Page 1

9800 Martel Road

Lenoir City, TN 37772

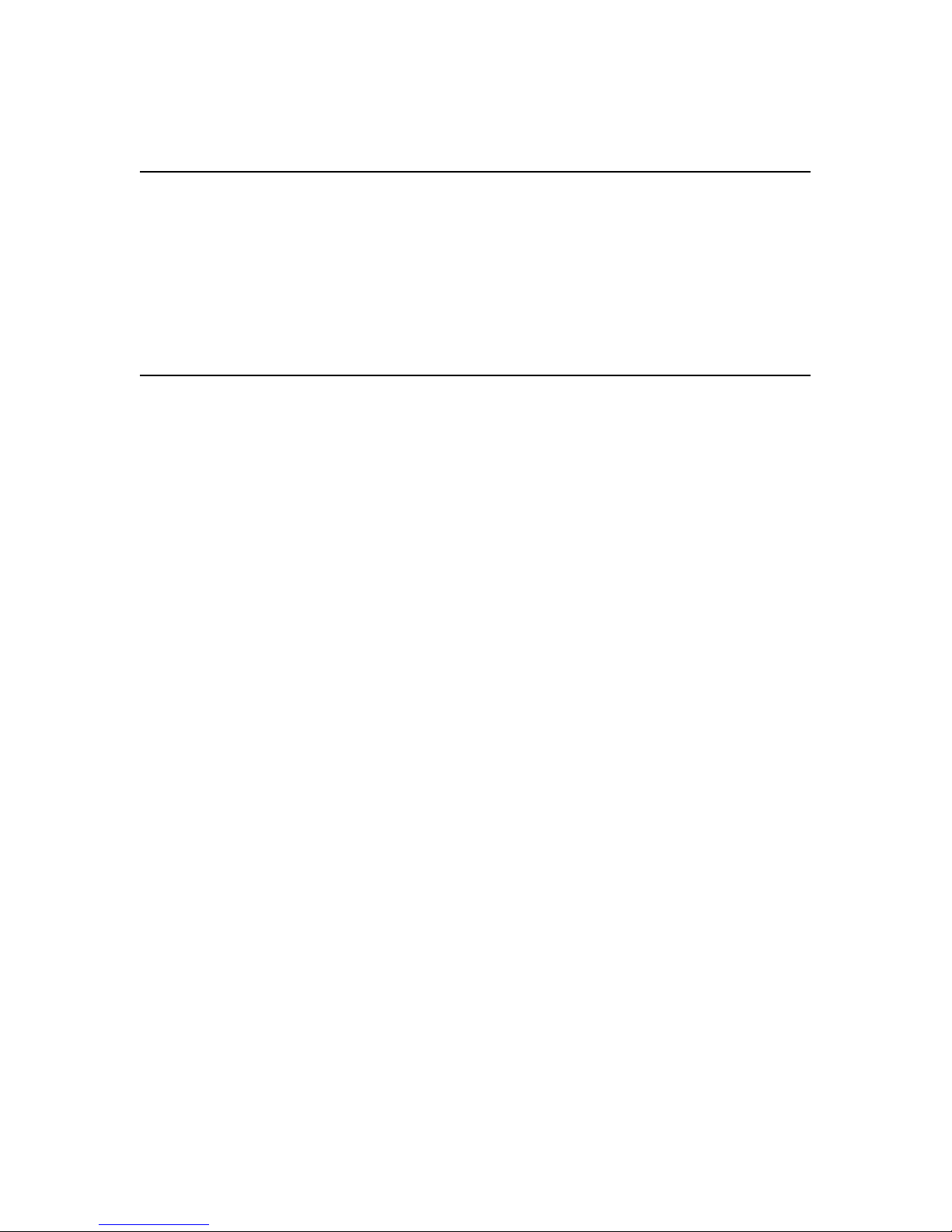

PMA7000S

PMA7000M-S

with Options

Com 1/2

V

o

l

u

m

e

O

M

I

Push

(Fail-Safe)

High

Com 1 Nav 1

Low

Test

Iso

All

Crew

Nav 2Com 2

ENGINEERING

INCORPORATED

Com 1

MKR ADF

AUXICS

R

PMA7000M-S

DME

SPR

Com 2

Com 3

Transmit Swap

Document P/N 200-070-0006

Revision 6, Nov 1998

FAA-Approved TSO C50c, C35d

High-fidelity Stereo Audio Selector Panel

Intercom System

Installation and Operation Manual

In certified aircraft, warranty is not valid unless this product is installed by

an Authorized PS Engineering dealer.

Com 2/1

Tel

Any reproduction or retransmittal of this publication, or any portion thereof, without the expressed written permission of PS

Engineering, Inc. is strictly prohibited. For further information contact the Publications Manager at PS Engineering, Inc., 9800

Martel Road, Lenoir City, TN 37772. Phone (423) 988-9800

PS Engineering, Inc. 1998 ©

Copyright Notice

Page 2

Table of Contents

1 SECTION I GENERAL INFORMATION ..................................................................... 1-1

1.1 INTRODUCTION ..................................................................................................... 1-1

1.2 SCOPE .......................................................................................................................1-1

1.3 EQUIPMENT DESCRIPTION.................................................................................1-1

1.4 APPROVAL BASIS - FAA........................................................................................ 1-2

1.5 SPECIFICATIONS.................................................................................................... 1-3

1.6 EQUIPMENT SUPPLIED......................................................................................... 1-4

1.7 EQUIPMENT REQUIRED BUT NOT SUPPLIED................................................. 1-4

1.8 LICENSE REQUIREMENTS ................................................................................... 1-4

2 SECTION II - INSTALLATION .................................................................................... 2-1

2.1 GENERAL INFORMATION.................................................................................... 2-1

2.1.1 SCOPE.................................................................................................................. 2-1

2.1.2 CERTIFICATION REQUIREMENTS............................................................................. 2-1

2.2 UNPACKING AND PRELIMINARY INSPECTION............................................................ 2-1

2.3 EQUIPMENT INSTALLATION PROCEDURES ................................................................ 2-2

2.3.1 COOLING REQUIREMENTS ...................................................................................... 2-2

2.3.2 MOUNTING REQUIREMENTS ................................................................................... 2-2

2.3.3 MOUNTING RACK INSTALLATION ........................................................................... 2-2

2.3.4 CONNECTOR ASSEMBLY......................................................................................... 2-2

2.4 CABLE HARNESS WIRING .......................................................................................... 2-2

2.4.1 NOISE .................................................................................................................... 2-3

2.4.2 EXISTING KMA-24 INSTALLATION ......................................................................... 2-3

2.4.3 EXISTING PMA6000 INSTALLATIONS...................................................................... 2-3

2.4.4 POWER................................................................................................................... 2-4

2.4.5 EXTERNAL PUSH-TO-TALK..................................................................................... 2-4

2.4.6 TRANSMIT INTERLOCK........................................................................................... 2-4

2.4.7 "SWAP" MODE ....................................................................................................... 2-4

2.4.8 BACKLIGHTING ...................................................................................................... 2-4

2.4.9 UNSWITCHED INPUTS ............................................................................................. 2-5

2.4.10 INTERCOM WIRING................................................................................................2-5

2.4.11 COM 3 AUDIO.......................................................................................................2-6

2.4.12 PA MUTE (J1, PIN 18).......................................................................................... 2-6

2.4.13 VOX OVERRIDE (J2, PIN U)................................................................................. 2-6

2.4.14 IRS INSTALLATION (OPTION 1, AND 2) ................................................................. 2-7

2.4.15 AUDIO MESSAGE INSTALLATION (OPTION 1 AND 2 ONLY)..................................... 2-7

2.5 MARKER INSTALLATION (PMA7000M-S) ................................................................. 2-7

2.5.1 MIDDLE MARKER SENSE........................................................................................ 2-7

2.5.2 EXTERNAL MARKER LIGHTS (7000MS).................................................................. 2-8

2.5.3 MARKER ANTENNA INSTALLATION......................................................................... 2-8

2.5.4 MARKER INPUT (7000, 7000S)............................................................................... 2-8

2.6 ADJUSTMENTS ............................................................................................................ 2-8

2.7 COMMUNICATIONS ANTENNA INSTALLATION NOTES............................................... 2-8

2.8 WIRELESS TELECOMMUNICATIONS INTERFACE........................................................ 2-9

2.8.1 HOOK SWITCHES.................................................................................................... 2-9

2.9 PMA7000M-S PIN ASSIGNMENTS ............................................................................ 2-11

Page 3

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

2.10 POST INSTALLATION CHECKOUT........................................................................... 2-12

2.11 UNIT INSTALLATION............................................................................................... 2-12

2.11.1 OPERATIONAL CHECKOUT.................................................................................. 2-12

2.11.2 RECEIVER SENSITIVITY....................................................................................... 2-13

2.12 CELLULAR INTERFACE CHECKOUT ....................................................................... 2-13

2.13 INTERNAL RECORDER CHECKOUT......................................................................... 2-13

2.14 DIGITAL ANNUNCIATION CHECKOUT.................................................................... 2-14

2.15 FINAL INSPECTION.................................................................................................. 2-14

3 SECTION III OPERATION .......................................................................................... 3-1

3.1 SCOPE .......................................................................................................................3-1

3.2 AUDIO SELECTOR (ALL MODELS).............................................................................. 3-1

3.2.1 SPEAKER AMPLIFIER .............................................................................................. 3-2

3.3 POWER SWITCH (FAIL SAFE OPERATION)................................................................. 3-2

3.4 MICROPHONE SELECTOR........................................................................................... 3-2

3.4.1 SWAP MODE (SWITCH FROM COM 1 TO COM 2 REMOTELY) ................................... 3-3

3.5 SPLIT MODE ............................................................................................................... 3-3

3.5.1 SPLIT MODE ICS.................................................................................................... 3-3

3.6 INTERCOM .................................................................................................................. 3-4

3.6.1 INTELLIVOX™ VOX-SQUELCH ............................................................................... 3-4

3.6.2 VOLUME CONTROL ................................................................................................ 3-4

3.6.3 INTERCOM MODES................................................................................................. 3-5

3.7 TELEPHONE MODE..................................................................................................... 3-6

3.8 MARKER BEACON (PMA7000M-S)............................................................................ 3-7

3.9 INTERNAL RECORDER SYSTEM (OPTION 1 AND 2 ONLY).......................................... 3-7

3.9.1 OPERATION............................................................................................................ 3-8

4 SECTION IV- WARRANTY AND SERVICE ............................................................... 4-1

4.1 WARRANTY................................................................................................................. 4-1

4.2 FACTORY SERVICE ..................................................................................................... 4-1

5 APPENDIX A EXTERNAL PTT HOOK UP ................................................................... A

6 APPENDIX B – INSTALLATION DRAWING ................................................................ B

7 APPENDIX C BOTTOM CONNECTOR INTERCONNECT ......................................... C

8 APPENDIX D TOP CONNECTOR INTERCONNECT ................................................... D

9 APPENDIX E- INSTRUCTIONS FOR FAA FORM 337 AND CONTINUING

AIRWORTHINESS ................................................................................................................. E

9.1 INSTRUCTIONS FOR FAA FORM 337, AUDIO PANELS................................................... E

INSTRUCTIONS FOR CONTINUING AIRWORTHINESS, AUDIO PANELS ................. E

10 APPENDIX F RTCA DO160C ENVIRONMENTAL QUALIFICATION FORM ......... F

200-070-0006 Page ii Rev 5, Nov 98

Page 4

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

1 Section I GENERAL INFORMATION

1.1 INTRODUCTION

The PMA7000M-S represents the next step in cockpit audio control and intercommunications. Using proprietary IntelliVox™ design, this unit eliminates the requirements for intercom squelch adjustments. The unit is designed for outstanding ergonomics and visually

defined mode annunciation and selection.

