Quadra-Fire TOPAZ-MBK-IPI, TOPAZD-PMH-IPI, TOPAZD-MBK-IPI, TOPAZD-CSB-IPI Installation Manual

Page 1

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/151

Installation Manual

Installation and Appliance Setup

INSTALLER: Leave this manual with party responsible for use and operation.

OWNER: Retain this manual for future reference.

NOTICE: DO NOT discard this manual!

This appliance may be installed as an OEM installation

in manufactured home (USA only) or mobile home and

must be installed in accordance with the manufacturer’s

instructions and the manufactured home construction

and safety standard, Title 24 CFR, Part 3280 or Standard

for Installation in Mobile Homes, CAN/CSA Z240MH, in

Canada.

This appliance is only for use with the type(s) of gas

indicated on the rating plate.

Models:

TOPAZ-MBK-IPI

TOPAZD-PMH-IPI

TOPAZD-MBK-IPI

TOPAZD-CSB-IPI

R

In the Commonwealth of Massachusetts installation must be

performed by a licensed plumber or gas tter.

See Table of Contents for location of additional Commonwealth

of Massachusetts requirements.

- DO NOT store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any other

appliance.

- What to do if you smell gas

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re

department.

- Installation and service must be performed by a qualied

installer, service agency, or the gas supplier.

WARNING: If the information in these

instructions is not followed exactly, a fire or

explosion may result causing property damage,

personal injury, or death.

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of burns

from the hot viewing glass is provided with

this appliance and shall be installed for the

protection of the children and other at-risk

individuals.

!

DANGER

Cabinet StyleSolitaire

Page 2

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/152

Safety Alert Key:

• DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury.

• WARNING! Indicates a hazardous situation which, if not avoided could result in death or serious injury.

• CAUTION! Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

• NOTICE: Used to address practices not related to personal injury.

Installation Standard Work Checklist ....................3

1 Product Specic and Important Safety Information

A. Appliance Certication ............................4

B. Glass Specications ..............................4

C. BTU Specications ............................... 4

D. High Altitude Installations .......................... 4

E. Non-Combustible Materials Specication. . . . . . . . . . . . . . 4

F. Combustible Materials Specication .................4

G. Electrical Codes .................................4

H. Requirements for the Commonwealth of Massachusetts . . 5

2 Getting Started

A. Design and Installation Considerations ............... 6

B. Tools and Supplies Needed ........................ 6

C. Inspect Appliance and Components .................. 6

3 Framing and Clearances

A. Appliance Dimension Diagram ......................7

B. Clearances to Combustibles .......................8

C. Hearth Extension/Floor Protection ................... 8

4 Termination Location and Vent Information

A. Vent Termination Minimum Clearances ............... 9

B. Chimney Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

C. Approved Pipe ................................. 11

D. Use of Elbows .................................12

E. Measuring Standards ............................ 12

F. Venting Guidelines for Horizontal Runs ..............13

G. Vent Diagrams ................................. 13

5 Vent Clearances and Framing

A. Pipe Clearances to Combustibles .................. 30

B. Wall Penetration Framing/Firestops .................30

C. Ceiling Firestop/Floor Penetration Framing ...........31

D. Install Attic Insulation Shield ....................... 31

6 Appliance Preparation

A. Top to Rear Vent Conversion ......................32

B. Securing and Leveling the Appliance ................35

7 Venting and Chimneys

A. Assemble Vent Sections. . . . . . . . . . . . . . . . . . . . . . . . . . 36

B. Assemble Slip Sections ..........................37

C. Secure the Vent Sections .........................38

D. Disassemble Vent Sections .......................38

E. Vertical Termination Requirements ..................40

F. Horizontal Termination Requirements ............... 42

8 Electrical Information

A. General Information .............................44

B. Wiring Requirements ............................45

9 Gas Information

A. Fuel Conversion ................................ 48

B. Gas Pressure ..................................48

C. Gas Connection ................................48

D. High Altitude Installations ......................... 48

E. Air Shutter Setting .............................. 49

10 Appliance Setup

A. Remove Fixed Glass Assembly ....................50

B. Remove the Shipping Materials ....................50

C. Clean the Appliance .............................50

D. Install the Refractory ............................ 51

E. Install the Log Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 52

F. Mineral Wool ................................... 53

G. Install Fixed Glass Assembly ......................53

H. Install Flue Restrictor ............................53

11 Reference Materials

A. Vent Components Diagrams ......................54

B. Accessories ................................... 60

= Contains updated information.

Table of Contents

Page 3

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/153

Installation Standard Work Checklist

Customer:

Lot/Address:

Model (circle one): TOPAZ-MBK-IPI

TOPAZ-D-PMH-IPI

TOPAZ-D-MBK-IPI

TOPAZ-D-CSB-IPI

Date Installed:

Location of Stove:

Installer:

Dealer/Distributor Phone #

Serial #:

Comments: Further description of the issues, who is responsible (Installer/ Builder/ Other Trades, etc) and corrective

action needed _____________________________________________________________________________________

_________________________________________________________________________________________________

_________________________________________________________________________________________________

Comments Communicated to party responsible ____________________ by ______________________on ___________

(Builder / Gen. Contractor/) (Installer) (Date)

Appliance Install YES IF NO, WHY?

Veri ed combustible or non-combustible clearances to walls. (Pg. 8) ___________________________

Stove is installed level. (Pg. 35) ___________________________

Venting/Chimney Section 7 (Pg 36-43)

Venting con guration complies with allowable vent requirements. ___________________________

Venting installed, locked and secured in place with proper clearance. ___________________________

Interior/Exterior restops installed and sealed. ___________________________

Attic insulation shield installed. ___________________________

Exterior wall/Roof ashing installed and sealed. ___________________________

Terminations/Roof ashing installed and sealed. ___________________________

Electrical Section 8 (Pg 44-47)

Unswitched power (110-120 VAC) provided for the appliance. ___________________________

Switch wires properly installed. ___________________________

Gas Section 9 (Pg 48-49)

Appliance con guration matches fuel type. ___________________________

Was a conversion performed? ___________________________

Leak check performed and inlet/outlet pressure veri ed. ___________________________

Set air shutter for optimal ame appearance. ___________________________

Appliance Setup Section 10 (Pg 50-53)

All packaging and protective materials are from removed inside/under/on

the appliance). ___________________________

Refractories, logs, and mineral wool installed correctly. ___________________________

Glass assembly installed and secured. ___________________________

Accessories installed properly. ___________________________

Door properly installed. Firescreen properly installed (if equipped). ___________________________

Manual bag and all of its contents are removed from inside/under

the appliance and given to party responsible for use and operation. ___________________________

Started appliance and veri ed no gas leaks exist. ___________________________

2341-982 6/14

= Contains updated information.

Hearth & Home Technologies recommends the following:

• Photographing the installation and copying this checklist for your le.

• That this checklist remain visible at all times on the appliance until the installation is complete.

This standard work checklist is to be used by the installer in conjunction with, not instead of, the instructions contained in

this

installation manual.

WARNING! Risk of Fire or Explosion! Failure to install appliance according to these instructions can

lead to a re or explosion.

ATTENTION INSTALLER:

Follow this Standard Work Checklist

Page 4

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/154

B. Glass Specications

This appliance is equipped with 5 mm ceramic glass.

Replace glass only with 5 mm ceramic glass. Please contact

your dealer for replacement glass.

C. BTU Specications

This product is listed to ANSI standards for “Vented Gas

Fireplace Heaters” and applicable sections of “Gas

Burning Heating Appliances for Manufactured Homes and

Recreational Vehicles”, and “Gas Fired Appliances for Use

at High Altitudes”.

NOTICE: This installation must conform with local codes. In

the absence of local codes you must comply with the National

Fuel Gas Code, ANSI Z223.1-latest edition in the U.S.A. and

the CAN/CGA B149 Installation Codes in Canada.

A. Appliance Certication

NOT INTENDED FOR USE AS A PRIMARY HEAT SOURCE.

This appliance is tested and approved as either supplemental

room heat or as a decorative appliance. It should not be

factored as primary heat in residential heating calculations.

1

Product Specic and Important Safety Information

D. High Altitude Installations

NOTICE: If the heating value of the gas has been reduced,

these rules do not apply. Check with your local gas utility or

authorities having jurisdiction.

When installing above 2000 feet elevation:

• In the USA: Reduce input rate 4% for each 1000 feet

above 2000 feet.

• In CANADA: Input ratings are certied without a

reduction of input rate for elevations up to 4500 feet

(1370 m)above sea level. Please consult provincial and/

or local authorities having jurisdiction for installations at

elevations above 4500 feet (1370 m).

Check with your local gas utility to determine proper orice

size.

E. Non-Combustible Materials Specication

Material which will not ignite and burn. Such materials are

those consisting entirely of steel, iron, brick, tile, concrete,

slate, glass or plasters, or any combination thereof.

Materials that are reported as passing ASTM E 136,

Standard Test Method for Behavior of Materials in a

Vertical Tube Furnace at 750 ºC shall be considered non-

combustible materials.

F. Combustible Materials Specication

Materials made of or surfaced with wood, compressed paper,

plant bers, plastics, or other material that can ignite and burn,

whether ame proofed or not, or plastered or unplastered

shall be considered combustible materials.

G. Electrical Codes

NOTICE: This appliance must be electrically wired and

grounded in accordance with local codes or, in the absence

of local codes, with National Electric Code ANSI/NFPA

70-latest edition or the Canadian Electric Code CSA

C22.1.

• A 110-120 VAC circuit for this product must be protected

with ground-fault circuit-interrupter protection, in

compliance with the applicable electrical codes, when

it is installed in locations such as in bathrooms or near

sinks.

MODELS: TOPAZ-MBK-IPI, TOPAZD-PMH-IPI, TOPAZD-MBK-

IPI, TOPAZD-CSB-IPI

LABORATORY: Underwriters Laboratories, Inc. (UL)

TYPE: Direct Vent Heater

STANDARD: ANSI Z21.88-2014/CSA 2.33-2014

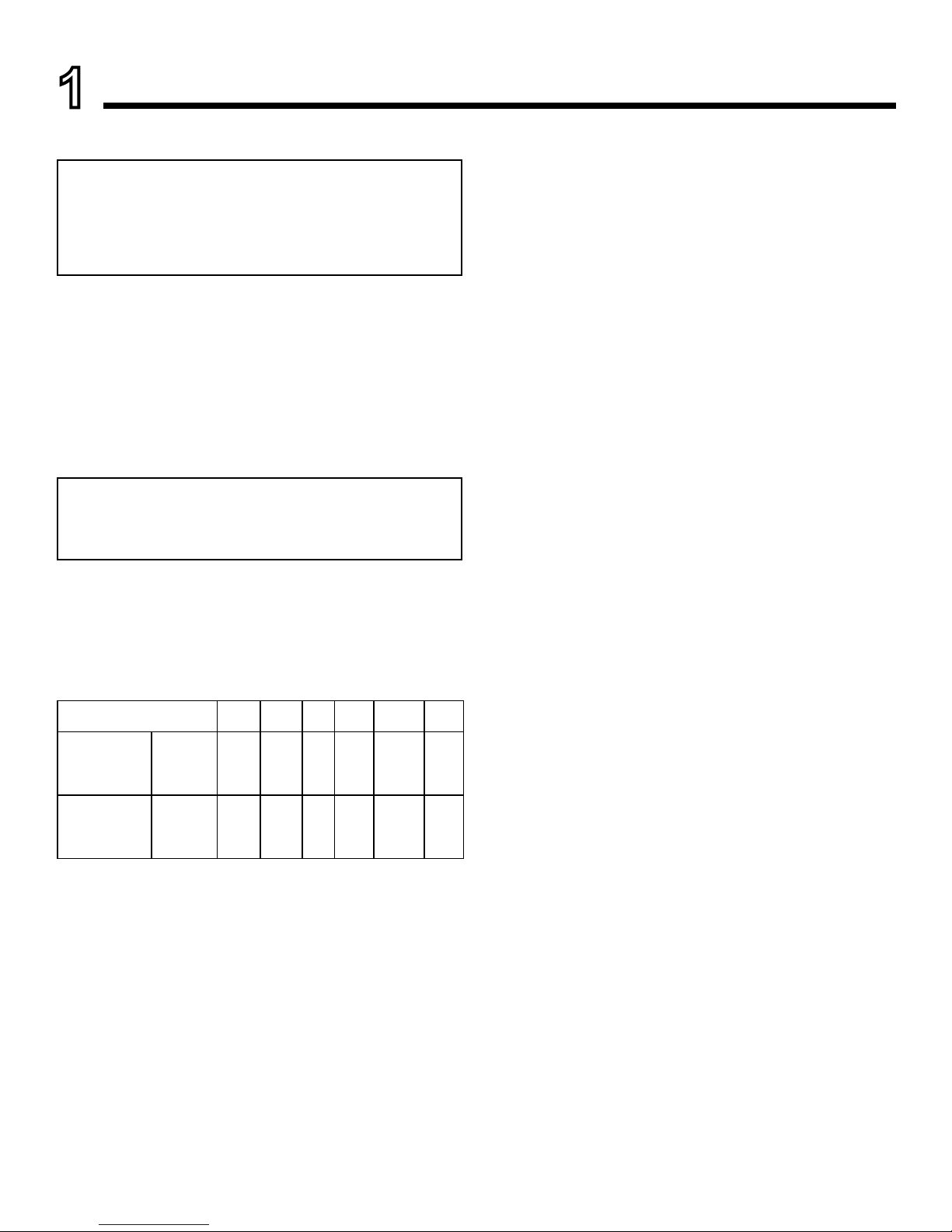

Models

(U.S. or Canada)

Maximum

Input

BTU/h

Minimum

Input

BTU/h

Orice

Size

(DMS)

AFUE

State

Steady

Efciency %

P4 %

TOPAZ-MBK-IPI

TOPAZD-PMH-IPI

TOPAZD-MBK-IPI

TOPAZD-CSB-IPI

(NG)

(0-2000 FT) 37,000 26,000 32 68.6% 69% 70%

TOPAZ-MBK-IPI

TOPAZD-PMH-IPI

TOPAZD-MBK-IPI

TOPAZD-CSB-IPI

(LP)

(0-2000 FT) 34,000 26,000 50 69.4% 69% 69%

Page 5

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/155

H. Requirements for the Commonwealth of

Massachusetts

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in

whole or in part for residential purposes, including those

owned or operated by the Commonwealth and where

the side wall exhaust vent termination is less than seven

(7) feet above nished grade in the area of the venting,

including but not limited to decks and porches, the following

requirements shall be satised:

Installation of Carbon Monoxide Detectors

At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gas tter

shall observe that a hard wired carbon monoxide detector

with an alarm and battery back-up is installed on the

oor level where the gas equipment is to be installed. In

addition, the installing plumber or gas tter shall observe

that a battery operated or hard wired carbon monoxide

detector with an alarm is installed on each additional level

of the dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment. It shall be the

responsibility of the property owner to secure the services

of qualied licensed professionals for the installation of hard

wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled

equipment is installed in a crawl space or an attic, the hard

wired carbon monoxide detector with alarm and battery

back-up may be installed on the next adjacent oor level.

