Page 1

Sound Quality. Sound Engineering.

PM1000

II

FAA-Approved

4-Place, Panel Mounted Intercom

Operator's and Installation Manual

Part Number 11920 (with Crew) and 11922 (without Crew)

FAA-TSO C50c

PS E

Phone (865) 988-9800 FAX (865) 988-6619

NOTICE: In certified aircraft, warranty is not

valid unless this product is installed by an

Authorized

PS Engineering dealer.

NGINEERING, INCORPORATED

9800 Martel Road

Lenoir City, TN 37772

www.ps-engineering.com

Document Number 200-123-0003

Revision 5, Feb. 29, 2012

Revision 5, Feb. 2012 Page 1 200-123-0003

Any reproduction or retransmittal of this publication, or any portion thereof, without the expressed written permission of PS Engi-

neering, Inc. is strictly prohibited. For further information contact the Publications Manager at PS Engineering, Inc., 9800 Martel

PS Engineering, Inc. 2012©

Copyright Notice

Road, Lenoir City, TN 37772. Phone (865) 988-9800

Page 2

Section I General Information

1.1 Introduction

The PM1000II, is an FAA-TSO approved, panel

mounted, 4-place intercom system (ICS). Please read

this manual completely before installation to minimize

the risk of damage to the unit and to become familiar

with all the features.

PM1000II, p/n 11920, Front Panel

1.2 Scope

This manual contains installation and operational instructions for the following PS Engineering units:

Model Description Part Number

PM1000II 4-place intercom system w/Pilot ISO 11922

PM1000II Same as above w/internal crew 11920

1.3 Description

The PM1000II is a 4-place, panel mounted intercom

with individual volume and squelch controls for the

pilot and copilot. The copilot's squelch control adjusts

the trip level of the copilot and passengers.

A front panel mode switch allows the pilot to select

multiple intercom configurations:

"ISO" mode isolates the pilot from the intercom and

connects to the aircraft radio. The passengers can continue to communicate with each other and listen to

entertainment without distracting the pilot. They do

not hear radio communications.

"ALL" mode places all headsets on a party line. Each

one hears aircraft radio, entertainment and can use the

intercom.

“CREW” (11920 only) allows the pilot and copilot

positions to hear the aircraft radios and use the intercom, while the rear passengers can have their own

intercom conversation without disturbing the crew.

This also activates music 2 input.

The PM1000II has an automatic fail-safe interconnect

to the aircraft radio. If power to the intercom is disrupted, an internal relay will connect the pilot's headset to the aircraft radio. This allows continuous radio

communications. Note: The copilot will no longer hear

aircraft radio when power is removed.

The 2-color LED shows green when power is on and

red during radio transmissions. This functions as a

stuck mic indicator.

An auxiliary input is provided, allowing the pilot, copilot and passengers the option to listen to music during

flight. During intercom or aircraft radio activity, this

music is automatically muted to allow communications

without distraction. When the activity ceases, the Soft

Mute circuit will gradually return the music to the

original listening volume.

The "ISO" mode provides uninterrupted aircraft radio

communications for the Pilot. Because the pilot's intercom volume control does not affect the aircraft radio

volume, it is possible to select various balances of volume level between the ICS and the aircraft radio while

in the ALL mode. Reducing the intercom volume, the

pilot places the aircraft radio in the foreground while

the ICS is in the background.

Both pilot and copilot have transmit capabilities over

the radio. The PM1000II allows only the person who

presses their PTT to be heard over the aircraft radio. If

both pilot and copilot press the PTT at the same time,

the copilot will override (Ideally suited for training

environments). Pilot regains priority by switching the

unit off.

1.4 Approval Basis

The PM1000II, part numbers 11920 and 11922 are

FAA-approved under TSO-C50c.

1.5 Specifications

Input power: 13.8 - 27.5 Volts DC

Current Drain: < 250 mA (Externally fused at 1 Amp)

Headphone Impedance: 150-1000 ohms typical

Audio Distortion: <10% @ 75 mW into 150 Ω load

Aircraft Radio Impedance: 1000 Ω typical

3 dB Mic Frequency Response: 350 Hz — 6000 Hz

3 dB Music Frequency Response: 200 Hz to 15 kHz

Unit weight: 12 Ounces (0.342 kg)

Dimensions: 1.25" H x 2.60" W x 5.50" D

(3.2 x 6.6 x 14 cm)

Environmental and technical qualifications:

RTCA DO-160B/DO-170

Temperature -20ºC to +55ºC

Altitude 50,000 ft.

