ProTeam P5, P6, PC8, PC6, AC6P Installation And Instruction Manual

...

1

SWIMMING POOL

HEAT PUMP UNIT

Installation & Instruction Manual

2

Applicable for:

P- Model

PC- Model

AC- Model

General information

1. Please read this manual carefully before you install the product. Failure to do so may lead to

damage of the heat pump or injury to operators as well as cause financial loss.

2. Scientific and technological developments may lead to product improvements as well:

please check with us regularly to ensure that you are up to date with the latest product

developments.

3. If you need any further technical information, please contact your local distributor.

4. Attention:

4.1 Before installing the heat pump, please check whether the local power supply corresponds

with the requirement of the heat pump. For details, refer to the label on the unit or performance

data in this manual.

4.2 Please install the electrical protection devices according to the local regulations.

4.3 Connecting the heat pump to a ground wire is necessary in order to prevent electrical

shock caused by an unexpected short circuit inside the unit.

4.4 An electrical wiring diagram is provided in this manual.

4.5 For safety reasons, please do not change or repair the heat pump by yourself. If it is

necessary, please contact your local distributor for help.

4.6 Do not put any objects into the heat pump when running as these may touch the fan and

damage it or lead to accidents (particularly for children).

4.7 Do not use the heat pump without the grid or plate work since it may lead to accidents or

abnormal operation of the unit.

4.8 If the unit is soaked in water, please contact your local distributor immediately. The unit

can only be restarted after a thorough inspection by professional technicians.

3

4.9 Unqualified technicians are not allowed to adjust any switches, valves or controllers in the

unit.

g

g

g

Contents

1. Performance data and installation

1.1 Performance and features..................................................................................................................... 5

1.2 Working principles ................................................................................................................................ 5

1.3 Where to install the heat pump.............................................................................................................. 6

1.4 Distance from the pool.......................................................................................................................... 7

1.5 Installation of the check-valve............................................................................................................... 8

1.6 Pool system set up ............................................................................................................................... 9

1.7 Connectin

the by-pass ........................................................................................................................9

1.8 Electrical connection............................................................................................................................. 10

1.9 First time start-up ................................................................................................................................. 11

1.10 Condensation ..................................................................................................................................... 11

2. Controlling the heat pump (LCD)

Only for LCD Display - not applicable.

3. Controlling the heat pump (LED)

3.1 Controller diagram ............................................................................................................................... 12

3.2 How to start heat pump ........................................................................................................................ 12

3.3 How to change mode ........................................................................................................................... 13

3.4 How to set desired water temperature ................................................................................................ 13

3.5 How to change parameter setting - ONLY FOR DEALERS................................................................. 13

3.6 How to check parameter setting & measured values of current status ................................................ 14

3.7 How to set the clock ............................................................................................................................. 15

3.8 How to set timer start and timer stop .................................................................................................... 16

3.9 How to cancel timer start and timer stop .............................................................................................. 16

3.10 Keypad lock and unlock ..................................................................................................................... 16

4.Protection systems

4.1 Water flow switch ................................................................................................................................. 17

4.2 Refri

erant gas high and low pressure protection ................................................................................17

4.3 Overheating protection on the compressor .......................................................................................... 17

4.4 Automatic defrost control ...................................................................................................................... 17

4.5 Temperature difference between in-flowing and out-flowing water ...................................................... 17

4.6 Low temperature cut-off ....................................................................................................................... 17

4.7 Anti-frost protection during winter ......................................................................................................... 17

4.8 First anti-frost protection ....................................................................................................................... 17

4.9 Second anti-frost protection ................................................................................................................. 18

5.Recommendations

5.1 Swimming pool water chemistry ........................................................................................................... 18

5.2 Heat pump winterizing .......................................................................................................................... 18

5.3 Restarting the pump after winter .......................................................................................................... 19

5.4 Check-up .............................................................................................................................................. 19

6.Maintenance and inspection

6.1 Maintenance ......................................................................................................................................... 27

