Page 1

AG35 Hardware Design

Automotive Module Series

Rev. AG35_Hardware_Design_V1.3

Date: 2019-05-20

Status: Released

www.quectel.com

Page 2

Automotive Module Series

AG35 Hardware Design

Our aim is to provide customers with timely and comprehensive service. For any

assistance, please contact our company headquarters:

Quectel Wireless Solutions Co., Ltd.

7th Floor, Hongye Building, No.1801 Hongmei Road, Xuhui District, Shanghai 200233, China

Tel: +86 21 5108 6236

Email: info@quectel.com

Or our local office. For more information, please visit:

http://www.quectel.com/support/sales.htm

For technical support, or to report documentation errors, please visit:

http://www.quectel.com/support/technical.htm

Or email to: support@quectel.com

GENERAL NOTES

QUECTEL OFFERS THE INFORMATION AS A SERVICE TO ITS CUSTOMERS. THE INFORMATION

PROVIDED IS BASED UPON CUSTOMERS’ REQUIREMENTS. QUECTEL MAKES EVERY EFFORT

TO ENSURE THE QUALITY OF THE INFORMATION IT MAKES AVAILABLE. QUECTEL DOES NOT

MAKE ANY WARRANTY AS TO THE INFORMATION CONTAINED HEREIN, AND DOES NOT ACCEPT

ANY LIABILITY FOR ANY INJURY, LOSS OR DAMAGE OF ANY KIND INCURRED BY USE OF OR

RELIANCE UPON THE INFORMATION. ALL INFORMATION SUPPLIED HEREIN IS SUBJECT TO

CHANGE WITHOUT PRIOR NOTICE.

COPYRIGHT

THE INFORMATION CONTAINED HERE IS PROPRIETARY TECHNICAL INFORMATION OF

QUECTEL WIRELESS SOLUTIONS CO., LTD. TRANSMITTING, REPRODUCTION, DISSEMINATION

AND EDITING OF THIS DOCUMENT AS WELL AS UTILIZATION OF THE CONTENT ARE

FORBIDDEN WITHOUT PERMISSION. OFFENDERS WILL BE HELD LIABLE FOR PAYMENT OF

DAMAGES. ALL RIGHTS ARE RESERVED IN THE EVENT OF A PATENT GRANT OR

REGISTRATION OF A UTILITY MODEL OR DESIGN.

Copyright © Quectel Wireless Solutions Co., Ltd. 2019. All rights reserved.

AG35_Hardware_Design 1 / 129

Page 3

AG35 Hardware Design

Revision

Date

Author

Description

1.0

2018-03-19

Eden LIU/

Dominic GONG

Initial

1.1

2018-12-12

Eden LIU/

Dominic GONG/

Ethan SHAN

1. Updated the variants and/or frequency bands of

AG35 (Table 1).

2. Updated the functional diagram (Figure 1).

3. Updated the pin assignment of AG35 (Figure 2).

4. Updated the drive current of STATUS pin (Table 4).

5. Enabled SHDN_N (pin 176), and added the

description of the interface in Chapter 3.7.2.3.

6. Enabled an optional audio interface (pins 132~141)

for AG35 (Chapter 3.12).

7. Updated the pin definition of PCM and I2C

interfaces in Chapter 3.13.

8. Updated the power domain of SGMII interface

(Chapter 3.15).

9. Added the description of RTC function (Chapter

3.22).

10. Added GNSS performance values of AG35-NA and

AG35-J (Chapter 4.2).

11. Completed the operating frequency of the module

(Chapter 5.1.2),

12. Updated the frequency of Galileo and QZSS (Table

34).

13. Updated current consumption values of the module

(Chapter 6.4).

14. Completed the RF output power values of the

module (Chapter 6.5).

15. Added the RF receiving sensitivity of AG35-E,

AG35-NA and AG35-J (Chapter 6.6).

About the Document

History

Automotive Module Series

AG35_Hardware_Design 2 / 129

Page 4

Automotive Module Series

16. Updated the recommended reflow soldering

thermal profile and involved parameters (Chapter

8.2).

1.2

2019-04-30

Eden LIU/

Dominic GONG

1. Removed the optional LTE-FDD B28 from

AG35-NA.

2. Enabled HSIC interface (pin 194/195) and added

related information thereof (Chapter 2.2, Chapter

2.3, Chapter 3.2, Chapter 3.3 and Chapter 3.23).

3. Added audio interface characteristics (Table 17).

4. Updated the reference circuit for connection with

AF20 module (Figure 29).

5. Added AG35-E and AG35-LA GNSS performance

parameters (Table 33 and Table 35).

6. Updated AG35-J GNSS performance parameters

(Table 36).

7. Updated GNSS frequency (Table 44).

8. Updated current consumption values of the module

(Chapter 6.4).

9. Updated RF receiving sensitivity (Chapter 6.6).

10. Updated electrostatic discharge characteristics

(Table 69).

11. Updated the recommended stencil thickness and

the peak reflow temperature (Chapter 8.2).

1.3

2019-05-20

Eden LIU

Corrected some pin names in the pin assignment

figure (Figure 2).

AG35 Hardware Design

AG35_Hardware_Design 3 / 129

Page 5

Automotive Module Series

AG35 Hardware Design

Contents

About the Document ................................................................................................................................... 2

Contents ....................................................................................................................................................... 4

Table Index ................................................................................................................................................... 7

Figure Index ................................................................................................................................................. 9

1 Introduction ........................................................................................................................................ 11

1.1. Safety Information ..................................................................................................................... 15

2 Product Concept ................................................................................................................................ 17

2.1. General Description .................................................................................................................. 17

2.2. Key Features ............................................................................................................................. 18

2.3. Functional Diagram ................................................................................................................... 21

2.4. Evaluation Board ....................................................................................................................... 22

3 Application Interfaces ....................................................................................................................... 23

3.1. General Description .................................................................................................................. 23

3.2. Pin Assignment ......................................................................................................................... 24

3.3. Pin Description .......................................................................................................................... 25

3.4. Operating Modes ....................................................................................................................... 36

3.5. Power Saving ............................................................................................................................ 37

3.5.1. Sleep Mode .................................................................................................................... 37

3.5.1.1. UART Application ................................................................................................ 38

3.5.1.2. USB Application with USB Remote Wakeup Function ....................................... 38

3.5.1.3. USB Application with USB Suspend/Resume and RI Functions ........................ 39

3.5.1.4. USB Application without USB Suspend Function ............................................... 40

3.5.2. Airplane Mode ................................................................................................................ 40

3.6. Power Supply ............................................................................................................................ 41

3.6.1. Power Supply Pins ......................................................................................................... 41

3.6.2. Decrease Voltage Drop .................................................................................................. 42

3.6.3. Reference Design for Power Supply .............................................................................. 43

3.6.4. Monitor the Power Supply .............................................................................................. 43

3.7. Turn on and off Scenarios ......................................................................................................... 43

3.7.1. Turn on Module Using the PWRKEY ............................................................................. 43

3.7.2. Turn off Module .............................................................................................................. 45

3.7.2.1. Turn off Module Using the PWRKEY Pin ............................................................ 45

3.7.2.2. Turn off Module Using AT Command .................................................................. 46

3.7.2.3. Turn off Module Using SHDN_N ......................................................................... 46

3.8. Reset the Module ...................................................................................................................... 48

3.9. (U)SIM Interface ........................................................................................................................ 49

3.10. USB Interface ............................................................................................................................ 51

3.11. UART Interfaces ........................................................................................................................ 53

AG35_Hardware_Design 4 / 129

Page 6

Automotive Module Series

AG35 Hardware Design

3.12. Audio Interface (Optional) ......................................................................................................... 55

3.13. PCM and I2C Interfaces ............................................................................................................ 57

3.14. SDIO Interfaces ......................................................................................................................... 60

3.14.1. SDIO1 Interface ............................................................................................................. 60

3.14.2. SDIO2 Interface ............................................................................................................. 60

3.15. SGMII Interface (Optional) ........................................................................................................ 62

3.16. Wireless Connectivity Interfaces ............................................................................................... 64

3.16.1. WLAN Interface .............................................................................................................. 66

3.16.2. BT Interface* .................................................................................................................. 67

3.17. ADC Interfaces .......................................................................................................................... 67

3.18. Network Status Indication ......................................................................................................... 68

3.19. STATUS ..................................................................................................................................... 69

3.20. Behaviors of RI .......................................................................................................................... 70

3.21. USB_BOOT Interface................................................................................................................ 71

3.22. RTC ........................................................................................................................................... 72

3.23. HSIC Interface* ......................................................................................................................... 72

4 GNSS Receiver ................................................................................................................................... 74

4.1. General Description .................................................................................................................. 74

4.2. GNSS Performance .................................................................................................................. 74

4.3. Layout Guidelines ..................................................................................................................... 77

5 Antenna Interfaces ............................................................................................................................. 78

5.1. Main/Rx-diversity Antenna Interface ......................................................................................... 78

5.1.1. Pin Definition .................................................................................................................. 78

5.1.2. Operating Frequency ..................................................................................................... 78

5.1.3. Reference Design of RF Antenna Interfaces ................................................................. 82

5.1.4. Reference Design of RF Layout..................................................................................... 83

5.2. GNSS Antenna Interface ........................................................................................................... 85

5.3. Antenna Installation .................................................................................................................. 86