1.6 Equipment required but not supplied

A.Headphones, 150Ω monaural, up to four as required

B.Microphones, up to four, as required

C.Interconnect wiring

D.Circuit Breaker—1 Amp.

PM1000II Operation/Installation Manual Page 2 Revision 5, Feb 2012

Page 3

1.7 License Requirements

None

Section 2 Installation

2.1 General Information

The PM1000II comes with all necessary hardware for

installation.

Installation of the PM1000II, using the available wiring and hardware supplied, does not require special

tools or knowledge other than described in FAA Advisory Circular 43.13-2. It is the installer's responsibility

to determine the approval basis for this installation. An

FAA From 337, or other approval may be required.

See Appendix B for example of FAA Form 337.

2.2 Unpacking and inspection

The PM1000II was carefully inspected mechanically

and thoroughly tested electronically before shipment.

It should be free of electrical or cosmetic defect. Upon

receipt, verify that the parts kit includes the following:

Part Number Description Quantity

475-442-0002 #4-40 Machine screws, black 2

625-002-0001 Concentric inner knobs 2

625-002-0002 Outer knobs w pointer 2

425-025-00095 25 pin Sub-d connector shell 1

425-020-5089 Male Pins– Crimp 25

625-025-0001 Connector hood 1

575-002-0004

575-002-0002

11910 4-place mono jack kit ,(incl. phones and

202-123-0001 Pilot’s Guide 1

Reversible aluminum face plate

Reversible face plate w/crew

mic jack, insulating washers and 1/8”

music jack)

