Page 1

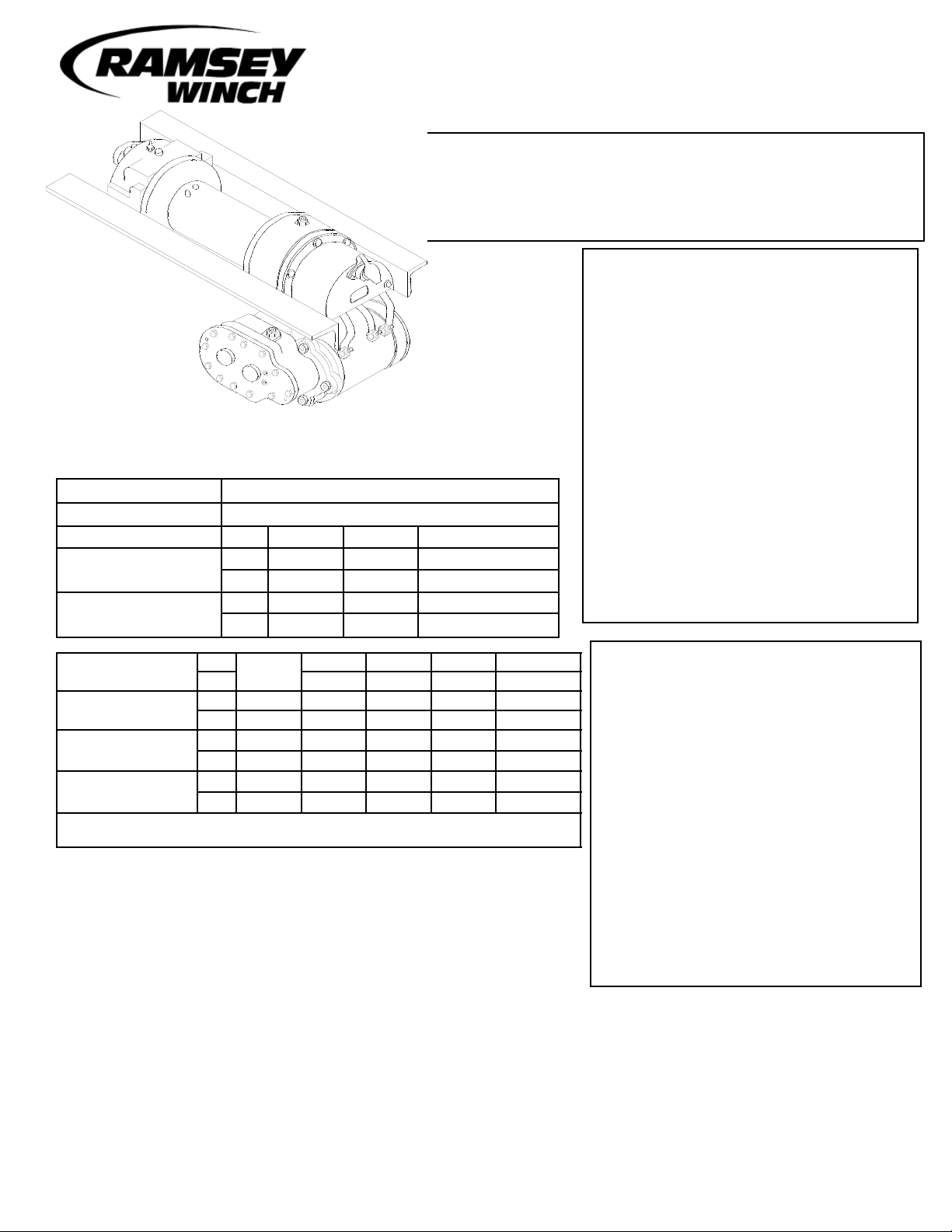

Ramsey Winch Company

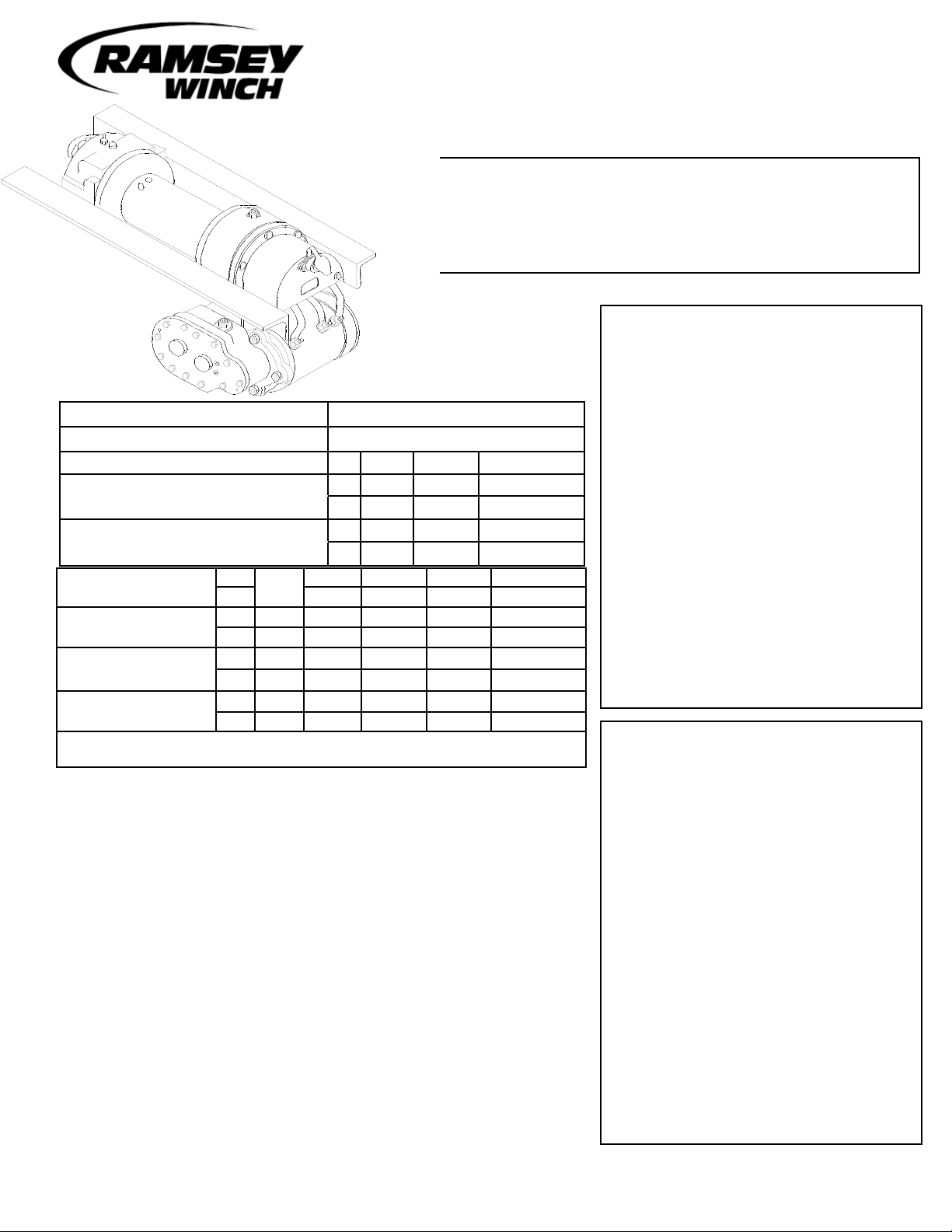

Model

Electric Winch

RE 34,9 Owner’s Manual

English (Original Instructions) .. . . . . . . . . . . . . . . . . . . 1

Français

(Traduction des instructions originales) . . . . . .13

Deutsch (Übersetzung der Originalanleitung) . . . . . . . . .23

Español (Traducción de las instrucciones originales) . . .33

Ambient Temp Range -28C

Noise Level

LAYER OF ROPE 1 2 3

Rated Line Pull Per Layer

Cummulative Rope Capacity

Per Layer

Line Pull First Layer

* Line Speed First

Layer 12 Volt

* Line Speed First

Layer 24 Volt

Amp Draw

* These specifications are based on recommended 10 mm (.393”) 1960 grade wire rope.

kN 34,9 28,9 24,9

lb 7,840 6,500 5,600

m 4 12 21

ft 15 40 70

kN

lb 2,000 4,000 6,000 7,840

MPM 6,1 2,9 2,1 1,6 1,3

FPM 20 9.5 7 5.3 4.3

MPM 4,5 2,2 1,6 1,2 0,9

FPM 15 7.5 5.5 4 3

12V 90 170 235 305 370

24V 36 75 105 140 170

No

Load

8,8 17,7 26,6 34,9

to 60C (-20F to 140F)

80db

Intended Purpose: Vehicle recovery and pulling of loads

RAMSEY WINCH COMPANY

Office Box 581510 Tulsa, Oklahoma 74158-1510 USA

Post

Phone: (918) 438-2760 Fax: (918) 438-6688

Visit us at http://ww.ramsey.com

CONTENTS

User’s

Responsibility for CE Compliance . . . . . . .2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . .2

Tips For Safe Operation . . . . . . . . . . . . . . . . . . . .2

Techniques of Operation . . . . . . . . . . . . . . . . . . .3

Rope Installation . . . . . . . . . . . . . . . . . . . . . . . . .2

Winch Installation . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical connections and Operations . . . . . . . . .4

Operating Instructions . . . . . . . . . . . . . . . . . . . . . 4

Rated Load Limiter Adjustment . . . . . . . . . . . . . .4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

End of Service Measures . . . . . . . . . . . . . . . . . . . 5

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . 5

Winch Parts List . . . . . . . . . . . . . . . . . . . . . . . 6-7

Solenoid Parts List/Fairleads & Switch . . . . . . . . .8

Test Procedure for Solenoid . . . . . . . . . . . . . . . .9

Test Procedure for Motor . . . . . . . . . . . . . . . . . .10

CE Declaration of Conformity . . . . . . . . . . . . . . .12

WARNINGS:

USER SHALL ENSURE THAT THE OPERATING

THE

PERSONNEL ARE GIVEN THE NECESSARY TRAINING.

THE OPERATOR SHALL ALWAYS WORK IN COMPLIANCE

WITH THE OPERATING INSTRUCTIONS.

CLUTCH MUST BE FULLY ENGAGED BEFORE STARTING

THE WINCH.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

STAY OUT FROM UNDER AND AWAY FROM RAISED

LOADS.

STAND CLEAR OF ROPE WHILE PULLING. DO NOT TRY

TO GUIDE ROPE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE

TRANSPORT PERSONNEL.

A MINIMUM OF 2 WRAPS OF ROPE AROUND THE DRUM

BARREL IS NECESSARY TO HOLD THE LOAD.

AVOID CONDITIONS WHERE LOAD SHIFTS OR JERKS

OCCUR. EXCESSIVE “INCHING” SHALL BE AVOIDED.

Ramsey Authorized Representative in the Community:

(Please

contact for regulatory inquiries only.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

914218-1012-

C

Page 2

4707 N. Mingo Tulsa, Oklahoma 74117 (918) 438-2760

EC DECLARATION OF CONFORMITY

as defined by Machinery Directive 2006/42/EC

Here with we declare that winch model RE 34,9 complies

with the following directive provided that the USER

complies with all responsibilities described in the Owner’s

Manual:

2006/42/EC

Applied harmonized standards:

EN 14492-1:2006

Power-Driven Winches

ISO 9001:2000

Quality Management Systems

Requirements

EC-KONFORMITÄTSERKLÄRUNG

gemäß Maschinenrichtlinie 2006/42/EC

Hiermit erklären wir, dass das Windenmodell RE

34,9 der folgenden Richtlinie entspricht, sofern der

BENUTZER alle Anweisungen im Benutzerhandbuch

befolgt:

2006/42/EC

Angewandte harmonisierte Normen:

EN 14492-1:2006

Kraftgetriebene Winden

ISO 9001:2000 Qualitätsmanagementsysteme Anforderungen

Ramsey Authorized Representative in the Community / Ramsey Représentant autorisé dans la comuauté /

Ramsey Bevollmächtigter in der Europäischen Union / Ramsey Representante autorizado en la comunidad.

DÉCLARATION DE CONFORMITÉ EC

aux termes de la directive Machines 2006/42/EC

Nous déclarons par la présente que le modèle de treuil RE

34,9 est conforme à la directive suivante, sous réserve que

l’UTILISATEUR ait assumé toutes les responsabilités figurant

dans le manuel de l’utilisateur :

2006/42/EC

Normes harmonisées appliquées :

EN 14492-1:2006

Treuils motorisés

ISO 9001:2000

Systèmes de gestion de la qualité - Exigences

DECLARACIÓN EC DE CONFORMIDAD

según se define en la directiva de máquinas 2006/42/EC

Con la presente declaramos que el modelo de cabestrante

RE 34,9 se halla en conformidad con la siguiente directiva

siempre que el USUARIO cumpla todas las responsabilidades

descritas en el Manual del propietario: 2006/42/EC

Normas armonizadas aplicadas:

EN 14492-1:2006

Cabestrantes accionados mecánicamente

ISO 9001:2000

Requisitos de los Sistema de gestión de la calidad

(Please contact for regulatory inquiries only. / Veuillez prendre contact uniquement pour des questions réglementaires.)