5.3.1. Antenna Requirements .................................................................................................. 86

5.3.2. Recommended RF Connector for Antenna Installation ................................................. 87

6 Electrical, Reliability and Radio Characteristics ............................................................................ 89

6.1. Absolute Maximum Ratings ...................................................................................................... 89

6.2. Power Supply Ratings ............................................................................................................... 90

6.3. Operation and Storage Temperatures ...................................................................................... 90

6.4. Current Consumption ................................................................................................................ 91

6.5. RF Output Power .................................................................................................................... 107

6.6. RF Receiving Sensitivity ..........................................................................................................111

6.7. Electrostatic Discharge ........................................................................................................... 115

6.8. Thermal Consideration ............................................................................................................ 115

7 Mechanical Dimensions .................................................................................................................. 118

7.1. Mechanical Dimensions of the Module ................................................................................... 118

7.2. Recommended Footprint ........................................................................................................ 120

AG35_Hardware_Design 5 / 129

Page 7

Automotive Module Series

AG35 Hardware Design

7.3. Design Effect Drawings of the Module .................................................................................... 121

8 Storage, Manufacturing and Packaging ........................................................................................ 122

8.1. Storage .................................................................................................................................... 122

8.2. Manufacturing and Soldering .................................................................................................. 123

8.3. Packaging ............................................................................................................................... 124

9 Appendix A References ................................................................................................................... 126

10 Appendix B GPRS Coding Schemes ............................................................................................. 130

11 Appendix C GPRS Multi-slot Classes ............................................................................................ 131

12 Appendix D EDGE Modulation and Coding Schemes ................................................................. 133

AG35_Hardware_Design 6 / 129

Page 8

Automotive Module Series

AG35 Hardware Design

Table Index

TABLE 1: FREQUENCY BANDS OF AG35 SERIES MODULES ..................................................................... 17

TABLE 2: AG35 KEY FEATURES ..................................................................................................................... 18

TABLE 3: I/O PARAMETERS DEFINITION ....................................................................................................... 25

TABLE 4: PIN DESCRIPTION ........................................................................................................................... 25

TABLE 5: OVERVIEW OF OPERATING MODES ............................................................................................. 36

TABLE 6: VBAT AND GND PINS ....................................................................................................................... 41

TABLE 7: PWRKEY PIN DESCRIPTION .......................................................................................................... 44

TABLE 8: PIN DEFINITION OF SHDN_N ......................................................................................................... 46

TABLE 9: RESET_N PIN DESCRIPTION ......................................................................................................... 48

TABLE 10: PIN DEFINITION OF (U)SIM INTERFACE ..................................................................................... 49

TABLE 11: PIN DEFINITION OF USB INTERFACE .......................................................................................... 51

TABLE 12: PIN DEFINITION OF MAIN UART INTERFACE ............................................................................. 53

TABLE 13: PIN DEFINITION OF UART2 INTERFACE (FOR BT FUNCTION*) ............................................... 53

TABLE 14: PIN DEFINITION OF DEBUG UART INTERFACE ......................................................................... 54

TABLE 15: LOGIC LEVELS OF DIGITAL I/O .................................................................................................... 54

TABLE 16: PIN DEFINITION OF ANALOG AUDIO INTERFACE ...................................................................... 55

TABLE 17: AUDIO INTERFACE CHARACTERISTICS ..................................................................................... 56

TABLE 18: PIN DEFINITION OF PCM INTERFACE ......................................................................................... 58

TABLE 19: PIN DEFINITION OF I2C INTERFACES ......................................................................................... 58

TABLE 20: PIN DEFINITION OF SDIO2 INTERFACE ...................................................................................... 60

TABLE 21: PIN DEFINITION OF SGMII INTERFACE ...................................................................................... 62

TABLE 22: PIN DEFINITION OF WIRELESS CONNECTIVITY INTERFACES ................................................ 64

TABLE 23: PIN DEFINITION OF ADC INTERFACES ....................................................................................... 67

TABLE 24: CHARACTERISTICS OF ADC INTERFACES ................................................................................ 68

TABLE 25: PIN DEFINITION OF NETWORK CONNECTION STATUS /ACTIVITY INDICATOR ..................... 68

TABLE 26: WORKING STATE OF THE NETWORK CONNECTION STATUS /ACTIVITY INDICATOR .......... 69

TABLE 27: PIN DEFINITION OF STATUS ........................................................................................................ 70

TABLE 28: DEFAULT BEHAVIORS OF RI ........................................................................................................ 71

TABLE 29: PIN DEFINITION OF USB_BOOT INTERFACE ............................................................................. 71

TABLE 30: PIN DEFINITION OF HSIC INTERFACE ........................................................................................ 72

TABLE 31: DESIGN GUIDELINES FOR HSIC.................................................................................................. 72

TABLE 32: AG35-CE GNSS PERFORMANCE ................................................................................................. 74

TABLE 33: AG35-E GNSS PERFORMANCE .................................................................................................... 75

TABLE 34: AG35-NA GNSS PERFORMANCE ................................................................................................. 75

TABLE 35: AG35-LA GNSS PERFORMANCE .................................................................................................. 76

TABLE 36: AG35-J GNSS PERFORMANCE .................................................................................................... 76

TABLE 37: PIN DEFINITION OF RF ANTENNA INTERFACES ........................................................................ 78

TABLE 38: AG35-CE OPERATING FREQUENCIES ........................................................................................ 78

TABLE 39: AG35-E OPERATING FREQUENCIES ........................................................................................... 79

TABLE 40: AG35-NA OPERATING FREQUENCIES ........................................................................................ 80

TABLE 41: AG35-LA OPERATING FREQUENCIES ......................................................................................... 80

AG35_Hardware_Design 7 / 129

Page 9

Automotive Module Series

AG35 Hardware Design

TABLE 42: AG35-J OPERATING FREQUENCIES ........................................................................................... 81

TABLE 43: PIN DEFINITION OF GNSS ANTENNA INTERFACE ..................................................................... 85

TABLE 44: GNSS FREQUENCY ....................................................................................................................... 85

TABLE 45: ANTENNA REQUIREMENTS .......................................................................................................... 86

TABLE 46: ABSOLUTE MAXIMUM RATINGS .................................................................................................. 89

TABLE 47: POWER SUPPLY RATINGS ........................................................................................................... 90

TABLE 48: OPERATION AND STORAGE TEMPERATURES .......................................................................... 90

TABLE 49: AG35-CE CURRENT CONSUMPTION (25°C, 3.8V POWER SUPPLY) ........................................ 91

TABLE 50: AG35-E CURRENT CONSUMPTION ............................................................................................. 94

TABLE 51: AG35-NA CURRENT CONSUMPTION ........................................................................................... 97

TABLE 52: AG35-LA CURRENT CONSUMPTION ......................................................................................... 100

TABLE 53: AG35-J CURRENT CONSUMPTION ............................................................................................ 104

TABLE 54: AG35-CE GNSS CURRENT CONSUMPTION ............................................................................. 106

TABLE 55: AG35-E GNSS CURRENT CONSUMPTION ................................................................................ 106

TABLE 56: AG35-NA GNSS CURRENT CONSUMPTION ............................................................................. 106

TABLE 57: AG35-LA GNSS CURRENT CONSUMPTION .............................................................................. 107

TABLE 58: AG35-J GNSS CURRENT CONSUMPTION................................................................................. 107

TABLE 59: AG35-CE RF OUTPUT POWER ................................................................................................... 107

TABLE 60: AG35-E RF OUTPUT POWER ...................................................................................................... 108

TABLE 61: AG35-NA RF OUTPUT POWER ................................................................................................... 109

TABLE 62: AG35-LA RF OUTPUT POWER .................................................................................................... 109

TABLE 63: AG35-J RF OUTPUT POWER ....................................................................................................... 110

TABLE 64: AG35-CE RF RECEIVING SENSITIVITY ...................................................................................... 111

TABLE 65: AG35-E RF RECEIVING SENSITIVITY ......................................................................................... 112

TABLE 66: AG35-NA RF RECEIVING SENSITIVITY ....................................................................................... 113

TABLE 67: AG35-LA RF RECEIVING SENSITIVITY ....................................................................................... 113

TABLE 68: AG35-J RF RECEIVING SENSITIVITY .......................................................................................... 114

TABLE 69: ELECTROSTATIC DISCHARGE CHARACTERISTICS ................................................................ 115

TABLE 70: RECOMMENDED THERMAL PROFILE PARAMETERS ............................................................. 123

TABLE 71: RELATED DOCUMENTS .............................................................................................................. 126

TABLE 72: TERMS AND ABBREVIATIONS .................................................................................................... 126

TABLE 73: DESCRIPTION OF DIFFERENT CODING SCHEMES ................................................................ 130

TABLE 74: GPRS MULTI-SLOT CLASSES .................................................................................................... 131

TABLE 75: EDGE MODULATION AND CODING SCHEMES ......................................................................... 133

AG35_Hardware_Design 8 / 129

Page 10

Automotive Module Series

AG35 Hardware Design

Figure Index

FIGURE 1: FUNCTIONAL DIAGRAM ............................................................................................................... 22

FIGURE 2: PIN ASSIGNMENT (TOP VIEW)..................................................................................................... 24

FIGURE 3: SLEEP MODE CURRENT CONSUMPTION DIAGRAM ................................................................ 37

FIGURE 4: SLEEP MODE APPLICATION VIA UART ....................................................................................... 38

