Page 1

Features

• Programmable DMUX Ratio:

– 1:4: Data Rate Max = 1 Gsps

– PD (8b/10b) < 4.3/4.7 W (ECL 50Ω output)

– 1:8: Data Rate Max = 2 Gsps

– PD (8b/10b) < 6/6.9 W (ECL 50Ω output)

– 1:16 with 1 TS8388B or 1 TS83102G0B and 2 DMUX

• Parallel Output Mode

• 8-/10-bit

• ECL Differential Input Data

• DataReady or DataReady/2 Input Clock

• Input Clock Sampling Delay Adjust

• Single-ended Output Data:

– Adjustable Common Mode and Swing

– Logic Threshold Reference Output

– (ECL, PECL, TTL)

• Asynchronous Reset

• Synchronous Reset

• ADC + DMUX Multi-channel Applications:

– Stand-alone Delay Adjust Cell for ADCs Sampling Instant Alignment

• Differential Data Ready Output

• Built-in Self Test (BIST)

• Dual Power Supply V

• Radiation Tolerance Oriented Design (More than 100 Krad (Si) Expected)

• TBGA 240 (Cavity Down) Package

= -5V, VCC = +5V

EE

DMUX 8-/10-bit

2 GHz 1:4/8

TS81102G0

Description

The TS81102G0 is a monolithic 10-bit high-speed (up to 2 GHz) demultiplexor,

designed to run with all kinds of ADCs and more specifically with Atmel’s high-speed

ADC 8-bit 1 Gsps TS8388B and ADC 10-bit 2 Gsps TS83102G0B.

The TS81102G0 uses an inn ovative architecture, including a sampling delay adjust

and tunable output levels. It allows users to process the high-speed output data

stream down to processor speed and uses the very high-speed bipolar technology (25

GHz NPN cut-off frequency).

Rev. 2105C–BDC–11/03

1

Page 2

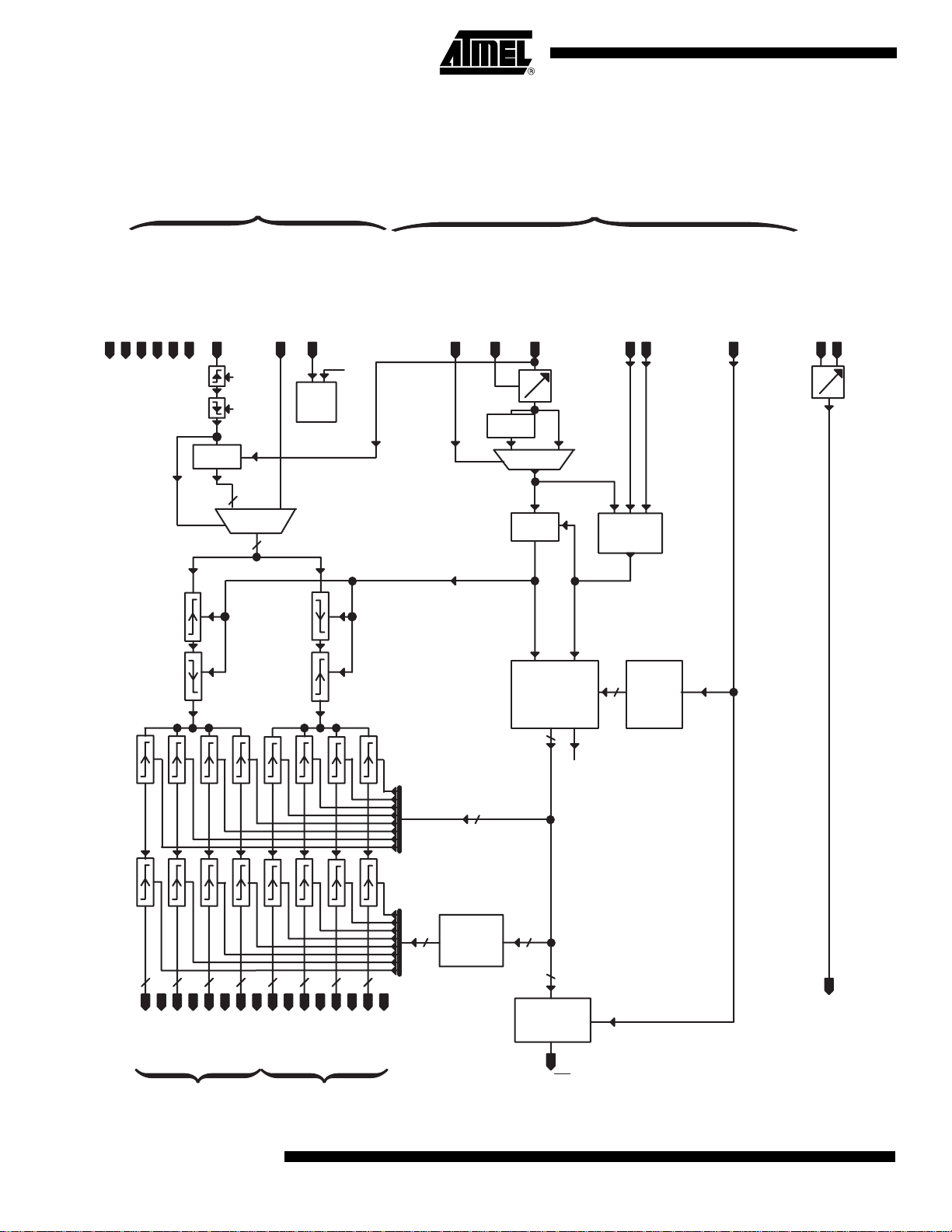

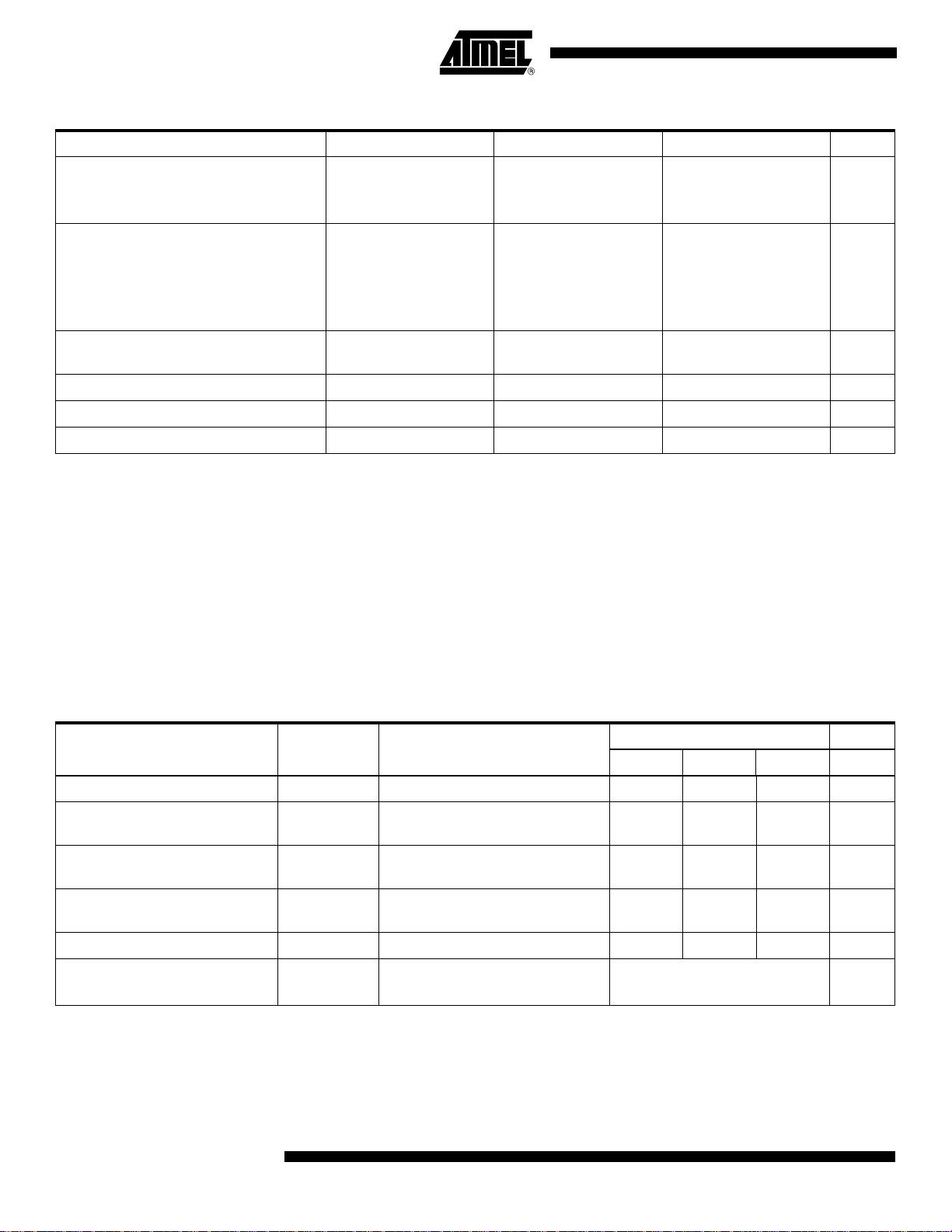

Block Diagram

Figure 1. Block Diagram

Data Path Clock Path

SwiAdj

VplusDOut

VCC

even

master

latch

even

slave

latch

GND

VEE

DIODE

BIST

8/10

BIST

8/10

FS/8

mux

I[0..7/9]

odd

master

latch

odd

slave

latch

NbBit

NAP

RatioSel

DEMUXDelAdjCtrl

ClkInType

B 2

Phase

control

ClkPar

shift register)

Port Selection Clock

8

ClkIn

delay

mux

Counter

(8 stage

8

FS/8

AsyncReset

SyncReset

(to be confirmed)

RstGen

Reset

8

Counter

Status

RatioSel

ADCDelAdjCtrl

ADCDelAdjIn

delay

Latch Sel Even/Odd [1..8/10]

Data

8

Output

Clock

8/10

A[0..7/9]

C[0..7/9]

E[0..7/9]

G[0..7/9]

B[0..7/9]

D[0..7/9]

F[0..7/9]

RefA

RefC

RefE

RefG

RefB

RefD

Even Ports Odd Ports

2

TS81102G0

H[0..7/9]

RefF

RefH

1

3

DataReady

generation

DR/DR

ADCDelAdjOut

2105C–BDC–11/03

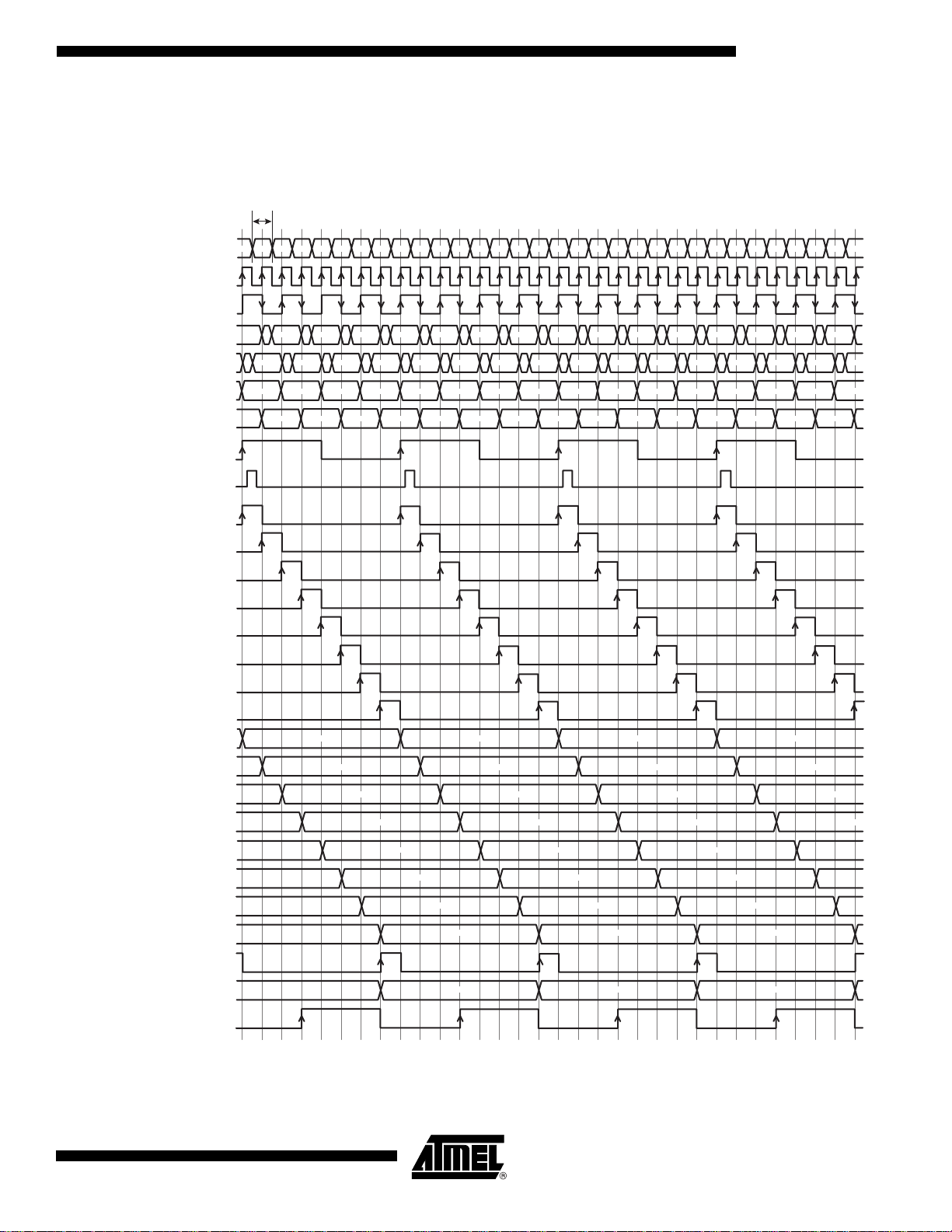

Page 3

TS81102G0

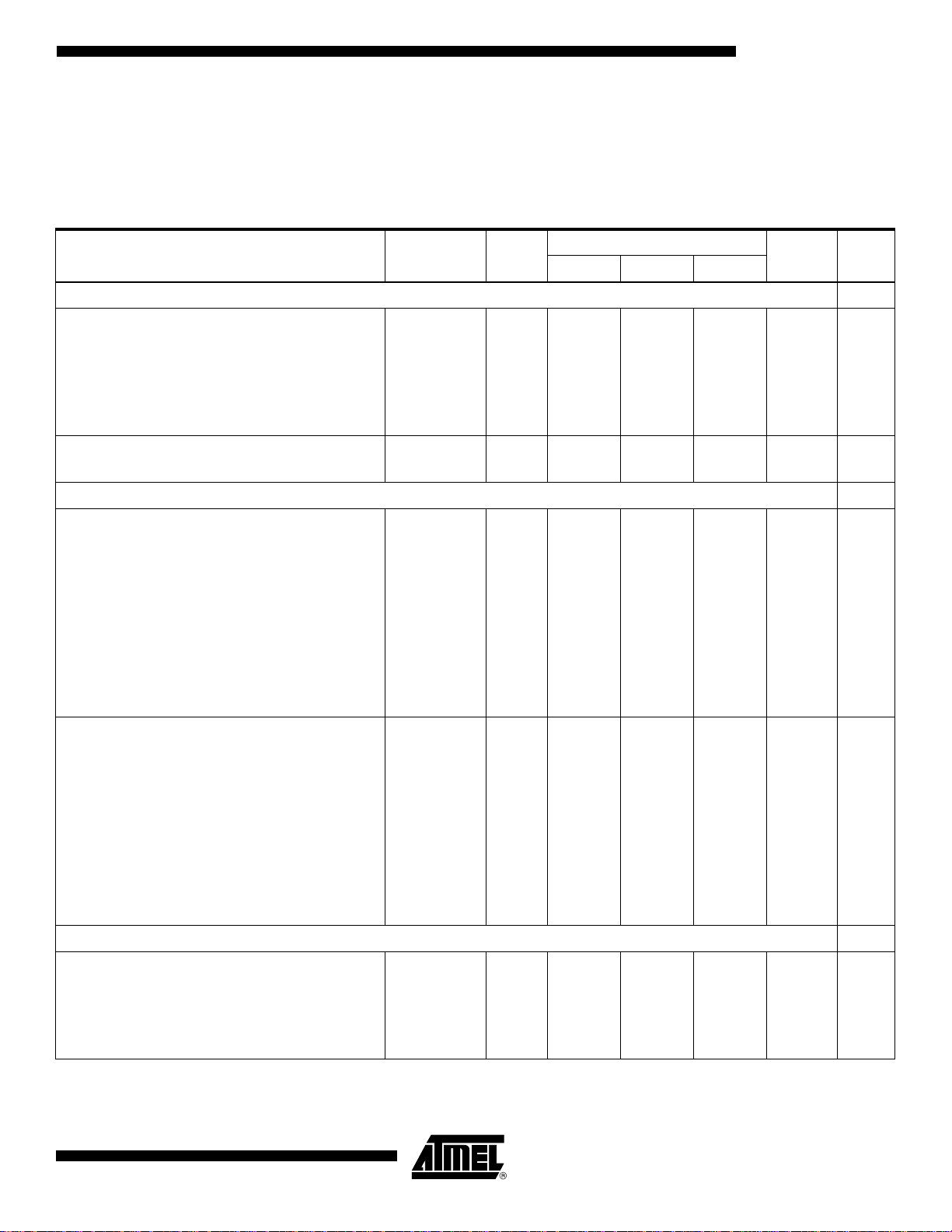

Internal Timing

This diagram corresponds to an established opera tion of the DMUX with Synchronous Reset.