Before installing and/or using this product, please read this manual completely. This will

ensure that you will take full advantage of all the advanced features in the PMA7000M-S.

1.2 SCOPE

This manual provides detailed installation and operation instructions for the PS Engineering PMA7000M-S-series of Audio Selector Panel/Intercom Systems. This includes the

following units:

Model Description Part Number

PMA7000S Stereo Audio Selector Panel 7000S

PMA7000M-S Stereo Audio Panel with Marker 7000MS

Option 1 added to any unit Same as above, with optional recorder and mes-

sage system

Option 2 added to any unit Same as above, with optional recorder and mes-

sage system for Vista Map Software

Option 3 added to any system Black bezel (no silver trim) Opt 3

Opt.1

Opt 2

Where the functions are identical to all units, it will be referred to herein as a PMA7000MS. Otherwise, the applicable units will be specified.

1.3 EQUIPMENT DESCRIPTION

The PMA7000M-S-series is a state of the art audio isolation amplifier and audio selector

that contains an automatic voice activated (VOX) intercom system. It can switch up to

three transceivers (Com 1, Com 2 and Com 3) and six receivers (Nav 1, Nav 2, ADF,

DME, MKR and AUX).

The TEL mode allows the PMA7000M-S to act as an audio interface between aircraft

headphone and microphones and specific aircraft approved (FAA/FCC) cellular telephone

equipment.

Warning

: Use of non-aviation approved cellular telephone equipment is prohibited by regul ation.

PS Engineering is not responsible for unauthorized use of cellular telephones.

The PMA7000M-S is only interfaced to the Trimble TrimConnect 3100 D at this time.

There are two unswitched inputs, for autopilot disconnect, and/or radar altimeter warning.

Push buttons select the receiver audio source provided to the headphones. A SPR button

200-070-0006 Page 1-1 Rev. 6, Nov 98

Page 5

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

allows the user to listen to the receiver(s) selected on the cabin speaker. Except for the

unswitched inputs, all speaker audio is muted during transmit.

A rotary switch selects one of the three communication transceivers for the pilot and copilot position, and allows radio transmission. In "Split Mode" the PMA7000M-S has the

ability to allow the pilot and copilot to operate different transceivers independently. The

TEL mode allows the pilot to use the cellular telephone interface. External switches permit telephone operation for the copilot and passengers.

A fail-safe mode connects the pilot headphone and microphone to COM 1 if power is removed for any reason, or if the power switch is placed in the Off (Fail-safe) position.

A six-station voice activated (VOX) intercom is included in the PMA7000M-S. This system has PS Engineering’s exclusive IntelliVox™ circuitry that eliminates manual adjustments. The system contains six separate VOX mic circuits, and only opens the microphone

channel in use.

The intercom system incorporates pilot isolate and crew modes, two stereo (or mono depending on unit) music inputs with "Soft Mute," and LED indicators for swap and transmit indications. Intercom control is through front panel-mounted knob and 3 position

mode switch. A single volume controls intercom level for the pilot and copilot. Passenger

headphone volume is factory set, and adjusted in flight with headset-mounted volume

controls. Passenger volume control is further adjustable through screwdriver access in the

top of the unit. Intercom squelch is automatic.

An optional 3-light Marker Beacon receiver is integrated in the PMA7000M-S. This provides the necessary Marker Beacon lights and audio indications necessary for an Instrument Landing System (ILS) approach.

1.4 APPROVAL BASIS - FAA

TSO Approval.

The PMA7000M-S, and PMA7000S Audio Selector Panels are FAA approved under

TSO C50c (Audio Amplifiers) and TSO C35d (Marker Beacon Receivers).

All systems comply with relevant portions of RTCA DO-143 (Marker Beacon Receivers),

DO-160C (Environmental Conditions and Test Procedures for Airborne Equipment),

DO-178B (Software Considerations for Airborne Equipment) and DO-214 (Audio Sys-

tems Characteristics and Minimum Operational Performance Standards for Aircraft

Audio Systems).

NOTE: The optional message annunciators contained in Option 1 and Option 2 are not

TSO-approved, and the installer must determine the relevant approval basis prior to installation. Contact PS Engineering for information regarding FAA approval.

200-070-0006 Page 1-2 Rev. 6, Nov 98

Page 6

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

Operation is subject to the following conditions:

This device may not cause harmful interference.

This device must accept any interference received, including interference that may cause

undesired operation.

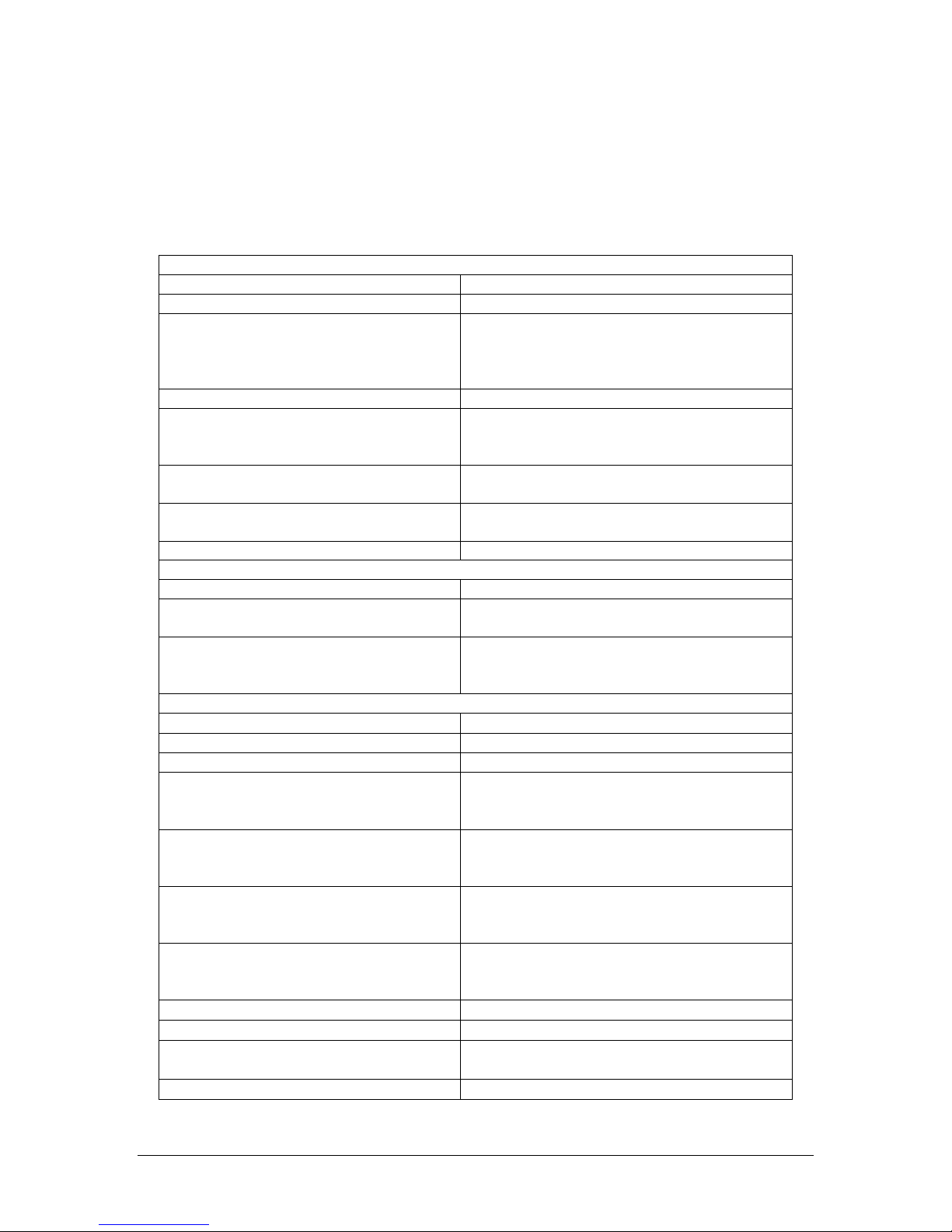

1.5 SPECIFICATIONS

TSO COMPLIANCE

Marker Beacon: C35d, Class A

Audio Selector/Intercom: C50c, Class A

APPLICABLE DOCUMENTS: RTCA/DO-214

RTCA/DO-143

RTCA/DO-160C

RTCA/DO-178B

ENVIRONMENTAL Qualifications: A1D1/CA(MN)XXXXXXBBBBTBKXX

Temperature Range:

Operating:

Storage:

Altitude: Up to 50,000 feet in an unpressurized area of the

DIMENSIONS: Height: 1.3 in. (3.3 cm) Width: 6.25 in. (16.9 cm)

WEIGHT (With Rack & Connectors): 1.5 lb. (0.54 kg)

POWER REQUIREMENTS (Including Internal Lighting):

Voltage: 11 to 33 VDC

Maximum Current: 1.5 Amp (Externally protected by a 3 Amp circuit

Typical operating current:

Speaker off:

Speaker on, 28V, full radio volume

Audio Selector Specifications

Audio selector panel input impedance:

Input Isolation: -60 dB (min.)

Speaker Muting: -60 dB (min.)