FIGURE 5: SLEEP MODE APPLICATION WITH USB REMOTE WAKEUP .................................................... 39

FIGURE 6: SLEEP MODE APPLICATION WITH RI ......................................................................................... 39

FIGURE 7: SLEEP MODE APPLICATION WITHOUT SUSPEND FUNCTION ................................................ 40

FIGURE 8: POWER SUPPLY LIMITS DURING BURST TRANSMISSION ...................................................... 42

FIGURE 9: STAR STRUCTURE OF THE POWER SUPPLY............................................................................ 42

FIGURE 10: REFERENCE CIRCUIT OF POWER SUPPLY ............................................................................ 43

FIGURE 11: TURN ON THE MODULE USING DRIVING CIRCUIT ................................................................. 44

FIGURE 12: TURN ON THE MODULE USING KEYSTROKE ......................................................................... 44

FIGURE 13: TIMING OF TURNING ON MODULE ........................................................................................... 45

FIGURE 14: TIMING OF TURNING OFF MODULE ......................................................................................... 46

FIGURE 15: SHUT DOWN THE MODULE USING DRIVING CIRCUIT ........................................................... 47

FIGURE 16: TIMING OF TURNING OFF MODULE VIA SHDN_N ................................................................... 47

FIGURE 17: REFERENCE CIRCUIT OF RESET_N BY USING DRIVING CIRCUIT ...................................... 48

FIGURE 18: REFERENCE CIRCUIT OF RESET_N BY USING BUTTON ...................................................... 48

FIGURE 19: TIMING OF RESETTING MODULE ............................................................................................. 49

FIGURE 20: REFERENCE CIRCUIT OF (U)SIM INTERFACE WITH AN 8-PIN (U)SIM CARD CONNECTOR

................................................................................................................................................................... 50

FIGURE 21: REFERENCE CIRCUIT OF (U)SIM INTERFACE WITH A 6-PIN (U)SIM CARD CONNECTOR . 50

FIGURE 22: REFERENCE CIRCUIT OF USB APPLICATION ......................................................................... 52

FIGURE 23: REFERENCE CIRCUIT WITH TRANSLATOR CHIP ................................................................... 54

FIGURE 24: REFERENCE CIRCUIT WITH TRANSISTOR CIRCUIT .............................................................. 55

FIGURE 25: PRIMARY MODE TIMING ............................................................................................................ 57

FIGURE 26: AUXILIARY MODE TIMING .......................................................................................................... 58

FIGURE 27: REFERENCE CIRCUIT OF PCM APPLICATION WITH AUDIO CODEC .................................... 59

FIGURE 28: REFERENCE CIRCUIT OF SD CARD APPLICATION ................................................................ 61

FIGURE 29: REFERENCE CIRCUIT FOR CONNECTION WITH AF20 MODULE .......................................... 66

FIGURE 30: REFERENCE CIRCUIT OF THE NETWORK INDICATOR .......................................................... 69

FIGURE 31: REFERENCE CIRCUIT OF THE STATUS ................................................................................... 70

FIGURE 32: REFERENCE CIRCUIT OF USB_BOOT INTERFACE ................................................................ 71

FIGURE 33: REFERENCE CIRCUIT OF RF ANTENNA INTERFACES ........................................................... 82

FIGURE 34: MICROSTRIP DESIGN ON A 2-LAYER PCB ............................................................................... 83

FIGURE 35: COPLANAR WAVEGUIDE DESIGN ON A 2-LAYER PCB ........................................................... 83

FIGURE 36: COPLANAR WAVEGUIDE DESIGN ON A 4-LAYER PCB (LAYER 3 AS REFERENCE GROUND)

................................................................................................................................................................... 84

FIGURE 37: COPLANAR WAVEGUIDE DESIGN ON A 4-LAYER PCB (LAYER 4 AS REFERENCE GROUND)

................................................................................................................................................................... 84

FIGURE 38: REFERENCE CIRCUIT OF GNSS ANTENNA ............................................................................. 85

AG35_Hardware_Design 9 / 129

Page 11

Automotive Module Series

AG35 Hardware Design

FIGURE 39: DIMENSIONS OF THE U.FL-R-SMT CONNECTOR (UNIT: MM) ................................................ 87

FIGURE 40: MECHANICALS OF U.FL-LP CONNECTORS ............................................................................. 87

FIGURE 41: SPACE FACTOR OF MATED CONNECTOR (UNIT: MM) ........................................................... 88

FIGURE 42: REFERENCED HEATSINK DESIGN (HEATSINK AT THE TOP OF THE MODULE) ................. 116

FIGURE 43: REFERENCED HEATSINK DESIGN (HEATSINK AT THE BACKSIDE OF CUSTOMERS’ PCB)

.................................................................................................................................................................. 117

FIGURE 44: MODULE TOP AND SIDE DIMENSIONS .................................................................................... 118

FIGURE 45: MODULE BOTTOM DIMENSIONS (TOP VIEW) ........................................................................ 119

FIGURE 46: MODULE BOTTOM DIMENSIONS (TOP VIEW) ....................................................................... 120

FIGURE 47: TOP VIEW OF THE MODULE .................................................................................................... 121

FIGURE 48: BOTTOM VIEW OF THE MODULE ............................................................................................ 121

FIGURE 49: RECOMMENDED REFLOW SOLDERING THERMAL PROFILE .............................................. 123

FIGURE 50: TAPE SPECIFICATIONS ............................................................................................................ 124

FIGURE 51: REEL SPECIFICATIONS ............................................................................................................ 125

AG35_Hardware_Design 10 / 129

Page 12

Automotive Module Series

AG35 Hardware Design

1 Introduction

This document defines the AG35 module and describes its air interface and hardware interfaces which

are connected with customers’ applications.

This document can help customers quickly understand module interface specifications, electrical and

mechanical details, as well as other related information of the module. Associated with application notes

and user guides, customers can use AG35 to design and set up automotive industry mobile applications

easily.

Hereby, [Quectel Wireless Solutions Co., Ltd.] declares that the radio equipment type [AG35-E, AG35-LA]

is in compliance with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet address:

http://www.quectel.com

The device could be used with a separation distance of 20cm to the human body.

AG35_Hardware_Design 11 / 129

Page 13

Automotive Module Series

AG35 Hardware Design

OEM/Integrators Installation Manual

Important Notice to OEM integrators

1. This module is limited to OEM installation ONLY.

2. This module is limited to installation in mobile or fixed applications, according to Part 2.1091(b).

3. The separate approval is required for all other operating configurations, including portable

configurations with respect to Part 2.1093 and different antenna configurations

4. For FCC Part 15.31 (h) and (k): The host manufacturer is responsible for additional testing to verify

compliance as a composite system. When testing the host device for compliance with Part

15 Subpart B, the host manufacturer is required to show compliance with Part 15 Subpart B while the

transmitter module(s) are installed and operating. The modules should be transmitting and the evaluation

should confirm that the module's intentional emissions are compliant (i.e. fundamental and out of band

emissions). The host manufacturer must verify that there are no additional unintentional emissions other

than what is permitted in Part 15 Subpart B or emissions are complaint with the transmitter(s) rule(s).

The Grantee will provide guidance to the host manufacturer for Part 15 B requirements if needed.

Important Note

notice that any deviation(s) from the defined parameters of the antenna trace, as described by the

instructions, require that the host product manufacturer must notify to Quectel Wireless Solutions Co., Ltd.

that they wish to change

the antenna trace design. In this case, a Class II permissive change application is required to be filed

by the USI, or the host manufacturer can take responsibility through the change in FCC ID (new

application) procedure followed by a Class II permissive change application.

End Product Labeling

When the module is installed in the host device, the FCC/IC ID label must be visible through a window on

the final device or it must be visible when an access panel, door or cover is easily re-moved. If not, a

second label must be placed on the outside of the final device that contains the following text: “Contains

FCC ID: XMR201905AG35LA”

Or “Contains FCC ID: XMR201907AG35E”

The FCC ID/IC ID can be used only when all FCC/IC compliance requirements are met.