(Bitte nur bei Regulierungsfragen kontaktieren. / Póngase en contacto sólo por cuestiones de reglamentación.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

Serial Number / Numéro de série/ Seriennummer/ Número de Serie:_____________________

Signature / Signature / Unterschrift / Firma:

Todd Brady

Engineering Manager / Directeur technique/ Technischer Leiter/ Director de ingeniería

Date / Date / Datum / Fecha:

05/03/11

Page 3

User’s Responsibility for CE Compliance

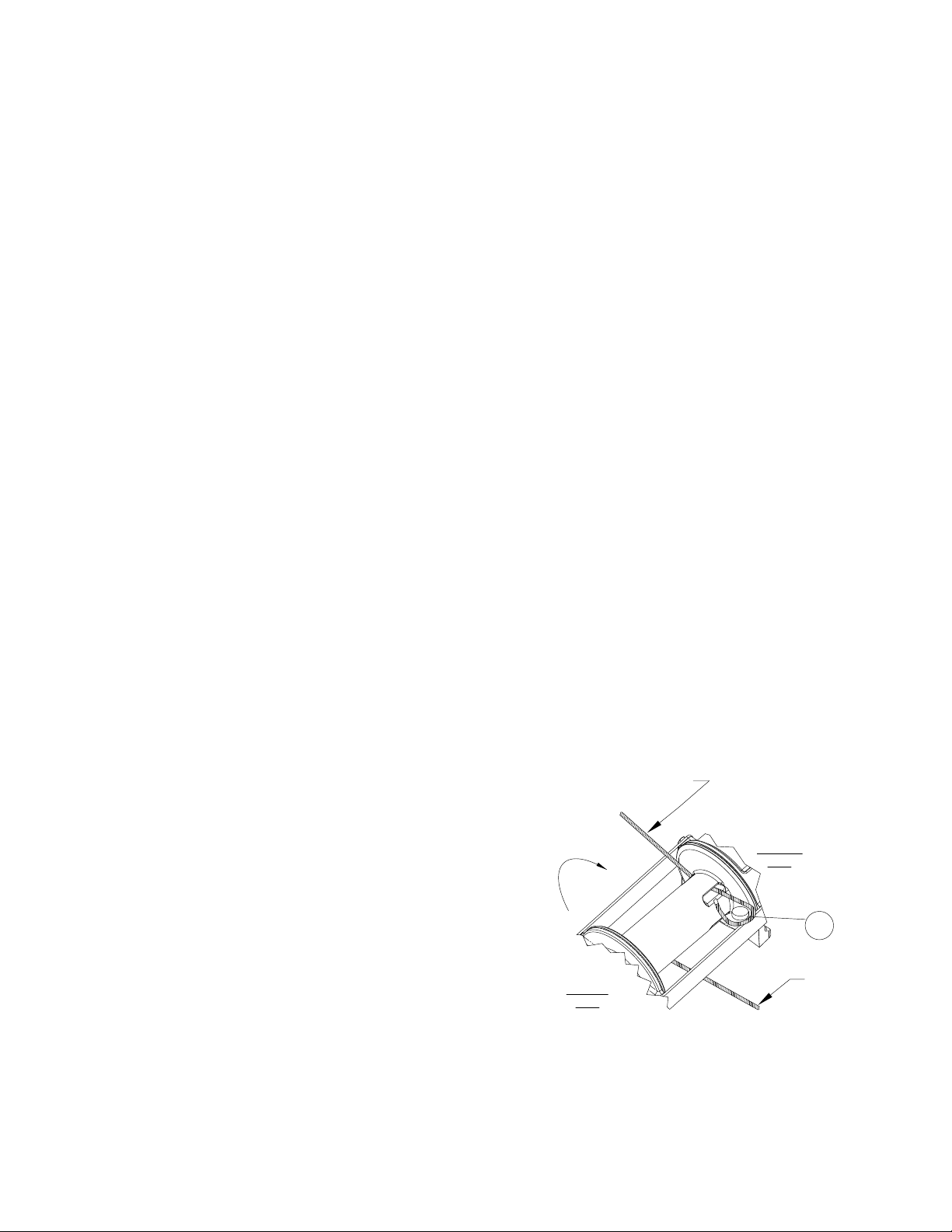

OVERWOUND

ROTATION

DIRECTION

TO REEL IN

MOTOR

END

UNDERWOUND

CLUTCH

END

38

1. Mount winch per Installation Instructions.

2. Install the emergency stop switch per Installation

Instructions included with the Emergency Stop Switch Kit.

3. Install 10 mm (.393 in) grade 1960 wire rope. Maximum

rope length of 21 M (70 ft) for three layers maximum.

4. Attach rope to the drum per Rope Installation Instructions.

5. Use a hook which includes a safety latch and has a

minimum breaking strength of 87 kN.

Safety Precautions

A. Keep yourself and others a safe distance to the side

of the rope when pulling under load.

B. Don’t step over a rope, or near a rope under load.

C. Don’t move the vehicle to pull a load on the winch rope.

This could result in rope breakage.

D. Use a heavy rag or gloves to protect hands from burrs

when handling winch rope.

E. Apply blocks to wheels when vehicle is on an incline.

F. Winch clutch should be disengaged when winch is not in

use and fully engaged when in use.

G. Modification, alteration, or deviation to the winch should

only be made by Ramsey Winch Company.

H. Keep the duration of your pulls as short as possible. If

the motor becomes uncomfortably hot to the touch, stop

and let it cool for a few minutes. Do not pull more than

two minutes at or near rated load. Do not maintain power

to the winch if the motor stalls. Electric winches are for

intermittent usage and should not be used in constant duty

applications.

I. Disconnect the remote control switch from the winch when

not in use.

J. Note: Do not use winch in hoisting applications due to

required hoist safety factors and features.

K. To respool correctly, it is necessary to keep a slight load on

the rope. This is accomplished by (wearing gloves) holding

the rope with one hand and the remote control switch with

the other, starting as far back and in the center as you

can, walking up keeping load on the rope as the winch is

powered in. Do not allow the rope to slip through your hand

and do not approach the winch too closely.

rope.

Store the remote control switch inside your vehicle where it will

not become damaged. Inspect it before you plug it in.

When ready to begin spooling in, plug in remote control switch

with clutch disengaged. Do not engage clutch with motor

running.

Never connect the hook back to the rope. This causes rope

damage. Always use a sling or chain of suitable strength as

shown in the illustration.

Do not attach tow hooks to winch mounting apparatus. They

must attach to vehicle frame.

When double lining during stationary winching, the winch hook

should be attached to the chassis of the vehicle.

Rope Installation

The winch has a tapered pocket cast into the drum, for

overwound or underwound applications.

1. Unwind rope by rolling it out along the ground to prevent

kinking. Securely wrap end of wire rope, opposite hook, with

plastic or similar tape to prevent fraying.

2. Slide the wire rope through narrow end of the pocket against

the drum flange and wrap the wire rope around the anchor

“puck” and pull the wire rope and anchor back into the wide

end of the pocket. Use a soft hammer to drive the back side

of the wire rope, firmly seating the wire rope and anchor, into

the pocket.

3. Caution: Be sure rope spools in direction shown below for

overwound or underwound applications. Carefully run winch

in the “reel-in” direction. Keeping tension on end of rope,

spool all the rope onto the rope drum, taking care to

form neatly wrapped layers.

Inspect the rope frequently. If the rope becomes frayed with

broken strands, replace immediately.

Tips for Safe Operation

The uneven spooling of rope, while pulling a load, is not a

problem, unless there is a rope pileup on one end of drum. If

this happens, reverse the winch to relieve the load and move

your anchor point further to the center of the vehicle. After the

job is done you can unspool and rewind for a neat lay of the

3

Page 4

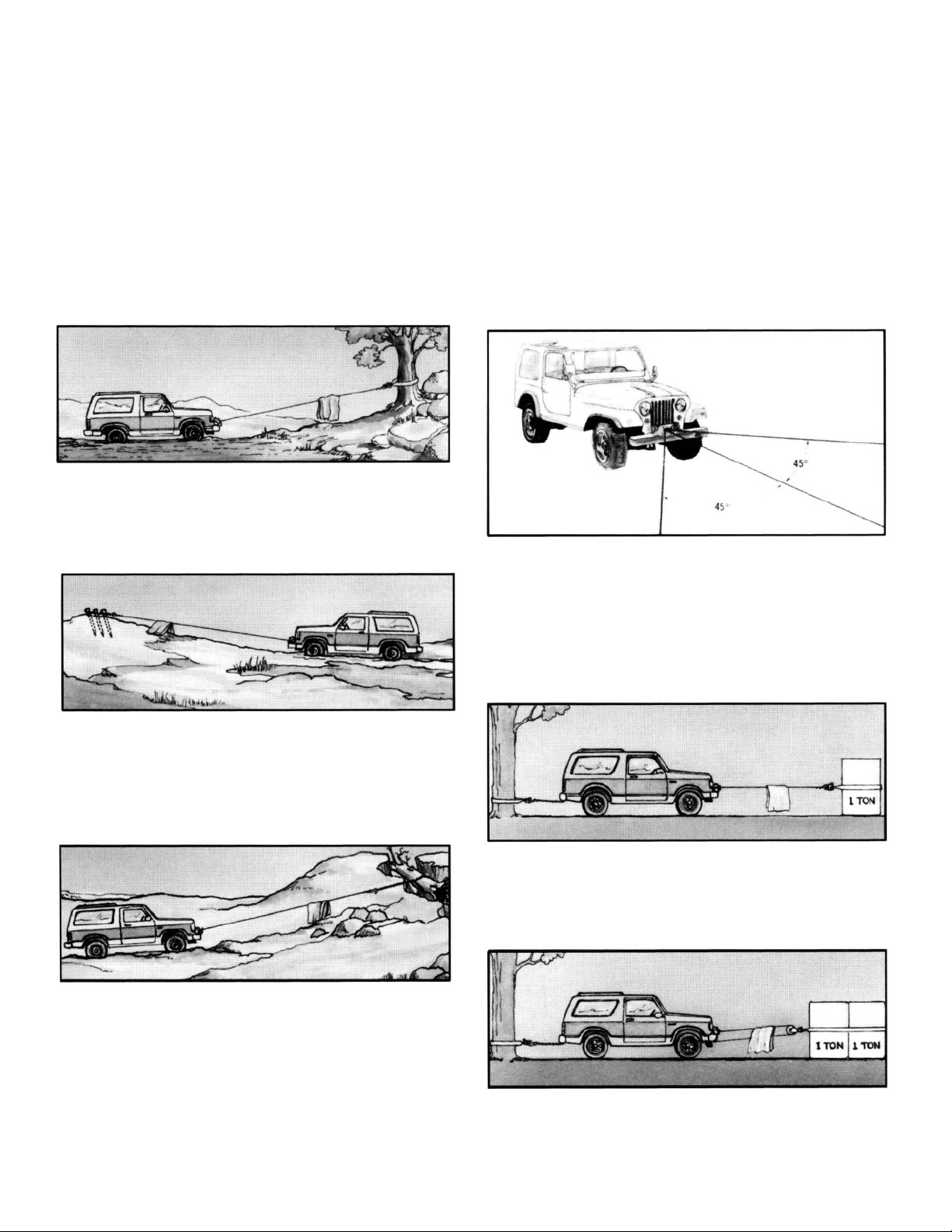

Techniques of Operation

The best way to get acquainted with how your winch operates

is to make a few test runs before you actually need to use it.

Plan your test in advance. Remember you hear your winch as

well as see it operate. Get to recognize the sound of a light

steady pull, a heavy pull, and sounds caused by load jerking

or shifting. Soon you will gain confidence in operating your

winch and its use will become second nature with you.

Your winch will not only pull you up or ease you down a steep

grade, it will also pull another vehicle or a load while your

vehicle is anchored in a stationary position. The following

sketches show you a few techniques.

For basic self-recovery, anchor to a tree or heavy rock. When

anchoring to a tree, always use a tree trunk protector.

When pulling a heavy load, place a blanket, jacket or tarpaulin

over the rope five or six feet from the hook. It will slow the

snap back in the event of a broken rope. Also open the vehicle

hood for additional protection.

Use the vehicle wheel power to help the winch, but do not

overtake the winch line. Plan your pull. You cannot always

hook up and pull out in one step. Examine all the areas

for anchoring possibilities as well as leverage situations,

direction, and goal.

Stakes driven in solid earth and chained together make a

good anchor point for self-recovery when no solid anchor

point is available.

Winches equipped with cable guide fairleads can pull from

several directions. Pull from an angle only to straighten up

the vehicle-otherwise you can damage structural members or

other parts of your vehicle and cause excess cable buildup on

one end of the winch drum.

For a direct pull of 1 ton, hitch truck to a tree or solid anchor,

and take out of gear.

For a solid anchor, bury a log with earth or sand or place it in

a deep ravine.

To double the pull, use 2-part line and tie off to chassis. Take

out of gear.

4

Page 5

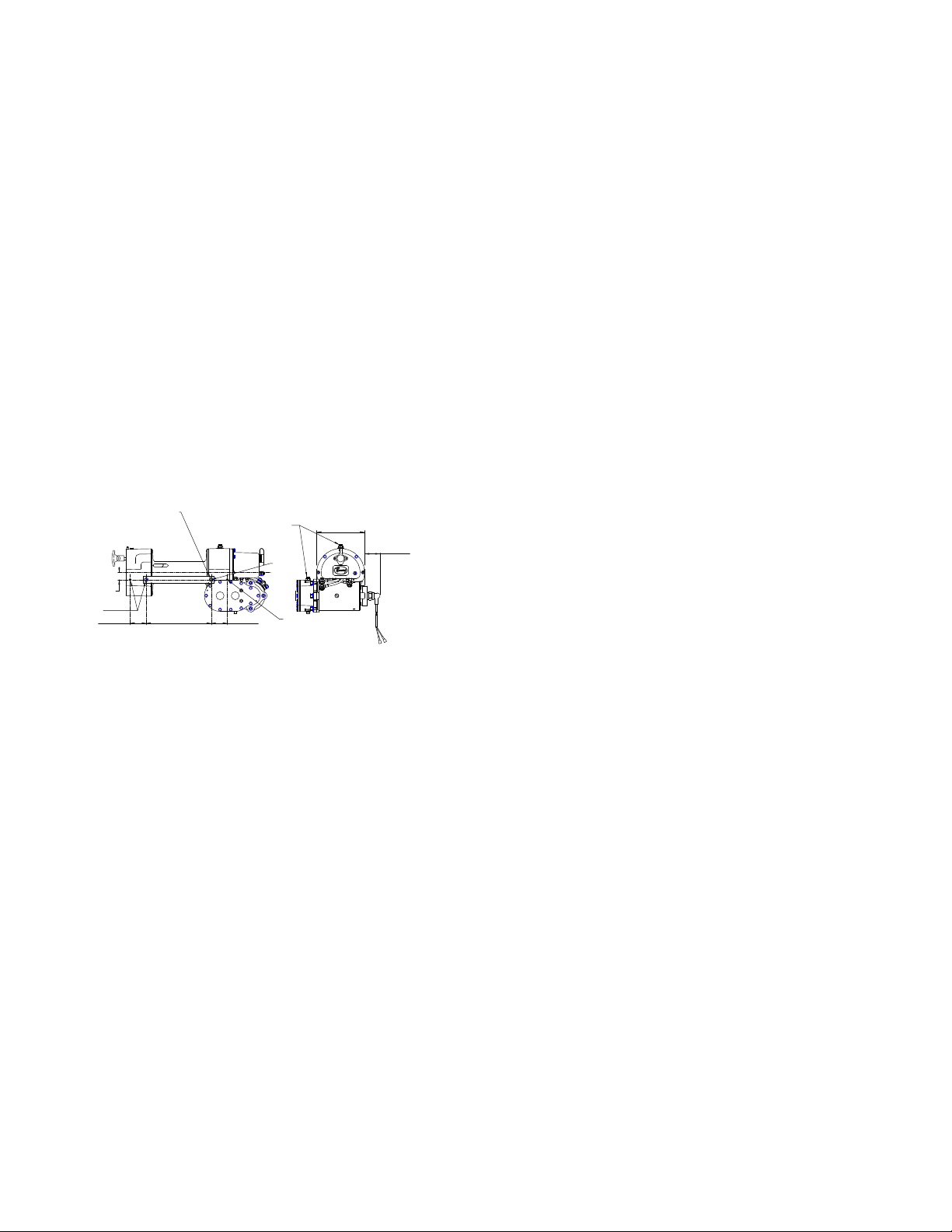

61,2 MM

2.41 IN.

F-1

F-2

A

7.44 IN.

188,8 MM

REMOVE RUBBER COVER FROM

RELIEF FITTINGS BEFORE PUTTING

WINCH INTO USE.

