Page 1

Installation Instructions Model 4500 Alcohol Conversion Kit

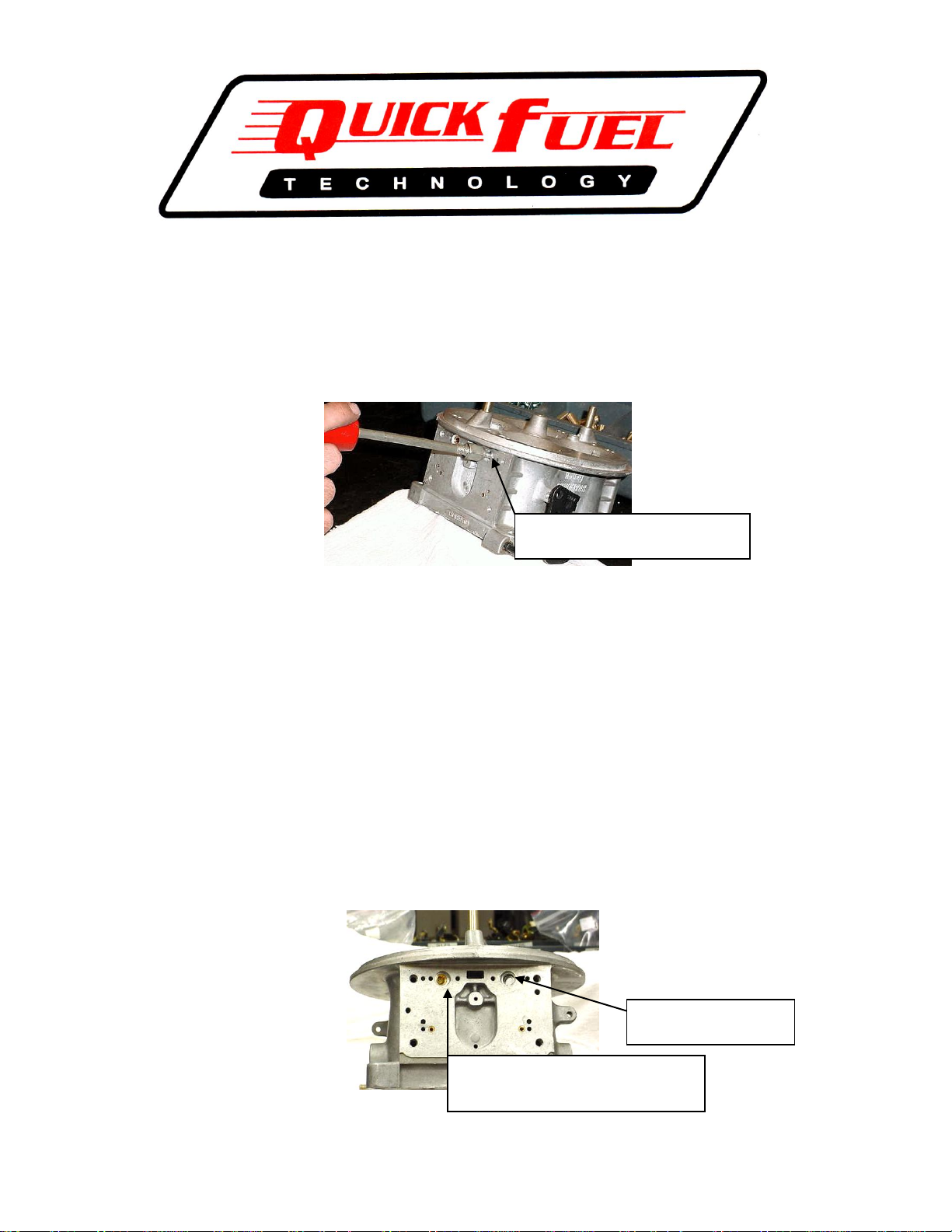

Remove booster pin with dent puller

(sheet metal screw)

Align brass pin with hole in booster, coat

with Loctite®, tap lightly, check alignment

drive until flush with casting recess.

Check alignment before

installing brass pin

Thank you for purchasing QFT’s alcohol conversion kit. This conversion is not particularly difficult

however. there are a few precautions and special instructions you should follow to be certain the conversion

goes smoothly.

1. Completely disassemble the major components; i.e. fuel bowls and metering blocks.

2. With the bowls and blocks removed, remove the locator pins that hold in the booster venturi. The

easiest way to accomplish this is to use a sheet metal screw and a dent remover as shown here.

3. With the booster venturi removed you can now install the new booster assemblies. This is a critical

step and essential that the fit and location of the booster venturi is correct. The casting that holds the

annular insert has a raised line on each side of the locator tab. This is to ensure a tight fit in the main

body casting.

