Page 1

5700 STEP TOP ACC WOOD BURNER INSTALLATION AND OPERATING INSTRUCTIONS

INSTALLATIONS TO COMPLY WITH AS/NZS2918:2001

AND WILL REQUIRE A BUILDING CONSENT

IMPORTANT: Read all instructions carefully before starting installation. Failure to follow these

.

• Fig. 3,4 and Table 1 & 2 relate to installations with

AS/NZS 2918:2001 -

Appendix F, with a ceiling angle between 0° - 30°

inclusive.

• For installations with a ceiling angle greater than

30°, refer to Fig. 6 & 7 and AS/NZS 2918:2001

4.6.3(b)

• Ceiling Plate may vary in size depending on ceiling angle. Please specify ceiling pitch prior to

ordering the ceiling plate.

• Quadra-Fire 5700 Step Top ACC wood burner’s

are tested and approved to the N.Z. National Envi-

ronmental Standards;

Model:

57ST-ACC-AU

• mable vapors and liquids in the vicinity of

this or any other appliance.

•

• Comply with all minimum clearances to

-

WARNING

If the information in these instruc-

could result causing property damage, personal injury, or death.

WARNING

Fire Risk.

For use with solid wood fuel only.

gases (i.e. carbon monoxide).

EXPLORER III ACC WOOD BURNER INSTALLATION AND OPERATING INSTRUCTIONS

Explorer III Wood Appliance

Model(s):

EXP-III-MBK-JP

EXP-III-PFT-JP

EXP-III-PMH-JP

WARNING

If the information in these instruc-

tions is not followed exactly, a

re may result causing property

damage, personal injury, or death.

• Donotstoreorusegasolineorotheram-

mablevaporsandliquidsinthevicinityof

thisoranyotherappliance.

• Donotoverre-Ifapplianceorchimney

connectorglows,youareoverring.Over

ringwillvoidyourwarranty.

• Complywithallminimumclearancesto

combustiblesasspecied.Failureto

complymaycausehousere.

HOT SURFACES!

Glassandothersurfacesarehot

duringoperationANDcooldown.

Hot glass will cause burns.

• Donottouchglassuntilitiscooled

WARNING

Installation Manual

Installation & Appliance Set-Up

NOTICE: DO NOT DISCARD THIS MANUAL

5700 STEP TOP ACC WOOD BURNER INSTALLATION AND OPERATING INSTRUCTIONS

INSTALLATIONS TO COMPLY WITH AS/NZS2918:2001

AND WILL REQUIRE A BUILDING CONSENT

IMPORTANT: Read all instructions carefully before starting installation. Failure to follow these

.

• Fig. 3,4 and Table 1 & 2 relate to installations with

AS/NZS 2918:2001 -

Appendix F, with a ceiling angle between 0° - 30°

inclusive.

• For installations with a ceiling angle greater than

30°, refer to Fig. 6 & 7 and AS/NZS 2918:2001

4.6.3(b)

• Ceiling Plate may vary in size depending on ceil-

ing angle. Please specify ceiling pitch prior to

ordering the ceiling plate.

• Quadra-Fire 5700 Step Top ACC wood burner’s

are tested and approved to the N.Z. National Envi-

ronmental Standards;

Model:

57ST-ACC-AU

• -

mable vapors and liquids in the vicinity of

this or any other appliance.

•

• Comply with all minimum clearances to

-

WARNING

If the information in these instruc-

could result causing property dam-

age, personal injury, or death.

WARNING

Fire Risk.

For use with solid wood fuel only.

gases (i.e. carbon monoxide).

Model:

EXP-III-APAC

EXP-III-APEC-EXPLORER III Hardwood Certied

Particulate Emissions = 1.1 g/kg Space Heating Eciency = 63%

Page 11 May, 2019 7038-201G

Page 2

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

and Welcome to the Quadra-Fire Family!

ITEM PART NUMBER PART NAME

5700 Step Top ACC Wood Burner

Hearth & Home Technologies welcomes you to our tradition

of excellence! In choosing a Quadra-Fire appliance, you

have our assurance of commitment to quality, durability, and

performance.

This commitment begins with our research of the market,

including ‘Voice of the Customer’ contacts, ensuring we

make products that will satisfy your needs. Our Research

and Development facility then employs the world’s most

advanced technology to achieve the optimum operation of

-

ioned when it comes to craftsmanship. Each unit is meticu-

beauty and enjoyment. Our pledge to quality is completed

as each model undergoes a quality control inspection.

We wish you and your family many years of enjoyment in

the warmth and comfort of your hearth appliance. Thank

you for choosing Quadra-Fire.

and Welcome to the Quadra-Fire Family!

5700 STEP TOP ACC

ITEM PART NUMBER PART NAME

Hearth & Home Technologies welcomes you to our tradition

of excellence! In choosing a Quadra-Fire appliance, you

have our assurance of commitment to quality, durability, and

performance.

This commitment begins with our research of the market,

including ‘Voice of the Customer’ contacts, ensuring we

make products that will satisfy your needs. Our Research

and Development facility then employs the world’s most

advanced technology to achieve the optimum operation of

ACC WOODFIRE COMPLIANCE LABEL

This appliance has been TESTED TO AS/NZS4013 for Hardwood by ASFT Report ASFT18014 Date tested: December 2018

MODEL QUADRA-FIRE EXPLORER III Freestanding Wood Stove

OVERALL AVERAGE EFFICIENCY BURNING HARDWOOD

WHEN TESTED IN ACCORDANCE WITH AS/NZS 4012: .........................................................

AVERAGE PARTICULATE EMISSION FACTOR BURNING HARDWOOD

WHEN TESTED IN ACCORDANCE WITH AS/NZS 4013: .........................................................

MAXIMUM AVERAGE HEAT OUTPUT BURNING HARDWOOD:

APPROVED FUEL:

LESS THEN 25% (dry basis).

Wetback - All Models: .........................................................................................

Manufactured By: ...............................................................................................Hearth & Home Technologies, 352 Mountain House Road,

Halifax, PA 17032, United States of America

Serial No. /

o

HF

de série:

N

...............................................................................................................

BARCODE LABEL

..........................

2017 2018 2019 JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

ioned when it comes to craftsmanship. Each unit is meticu-

beauty and enjoyment. Our pledge to quality is completed

as each model undergoes a quality control inspection.

We wish you and your family many years of enjoyment in

the warmth and comfort of your hearth appliance. Thank

you for choosing Quadra-Fire.

63%

1.1 g/kg

8.3 kW

BURN ONLY HARDWOOD WITH A MOISTURE CONTENT

Date of Manufacture / Date de fabrication:

7038-200_R4

-

PERFORMANCE MAY VARY FROM TEST VALUES DEPENDING ON ACTUAL OPERATING CONDITIONS.

NOTE:

U.S. ENVIRONMENTAL PROTECTION AGENCY

Export stove. May not be operated within the United States

Page 2 1 May, 20197038-201G

INSTALLATION

DATE:

Page 3

EXP-III Wood Burner

Explorer III JP

(797mm)