2.50 IN.

63,5 MM

1.12

28,5

DEEP THREADS

(EACH SIDE)

3/8-16 x 0.50" DEEP THREADS

(EACH SIDE)

3/8-16x1"

DEEP

THREADS

(EACH

SIDE)

ATTACH BLACK GROUND CABLE

TO WINCH USING MOUNTING BOLT

AT THIS LOCATION

3/8-16 x .75"

USE SOCKET HEAD MTG BOLTS

ON SIDE WITH SPUR GEAR HSG.

257,2 MM

10.19 IN

63,5 MM

2.50 IN.

Winch Installation

NOTE: The winch must be mounted to angles 9 x 63 x 63

(3/8” x 2-1/2” x 2 1/2” minimum) high strength 344,000 kPa

(50,000 PSI) yield steel angle or in a frame with both sides of

the clutch housing and gear housing bolted to the angles or

frame. See diagram below for recommended mounting dimensions.

Note various thread depths of mounting holes and use

correspondingly different bolt lengths for proper mounting.

Substitution of attaching hardware items) bolts, nuts, or washers)

different from those supplied with your winch mounting kit can

lead to failure causing damage or serious injury. Use a socket head

mounting bolt on side with Spur Gear Housing (see diagram) to

prevent clearance problems. Use SAE grade 5 bolts or better.

Electrical Connections and Operations

For normal self-recovery work, your existing electrical system is

adequate.

Your battery must be kept in good condition. A fully

charged battery and proper connections are essential. Run the

vehicle engine during winching operation to keep battery charged.

Connect red cable from stud on plastic solenoid cover on winch

to emergency stop solenoid. Important: Hold inner nut with end

wrench while tightening outer nut. Install emergency stop switch and

solenoid per kit # 282067 (12V) or 282068 (24V) as applicable.

Connect black cable from winch mounting bolt nearest drum (as

shown below) to negative battery terminal. A good electrical ground

is required for proper performance.

The remote control switch is waterproof and has push button

stations on either side. It is designed this way to prevent quick

winch reversals, which lead to solenoid failure. Make sure the winch

motor has stopped fully before reversing.

When first setting up your winch, follow the directions for inserting

the proper “IN” or “OUT” label in the thumb button. The switch is

also color coded to aid you in determining the direction your winch

will run.

Maintenance

Check monthly the action of the sliding clutch, making sure it is fully

engaging

engaged position, remove the plastic plug in top of the housing and

observe if the clutch is fully engaging. If clutch is not fully engaging,

inspect the clutch shifter assembly parts, check for damage or

excessive wear and replace as necessary. Observe the jaws on both

the clutch and rope drum, checking for rounding of the driving faces.

If rounding has occurred they should be replaced immediately.

Spool the rope properly on the drum when storing between each

usage.

Check the oil level in the gearboxes every six months. At the same

and disengaging with the rope drum. With the clutch in the

time, check electrical connections and mounting bolts – tighten if

necessary.

Corrosion on electrical connections will reduce performance or may

cause a short. Clean all connections, especially in remote switch

receptacle. In salty environments use a silicone sealer to protect

from corrosion.

Replace oil annually or more often if winch is used frequently.

Fill the worm gear box with 3/4 pint of Phillips SMP 80W-90, Mobil

HD 80W-90, or Shell Spirax HD 80W-90. Use 1/2 pint of SAE 20

for spur gear box. Apply cup grease to lube fitting at top of clutch

housing. Should winch be submerged for a brief period, drain

oil, flush and replace oil in gearboxes, and grease all fittings (see

Troubleshooting Guide).

To minimize corrosion of the internal motor components that may

occur due to condensation, power the winch in or out periodically.

Energizing the motor will generate heat, which will dissipate any

moisture buildup in the motor. This should be performed at periodic

intervals (such as with each oil change to your vehicle).

Lubricate rope periodically using light penetrating oil. Inspect for

broken strands and replace if necessary. Install new rope per

“Rope Installation”, Page 2.

Operating Instructions

The RAM-LOK® semi-automatic clutch provides free spooling and

engagement with the rope drum. With the clutch disengaged,

clutch

the rope can be pulled off the drum by hand. For winching in the

load, the clutch must be fully engaged with the drum.

To disengage the clutch: run the winch in the reverse (“reelout”) direction until the load is off the rope and the rope drum stops

turning. Pull outward on the clutch handle, rotate it counter-clockwise

90º and release. The clutch is now locked out and the rope may be

pulled by hand. (NOTE: If the clutch handle cannot be pulled out,

again run the winch momentarily in reverse to relieve pressure on the

clutch jaws.) WARNING: DO NOT ATTEMPT TO DISENGAGE THE

ROPE DRUM WHEN THERE IS A LOAD ON THE ROPE.

To engage the clutch: pull outward on the handle, rotate it

clockwise 90º and release. Run the winch in reverse until the clutch

handle snaps fully in or until the rope drum starts turning. At this

point make sure the clutch handle is all the way in. The plastic plug

in top of clutch housing may be removed, for inspection of clutch to

assure total engagement. After the clutch is fully engaged, the winch

is ready for winching in the rope.

Adjustment of Rated Load Limiter

1.

Make some test pulls with winch (using a load cell or

spring scale) to determine if switch is at desired rated

load setting. Acceptable setting is 100% to 125% of

rated load.

2. If load is not within above range, remove tamper-proof

compound in threaded hole (on top of set screws #4).

Remove top set screw.

3. Loosen bottom set screw approximately 2 turns counter

clockwise.

4. To reduce line pull, thread switch #1 “IN” by turning

clockwise. To increase line pull, thread switch “OUT”.

5. After desired setting is reached, tighten bottom set

screw securely.

6. Re-install top set screw and tighten securely. Fill threaded

5

Page 6

hole with a potting-type compound which must be removed

before any future adjustment is made.

End of Service Measures

When winch reaches the end of its serviceable life, dispose of

per local environmental regulations

Troubleshooting Guide

CONDITIONS POSSIBLE CAUSE CORRECTION/ACTION

MOTOR RUNS IN ONE

DIRECTION

ONLY

1. Inoperative solenoid or stuck

solenoid

2. Inoperative remote control switch 2. Disengage winch clutch, remove remote control switch plug from the

1. Jar solenoid to free contacts. Check by applying 12 volts to coil

terminal

(it should make an audible click when energized).

socket and jump pins at 8 and 4 o’clock. Motor should run.

MOTOR RUNS EXTREMELY

HOT

MOTOR RUNS, BUT WITH

INSUFFICIENT POWER, OR

WITH LOW LINE SPEED

WINCH WILL NOT PULL

RATED LOAD

MOTOR RUNS, BUT DRUM

DOES NOT TURN

MOTOR WILL NOT

OPERATE

1. Long period of operation 1. Cooling-off periods are essential to prevent overheating.

2. Insufficient battery 2. Check battery terminal voltage under load. If 10 volts or less, replace

or parallel another battery to it.

1. Electrical cable from battery to

winch or ground strap from engine

block to vehicle chassis too small.

2. Bad electrical connections 2. Check all connections for looseness or corrosion; tighten, clean and

3. Insufficient charging system

1. Rated load limiter mis-adjusted.

1. Clutch not engaged 1-4 If clutch engaged by symptom still exists, it will be necessary to

2. Sheared drum shaft key

3. Stripped bronze gear

4. Parted shaft

1. Inoperative solenoid or stuck

solenoid

2. Inoperative remote control switch 2. Disengage winch clutch, remove remote control switch plug from the

3. Inoperative motor 3. If solenoids operate, check for voltage at armature post, replace

4. Loose connections 4. Tighten connections on bottom side of hood and on motor.

1. Must be Grade 2 or equivalent or larger if longer than 4,5 M (15 feet).

grease.

3. Replace with larger capacity charging system.

1. Adjust rated load limiter per instructions on page 4 and 5.

disassemble winch to determine cause and repair.

1. Jar solenoid to free contacts. Check by applying 12 volts to coil

terminal (it should make an audible click when energized).

socket and jump pins at 8 and 4 o’clock. Motor should run.

motor.

MOTOR WATER DAMAGED 1. Submerged in water or water from

high pressure car wash

CLUTCH INOPERATIVE OR

BINDS UP

CLUTCH SPRING DOES

NOT OPERATE

CLUTCH DOES NOT

LOCK AT DISENGAGED

POSITION

OIL LEAKS FROM HOUSING

1. Dry or rusted shaft 1. Clean and lubricate

2. Dog point setscrew too tight 2. Remove rubber plug from clutch housing and rotate setscrew

3. Bent yoke 3. Replace yoke or shifter assembly.

4. Keys pulled out of shape by

overload

1. Broken spring 1. Replace

1. Setscrew loose or worn 1. Remove rubber plug from clutch housing, tighten setscrew or replace.

1. New seal 1. New seals sometimes leak until seated to shaft.

2. Seal damaged or worn 2. Replace.

3. Too much oil 3. Drain excess oil per lubrication instructions.

4. Damaged gasket 4. Replace.

1. Allow to drain and dry thoroughly, then run motor without load in

short bursts to dry windings

outward until clutch operates smoothly. Replace rubber plug.

4. If drum shaft keyways are rounded or damaged replace shaft and

keys. If not, file off burrs and replace keys.

Replace plug.

6

Page 7

33

24

1

7

6

69

42

66

66

42

48

37

27

75

78

78

74

76

78

72

73

78

78

77

70

9

27

19

58

17

50

59

60

67

4

38

27

12

39

41

43

49

49

26

51

53

63

47

65

26

43

62

18

34

28

57

10

30

55

57

44

68

14

13

28

68

54

21

14

22

68

28

64

53

51

54

25

20

29

70

16

70

27

45

11

31

56

61

35

40

32

5

8

2

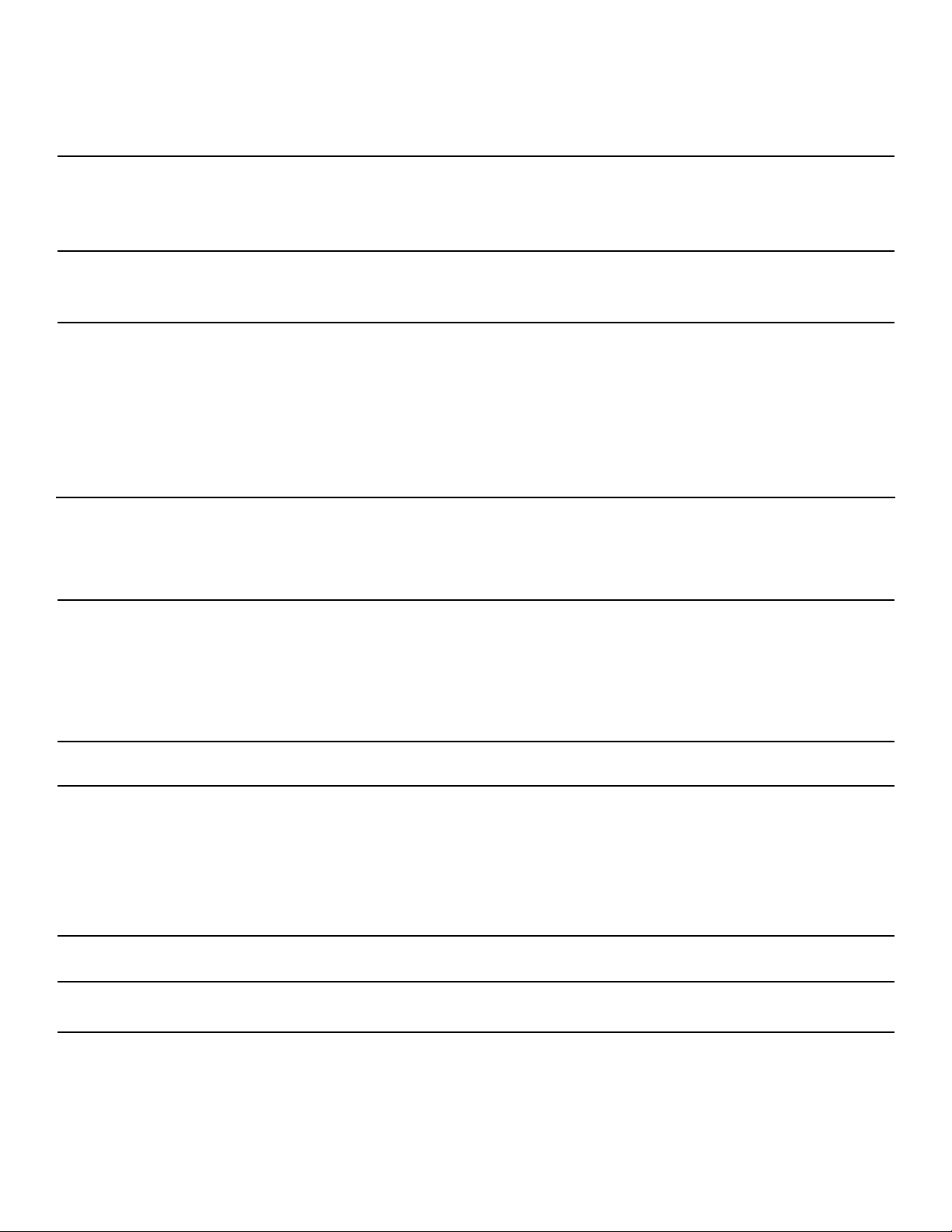

NOT

SHOWN

3

GEAR HOUSING

SECTION

RATED LOAD LIMITER

THRUST DISC

BEARING

THRUST ACTUATOR

SWITCH BUTTON

SWITCH

BEARING CAP

SETSCREW

48

23

RE 34,9 PARTS DRAWING

7

Page 8

RE 34,9 PARTS LIST

Item

Qty Part No. Description

No.

