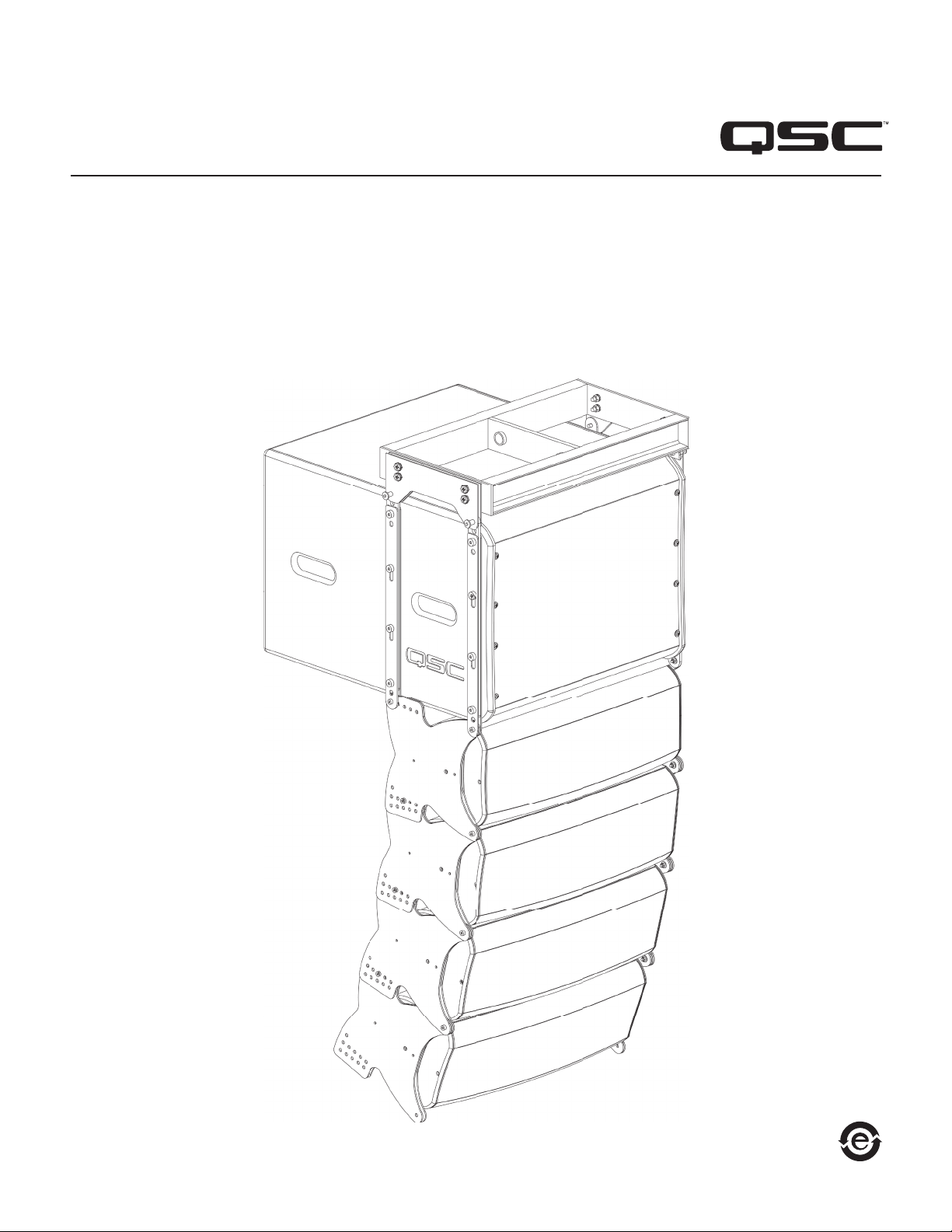

QSC WL118-sw, WL2082-i Owner's Manual

ILA System v2

User Manual

WL2082-i – Full-range line array loudspeaker

WL118-sw – Subwoofer line array loudspeaker

FB2082-i – Array frame

EB2082-i – Extension bar

PB2082-i – Pull-back bar

GS115-sw – Ground stack kit

TD-000218-00-E

*TD-000218-00*

2

IMPORTANT SAFETY PRECAUTIONS AND EXPLANATION OF SYMBOLS

Install in accordance with instructions by QSC Audio Products, LLC instructions and under the supervision of a licensed Professional Engineer.

