Page 1

TOOLS WITH CHARACTER!

MICROMOT

System

2006

Updated Edition

With PROXXON System News

Page 2

MICROMOT

System

Welcome

Superior Technology and Quality!

To any professional working with

electronic hand and power

tool - PROXXON means

competitive, high quality technology.

PROXXON individually test each product

as it leaves the factory to ensure it

arrives with you in immaculate

condition.

Further information, log on

advanced,

www.proxxon.com

[The drill/grinder

shown here

is not included]

2

Tile cutting attachment FEX

Complete with tungsten carbide cutter.

Ideal for smaller cuts in wall tiles, wood and plaster of paris.

The 20mm neck collar allows the rapid connection of the drill/grinder FBS 240/E, MICROMOT

50 and 50/E and the professional drill/grinder IB/E.The clever, stable construction of fibre

reinforced POLYAMIDE allows height adjustment, a clear scale as well as a flattened edge

allowing one to work close to edges.

No 28 756 Complete with 3.2mm rasp cutter

Spare cutter for the FEX

Rasp cutter of tungsten vanadium with shaft of 3.2mm. Ideal for wall tiles.

No 28 757

Page 3

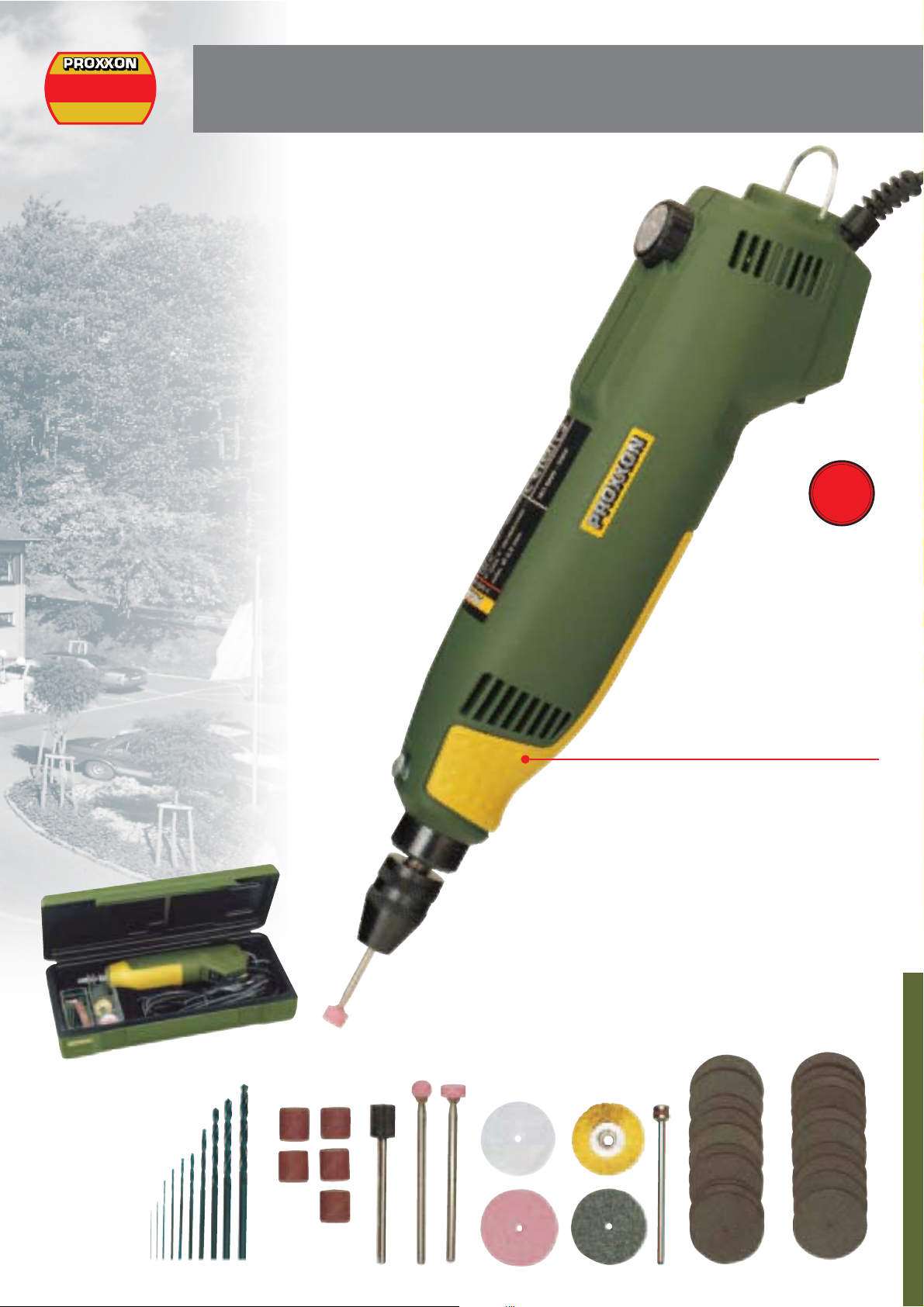

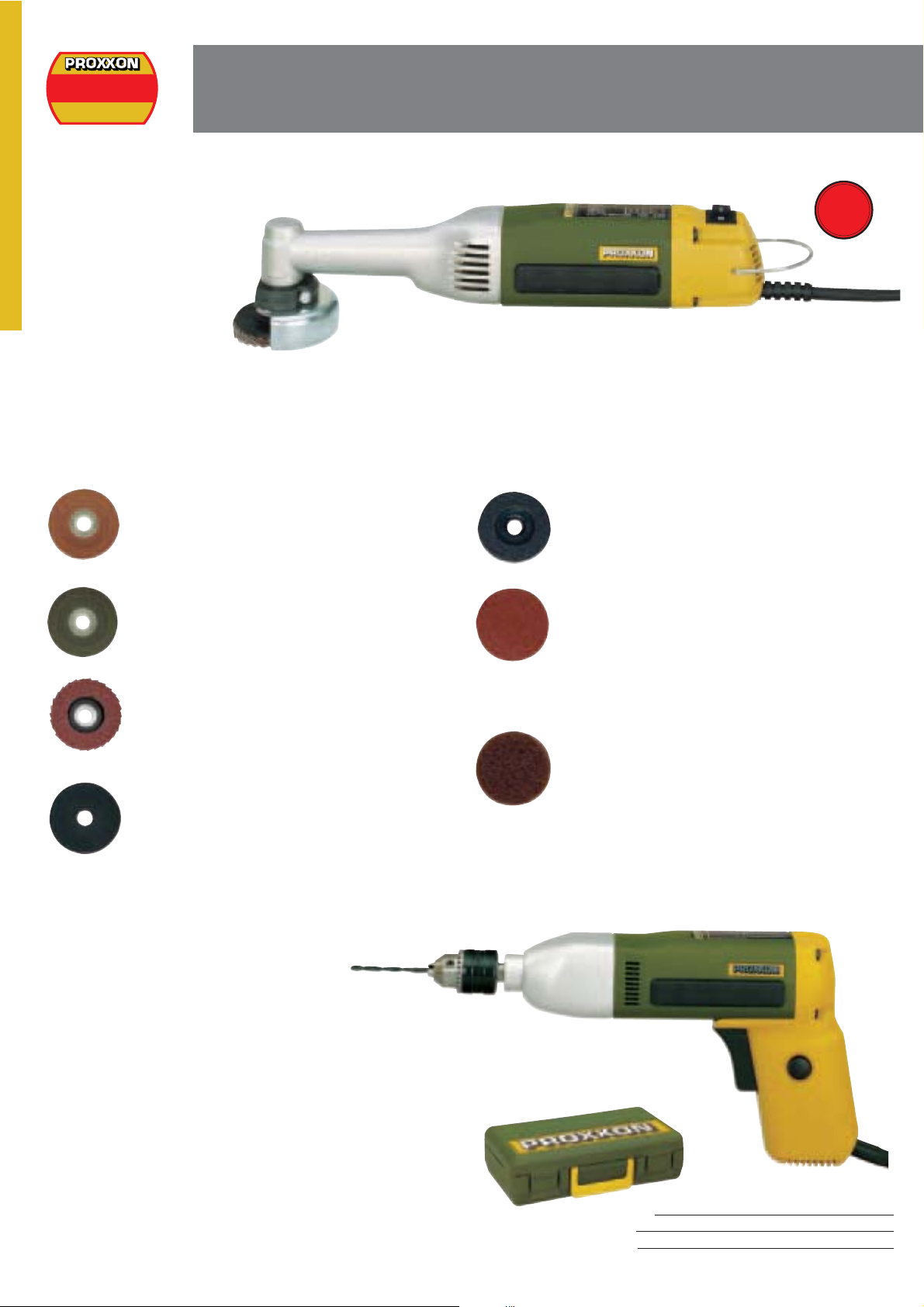

The versatile mighty mini! Precision Drill/Grinder FBS 240/E:

MICROMOT

System

220-240

VOLT

The quiet powerhouse with keyless chuck 0.3 – 3.2 mm

Precision Drill/Grinder FBS 240/E

1001 uses for every conceivable operation: milling, drilling,

grinding, polishing, brushing, cleaning, de-rusting, sawing, carving,

engraving, etc. The maximum speed of 20,000rpm is continuously

variable down to 5,000rpm. The full wave electronic speed control

results in virtually constant torque, even at lower speeds, in turn

facilitating micro drilling. The spindle runs in a precision ball bearing

and is fitted with a lock button. The 20mm collar fits MICROMOT

drill stands and vices. The machine is fitted with a quality, balanced,

low noise motor with high life expectancy. Stable housing of

POLYAMIDE with soft components in the finger grip area. Complete

with 40 quality inserts in a sturdy plastic case.

Technical data:

5,000 - 20,000rpm. Maximum power consumption 100W, 230V,

keyless chuck with 0.3 – 3.2mm capacity. Length 185mm and

mass 450g. Insulated according to class 2 requirements.

No 28 472

.

Stable housing of POLYAMIDE with soft

The FBS 240/E may also be fitted with the

optional MICROMOT steel collets (see page 20).

Complete with 43 high quality bits and cutters

in a durable plastic case.

components in the finger grip area.

NOTE:

3

Page 4

220-240

VOLT

MICROMOT

System

Miniature precision machines, genuine single handed use.