Diagram

Figure 2. Internal Timing Diagram

500 ps min

N N+2 N+3 N+4 N+5 N+6 N+7 N+8 N+9 N+10 N+11 N+12 N+13 N+14 N+15 N+16 N+17 N+18 N+19 N+20 N+21 N+22 N+23 N+24

Data In

DR In = Fs

DR/2 In = Fs/2 = ClkPar

Master Even Latch

Master Odd Latch

Slave Even Latch

Slave Odd Latch

Synchronous reset = Fs/8

Internal reset pulse

Port Select A

Port Select B

Port Select C

N+1

N+1 N+31

N

N+1

N+25 N+26 N+27 N+28 N+29 N+30 N+31

N+24 N+26 N+28 N+30N+14 N+16 N+18 N+20 N+22N+6 N+8 N+10 N+12N N+2 N+4

N+3 N+5 N+7 N+9 N+11 N+13 N+15 N+17 N+19 N+21 N+23 N+25 N+27 N+29

N+2

N+4

N+6

N+8

N+10

N+12

N+14

N+16

N+18

N+20

N+22

N+24

N+26

N+3

N+5

N+7

N+9

N+11

N+13

N+15

N+17

N+19

N+21

N+23

N+25

N+27

N+28

N+30

N+29

Port Select D

Port Select E

Port Select F

Port Select G

Port Select H

Latch Select A

Latch Select B

Latch Select C

Latch Select D

Latch Select E

Latch Select F

Latch Select G

Latch Select H

A to H Port Out

A to H LatchOut

DROut

N N+8 N+16 N+24

N+1 N+9 N+17 N+25

N+2 N+10 N+18 N+26

N+3 N+11 N+19 N+27

N+4 N+12 N+20

N+5 N+13 N+21

N+6 N+14 N+22

N+7 N+15 N+23

N to N+7 N+8 to N+15 N+16 to N+23

2105C–BDC–11/03

3

Page 4

Functional

Description

The TS81102G0 is a demultiplexer based on an advanced high-speed bipolar technology featuring a cutoff frequency of 25 GHz. Its role is to reduce the data rate so that the data can be

processed at the DMUX output.

The TS81102G0 provides 2 programmable ratios: 1:4 and 1:8. The maximum data rate is 1

Gsps for the 1:4 ratio and 2 Gsps for the 1:8 ratio.

The TS81102G0 is able to process 8 or 10-bit data flows.

The input clock can be an ECL differential signal or single-ended DC cou pled signal. Mo reover

it can be a DataReady or DataReady/2 clock.

The input digital data must be an ECL differential signal.

The output signals (Data Ready, digital data and reference voltage) are adjustable with

VplusD independent power supply. Typical output modes are ECL, PECL or TTL.

The Data Ready output is a differential signal. The digital output data and reference voltages

are single-ended signals.

The TS81102G0 is started by an Asynchronous Reset. A Synchronous Reset enables the

user to re-synchronize the output port selection and to minimize loss of data that could occur

within the DMUX.

A delay adjust cell is available to ensure a good phase between the DMUX’ input clock and

input data.

Another delay adjust cell is available to contro l the ADCss sampling instant alignment, in case

of the ADCs interleaving.

A 10-bit generator is implemented in the TS81102G0, the Built-In Self Test (BIST). This test

sequence is very useful for testing the DMUX at first use.

A fine tuning of the output swing is also available.

The TS81102G0 can be used with the following Atmel ADCs:

• TS8388B(F/FS/GL), 8-bit 1 Gsps ADC

• TS83102G0B, 10-bit 2 Gsps ADC

4

TS81102G0

2105C–BDC–11/03

Page 5

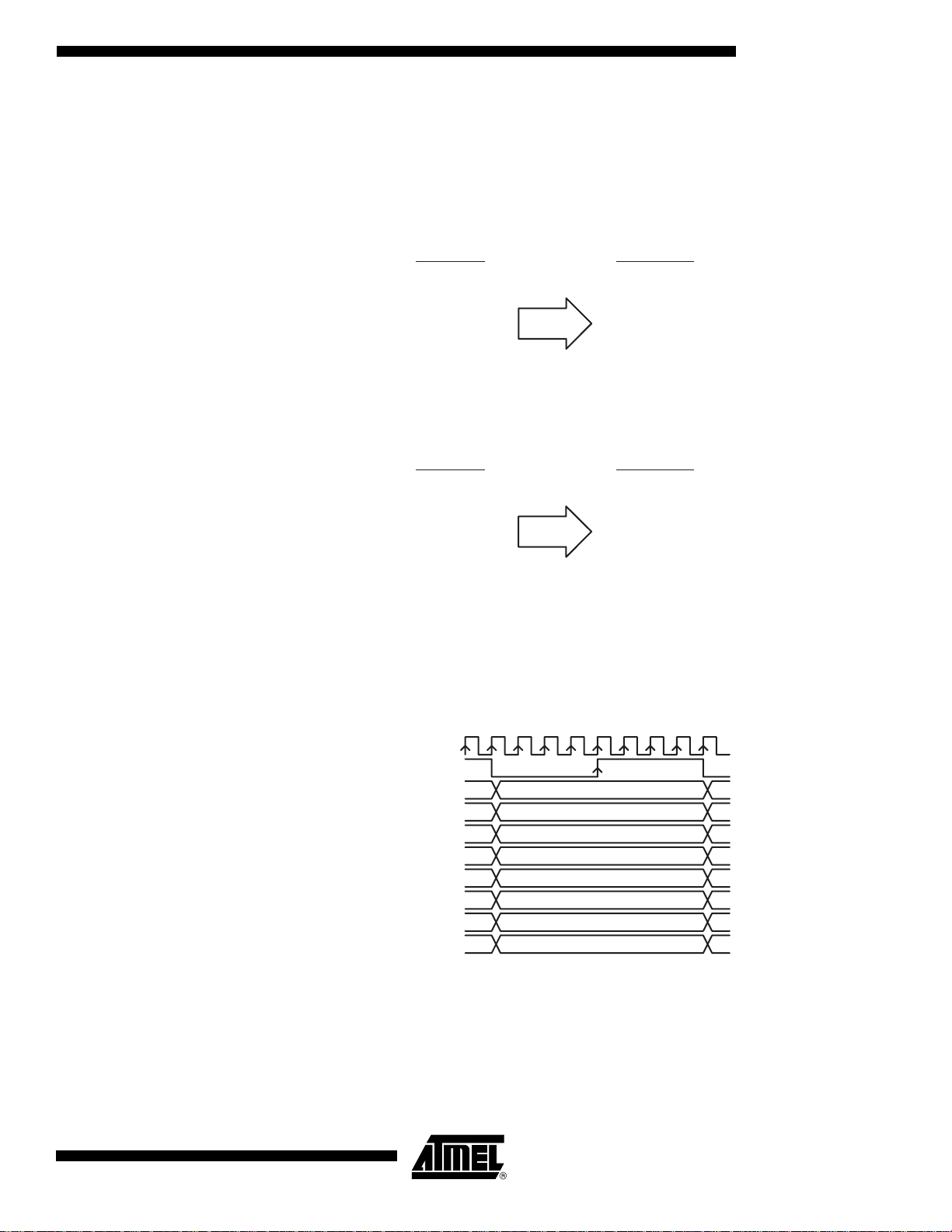

Main Function

Description

TS81102G0

Programmable

DMUX Ratio

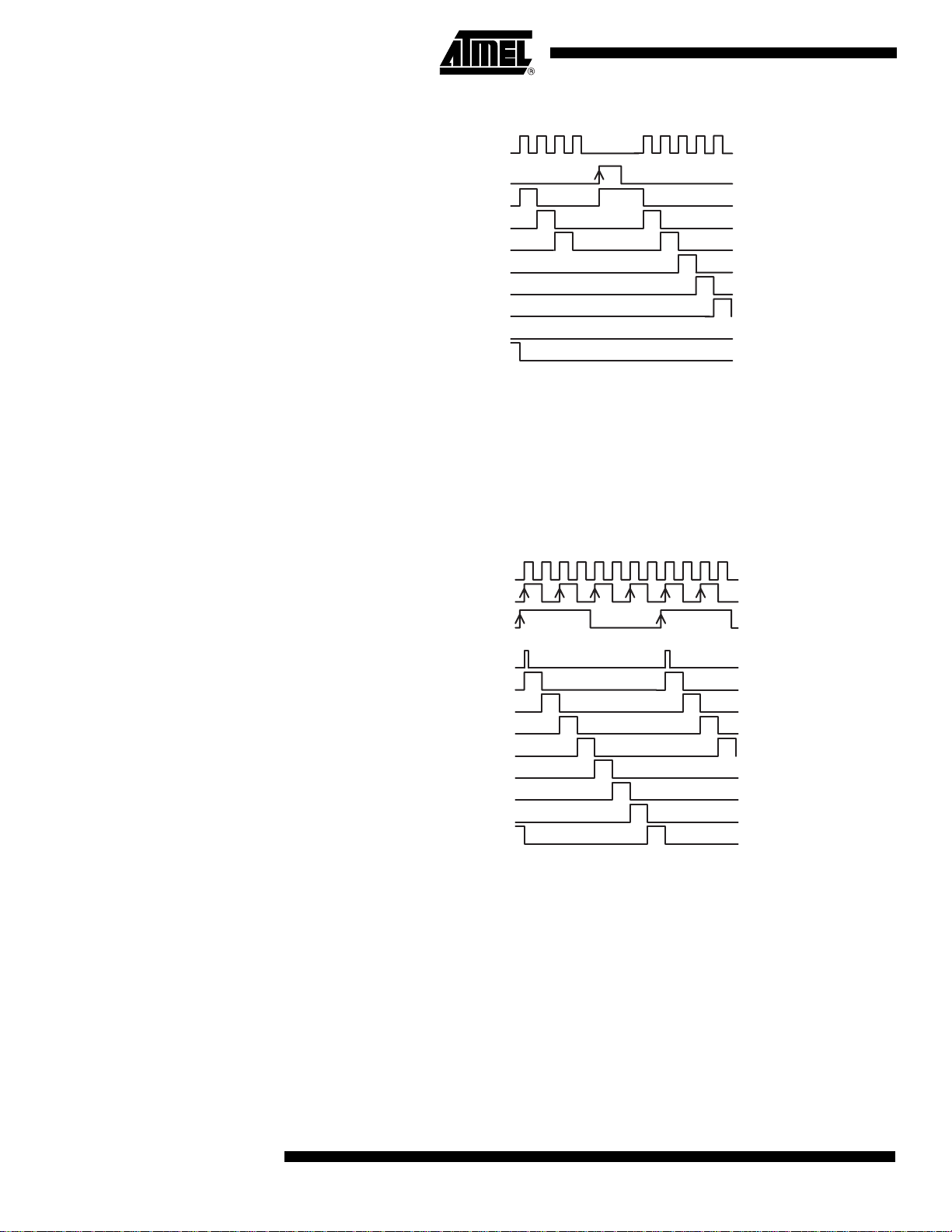

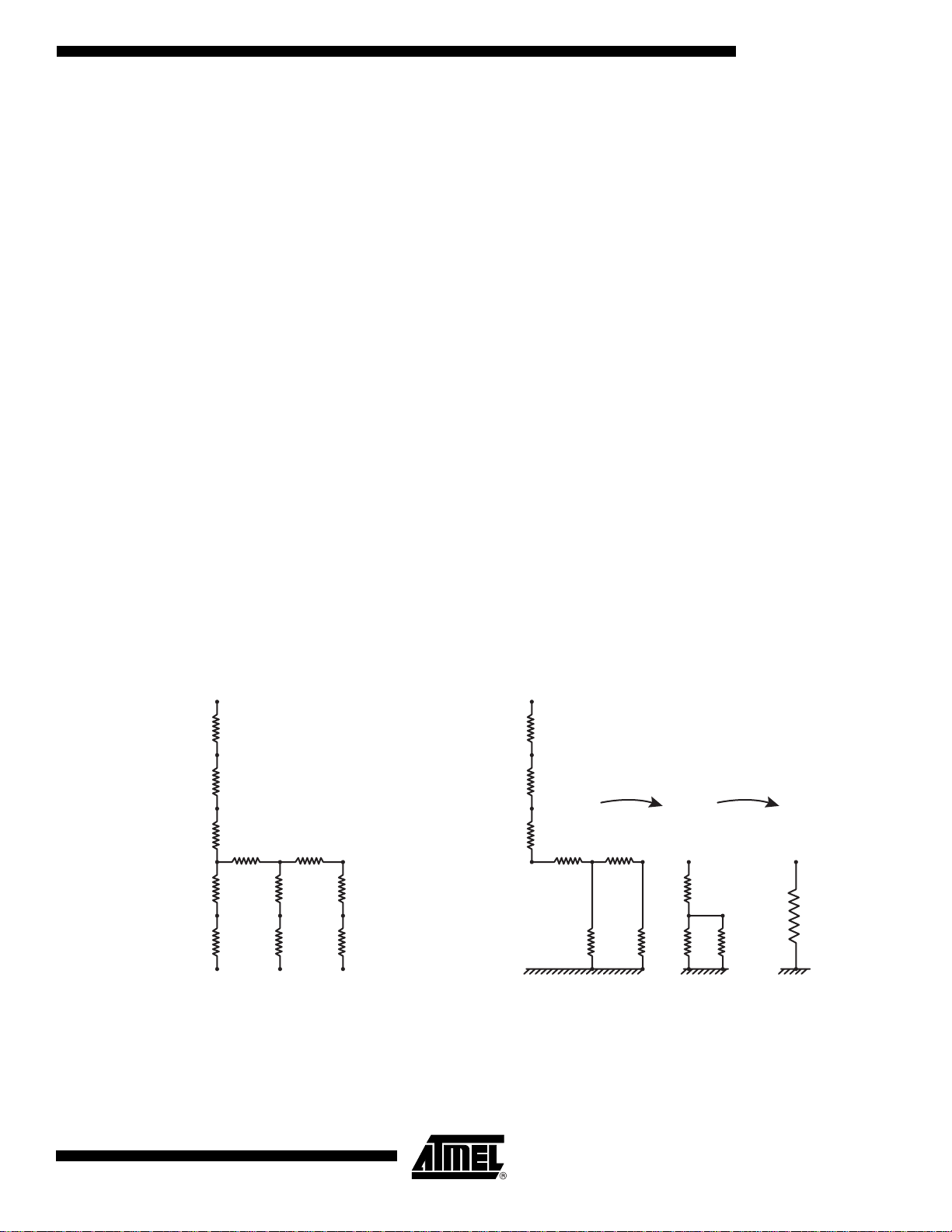

The conversion ratio is programmable: 1:4 or 1:8.

Figure 3. Programmable DMUX Ratio

Input Words:

1,2,3,4,5,6,7,8,...

1:4

Input Words:

1,2,3,4,5,6,7,8,...

1:8

Output Words:

PortA

PortB

PortC

PortD

PortE

PortF

PortG

PortH

Output Words:

PortA

PortB

PortC

PortD

PortE

PortF

PortG

PortH

1

2

3

4

not used

not used

not used

not used

1

2

3

4

5

6

7

8

5

6

7

8

9

10

11

12

13

14

15

16

...

