Page 1

Scalar 1000 Library

Operator Guide

Page 2

Copyright Notice

© 2002–2004 ADIC

The information contained in this document is subject to change without notice.

This document contains proprietary information which is protected by copyright. All rights are

reserved. No part of this document may be photocopied, reproduced, or translated to another

language without prior written consent of ADIC.

ADIC shall not be liable for errors contained herein or for incidental or consequential damages

(including lost profits) in connection with the furnishing, performance or use of this material

whether based on warranty, contract, or other legal theory.

All trademarks are the property of their respective owners.

Copyright Notice (Europe)

© 2002–2004 ADIC Europe™

All rights reserved. No part of this document may be copied or reproduced in any form or by any

means, without prior written permission of ADIC Europe, ZAC des Basses Auges, 1,rue Alfred de

Vigny, 78112 - Fourqueux, France.

ADIC Europe assumes no responsibility for any errors that may appear in this document, and

retains the right to make changes to these specifications and descriptions at any time, without

notice.

This publication may describe designs for which patents are pending, or have been granted. By

publishing this information, ADIC Europe conveys no license under any patent or any other right.

ADIC Europe makes no representation or warranty with respect to the contents of this document

and specifically disclaims any implied warranties of merchantability or fitness for any particular

purpose. Further, ADIC Europe reserves the right to revise or change this publication without

obligation on the part of ADIC Europe to notify any person or organization of such revision of

change.

Every effort has been made to acknowledge trademarks and their owners. Trad emarked names are

used solely for identification or exemplary purposes, any omission is unintentional.

ADIC is a registered trademark and ADIC Europe is a trademark of Advanced Digital Information

Corporation.

ADIC USA

Tel.: +1-303-705-3900

Fax: +1-303-792-2465

ATAC: 1-800-827-3822

www.adic.com

Document number: 6-00054-02 Rev A

Published: 22 June 2004 Printed in the USA

ADIC Europe

ZAC des Basses Auges

1, rue Alfred de Vigny

78112 Fourqueux, France

Tel.: +33.1.3087.5300

Fax: +33.1.3087.5301

ADIC Germany Beteiligungs GmbH, KG

Eschenstraße 3

D-89558

Böhmenkirch, Germany

Tel: +00.800.9999.3822

ADIC CORPORATE • 11431 WILLOWS ROAD, NE • REDMOND, WASHINGTON , USA • 1-800-33 6-1233

ADIC • 8560 UPLAND DRIVE• ENGLEWOOD, COLORADO, USA • 1-800-827-3822

ADIC • 10 BROWN ROAD • ITHACA, NEW YORK, USA • 1-607-241-4800

Page 3

Contents

1

About this Guide

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Associated Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Explanation of Symbols and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

ADIC Technical Assistance Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Regulatory Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Federal Communication Commission Class A Notice . . . . . . . . . . . . . . . . . . . . . .1-6

IC Notice (Canada Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

EN 55022 Compliance (Czech Republic Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

CE Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

VCCI Notices (Japan Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

iii

Page 4

2

System Description

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Tape Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Cartridge Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Cartridge Accessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Insert/Eject Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