11922

11920

1

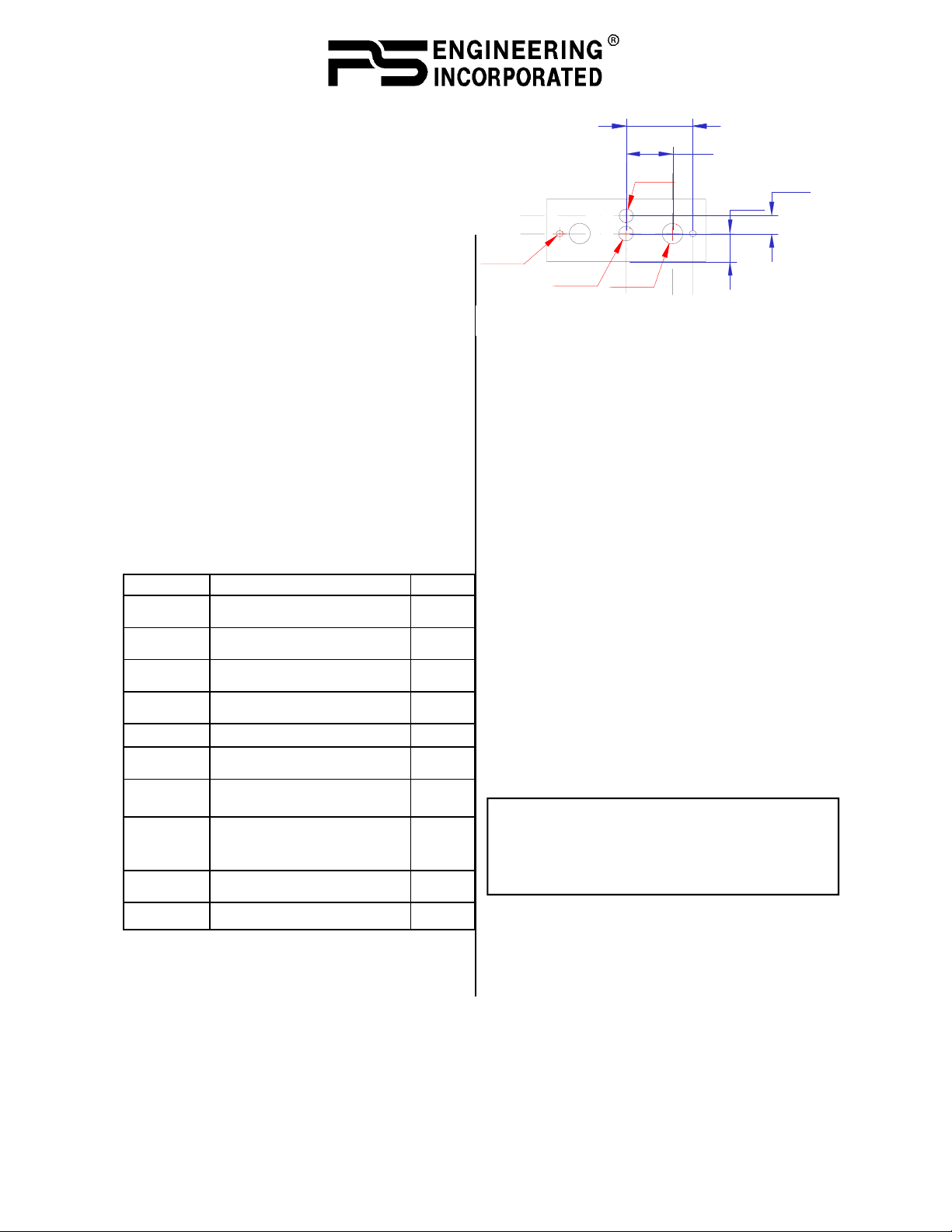

1.2 in

0.838 in

Ø0.125 in

Ø0.265 in

Ø0.25 in

Ø0.375 in

0.32 in

0.5 in

PM1000II Hole spacing (Not to scale)

3.Place the aluminum face-plate over the knob shafts

and secure, using the two # 4-40 round head

screws provided.

4.Install the knobs over the volume and squelch control shafts.

2.4 Cable harness wiring

To complete the installation, a wire harness must be

made as shown in Appendix D.

PS Engineering can make a custom-tailored wiring

harness for the installer. All harnesses use Mil-spec

quality components with professional techniques, and

are fully tested before shipment. Contact PS Engineering for more information.

If the aircraft already has pilot and copilot headset

jacks installed, you may re-use them. Remove and

discard all wires from the copilot headset jacks. You

may use the existing pilot headset jacks as the Auxiliary Aircraft Radio Headset Jacks, but they should be

moved to a new location to avoid confusion with the

pilot's headphone jacks. In the event the intercom has

to be removed for any reason, these jacks provide access to the aircraft radio system.

NOTE: Auxiliary microphone and headset

jacks are required for a complete installation.

These provide troubleshooting and a back-up

access to the aircraft radios.

122-102-0001 Drill Template 1

2.3 Equipment installation procedures

1.Using the template, drill six holes in the instrument

panel in a location convenient to the pilot position

(s).

To connect intercom into the aircraft audio system,

parallel the appropriate set of cables from the intercom

to the Auxiliary Aircraft Radio Headset Jacks. Finally,

install new headset jacks into the aircraft and connect

them directly to the appropriate pins of the PM1000II.

See the wiring diagram for all details of the wire harness interconnects.

2.Insert the PM1000II from behind the instrument

panel, aligning the holes for the knobs, LED, and

switch.

Revision 5, Feb. 2012 Page 3 200-123-0003

2.4.1 Electrical Noise Issues

WARNING: You must use separate shielded cables

Page 4

for the microphone and headphone jacks. Combining

these two wires WILL cause loud oscillations and degrade the intercom function. The oscillation is caused

by the cross-coupling between the large headphone

signal and the small microphone signal. The resulting

feedback is a high-pitched squeal that varies with the

volume controls.

Due to the variety of the radio equipment found in

today's general aviation aircraft, there is the potential

of both radiated and conducted noise interference. The

PM1000II has a specially designed power supply to

reduce conducted electrical noise on the power bus of

the aircraft by at least 50dB. Although this is a very

large amount of attenuation, it does not eliminate all

noise when the amount is excessive. There must be at

least 12 Volts DC present at the PM1000II for the

power supply to work within its designed regulation.

Otherwise, it will not be able to attenuate noise properly.

Shielding can protect the system from radiated noise

(rotating beacon, electric gyros, switching po wer supplies, etc.). However, installation combinations can

occur where minor interference is possible. The

PM1000II was designed in an interference -protected

chassis and has internal filter capacitors on all input

lines.

Ground loop noise occurs when there are two different

return paths for the same signal, such as airframe and

ground return wire. Large cyclic loads such as strobes,

inverters, etc., can inject audible signals onto the airframe return path. Follow the wiring diagram very

carefully to help insure a minimum of ground loop

potential. Radiated signals can be a factor when low

level mic signals are bundled with current carrying

power wires. Keep these cables separated.