...

Parallel Output

Mode

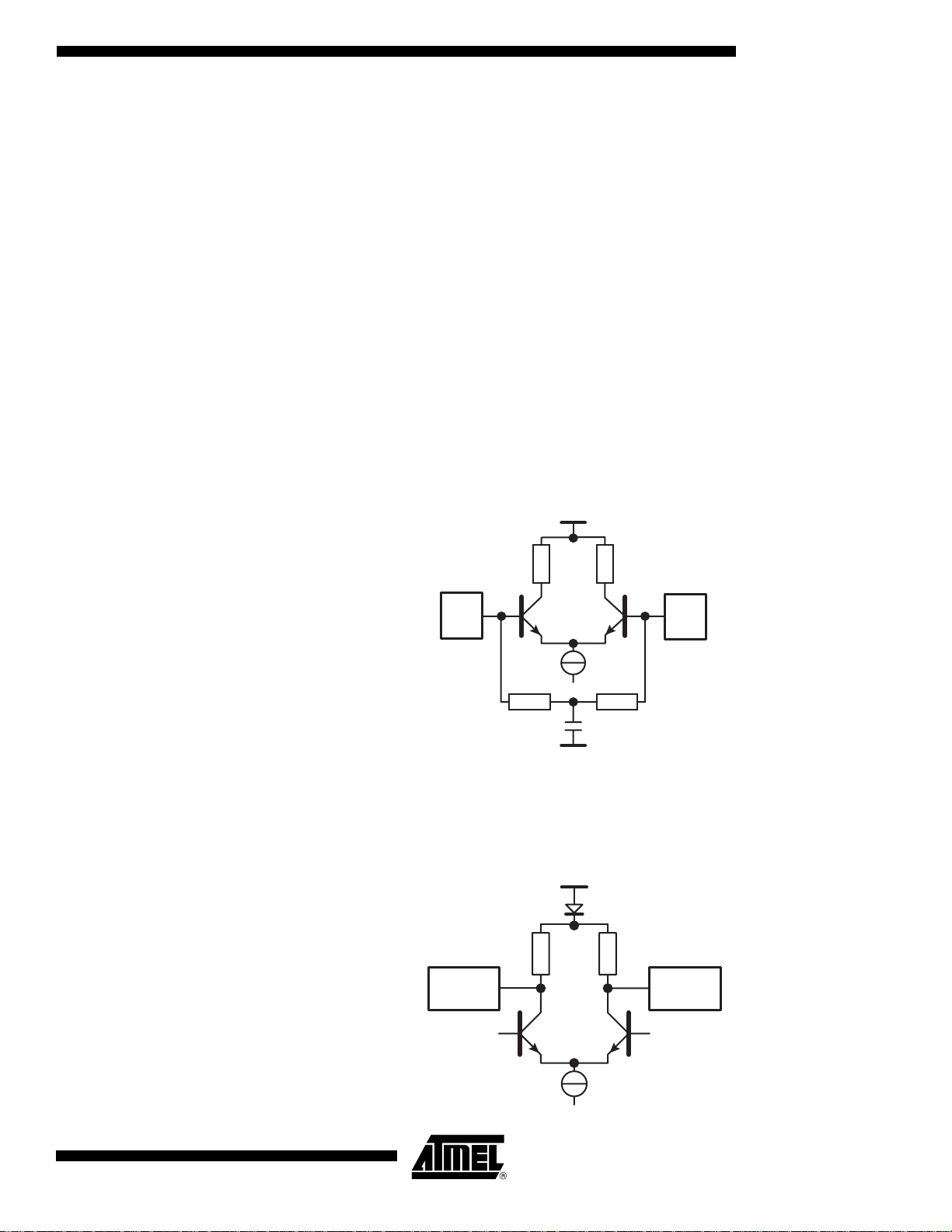

Figure 4. Parallel Mode

ClkIn

DR

PortA

PortB

PortC

PortD

PortE

PortF

PortG

PortH

Input Clock Sampling Delay Adjust (DEMUXDELADJCTRL)

The input clock phase can be adjusted with an adjustable delay (from 250 to 750 ps). This is to

ensure a proper phase between the clock and input data of the DMUX.

2105C–BDC–11/03

N

N+1

N+2

N+3

N+4

N+5

N+6

N+7

5

Page 6

Asynchronous

Reset

(ASYNCRESET)

Figure 5. Asynchronous Reset

CLKIN

AsyncReset

Port A selected

Port B selected

Port C selected

Port D selected

Port E selected

Port F selected

Port G selected

Port H selected

The Asynchronous Reset is a master reset of the port selection, which works on TTL levels. It

is active on the high level. During an asynchronous reset, the clock must be in a known state.

It is used to start the DMUX.

When it is active, it paralyzes the outputs (the out put clock and output d ata remain at the same

level as before the asynchronous reset). When it comes back to its low leve l, the DMUX star ts:

the outputs are active and the first processed data is on port A.

Synchronous

Reset

(SYNCRESET)

Figure 6. Synchronous Reset

FS

DR/2

SyncReset = FS/8

Internal reset

pulse

Port A selected

Port B selected

Port C selected

Port D selected

Port E selected

Port F selected

Port G selected

Port H selected

The DMUX can be synchronously reset to a programmable state dependin g on the conversion

ratio. The clock must not be stopped during reset. The synchronizat ion signal is a clock

(SyncRest) whose frequency is FS/8*n where n is an integer (n = 1,2,3,…) in 1:8 mode and

FS/4*n in 1:4 mode. The front edge of this clock is synchronized with Clkln inside the DMUX,

and generates a 200 ps reset pulse. This reset pulse occurs during a f ixed level of Clkln.

If the DMUX was synchronized with Syncreset previous to a possible loss of synchronization,

then the output data is immediately corre ct, no modification can b e seen at the output o f the

DMUX, and no data is lost (“Internal Timing Diagram” on page 3).

If the DMUX was not synchronized with SyncReset previous to a possible lo ss o f syn chronization, then the output data and data r eady of the DM UX are chang ed. The outp ut data is corr ect

after a number of input clocks corresponding to the pipe line delay (“Timing Diagr ams with Synchronous Reset” on page 19).

6

TS81102G0

2105C–BDC–11/03

Page 7

TS81102G0

Counter

Programmable

State

When the counter is reset, its initial states depends on the conversion ratio:

• 1:8: counting on 8 bits,

• 1:4: counting on 4 bits.

Pipeline Delay The maximum pipeline delay depends on the conversion ratio:

• 1:8: pipeline delay = 7

• 1:4: pipeline delay = 3

8-/10-bit, with NAP

Mode for the 2

The DMUX is a 10-bit parallel device. The last two bits (bits 8 and 9) may not be used, a nd the

corresponding functions are set to nap mode to reduce power consumption.

Unused Bit

ECL Differential

Input Data

Input data are ECL compatible (Voh = -0.8V, Vol = -1.8V).

The minimum swing required is 100 mV differential.

All inputs have a 100Ω differential termination resistor. The middle point of these resistor s is

connected to ground through a 10 pF capacitor.

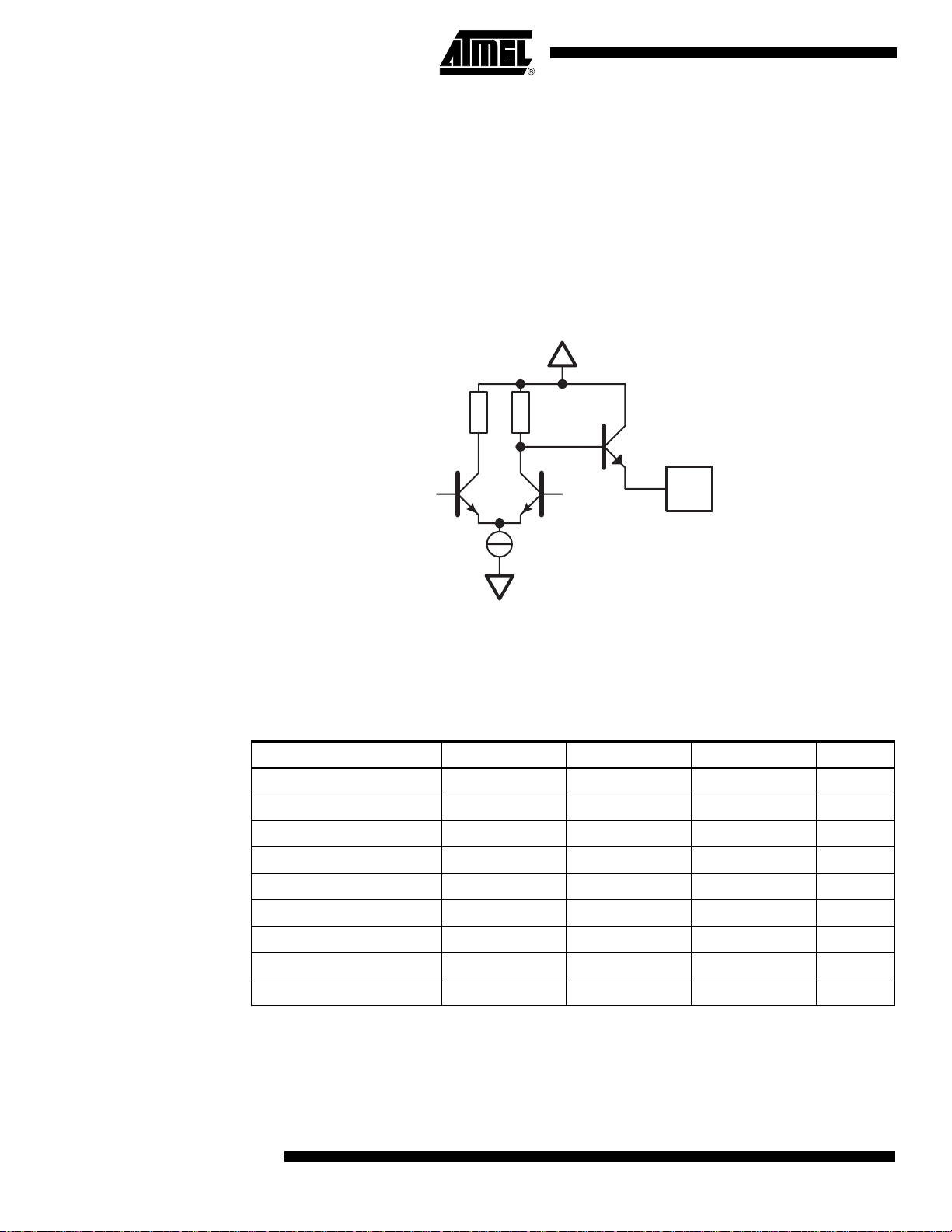

Figure 7. ECL Differential Input Data

Gnd

50Ω Differential

Output Data

ClkIn ClkInb

50Ω 50Ω

10 pF

The output clock for the ADC is generate d th ro ug h a 50Ω loaded long tailed. The 50Ω resistor

is connected to the ground pad via a diode. The levels are (on the 100Ω differential termination resistor): Vol = -1.4V, Voh = -1.0V.

Figure 8. 50Ω Differential Output Data

Gnd

50Ω

ADCDelAdjOut

50Ω

ADCDelAdjOutb

2105C–BDC–11/03

7

Page 8

Single-ended

Output Data

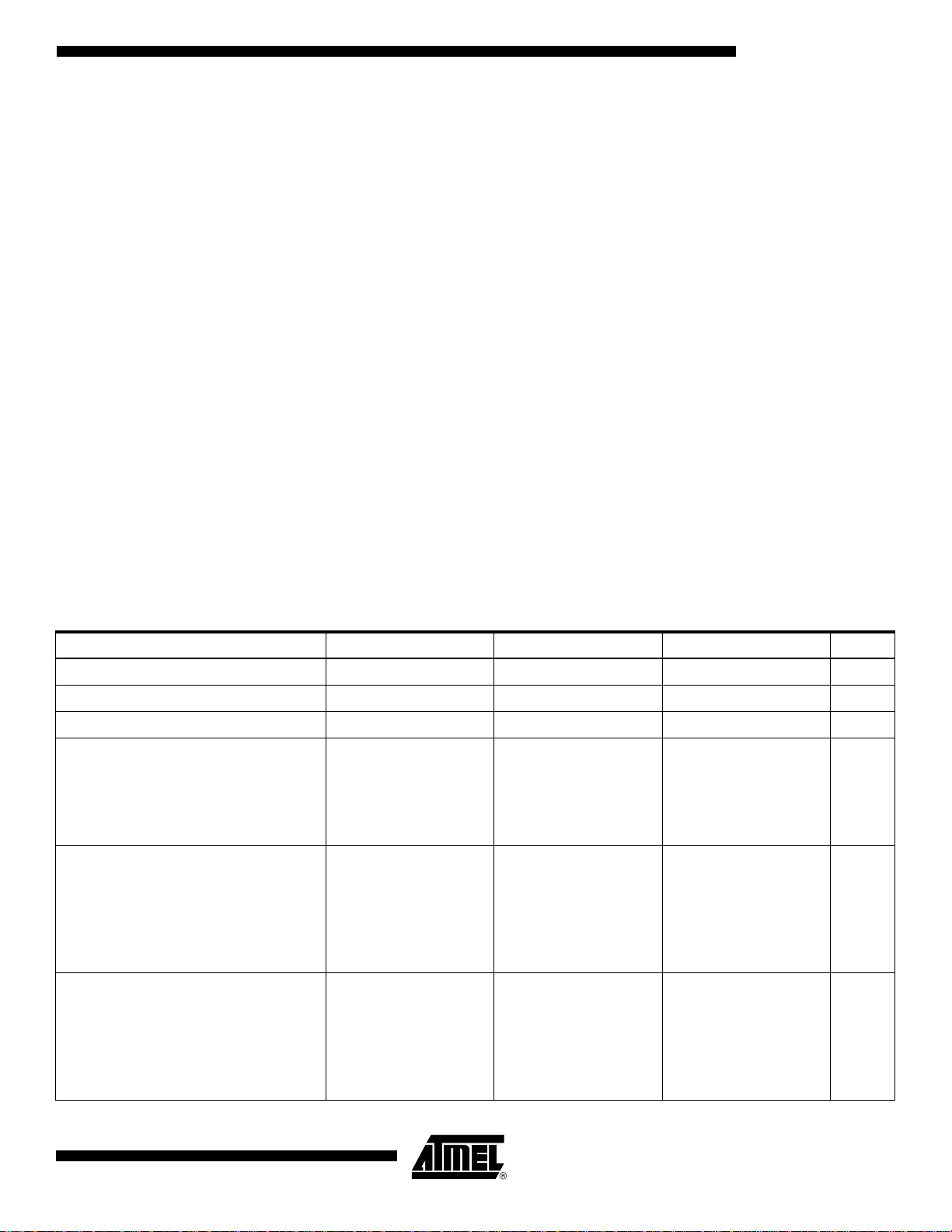

To reduce the pin number and power consumption of the DMUX, the eight output ports are

single-ended.

To reach the high frequency output (up to 250 MHz) with a reasonable power consumption,

the swing must be limited to a maximum of ±500 mV. The common mode is adjustab le from

-1.3V to +2V, with Vplus DOut pins. To ensure better noise immunity, a reference level (common mode) is available (one level by output port).

The output buffers are of ECL type (open emitters – not resistive adapted impedances). They

are designed for a 15 mA average output current, and may be used with a 50Ω termin ation

impedance.

Figure 9. Single-ended Output Data

VPlusDOut

PadOut

Vee

Following are three application examples for these buffers: ECL/PECL/TTL. Please note that it

is possible to have any other odd output format as far as current (36 mA max) and voltage

(Vplus Dout – V

≤ 8.3V) limits are not overrid den. The maximum frequency in TTL output

EE

mode depends on the load to be driven.

Table 1. Examples of Application of Buffers

Parameter ECL PECL TTL Unit

VplusDout 0 3.3 3.3 V

Vtt -2 1.3 0 V

Swing ±0.5 ±0.5 ±1 V

Reference -1.3 2 1.5 V

Voh -0.8 2.5 2.5 V

Vol -1.8 1.5 0.5 V

Load 50 50 ≥75 Ω

Average Output Current 14 14 15 mA

Output Data rate max. 250 250 250 Msps

This corresponds to the “Adjustable Logic Single” in the pinout description.

The “Adjustable Single” buffers for reference voltage are the same buffers, but the information

available at the output of these buffers is more like analog than logic.

