Page 1

P/N 132305–001, Rev E

P9012 Multifunction Line Printer

Page 2

WARNING

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the user will be required

to correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission limits.

The manufacturer is not responsible for any radio or television interference caused by using other than

recommended cables and connectors or by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

The input/output (I/O) cable must be shielded for the printer to comply with FCC rules and regulations Part

15 governing the radiation limits for Class “A” equipment.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set

out in the radio interference regulations of the Canadian Department of Communications.

Ce matériel numérique n’émet pas de bruits radio–électriques supérieurs aux limites fixées pour les

appareils numériques de la Classe A dans le règlement sur le brouillage radio–électrique publié par le

Ministère des Communications du Canada.

Printronix, Inc. makes no representations or warranties of any kind regarding this material, including, but not

limited to, implied warranties of merchantability and fitness for a particular purpose. Printronix, Inc. shall not

be held responsible for errors contained herein or any omissions from this material or for any damages,

whether direct, indirect, incidental or consequential, in connection with the furnishing, distribution,

performance or use of this material. The information in this manual is subject to change without notice.

This document contains proprietary information protected by copyright. No part of this document may be

reproduced, copied, translated or incorporated in any other material in any form or by any means, whether

manual, graphic, electronic, mechanical or otherwise, without the prior written consent of Printronix, Inc.

All rights reserved.

September

, 1992.

P9012 Multifunction Line Printer Maintenance Manual

, P/N 132305–001, Revision E,

Trademark Acknowledgements

IBM is a registered trademark of International Business Machines Corporation.

Printronix is a registered trademark of Printronix, Inc.

17500 Cartwright Road, P.O. Box 19559

Irvine, California 92713

Telephone (714) 863–1900 FAX (714) 660–8682

Technical Support (714) 553–1515

COPYRIGHT 1992, PRINTRONIX, INC.

Page 3

Table of Contents

1

Overview

Chapter Contents 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Use This Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings and Special Information 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Conventions 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Features 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Features 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel Switches and Indicators 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Controls 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Panel 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools, Test Equipment, and Supplies 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Principles of Operation

Chapter Contents 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Matrix Printing 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Dot Matrix 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Hammer Bank 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Generation 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Functional Elements 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Control Unit (DCU) PCBA 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanism Control Unit (MCU) PCBA 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanism Driver PCBA 2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

i

Page 4

Hammer Driver PCBA 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Bank and Shuttle Mechanics/MPU 2–28. . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Bank Assembly/Shuttle 2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetic Pickup Unit (MPU) 2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 2–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Deck 2–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Feed Control Circuits 2–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platen Open/Paper Out Switches 2–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Circuits 2–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal Operation 2–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Printing 2–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self–Test 2–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

4

Scheduled Maintenance

Chapter Contents 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance Checks and Services (PMCS) 3–2. . . . . . . . . . . . . . . . .

Inspecting the Printer 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Printer 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior of Cabinet 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interior of Cabinet 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Bank Assembly 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

Chapter Contents 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Messages 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Correctable Faults 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Service Required 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symptoms Not Indicated by Fault Messages 4–11. . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Self–Tests 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Self–Tests 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hex Code Printout 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Table of Contents

Page 5

5

Alignments and Adjustments

Chapter Contents 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alignments and Adjustments 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Tracking Check and Adjustment 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Hub Height Adjustment 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Shuttle and Counterweight Preload 5–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Shuttle and Counterweight Spring Adjustment 5–10. . . . . . . . . . . . . . . . . . . . . . .