Insulating washers are required

on all mic and headphone jacks to isolate them from aircraft ground. The

use of a conductor instead of a shield for ground return

eliminates these ground loop paths.

2.4.2 Power Requirements

The PM1000II was designed to work with either

12/28 volt DC negative ground systems. The

PM1000II must be externally protected with a one

ampere (1A) circuit breaker or fuse.

2.4.3 Entertainment Input

Entertainment devices can be connected to the

PM1000II. Install 1/8" jacks convenient the pilot to

connect the entertainment device into the system. A

"Soft Mute" system is installed in the PM1000II that

will mute the music during intercom or radio activity.

The 11920 has two entertainment inputs.

Note: Use the low level (or line) output from any music device to connect

to the PM1000II. Maximum input level is 2 V peak-to-peak.

DO NOT USE SPEAKER OUTPUT.

These levels will cause internal damage.

In the ALL or ISO modes, Music #1 is heard by everyone (except by the pilot in ISO mode). In the CREW

mode, pilot and copilot will hear Music #1 while the

passengers will hear entertainment #2.

WARNING: Local oscillators and other internal signals from CD or radio equipment can cause undesired

interference with VHF navigation and communication

equipment. Before takeoff, operate the entertainment

device to determine if there is any adverse effect on

aircraft systems. If any unusual operation is noted in

flight, immediately switch the entertainment device

off.

2.4.4 External PTT hook-up

Part of the installation includes the installation of PTT

(Push To Talk) switches that allow radio transmissions

from pilot and copilot positions.

There are three configurations that can be used. You

must select the case that best fits your installation.

NOTE

: Only the person who presses their PTT switch

will be heard over the radio.

CASE I

The PTT is built into the pilot and copilot yokes

Simply install the plugs from the headset into the aircraft headphone jacks. Then use the yoke mounted

PTT to transmit. No other action is required.

CASE II

Built in PTT only on the pilot side only

This configuration requires a modified external PTT

switch plugged into the copilot's mic jack. (See Appendix A) When the copilot's PTT is depressed, this

activates an internal relay that switches the mic audio

to the aircraft radio from the pilot to the copilot.

Case III

No built in PTT switch at all.

Two built-in PTT must be installed or two external,

modified PTT switches will be required for both the

pilot and copilot. Modifications to the PTT may be

required. (See Appendix A)

2.5 Post installation checkout

After wiring is complete, verify power is ONLY on

pin 14 of the connector, and airframe ground on pin 1.

Failure to do so will cause internal damage and void

PS Engineering's warranty.

1.Apply power to the aircraft and avionics.

PM1000II Operation/Installation Manual Page 4 Revision 5, Feb 2012

Page 5

2.Plug headsets into the pilot, copilot and passenger positions.

3.Verify that the pilot position can transmit and

receive with the PM1000II in the OFF position (left hand volume knob fully counte r clockwise).

4.Rotate the pilot volume clockwise, about half

way. Verify that the Pwr/Xmt light comes on,

and shows green. If the LED is red, stop testing and trouble-shoot the microphone PTT

installation.

5.Verify that the pilot can transmit and receive on

the com transceivers.

6.Verify that the LED in the intercom changes

from green to red when a microphone is

keyed.

7.Verify proper intercom operati on f or pi l ot, copilot and passengers. For more information,

consult Section III.

8.Verify proper transmit and receive operation on

the copilot position, noting that the copilot

PTT switch allows proper transmission on the

selected transceiver.

9.Verify proper Intercom system operation in the

ALL, ISO And CREW (if equipped) modes.

10.Verify that the intercom system does not adversely affect any other aircraft system by

systematically switching the unit on and off,

while monitoring the other avionics and electrical equipment on the aircraft.

Section III OPERATION

With the installation complete, turn the PM1000II on

by rotating pilot's volume control. This also engages

the automatic fail-safe system. The pilot's volume control does not

allowing an additional degree of aircraft radio listening

flexibility.

control the volume of the aircraft radio,

PM1000II w/crew, p/n 11920

copilot's volume control adjusts the volume for the

copilot.

In the 11920 units, the volume level for both passengers can be adjusted by a screwdriver adjusted potentiometer located on the left hand side of the intercom as

viewed from the front. It is possible to adjust the overall output power to the passenger headsets by changi n g

this potentiometer. Rotating the potentiometer counterclockwise increases the passenger volume.