WARNING!

Before placing, installing, rigging, or suspending any speaker product, inspect all hardware, suspension, cabinets, transducers, brackets and associated

equipment for damage. Any missing, corroded, deformed, or non-load rated component could significantly reduce the strength of the installation,

placement or array. Any such condition severely reduces the safety of the installation and should be immediately corrected. Use only hardware

which is rated for the loading conditions of the installation and any possible short-term, unexpected overloading. Never exceed the rating of the

hardware or equipment.

Consult a licensed, Professional Engineer regarding physical equipment installation. Ensure that all local, state and national regulations regarding the

safety and operation of suspended equipment are understood and adhered to.

Warranty (USA only; other countries, see your dealer or distributor)

Disclaimer

QSC Audio Products, LLC is not liable for any damage to amplifiers or any other equipment that is caused by negligence or improper installation and/

or use of this loudspeaker product.

QSC Audio Products 3-Year Limited Warranty

QSC Audio Products, LLC (”QSC”) guarantees its products to be free from defective material and/or workmanship and will replace defective parts and

repair malfunctioning products under this warranty when the defect occurs under normal installation and use-provided the unit is returned to our factory,

one of our authorized service stations or an authorized QSC International Distributor via pre-paid transportation with a copy of proof of purchase (i.e.,

sales receipt). This warranty provides that the examination of the return product must indicate, in our judgment, a manufacturing defect. This warranty

does not extend to any product which has been subjected to misuse, neglect, accident, improper installation, or where the date code has been removed

or defaced. QSC shall not be liable for incidental and/or consequential damages. This warranty gives you specific legal rights. This limited warranty is

freely transferable during the term of the warranty period. The warranty on QSC products is NOT VALID if the products have been purchased from an

unauthorized dealer/online e-tailer, or if the original factory serial number has been removed, defaced, or replaced in any way. Damage to, or loss of any

software or data residing on the product is not covered. When providing repair or replacement service, QSC will use reasonable efforts to reinstall the

product’s original software configuration and subsequent update releases, but will not provide any recovery or transfer of software or data contained on

the serviced unit not originally included in the product.

Customers may have additional rights, which vary from state to state or from country to country. In the event that a provision of this limited warranty is

void, prohibited or superseded by local laws, the remaining provisions shall remain in effect.

Periodically, this warranty is updated. To obtain the most recent version of QSC’s warranty statement, please visit www.qscaudio.com.

Contact us at 800-854-4079 or visit our website at www.qscaudio.com.

The QSC limited warranty is valid for a period of three (3) years from date of purchase in the United States and many (but not all)

other countries.

For QSC warranty information in countries other than the United States, contact your authorized QSC international distributor. A list of QSC International

distributors is available at www.qscaudio.com.

To register your QSC product online, go to www.qscaudio.com and select ”Product Registration”. Other questions regarding this warranty can be

answered by calling, e-mailing or contacting your authorized QSC distributor.

© 2009, QSC Audio Products, LLC.

Patents may apply or be pending.

QSC is a registered trademark of QSC Audio Products, LLC.

“QSC” and the QSC logo are registered with the U.S. Patent and Trademark Office.

All trademarks are the property of their respective owners.

1

Introduction

The Installation Line Array (ILA) is a high performance line array system designed for the needs of Houses of Worship, Performing Arts facilities and a

multitude of other venue types. The current ILA family is composed of the WL2082-i line array element, WL118-sw subwoofer, FB2082-i array frame,

PB2082-i pull-back bar, EB2082-i extension bar, and GS115-sw ground stack kit.