Hammer Spring Retensioning 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Tip Alignment 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platen Gap 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetic Pickup Gap 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetic Pickup Phasing Adjustment 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shuttle Belt Tension 5–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Feed Belt Tension 5–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Motion Sensor 5–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Paper Out Detector 5–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Procedures

Chapter Contents 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Procedures 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools, Test Equipment, and Supplies 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side Panels 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Deck 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Control PCBA 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Drive Motor 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower and Airflow Assembly 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shuttle Assembly 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Spring 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Coil 6–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Counterweight Assembly 6–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel Assembly 6–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

iii

Page 6

Cam Wick 6–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetic Pickup Unit 6–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shuttle Motor 6–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shuttle Belt 6–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Ironer 6–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Feed Belt 6–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Feed Motor 6–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tractors 6–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Motion Sensor 6–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Out Switch 6–66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platen Open Switch 6–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Fan 6–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DCU, MCU, Mechanism Driver PCBAs 6–72. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Driver and Power Supply PCBAs 6–74. . . . . . . . . . . . . . . . . . . . . . . . . .

Card Cage 6–76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Card Cage Fan 6–86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power Bus Assembly 6–88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Bus Assembly 6–90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Driver Backplane PCBA 6–92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Backplane 6–94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Power Paper Stacker Maintenance

B Interconnect Diagram

C Mnemonics

D Torque Table

E Metric Conversion Tables

iv

Table of Contents

Page 7

1

Chapter Contents

Overview

About This Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel Switches and Indicators 1–6. . . . . . . . . . . . . . . . . . . .

Mechanical Controls 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Panel 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools, Test Equipment, and Supplies 1–11. . . . . . . . . . . . . . . . . . . . .

Overview

1–1

Page 8

About This Manual

This manual explains how to maintain and repair P9012 floor cabinet printers

at the field service level of maintenance. This manual covers alignments and

adjustments, preventive and corrective maintenance, basic troubleshooting,

and principles of operation.

This manual does not explain how to configure or operate the P9012 printer.

That information is in the P9012 User’s Manual. The User’s Manual

therefore supplements this manual.

How to Use This Manual

This manual is designed so that you can quickly find the information you

need to maintain and repair the P9012 printer. You can locate maintenance

information three ways:

• Use the Table of Contents at the front of the manual.

• Use the Chapter Contents list on the first page of each chapter.

• Use the Index at the back of the manual.

Read the entire procedure before beginning any maintenance task. Gather all

required tools and make sure you understand all warnings, cautions, and

notes before you begin working on the printer.

Warnings and Special Information

Always read and comply with information highlighted by special headings.

The headings reveal the nature of the information:

WARNING

Conditions that could harm you as well as damage the equipment.

CAUTION

Conditions that could damage the printer or related equipment.

IMPORTANT

Information vital to proper operation of the printer.

1–2

Overview

Page 9

NOTE: Information concerning printer maintenance considered important

enough to emphasize.

Printing Conventions

Switches, indicators, and switch positions, if labeled on the printer, are

printed in uppercase letters.

Messages that appear on the control panel display are also printed in

uppercase letters. Example: “Press the CLEAR switch to take the printer to

the OFFLINE READY state.”

Related Documents

For additional information about printer configuration and operation, and

optional interfaces, refer to the following documents:

• P9012 Multinational User’s Manual (p/n 133397–001)

• PI 5225 Interface User’s Reference Manual (p/n 140351–001)

• PI 3287 Interface User’s Reference Manual (p/n 108174–001)

• IGP–100/200/400 User’s Manual (p/n 141332–001)

• IGP–110/210/410 User’s Manual (p/n 141333–001)

