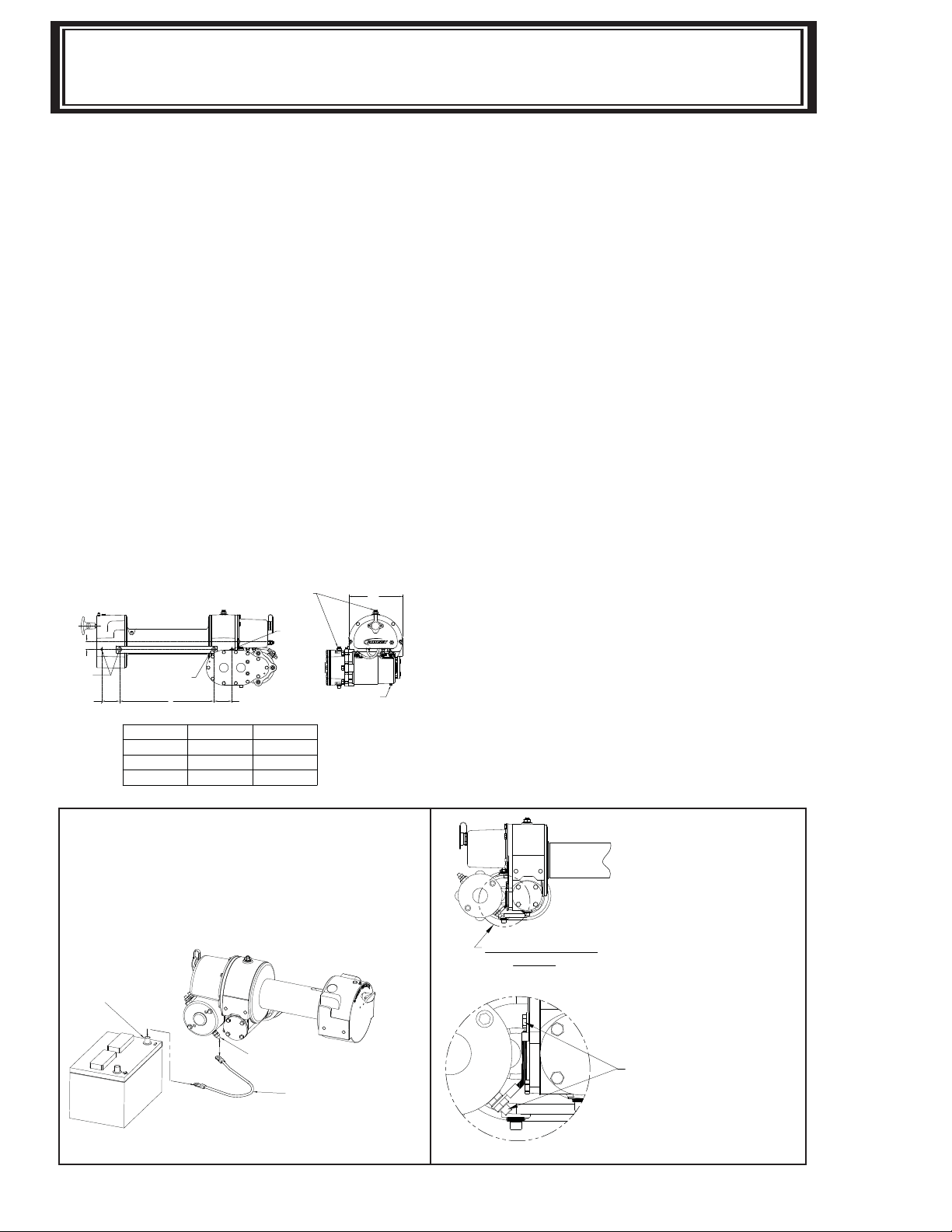

WINCH INSTALLATION / ELECTRICAL CONNECTIONS

Installation

Winches shown in this owner’s manual are

solely and exclusively designed for vehicle

mounted, non-industrial applications. Use

in other applications will void warranty. It is

recommended that Ramsey Mounting Kits

be used to mount the winch. They are designed to align the winch and distribute up to

the full rated load correctly to avoid possible

damage to the winch or vehicle.

NOTE: If Ramsey Kits are not used, the

winch must be mounted to angles (3/8”

x 2 1/2” x 3” min) or in a frame with both

sides of the clutch housing and gear

housing bolted to the angles or frame.

See diagram below for recommended

mounting dimensions.

Note various thread

depths of mounting holes and use

correspondingly different bolt lengths for

proper mounting.