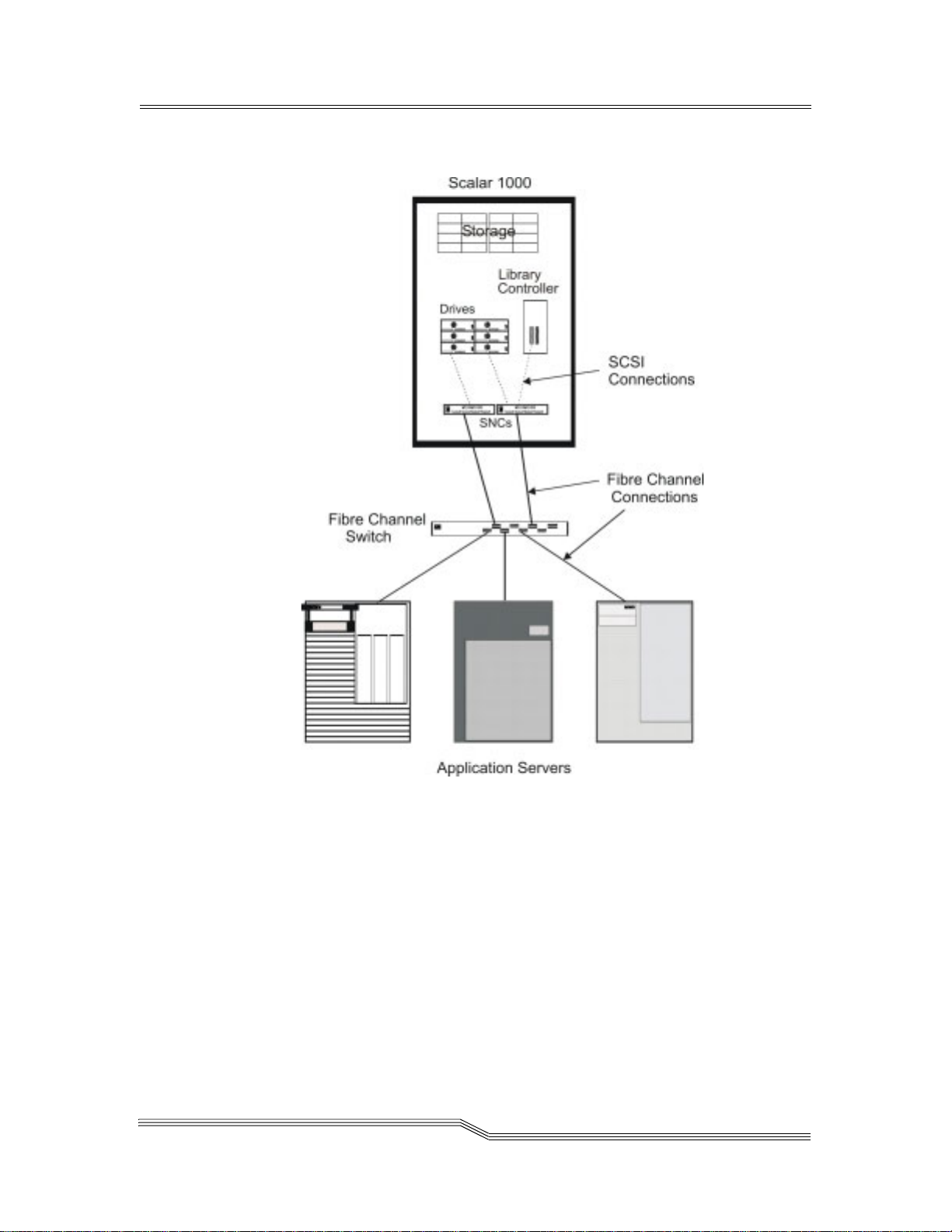

SAN Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

SCSI Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Scalar DLC Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Remote Management Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

3

Safety

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Hazard Alert Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Area of Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Library Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Mechanical Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Main Circuit Breaker (Power) Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

iv Contents

6-00054-02 Rev A

Page 5

4

Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Using the Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Starting the Scalar 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Shutting Down the Scalar 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Normal Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Emergency Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Restarting the Scalar 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Using the Remote Management Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Supported Browsers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

System Administrator Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

RMU Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Setting up the RMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Accessing the RMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Logging into the RMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Checking Status and General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Configuring Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Configuring SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Downloading the SNMP MIB File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Configuring RMU Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Adding/Removing Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Changing a Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Configuring the Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Synchronizing with an NTP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Updating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Viewing Diagnostic Files (Library and RMU Logs) . . . . . . . . . . . . . . . . . . . . . . .4-20

Using the Operator Panel (via the RMU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Viewing Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

22 June 2004

Contents v

Page 6

5

Menus and Commands

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Using the Operator Panel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Accessing the Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Special Characters or Cursors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Help Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Operator Intervention Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Mode Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Library Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

SCSI Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Mode Parms Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Element Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Mixed-Media Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Reservations Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

System Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

Element Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

Logs Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Command Log Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Error Log Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Drive Error Log Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-30

Drives Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-30

Drive State Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-31

Media Info Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

vi Contents

Commands Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-35

Park . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Move Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Position to Elem Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-37