Overview

1–3

Page 10

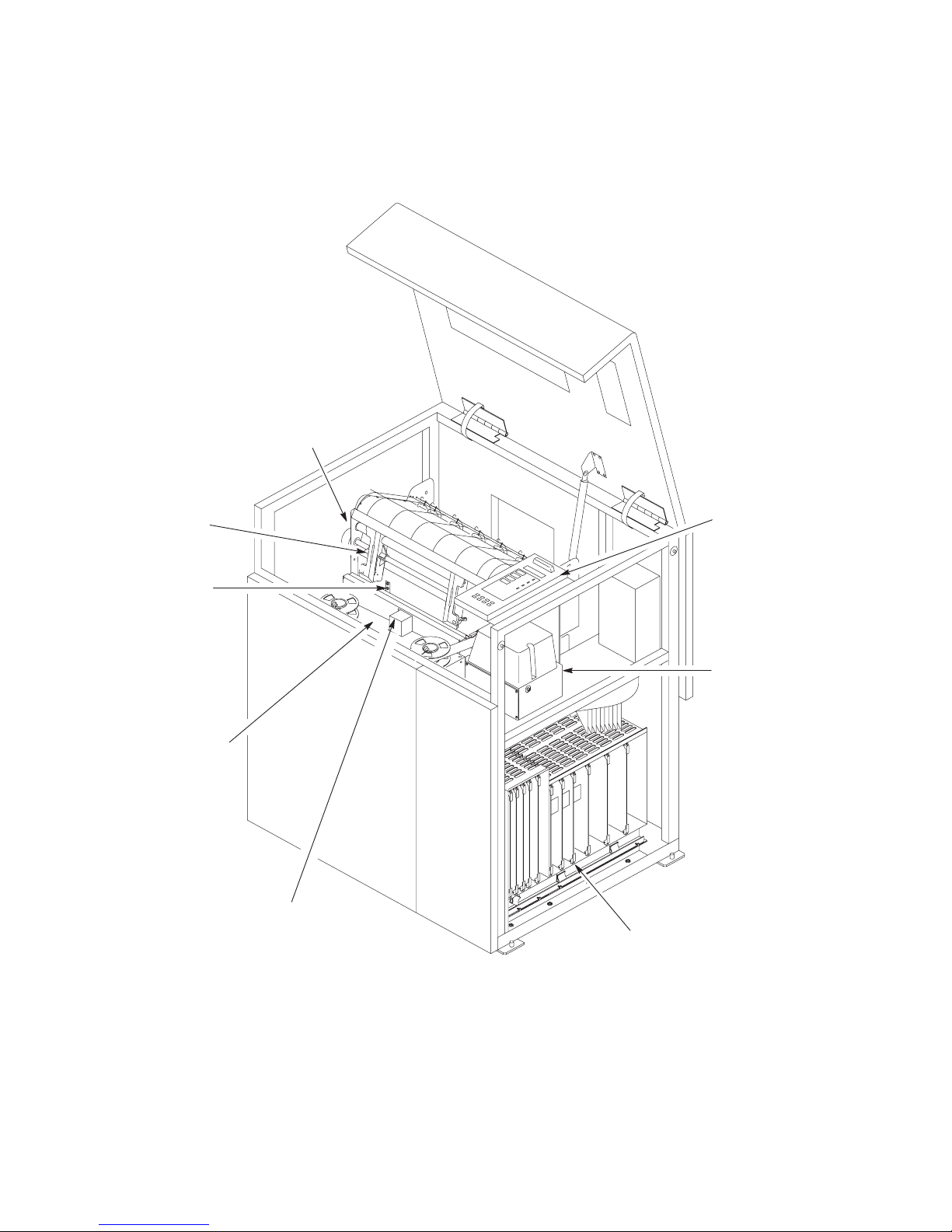

Description

The P9012 Printer (Figure 1–1) is a highly reliable, multi–function dot

matrix line printer. In addition to basic functions, the printer can produce

correspondence quality print for near letter quality (NLQ) printing

requirements, draft print for higher speed, and character attributes (dynamic

character generation) for wider application compatibility.

1–4

Figure 1–1. P9012 Printer

Overview

Page 11

Standard Features

• Extra Quiet Operation

• P–Series or Serial Matrix Protocols

• Raster Plot and Bit Image Graphics

• Dynamic Character Generation

Selectable Pitch Automatic Underline

Shadow Print Superscript Printing

Elongated Print Subscript Printing

Expanded Print

• Selectable Forms Length

• Nonvolatile Electronic Vertical Formatting

• Resident International Character Sets

• Resident OCR–A and OCR–B Character Sets

• Downloadable Character Sets

• Built–in Self–Tests and Diagnostics

• Configuration Printout

• Datastream Hex Code Printout

• Ribbon Fault Detector

• Resident Serial and Parallel Interfaces

Optional Features

• Intelligent Graphics Processing (IGP)