Speaker Output (into 4 Ω) with no clipping

14 VDC:

28 VDC:

Receiver Inputs: 9

Unswitched Inputs: 2

Transmitter Selections: 6

Speaker Impedance:

Headphone Impedance:

Headphone Output: 38 mW each headset, no clipping <1% THD

Microphone Impedance:

-20º C to 55ºC

-40º C to 85ºC

cockpit.

Depth: 6.8 in. (17.3 cm)

breaker.)

350 mA

1.5 A

510 Ω

3 Watts (min.)

10 Watts (min.)

(Com 1, Com 2, Com 3, Nav 1, Nav 2, ADF,

DME, MKR, AUX)

(examples: GPS WPT, Value, Autopilot Disconnect, Altimeter DH)

(Com 1, Com 2, Com 3

Com1/2, Com2/1, Telephone)

4 Ω

150 - 1000 Ω

70 mW each headset with < 10% THD into 150Ω

150 - 600 Ω

200-070-0006 Page 1-3 Rev. 6, Nov 98

Page 7

PMA7000M-S Series Audio Selector Panel and Intercom System

Intercom Positions: 6 places (with individual IntelliVOX circuits)

Music Inputs: 2 (Stereo)

Music Muting: >-50 dB "Soft Mute" when Com or intercom ac-

Distortion:

Mic Freq. Response, 3 dB: 300 Hz - 6000 Hz

Music Freq. Response, 3 dB: 100 Hz - 18kHz

MARKER BEACON RECEIVER:PMA7000M-S only

Frequency: 75 MHz Crystal Controlled

Sensitivity:

Low:

High:

Selectivity: -6 dB at ±110 kHz

External Lamp Output: 9.0 (±2.5 photocell dimmed) VDC positive when

MM Sense: Active high (4.7 VDC ± 0.5V) during Middle

PS Engineering

Installation and Operator’s Manual

Intercom Specifications

tive.

<1% THD @ 38 mW into 150Ω

<10% THD @ 70mW into 150 Ω

1000 µVolts (Hard)

200 µVolts (Hard)

(Field Adjustable)

-40 dB at ±120 kHz

active, max. current 125 mA

Marker acquisition, for autopilot use.

1.6 EQUIPMENT SUPPLIED

1 ea. of the following units:

Model Part Number

PMA7000S 7000S

PMA7000M-S 7000M-S

PMA7000M-S Installation Kit: 250-007-002

Part Number Description Quantity

001-006-0001 Tray with (2) 44 Pin Connectors 1

655-000-0001 Gold Plated Crimp Pins 88

200-070-0001 Operator's and Installation Manual 1

1.7 EQUIPMENT REQUIRED BUT NOT SUPPLIED

a) Circuit Breaker: 1 ea. 2 amp. (14V) or 3 amp (28V)

b) Speaker, 4 Ω

c) Headphone Jacks (mono or stereo, as Required)

d) Microphone Jacks (as Required)

e) Headphones, 150 Ω (mono or stereo), up to 6 as required

f) Microphones, up to 6 as required

g) Marker Antenna (75 MHz, VSWR <1:1.5, and appropriate for the airspeed)

h) Interconnect Wiring

1.8 LICENSE REQUIREMENTS

None

200-070-0006 Page 1-4 Rev. 6, Nov 98

Page 8

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

2 Section II - Installation

2.1 GENERAL INFORMATION

2.1.1 SCOPE

This section provides detailed installation and interconnect instructions for the PS Engineering PMA7000S-Series Audio Selector Panel/Intercom System and PMA7000M-SSeries Audio Selector Panel/Intercom System with internal Marker Beacon.

With the exception of the internal marker beacon receiver, the PMA7000S, and

PMA7000M-S are identical. All units will be identified hereafter as the PMA7000M-S,

where the information applies to all.

Please read this manual carefully before beginning any installation to prevent damage and

post-installation problems. Installation of this equipment requires special tools and knowledge.

NOTE: An appropriately rated Certified Aircraft Repair Station must install this equipment in accordance with applicable regulations. PS Engineering, Incorporated warranty is

not valid unless the equipment is installed by an authorized PS Engineering, Incorporated

dealer. Failure to follow any of the installation instructions, or installation by a noncertified individual or agency will void the warranty, and may result in an unairworthy installation.

2.1.2 Certification Requirements

When the digital audio warning system is installed in a certified aircraft, certification basis

is the installer’s responsibility. Due to the variety and options available for interface, PS

Engineering, will only provide manufacturers data for our equipment interface. Contact PS

Engineering for more details.

2.2 Unpacking and Preliminary Inspection

Use care when unpacking the equipment. Inspect the units and parts supplied for visible

signs of shipping damage. Examine the unit for loose or broken buttons, bent knobs, etc.

Verify the correct quantity of components supplied with the list in Section 1.6 (B). If any

claim is to be made, save the shipping material and contact the freight carrier. Do NOT

return units damaged in shipping to PS Engineering. If the unit or accessories shows any

sign of external shipping damage, contact PS Engineering to arrange for a replacement.

Under no circumstances attempt to install a damaged unit in an aircraft. Equipment returned to PS Engineering for any other reason should be shipped in the original PS Engineering packaging, or other UPS approved packaging.

200-070-0006 Page 2-1 Rev. 6, Nov 98

Page 9

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

2.3 Equipment Installation Procedures

2.3.1 Cooling Requirements

Forced air cooling of the PMA7000M-S is not required. However the unit should be kept

away from heat producing sources (i.e. defrost or heater ducts, dropping resistors, heat

producing avionics) without adequate cooling air provided.

2.3.2 Mounting Requirements

The PMA7000M-S must be rigidly mounted to the instrument panel of the aircraft structure and within view and reach of the pilot position(s). Installation must comply with FAA

Advisory Circular AC 43.13-2A. The unit may be mounted in any area where adequate

clearance for the unit and associated wiring bundle exist.

Avoid installing the audio panel close to high current devices or systems with high-voltage

pulse type outputs, such as DME or transponders.

NOTE: The mounting hole configuration for the PMA7000M-S is identical to the

PMA6000 series and KMA-24 Audio Selector Panels.

2.3.3 Mounting Rack Installation

Remove the unit from the mounting tray by unscrewing the 3/32" hex-head screw that is in

the center of the unit. Use caution to avoid hitting the photo-detector lens. Carefully slide

the unit free of the tray. Set the unit aside in a safe location until needed. Install the tray

using six FHP 6-32 x ½" screws. The audio selector panel must be supported at front and

rear of the mounting tray.

2.3.4 Connector Assembly

The unit connectors mate directly with the circuit boards in the PMA7000M-S. The connectors are a Molex crimp-type, and require the use of a Molex hand crimp tool, EDP P/N

11-01-0203, CR6115B (or equiv.). The connectors are mounted to the unit tray with #440 screws, from the inside of the tray. Ensure that proper strain relief and chafing precautions are made during wiring and installation.

2.4 Cable Harness Wiring

Referring to the appropriate Appendix, assemble a wiring harness as required for the installation. All wires must be MIL-SPEC in accordance with current regulations. Two- and

three-conductor shielded wire must be used where indicated, and be MIL-C-27500 or

equivalent specification. Proper stripping, shielding and soldering technique must be used

at all times. It is imperative that correct wire be used.

Refer to FAA Advisory Circular 43.13-2A for more information. Failure to use correct

techniques may result in improper operation, electrical noise or unit failure. Damage

caused by improper installation will void the PS Engineering warranty.

200-070-0006 Page 2-2 Rev. 6, Nov 98

Page 10

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

2.4.1 Noise

Due to the variety and the high power of radio equipment often found in today's general

aviation aircraft, there is a potential for both radiated and conducted noise interference.

The PMA7000M-S power supply is specifically designed to reduce conducted electrical

noise on the aircraft power bus by at least 50dB. Although this is a large amount of attenuation, it may not eliminate all noise, particularly if the amplitude of noise is very high.

There must be at least 13.8 VDC present at the bottom connector, pin 20, of the

PMA7000M-S for the power supply to work in its designed regulation. Otherwise, it cannot adequately attenuate power line noise. Shielding can reduce or prevent radiated noise

(i.e., beacon, electric gyros, switching power supplies, etc.) However, installation combinations can occur where interference is possible. The PMA7000M-S was designed in a

RFI hardened chassis and has internal Electromagnetic Interference (EMI) filters on all

inputs and outputs.

Ground loop noise occurs when there are two or more ground paths for the same signal

(i.e., airframe and ground return wire). Large cyclic loads such as strobes, inverters, etc.,

can inject noise signals onto the airframe that are detected by the audio system. Follow the

wiring diagram very carefully to help ensure a minimum of ground loop potential. Use

only Mil Spec shielded wires (MIL-C-275000, or better).

Radiated signals can be a factor when low level microphone signals are "bundled" with

current carrying power wires. Keep these cables physically separated. It is very important

that you use insulated washers to isolate the ground return path from the airframe to all

headphone and microphone jacks.

2.4.2 Existing KMA-24 Installation

If the installation replaces a KMA-24 (series -01, -02 or -03), the existing 44 pin connector can be used for the bottom connector of the PMA7000M-S tray as is, providing it is

properly installed and wired. No other changes are required except for external marker

lights (see Section 3.7.2 for details). The "key" in the existing connector must be located

between pins 7 and 8. This connector will be used in the bottom connector position. (See

Appendix for complete wiring harness details.)

The existing ground bus may be reused for radio shield connections, if it was constructed

so it can be relocated to the PMA7000M-S tray.

2.4.3 Existing PMA6000 installations

In 28-Volt aircraft, the dropping resistor may be removed, however, the 2 Amp breaker

should be changed to 3 Amp. If both old unit is stereo (PMA6000S or PMA6000MS), no

rewiring is necessary unless additional features are added.

200-070-0006 Page 2-3 Rev. 6, Nov 98

Page 11

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

2.4.3.1 Stereo PMA7000M-S installations into monaural PMA6000, PMA6000M.

Installations replacing PMA6000 or PMA6000M require re-wiring of the top connector to

accommodate the stereo configuration. See appendixes for detailed interconnect information.

2.4.4 Power

The PMA7000M-S-Series are compatible with both 14 and 28 Volt DC systems. A two

(2) Amp circuit breaker is required for 14 VDC installations, and a three (3) Amp breaker

for 28 VDC aircraft. Power and ground wires must be a twisted #18 AWG pair. Connect

airframe power ground to J1 (bottom connector) Pin Z only. No dropping resistors are

required.