3.2 Squelch Control (2)

The PM1000II provides individual VOX circuits for

the pilot and copilot. The ability to adjust the trip level

of these VOX circuits (squelch control) allows the use

of dissimilar headsets without the frustration of clipping the first syllables. The PM1000II has three

squelch circuits, one for the pilot, copilot, and one for

the passengers. With individual VOX circuits, background noise is dramatically reduced.

With the engine running, set the squelch control knob

by slowly rotating the squelch control knob clockwise

until you no longer hear the background noise in the

earphones. When the microphone is positioned properly near the lips, normal speech levels should open

the channel. When you have stopped talking, there is a

delay of about one second before the channel closes.

This prevents squelch closure between words , and

helps eliminates choppy intercom conversations.

PM1000II w/out crew, p/n 11922

3.1 Adjusting The Volume (1)

The pilot's volume control knob adjusts the loudness

of the intercom and music for the pilot's headset only.

It has no effect on aircraft radio volume level. The

Revision 5, Feb. 2012 Page 5 200-123-0003

3.3 Mode Select (3)

The center switch is a three position mode control that

allows the pilot to tailor the intercom function to suit

flight conditions. Regardless of configuration, the

pilot will always hear the aircraft radio. NOTE: If

there is a power failure to the PM1000II, or if the

power switch is turned off, the copilot will not hear the

aircraft radio. Only the pilot is connected directly to

the aircraft radio.

ISO (Up Position): The pilot is isolated from the intercom and is connected only to the aircraft radios. He

will hear the aircraft radio reception (and sidetone during radio transmissions). The pilot will not hear anything when he speaks into the mic on intercom. Copi-

Page 6

lot and passengers will hear themselves and music but

not the aircraft radio traffic.

ALL (Middle position): All parties will hear the aircraft radio, intercom, and music. However, during any

ICS or radio communications, the music volume automatically mutes. The music volume increases gradually back to the original level after communications

have been completed.

CREW (Down Position) (ONLY version with crew,

part number 11920 ): Pilot and copilot are connected

on one intercom channel while the passengers are on a

separate and independent channel. The pilot and copilot are connected to the aircraft radio and may listen to

Music #1. Passengers can continue to communicate

with themselves without disturbing the pilot and copilot and may listen to Music #2.

Section 4

Warranty and Service

4.1 Warranty

In order for the factory warranty to be valid, the installations in a certified aircraft must be accomplished by

an FAA- certified avionics shop and authorized PS

Engineering dealer. If the unit is being installed by a

non-certified individual in an experimental aircraft, a

factory-made harness must be used for the warranty to

be valid.

PS Engineering, Inc. warrants this product to be free

from defect in material and workmanship for a period

of one year from the date of sale. During this one year

warranty period, PS Engineering, Inc., at its option,

will send a replacement unit at our expense if the unit

should be determined to be defective after consultation

with a factory technician. The customer is responsible

for return shipment costs.

This warranty is not transferable. Any implied warranties expire at the expiration date of this warranty. PS

Engineering SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. This

warranty does not cover a defect that has resulted from

improper or unreasonable use or maintenance as determined by us. This warranty is void if there is any attempt to dissemble this product without factory authorization. This warranty gives you specific legal

rights, and you may also have other rights which may

vary from state to state. Some states do not allow the

exclusion of limitation of incidental or consequential

damages, so the above limitation or exclusions may

not apply to you.

4.2 Factory Service

The PM1000II is covered by a one-year limited warranty. See warranty information.

The unit is covered by a one-year limited warranty.

See warranty information. Call PS Engineering, Inc. at

(865) 988-9800 before you return the unit. This will

allow the service technician to provide any other suggestions for identifying the problem and recommend

possible solutions.

After discussing the problem with the technician and

you obtain a Return Authorization Number, ship product to:

PS Engineering, Inc.

Attn: Service Department

9800 Martel Road

Lenoir City, TN 37772

(865) 988-9800 FAX (865) 988-6619.

NOTE:

PS Engineering is not responsible for units shipped US

Mail.

If no method of payment is provided, the units will be

returned COD.

Appendix A

PTT Modifications

When received from the manufacturer, an after-market

PTT switch opens the mic audio path to the "ring"

connection of the PTT mic plug. When the PTT is between the intercom and the headset, the intercom function will not work until the PTT switch is depressed. A

simple modification can be performed to allow proper

intercom operation. NOTE: This mod does not alter

normal operation. The following are sample procedures for common PTT switches. Contact the PTT

manufacturer if you require more information.