Forms Generation Reverse Image Printing

Bar Code Printing Logo Generation

Expanded Character Printing

• Additional Character Sets

• Downline Loadable Character Sets

• IBM Interfaces

3287 5225/5224

• Power Paper Stacker

• Dataproducts Long–Line Interface

Overview

1–5

Page 12

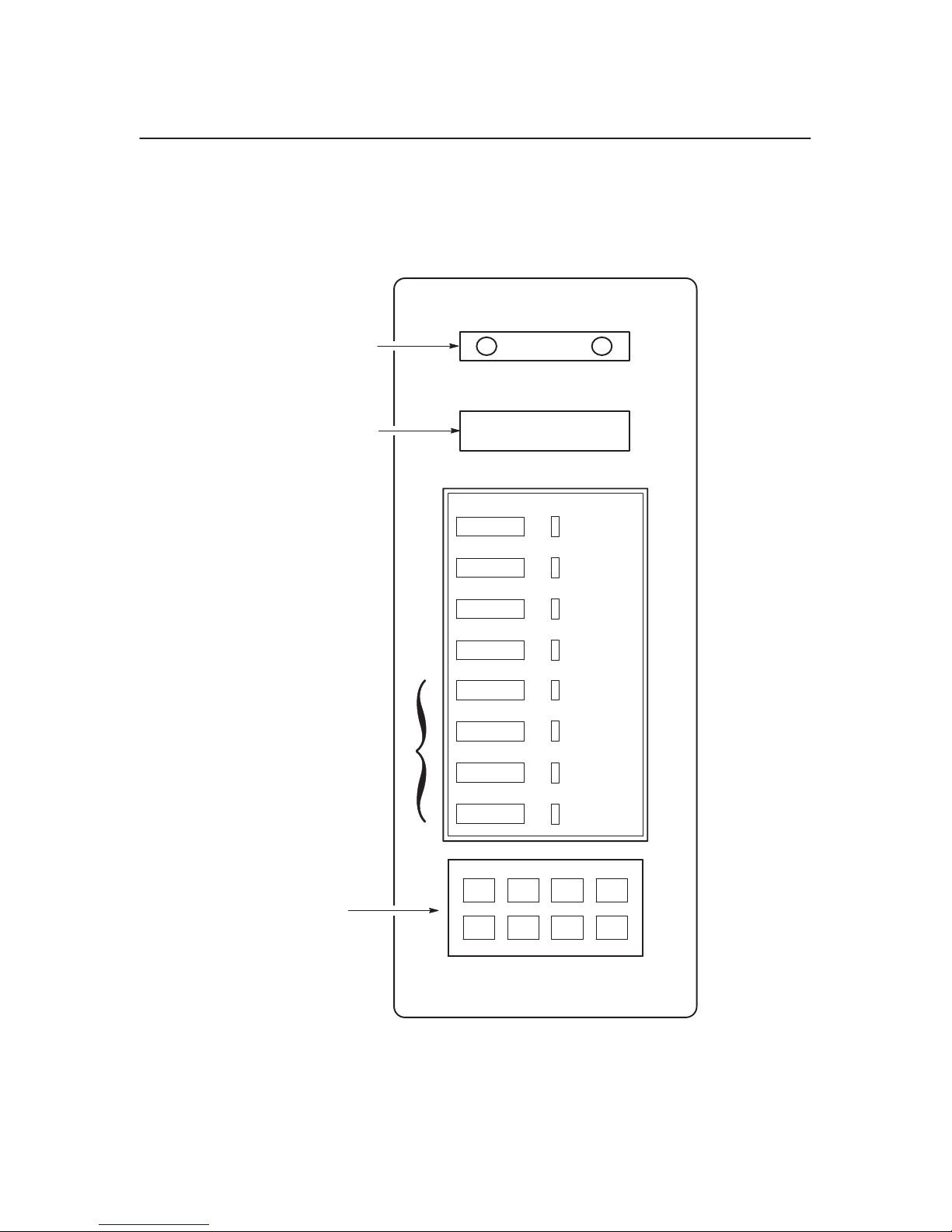

Control Panel Switches and Indicators

The P9012 operator control panel switches and indicators are illustrated in

Figure 1–2 and described in Table 1–1. Refer to the P9012 User’s Manual for

details on control panel operation.