6.2 Troubleshooting guide .......................................................................................................................... 27

6.3 Overview of failure code on display (LCD CONTROLLER) - only for LCD - not applicable................. 30

6.4 Overview of failure code on display (LED CONTROLLER) ................................................................. 30

6.5 Failure code table for Chiller-300 three phase ..................................................................................... 31

6.6 Failure code table for Protect 300 ........................................................................................................ 33

6.7 Failure code table for general PCB (single-system) ............................................................................ 34

6.8 Failure code table for

eneral PCB (dual-system)- only for dual-system- not applicable...................... 35

4

7.Name plate & wiring diagram

7.1Name plate - not applicable.................................................................................................................... 35

7.2 Wiring diagram - not applicable............................................................................................................. 35

1. Performance and Installation

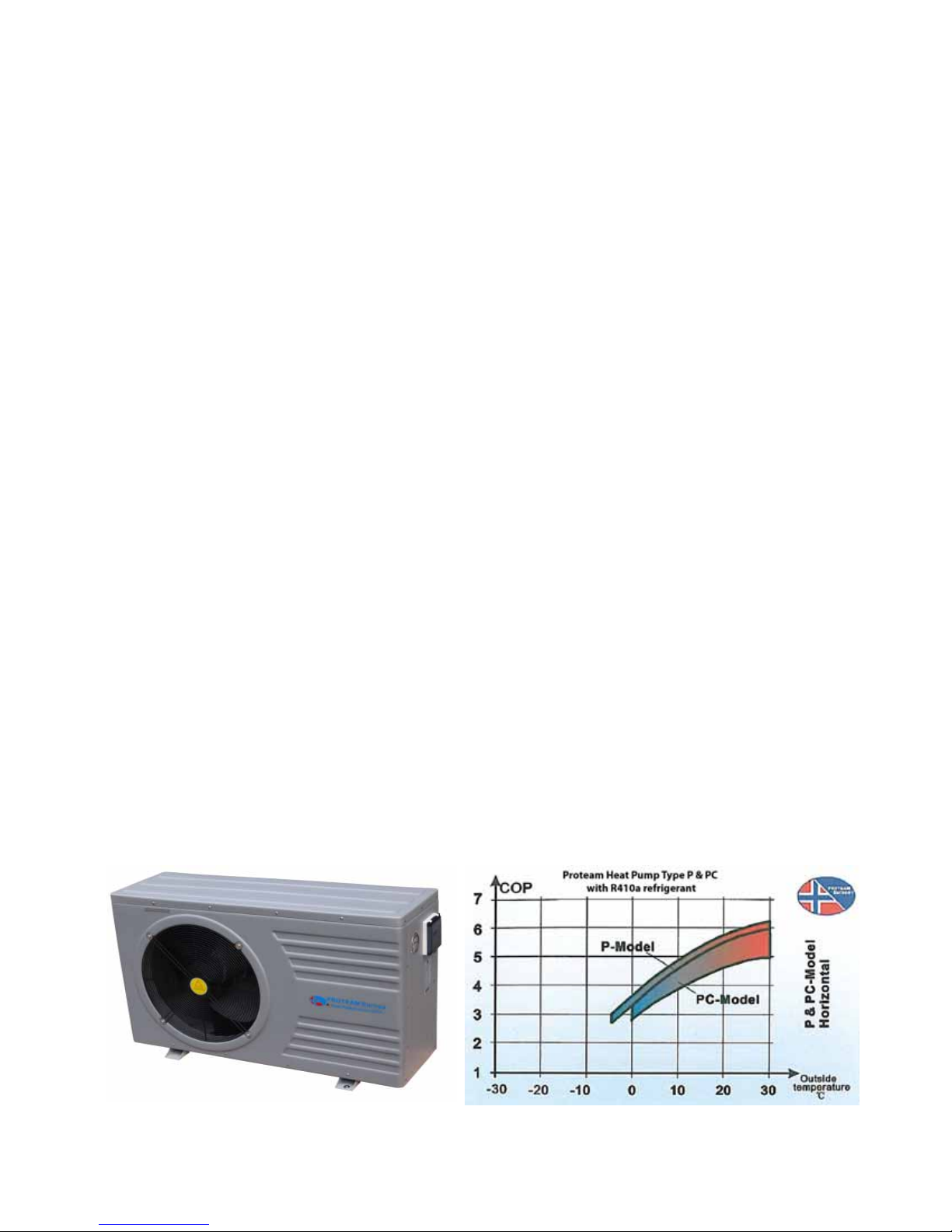

1.1. Performance and Features

High Efficiency

With a COP value up to 5.0, our heat pumps are very efficient when transferring heat from the

air to the swimming pool water. You can save as much as 80% of cost compared to an

electrical heater.

Long lifespan

The heat exchanger is made of PVC with titanium tube, which enables it to withstand

prolonged exposure to swimming pool water.

Easy control and operation

The unit is very easy to operate: simply switch it on and set the desired pool water

temperature. The system is equipped with a micro-computer controller, allowing all operating

parameters to be set. Operation status can be displayed on the controller with LED display.