4. Trial fit the booster in the main body to ensure it can be placed deep enough to align with the booster

pin hole in the main body. Look through the booster pin hole on the metering block surface of the

main body, trial fit each booster assembly to check alignment of the booster pin holes. If the holes do

not align it will be necessary to remove material from the raised casting line to achieve a tight fit,

however to enable proper alignment. Material can be removed using a hand file.

5. Once boosters are properly aligned, place a drop of two of Red Loctite® on the booster pin provided.

Insert the booster pin through the main body and into the booster. Lightly tap initially in place with a

small hammer, using a punch with the same OD as the booster pin. Check your progress frequently to

be certain the alignment is maintained. NOTE: When the last step of the booster pin enters the main

body boss the resistance to drive in the pin will become greater. Check the alignment one additional

time then finish driving the booster pin until the pin is flush with the relief cut in the main body.

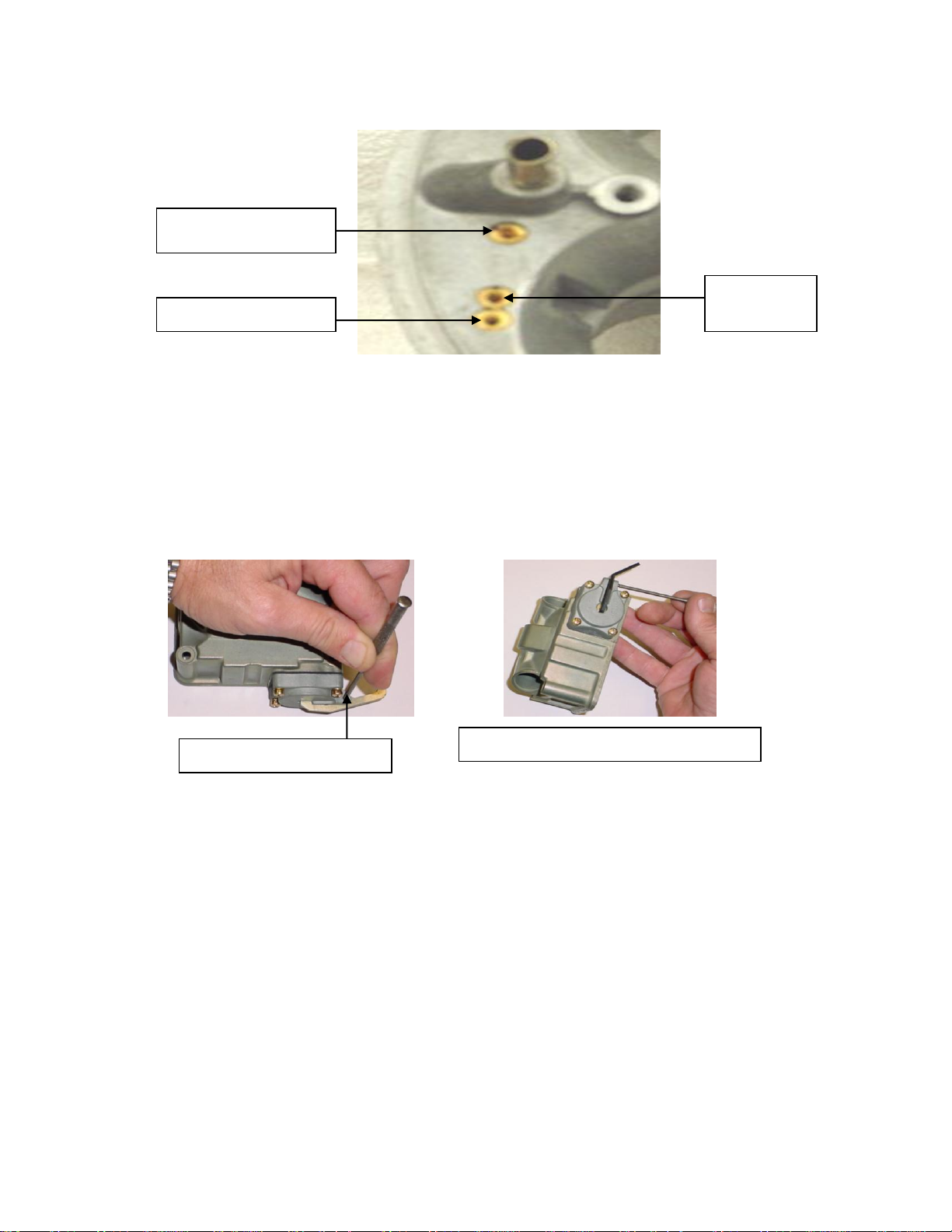

6. Remove all of the air bleeds from the top section of the main body. Each throttle bore has three

threaded bleed bosses. Working from the outside, in the boss furthest away from the center of the

Page 2

carburetor install the BLANK bleed. In the boss right next to it, moving toward the center, install the

Install blank air bleed here

Install #40 here

this is the idle

air bleed.