REMOVE RUBBER COVER FROM

RELIEF FITTINGS BEFORE PUTTING

WINCH INTO USE.

.38-16UNC X .50"

DEEP THREADS

(EACH SIDE)

2.50

63,5

GROUND CABLE FROM MOTOR ISOLATED

GROUND TERMINAL TO NEGATIVE

BATTERY TERMINAL.

MM ± .4

257.2

333.3

.38-16UNC X .75"

DEEP THREADS

(EACH SIDE)

1.12

.38-16UNC X 1"

DEEP THREADS

2.50

63,5

(EACH SIDE)

A

DIMENSIONS SHOWN ARE INCHES OVER MILLIMETERS

Model

RE 8/10/12

RE 12,000X

"A" Dimension

In. ± .15

10.12

13.12

7.44

188,9

Substitution of attaching hardware items

(bolts, nuts, or washers) different from

those supplied with your winch mounting

kit can lead to failure causing damage or

serious injury. Use a socket head mounting

bolt on side with Spur Gear Housing (see

diagram) to prevent clearance prob lems.

Use SAE grade 5 bolts or better.

Electrical Connections and

Operations

For normal self recovery work, your existing

electrical sys tem is adequate. Your battery must be kept in good condition. Afully

charged battery and proper connections are

essential. Run the vehicle engine during

winching oper ation to keep battery charged.

Connect red cable from stud on plastic

solenoid cover on winch to positive battery

terminal. Important: Hold inner nut with

end wrench while tightening outer nut.

Connect black cable from negative battery

terminal to the motor isolated ground terminal. In applications where the chassis is

non-grounded, a jumper wire (#440315) will

be required between the winch and the motor isolated ground terminal. (See illustration below.)

NEGATIVE BATTERY POST

WINCH WILL NOT OPERATE UNLESS

GROUND CABLE IS INSTALLED FROM THE

ISOLATED GROUND TERMINAL TO THE

NEGATIVE BATTERY POST.

(SEE DIAGRAM BELOW)

ISOLATED GROUND

TERMINAL

GROUND CABLE

SEE ILLUSTRATION

BELOW

JUMPER CABLE (#440315) MUST BE

INSTALLED ON WINCH FROM MOTOR

ISOLATED GROUND STUD TO GEAR

HOUSING COVER BOLT AS SHOWN

FOR NON GROUNDED CHASSIS

APPLICATIONS.

4

Page 7

CABLE INSTALLATION / OPERATING / MAINTENANCE

This ground is required to insure a suffi cient ground to operate the solenoid

assembly (see diagram below). A good

electrical ground is required for proper

performance. The remote control switch is

water proof and has push but ton stations

on either side. It is designed this way to

prevent quick winch reversals which lead to

solenoid failure. Make sure the winch motor has stopped fully before revers ing.

When fi rst setting up your winch, follow

the directions for inserting the proper “IN”

or “OUT” label in the thumb button. The

switch is also color coded to aid you in not

having to guess at the direction your winch

will run.

Cable Installation

1 Unwind cable by rolling it out along the

ground to pre vent kinking. Securely

wrap end of cable, opposite hook, with

plastic or similar tape to prevent fray ing.

2. Insert the end of the cable, opposite

hook end, under drum and into the

7/16” dia. hole in drum barrel. Secure

cable to drum barrel, using setscrew

furnished with winch. Tighten setscrew

securely.

3. Carefully run winch in the “reel-in” di rection. Keeping tension on end of

cable, spool all the cable onto drum,

taking care to form neatly wrapped lay ers.

Inspect the cable frequently. If the cable

becomes frayed with broken strands, replace immediately. Cable and hook assemblies may be purchased from a Ramsey

distributor.

The RAM-LOK™ semi-automatic clutch

provides free spooling and clutch engagement with the cable drum. With the clutch

disengaged, the cable can be pulled off the

drum by hand. For winching in the load, the

clutch must be fully engaged with the drum.

To disengage the clutch, run the winch in the

reverse (“reel out”) direction until the load

is off the cable and the cable drum stops

turning. Pull outward on the clutch handle,

rotate it counterclockwise 90° and release.

The clutch is now locked out and the cable

may be pulled by hand. (NOTE: if the clutch

handle can not be pulled out, again run the

winch momentarily in reverse to relieve pressure on the clutch jaws.)

WARNING: DO NOT ATTEMPT TO

DISENGAGE THE CABLE DRUM

WHEN THERE IS A LOAD ON THE

CABLE.