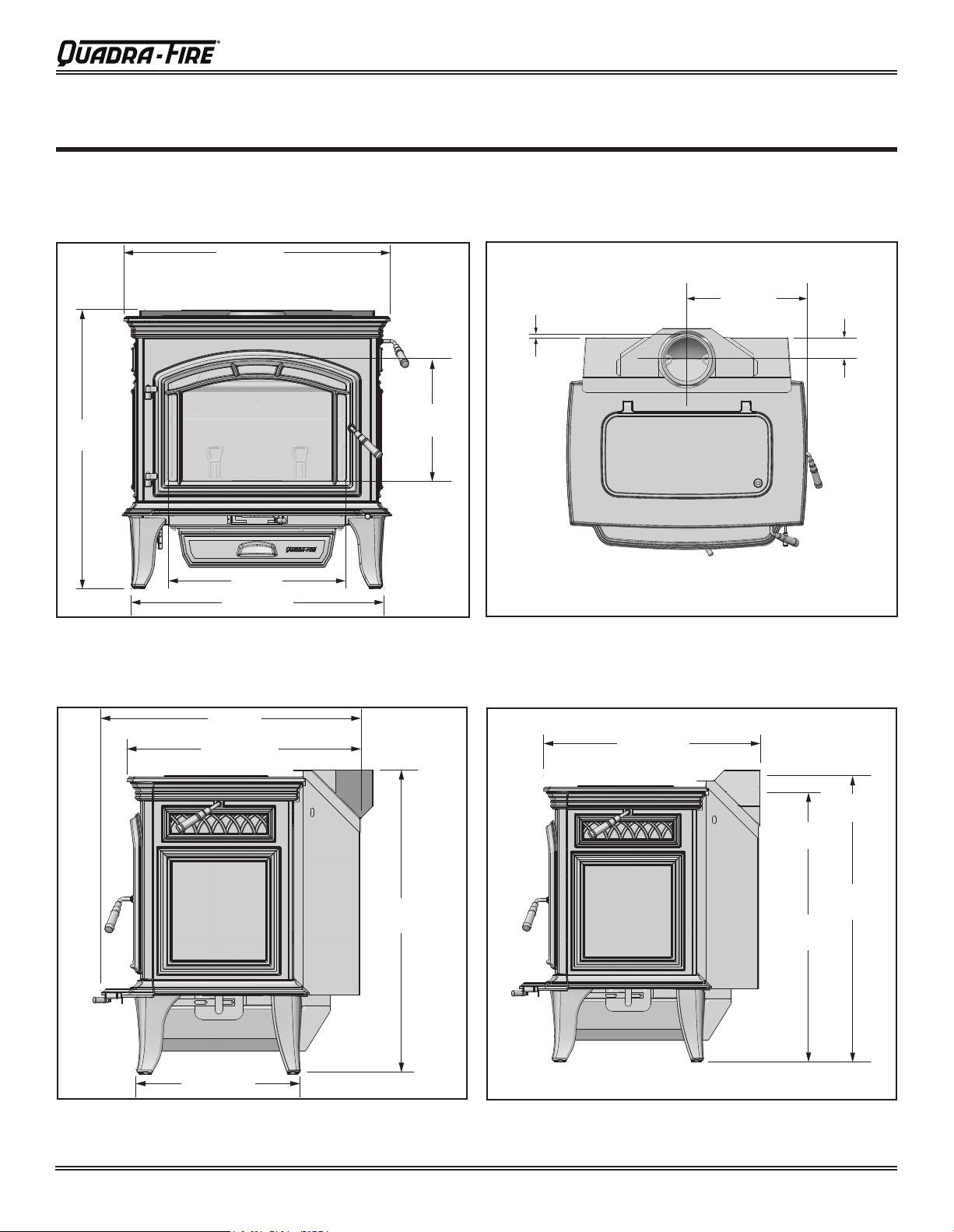

3 Dimensions and Clearances

A. Appliance Dimensions

NOTE:FlueCollarsizeis6inch(152mm)diameter(ID)

Explorer III JP

Figure 7.1 Front View

Figure 7.2 Top View

28-1/4 (718mm)

31-3/8

(797mm)

13

(330mm)

20 (508mm)

30-1/8 (765mm)

15-1/4 (387mm)

2-1/4

(70mm)

3/8

(10mm)

28 (711

3 Dimensions and Clearances

A. Appliance Dimensions

NOTE:FlueCollarsizeis6inch(152mm)diameter(ID)

Explorer III JP

28-1/4 (718mm)

31-3/8

(797mm)

13

(330mm)

20 (508mm)

30-1/8 (765mm)

15-1/4 (387mm)

2-1/4

(70mm)

3/8

(10mm)

3 Dimensions and Clearances

A. Appliance Dimensions

NOTE:FlueCollarsizeis6inch(152mm)diameter(ID)

Explorer III JP

3 Dimensions and Clearances

Explorer III JP

3 Dimensions and Clearances

A. Appliance Dimensions

30-1/8 (765mm)

31-3/8

20 (508mm)

28-1/4 (718mm)

Figure 7.1 Front View

13

(330mm)

NOTE:FlueCollarsizeis6inch(152mm)diameter(ID)

15-1/4 (387mm)

3/8

(10mm)

Figure 7.2 Top View

2-1/4

(70mm)

16-7/8 (429mm)

Figure 7.2 Side View

mm)

25-3/8 (645mm)

31-3/8

(797mm)

24-1/8 (613mm)

Figure 7.4 Side View with horizontal ue

Top of

Flue

Center

of Flue

33-1/8

(841mm)

28-5/8

(727mm)

Page 31 May, 2019 7038-201G

Page 4

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

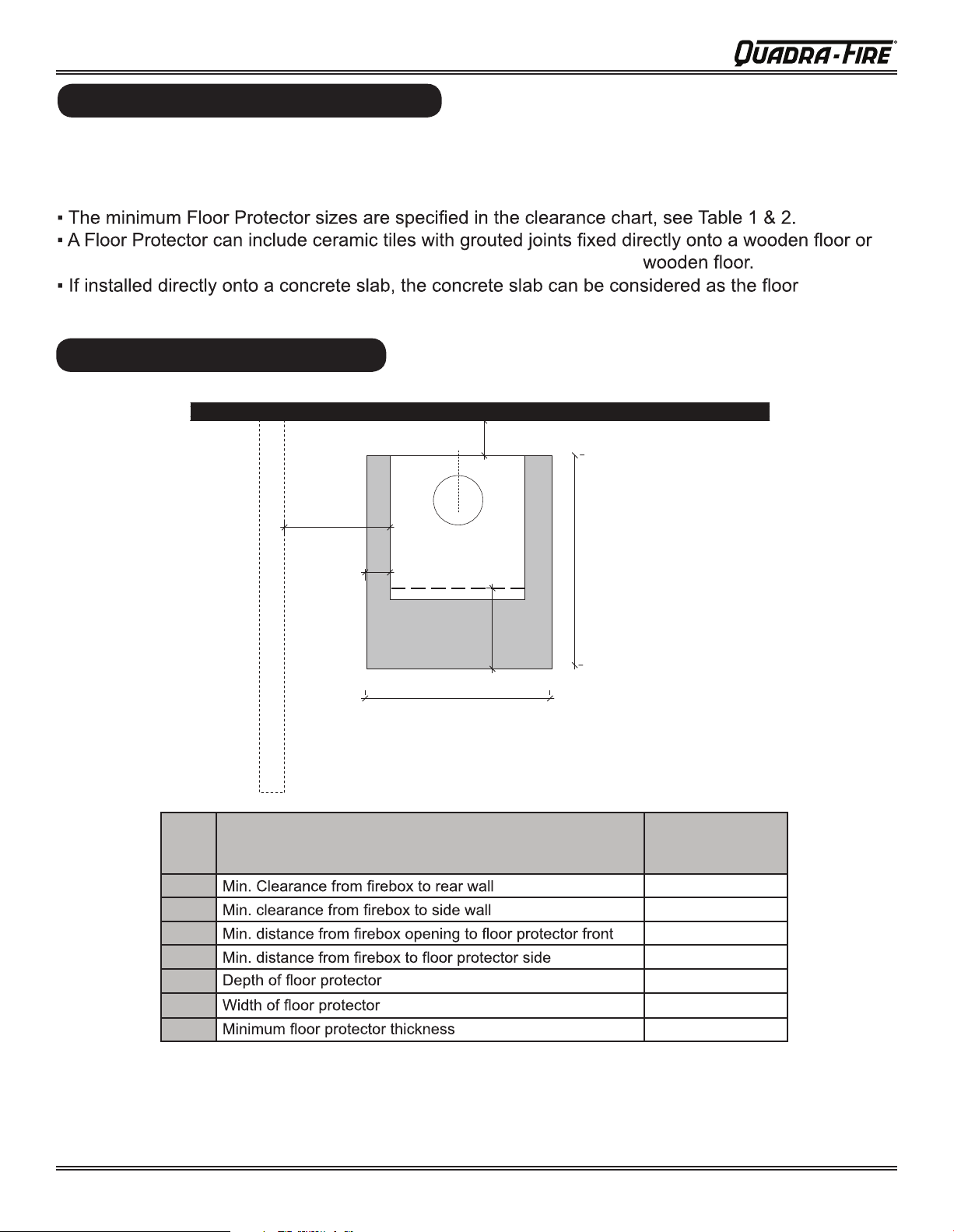

comply with the minimum Floor Protector requirements of

Quadra-fire EXPLORER III does not require an insulating Floor Protector, as they are tested and

AS/NZS 2918:2001.

Note:

a steel panel or any other non combustible material laid directly onto a

protector,but must maintain the minimum measurement listed.

FLOOR PROTECTOR

5700 Step Top ACC Wood Burner

FLOOR PROTECTOR

Quadra-fire EXPLORER III does not require an insulating Floor Protector, as they are tested and

comply with the minimum Floor Protector requirements of

Note:

a steel panel or any other non combustible material laid directly onto a

protector,but must maintain the minimum measurement listed.

PARALLEL POSITIONING

Fig. 3

A

B

AS/NZS 2918:2001.

F

Table 1

A

B

C

D

E

F

G

*Rear wall clearance can be reduced to 150mm when an additional heat sheild is used between active SS & Decromesh.