Installation Line Arrays may be used in outdoor applications where the system is somewhat protected from the elements. The enclosure material is

formulated with UV inhibitors, the grille is made of aluminum and the woofer cones are weather resistant.

WL2082-i

The WL2082-i line array element uses two high-power, neodymium magnet, 2" voice-coil, 8" low-frequency drivers in a two-and-a-half-way configuration. Both woofers produce low frequencies but only one covers the mid-range, resulting in far better horizontal directivity control in the crossover

region. Excellent high-frequency output and clarity are provided by a pair of 1.75" voice coil, neodymium magnet compression drivers with titanium

diaphragms. These drivers are mounted to QSC’s patented* multiple-aperture diffraction waveguide that provides an extremely wide horizontal coverage of 140º. As a result, systems will rarely require side or center fill speakers and solid stereo imaging is preserved across the listening area.

The low-frequency capability of a WL2082-i array extends to 68 Hz (-10 dB); adequate for speech/vocal and acoustic music program material. For

reinforcement of program material with more demanding low-frequency content, the WL118-sw companion subwoofer is available.

WL2082-i Loudspeaker

Rigging plate attachment holes1.

Grille2.

Splay angle selection holes (rear of rigging plates)3.

Grille retaining screws (one on each end of enclosure)4.

Rigging plate retaining bolt5.

Rigging alignment notch6.

Rigging plates7.

Input plate8.

Rigging alignment pin9.

Horizontal Shading selector switch10.

BI AMP/TRI AMP Mode selector switch11.

Wiring table12.

NL8 Speakon™ connectors13.

3

1

6

2

4

5

7

8

9

*Patent number 7,177,437

10

13

11

12

2

4

Introduction (continued)