Operating Instructions

To engage the clutch, pull outward on the

handle, rotate it clockwise 90° and release.

Run the winch in reverse until the clutch

handle snaps fully in or until the cable drum

starts turning. At this point make sure the

clutch handle is all the way in. The plastic

plug in top of clutch housing may be removed, for inspection of clutch to assure

total engage ment. After the clutch is fully

engaged, the winch is ready for winching in

the cable.

Maintenance

Check monthly the action of the sliding

clutch, making sure it is fully engaging and

disengaging with the cable drum. With the

clutch in the engaged position, remove the

plastic plug in top of the housing and observe

if the clutch is fully engaging. If clutch is not

fully engaging, inspect the clutch shifter assembly parts, check for damage or excessive

wear and replace as necessary.

Observe the jaws on both the clutch and

cable drum, checking for rounding of the

driving faces. If rounding has occurred they

should be replaced immediately.

5

Page 8

MAINTENANCE (continued)

Spool the cable properly on the drum when storing between each usage. Check the oil

level in the gear boxes every six months. At the same time, check electrical connections

and mounting bolts - tighten if necessary.

Corrosion on electrical connections will reduce performance or may cause a short.

Clean all connections, especially in remote switch receptacle. In salty environments

use a silicone sealer to protect from corrosion.

Be sure the winch has plenty of battery power avail able.

Use 1/2 pint of SAE 20 for spur gear box. Apply cup grease to lube fi tting at top of clutch

housing. Should winch be submerged for a brief period, drain oil, fl ush and replace oil in

gear boxes, and grease all fi ttings (see Troubleshooting Guide on page 7).

To minimize corrosion of the internal motor components that may occur due to condensation, power the winch in or out periodically. Energizing the motor will generate heat,

which will dissipate any moisture buildup in the motor. This should be performed at periodic intervals (such as with each oil change to your vehicle).

Lubricate cable periodically using light penetrating oil.

Inspect for broken strands and replace if necessary with Ramsey part number listed in

Parts List.

Install new cable per “Cable Installation” page 5.

6

Page 9

Ramsey Electric Winches Troubleshooting Guide

CONDITION

MOTOR RUNS IN

DIRECTION ONLY

MOTOR

EXTREMELY

MOTOR RUNS, BUT WITH

INSUFFICIENT POWER, OR

WITH LOW LINE SPEED

MOTOR RUNS, BUT DRUM

DOES NOT

MOTOR WILL NOT OPERATE

MOTOR WATER

CLUTCH INOPERATIVE OR

BINDS

UP

CLUTCH SPRING DOES

OPERATE

CLUTCH DOES NOT LOCK AT

DISENGAGED POSITION

OIL LEAKS FROM HOUSING

RUNS

TURN

HOT

DAMAGED

ONE

POSSIBLE CAUSE

(1) Inoperative solenoid or stuck solenoid

(2) Inoperative remote control switch

(1) Long period of operation

(2) Insufficient battery

(3) Electrical cable from battery to winch

or ground strap from engine block

vehicle chassis too small.

(4) Bad electrical connections

(5) Insufficient charging system

(1) Clutch not engaged

(2) Sheared drum shaft key

(3) Stripped bronze gear

(4) Parted shaft

(1) Inoperative solenoid or stuck

(2) Inoperative remote control switch

(3) Inoperative motor

(4) Loose connections

(1) Submerged in water or water

from high pressure car wash

(1) Dry or rusted shaft

(2) Dog point setscrew too tight

(3) Bent yoke

(4) Keys pulled out of shape by overload

NOT

(1) Broken spring

(1) Setscrew loose or worn

(1) New

(2) Seal damaged or worn

(3) Too much oil

(4) Damaged gasket

seal

(1) Jar solenoid to free contacts. Check by applying 12 volts to coil

terminal (it should make an audible click when energized).

(2) Disengage winch clutch, remove remote control switch

from the socket and jump pins at 8 and 4 o'clock. Motor should run.

Jump pins at 8 and 10 o'

(1) Cooling-off periods are essential to prevent overheating.

(2) Check battery term

or parallel another battery to it.

(3) Must be No.2 equivalent (or larger if longer than

to

solenoid

(4) Check all

(5) Replace with larger capacity charging system.

(1-4) If clutch engaged but symptom still exists, it will be necessary to

disassemble winch to determine cause and repair.

(1) Jar solenoid to free contacts. Check by applying 12 volts to coil

terminal (it should make an audible click when energized).

(2) Disengage winch clutch, remove remote control switch

from the socket and jump pins at 8 and 4 o'clock. Motor should run.