In the event that the requirements of this subdivision can not

be met at the time of completion of installation, the owner

shall have a period of thirty (30) days to comply with the

above requirements; provided, however, that during said

thirty (30) day period, a battery operated carbon monoxide

detector with an alarm shall be installed.

Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in accordance

with the above provisions shall comply with NFPA 720 and

be ANSI/UL 2034 listed and IAS certied.

Signage

A metal or plastic identication plate shall be permanently

mounted to the exterior of the building at a minimum height

of eight (8) feet above grade directly in line with the exhaust

vent terminal for the horizontally vented gas fueled heating

appliance or equipment. The sign shall read, in print size no

less than one-half (1/2) in. in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

Note: The following requirements reference various

Massachusetts and national codes not contained in this

document.

Inspection

The state or local gas inspector of the side wall horizontally

vented gas fueled equipment shall not approve the

installation unless, upon inspection, the inspector observes

carbon monoxide detectors and signage installed in

accordance with the provisions of 248 CMR 5.08(2)(a)1

through 4.

Exemptions

The following equipment is exempt from 248 CMR 5.08(2)

(a)1 through 4:

• The equipment listed in Chapter 10 entitled “Equipment

Not Required To Be Vented” in the most current edition

of NFPA 54 as adopted by the Board; and

• Product Approved side wall horizontally vented gas fueled

equipment installed in a room or structure separate from

the dwelling, building or structure used in whole or in part

for residential purposes.

MANUFACTURER REQUIREMENTS

Gas Equipment Venting System Provided

When the manufacturer of Product Approved side wall

horizontally vented gas equipment provides a venting

system design or venting system components with the

equipment, the instructions provided by the manufacturer

for installation of the equipment and the venting system

shall include:

• Detailed instructions for the installation of the venting

system design or the venting system components; and

• A complete parts list for the venting system design or

venting system.

Gas Equipment Venting System NOT Provided

When the manufacturer of a Product Approved side wall

horizontally vented gas fueled equipment does not provide

the parts for venting the ue gases, but identies “special

venting systems”, the following requirements shall be

satised by the manufacturer:

• The referenced “special venting system” instructions

shall be included with the appliance or equipment

installation instructions; and

• The “special venting systems” shall be Product Approved

by the Board, and the instructions for that system shall

include a parts list and detailed installation instructions.

A copy of all installation instructions for all Product Approved

side wall horizontally vented gas fueled equipment, all

venting instructions, all parts lists for venting instructions,

and/or all venting design instructions shall remain with the

appliance or equipment at the completion of the installation.

See Gas Connection section for additional

Commonwealth of Massachusetts requirements.

Page 6

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/156

2

Getting Started

A. Design and Installation Considerations

Heat & Glo direct vent gas appliances are designed to

operate with all combustion air siphoned from outside of the

building and all exhaust gases expelled to the outside. No

additional outside air source is required.

Installation MUST comply with local, regional, state and

national codes and regulations. Consult insurance carrier,

local building inspector, re ofcials or authorities having

jurisdiction over restrictions, installation inspection and

permits.

Before installing, determine the following:

• Where the appliance is to be installed.

• The vent system conguration to be used.

• Gas supply piping requirements.

• Electrical wiring requirements.

• Whether optional accessories—devices such as a fan or

remote control—are desired.

C. Inspect Appliance and Components

• Carefully remove the appliance and components from the

packaging.

• The vent system components and optional accessories

may be shipped in separate packages.

• If packaged separately, the log set must be installed.

• Report to your dealer any parts damaged in shipment,

particularly the condition of the glass.

• Read all of the instructions before starting the

installation. Follow these instructions carefully during

the installation to ensure maximum safety and benet.

WARNING! Risk of Fire or Explosion! Damaged parts

could impair safe operation. DO NOT install damaged,

incomplete or substitute components. Keep appliance dry.

B. Tools and Supplies Needed

Before beginning the installation be sure that the following

tools and building supplies are available.

Tape measure Framing material

Pliers Hammer

Phillips screwdriver Manometer

Gloves Framing square

Voltmeter Electric drill and bits (1/4 in.)

Plumb line Safety glasses

Level Reciprocating saw

Flat blade screwdriver

Non-corrosive leak check solution

1/2 - 3/4 in. length, #6 or #8 Self-drilling screws

Caulking material (300ºF minimum continuous exposure

rating)

One 1/4 in. female connection (for optional fan).

Hearth & Home Technologies disclaims any responsibility for,

and the warranty will be voided by, the following actions:

• Installation and use of any damaged appliance or vent system

component.

• Modication of the appliance or vent system.

• Installation other than as instructed by Hearth & Home

Technologies.

• Improper positioning of the gas logs or the glass door.

• Installation and/or use of any component part not approved

by Hearth & Home Technologies.

Any such action may cause a re hazard.

WARNING! Risk of Fire, Explosion or Electric Shock! DO

NOT use this appliance if any part has been under water.

Call a qualied service technician to inspect the appliance

and to replace any part of the control system and/or gas

control which has been under water.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. For

assistance or additional information, consult a qualied service

technician, service agency or your dealer.

Installation and service of this appliance should be

performed by qualied personnel. Hearth & Home

Technologies suggests NFI certied or factory trained

professionals, or technicians supervised by an NFI

certied professional (www.ncertied.org).

Page 7

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/157

3

Framing and Clearances

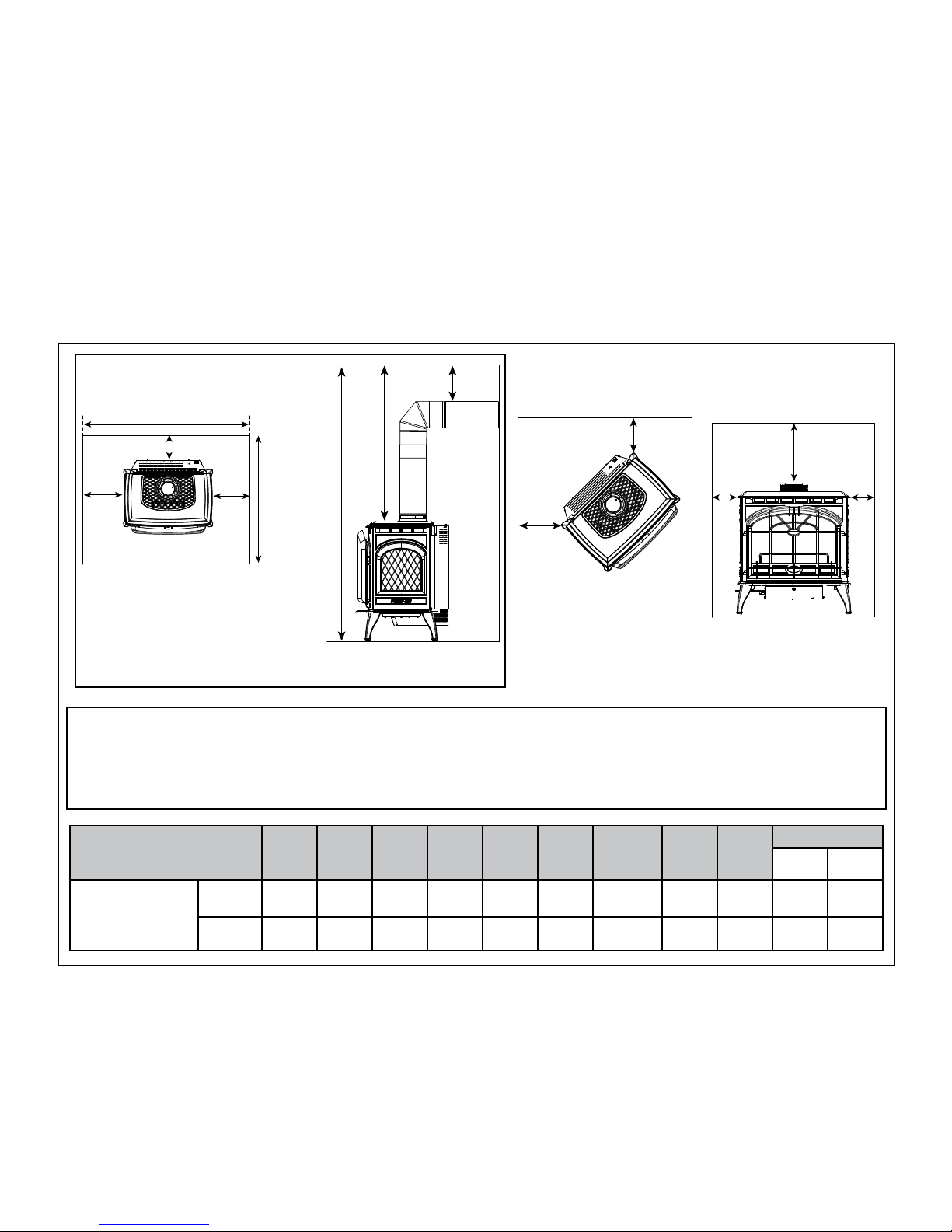

A. Appliance Dimension Diagram

Dimensions are actual appliance dimensions. Use for reference only.

Figure 3.1 Appliance Dimensions

Location Inches Millimeter Location Inches Millimeter

A 27-3/8 695 E 13-3/4 349

B 8-7/8 225 F 23-1/8 587

C 29-1/2 749 G 27-3/4 705

D 22-7/8 581 H 18 457

NOTE: Diagrams show gas appliance equipped without optional Blower, Part #GFK-160A.

Installation of optional blower does not affect overall dimensions.

TOP

B

E

BACK

F

FRONT

ELECTRICAL

CORD

A

SIDE

D

GAS LINE

C

C

L

VENT

G

H

Page 8

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/158

B. Clearances to Combustibles

When selecting a location for the appliance it is important to

consider the required clearances to walls (see Figure 3.2).

WARNING! Risk of Fire or Burns! Provide adequate

clearance around air openings and for service access. Due

to high temperatures, the appliance should be located out of

trafc and away from furniture and draperies.

NOTICE: Illustrations reect typical installations and are FOR

DESIGN PURPOSES ONLY. Illustrations/diagrams are not

drawn to scale. Actual installation may vary due to individual

design preference.

NOTICE: Some carpet materials may be sensitive to radiant

heat from the appliance causing discoloration or odor.

Figure 3.2 Appliance Locations

Model A B *B C *C D

E

(MAX.)

F G

H

Top of

pipe

Side of

pipe

TOPAZ-MBK-IPI

TOPAZD-PMH-IPI

TOPAZD-MBK-IPI

TOPAZD-CSB-IPI

Inches

6-1/2 3 5 1 2 66-1/4 36 40 36-3/4 3 1

Millimeters

165 76 127 25 51 1683 914 1016 933 76 25

C

or *C

C

or *C

G

AA

C. Hearth Extension/Floor Protection

CAUTION! Risk of Fire or Injury! Install appliance on

a stable, level, platform or oor strong enough to support

appliance without tipping.

A non-combustible hearth pad is not required. However,

the floor beneath the appliance must be stable, level, and

strong enough to support the appliance without a tipping

hazard. It is permissible to place the appliance on carpet.

NOTE: Flooring beneath appliance may reach 90

degrees plus room ambient temperature. Check with

flooring manufacturer for maximum temperature allowed

on flooring surfaces.

A

B

F

E

(MAX.)

A

"A"

measurement is from

stove top, not side

or *B

H

G

D

Alcove Installation

Note: Dimensions are minimums as shown and may not be typical for all applications. An alcove installation is

shown above on left.

*Installation of optional blower does not effect minimum clearance dimensions, however, if frequent blower removal

service is desired, clearance to the wall should be increased to *B and *C Dimensions.