Insert #25 bleed here, this is

the high speed bleed.

Remove roll pin with small punch

Reinstall roll pin with new pump arm as shown.

air bleed marked with the number 40. In the boss next to the accelerator pump discharge nozzle insert

the air bleed marked with the number 25. Repeat this same sequence in the remaining throttle bores.

7. Remove the two pump discharge nozzles (squirters) and stainless screws. In the small parts bag find

the two thick composite gaskets, two thin paper gaskets. Place the composite gasket on the accelerator

pump nozzle hole in the main body, slip the paper gasket over the nozzle screw, then the nozzle

(squirter) and install as a unit on top of the composite gasket, center on the locator tab and tighten with

an 5/32” Allen wrench. The main body portion is now complete

8. Place the fuel bowl so the opening is facing down on your workbench. With a small punch drive the

roll pin that retains the operating arm out of the accelerator pump housing. Install the bent pump arm

supplied with the angled section facing away or pointing down. Tap in the original roll pin with a

small punch until the roll pin is just about flush with the housing. Repeat the process on the second

bowl.

9. While the fuel bowl is still facing down on the workbench remove the old needle and seat assembly.

Hold the adjustment nut with a 5/8” wrench, with a large blade screwdriver loosen the lock screw

while holding the nut. Remove the needle and seat assembly. Set this assembly aside temporarily.

10. Turn the fuel bowl over. With a medium common tip screwdriver, remove the two screws holding in

the float assembly. Remove the entire assembly. Do both fuel bowls at the same time.

11. Lay both floats down on the workbench the same way it came out of the float bowl, with the hinge on

top. Remove the float hinge by pulling it through both the float bracket, float hinge and spring.

12. Reassemble using the new float. Place the float on the workbench in the same orientation as the bowl,

place the hinge on top of the float, and align the holes. Place the small end of the spring in the float

hinge locator hole. Slide the float hinge through the bracket and hinge holes as well as the float spring.

Once all the way through the assembly take the long end of the spring and position it in the cutout in

the float hinge. Use the other float assembly as a guide if needed. Repeat, using the first assembly as a

reference if needed.

13. Install the float assembly into each bowl. Insert the original screws and tighten. Note; these are self-

tapping screws so do not over-tighten.

14. Remove the adjusting nut and lock screw from the needle and seat assemblies. Locate the appropriate

gaskets in the small parts bag. Thread in the new needle and seat assembly into the fuel bow. When

the resistance makes it difficult, turn the fuel bowl upside down, place the large gasket on top of the

adjusting nut, slip the gasket and nut over the notch in the needle and seat assembly. Turn the nut

clockwise until the straight edge of the float is even with the center of the float bracket retainer screws.

With the float bowl still inverted, use a 3/8” drill bit, adjust the needle and seat until the drill just fits

Page 3

between the flat surface of the float and surface directly below. This is the correct dry setting and you

should not have to alter this initial setting a great deal when running. Repeat this process with the

second bowl.

15. Install the jets supplied in the metering blocks; install the power valve plug and gaskets.

16. Install the metering block gasket and fuel bowl gasket on the metering blocks.

17. Install the second fuel bowl gasket on the fuel bowl extension. Note the location of the accelerator

pump discharge hole to be certain the fuel bowl extension is properly oriented.

18. Place the metering block on the main body, install the fuel bowl extension, then install the fuel bowl

(be sure the accelerator pump operating arm is oriented correctly over the fuel bowl pump arm). Install

the blue nylon gaskets over the new, longer fuel bowl screws and insert through the fuel bowl, fuel

bowl extension and metering block. Tighten in sequence and torque to 35 inch pounds.

19. It may be necessary to re-adjust the accelerator pump orientation and over-ride spring adjustment.

With the carburetor inverted, check the alignment of the fuel bowl accelerator pump arm to be sure it is

centered on the adjustment bolt head. If necessary re-align with an adjustable wrench or suitable pliers

that will not mare the finish. Once aligned, check the pump override adjustment. There should be

tension on the fuel bowl pump arm at idle and some clearance at wide-open throttle. The

recommended clearance at wide open is .015”. The clearance does not have to be exact; the primary

reason for this measurement is to prevent the pump arm from bottoming out against the bowl. This

could possibly result in the accelerator pump housing loosening up over time resulting in a fuel leak.