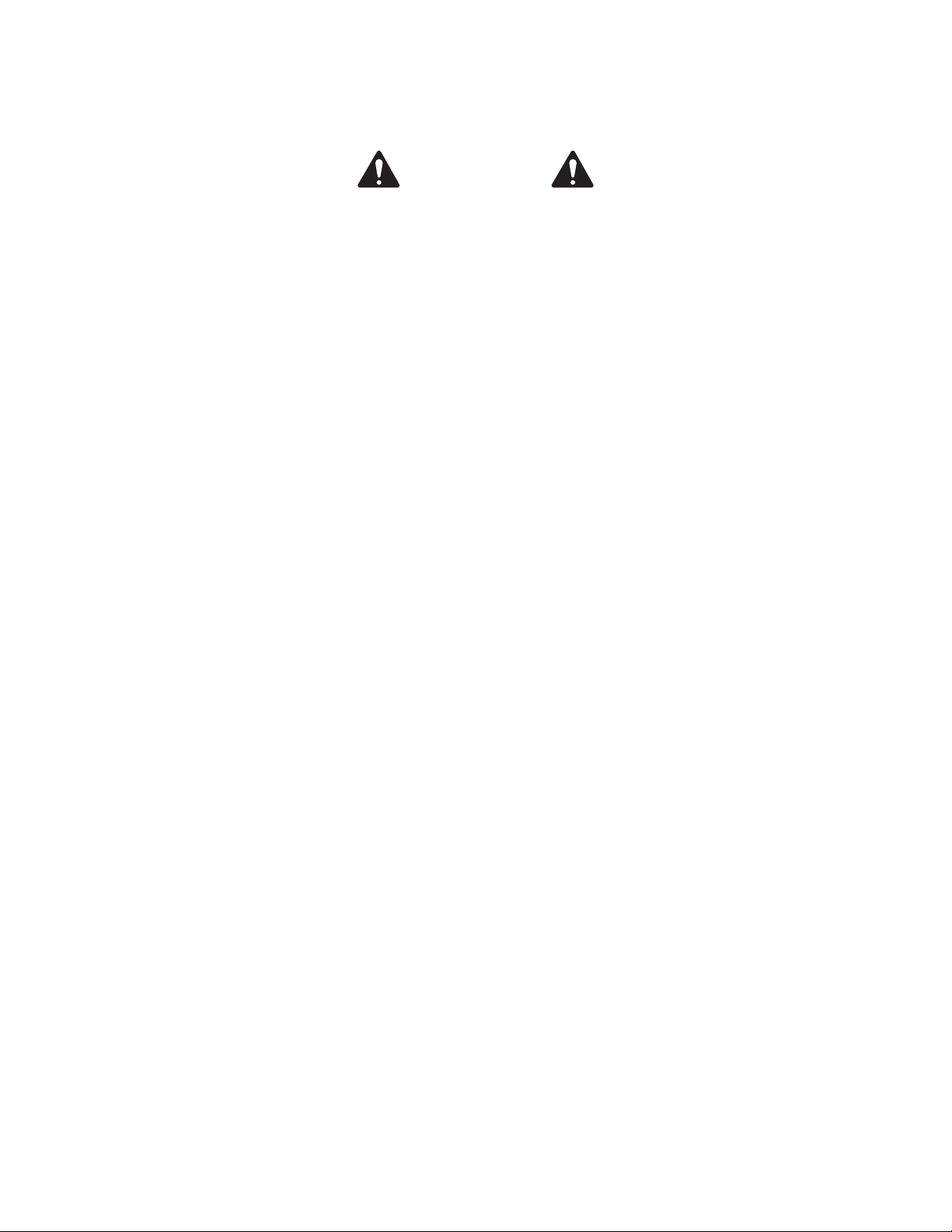

WL118-sw

The WL118-sw subwoofer extends the system’s low-frequency capability to 35 Hz. Its ceramic magnet, 4" voice coil, 18" transducer provides 850 watt

continuous power handling capability.

Many users of line array systems have found that suspending the subwoofers with the array provides audible benefit. Additionally, many venues lack

physical space for floor-mounted subs. For these reasons, the WL118-sw includes rigging hardware and, with selection of the appropriate rigging accessories, subwoofers may be flown at the top of or behind a WL2082-i array.

WL118-sw Subwoofer

Rigging straps1.

Grille2.

Handles3.

Rigging strap retaining bolts4.

Input panel 5.

NL8 and NL4 Speakon™ connectors6.

1

6

2

3

4

5

Rigging

Rigging the Installation Line Array is simple and flexible. Enclosures are bolted together with the provided M8 shoulder bolts or pinned together with

optional quick-release ball-lock pins.

The FB2082-i array frame supports most flown array applications, and the EB2082-i extension bar supports suspension where the center of gravity

is beyond the limits of the FB2082-i. Additionally, the EB2082-i is used for arrays where subwoofers are flown behind the main array. The PB2082-i

pull-back bar is used for pulling back the bottom element of the array for aiming and stability or as the primary suspension component for certain

small arrays.

Ground stacking is easily accomplished using the GS115-sw ground stack kit. The kit includes two ground stack rails which attach to the rigging straps

under the WL118-sw. These rails provide added stability and allow for ground stacked arrays to be constructed.

3

Introduction (continued)