Jump pins at

(3) If solenoids operate, check for voltage at armature post; replace motor.

(4) Tighten connections on bottom side of hood and on motor.

(1) Allow to drain and dry

bursts to dry windings

(1) Clean and lubricate

(2) Remove rubber plug from clutch housing and rotate setscrew outward

until clutch operates smoothly. Replace rubber plug.

(3) Replace yoke or shifter assembly

(4) If drum shaft keyways are rounded or damaged replace shaft and

. If not, file off burrs and replace keys.

keys

(1) Replace

(1) Remove rubber plug from clutch housing, tighten setscrew or replace.

Replace plug.

(1) New seals sometimes leak until seated to shaft.

(2) Replace.

(3) Drain excess oil per lubrication instructions.

(4) Replace.

CORRECTION

clock. Motor should run.

inal voltage under load.

connections

8 and 10 o'clock. Motor should run.

for

looseness

thoroughly,

or

corrosion; tighten, clean

then run motor without load in short

plug

If

10 volts or less, replace

15ft.).

and grease.

plug

7

Page 10

58

48

57

14

16

35

59

66

1

24

6

69

24

36

9

24

46

46

20

47

47

68

31

62

49

52

17

45

64

22

23

41

5

29

27

69

13

24

43

8

29

55

38

33

30

2

50

41

23

63

61

49

52

15

26

67

37

39

53

18

19

11

10

11

26

56

7

28

54

56

42

67

53

32

40

65

40

65

3

60

21

72

4

71

RE 8000

EXPLODED VIEW

8

Page 11

RE 8000

PARTS LIST

asket

No. DescripƟon

Part

Qty.

Item

Req'd

No.

4 2 468017 Pipe Pl ug Soc. Hd.

64 1 490003 Snap Ring

72 1 289141 G round Wire-Black

d Cup 71 1 251122 Cabl e & Hook-150' x 5/16" di a.

Part

Qty.

Item

No. DescripƟon

Req'd

No.

2 1 278170 Sol enoi d Assembl y 38 3 418154 W ashe r- 1/4 Flat Alum.

1 1 276056 Shi Ōer Assembl y 37 3 418040 Nut-3/8-24NF Hex Re g Zinc Plate d

8 1 328134 Cover-Worm Gear Hsg. 44

9 1 332136 Cable Drum 45 1 450005 Key

10 1 334001 Idler Gear 46 2 450006 Ke y (Barth)

13 1 334163 G ear R. H.-46:1 49 2 456008 Re lie f Fi ƫng

12 48 1 456001 Lube Fiƫng

11 2 334003 Spur Gear 47 4 450016 Key ( Barth)

14 1 336010 Handl e 50 1 262035 Motor-12V

15 1 338203 Spur Gear Housi ng 262036 Motor- 24V

16 1 338208 Clutch Housing 51

19 1 356901 ShaŌ-Spur 5

18 1 342033 Key 53 2 468011 Pipe Pl ug Sq. Hd.

17 1 338273 G ear Housing 52 2 468002 Re ducer

20 1 357484 ShaŌ- Drum 55 1 468018 Pipe Pl ug Soc. Hd.

23 2 402002 Be aring-Ball 58 1 472012 Plug

22 1 368162 W orm-R.H.- 46:1 57 1 470033 Spiral Pin

21 1 364029 Strap 56 2 470001 Pin

26 3 412038 Bushing 61 1 486009 Oil Seal

25 60 1 482013 Rubber Boot

24 4 412003 Bushing 59 1 472013 Plug

29 9 414045 Capscre w-1/4-20NCx7/8 Lg. HxHd. Gr. 5, Z/P

28 12 414038 Capscrew 1/4-20NCx3/4Lg. Hx.G r.5 63 1 486023 Oil Seal

27 1 412045 Bushing 62 1 486017 Oil Seal

30 3 414059 Capscre w-1/4-20NCx1 Lg.Gr.5 HxHd.Z/P 65 2 494002 Spri ng

33 2 414856 Capscre w-1/4-20NCx3/4 Lg. HxSocHd. Z/P 68 1 518014 Thrust Washer

32 4 414845 Capscre w-1/4-20NCx1 Lg. HxSocHd,Nylok 67 3 518002 Thrus t W asher

31 2 414279 Capscre w-3/8-16NCx3/4 Lg. HxHd.Gr.5 66 1 494053 Spri ng

36 1 416059 Setscrew3/8- 16NCx1/2 HxSockH

35 1 416030 Setscrew-1/4-20NC x3/8 Lg. HxSoc.( Full Dog Pt.),NYL,Z/P 70

34 69 2 518015 Thrus t W asher

7 1 328106 Cover-Spur G ear Hsg. 43 1 442205 G

6 1 324137 Jaw Clutch 42 1 442185 G asket

5 1 316083 Bearing Cap 41 2 442184 G asket

4 1 289015 BaƩery Cabl e-Re d 40 2 330010 Drag Brake

3 1 282001 Swi tch Asse mbly 39 3 418177 Lockwashe r- 3/8 Med Se ct,Zi nc Pl ated