5

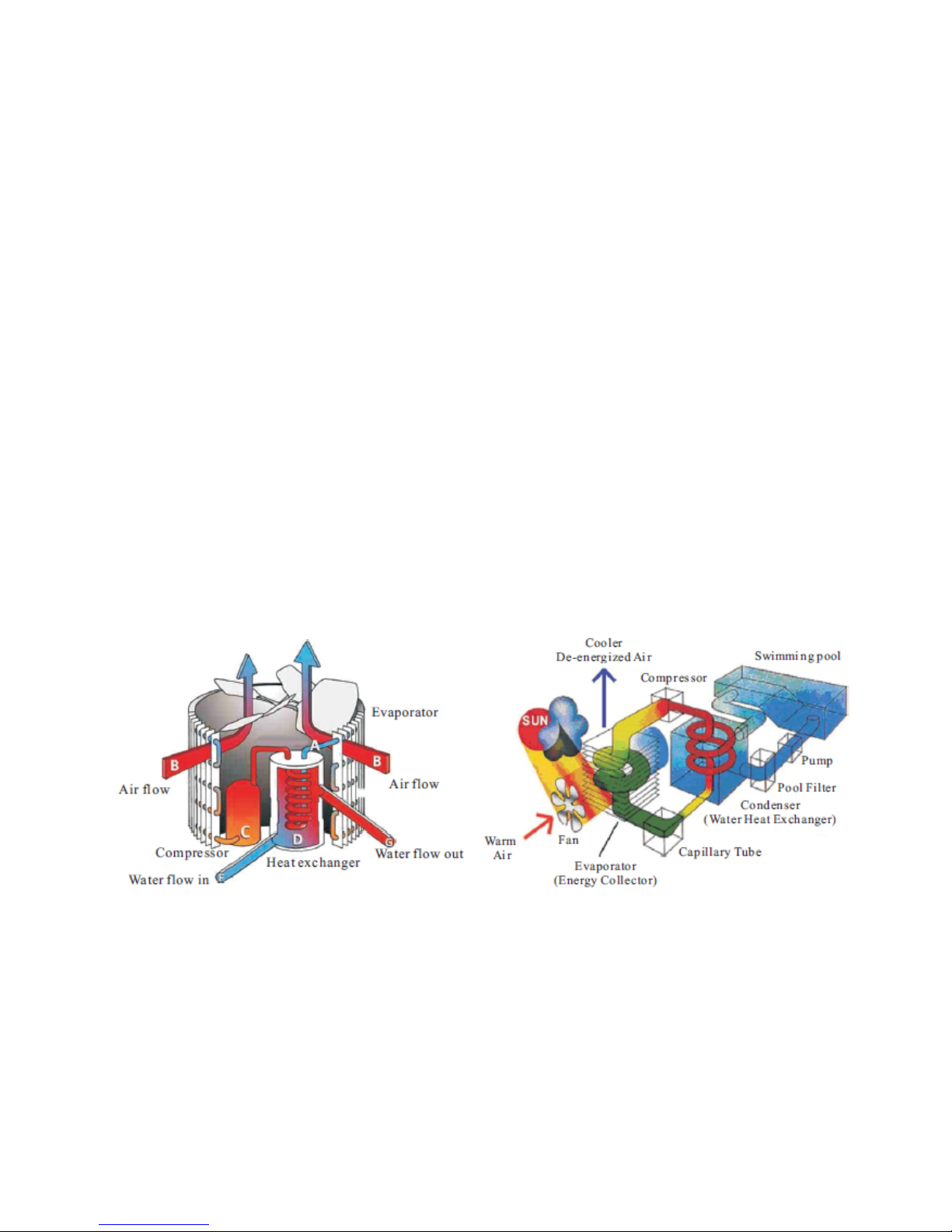

1.2 Working Principles

Heat pumps use heat from the sun by collecting and absorbing energy from the outside air.

This energy is then compressed and transferred to the pool water. Your existing water pump

circulates the water through the heat pump, which is normally installed next to the pool

filtration system, and the water warms up. The heat pump timer can be set so that the pump

operates at the times you want: for example, during daylight hours from 9am to 5pm.

The unit contains a fan that draws in outside air and directs it over the surface of the

EVAPORATOR (energy collector). The liquid refrigerant inside the EVAPORATOR coil

absorbs the heat from the outside air and becomes a gas.

The warm gas inside the coil passes through the COMPRESSOR, which concentrates

and increases the heat to form a very hot gas, which then passes through the

CONDENSER (water heat exchanger). It is here that the heat exchange occurs as the

heat from the hot gas is transferred to the cool swimming pool water circulating through

the heat exchanger.

The pool water becomes warmer and the hot gas returns to its liquid form as it flows

through the CONDENSER coil. The gas then passes through the CAPILLARY TUBE

and the whole process begins again.

Developments in heat pump technology mean that today heat pumps can efficiently

collect heat from the outside air even when the temperature is as low as 7-10°C. This

means that for tropical and subtropical climates the pool can be maintained between

26°C and 32°C.

1.3 Where to install the heat pump

The unit will perform well in any location as long as the following are available:

Fresh air

Electricity

Pool filtration piping