1 1 251110 SWITCH ASSY-12FT LG 39 3 418040 NUT-3/8-24NF HEX REG Z/P

2 1 282067 E-STOP SWITCH KIT (12V) (NOT SHOWN) 40 3 418154 WASHER-1/4 FLAT ALUM.

1 282068 E-STOP SWITCH KIT (24V) (NOT SHOWN) 41 3 418177 LOCKWASHER-3/8 MED SECT, Z/P

3 1 262040 MOTOR (12V) 42 2 438014 DRAG BRAKE

1 262038 MOTOR (24V) 43 2 442184 GASKET

4 1 276056 SHIFTER ASSEMBLY 44 1 442185 GASKET

5 1 458108 SOLENOID ASSEMBLY (24V) 45 1 442205 GASKET

1 458005 SOLENOID ASSEMBLY (12V) 46

6 1 289015 ASSEMBLY-WIRE, BATTERY CABLE, RED 47 1 450005 KEY

7 1 289141 ASSEMBLY-WIRE, GROUND, BLACK 48 2 450006 BARTH KEY

8 1 434566 NAME AND DATA PLATE 49 4 450016 BARTH KEY

9 1 324137 JAW CLUTCH 50 1 456001 LUBE FITTING

10 1 328106 COVER - SPUR GEAR HOUSING 51 2 456008 RELIEF FITTING

11 1 328134 COVER - GEAR HOUSING 52

12 1 332251 CABLE DRUM ASSEMBLY 53 2 468002 REDUCER

13 1 334001 IDLER GEAR 54 2 468011 PIPE PLUG

14 2 334003 SPUR GEAR 55 2 468017 PIPE PLUG

15 56 1 468018 PIPE PLUG

16 1 334163 GEAR R.H. 57 2 470001 DOWEL PIN

17 1 336010 SHIFTER HANDLE 58 1 470033 SPIROL PIN

18 1 338203 HOUSING-SPUR GEAR 59 1 472012 PLUG

19 1 338208 HOUSING-CLUTCH 60 1 472013 PLUG

20 1 338273 HOUSING-GEAR 61 1 482013 BOOT

21 1 342033 KEY 62 1 486009 OIL SEAL

22 1 356901 SHAFT-SPUR 63 1 486017 OIL SEAL

23 1 357484 SHAFT-DRUM 64 1 486023 OIL SEAL

24 1 364029 STRAP 65 1 490003 SNAP RING

25 1 368162 WORM-R.H. 66 2 494002 SPRING

26 2 402002 BALL BEARING 67 1 494053 SPRING

27 4 412003 BUSHING 68 3 518002 THRUST WASHER

28 3 412038 BUSHING 69 1 518014 THRUST WASHER

29 1 412040 BUSHING 70 2 518015 THRUST WASHER

30 12 414038 CAPSCREW-1/4-20NC X 3/4, HXHD,GR-5,Z/P 71

31 9 414045 CAPSCREW-1/4-20NC X 1 HXHD, GR-5, Z/P 72 1 282039 SWITCH ASSEMBLY

32 3 414059 CAPSCREW-1/4-20NC X 1 GR-5 HXHD Z/P 73 1 316093 BEARING CAP

33 2 414279 CAPSCREW-3/8-16NC X 3/4 HX HD GR-5 74 4 414857 CAPSCREW

34 4 414845 CAPSCREW-1/4-20NC X 1 HXSOCHD, NYLOK 75 2 416003 SETSCREW

35 2 414856 CAPSCREW-1/4-20NC X 3/4 HXSOCHD Z/P 76 1 462039 O-RING

36 77 1 518034 THRUST ACTUATOR

37 1 416030 SETSCREW-1/4-20 X 3/8 HX SOC FULL DOG PT. 78 5 518035 THRUST DISC

38 1 315008 ROPE ANCHOR

Item

No.

Qty Part No. Description

8

Page 9

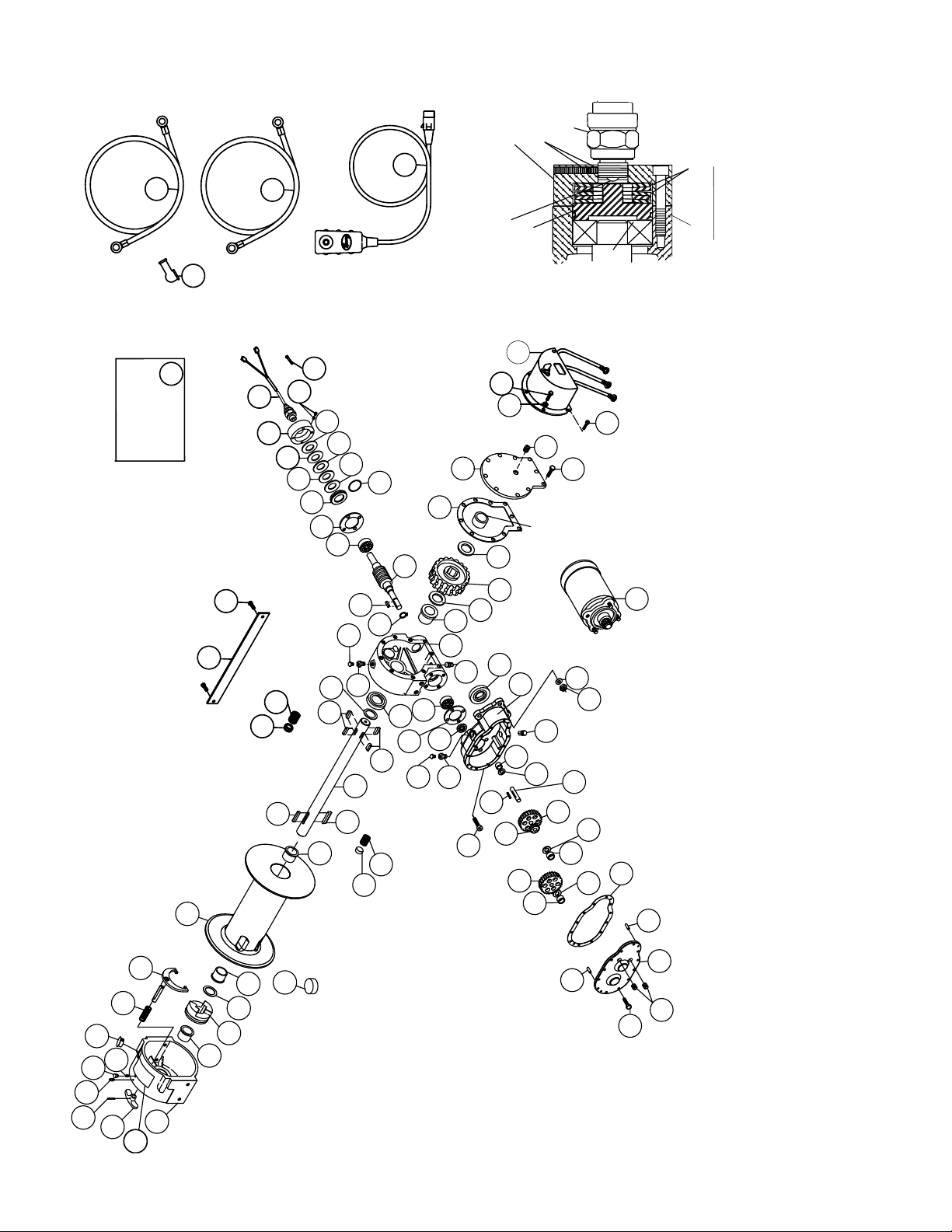

Solenoid Assembly Parts List

7

11

2

21

21

17

18

7

4

11

21

4

3

17

3

5

18

6

5

21

9

3

1

15

10

13

10

14

20

9

19

15

8

8

Yellow

Red

Green

12

To Yellow

To Green

To Red

A

B

C

278170

2

78028

12V

24V

Item

No.

Qty Part No. D escription

Item

No.

Qty Part No. D escription

1 1 251110 SW ITCH ASSY-12FT LG 39 3 418040 N UT-3/8-24NF HEX REG Z/P

2 1 282067 E-STOP SWITCH KIT (12V) (NOT SHOWN) 40 3 418154 WASHER-1/ 4 FLAT ALUM.

1 282068 E-STOP SWITCH KIT (24V) (NOT SHOWN) 41 3 418177 LOCKWASHE R-3/8 MED SECT, Z/P

3 1 262040 MOTOR (12V) 42 2 438014 D RAG BRAKE

1 262038 MOTOR (24V) 43 2 442184 GASKET

4 1 276056 SHIF TER ASSEMBLY 44 1 442185 GASKET

5 1 27028 SOLENOID AS

SEMBLY (24V) 45 1 442205 GASKET

1 278170 SOLENOID ASSEMB LY (12V) 46

6 1 289015 ASSEMB LY-WIRE, BATTERY CABLE, RED 47 1 450005 KEY

7 1 289141 ASSEMB LY-WIRE, GROUND, BLACK 48 2 450006 B ARTH KEY

8 1 434713 NAME AND DATA PLATE - ENGLISH 49 4 450016 BARTH KEY

9 1 324137 JAW CLUTCH 50 1 456001 LUBE FITTING

10 1 328106 C OVER - SPUR GEAR HOUSING 51 2 456008 R ELIEF FITTING

11 1 328134 C OVER - GEAR HOUSING 52

12 1 332251 C ABLE DRUM ASSEMBLY 53 2 468002 RED UCER

13 1 33400

1 I DLER GEAR 54 2 468011 PIPE PLUG

14 2 334003 S PUR GEAR 55 2 468017 PIPE PLUG

15 56 1 468018 PIPE PLUG

16 1 334163 GEAR R.H. 57 2 470001 D OWEL PIN

17 1 336010 S HIFTER HANDLE 58 1 470033 SPIROL PIN

18 1 338203 HO USING-SPUR GEAR 59 1 472012 PLUG

19 1 338208 HO USING-CLUTCH 60 1 472013 PLUG

20 1 338273 HO USING-GEAR 61 1 482013 BOOT

21 1 342033 KE Y 62 1 486009 OIL SEAL

22 1 356901 S HAFT-SPUR 63 1 486017 OIL SEAL

23 1 357480 S HAFT-DRUM 64 1 486023 OIL SEAL

24 1 364029 S TRAP 65 1 490003 S NAP

RING

25 1 368162 W ORM-R.H. 66 2 49400 2 SPRING

26 2 402002 B ALL BEARING 67 1 494053 S PRING

27 4 412003 B USHING 68 3 518002 THRUS T WASHER

28 3 402001 B USHING 69 1 518014 THRUS T WASHER

29 1 412045 B USHING 70 2 518015 THRUS T WASHER

30 12 414038 CAPSCREW-1/4-20N C X 3/4, HXHD,GR-5,Z/P 71

31 9 414045 C APSCREW -1/4-20NC X 1 HXHD, GR-5, Z/P 72 1 282039 S WITCH ASSEMBLY

32 3 414059 C APSCREW -1/4-20NC X 1 GR-5 HXHD Z/P 73 1 316093 BE ARING CAP

33 2 414279 C APSCREW -3/8-16N

C X 3/4 HX HD GR-5 74 4 414857 CAPSCREW

34 4 414845 C APSCREW -1/4-20NC X 1 HXSOCHD , NYLOK 75 2 416003 SETSCREW

35 2 414856 C APSCREW -1/4-20NC X 3/4 HXSOCHD Z/P 76 1 462039 O-RI NG

36 77 1 518034 THR UST ACTUATOR

37 1 416030 S ETSCREW-1/4-20 X 3/8 HX SOC FULL DOG PT. 78 5 518035 THRU ST DISC

38 1 315008 R OPE ANCHOR

278170 12V

278028 24V

Remote Control

Switch

#251110

Roller Fairlead

#251183

Mounting hardware included with

mounting kits

9

Page 10

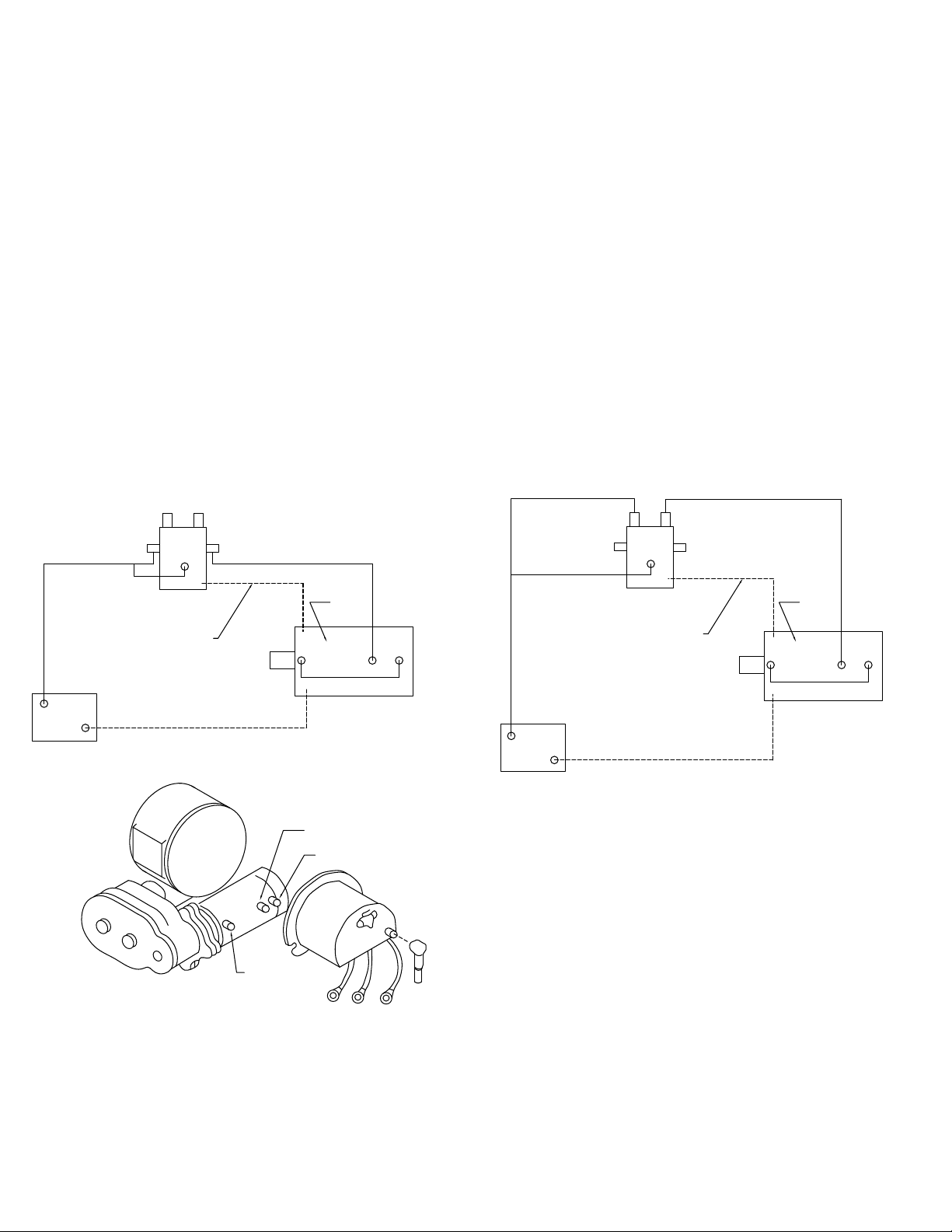

TEST PROCEDURE FOR SOLENOIDS

(MOTOR

HOUSING)