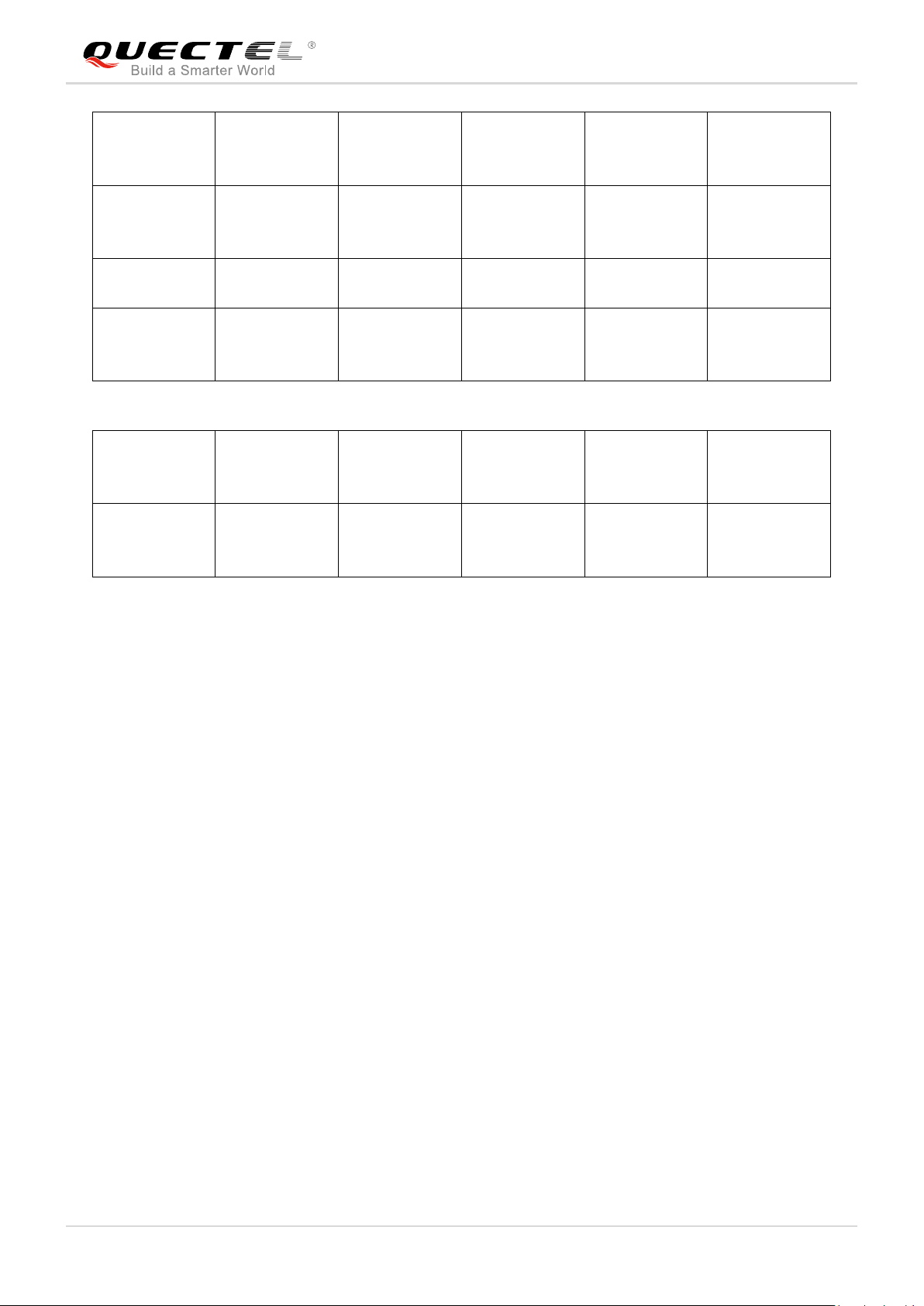

Antenna Installation

(1) The antenna must be installed such that 20 cm is maintained between the antenna and users,

(2) The transmitter module may not be co-located with any other transmitter or antenna.

(3) Only antennas of the same type and with equal or less gains as shown below may be used with this

module. Other types of antennas and/or higher gain antennas may require additional authorization for

operation.

AG35_Hardware_Design 12 / 129

Page 14

Antenna type

GSM850

Gain (dBi)

GSM1900

Gain (dBi)

WCDMA

Band II Gain

(dBi)

WCDMA

Band IV Gain

(dBi)

WCDMA

Band V Gain

(dBi)

Fixed

External

Antenna

4.50

2.00

2.00

5.00

4.50

Antenna type

LTE Band 2

Gain (dBi)

LTE Band 4

Gain (dBi)

LTE Band 5

Gain (dBi)

LTE Band 7

Gain (dBi)

Fixed

External

Antenna

2.00

5.00

4.50

7.00

Antenna type

WCDMA

Band V Gain

(dBi)

LTE Band 5

Gain (dBi)

LTE Band 7

Gain (dBi)

LTE Band 38

Gain (dBi)

Fixed

External

Antenna

9.00

9.00

8.00

8.00

AG35-E:

Automotive Module Series

AG35 Hardware Design

In the event that these conditions cannot be met (for example certain laptop configurations or co-location

with another transmitter), then the FCC/IC authorization is no longer considered valid and the FCC ID/IC

ID cannot be used on the final product. In these circumstances, the OEM integrator will be responsible for

re-evaluating the end product (including the transmitter) and obtaining a separate FCC/IC authorization.

Manual Information to the End User

The OEM integrator has to be aware not to provide information to the end user regarding how to install or

remove this RF module in the user’s manual of the end product which integrates this module. The end

user manual shall include all required regulatory information/warning as show in this manual.

Federal Communication Commission Interference Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

AG35_Hardware_Design 13 / 129

Page 15

Automotive Module Series

AG35 Hardware Design

be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Any changes or modifications not expressly approved by the party responsible for compliance could void

the user's authority to operate this equipment. This transmitter must not be co-located or operating in

conjunction with any other antenna or transmitter.

List of applicable FCC rules

This module has been tested and found to comply with part 22, part 27 requirements for Modular

Approval.

The modular transmitter is only FCC authorized for the specific rule parts (i.e., FCC transmitter

rules) listed on the grant, and that the host product manufacturer is responsible for compliance to

any other FCC rules that apply to the host not covered by the modular transmitter grant of

certification. If the grantee markets their product as being Part 15 Subpart B compliant (when it also

contains unintentional-radiator digital circuity), then the grantee shall provide a notice stating that

the final host product still requires Part 15 Subpart B compliance testing with the modular

transmitter installed.

This device is intended only for OEM integrators under the following

conditions: (For module device use)

1) The antenna must be installed such that 20 cm is maintained between the antenna and users, and

2) The transmitter module may not be co-located with any other transmitter or antenna.

As long as 2 conditions above are met, further transmitter test will not be required. However, the

OEM integrator is still responsible for testing their end-product for any additional compliance

requirements required with this module installed.

Radiation Exposure Statement

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment.

This equipment should be installed and operated with minimum distance 20 cm between the radiator &

your body.

AG35_Hardware_Design 14 / 129

Page 16

Automotive Module Series

Full attention must be given to driving at all times in order to reduce the risk of an

accident. Using a mobile while driving (even with a handsfree kit) causes

distraction and can lead to an accident. Please comply with laws and regulations

restricting the use of wireless devices while driving.

Switch off the cellular terminal or mobile before boarding an aircraft. The operation

of wireless appliances in an aircraft is forbidden to prevent interference with

communication systems. If the device offers an Airplane Mode, then it should be

enabled prior to boarding an aircraft. Please consult the airline staff for more

restrictions on the use of wireless devices on boarding the aircraft.

Wireless devices may cause interference on sensitive medical equipment, so

please be aware of the restrictions on the use of wireless devices when in

hospitals, clinics or other healthcare facilities.

Cellular terminals or mobiles operating over radio signals and cellular network

cannot be guaranteed to connect in all possible conditions (for example, with

unpaid bills or with an invalid (U)SIM card). When emergent help is needed in such

conditions, please remember using emergency call. In order to make or receive a

call, the cellular terminal or mobile must be switched on in a service area with

adequate cellular signal strength.

The cellular terminal or mobile contains a transmitter and receiver. When it is ON, it

receives and transmits radio frequency signals. RF interference can occur if it is

used close to TV set, radio, computer or other electric equipment.

AG35 Hardware Design

1.1. Safety Information

The following safety precautions must be observed during all phases of operation, such as usage, service

or repair of any cellular terminal or mobile incorporating AG35 module. Manufacturers of the cellular

terminal should send the following safety information to users and operating personnel, and incorporate

these guidelines into all manuals supplied with the product. If not so, Quectel assumes no liability for

customers’ failure to comply with these precautions.

AG35_Hardware_Design 15 / 129

Page 17

Automotive Module Series

In locations with potentially explosive atmospheres, obey all posted signs to turn

off wireless devices such as your phone or other cellular terminals. Areas with

potentially explosive atmospheres include fuelling areas, below decks on boats,

fuel or chemical transfer or storage facilities, areas where the air contains

chemicals or particles such as grain, dust or metal powders, etc.

AG35 Hardware Design

AG35_Hardware_Design 16 / 129

Page 18

Automotive Module Series

Network

Type

AG35-CE

AG35-E

AG35-NA

AG35-LA

AG35-J

LTE-FDD

(with

Rx-diversity)

B1/B3/

B5/B8

B1/B3/B5/

B7/B8/B20/

B28

B2/B4/B5/

B7/B12/B13/

B17

B1/B2/B3/

B4/B5/B7/

B8/B28

B1/B3/B5/B8/

B9/B19/B21/

B28

LTE-TDD

(with

Rx-diversity)

B34/B38/

B39/B40/

B41

B38/B40

N/A

N/A

B41

WCDMA

(with

Rx-diversity)

B1/B8

B1/B5/B8

B2/B4/B5

B1/B2/B3/

B4/B5/B8

B1/B3/B5/

B6/B8/B19

TD-SCDMA

B34/B39

N/A

N/A

N/A

N/A

EVDO/CDMA

BC0 1)

N/A

N/A

N/A

N/A

GSM

900/1800MHz

900/1800MHz

850/1900MHz

850/900/

1800/1900MHz

N/A

AG35 Hardware Design

2 Product Concept

2.1. General Description

AG35 is a series of automotive-grade LTE-FDD/LTE-TDD/WCDMA/TD-SCDMA/EVDO/CDMA/GSM

wireless communication module with LTE/WCDMA receive diversity. Engineered to meet the demanding

requirements in automotive applications and other harsh operating conditions, it offers a premium solution

for high performance automotive and intelligent transportation system (ITS) applications, such as fleet

management, onboard vehicle telematics, in-car entertainment systems, emergency calling, and roadside

assistance. It provides data connectivity on LTE-FDD, LTE-TDD, DC-HSDPA, HSPA+, HSDPA, HSUPA,

WCDMA, TD-SCDMA, EVDO, CDMA, EDGE and GPRS networks. Also it can provide GNSS and voice

functionality to meet customers’ specific application demands.