Elektro-Feinwerkzeuge. Echte Einhandgeräte. Mit Gehäuse-

MICROMOT

System

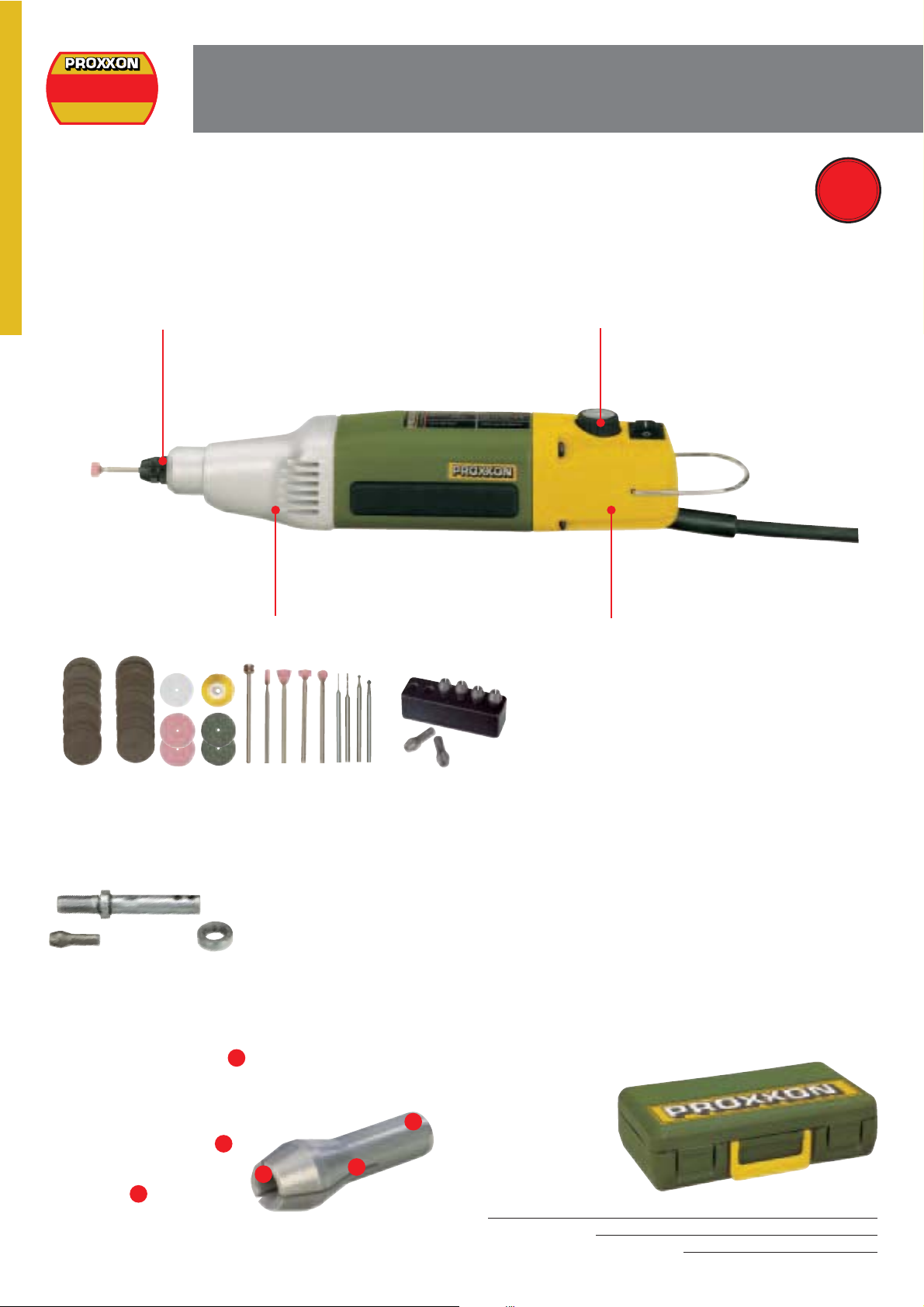

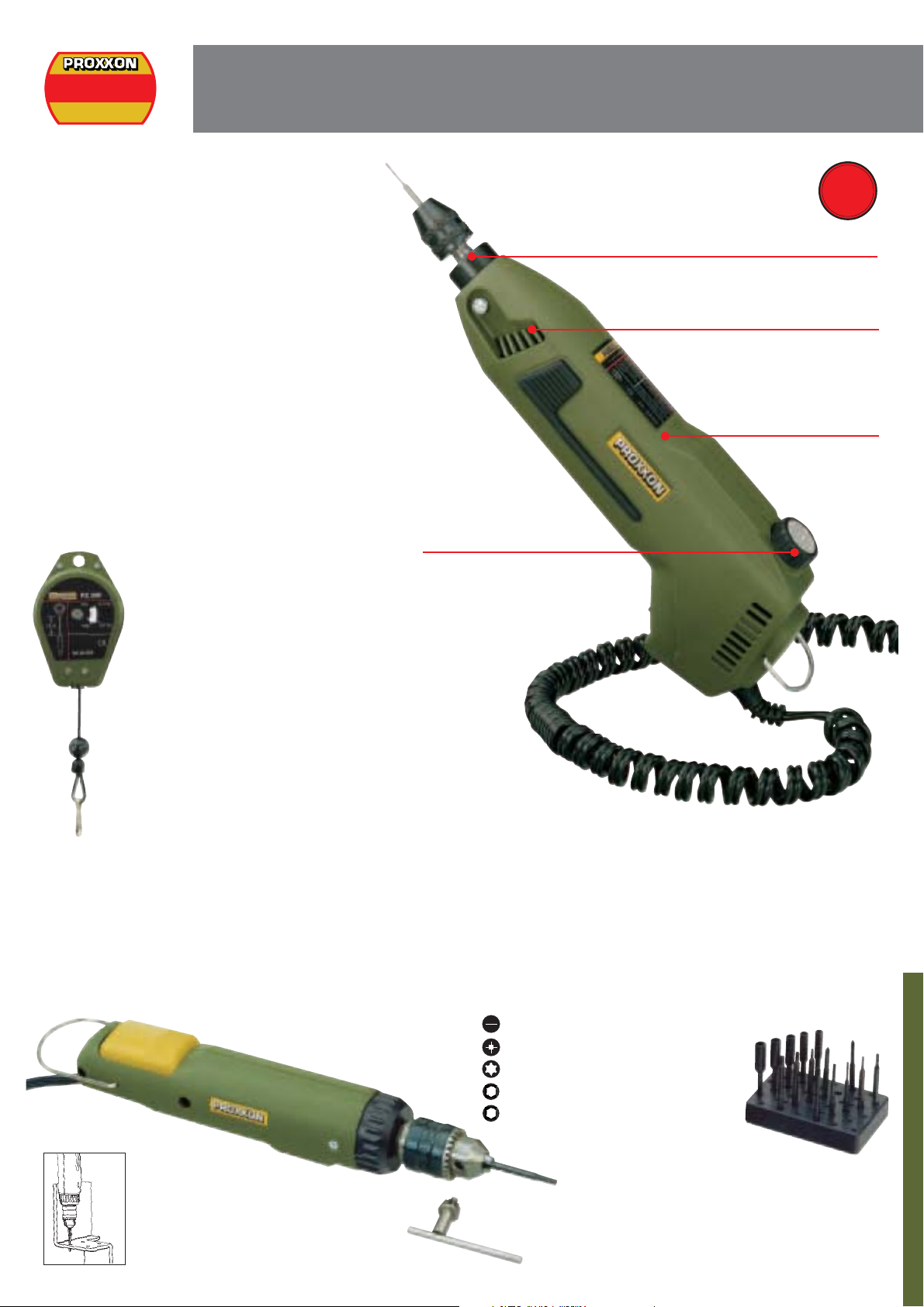

Professional drill/grinder IB/E

Lightweight tools with die-cast aluminium heads:

kopf aus Alu-Druckguss. Leise, präzise und effizient!

quiet, precise and efficient.

• Usable for prolonged periods when drilling, milling,

grinding, polishing, cleaning, cutting and even

engraving.

Ball bearing spindle, of ground steel,

with lock button for rapid cutter

changing.

Streamlined head of die-cast aluminium

for exact bearing seats and optimal stability.

• Ideal for mechanics, model builders, jewellers,

opticians, artists and electronic enthusiasts.

Quiet, powerful 100W motor with full

wave electronics for speeds between

5,000 and 20,000rpm.

Quality without compromise:

isolation to class 2.

High concentric accuracy (maximum runout 3/100mm).

This high-revving, special motor has full-wave electronic speed control

for speeds between 5,000 and 20,000rpm and is usable for extended

periods at a time. The ground

steel spindle runs in a ball bearing,

minimising play.

Six high concentricity collets,

(1.0 – 1.5 – 2.0 – 2.4 – 3.0 and

3.2 mm and closure nut).

NOTE: MICROMOT steel collets They are hardened and thus have

a high, consistent flexibility. They also maintain prolonged accuracy,

even after regular use (these collets should not be compared with

unhardened, four-slit

collets of brass and aluminium).

The triple slit collet is

substantially more difficult to manufacture

than the four-slit type, but offers a bette r load-bearing surface. This is

especially important for cutters

with small shank diameters.

3

4

1

1

2

3

2

With 34 bits & cutters of industrial quality,

all shafts 2.35mm. Complete with six triple slit steel collets

covering 1.0 to 3.2 mm (see also page 20).

Technical data:

Speed 5,000 to 20,000rpm. Power consumption (max) 100W, 220 –

240V. Stable head of die-cast alu and POLYAMIDE main housing.

Length 230mm, and weight approx 500g. Insulated to class 2. The

20mm collar allows fitting of optional drill stands, horizontal stands,

etc. Supplied with 34 bits and cutters in a stable plastic case.

No 28 481

The IB/E professional drill/grinder, Long neck angle milling/drilling unit

WB 220/E and Long neck straight drill/grinder LB/E

are supplied in stable plastic cases.

Page 5

MICROMOT

220-240

VOLT

MICROMOT

System

System

Long neck angle milling/drilling unit MICROMOT WB 220/E

A slender, low weight right-angled drill for the places you can’t always reach.

Ideal for milling, drilling, etc. in inaccessible places, e.g. in

model ships' hulls, as well as the parting of stock. Special,

balanced motor with maximum power input of 100W, full

wave electronic speed control.

Ideal for installation, the tool box and work bench.

Technical Data:

No load speeds of 3,000 – 15,000rpm. Power consumption (max)

100W, 220 – 240V. Stable head of die-cast alu and POLYAMIDE main

housing. Length 270mm, and weight approx 550g. Insulated to class 2.

Six triple slit, hardened steel collets 1.0 – 1.5 – 2.0 – 2.4 – 3.0 and

3.2mm and closure nut are included. Packed in stable plastic case.

No 28 492

Weighs in at only 500g and easily drills 5mm mild steel.

MICROMOT quick-change (QC) sanding system

Sand with different grits of sandpaper. The PROXXON system is far easier to use than the method that uses glued

sandpaper.

Spare sanding discs for the MICROMOT QC system

(ø 25mm)

Removal is effected

by turning the disk

CCW while locking

the spindle.

The quick change adapter fits the long neck angle

milling/drilling unit WB 220/E, long neck straight drill/grinder LB/E, professional drill/grinder IB/E, the precision

drill/grinders FBS 240/E and FBS 12/E as well as the

mill/drill units MM 50 and MM 50/E. Three aluminium

oxide discs (grits 40, 80 and 180) for steel, three Zirconcorundum discs (50, 80 and 120 grits) for stainless and alloy steels, as

well as three polishing fleeces for cleaning, finishing, and removal of

paints (in extra fine, fine and coarse) are all included.

No 28 785 Complete set as above

Aluminium Oxide (for steel)

No 28 786 40 grit 5 off

No 28 787 80 grit 5 off

No 28 788 180 grit 5 off

Zircon corundum (for stainless and alloy steels)

No 28 789 50 grit 5 off

No 28 790 80 grit 5 off

No 28 791 120 grit 5 off

Polishing fleece (for cleaning & finishing)

No 28 792 coarse 5 off

No 28 793 fine 5 off

No 28 794 extra fine 5 off

Long neck straight drill/grinder LB/E

Head of die-cast alu with 100mm neck and 20mm MICROMOT collar.

Ideal for use in inaccessible areas. Mill, drill, grind, drill, polish operations.

The design allows use in slots and channels, ideal

for internal cuts. Collets 1.0 – 1.5 – 2.0 – 2.4 – 3.0

and 3.2mm and closure nut are included. Well presented in a plastic case.

Technical data:

Length 300mm and weight 630g. Other details as per IB/E on page 4.

No 28 485

5

Page 6

MICROMOT

System

Long neck Angle Grinder LWS

A carborundum grinding disc of

grit 60, a fan sander of grit 100

and a reinforced cutting disc are

included.

Features include a special, balanced motor. Used on steel, non-ferrous

metals, glass, ceramics and wood too.

the LWS ideal in numerous applications, even parting.

The long, slim head of die-cast aluminium makes

220-240

VOLT

Technical data:

Disc diameter 50mm Ø. Mains voltage 220 – 240V, 50/60Hz, 100W

max power consumption. 13,000rpm. Stable head of die-cast alu and

POLYAMIDE main housing. Length 280mm, and weight approx 550g.

Run down time less than 1 second. Insulated to class 2.

No 28 547

Corundum grinding disc, 50mm diameter, for LWS

Used for de-burring, grinding, sharpening and de-rusting

steel and non-ferrous metals.

No 28 585 (60 grit)

No 28 586 (36 grit)

Silicon Carbide grinding disc, 50mm diameter,

for LWS

Used on glass, stone, ceramics and very hard materials.