D

C

G

Drawing not to scale

DESCRIPTION

Au Default

Flue Kit

250mm*

400mm

320mm

84mm

960mm

885mm

6mm

NOTE: HEAT SHIELD REQUIREMENTS FOR HEAT SENSITIVE WALLS

Clearances may be reduced by provision of an appropriately located heat shield refer to

AS/NZS 2198:2001 3.2.3 TABLE 3.1

Page 4 1 May, 20197038-201G

Page 5

5700 Step Top ACC Wood Burner

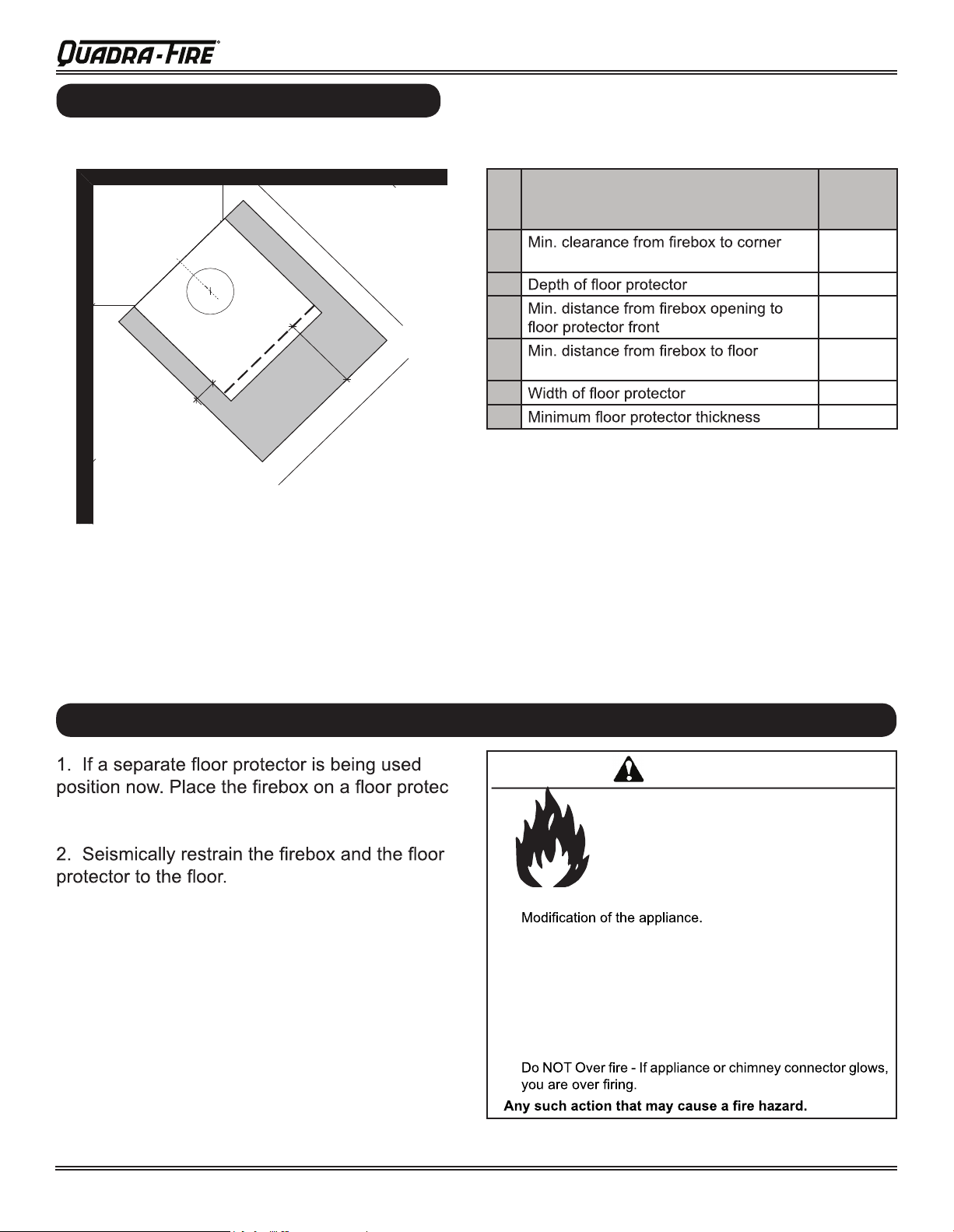

CORNER POSITIONING (45°)

CORNER POSITIONING (45°)

Fig. 4

EXP-III Wood Burner

Table 2

A

B

A

D

C

E

Drawing not to scale

A

walls

B

C

D

protector side

E

DESCRIPTION

AU Default flue kit

Shall be Fitted

175mm

960mm

320mm

84mm

885mm

6mm

FIREBOX INSTALLATION

tor that is at least 6mm thick to suit the minimum

installation clearances. (See Fig 3 or 4).

WARNING

-

Fire Risk.

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be

voided by, the following actions:

• Installation and use of any damaged appliance.

•

• Installation other than as instructed by Hearth & Home

Technologies.

• Installation and/or use of any component part not approved

by Hearth & Home Technologies.

• Operating appliance without fully assembling all components.

• Operating appliance without legs attached (if supplied with

appliance).

•

Page 51 May, 2019 7038-201G

Page 6

EXP-III Wood Burner

Explorer III Wood Stove

Install Guide

Explorer III Wood Stove

Install Guide

Explorer III Wood Stove

Install Guide

2 Getting Started

Explorer III Wood Stove

Getting Started

A. Design and Installation Considerations

Consideration must be given to:

• Safety

• Convenience

• Trafc ow

• Chimney and chimney connector required

It is a good idea to plan your installation on paper, using

exact measurements for clearances and oor protection,

before actually beginning the installation. If you are not

using an existing chimney, place the appliance where there

will be a clear passage for a factory-built listed chimney

through the ceiling and roof.

We recommend that a qualied building inspector and

your insurance company representative review your plans

before and after installation.

If this appliance is in an area where children may be near

it is recommended that you purchase a decorative barrier

to go in front of the appliance.

children away while it is operating and do not let anyone

operate this appliance unless they are familiar with these

operating instructions.

Remember to always keep

CAUTION

B. Fire Safety

To provide reasonable re safety, the following should be

given serious consideration:

1. Install at least one smoke detector on each oor of

your home to ensure your safety. They should be

located away from the heating appliance and close

to the sleeping areas. Follow the smoke detector

manufacturer’s placement and installation instructions,

and be sure to maintain regularly.

2. A conveniently located Class A re extinguisher to

contend with small res resulting from burning embers.

3. A CO detector should be installed in the room with the

appliance.

4. A practiced evacuation plan, consisting of at least two

escape routes.

5. A plan to deal with a chimney re as follows:

In the event of a chimney re:

a. Evacuate the house immediately

b. Notify re department.

C. Negative Pressure

WARNING

Check building codes prior to installation.

• Installation MUST comply with local, regional, state

and national codes and regulations.

• Consult insurance carrier, local building, re ofcials

or authorities having jurisdiction about restrictions,

installation inspection, and permits.

Asphyxiation Risk.

• Do NOT connect this appliance to a

• Do NOT connect to any air distribution duct

May allow ue gases to enter the house.

NOTICE: HEARTH & HOME TECHNOLOGIES ASSUMES

NO RESPONSIBILITY FOR THE IMPROPER

PERFORMANCE OF THE APPLIANCE SYSTEM

CAUSED BY:

• Inadequate draft due to environmental conditions

• Down drafts

• Tight sealing construction of the structure

• Mechanical exhausting devices

• Over drafting caused by excessive chimney heights

• Ideal performance is with height of chimney between

14-16 feet (4.26-4.88m) measured from the base of

the appliance.

WARNING

chimney ue servicing another appliance.

or system.

Asphyxiation Risk.

• Negative pressure can cause spillage

of combustion fumes, soot and carbon

monoxide.

• Appliance needs to draft properly for

safety.

Negative pressure results from the imbalance of air

available for the appliance to operate properly. It can be

strongest in lower levels of the house.

Causes include:

• Exhaust fans (kitchen, bath, etc.)

• Range hoods

• Combustion air requirements for furnaces, water

appliances and other combustion appliances

• Clothes dryers

• Location of return-air vents to furnace or air

conditioning

• Imbalances of the HVAC air handling system

• Upper level air leaks such as:

- Recessed lighting

- Attic hatch

- Duct leaks

Page 6 1 May, 20197038-201G

Page 7

EXP-III Wood Burner

Explorer III Wood Stove

and benet.

To minimize the effects of negative air pressure:

• Install optional outside air kit with the intake facing

prevailing winds during the heating season

• Ensure adequate outdoor air for all combustion

appliances and exhaust equipment

• Ensure furnace and air conditioning return vents are

not located in the immediate vicinity of the appliance

• Avoid installing the appliance near doors, walkways or

small isolated spaces

• Recessed lighting should be a “sealed can” design

• Attic hatches weather stripped or sealed

• Attic mounted duct work and air handler joints and

seams taped or sealed

• Basement installations should be avoided

WARNING

Fire Risk.

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be voided

by, the following actions:

• Installation and use of any damaged appliance.

• Modication of the appliance.

• Installation other than as instructed by Hearth &

Home Technologies.

• Installation and/or use of any component part not

approved by Hearth & Home Technologies.

• Operating appliance without fully assembling all

components.

• Operating appliance without legs attached (if supplied

with appliance).

• Do NOT Over re - If appliance or chimney connector

glows, you are over ring.

Any such action that may cause a re hazard.