Move Media Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-39

Inventory Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-43

Insert/Eject Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-45

Insert Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-45

Insert Clean Tape Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-47

Eject Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-52

Eject Clean Tape Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-55

Expired Tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-55

6-00054-02 Rev A

Page 7

By Coordinate Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-57

By Volser Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-60

Database Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-62

Media Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-63

Element Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

Config Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-67

Advanced Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-69

Learn Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-69

Manipulate Get . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-70

Manipulate Put . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-70

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5- 7 1

Library Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-72

SCSI Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-73

Target ID Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-74

Parity Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-75

Ports Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-76

Host Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-77

Trace Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-78

Security Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-79

Switching Security From Off to On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-79

Switching Security From On to Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-81

Changing the Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-82

Media Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-84

Emulate Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-86

RMU Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-87

Name Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-87

IP Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-88

Advanced Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-89

Drives Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-91

Cleaning Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-93

Drives Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-93

Media Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-94

View Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-96

Utils Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-97

Library Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-97

Screen Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-98

Audio Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-100

Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-101

Time Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-101

Date Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-102

Drives Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-103

Update Microcode Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-104

Clean Drives Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 -108

Unload Drives Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-110

Initialize Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-111

Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-112

SCSI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-112

22 June 2004

Contents vii

Page 8

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-113

Start Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-114

Diags Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-116

DI/DO Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-117

Loopback Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-117

Sensors Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-118

Wrap Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-118

Real Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-120

Locks Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-121

Gripper Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-121

Get/Put Storage Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-122

Get/Put Drives Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-125

Step Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-128

Scanner Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-130

Adjust Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-130

Trigger Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-131

Fiducial Test Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-132

Accessor Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-133

Move Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-134

Step Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-135

SelfTest Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-136

PowerSup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-137

Teach Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-138

Teach New Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-138

Teach Current Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-140

SAC Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-143

Demo Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-143

Advanced Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-146

Other Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-147

viii Contents

About Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-148

6

Processing Media

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Tape Cartridge Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Inspecting Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Handling Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Storing Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Acclimating Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Transporting Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Inserting Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6-00054-02 Rev A

Page 9

Using the Insert/Eject Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Manually Inserting Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Ejecting Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Using the Insert/Eject Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Manually Removing Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Understanding Barcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Barcode Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Applying Barcode Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Barcode Label Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Cleaning Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Manual Clean without Library Cleaning Tapes . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Manual Clean with Library Tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

Immediate AutoClean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

Library Delayed AutoClean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Host Controlled Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Enabling Library AutoClean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Using Cleaning Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Inserting a Cleaning Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Ejecting a Cleaning Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Declaring a Cleaning Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Viewing Cleaning Cartridge Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

7

Error Messages

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Service Action Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Operator Intervention Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

Error Log Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-28

Index

22 June 2004

Contents ix

Page 10

xContents

6-00054-02 Rev A

Page 11

Figures

Figure 2-1 Control Module and Expansion Module. . . . . . . . . . . . . . . . . . . . . . .2-5

Figure 2-2 Coordinate System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Figure 2-3 Cartridge Accessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Figure 2-4 Indirect Fibre Channel Attachment . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Figure 2-5 Direct SCSI Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Figure 2-6 Network Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Figure 4-1 Operator Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Figure 4-2 Main Circuit Breaker Switch Locations (Back View of CM/EM). . .4-7

Figure 4-3 Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Figure 4-4 Reboot Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Figure 5-1 Operator Panel Directory Structure . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Figure 5-2 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Figure 5-3 Mode Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Figure 5-4 Ready Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Figure 5-5 Not Ready Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Figure 5-6 Shutdown Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Figure 5-7 Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Figure 5-8 Library Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Figure 5-9 SCSI Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Figure 5-10 Mode Parms Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Figure 5-11 Element Address Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Figure 5-12 Mixed-Media Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

xi

Page 12

Figure 5-13 Parity Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

Figure 5-14 LCD Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Figure 5-15 Reservation Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Figure 5-16 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

Figure 5-17 System Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

Figure 5-18 Continuation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-21

Figure 5-19 Continuation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

Figure 5-20 Element Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

Figure 5-21 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-23

Figure 5-22 Continuation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

Figure 5-23 Continuation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-25

Figure 5-24 Logs Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Figure 5-25 Command Log Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Figure 5-26 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-27

Figure 5-27 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-27

Figure 5-28 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-27

Figure 5-29 Error Log Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Figure 5-30 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-29

Figure 5-31 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-29

Figure 5-32 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-29

Figure 5-33 Drive Error Log Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-30

Figure 5-34 Drives Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-30

Figure 5-35 Drive State Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-31

Figure 5-36 Continuation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

Figure 5-37 Element Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

Figure 5-38 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

Figure 5-39 Commands Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-35

Figure 5-40 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Figure 5-41 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Figure 5-42 Move Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