No 28 587 (60 grit)

Fan sander, 50mm diameter, for LWS

Standard corundum for superior stock removal on tempered cast iron, cast iron, stainless steel, non-ferrous metals,

wood and plastic.

No 28 590 (100 grit)

No 28 591 (150 grit)

Corundum bound cutting disc for LWS

With woven reinforcing, ideal for cutting steel, non-ferrous

metals, plastic and wood. 50mm diameter, 10mm bore and

1mm thick.

No 28 154

Pocket drilling machine Colt 220/E

Weighs in at only 900g and easily drills 5mm mild steel.

Backing disc for LWS

Self-adhesive type, for use with sanding discs and sanding fleece.

No 28 548 1 off

Corundum sanding discs

Self-adhesive type, used on flat and convex surfaces.

No 28 549 80 grit 5 off

No 28 550 120 grit 5 off

No 28 551 180 grit 5 off

No 28 552 240 grit 5 off

Sanding fleece for LWS

Self-adhesive type, used for cleaning, matting and sanding of steel, stainless, steel, non-ferrous metals. Also

used for paint removal.

No 28 554 medium 5 off

No 28 555 fine 5 off

Tough and durable permanent magnet motor drives the planetary

gear gearbox. The 20 mm collar facilitates use in MICROMOT drill

and horizontal stands. Housing of fibreglass reinforced POLYAMIDE.

Handy switch with integral electronic speed control and lock. Superlong power cord of 250mm. The RÖHM chuck offers a range of 0.5 to

6mm. The Colt fits into the leather holster supplied as standard

equipment.

Technical Data:

220 – 240V, 50 – 60Hz, maximum power consumption of 100W.

Speed approx. 0-3,000rpm. Chuck capacity 0.5 – 6mm. Capacity in

mild steel 5mm. Weighs 900g and isolated to class 2.

No 28 490

6

Long neck angle grinder LWS, COLT 220/E,

belt sander BSL 220/E and super jig saw 230/E

are all packed in a sturdy plastic carrying case.

Page 7

Precision equipment for cutting. Small and comfortable.

MICROMOT

System

Die-cast aluminium heads.

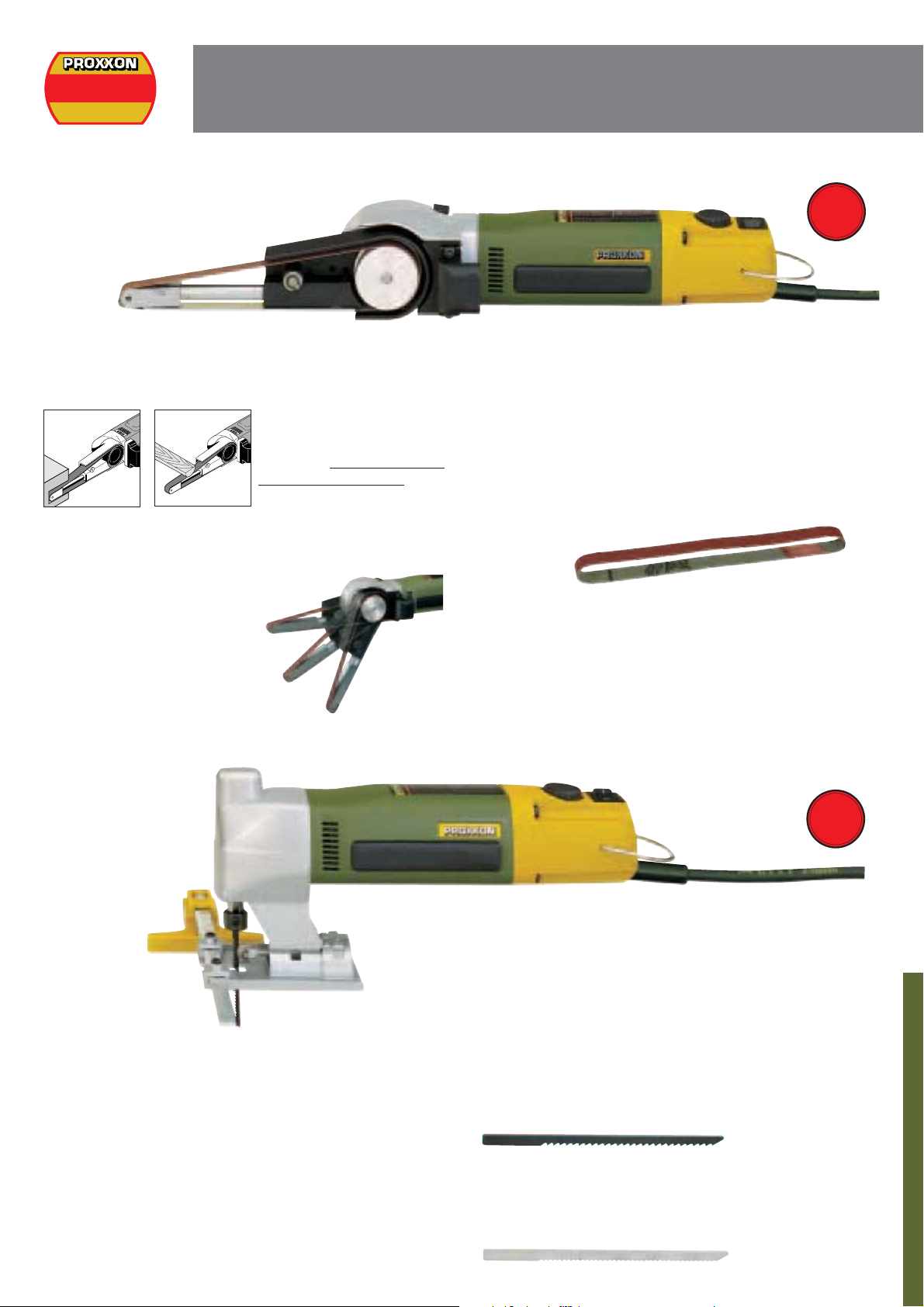

Belt sander BSL 220/E

220-240

VOLT

For shape finishing, mortising, fine polishing (flat surfaces). Also for

de-burring metal, paint removal and fine finishing. Head of die-cast

aluminium, and full wave

A

A

12 V

V

VA

2

A

1

V

2

1

12 VA

k

g

fj

f

l

d

f

VA

3

dg

öfjdkg

d

d

j

sg

d

,dlg

j

b

lg

g

d

d

3 VA

a

s

d

j

i

f

g

l

d

d

k

f

j

ö

d

2 V

1

2

A

1

V

12

k

g

j

f

f

l

g

A

d

k

f

d

V

j

f

dg

3

dö

d

j

g

lg

s

jd

b

lg,d

VA

d

3

sdg

j

ida

f

g

l

d

d

fk

j

ö

d

V

12

elect ro nic speed control. Sanding

belt can be changed in a matter

of seconds. Complete with 2 off

80 and 2 off 180 grit belts.

The head rotates through 60°.

Super jig saw SS 230/E

Technical data:

Belt size 10 x 330mm and usable sanding area 10 x 110mm. Belt speed

electronically controllable from 300 – 700rpm. Mains voltage 220 240V. 100W max power consumption. 13,000rpm. Stable head of diecast alu and POLYAMIDE main housing. Length 350mm, and weight

approx 650g. Run down time less than 1 second. Insulated to class 2.

No 28 536

Replacement corundum sanding belts 10 x 330mm

on tough, woven backing. Sands metal, non-ferrous metals, wood and

plastics efficiently

No 28 581 180 grit set of 5

No 28 582 120 grit set of 5

No 28 583 80 grit set of 5

220-240

VOLT

This unit offers fantastic cutting capacity with footplate adjustable up to

45° for mitre cuts. The housing head is in die-cast aluminium. The stroke

speed is variable by means of full wave electronic speed control. Ideal

for tight curves in wood (up to 12mm), PC cards and non-ferrous

metals to 3mm.

Technical data:

Stroke speed of 2,000 – 4,500/min. Mains voltage 220 – 240V, 100W

max power concumption. 13,000rpm. Stable head of diecast alu and

POLYAMIDE main housing. Length 230mm, and weight approx 700g.

Insulated to class 2. Packed in a sturdy plastic case, complete with 4

super cut blades of various pitches for wood, plastic and metal.

No 28 530

The alternative 12V jig saw

STS 12/E is described

on page 12.

Jig saw blades. Special steel.

Pitch of 1.06mm, teeth ground & set. Usable on hard & soft woods,

plywood, fibreglass reinforced sheets as well as various plastics.

Ideal for tight curves and clean cuts. Fits SS 230/E and STS 12/E.

No 28 054 Pack of 2

Jig saw blades. HSS

Tooth pitch of 1.5mm, with teeth set & ground. Usable on metals,

aluminium and softer alloys, fibreglass, Plexiglass and insulating materials.

Fits SS 230/E and STS 12/E.

No 28 056 Pack of 2

7

Page 8

MICROMOT

System

Delta sander OZI 220/E

Sanding area 65 x 65 x

65mm with gummed

pads allows quick changing

and use of all 3 corners.

orbital motion. Sanding pad oscillates about its centre.

Oscillating motion far better than the conventional

Head of die-cast zinc, ensuring exact and

stable housing for the moving parts.

MICROMOT OZI 220/E

Spannung ~ 230 V

D-54518 Niersbach

Input 100 Watt Schleiffrequenz

50/60 Hz

3.000 - 10.000/min

The oscillating motion ensures lack of

vibration and kickback and allows the fitting

of cutting blades too!

Four sanding pads included

(Two 80 and one each 150 and 280 grit).

Small yet efficient sander for very tight spots,

e.g. corners, sides and inaccessible areas.

The oscillating motion ensures quiet operation and also facilitates cutting. The variable speed between 3,000 and 10,000rpm facility ensures

the correct speed for every material.

IMPORTANT: The self-adhesive sanding pads ensure quick changing

and optimal usage. Simply remove and rotate through 120° for a fresh

corner.

Flexible scraper of spring steel (50 x 70mm)

Utilises the oscillating motion of the OZI, yielding exceptionally high efficiency at 10,000rpm. Ideal for the removal of paint, tile adhesive, silicon

removal, and even the removal tar and under-body muck.

Packed in a sturdy, plastic case, with 4

sanding pads, a sanding fleece and one

each hard and soft polishing felt.

No compromise

class 2 isolation.

220-240

VOLT

Technical data:

Sanding shoe size is 65 x 65 x 65mm. Sanding frequency of 3,000 –

10,500rpm. Mains voltage 220 – 240V. 100W max power consumption.

Stable head of die-cast alu and POLYAMIDE main housing. Length

230mm, and weight approx 630g. Insulated to class 2.

No 28 520

Its neat and compact design will have you working

where often you will struggle. Here the OZI is using the

HSS Blade for precise work.

No 28 904

8

Page 9

Handy, precise and particularly easy to handle.

MICROMOT

System

Sanding pads for OZI 220/E

High durability aluminium oxide pads. Grain filled with special filler to prevent premature clogging and deposited on special backing paper.

Self-adhesive.

Standard packing of 5 sheets per packet:

No 28 880 grit 80 5 pieces

No 28 882 grit 150 5 pieces

No 28 886 grit 280 5 pieces

Bulk pack contains 25 each of:

No 28 891 grit 80 25 pieces

No 28 893 grit 150 25 pieces

No 28 895 grit 280 25 pieces

MICRO router MOF

Practical spindle lock button

eases bit changing.

Support columns set back to

optimize viewing of cut.

220-240

VOLT

Lock button for depth.

Parallel and circle jig of

die-cast alu.

HSS cutting blade (65mm diameter)

Oscillates at up to 10,000 strokes per minute,

making it ideal

for parting in,

e.g., the panelbeating industry,

wood (model

building and

house decor),

PC cards, plaster of paris, etc. The segment cut

facilitates exact cutting right into corners.