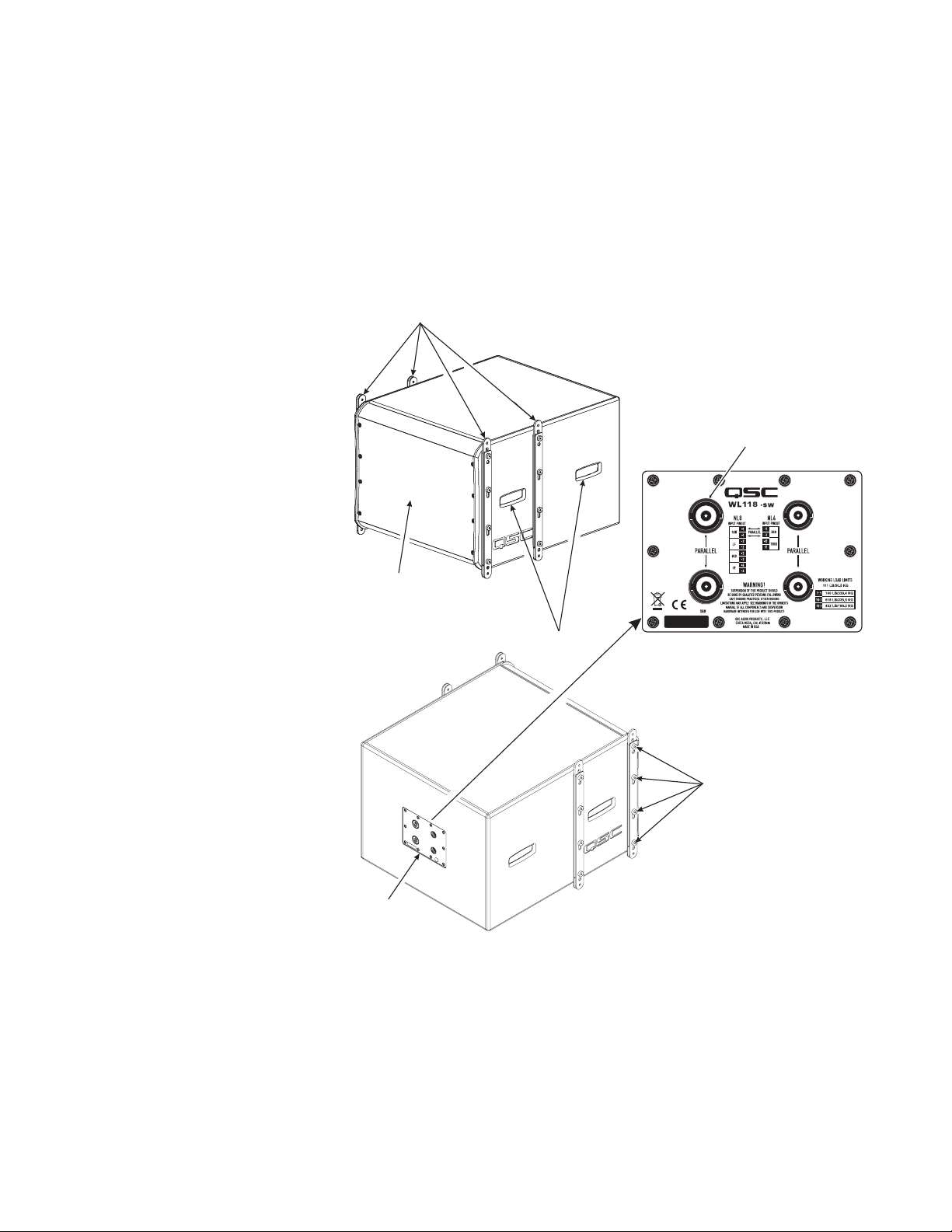

FB2082-i Array Frame

Shackle holes (accept 3/41. " (20 mm) screw pin anchor shackle)

Center support bar2.

Rigging plates3.

Rigging plate retaining bolts4.

Rigging plate attachment holes5.

WARNING! Use only shackle holes for suspension of array!

1

3

4

5

2

PB2082-i Pull-Back Bar

Shackle hole (accepts 5/81. " (16 mm) screw pin anchor shackle)

Rigging plate attachment holes2.

Rigging plates3.

Rigging plate retaining bolts4.

WARNING! Use only shackle hole for suspension of array!

EB2082-i Extension Bar

Extension bar1.

Rigging plate retaining bolts2.

Shackle holes (accept 3/43. " (20 mm) screw pin anchor shackle)

Rigging plates4.

WARNING! Use only shackle hole for suspension of array!