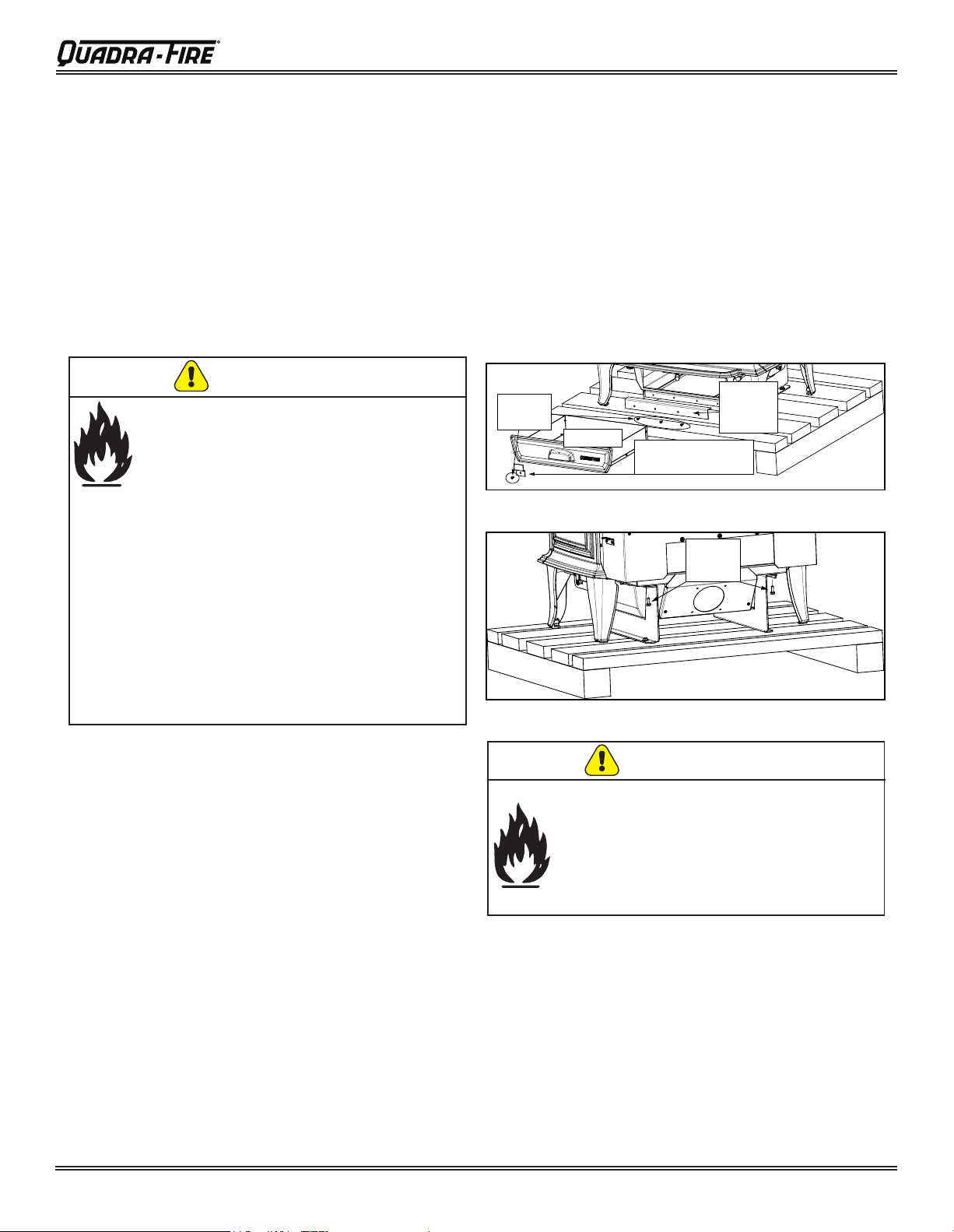

F. Removal of Appliance from Shipping

Materials

1. Remove box and 2x4 structural boards being careful

not to damage product.

2. Using a Phillips screw driver, remove and discard the

4 screws and ash pan retention bracket from front of

appliance (Figure 6.1).

3. Remove ash pan and set aside (Figure 6.1).

4. Remove and discard the pallet attach bracket (Figure

6.1).

5. Using a 3/8 socket or open end wrench, remove two

bolts on back side as shown (Figure 6.2).

6. Slide appliance forward off of pallet support brackets.

7. Replace ash pan (Figure 6.1).

Screws

x4

Figure 6.1

Figure 6.2

Ash pan

Ash Pan

Retention Bracket

Pallet

Attach

Bracket

Bolts

x2

D. Tools And Supplies Needed

Before beginning the installation be sure the following tools

and building supplies are available:

Reciprocating saw

Framing material

Pliers

High temp caulking material

Hammer

Gloves

Phillips screwdriver

Framing square

1/2-3/4 in. length, #6 or #8 self-drilling screws

Flat blade screwdriver

Electric drill and bits

Plumb line

Safety glasses

Level

Tape measure

Misc. screws and nails

7/16 socket or wrench

E. Inspection of Appliance and Components

• Remove appliance and components from packaging

and inspect for damage.

• Report to your dealer any parts damaged in shipment.

• Read all the instructions before starting the

installation. Follow these instructions carefully

during the installation to ensure maximum safety

WARNING

Fire Risk.

Inspect appliance and components for damage.

Damaged parts may impair safe operation.

• Do NOT install damaged components.

• Do NOT install incomplete components.

• Do NOT install substitute components.

Report damaged parts to dealer.

Page 71 May, 2019 7038-201G

Page 8

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

OPERATING INSTRUCTIONS

Air Controls

1. Start-Up Air Control

The Start-Up Air Control has two primary functions. The

rst function is to activate the Automatic Combustion Control

system (ACC). This function is performed by sliding the con-

trol all the way back until it stops at the “HI” indicator on the

label and then pulling forward to the front of the stove until

it stops. This activates the ACC system and opens the front

air channel and allows air to enter the front of the stove for

approximately 25 minutes. The front air channel gradually

shuts down until it is completely closed at the end of the 25

minutes. The re is now controlled by the air supplied by the

Burn Rate Air Control. This function should be performed

each time you reload the stove. Figure 6.1.

2. Burn Rate Air Control

This air supply enters at the upper front of the rebox, near

the top of the glass door. This preheated air supplies the

necessary fresh oxygen to mix with the unburned gases,

helping to create second, third and fourth combustions. This

air is regulated by the Burn Rate Air Control. There are four

settings High, Medium-High, Medium-Low and Low. When

the control is raised all the way up it is on the High setting and

when pushed all the down it is on the Low setting. Figure 6.1.

HIGH

MED

LOW

Burn Rate

Air Control

Start-Up

Air Control

Figure 6.1

Burn Rates

1. Starting a Fire and Reloading

Open both controls fully by raising the Burn Rate Air Control

all the way up until it stops and slide the Start-Up Air Control

back until it stops. After loading the stove with wood and

starting the re, set both controls to the desired setting by

following the burn rate instructions below.

2. High Burn Rate - Maximum Heat

Raise the Burn Rate Air Control all the way up until it stops

(top marker) to a fully open position. Slide the Start-Up Air

Control all the way back until it stops (HI marker) and leave it

there. This setting over-rides the timer system (ACC) so you

must monitor the re closely while in this setting.

3.

Medium-High Burn Rate

Raise the Burn Rate Air Control all the way up until it stops

(top marker) to a fully open position. Slide the Start-Up Air

Control all the way back until it stops (HI marker) and then pull

forward until it stops. This activates the timer system (ACC).

4.

Medium-Low Burn Rate

Raise the Burn Rate Air Control up to the bottom of the middle

marker and stop. Slide the Start-Up Air Control all the way

back until it stops (HI marker) and then pull forward until it

stops. This activates the timer system (ACC).

5. Low Burn Rate

Leave the Burn Rate Air Control at the bottom marker. Slide

the Start-Up Air Control all the way back until it stops (HI

marker) and then pull forward until it stops. This activates

the timer system (ACC).

High (Open)

Low (Closed)

Start-Up Air

Control

Burn Rate

A

ir Control

Front Air Channel

Operated by Timer

Rear Air Channel

Operates independently

from Timer

Timer

Timer Manual

Shut-off

HIGH

LOW

Shown with Side

Shield Removed

Explorer III Wood Stove

ATTENTION INSTALLER:

G. Install Checklist

ATTENTION INSTALLER

Follow this Standard Work Checklist

This standard work checklist is to be used by the installer in conjuction with, not istead of, the instructions contained in this installation manual.

Customer:

Date Installe:

Lot / Address:

Location of Appliance:

Installer:

Dealer / Distributor Phone #:

Serial #:

Model:

_________________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

____________________________________________________________________________________

WARNING! Risk of Fire or Exposion!

Appliance Install

Verified clearances to combustibles.

Appliance is leveled and connector is secured to appliance.

Hearth extension size/height decided.

Outside air kit installed.

Floor protection requirements have been met.