GROUND WIRE

FROM SOLENOID

TO MOTOR

(MOTOR

HOUSING)

(TOP TERMINALS)

SIDE SIDE

SOLENOID

BATTERY

MOTOR

(+)

(-)

F1

F2

A

(SMALL)

(TOP TERMINALS)

SIDE SIDE

SOLENOID

(SMALL)

BATTERY

(+)

(-)

FIGURE 1

F

IGURE 2

SOLENOID

ASSEMBLY

TO BATTERY

B*

C*

A*

TO ARMATURE

* See Solenoid Assembly

page 21 for connection of A,

B, & C cable to solenoids.

Field (A)

Armature

Field (B)

Field (C)

GROUND WIRE

FROM SOLENOID

TO MOTOR

F1

F2

A

Steps to follow when testing current flow through DC

solenoids.

It should be noted that when testing a 12 volt or 24 volt

solenoid, the DC motor and battery must be of the same

voltage.

To test the solenoids: (See Figure 1).

1. Securely clamp a motor to a bench or work surface.

2. Attach a #6 gauge jumper wire from “A” terminal on the

motor to one of the field terminals on the motor, (F-2).

3. Attach the other motor field terminal (F-1) to one of the

side terminals of the solenoid.

4. Ground the solenoid to the motor with a wire as shown.

5. Attach positive (+) battery wire to the opposite side

terminal of solenoid. Ground the negative (-) battery wire

to the motor housing.

6. Touch “hot” wire, from the positive battery terminal, to

small terminal of the solenoid.

7. The motor should now be running if the solenoid is good.

If not, make sure the motor will run directly from the

battery. (See motor test procedure, Page 10).

8. To test the upper contacts use the same hookup except

use the top terminals. (See Figure 2). When hooked up

as shown in Figure 2, motor should start running.

When the “hot” wire is touched to the small terminal the motor

will stop operating.

The top terminals are normally closed; i.e. connected, and

the side terminals open, or not connected. When the solenoid

operates, the top terminals are disconnected and the side

terminals are connected.

Take care not to bring “hot” wires into contact with ground in

order to prevent electrical arcing.

10

Page 11

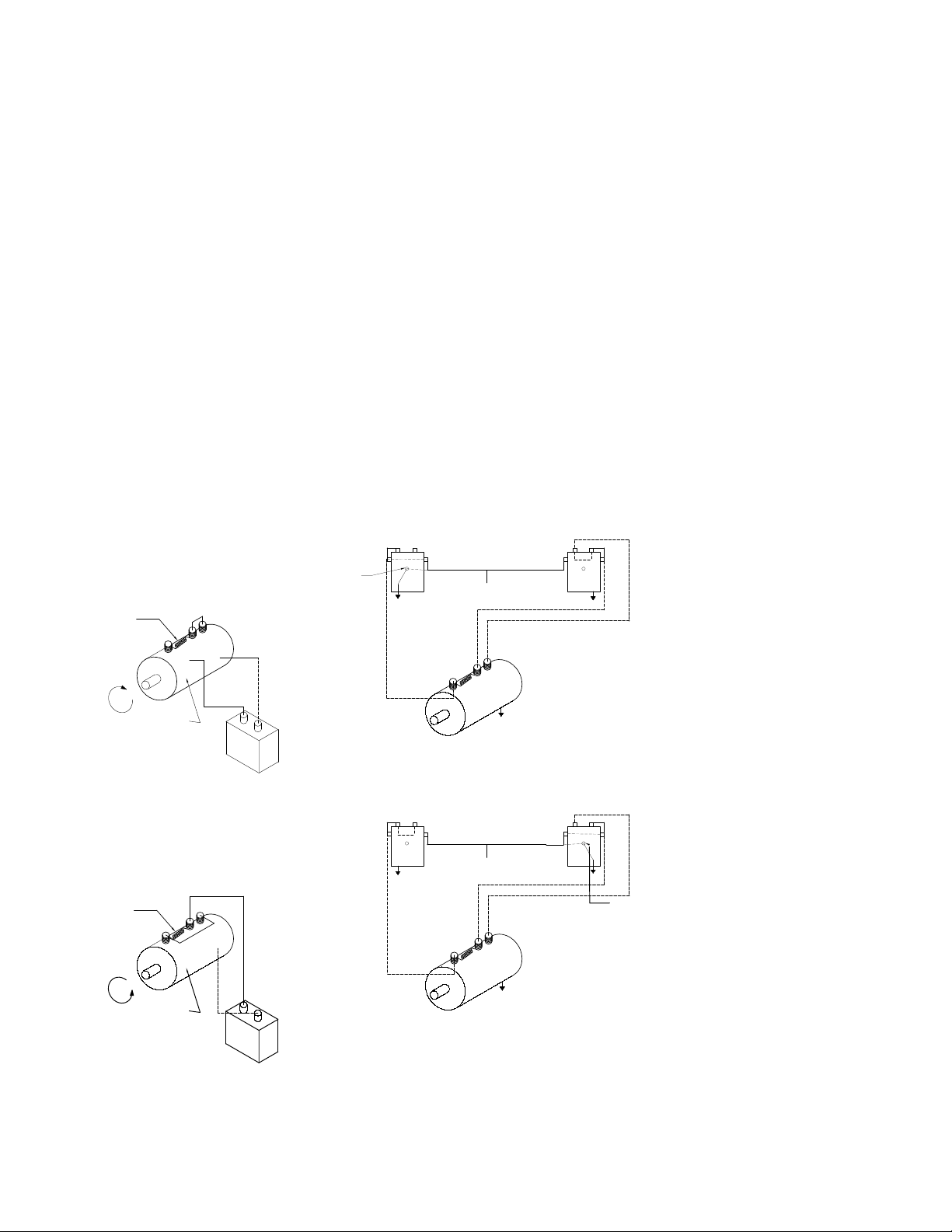

CCW

CW

BATTERY

(MOTOR HOUSING)

(PULL COILS

INSIDE MOTOR)

GROUND

A

F2

F1

FIGURE 1

MOTOR-CLOCKWISE ROTATION

BATTERY

(MOTOR HOUSING)

GROUND

FIGURE 2

MOTOR-COUNTER-CLOCKWISE ROTATION

SMALL TERMINAL

SMALL TERMINAL

TO BATTERY'S

POSITIVE TERMINAL

TO BATTERY'S

POSITIVE TERMINAL

MOTOR

MOTOR

SOLENOID

SOLENOID

SOLENOID

SOLENOID

GROUND

GROUND

FIGURE 3

SOLENOIDS TO MOTOR CONNECTIONS

THE DASHED LINES ARE CURRENT'S PATH IN FORWARD ROTATION.

SOLID LINES ARE CURRENT'S PATH AT ALL TIMES.

NOTE: DIRECTION OF MOTOR ROTATION DEPENDS ON WHICH SMALL

TERMINAL OF EITHER SOLENOID IS CONNECTED TO BATTERY'S

POSITIVE TERMINAL.

THE DASHED LINES ARE CURRENT'S PATH IN REVERSE ROTATION.

SOLID LINES ARE CURRENT'S PATH AT ALL TIMES.

A

F2

F1

(PULL COILS

INSIDE MOTOR)

A

F2

F1

A

F2

F1

TEST PROCEDURE FOR MOTOR

Ramsey Winch motor is a (4 pole-4 coil) series wound

The

12 volt or 24 volt DC motor.

The 4 pole-4 coil feature provides high torque at low speeds.

To test the motor to determine if it is functioning properly, first

securely fasten the motor to a bench or work surface so it will

not jump or move around during test procedure (the starting

torque of motor is high).

1. Connect a jumper wire (at least a number 6 wire) from

F-1 to “A” motor terminals (See Figure 1)

2. Attach a wire (at least a number 6 wire) from positive

(+) battery terminal to F-2 motor terminal. Ground

negative (-) battery terminal to motor housing

(See Figure 1). Motor should now run.

To reverse the direction of rotation:

1. Attach jumper wire from F-2 to “A” motor terminals (See

Figure 2).

2. Attach wire from positive (+) battery terminal to F-1

motor terminal. Ground negative (-) battery terminal to

motor housing (See Figure 2).

NOTE: Always attach battery wire solidly to motor terminals.

Make and break the connection of the negative (-) battery

terminal at the motor housing. This avoids burning the motor

terminals.

CAUTION: DO NOT RUN THE MOTOR FOR A LONG PERIOD OF TIME

IN FASHION MENTIONED ABOVE, BECAUSE THE MOTOR COULD BECOME

DAMAGED.

The motor running idle on the bench will draw 55 amperes

and must run free and easy. If the ampere draw is more than

60 amperes and the motor runs rough or has a strange sound,

it should be replaced.

With the motor attached in place on a winch (less rope on

drum) the ampere draw should be approximately 65 to 70

amperes.

If after following the procedure outlined, the test on the winch

significantly exceeds 70 amperes, refer to your Owner’s

Manual for trouble shooting suggestions on the mechanical

portion of the winch.

See Figure 3 for the solenoids connection to the motor and the

battery.

11

Page 12

12

Page 13

Ramsey Winch Company

Modèle

Treuil électrique

English (Original Instructions) .. . . . . . . . . . . . . . . . . . . 1

RE 34,9 - Manuel de l’utilisateur

Français

(Traduction des instructions originales) . . . . . .13

Deutsch (Übersetzung der Originalanleitung) . . . . . . . . . 23

Español (Traducción de las instrucciones originales) . . . 33

Plage de températures ambientes -28

Niveau sonore

COUCHE DE CÂBLE 1 2 3

Traction nominale par couche de câble

Capacité cumulative de câble par couche

(Tambour court)

Traction du câble,

première

*Vitesse du câble,

première couche 12 V

*Vitesse du câble,

première couche 24 V

Intensité du moteur

* Ces caractéristiques sont basées sur l’utilisation du câble métallique recommandé

de 10 mm (0,393 po) de calibre 1960.

couche

kN

À vide

lb 2,000 4,000 6,000 7,840

MPM 6,1 2,9 2,1 1,6 1,3

FPM 20 9,5 7 5,3 4,3

MPM 4,5 2,2 1,6 1,2 0,9

FPM 15 7,5 5,5 4 3

12V 90 170 235 305 370

24V 36 75 105 140 170

kN 34,9 28,9 24,9

lb 7,840 6,500 5,600

m 4 12 21

pi 15 40 70

8,8 17,7 26,6 34,9

°C à 60 °C

Utilisation prevue : Dépannage de véhicule et traction de charges

RAMSEY WINCH COMPANY

Office Box 581510 Tulsa, Oklahoma 74158-1510 USA

Post

Phone: (918) 438-2760 Fax: (918) 438-6688

Visit us at http://ww.ramsey.com

Ramsey Représentant autorisé dans la

comuauté:

(Veuillez

réglementaires.)

Alura Group BV

2502 EP The Hague

The Netherlands

prendre contact uniquement pour des questions

P.O. Box 18626

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

80db

TABLES DES MATIÈRES

Responsabilité

conformité au marquage CE . . . . . . . . . . . . . . . . 14

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . 14

Conseils de sécurité . . . . . . . . . . . . . . . . . . . . . . 14

Pose du câble . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Trucs et techniques . . . . . . . . . . . . . . . . . . . . . . . 15

Installation du treuil . . . . . . . . . . . . . . . . . . . . . . . 16

Fonctionnement et branchements électriques . . . . 16

Mode d’emploi . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ajustement du limiteur de charge nominale . . . . . 16

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mesures à prendre au terme de la mise en

service du treuil . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Guide de résolution des problèmes . . . . . . . . . . . 17

Nomenclature des pièces . . . . . . . . . . . . . . . 18-19

Liste des pièces de solénoïde/guide-câbles

et commutateurs . . . . . . . . . . . . . . . . . . . . . . . . .20

Test des solénoïdes . . . . . . . . . . . . . . . . . . . . . . . 21

Test du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AVERTISSEMENTS :

L’UTILISATEUR

OPÉRATEUR REÇOIVE LA FORMATION NÉCESSAIRE.

L’OPÉRATEUR DOIT TOUJOURS TRAVAILLER

EN CONFORMITÉ AVEC LES INSTRUCTIONS

D’UTILISATION.

L’EMBRAYAGE DOIT ÊTRE COMPLÈTEMENT

ENCLENCHÉ AVANT DE DÉMARRER LE TREUIL.

NE RELÂCHEZ JAMAIS L’EMBRAYAGE EN PRÉSENCE

D’UNE CHARGE.

NE JAMAIS SE PLACER SOUS UNE CHARGE SOULEVÉE

NI À PROXIMITÉ.