Page 9

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/159

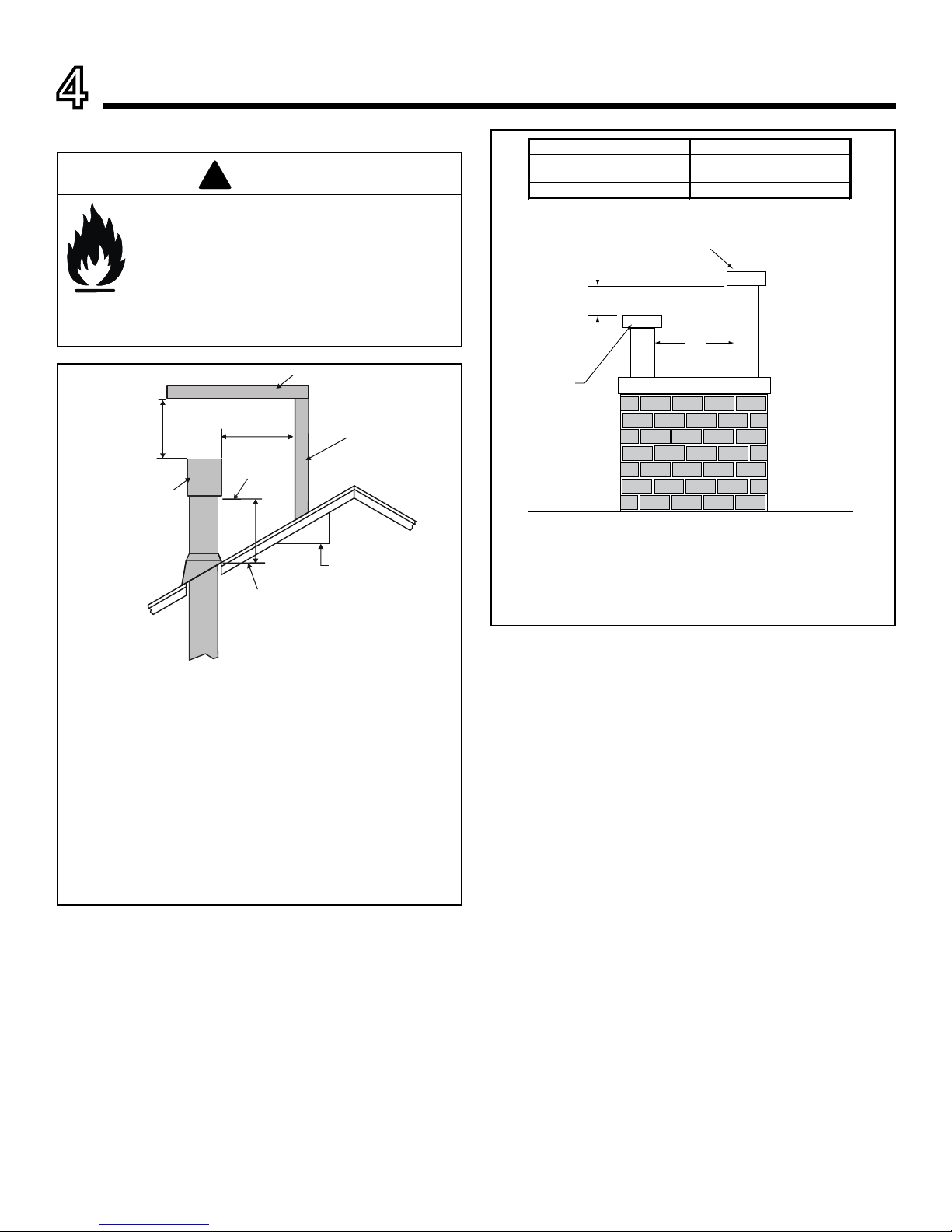

A. Vent Termination Minimum Clearances

Roof Pitch H (Min.) Ft.

Flat to 6/12...........................................................1.0*

Over 6/12 to 7/12 .................................................1.25*

Over 7/12 to 8/12 .................................................1.5*

Over 8/12 to 9/12 .................................................2.0*

Over 9/12 to 10/12 ...............................................2.5*

Over 10/12 to 11/12 .............................................3.25

Over 11/12 to 12/12 .............................................4.0

Over 12/12 to 14/12 .............................................5.0

Over 14/12 to 16/12 .............................................6.0

Over 16/12 to 18/12 .............................................7.0

Over 18/12 to 20/12 .............................................7.5

Over 20/12 to 21/12 .............................................8.0

* 3 foot minimum in snow regions

Figure 4.1 Minimum Height From Roof To Lowest Discharge Opening

HORIZONTAL

OVERHANG

VERTICAL

WALL

GAS DIRECT VENT

TERMINATION CAP

12

X

ROOF PITCH

IS X/ 12

LOWEST

DISCHARGE

OPENING

2 FT.

MIN.

20 INCHES MIN.

H (MIN.) - MINIMUM HEIGHT FROM ROOF

TO LOWEST DISCHARGE OPENING

4

Termination Location and Vent Information

Fire Risk.

Maintain vent clearance to combustibles as

specied.

• DO NOT pack air space with insulation or other

materials.

Failure to keep insulation or other materials away

from vent pipe may cause overheating and re.

Figure 4.2 Staggered Termination Caps

Gas, Wood or Fuel Oil

Termination Cap

B

Gas

Termination

Cap **

A *

*

If using decorative cap cover(s), this distance may need to be

increased. Refer to the installation instructions supplied with the

decorative cap cover.

**

A B

6 in. (minimum) up to 20 in.

152 mm/508 mm

18 in. minimum

457 mm

20 in. and over 0 in. minimum

In a staggered installation with both gas and wood or fuel oil

terminations, the wood or fuel oil termination cap must be

higher than the gas termination cap.

WARNING

!

Page 10

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1510

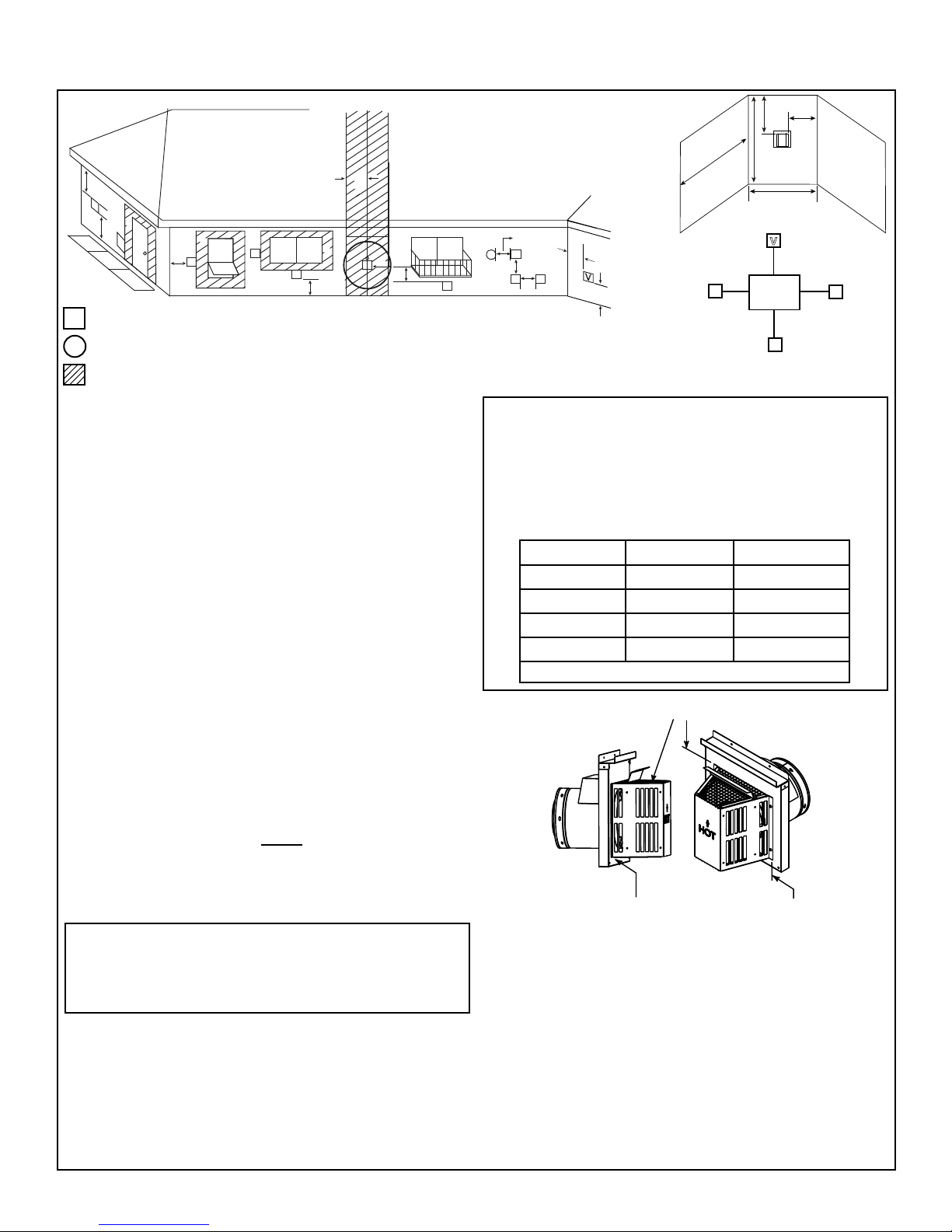

B. Chimney Diagram

Figure 4.3 Minimum Clearances for Termination

A = 12 inches.................clearances above grade, veranda,

porch, deck or balcony

B = 12 inches.................clearance to window or door that may

be opened, or to permanently closed

window

C = 18 inches.................clearance below unventilated soft

18 inches.................clearance below ventilated soft

30 inches .................clearance below vinyl soffits and

electrical service

D = 9 inches...................clearance to outside corner

E = 6 inches...................clearance to inside corner

F = 3 ft. (Canada) ..........not to be installed above a gas

meter/regulator assembly within 3 feet

horizontally from the center-line of the

regulator

G = 3 ft ...........................clearance to gas service regulator vent

outlet

H = 12 inches.................clearance to non-mechanical

(unpowered) air supply inlet,

combustion air inlet or direct-vent

termination

i = 3 ft. (U.S.A.)

6 ft. (Canada) ...........clearance to a mechanical (powered)

air supply inlet

All mechanical air intakes within 10 feet of a termination cap must

be a minimum of 3 feet below termination.

J = 7 ft. ......................... On public property: clearance above

paved sidewalk or a paved driveway.

A vent shall not terminate directly above a sidewalk or paved

driveway which is located between two single family dwellings and

serves both dwellings.

C

J

B

D

B

F

B

A

E

V

V

V

V

V

V

M

H or i

V

G

X

V

H

A

V

V

H

X

= AIR SUPPLY INLET

V

= VENT TERMINAL

= AREA WHERE TERMINAL IS NOT PERMITTED

O

N

P

R

Q

Electrical

Service

V

K

V

K

V

L

C

V

Q

MIN

R

MAX

1 cap 3 feet 2 x Q

ACTUAL

2 caps 6 feet 1 x Q

ACTUAL

3 caps 9 feet 2/3 x Q

ACTUAL

4 caps 12 feet 1/2 x Q

ACTUAL

Q

MIN

= # termination caps x 3 R

MAX

= (2 / # termination caps) x Q

ACTUAL

Covered Alcove Applications

(Spaces open only on one side and with an overhang)

N = 6 inches ........... non-vinyl sidewalls

12 inches ......... vinyl sidewalls

O = 18 inches ......... non-vinyl soft and overhang

42 inches ......... vinyl soft and overhang

P = 8 ft.

Measure horizontal clearances from this surface.

Measure vertical clearances from this surface.

CAUTION! Risk of Burns! Termination caps are HOT, consider

proximity to doors, trafc areas or where people may pass or

gather (sidewalk, deck, patio, etc.). Listed cap shields available.

Contact your dealer.

• Local codes or regulations may require different clearances.

• Vent system termination is NOT permitted in screened porches.

• Vent system termination is permitted in porch areas with two or

more sides open.

• Hearth & Home Technologies assumes no responsibility for the

improper performance of the appliance when the venting system

does not meet these requirements.

• Vinyl protection kits are suggested for use with vinyl siding.

M = 18 inches .................... clearance under veranda, porch, deck,

balcony or overhang

42 inches ................vinyl or composite overhang

Permitted when veranda, porch, deck or balcony is fully open on a

minimum of 2 sides beneath the oor.

K = 6 inches................. clearance from sides of electrical

service

L = 12 inches................ clearance above electrical service

Location of the vent termination must not interfere with access to the

electrical service.

Page 11

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1511

C. Approved Pipe

This appliance is approved for use with Hearth & Home

Technologies SLP, Simpson Duravent and ICC venting

systems. Refer to Section 11.A for vent component

information and dimensions.

DO NOT mix pipe, ttings or joining methods from different

manufacturers.

The pipe is tested to be run inside an enclosed wall. There

is no requirement for inspection openings at each joint

within the wall.

WARNING! Risk of Fire or Asphyxiation. This appliance

requires a separate vent. DO NOT vent to a pipe serving a

separate solid fuel burning appliance.

DO NOT USE FIELD-FABRICATED VENTING

COMPONENTS.

This product is approved to be vented either horizontally,

through the side wall or vertically through the roof. You may

vent through a Class A or masonry chimney if an approved

adapter is used.

This appliance is a direct vent heater. All combustion air must

come directly from the outside of the building. The vent pipe

for this unit consists of an inner and an outer pipe. The inner

pipe carries the appliance exhaust out of the system, and

the outer pipe brings fresh combustion air into the appliance.

• A round support box/wall thimble or heat shield is

required when the venting passes through a combustible

wall.

• A support box or ceiling restop is required when the

venting passes through a ceiling.

• Roof ashing and a storm collar are required when

venting passes through the roof.

• Follow instructions provided with the venting for

installation of these items.