Figure 5-43 Position to Elem Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-37

Figure 5-44 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

Figure 5-45 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

xii Figures

6-01151-01 Rev A

Page 13

Figure 5-46 Move Media Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-39

Figure 5-47 Target Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

Figure 5-48 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

Figure 5-49 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

Figure 5-50 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

Figure 5-51 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-42

Figure 5-52 Inventory Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-43

Figure 5-53 Number of Elements Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-44

Figure 5-54 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-44

Figure 5-55 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-44

Figure 5-56 Insert/Eject Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-45

Figure 5-57 Insert Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-45

Figure 5-58 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-46

Figure 5-59 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-46

Figure 5-60 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-46

Figure 5-61 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-47

Figure 5-62 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-47

Figure 5-63 Insert Clean Tape Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-48

Figure 5-64 Insert Range Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-49

Figure 5-65 Target Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-49

Figure 5-66 Usage Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-50

Figure 5-67 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-51

Figure 5-68 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-52

Figure 5-69 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-52

Figure 5-70 Eject Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-53

Figure 5-71 Eject Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-54

Figure 5-72 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-54

Figure 5-73 Eject Clean Tape Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-55

Figure 5-74 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-55

Figure 5-75 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-56

Figure 5-76 Expired Tapes Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-56

Figure 5-77 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-56

Figure 5-78 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-57

22 June 2004

Figures xiii

Page 14

Figure 5-79 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-57

Figure 5-80 Eject Clean Tape By Coordinate Dialog. . . . . . . . . . . . . . . . . . . . . . .5-58

Figure 5-81 Eject Clean Tape By Coordinate Screen . . . . . . . . . . . . . . . . . . . . . . .5-59

Figure 5-82 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-59

Figure 5-83 By VOLSER Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-60

Figure 5-84 Eject Clean Tape By VOLSER Screen . . . . . . . . . . . . . . . . . . . . . . . . .5-61

Figure 5-85 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-61

Figure 5-86 Database Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-62

Figure 5-87 Media Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-63

Figure 5-88 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-63

Figure 5-89 Element Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

Figure 5-90 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-65

Figure 5-91 Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-66

Figure 5-92 Config Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-67

Figure 5-93 Continuation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-68

Figure 5-94 Advanced Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-69

Figure 5-95 Learn Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-69

Figure 5-96 Manipulate Get . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-70

Figure 5-97 Manipulate Put . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-70

Figure 5-98 Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-71

Figure 5-99 Library Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-72

Figure 5-100 SCSI Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-73

Figure 5-101 Target ID Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-74

Figure 5-102 Parity Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-75

Figure 5-103 Ports Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-76

Figure 5-104 Host Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-77

Figure 5-105 Trace Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-78

Figure 5-106 Security Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-79

Figure 5-107 Password Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-80

Figure 5-108 Security is ON Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-80

Figure 5-109 Password Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-81

Figure 5-110 Security is OFF Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-81

Figure 5-111 Change Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-82

xiv Figures

6-01151-01 Rev A

Page 15

Figure 5-112 Password Changed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-83

Figure 5-113 Invalid Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-83

Figure 5-114 Media Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-84

Figure 5-115 Emulate Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-86

Figure 5-116 RMU Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-87

Figure 5-117 Name Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-87

Figure 5-118 IP Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-88

Figure 5-119 Advanced Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-89

Figure 5-120 Drives Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-91

Figure 5-121 SCSI ID Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-92

Figure 5-122 Cleaning Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-93

Figure 5-123 Drives Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-93

Figure 5-124 Media Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-94

Figure 5-125 Usage Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-95

Figure 5-126 View Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-96

Figure 5-127 Utils Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-97

Figure 5-128 Library Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-97

Figure 5-129 Screen Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-98

Figure 5-130 Timeout Value Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-98

Figure 5-131 Password Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-99

Figure 5-132 Password Change Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-99

Figure 5-133 Invalid Password Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-100

Figure 5-134 Audio Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-100

Figure 5-135 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-101

Figure 5-136 Time Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-101

Figure 5-137 Date Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-102

Figure 5-138 Drives Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-103

Figure 5-139 Inventory Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-104

Figure 5-140 Update Microcode Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-105

Figure 5-141 Element Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-106

Figure 5-142 Drive Range Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-107

Figure 5-143 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-107

Figure 5-144 Clean Drives Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-108