9

Page 12

59

48

57

14

16

36

59

66

1

25

6

69

25

37

9

25

46

46

21

47

47

68

32

62

49

52

17

18

64

23

24

42

5

30

28

69

13

25

44

8

30

55

39

34

31

2

50

42

24

63

61

49

52

15

27

67

38

40

53

19

20

11

10

11

27

56

7

29

54

56

43

67

53

33

41

65

41

65

3

60

22

71

4

72

RE 10000

EXPLODED VIEW

10

Page 13

RE 10000

Item

No.

Qty.

Req'd

Part

No. DescripƟon

Item

No.

Qty.

Req'd

Part

No. DescripƟon

1 1 276056 ShiŌer Asse mbly 37 1 416059 Setscre w3/8-16N Cx1/2 Hx SockHd Cup

2 1 278170 Sole noid Asse mbly 38 3 418040 Nut-3/8-24NF Hex Reg Zi nc Pl ated

3 1 282001 Switch Assembly 39 3 418154 Washer-1/4 Fl at Alum.

4 1 289015 BaƩery Cable-Re d 40 3 418177 Lockwasher-3/8 Med Sect,Zi nc Pl ated

5 1 316083 Beari ng Cap 41 2 330010 Drag Brake

6 1 324137 Jaw Cl utch 42 2 442184 Gaske t

7 1 328106 Cove r- Spur G ear Hs g. 43 1 442185 Gaske t

8 1 328134 Cove r- Worm G

ear Hsg. 44 1 442205 Gaske t

9 1 332136 Cable Drum 45

10 1 334001 Idler Gear 46 2 450006 Key (Barth)

11 2 334003 Spur Gear 47 4 450016 Ke y (Barth)

12 48 1 456001 Lube Fiƫng

13 1 334161 Gear R.H.-60:1 49 2 456008 Reli ef Fi ƫng

14 1 336010 Handl e 50 1 262035 Motor- 12V

15 1 338203 Spur Gear Housing 1 262036 Motor- 24V

16 1 338208 Clutch Housing 51

17 1 338273 Gear Housing 52 2 468002 Re duce r

18 1 342023 Key 53 2 468011 Pipe Plug Sq.Hd.

19 1 342033 Key 54 2 468017 Pipe Plug Soc.Hd.

20 1

356901 ShaŌ- Spur 55 1 468018 Pi pe Plug Soc.Hd.

21 1 357484 ShaŌ- Drum 56 2 470001 Pi n

22 1 364029 Strap 57 1 470002 Spiral Pi n

23 1 368001 Worm-R.H.- 60:1 58 1 472012 Pl ug

24 2 402002 Bearing- Ball 59 1 472013 Plug

25 4 412003 Bushing 60 1 482013 Rubber Boot

26 61 1 486009 Oil Seal

27 3 412038 Bushing 62 1 486017 Oil Seal

28 1 412045 Bushing 63 1 486023 Oil Seal

29 12 414038 Capscrew 1/4- 20NCx3/4Lg. Hx.Gr.5 64 1 490003 Snap Ri ng

30 9 414045 Capscre w-1/4-20NCx7/8 Lg. HxHd. Gr.

5, Z/P 65 2 494002 Spring

31 3 414059 Capscre w-1/4-20NCx1 Lg.Gr.5 HxHd.Z/P 66 1 494053 Spring

32 2 414279 Capscre w-3/8-16NCx3/4 Lg. HxHd.Gr.5 67 3 518002 Thrust Washer

33 4 414845 Capscre w-1/4- 20NCx1 Lg. HxSocHd,Nylok 68 1 518014 Thrust Washer

34 2 414856 Capscre w-1/4-20NCx3/4 Lg. HxSocHd. Z/P 69 2 518015 Thrust W asher

35 70

36 1 416030 Setscrew-1/4-20NCx3/8 Lg. HxSoc.( Full Dog Pt.),N YL,Z/P 71 1 251123 Cable & Hook-100'x 3/8" dia.