RESTEZ À L’ÉCART DU CÂBLE LORS DU TREUILLAGE.

N’ESSAYEZ PAS DE GUIDER LE CÂBLE.

N’UTILISEZ PAS LE TREUIL POUR SOULEVER,

MAINTENIR OU TRANSPORTER DES PERSONNES.

IL CONVIENT DE CONSERVER AU MINIMUM DEUX

TOURS DE CÂBLE AUTOUR DU TAMBOUR POUR

MAINTENIR LA CHARGE.

ÉVITEZ TOUTE SITUATION DE DÉPLACEMENT DE LA

CHARGE OU D’À-COUPS. ÉVITEZ LES MOUVEMENTS

SACCADÉS.

de l’utilisateur en matière de

DOIT VEILLER À CE QUE TOUT

914218-1012-C

Page 14

conformité au marquage CE

ENROULEMENT PAR LE DESSUS

DIRECTION DE

ROTATION

DANS LE SENS DE

L'ENROULEMENT

EXTRÉMITÉ

MOTEUR

ENROULEMENT

PAR LE DESSOUS

EXTRÉMITÉ

EMBRAYAGE

38

1. Fixez le treuil en suivant les instructions d’installation.

2. Placez le commutateur d’arrêt d’urgence en suivant les

instructions d’installation comprises avec le coffret de

commutateur d’arrêt d’urgence.

3. Posez le câble métallique recommandé de 10 mm (0,393 po)

de calibre 1960. Longueur de câble maximum de 21 m pour

trois couches maximum.

4. Fixez le câble au tambour en suivant les instructions

d’installation.

5. Utilisez un crochet qui comprend un verrou de sécurité et

possède une charge de rupture minimum de 87 kN.

Consignes de sécurité

A. Se tenir à une distance latérale de sécurité pendant le

treuillage.

B. Ne pas enjamber le câble sous charge, ni s’en approcher.

C. Ne pas tracter la charge accrochée au câble en déplacant le

véhicule. Ceci pourrait rompre le câble.

D. Se protéger les mains des ébarbures avec un chiffon épais ou

des gants lors de la manipulation du câble.

E. Caler les roues du véhicule lorsqu’il est sur un terrain en pente.

F. Le tambour doit être débrayé lorsque le treuil est en repos, et

embrayé à fond pendant le treuillage.

G. Toute manipulation du treuil dans le but de le modifier doit être

confiée à la société Ramsey Winch Company.

H. La durée des tractions doit être aussi courte que possible.

Si le moteur devient trop chaud au toucher, arrêter et le laisser

refroidir quelques minutes. Ne pas tirer pendant plus de deux

minutes à la capacité nominale de traction du treuil (ou proche

de celle-ci). Couper l’alimentation du treuil si le moteur cale.

Les treuils électriques sont étudiés pour un usage intermittent

et ne doivent pas rester en service continu.

I. Déconnecter la télécommande du treuil lorsqu’il est en repos.

J. Remarque : Ne pas utiliser le treuil pour le grutage : n’étant

pas fabriqué dans ce but, il n’est pas conforme aux normes

de sécurité pour les levages.

K. Le câble doit être un peu tendu pour bien se rembobiner.

Pour ce faire, il est nécessaire de tenir le câble (en portant des

gants) d’une main et la télécommande de l’autre. Commencer

à marcher en partant, autant que possible de l’arrière et en

restant au centre. Maintenir le câble tendu lors de la mise sous

tension du treuil. Ne pas laisser le câble glisser des mains et

ne pas s’approcher du treuil de trop près.

Ranger la télécommande à l’intérieur de votre véhicule pour ne

pas risquer de l’endommager ; l’inspecter avant de la brancher.

Vérifier que le tambour est débrayé avant de brancher la

télécommande pour enrouler le câble. Ne pas embrayer lorsque

le moteur tourne.

Ne jamais rattacher le crochet au câble, ce qui endommagerait ce

dernier. Toujours utiliser une sangle ou chaîne assez solide pour

résister à la tension exercée, comme sur l’illustration.

Ne pas fixer les crochets de remorquage à l’appareil de fixation du

treuil. Ils doivent se fixer au cadre du véhicule.

Lorsque deux câbles sont utilisés pour un treuillage fixe, le crochet

du treuil doit être fixé au châssis du véhicule.

Pose du câble

Le treuil comporte un logement effilé, moulé dans le

tambour, pour les applications avec enroulement par le

dessus ou par dessous.

1. Déroulez le câble sur le sol pour éviter qu’il ne se torde.

Recouvrez bien l’extrémité du câble opposée au crochet

d’un ruban adhésif plastique ou de type équivalent

pour éviter qu’elle ne s’effiloche.

2. Insérez le câble dans la partie étroite du logement,

contre la bride du tambour, enroulez-le autour du

« galet » d’ancrage, puis retirez le câble et l’ancrage

dans la partie large du logement. Utilisez un marteaucaoutchouc pour acheminer l’arrière du câble, en le

plaçant fermement avec l’ancrage dans le logement.

3.

Mise en garde : Assurez-vous que le câble s’enroule

dans la direction indiquée ci-dessous pour pour les

applications avec enroulement par le dessus ou par

dessous. Faites tourner avec précaution le treuil dans

le sens de l’enroulement. Maintenez une tension sur

l’extrémité du câble et enroulez tout le câble sur le

tambour en veillant à former des couches régulières.

Inspectez fréquemment le câble. Tout câble effiloché

ou comportant des brins brisés doit être remplacé

immédiatement.

Conseils de sécurité

L’enroulement irrégulier du câble lors de la traction d’une charge

ne présente pas de problème sauf en cas d’accumulation du

câble sur un côté du tambour. Dans ce cas, inversez le

fonctionnement du treuil afin de soulager la charge et déplacez

votre point d’attache vers le centre du véhicule. Une fois le travail

terminé, vous pouvez dérouler le câble et l’enrouler à nouveau

14

Page 15

Trucs et techniques

Le meilleur moyen de se familiariser avec le treuil est de faire

quelques marches d’essai avant d’en avoir réellement besoin.

Préparez l’essai. Ne pas oublier que l’on entend le treuil autant

qu’on le voit fonctionner. Il faut donc apprendre à reconnaître le

son d’une traction légère et régulière, celui d’une lourde charge

ou encore celui provoqué par des à-coups ou une déviation de

la charge. C’est en forgeant que l’on devient forgeron.

Non seulement votre treuil vous tire vers le haut d’une pente

abrupte ou vous facilite la descente d’une telle pente, mais il

tire aussi un autre véhicule ou une autre charge lorsque votre

véhicule est dans une position stationaire. Les croquis suivants

vous montrent certaines techniques.

Lorsque la charge tirée est lourde, placer une couverture, un

manteau ou une bâche sur le câble, à environ deux mètres du

crochet, pour absorber l’énergie en cas de rupture du câble.

Ouvrir également le capot du véhicule pour obtenir une protection

supplémentaire.

Utiliser la puissance des roues du véhicule pour aider le treuil

mais ne pas dépasser le câble du treuil. Préparer la traction. Il

n’est pas toujours possible d’accrocher et de tirer en une seule

étape. Étudier le terrain pour détecter les points d’ancrage

possibles, les conditions de traction, sa direction et son but.

Pour l’autodépannage de base, se fixer à un arbre ou à un

rocher lourd. Lors de la fixation à un arbre, toujours utiliser

un protecteur de tronc d’arbre.

Les pieux enfouis dans la terre ferme et attachés ensemble

à l’aide d’une chaîne constituent un bon point d’attache

pour l’auto-dépannage lorsqu’aucun point d’attache solide

n’est disponible.

Les treuils equipés de guide-câbles peuvent fournir de la

traction dans plusieurs directions. Tirer en maintenant une

inclinaison seulement pour redresser le véhicule. Dans le

cas contraire, il est possible d’endommager les parties

structurelles ou d’autres parties du véhicule et causer un

empilement de câble sur un côté du tambour du treuil.

Pour une traction directe de 1 tonne, fixer le véhicule à un

arbre ou à un point d’attache solide et débrayer.

Pour une attache solide, enfouir un rondin avec de la terre ou

du sable ou le placer dans un ravin profond.

Pour doubler la traction, utiliser un câble en 2 parties et

attacher au châssis. Débrayer.

15

Page 16

61,2 MM

2.41 PO

F-1

F-2

A

7.44 PO

188,8 MM

RETIREZ LES CHAPEAUX EN CAOUTCHOUC

DES RACCORDS DE DEGAGEMENT AVANT

D’UTILISER LE TREUIL.

2.50 PO

63,5 MM

1.12

28,5

FILETS PROFONDS

(CHAQUE COTE)

3/8-16 x 1 po

FILETS

PROFONDS

(CHAQUE

COTE)

FIXEZ LE CABLE DE MASSE NOIR

AU TREUIL AU MOYEN D’UN BOULON

DE FIXATION ICI.

3/8-16 x 0,75 po

257,2 MM

12.12 PO

63,5 MM

2.50 PO

3/8-16 x 0,50 po

FILETS PROFONDS

(CHAQUE COTE)

UTILISEZ UN BOULON DE

MONTAGE A TETE CREUSE SUR

LE COTE DE LA BOITE DE ROUE

DROITE CYLINDRIQUE.

Installation du treuil

REMARQUE : Le treuil doit être mounté sur des cornières de 9 x 63 x

63 mm au minimum, fabriquées en acier haute résistance de

344 000 kPa ou dans un châssis avec les deux côtés de la boîte

d’engrenages et du carter d’embrayage fixés sur les cornières ou

sur le châssis. Reportez-vous au schéma ci-dessous pour les

recommandations relatives aux dimensions.

Notez les diverses profondeurs de filet des trous de fixation et

utilisez des boulons de longueurs correspondantes pour un montage

correct.

Un remplacement des pièces de fixation (boulons, écrous ou rondelles)

par d’autres que celles fournies avec le coffret de montage de votre treuil

pourrait provoquer des défaillances susceptibles de causer des blessures

graves ou des dommages matériels. Utilisez un boulon de montage à tête

creuse sur le côté de la boîte de roue droite cylindrique (cf. schéma) pour

éviter les problèmes de dégagement. Utilisez des boulons d’une qualité au

moins équivalente à SAE grade 5.

Fonctionnement et branchements électriques

Le système électrique existant est adéquat pour tout travail d’autodépannage

normal. La batterie doit être maintenue en bon état (une batterie

complètement chargée et des branchements corrects sont essentiels).

Faites tourner le moteur du véhicule pendant les opérations de treuillage afin

de conserver la charge de la batterie.

Branchez le câble rouge du goujon du chapeau de solénoïde en plastique

du treuil sur le solénoïde d’arrêt d’urgence. Important : maintenez l’écrou

intérieur avec une clé plate tout en serrant l’écrou extérieur. Placez le

commutateur d’arrêt d’urgence et le solénoïde du coffret n° 282067 (12 V)

ou 282068 (24 V), selon le cas.

Reliez le câble noir du boulon de fixation du treuil le plus proche du tambour

(comme indiqué ci-dessous) à la borne négative de la batterie. Une bonne

connexion à la masse est nécessaire pour un fonctionnement correct.

Le commutateur de commande à distance est étanche et comporte des

postes de bouton-poussoir des deux côtés. Il est ainsi conçu pour éviter

les inversions rapides de sens de fonctionnement du treuil qui mènent à

une défaillance du solénoïde. Assurez-vous que le moteur du treuil s’est

entièrement arrêté avant toute inversion.

Lors de la première installation de votre treuil, suivez les indications

d’insertion des étiquettes d’enroulement et de déroulement du boutonpoussoir. Ce commutateur comporte également un code couleur afin de

vous aider à établir le sens de fonctionnement de votre treuil.

Entretien

Vérifiez tous les mois l’action du crabot baladeur et assurez-vous qu’il

s’enclenche sur le tambour du câble et s’en dégage complètement.

Avec l’embrayage enclenché, retirez le bouchon en plastique du haut du

carter et vérifiez si l’embrayage s’enclenche bien. S’il ne s’enclenche pas

à fond, examinez les pièces de l’embrayeur afin de déceler toute trace

de détérioration ou d’usure excessive, et procédez aux remplacements

éventuellement nécessaires. Observez les mâchoires de l’embrayage et du

tambour afin de déceler tout arrondissement des surfaces. Si elles se sont

arrondies, changez immédiatement les pièces.

Enroulez correctement le câble sur le tambour lors du stockage entre

chaque usage.

Vérifiez le niveau d’huile dans les boîtes d’engrenages tous les six mois.

Vérifiez en même temps les branchements électriques et les boulons de

fixation. Resserrez-les, le cas échéant.

La corrosion des connexions électriques compromet le rendement du treuil

ou risque de provoquer un court-circuit. Nettoyez tous les branchements,

surtout dans le boîtier du commutateur à distance. En milieux salins,

appliquer une pâte à base de silicone comme protection anticorrosion.

Remplacez l’huile tous les ans ou plus souvent en cas d’utilisation

fréquente. Remplissez la boîte d’engrenages à vis sans fin de 0,35 l de

Phillips SMP 80W-90, Mobil HD 80W-90 ou Shell Spirax HD 80W-90.

Utilisez 0,24 l de SAE 20 pour pour la boîte à engrenage droit. Appliquez

de la graisse consistante pour lubrifier le raccord en haut du carter

d’embrayage. Si le treuil a été immergé pendant un court instant,

vidangez l’huile, rincez les boîtes d’engrenages et remplacez l’huile, puis

graissez tous les raccords (cf. Guide de résolution des problèmes).

Pour réduire au minimum la corrosion des pièces internes du moteur,

susceptible de se produire en cas de condensation, faire régulièrement

fonctionner le treuil dans un sens ou dans l’autre. Le fonctionnement du

moteur produit de la chaleur qui dissipe l’accumulation d’humidité à ce

niveau. il est donc utile de faire tourner le moteur à intervalles réguliers

(par exemple, à chaque vidange d’huile du véhicule).

Le câble doit être lubrifié régulièrement avec de l’huile légère pénétrante.

Inspecter le câble et le remplacer s’il est éraillé. Installez le câble neuf selon

les instructions de la rubrique « Installation du câble », en page 14.

Mode d’emploi

L’embrayage semi-automatique RAM-LOK® permet d’enrouler librement et

d’enclencher l’embrayage avec le tambour du câble. Lorsque l’embrayage

est désenclenché, le câble peut être déroulé librement du tambour à la main.