2.4.5 External Push-to-Talk

An important part of the installation is the PTT (Push-To-Talk) switches that allow the

use of your aircraft communications radio for transmissions. There are three typical configurations that can be used. Select the case that best fits the installation. Only the person

who presses their PTT switch will be heard over the radio. If the pilot and copilot both use

the PTT, the only pilot position has access to the radio. The pilot position will have PTT

control regardless of the mic selector switch or copilot PTT when the PMA7000M-S is in

the FAIL-SAFE mode.

CASE I: PTT is built into both pilot and copilot yokes.

CASE II: PTT is in pilot yoke only. This configuration requires a modified external PTT

switch plugged into the copilot's microphone jack. (See Appendix A). When the copilot's

PTT is pressed, the intercom switches the microphone audio from pilot to copilot mic.

CASE III: No built in PTT. This requires two built in PTTs to be installed, or modified

external PTT switches to be used. Modify external PTT as required (See Appendix A).

2.4.6 Transmit Interlock

Some communications transceivers use a transmit-interlock system. To fully utilize the

Split Mode feature, this function must be disabled. Consult that manufacturer's installation

manual.

2.4.7 "Swap" Mode

When a momentary, normally open, push-button switch is connected between pin 10 on

the top connector and aircraft ground, the user can switch between Com 1 and 2 by depressing this switch without having to turn the mic selector switch. This yoke-mounted

switch eliminates the need to remove your hands from the yoke to change transceivers.

2.4.8 Backlighting

The PMA7000M-S has an automatic dimming of the pushbutton annunciator LEDs and

marker lamps controlled by a photocell. Control of the unit backlighting is through the air-

200-070-0006 Page 2-4 Rev. 6, Nov 98

Page 12

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

craft avionics dimmer. Connect the dimmer control line to J1 pin D for 14 volt systems,

and to J1 pin F for 28 volt systems. Pin E is light ground.

If an external dimmer control is not used, a constant low level back light illumination can

be established for nighttime viewing. Pin D or F (depending on system voltage) must be

tied to power (J1, pin 20) for the back lighting system to work. The photocell mounted in

the unit face will automatically adjust the intensity of the push-button annunciator LEDs.

2.4.9 Unswitched inputs

J1, pin T is the unswitched input number 1 and J1 pin 17 is unswitched input 2. These inputs are presented to the pilot and copilot regardless of the audio configuration, and will

always mute the entertainment inputs. These 510Ù inputs can be used for altimeter DH

audio, GPS waypoint audio, autopilot disconnect tones, air-to-ground (Flitefone) telephone ringer or any other critical audio signal. This input is not related to the cellular telephone interface.

2.4.10 Intercom wiring

The top connector (J2) is for the intercom and additional functions. See Appendix for intercom connection configurations. It is critical to the proper operation of this system to

have this connector wiring made in accordance with these diagrams. Use 2- and 3conductor. MIL-spec cable as shown. Connect the shields at the audio panel end only, and

tie to the audio low inputs as shown.

NOTE: The top connector harness can be custom made by PS Engineering, Inc. Simply

call the factory and obtain a wire harness work-sheet. The harness will be made to your

specifications and fully functionally tested. All hardware is included.

2.4.10.1 Entertainment Input

NOTE: Use the low level output of any entertainment device to connect to

the audio panel. Maximum signal level is 1 VAC p-p.

DO NOT use a speaker-level output, this will cause internal damage in the

audio panel

2.4.10.1.1 Stereo entertainment (7000S, 7000MS)

Two stereo entertainment devices (CD player, cassette player, etc.) can be connected to

the unit. Install two 1/8-inch stereo jacks in a convenient location so that the pilot can plug

in the entertainment devices into the system. The audio signal at the entertainment input

must be a minimum of 500 mV P-P per channel for optimum music performance.

All entertainment devices must be switched off for both takeoff and landing.

2.4.10.1.2 Entertainment distribution

Entertainment source #1 provides music for the pilot and copilot positions, while entertainment source #2 provides music for the four passenger positions. The PMA7000M-S-

200-070-0006 Page 2-5 Rev. 6, Nov 98

Page 13

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

system incorporates a "Soft Mute" system. This will mute the entertainment devices during ICS or radio conversation.

Any signal appearing in the unswitched audio inputs will always mute the entertainment

sources, even though the passengers may not hear the audio tone itself.

Entertainment inputs #1 and #2 can be paralleled so a single entertainment source can

serve both the passengers and the crew. It is suggested however, that a switch (DPDT) is

installed between the single entertainment device and entertainment input #1. This will allow the pilot and copilot to decide if they hear entertainment while in the Crew mode.

Caution: Local oscillators and internal signals from some entertainment equipment can

cause undesired interference with other aircraft systems. Before takeoff, operate the entertainment devices to determine if there is any adverse effect within the aircraft systems.

If any unusual operation is noted in flight, immediately switch off the entertainment devices.

All entertainment devices must be switched off for both takeoff and landing.

2.4.10.1.3 Entertainment 2 Mute (Pin V)

The ICS button on the PMA7000M-S controls the muting (“Karaoke mode”) of entertainment source #1.

Connecting J2 pin V to ground through a SPST switch places the entertainment #2 music

source into the Karaoke Mode. In this mode, incoming music and intercom conversation

will not mute the music for the passengers’ intercom net. This allows uninterrupted music

during casual conversation and at times when radio communications are of lessor importance.

2.4.11 Com 3 Audio

As installed in the standard configuration, the PMA7000M-S Com 3 audio is placed in the

audio when the mic selector switch is in the Com 3 position (fully CCW). Pushing the receiver selector buttons can monitor Com 1 and Com 2 audio. If monitoring of Com 3 is

desired in the Com 1 or Com 2, connect Com 3 audio in parallel to the AUX input (J1, pin

11).

2.4.12 PA Mute (J1, Pin 18)

Pin 18 of J1 is a TTL logic output that is pulled low during PTT operation. This serves as

an input to external public address system to prevent feedback during transmissions.

2.4.13 VOX Override (J2, Pin U)

Connecting pin U of the PMA7000M-S of J2 to ground will force the IntelliVox™ open.

This can be hooked up as a hot mic switch which will place all microphones on the intercom. This can also be connected through a momentary switch to serve as a VOX test

switch, if desired. Because the IntelliVox™ will close in the presence of a steady tone, this

pin is used in testing to defeat the IntelliVox™ software.

200-070-0006 Page 2-6 Rev. 6, Nov 98

Page 14

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

2.4.14 IRS Installation (Option 1, and 2)

To install the IRS, a momentary push button switch is required. This switch can be located

any where in cockpit convenient to the pilot's reach. The switch must be connected to pin

19 of J2 of the PMA7000M-S.

2.4.15 Audio Message Installation (Option 1 and 2 only)

The audio message installation requires inputs from an external annunciator, such as an

Electronics International engine gage system. A falling edge (input pulled low) when applied to the appropriate pin of the connector will cause the message to be played, repeating every two seconds, until the acknowledge (“ACK”) button is pushed.

Install the “ACK” button in a location convenient to the pilot and copilot position. This

switch is a momentary SPST switch between J2 Pin W and ground.

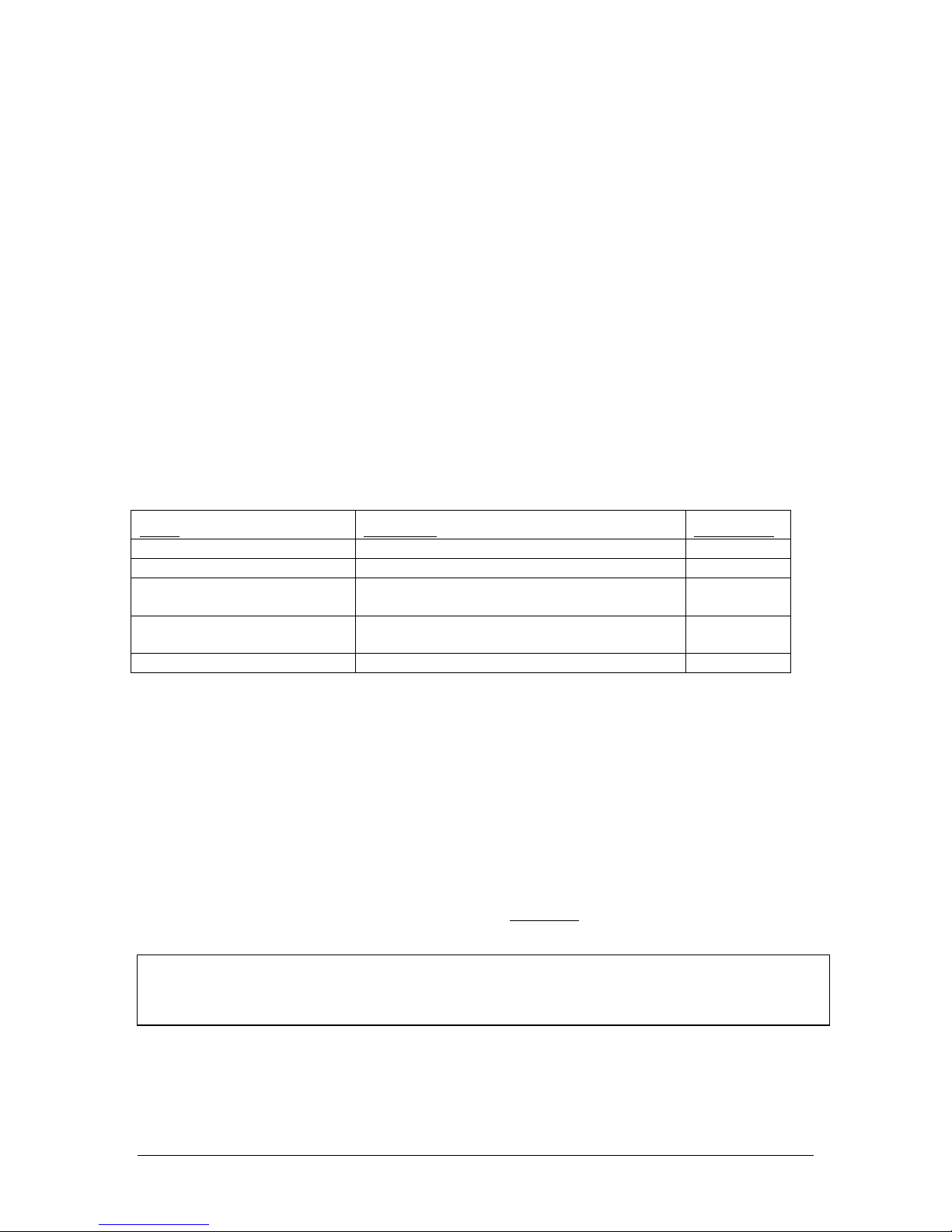

The following table contains information regarding various inputs.