The unit can be installed almost anywhere outside provided the minimum distance

requirements with respect to other objects are met (see diagram below). For indoor pools,

please seek advice from your installer. If the unit is placed in a windy area, there are no

problems with the pilot light as is often the case with gas heaters.

6

Warning: Do not place the unit in an enclosed area with a limited air volume where the air

discharged by the unit will be re-circulated or near shrubs that could block the air inlet.

Installation in such locations will deny the unit a continuous supply of fresh air, which will

reduce its efficiency and may prevent adequate heat yield.

See diagram below for minimum distance requirements:

Warning:

- Do not place your hand or any other objects into the air outlet and fan. It could damage

the heat pump and cause injuries;

- In case of any abnormality with the heat pump, cut off the power immediately and

contact a professional technician;

- It is strongly advised to place a protective guard around the unit to keep children away

from the heat pump.

1.4 Distance from the pool

Normally, the heat pump is installed within a 7.5m radius of the pool. The greater the distance

from the pool, the greater will be the heat loss from the piping. Since the piping is buried for

the most part, heat loss is minimal for distances up to 15m between pump and pool (total to

and from pump: 15m x 2 = 30m), unless the soil is wet or the water level is high. Heat loss per

30 metres could roughly be estimated at 0.6kw-hour (2000BTU) for every 5°C temperature

difference between the pool water and the soil surrounding the pipe, which translates into an

increase in operating time of 3-5%.