AG35 contains five variants: AG35-CE, AG35-E, AG35-NA, AG35-LA and AG35-J. Customers can

choose a dedicated type based on the region or operator. The following table shows the frequency bands

of AG35 series modules.

Table 1: Frequency Bands of AG35 Series Modules

AG35_Hardware_Design 17 / 129

Page 19

Automotive Module Series

GNSS

GPS,

GLONASS,

BeiDou/

Compass,

Galileo, QZSS

GPS,

GLONASS,

BeiDou/

Compass,

Galileo, QZSS

GPS,

GLONASS,

BeiDou/

Compass,

Galileo, QZSS

GPS,

GLONASS,

BeiDou/

Compass,

Galileo,

QZSS,SBAS

GPS,

GLONASS,

BeiDou/

Compass,

Galileo, QZSS

1. 1) EVDO/CDMA BC0 for AG35-CE is optional.

2. “*” means under development.

Feature

Details

Power Supply

Supply voltage: 3.3V~4.3V

Typical supply voltage: 3.8V

Transmitting Power

Class 4 (33dBm±2dB) for GSM850

Class 4 (33dBm±2dB) for EGSM900

Class 1 (30dBm±2dB) for DCS1800

Class 1 (30dBm±2dB) for PCS1900

Class E2 (27dBm±3dB) for GSM850 8-PSK

Class E2 (27dBm±3dB) for EGSM900 8-PSK

Class E2 (26dBm±3dB) for DCS1800 8-PSK

Class E2 (26dBm±3dB) for PCS1900 8-PSK

Class 3 (24dBm+2/-1dB) for EVDO/CDMA BC0

Class 3 (24dBm+1/-3dB) for WCDMA bands

Class 2 (24dBm+1/-3dB) for TD-SCDMA bands

Class 3 (23dBm±2dB) for LTE-FDD bands

Class 3 (23dBm±2dB) for LTE-TDD bands

LTE Features

Support up to non-CA Cat 4 FDD and TDD

Support 1.4 to 20MHz RF bandwidth

NOTES

AG35 Hardware Design

AG35 is an SMD type module which can be embedded in applications through its 299-pin LGA pads. This,

coupled with its compact profile of 33.0mm × 37.5mm × 3.0mm, makes AG35 a ruggedized module for

the most demanding applications and environments.

2.2. Key Features

The following table describes the detailed features of AG35 module.

Table 2: AG35 Key Features

AG35_Hardware_Design 18 / 129

Page 20

Automotive Module Series

Support Multiuser MIMO in DL direction

FDD: Max 150Mbps (DL)/50Mbps (UL)

TDD: Max 130Mbps (DL)/30Mbps (UL)

WCDMA Features

Support 3GPP R8 DC-HSDPA, HSPA+, HSDPA, HSUPA, WCDMA

Support QPSK, 16-QAM and 64-QAM modulation

DC-HSDPA: Max 42Mbps (DL)

HSUPA: Max 5.76Mbps (UL)

WCDMA: Max 384Kbps (DL)/384Kbps (UL)

TD-SCDMA Features

Support CCSA Release 3 TD-SCDMA

Max 4.2Mbps (DL)/2.2Mbps (UL)

CDMA2000 Features

Support 3GPP2 CDMA2000 1X Advanced, CDMA2000 1x EV-DO Rev.A

EVDO: Max 3.1Mbps (DL)/1.8Mbps (UL)

1X Advanced: Max 307.2Kbps (DL)/307.2Kbps (UL)

GSM Features

GPRS:

Support GPRS multi-slot class 33 (33 by default)

Coding scheme: CS-1, CS-2, CS-3 and CS-4

Max 107Kbps (DL)/85.6Kbps (UL)

EDGE:

Support EDGE multi-slot class 33 (33 by default)

Support GMSK and 8-PSK for different MCS (Modulation and Coding

Scheme)

Downlink coding schemes: CS 1-4 and MCS 1-9

Uplink coding schemes: CS 1-4 and MCS 1-9

Max 296Kbps (DL)/236.8Kbps (UL)

Internet Protocol Features

Support TCP/UDP/PPP/FTP/HTTP/NTP/PING/QMI/HTTPS/SMTP/MMS/

FTPS/SMTPS/SSL protocols

Support the protocols PAP (Password Authentication Protocol) and CHAP

(Challenge Handshake Authentication Protocol) usually used for PPP

connections

SMS

Text and PDU mode

Point to point MO and MT

SMS cell broadcast

SMS storage: ME by default

(U)SIM Interface

Support USIM/SIM card: 1.8V, 3.0V

Audio Features

(Optional)

Built-in audio codec with two microphone inputs and one stereo output or

two mono outputs

GSM: HR/FR/EFR/AMR/AMR-WB

WCDMA: AMR/AMR-WB

LTE: AMR/AMR-WB

Support echo cancellation and noise suppression

PCM Interface

Used for audio function with external codec

Support 16-bit linear data format

Support long frame synchronization and short frame synchronization

AG35 Hardware Design

AG35_Hardware_Design 19 / 129

Page 21

Automotive Module Series

Support master and slave modes, but must be the master in long frame

synchronization

SGMII Interface (Optional)

Support 10/100/1000Mbps

WLAN Interface

Compliant with 802.11, 4-bit, 1.8V WLAN interface

SDIO Interfaces

SDIO1:

Compliant with SD 3.0 protocol

Used for WLAN function

SDIO2:

Compliant with SD 3.0 protocol

USB Interface

Compliant with USB 2.0 specification (slave only), and the data transfer

rate can reach up to 480Mbps

Used for AT command communication, data transmission, GNSS NMEA

output, software debugging and firmware upgrade

Support USB serial driver under Windows 7/8/8.1/10, Windows CE

5.0/6.0/7.0*, Linux 2.6/3.x/4.1~4.14, Android 4.x/5.x/6.x/7.x/8.x/9.x

HSIC Interface*

High-speed inter-chip USB electrical specification compliant

UART Interfaces

Main UART:

Used for AT command communication and data transmission

Baud rate reach up to 921600bps, 115200bps by default

Support RTS and CTS hardware flow control

UART2:

Used for BT function*

Baud rate reach up to 921600bps, 115200bps by default

Support RTS and CTS hardware flow control

Debug UART:

Used for Linux console and log output

115200bps baud rate

Rx-diversity

Support LTE/WCDMA Rx-diversity

GNSS Features

Gen8C-Lite of Qualcomm

Protocol: NMEA 0183

Data update rate: 1Hz by default and maximally up to 10Hz

AT Commands

3GPP TS 27.007/3GPP TS 27.005 AT commands and Quectel enhanced

AT commands

Network Indication

Two pins including NET_MODE and NET_STATUS to indicate network

connectivity status

Antenna Interface

Including main antenna interface (ANT_MAIN), Rx-diversity antenna

interface (ANT_DIV) and GNSS antenna interface (ANT_GNSS)

Physical Characteristics

Size: (33.0±0.15)mm × (37.5±0.15)mm × (3.0±0.2)mm

Weight: Approx. 8.1g

Temperature Range

Operation temperature range: -35°C ~ +75°C 1)

AG35 Hardware Design

AG35_Hardware_Design 20 / 129

Page 22

Automotive Module Series

Extended temperature range: -40°C ~ +85°C

2)

eCall temperature range: -40°C ~ +90°C 3)

Storage temperature range: -40°C ~ +95°C

Firmware Upgrade

USB interface

DFOTA

RoHS

All hardware components are fully compliant with EU RoHS directive

1. 1) Within operation temperature range, the module is 3GPP compliant, and emergency call can be

dialed out with a maximum power and data rate.

2. 2) Within extended temperature range, the module remains fully functional and retains the ability to

establish and maintain a voice, SMS, data transmission, emergency call, etc. There is no

unrecoverable malfunction. There are also no effects on radio spectrum and no harm to radio

network. Only one or more parameters like P

out

might reduce in their value and exceed the specified

tolerances. When the temperature returns to normal operation temperature levels, the module will

meet 3GPP specifications again.

3. 3) Within eCall temperature range, the emergency call function must be functional until the module is

broken. When the ambient temperature is between 75°C and 90°C and the module temperature has

reached the threshold value, the module will trigger protective measures (such as reduce power,

decrease throughput, unregister the device, etc.) to ensure the full function of emergency call.

4. “*” means under development.