Pour treuiller une charge, l’embrayage doit être complètement enclenché

sur le tambour. Désenclenchement de l’embrayage : Faites fonctionner

le treuil en marche arrière (déroulement) jusqu’à ce que la charge ne porte

plus sur le câble et que le tambour arrête de tourner. Tirez la poignée

d’embrayage vers l’extérieur, faites-la tourner de 90º dans le sens inverse

des aiguilles d’une montre, puis relâchez-la. L’embrayage est alors

supprimé et le câble peut être tiré à la main. (REMARQUE : si la poignée

d’embrayage ne peut pas être tirée, refaites fonctionner le treuil pendant un

court instant en arrière afin de relâcher la tension placée sur les griffes de

l’embrayage.) AVERTISSEMENT : N’ESSAYEZ PAS DE DÉSENCLENCHER

LE TAMBOUR DU CÂBLE LORSQU’IL Y A UNE CHARGE SUR LE CÂBLE.

Enclenchement de l’embrayage : Tirez la poignée vers l’extérieur, faites-la

tourner de 90º dans le sens des aiguilles d’une montre, puis relâchez-la.

Faites tourner le treuil en marche arrière jusqu’à ce que sa poignée se

réenclenche complètement ou jusqu’à ce que le tambour commence à

tourner. À ce point, assurez-vous que la poignée est complètement rentrée.

Il est possible de retirer le bouchon en plastique du haut afin de vérifier

si l’embrayage est bien enclenché. Une fois l’embrayage entièrement

enclenché, le treuil est prêt à enrouler le câble.

Ajustement du limiteur de charge nominale

1. Effectuez quelques tractions test avec le treuil (en utilisant une

cellule de charge ou une balance à ressort) pour determiner si

le commutateur est réglé sur la charge nominale souhaitée. Un

réglage acceptable est de

100 % à 125 % de la charge nominale.

2. Si la charge n’est pas comprise dans la plage ci-dessus, enlevez

le composé inviolable dans l’orifice fileté (au dessus des vis de

pression n°4). Enlevez la vis de pression du dessus.

3. Desserrez la la vis de pression du dessous d’envrion 2 tours dans

le

sens inverse des aiguilles d’une montre.

4. Pour réduire la traction du câble, mettez le commutateur n°1

dans la position « ENTRÉE » en tournant dans le sens des aiguilles

16

Page 17

d’une montre. Pour augmenter la traction du câble, mettez le

commutateur en position

« SORTIE ».

5. Après avoir atteint le réglage souhaité, serrez fermement la vis de

enlevé avant d’effectuer tout ajustement ultérieur.

Mesures à prendre au terme de la mise en

service du treuil

pression du dessous.

6. Replacez la vis de pression du dessous et serrez fermement.

Remplissez l’orifice fileté d’un matériau d’enrobement qui doit être

Lorsque le treuil est au terme de sa mise en service, éliminez-le en suivant

la réglementation locale sur l’environnement

Guide de résolution des problèmes

PROBLÈME POSSIBLE CAUSE CAUSE PROBABLE

LE MOTEUR NE

FONCTIONNE QUE

DANS UN SENS

LE MOTEUR SURCHAUFFE 1. Trop longue utilisation. 1. Il est indispensable d’observer des périodes de refroidissement pour éviter la

LE MOTEUR FONCTIONNE,

MAIS SANS LA PUISSANCE

SUFFISANTE OU À FAIBLE

VITESSE

LE TREUIL NE TIRE PAS LA

CHARGE NOMINALE

LE MOTEUR TOURNE, MAIS

PAS LE TAMBOUR

LE MOTEUR REFUSE DE

TOURNER

MOTEUR IMMERGÉ 1. Le moteur a été plongé dans l’eau ou a

L’EMBRAYAGE NE

FONCTIONNE PAS OU SE

GRIPPE

1. Solénoïde bloqué ou défaillant. 1. Faites coulisser le solénoïde pour libérer les contacts. Procédez à une

2. Télécommande défaillante. 2. Débrayez le tambour, débranchez la télécommande, puis établissez un pont

2. Tension de batterie insuffisante.

1. Câble électrique de la batterie vers

le treuil ou barette à la terre du bloc

moteur vers le châssis de véhicule trop

petit.

2. Mauvais branchements électriques.

3. Système de charge insuffisant.

1. Limiteur de charge nominale mal

ajusté.

1. Le tambour n’est pas embrayé. 1-4 Si l’embrayage est enclenché et que le problème persiste, il sera nécessaire de

2. Clavette d’arbre du tambour cisaillée.

3. Engrenage en bronze usé.

4. Arbre sectionné.

1. Solénoïde bloqué ou défaillant. 1. Faites coulisser le solénoïde pour libérer les contacts. Procédez à une

2. Télécommande défaillante. 2. Débrayez le tambour, débranchez la télécommande, puis établissez un pont

3. Panne du moteur.

4. Connexions lâches. 4. Serrez les connexions sur la partie inférieure du capot et sur le moteur.

traversé un poste de lavage haute

pression.

1. Arbre sec ou rouillé. 1. Nettoyez et lubrifiez.

2. Vis de pression à téton long trop serrée. 2. Retirez le bouchon en caoutchouc du carter d’embrayage et faites tourner

3. Fourchette courbée. 3. Remplacez la fourchette ou l’embrayeur.

vérification en appliquant 12 volts à la borne de bobine (un déclic doit se faire

entendre lors de la mise sous tension).

entre les broches à 8 et à 4 heures. Le moteur devrait tourner.

surchauffe.

2. Vérifiez la tension aux bornes de la batterie en cours de fonctionnement. Si elle est

inférieure ou égale à 10 volts, remplacez la batterie ou placez-en une deuxième en

parallèle.

1. Doit être de grade 2 ou équivalent ou plus si la longueur est supérieure à 4,5

m.

2. Vérifiez l’absence de corrosion au niveau de tous les branchements et assurezvous qu’ils sont bien serrés ; serrez, nettoyez et graissez.

3. Remplacer par un système de charge plus puissant.

1. Ajustez le limiteur de charge nominale en suivant les instructions aux pages 16

et 17.

démonter le treuil pour déterminer la cause du problème et réparer.

vérification

en appliquant 12 volts à la borne de bobine (un déclic doit se faire entendre

lors de

la mise sous tension).

entre les broches à 8 et à 4 heures. Le moteur devrait tourner.

3. Si les solénoïdes fonctionnent, vérifiez la tension à la borne de l’induit et remplacez

le moteur.

1. Laissez s’égoutter et séchez complètement, puis faites tourner à vide le moteur

par

à-coups pour faire sécher l’armature.

la vis de pression vers l’extérieur jusqu’à ce que l’embrayage fonctionne

correctement.

Reposez le bouchon en caoutchouc.

LE RESSORT DE L’EMBRAYAGE

NE FONCTIONNE PAS

L’EMBRAYAGE NE SE

BLOQUE PAS EN POSITION

DÉSENCLENCHÉE

FUITE D’HUILE AU NIVEAU

DU CARTER

4. Clavettes déformées par la surcharge. 4. Si les clavettes de l’arbre du tambour sont arrondies ou endommagées,

remplacez l’arbre et les clavettes. Sinon, limez les ébavurages et remplacez les

clavettes.

1. Ressort brisé. 1. Remplacez.

1. Vis de pression desserrée ou usée. 1. Retirez le bouchon en caoutchouc du carter d’embrayage, serrez la vis de

pression ou remplacez. Reposez le bouchon.

1. Joint d’étanchéité neuf. 1. Il arrive que les joints neufs fuient jusqu’à ce que qu’ils soient correctement

placés sur l’arbre.

2. Joint d’étanchéité endommagé ou usé. 2. Remplacez.

3. Trop d’huile. 3. Vidangez les excédents d’huile selon les instructions de lubrification.

4. Joint statique endommagé. 4. Remplacez.

17

Page 18

33

24

1

7

6

69

42

66

66

42

48

75

78

78

74

76

78

72

73

78

78

77

39

41

43

49

49

26

51

53

63

47

65

26

43

62

18

34

28

57

10

30

55

57

44

68

14

13

28

68

54

21

14

22

68

28

64

53

51

54

25

20

29

70

16

70

27

45

11

31

56

6

1

35

40

32

5

2

NON

INDIQUÉE

BOÎTE D’ENGRENAGES

LIMITEUR DE CHARGE

NOMINALE À SECTION

DISQUE DE BUTÉE

PALIER

ACTIONNEUR DE BUTÉE

COMMUTATEUR

COMMUTATEUR

CAPUCHON DE PALIER

VIS DE PRESSION

3

48

37

27

23

70

9

27

19

58

17

50

59

60

67

4

38

27

12

8

RE 34,9 SCHÉMA DES PIÈCES

18

Page 19

RE 34,9 LISTE DES PIÈCES

Nº Qté Nº réf. Description Nº

1 1 251110 COMMUTATEUR, 3,7 m LONG 39 3 418040 ÉCROU HEX, 3/8-24NF RÉG GALVANISÉ

2 1 282067 COMMUTATEUR E-STOP (12 V) (NON ILLUSTRÉ) 40 3 418154 RONDELLE-PLATE 1/4 ALUMINIUM

1 282068 COMMUTATEUR E-STOP (24 V) (NON ILLUSTRÉ)

3 1 262040 MOTEUR (12 V) 42 2 438014 SABOT D’APPUI

1 262038 MOTEUR (24 V) 43 2 442184 JOINT STATIQUE

4 1 276056 EMBRAYEUR 44 1 442185 JOINT STATIQUE

5 1 458108 SOLENOÏDE (24 V) 45 1 442205 JOINT STATIQUE

1 458005 SOLENOÏDE (12 V) 46

6 1 289015 FIL DE MONTAGE, CÂBLE DE BATTERIE, ROUGE 47 1 450005 CLAVETTE

7 1 289141 FIL DE MONTAGE, MASSE, NOIR 48 2 450006 CLAVETTE BARTH

8 1 434566 PLAQUE SIGNALÉTIQUE 49 4 450016 CLAVETTE BARTH

9 1 324137 EMBRAYAGE À GRIFFES 50 1 456001 RACCORD DE GRAISSAGE

10 1 328106 COUVERCLE - BOÎTE DE ROUE DROITE CYLINDRIQUE 51 2 456008 RACCORD DE DÉGAGEMENT

11 1 328134 COUVERCLE - BOÎTE D’ENGRENAGES 52

12 1 332251 TAMBOUR DE CÂBLE 53 2 468002 RÉDUCTEUR

13 1 334001 PIGNON FOU 54 2 468011 BOUCHON CYLINDRIQUE

14 2 334003 ROUE DROITE CYLINDRIQUE 55 2 468017 BOUCHON CYLINDRIQUE

15 56 1 468018 BOUCHON CYLINDRIQUE

16 1 334163 ENGRENAGE DROIT 57 2 470001 CHEVILLE DE CENTRAGE

17 1 336010 MANETTE D’EMBRAYEUR 58 1 470033 GOUPILLE SPIROL

18 1 338203 BOÎTE - ROUE DROITE CYLINDRIQUE 59 1 472012 BOUCHON

19 1 338208 CARTER - EMBRAYAGE 60 1 472013 BOUCHON

20 1 338273 BOÎTE - ENGRENAGES 61 1 482013 MANCHON

21 1 342033 CLAVETTE 62 1 486009 JOINT À HUILE

22 1 356901 TIGE - ROUE A DENTURE DROITE 63 1 486017 JOINT À HUILE

23 1 357484 ARBRE - TAMBOUR 64 1 486023 JOINT À HUILE

24 1 364029 BARRETTE 65 1 490003 CIRCLIP

25 1 368162 VIS SANS FIN DROITE 66 2 494002 RESSORT

26 2 402002 ROULEMENT À BILLE 67 1 494053 RESSORT

27 4 412003 BAGUE 68 3 518002 RONDELLE DE BUTÉE

28 3 412038 BAGUE 69 1 518014 RONDELLE DE BUTÉE

29 1 412040 BAGUE 70 2 518015 RONDELLE DE BUTÉE

30 12 414038

31 9 414045

32 3 414059

33 2 414279

34 4 414845

35 2 414856

36

37 1 416030

38 1 315008 GALET D’ANCRAGE DU CÂBLE

VIS D’ASSEMBLAGE, 1/4-20NC X 3/4, TÊTE HEX, gr. 5,

GALVANISÉE

VIS D’ASSEMBLAGE, 1/4-20NC X 1 TÊTE HEX, gr. 5,

GALVANISÉE

VIS D’ASSEMBLAGE, 1/4-20NC X 1 TÊTE HEX, gr. 5,

GALVANISÉE

VIS D’ASSEMBLAGE, 3/8-16NC X 3/4 TÊTE HEX, gr. 5 74 4 414857 VIS D’ASSEMBLAGE

VIS D’ASSEMBLAGE, 1/4-20NC x TÊTE CREUSE HEX,

NYLOK

VIS D’ASSEMBLAGE, 1/4-20NC X 3/4, TÊTE CREUSE HEX,

GALVANISÉE

VIS DE PRESSION, 1/4-20 X 3/8 TÊTE CREUSE HEX TÉTON

LONG

Qté Nº réf. Description

41 3 418177

71

72 1 282039 COMMUTATEUR

73 1 316093 CAPUCHON DE PALIER

75 2 416003 VIS DE PRESSION

76 1 462039 JOINT TORIQUE

77 1 518034 ACTIONNEUR DE BUTÉE

78 5 518035 DISQUE DE BUTÉE

RONDELLE DE SÉCURITÉ, 3/8 SECT. MOY.