Status Lamps

Message Display

These

switches are provided only if the

printer is equipped with an IBM 3287

interface.

These switches are visible only

with the printer cover open.

ON LINE

CLEAR

6/8 LPI

PAPER ADV

HOLD ENABLE

REPRINT

P

CANCEL PA2

MODE

ALT

MENU UP

MENU DOWN

ON LINE

CHECK

8 LPI

VFU LOADED

A1

NEXT

PREV

RUN/STOP

ENTER F/L

PRINT

MODE

Figure 1–2. Control Panel Switches and Indicators

1–6

Overview

Page 13

Table 1–1. Control Panel Switches and Indicators

Switch / Indicator Function

Except for ON LINE, all switches function only when the printer is off line.

Status lamps

Message display

ON LINE switch Press to place the printer on line or off line.

ON LINE indicator Illuminates when the printer is on line.

CLEAR switch

CHECK indicator Illuminates when a fault condition occurs.

6/8 LPI switch

8 LPI indicator Illuminates when line spacing is other than 6 lpi.

PAPER ADV

switch

VFU LOADED

indicator

Illuminate when the printer is on line, flash alternately to indicate a fault

condition, and remain off when the printer is off line.

Displays printer status and error messages.

Press to clear a fault indication after a fault has occurred. Press while in a

configuration menu to return the printer to the of

RUN/STOP at the same time to reset the printer.

Press to display and select the current line spacing.

Press momentarily to advance the paper one line. Press and hold to advance the

paper to the next top of form.

Illuminates when the format is being controlled by the vertical format unit.

f line state. Press CLEAR and

HOLD ENABLE

REPRINT PA1

CANCEL PA2

ALT MODE

switches

MENU UP switch Press to view the next menu or submenu. Press MENU UP and

MENU DOWN

switch

NEXT switch Press to display the next parameter and its current value in a configuration or

PREV switch

RUN/ST

OP switch Press to run and stop configuration and self tests. Runs and stops hex dump.

Used only if the printer is equipped with an IBM 3287 interface. For details,

refer to the

same time to lock or unlock the ENTER switch.

Press to view the previous menu or submenu. Press MENU DOWN and

at the same time to lock or unlock the ENTER switch.

diagnostic test menu.

Press to display the previous parameter and its current value in a configuration

or diagnostic test menu.

Press RUN/ST

PI 3287 Interface User’s Refer

OP and CLEAR at the same time to reset the printer.

ence Manual, P/N 108174–001.

(???)

at the

(???)

Overview

1–7

Page 14

Switch / Indicator Function

ENTER switch Press to enter a displayed parameter into the printer’s nonvolatile memory.

Must be unlocked before using, via the MENU UP or MENU DOWN switch.

PRINT MODE

switch

F/L switch Press to display and select the current forms length.

Press to display and select the current print mode.

Mechanical Controls

P9012 mechanical controls are described in Table 1–2 and illustrated in

Figure 1–3.

Table 1–2. Mechanical Controls

Item No.

(Figure 1–3)

1

Control or

Indicator Function

Forms Thickness

Adjustment Lever

Sets the platen for different thickness forms or paper. Open (raise)

fully for loading paper.

2

3 Horizontal

4 Tractor Lock (2) Locks tractors in position.

5 Vertical

6 Tractor (2) Used to set the left margin and paper width. The left tractor moves

Forms Thickness

Scale and Pointer

Adjustment Knob

Adjustment Knob

Indicates the relative thickness of forms or paper.