Note: The Max Output Data Rate is given for a typical 50Ω/2 pF load.

8

TS81102G0

2105C–BDC–11/03

Page 9

TS81102G0

Differential Data

Ready Output

Built-in Self Test

(BIST)

Specifications

Absolute

Maximum Ratings

The front edge of the DataReady output occurs when data is available on the correspo nding

port. The frequency of this clock depends on the conversion ratio (1: 8 or 1:4), with a dut y cycle

of 50%.

The definition is the same as for single-ended output data, but the buffers are differential.

This corresponds to the “Adjustable Logic Differential” in the pinout description.

A pseudo-random 10-bit generator is impleme nted in t he DMUX. It generat es a 10-bit signal in

the output of the DMUX, with a period of 512 input clocks. The probability of occurrence of

codes is uniformly spread over the 1024 possible codes: 0 or 1/1024.

Note that the 256 codes of bits 1 to 8 occur at least once. They start with a BIST command, in

phase with the FS/8 clock on Port A. The logic output obt ained on the A to H ports depend s on

the conversion ratio. The driving clock of BIST is Clkln. The ClklnType must be set to ‘1’

(DataReady ADC clock) to have a different 10-bit code on each output.

The complete BIST sequence is available on request.

Table 2. Absolute Maximum Ratings

Parameter Symbol Comments Value Unit

Positive supply voltage V

Positive output buffer supply voltage V

Negative supply voltage V

Analog input voltages ADCDelAdjCtrl,

ECL 50Ω input voltage Clkln or Clklnb or

Maximum difference between ECL 50Ω

input voltages

CC

PLUSD

EE

ADCDelAdjCtrlb or

DMUXDelAdjCtrl,

DMUXDelAdjCtrlb or

SwiAdj

I[0…9] or I[0…9]b or

SyncReset or

SyncResetb or

ADCDelAdjln or

ADCDelAdjlnb

Clkln – Clklnb or

I[0…9] - I[0…9]b or

SyncReset –

Syncresetb or

ADCDelAdjln ADCDelAdjlnb

Voltage range for each

pad

Differential voltage

range

Voltage range for each

pad

Minimum differential

swing

Maximum differential

swing

GND to 6 V

GND to 4 V

GND to -6 V

-1 to +1

-1 to +1

-2.2 to +0.6 V

0.1

2

V

V

2105C–BDC–11/03

9

Page 10

Table 2. Absolute Maximum Ratings (Continued)

Parameter Symbol Comments Value Unit

Data output current A[0…9] to H[0…9] or

RefA to RefH or

DR or DRb

Maximum current 36 mA

TTL input voltage Clkln Type

GND to V

CC

V

RatioSel

NbBit

AsyncReset

BIST

Maximum input voltage on diode for

DIODE 700 mV

temperature measurement

Maximum input current on diode DIODE 8 mA

Maximum junction temperature T

Storage temperature T

j

stg

135 °C

-65 to 150 °C

Note: Absolute maximum ratings are limiting values, to be applied individually, while other parameters are within specified operating

conditions. Long exposure to maximum rating may affect device reliability. The use of a thermal heat sink is mandator y. See

“Thermal and Moisture Characteristics” on page 26.

Recommended

Operating

Conditions

Table 3. Recommended Operating Conditions

Parameter Symbol Comments

Positive supply voltage V

Positive output buffer supply

voltage

Positive output buffer supply

voltage

Positive output buffer supply

voltage

Negative supply voltage V

Operating temperature range T

10

TS81102G0

CC

V

PLUSD

V

PLUSD

V

PLUSD

EE

J

ECL output compatibility – 0 – V

PECL output compatibility – 3.3 – V

TTL output compatibility – 3.3 – V

Commercial grade: “C”

Industrial grade: “V”

Recommended Value

Min Typ Max Unit

4.45 5 5.25 V

-5.25-5-4.75V

0 < Tc; Tj < 90

°C

-40 < Tc; Tj < 110

2105C–BDC–11/03

Page 11

TS81102G0

Electrical

Operating

Tj (typical) = 70°C. Full Temperature Range: -40°C < Tc; Tj < 110°C.

(Guaranteed temperature range are depending on part number)

Characteristics

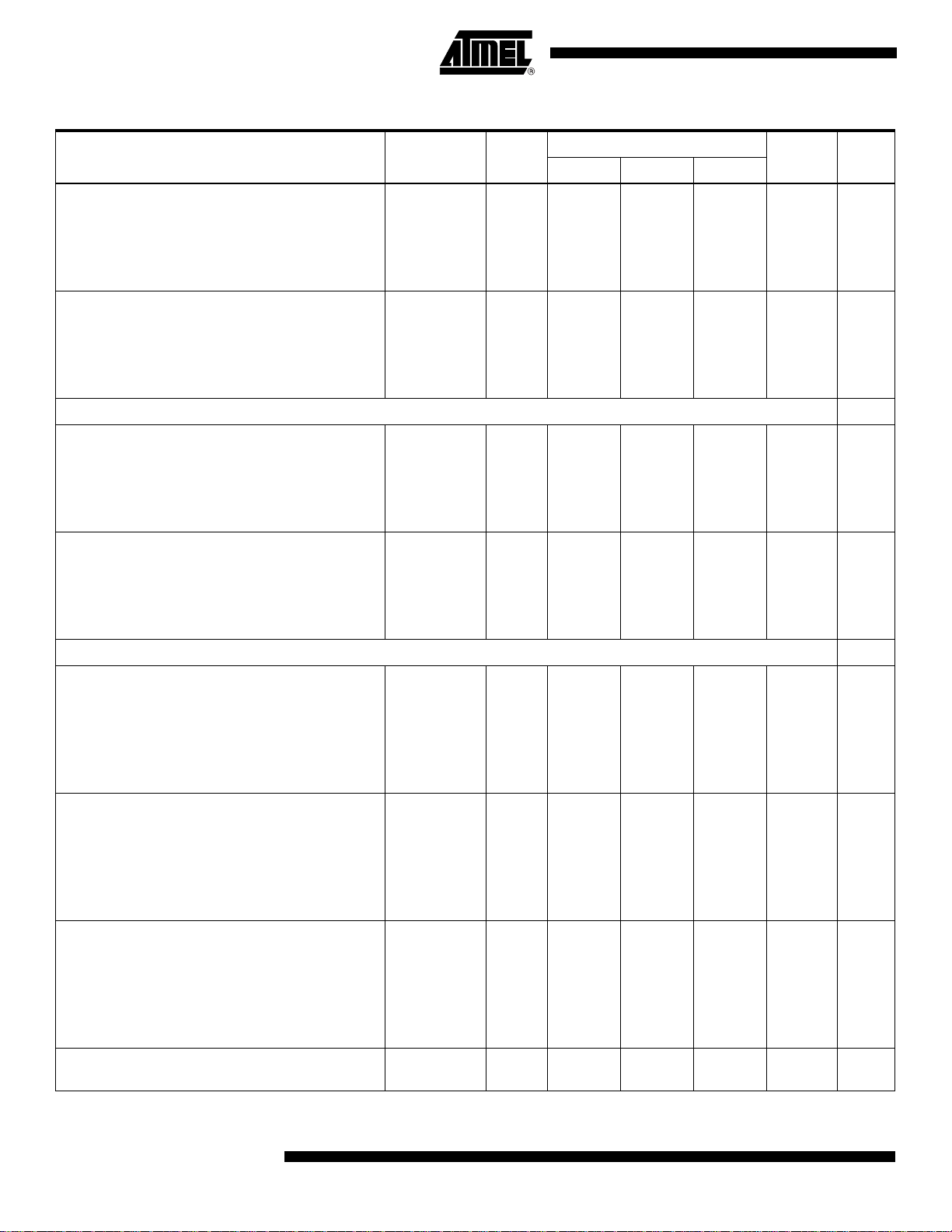

Table 4. Electrical Specifications

Parameter Symbol

Power Requirements

Positive supply voltage

V

V

PLUSD

V

PLUSD

V

PLUSD

V

I

I

PLUSD

I

I

PLUSD

I

I

PLUSD

I

I

PLUSD

I

I

I

PLUSD

I

I

PLUSD

I

I

PLUSD

I

I

PLUSD

I

Negative supply voltage

Supply Currents

ECL (50Ω) and PECL (50Ω)

V

(for every configuration)

CC

1:8, 8 bits

1:8, 10 bits

1:4, 8 bits

1:4, 10 bits

TTL (75Ω)

(for every configuration)

V

CC

1:8, 8 bits

1:8, 10 bits

1:4, 8 bits

1:4, 10 bits

Nominal power dissipation

V

PLUSDOUT

PECL

V

CC

ECL

TTL

V

EE

–

CC

EE

EE

EE

EE

CC

EE

EE

EE

EE

CC

EE

Test

Value

Level

4.75

–

1

-0.25

3.135

3.135

5

–

0

3.3

3.3

5.25

–

0.25

3.465

3.465

1 -5.25 -5 -4.75 V

–

540

–

640

1

–

270

–

320

–

–

760

–

900

1

–

380

–

450

–

31

1180

719

1140

790

590

592

720

634

31

1610

872

1770

980

810

670

880

729

–

1820

–

2240

–

910

–

1120

–

–

2440

–

3010

–

1220

–

1510

–

Unit NoteMin Typ Max

V

–

V

V

V

(1)

mA

mA

mA

mA

mA

mA

mA

mA

mA

mA

mA

mA

mA

mA

mA

mA

mA

mA

(1)

ECL (50Ω)

1:8, 8 bits

1:8, 10 bits

1:4, 8 bits

1:4, 10 bits

2105C–BDC–11/03

PD

PD

PD

PD

5.2

1

5.9

3.9

4.2

5.6

6.4

4.1

4.5

6

6.9

4.3

4.7

W

W

W

W

11

Page 12

Table 4. Electrical Specifications (Continued)

Parameter Symbol

PECL (50Ω)

1:8, 8 bits

1:8, 10 bits

1:4, 8 bits

1:4, 10 bits

PD

PD

PD

PD

TTL (75Ω)

1:8, 8 bits

1:8, 10 bits

1:4, 8 bits

1:4, 10 bits

PD

PD

PD

PD

Delay Adjust Control

DMUXDelAdjCtrl differential voltage

DDAC

250 ps

500 ps

750 ps

Input current

ADCDelAdjCtrl differential voltage

IDDAC

ADAC

250 ps

500 ps

750 ps

Input current

IADAC

Digital Outputs

ECL Output

(assuming V

= 0V, SWIADJ = 0V, 50Ω

PLUSD

termination resistor on board)

Logic “0” voltage

Logic “1” voltage

Reference voltage

V

OL

V

OH

V

REF

PECL Output

(assuming V

= 3.3V, SWIADJ = 0V, 50Ω

PLUSD

termination resistor on board)

Logic “0” voltage

Logic “1” voltage

Reference voltage

V

OL

V

OH

V

REF

TTL Output

(assuming V

= 3.3V, SWIADJ = 0V, 75Ω

PLUSD

termination resistor on board)

Logic “0” voltage

Logic “1” voltage

Reference voltage

Output level drift with temperature (data and DR

outputs)

V

OL

V

OH

V

REF

–––-1.3–mV/

Test

Level

5.8

1

6.6

4.2

4.6

6.8

1

7.8

4.7

5.2

–

–

–

–

–

–

–

–

–

–

–

–

1–

–

–

1–

–

–

1–

–

–

Value

6.2

7.1

4.4

4.8

7.3

8.4

4.9

5.5

–

-0.5

0

0.5

–

–

-0.5

0

0.5

–

-2.12

-1.16

-1.40

1.27

2.44

1.83

0.9

2.31

1.2

6.6

7.6

4.6

5.1

7.7

9

5.1

5.8

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

Unit NoteMin Typ Max

W

W

W

W

W

W

W

W

V

V

V

mA

V

V

V

mA

V

V

V

V

V

V

V

V

V

°C

12

TS81102G0

2105C–BDC–11/03

Page 13

Table 4. Electrical Specifications (Continued)

TS81102G0

Parameter Symbol

Output level drift with temperature (reference

outputs)

Digital Inputs

ECL Input Voltages

Logic “0” voltage

Logic “1” voltage

TTL Input Voltages

Logic “0” voltage

Logic “1” voltage

Note: 1. The supply current I

- the minimum values correspond to all the output buffers at low level,

- the maximum values correspond to all the output buffers at high level,

- the typical values correspond to an equal sharing-out of the output buffers between high and low levels.

Switching

Performance and

Characteristics

and the power dissipation depend on the state of the output buffers:

PLUSD

50% clock duty cycle (CLKIN, CLKINB). Tj (typical) = 70°C.

Full temperature range: -40°C < Tc; Tj < 110°C.

(Guaranteed temperature ranges depend on the part number)

V

V

V

V

Test

Level

–1–-0.9–mV/

IL

IH

IL

IH

1

1

–

-1.1

–

2.0

Value

–

–

–

–

-1.4

–

0.8

–

Unit NoteMin Typ Max

°C

V

V

V

V

See Timing Diagrams Figure 10 on page 16 to Figure 19 on page 21.

Table 5. Switching Performances

Test

Parameter Symbol

Input Clock

Maximum clock frequency

1:8 ratio

1:4 ratio

Clock pulse width (high) TC1 – 100 – – ps

Clock pulse width (low) TC2 – 100 – – ps

Clock Path pipeline delay

DR input clock

DR/2 input clock

Clock rise/fall time TRCKIN

Asynchronous Reset

Asynchronous Reset pulse width PWAR – 1000 – – ps

Setup time from Asynchronous to Clkln TSAR – – 1500 – ps

Rise/fall time for (10% – 90%) TRAR

FMAX – 2

TCPD

TCPD

TFCKIN

TF AR

Level

1

–––981

– – 100 – ps

– 1000 – – ps

Value

–

–

1084

2.2

1.1

–

–

Unit NoteMin Typ Max

GHz

ps

ps

(1)

(2)

2105C–BDC–11/03

13

Page 14

Table 5. Switching Performances (Continued)

Value

Unit NoteMin Typ Max

Parameter Symbol

Test

Level

Synchronous Reset

Setup time from SyncReset to Clkln

DR input clock

DR/2 input clock

TSSR – –

-580

–

-477

–

–

ps

ps

Hold time from Clkln to SyncReset

DR input clock

DR/2 input clock

THSR – –

780

–

677

–

–

ps

ps

Rise/fall for (10% – 90%) TSRR/TFSR – 100 – – ps

Input Data

Setup time from I[0…9] to Clkln

DR input clock

DR/2 input clock

TSCKIN – –

-794

–

-691

–

–

ps

ps

Hold time from Clkln to I[0…9]

DR input clock

DR/2 input clock

THCKIN – –

994

–

891

–

–

ps

ps

Rise/fall for (10% – 90%) TRDI/TFDI – 100 – – ps

Output Data

Data output delay

DR input clock

DR/2 input clock

TOD – –

1820

–

1717

–

–

ps

ps

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

Data pipeline delay

DR input clock, 1:4 ratio

DR input clock, 1:8 ratio

DR/2 input clock, 1:4 ratio

DR/2 input clock, 1:8 ratio

TPD –

–

–

–

–

3

7

3/2

7/2

–

–

–

Number

of input

clock

–

Rise/fall for (10% – 90%) TROD/tfod – – 497/484 – ps

Data Ready

Data ready Falling edge

DR input clock

DR/2 input clock

TDRF – –

1856

–

1753

–

–

ps

ps

Data ready Rising edge

DR input clock

DR/2 input clock

TDRR – –

1828

–

1725

–

–

ps

ps

Asynchr; Reset to DataReady delay TARDR – – 1918 – ps

Synchr. Reset to DataReady delay TSRDR – – 1037 – ps

Rise/fall for (10% – 90%) TRDR/TFDR – – 450 – ps

Rising edge uncertainty JITTER – – 62 – ps

Built-In Self Test

Hold time from Clkln to BIST THBIST – – – – ps

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(21)

(22)

14

TS81102G0

2105C–BDC–11/03

Page 15

Table 5. Switching Performances (Continued)

TS81102G0

Test

Parameter Symbol

Setup time from Bist to Clkln TSBIST – – 1000 – ps

Rise/fall time for (10% – 90%) TRBIST/

TFBIST

ADC Delay Adjust

Input frequency FMADA – 2 – 2.2 GHz

Input pulse width (high) TC1ADA – 90 – – ps

Input pulse width (low) TC2ADA – 90 – – ps

Input rise/fall time TRIADA/

TFIADA

Output rise/fall time TROADA/

TFOADA

Data output delay (typical delay adjust setting)

Output delay drift with temperature TADAT – – 2.5 – ps/°C

Output delay uncertainly JITADA – – 30 – ps

Notes: 1. TCPD is tuned with DMUXDelAdjCtrl: TCPD = 981 ± 250 ps.