No 28 900

Diamond cutting blade

(65mm diameter)

Operation as

described above

for the HSS

blade. Cuts marble, bricks, dry

walling and

many other

materials in the sanitary and electrical fields.

The segment cut facilitates the cutting right

into corners.

The MICRO router MOF is fitted with a

vacuum cleaner or dust extractor adapter,

for use in a dust-free environment.

Base of die-cast alloy and face of smooth gliding POLYCARBONATE.

Ideal for slotting, rounding over, counter

boring, and stock removal in wood, plastic,

Perspex, MDF, ceilings and many more.

Supplied with MICROMOT collets 1.0 – 1.5 –

2.0 – 2.4 – 3.0 and 3.2mm and closure nut.

Technical data:

Runs at 27,500rpm (no load). Mains voltage

220 – 240V, 130W max. Footprint 70 x

100mm. Milling depth up to 20mm. Insulated to class 2.

No 28 568

We recommend our vacuum cleaner controller AS/E

Scale for micro

adjustment of depth

in 0.2mm increments

and possibility

to trench.

NOTE:

on page 31.

No 28 902

NOTE:

Router cutters for wood are

detailed on page 34.

9

Page 10

MICROMOT

System

Precision milling/drilling machines MICROMOT 50 and 50/E:

Ball bearing spindle and efficient cooling system for extended use.

MICROMOT 50 and 50/E

• 1001 uses: milling, drilling, routing, de-scaling, polishing,

cutting, cleaning, sawing, engraving, etc.

• Useable on any workable material e.g. steel, precious metals,

glass, ceramics, plastics, precious stones, etc.

• Ideal for electronic hobbyists, model builders, tool and die

makers, jewellers, opticians, artists, chiropractors, dental

technicians, etc.

• 12V supply allows the safe use of coolant, e.g. when grinding

and cutting semi-precious stones.

Stable housing of fibreglass reinforced

POLYAMIDE. With soft component in the

finger grip area for extended use.

12

VOLT

The MICROMOT standard 20mm collar

allows use in the drill stand MB 140/S,

router base OFV, stand UHV and angle

adapter WS 90.

The tens of thousands of these units in use speak for themselves: they are a joy

to use. Here is why they are so loved:

The diameter of only 35mm makes it easy to handle. The weight of 230g, quietness and effortless drive via the special motor, ground spindle and collar bearing all contribute to the ergonomic design. The high quality steel collets (see

page 4) ensure accurate clamping of the cutters. The size of the machine dictates a 12V drive system, use of a transformer is thus required. MICROMOT transformers of at least 1A are recommended.

Mill/drill unit MICROMOT 50/E

The thyristor electronic speed control enables the selection of speeds

from 5,000 to 20,000rpm. Phase angle control and feedback effect circuitry yield high torques, even at low speeds. Six MICROMOT collets for

shanks covering 1.0 – 1.5 – 2.0 – 2.4 – 3.0 and 3.2mm are supplied.

Power consumption is 40W max. Length 220mm and weight approx.

230g.

No 28 510

Mill/drill unit MICROMOT 50

As 50/E, except that no speed control is fitted. No load speed is 20,000

rpm.

No 28 500

Footswitch FS

Frees one’s hands for easy operation.

For all machines with a Euro plug,

class 2 insulation and maximum of

500W. Ideal for both portable and

stationary machines. Housing of

fibreglass reinforced NYLON. The

connecting cord is 250cm in length

and the output cord 50cm. The

transformer is connected to the FS

when using 12V machines.

No 28 700

10

Page 11

MICROMOT

System

Two complete MICROMOT kits: mains adapter,

mill/grinder MICROMOT 50/E and 34 cutters.

Model building and engraving set

With MICROMOT dill/grinder 50/E as described on page 10. Includes

34 industrial quality cutters: 1 diamond grinding bit, 1 fine miller,

0.5 and 1.0mm micro-drills, 1 brass brush, 4 carborundum grinding

bits (cylinder, sphere, disc and cone shaped), 1 saw blade, 4

grinding wheels 22 x 3.0mm (2 carborundum, 2 silicon carbide), 20

cutting discs, 1 arbor. The 6 MICROMOT collets described on page

20 are also included. With mains adapter for 220 – 240V operation

(12V, 1.0A).

No 28 515

Both sets are packed in an attractive plastic case, with 34 industrial quality cutters.

Complete set for detailed work

The complete set includes drill/mill tool MICROMOT 50/E, drill stand, triple ball bearing flexible shaft 100/P and

a suitable mains adapter (220V supply, output 12V at 1.0A). 34 industrial quality bits: 1 diamond grinding bit, 1

fine milling bit, 0.5 and 1.0mm micro-drills, 1 brass brush, 4 carborundum grinding bits (cylinder, ball, wheel,

cone), 1 saw blade, 4 grinding wheels (2 silicon carbide, 2 carborundum), 20 cutting discs and arbor. The 6

hardened steel collets fit both the MICROMOT 50/E and flexible shaft. Supplied in a gift case.

No 28 514

MICROMOT angle adapter WS 90

Facilitates working in otherwise difficult areas. May

also be used for parting metal profiles such as model

railroad tracks. The rubber discs (28 982) convert your

machine into an angle grinder. Standard with the

20mm MICROMOT collar and accepts all MICROMOT

collets.

Technical Data:

Transmission ratio 1:1. Double bearings at input and output

ends. Housing of fiberglass reinforced POLYAMIDE.

No 28 405

NOTE:

Quality, triple slit hardened steel collets are

ideal for optimum concentricity

and tightening force.

Furthermore, bits and

cutters may be fitted

close to the machine.

This is especially important when sanding,

routing and milling as

side play is minimised.

11

Page 12

MICROMOT

System

Pensander PS 12

Ideal for working on surfaces in recesses, slots and small corners. Linear

stoke of 8,000 per minute, 2.5 mm stroke length. Housing of fiberglass

reinforced POLYAMIDE. Four sanding arbours with straight shanks and

four angled (all different shapes) as well as three sheets of pre-profiled

self-adhesive sanding pads are included. The sheets are of grits 180, 240

and 400 with 5 of each shape per sheet.

No 28 594

Additional Sandpaper for the PS 12

Three sheets, each with 20 pads (5 each of the four shapes, self-adhesive)

No 28 822 grit 180

No 28 824 grit 240

No 28 826 grit 400

where space is at a premium.

Pensander PS12 sands linearly

12

VOLT

Note: A mains adapter of at least 1A at 12-18VDC is required. We

recommend PROXXON power supplies NG 2/E or NG 5/E. The electronic

speed control on these units allows the selection of different speeds for

different applications and materials.

Orbital sander SL12/E

Shaping, rough and fine sanding of flat surfaces and sides. Flat sanding

of primers and finish-polishing. Use on 12VDC (safety voltage) and low

speeds allow wet sanding. The easy to use paper clamp allows the use

of any sand paper. Sanding area 80 x 58mm has no overhanging parts,

allowing sanding into corners.

Jig saw STS 12/E

Easy curved and intricate sawing of wood (up to 10mm), printed circuit

cards (up to 3mm) and non-ferrous metal (up to 2.5mm). The powerful

5-pole motor operates off 12 – 18VDC with power consumption up to

100W. The stroke is 6 mm and speed is variable between approx. 2,000

and 5,000 per min. Housing of fiberglass reinforced POLYAMIDE. Includes

2 blades (coarse & fine). We recommend the use of MICROMOT mains

adapters of at least 2A/24VA.

No 28 534

Housing of fiberglass reinforced POLYAMIDE. The 100W (max) motor

operates off 12 – 18VDC. Stroke speed 1,000 – 5,000 per minute. We

recommend the use of MICROMOT mains adapters of at least 2A/24VA.

No 28 542

12

VOLT

Jig saw blades

can be found on page 7.

12

Page 13

Power and precision also when using coolant.

MICROMOT

System

VOLT

12

Includes keyless chuck (capacity 0.3 - 3.2mm).

MICROMOT precision drill

grinder FBS 12/E

Ideal precision tools for delicate jobs that aren't possible

with a normal drill: e.g. precision drilling, milling, sanding,

polishing, brushing, de-rusting, engraving and cutting.

Includes keyless chuck (capacity 0.3 – 3.2mm). A precision ball

bearing minimises spindle side play. Spindle lock button for bit

changing obviates the need for spanners. Recessed spindle head

for inserting MICROMOT steel collets (see page 4). Efficient

forced ventilation cooling of high quality, 5 pole motor.

Fibreglass reinforced POLYAMIDE casing.

Technical data:

12 – 18VDC, maximum power consumption 100W. Electronic

speed control of 3,000 - 15,000rpm. Length 185mm and weight

approx. 450g.

Recommended for use with MICROMOT transformers of at least

2.0A (see page 15).

No 28 462

Load balancer FZ 300

20mm MICROMOT standard collar.

Efficient forced ventilation cooling for

extended periods of use.

High quality, 5 pole motor

with high torque.

Speed control with feedback effect for speeds of

3,000 – 15,000rpm.

Load capacity 300 – 600g, cord length to 180cm.

Housed in a sheet steel case with plastic outer

cover. Weight approx. 400g and size approx. 220 x

100 x 40mm. Ideal for assembly lines and work

benches.

No 28 699

MICRO screwdriver MIS 1

Forget about compressed air! Easy, quiet and environmentally-friendly screw driving. With pre-selectable torques of

0.35 – 2.0Nm. Complete with 16 inserts of Chrome Molybdenum steel.

The gearbox yields the ideal speed of about 200 – 250rpm (depending

on mains adapter used). The clutch, adjustable in the range 0.35 to

1.0Nm in 5 steps. Means tightening torques can be selected precisely.

The sixth stage bypasses the clutch and yields approx. 2Nm. An ideally

positioned rocker switch provides on/off/reverse. A ROEHM chuck

Recommendation:

The MICRO screwdriver MIS 1 is

eminently suitable to cut threads!

facilitates acceptance of all bit shanks of up to 6.5mm / 1/4". A set,

packed in a cardboard box, also includes 16 inserts of Chrome Molybdenum steel. We recommend the use of MICROMOT mains adaptors.

No 28 690

Slot: 0,3 x 1,5 / 0,35 x 2,0 / 0,4 x 2,5 mm

Philips: Size 0 and 1

Torx: T 6, T 8, T 10

Allen key, internal: 3,0 - 3,5 - 4,0 - 4,5 - 5,0 mm

Allen key, external: 1,5 - 2,0 and 2,5 mm

The bit holder shown here,

usable with bits of 2.35, 3.0 and 3.2 mm

is available as NO 28 359 (2 pcs without bits).

NOTE:

13

Page 14

MICROMOT

VOLT

12

System

Complete engraving kit with „trial glass“

Complete engraving kit with „trial glass“, supplied with the tried and tested

engraving tool GG 12 (12 – 18V, 20,000rpm spindle speed, fitted with ball bearing),

TUV approved mains adapter (12V, 0.5A), motifs and instruction booklet as well

as all necessary bits: 1.0 and 1.8mm diamond grinding bits with spherical head

for engraving and line work, silicon carbide grinding bits in both conical and

bullet shape for frosting glass as well as carborundum grinding bits in ball and

cylinder shape for grinding and engraving. Every component is securely packed

in an attractive plastic case and bit holder is included for.

No 28 635

Engraving tool GG 12, 12 Volt

Available individually, includes one diamond bit (1.8mm spherical head).

No 28 592

allowing anyone to start immediately!

The complete engraving kit: with trial glass and motifs

Flexishaft MICROMOT 110/P

with triple ball bearings, up to 25,000rpm.

Supplied in durable plastic case.

Two ball bearings in the turned, light

aluminium hand piece and one in the

drive end prevent tool bit chatter.

The highly flexible shroud and core

effortlessly transmit power without

heating up when bent tightly. Antikink

springs at the grip and drive end prevent kinks. Six MICROMOT collets

1.0 – 1.5 – 2.0 – 2.4 – 3.0 and

3.2mm are supplied.

The UHV shown is described

on page 17.