Procedures for the David Clark PTT

1.Unscrew the round black plastic cover from the

jack.

2.Connect the joined black wires to the red wire

3.Replace the black plastic cover

Procedures for the Telex PT-200

1.Unscrew the round black plastic cover from the

jack.

2.Cut the red wire in the middle of the wire

3.Strip both ends of the insulation

4.Solder the two ends to the ground lug to the PTT

jack

5.Replace the plastic cover

PM1000II Operation/Installation Manual Page 6 Revision 5, Feb 2012

Page 7

Procedures for the Telex PT-300

1.Unscrew the round black plastic cover from the

jack

2.Remove the heat shrink material from the joined

black wires

3.Solder these two wires to the lug that has a

white wire already soldered to it.

4.Replace the black plastic cover

Appendix B

Instructions for FAA Form 337

It is up to the installer to determine if the installation is

a major or minor aircraft alteration. (Refer to AC 20-

177). One possible method of airworthiness approval

is through an FAA Form 337, Major Repair and Al-

teration (Airframe, Powerplant, Propeller, or Appliance) In the case of the PM1000II , you may use the

following text as a guide.

Installed 4-place intercom, PS Engineering

PM1000II, part number (xxxxx) in ( loca-

tion ) at station . Installed per

AC43.13-2B, Chapter 2,. Installed per PS

Engineering Installation Operators Manual p/

n 200-123-0003, revision 1, dated ________.

This unit is FAA-Approved under TSO C50c

for audio amplifiers, and meets environmental

tests outlined in RTCA DO-170B as appropriate or this aircraft.

Interface to existing aircraft radios in accordance with installation manual and in compliance with practices listed in AC43.13-2B,

Chapter 2. All wires are Mil-Spec 22759 or

27500. No connection to the aircraft dimmer

bus is required. Power is supplied to the unit

through a 1A circuit breaker (type and part

number), and total electrical load does not

exceed % of the electrical system capacity with the PM1000II added.

Aircraft equipment list, weight and balance

amended. Compass compensation checked. A

copy of the operation instructions, contained

in PS Engineering document 202-123-0001,

revision _, Dated:_____, is placed in the aircraft records. All work accomplished listed

on Work Order .

Appendix C

Instructions for Continuing Air-

worthiness

The PM1000II is considered an “on-condition” maintenance item. It is checked prior to each flight during

normal operation. There are no additional considerations for continuing airworthiness other than the practices detailed in AC 43.13-1A, Chapter 11. This includes, inspecting the unit to be sure it is securely fastened in its location, and that the wiring harness is not

chafed or pinched, and remains secure. All panel jacks

should be checked at each periodic inspection to ensure that they are tight and not in contact with other

items behind the instrument panel.

Revision 5, Feb. 2012 Page 7 200-123-0003

Page 8

PM1000II with crew, p/n 11920

11920 Sub-D DB-25 Female (Sockets) on unit

Power In

Ground

A/C Radio Phone Audio Hi

A/C Radio Phone Audio Lo

14

1

17

4

Aircraft Radio PTT

Aircraft Mic Audio Hi

Aircraft Mic Audio Lo

Pass 1 & 2 Phones Hi

Pass 1& 2 Phones Lo

Copilot Phones Hi

Copilot Phones Lo

Pilot Phone Audio Hi

Pilot Phone Audio Lo

Pass 1 Mic Audio Hi

Pass 1 Mic Audio Lo

Pass 2 Mic Audio Hi

Pass 2 Mic Audio Lo

12

25

13

15

2

19

6

18

5

9

8

no connection

1A

11-33 VDC

To Aircraft Radio

Phone Hi

AUX Headphone Jack

To Aircraft Radio

Phone Low

Passenger 1

Phones

Copilot Headphone Jack

Pilot Headphone Jack

Pass 1 Mic

no connection

Pass 2 Mic

Aircraft Radio PTT

Aux Mic Jack

To Aircraft Radio Mic Audio Lo

To A/C Radio Mic Audio Hi

Passenger 2

Phones

N

O

T

A

.

1

w

l

l

M

I

-

L

u

n

M

i

U

.

2

s

e

h

t

w

i

s

U

.

3

e

o

n

a

C

.

4

o

n

n

i

t

a

A

.