72 1 289141 Gro

und Wire-Black

PARTS LIST

11

Page 14

RE 120000

EXPLODED VIEW

2

4

59

29

70

31

22

26

9

36

1

41

48

64

67

40

46

21

45

45

71

5

25

23

18

17

51

61

46

40

43

26

13

63

68

27

25

41

60

48

51

15

64

24

30

38

8

52

32

54

62

39

37

19

66

20

11

11

24

55

33

29

3

49

52

10

66

42

55

53

7

28

65

59

35

57

47

56

16

14

26

68

6

26

12

Page 15

RE 120000

PARTS LIST

3/8" dia.

Plug Soc.Hd.

No. DescripƟon

Part

Qty.

Item

Req'd

No.

ar Hsg. 43 1 442205 G asket

64 2 494002 Spri ng

Part

Qty.

Item

No. DescripƟon

Req'd

No.

1 364017 Strap (RE 12,000X) 59 1 482013 Rubber Boot

1 332105 Cabl e Drum (RE 12,000X) 45 2 450006 Key (Barth)

8 1 328134 Cover-Worm Ge

7 1 328106 Cover-Spur Ge ar Hsg. 42 1 442185 Gaske t

6 1 324137 Jaw Cl utch 41 2 442184 Gaske t

5 1 316083 Bearing Cap 40 2 330010 Drag Brake

4 1 289015 BaƩery Cabl e-Red 39 3 418177 Lockwasher-3/8 Me d Sect,Zinc Plate d

3 1 282001 Swi tch Asse mbly 38 3 418154 W ashe r- 1/4 Flat Alum.

2 1 278170 Sole noid Asse mbly 37 3 418040 Nut-3/8-24NF Hex Reg Zinc Plate d

1 1 276056 ShiŌe r Asse mbly 36 1 416059 Setscrew3/8-16NCx1/2 HxSockHd Cup

9 1 332136 Cable Drum 44

10 1 334001 Idl er Gear 46 4 450016 Key (Barth)

19 1 342033 Key 54 1 468018 Pipe Pl ug Soc.Hd.

18 1 342023 Key 53 2 468017 Pipe

17 1 338273 G ear Housi ng 52 2 468011 Pipe Pl ug Sq.Hd.

16 1 338208 Clutch Housing 51 2 468002 Re ducer

15 1 338203 Spur Gear Housing 50

14 1 336010 Handle 262036 Motor- 24V

13 1 334161 G ear R.H.- 60:1 49 1 262035 Motor-12V

12 48 2 456008 Re lie f Fi ƫng

11 2 334003 Spur Gear 47 1 456001 Lube Fiƫng

1 357479 ShaŌ- Drum (RE 12,000X) 57 1 472012 Plug

27 1 412045 Bushing

26 4 412003 Bushing 63 1 490003 Snap Ring

25 2 402002 Be aring-Ball 62 1 486023 Oi l Seal

24 3 402001 Be aring-Ne e dl e 61 1 486017 Oil Seal

23 1 368001 W orm-R.H.- 60:1 60 1 486009 Oil Seal

22 1 364029 Strap 58 1 472013 Plug

21 1 357480 ShaŌ-Drum 56 1 470033 Spiral Pin

20 1 356901 ShaŌ-Spur 55 2 470001 P in

30 3 414059 Caps cre w-1/4- 20NCx1 Lg.Gr.5 HxHd.Z/P 67 1 518014 Thrus t W asher

29 9 414045 Caps cre w-1/4- 20NCx7/8 Lg. HxHd. Gr. 5, Z/P 66 3 518002 Thrus t W asher

28 12 414038 Capscrew 1/4- 20NCx3/4Lg. Hx.G r.5 65 1 494053 Spri ng

33 2 414856 Caps cre w-1/4- 20NCx3/4 Lg. HxSocHd. Z/P 70 1 251123 C able & Hook-100'x

32 4 414845 Caps cre w-1/4- 20NCx1 Lg. HxSocHd,Nylok 69

31 2 414279 Caps cre w-3/8- 16NCx3/4 Lg. HxHd.Gr.5 68 2 518015 Thrus t W asher

35 1 416030 Setscrew- 1/4- 20NCx3/8 Lg. HxSoc.( Full Dog Pt.),N YL,Z/P 71 1 289141 G round Wire-Black

34 1 416029 1 251124 Cabl e & Hook (RE 12,000X)-125'x 3/8" dia.

13

Page 16

NOTES

Page 17

SOLENOID ASSEMBLY

AND PARTS LIST

Item

No.