14

No 28 620

Page 15

MICROMOT mains adaptors: safe and efficient power sources

MICROMOT

System

for hand operated 12 Volt PROXXON machines.

MICROMOT mains adaptor NG 2/E

NOTE:

Power consumption of portable machine tools is

measured according to the internationally accepted

ICE-745-1 specification. The current drawn is measured,

not the power consumption with a hot motor just

before stalling. In practice, this condition seldom

appears, if ever. All PROXXON mains adaptors are

suitably dimensioned for the recommended purposes.

Adaptors do not include drill.

Very compact design. NORYL casing (heat resistant -a necessity for

transformer enclosures). Capacity 2,0A at 16 Volt open circuit - and 12

Volt under load = 24VA (DC). Primary supply 220 – 240V. Polarised

socket for MICROMOT plug. Red LED indicates readiness for use. PTC

(Positive temperature coefficient) element prevents overload (and plugged

in tool will not automatically restart). After cooling down, the mains

plug should be disconnected briefly to reset the adaptor. Modern

design with holes for storing bits. Foldable tool rest provides a secure

place for keeping the MICROMOT tool at the ready.

MICROMOT mains adaptor NG 5/E

In compact NORYL casing (recommended for transformers). With

superior capacity of 5A at 16V no load and 12 Volt under load = 60

VA (DC). Primary supply 220 – 240V. Thyristor electronic control

(with feedback) for optimum tool speed and high torque at low

speeds.

Three polarised sockets for MICROMOT machines. A pair of

sockets for standard banana plugs (4mm diameter) is also supplied.

Master switch for turning off the transformer without needing to

unplug. Red LED indicates „ready“.

PTC protection against overload (plugged in machine will not

restart automatically. After cooling down, the mains plug should

briefly be unplugged to reset the adapter).

Practical design with storage holes for tools with 2.35mm and

3mm shafts. Foldable tool rest – keeps the MICROMOT tool being

used safely on standby.

Thyristor electronic speed control (with feedback) for adjusting bit

speed to suit the job, as well as providing high torque at low speeds.

No 28 707

MICROMOT mains adaptor NG 2/S

Exactly as above, without electronic speed control. For 220 - 240V.

No 28 706

No 28 704

15

Page 16

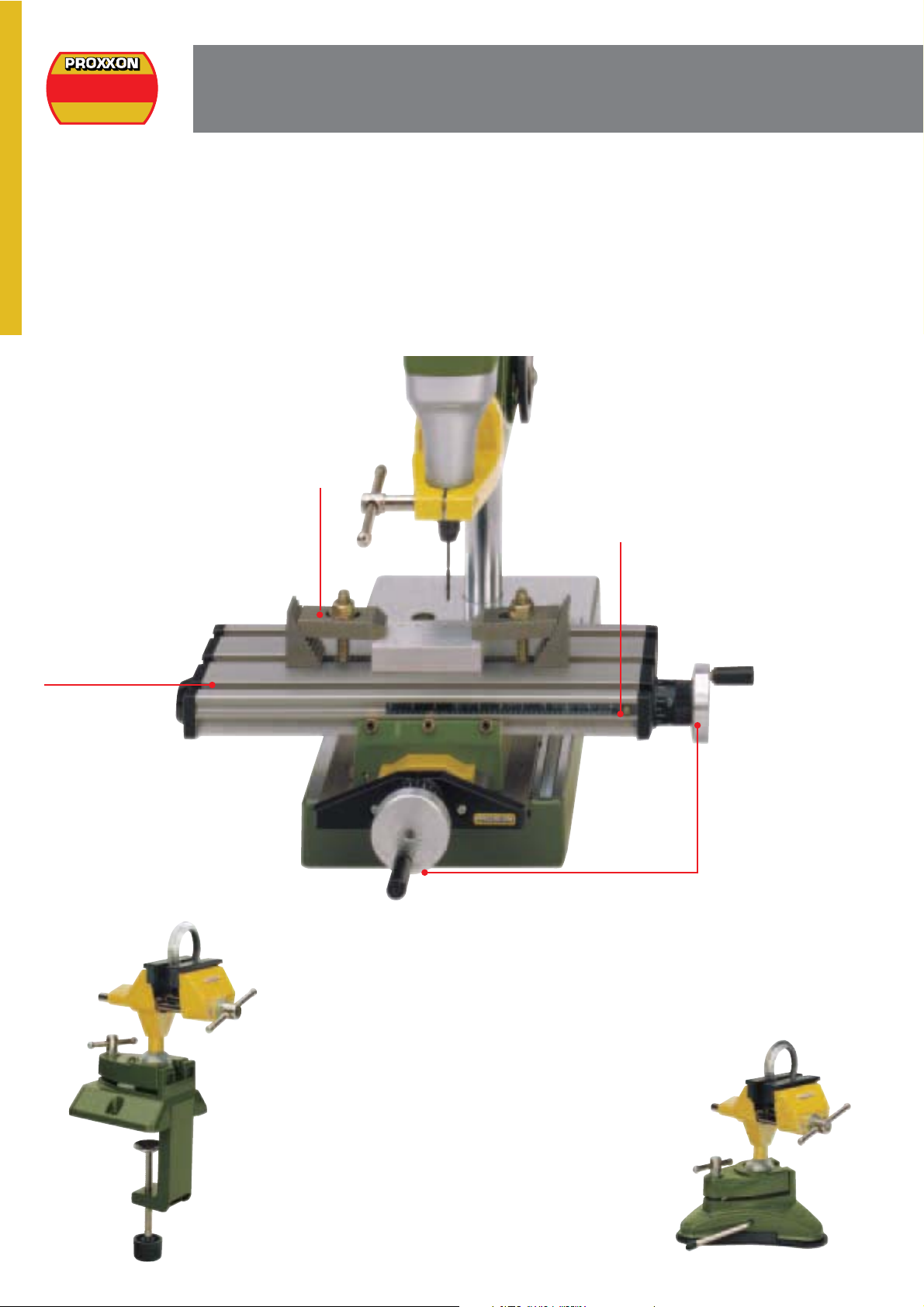

MICROMOT

System

The KT 70, small and accurate.

Ideal for Drill stand MB 140/S and Drill press TBM 220.

MICRO compound table KT 70

Made of solid aluminium with surface treatment and fitted

with adjustable dovetail gibs and three T-slots of the

MICROMOT standard (12 x 6 x 5mm). Adjustable ruler

eases workpiece positioning. Both handwheels have zeroresettable dials with graduations indicating 1 revolution =

1.0mm and 1 division = 0.05mm. The clamps and securing

bolts for the MB 140/S and TBM are included.

General details:

Table size 200 x 70mm. X travel 134mm and Y travel

46mm, maximum height 43mm.

No 27 100

Two step clamps

.

Table of 200 x 70mm with

3 T-slots

.

are included

Step clamps made of steel

The step clamps set is supplied with the KT 70, but can also be ordered

separately. Set consists of 2 ea. stepped blocks and clamps, T-slot nuts

of the MICROMOT standard (11.5 x 11 x 4mm), bolts. This set also fits

the mill/lathe systems PD 230/E and PD 400.

No 24 256

Moveable ruler eases workpiece

positioning.

16

Handwheels with adjustable dials,

1 revolution = 1.0mm,

1 division = 0.05mm.

Precision vise FMZ

With integral clamp.

Easily clamps to workbenches and tables of up to 60mm. Alternatively,

use 2 standard screws to secure to the work surface. Zinc die-casting

with ball and socket: rotates in all directions (even downwards). 75mm

jaws with protective covers (for delicate workpieces). Jaws also with

vertical and horizontal V-slots for clamping round workpieces.

Maximum clamping width 70mm and weight 1.6kg.

No 28 608

Precision vise FMS 75

As detailed above, but without clamp. A strong suction cup facilitates

instantaneous fixing to any smooth, flat surface.

No 28 602

Page 17

The MB 140/S offers fine feed via the drive

MICROMOT

System

disc and ball-bearing drive.

MICROMOT drill stand MB 140/S

The 120 x 220mm table is milled and fitted with a fence and scale. The

solid column is chrome plated. The headstock is of die-cast aluminium,

offering a throat capacity of 140mm and 30mm travel. A chromed feed

lever operates via drive disc and ball bearing system, offering a sensitive

feed set-up. T-bars allow simple height

adjustment as well as the fixing of the

mill drill in the 20mm bore fitting.

The mill drill collar, with scale, tilts

through 90° in both directions.

A depth stop as well as drilled, tapped

holes for securing the KT 70 compound

table and holes to fix the MBS itself are

also provided.

No 28 606

NOTE

Our technicians prefer the use of aluminium as it is clean and stable.

All fittings and feeds are machined on our ultra-modern CNC machines,

i.e. milling, turning, etc. Pure precision!

Machine Vice MS 4

Die-cast zinc with three machined sides. The slot fits the adjustable

fence of the drill stand MB 140/S and bench drill TBM 220.

Horizontal and vertical V-slots in jaw. Jaw width 50mm and height

10mm. Maximum clamping width 34mm.

No 28 132

MICROMOT universal holder UHV.

The suction food ensures rapid fixing to smooth surfaces.

The ball joint may be swivelled in all directions. The 20mm bore

accepts all MICROMOT machines, e.g. FBS 240/E, IB/E, MICROMOT

50, 50/E, FBS 12/E.

No 28 603

Universal holder UHZ

Easily clamps to workbenches and tables of up to 60mm. Alternatively,

use 2 standard screws to secure to the work surface. Zinc die-casting

with ball and socket: rotates in all directions

(even downwards). Other details as for the UHV.

No 28 610

17

Page 18

MICROMOT

System

Bits and cutters for MICROMOT drills and mills of industrial quality.

ly

Drills

d 1

l 1

l 2

0,5

644 44 44 44 44 4468 81010

0,8 1,0 1,2 1,6 2,1

NO 28 874

HSS twist drill set to DIN 338.

One each of 0.3 – 0.5 – 0.8 – 1.0 –

1.2 – 1.5 – 2.0 – 2.5 – 3.0 – 3.2mm

diameter.

NO 28 864 NO 28 852 NO 28 854 NO 28 856 NO 28 858 NO 28 862

HSS drill bits

Purpose-made, selected, tungsten vanadium steel with high concentricity. Manufactured from a one-piece blank. High hardness for

optimum life expectancy. For drilling metal, non-ferrous metals, plastic, PC cards and wood. Work speeds: hard materials approx.

3,000rpm, soft materials approx. 8 000rpm. All shanks 2.35mm.

Grinding bits

2,5

2,5

5 x 5 x 5 x 5 x

7,0 6,0 5,0 2,5 6,0 7,0 5,0

6,07,0

NO 28 774 NO 28 778 NO 28 776 NO 28 772 NO 28 770 NO 28 780

Carborundum grinding bits

High quality bits and sets of quality base materials of consistent hardness. Various shapes for widest possible range of applications. For working especially hard materials such as

as well as hard metal alloys. Accurately dimensioned shafts of 2.35 or 3.0mm ensure maximum concentricity.

5,0

6,02,5

7,0

5,0

8,0 9,0 13

8,0

13

1

3

3,0

3,0

9,0

13

Milling bits

5,05,0

3,0

6,0

6,0 4,010,0

8,0

5,0

2,35 2,353,03,0 2,352,35

6,0

2,35

NO 28 722 NO 28 727 NO 28 725 NO 28 724 NO 28 723 NO 28 726 NO 28 720

Tungsten vanadium milling bits

Selected tungsten vanadium steel. Purpose made of stable construction with head and shaft out of a single blank. The precise flutes and optimal concentricity ensure best life

hard and soft woods, NF and precious metals, as well as plastics and plaster of paris. Ideal for milling, routing, shaping, profiling and slotting.

Cutting discs

38

22

22

1,8

1,8

10 x 5 x

50 x

1,8

1,8

1,8

NO 28 810 NO 28 812 NO 28 820

Corundum discs

Discs made of a special compound of diameter 22 or 38 x 0.7mm. Used to part alloys and metals, stainless steels,

and NF metals as well as wood and plastics. All arbors 2.35mm.