Function EGT or CHT Fuel

Flow or

Level

PMA7000 Pin Z 22 Y 21 X 20

Message Number 1 2 3 4 5 6

Option 1

Message Text “Check tem-

perature”

OPTION 2

Function

Message Text “Check tem-

perature”

“Check

fuel”

“Check

fuel”

Oil Pres-

sure or

tempera-

ture

“Check

oil”

“Check

oil”

Volt/

Amp

“Check

battery”

“Check

battery”

RPM Manifold

“Check engine speed”

Vista Map

System

“Check Vista

Map”

“Check boost”

CHT Cooling

“Shock Cool”

Pressure

Other combinations can be created at additional cost.

NOTE: PS Engineering can only provide input information at this time. Approval basis is

the responsibility of the installer. Contact PS Engineering for more information.

2.5 Marker Installation (PMA7000M-S)

The marker beacon receiver is an option included in the PMA7000M-S. Non-marker

(PMA7000S) units can provide audio interface with the external receiver (see section

2.5.4).

2.5.1 Middle Marker Sense

A Middle Marker sense output signal is available from the 7000M-S to flight control systems. This function will not operate during the test mode. This output will go to +4.7

VDC (± 0.5 VDC) when a valid Middle Marker signal is received. This output is J1, pin 2.

200-070-0006 Page 2-7 Rev. 6, Nov 98

Page 15

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

2.5.2 External Marker Lights (7000MS)

For installations that require external marker beacon lights, there are three outputs that

can drive 12-Volt lamps only. The external output lamps are driven high (+9 VDC ±1.5

VDC) when active. Maximum source current per lamp is 125 mA. Voltage varies with

photocell dimming.

2.5.3 Marker Antenna Installation

Refer to aircraft and antenna manufacturer's installation instructions, as well as AC43.132A (or later revision), Chapter 3, for information on proper antenna installation techniques. The marker beacon antenna must be mounted on the bottom of the aircraft.

2.5.4 Marker Input (7000, 7000S)

If using an external marker receiver, the audio input is J1, pin 21 (MKR. input).

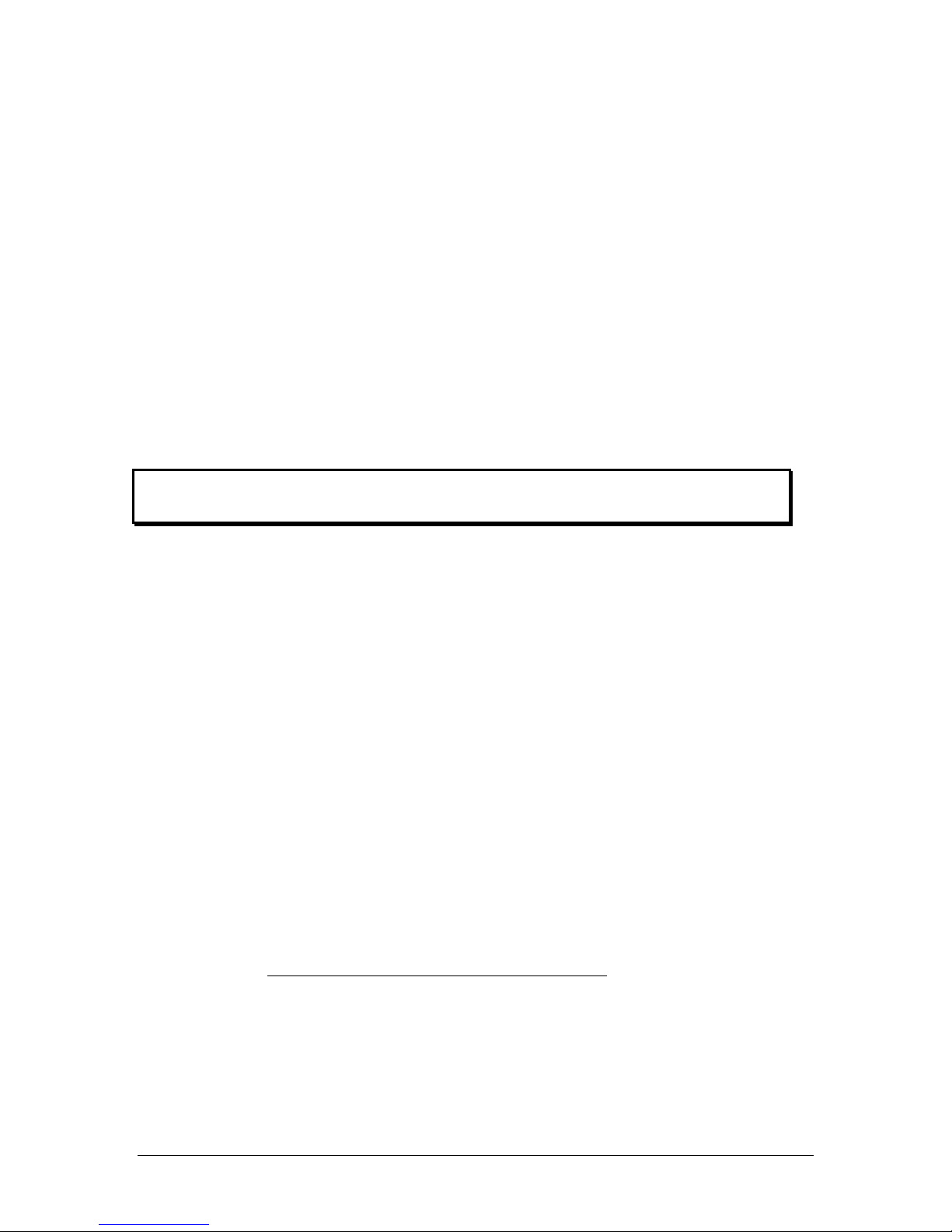

2.6 Adjustments

The PMA7000M-S is factory adjusted to accommodate the typical requirements for most

aircraft configurations. There are five adjustments however, that will allow the installer to

tailor the specific functions.

Marker Gain

CW- Reduce

MKR Low Sense

CW Decrease Sens.

Front of Unit

Speaker Volume

CW-Increase

Marker Audio

CW Decrease Volume

Passenger Volume

CCW Increases

PMA 7000 adjustment holes

Not used

Figure 2-1- PMA7000M-S Adjustments

2.7 Communications Antenna Installation Notes

For best results while in Split Mode, it is suggested that the one VHF communications

antenna is located on top of the aircraft while the other communications antenna is installed on the bottom. Any antenna relocation must be accomplished in accordance with

200-070-0006 Page 2-8 Rev. 6, Nov 98

Page 16

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

AC 43.13-2A, aircraft manufacturers’ recommendations and FAA-approved technical

data.

Warning:

It is probable that radio interference will occur in the split mode when the frequencies of

the two aircraft radios are adjacent, and/or the antennas are physically close together.

PS Engineering makes no expressed or implied warranties regarding the suitability of

the PMA7000M-S in Split Mode.

2.8 Wireless telecommunications interface

The PMA7000M-S has interface capability with units such as the Trimble TrimConnect

3100 D. It is the user’s responsibility to determine the appropriate legal use of the

equiment, and provide the services.

Interface to the 3100 D is through the J1 (bottom) connector, pins 14 and N. Pin 14, labeled cellphone ring, is connected to pin V of the 3100D J3 connector and pin N of J1 is

connected to pin W of the J3 connector. On the TrimConnect interface these are listed as

data/fax lines, but they are used for voice interface in this case.

Use a 2-conductor with shield cable, and connect the shield to Pin M of the 3100 D J3.

If interface is desired with another type of wireless telecommunications unit, the aircraft

owner can purchase an after-market interface cable. By Federal Communications Commission (FCC) regulations, these can only be used on the ground in the United States.

Interface cables manufactured by AXCELL are available from Mobile Quest (800) 8821288, (215) 734-7000 phone, (215) 734-8000 fax. The following is a partial list of available interface cables:

ITEM NUMBER Compatible Phones

AXC AUD STI95 Audiovox Series 5

AXC MOT/FLIP Motorola TeleTAC, DPC 550, DPC65-, Lite Series, Profile Series

AXC MOT/ELITE Motorola Elite, M70, M75, SC-725

AXC MOT/3WATT Motorola Bag Phones, Mobiles

AXC NEC 100 NEC100 Series, 110, 120, 180, Sport

AXC NEC 700/800 NEC 700 & 800 Series

AXC OKI 900/910 OKI 900/910, AT&T 3730/3710

AXC FUJI/PCX OKI 1150/1145, AT&T 3760

AXC FUJI/PCX Fujitsu PCX

AXC MITS 4000/22X Mitsubishi 4000, DiamondTel 22X/20X/18X

AXC NEC 960

AXC NEC DT2000 NEC DT2000 Digital Phone

Unauthorized use of cellular telephone devices in aircraft is subject to FCC enforcement action,

which may include a $10,000 fine per incident. PS Engineering, Inc. does not endorse using unap-

proved cellular telephone equipment in flight, and takes no responsibility for the user’s action.

2.8.1 Hook Switches

While the mic selector acts as the hook switch for the pilot, additional hook switches must

be installed to have full access to the cellphone system. The copilot hook switch is a SPST

switch that connects pin L of J2 on the PMA7000M-S to ground to place the copilot on

the cellphone.

200-070-0006 Page 2-9 Rev. 6, Nov 98

Page 17

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

PMA7000M-S J2, pin M is the passenger hook switch. Install a SPST switch in a location

adjacent to each passenger headset where cellphone use is desired. When pin M is connected to ground through any switch, the passenger microphones are all on the cellphone

system.

The wireless communication “tel” system utilizes an intercom loop. Therefore, any time

the cellphone is in use from the pilot or copilot side, pilot and copilot will lose intercom

capability. In the ALL mode, when the passengers’ activate the cell phone, the pilots will

have intercom, and continue to hear and transmit over the avionics normally. However the

passengers will not have intercom, because they are on the telephone.

To prevent unwanted distractions, only the pilot and copilot will hear an incoming call ring

signal. They can then decide to allow a passenger to activate the hook switch and use the

telephone.

If the pilot has selected “TEL” mode, the passengers cannot access the telephone in the

“CREW” intercom mode, but they will hear the call.