5

X

U

m

i

c

r

E

S

:

r

i

e

m

u

n

c

o

s

t

f

r

m

o

o

7

2

2

9

r

5

o

m

m

u

4

2

-

,

2

a

-

,

3

e

s

i

h

l

a

d

s

n

i

i

t

n

a

l

u

g

c

a

l

j

l

k

s

.

e

n

i

s

h

c

t

e

r

c

o

e

t

m

n

e

h

p

d

a

e

o

h

h

p

o

e

n

j

o

a

t

0

5

7

2

.

0

a

g

e

s

g

h

l

e

e

i

d

r

i

d

w

.

4

d

n

d

n

-

c

o

s

c

i

d

n

i

t

a

e

s

a

w

r

e

h

s

d

l

l

n

d

o

y

e

n

d

n

a

c

k

s

u

q

r

e

e

c

t

u

o

r

.

d

s

i

.

d

r

e

Copilot Mic PTT

Copilot Mic Audio Hi

Mic Audio Lo

Pilot Mic PTT

Pilot Mic Audio Hi

Pilot Mic Audio Lo

Music Input 1 Hi

Music Input 1 Lo

Music Input 2 Hi

Music Input 2 Lo

22

21

10

24

23

11

20

7

16

3

Pilot Mic

Jack

Music Jack 1

Music Jack 2

Copilot Mic Jack

Pilot PTT

ECO

Copilot PTT

9800 MARTEL ROAD, LENOIR CITY TN 37922

TITLE:

PM1000II (11920) WIRING DIAGRAM

DOCUMENT NUMBER:SIZE

120-192-0000

DATE:

06/25/98 1 1

REV

SHEET OF

1

PM1000II (11920) with CREW Function

11122513

6789

19202122102324

M

A

/

C

R

a

d

i

o

G

n

d

C

P

P

A

/

C

A

R

/

a

C

d

i

M

o

i

P

c

T

A

T

u

d

i

o

H

i

a

o

i

l

s

o

p

s

C

t

i

l

P

o

P

M

o

1

i

t

l

i

p

o

i

l

M

&

c

o

i

t

l

t

o

i

L

M

P

c

P

t

o

a

i

P

H

T

c

s

T

T

i

s

A

T

u

M

d

i

c

i

o

L

H

o

i

C

A

P

a

s

s

C

2

o

M

p

i

l

i

o

c

t

H

M

i

i

c

H

i

P

o

u

s

i

c

M

I

n

u

p

s

i

u

c

t

I

L

n

o

p

u

t

H

i

/

i

C

l

p

o

i

t

l

R

C

A

o

P

P

a

t

/

o

i

C

h

l

d

&

o

p

o

i

t

i

o

R

l

n

P

o

P

e

a

G

a

t

h

s

d

s

&

r

o

i

s

o

G

o

n

P

u

P

e

n

I

n

a

n

s

h

d

d

s

p

o

H

s

u

n

i

t

P

e

h

s

o

L

n

o

e

s

H

i

12345

11920 Connector layout,

1415161718

viewed from rear

G

P

M

r

a

o

u

s

u

s

s

i

n

M

.

P

c

P

d

1

o

2

a

u

&

w

s

s

I

s

i

n

e

2

c

p

r

1

2

P

u

(

1

&

h

t

I

n

1

o

L

2

p

-

n

o

3

u

e

P

3

t

s

h

H

V

o

L

i

D

n

o

e

C

s

)

H

i

PM1000II Operation/Installation Manual Page 8 Revision 5, Feb 2012

Page 9

PM1000II NO crew, p/n 11922

(p

)