7

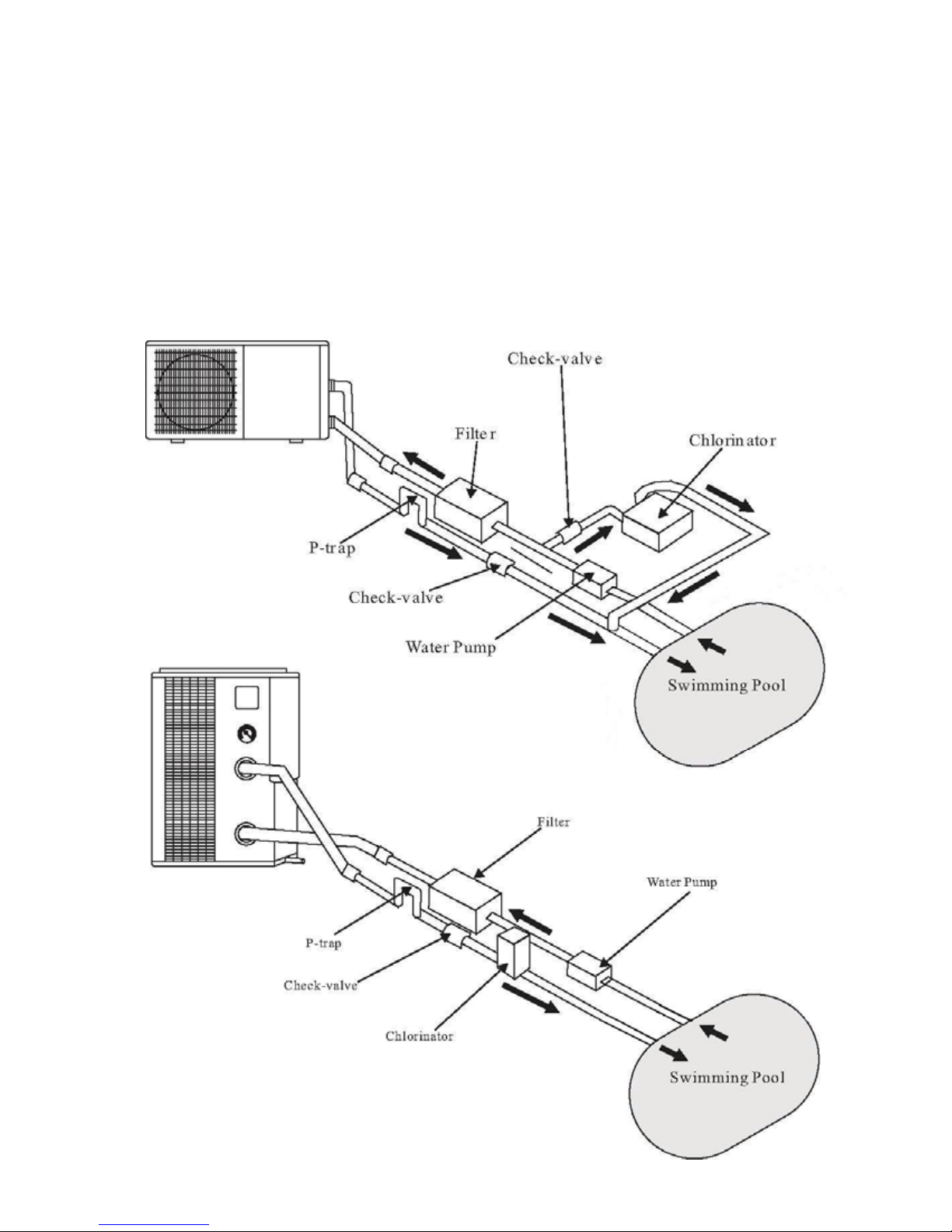

1.5 Installation of check-valve

Warning: When using automatic chlorine and pH dosing systems, it is of utmost importance to

protect the heat pump from high concentrations of chemicals as they could corrode the heat

exchanger. It is therefore recommended that these systems should add the chemicals into the

pipes located DOWNSTREAM (after) of the heat pump, and it is also recommended that a

check-valve be installed in order to prevent backflow when there is no water in circulation.

Damage to the heat pump caused by disregarding any of these recommendations will

invalidate the warranty.