Qty.

Req'd

1 1 280009 Cable-Bolt Ass' y.-24V

2 3 289077 Wire A ss'y.- 24V

3 1 289091 Wire A ss'y.

4 2 364001 St rap

5 2 364002 St rap

6 1 408035 So leno id Bracket

7 2 416216 Sc rew

8 2 416227 Sc rew

9 4 418004 Nut

10 2 418022 Nut 5/16- 18NC Hx. Re g.

11 2 418140 Flat Washer #10

12 1 418163 Lockwasher 5/16 Med. Sect.

13 1 418164 Lockwasher 5/16 Internal

14 1 418165 Lockwasher 5/16 External

15 1 430013 Female Connect

16 2 440071 Te rminal- Tab

17 2 440110 So len oid- 12V

18 1 472071 Cove r

19 1 482029 Cove r-Co nnector

20 4 530106 Cove r-Te rminal

Part

No. DescripƟon

1 280013 Cabl e-Bo lt Ass 'y.- 12V

3 289169 W ire A ss'y.- 12V

or

2 440114 S olen oid- 24V

14

Page 18

SOLENOID TEST PROCEDURE

Steps to follow when testing current fl ow through DC solenoids. It should be noted that

when testing a 12 volt or 24 volt solenoid, the DC motor and battery must be of the same

voltage.

To test the solenoids: (See Figure 1).

1. Securely clamp a motor to a bench or work surface.

2. Attach a jumper wire from (A) terminal on the motor to one of the fi eld terminals on the

motor, (F-2).

3. Attach the other motor fi eld terminal (F-1) to one of the side terminals of the solenoid.

4. Ground the solenoid to the motor with a wire as shown.

5. Attach positive (+) battery wire to the opposite side terminal of the solenoid. Ground

the negative(-) battery wire to the motor isolated ground terminal.

6. Touch "hot" wire, from the positive battery terminal, to small terminal of the solenoid.

7. The motor should now be running if the solenoid is good. If not, make sure the motor

will run directly from the battery.

8. To test the upper contacts use the same hookup except use the top terminals. (See

Figure 2).

When the "hot" wire is touched to the small terminal the motor will stop operating. The

top terminals are normally closed; ie: connected, and the side terminals open, or not connected. When the solenoid operates, the top terminals are disconnected and the side

terminals are connected. Take care not to bring hot wires into contact with ground in

order to prevent electrical arcing.

BATTERY

(TOP TERMINALS)

SIDE SIDE

(SMALL)

SOLENOID

GROUND WIRE(-) FROM

SOLENOID TO MOTOR

MOTOR

A

F2

F1

BATTERY

(TOP TERMINALS)

(SMALL)

SOLENOID

GROUND WIRE(-) FROM

SOLENOID TO MOTOR

SIDESIDE

MOTOR

F2

A

F1

FIGURE-1

ISOLATED GROUND

TERMINAL

15

FIGURE-2

ISOLATED GROUND

TERMINAL

Page 19

TEST PROCEDURE for MOTOR

The Ramsey Winch motor is a 4 pole, 4 coil

series wound 12 volt or 24 volt DC motor.

The 4 pole, 4 coil feature provides high

torque at low speeds.

To test the motor to determine if it is functioning properly, fi rst securely fasten the motor

to a bench or work surface so it will not jump

or move around during test procedure (the

starting torque of motor is high).

1. Connect a jumper wire (at least a number

6 wire) from F-1 to A motor terminals (See

Figure1).

2. Attach a wire (at least a number 6 wire)

from positive(+) battery terminal to F-2

motor terminal. Ground negative(-) battery

terminal to motor isolated ground terminal

(See Figure 1).

Motor should now run.

To reverse the direction of rotation:

NOTE: Always attach battery wire solidly

to motor terminals. Make and break the

connection of the negative (-) battery terminal at the motor isolated ground terminal.

This avoids burning the motor terminals.

CAUTION: Do not run the motor for a long

period of time in fashioned above, because

the motor could become damaged. The

motor running idle on the bench will draw

55 amperes and must run free and easy.

If the ampere draw is more than 60 amps

and the motor runs rough or has a strange

sound, it should be replaced.

With the motor attached in place on a

winch (less cable on drum) the ampere

draw should be approximately 65 to 70

amps. If after following the procedure

outlined, the test on the winch signifi cantly

exceeds 70 amperes refer to your Owners

Manual for troubleshooting suggestions on

the mechanical portion of the winch.