2. TCPD is tuned with DMUXDelAdjCtrl: TCPD = 1084 ± 250 ps.

3. TSSR depends on DMUXDelAdjCtrl: TSSR = -580 ± 250 ps. TSSR < 0 because of Clock Path internal delay.

4. TSSR depends on DMUXDelAdjCtrl: TSSR = -477 ± 250 ps. TSSR < 0 because of Clock Path internal delay.

5. THSR depends on DMUXDelAdjCtrl: THSR = 780 ± 250 ps.

6. THSR depends on DMUXDelAdjCtrl: THSR = 677 ± 250 ps.

7. TSCKIN depends on DMUXDelAdjCtrl: TSCKIN = -794 ± 250 ps. TSCKIN < 0 because of Clock Path internal delay.

8. TSCKIN depends on DMUXDelAdjCtrl: TSCKIN = -691 ± 250 ps. TSCKIN < 0 because of Clock Path internal delay.

9. THCKIN depends on DMUXDelAdjCtrl: THCKIN = 994 ± 250 ps.

10.THCKIN depends on DMUXDelAdjCtrl: THCKIN = 891 ± 250 ps.

11.TOD depends on DMUXDelAdjCtrl: TOD = 1820 ± 250 ps. TOD is given for ECL 50Ω/2 pFoutput load.

12.TOD depends on DMUXDelAdjCtrl: TOD = 1717 ± 250 ps. TOD is given for ECL 50Ω/2 pFoutput load.

13.TPD is the number of Clkln clock cycle from selection of Port A to selection of Port H in 1:8 conversion mode, and from

selection of Port A to selection of Port D in 1:4 conversion mode. It is the maximum number of Clkln clock cycle, or pipeline

delay, that a data has to stay in the DMUX before being sorted out. This maximum delay occurs for the data sent to Port A.

For instance, the data sent to Port H goes directly from the input to the Port H, and its pipeline is 0. Bu t even for this data,

there is an additional delay due to physical propagation time in the DMUX.

14.TROD and TFOD are given for ECL 50Ω/2 pF output load. In TTL mode, the TROD and TFOD are twice the ones for ECL.

(For other termination topology, apply proper derating value 50 ps/pF in ECL, 100 ps/pF in TTL mode.)

15.TDRF depends on DMUXDelAdjCtrl: TDRF = 1856 ± 250 ps. It is given for ECL 50Ω/2 pF output load.

16.TDRF depends on DMUXDelAdjCtrl: TDRF = 1753 ± 250 ps. It is given for ECL 50Ω/2 pF output load.

17.TDRR depends on DMUXDelAdjCtrl: TDRR = 1858 ± 250 ps. It is given for ECL 50Ω/2 pF output load.

18.TDRR depends on DMUXDelAdjCtrl: TDRR = 1725 ± 250 ps. It is given for ECL 50Ω/2 pF output load.

19.TARDR is given for ECL 50Ω/2 pF output load.

20.TSRDR is given for ECL 50Ω/2 pF output load. It is minimum value since RstSync clock is synchronized with Clkln clock.

21.TRDR and TFDR are given for ECL 50Ω/2 pF output load.

22.THBIST depends on the configuration of the DMUX. There must be enough Clkln clock cycles to have all the 512 codes,

(see different Timing Diagrams).

23.With transmission line (ZO = 50Ω) and output load R = 50Ω; C = 2 pF.

24.Without output load.

25.With transmission line (ZO = 50Ω) and output load R = 50Ω; C = 2 pF.

TADA –

Level

– 1000 – – ps

–

–

100

100

–

–

–

–

Value

150

150

145

104

784

896

–

–

–

–

–

–

Unit NoteMin Typ Max

ps

ps

ps

(23)

(24)

(25)

2105C–BDC–11/03

15

Page 16

Input Clock Timings

Figure 10. Input Clock

TC2

TFCKIN

TC1

TRCKIN

Clkln

Data [0..9]

TSCKIN

d1 d2 d3 d4

Clkln Type = 1

DataReady Mode (DR)

THCKIN

ADC Delay Adjust

Timing Diagram

Figure 11. ADC Delay Adjust Timing Diagram

d5

TC2

TFCKIN

TC1

TRCKIN

TSCKIN

d1 d2 d3 d4 d5

Clkln Type = 0

DataReady/2 Mode (DR/2)

THCKIN

TC2ADA

TFIADA

TC1ADA

TRIADA

ADCDelAdjIn

TFOADA

ADCDelAdjOut

TROADA

TADA

16

TS81102G0

2105C–BDC–11/03

Page 17

TS81102G0

Timing Diagrams with

Asynchronous Reset

With a nominal tuning of DMUXDelAdj at a frequency of 2 GHz, d1 and d2 data is lost because

of the internal clock’s path propagation delay TCPD. TCPD is tuned with DMUXDelAdjCt rl pins

to obtain good setup and hold times between Clkln and the da ta.

Figure 12. Start with Asynchronous Rest, 1:8 Ratio, DR Mode

ASyncReset

Clkn

Internal Port Selection

(not available out of the DEMUX)

I[0..9]

A[0..9]

B[0..9]

C[0..9]

D[0..9]

E[0..9]

F[0..9]

G[0..9]

H[0..9]

DR

TRAR

TARDR

PWAR

TFAR

TCPD

ABCD

d1 d2 d3 d4 d5 d6 d7 d8 d9 d10 d11

TDRR

TPD

EFGH BACDEFGH

TOD

TDRF

d12 d13 d14 d15 d16 d17

d3

d4

d5

d6

d7

d8

d9

TRDR TFDR

TOD

TROD/TFOD

d10

d11

d12

d13

d14

d15

d16

d17

With a nominal tuning of DMUXDelAdj at 2 GHz, d1 an d d 2 dat a is lost be ca use of t he int er nal

clock’s path propagation delay TCPD. TCPD is tuned with DMUXDelAdjCtrl pins to obtain

good setup and hold times between Clkln and the input data. This timing diagram does not

change with the opposite phase of Clkln.

Figure 13. Start with Asynchronous Rest, 1:8 Ratio, DR/2 Mode

ASyncReset

Clkn

Internal Port Selection

(not available out of the DEMUX)

I[0..9]

A[0..9]

B[0..9]

C[0..9]

D[0..9]

E[0..9]

F[0..9]

G[0..9]

H[0..9]

DR

TRAR

TARDR

TFAR

PWAR

TCPD

ABCD

d1 d2 d3 d4 d5 d6 d7 d8 d9 d10 d11

TDRR

TPD

TCPD

EFGH BACDEFGH

TOD

TDRF

d12 d13 d14 d15 d16 d17

d3

d4

d5

d6

d7

d8

d9

TRDR TFDR

TOD

TROD/TFOD

d10

d11

d12

d13

d14

d15

d16

d17

2105C–BDC–11/03

17

Page 18

With a nominal tuning of DMUXDelAdj, at 1 GHz (1:4 mode) d1 data is lost because of the

internal clock’s path propagation delay TCPD. TCPD is tuned with DMUXDelAdjCtrl pins and

is used to obtain good setup and hold times between Clkln and the input data.

Figure 14. Start with Asynchronous Reset, 1:4 Ratio, DR Mode

ASyncReset

Clkn

Internal Port Selection

(not available out of the DEMUX)

TRAR

PWAR

TFAR

TCPD

ABCD

TPD

BACD

I[0..9]

A[0..9]

B[0..9]

C[0..9]

D[0..9]

TARDR

DR

d1 d2 d3 d4 d5 d6 d7 d8

TDRR

TRDR

With a nominal tuning of DMUXDelAdj, at 1 GHz (1:4 mode) d1 data is lost because of the

internal clock’s path propagation delay TCPD. TCPD is tuned with DMUXDelAdjCtrl pins and

is used to obtain good setup and hold times betwe en Clkln and the input data. This timing diagram does not change with the opposite phase of Clkln.

Figure 15. Start with Asynchronous Reset, 1:4 Ratio, DR/2 Mode

ASyncReset

Clkn

Internal Port Selection

(not available out of the DEMUX)

TRAR

PWAR

TFAR

TCPD

A

B

TOD

TDRF TDRR

TFDR

TCPD

CD

TPD

d2

d3

d4

TOD

d5

d6

d7

d8

TROD/TFOD

BA C

18

I[0..9]

A[0..9]

B[0..9]

C[0..9]

D[0..9]

DR

TS81102G0

TARDR

d1 d2 d3 d4 d5 d6 d7 d8

TOD

d5

d6

d7

d8

TROD/TFOD

TDRR

TRDR

TOD

d2

d3

d4

TDRF

TFDR

2105C–BDC–11/03

Page 19

TS81102G0

Timing Diagrams with

Synchronous Reset

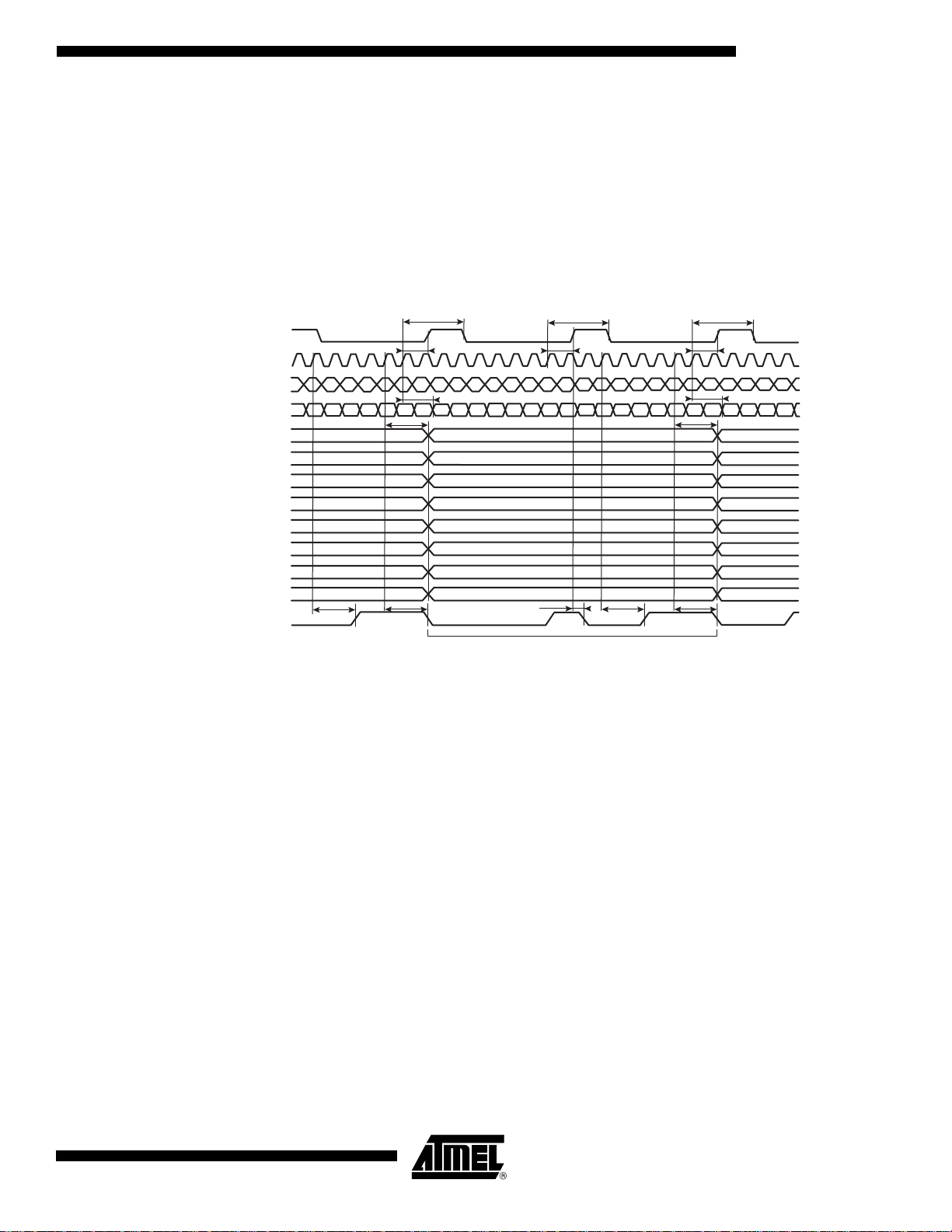

Following is an example of the Synchronous Reset’s utility in case of de-synchronization of the

DMUX output port selection. The de-synchronization event happens after the selection of Port

D.

DMUXDelAdjCtrl value is nominal. TSSR < 0 because of Clkln’s internal propagation delay

TCPD. After selection of Port C, instead of selecting Por t D, t he de -synchronization makes the

port selection to restart on Port A. Since Port H was not selected, the data is not output to the

ports but the last data (d1 to d 8) is latc hed unt il t he ne xt sel ectio n of Por t H. d9 to d16 ar e lo st .

The synchronous Reset ensures a re-synchronization of the port selection.

Figure 16. Synchronous Reset, 1:8 Ratio, DR Mode

SyncReset

Clkn

I[0..9]

Internal Port Selection

(not available out of the DEMUX)

A[0..9]

B[0..9]

C[0..9]

D[0..9]

E[0..9]

F[0..9]

G[0..9]

H[0..9]

DR

d1d0 d2 d3 d4 d5 d6 d7 d8 d9 d10 d11

ABCD

TDRR

TSSR

EDEFGH BACBAC DEFGHBAC DBA C

TOD

TDRF TDRR TDRF

TCPD

THSR

THSR

TSSR

d12 d13 d14 d15 d16 d17 d18 d19 d20 d21 d22 d23 d24 d25 d26 d27

d2

TSRDR

THSR

TSSR

TCPD

TOD

d17d1

d18

d19d3

d20d4

d21d5

d22d6

d23d7

d24d8

Period of uncertainty due to desynchronization

Example of the Synchronous Reset’s utility in case of de-synchronization of the DMUX output

port selection. The de-synchronization event happens after the selection of Port D.

DMUXDelAdjCtrl value is nominal. TSSR < 0 because of Clkln’s internal propagation delay

TCPD. After selection of Port C, instead of selecting Por t D, t he de -synchronization makes the

port selection to restart on Port A. Since Port H was not selected, the data is not output to the

ports but the last data (d1 to d4) is latched until the next selection of Port H. d5 to d8 are lost.

The synchronous Reset ensures a re-synchronization of the port selection.

2105C–BDC–11/03

19

Page 20

Figure 17. Synchronous Reset, 1:4 Ratio, DR Mode

SyncReset

Clkn

I[0..9]

Internal Port Selection

(not available out of the DEMUX)

A[0..9]

B[0..9]

C[0..9]

D[0..9]

d1 d2 d3 d4 d5 d6 d7 d8 d9 d10 d11

DR

Example of Synchronous Reset’s utility in case of de-synchronization of the DMUX output port

selection. The de-synchronization event happens after the selection of Port D.

DMUXDelAdjCtrl value is nominal. TSSR < 0 because of Clkln’s internal propagation delay

TCPD. After selection of Port C, instead of selecting Por t D, t he de -synchronization makes the

port selection to restart on Port A. Since Port H was not selected, the data is not output to the

ports but the last data (d1 to d 8) is latc hed unt il t he ne xt sel ectio n of Por t H. d9 to d16 ar e lo st .

The synchronous Reset ensures a re-synchronization of the port selection.

THSR

TSSR

TCPD

d12 d13 d14 d15

ABCD BCDAB CDAB CD

d1

d2

d3

d4

Period of uncertainty due to desynchronization

TOD

d9

d10

d11

d12

TDRF TDRR

d16

Figure 18. Synchronous Reset, 1:8 ratio, DR/2 Mode

SyncReset

Clkn

I[0..9]

Internal Port Selection

(not available out of the DEMUX)

A[0..9]

B[0..9]

C[0..9]

D[0..9]

E[0..9]

F[0..9]

G[0..9]

H[0..9]

DR

d1d0 d2 d3 d4 d5 d6 d7 d8 d9 d10 d11

ABCD

TOD

TSSR

TCPD

EDEFGH BACBAC DEFGHBAC DBA C

TDRF

Example of Synchronous Reset’s utility in case of de-synchronization of the DMUX output port

selection. The de-synchronization event happens after the selection of Port D.