If appliance is connected to a masonry chimney, it should be cleaned and

inspected by a professional. If installed to a factory built metal chimney, the

chimney must be installed according to the manufacturer’s instructions and

clearances.

Chimney

Chimney configuration complies with diagrams.

Chimney installed, locked and secured in place with proper clearance.

Chimney meets recommended height requirements (14-16 feet).

Roof flashing installed and sealed.

Terminations installed and sealed.

Clearances

Combustible materials not installed in non-combustible areas.

Verified all clearances meet installation manual requirements.

Mantels and wall projections comply with installation manual requirements.

Protective hearth strips and hearth extension installed per manual requirements.

Appliance Setup

All packaging and protective materials removed.

Firebrick, baffle and ceramic blanket installed correctly.

All labels have been removed from the door.

All packaging materials are removed from inside/under the appliance.

Manual bag and all of its contents are removed from inside/under the appliance

and given to the party responsible for use and operation.

Hearth & Home Technologies recommends the following:

• Photographing the installation and copying this checklist for your file.

• That this checklist remain visible at all times on the appliance until the installtion is complete.

Comments: Further description of the issues, who is responsible (Installer/Builder/Other Trades, etc.) and corrective action needed:

Comments communicated to party responsible ____________________________ by _____________________ on ___________

Page 8 1 May, 20197038-201G

___________________________________________________________________

Failure to install appliance according to these instruction can lead to a fire or explosion.

YES IF NO, WHY?

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

(Builder / Gen. Contractor) (Installer) (Date)

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

______________________________________

Page 9

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

the timer system (ACC).

A

Explorer III Wood Stove

Figure 11.1

Burn Rate Control

ACC Control

Figure 11.2

E. Air Controls

1. Burn Rate Air Control

This air supply enters at the upper front of the rebox,

near the top of the glass door. This preheated air

supplies the necessary fresh oxygen to mix with the

unburned gases, helping to create second, third and

fourth combustions. This air is regulated by the Burn

Rate Air Control. When the control is moved all the way

to the left it is on the High setting and when moved

all the way to the right it is on the Low setting (Figure

11.1).

2. Start-Up Air Control

The Start-Up Air Control function is to activate the

Automatic Combustion Control system (ACC). This

function is performed by pushing the control all the way

back until it stops and then pulling forward to the front

of the appliance until it stops. This activates the ACC

system and opens the front air channel and allows air

to enter the front of the appliance for approximately

25 minutes. The front air channel gradually shuts

down until it is completely closed at the end of the 25

minutes. The re is now controlled by the air supplied

by the Burn Rate Air Control. This function should be

performed each time you reload the appliance. Start up

air can be locked open for High burn setting if desired;

see page 10 for instructions (Figure 11.1).

3. Manual Timer Over-Ride

If you need to shut the ACC system off before it shuts

itself off after 25 minutes (i.e. over re situation), reach

down to the bottom right and pull the lever toward you

(Figure 11.2).

D. Automatic Combustion Control (ACC)

Typically, when you build a re, you open the air controls

fully and monitor the re to prevent it from going into an

over re situation and/or burning your wood up too quickly

before you shut down the air controls to the desired burn

rate. With the Automatic Combustion Control (ACC)

system, you do not have to continually monitor the re.

Once you set the ACC system it will control the re for you.

Follow the instructions below to learn how to operate your

appliance with ease.

2. Second Stage

The next stage of burning, the secondary stage, is the

period when the wood gives off ammable gases which

burn above the fuel with bright ames. During this stage of

burning it is very important that the ames be maintained

and not allowed to go out. This will ensure the cleanest

possible re. If the ames tend to go out, it is set too low for

your burning conditions. The air control located at the upper

right hand corner is used to adjust for burn rates. This is

called the Burn Rate Air Control (Figure 11.1).

3. Final Stage

The nal stage of burning is the charcoal stage. This occurs

when the ammable gases have been mostly burned and

only charcoal remains. This is a naturally clean portion of

the burn. The coals burn with hot blue ames.

It is very important to reload your appliance while enough

lively hot coals remain in order to provide the amount of

heat needed to dry and rekindle the next load of wood. It

is best to open the Burn Rate Air and Start-Up Air Controls

before reloading. This livens up the coal bed and reduces

excessive emissions (opacity/smoke). Open door slowly so

that ash or smoke does not exit appliance through opening.

You should also break up any large chunks and distribute

the coals so that the new wood is laid on hot coals.

Air quality is important to all of us, and if we choose to

use wood to heat our homes we should do so responsibly.

To do this we need to learn to burn our appliances in the

cleanest way possible. Doing this will allow us to continue

using our wood appliances for many years to come.

Injury Risk.

• Gloves recommended

CAUTION

Explorer III Wood Stove

Figure 11.2

This air supply enters at the upper front of the rebox,

near the top of the glass door. This preheated air

supplies the necessary fresh oxygen to mix with the

unburned gases, helping to create second, third and

fourth combustions. This air is regulated by the Burn

Rate Air Control. When the control is moved all the way

to the left it is on the High setting and when moved

all the way to the right it is on the Low setting (Figure

11.1).

The Start-Up Air Control function is to activate the

Automatic Combustion Control system (ACC). This

function is performed by pushing the control all the way

back until it stops and then pulling forward to the front

of the appliance until it stops. This activates the ACC

system and opens the front air channel and allows air

to enter the front of the appliance for approximately

25 minutes. The front air channel gradually shuts

down until it is completely closed at the end of the 25

minutes. The re is now controlled by the air supplied

by the Burn Rate Air Control. This function should be

performed each time you reload the appliance. Start up

air can be locked open for High burn setting if desired;

see page 10 for instructions (Figure 11.1).

If you need to shut the ACC system off before it shuts

itself off after 25 minutes (i.e. over re situation), reach

down to the bottom right and pull the lever toward you

(Figure 11.2).

Injury Risk.

• Gloves recommended

CAUTION

OPERATING INSTRUCTIONS

Air Controls

1. Start-Up Air Control

The Start-Up Air Control has two primary functions. The

rst function is to activate the Automatic Combustion Control

system (ACC). This function is performed by sliding the control all the way back until it stops at the “HI” indicator on the

label and then pulling forward to the front of the stove until

it stops. This activates the ACC system and opens the front

air channel and allows air to enter the front of the stove for

approximately 25 minutes. The front air channel gradually

shuts down until it is completely closed at the end of the 25

minutes. The re is now controlled by the air supplied by the

Burn Rate Air Control. This function should be performed

each time you reload the stove. Figure 6.1.

2. Burn Rate Air Control

This air supply enters at the upper front of the rebox, near

the top of the glass door. This preheated air supplies the

necessary fresh oxygen to mix with the unburned gases,

helping to create second, third and fourth combustions. This

air is regulated by the Burn Rate Air Control. There are four

settings High, Medium-High, Medium-Low and Low. When

the control is raised all the way up it is on the High setting and

when pushed all the down it is on the Low setting. Figure 6.1.

Burn Rates

1. Starting a Fire and Reloading

Open both controls fully by raising the Burn Rate Air Control

all the way up until it stops and slide the Start-Up Air Control

back until it stops. After loading the stove with wood and

starting the re, set both controls to the desired setting by

following the burn rate instructions below.

2. High Burn Rate - Maximum Heat

Raise the Burn Rate Air Control all the way up until it stops

(top marker) to a fully open position. Slide the Start-Up Air

Control all the way back until it stops (HI marker) and leave it

there. This setting over-rides the timer system (ACC) so you

must monitor the re closely while in this setting.

3.

Medium-High Burn Rate

Raise the Burn Rate Air Control all the way up until it stops

(top marker) to a fully open position. Slide the Start-Up Air

Control all the way back until it stops (HI marker) and then pull

forward until it stops. This activates the timer system (ACC).

Medium-Low Burn Rate

4.

Raise the Burn Rate Air Control up to the bottom of the middle

marker and stop. Slide the Start-Up Air Control all the way

back until it stops (HI marker) and then pull forward until it

stops. This activates the timer system (ACC).

5. Low Burn Rate

Leave the Burn Rate Air Control at the bottom marker. Slide

the Start-Up Air Control all the way back until it stops (HI

marker) and then pull forward until it stops. This activates

Burn Rate

Air Control

Figuer 9.1

Start-Up

Air Control

Figure 6.1

HIGH

Shown with Side

Shield Removed

LOW

HIGH

MED

LOW

Low (Closed)

Figuer 9.2

Burn Rate

ir Control

Start-Up Air

Control

Front Air Channel

Operated by Timer

Operates independently

High (Open)

Rear Air Channel

from Timer

Timer

Timer Manual

Shut-off

Page 91 May, 2019 7038-201G

Page 10

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

GENERAL INSTRUCTIONS FOR FLUE SYSTEM

▪ Flue pipe installed crimp/narrow end down

▪ Outer casings installed crimped/narrow end up. (Critical when exposed above the roof)

▪ Inner casings - direction not critical

▪ Flue pipes - seal all joints including rebox spigot.