Page 12

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1512

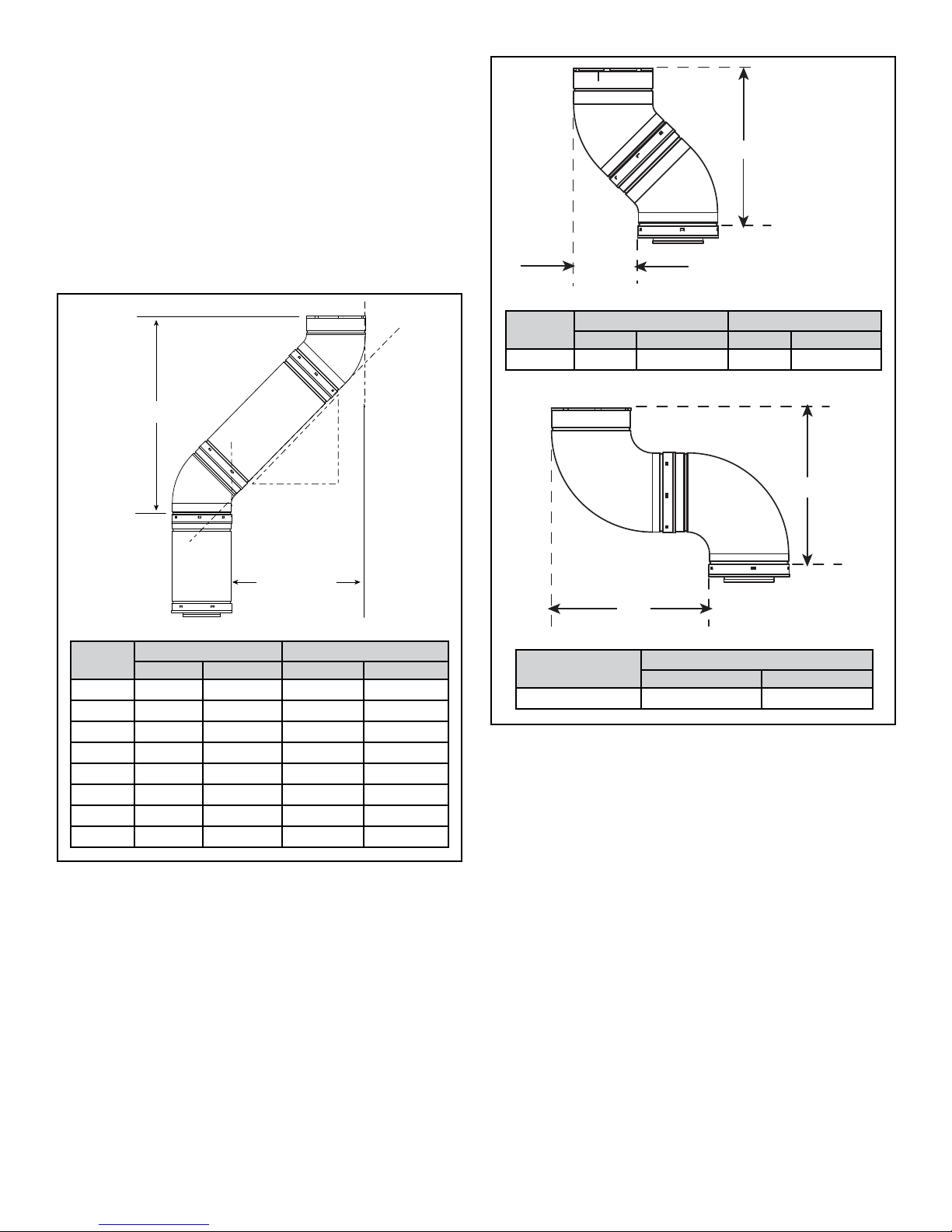

D. Use of Elbows

Diagonal runs have both vertical and horizontal vent aspects

when calculating the effects. Use the rise for the vertical

aspect and the run for the horizontal aspect. See Figure 4.4.

Two 45º elbows may be used in place of one 90º elbow. On

45º runs, one foot of diagonal is equal to 8-1/2 in. (216 mm)

horizontal run and 8-1/2 in. (216 mm) vertical run. A length

of straight pipe is allowed between two 45º elbows. See

Figure 4.4.

Figure 4.5 shows the vertical and horizontal offsets for SLP

elbows.

Figure 4.4

HORIZONTAL

VERTICAL

RUN

RISE

EFFECTIVE

LENGTH

Y

X

Vent Type

X

Inches Millimeters

SLP 11-1/4 286

Figure 4.5 Vertical and Horizontal Offset for SLP Elbows

Vent

Type

X Y

Inches Millimeters Inches Millimeters

SLP 5 127 11-3/4 298

SLP

Pipe

Effective Length Rise/Run

Inches Millimeters Inches Millimeters

SLP4 4 102 2-3/4 70

SLP6 6 152 4-1/4 108

SLP12 12 305 8-1/2 216

SLP24 24 610 17 432

SLP36 36 914 25-1/2 648

SLP48 48 1219 34 864

SLP6A 3 to 6 76 to 152

2-1/8-4-1/4 54-108

SLP12A 3 to 12 76 to 305

2-1/8-8-1/2 54-216

E. Measuring Standards

Vertical and horizontal measurements listed in the vent

diagrams were made using the following standards:

• Pipe measurements are shown using the effective length

of pipe. See Figure 11.1 for SLP for information on

effective length of pipe components.

• Horizontal terminations are measured to the outside

mounting surface (ange of termination cap) (see Figure

4.3).

• Vertical terminations are measured to bottom of

termination cap.

• Horizontal pipe installed level with 1/4 inch rise per foot.

Y

X

X

X

Page 13

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1513

G. Vent Diagrams

To replace the rst 90º starter elbow with two 45º elbows,

refer to Figure 4.7. All other 90º elbows can be replaced

with two 45º elbows.

General Rules:

• SUBTRACT 3 ft. from the total H measurement for each

90º elbow installed horizontally.

• SUBTRACT 1 ft. from the total H measurement for each

45º elbow installed horizontally.

• A maximum of three 90º elbows (or six 45º elbows) may

be used in any vent conguration. Some elbows may be

installed horizontally. See specic vent diagrams.

• When penetrating a combustible wall, a wall shield restop

must be installed.

• When penetrating a combustible ceiling, a ceiling restop

must be installed.

Top Vent—Horizontal Termination—Two 45º Elbows

Installation requirements to replace the rst 90º elbow

with two 45º elbows:

4 ft min.

(1.22 m)

Figure 4.7

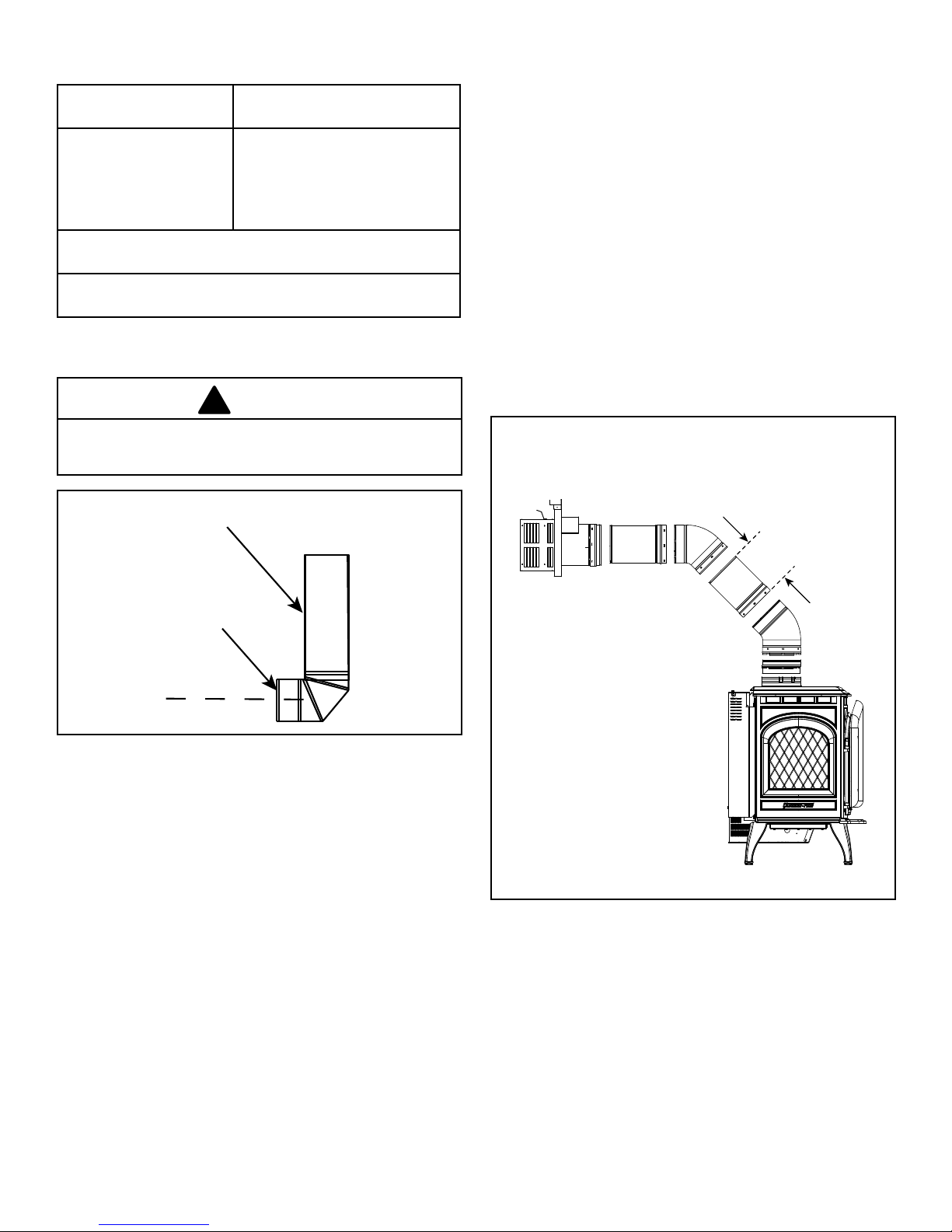

F. Venting Guidelines for Horizontal Runs

Figure 4.6

Max Horizontal Run 20 ft. (6.1 m) when vertical

rise is 10 ft (3m)

Rear Vent with Vertical

Rise

Min of 3 ft vertical (914 mm)

must be used prior to any

horizontal run. Derating ori

-

ce must be used.

See Figure 4.6.

Horizontal Run requires a non-combustible support

every 5 ft (1.5 m), i.e., plumbing tape

A vent run off the top of the appliance must have a

minimum vertical of 2 feet.

C

L

3 FT. MIN.

REAR VENT

CAUTION

!

VENTING STRAIGHT OUT THE REAR WITHOUT

VERTICAL RISE IS PROHIBITED

All rear vent applications will require the use of a derating

orice, included in the Rear Vent Kit

Page 14

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1514

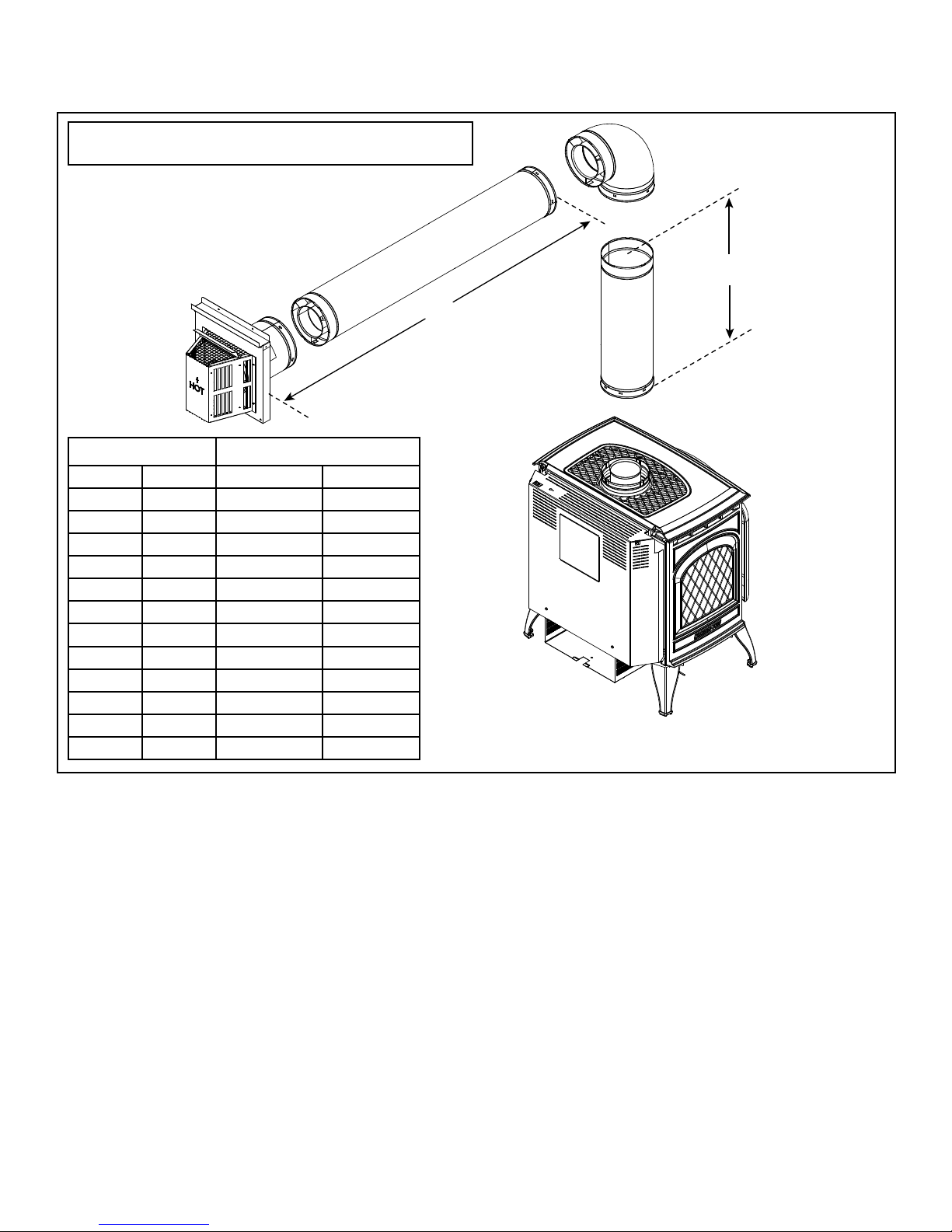

H

1

V

1

Figure 4.8

Top Vent - Horizontal Termination

One Elbow

V1 Minimum H1 Maximum

2 ft. 610 mm 2 ft. 610 mm

3 ft. 914 mm 8 ft. 2.4 m

4 ft. 1.2 m 12 ft. 3.7 m

6 ft. 1.8 m 14 ft., 8 in. 4.5 m

8 ft. 2.4m 17 ft., 4 in. 5.3 m

10 ft. 3.0 m 20 ft. 6.1 m

12 ft. 3.7 m 18 ft.,10 in. 5.7 m

16 ft. 4.9 m 16 ft., 4 in. 5.0 m

20 ft. 6.1 m 13 ft., 10 in. 4.2 m

24 ft. 7.3 m 11 ft., 4 in. 3.4 m

28 ft. 8.5 m 8 ft., 10 in. 2.7 m

32 ft. 9.8 m 6 ft., 4in. 2.0 m

36 ft. 11.0 m 3 ft., 10 in. 1.2 m

Note: As vertical pipe increases, a ue restrictor may be

required.