8

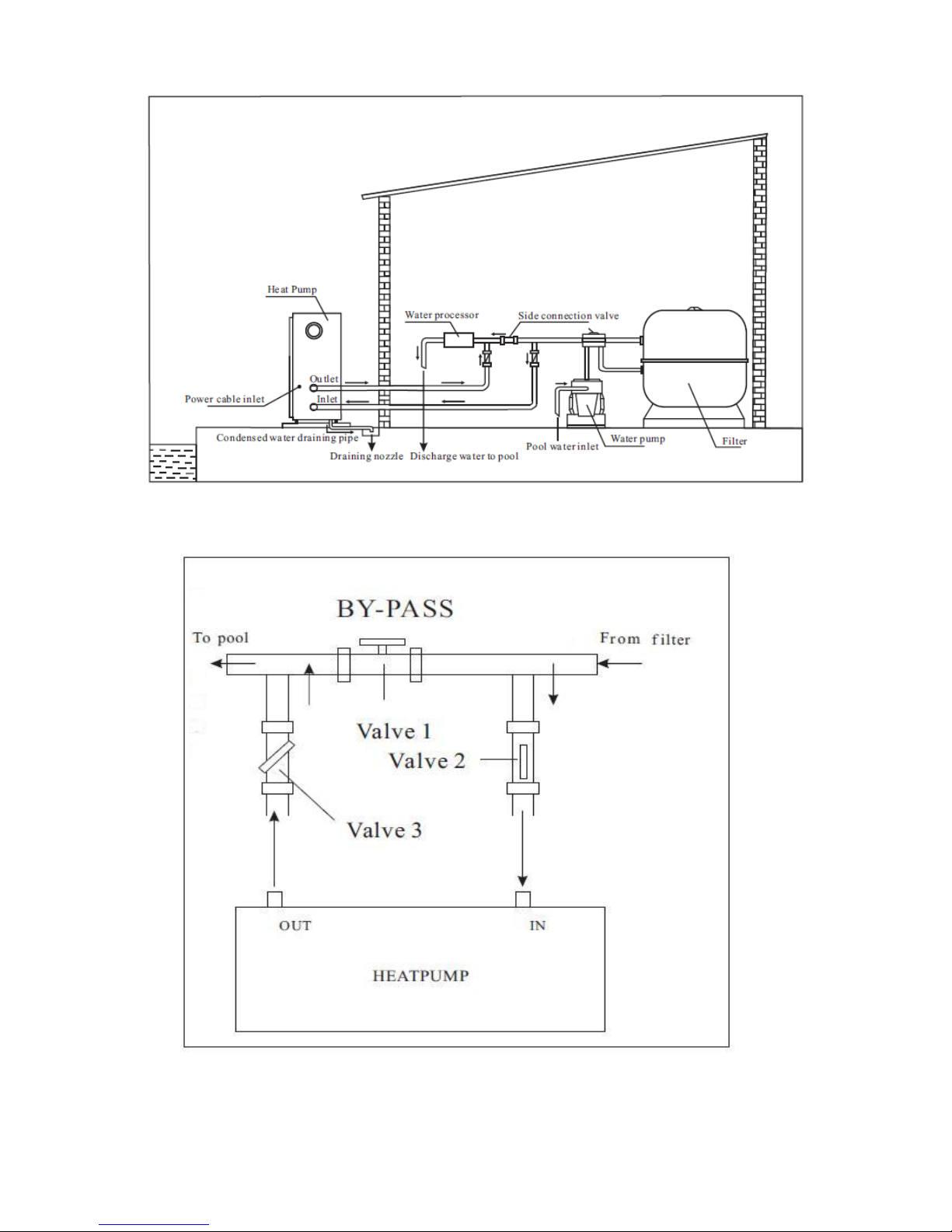

1.6 Pool system set up

9

1.7 Connecting the by-pass

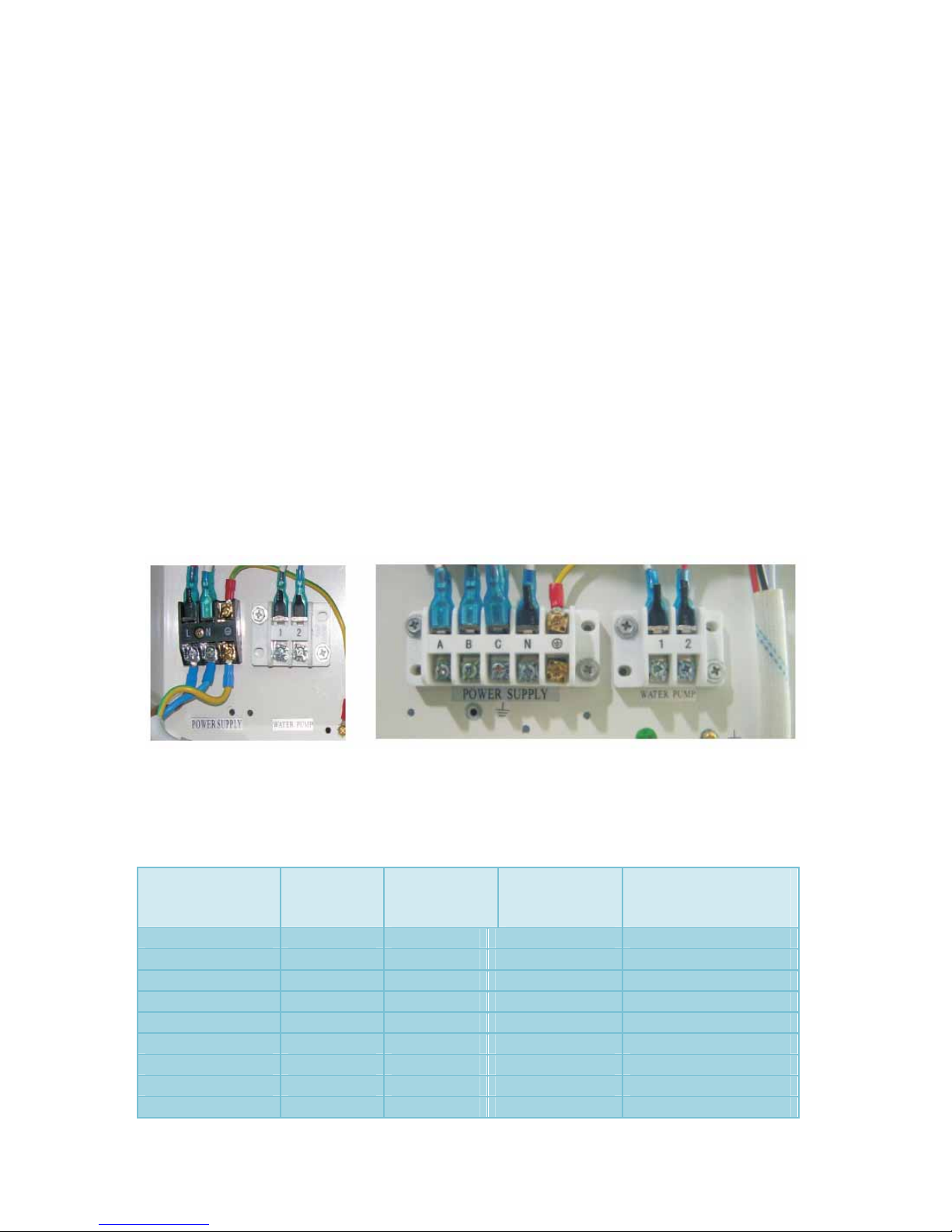

1.8 Electrical Connection

Important – although the heat pump is electrically isolated from the rest of the unit, this only

prevents the passage of water to or from the pool water. It is still necessary to ground the unit

to protect yourself from short circuits inside the unit. Make sure there is an adequate ground

connection.

Check if the voltage of the electrical mains corresponds with the operating voltage of the heat

pump prior to connecting the unit.