Allows fine positioning of the left print mar

slightly to the left or right.

Sets the top of form or first line to be printed. Rotate to move

paper vertically.

approximately one inch. The right tractor moves the full range.

gin. Moves paper

1–8

Overview

Page 15

1. Forms

2. Forms Thickness Scale/Pointer

3.

4. Tractor Lock (2)

5. V

6. Tractor (2)

Thickness Adjustment Lever

Horizontal Adjustment Knob

ertical Adjustment Knob

3

2

1

4

5

Overview

6

Figure 1–3. Mechanical Controls

1–9

Page 16

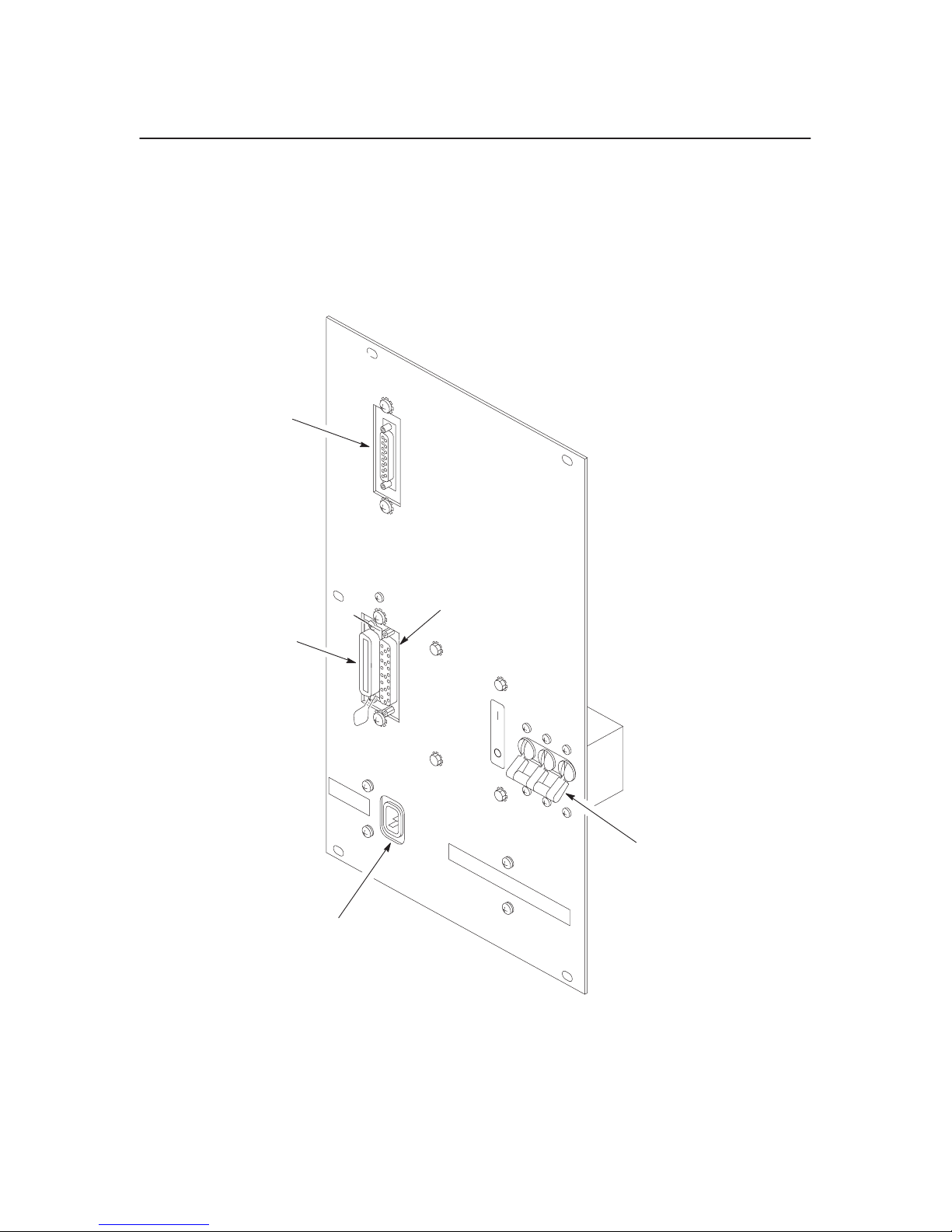

I/O Panel

The P9012 printer supports serial and parallel interfaces. Figure 1–4 shows

the I/O panel on the rear of the printer.