Page 15

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1515

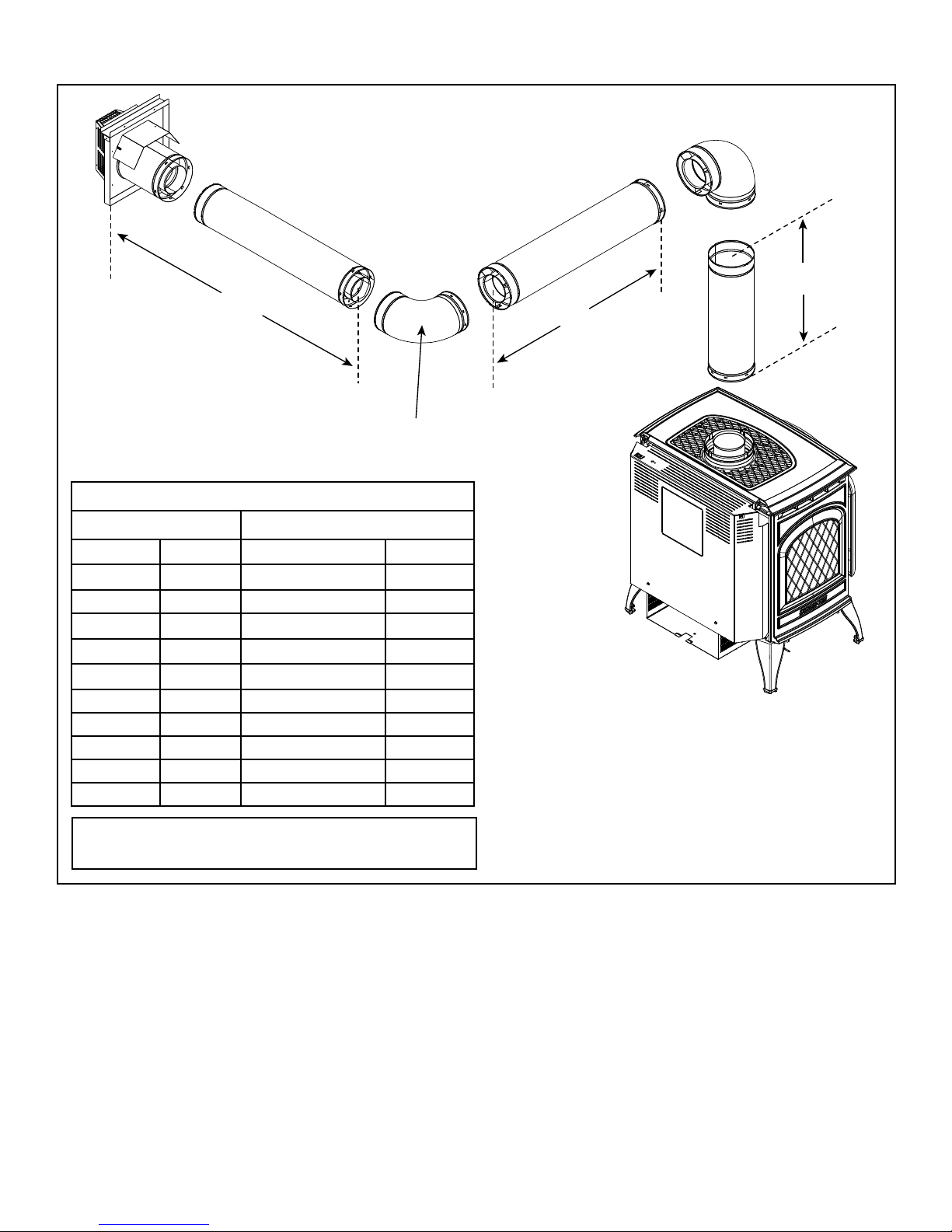

Note: As vertical pipe increases, a ue restrictor may be

required.

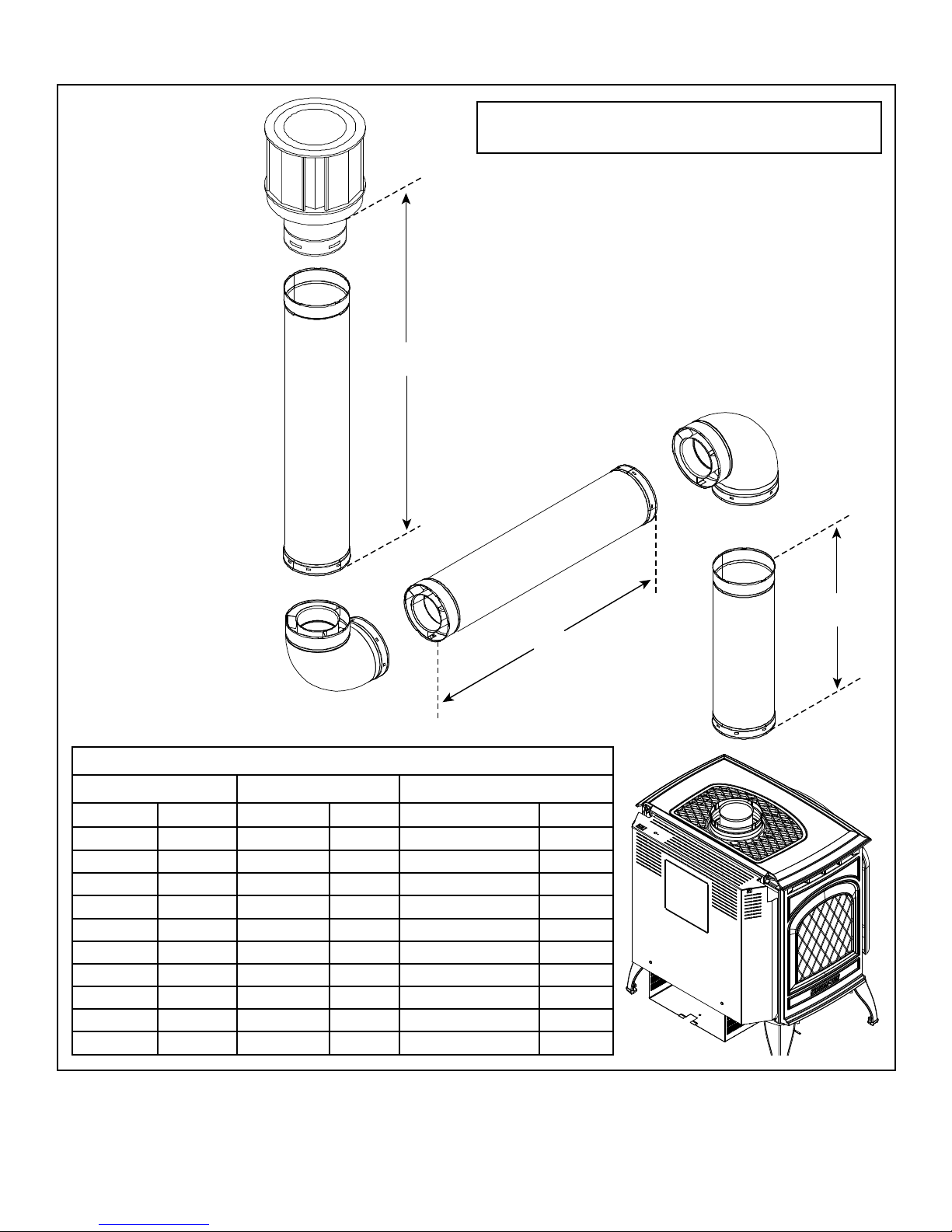

Two Elbows

INSTALLED

HORIZONTALLY

H

1

H

2

V

1

Figure 4.9

2 Elbows to Max. Horizontal

V

1

Minimum H1 + H2 Maximum

3 ft. 914 mm 5 ft. 1.5 m

4 ft. 1.2 m 9 ft. 2.7 m

6 ft. 1.8 m 11 ft., 8 in. 3.6 m

8 ft. 2.4 m 14 ft.,4 in. 4.4 m

10 ft. 3.1 m 17 ft. 5.2

12 ft. 3.7 m 15 ft., 10 in. 4.8

16 ft. 4.9 m 13 ft., 4 in. 4.1

20 ft. 6.1 m 10 ft., 10 in. 3.3

24 ft. 7.3 m 8 ft., 4 in. 2.5

28 ft. 8.5 m 5 ft., 10 in. 1.8

32 ft. 9.8 m 3 ft., 4 in. 1.0

Page 16

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1516

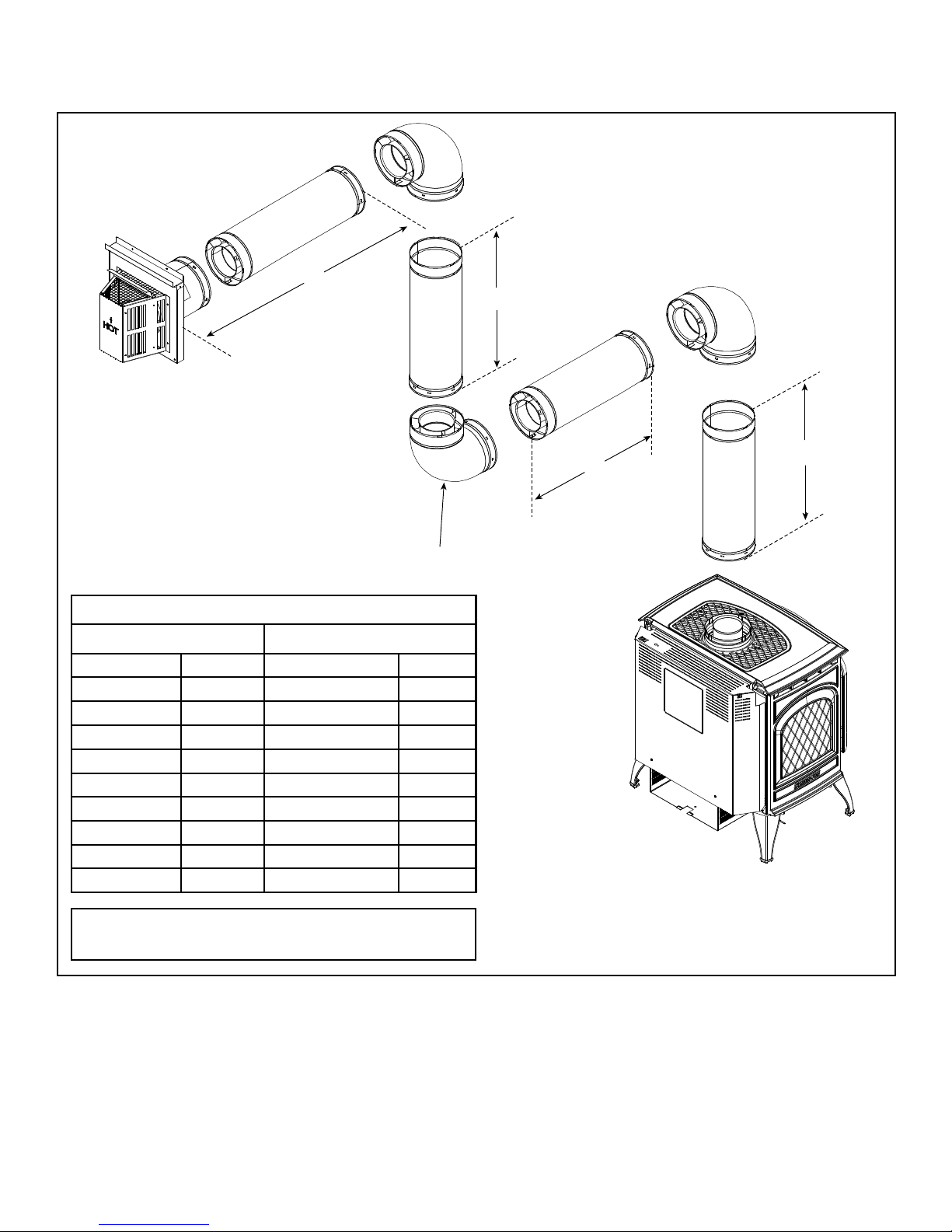

Note: As vertical pipe increases, a ue restrictor may be

required.

H

2

H

1

V

2

V

1

INSTALLED VERTICALLY

OR

HORIZONTALLY

Figure 4.10

Top Vent - Horizontal Termination - (continued)

Three Elbows

3 Elbows to Max. Horizontal

V

1

Minimum H

TOTAL

Maximum

3 ft. 914 mm 2 ft. 610 mm

4 ft. 1.2 m 6 ft. 1.8 m

6 ft. 1.8 m 8 ft., 8 in. 2.6

8 ft. 2.4 m 11 ft., 4 in. 3.5

10 ft. 3.1 m 14 ft. 4.3

12 ft. 3.7 m 12 ft., 10 in. 3.9

16 ft. 4.9 m 10 ft., 4 in. 3.1

20 ft. 6.1 m 7 ft., 10 in. 2.4

24 ft. 7.3 m 5 ft., 4 in. 1.6

28 ft. 8.5 m 2 ft., 10 in. 864 mm

Page 17

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1517

Note: As vertical pipe increases, a ue restrictor may be

required.