22 June 2004

Figures xv

Page 16

Figure 5-145 Progress Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-109

Figure 5-146 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-109

Figure 5-147 Unload Drives Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-110

Figure 5-148 Progress Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-111

Figure 5-149 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-111

Figure 5-150 Initialize Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-111

Figure 5-151 Progress Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-112

Figure 5-152 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-112

Figure 5-153 Progress Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-112

Figure 5-154 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-113

Figure 5-155 Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-113

Figure 5-156 Preventive Maintenance Due Dialog . . . . . . . . . . . . . . . . . . . . . . . .5-114

Figure 5-157 Confirm Change Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-114

Figure 5-158 Start Dialog with No Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-115

Figure 5-159 Start Dialog with Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-115

Figure 5-160 Diags Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-116

Figure 5-161 DI/DO Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-117

Figure 5-162 Loopback Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-117

Figure 5-163 Sensors Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-118

Figure 5-164 Wrap Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-119

Figure 5-165 Real Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-120

Figure 5-166 Locks Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-121

Figure 5-167 Gripper Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-121

Figure 5-168 Get/Put Storage Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-122

Figure 5-169 Continuation Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 -122

Figure 5-170 Number of Elements Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-123

Figure 5-171 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-124

Figure 5-172 Get/Put Drives Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 -125

Figure 5-173 Continuation Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 -125

Figure 5-174 Number of Drives Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-126

Figure 5-175 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-127

Figure 5-176 Step Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-128

Figure 5-177 Continuation Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 -128

xvi Figures

6-01151-01 Rev A

Page 17

Figure 5-178 Scanner Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-130

Figure 5-179 Adjust Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-130

Figure 5-180 Trigger Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-131

Figure 5-181 Fiducial Test Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-132

Figure 5-182 Accessor Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-133

Figure 5-183 Move Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-134

Figure 5-184 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-134

Figure 5-185 Step Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-135

Figure 5-186 Movement Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-135

Figure 5-187 SelfTest Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-136

Figure 5-188 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-136

Figure 5-189 Power Supply Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-137

Figure 5-190 Function Not Available Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-137

Figure 5-191 Teach Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-138

Figure 5-192 Teach New Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-138

Figure 5-193 Keep Learned Offsets Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-139

Figure 5-194 Confirmation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-139

Figure 5-195 Progress Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-140

Figure 5-196 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-140

Figure 5-197 Error Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-140

Figure 5-198 Teach Current Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-140

Figure 5-199 Keep Learned Offsets Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-141

Figure 5-200 Confirmation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-141

Figure 5-201 Starting and Ending Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-142

Figure 5-202 Progress Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-142

Figure 5-203 Response Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-142

Figure 5-204 SAC Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-143

Figure 5-205 Password Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-143

Figure 5-206 Demo Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-143

Figure 5-207 Include Drives Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-144

Figure 5-208 Response Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-144

Figure 5-209 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-145

Figure 5-210 Warning Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-145

22 June 2004

Figures xvii

Page 18

Figure 5-211 Advanced Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-146

Figure 5-212 Password Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-146

Figure 5-213 Other Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-147

Figure 5-214 About Screen (RMU Connected). . . . . . . . . . . . . . . . . . . . . . . . . . . .5-148

Figure 5-215 About Screen (RMU Not Connected). . . . . . . . . . . . . . . . . . . . . . . .5-148

Figure 6-1 Barcode Label Application (LTO example). . . . . . . . . . . . . . . . . . . .6-14

Figure 6-2 Barcode Label Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Figure 6-3 Cleaning Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Figure 6-4 AutoClean Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Figure 6-5 Insert Clean Tape Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Figure 6-6 Range Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Figure 6-7 Enter Target Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Figure 6-8 Current Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Figure 6-9 Command Complete Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Figure 6-10 Media Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Figure 6-11 Selected Cleaning Tape. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Figure 6-12 Usage Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

Figure 6-13 View Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

xviii Figures

6-01151-01 Rev A

Page 19

Tables

Table 2-1 Drives and Storage Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Table 2-2 Scalar 1000 Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Table 2-4 Element Coordinates for Firmware 2.3 or Later . . . . . . . . . . . . . . . . 2-8

Table 2-5 Library Internal Indexing for Firmware 2.30 or Earlier. . . . . . . . . 2-10

Table 2-6 Library Internal Indexing for Firmware 3.0 or Later . . . . . . . . . . . 2-10