18

38

38

38

1,8

22

22

1,8

1,8

10 x 50 x

NO 28 808 NO 28 809

Aluminium Oxide with reinforcement

The cutting discs are available in 22 x 0.8 and 38 x 1.0mm. Near

stock. Will cut alloyed, standard and stainless steels, NF metals,

Arbor shaft 2.35mm.

Page 19

1

0

1,0 1,5 2,0

38

1,8

1,0 u. 1,2 0,6 u. 0,8 0,8 u. 1,2

38 38

388 8 8

NO 28 324 NO 28 326 NO 28 328

Hard microdrills

Made of tungsten for optimum lifetime. For drilling glass, semi-precious stones, porcelain,

ceramics, marble and other hard stones. With ideal cutting angle of 6°. Shaft of 3mm.

2,0

2,0

7 5

7

2,5

3,0

2,5

2,5

7

8,0

8,0

NO 28 270 NO 28 272

5

3

30 30 44

NO 28 320 NO 28 321

Tungsten carbide milling drills (Speardrill)

For drilling, milling and cutting fibre glass or

PERTINAX circuit boards. Also for drilling pearls

and similar. Shaft 2.35mm.

3

NO 28 255

Diamond twist drills

With natural diamond

dust for drilling precious

stones (pearls, coral, turquoise). Shafts 2.35mm.

1,8

1,8

5,0

5,0

5,0

5,0

1,0 1,8

d 1

NO 28 240 NO 28 250 NO 28 212 NO 28 222

d 1

Silicon carbide grinding bits

cast iron, steel,

Fine particles of consistent hardness for engraving and frosting of

glass, ceramics and stellites. Also for use on cast steel, cast iron

and other hard steels. All shafts 2.35mm.

3,1

2,3

2,3

2,35

2,3

2,3

NO 28 710

expectancy. All shafts 2.35 or 3.0mm. For use on

38

38

1,8

1,8

Diamond grinding bits

With consistently even coating of diamond dust. Shafts of 2.35mm made

from stainless steel. Used for grinding and engraving hard materials: steel

(even chrome-cobalt alloy), glass, ceramics, porcelain, plastics.

1,0 2,0

1 St. 1 St. 1 St. 1 St.

3,0

d1

d 1

12

l 2

l

44

3,0

5,0

5,0

2,35 2,352,35

2,3

1,2

2,3

5,

5,0

2,3

2,3

1,2

4,0

4,0

2,1

2,1

2,3

2,3

NO 28 758 NO 28 759 NO 28 761 NO 28 760 NO 28 750 NO 28 752

Tungsten carbide millers

Made of wear-resistant tungsten. Used for vibration-free milling of high accuracy dimensions. It is advisable to secure workpieces well, avoiding accidents. For technical work on extremely hard materials: chrome-cobalt alloy, steel,

non-ferrous metals, plastics. May be used for engraving and milling of PC cards.

16

1,8

1,8

19

20

38

5 x

NO 28 818

unbreakable, making it usable to remove

and even wood and plastics.

22

1,8

NO 28 830

Metal cutting blades

Spring steel, 0.1mm thick. For nonferrous metals, plastic and wood.

Shaft 2.35mm

NO 28 840 NO 28 842

Diamond cutting disc

Only 0.6mm thick. For cutting very hard materials such as steel, porcelain, fibreglass, non-ferrous metals. Arbor 2.35mm.

19

Page 20

Selected sanding and polishing bits for all surfaces and longest

Sanding

ø 18

ø 18

10 10

10

10

9

13

9

13

5 x grit 120

5 x grit 150

NO 28 982 NO 28 983 NO 28 980 NO 28 981 NO 28 987 NO 28 989

Sanding discs, drums and wheels Made of standard compounds of tough consistency and different grits for different sanding stages. With superior lasting characteristics

and of various shapes for numerous operations. All shafts 3.0mm. For working steel, non-ferrous metals, plastic, rubber, leather, wood (even edges). Rough grinding of V2A-steel,

grinding, welding joints and die-cast aluminium. Ideal for surface and shape sanding.

10 x grit 120

10 x grit 150

10 x

grit 150

10 x

grit 150

5 x grit 80

5 x grit 150

5 x grit 80

5 x grit 150

Cleaning and polishing

8

NO 28 951 NO 28 953 NO 28 952

Steel brushes, cups amd wheels High quality components for best operation. For

cleaning, sanding, frosting, rounding-off and fine polishing of metal (incl. nonferrous), precious metals, plastic, stone and wood. Shafts 2.35mm.

13

5 St.

22

8

NO 28 961 NO 28 963 NO 28 962

Brass

brushes, cups and wheels Ideal for working on alloys, copper, precious

metals, semi-precious stones, plastic and wood. Acid proof. Electrically neutral,

thus suitable for working with electronic components.

13

2 x2 x2 x2 x

Polishers

22

8 7 16 22 22 22

10 x

NO 28 798

Felt discs

For polishing metal, gold, silver brass and

aluminium when using the polishing

paste. All shafts 2.35mm.

15

NO 28 800

Felt Polishers

Used on gold and white gold, silver

and finishing on tool and die

making.

15

Multiway adapter MF 5 for 12 Volt tools

Fitted with 150cm spiral cable, 4 MICROMOT sockets and one pair of standard

4mm banana sockets. The LED indicates power availability. Mounting holes are

provided.

No 28 994

3

NO 28 291

Cotton, leather and felt polishers

For high gloss finishes on metal, gold, silver, nonferrous metals, aluminium when using polishing

paste. 2.35mm shafts.

NO 28 292

Polishing paste

Essential for polishing

metal and plastic.

MICROMOT collets

Fits all MICROMOT machines, excluding the engraver GG 12.

One of each 1.0 – 1.5 – 2.0 – 2.4 – 3.0 and 3.2mm, closure nut and holder are

included.

No 28 940

MICROMOT extension cord

The plug and socket are coded to prevent polarity reversal. The 300mm spiral

cable may be rolled in a ball for storage purposes and won’t tangle.

No 28 992

20

Three jaw keyless chuck

Used on all MICROMOT machines, excluding the engraver GG 12,

Professional Drill/Grinder IB/E and COLT 220/E. Capacity is 0.5-3.2mm.

No 28 941

Page 21

life expectancy!

20

10

10

30

20

20 22

3

grit 120

NO 28 984 NO 28 985

Flap wheels

These flap wheels are elastic and take on the

shape of the workpiece. Ideal for sanding in

inaccessible spots. Shaft 3.0mm.

Fine polishing

5

grit 120

NO 28 282

Nylon fleece brushes

used for cleaning, frosting

and sanding steel, precious

NO 28 302 NO 28 304

Carborundum Silicon carbide

Wheels for free-hand and stationary grinding of

various metals and materials.

metal, non-ferrous metals.

Shaft 2.35mm

22

2222

.

5

15

15

3

3

2 x 2 x 10 x 5 x 4 x

NO 28 290 NO 28 294 NO 28 288

10 x

22

3

10 x 5 x

44

14

12

6

NO 28 295 NO 28 296

NO 28 815

Spare arbors

Shaft 2.35 x 44mm.

22

Flexible polisher. Plastic compound, used for surface smoothing and polishing of precious metals, non-ferrous

metals, hardened metals as well as glass, porcelain, wood, rubber, plastic. Shaft 2.35mm.

Selected sets for many applications!

Glass working Electronic technician set

Four piece set consisting of:

2 diamond grinding bits and 2 silicon carbide grinding bits. For

engraving, grinding and frosting glass. Diamond bit 1: ball ø

1.0mm, diamond bit 2: ball ø 1.8mm. Silicon carbide bit cone

3/2 x 5mm and cylinder 2/2.5 x 7mm. All shafts 2.35mm.

NO 28 920

Nine piece set consisting of:

1 micro drill each 0.5 – 0.8 – 1.0mm, milling bits ball shape ø

0.5 and 2.3mm, 3 cutting discs ø 22mm with arbor.

For drilling, milling and cutting of PC cards. All shafts 2.35mm.

NO 28 930

Jewellery set Modeller’s set

Flexible polishing pad set of 2. Silicon carbide in a resilient, flexible compound (no rubber). Especially suitable for working precious metals (gold, platinum, silver) as well as for tool making

and castings, and for precision engineering. Shaft 2.35mm.

Polishing set

Seven piece set for jewellers and goldsmiths.

Contents: 3 ball milling bits with hole (for milling fittings for

pearls etc.) in sizes 3 – 4 and 5mm. 1 double cone miller for

milling bases for stones with 1.4mm diameter. 1.0 and 1.4mm

millers with concave heads (for rounding off wires etc.).

1.0mm hardened spear drill for pearls and stones included. All

shafts 2.35mm. NO 28 911

13 piece set consisting of:

1 fine milling bit each ball shape and cylinder 2.3mm, 1 carborundum grinding bit each ball and cone shape 5.0mm. 1

micro drill each 1.0 and 2.3mm. 5 cutting discs ø 22mm, 1

saw blade ø 22mm and arbor ø 2.35mm. For cutting, milling,

polishing and drilling. All shafts 2.35mm.

NO 28 910

10 piece set consisting of:

For polishing metal, glass, precious metal, porcelain and plastic. Consists of 3 felt polishing bits (cylinder, cone, wheel).3

silicon polishing bits (bullet, cylinder and wheel). Cotton wool

polishing wheel; chamois buffing wheel and polishing paste

(incl. 2.35mm arbor).

NO 28 285

21

Page 22

MICROMOT

System

Value for money kit for modellers and DIY’ers.

Mini compressor MK 230,

complete with airbrush AB 100

NOTE:

The AB 100 is for use

exclusively with acrylics.

Mini compressor MK 230

The set is light, small and quiet. With adapter and 200cm hose to

connect to the AB 100, as well as 2 paint containers.

The single action airbrush AB 100

is ideal for the beginner. Plastic hand piece with adjustable nozzle.

220-240

VOLT

Technical data:

The compressor MK 230 delivers 12 l/minute, maximum pressure of 2

bar. Mains voltage is 220 – 240V, 50/60Hz, 85W. Weight 1.3kg.

For airbrush purposes only!

No 22 600

MICROFLAME burner MFB/E

Used for soldering, de-soldering, brazing, heating of work pieces, tinning. Ideal for model building, electronics, jewellery repairs, dental

laboratories, stained glass. Super fine flame shape with temperature

attaining 1,300 °C, using butane cartridge, rechargeable with standard

lighter fuel.

Fitted with piezo lighter and 50cc cartridge yielding a typical usage of

120min. Independent air and fuel adjustments.

Includes removable foot that ensures

stability on the worktop. Weight approx.

250g.

No 28 146

Soldering iron EL 12

Ideal for working on electronic components. Heating time approx. 10

sec, with ready access to on/off switch, lockable in the „on“ position.

PTC technology ensures exact tip temperature of 310 °C, preventing

damage to sensitive electronic components such as transistors and ICs,

while minimising possibility of generating noxious gases from the solder/flux. Light for illuminating working area.

Operates off 12 – 14V DC, including standard

power supplies, rated at 1A or more.

Complete with spiral cable and standard MICROMOT jack plug.

22

Soldering tip

for EL 12.

No 28 141

Page 23

Miniature screwdriver for electronics, cameras, jewellery,

MICROMOT

System

mechanics and model builders.

MICRO-Screwdrivers

Shafts of high alloy Nickel-Chrome-Molybdenum (SAE 8660) for

maximum hardness and toughness. Chromed with brinelled tip. The

ergonomically formed plastic handles are oil and impact resistant. The

revolving top and finger mould improve ease of use.

Slot: 1,0 x 40, 2,0 x 40, 3,0 x 40

Philips: PH 0 – 3 x 40, PH 0 x 40, PH 1 – 2 x 40

Torx: T 5 x 40, T 6 x 40, T 8 x 40, T 10 x 40, T 15 x 40

Allan key: 1,5 x 40, 2,0 x 40, 2,5 x 40, 3,0 x 40

No 28 148 15 pieces in a stand

Fixed place for each item in the

practical holder. May be used as

desktop stand or fixed to a wall.