- x with a minimum of 3 stainless steel rivets

▪ Flue pipe spacers - afx to ue pipe

▪ Flue system termination point - Refer to AS/NZS 2918:2001 4.9.1.

▪ Flue pipe shall extend not less than 4.6m above top of the oor protector as per

AS/NZS 2918:2001 4.9.1(a)

▪ Façade or chase systems - same rule applies as above.

▪ Roof penetration and ashing method refer to NZ Building Code E2.(From 01/07/05)

Note: These instructions apply to 150mm diameter ue pipe systems as tested to

AS/NZS 2918:2001

1. Either locate the appliance in position or by measuring at the ceiling mark the ue pipe centre position.

Check that the outer casing is unobstructed through the attic space or roof area.

2. Spike the centre with a nail. Transfer this position to the next surface above. Plumb bob/laser.

3. Cut out the ceiling penetration hole – square or rectangle – short axis equals outer casing diameter

plus 50mm, long axis as required. See Table 5 . Perform the same at the roof penetration.

4. Frame out the hole with minimum 75 x 50 timber or as required for roong material. Minimum

requirement at roof penetration see NZ Building Code E2 Acceptable Solution (from 01/07/05).

5. Install the outer casing so that :-

(i) lower end is ush with the underside of the ceiling material and

(ii) with the addition of metal “L” brackets, afx to the outer casing at 90 degrees secure the outer

casing centrally to the ceiling and roof nogs. Alternatively substitute the “L” brackets for 25mm thick

non heat sensitive packers. Secure the outer casing through the packers with horizontal xings to

the nogs. Refer to the General Instruction for termination height. The option of outer casing slips to

be taken into account.

6. Flash the outer casing to the roof material with the appropriate approved ashing.

7. If using an outer/inner casing combination, now install the inner casing ensuring it extends a minimum

200mm above the high side of the roof penetration. If not using a combination see ‘11’ below.

8. Refer to Firebox Installation, points 1 & 2.

9. Prepare the ceiling plate and place upside down over the ue spigot.

10. Install the ue pipes by preferred method – either up or down the outer casing. Afx each length

per the notes in General Instructions (above). Extend the ue pipe above the outer

casing to suit the casing cover/cowl assembly.

11. If the inner casing has not been installed, install now. Refer to 7 above for minimum height.

12. Install the cowl assembly, i.e. Top spacer, casing cover and cowl.

13. Position and secure the ceiling plate with the screws and spacers.

14. Wipe the ue pipe to remove nger marks.

15. Refer to Firebox Installation, point 3.

16. If ue offset is required, refer to AS/NZS 2918:2001 4.1

Page 10 1 May, 20197038-201G

Page 11

5700 Step Top ACC Wood Burner

C

L

Drawing not to scale

12

Tested flue systems, as per AS/NZS 2918:2001

Fig. 5

ADD Cowl

Casing Cover

Spider Bracket

oversized casing cover

is necessary

minimum 25mm gap

between flue pipe casing &

combustible material

Non combustible material

Hebel block or 12mm

Promina board or similar

under the flashing

25 25

Approved Flashing

Roof Line

Inner Casing 200mm

above roof line

Outer Casing

Inner Casing

25

Internal Swage

25 25

12.5

V

ented

C

eiling Plate

Flue Pipe

C

L

C L

Quadra-fire 5700

Floor

The flue crimp must be cut so the swage

(half-moon bulge after the crimp) fits

tightly into the spigot.

FLUE PENETRATION

EXP-III Wood Burner

Page 111 May, 2019 7038-201G

Page 12

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

FLUE PENETRATION

Un-tested flue systems, as per AS/NZS 2918:2001, 4.6.3(b)

1.QF.1F

Fig. 6

AS/NZS2918:2001

Un-tested flue with sloped ceiling

penetration greater than 30° from

horizontal

A = 25mm

4.6.3(b)

Fig 4.6 = downward distance of

casing and 3 x ø flue distance of

the ceiling plate

Batten

150

ADD Cowl

A

A

Casing Cover

Spider Bracket

Approved Flashing

Ceiling Plate

Fig. 7

Ceiling

AS/NZS2918:2001

Un-tested flue with sloped ceiling

penetration greater than 30° from

horizontal

A = 25mm

4.6.3(b)

Fig 4.6 = 3 x ø flue from active flue

to heat sensitive surface

Batten

3 x Ø flue pipe

flue pipe

Ø

A

ADD Cowl

Casing Cover

Spider Bracket

Approved Flashing

A

Ceiling Plate

Ceiling

flue pipe

Ø

Page 12 1 May, 20197038-201G

Page 13

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

GENERAL INSTRUCTIONS FOR FLUE SYSTEM

1. Unpack the Flue Mounted Shield, detach the three brackets and familarize yourself with the illustrations.

it meets the outer shield (refer sketch). Cut along the full length of the Flue Mounted Shield on both

4. Fit the top bracket to the Flue Mounted Shield as illustrated ensuring the rear mid section of the

f both the lower outer legs from the

.

Two tabs are provided and if folded back at 90 degrees the bracket and Flue Mounted Shield will

mount lower onto the appliance.

The Flue Mounted Shield then locates into the two notches provided n bracket “5B” as illustated.

grill to be removed.

7. Using the pre-punched holes in the two tabs provided on the top bracket as guides, drill into the

MINIMUM HEIGHT OF FLUE SYSTEM EXIT

Fig. 8

6000

3000

or

less

600

More than

min.

3000

3000

increase from 1000mm

minimum until clear within

increase as

until nothing

6000mm of flue

Any nearby

necessary

within

top

structure

3000mm of flue top

Page 131 May, 2019 7038-201G

Page 14

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

HAZARDOUS.

AS/NZS 2918:2001 General Notes

WARNING: THE APPLIANCE AND FLUE SYSTEM SHALL BE INSTALLED IN ACCORDANCE

WITH AS/NZS 2918 AND THE APPROPRIATE REQUIREMENTS OF THE RELEVANT BUILDING

CODE OR CODES.

WARNING: APPLIANCES INSTALLED IN ACCORDANCE WITH THIS STANDARD SHALL

COMPLY WITH THE REQUIREMENTS OF AS/NZS 4013 WHERE REQUIRED BY THE REGULATORY AUTHORITY, I.E. THE APPLIANCE SHALL BE IDENTIFIABLE BY A COMPLIANCE PLATE

WITH THE MARKING ‘TESTED TO AS/NZS 4013’.

ANY MODIFICATION OF THE APPLIANCE THAT HAS NOT BEEN APPROVED IN WRITING BY

THE TESTING AUTHORITY IS CONSIDERED TO BE IN BREACH OF THE APPROVAL GRANTED

FOR COMPLIANCE WITH AS/NZS 4013.

CAUTION: MIXING OF APPLIANCE OR FLUE SYSTEM COMPONENTS FROM DIFFERENT

SOURCES OR MODIFYING THE DIMENSIONAL SPECIFICATION OF COMPONENTS MAY

RESULT IN HAZARDOUS CONDITIONS. WHERE SUCH ACTION IS CONSIDERED, THE MANUFACTURER SHOULD BE CONSULTED IN THE FIRST INSTANCE.

CAUTION: THIS APPLIANCE SHOULD NOT BE OPERATED WITH CRACKED AND BROKEN

COMPONENTS, e.g. GLASS PANELS OR CERAMIC TILES, MAY RENDER THE INSTALLATION

UNSAFE.

WARNING: ANY MODIFICATION OF THE APPLIANCE THAT HAS NOT BEEN APPROVED IN

WRITING BY THE TESTING AUTHORITY IS CONSIDERED AS BREACHING AS/NZS 4013.

WARNING: DO NOT USE FLAMMABLE LIQUIDS OR AEROSOLS TO START OR REKINDLE THE FIRE.

WARNING: DO NOT USE FLAMMABLE LIQUIDS OR AEROSOLS IN THE VICINITY OF THIS

APPLIANCE WHEN ITS OPERATING.

WARNING: DO NOT STORE FUEL WITHIN HEATER INSTALLATION CLEARANCES.

WARNING: OPEN AIR CONTROLS AND DAMPER WHEN FITTED BEFORE OPENING FIRING

DOOR.

WARNING: FOR OPTIMUM PERFORMANCE FUEL MUST BE LOADED SO THE LOGS LAY

“FRONT TO REAR” IN PREFERENCE TO LAYING ACROSS THE WIDTH OF THE FIREBOX.

SPACES SHOULD BE LEFT BETWEEN THE LOGS TO ENABLE OXYGEN TO GET TO AS MUCH

OF THE SURFACE OF THE FUEL AS POSSIBLE.

CAUTION: THIS APPLIANCE SHOULD BE MAINTAINED AND OPERATED AT ALL TIMES IN

ACCORDANCE WITH THESE INSTRUCTIONS.