1

2

3

1

4

3

2

4

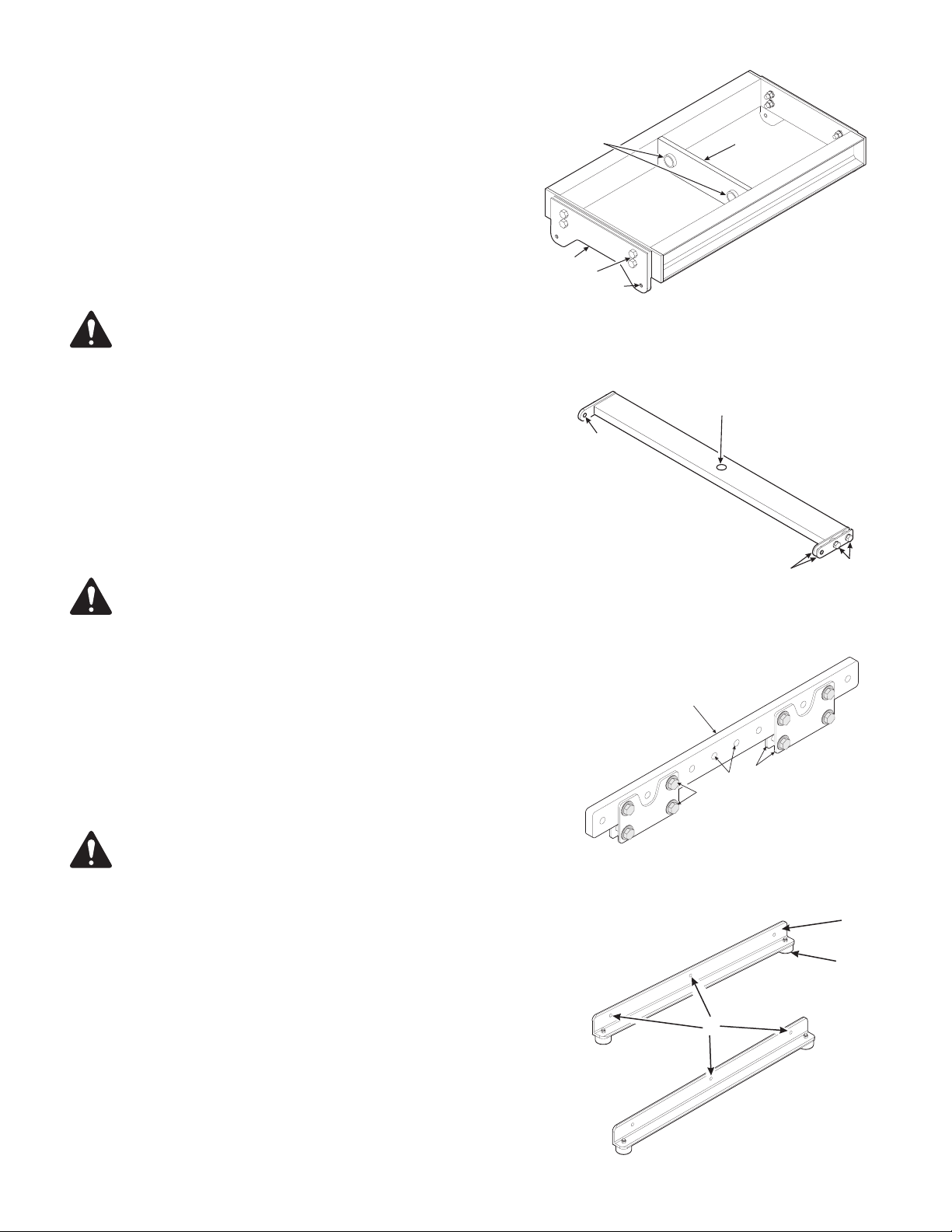

GS115-sw Ground Stack Kit

Rail1.

Rubber foot2.

Attachment holes3.

1

2

3

4

6

Rigging the Installation Line Array

Rules for Suspension

Correct use of all suspension hardware and components is imperative in sound system rigging and deployment.•

Always calculate suspended loads before lifting to ensure suspension components and hardware are used within their respective load limits.•

Research local codes and regulations to fully understand the requirements for suspended loads in the venue in which the equipment is •

to be suspended.