200-070-0006 Page 2-10 Rev. 6, Nov 98

Page 18

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

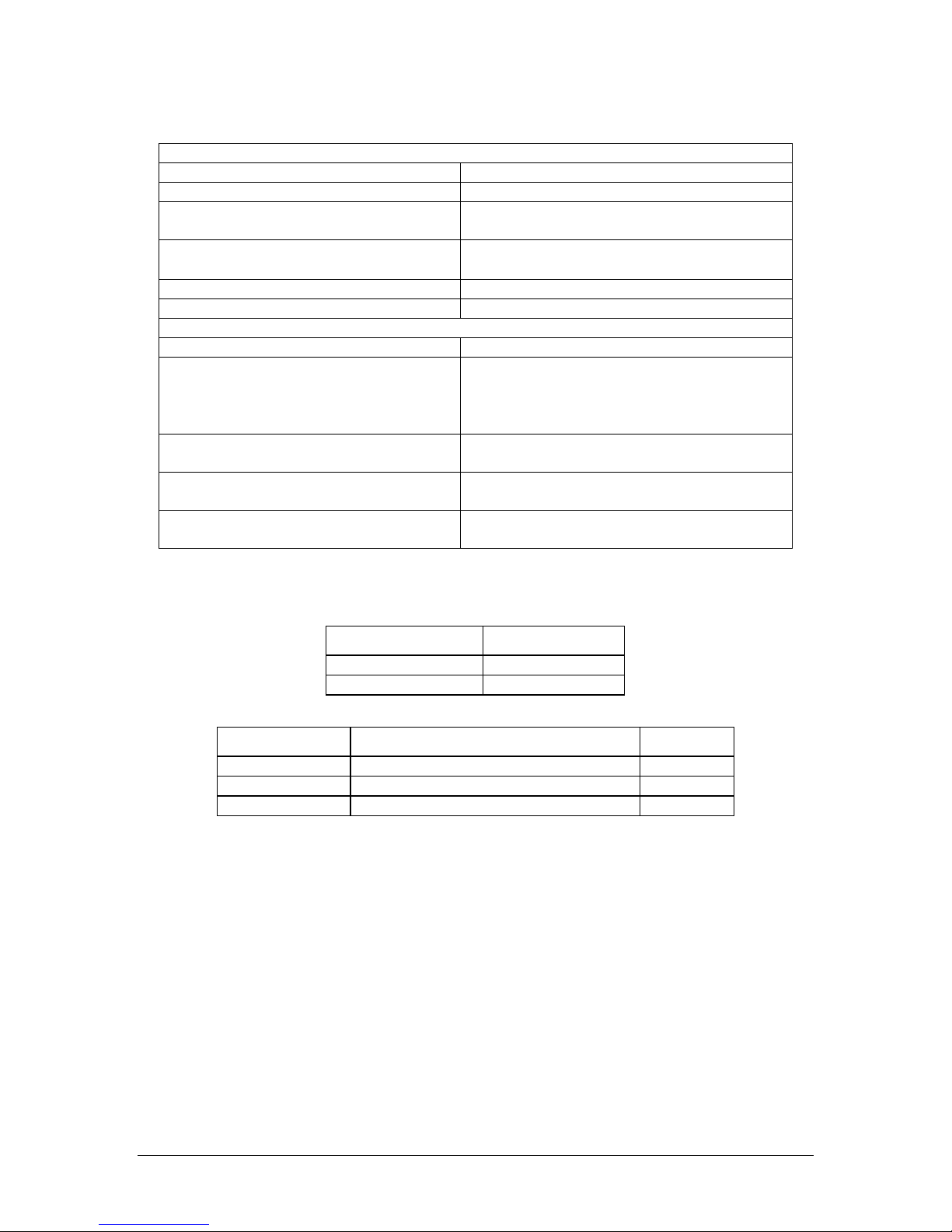

2.9 PMA7000M-S Pin assignments

J1 Bottom Connector (Mono & Stereo)

Chassis Ground

MKR Coax Lo

MM Sense Output

MKR Antenna

Pilot Headphones

White Lamp Output

Amber Lamp Out

14 V Light Hi

Blue Lamp Out

Light Lo

DME Audio Hi

28V Lights Hi

Com 2 Mic Audio Out

Pilot Mic Audio Hi In

Com 3 Audio Hi

Com 1 Audio Hi

Com 3 Mic Audio Hi

Com 2 Audio Hi

Com 1 Spkr Load

AUX Audio Input Hi

Com 2 SPKR Load

Nav 1 Audio Hi

Cellphone tip

Nav 2 Audio Hi

Com 1 Mic Audio Hi

Cellphone ring

Com 1 Mic Key

Com 3 Mic Key

ADF Audio Hi

Com 2 SPKR load

Unswitched Audio In #1

Unswitched Audio in #2

PA Mute

Com 2 Mic Key

Com 1 SPKR load

Cabin Spkr Out

Aircraft Power 11-33 VDC

Ext. Marker Audio In

Pilot Mic Key

Cabin Spkr Lo

Aircraft Ground

1

A

2

B

3

C

4

D

5

E

6

F

7

H

8

J

9

K

10

L

11

M

12

N

13

P

14

R

15

S

16

T

17

U

18

V

19

W

20

X

21

Y

22

Z

J2 PMA7000S, 7000MS (Stereo) Top Connector

1

Pilot Phone Audio Hi (Left)

A

2

B

3

C

4

D

5

E

6

F

7

H

8

Copilot Phone Audio (Lt)

Copilot Phone Audio Lo

Copilot Phone Audio (Rt)

Pass 1 Mic Audio Hi

Pass 1 Mic Audio Lo

Pass 2 Mic Audio Hi

Pass 2 Mic Audio Lo

Pass 3 Mic Audio Hi

Pass 3 Mic Audio Lo

Pass 4 Mic Audio Hi

Pass 4 Mic Audio Lo

Copilot Mic Audio Hi

J

9

K

10

L

11

M

12

N

13

Copilot Mic Key

Copilot Mic Audio Lo

Swap Switch

Copilot Cellphone Off Hook

Passenger Headphone Audio (R)

Pass Cellphone Off Hook

Passenger Audio (L)

Passenger Headphone Audio Lo

Entertainment #2 in (R)

P

14

R

15

S

16

T

17

U

Entertainment #2 In (L)

Ent. # 2 Low

Entertainment #1 In (R)

Entertainment #1 Input (L)

Ent. #1 Input Lo

Ground

Hot Mic Mode (VOX O'ride)

18

V

19

W

20

X

21

Y

22

Z

Input

Output

Mute 2

Playback

Message Acknowledge

Message 6 Play

Message 5 Play

Message 4 Play

Message 3 Play

Message 2 Play

Message 1 Play

200-070-0006 Page 2-11 Rev. 6, Nov 98

Page 19

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

2.10 Post Installation Checkout

After wiring is complete, verify power is ONLY on pin 20 of the J1 (bottom connector),

and airframe ground on bottom connector pin Z. Failure to do so will cause serious internal damage and void PS Engineering's warranty.

2.11 Unit Installation

To install the PMA7000M-S, gently slide the unit into the mounting rack until the holddown screw is engaged. While applying gentle pressure to the face of the unit, tighten the

3/32" hex-head in the canter of the unit until it is secure. DO NOT OVER TIGHTEN.

Warning: Do not over-tighten the lock down screw while installing the

unit in tray. Internal damage will result.

2.11.1 Operational Checkout

1. Apply power to the aircraft and avionics. Switch on the unit by pressing the volume

knob.

2. Plug headsets into the pilot, copilot, and occupied passenger positions.

3. Rotate the Mic Selector Switch to the Com 1 position.

4. Verify that the Com 1 button lights. Verify that the green transmit LED (Light Emit-

ting Diode) near the mic selector is not illuminated. If the LED is on, stop testing and

troubleshoot the microphone PTT installation.

5. Verify proper transmit and receive operation from the copilot position, noting that the

copilot PTT switch allows proper transmission on the selected transceiver.

6. Verify that pushing the COM 2 button causes the button to illuminate, and the Com 2

receiver to be heard. Verify operation on Com 1 from the pilot position.

7. Repeat for Com 2 and Com 3, (if installed).

8. Rotate the mic selector switch to the COM 1/2 position. Verify that the pilot commu-

nicates on Com 1 and the copilot on Com 2.

9. Rotate the mic selector switch to the COM 2/1 position. Verify that the pilot commu-

nicates on Com 2 and the copilot on Com 1.

10. Rotate the mic selector switch to the TEL position. Verify that the pilot headset is

connected to the cellular telephone system (if installed). Verify that by using the pilot

side PTT, the pilot can transmit on Com 1. The copilot has no transmit capability in

TEL mode.

11. Verify proper operation of all receiver sources by selecting them using the button.

Note that the button for the receiver sources stays in, and the button illuminates to

show which source is in use.

12. Push in the SPR button. Verify that all selected audio is heard in the cockpit speaker.

Verify that the audio mutes when the mic is keyed.

13. Verify that the LED in the lower right side illuminates when either push to talk is

keyed.

14. Verify proper Intercom system operation in the ALL, ISO and CREW modes (see Table

3-1).

200-070-0006 Page 2-12 Rev. 6, Nov 98

Page 20

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

15. Verify that the audio selector panel system does not adversely affect any other aircraft

system by systematically switching the unit on and off, while monitoring the other avionics and electrical equipment on the aircraft.

2.11.1.1 Marker Checkout (7000M-S only)

1. Connect a ramp generator at the antenna end of the marker coax. With the unit under

test in HI sensitivity, verify that a 160 µV, modulated 95% with 1300 Hz, signal will

illuminate the amber (M) marker light, and that marker audio is present in the headphones when the Marker Audio (M) push-button has been depressed. Select SPR for

speaker to verify marker audio availability on the cabin speaker. Verify that the white

(A) and blue (O) lights will illuminate within ± 3dB of the amber lamp, with 3000 HZ

and 400 Hz applied, respectively.

2. Repeat with the unit in LOW sensitivity, with 430 µVolts applied.

3. Connect the marker antenna and verify proper operation.

2.11.2 Receiver Sensitivity

Although the PMA7000M meets FAA TSO-C35d sensitivity specifications, the sensitivity

of the receiver has been adjusted to meet real world requirements (150µV and 430µV,

soft). This will usually eliminate the need for the avionics shop to reduce the sensitivity in

the field so as to prevent early detection of the marker beacons. If your particular installation requires more or less sensitivity, see adjustment section 2.6, and figure 2-1.