Table 2-7 Library External Addressing for Firmware 3.0 or Later . . . . . . . . 2-11

Table 3-1 Hazard Alert Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Table 4-1 Operator Panel Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Table 4-2 Operator Panel Push-Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Table 5-1 Operating State and Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Table 6-1 Barcode Label Characters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Table 6-2 Supported Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Table 7-1 SAC Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Table 7-2 Operator Intervention Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Table 7-3 Error Log Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

xix

Page 20

xx Tables

6-00054-02 Rev A

Page 21

1

About this

Guide

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Associated Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Explanation of Symbols and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

ADIC Technical Assistance Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Regulatory Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Federal Communication Commission Class A Notice . . . . . . . . . . . . . . . . . . . . . .1-6

IC Notice (Canada Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

EN 55022 Compliance (Czech Republic Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

CE Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

VCCI Notices (Japan Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Page 22

1-2 About this Guide

6-00054-02 Rev A

Page 23

Overview

1-

This guide contains information and instructions necessary

for the safe operation of the Scalar 1000

is organized as follows:

• Intended Audience on page 1-3

• Organization on page 1-3

• Associated Documents on page 1-4

• Explanation of Symbols and Notes on page 1-4

• ADIC Technical Assistance Center on page 1-5

• Regulatory Notices on page 1-6

Intended Audience

This guide is intended for operators, trained customer

specialists, and maintenance personnel of the service partner

who interacts with the Scalar 1000.

Organization

This publication contains chapters detailing the operation of

the Scalar 1000. The chapters topics include:

Chapter 1 About this Guide - Describes the intended

1

Library. This chapter

audience, organization, associated

documents, explanation of symbols and

notes, and how to obtain additional

assistance.

Chapter 2 System Description - Describes general

Chapter 3 Safety - Describes the hazard symbols,

Chapter 4 Operation - Describes the Operator Panel,

1. Scalar 1000 is a registered trademark of ADIC. Throughout the remainder of this document the

Scalar 1000 library is referred to as the Scalar 1000 or the library.

22 June 2004

information, library modules, internal

components, connectivity, and I/O status

and control.

messages, safety features, and

considerations for safe operation.

the Scalar 1000 start-up and shutdown

operations, and the Remote Management

Unit operations and menus.

Overview 1-3

Page 24

Chapter 5 Menus and Commands - Describes the Scalar

1000 menus and commands.

Chapter 6 Processing Media - Describes the Insert/

Eject Station, media types, media

processing, and cleaning media.

Chapter 7 Error Messages - Describes message

processing, Service Action Code (SACs),

and Operator Intervention Messages.

Index

Associated Documents

6-01151-xx Scalar 1000 Maintenance Guide

6-00055-xx Scalar 1000 SCSI Reference Manual

Explanation of Symbols and Notes

The following symbols and highlighted passages note

important information.

1-4 About this Guide

Detailed explanations for the above symbols are provided in

Hazard Alert Messages on page 3-3.

<1> + <2> Press these keys simultaneously.

Italics Headline, for example, Chapter 2,

Description

File name, for example, AMUINST.EXE

Bold Terms appearing on the Operator Panel

for example, Utilities

Operating element/key on the Operating

Panel

Courier Command line,

Switch position, for example, ON, OFF

6-00054-02 Rev A

Page 25

ADIC Technical Assistance Center

If problems cannot be solved with the aid of this document,

contact the ADIC Technical Assistance Center (ATAC).

• In the USA: 800.827.3822

• Outside the USA, toll free: 00.800.9999.3822

• email: support@adic.com

Before contacting the ATAC, make sure you have the Serial

Number for your library. To locate the Serial Number, do one

of the following:

• Open the Control Module (CM) back door. Look for the

Serial Number located in the upper left inside panel.

• From the Operator Panel Main Menu, select Database

Menu Config Dialog. The library Serial Number is

listed in the Serial# field.

22 June 2004

ADIC Technical Assistance Center 1-5

Page 26

Regulatory Notices

Federal Communication Commission Class A Notice

This equipment has been tested and found to comply with the

limits for a Class A digital device pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own

expense.

To meet FCC emissions limits, properly shielded and

grounded cables and connectors must be used. The user

accepts responsibility for radio or television interference

caused by improperly shielded or grounded cables and

connectors or by unauthorized modifications or changes to

the equipment. Unauthorized modifications or changes could

void the user’s authority to operate the equipment.