CAUTION: THE USE OF SOME TYPES OF PRESERVATIVE-TREATED WOOD AS A FUEL CAN BE

Page 14 1 May, 20197038-201G

Page 15

5700 Step Top ACC Wood Burner

Service And Maintenance Log

Date of Service Performed By Description of Service

EXP-III Wood Burner

Page 151 May, 2019 7038-201G

Page 16

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

AUSTRALIAN WARRANTY INFORMATION

Hearth & Home Technologies Inc (HHT)

1445 N. Highway | Colville, WA 99114 | (509-684-3745)

HHT extends the following manufacturer’s warranty for HHT gas, wood, pellet, coal and electric hearth appliances that are purchased

from an HHT authorized dealer.

HHT warrants to the original owner of the HHT appliance at the site of installation, and to any transferee taking ownership of the appliance

at the site of installation within two years following the date of original purchase, that the HHT appliance will be free from defects in

materials and workmanship at the time of manufacture.

After installation, if covered components manufactured by HHT are found to be defective in materials or workmanship during the applicable

warranty period, HHT will, at its option, repair or replace the covered components. HHT, at its own discretion, may fully discharge all of

its obligations under this manufacturer’s warranty by replacing the product itself or refunding the veri ed purchase price of the product

itself. The maximum amount recoverable under this warranty is limited to the purchase price of the product. This warranty is subject to

conditions, exclusions and limitations as described below.

Warranty coverage begins on the date of original purchase. In the case of new home construction, coverage under this manufacturer’s

warranty begins on the date of rst occupancy of the dwelling or six months after the sale of the product by an independent, authorized

HHT dealer/ distributor, whichever occurs earlier. The warranty period for this manufacturer’s warranty shall commence no later than 24

months following the date of product shipment from HHT, regardless of the installation or occupancy date. The manufacturer’s warranty

period for parts and labor for covered components is produced in the following table.

The term “Limited Lifetime” in the table below is de ned as: 20 years from the beginning date of warranty coverage for gas appliances,

and 10 years from the beginning date of warranty coverage for wood, pellet and coal appliances. These time periods re ect the minimum

expected useful lives of the designated components under normal operating conditions.

Warranty Period Hearth and Home Technologies Manufactured Appliances and Venting

Parts Labor Gas Wood Pellet

1 Year X X X X X X X

X X X

2 years

3 years X Firepots and Burnpots

5 years 1 year X X Castings and baf es

7 years 3 years X X X

10

years

1 year X

X X X X X

X Molded refractory panels

EPA

Wood

Coal Electric Venting

Components Covered

All parts and material

except as covered by

Conditions, Exclusions,

and Limitations listed

Igniters, electronic

components, and glass

Factory-installed blowers

Manifold tubes,

HHT chimney and

termination

Burners, logs and

refractory

Limited

Lifetime

3 years X X X X X

90 Days X X X X X X X

Page 16 1 May, 20197038-201G

Firebox and heat

exchanger

All replacement parts

beyond warranty period

Page 17

EXP-III Wood Burner

5700 Step Top ACC Wood Burner

OTHER RIGHTS

The HHT manufacturer’s warranty is in addition to other rights and remedies that you may have under Australian

law.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled

to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality

and the failure does not amount to a major failure.

WARRANTY CONDITIONS AND EXCLUSIONS:

• The HHT manufacturer’s warranty only covers HHT appliances that are purchased through an HHT authorized dealer or distributor.

A list of HHT authorized dealers is available on the HHT branded websites.

• This warranty is only valid while the HHT appliance remains at the site of original installation.

WARRANTY EXCLUSIONS:

This HHT manufacturer’s warranty does not cover the following:

• Changes in surface nishes as a result of normal use. As a heating appliance, some changes in color of interior and exterior surface

nishes may occur. This is not a aw and is not covered under warranty.

• Damage to printed, plated, or enamelled surfaces caused by ngerprints, accidents, misuse, scratches, melted items, or other

external sources and residues left on the plated surfaces from the use of abrasive cleaners or polishes.

• Repair or replacement of parts that are subject to normal wear and tear during the warranty period. These parts include: paint, wood,

pellet and coal gaskets, rebricks, grates, ame guides, light bulbs, batteries and the discoloration of glass.

• Minor expansion, contraction, or movement of certain parts causing noise. These conditions are normal and complaints related to this

noise are not covered by this warranty.

• Damages resulting from: (1) failure to install, operate, or maintain the appliance in accordance with the installation instructions,

operating instructions, and listing agent identi cation label furnished with the appliance; (2) failure to install the appliance in

accordance with local building codes; (3) shipping or improper handling; (4) improper operation, abuse, misuse, continued operation

with damaged, corroded or failed components, accident, or improperly/incorrectly performed repairs; (5) environmental conditions,

inadequate ventilation, negative pressure, or drafting caused by tightly sealed constructions, insuf cient make-up air supply, or

handling devices such as exhaust fans or forced air furnaces or other such causes; (6) use of fuels other than those speci ed in the

operating instructions; (7) installation or use of components not supplied with the appliance or any other components not expressly

authorized and approved by HHT (8) modi cation of the appliance not expressly authorized and approved by HHT in writing; and/or

(9) interruptions or uctuations of electrical power supply to the appliance.

• Non HHT venting components, hearth components or other accessories used in conjunction with the appliance.

• Any part of a pre-existing replace system in which an insert or a decorative gas appliance is installed.

• Removal, installation, reinstallation, set up or any other costs associated with a claim including travel and shipping charges for parts.

• HHT’s obligation under this warranty does not extend to the appliance’s capability to heat the desired space. Information is provided

to assist the consumer and the dealer in selecting the proper appliance for the application. Consideration must be given to appliance

location and con guration, environmental conditions, insulation and air tightness of the structure.

This warranty is void if:

• The appliance has been over- red or operated in atmospheres contaminated by chlorine, uorine, or other damaging chemicals.

Over- ring can be identi ed by, but not limited to, warped plates or tubes, rust coloured cast iron, bubbling, cracking and discoloration

of steel or enamel nishes.

• The appliance is subjected to prolonged periods of dampness or condensation.

• There is any damage to the appliance or other components due to water or weather damage which is the result of, but not limited to,

improper chimney or venting installation.

HOW TO CLAIM

• To make a claim against this warranty, contact your local distributor during regular business hours. See addresses below for a dealer

nearest you. (Vic) Pty Ltd ACN 005 872 159 (Jetmaster).

• Additional service fees may apply if you are seeking warranty service from a dealer other than the dealer from whom you originally

purchased the product.

• Check with Jetmaster in advance for any costs to you when arranging a warranty call. Travel and shipping charges for parts are not

covered by this manufacturers’ warranty.

• HHT and Jetmaster will assess your claim. HHT or Jetmaster may need to inspect the product as part of the assessment of your

claim. If the product requires inspection, HHT or Jetmaster will discuss with you the best way for this to occur.

• To make a claim under this manufacturer’s warranty, you must be able to prove when you purchased the product. The easiest way to

do this is through your original proof of purchase, for example your invoice or receipt. However, if you do not have your original proof

of purchase HHT or Jetmaster may accept other evidence of the date of purchase.

Local Distributors:

Melbourne Jetmaster 44 Swan Street Richmond 3121 (03) 9429-5573

Perth Fireplace Corner 277 Lord Street East Perth 6000 (08) 9228-2600

Sydney Jetmaster 10 Martin Avenue Arncliff 2205 (02) 9597-7222

Page 171 May, 2019 7038-201G

Page 18

EXP-III Wood Burner

R

Service Parts

Explorer III

Wood Stove

Color SKU Mfg. Dates

Matte Black EXPLR-III-MBK 02/15-

Porcelain Black EXPLR-III-PBK 02/15-

Porcelain Dark Blue EXPLR-III-PDB 02/15-

Porcelain Frost EXPLR-III-PFT 02/15-

Porcelain Mahogany EXPLR-III-PMH 02/15-

6

7

8

9

1

2

5

30

Beginning Manufacturing Date: Feb 2015

Ending Manufacturing Date: Active

38

3

4

37

36

35

34

33

32

11

10

12

19

20

17

18

22

21

16

23

14

13

15

24

25

28

31

29

27

26

Part number list on following page.

Page 18 1 May, 20197038-201G

08/18

Page 19

EXP-III Wood Burner

R

Service Parts

Beginning Manufacturing Date: Feb 2015

Ending Manufacturing Date: Active

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or

distributor.

model number and serial number when requesting service parts from your dealer or distributor.