1. RS–232

2. AC On/Off Switch

3. AC Power Connector

4.

5.

1

4

5

Serial Connector

Dataproducts Parallel Connector

Centronics Parallel Connector

1–10

2

3

Figure 1–4. I/O Panel

Overview

Page 17

Tools, Test Equipment, and Supplies

The tools, test equipment, and supplies required for field level maintenance

of P9012 printers are listed in Table 1–3.

Table 1–3. Tools, Test Equipment, and Supplies

Item Part Number Recommended Item

Adjustable W

Diagonal Cutters

Digital Voltmeter — —

Extension, 3 in., 3/8 Drive — —

Feeler Gauge Set — Proto 000AA

Hammer Tip Alignment Tool 132266–001 —

Isopropyl Alcohol — —

Kimwipes — —

Lubricant 101805–001 —

Nut Driver Set — Xcelite P2120

Oscilloscope and Probes (≥35 MHz)

Pliers, Grip Ring — Truarc 1120

Pliers, Chain Nose

Ratchet, 3/8 in. Drive — —

Rule, Steel, 6 in. — General 616

Scale, Spring, 0 to 40 lbs. — —

Driver, Torque Screwdriver — Utica TS35

Adapter, Torque Screwdriver —

rench —

— Erem 91EH

— —

— Erem 11DH

Utica 91–4C

Utica HW–18

Extension, 6 in., Torque Screwdriver — —

Hex Bit, 3/16 in., Torque Screwdriver —

Hex Bit, 3/32 in., Torque Screwdriver —

Hex Bit, 5/32 in., Torque Screwdriver —

Hex Bit, 5/64 in., Torque Screwdriver — —

Screwdriver, Allen Hex — Xcelite 99PS40

Screwdriver, Phillips —

Screwdriver, Phillips —

Screwdriver, Slot —

Screwdriver, Slot —

Overview

Utica W–8

Utica HW–4

Utica HW–6

Xcelite X100

Xcelite X102

Xcelite A184

Xcelite R3164

1–11

Page 18

Item Recommended ItemPart Number

Shims, Counterweight 101564–001 —

Shims, Shuttle Assembly

Socket, 7/16 in., 3/8 in. Drive — —

Soldering Iron and Tips — —

X–acto Knife and Blades

103422–001 —

— —

1–12

Overview

Page 19

2

Chapter Contents

Principles of Operation

Scope 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Matrix Printing 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Functional Elements 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Control Unit (DCU) PCBA 2–14. . . . . . . . . . . . . . . . . . . . . . . .

Mechanism Control Unit (MCU) PCBA 2–18. . . . . . . . . . . . . . . . . .

Mechanism Driver PCBA 2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Driver PCBA 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hammer Bank and Shuttle Mechanics/MPU 2–28. . . . . . . . . . . . . . .

Power Supply 2–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Deck 2–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Feed Control Circuits 2–34. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platen Open/Paper Out Switches 2–36. . . . . . . . . . . . . . . . . . . . . . . .

Safety Circuits 2–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal Operation 2–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Principles of Operation

2–1

Page 20

Scope

Purpose

This chapter presents the principles of operation for the P9012 printer. This

information is intended to provide the technician with a basic understanding

of printer functional operation.

This chapter also provides illustrations which show the location of test points

on the P9012 PCBAs.

For a complete list of signal mnemonics mentioned in this chapter, refer to

Appendix C.