Obtain a copy of the following booklet:

FCC Interference Handbook, 1996, available from the U.S.

Government Printing Office, Washington, DC 20402, Stock

No. 004-000-00450-7.

This device complies with Part 15 of the FCC rules. Operation

is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference received,

including interference that may cause undesired

operation.

Use only shielded cables for connecting peripherals to this

device to reduce the possibility of interference with radio

and television reception. Using shielded cables ensures that

you maintain the appropriate FCC radio frequency

emissions compliance (for a Class A device) or FCC

certification (for a Class B device) of this product.

In compliance with FCC regulations, the following

information is provided on the device or devices covered in

this document.

1-6 About this Guide

6-00054-02 Rev A

Page 27

Product Name Scalar 1000

Model number SC1000

Company name Advanced Digital Information Corporation

PO Box 97057

Redmond, WA 98073-9757 USA

(425) 881-8004

IC Notice (Canada Only)

Most tape libraries are classified by the Industry Canada (IC)

Interference-Causing Equipment Standard #3 (ICES-003) as

Class A digital devices. To determine which classification

(Class A or B) applies to your tape library, examine all

registration labels located on the bottom or the back panel of

your library. A statement in the form of “IC Class A ICES-3”

or “IC Class B ICES-3” will be located on one of these labels.

Note that Industry Canada regulations provide that changes

or modifications not expressly approved by the tape library

manufacturer could void your authority to operate this

equipment.

This Class A (or Class B, if so indicated on the registration

label) digital apparatus meets the requirements of the

Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe B (ou Classe A, si ainsi

indiqué sur l’étiquette d’enregistration) respecte toutes les

exigences du Reglement sur le Materiel Brouilleur du Canada.

22 June 2004

Regulatory Notices 1-7

Page 28

EN 55022 Compliance (Czech Republic Only)

This device belongs to category A devices as describe d in EN

55022, unless it is specifically stated that it is a category B

device on the specification label. The following applies to

devices in category A of EN 55022 (radius of protection up to

30 meters). The user of the device is obliged to take all steps

necessary to remove sources of interference to

telecommunication or other devices.

CE Notice

Marking by the symbol indicates compliance of this tape

library to the EMC (Electromagnetic Compatibility) directive

of the European Community. Such marking is indicative that

this tape library meets or exceeds the following technical

standards:

EN 55022:1998 Limits and Methods of Measurement of

Radio Interference Characteristics of

Information Technology Equipment.

This system is an EN 55022 Class A device.

EN 50082-1 “Information technology equipment -

Immunity characteristics Limits and

methods of measurements.”

EN 61000-3-2 Harmonic current emissions test.

EN61000-3-3 Voltage fluctuations and flicker in

low-voltage supply systems test.

EN 61000-4-2 Electrostatic discharge immunity test.

EN 61000-4-3 Radiated, radio-frequency, electromagnetic

field immunity test.

EN 61000-4-4 Electrical fast transient/burst immunity

test.

EN 61000-4-5 Surge immunity test.

1-8 About this Guide

6-00054-02 Rev A

Page 29

EN 61000-4-6 Immunity to conducted di sturbances ,

induced by radio-frequency fields.

EN 61000-4-8 Power frequency magnetic field immunity

test.

EN 61000-4-11 Voltage dips, short interruptions and

voltage variations immunity test.

EN 60950:1992 Safety of Information Technology

+ Amd.1:1993 Equipment including “Electrical Business

+ Amd.2:1993 Equipment.”

with

considerations

to Amd.3:1995

22 June 2004

Regulatory Notices 1-9

Page 30

VCCI Notices (Japan Only)

This is a Class A product based on the standard of the

Voluntary Control Council for Interference by Information

Technology Equipment (VCCI). If this equipment is used in a

domestic environment, radio disturbance may occur, in which

case, the user may be required to take corrective actions.

NOTE: VCCI regulations provide that changes or

modifications not expressly approved by the Dell Computer

Corporation could void your authority to operate this

equipment.