NOTES

AG35 Hardware Design

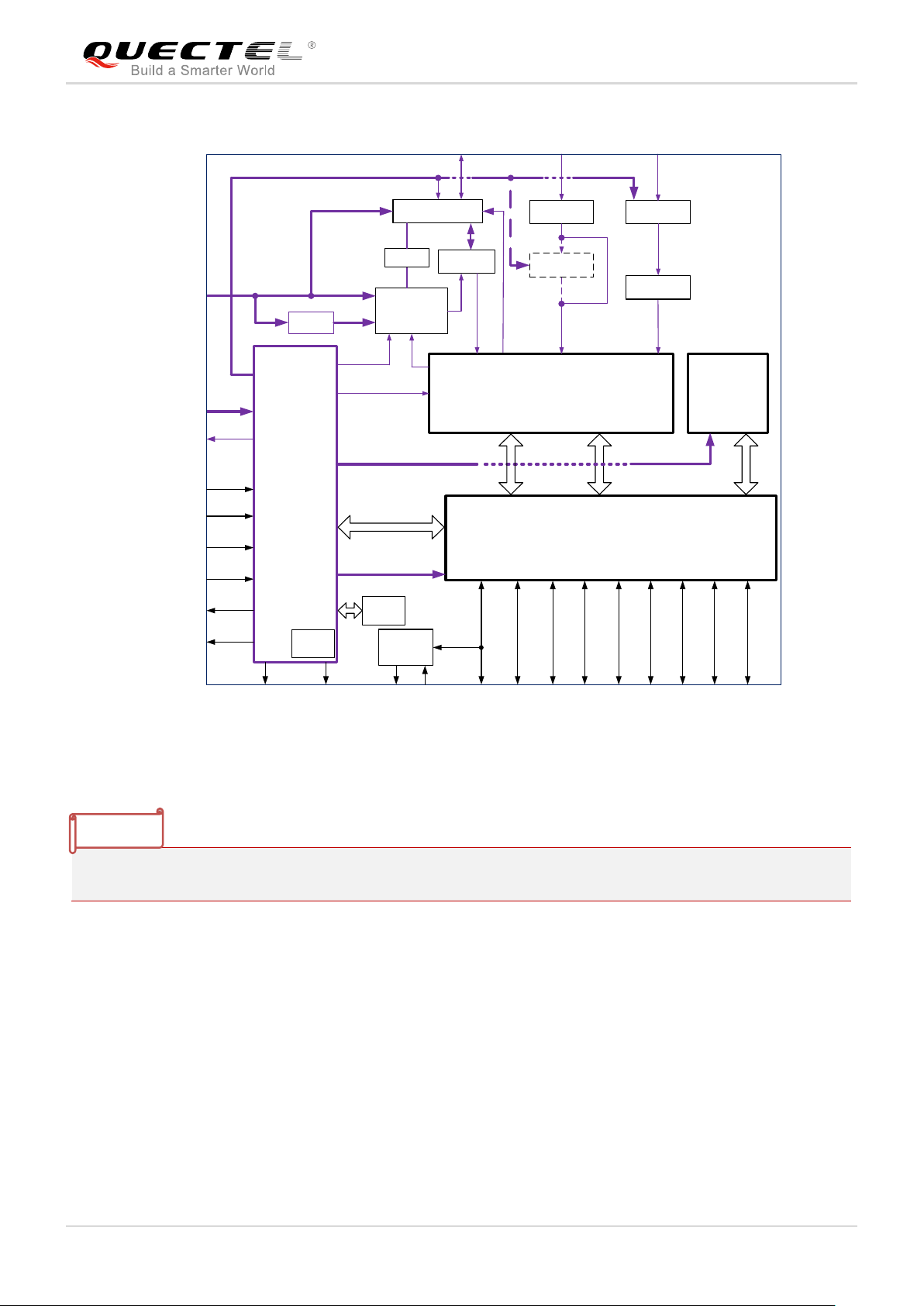

2.3. Functional Diagram

The following figure shows a block diagram of AG35 and illustrates the major functional parts.

Power management

Baseband

DDR+NAND flash

Radio frequency

Peripheral interface

AG35_Hardware_Design 21 / 129

Page 23

Automotive Module Series

Baseband

PMIC

Transceiver

NAND

DDR2

SDRAM

PA

PAM

LNA

Switch

ANT_MAIN ANT_DIVANT_GNSS

VBAT_BB

VBAT_RF

APT

PWRKEY

ADCs

VDD_EXT

RESET_N

19.2M

XO

STATUS

SAW

Control

IQ Control

Duplex

SAW

Tx

PRx DRx

PCM SGMII WLAN SDIOs USB (U)SIM I2CS UARTs HSIC*

PM_ENABLENET_STATUS

STATUS

BT_EN*

Audio

SPKS MICS

SHDN_N

RTC

SAW

“*” means under development.

NOTE

AG35 Hardware Design

Figure 1: Functional Diagram

2.4. Evaluation Board

In order to help customers develop applications with AG35 conveniently, Quectel supplies the evaluation

board (EVB), USB data cable, earphone, antenna and other peripherals to control or test the module. For

more details, please refer to document [3].

AG35_Hardware_Design 22 / 129

Page 24

Automotive Module Series

“*” means under development.

NOTE

AG35 Hardware Design

3 Application Interfaces

3.1. General Description

AG35 is equipped with 299-pin LGA pads that can be connected to cellular application platform.

Sub-interfaces included in these pads are described in detail in the following sub-chapters:

Power supply

(U)SIM interface

USB interface

UART interfaces

Audio interface (optional)

PCM and I2C interfaces

SDIO interfaces

SGMII interface (optional)