NOTE:

It is important to use the MICRO screwdrivers with care and

feel. The brute force associated with larger screw-drivers is

best left for other tools.

MICROMOT-glue gun HKP 220

Quick and reliable gluing of metal, wood, plastic

(including Plexiglass), glass, ceramics, stoneware, cardboard, leather, polystyrene foams and

textiles. The adhesive sets in about 2 min, allowing positional corrections, which is impossible

with instant glues.

The 7mm glue sticks are perfect for delicate work such as model building, toy and jewellery making, etc. Sensitive mechanical feed ensures

correct glue quantity delivery. Integral stand positions gun on worktop

when not in use.

Technical Data:

220 – 240V. PTC controlled element for exact temperature of 200 °C.

Four glue sticks 7x100mm and 3 interchangeable metal nozzles included

in the set.

No 28 192

Replacement glue sticks for HKP 220

12 off transparent 7 x 100mm glue sticks for materials as above.

No 28 194 12 pieces

Including 3 interchangeable

metal nozzles.

23

Page 24

MICROMOT

System

NOTE:

The Drill/Grinder depicted

here is not included!

A router table for delicate profiles: ideal for model

building, picture framing, doll houses and antiques.

Independently adjustable fence halves

means even the profiled or machined

section slides securely against the outfeed part of the fence.

Router table FT 300

Router bits for wood, used

NOTE:

for picture frames, slots,

rounding over radii and

others are shown on page 34!

MICROMOT router base OFV

Made from die-cast aluminium, with milled work surfaces. Used to route

slots, grooves, edges, and profiles with or without the fence or circle

attachment (both supplied). Adjustable depth stop with selectable travel

stroke. May also be used as a drill or horizontal stand. Max. width of cut

with fence 150mm and circle diameter 100 to 400mm.

Fits all MICROMOT mill drill units, except GG 12.

No 28 566

The table fits all mill/drill units with 20mm collars. The 300 x 180mm

table is die-cast in aluminium and supplied with an adjustable, double

section fence. The transparent guard prevents accidental contact with the

cutter and the mitre gauge slides in a machined slot. The drive unit is fitted under the table in the 20mm collar adapter. Depth of cut is adjustable

by means of a knob and the cutter/drive may be tilted through 45°. This

facilitates additional profiles without having to purchase numerous cutters. The complete table is secured to the worktop by means of 4 screws.

When using the unit occasionally, a plate and 2 clamps should suffice.

No 28 050

NOTE:

The Drill/Grinder depicted

here is not included!

24

Page 25

MICROMOT

220-240

VOLT

System

Motorised carver SGM

The outline of the workpiece may be sawed

with the scroll saw (see pages 29 and 36).

Light wood, e.g. jelotung should be used.

Carving with

the SGM.

and artists.

Motorised carver for wood-carvers, model builders

Perfect for carving all wood types, e.g. renovating and working on furniture,

reconditioning antiques, lino cutting, delicate paint removal and working plaster of paris. Fibreglass reinforced POLYAMIDE casing. Diecast aluminium gear housing. Multiple ball bearings and thrust bearing.

Replacement carving blades

High quality laminated steel (bi-metallic).

Knives in V shape, large and small

gouge, flat with straight and rounded

cutting edge. All 5 to a set.

If required, sanding may be effected

with the belt sander BSL 220/E

(see page 7)

Decoration by means of airbrush

(see page 22).

Technical Data:

Powerful motor 220 – 240V (50/60Hz), approx. 65W. 15,000 cuts/min.

Includes 3 bi-metallic knives (U, V and flat shapes). Length (without

knives) approx. 240mm, weight approx 675g.

No 28 642

PROXXON model builder handbook

A5 book of over 270 pages

explaining the use of

PROXXON tools and bits.

Available in German only.

No 28 572 5 piece set

Profiled sharpening stone

With pre-profiled surface for sharpening the

knives described above. Pure oil stone for a

razor sharp cutting edge. Approx. dimensions 100 x 65 x 15mm.

No 28 578

No 28 996

25

Page 26

MICROMOT

220-240

VOLT

System

MICRO Woodturning lathe DB 250

Infinitely adjustable speeds covering 1,000 – 5,000rpm.

Centre distance 250mm and 40mm swing.

Turning in miniature is a pleasing hobby. One can

make glasses, cups, saucers, vases and columns for a

doll house. In model trains, one can make lighting

The tool rest is adjustable in all directions,

including height. Used here for turning

with a face plate (workpiece is fixed with

ordinary wooden screws).

Electronic speed control

assists in the painting process.

Ball bearing spindle is bored

through at 10mm.

For series production of small parts.

masts, windows, tanks. Limbs for marionettes and

hundreds of classical miniature turning may be carried

out with ease.

Technical data:

Centre distance of 250mm, 40mm swing. Motor 220 – 240V, 150W,

50/60Hz. Electronic speed control between 1,000 and 5,000rpm. Tailstock travel 20mm, total length 400mm.

Includes 6 collets (2 – 3 – 4 – 6 – 8 – 10mm), drive centre, live centre

and face plate.

No 27 020

Workpieces are secured by means of collets

(1 each of 2 – 3 – 4 – 6 and 8 are included as standard).

Tailstock

with quill travel.

Stable tool rest is adjustable in all directions.

Powerful drive motor with speed

control between 1,000 and 5,000rpm.

Three piece chisel set

One each of the flat, gouge and parting chisels.

No 27 022

26

The bed is made from a stable, thick-walled aluminium profile.

A face plate for turning

larger items is included.

Independent four jaw chuck for the DB 250

Used to clamp asymmetrical pieces such as rectangles. The

reversible jaws clamp from 0 – 35mm (inside) and 14 – 67mm

(outside). The DB 250 headstock spindle of thread M16 x 1 screws

directly into the chuck.

No 27 024

Three jaw chuck for the lathe DB 250

used for concentric clamping.

Made from zinc diecast and offering 1.5 to 32mm and 12 to

65mm when reversing the jaws. The chuck has a M16 x 1 thread

for fitting directly to the DB 250 spindle.

No 27 026

Page 27

Used to cut styrofoam and thermoplastic materials,

MICROMOT

System

220-240

VOLT

both freehand and with stencils.

Hot wire cutter THERMOCUT

The working surface now of Alu Cobond

compound. This eases the pushing of

work pieces. A printed grid and protractor

are applied to the base.

NOTE:

Styrofoam is a cheap material compared to

others and does not harm the

environment. It is easily

available in art, craft, hobby and similar shops.

Ideal for architectural models, designers, decorators, artists (teaching too), prototypes as

well as classical railroad, plane and boat model building.

NOTE: The unit’s double wound transformer and insulation to class 2 ensure the

cutter is absolutely safe. The cutting wire operates at 10V, 1A.

The large base with 390 x 280mm table with surface of Alu cobond compound

ensures compound smooth and easy movement of the workpiece. The printed

grid and protractor ease division and cutting. Solid aluminium overarm has a

350mm throat and offers 140mm capacity in height. The holder and wire coil

(30m, 0.2mm diameter is included) may be shifted along the overarm to enable

mitre cutting. A LED indicates operation and prevents burnt fingers (the cutting

wire heats to maximum in less than 1 second).

NOTE: The correct temperature, being material type and thickness dependent, is

learnt from experience. Optimum profiles are cut at lower temperatures and

cutting force.

Technical Data

220 – 240V, 50/60Hz, insulated to class 2 requirements. Transformer secondary

max. 10V, 1A. Cutting wire temperature with 0.2mm diameter is variable

between approx. 100 and 200 °C. Weight approx. 3kg.

No 27 080

Double function fence with lockable feed bar

Spare cutting wire

Used on the THERMOCUT and other similar units. Made of NiCr 8020. Spool of

30m x 0.2mm.

(German Patent 100 00 102.5).

No 28 080

Crosscuts are achieved by means of a simple yet efficient

solution: Secure drawing-pin to table by means of tape,

it serves as a fixed centre.

27

Page 28

MICROMOT

220-240

VOLT

System

Bench circular saw KS 230

The 58mm diameter Super Cut blade cuts soft woods up to 8mm, plastics (Pertinax too) to approx. 3mm, non-ferrous metals to approx.

1.5mm. Fibreglass reinforced PC cards could be cut with the tungsten

blade.

The 85W, VDE tested motor is quiet, operates off 220 – 240V and has a

prolonged life expectancy. The side door allows easy sawdust removal.

Overall size approx. 240 x 180 x 80mm. Weight 1.8kg.

plastic and PC cards.

For perfect straight cuts in wood, non-ferrous metals,

Crosscut blade „super-cut“ 58mm diameter (10mm bore). 80

alternately set teeth. Ideal for hard and soft wood as well

as plastic and Pertinax. For fast, clean cuts. Teeth are

individually set and sharpened. Superior cutting power!

No 28 014

Solid carbide saw blade 50mm diameter (10mm bore) 0.5mm

thick. Fine toothed: Ideal for cutting fibreglass sheets, up

to 3mm, non-ferrous metals, duro-plastics and other

"difficult” materials.

No 28 011

No 27 006

IMPORTANT:

Power transmission by toothed belt via ball bearings, housed in sturdy

casing, ensures the right blade speed for the job (approx. 5,000rpm)

with a doubling of torque (approx.). Above all, it ensures good cutting

depth.

Diamond blade

50mm diameter (10mm bore). With 0,5mm layer of

class „D107“ diamond for cutting ceramics, as well

as fibreglass sheets.

No 28 012

NOTE:

The larger version of the circular saw KS 230 (model

FKS/E) is described on page 37.

Spring steel saw blade 50mm diameter (10 mm bore), fine teeth.

Designed for precision cutting.

No 28 020

Tungsten tipped saw blades 50mm Ø x 1.1mm (10mm bore).

10 teeth. Used to cut hard and soft woods, PC cards,

PERTINAX and Alu.

No 28 016

50mm Ø x 1,1mm (10mm bore). 20 teeth. For extremely

clean cuts of balsa, plywood. Can also be used for cutting

PC cards and POLYCARBONATE.

No 28 017

Super cut blade 58mm dia.,

80 teeth, individually set and

sharpened, is included.

Adjustable fence

with scale.

Graduated mitre stop.

Machined, die-cast aluminium

table of 160 x 160mm.

Quiet, high performance 230V

motor for prolonged use.

Base of ABS with a sawdust door

on the right.

Very important when sawing: use our vacuum

cleaner adaptor for a cleaner work environment.

28

Page 29

Cuts aluminium, wood, PC cards and plastics with

MICROMOT

System

standard fret saw blades.

Scroll saw DS 230/E

Adjustable head (patent EP 09783341) offers

numerous advantages (see description below).

220-240

VOLT

NOTE:

Please also see the scroll saw DSH/E (page 36).

The new blade clamping system enables the use of the saw

blades (without pin) described below.

The ideal machine for that delicate project: model building, toy making and precision work.

Cuts soft wood (e.g. balsa) up to 40mm, hard wood up to approx.

10mm, plastic (including PC cards) up to approx. 4mm and non-ferrous

metals up to 2mm. Very stable ribbed die-cast aluminium saw frame

with 300mm throat. Blade guide with integrated blower. Height adjustable head (3 positions).

Blade usage is improved as the head may be lowered

in two steps, making new blade

teeth available.

This effectively triples blade life.

The lowest head position still allows

blades, shortened by 60mm, to be used.

Machined worktable of die-cast aluminium, 160 x

160mm. ABS plastic body with side sliding panel for

removal of saw dust. VDE approved 220 – 240V motor (85W) for prolonged, low noise performance. Quiet, wear-resistant toothed belt drive

running in a ball bearing. Electronically controllable stroke rate from

approx. 150 – 2,500/min. Adjustable fence and mitre stop with scale.

No 27 088

Use the vacuum cleaner adaptor

to keep your work area cleaner.