2.12 Cellular Interface Checkout

When a wireless telecommunication system is installed and configured, a dial tone will appear in the headset of the pilot when the mic selector is in the “Tel” position. In “ALL”

intercom mode, a dial tone will be heard whenever the copilot or passenger’s hook switch

is closed.

2.13 Internal Recorder Checkout

With headset plugged into pilot’s side jacks, tune COM 1 to local frequency, such as FSS

or ATC ground.

Select Com 1 on mic selector switch, and record at least five incoming radio transmissions.

This audio should only appear in the pilot’s headset, and only be incoming transmissions

from the transceiver selected in the mic select switch.

Depress the panel or yoke mounted playback switch, and verify that all five messages play,

in the order received.

Repeat for COM 2, and COM 3 (if installed).

200-070-0006 Page 2-13 Rev. 6, Nov 98

Page 21

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

2.14 Digital Annunciation Checkout

If interfaced with an annunciation system, verify that all alert messages play at the appropriate time, and that they are silenced by the “ACK” button.

2.15 Final Inspection

Verify that the wiring is bundled away from all controls and no part of the installation interferes with aircraft control operation. Move all controls through their full range while

examining the installation to see that no mechanical interference exists. Verify that the cables are secured to the aircraft structure in accordance with good practices, with adequate

strain relief. Ensure that there are no kinks or sharp bends in the cables and coaxial cables.

Verify that the cables are not exposed to any sharp edges or rough surfaces, and that all

contact points are protected from abrasion.

Complete log book entry, FAA Form 337, weight and balance computation and other

documentation as required. Sample text for FAA Form 337, and instructions for continuing airworthiness can be found in Appendix F.

Return completed warranty registration application to PS Engineering.

200-070-0006 Page 2-14 Rev. 6, Nov 98

Page 22

PMA7000M-S Series Audio Selector Panel and Intercom System

3-1

PS Engineering

Installation and Operator’s Manual

3 Section III OPERATION

GENERAL INFORMATION

3.1 SCOPE

This section provides detailed operating instructions for the PS Engineering PMA7000MS, and PMA7000S Audio Selector Panel/Intercom Systems. Please read it carefully before

using the equipment so that you can take full advantage of its capabilities.

This section is divided into four sections covering the basic operating areas of the

PMA7000M-S systems. They are Audio Selector, Transceiver Selection, Intercom, and

Marker Beacon Receiver (7000M-S only).

Marker Indicator Lamps

O

M

I

V

o

l

u

m

e

Push

(Fail-Safe)

Marker Mode Selector

High

Low

Com 1 Nav 1

Test

Iso

All

Crew

ENGINEERING

INCORPORATED

Mounting

Screw

Nav 2Com 2

Crew ICS/

Music 1 Mute

Receive Audio Selectors

Photo

Detector

MKR ADF

R

Speaker Switch

AUXICS

PMA7000M-S

DME

SPR

Com 1 Com 1/2

Com 2

Com 3

Transmit Swap

Mic Selector

Com 2/1

Tel

TX Indicator

Intercom Mode Sel.

Swap Indicator

Intercom Vol.

Figure 3-1 PMA7000M-S controls

3.2 Audio Selector (All models)

Receiver audio is selected through two momentary and six latched, push-button, backlit

switches. Com 1 and Com 2 are the momentary switches.

Because the rotary microphone selector switch controls what transceiver is being heard,

the Com l and Com 2 push-buttons are of the momentary type and do not remain in when

selected. This is also part of the "auto” function. You will always hear the audio from the

transceiver that is selected for transmit by the rotary mic selector switch.

The users can identify which receivers are selected by noting which of the green switch

LEDs are illuminated. Push buttons labeled Nav 1, Nav 2, DME, MKR (Marker), ADF,

AUX (auxiliary), and SPR (Speaker) are "latched" type switches. When one of these but-

200-070-0004 Page 3-1 Rev. 4, Oct.200-070-0006 Page

Page 23

PMA7000M-S Series Audio Selector Panel and Intercom System

3-2

PS Engineering

Installation and Operator’s Manual

tons is pressed, it will stay in the "in" position. Press the switch again and it be in the "out"

position and remove that receiver from the audio.

3.2.1 Speaker Amplifier

The "SPR" in the push-button section stands for speaker. This switch will place all selected audio on the cockpit speaker when this switch is selected. NOTE: The speaker amplifier is not active in the "Split Mode."

3.3 Power Switch (Fail Safe Operation)

Unit power is turned on and off by pushing the volume knob. In the OFF or "FAIL-SAFE"

position, the pilot is connected directly to Com 1. This allows communication capability

regardless of unit condition. Any time power is removed or turned OFF, the audio selector

will be placed in the fail-safe mode.

The power switch also controls the audio selector panel functions, intercom, and marker

beacon receiver, (PMA7000M-S only). Unless the mic selector is in Com 3 mode, at least

one of the selected audio LEDs will be on (Com 1 or Com 2).

3.4 Microphone Selector

When the mic selector switch is in the Com 1 position, both pilot and copilot will be connected to the Com l transceiver. Only the person who presses their Push To Talk (PTT),

will be heard over the aircraft radio. Turning the rotary switch to the COM 2 position will

place pilot and copilot on Com 2.

The PMA7000M-S gives priority to the pilot’s PTT. If the copilot it transmitting, and the

pilot presses his PTT, the pilot’s microphone will be heard over the selected com transmitter.

Turning the mic selector fully counterclockwise places the pilot and copilot on Com 3.

Com 3 receive audio is automatically placed in the headset (and speaker if selected). Com

1 and/or Com 2 receiver audio can be selected to monitor those transceivers.

The PMA7000M-S-Series has an automatic selector mode. Audio from the selected transceiver is automatically heard in the headsets and speaker. You can check this function by

switching from COM 1 to COM 2 and watch the selected audio light on the selector change

from COM 1 to COM 2. This ensures the pilot will always hear the audio from the transceiver he is transmitting on.

When switching the mic selector rotary switch from COM 1 to COM 2, while COM 2 audio

had been selected, Com 1 audio will continue to be heard. This eliminates the pilot having

to switch Com 1 audio back on, if desired.

When switching from COM 1 to COM 2 while Com 2 has NOT been selected, Com 1 audio

will be switched off. In essence, switching the mic selector will not effect the selection of

Com audio.

The “TEL” position, fully CW on the mic selector switch, is the pilot’s “hook” switch,

when the system is interfaced to an appropriate approved wireless telecommunication

200-070-0004 Page 3-2 Rev. 4, Oct.200-070-0006 Page

Page 24

PMA7000M-S Series Audio Selector Panel and Intercom System

3-3

PS Engineering

Installation and Operator’s Manual

system, such as the Trimble 3100 D. Placing the mic selector in TEL placed the pilot microphone and headphones on the cellphone. The pilot PTT will switch the pilot mic to the

COM 1, and allow continued aircraft communications as well.

NOTE: Placing the mic selector switch in the TEL position will disable pilot and copilot

intercom, as the intercom circuit is transferred to the telephone use. In crew or ISO mode,

placing the switch in TEL mode removes the passengers access to the telephone.

3.4.1 Swap Mode (Switch from Com 1 to Com 2 remotely)

With a yoke mounted, momentary switch, the pilot can change from the current Com

transceiver to the other by depressing this switch. When "Swap Mode" is active, an annunciator in the lower right corner of the unit will illuminate, indicating that the Mic Selector switch position is no longer current. To cancel "Swap Mode," the pilot may either

press the yoke mounted switch again, or turn the Mic Selector Switch to the Com that is

active.

3.5 Split Mode

Turning the rotary switch to COM 1/COM 2 places the PMA7000M-S into "Split Mode."

This places the pilot on Com 1 and the copilot on Com 2. An example of this useful feature is when the pilot may want to talk to Air Traffic Control, while the copilot may be

speaking to Flight Watch. Although this mode has limitations (see below) we believe you

will find this to be a useful feature.

Switching to Com 2/Com l will reverse the “Split Mode” radio selection. The pilot will be

on Com 2 and the copilot will be on Com 1.

Note:

Due to the nature of VHF communications signals, and the size constraints in

general aviation aircraft, it is probable that there will be some bleed-over in the

Split mode, particularly on adjacent frequencies.

PS Engineering makes no warranty about the suitability of Split Mode

in all aircraft conditions.

Note: Split Mode does not turn off other (Nav, ADF, etc.) selected audio to pilot. However, the

copilot will only hear the selected communications receiver.

3.5.1 Split Mode ICS

In split mode, the pilot and copilot are usually isolated from each other on the intercom,

simultaneously using their respective radios. Depressing the ICS button in Split Mode will

activate VOX intercom between the pilot and copilot positions. This permits intercommunication when desired between the crew. Pressing the ICS button again disables this crew

intercom function.

200-070-0004 Page 3-3 Rev. 4, Oct.200-070-0006 Page

Page 25

PMA7000M-S Series Audio Selector Panel and Intercom System

3-4

PS Engineering

Installation and Operator’s Manual

3.6 Intercom

3.6.1 IntelliVox™ VOX-Squelch

No adjustment of the IntelliVox™ squelch control is necessary. Through three individual

signal processors, the ambient noise appearing in all six microphones is constantly being

sampled. Non-voice signals are blocked. When someone speaks, only their microphone

circuit opens, placing their voice on the intercom.

The system is designed to block continuous tones, therefore people humming or whistling

in monotone may be blocked after a few moments.

For best performance, the headset microphone must be placed within ¼ inch of your lips,

preferably against them. It is also a good idea to keep the microphone out of a direct wind

path. Moving your head through a vent air stream may cause the IntelliVox™ to open

momentarily. This is normal.

For optimum microphone performance, PS Engineering, Inc. recommends installation of a

Microphone Muff Kit from Oregon Aero (1-800-888-6910). This will not only optimize

VOX performance, but will improve the overall clarity of all your communications.

Table 3-1 Mic Muff ™ Part Numbers

Manufacturer Model Mic Muff™ Part

Bose Dynamic

Electret

M87 Dynamic

David Clark H10-30

H10-20, H10-40

H10-13.4

Lightspeed 15K & 20K 90015

Peltor 7003

7004

Pilot 11-20 & 11-90 90015

Sennheiser 90015

Telex Airman 750

AIR3000

3.6.2 Volume Control

Number

90010

90015

90020

90010

90015

90015

90010

90015

90015

90010

The volume control knob adjusts the loudness of the intercom for the pilot and copilot

only. It has no effect on selected radio levels, music input levels or passengers' volume

level.