1. Attach jumper wire from F-2 to (A) motor

terminals (See Figure 2).

2. Attach wire from positive(+) battery termi nal to F-1 motor terminal. Ground nega tive(-) battery terminal to motor isolated

ground terminal (See Figure 2).

CW

F2

F1

ISOLATED

GROUND

A

FIGURE-1

MOTOR-CLOCKWISE ROTATION

CCW

F2

BATTERY

See Figure 3 for the solenoids connection

to the motor and battery.

BATTERY

A

F2

F1

ISOLATED GROUND

SOLENOIDS TO MOTOR CONNECTIONS

THE DASHED LINES ARE CURRENT'S PATH IN FORWARD ROTATION.

SOLID LINES ARE CURRENT'S PATH AT ALL TIMES.

NOTE:

DIRECTION OF MOTOR ROTATION DEPENDS ON WHICH SMALL

TERMINAL OF EITHER SOLENOID IS CONNECTED TO BATTERY'S

POSITVE TERMINAL.

BATTERY

F2

TERMINAL

A

F1

ISOLATED

GROUND

F1

A

FIGURE-2

MOTOR-COUNTER CLOCKWISE ROTATION

BATTERY

16

SOLENOIDS TO MOTOR CONNECTIONS

THE DASHED LINES ARE CURRENT'S PATH IN REVERSE

ROTATION. SOLID LINES ARE CURRENT'S PATH AT ALL TIMES.

FIGURE-3

ISOLATED GROUND

TERMINAL

Page 20

LIMITED WARRANTY

Warranty Information

Ramsey Winches are designed and built to exacting specifi cations. Care and skill go into

every winch we make.. If you have problems with your winch, please follow instructions for

proper service on all warranty claims.

Ramsey Winch offers a limited lifetime warranty for

each new Ramsey consumer/RV winch against manufacturing defects in workmanship and materials on all

mechanical components.

Some states do not allow the above exclusions or

disclaimers in consumer transactions and as such

this disclaimer/exclusion may not apply to your

particular case.

New cable assemblies are warranted against defects

in workmanship and materials. No warranty applies

after initial use. All Ramsey mounting kits and other

accessories carry a 1-year limited warranty against

defects in material and workmanship.

Chrome fi nish warranted for one year against manu-

facturing defects. Cracking, scratching, or corrosion

caused by winching not covered by warranty.

This warranty is void if winch is used in commercial/

industrial applications other than front mount selfrecovery.

Electrical components consisting of motors, solenoids,

wiring, wire connectors and associated parts carry a

1-year limited warranty. Battery isolators carry a 90day limited warranty.

The obligation under this Warranty, statutory or

otherwise, is limited to the replacement or repair at

the manufacturer’s factory, or at a point designated

by the manufacturer, upon inspection of such part, to

have been defective in material or workmanship. This

Warranty does not obligate Ramsey Winch Company

to bear the cost of transportation charges in connection with the replacement or repair of defective parts,

nor shall it apply to a product upon which repairs or

alterations have been made, unless authorized by the

manufacturer, or for equipment misused, neglected,

or improperly installed.

To the extent such warranties of fi tness for a par-

ticular purpose or merchantability are deemed to

apply to this product, they exist for only so long as

the express limited warranty elsewhere set forth is

in existence.

Ramsey Winch Company makes no warranty in

respect to accessories, same being subject to the

warranties of their respective manufacturers.

Ramsey Winch Company, whose policy is one of

continuous product, improvement, reserves the right

improve any product through changes in design and

materials as it may deem desirable without being

obligated to incorporate such changes in products of

previous manufacture.

If fi eld service at the request of the buyer is ren-

dered and the fault is found not to be with Ramsey

Winch Company’s product, the buyer shall pay the

time and expense cost of the fi eld representative.

Bills for service, labor, or other expenses which

have been incurred by the buyer without express

approval or authorization by Ramsey Winch Company will not be accepted.

This warranty gives you specifi c legal rights and you

may also have other legal rights which vary from

state to state.

IMPORTANT NOTICE: To the fullest extent permitted by applicable law, the following are hereby

excluded and disclaimed: 1. All warranties of fi t-

ness for a particular purpose; 2. All warranties of

merchantability; 3. All claims for consequential or

incidental damages. There are no warranties that

extend beyond the description that appears on the

face hereof.

17

RAMSEY WINCH COMPANY

Post Offi ce Box 581510

Tulsa, OK 74158-1510

Phone: (918) 438-6688

www.ramsey.com

OM-912499-1013-K

Loading...

Loading...