Declaration of Conformity

The signed Declaration of Conformity is on file with

Advanced Digital Information Corporation, 17275 NE 67th

Court, Redmond, Washington 98052, and ADIC Europe, ZAC

des Basses Auges 1, rue Alfred de Vigny, 78112 Fourqueux,

France.

1-10 About this Guide

6-00054-02 Rev A

Page 31

2

System

Description

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Tape Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Cartridge Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Cartridge Accessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Insert/Eject Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

SAN Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

SCSI Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Scalar DLC Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Remote Management Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Page 32

2-2 System Description

6-00054-02 Rev A

Page 33

General Description

Note

If the ADIC 8590/

IBM 3590 tape

drive is installed in

either the Control

or the Expansion

Module, the

modules must be of

the large footprint

type. Adding an

extension frame to

a normal frame

increases the depth

of the frame.

Table 2-1 Drives and Storage Capacities

The Scalar 1000 automates the storage, retrieval, and control

of 3590, LTO, DLT, SDLT, and AIT cartridge tapes. Cartridges

are mounted and dismounted in tape drives using application

software from the host without operator intervention.

The Scalar 1000 is a linear storage library that can be expanded

from a single media library to a mixed media library. The

Scalar 1000 consists of a Control Module (CM) and up to three

Expansion Modules (EMs). See Figure 2-1 on page 2-5. The

CM contains library control hardware, the Cartridge

Accessor, an Insert/Eject Station (I/E) Station, an Operator

Panel, cartridge storage cells, and tape drives. The EM can

contain tape drives and cartridge storage.

The Scalar 1000 can be configured for approximately

118 to 1182 cartridges (the cartridge capacity depends on the

library configuration and features installed). See Table 2-1.

22-

High Profile Low Profile

3590/DLT LTO DLT/SDLT AIT

Drives 1 - 16 1 - 48 1 - 48 1 - 48

Cartridges 118 - 788 140 - 938 118 - 788 237 - 1182

22 June 2004

General Description 2-3

Page 34

Frame

Cartridge storage quantity varies by the number of modules

and tape drives in the modules. Table 2-2 lists the quantity of

media contained by the storage cells for the CM and EMs

configured for the different media types.

Table 2-2 Scala r 10 00 Con fig ur a tions

High Profile Low Profile

DLT/

Tape

Drives

3590/DLT

Cartridge

Capacity

AIT

Tape

Drives

AIT

Cartridge

Capacity

SDLT/

Tape

Drives

LTO

DLT/SDLT

Cartridge

Capacity

LTO

Cartridge

Capacity

Control

Module

Control

Module

and 1

Expansion

Module

Control

Module

and 2

Expansion

Modules

Control

Module

and 3

Expansion

Modules

1 - 2

3 - 4

1 - 2

3 - 4

5 - 6

7 - 8

1 - 2

3 - 4

5 - 6

7 - 8

9 - 10

11 - 12

1 - 2

3 - 4

5 - 6

7 - 8

9 - 10

11 - 12

13 - 14

15 - 16

158

118

368

328

288

248

578

538

498

458

418

378

788

748

708

668

628

588

548

508

2 - 12 237 1 - 6

7 - 12

2 - 12

552

1 - 6

7 - 12

14 - 24

432

13 - 18

19 - 24

2 - 12

867

1 - 6

7 - 12

14 - 24

747

13 - 18

19 - 24

26 - 36

627

25 - 30

31 - 36

2 - 12

1182

1 - 6

7 - 12

14 - 24

1062

13 - 18

19 - 24

26 - 36

942

25 - 30

31 - 36

38 - 48

822

37 - 42

43 - 48

158

118

368

328

288

248

578

538

498

458

418

378

788

148

708

668

628

588

548

508

200

152

450

402

352

306

700

652

604

556

508

460

950

902

854

806

758

710

662

641

2-4 System Description

When mixing high-profile drive technology with DLT/SDLT,

the CM must be configured for high-profile drive technology,

while DLT/SDLT consumes separate EMs.

6-00054-02 Rev A

Page 35

Modules

The Scalar 1000 Library consists of two types of modules: a

Control Module (CM) and an Expansion Module (EM). The

information in this section is organized as follows:

• Control Module on page 2-6

• Expansion Module on page 2-6

Operator

Panel

Insert/Eject

Station

Figure 2-1 Control Module and Expansion Module

Door