Super-Cut scroll saw blades

High quality steel for extended use and prolonged cutting capacity in

hard and soft woods, plastic, Perspex and soft NF materials. Standard

verson (without pin).

Hard and soft woods, plastic, Perspex and soft NF materials.

Set of 6 coarse-toothed blades (14 TPI):

No 28 110 130 x 1.50 x 0.48mm

Set of 6 standard-toothed blades (17 TPI):

No 28 108 130 x 1.20 x 0.38mm

Set of 6 fine-toothed blades (25 TPI):

No 28 107 130 x 0.77 x 0.30mm

Hard materials such as steel and PERTINAX.

Set of 6 fine-toothed blades (28 TPI):

No 28 104 130 x 1.10 x 0.50mm

Set of 6 very fine-toothed blades (41 TPI):

No 28 106 130 x 0.74 x 0.36mm

29

Page 30

MICROMOT

220-240

VOLT

System

Grinding and Polishing Machine SP/E

from 8 to 24 m/sec.

For 50mm discs and brushes. With electronic speed control

Vacuum cleaner adaptor can be used.

The slim housing facilitates the grinding of long workpieces and includes

an adapter to connect a vacuum cleaner to the unit. The tool rests and

eye guards are both adjustable. A spindle lock eases the changing of

wheels and discs. Supplied with a 50 x 13mm corundum (grade N) and

silicon carbide (soft compound) wheel for general grinding/sharpening

and hard materials respectively. The right hand spindle accepts the

polishing arbor, which is supplied as

standard equipment.

Technical Data:

Variable speed of 3,000 – 9,000rpm,

or 8 – 24m/sec with standard wheels.

Motor 220 – 240V. Insulated to class

2. Wheels 50 x 13 x 12.7mm. Weight

approx. 1.2kg and size approx. 250 x 130 x 100mm.

No 28 030

Polishing set (50mm ø) easily

fitted to the arbor.

Steel wire brush for de-rusting and cleaning

steel and NF metals. Brass wire brush to

polish non-ferrous metals and precious

metals. Felt wheel is used on painted surfaces

and the chamois and cotton wheels provide a high gloss finish on nonferrous metals and precious metals.

No 28 312 complete set

Spare discs for the SP/E and BSG 220 (50 x 13mm)

Corundum (grade N) with 12.7mm bore

No 28 308

Silicon carbide with 12.7mm bore. Soft compound for very hard materials.

No 28 310

Cut off saw KG 50

Accurately cuts small items of metal, wood and plastic.

Table moveable through 45°, allowing mitre

cuts. Workpiece is fastened tightly and accurately

by means of the integrated clamping device.

Clamp jaws 27mm wide and maximum workpiece

diameter 20mm. Depth of cut to 13mm. A special slot is provided to clamp HO model tracks.

The fence accepts lengths up to 140mm. Five

ceramic cutting discs 50 x 1 x 10mm are also

included suitable for cutting steel, non-ferrous metals as well as wooden

or plastic rods.

Technical Data: 220 – 240V. 85W. 50/60Hz. Peripheral speed 20m/sec.

Weight approx. 1.5kg.

No 27 150

Replacement cutting discs

Made of ceramic compound: 50% alu oxide and 50% silicon carbide.

Suitable for cutting steel, NF metal as well as small wood and ceramic

bars.

No 28 152

30

Page 31

Easy sharpening of drill bits from 3 to 13mm diameter,

MICROMOT

System

220-240

VOLT

standard 118°.

Drill Sharpener BSG 220

NOTE:

The use of the BSG 220 is quite simple and even allows novices to

sharpen drill bits to DIN. However, carefully study the instructions before using the BSG 220 if you wish to sharpen drill bits expertly.

The operation is relatively simple, enabling everybody to sharpen standard

118° HSS, CrV and tungsten bits of 3 - 13mm diameter professionally.

Dressing the stone

stone, ensuring a sharp cutting surface, is also fitted.

Technical Data: Carborundum grinding disc size 50 x 13mm. 220 –

240V, 85W. ABS housing with fixing holes. Weight 1.7kg. An easy to

understand operating manual and replacement disc accompany the

unit. For further spare discs see page 30.

No 21 200

The sharpening operation is controlled

exactly by means of the movable

car riage. This moves from left to right

and also rotates the drill bit on its own

axis. This operation yields the correct

relief angle. The carriage is fitted with

a feed screw for fine feed. A dressing

Adapters for sharpening of small drill bits

These adapters extend the BSG 220's

range to cover 1.5 – 3mm. One each

adapter for sizes 1.5 – 1.6 – 2.0 – 2.4

– 2.5 and 3.0mm. Neatly packed in a

wooden box with sliding lid.

No 21 232

Vacuum cleaner controller AS/E

Switches your dust extractor or vacuum cleaner on and off.

The controller supplies the powertool (either portable or stationary) and

vacuum cleaner with power. It switches on the vacuum cleaner while

the powertool is operational. Once the powertool is switched off, a 3

second run-down period ensures the workplace is properly vacuumed.

Additional switch positions switch the vacuum cleaner on or off permanently. Usable with powertools of 25 – 500W and vacuum cleaners of

up to 1,500W.

No 27 032

NOTE:

The wooden mount, used to position

the vacuum cleaner hose on the work

surface, is not included.

31

Page 32

MICROMOT

System

Even 0.5mm holes may be drilled. With three step pulleys.

Bench drill machine TBM 220

The optional MICRO compound

table to suit is described on page 16.

Practical, adjustable depth gauge.

220-240

VOLT

Machine vice MS 4 made of die-cast zinc

is an invaluable accessory

and is described in detail

on page 17.

Machined worktop of high quality, ribbed die-cast aluminium (220 x

120mm). Adjustable fence with scale. Solid, hard-chromed steel

column, 280mm high, 20mm diameter. Super stable die-cast head with

VDE approved 220 – 240V, 85W motor. Very quiet and of long life

expectancy type. Power transmission by aluminium pulleys and flat

belt. Three spindle speeds of 1,800, 4,700 and 8,500rpm. (Triple torque

at low speeds). Chrome feed lever with adjustable depth scale. The

spindle is essentially play-free as a result of the 3 high quality ball bearings.

Recessed spindle for insertion of MICROMOT steel collets, but also

threaded for drill chucks (3/8" thread).

Extremely high rotational accuracy, 30mm feed. Quill diameter 32mm,

with return spring. Throat depth (column to drill spindle) 140mm. Quick

coarse height adjustment of headstock with clamp levers. Max. height

140mm. Six triple slit precision collets for shaft sizes 1.0 – 1.5 – 2.0 –

2.4 – 3.0 – 3.2mm are included.

No 28 128

Chuck

For drill shank sizes 0.5 to 6.0mm. Max. speed

10,000rpm. Industrial quality with extra high

speed accuracy. With 3/8" thread for MICROMOT

bench drill TBM 220, including chuck key.

No 28 122

32

Dividing head for MICRO miller MF 70 and

MICRO comound table KT 70

This accessory is used to drill offset holes, holes with equal spacing as

well as milling key surfaces in

4 sided, 6 sided, etc materials.

Graduated on the base. The

chuck jaws may be reversed to

yield 1.5 – 32mm (inside) and

12 – 65mm (outside) and bore

of 11mm. This through hole

allows long items to be clamped

vertically in the chuck. Mounting

holes to secure the unit vertically or horizontally are provided. T-nuts, complying with the MICROMOT

norm, as well as mounting screws are included. Size 72 x 64 x 38mm.

Supplied in wooden box with sliding lid.

No 24 264

Page 33

Small and beautiful: the accurate miller for lab technician,

MICROMOT

System

220-240

VOLT

optician, jeweller, electronic/model builder.

MICRO miller MF 70

Tungsten milling cutters

These double flute cutters are

made from solid tungsten,

clockwise cutting. The fishtail

profile ensures cutting to the

centre, allowing boring. Usable

on cast iron, hardened cast iron,

steel, cast steel, brass, aluminium,

and even glass, plastics and carbon fibre. One each of 1.0-2.0

and 3.0mm. 3.0mm shaft diameter.

No 27 116 3 pieces

Now supplied complete with stepped

clamp blocks of steel.

These are shown on page 16.

Handwheels with zero adjustable scales,

1 revolution = 1.0mm, 1 division = 0.05mm.

Continuously variable

speed from 5,000-

20,000rpm, perfect

for even the smallest

milling cutter.

Cutter clamping in

MICROMOT

system collets.

Table of stable aluminium.

Both axes are fitted with

adjustable dovetail slides.

MICROMOT steel collets, triple slit

and hardened, cover 1.0 to 3.2mm.

For work with extremely small cutters.

Base of cast iron. Including both vertical column and compound table

of treated, quality aluminium. All axes are play-free and have adjustable

gibs. Headstock of die-cast aluminium contains the 24 pole balanced

special motor and is super stable even at high operating speeds. This

stability facilitates the use of the finest cutters. The triple slit, hardened

steel MICROMOT collets cover 1.0 – 1.5 – 2.0 – 2.35 – 3.0 – 3.2mm.

The table is fitted with 3 T-slots of the 12 x 6 x 6mm MICROMOT

norm. An adjustable ruler scale eases the positioning of the workpiece.

All handwheels are zero adjustable with 1 revolution = 1.0mm, 1 division

= 0.05mm.

Technical Data:

220 – 240V, 100W, 50/60Hz. Spindle speeds 5,000 – 20,000rpm. Table

200 x 70mm with X-Y travel of 134 and 46mm respectively, with vertical

travel 80mm. Footprint size 130 x 225mm and overall height 340mm.

Weight approx. 7kg. The clamping blocks depicted are included too,

but not the workpiece.

No 27 110

Stable cast iron base.

Precision steel vice PM 40

Milled of steel.

Completely angular. Jaw width 46mm,

clamping capacity 30mm. Total length

70mm. Especially suited for filigree and

accurate working with MICRO miller MF

70 or Compound table KT 70. Sliding

blocks and fixing screws included. Comes

in a wooden box.

No 24 260

33

Page 34

MICROMOT

220-240

VOLT

5

2.5

R 2.5

6.5

6.5

R 3.2

3.2

6.5

R 3.2

3.2

R 2.5

R 5

6.5

For difficult work with wood and specialist plastics.

System

MICRO shaper MT 300

NOTE:

The MT 300 is fitted with a

dust collection channel and

vacuum adapter.

Using a vacuum extractor

ensures a cleaner environment.

Used to profile, slot, route, chamfer, trim and cut. Also used for precision

details on sides and long sections, e.g. doors, flaps and housing components.

Powerful, dust protected motor with toothed belt drive. Double ball

bearing spindle. Cutters fitted in triple slit collets (1 each 2.4 - 3.0 and

3.2mm are supplied).

Cutter height adjusted by means of handwheel, zero adjustable with 1

rev = 1.0mm and 1 division = 0.05mm. Stable aluminium table with

mitre gauge and parallel fence, as well as cutter guard and hold-down.

Housing of ABS. Adapter for vacuum cleaner, fits standard household

appliances.

Technical data:

220 – 240V, 50/60Hz, 30,000rpm no load, maximum input 100W.

Table 300 x 150mm. Weight approx. 2.0kg.

No 27 050

Wood Router Cutter Set, 10 pieces

A set with one each of the described cutters, neatly arranged in a wooden

box.

No 29 020

Note:

These router cutters should only

be used in machines or accessories

such as the router MT 300, router base OFV or the router table

FT 300. Free-hand use of these

cutters is extremely dangerous!

34

Wood Router Cutters

Made of molybdenum-chrome vanadium steel. Used in the

manufacture of picture frames, for sloting, cutting radii and

various profiles. Inverse relief ground for cleaner cuts. All

shafts 3.2mm.

Slot cutter ø 3.2mm

No 29 024

Slot cutter ø 5.0mm

No 29 026

Slot cutter ø 6.5mm

No 29 028

Rounding over cutter

ø 6.4mm

No 29 030

V-slot cutter ø 6.5mm

No 29 032

Combi cutter

6.5/2.5mm

No 29 034

Core box bit R 3.2mm

No 29 036