Adjust the radios and intercom volume for a comfortable listening level for the pilot. Most

general aviation headsets today have built-in volume controls; therefore, passenger volume

200-070-0004 Page 3-4 Rev. 4, Oct.200-070-0006 Page

Page 26

PMA7000M-S Series Audio Selector Panel and Intercom System

3-5

PS Engineering

Installation and Operator’s Manual

can be adjusted at the headset. If desired, passenger volume level can be adjusted by a

screwdriver adjustment at the top of the tray (see figure 2-1).

3.6.2.1 Mono headsets in Stereo Installation

All passenger headsets are connected in parallel. Therefore, if a monaural headset is

plugged in to a PMA7000M-S Stereo installation, one channel will be shorted. Although

no damage to the unit will occur, all passengers will lose one channel. PS Engineering

modifies headsets to add stereo capability, using high-fidelity speakers. Contact factory for

details.

3.6.3 Intercom Modes

The lower switch on the left side is a 3-position mode switch that allows the pilot to tailor

the intercom function to best meet the current cockpit situation. The description of the

intercom mode function is valid only when the unit is not in the "Split" mode. Then, the

pilot and copilot intercom is controlled with the ICS button.

ISO: (Up Position): The pilot is isolated from the intercom and is connected only to the

aircraft radio system. He will hear the aircraft radio reception (and sidetone during radio

transmissions). Copilot will hear passengers’ intercom and Entertainment 1, while passengers will hear copilot intercom and Entertainment 2. Neither will hear aircraft radio receptions or pilot transmissions.

ALL: (Middle Position): All parties will hear the aircraft radio and intercom. Crew will

hear Entertainment 1, passengers will hear Entertainment 2. During any radio or intercom

communications, the music volume automatically decreases. The music volume increases

gradually back to the original level after communications have been completed.

CREW (Down Position): Pilot and copilot are connected on one intercom channel and

have exclusive access to the aircraft radios. They may also listen to Entertainment 1. Passengers can continue to communicate with themselves without interrupting the Crew and

also may listen to Entertainment 2.

Anytime the PMA7000M-S is in either the COM 1/COM 2, COM 2/COM 1, ("Split Mode"),

the pilot and copilot intercom is controlled with the ICS button. The passengers will

maintain intercommunications, but never hear aircraft radios.

3.6.3.1 Entertainment Input

The audio selector panel has provisions for two separate entertainment input devices.

They operate independently in the PMA7000M-S. The volume control does not affect music level.

While in the ISO (Isolate) mode, the copilot will hear Entertainment 1 while the four passengers will hear Entertainment #2. The pilot will hear entertainment 1, at a muted level.

In normal operation, whenever a person speaks, or if the aircraft radio becomes active, the

music will automatically mute and then will gradually return to the original listening level

when the intercom or radio conversation ceases.

200-070-0004 Page 3-5 Rev. 4, Oct.200-070-0006 Page

Page 27

PMA7000M-S Series Audio Selector Panel and Intercom System

3-6

PS Engineering

Installation and Operator’s Manual

When in the ALL mode, pilot and copilot will hear Entertainment 1 input while all passengers will hear the Entertainment 2 source. While in the CREW mode, pilot and copilot will

hear entertainment input #1 while the passengers may listen to entertainment input #2.

It is also possible to use only one entertainment input device for both entertainment inputs.

It is suggested however, that a switch (DPDT) is installed between the single entertainment device and entertainment input #1. This will allow the pilot and copilot decide if they

hear entertainment while in the Crew mode.

3.6.3.2 Soft Mute and Soft Mute inhibit

The Soft Mute feature assures that the aircraft radio transmissions will not be missed due

to entertainment playing. When there is radio reception or intercom conversation, the music level is dropped to a low, or background level. When the radio or intercom traffic

ceases, the level gradually returns to normal.

The front panel ICS switch controls muting of entertainment source #1. Pushing this button places the ICS in Karaoke (or sing along) mode, which inhibits the soft mute feature.

This allows the music to continue uninterrupted by intercom or radio traffic when cockpit

workload is appropriate. Pushing the button again will release the mute inhibit function.

The passenger music, source #2, can be placed in the Karaoke mode if a remote switch is

installed in the aircraft. See wiring information for details.

Table 3-2 Intercom Modes

Mode Pilot Hears Copilot Hears Passenger Hears Telephone Comments

Isolate A/C Radios

Pilot Sidetone

(during radio transmission)

Entertainment 1 is

Muted

All Pilot

Copilot

A/C Radio

Passengers

Entertainment #1

Crew Pilot

Copilot

A/C Radio

Entertainment #1

Copilot and passenger

intercom

Entertainment #1

Copilot

Pilot

A/C Radio

Passengers

Entertainment #1

Copilot

Pilot

A/C Radio

Entertainment #1

Passenger and Copilot

intercom

Entertainment #2

Passengers

Pilot

Copilot

A/C Radio

Entertainment #2

Passengers

Entertainment #2

“Phone Booth” mode

Pilot has exclusive use of the

telephone.

In TEL, Pilot connected to

Com 1 for PTT TX and receive. Others hear Tel if off

hook.

All have access to phone

through Hook Switch. Pilot

access through TEL switch.

All hear telephone audio if off

hook.

Pilot and copilot don’t have

phone access, unless mic sel

in TEL. Passengers have

phone through Hook Switch,

Passengers hear phone

audio.

This mode allows the pilot

to communicate without

the others bothered by the

conversations. Copilot and

passengers can continue

to communicate and listen

to music

This mode allows all on

board to hear radio reception as well as communicate on the intercom.

Music and intercom is

muted during intercom

and radio communications

This mode allows the pilot

and copilot to concentrate

on flying, while the passengers can communicate

amongst themselves.

3.7 Telephone Mode

Each intercom position has a "hook switch." The pilot's hook switch is the "TEL" mode

on the audio panel, the others are discrete switches mounted adjacent to the headset jacks.

When the intercom is in ALL mode, the pilot can speak on the phone only if the mic selector switch is in TEL position. All intercom positions will hear the telephone conversation. Anyone who places his or her switch into the “off-hook” position will also be heard

200-070-0004 Page 3-6 Rev. 4, Oct.200-070-0006 Page

Page 28

PMA7000M-S Series Audio Selector Panel and Intercom System

3-7

PS Engineering

Installation and Operator’s Manual

on the phone. All will hear selected audio. Com 1 audio is automatically heard in the headsets. The pilot will have transmit capability on Com 1, simply by using the PTT switch.

In CREW mode, the pilot and copilot are may use the telephone, with their respective

hook switch (the pilot selects TEL on the mic selector). Any passenger who places their

switch into the off-hook position will also have access to the phone, and all four passengers will hear the conversation.

In ISO intercom mode, when the PMA7000M-S is in the TEL mode, the pilot position is

in the "Phone Booth." Only the pilot will hear the telephone, and only he will be heard. He

will also have access to Com 1, and will transmit on that radio using the PTT. All selected

audio is provided. If any other passenger goes “off hook” they will hear the phone.

In all cases, only the pilot (and copilot in ALL or CREW) will hear the cellphone ring. At

that time they can chose to allow a passenger to take the call, or answer the phone.

Note: Because the cellphone uses an intercom circuit, all stations on that cir-

cuit will lose intercom capability when the cellphone is in use.

3.8 Marker Beacon (PMA7000M-S)

The optional Marker Beacon Receiver uses visual and audio indicators to alert you when

the aircraft passes over a 75 MHz transmitter.

The Blue lamp, labeled "O," is the Outer Marker lamp and has an associated 400 Hertz

'dash' tone. The lamp and tone will be keyed at a rate of two tones/flashes per second

when the aircraft is in the range of the Outer Marker Beacon.

The Amber lamp, labeled "M," is the Middle Marker lamp and is coupled with a 1300

Hertz tone. It is keyed alternately with short 'dot' and long 'dash' bursts at 95 combinations

per minute.

The White lamp, labeled "I," is the Inner marker and has a 3000 Hertz 'dot' tone. The lamp

and tone will be keyed at a rate of six times per second.

The audio from the Marker Beacon Receiver can be heard by selecting the "MKR" pushbutton switch. To adjust the volume level, there is a service adjustment located on the top

of the unit. See Section 2.5

A three position switch is used to set the receiver sensitivity and to test the indicator

lamps. Use "HIGH" sensitivity initially. This allows you to hear the outer marker beacon

about a mile out. Then select the “LOW” sensitivity to give you a more accurate location

of the Outer Marker. The momentary down switch position is labeled "TEST" and illuminates all three lamps simultaneously to assure the lamps(internal and external) are in

working order. TST does not activate MM sense ouput.

3.9 Internal Recorder System (Option 1 and 2 only)

The Intercom Recording System (referred to here as the IRS) is a digital recording system

allowing automatic storage and immediate playback of all incoming aircraft radio receptions.

200-070-0004 Page 3-7 Rev. 4, Oct.200-070-0006 Page

Page 29

PMA7000M-S Series Audio Selector Panel and Intercom System

3-8

PS Engineering

Installation and Operator’s Manual

Operating as a continuous loop recorder, (first message received will be the last heard),

the recorder has one minute of recording time and up to 16 messages. With its own built

in VOX circuit, there are no buttons to press to start recording. The system automatically

begins to record the instant the radio becomes active. Only aircraft radio audio in pilots

headset is recorded and only the pilot will hear the playback audio.

3.9.1 Operation

Recording is automatic; there is no action required by the pilot. To play back the last recorded message, simply press the momentary switch associated with the IRS. Each additional press of the button will play the preceding recorded message.

3.9.1.1 Audio Messaging system (Option 1, Option 2, only)

When this option is installed, the PMS7000M-S contains six stored messages. An outside

annunciator, such as an Electronics International engine gage system triggers these messages. When there is an announcement, it will be repeated every two seconds until the remote- mounted ACK button is pushed. This stops the played annunciation, until the next

announcement is required (the next falling edge).

3.9.1.2 Concurrent Messages

When a recorded message or audio annunciation is playing, the other audio source is momentarily inhibited. For instance, if an IRS message is being played, the audio annunciation

will not begin until the IRS message is finished. Conversely, the IRS recording cannot be

played as long as there is an aural alert being played. There is no recording made if playing

a recording or annuncuation.

200-070-0004 Page 3-8 Rev. 4, Oct.200-070-0006 Page

Page 30

PMA7000M-S Series Audio Selector Panel and Intercom System

PS Engineering

Installation and Operator’s Manual

4 Section IV- Warranty and Service

4.1 Warranty

In order for the factory warranty to be valid, the installations in a certified aircraft must be

accomplished by an FAA- certified avionics shop and authorized PS Engineering dealer.