Wireless connectivity interfaces

ADC interfaces

Status indication interfaces

USB_BOOT interface

HSIC interface*

AG35_Hardware_Design 23 / 129

Page 25

AG35 Hardware Design

299

176

298

174

172

170

168

166

164

162

160

158

156

154

152

150

148

146

144

142

140

138

136

134

132

130

175

173

171

169

167

165

163

161

159

157

155

153

151

149

147

145

143

141

139

137

135

133

131

129

127

125

123

121

119

117

115

111

109

107

105

103

101

99

97

95

128

113

126

124

122

120

118

116

114

112

110

108

106

104

102

100

98

96

214

213

212

211

210

209

208

207

206

205

204

203

202

201

200

199

198

93

91

89

94

92

90

197

196

43

45

47

49

51

53

55

57

59

61

63

65

67

69

71

73

75

77

79

81

83

85

87

42

44

46

48

50

52

54

56

58

60

62

64

66

68

70

72

74

76

78

80

82

84

86

88

41

39

37

35

33

31

29

27

23

21

19

17

15

13

11

9

7

402538

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

195

194

193

192

191

190

189

188

187

186

185

184

183

182

181

180

179

5

3

1

6

4

2

178

177

297

296

216 217 218215 219 220 221 222 223

224

233

242

251

260

269

278

287

225

234

243

252

261

270

279

288

226

235

244

253

262

271

280

289

227

236

272

281

290

228

237

273

282

291

229

238

274

283

292

230

239

248

257

266

275

284

293

231

240

249

258

267

276

285

294

232

241

250

259

268

277

286

295

RESET_N

PWRKEY

BT_EN*

PM_ENABLE

USIM_PRESENCE

USIM_CLK

USIM_DATA

USIM_VDD

USIM_RST

USB_VBUS

USB_DM

USB_DP

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

I2C1_SDA

I2C1_SCL

VDD_SDIO

SDC2_DATA2

SDC2_DATA3

SDC2_DATA0

SDC2_DATA1

SDC2_CMD

SD_INS_DET

SDC2_CLK

UART1_CTS

UART1_RTS

UART1_RXD

UART1_DCD

UART1_TXD

UART1_RI

UART1_DTR

PCM_SYNC

PCM_CLK

PCM_IN

PCM_OUT

RESERVED

RESERVED

RESERVED

RESERVED

VBAT_RF

VBAT_RF

VBAT_RF

VBAT_RF

ANT_MAIN

ANT_GNSS

ANT_DIV

SPK1_P

MICBIAS

MIC2_P

MIC_P

SPK1_N

MIC2_N

MIC1_N

RESERVED

COEX_UART_TX

NET_MODE

WLAN_EN

W_DISABLE#

SLEEP_IND

COEX_UART_RX

WAKEUP_IN

MCLK

VBAT_BB

VBAT_BB

WLAN_WAKE

UART2_TXD

UART2_RXD

UART2_CTS

UART2_RTS

VDD_EXT

WLAN_SLP_CLK

GND

NET_STATUS

STATUS

ADC0

ADC1

GND

GND

GND

GND

GND

GND

GND

AGND

SPK2_P

GND

GND

SPK2_N

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

USIM_GND

245 246 247

254 255 256

263 264 265

RESERVED

RESERVED

RESERVED

ADC2

SHDN_N

VDD_MDIO

EPHY_RST_N

SGMII_MCLK

SGMII_MDATA

EPHY_INT_N

GND

SGMII_RX_M

GND

SGMII_RX_P

SGMII_TX_P

GND

SDC1_CMD

SDC1_DATA0

SDC1_DATA2

GND

GND

GND

GND

SDC1_DATA3

SDC1_DATA1

SDC1_CLK

GND

SGMII_TX_M

GND

GND

GND

GND

GND

GND

RESERVED

RESERVED

HSIC_STROBE*

HSIC_DATA*

RESERVED

RESERVED

RESERVED

RESERVED

I2C2_SCL

I2C2_SDA

DBG_RXD

DBG_TXD

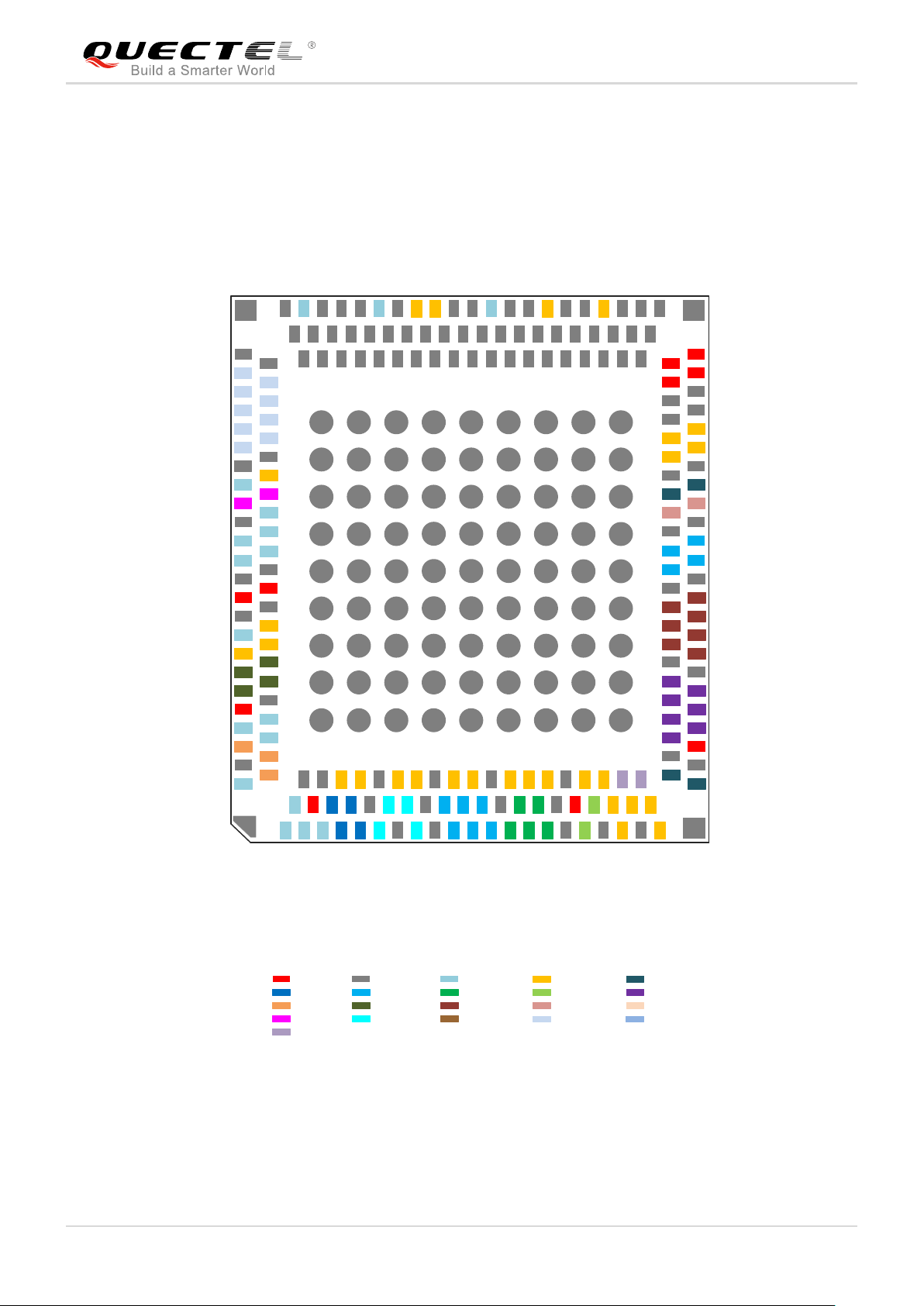

Power Pins GND Pins Signal Pins RESVRVED Pins

MDIO Pins

SDIO Pins

(U)SIM Pins

USB Pins

IIC Pins

SD Pins

ADC Pins

UART2 Pins

UART1 Pins

Debug UART Pins

GPIO Pins

COEX_UART Pins SGMII Pins

SPI Pins

Audio Pins

PCM Pins

HSIC Pins

/USB_BOOT

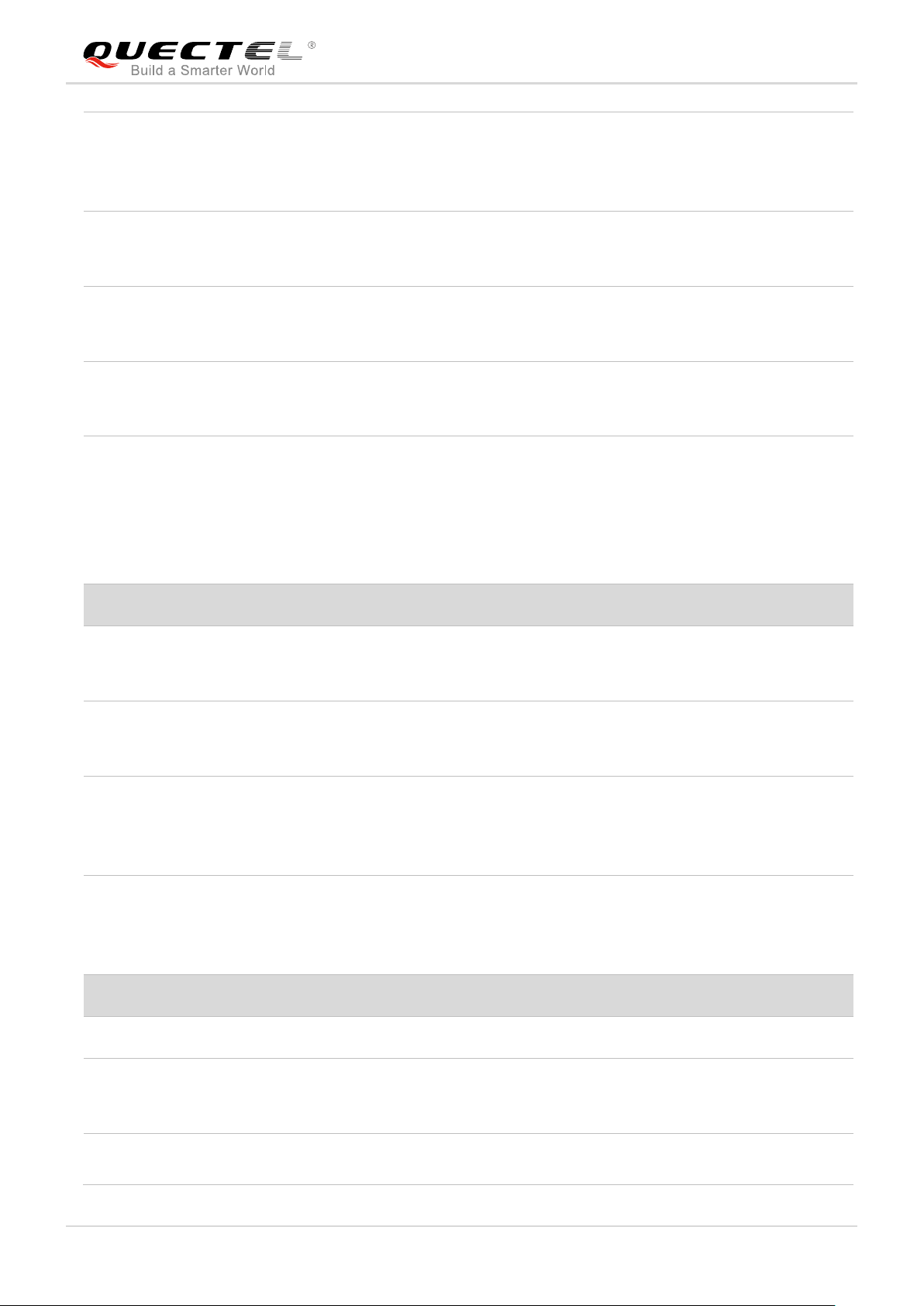

3.2. Pin Assignment

The following figure shows the pin assignment of AG35 module.

Automotive Module Series

Figure 2: Pin Assignment (Top View)

AG35_Hardware_Design 24 / 129

Page 26

AG35 Hardware Design

1. Pins 59, 65, 67, 144~147 and 149 cannot be pulled up before power-up.

2. PWRKEY (pin 2) output voltage is 0.8V because of the diode drop in the Qualcomm chipset.

3. GND pins 215~299 should be connected to ground in the design.

4. Keep all RESERVED pins and unused pins unconnected.

5. “*” means under development.

Type

Description

AI

Analog input

AO

Analog output

DI

Digital input

DO

Digital output

IO

Bidirectional

PI

Power input

PO

Power output

Power Supply

Pin Name

Pin No.

I/O

Description

DC

Characteristics

Comment

VBAT_BB

155, 156

PI

Power supply for

module’s baseband

part

Vmax=4.3V

Vmin=3.3V

Vnorm=3.8V

It must be able to

provide sufficient

current up to 0.8A.

VBAT_RF

85, 86, 87, 88

PI

Power supply for

module’s RF part

Vmax=4.3V

Vmin=3.3V

Vnorm=3.8V

It must be able to

provide sufficient

current up to 1.8A in a

NOTES

3.3. Pin Description

The following tables show the pin definition and description of AG35.

Automotive Module Series

Table 3: I/O Parameters Definition

Table 4: Pin Description

AG35_Hardware_Design 25 / 129

Page 27

Automotive Module Series

transmitting burst.

VDD_EXT

168

PO

Provide 1.8V for

external circuit

Vnorm=1.8V

IOmax=50mA

Power supply for

external GPIO’s pull up

circuits.