DMUXDelAdjCtrl value is nominal. TSSR < 0 because of Clkln’s internal propagation delay

TCPD. After selection of Port C, instead of selecting Por t D, t he de -synchronization makes the

port selection to restart on Port A. Since Port H was not selected, the data is not output to the

ports but the last data (d1 to d4) is latched until the next selection of Port H. d5 to d8 are lost.

The synchronous Reset ensures a re-synchronization of the port selection.

THSR

THSR

TSRR

d12 d13 d14 d15 d16 d17 d18 d19 d20 d21 d22 d23 d24 d25 d26 d27

d1

d2

TSDRR

Period of uncertainty due to desynchronization

TDRR

THSR

TSRR

TCPD

TDRF

TOD

d17

d18

d19d3

d20d4

d21d5

d22d6

d23d7

d24d8

20

TS81102G0

2105C–BDC–11/03

Page 21

TS81102G0

Figure 19. Synchronous Reset, 1:4 ratio, DR/2 Mode

SyncReset

Clkn

I[0..9]

Internal Port Selection

(not available out of the DEMUX)

A[0..9]

B[0..9]

C[0..9]

D[0..9]

d1 d2 d3 d4 d5 d6 d7 d8 d9 d10 d11

ABCD BC AABCDABCD

DR

Period of uncertainty due to desynchronization

Note: In case of low clock frequency and start with asynchronous reset, o nly the first data is lost and the fi rst data to b e pro cessed is

the second one. This data is output from the DMUX through port B.

TSSR

TCPD

d1

d2

d3

d4

THSR

TOD

TDRF

d12 d13 d14 d15

d9

d10

d11

d12

TDRR

d16

2105C–BDC–11/03

21

Page 22

Explanation of

Test Levels

Table 6. Explanation of Test Levels

Num Characteristics

(1)

1 100% production tested at +25

2 100% production tested at +25°C, and sample tested at specified temperatures.

3 Sample tested only at specified temperatures.

4

5 Parameter is a typical value only.

Notes: 1. The level 1 and 2 tests are performed at 50 MHz.

Parameter is guaranteed by design and characterization testing (thermal steady-state

conditions at specified temperature).

2. Only MIN and MAX values are guaranteed (typical values are issuing from characterization

results).

°C.

(1)

22

TS81102G0

2105C–BDC–11/03

Page 23

TS81102G0

Package Description

Pin Description

Table 7. TS81102G0 Pin Description

Type Name Levels Comments

Digital Inputs I[0…9] Differential ECL Data input.

On-chip 100Ω differential termination resistor.

Clkln Differential ECL Clock input (Data Ready ADC).

On-chip 100Ω differential termination resistor.

Outputs A[0…9] → H[0…9] Adjustable Logic

Single

DR Adjustable Logic

Differential

RefA → RefH Adjustable Single Reference voltage for output channels A to H.

Control Signals ClklnType TTL DataReady or Dataready/2: logic 1: Data Ready.

RatioSel TTL DMUX ratio; logic 1: 1:4

Data ready for port A to H.

Common mode is adjusted with VplusDOut. Swing is adjusted with

SwiAdj. 50Ω termination possible.

Data ready for channel A to H.

Common mode is adjusted with VplusDOut. Swing is adjusted with

SwiAdj. 50Ω termination possible.

Common mode is adjustable with VplusDOut. 50Ω termination

possible.

Bist TTL Reset and Switch of built-in Self Test (BIST): logic 0: BIST active.

SwiAdj 0V ± 0.5V Swing fine adjustment of output buffers.

Diode Analog Diode for chip temperature measurement.

NbBit TTL Number of bit 8 or 10: logic 1: 10-bit.

Synchronization AsyncReset TTL Asynchronous reset: logic 1: reset on.

SyncReset Differential ECL Synchronous reset: active on rising edge.

DMUXDelAdjCtrl Differential analog

input of ±0.5V

around 0V

common mode

ADCDelAdjCtrl Differential analog

input of ±0.5V

around 0V

common mode

ADCDelAdjln Differential ECL Stand-alone delay adjust input for ADC.

ADCDelAdjOut 50Ω differential

output

Power Supplies GND Ground 0V Common ground.

V

EE

V

PlusDOut

V

CC

Power -5V Digital negative power supply.

Adjustable power

from 0V to +3.3V

Power +5V Digital positive power supply.

Control of the delay line of DataReady input:

differential input = -0.5V: delay = 250 ps

differential input = 0V: delay = 500 ps

differential input = 0.5V: delay = 750 ps

Control of the delay line for ADC:

differential input = - 0.5V: delay = 250 ps

differential input = 0V: delay = 500 ps

differential input = 0.5V: delay = 750 ps

Differential termination of 100Ω inside the buffer.

Stand-alone delay adjust output for ADC.

Common mode adjustment of output buffers.

2105C–BDC–11/03

23

Page 24

TBGA 240 Package – Pinout

Row Col Name Row Col Name Row Col Name Row Col Name

VEE

17

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

D

D

D

E3

2

E5

3

E7

4

E9

5

C0

6

C2

7

C4

8

C6

9

C8

10

REFA

11

A1

12

A3

13

A5

14

A7

15

A9

16

DEMUXDELADJCTRL

17

RSTSYNCB

18

NC

19

E1

1

E2

2

E4

3

E6

4

E8

5

REFC

6

C1

7

C3

8

C5

9

C7

10

C9

11

A0

12

A2

13

A4

14

A6

15

A8

16

ASYNCRESET

17

DEMUXDELADJCTRLB

18

RSTSYNC

19

REFE

1

E0

2

VEE

3

VPLUSDOUT

4

VPLUSDOUT

5

VPLUSDOUT

6

VPLUSDOUT

7

VEE

8

VPLUSDOUT

9

VEE

10

VPLUSDOUT

11

VEE

12

VPLUSDOUT

13

VPLUSDOUT

14

VPLUSDOUT

15

GND

16

GND

17

GND

18

DIODE

19

G8

1

G9

2

VEE

3

NC

1

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

E

E

E

E

E

E

E

E

F

F

F

F

F

F

F

F

G

G

G

G

G

G

G

G

H

H

H

H

H

H

H

H

J

J

J

J

J

J

J

J

K

K

K

K

VEE

5

VPLUSDOUT

6

VPLUSDOUT

7

VEE

8

VPLUSDOUT

9

VEE

10

VPLUSDOUT

11

VEE

12

VPLUSDOUT

13

GND

14

VCC

15

VCC

16

GND

17

I0B

18

I0

19

G6

1

G7

2

VPLUSDOUT

3

VEE

4

VEE

16

VEE

17

I1B

18

I1

19

G4

1

G5

2

GND

3

GND

4

GND

16

GND

17

I2B

18

I2

19

G2

1

G3

2

VEE

3

VEE

4

VEE

16

VEE

17

I3B

18

I3

19

G0

1

G1

2

GND

3

GND

4

GND

16

GND

17

CLKINB

18

CLKIN

19

DR

1

REFG

2

VPLUSDOUT

3

VCC

4

VEE

16

VEE

17

I4B

18

I4

19

SWIADJ

1

DRB

2

VEE

3

VEE

4

VEE

4

K

K

K

K

L

L

L

L

L

L

L

L

M

M

M

M

M

M

M

M

N

N

N

N

N

N

N

N

P

P

P

P

P

P

P

P

R

R

R

R

R

R

R

R

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

GND

17

I5B

18

I5

19

H9

1

RATIOSEL

2

VPLUSDOUT

3

VPLUSDOUT

4

VEE

16

VEE

17

I6B

18

I6

19

H7

1

H8

2

GND

3

GND

4

GND

16

GND

17

I7B

18

I7

19

H5

1

H6

2

VPLUSDOUT

3

VPLUSDOUT

4

VEE

16

VEE

17

I8B

18

I8

19

H3

1

H4

2

GND

3

GND

4

GND

16

GND

17

I9B

18

I9

19

H1

1

H2

2

VPLUSDOUT

3

VPLUSDOUT

4

VEE

16

GND

17

ADCDELADJOUT

18

ADCDELADJOUTB

19

REFH

1

H0

2

VEE

3

VEE

4

VEE

5

VPLUSDOUT

6

VPLUSDOUT

7

VEE

8

VPLUSDOUT

9

VEE

10

VPLUSDOUT

11

VEE

12

VPLUSDOUT

13

VPLUSDOUT

14

GND

15

VEE

16

VEE

16

T

T

T

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

W

ADCDELADJIN

18

ADCDELADJINB

19

F8

1

F9

2

VEE

3

VPLUSDOUT

4

VPLUSDOUT

5

VPLUSDOUT

6

VPLUSDOUT

7

VEE

8

VPLUSDOUT

9

VEE

10

VPLUSDOUT

11

VEE

12

VPLUSDOUT

13

VPLUSDOUT

14

VPLUSDOUT

15

GND

16

GND

17

GND

18

GND

19

F7

1

F6

2

F4

3

F2

4

F0

5

D9

6

D7

7

D5

8

D3

9

D1

10

REFD

11

B8

12

B6

13

B4

14

B2

15

B0

16

BIST

17

CLKINTYPE

18

ADCDELADJCTRL

19

NC

1

F5

2

F3

3

F1

4

REFF

5

D8

6

D6

7

D4

8

D2

9

D0

10

B9

11

B7

12

B5

13

B3

14

B1

15

REFB

16

NBBIT

17

ADCDELADJCTRLB

18

NC

19

24

TS81102G0

2105C–BDC–11/03

Page 25

Figure 20. TBGA 240 Package: Bottom View

19181716151413121110987654321

TS81102G0

RstSyncb

RstSync

Demuxdeladjctrclb

DIODE

GND

I0

I0b

I1b

I1

I2b GND GND

I2

I3 I3b

CLK CLKb

I4b

I4

I5

I5b

I6b

I6

I7b

I7

I8b

I8

Demuxdeladjctrcl

Asyncreset

GND

GND

VEE VEE

VEE VEE

GND GND

VEE VEE

GND VEE

VEE VEE

GND

VEE VEE

C8A1

A0 C9

VEE

VEE

REFA

VPLUSD

VPLUSD

C6

C7

C5 C3 E6

VPLUSD

VEE

VPLUSD

VEE

A9 A5A7

A3

A4A8 A6 A2

VPLUSD

VPLUSD

GND

VCC VCC VEE

GND

VPLUSD

VPLUSD

C4

VEE

VEE

C2

C1

VPLUSD

VPLUSD

C0

REFC

VPLUSD

VPLUSD

E9

E8

VPLUSD

VEE

VPLUSD

VEE

GND GND

VEE

GND GND

VCC

VEE VEE

VPLUSD

GND

GND GND

VPLUSD VPLUSD

E5 E3E7

E4

VEE

VEE

VPLUSD

VEE

VPLUSD

VPLUSD

E2 E1

E0

G9 G8

G7 G6

G5 G4

G1 G0

REFG

DRb

RATIOSEL

H8 H7

H6

REFE

G2G3

DR

SWIadj

H9

H5

A

B

C

D

E

F

G

H

J

K

L

M

N

I9

GND

ADCDELADJCTRL

ADCDELADJCTRLb

2105C–BDC–11/03

I9b

ADCdelayadjoutADCdelayadjoutB

ADCdelayadjinADCdelayadjinB

GND

CLKINTYPE

GND

GND

VEE

GND

BIST

NbBIT

GND

VEE

VEE

GND

B0

REFB

GND

VPLUSD

B2

VPLUSD

VPLUSD

B4

B3B1 B5

VPLUSD

VPLUSD

B6

VEE

VEE

B8

VPLUSD

VPLUSD

REFD

VEE

VEE

D1

VPLUSD

VPLUSD

D3

VEE

VEE

VPLUSD

VPLUSD

D7D5

VPLUSD

VPLUSD

D9 F0

VEE

VPLUSD

REFF

GND

VPLUSD

VEE

VPLUSD

F2

F1B9B7 D0 D2 D6D4 D8

GND

VPLUSD

VEE

VEE

F4

F3 F5

H4

H3

H2

H1

REFH

H0

F9

F8

F7F6

P

R

T

U

V

W

25

Page 26

Outline

Dimensions

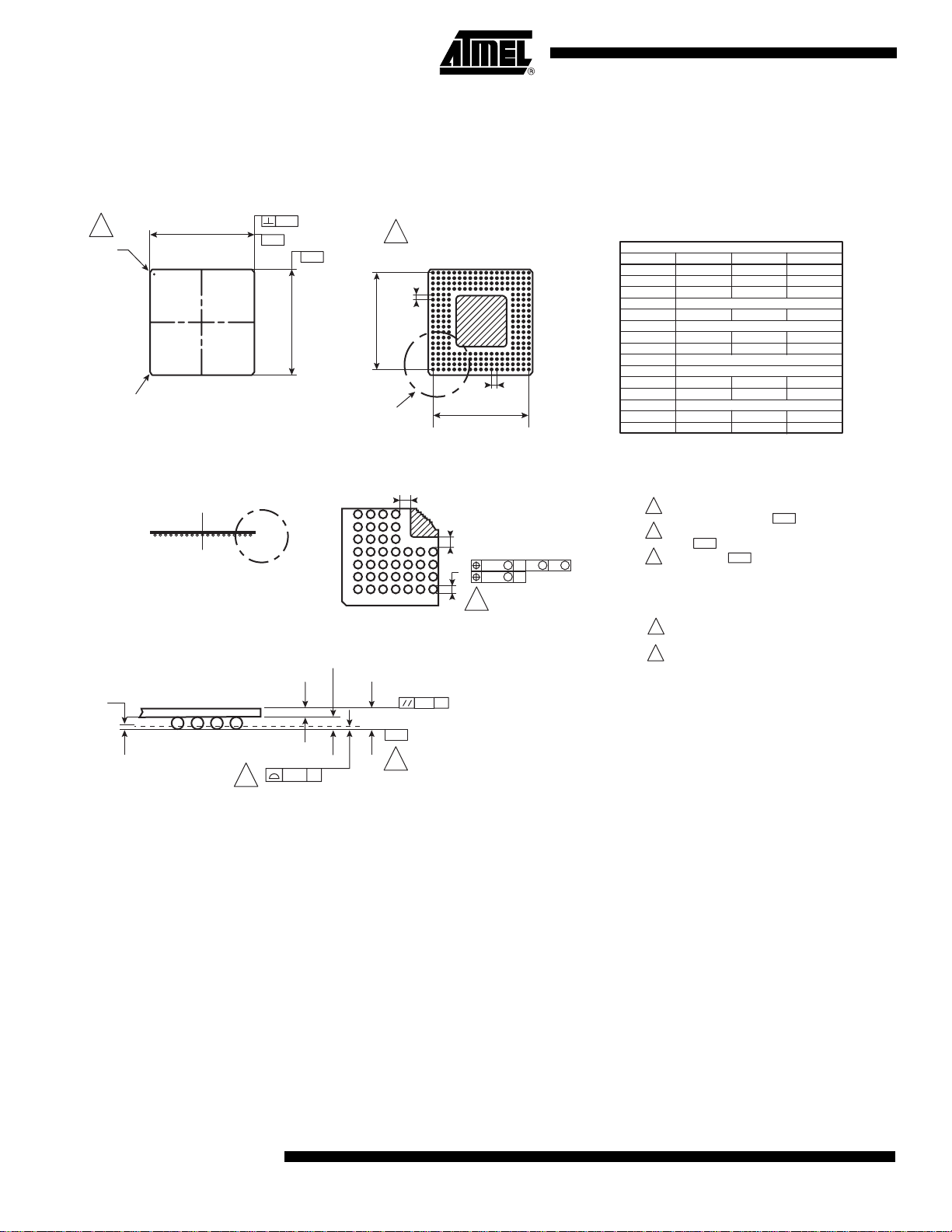

Figure 21. Package Dimension – 240 Tape Ball Grid Array

11

Corner

45 degree

0.5 mm chamfer

(4 PLCS)

P

D

Top View

Detail A

Side View

0.10

- A -

- B -

E E1

C

10

18

e

Detail B

D1

Bottom View

g

g

b

4

Detail B

A1

A

ccc C

e

0.30

M M M

M

0.30

1

35791113151719

246810121416

A

C

E

G

J

L

N

R

U

W

A

C B

C

Dimensional References

Ref.

B

D

F

H

K

M

P

T

V

A

A1

D

D1

E

E1

b

c

M

N

aaa

ccc

e

g

P

Notes: 1. All dimensions are in millimeters.