Use only shackle holes for suspension of array.•

Be absolutely certain of the integrity of any structural member intended to support suspended loads. Hidden structural members can have hidden •

structural weakness.

Consult a Professional Mechanical or Structural Engineer licensed in the jurisdiction of the sound system installation to review, verify, and approve •

all attachments to the building or structure.

Never assume anything• —owner or third-party supplied suspension attachment points may not be adequate for the loads to be suspended.

Employ the services of a Professional Rigger for hoisting, positioning, and attaching the equipment to the supporting structure.•

Always inspect all components (enclosures, suspension brackets, pins, frames, bolts, nuts, slings, shackles, etc.) for cracks, wear, deformation, •

corrosion, missing, loose, or damaged parts that could reduce the strength of the assembly before lifting. Discard any worn, defective, or suspect

parts and replace them with new appropriately load-rated parts.

Shock Loading

When a load is either moved or stopped, its static weight is magnified. Sudden movements can magnify the static weight several times. This

magnification of static weight is termed “shock loading.” Shock loading poses a danger to equipment and workers. The effects of shock loading can

be instantaneous, or they may remain undetected unless the equipment is visually damaged. Avoiding shock loading requires careful planning and

knowledge of equipment, rigging, and lifting practices.

Shock loading of equipment and structures is usually confined to lifting and installation, but natural forces (winds, earthquakes) can impose shock

loads several times the static load. This is why structures and suspension equipment must be capable of supporting several times the weight of the

equipment suspended.

ILA Working Load Limits and Design Factors

The following table lists ILA suspension components and provides Working Load Limit data at various Design Factors. The tabulated Design Factors are

for static loads only. The choice of which Design Factor to use will depend upon the jurisdiction and venue of installation, as well as the conditions of

suspension. Dynamic conditions are determined by unknown, installation-specific factors and should be referred to a Licensed Structural Engineer for

clarification before proceeding with any suspension of the equipment. The data presented is based upon the listed component weights:

Table 1: ILA Working Load Limits

Component Weight 7:1 Design Factor 10:1 Design Factor 12:1 Design Factor

EB2082-i Extension Bar 38 lb (17.3 kg) 1714 lb (779.2 kg) 1200 lb (545.5 kg) 1000 lb (454.5 kg)

FB2082-i Array Frame 17 lb (7.7 kg) 740 lb (336.4 kg) 518 lb (235.5 kg) 432 lb (196.2 kg)

PB2082-i Pull-Back Bar 6 lb (2.7 kg) 423 lb (192.2 kg) 296 lb (134.5 kg) 247 lb (112.1 kg)

WL2082-i Loudspeaker 37 lb (16.8 kg) 634 lb (288.3 kg) 296 lb (134.5 kg) 371lb (168.6 kg)

WL118-sw Loudspeaker 111 lb (50.5 kg) 740 lb (336.4 kg) 518 lb (235.5 kg) 432 lb (196.2 kg)

M8 Shoulder Bolt

M8 Ball-lock Pin

M8 Locking Plate

M12 Shoulder Bolt

3/8" Fastener

7/8" Fastener

1- Working Load Limits are per fastener loaded in double shear. Data is for informational purposes only.

1

1

1

1

1

1

N/A 1003 lb (455.8 kg) 702 lb (319.1 kg) 585 lb (265.9 kg)

N/A 1810 lb (822.7 kg) 1267 lb (575.9 kg) 1056 lb (479.9 kg)

N/A 1286 lb (584.4 kg) 900 lb (409.1 kg) 750 lb (340.9 kg)

N/A 4744 lb (2156.3 kg) 3321 lb (1509.4 kg) 2767 lb (1257.8 kg)

N/A 1943 lb (883.4 kg) 1360 lb (618.4 kg) 1134 lb (515.3 kg)

N/A 8110 lb (3686.4 kg) 5677 lb (2580.5 kg) 4731 lb (2150.4 kg)

5

Loading...

Loading...