20. Adjust the idle mixture screws to 2 turns from lightly seated as your baseline. You can leave your idle

speed screws in approximately the same position although this would be a good time to be certain that

your primary and secondary idle speed screws are an equal number of turns open. This helps to

balance the carburetor.

21. Install your carburetor on the intake manifold. Run your electric pump for approximately 15 seconds.

If you have a belt or engine driven mechanical pump crank the engine for approximately 15 seconds.

Operate the throttle by hand or have a helper observe that fuel is coming out the accelerator pump (this

may take a couple of strokes to fill the passage). Once you have accelerator pump shot from both the

primary and secondary you can now start the engine.

22. Note in extremely cold air temperatures or if the mixture happens to be too rich, it may be necessary to

“prime” the engine with either gasoline or in some cases carburetor cleaner will work. It does not

require a large volume just enough to give the engine a shot of a more combustible mixture.

23. Once the engine has started allow it to run at a slightly elevated speed to build a little heat in the

engine. This is a good time to check the float level to make sure they are correct. If the carburetor is

flooding or you have to adjust it down a great deal your fuel pressure is too high. The larger needle

and seat (.150” versus the standard .110”) is more difficult to close with elevated fuel pressure. If you

have to adjust the needle and seat assembly down (clockwise) then you are reducing the amount of

float drop. This will ultimately reduce the flow ability of the needle, regardless of pressure. A

properly set float level (the 3/8” dry setting you did earlier on the float bowl) will flow more at 6 P.S.I.

than a larger needle and seat adjusted down only .075” will flow at 9 P.S.I. The higher fuel pressure

will not “force” the needle to flow more. Do not confuse pressure with volume. Just because you have

pressure does automatically mean you have volume. Lower your fuel pressure and concentrate on

volume delivery. Your carburetor will work a whole lot better at low speed and you won’t have to

worry about “running out of fuel” at the top end.

24. Once the float level has been established and the engine has run long enough to build some heat, adjust

the idle mixture screws the same way you would a gasoline engine. It is necessary to find the “lean”

position of the idle mixture screws, the point at which the engine begins to slow down or labor because

it is too lean. If you turn the mixture screws in and the engine speed picks up then the mixture is too

rich. Should all the mixture screws be turned in all the way and the engine speed does not fall off then

it may be necessary to either change the idle feed restriction (reduce the size) or increase the size of the

idle air bleed (larger number). Ultimately you want to have the mixture lean out before the mixture

screw is seated, then back it out approximately ¼ turn. This gives you the best idle air/fuel mixture

setting and quality.

25. You may also want to consider installing a “lean out” valve in your intake manifold. This is simply a

device that induces a vacuum leak. The helps the engine heat up quicker when first started.

26. Once you have the float level and idle mixture settings established you can now make wide open

throttle runs. While there are numerous ways to determine the proper jetting a couple of basic

parameters help establish if you are in the correct range. First, the engine should gain a little heat

going down track, something on the order of 20 to 30 degree engine temperature. Second, you can

change jets using the MPH as a reference. If the MPH picks up you are obviously heading in the right

direction. Conversely if the MPH declines then the last change hurt the performance and probably in

the wrong direction.

Page 4

27. Alcohol is not effected as much by air temperature and/or atmospheric conditions. Therefore the

performance should be more consistent and predictable during a day of racing. The general rule of

thumb is every 40 degrees represents a 4% change in air/fuel. Normally this would be one jet number

in a gasoline jet, however, with alcohol a 4% change is going to be a wider spread, as the hole in the

main jet is so much larger. With a baseline jet of 188 a 4% increase is to a #192 a 4% decrease is to

#184.

28. We hope you enjoy your alcohol conversion kit. We remind you that alcohol, as a racing fuel is a high

maintenance product. It is not stable over a long period of time, it will absorb water from the air to the

point of equaling its own weight in water. It is our recommendation to mix your own top lube and

scent rather than purchase your fuel with these elements pre-mixed. Methanol is petroleum based

product and can transform into paraffin when it becomes unstable or with the use of mixing products

that accelerate a breakdown over a short period of time. If performance begins to fall off or flooding

begins, disassemble the fuel bowl to check for dirt, debris or paraffin.

Thank you for purchasing a Quick Fuel Technology alcohol conversion kit we are confident you will be

extremely happy with the performance. This confidence is based on the high quality; race proven

components used in this kit.

P/N 99-6

Quick Fuel Technology© 2004

Loading...

Loading...