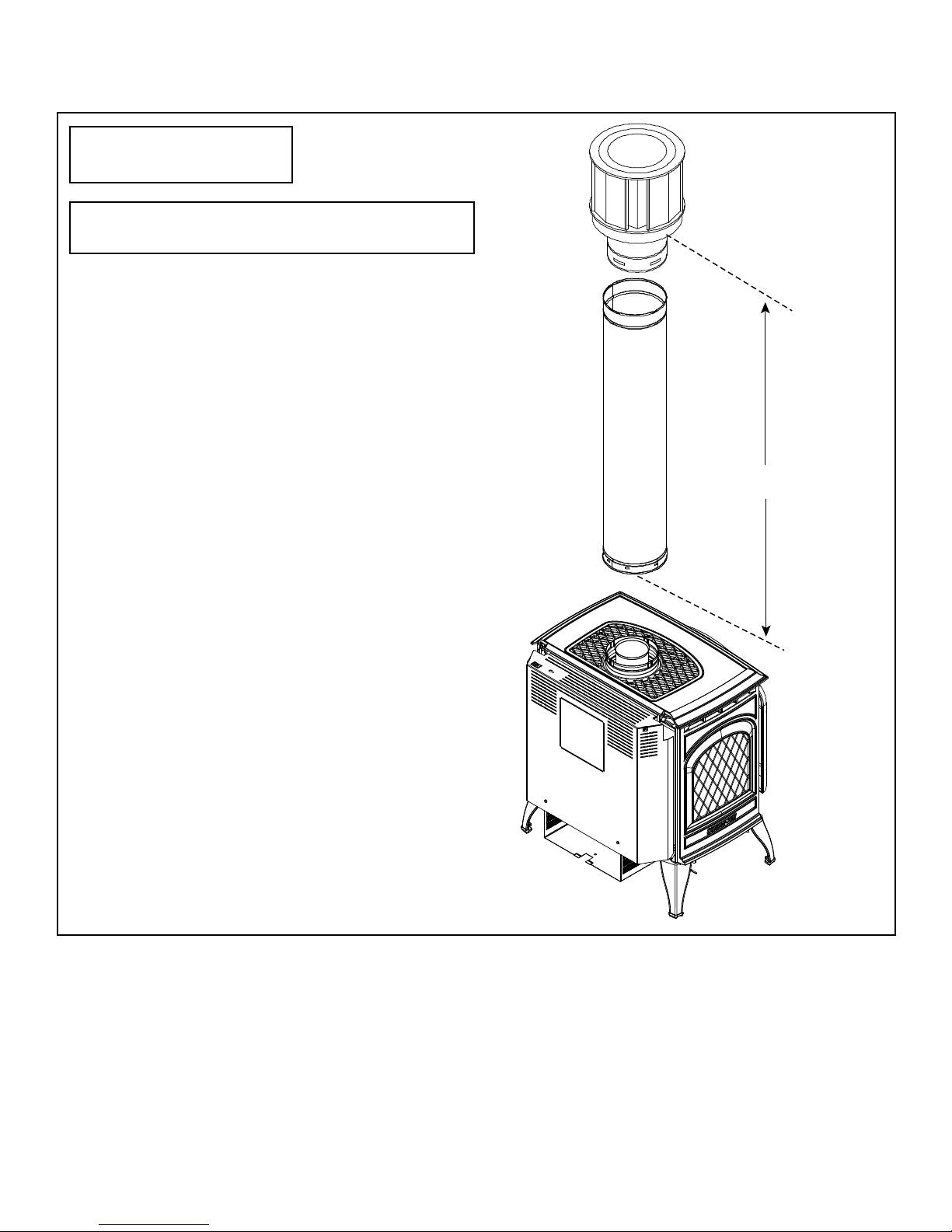

Top Vent - Vertical Termination

No Elbow

Figure 4.11

V

1

V1 = 40 ft. Max. (12.2 m)

V1 = 6 ft. Min. (1.8 m)

Page 18

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1518

H

1

V

1

V

2

Note: As vertical pipe increases, a ue restrictor may be

required.

Figure 4.12

Two Elbows

2 Elbows to Max. Horizontal

V

1

Minimum V1 + V2 Maximum H1 Maximum

3 ft. 914 mm 34 ft. 10.3 m 5 ft. 1.5 m

4 ft. 1.2 m 27 ft., 9 in. 8.5 m 9 ft. 2.7 m

6 ft. 1.8 m 23 ft., 6 in. 7.2 m 11 ft., 8 in. 3.6 m

8 ft. 2.4 m 19 ft., 3 in. 5.9 m 14 ft., 4 in. 4.4 m

10 ft. 3.1 m 15 ft. 4.6 m 17 ft. 5.2 m

12 ft. 3.7 m 16 ft., 10 in. 5.1 m 15 ft., 10 in. 4.8 m

16 ft. 4.9 m 20 ft., 10 in. 6.4 m 13 ft., 4 in. 4.1 m

20 ft. 6.1 m 24 ft., 9 in. 7.5 m 10 ft., 10 in. 3.3 m

24 ft. 7.3 m 28 ft., 9 in. 8.8 m 8 ft., 4 in. 2.5 m

28 ft. 8.5 m 32 ft., 6 in. 9.9 m 5 ft., 10 in. 1.8 m

32 ft. 9.8 m 36 ft., 3 in. 11.0 m 3 ft., 4 in. 1.0 m

Page 19

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1519

Figure 4.13

Top Vent - Vertical Termination - (continued)

Three Elbows

IN STA LLE D

HORIZONTALLY

H

1

H

2

V

1

V

2

Note: As vertical pipe increases, a ue restrictor may be

required.

3 Elbows to Max. Horizontal

V

1

Minimum V1 + V2 Maximum H1 + H2 Maximum

3 ft. 914 mm 38 ft., 3 in. 11.7 m 2 ft. 610 mm

4 ft. 1.2 m 32 ft., 3 in. 9.8 m 6 ft. 1.8 m

6 ft. 1.8 m 28 ft., 3 in. 8.6 m 8 ft., 8 in. 2.6 m

8 ft. 2.4 m 24 ft. 7.3 m 11 ft., 4 in. 3.5 m

10 ft. 3.1 m 19 ft., 10 in. 6.0 m 14 ft. 4.3 m

12 ft. 3.7 m 21 ft., 9 in. 6.6 m 12 ft., 10 in. 3.9 m

16 ft. 4.9 m 25 ft., 6 in. 7.8 m 10 ft. 4 in. 3.1 m

20 ft. 6.1 m 29 ft., 6 in. 9.0 m 7 ft., 10 in. 2.4 m

24 ft. 7.3 m 33 ft., 3 in. 10.1 m 5 ft., 4 in. 1.6 m

28 ft. 8.5 m 37 ft., 3 in. 11.4 m 2 ft., 10 in. 864 mm

Page 20

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1520

Rear Vent - Horizontal Termination - (continued)

Two Elbows

Figure 4.14

H

1

H

2

V

1

2 Elbows to Max. Horizontal

V

1

Minimum H1 Minimum H1 + H2 Maximum H1 Maximum

3 ft. 914 mm 6 in. 152 mm 5 ft. 1.5 m 6 in. 152 mm

4 ft. 1.2 m 6 in. 152 mm 9 ft. 2.7 m 14 in. 356 mm

6 ft. 1.8 m 6 in. 152 mm 11 ft., 8 in. 3.6 m 14 in. 356 mm

8 ft. 2.4 m 6 in. 152 mm 14 ft., 4 in. 4.4 m 14 in. 356 mm

10 ft. 3.1 m 6 in. 152 mm 17 ft. 5.2 m 14 in. 356 mm

12 ft. 3.7 m 6 in. 152 mm 15 ft., 10 in. 4.8 m 14 in. 356 mm

16 ft. 4.9 m 6 in. 152 mm 13 ft., 4 in. 4.1 m 14 in. 356 mm

20 ft. 6.1 m 6 in. 152 mm 10 ft., 10 in. 3.3 m 14 in. 356 mm

24 ft. 7.3 m 6 in. 152 mm 8 ft., 4 in. 2.5 m 14 in. 356 mm

28 ft. 8.5 m 6 in. 152 mm 5 ft., 10 in. 1.8 m 14 in. 356 mm

32 ft. 9.8 m 6 in. 152 mm 3 ft., 4 in. 1.0 m 14 in. 356 mm

Note: A derating orice is required with this application and is

included in the Rear Vent Kit.

Note: As vertical pipe increases, a ue restrictor may be

required.

CAUTION

!

VENTING STRAIGHT OUT THE REAR WITHOUT

VERTICAL RISE IS PROHIBITED

Page 21

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1521

Figure 4.15

Three Elbows

INSTALLED

HORIZONTALLY

H

3

H

1

H

2

V

1

3 Elbows to Max. Horizontal

V

1

Minimum H1 Minimum H1 Maximum H

TOTAL

3 ft. 914 mm 6 in. 152 mm 6 in. 152 mm 2 ft. 610 mm

4 ft. 1.2 m 6 in. 152 mm 14 in. 356 mm 6 ft. 1.8 m

6 ft. 1.8 m 6 in. 152 mm 14 in. 356 mm 8 ft., 8 in. 2.6 m

8 ft. 2.4 m 6 in. 152 mm 14 in. 356 mm 11 ft., 4 in. 3.5 m

10 ft. 3.1 m 6 in. 152 mm 14 in. 356 mm 14 ft., 0 in. 4.3 m

12 ft. 3.7 m 6 in. 152 mm 14 in. 356 mm 12 ft., 10 in. 3.9 m

16 ft. 4.9 m 6 in. 152 mm 14 in. 356 mm 10 ft., 4 in. 3.1 m

20 ft. 6.1 m 6 in. 152 mm 14 in. 356 mm 7 ft., 10 in. 2.4 m

24 ft. 7.3 m 6 in. 152 mm 14 in. 356 mm 5 ft., 4 in. 1.6 m

28 ft. 8.5 m 6 in. 152 mm 14 in. 356 mm 2 ft., 10 in. 864 mm

Note: As vertical pipe increases, a ue restrictor may be

required.

Note: A derating orice is required with this application and is

included in the Rear Vent Kit.

CAUTION

!

VENTING STRAIGHT OUT THE REAR WITHOUT

VERTICAL RISE IS PROHIBITED

Page 22

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1522

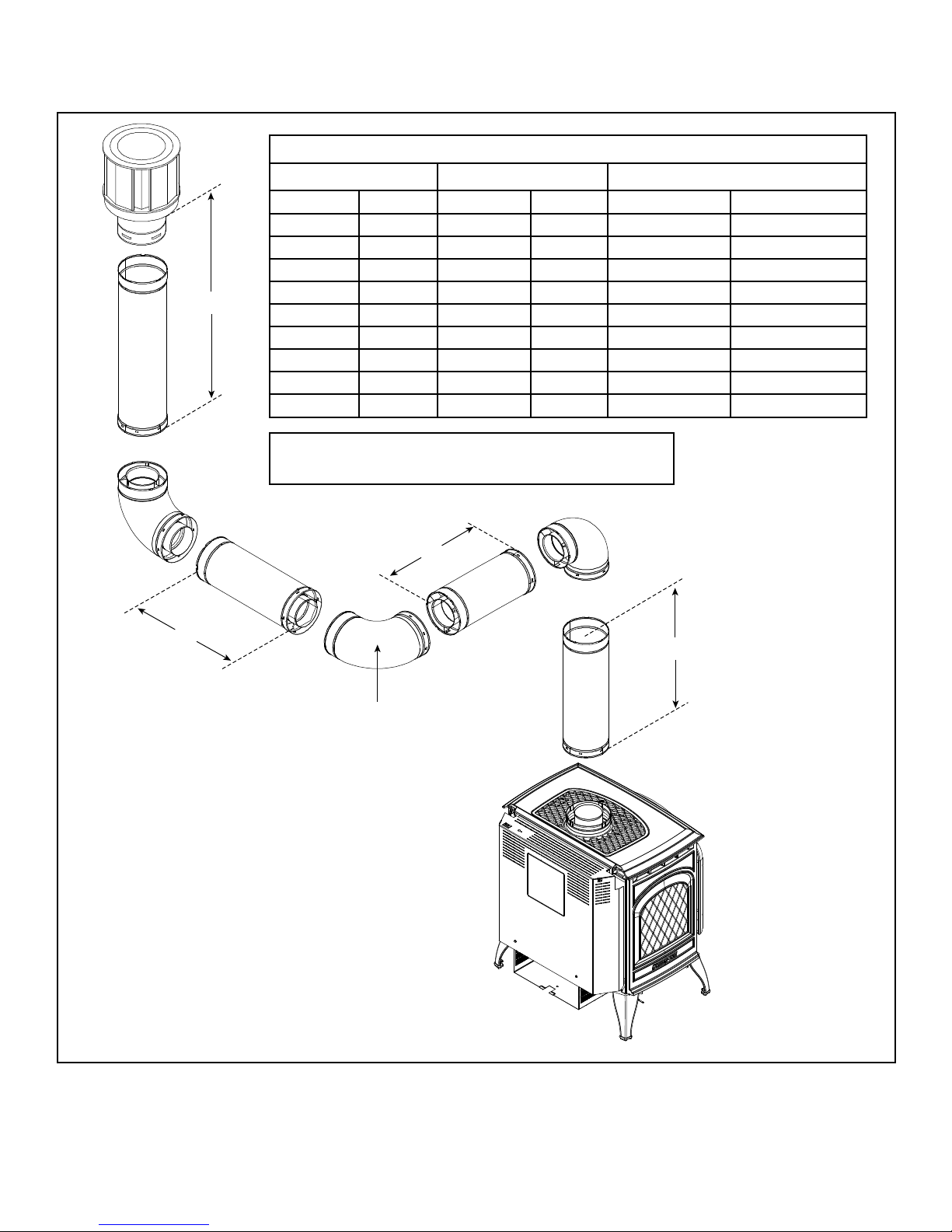

Rear Vent - Vertical Termination

One Elbow

Figure 4.16

H

1

V

1

H1 Minimum H1 Maximum V1 Minimum V1 Maximum

6 in. 152 mm 14 in. 356 mm 6 ft. 1.8 m 40 ft. 12.2 m

Note: As vertical pipe increases, a ue restrictor may be

required.