It is recommended to use a separate fuse (slow-type D-curve) as well as adequate wiring (see

table below).

For horizontal models: remove the panel on the right of the fan opening.

For vertical models: remove the curved panel on the front side.

Connect the terminal wires with the terminal block labelled ‘Power Supply’. Next to this

connection there is a second terminal block labelled ‘Water Pump’, to which the filter pump

(max 5A / 240V) can be connected. This connection makes it possible to control the filter

pump operation with the heat pump. See the Parameter Setting Table below (Parameter 9) for

other possibilities.

10

Remarks: for models with 3 phases, switching 2 phases may cause an inversion of the

rotational direction of the electrical motors, which could damage the unit. Therefore, a

protection device has been built in, which will interrupt the circuit if the connection has not

been carried out correctly.

Model Voltage

(volt)

Fuse

T3/ slow blow

(A)

Nominal

current

(A)

Cable diameter (mm2)

(for max. Length of 20

meters)

P5/ PC6 220 - 240 10 3.9 2x2.5 mm2+ Ground

P6/ PC8/ AC6P 220 - 240 10 4.55 2x2.5 mm2+ Ground

P8/ PC10/ AC10P 220 - 240 16/ 13 6.64 2x2.5 mm2+ Ground

P10/ PC13/ AC13P 220 - 240 16/ 13 7.87 2x2.5 mm2+ Ground

P13/ PC15/ AC15P 220 - 240 16/ 13 9.78 2x2.5 mm2+ Ground

P15/ PC17/ AC17P 220 - 240 20/ 16 11.03 2x2.5 mm2+ Ground

P17/ PC20 220 - 240 25/ 20 14.88 4x2.5 mm2+ Ground

P21/PC25/AC25P 380- 400 16 6.36 3x2.5 mm2+ Ground

P25/PC30 380- 400 16 7.42 3x2.5 mm2+ Ground

1.9 First-time start-up

Note: in order for the unit to heat the pool (or spa), the filter pump must be running so

that the water can circulate through the heat pump. Without this circulation, the heat

pump will not start.

When all connections have been made and checked, the following steps should be followed:

1. Turn on the filter pump. Check for leaks and verify that there is a flow to and from the

pool.

2. Turn on the electrical power supply to the unit, then press the ON/OFF key on the

electronic control panel. The unit should start when the time delay period has lapsed.

3. When the unit has been running for a couple of minutes, check if the air leaving the unit

is cooler.

4. Check the performance of the flow switch as follows: with the unit running turn the filter

pump off. The unit should also switch off automatically. If not, the flow switch must be

readjusted.

5. The unit and the filter pump should run 24 hours a day until the desired pool water

temperature has been reached. Once the set temperature is reached, the unit will

switch itself off. As long as the filter pump is running, the unit will restart automatically

when the temperature of the pool water drops more than 1°C below the set

temperature.

11

Depending on the starting temperature of the pool water and the air temperature, it can take

several days for the water to reach the desired temperature. Covering the pool with a pool

cover can reduce this period significantly.

Water flow switch: the unit is equipped with a flow switch that switches on when enough

water flows through the unit and switches off when the water flow becomes too low (e.g. when

the filter pump is switched off).

Time delay: the unit is equipped with a built-in 3-minute start delay to protect electrical

components and contacts. After this time delay, the unit will automatically restart. Even a brief

interruption in the power supply will activate the start delay and prevent the unit form starting

immediately. Additional interruptions of the power supply during the delay period will have no

effect on the 3-minute countdown.

1.10 Condensation

When the swimming pool water is being heated by the heat pump, the incoming air is cooled

down considerably, which can cause condensation on the fins of the evaporator.

Condensation volumes can reach several litres per hour under high atmospheric humidity.

This can sometimes be incorrectly interpreted as water leakage.

2. Controlling the heat pump (LCD)

Not applicable.

3. Controlling the heat pump

Preparation before start-up

(LED)

Loading...

Loading...