GND

10, 13, 16,

17, 30, 31,

35, 39, 44,

45, 54, 55,

63, 64, 69,

70, 75, 76,

81~84,

89~94,

96~100,

102~106,

108~112,

114,

116~118,

120~126,

128~131,

142, 148,

153, 154,

157, 158,

167, 174,

177, 178,

181, 184,

187, 191,

196~299

Ground

Turn on/off

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

PWRKEY

2

DI

Turn on/off the

module

VIHmax=2.1V

VIHmin=1.3V

VILmax=0.5V

The output voltage is

0.8V because of the

diode drop in the

Qualcomm chipset.

RESET_N

1

DI

Reset the module

VIHmax=2.1V

VIHmin=1.3V

VILmax=0.5V

Internally pulled up to

1.8V. Active low.

SHDN_N

176

DI

Emergency

shutdown for the

module

VIHmax=2.1V

VIHmin=1.3V

VILmax=0.5V

Status Indication

AG35 Hardware Design

AG35_Hardware_Design 26 / 129

Page 28

Automotive Module Series

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

STATUS

171

OD

Indicate the

module’s operation

status

The drive current

should be less than

0.15mA.

Require external

pull-up. If unused,

keep it open.

NET_MODE

147

DO

Indicate the

module’s network

registration status

VOHmin=1.35V

VOLmax=0.45V

1.8V power domain.

If unused, keep it

open.

NET_

STATUS

170

DO

Indicate the

module’s network

activity status

VOHmin=1.35V

VOLmax=0.45V

1.8V power domain.

If unused, keep it

open.

USB Interface

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

USB_VBUS

32

PI

USB connection

detection

Vmax=5.25V

Vmin=3.0V

Vnorm=5.0V

Maximum Current:

1mA

USB_DM

33

IO

USB differential

data bus (-)

Compliant with USB

2.0 standard

specification.

Require differential

impedance of 90Ω.

USB_DP

34

IO

USB differential

data bus (+)

Compliant with USB

2.0 standard

specification.

Require differential

impedance of 90Ω.

HSIC Interface*

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

HSIC_

STROBE*

194

IO

High speed inter

chip interface strobe

VILmax=0.4V

VIHmin=0.8V

VOLmax=0.3V

VOHmin=0.9V

1.2V power domain.

If unused, keep them

open.

HSIC_DATA*

195

IO

High speed inter

chip interface - data

(U)SIM Interface

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

USIM_GND

24

Specified ground for

(U)SIM card

Connect to ground of

(U)SIM card

connector.

USIM_

PRESENCE

25

DI

(U)SIM card

insertion detection

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V power domain.

If unused, keep it

open.

AG35 Hardware Design

AG35_Hardware_Design 27 / 129

Page 29

Automotive Module Series

USIM_VDD

26

PO

Power supply for

(U)SIM card

For 1.8V (U)SIM:

Vmax=1.9V

Vmin=1.7V

For 3.0V (U)SIM:

Vmax=3.05V

Vmin=2.7V

IOmax=50mA

Either 1.8V or 3V is

supported by the

module automatically.

USIM_CLK

27

DO

Clock signal of

(U)SIM card

For 1.8V USIM:

VOLmax=0.45V

VOHmin=1.35V

For 3.0V USIM:

VOLmax=0.45V

VOHmin=2.55V

USIM_RST

28

DO

Reset signal of

(U)SIM card

For 1.8V USIM:

VOLmax=0.45V

VOHmin=1.35V

For 3.0V USIM:

VOLmax=0.45V

VOHmin=2.55V

USIM_DATA

29

IO

Data signal of

(U)SIM card

For 1.8V USIM:

VILmax=0.6V

VIHmin=1.2V

VOLmax=0.45V

VOHmin=1.35V

For 3.0V USIM:

VILmax=1.0V

VIHmin=1.95V

VOLmax=0.45V

VOHmin=2.55V

Main UART Interface

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

UART1_CTS

56

DO

DTE clear to send

VOLmax=0.45V

VOHmin=1.35V

1.8V power domain.

If unused, keep it

open.

UART1_RTS

57

DI

DTE request to

send

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V power domain.

If unused, keep it

open.

AG35 Hardware Design

AG35_Hardware_Design 28 / 129

Page 30

Automotive Module Series

UART1_RXD

58

DI

Receive data

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V power domain.

If unused, keep it

open.

UART1_DCD

59

DO

Data carrier

detection

VOLmax=0.45V

VOHmin=1.35V

1.8V power domain.

If unused, keep it

open.

UART1_TXD

60

DO

Transmit data

VOLmax=0.45V

VOHmin=1.35V

1.8V power domain.

If unused, keep it

open.

UART1_RI

61

DO

Ring indicator

VOLmax=0.45V

VOHmin=1.35V

1.8V power domain.

If unused, keep it

open.

UART1_DTR

62

DI

Data terminal ready.

Sleep mode control

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V power domain.

Pulled up by default.

Low level wakes up

the module.

If unused, keep it

open.

UART2 Interface (for BT Function*)

UART2_TXD

163

DO

Transmit data

VOLmax=0.45V

VOHmin=1.35V

1.8V power domain.

If unused, keep it

open.

UART2_CTS

164

DO

DTE clear to send

VOLmax=0.45V

VOHmin=1.35V

1.8V power domain.

If unused, keep it

open.

UART2_RXD

165

DI

Receive data

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V power domain.

If unused, keep it

open.

UART2_RTS

166

DI

DTE request to

send

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V power domain.

If unused, keep it

open.

Debug UART Interface

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

DBG_TXD

71

DO

Transmit data

VOLmax=0.45V

VOHmin=1.35V

1.8V power domain.

If unused, keep it

open.

DBG_RXD

72

DI

Receive data

VILmin=-0.3V

VILmax=0.6V

1.8V power domain.

If unused, keep it

AG35 Hardware Design

AG35_Hardware_Design 29 / 129

Page 31

Automotive Module Series

VIHmin=1.2V

VIHmax=2.0V

open.

ADC Interfaces

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

ADC2

172

AI

General purpose

analog to digital

converter interface

Voltage Range:

0.1V to 1.7V

If unused, keep it

open.

ADC0

173

AI

General purpose

analog to digital

converter interface

Voltage Range:

0.3V to VBAT_BB

If unused, keep it

open.

ADC1

175

AI

General purpose

analog to digital

converter interface

Voltage Range:

0.3V to VBAT_BB

If unused, keep it

open.

Audio Interface (Optional)

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

SPK2_P

132

AO

Earphone analog

output 2 (+)

If unused, keep it

open.

SPK2_N

133

AO

Earphone analog

output 2 (-)

If unused, keep it

open.

SPK1_P

134

AO

Earphone analog

output 1 (+)

If unused, keep it

open.

SPK1_N

135

AO

Earphone analog

output 1 (-)

If unused, keep it

open.

MICBIAS

136

AO

Bias voltage output

for microphone

Vmax=1.55V

Vmin=1.5V

Vnorm=1.525V

If unused, keep it

open.

MIC2_N

137

AI

Microphone analog

input 2 (-)

If unused, keep it

open.

MIC2_P

138

AI

Microphone analog

input 2 (+)

If unused, keep it

open.

MIC1_N

139

AI

Microphone analog

input 1 (-)

If unused, keep it

open.

MIC1_P

140

AI

Microphone analog

input 1 (+)

If unused, keep it

open.

AGND

141

Analog ground

If unused, keep it

open.

PCM Interface

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

AG35 Hardware Design

AG35_Hardware_Design 30 / 129

Page 32

Automotive Module Series

PCM_SYNC

65

IO

PCM data frame

synchronization

signal

VOLmax=0.45V

VOHmin=1.35V

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V power domain.

In master mode, it is

an output signal. In

slave mode, it is an

input signal.

If unused, keep it

open.

PCM_IN

66

DI

PCM data input

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V power domain.

If unused, keep it

open.

PCM_CLK

67

IO

PCM clock

VOLmax=0.45V

VOHmin=1.35V

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V power domain.

In master mode, it is

an output signal. In

slave mode, it is an

input signal.

If unused, keep it

open.

PCM_OUT

68

DO

PCM data output

VOLmax=0.45V

VOHmin=1.35V

1.8V power domain.

If unused, keep it

open.

MCLK

152

DO

Output 12.288MHZ

VOLmax=0.45V

VOHmin=1.35V

1.8V power domain.

If unused, keep it

open.

I2C1 Interface (for Codec Configuration by Default)

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

I2C1_SDA

42

IO

I2C1 serial data.

Used for external

codec.

VOLmax=0.45V

VOHmin=1.35V

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

External pull-up

resistor is required.

1.8V only. If unused,

keep it open.

I2C1_SCL

43

DO

I2C1 serial clock.

Used for external

codec.

VOLmax=0.45V

VOHmin=1.35V

External pull-up

resistor is required.

1.8V only. If unused,

keep it open.

I2C2 Interface

Pin Name

Pin No.

I/O

Description

DC Characteristics

Comment

I2C2_SDA

73

IO

I2C2 serial data

VOLmax=0.45V

VOHmin=1.35V

External pull-up

resistor is required.

AG35 Hardware Design

AG35_Hardware_Design 31 / 129

Page 33

Automotive Module Series

VILmin=-0.3V

VILmax=0.6V

VIHmin=1.2V

VIHmax=2.0V

1.8V only. If unused,