Min.

1.30

0.50

24.80

24.80

0.60

0.80

-

-

0.35

0.15

2. "e" represents the basic solder ball grid pitch.

3. "M" represents the basic solder ball matrix size,

and symbol "N" is the maximum allowable number

of balls after depopulating.

4 "b" is measured at the maximum solder ball diameter

parallel to primary datum - C -

5 Dimension "aaa" is measured parallel to primary

datum - C -

6 Primary datum - C - and seatin plane are defined by

the spherical crowns of the solder balls.

7. Package surface shall be black oxide.

8. Cavity depth various with die thickness.

9. Substrate material base is copper.

10

Bilateral tolerance zone is applied to each side of

package body.

11

45 deg. 0.5 mm chamfer corner and white dot for

pin 1 identification.

Nom.

1.50

0.60

25.00

22.86 (BSC.)

25.00

22.86 (BSC.)

0.75

0.90

19.00

240.00

---

-

1.27 TYP.

-

-

Max.

1.70

0.70

25.20

25.20

0.90

1.00

0.15

0.25

-

-

Detail A

Thermal and Moisture

Characteristics

Thermal Resistance

from Junction to

Case: RTHJC

26

TS81102G0

- C -

aaa

5

C

6

The Rth from junction to case for th e TBGA package is estimated at 1.05 °C/W that ca n be broken down as follows:

• Silicon: 0.1°C/W

• Die attach epoxy: 0.5°C/W (thickness # 50 µm)

• Copper block (back side of the package): 0.1°C/W

• Black Ink: 0.251°C/W.

2105C–BDC–11/03

Page 27

TS81102G0

Thermal Resistance

from Junction to

Ambient: RTHJA

A pin-fin type heat sink of a size 40 mm x 40 mm x 8 mm can be used to r edu ce ther ma l re si stance. This heat sink should not be glued to the t op of the pa ckage as Atmel cannot guar antee

the attachment to the board in such a configurat ion. The h eat sink could be clip ped or screwed

on the board.

With such a heat sink, the Rthj-a is about 6°C/W (if we take 10°C/W for Rth from the junction

to air through the package and heat sink in para llel with 15°C/W from the junction to the board

through the package body, through balls and thr ough board copper).

Without the heat sink, the Rth junction to air for a p ackage reported on-board can be estimated

at 13 to 20°C/W (depending on the board used).

The worst value 20°C/W is given for a 1-layer board (13°C for a 4-layer board).

Thermal Resistance

from Junction to

Bottom of Balls

The thermal resistance from the junction to the bottom of the balls of the package corresponds

to the total thermal resistance to be considered from the silicon’s die junction to the interface

with a board. This thermal resistance is estimated to be 4.8°C/W max.

The following diagram points out how the previous thermal resistances were calcula ted for this

packaged device.

Figure 22. Thermal Resistance from Junction to Bottom of Balls

DEMUX − Axpproximative Model for 240 TBGA

Assumptions:

Square die 7.0 x 7.0 = 49 mm², 75 µm thick Epoxy/Ag glue, 0.40 mm copper thickness under die,

Sn60Pb40 columns diameter 0.76 mm, 23 x 23 mm TBGA

Typical values

(values are in °C/Watt)

Silicon Die

49 mm²

λ = 0.95Watt/°C

Epoxy/Ag glue

λ = 0.025Watt/°C

(Top half of thickness)

Copper base

λ = 25Watt/°C

Copper base

Black ink

Thermal Resistance Junction to case typical =

0.10 + 0.60 + 0.05 + 0.05 + 0.25 = 1.05°C/W

Thermal Resistance Junction to case Max = 1.40°C/W

0.10

0.60

0.05

0.05

0.25

Top of

package

1.87

0.40

2 internal

rows

(104 balls)

0.251.70

2 external

(136 balls)

rows

1.43

0.31

Tape + glue

over balls

λ = 0.02Watt/°C

Balls

PbSn

λ = 0.40Watt/°C

Case were all Bottom of Balls are connected to infinite heatsink

(values are in °C/Watt)

Silicon JunctionSilicon Junction

0.10

0.60

0.05

Infinite heatsink

at bottom of balls

Thermal Resistance Junction to bottom of balls = 4.8°C/W Max

Reduction

Silicon

0.251.70

2.47 1.74 1.99

Junction

Infinite heatsink

at bottom of balls

Reduction

Silicon

Junction

2.45

3.55

2.47

Infinite heatsink

at bottom of balls

2105C–BDC–11/03

27

Page 28

Temperature Diode

Characteristic

The theoretical characteristic of the diode according to the temperature when I = 3 mA is

depicted below.

Figure 23. Temperature Diode Characteristic

Moisture

Characteristic

Vdiode

1.0

900m

(V)

800m

700m

-70.0 -20.0 30.0 80.0

DiodeT

I = 3 mA

dV/dT = 1.32 mV/°C

130.0

Temperature (°C)

This device is sensitive to moisture (MSL3 according to the JEDEC standard).

The shelf life in a sealed bag is 12 months at < 40°C and < 90% relative humidity (RH).

After this bag is opened, devices that might be subjected to infrared reflow, vapor-phase

reflow, or equivalent processing (peak package body temperature 220°C) must be:

• mounted within 168 hours at factory conditions of ≤ 30°C/60% RH, or

•stored at ≤ 20% RH.

28

The devices require baking before mounting, if the humidity indicator is > 20% when read at

23°C ±5°C.

If baking is required, the devices may be baked for:

• 192 hours at 40°C + 5°C/-0°C and < 5% RH for low temperature device containers, or

• 24 hours at 125°C ± 5°C for high-temperature device containers.

TS81102G0

2105C–BDC–11/03

Page 29

TS81102G0

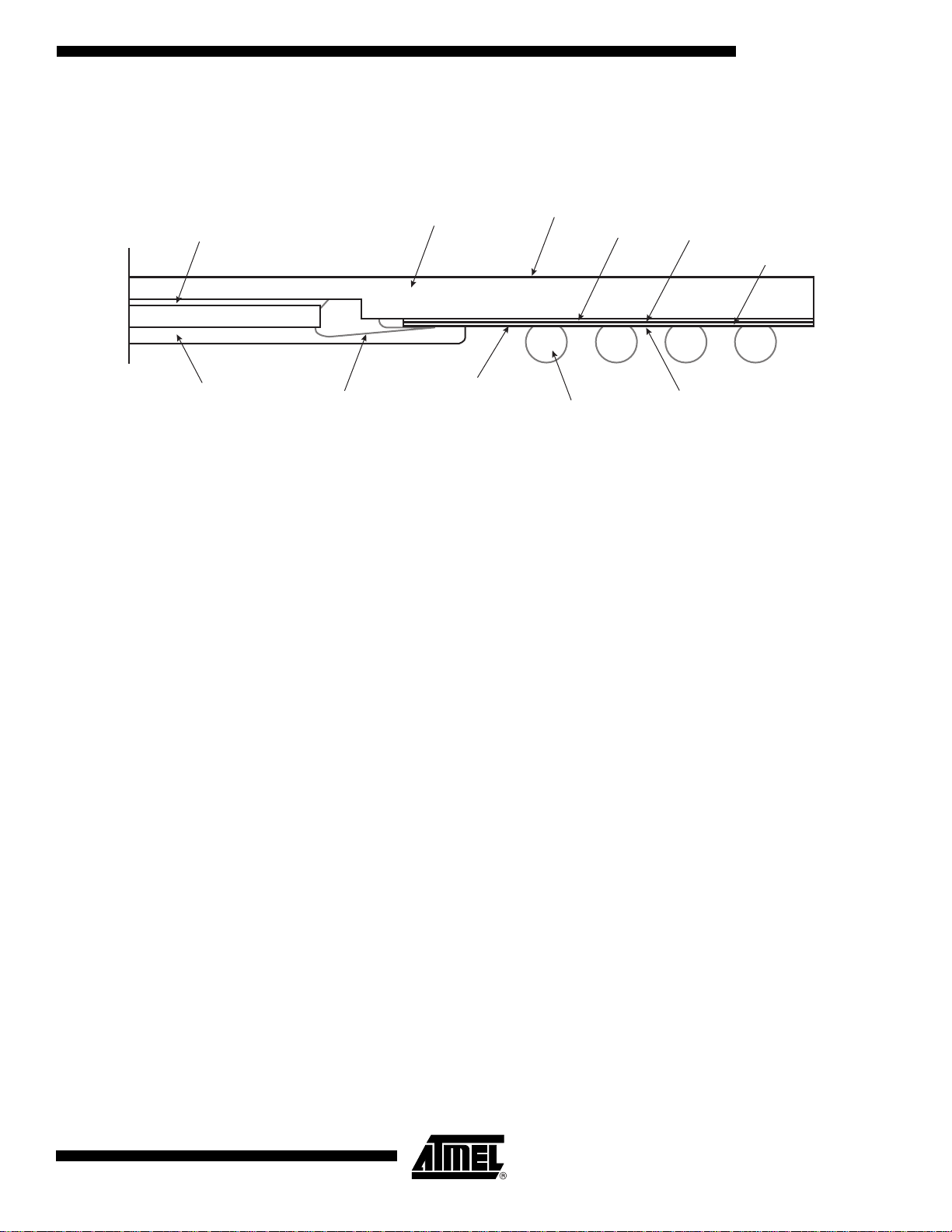

Detailled Cross

The following diagram depicts a detailed cross sectio n of the DM UX TBG A packa ge .

Section

Figure 24. TBGA 240: 1/2 Cross Section

Die Attach Epoxy/Ag

Silicon Die

Block Epoxy resin

encapsulant

In the DMUX package shown above, the die’s rear side is attached to the copper heat

spreader, so the copper heat spreader is at -5V.

Gold

wires

Copper Heatspreader

Copper traces

and

Solder Balls Pads

on metal 1 side

Block overcoat

Sn/Pb/Ag

62/36/2 Eutectic

Solder Balls

Adhesive

Solder Mask

Metal 2 side

Polyimide Tape

Solder Mask

Metal 1 side

It is necessary to use a heat sink tied to the copper heat speader.

Moreover, there is only a little layer of painting over the copper heat spreader which does not

isolate it.

It is therefore recommended to either isolate the heat sink from the other components of the

board or to electrically isolate the copper heat spreader from the heat sink. In the latter case,

one should use adequate low Rth electrical isolation.

2105C–BDC–11/03

29

Page 30

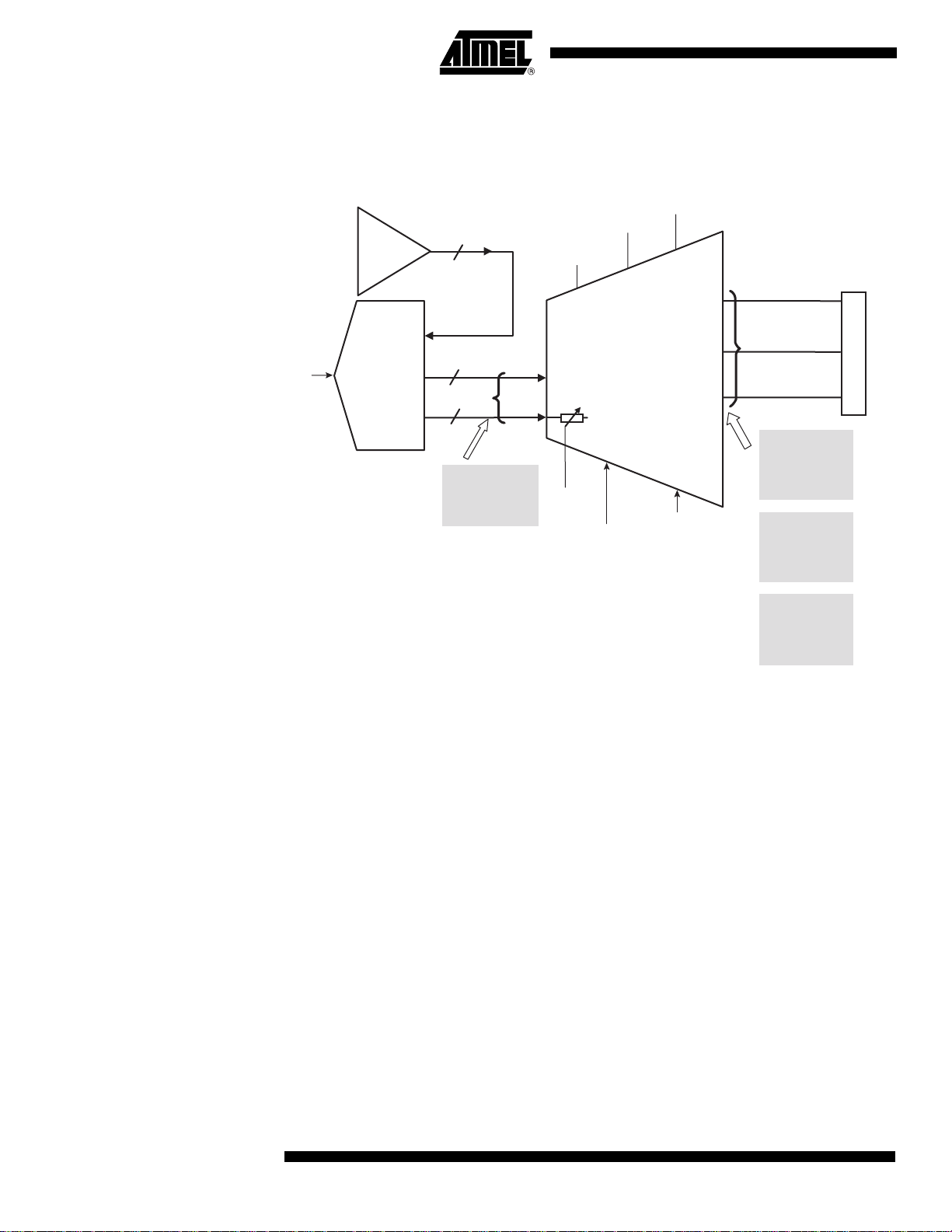

Applying the

TS81102G0

DMUX

The TSEV81102G0 DMUX evaluation board is designed to be connected with the

TSEV8388G and TSEV83102G0 ADC evaluation boards.

Figure 25. TSEV81102G0 DMUX Evaluation Boards

VplusD = 0V → 3.3V

CLOCK

BUFFER

Clkln

Analog

Input

ADC

Data

Bus

Data

Ready

8bits 1 GHz TS8388B

10bits 2 GHz TS83102G0

s-e or diff.

(2 GHz)

(1 GHz)

8b/10b diff.

(1 - 2 GHz)

1b diff.

ECL

Rload = 50Ω

Vih = -1.0V

Vil = -1.4V

FS

Vcc = +5V

I[0..9]

Clkln

Delay

adjust

control

DEMUX

delay

Number

of bits

(8/10)

Vee = -5V

A[0..9] → H[0..9]

Synchronous or

Asynchronous

TS81102G0

RefA → RefH

DR

Reset

(125 MHz)

8x8b/10b single

(DC)

8 ref

(250 MHz)

1b diff.

ECL + ref

VplusD = ground

Rload = 50Ω

Vtt = -2V

Voh = -0.8V

Vol = -1.8V

TTL + ref

VplusD = 3.3V

Rload ≥ 75Ω

Vtt = ground

Voh = 2.5V

Vol = 0.5V

PECL + ref

VplusD = 3.3V

Rload = 50Ω

Vtt = 1.3V

Voh = 2.5V

Vol = 1.5V

ASIC

30

Please refer to the "ADC and DMUX Application Note" for more information.

TS81102G0

2105C–BDC–11/03

Page 31

TS81102G0

ADC to DMUX

Connections

The DMUX inputs configuration has been optimized to be connected to the TS8388B ADC.

The die in the TBGA package is up. For the ADC, different types of packages can be used

such as CBGA with die up or the CQFP68 down. The DMUX device being completely symmetrical, both ADC packages can be connected to the TBGA pa ckage of the DMUX crisscrossing the lines (see Table 8).

Table 8. ADC to DMUX Connections

ADC Digital Outputs

CQFP68 Package

D0 I7 D0 I0

D1 I6 D1 I1

D2 I5 D2 I2

D3 I4 D3 I3

D4 I3 D4 I4

D5 I2 D5 I5

D6 I1 D6 I6

D7 I0 D7 I7

– 18 not connected – 18 not connected

– 19 not connected – 19 not connected

DMUX Data Inputs

TBGA Package

ADC Digital Outputs

CBGA Package

DMUX Data Inputs

TBGA Package

Note: The connection between the ADC evaluation board and the DMUX evaluation board requires a

4-pin shift to make the D0 pin match either the I7 or I0 pin of the DMUX evaluation board.