ITEM DESCRIPTION COMMENTS PART NUMBER

10 Rear Brick Retainer SRV7060-133

11 Side Brick Retainer Qty 2 req SRV7060-193

12 Brick Assembly SRV7060-017

13 Ashlip

Hearth and Home Technologies does not sell directly to consumers. Provide

1 Shroud Assembly SRV7060-009

2 Flue Collar SRV7061-201

3 Outside Air Chamber SRV7061-014

4 Convection Mount Plates Qty 2 req SRV7060-197

5 Flue Transition SRV29138

6 Top Load Handle Assembly SRV7060-055

Top Load Handle Receiver SRV7060-257

7 Lid Assembly SRV7060-006

Gasket, Rope 1/4” 834-1460 Y

Matte Black 7060-101MBK

Porcelain Mahogany 7060-101PMH

8 Top

Gasket, 7/16” 844-3980 Y

9 Side Left

Porcelain Dark Blue 7060-101PDB

Porcelain Black 7060-101PBK

Porcelain Frost 7060-101PFT

Matte Black 7060-034MBK

Porcelain Mahogany 7060-034PMH

Porcelain Dark Blue 7060-034PDB

Porcelain Black 7060-034PBK

Porcelain Frost 7060-034PFT

Matte Black 7060-113MBK

Porcelain Mahogany 7060-113PMH

Porcelain Dark Blue 7060-113PDB

Porcelain Black 7060-113PBK

Porcelain Frost 7060-113PFT

Explorer III

Stocked

at Depot

Additional service part numbers appear on following page.

Page 191 May, 2019 7038-201G

Page 20

EXP-III Wood Burner

R

Service Parts

Beginning Manufacturing Date: Feb 2015

Ending Manufacturing Date: Active

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or distributor.

Hearth and Home Technologies does not sell directly to consumers. Provide model number

and serial number when requesting service parts from your dealer or distributor.

ITEM DESCRIPTION COMMENTS PART NUMBER

#14 Door Assembly

Explorer III

Stocked

at Depot

14.1

14.9

14.8

14.2

14.7

14.10

14.3

14.6

14.5

14.4

Matte Black 7060-028MBK

Porcelain Mahogany 7060-028PMH

14 Door Assembly

Gasket, Rope 1/4” 834-1460 Y

14.1 Glass Retainers SRV7063-166 Y

14.2 Glass Assembly SRV7060-029

14.3 Door

14.4 Door Handle Assembly SRV7060-031 Y

14.5 Fiber Handle SRV7060-212 Y

14.6 Door Handle SRV7063-137

14.7 Washer, Sae, 3/8 (3 Ea) Pkg of 3 832-0990 Y

14.8 Cam Latch SRV430-1141

14.9 Nut, 2Wy Side Lock Jam 3 Pkg of 24 226-0100/24 Y

14.10 Key, Cam Latch SRV430-1151

Additional service part numbers appear on following page.

Porcelain Dark Blue 7060-028PDB

Porcelain Black 7060-028PBK

Porcelain Frost 7060-028PFT

Matte Black 7060-204MBK

Porcelain Mahogany 7060-204PMH

Porcelain Dark Blue 7060-204PDB

Porcelain Black 7060-204PBK

Porcelain Frost 7060-204PFT

Page 20 1 May, 20197038-201G

Page 21

EXP-III Wood Burner

R

Service Parts

Beginning Manufacturing Date: Feb 2015

Ending Manufacturing Date: Active

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or

distributor.

model number and serial number when requesting service parts from your dealer or distributor.

ITEM DESCRIPTION COMMENTS PART NUMBER

15 Front

16 Andirons 2 pcs SRV7061-020

17 Front Air Channel SRV7060-132

18 ARS Channel SRV7061-184

19 ARS Access Cover SRV7038-196

20 ARS Latch Assembly

21 Burn Rate Indicator SRV7061-191

22 Burn Rate Control SRV7060-027

23 Access Panel SRV7061-185

24 ARS Door Assembly

25 Gasket, ARS SRV7033-296 Y

26 Ashpan SRV7060-023

27 ARS Box SRV7060-005

28 Timer Door SRV7060-040

29 Timer Assembly SRV7060-036

30 Secondary Channels Qty 2 req SRV7060-208

Hearth and Home Technologies does not sell directly to consumers. Provide

Matte Black 7060-103MBK

Porcelain Mahogany 7060-103PMH

Porcelain Dark Blue 7060-103PDB

Porcelain Black 7060-103PBK

Porcelain Frost 7060-103PFT

Gasket, 7/16” 844-3980 Y

Pre 00706300534 SRV7061-023

Post 00706300535 SRV7060-050

Handle, Fiber SRV7060-202

Pre 00706300534 SRV7061-021

Post 00706300535 SRV7060-048

Handle Cover, Access SRV7038-197

Knob SRV7000-343

Timer (Only) Replacement Assembly SRV480-1940

Explorer III

Stocked

at Depot

Additional service part numbers appear on following page.

Page 211 May, 2019 7038-201G

Page 22

EXP-III Wood Burner

Additional service part numbers appear on following page.

R

Service Parts

Beginning Manufacturing Date: Feb 2015

Ending Manufacturing Date: Active

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or

distributor.

model number and serial number when requesting service parts from your dealer or distributor.

ITEM DESCRIPTION COMMENTS PART NUMBER

Hearth and Home Technologies does not sell directly to consumers. Provide

#30 Baf e Assembly

31.1

31.2

31.3

31.4

Explorer III

Stocked

at Depot

31.5

31.7

31.8

31.6

31 Baf e Assembly SRV7060-025

31.1 Baf e Cover Top ( Includes Insulation Blanket ) SRV7060-238

31.2 Baf e Blanket SRV7060-233 Y

31.3 Baf e Plate SRV7060-205

31.4 Baf e Board SRV7060-148 Y

31.5 Secondary Tubes Qty 3 req SRV7060-226 Y

31.6 Baf e Cover Plates SRV7060-206

31.7 Baf e Linkage SRV7060-044

31.8 Baf e Door Handle SRV7060-217

Matte Black 7060-033MBK

Porcelain Mahogany 7060-033PMH

32 Side Right

33 Manifold Gaskets Qty 2 req SRV7060-221

34 Air Supply Chambers Right and Left SRV7060-189

35 Pivot Tube Assemblies Qty 2 req SRV7060-018

36 Rear Baf e Plate SRV7060-201

37 Baf e Board Rear SRV7060-213

38 Top Load Handle Hanger SRV7060-262

Porcelain Dark Blue 7060-033PDB

Porcelain Black 7060-033PBK

Porcelain Frost 7060-033PFT

Page 22 1 May, 20197038-201G

Page 23

EXP-III Wood Burner

R

Service Parts

Beginning Manufacturing Date: Feb 2015

Ending Manufacturing Date: Active

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or

distributor.

model number and serial number when requesting service parts from your dealer or distributor.

ITEM DESCRIPTION COMMENTS PART NUMBER

Hearth and Home Technologies does not sell directly to consumers. Provide

Matte Black SRV7060-038

Porcelain Mahogany SRV7060-039

Component Pack

Leveling Assembly 7000-000

Paint Touch-Up

Porcelain Dark Blue SRV7060-041

Porcelain Black SRV7060-042

Porcelain Frost SRV7060-043

Matte Black 812-0910

Porcelain Mahogany 855-1450

Porcelain Dark Blue 1-00-0020

Porcelain Black 1-00-0022

Porcelain Frost 1-00-0021

Explorer III

Stocked

at Depot

ACCESSORIES

Blower Assembly BK-ACC

Blower Control Box W/Switch SRV7000-194

Component Pack 7033-051

Magnet Round SRV7000-140

Snap Disc Bracket Assembly 7033-036

Snap Disc, # 1, Convection Blower SRV230-0470

Speed Control Only (Rheostat) 842-0370

Wire Harness (Blower) 7033-262

Blower, Convection Blower Only 812-4900 Y

Outside Air Kit, Floor & Rear OAK-ACC

Outside Air Collar Assembly 7033-039

Outside Air Shield SRV33271

Firescreen SCR-7060

FASTENERS

Avk Rivnut Repair Kit - 1/4-20 & 3/8-16 Rivnut Tools RIVNUT-REPAIR

Nut, Ser Flange Small 1/4-20 Pkg of 24 226-0130/24

Screw, Pan Head Philips 8-32 X 3/8 Pkg of 40 225-0500/40

Screw, Sheet Metal #8 X 1/2 S-Grip Pkg of 40 12460/40

Washer, 1/4 Sae Pkg of 24 28758/24

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Page 231 May, 2019 7038-201G

Page 24

CONTACT INFORMATION

Hearth & Home Technologies

352 Mountain House Road

Halifax, PA 17032

Division of HNI INDUSTRIES

Please contact your Quadra-Fire dealer with any questions or concerns.

For the number of your nearest Quadra-Fire dealer

log onto www.quadrafire.com

CAUTION

DO NOT DISCARD THIS MANUAL

• Important operating and

maintenance instructions included.

• Read, understand and

follow these instructions for safe installation and operation.

• Leave this manual with

party responsible for use

and operation.

DO NOT

DISCARD

We recommend that you record the following pertinent

information for your heating appliance.

Date purchased/installed:_________________________________________________________________________

Serial Number:____________________________________ Location on appliance:___________________________

Dealership purchased from:________________________________________ Dealer phone:_1(_____)_____-______

Notes:________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

This product may be covered by one or more of the following patents: (United States) 5341794, 5263471, 6688302, 7216645, 7047962

or other U.S. and foreign patents pending.

Page 24 1 May, 20197038-201G

Loading...

Loading...