Note: A derating orice is required with this application and is

included in the Rear Vent Kit.

CAUTION

!

VENTING STRAIGHT OUT THE REAR WITHOUT

VERTICAL RISE IS PROHIBITED

Page 23

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1523

V

2

V

1

H

2

H

1

Rear Vent - Vertical Termination - (continued)

Three Elbows

Figure 4.17

3 Elbows to Maximum Horizontal

V

1

Minimum H1 Minimum H1 Maximum H

TOTAL

V1 + V2 MAXIMUM

3 ft. 914 mm 6 in. 152 mm 6 in. 152 mm 2 ft. 610 mm 38 ft., 3 in. 11.7 m

4 ft. 1.2 m 6 in. 152 mm 14 in. 356 mm 6 ft. 1.8 m 32 ft., 3 in. 9.8 m

6 ft. 1.8 m 6 in. 152 mm 14 in. 356 mm 8 ft., 8 in. 2.6 m 28 ft., 3 in. 8.6 m

8 ft. 2.4 m 6 in. 152 mm 14 in. 356 mm 11 ft., 4 in. 3.5 m 24 ft. 7.3 m

10 ft. 3.1 m 6 in. 152 mm 14 in. 356 mm 14 ft. 4.3 m 19 ft., 10 in. 6.0 m

12 ft. 3.7 m 6 in. 152 mm 14 in. 356 mm 12 ft., 10 in. 3.9 m 21 ft., 9 in. 6.6 m

16 ft. 4.9 m 6 in. 152 mm 14 in. 356 mm 10 ft., 4 in. 3.1 m 25 ft., 6 in. 7.8 m

20 ft. 6.1 m 6 in. 152 mm 14 in. 356 mm 7 ft., 10 in. 2.4 m 29 ft., 6 in. 9.0 m

24 ft. 7.3 m 6 in. 152 mm 14 in. 356 mm 5 ft., 4 in. 1.6 m 33 ft., 3 in. 10.1 m

28 ft. 8.5 m 6 in. 152 mm 14 in. 356 mm 2 ft., 10 in. 864 mm 37 ft., 3 in. 11.4 m

Note: As vertical pipe increases, a ue restrictor may be

required.

Note: A derating orice is required with this application and is

included in the Rear Vent Kit.

CAUTION

!

VENTING STRAIGHT OUT THE REAR WITHOUT

VERTICAL RISE IS PROHIBITED

Page 24

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1524

TERMINATION CAP

(Includ. in Link-Stove Kit)

EXISTING METAL

CHIMNEY SYSTEM

TOP ADAPTOR

(Includ. in Link-Stove Kit)

DIRECT VENT PIPE

(Length as required)

FLASHING

(Includ. in Link-Stove Kit)

4 in. (102mm) FLEX PIPE

(Includ. in Link-Stove Kit)

RETRO CONNECTOR

(Includ. in Link-Stove Kit)

Class A Metal Chimney

Prior to installing the gas stove, ensure that the existing

chimney is functionally sound and clean.

• Have the chimney and adjacent structure inspected

and cleaned by qualied professionals. Hearth & Home

Technologies recommends that NFI or CSIA certied

professionals, or technicians under the direction of

certied professionals, conduct a minimum of a NFPA

211 Level 2 inspection of the chimney.

• Replace component parts of the chimney and replace

as specied by the professionals.

• See Section 11 for venting components.

High Wind Termination Cap

(Part SLP-TVHW)

Sheet Metal Screws

Drill Four 1/8 in.

(3mm) Diamater

Holes

Figure 4.20

Figure 4.21

5. Pull the flex pipe down through the ceiling support box,

until it protrudes approximately 3 in. (76mm). Connect

the flex pipe to the retro connector, and attach with sheet

metal screws.

6. Push the flex pipe back up into the ceiling support box,

center the retro connector, and attach it to the support

box with sheet metal screws.

7. The connection between the appliance and the retro

connector may be completed with sections of direct vent

pipe.

Top Adapter

(Included in Link-Stove Kit)

Sheet Metal Screws

4” Flex Pipe

(Included in Link-Stove Kit)

Figure 4.19

Figure 4.18

1. Remove existing chimney cap.

2. Measure the distance from the top of the chimney to the

bottom of the ceiling support box, add 3 in. (76mm) to

this measurement, and cut a section of 4 in. (101mm)

flex pipe to that length (the flex should be fully extended).

3. Connect the end of the flex pipe section to the underside

of the top adapter, using four sheet metal screws. See

Figure 4.19.

4. Pass the flex pipe down through the center of the

chimney system, and center the top adapter on the top

of the chimney pipe. Drill four 1/8 in. (3mm) diameter

holes through the top adapter, and into the chimney

top. Ensure that you are drilling into the metal on the

chimney. Twist lock the high wind termination cap onto

the top adapter. See Figure 4.20 and Figure 4.21.

Page 25

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1525

Existing Masonry Chimney

Prior to installing the gas stove, ensure that the existing chimney is functionally sound and clean.

• Have the chimney and adjacent structure inspected and cleaned by qualied professionals. Hearth & Home

Technologies recommends that NFI or CSIA certied professionals, or technicians under the direction of certied

professionals, conduct a minimum of a NFPA 211 Level 2 inspection of the chimney.

• Replace component parts of the chimney and replaceas specied by the professionals.

• See Section 11 for venting components.

Type C - Up & Out Installation Type D - Hearth Mount

Figure 4.22

Type A & B Co-Axial to Co-Linear

Chimney Liner Termination Cap

(Included in Chimney Liner

Termination Kit)

Co-Axial to

Co-Linear Connector

(Part 46DVA-GCL)

3 in. (76mm) Flex Liner

(Included in Chimney Liner

Termination Kit)

Showing two 30 ft.

(9m) Sections of

Flex Liner

Chimney Liner Termination Cap

(Included in Chimney Liner Termination Kit)

Co-Axial to Co-Linear

Connector

(Part 46DVA-GCL)

30 ft. (9m) of 3 in. (76mm) Flex

Liner Exhaust Section

(Included in Chimney Liner Termination Kit)

4 ft. (1m) of 3 in. (76mm)

Flex Liner Air Intake Section

(Included in Chimney Liner Termination Kit)

The chimney must be sealed from the

4 ft. (1m) section to termination using

a smoke shelf or a flue restrictor. The

seal should be a minimum of 6 in.

(152mm) below the end of the 4 ft.

(1m) Air Intake section.

This section of the chimney

must be sealed

TERMINATION CAP

(Included in Link-Stove kit)

FLASHING

(Included in Masonry

Chimney Conversion Kit)

4 in. (102mm) FLEX LINER

(Included in Link-Stove kit)

TOP ADAPTOR

(Included in Masonry Chimney

Conversion Kit)

RETRO CONNECTOR

(Included in Masonry Chimney

Conversion Kit)

90° ELBOW

DIRECT VENT PIPE

(Length as required)

Chimney Liner Termination Cap

(Included in Chimney Liner

Termination Kit)

30 ft. (9m) of 3 in. (76mm)

Flex Liner Exhaust Section

(Included in Chimney Liner

Termination Kit)

4 ft. (1m) of 3 in. (76mm)

Flex Liner Air Intake Section

(Included in Chimney Liner

Termination Kit)

Chimney must be sealed

from 4 ft. (1m) section to

termination using a smoke

shelf or a flue restrictor.

Seal should be a minimum of

6 in. (152mm) below end of

4 ft. (1m) Air Intake section.

This section of the

chimney must be sealed

Co-Axial to Co-Linear Connector

(Part 46DVA - GCL)

Alcove Clearance to

Combustibles must be

maintained. See Figure 3.2.

See COAXIAL/COLINEAR

Section and Figure 4.31.

Page 26

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1526

Cut and bend flashing as needed

to fit

1. Before cutting any holes, assemble the desired sections

of direct vent pipe to determine the center of the masonry

penetration.

2. Once the center point of the penetration has been

determined, cut a 6 in. (152mm) diameter hole in the

masonry. If the hole is too large, the retro connector

might not mount properly; if the hole is too small, the

appliance might starve for intake air. If there is a frame

wall in front of the masonry wall, cut and frame a 10 in.

(254mm) square opening in the wall (centered around

the 6 in. (152mm) masonry opening). If there is sheet

rock only (no studs) in front of the masonry the 10 in.

(254mm) opening is still needed, but does not need to be

framed. If the hole is framed a wall thimble is required.

This allows the retro connector to mount directly on

the masonry and provide the correct clearances to

combustibles. See Figure 4.23.

Figure 4.24

4. To determine the length of flex needed, measure from

3 in. (76mm) above the top of the flashing down to the

level of the opening. Add the distance from the center

of the chimney out through the wall. Cut a piece of 4

in. (102mm) flex to this length (extended to its nominal

length). Be sure to leave 2-3 in. (51-76mm) of flex above

the existing chimney to allow for connection to the

termination kit.

5. Connect the flex liner to the top adapter using three

sheet metal screws. See Figure 4.19.

6. Feed the flex liner through the flashing into the chimney.

Carefully feed the flex liner down the chimney to the

bottom and out the opening in the masonry wall, forming

an angle to line up the flex liner with the vent opening on

the appliance.

WARNING! Risk of Fire, Explosion or Asphyxiation!

Improper support may allow vent to sag and separate. Use

vent run supports and connect vent sections per installation

instructions. DO NOT allow vent to sag below connection

point to appliance.

7. If additional lengths of flex liner are needed to span the

chimney height, use a flex coupler to connect the pieces

of flex liner together. Connect the flex to the coupler by

using four sheet metal screws for each side. See Figure

4.25.

Figure 4.23

3. Secure the flashing to the top of the masonry chimney

using a bead of non-hardening sealant-adhesive. If the

flashing is larger than the top of the chimney, cut and fold

flashing as needed to fit chimney. See Figure 4.24.

10 in. x 10 in. (254mm x 254mm)

framed opening in wall

Studwall

Masonry

Chimney

Retro Connector

(Included in Masonry Chimney

Conversion Kit)

(4) Masonry Bolts

(Not Included)

Wall Thimble Cover

(Included in Masonry

Chimney Conversion Kit)

NOTE: For hearth applications, refer to page 29 for the use of a

co-axial to co-linear appliance connector.

Page 27

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1527

High Wind Termination Cap

(Part SLP-TVHW)

Top Adaptor

(Included in Link-Stove Kit)

(3) Sheet Metal

Screws

Flashing

(Included in Link-Stove Kit)

Figure 4.26

9. Attach the flex to the retro connector. Use three sheet

metal screws to attach the flex liner to the connector.

Mount the retro connector to the masonry wall using

masonry bolts. See Figure 4.27. Redrill larger holes

on connector as needed. Be careful to ensure that the

connector is centered in the opening and the mounting

holes line up with the masonry wall.

6 in. (152mm) diameter

opening in masonry wall

(3) Masonry Bolts

(Not included)

Retro Connector

(Included in Masonry Chimney

Conversion Kit)

(4) Masonry Bolts

(Not included)

Retro Connector

(Included in Masonry

Chimney Conversion Kit)

Wall Thimble Cover

(Included in Masonry Chimney Conversion Kit)

Figure 4.25

8. Secure the top adapter to the flashing. Use three sheet

metal screws through the side of the top adapter into the

flange on the flashing See Figure 4.26. Twist lock the

high wind termination cap on to the top adapter.

Flex Liner

(3 in. Part 3DFA-35)

(4 in. Part 4DFA-35)

Flex Coupler

(3 in. Part 3DFA-FC)

(4 in. Part 4DFA-FC)

Sheet Metal Screws

Figure 4.28

Figure 4.27

10. Slide wall thimble cover over retro connector and secure

with masonry bolts. See Figure 4.28. If you have a

framed wall in front of the masonry, use wood screws

to mount wall thimble cover to framed wall, over retro

connector and 10 in. (254mm) square framed opening

See Figure 4.23. If needed, add a section of direct vent

pipe to the retro connector in order to extend through

the opening in the wall thimble cover.

11. The connection between the appliance and the retro

connector may be completed with sections of direct

vent pipe.

Page 28

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1528

EXHAUST VENT PIPE

INLET AIR VENT PIPE

Coaxial to Colinear Venting

The coaxial to colinear adapter (DV-46DVA-GCL) is

approved for installations into solid fuel masonry or factory

built replaces that have been installed in accordance with

the National, Provincial, State and local building codes.

Figure 4.29 Coaxial/Colinear Appliance Connector

WARNING! Risk of Fire! Coaxial to colinear venting

conguration may only be used in existing non-

combustible chimney. Installation in any other venting

application could cause re.

CAUTION! DO NOT use any ue restrictor when

venting with the DV-46DVA-GCL adapter and LINKDV30B kit. This may result in poor ame appearance,

sooting, pilot malfunction, or overheating.

WARNING! Risk of Fire, Explosion or Asphyxiation!

Do NOT connect this gas appliance to a chimney ue

serving a separate solid fuel or gas burning appliance.

• May impair safe operation of this appliance or other

appliances connected to the ue.

• Vent this appliance directly outside.

• Use separate vent system for this appliance.

Page 29

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1529

A. Pipe Clearances to Combustibles

WARNING! Risk of Fire! Maintain air space clearance to

vent. DO NOT pack insulation or other combustibles:

• Between ceiling restops

• Between wall shield restops

• Around vent system

Failure to keep insulation or other material away from

vent pipe may cause overheating and re.