GALVANISÉE

19

Page 20

Liste des pièces du solénoïde

7

11

2

21

21

17

18

7

4

11

21

4

3

17

3

5

18

6

5

21

9

3

1

15

10

13

10

14

20

9

19

15

8

8

Yellow

Red

Green

12

To Yellow

To Green

To Red

A

B

C

278170

2

78028

12V

24V

LISTE DES PIÈCES du Modèle DC 34,9 Ram-Lok®

Pièce Qté Nº réf. DescripƟon Pièce Qté Nº réf. DescripƟon

1 1 251110 COMMUTATEUR, 4 M (12 pi) LG 41 10 418177 RON DELLE DE SÉCURITÉ - 3/8 SE

282032 COMMUTATEUR À GRANDE CAPACITÉ,

4 M

42 2 438014 SABOT D'APPUI

2 1 282067 KIT DE COMMUTATEUR D'ARRÊT D'URGE

N

43 2 442184 JOINT STATIQUE

1 282068 KIT DE COMMUTATEUR D'ARRÊT D'URGE

N

44 1 442185 JOINT STATIQUE

3 1 262039 MOTEUR (12 V) 45 1 442205 JOINT STATIQUE

1 262038 MOTEUR (24 V) 46

4 1 276056 EMBRAYEUR 47 1 340023 CLAV ETTE

5 1 278028 SOLÉNOÏDE (24 V) 48 2 450006 CLAVETTE BARTH

1 278170 SOLÉNOÏDE (24 V) 49 4 450016 CLAVETTE BARTH

6 1 289015 FIL, CÂBLE DE BATTERIE, ROUGE 50 1 456001 RACCORD DE GRAISSAGE

7 1 289141 FIL, MASSE, NOIR 51 2 456008 RA CCORD DE DÉGAGEMENT

8 1 434568 PLAQUE SIGNALÉTIQUE 52

9 1 324160 EMBRAYAGE À GRIFFE 5

3 2 468002 RÉDUCTEUR

10 1 328106 COUVERCLE, BOÎTE D'ENGRENAGES CYLI

ND

54 2 468011 BOUCHON CYLINDRIQUE

11 1 328134 COUVERCLE - BOÎTE D'ENGRENAGES 55 2 468017 BOUCHON CYLINDRIQUE

12 1 332550 TAMBOUR-USINÉ, DC 34,9 W /PIÈCE DE

MO

56 1 468018 BOUCHON CYLINDRIQUE

13 1 334001 PIGNON FOU 57 2 470001 CHEVILLE DE CENTRAGE

14 2 334003 ROUE DROITE CYLINDRIQUE 58 1 470033 GOUPILLE SPIROL

15 59 1 472012 BOUCHON

16 1 334161 ENGRENAGE DROIT, RAPPORT DE 60/1. 60 1 472013 BOUCHON

17 1 336010 MANETTE D'EMBRAYEUR 61 1 482013 MANCHON

18 1 338203 BOÎTE D'ENGRENAGE CYLINDRIQUE 62 1 486009 J OINT À HUILE

19 1 338208 CARTER - EMBRAYAGE 63 1 486017 JOINT À HUILE

20 1 338273 BOÎTE - ENGRENAGES 64 1 4860

23 JOINT À HUILE

21 1 342033 CLAVETTE 65 1 490003 CIRCLIP

22 1 356901 TIGE, ROUE À DENTURE DROITE 66 2 494002 RESSORT

23 1 357479 ARBRE, TAMBOUR (STD) 67 1 494053 RESSORT

1 357481 ARBRE, TAMBOUR, ENTRÉE « Y » 68 3 518002 RONDELLE DE BUTÉE

25 1 368001

VIS SANS FIN DROITE. RAPPORT DE 60/1. V

69 1 518014 RONDELLE DE BUTÉE

26 2 402002 ROULEMENT À BILLES 70 2 518015 RONDELLE DE BUTÉE

27 4 412003 BAGUE 71

28 3 402001 BAGUE 72 1 282064 COMMUTATEUR

29 1 412045 BAGUE 73 1 316093 CHAPEAU DE PALIER

30 12 414038

VIS D'ASSEMBLAGE, 1/4-20NC X 0,75 po, TÊ

74 4 414857 VIS D'ASSEMBLAGE

414045 gALVA NISÉE

31 9 414059

VIS D'ASSEMBLAGE, 1/4-20NC X 1 po TÊTE H

75 2 416003 VIS DE PRESSION

32 3 414279

VIS D'ASSEMBLAGE, 1/4-20NC X 1 po TÊTE H

76 1 462039 JOINT TORIQUE

33 1

VIS D'ASSEMBLAGE, 3/8-16NC X 0,75 po TÊ

77 1 518034 ACTIONNEUR DE BUTÉE

GALVANISÉE

34 4 414845

VIS D'ASSEMBLAGE, 1/4-20 NC x 1 po, TÊTE

78 5 518035 DISQUE DE BUTÉE

35 2 414856

VIS D'ASSEMBLAGE, 1/4-20NC X 0,75 po, TÊ

79 1 302808 CORNIÈRE, STD.

GALVANISÉE

36 1 302811 CORNIÈRE, Y.

37 1 416030

VIS DE PRESSION, 1/4-20 X 3/8, TÊTE CREU

80 1 302809 CORNIÈRE, STD.

38 1 315008 GALET D'ANCRAGE DU CÂBLE 1 302810 CORNI ÈRE, Y.

39 3 418040 ÉCROU NORMAL, HEX 3/8-24NF GALVAN

IS

81 6 414282 VIS D'ASSEMBLAGE 3/8-16 NC x

40 3 418154 RONDELLE, 1/4, PLATE, ALUM. 82 1 414912 VIS D'ASSEMBLAGE 3/8-16 NC

X

278170 12 V

278028 24 V

Commutateur de

commande à distance

nº 251110

Guide-câble à

rouleaux nº 251183

Visserie incluse avec les coffrets de

montage

20

Page 21

TEST DES SOLÉNOÏDES

(CARTER

DU

MOTEUR)

FIL DE MASSE DU

SOLÉNOÏDE VERS

LE MOTEUR

(CARTER

DU

MOTEUR)

(BORNES DU DESSUS)

CÔTÉ

CÔTÉ

SOLÉNOÏDE

BATTERIE

MOTEUR

(+)

(-)

F1

F2

A

(PETIT)

(BORNES DU DESSUS)

CÔTÉ CÔTÉ

SOLÉNOÏDE

(PETIT)

BATTERIE

(+)

(-)

FIGURE 1

F

IGURE 2

SOLENOÏDE

VERS LA BATTERIE

B*

C*

A*

VERS L'INDUIT

* Reportez-vous à la section

Composants du solénoïde,

page 20, pour les

connexions des câbles A, B

et C aux solénoïdes.

Borne inductrice (A)

Borne de l'induit (B)

Borne inductrice (C)

FIL DE MASSE DU

SOLÉNOÏDE VERS

LE MOTEUR

F1

F2

A

Étapes à suivre pour tester le passage du courant continu

dans les solénoïdes.

Notez bien que lors du test d’un solénoïde de 12 ou de

24 volts, la batterie et le moteur fonctionnant sur courant

continu doivent avoir la même tension.

Test des solénoïdes (cf. figure 1).

1. Fixez fermement le moteur sur un établi ou une surface

de travail.

2. Fixez un fil de connexion temporaire de calibre 6 de la

borne (A) du moteur à une borne inductrice du moteur,

(F-2).

3. Fixez l’autre borne inductrice du moteur (F-1) à l’une des

bornes latérales du solénoïde.

4. Mettez le solénoïde à la masse sur le moteur, comme

indiqué sur le schéma.

5. Reliez le fil de batterie positif (+) à la borne du côté

opposé du solénoïde. Mettez le fil de batterie négatif

(–) à la masse sur le carter du moteur.

6. Mettez en contact le fil chargé, de la borne positive de la

batterie, avec la petite borne du solénoïde.

7. Si le solénoïde est en bon état, le moteur doit alors

fonctionner. Dans le cas contraire, assurez-vous que le

moteur fonctionne directement sur la batterie.

(cf. test de moteur, Page 22).

8. Pour tester les contacts supérieurs, utilisez le même

branchement mais avec les bornes du dessus

(cf. figure 2). Lorsqu’il est branché comme indiqué

dans la figure 2, le moteur doit commencer à fonctionner.

Lorsque le fil chargé entre en contact avec la petite borne, le

moteur cesse de fonctionner.

Les bornes supérieures sont normalement fermées ; (c.-à-d.

connectées), tandis que les bornes latérales sont ouvertes

(c.-à-d. non connectées). Lorsque le solénoïde fonctionne,

les bornes supérieures sont déconnectées et les bornes

latérales sont connectées.

Veillez à ne pas laisser de fils « chargés » entrer en contact

avec la masse afin de ne pas former d’arcs électriques.

21

Page 22

TEST DU MOTEUR

SENS

ANTIHORAIRE

SENS

HORAIRE

BATTERIE

(CARTER DU MOTEUR)

(BOBINES DE TIRAGE À

L'INTÉRIEUR DU MOTEUR)

MASSE

A

F2

F1

FIGURE 1

MOTEUR : ROTATION SENS HORAIRE

BATTERIE

(CARTER DU MOTEUR)

MASSE

FIGURE 2

MOTEUR : ROTATION SENS ANTIHORAIRE

PETITE BORNE

PETITE BORNE

VERS LA BORNE POSITIVE

DE LA BATTERIE

VERS LA BORNE POSITIVE

DE LA BATTERIE

MOTEUR

MOTEUR

SOLÉNOÏDE

SOLÉNOÏDE

SOLÉNOÏDE

SOLÉNOÏDE

MASSE

MASSE

FIGURE 3

CONNEXIONS DU SOLÉNOÏDE AU MOTEUR

LES LIGNES TIRETÉES REPRÉSENTENT L'ACHEMINEMENT DU

C

OURANT EN MARCHE AVANT. LES LIGNES CONTINUES

REPRÉSENTENT L'ACHEMINEMENT DU COURANT À TOUT MOMENT.

REMARQUE : LE SENS DE ROTATION DU MOTEUR DÉPEND DE LA

PETITE BORNE DE SOLÉNOÏDE RELIÉE À LA BORNE POSITIVE DE LA

BATTERIE.

LES LIGNES TIRETÉES REPRÉSENTENT L'ACHEMINEMENT DU

COURANT EN MARCHE ARRIÈRE. LES LIGNES CONTINUES

REPRÉSENTENT L'ACHEMINEMENT DU COURANT À TOUT MOMENT.

A

F2

F1

(BOBINES DE TIRAGE

À L'INTÉRIEUR DU MOTEUR)

A

F2

F1

A

F2

F1

moteur Ramsey Winch est un moteur à courant continu de

Le

12 ou 24 volts, à quatre pôles et quatre bobines enroulées.

Les quatre pôles et bobines permettent d’obtenir un couple

important à de faibles vitesses.

Pour tester ce moteur afin de déterminer s’il fonctionne

correctement, commencez par bien le fixer solidement sur un

établi ou sur une surface de travail afin qu’il ne risque pas de

bouger pendant le test (son couple de démarrage est élevé).

1. Branchez un fil de connexion temporaire (de calibre 6

minimum) des bornes F-1 à « A » du moteur

(cf. figure 1).

2. Reliez la borne de batterie positive (+) à la borne

de moteur F-2 au moyen d’un autre fil (de calibre 6

minimum). Mettez la borne négative de la batterie (–)

à la masse sur le carter du moteur (cf. figure 1).

Le moteur doit alors fonctionner.

Inversion du sens de rotationx

1. Reliez les bornes F-2 et « A » du moteur avec un fil

temporaire (cf. figure 2).

2. Reliez la borne positive (+) de la batterie à la borne F-1

du moteur. Mettez la borne négative de la batterie (–)

à la masse sur le carter du moteur (cf. figure 2).

REMARQUE : fixez toujours fermement le fil de la batterie

aux bornes du moteur. Effectuez et coupez la connexion de la

borne négative (–) de la batterie au niveau du carter du moteur,

ceci afin de ne pas risquer de griller les bornes du moteur.

MISE EN GARDE : NE FAITES PAS FONCTIONNER

LONGTEMPS LE MOTEUR DE CETTE MANIERE CAR CELA

RISQUERAIT DE L’ENDOMMAGER.

Un moteur tournant au ralenti sur un établi utilise 55 ampères.

Il doit tourner facilement et librement. Si la consommation est

supérieure à 60 ampères, et si le moteur tourne moins

facilement ou émet un bruit bizarre, il convient alors de le

remplacer.

Un moteur fixé sur un treuil (sans câble sur le tambour) doit

consommer environ 65 à 70 ampères.

Si, après avoir suivi la procédure indiquée, le test sur treuil

dépasse largement les 70 ampères, reportez-vous au manuel

de l’utilisateur pour les conseils de résolution des problèmes

sur la partie mécanique du treuil.

Reportez-vous à la figure 3 pour le branchement des

solénoïdes au moteur et à la batterie.

22

Page 23

Ramsey Winch Company

Modell

Elektrische Winde

RE 34,9 Benutzerhandbuch

English (Original Instructions) .. . . . . . . . . . . . . . . . . . . 1

Français

(Traduction des instructions originales) . . . . . .13

Deutsch (Übersetzung der Originalanleitung) . . . . . . . . . 23

Español (Traducción de las instrucciones originales) . . . 33

Umgebungstemperaturbereich -28

Lärmpegel

SEILLAGE 1 2 3

Nominale Zugkraft pro Lage

Kumulative Seilaufnahme pro Lage

(kurze Trommel)

Seilzugkraft, erste

Lage

*Seilgeschwindigkeit,

erste Lage, 12 V

*Seilgeschwindigkeit,

erste Lage, 24 V

Stromaufnahme

* Diese technischen Daten basieren auf dem empfohlenen Drahtseil (10 mm

Drahtstärke, Sorte 1960).

kN

lbs 2,000 4,000 6,000 7,840

m/min 6,1 2,9 2,1 1,6 1,3

Fuß/min 20 9,5 7 5,3 4,3

m/min 4,5 2,2 1,6 1,2 0,9

Fuß/min 15 7,5 5,5 4 3

12V 90 170 235 305 370

24V 36 75 105 140 170

kN 34,9 28,9 24,9

lbs 7,840 6,500 5,600

m 4 12 21

Fuß 15 40 70

Ohne

Last

8,8

17,7 26,6 34,9

°C bis 60 °C

80 dB

Verwendungszweck: Bergen von Fahrzeugen und Ziehen von

Lasten

RAMSEY WINCH COMPANY

Office Box 581510 Tulsa, Oklahoma 74158-1510 USA

Post

Phone: (918) 438-2760 Fax: (918) 438-6688

Visit us at http://ww.ramsey.com

Ramsey Bevollmächtigter in der Europäischen

Union

(Bitte

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

nur bei Regulierungsfragen kontaktieren.)

INHALTSVERZEICHNIS

Verantwortung

CE-Konformität . . . . . . . . . . . . . . . . . . . . . . . . .

Vorsichtsmaßnahmen . . . . . . . . . . . . . . . . . . . .25