2105C–BDC–11/03

31

Page 32

TSEV81102G0TP: Device Evaluation Board

General

Description

The TSEV81102G0TP DMUX Evaluation Board (EB) is designed to simplify the characterization and the evaluation of the TS81102G0 device (2 Gsps DMUX). The DMUX EB enables

testing of all the DMUX functions: Synchronous and Asynchronous reset functions, selection

of the DMUX ratio (1:4 or 1:8), selection of the number of bits (8 or 10), output data common

mode and swing adjustment, die junction temperature measurements over military temperature range, etc.

The DMUX EB has been designed to enable easy connection to Atme’s ADC Evaluation

Boards (such as TSEV8388BGL or TSEV83102G0BGL) for an extended functionality evaluation (ADC and DMUX multi-channel applications).

The DMUX EB comes fully assembled and tested, with a TS81102G0 device implemented on

the board and a heat sink assembled on the device.

32

TS81102G0

2105C–BDC–11/03

Page 33

TS81102G0

Ordering

Information

Table 9. Ordering Information

Part Number Package Temperature Range Screening Comments

JTS81102G0-1V1A Die Ambient Visual inspection

TS81102G0CTP TBGA 240 "C" grade

0°C < Tc; Tj < 90°C

TS81102G0VTP TBGA 240 "V" grade

-40°C < Tc; Tj < 110°C

TSEV81102G0TPZR3 TBGA 240 Ambient Prototype Evaluation board (delivered

Datasheet

Standard

Standard

with heatsink)

Status

Description

Table 10. Datasheet Status

Datasheet Status Validity

Objective specification This datasheet contains target and

goal specifications for discussion with

customer and application validation.

Target specification This datasheet contains target or

goal specifications for product

development.

Preliminary specificati on

α-site

Preliminary specificati on

β-site

Product specification This datasheet contai ns final product

Limiting Values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress

above one or more of the limiting values may cause permanent damage to the device. These are

stress ratings only and operation of the device at these or at any other conditions above those given in

the Characteristics sections of the specification is not implied. Exposure to limiting values for extended

periods may affect device reliability.

Application Information

This datasheet contains preliminary

data. Additional data may be

published later; could include

simulation results.

This datasheet contains also

characterization results.

specification.

Before design phase

Valid during the design phase

Valid before characterization

phase

Valid before the

industrialization phase

Valid for production purposes

Life Support

Applications

2105C–BDC–11/03

Where application information is given, it is advisory and does not form part of the specification.

These products are not designed for use in life-support appliances, devices or systems where

malfunction of these products can reasonably be expected to result in person al injury. Atmel

customers using or selling these products for use in such applications do so at their own risk

and agree to fully indemnify Atmel for any damages resulting from such improper use or sale.

33

Page 34

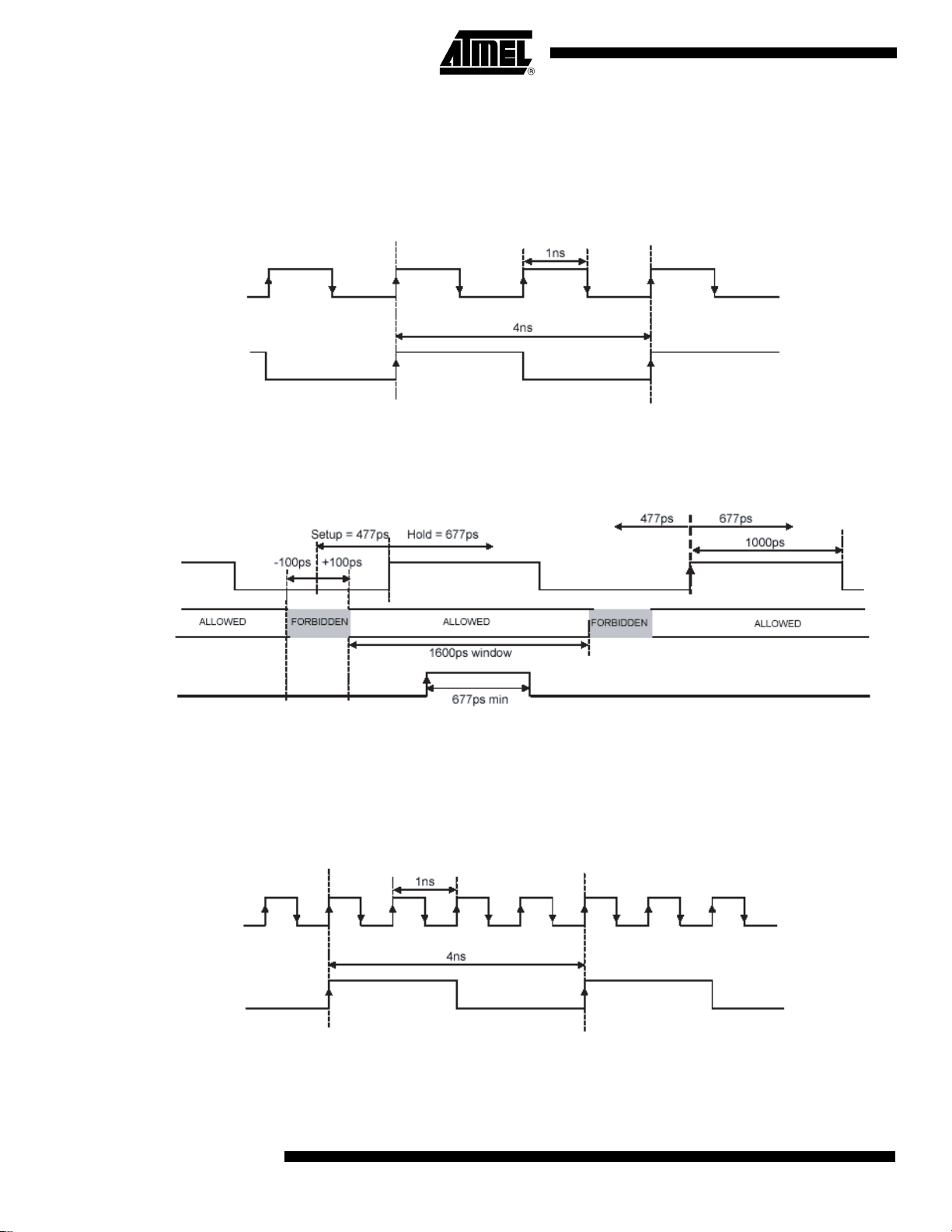

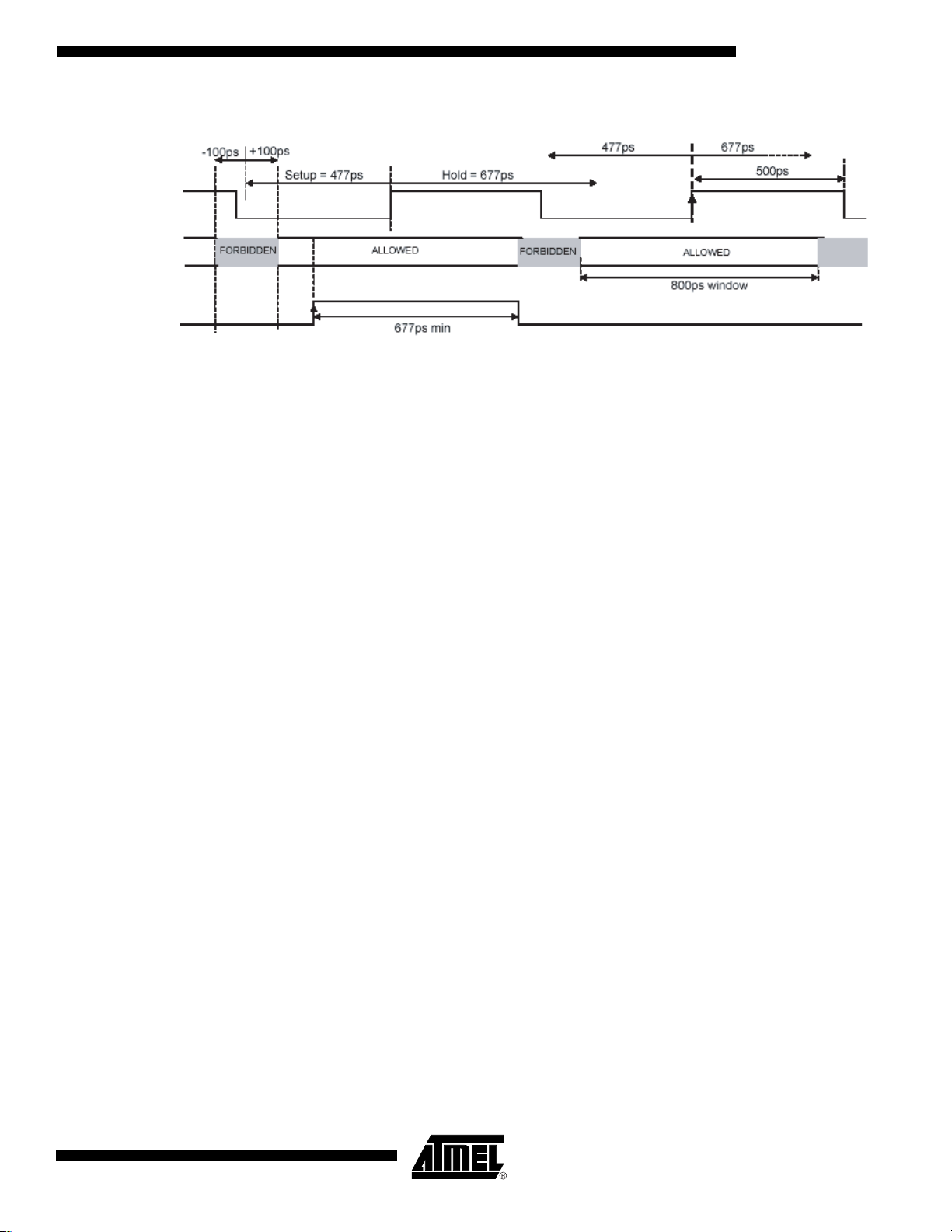

Addendum This section has been added to the description of the device for better understanding of the

synchronous reset operation. It puts particular stress on the setup and hold times defined in

the switching characteristics table (Table 5), linked with the device performances when used

at full speed (2 Gsps).

Synchronous

Reset Operation

SETUP and HOLD

Timings

It first describes the operation of the synchron ous reset in case the DMUX is used in DR mode

and then when used in the DR/2 mode.

As a reminder, the synchronous reset has to be a signal frequency of Fs/8N in 1:8 ratio or

Fs/4N in 1:4 ratio, where N is an integer.

The effect of the synchronous reset is to ensure that at each new port selection cycle, the first

port to be selected is port A. The synchronous reset ensures the internal cyclic synchronization of the device during operation. It is also highly recommended in the case of multichannel

applications using 2 synchronized DMUXs.

The setup and hold times for the reset are defined as follows:

• SETUP from SynchReset to Clkin:

Required delay between the rising edge of the reset and the rising edge of the clock to ensure

that the reset will be taken into account at the next clock edge. If the reset rising edge occurs

at less than this setup time, it will be taken into account only at the second next rising edge of

the clock.

A margin of ± 100ps has to be added to this setup time to compensate for the delays from the

drivers and lines.

• HOLD from Clkin and SynchReset:

Minimum duration of the reset signal at a high level to be taken int o account by the DMUX.

This means that the reset signal has to s atisfy 2 requ iremen ts: a frequ ency of Fs/8 N or Fs/4N

(N is an integer) depending on the ratio and a duty cycle such that it is high during at least the

hold time.

Operation in DR Mode In DR mode, the DMUX input clock can run at up to 2 GHz in 1:8 ratio or 1 GHz in 1:4 ratio.

Both cases are described in the following timing diagrams.

Figure 26. Synchronous Reset Operation in DR Mode, 1:4 ratio, 1GHz (Full Speed) – Principle of Operation

Fs

Sync_RESET

34

TS81102G0

2105C–BDC–11/03

Page 35

TS81102G0

Figure 27. Synchronous Reset Operation in DR Mode, 1:4 ratio, 1GHz (Full Speed) – TIMINGS

Fs

Time Zones

Allowed for

the reset

Sync_RESET

Note: The clock edge to which the reset applies is the one identified by the arrow.

If the reset rising edge had occurred in the second allowed window, the reset would have been effective on the third clock rising edge (not

represented, on the right of the edge represented with the arrow).

Figure 28. Synchronous Reset Operation in DR Mode, 1:8 ratio, 2 GHz (Full-speed) – Principle of Operation

Fs

Sync_RESET

Figure 29. Synchronous Reset Operation in DR Mode, 1:8 rati o, 2 GHz (Full-speed) – Timings

Fs

Times Zones

Allowed for

the reset

Sync_RESET

Note: The clock edge to which the reset applies is the one identified by the arrow.

If the reset rising edge had occurred in the second allowed window, the reset would have been effective on the fourth clock

rising edge (last clock rising edge, on the right of the edge re presented with the arrow).

This case is the most critical one with only a 300 ps window for the reset.

2105C–BDC–11/03

35

Page 36

Operation in DR/2

Mode

In DR/2 mode, the DMUX input clock can run at up to 1 GHz in 1:8 ratio or 500 MHz in 1:4

ratio, since the DR/2 clock from the ADC is half the sampling frequency.

Both cases are described in the following timing diagrams.

Figure 30. Synchronous Reset Operation in DR/2 Mode, 1:4 ratio, 500MHz (Full Speed) – Principle of Operation

Fs/2

Sync_RESET

Figure 31. Synchronous Reset Operation in DR/2 Mode, 1:4 ratio, 500 MHz (Full-speed) – Timings

Fs/2

Times Zones

Allowed for the

reset

Sync_RESET

Note: The clock edge to which the reset applies is the one identified by the arrow.

If the reset rising edge had occurred in the first allowed window (on the le ft) , the re set w ould have been effective on the fi rst

represented clock rising edge (first clock rising edge of the schematic, on the left of the edge represented with the arrow).

Figure 32. Synchronous Reset Operation in DR/2 Mode, 1:8 ratio, 1GHz (Full Speed) – Principle of Operation

Fs/2

Sync_RESET

36

TS81102G0

2105C–BDC–11/03

Page 37

TS81102G0

Figure 33. Synchronous Reset Operation in DR/2 Mode, 1:8 ratio, 1GHz (Full-speed) – Timings

Fs/2

Times Zones

Allowed for the

reset

Sync_RESET

Note: The clock edge to which the reset applies is the one identified by the arrow.

If the reset rising edge had occurred in the second allowed window, the reset would have been effective on the fourth clock rising edge

(not represented, on the right of the edge represented with the arrow).

2105C–BDC–11/03

37

Page 38

Atmel Headquarters Atmel Operations

Corporate Headquarters

2325 Orchard Parkway

San Jose, CA 95131, USA

TEL 1(408) 441-0311

FAX 1(408) 487-2600

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

TEL (41) 26-426-5555

FAX (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimhatsui

East Kowloon

Hong Kong

TEL (852) 2721-9778

FAX (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

TEL (81) 3-3523-3551

FAX (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

TEL 1(408) 441-0311

FAX 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

TEL 1(408) 441-0311

FAX 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

TEL (33) 2-40-18-18-18

FAX (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

TEL (33) 4-42-53-60-00

FAX (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

TEL 1(719) 576-3300

FAX 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

TEL (44) 1355-803-000

FAX (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

TEL (49) 71-31-67-0

FAX (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

TEL 1(719) 576-3300

FAX 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

TEL (33) 4-76-58-30-00

FAX (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

© Atmel Corporation 2002.

Atmel Corporation makes no warranty for the use of its products, other than those expressly contained in the Company’s standard warrant y

which is detailed in Atmel’s Terms and Conditions located on the Company’s web site. The Company assumes no responsibility for any errors

which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without notice, and does

not make any commitment to update the information contained herein. No licenses to patents or other intellectual property of Atmel are granted

by the Company in connection with the sale of Atmel products, expressly or by implication. Atmel’s products are not auth ori zed for use as critical

components in life support devices or systems.

ATMEL® is the registered trademark of Atmel.

Other terms and product names may be the trademark of others.

Printed on recycled paper.

2105C–BDC–11/03

0M

Loading...

Loading...