5

Vent Clearances and Framing

Figure 5.1 Horizontal Venting Clearances To Combustible Materials

* When using SLP pipe, minimum clearances from the vent pipe to combustible

materials at inside wall firestops are: Top: 2-1/2 in. (64 mm)

Bottom: 1/2 in. (13 mm)

Sides: 1 in. (25 mm)

Note: Heat shields MUST overlap by a minimum of 1-1/2 in. (38 mm).

• If wall thickness is less than 4 in. the existing heat shields must be field trimmed. If

wall thickness is greater than 7-1/4 in. a DVP-HSM-B will be required.

• SLP heat shield - designed to be used on a wall 4-3/8 in. to 7-5/8 in. (111 mm to

194 mm thick).

• If wall thickness is less than 4-3/8 the existing heat shields must be field trimmed.

If wall thickness is greater than 7-5/8 in. a DVP-HSM-B will be required.

(SLP Pipe Shown)

1 in. (25 mm)

clearance

bottom & sides

Heat

Shield

Wall

Shield

Firestop

WALL

3 in. (76 mm)

top clearance

1 in. (25 mm)

clearance around

vertical sections

3 in. (76 mm)

top clearance *

Heat

Shield

(SLP Pipe Shown)

1 in. (25 mm)

clearance

bottom & sides

Heat

Shield

Wall

Shield

Firestop

WALL

3 in. (76 mm)

top clearance

1 in. (25 mm)

clearance around

vertical sections

3 in. (76 mm)

top clearance *

Heat

Shield

Page 30

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1530

B. Wall Penetration Framing/Firestops

Combustible Wall Penetration

Whenever a combustible wall is penetrated, you must

frame a hole for the wall shield restop(s). The wall shield

restop maintains minimum clearances and prevents cold

air inltration.

• The opening must be framed on all four sides using the

same size framing materials as those used in the wall

construction.

• SLP pipe - A wall shield restop must be placed on each

side of an interior wall. A minimum 1-1/2 in. (38 mm)

overlap of attached heat shields must be maintained.

• See Section 7.F. for information for regarding the

installation of a horizontal termination cap.

Non-Combustible Wall Penetration

If the hole being penetrated is surrounded by noncombustible materials such as concrete, a hole with

diameter one inch greater than the pipe is acceptable.

Whenever a non-combustible wall is penetrated, the wall

shield restop is only required on one side and no heat

shield is necessary.

A

C

10 in.

10 in.

MEASURED

FROM FLOOR

E*

Figure 5.2 Wall Penetration

*As dimensions “E” and “F” change, dimensions “A” and

“B” must change accordingly.

A B C D E* F*

Inches 59-3/4 71-1/8 59 -3/4 71-1/8 24 36

mm 1518 18 07 1518 1807 610 914

B

10 in.

D

MEASURED

FROM FLOOR

F*

Page 31

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1531

C. Ceiling Firestop/Floor Penetration Framing

A ceiling restop MUST be used between oors and attics.

• SLP Pipe - Frame opening 9 in. x 9 in. (229 mm x 229

mm) whenever the vent penetrates a ceiling/oor (see

Figure 5.3).

• Frame the area with the same sized lumber as used in

ceiling/oor joist.

• The ceiling restop may be installed above or below the

ceiling joists when installed with an attic insulation shield. It

must be under joists between oors that are not insulated.

Refer to Figure 5.4.

• Secure with three fasteners on each side.

WARNING! Risk of Fire! DO NOT pack insulation around

the vent. Insulation must be kept back from the pipe to

prevent overheating.

D. Install Attic Insulation Shield

WARNING! Fire Risk. DO NOT allow loose materials or

insulation to touch vent. Hearth & Home Technologies

requires the use of an attic shield.

The International Fuel Gas Code requires an attic shield

constructed of 26 gauge minimum steel that extends at least

2 in. (51 mm) above insulation.

• Attic insulation shields must meet specied clearances to

combustible materials and be secured in place.

• An attic insulation shield kit is available from Hearth &

Home Technologies. Contact your dealer to order. Install

attic insulation shield according to instructions included

with kit.

Figure 5.3 Installing Ceiling Firestop

Figure 5.4 Installing the Attic Shield

INSTALL ATTIC INSULATION SHIELDS

BEFORE OR AFTER INSTALLATION OF VENT SYSTEM

CEILING FIRESTOP

INSTALLED BELOW CEILING

CEILING FIRESTOP

INSTALLED ABOVE CEILING

ATTIC ABOVE

A

PIPE

SLP

A

9 in. (229 mm)

A

Page 32

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1532

6

Appliance Preparation

A. Top to Rear Vent Conversion

This model comes from the factory set up for a top vented

application. To vent this model from the rear, follow the

conversion instructions below. If venting off the top, no

further preparation is needed. Proceed to next section.

See Service Parts list in Owner’s Manual for Kit information.

CAUTION! Risk of Cuts, Abrasions or Flying Debris.

Wear protective gloves and safety glasses during

installation. Sheet metal edges are sharp.

Included in Kit: Rear vent grille, NG Orice (#33), LP Orice

(#54)

Tools Required: Power drill, 1/4 in. hex driver bit, #2 Phillips bit,

3/8 in. open end wrench, high temperature sealant (if required)

Note: See appliance Installation Manual for proper venting

congurations.

1. Remove top grille, as highlighted in Figure 6.1.

Figure 6.2

Figure 6.3

4. Locate the knock out on rear of appliance. Break the seal

on the knock out and discard the knock out.

Figure 6.4

3. Remove the inner pipe adapter shown in Figure 6.3

by removing six screws. Remove gasket and discard.

Replace six screws into holes and tighten.

REMOVE

KNOCKOUT

Figure 6.1

2. Remove starting collar and gasket by removing 4 screws.

See Figure 6.2. Save the screws. (If gasket breaks, apply

high-temp sealant to bottom of collar before installing as

shown in Figure 6.8.)

INNER PIPE

ADAPTER

REMOVE

SCREWS (6)

Page 33

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1533

5. Remove rear access plate and gasket by removing four

screws. Save the screws.

Figure 6.8 Attach inner collar adapter to rear ue vent.

Figure 6.9

8. Install starting collar with gasket or high-temp sealant

to rear vent opening. Attach with screws removed in

Figure 6.5.

Place grille gently into the opening on top of appliance.

The grille does not have a hole and is included with the

kit.

9. Remove safety barrier and front casting, if not previously

removed, by grasping it at the top and lifting up. The top

casting may need to be lifted slightly to accommodate

removal of the front casting. See Figure 6.10.

10. Using a #2 Phillips screwdriver, remove the three screws

on the front glass assembly and take the glass assembly

off the appliance. See Figure 6.11.

11. Remove the logs and refractory.

12. The pilot needs to be lifted slightly to accommodate the

burner removal. Using 1/4 in. bit, remove the two screws

that attach the pilot to the burner. Remove the pilot shield

and lift the pilot slightly until it clears the pilot mounting

tabs. See Figure 6.12.

13. Using a 1/4 in. bit, remove the two burner mounting

screws from each side of the burner. Remove the two

screws that hold the burner to the rear rebox wall. See

Figure 6.12. Remove burner from appliance.

Figure 6.6

7. Remove six screws under the rear access plate removed

in Figure 6.5. See Figure 6.7. Install inner pipe adapter

and new gasket (included with kit) using six screws. See

Figure 6.8.

REAR PLATE

AND GASKET

Figure 6.5

6. Place rear access plate and gasket over top vent and

attach with the four screws removed in Figure 6.2.

REMOVE

SCREWS (6)

Figure 6.7 Remove Screws Under Rear Access Plate

Remove Screws

Page 34

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1534

Figure 6.11 Remove Glass Frame

Figure 6.10 Remove Casting

TOP CASTING

FRONT CASTING

Figure 6.12 Remove Burner

14. Using the 3/8 in. open end wrench, replace the main

burner orice with the orice included in the conversion

kit. Use appropriate orice for gas type. See Figure 6.13.

Explosion Risk

• Pilot must be reattached to burner.

• Delayed ignition or an explosion may occur if

the pilot is not attached to the burner shield.

Figure 6.13

15. Reinstall burner with six screws.

16. Reinstall the pilot and the pilot shield to the burner.

17. On inside of rebox, remove plate and gasket on rear

of rebox by removing three screws as shown in Figure

6.14. Discard gasket. Replace screws on rear of rebox.

Remove three screws as shown in Figure 6.14. Attach

plate and new gasket, included in kit, with three screws.

PHILLIPS SCREWS

PILOT

ASSEMBLY

BURNER MOUNTING SCREWS

(UNDER REFRACTORY, BOTH SIDES AND REAR)

BURNER ASSEMBLY

PILOT

ASSEMBLY

MAIN BURNER ORIFICE

Figure 6.14

18. Reinstall side refractory and logs.

19. Reinstall the glass frame using the three Phillips head

fasteners removed in step 6.10. Tighten until snug. Do

not overtighten.

20. Reinstall front casting.

21. Reinstall safety barrier.

REMOVE THESE SCREWS (3) USE TO ATTACH

PLATE

REMOVE THESE SCREWS (3), REMOVE PLATE,

REPLACE SCREWS

WARNING

!

Page 35

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1535

B. Securing and Leveling the Appliance

WARNING! Risk of Fire! Prevent contact with combustible

materials.

WARNING! Risk of Fire! Failure to maintain air space

clearance may cause overheating and re.

Figure 6.1

1. Thread Allen bolts through nuts until ush.

NOTE: Two Allen bolts and two nuts are included in the

component bag. Normally, only one is required on the leg

not touching the oor.

Figure 6.3

3. Use a 5/32 in. (4mm) Allen wrench to adjust legs up and

down to desired level.

Figure 6.2

2. Slide assembled nuts and bolts into slots on legs with the

nuts on the bottom.

Page 36

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1536

7

Venting and Chimneys

Figure 7.1 High Temperature Silicone Sealant

A. Assemble Vent Sections

To attach the rst vent component to the starting collars of

the appliance:

• Lock the vent components into place by sliding the pipe

section onto the collar.

• Align the seam of the pipe and seam of collar to allow

engagement. Rotate the vent component to lock into

place. Use this procedure for all vent components. See

Figure 7.2.

• Slide the gasket over the rst vent section and place it

ush to the appliance. This will prevent cold air inltration.

Caulk with a minimum of 300ºF continuous exposure

rating may be used to hold the part in place.

• Continue adding vent components, locking each

succeeding component into place.

• Ensure that each succeeding vent component is securely

tted and locked into the preceding component.

Required Commercial, Multi-family (Multi-level exceeding

two stories), or High-Rise Applications

For installation into a commercial, multi-family (multi-level

exceeding two stories) or high-rise applications: All outer

pipe joints must be sealed with high temperature silicone

(300º F minimum continuous exposure rating), including

the slip section that connects directly to the horizontal

termination cap.

• Apply a bead of silicone sealant (300º F minimum

continuous exposure rating) inside the female outer pipe

joint prior to joining sections. See Figure 7.1.

• Only outer pipes need to be sealed. All unit collar, pipe,

slip section, elbow and cap outer ues shall be sealed in

this manner, unless otherwise stated.

WARNING! Risk of Fire or Explosion! DO NOT break

silicone seals on slip sections. Use care when removing

termination cap from slip pipe. If slip section seals are

broken during removal of the termination cap, vent may

leak.

Figure 7.2 Adding Venting Components

Note: Align seams to engage pipe,

then rotate counterclockwise to lock

Page 37

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1537

B. Assemble Slip Sections

• Slide the inner ue of the slip section into the inner ue

of the pipe section and the outer ue of the slip section

over the outer ue of the pipe section. See Figure 7.3.

• Slide together to the desired length.

Figure 7.4 Screws into Slip Section

• Continue adding pipe as necessary following instructions

in “Assembling Pipe Sections.”

NOTICE: If slip section is too long, the inner and outer ues

of the slip section can be cut to the desired length.

• Apply a bead of silicone sealant (300º F minimum

continuous exposure rating) inside the female outer pipe

joint prior to joining sections.

• Only outer pipes are sealed, sealing the inner ue is not

required.

• All unit collar, pipe, slip section, elbow and cap outer ues

shall be sealed.

Figure 7.3 Slip Section Pilot Holes

• Maintain a 1-1/2 in. (38 mm) overlap between the slip

section and the pipe section.

• Secure the pipe and slip section with three screws no

longer than 1/2 in. (13 mm), using the pilot holes in the

slip section. See Figure 7.4.

Pilot hole

Page 38

Quadra-Fire • TOPAZ-MBK-IPI, TOPAZ-D-PMH-IPI, TOPAZ-D-MBK-IPI, TOPAZ-D-CSB-IPI Installation Manual • 2341-980_R10 • 11/1538

120º

Figure 7.5 Securing Vertical Pipe Sections

120º

Figure 7.6 Securing Horizontal Pipe Sections

D. Disassemble Vent Sections

• Rotate either section (see Figure 7.7) so the seams on

both pipe sections are aligned as shown in Figure 7.8.

• Pull carefully to separate the pieces of pipe.

C. Secure the Vent Sections

• Vertical runs originating off the top of the appliance, with

no offsets, must be supported every 8 ft. (2.44 m) after

the maximum allowed 25 ft. (7.62 m) of unsupported rise.

• Vertical runs originating off the rear of the appliance, or

after any elbow, must be supported every 8 ft. (2.44 m).

• Horizontal runs must be supported every 5 feet (1.52 m).

• Vent supports or plumbers strap (spaced 120º apart)

may be used to support vent sections. See Figures 7.5

and 7.6.

• Wall shield restops may be used to provide horizontal

support to vent sections.

• SLP ceiling restops have tabs that may be used to

provide vertical support.

WARNING! Risk of Fire, Explosion or Asphyxiation!

Improper support may allow vent to sag and separate. Use