11922 Sub-D DB-25-- Unit has female (socket)

Power In

Ground

A/C Radio Phone Audio Hi

A/C Radio Phone Audio Lo

14

1

17

4

Aircraft Radio PTT

Aircraft Mic Audio Hi

Aircraft Mic Audio Lo

Copilot, Pax 1 & 2 Phones Hi

Copilot, Pax 1 & 2 Phones Lo

Pilot Phone Audio Hi

Pilot Phone Audio Lo

Pass 1 Mic Audio Hi

Pass 1 Mic Audio Lo

Pass 2 Mic Audio Hi

Pass 2 Mic Audio Lo

Copilot Mic PTT

Copilot Mic Audio Hi

Mic Audio Lo

Pilot Mic PTT

Pilot Mic Audio Hi

Pilot Mic Audio Lo

Music Input Hi

Music Input Lo

12

25

13

19

6

18

5

9

8

22

21

10

24

23

11

20

7

Copilot

Phones

1A

11-33 VDC

To Aircraft Radio

Phone Hi

AUX Headphone Jack

To Aircraft Radio

Phone Low

Passenger 1

Phones

Pilot Headphone Jack

Pass 1 Mic

Pass 2 Mic

Pilot Mic Jack

Music Jack

Aircraft Radio PTT

Aux Mic Jack

To Aircraft Radio Mic Audio Lo

To A/C Radio Mic Audio Hi

Passenger 2

Phones

Copilot Mic Jack

Pilot PTT

Copilot PTT

Expansion Power

Expansion Audio In

Expansion Audio Out

Ground

15

3

16

2

To Pin 1 of 11616 expansion module

To Pin 3 of 11616

To Pin 2 and 15 of 11616

To Pin 14 of 11616

Used with 11922 and

Expansion module only

These pins used for expansion modules only

.

1

A

l

w

l

i

r

e

t

s

m

u

f

n

o

o

c

r

m

t

o

M

I

-

L

5

7

2

2

o

5

r

7

2

.

0

0

M

m

i

u

n

m

4

2

u

.

2

U

e

2

s

-

,

-

,

3

d

n

N

E

O

T

:

S

s

a

.

3

U

s

.

4

C

o

.

5

A

U

q

r

e

11122513

6789

19202122102324

a

i

i

a

d

c

n

.

t

d

e

e

i

s

n

l

t

u

a

i

n

g

e

n

n

t

c

h

s

i

l

e

X

u

d

p

d

a

e

h

n

o

h

i

.

d

r

e

1415161718

g

n

o

-

c

4

c

u

d

s

w

a

r

s

e

h

o

s

t

a

i

t

n

e

r

o

c

e

d

n

a

m

i

c

12345

11922 Connector lay-

9

g

a

i

h

e

e

s

d

e

d

l

w

i

.

r

t

e

r

t

o

w

i

i

h

h

e

s

l

d

l

n

a

l

s

k

j

c

a

.

m

d

n

e

l

n

y

o

r

o

n

o

h

p

k

e

j

c

a

r

s

e

a

9800 MARTEL ROAD, LENOIR CITY TN 37772

TITLE:

PM1000II (11922) WIRING DIAGRAM

DOCUMENT NUMBER:

SIZE

DATE:

ECO

A

120-120-0000

07/25/98

SHEET OF

1

REV

0

1

11922, PM1000II without CREW

Microphone

out, viewed from rear

M

A

/

C

R

a

d

i

o

G

n

d

C

A

/

C

A

R

/

a

C

d

i

M

o

i

P

c

T

A

T

u

d

i

o

H

i

P

P

a

o

i

l

s

o

p

s

C

t

i

l

P

o

P

M

o

1

i

t

l

i

p

o

i

l

M

&

c

o

i

t

l

t

o

i

L

M

P

c

P

t

o

a

i

P

H

T

c

s

T

T

i

s

A

T

u

M

d

i

c

i

o

L

H

o

i

C

P

u

a

s

s

i

s

c

C

M

2

I

o

n

u

M

p

p

s

i

i

u

l

i

c

o

c

t

t

I

L

H

n

M

o

p

i

i

u

c

t

H

H

i

i

A

P

o

/

i

C

l

p

o

i

t

l

R

C

A

o

P

P

a

t

/

o

i

C

h

l

d

&

o

p

o

i

t

i

o

R

l

n

P

o

P

e

a

G

a

t

h

s

d

s

&

r

o

i

s

o

G

o

n

P

u

P

e

n

I

n

a

n

s

h

d

d

s

p

o

H

s

u

n

i

t

P

e

s

h

o

L

n

o

e

s

H

i

G

E

E

r

x

x

o

p

p

u

.

.

n

E

P

P

E

A

d

x

o

w

x

u

p

w

p

d

r

.

.

e

i

G

o

A

P

r

n

u

I

w

(

n

d

1

d

r

p

1

i

o

u

I

-

n

3

t

O

p

3

u

u

V

t

t

p

(

D

9

u

C

V

t

)

D

C

)

Monaural Headset Jack Details

Revision 5, Feb. 2012 Page 9 200-123-0003

TIP

(PTT)

TIP

hone audio

Headphone

Ring

(mic audio)

Barrel

(gnd)

Barrel

(audio

gnd)

Loading...

Loading...