The P9012 printer is a computer output device. It receives data from a host

computer and provides hard copy text or graphics. The hard copy is

composed of an array of dots. In the case of text, these dots are arranged in a

matrix to produce characters.

2–2

Principles of Operation

Page 21

Matrix Printing

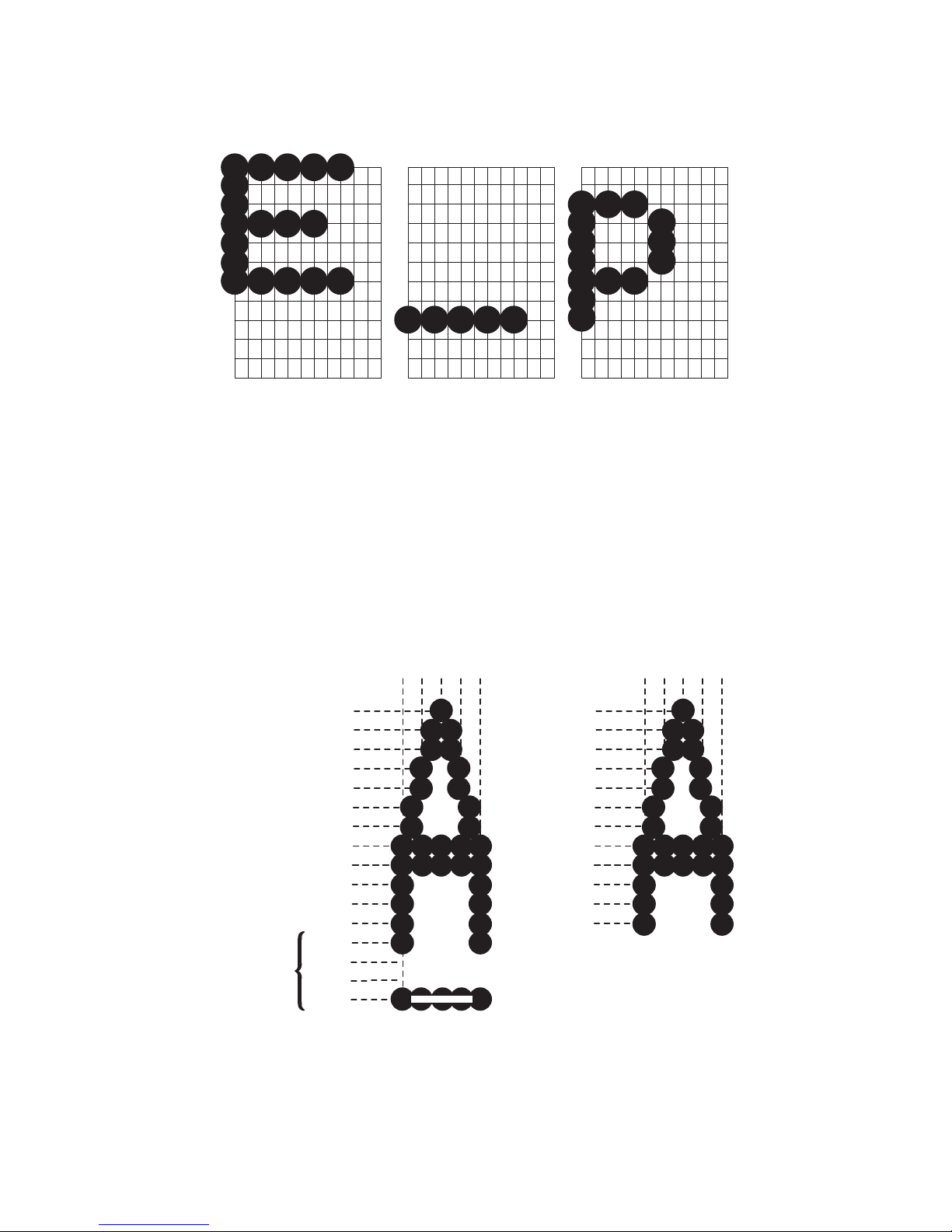

The Dot Matrix

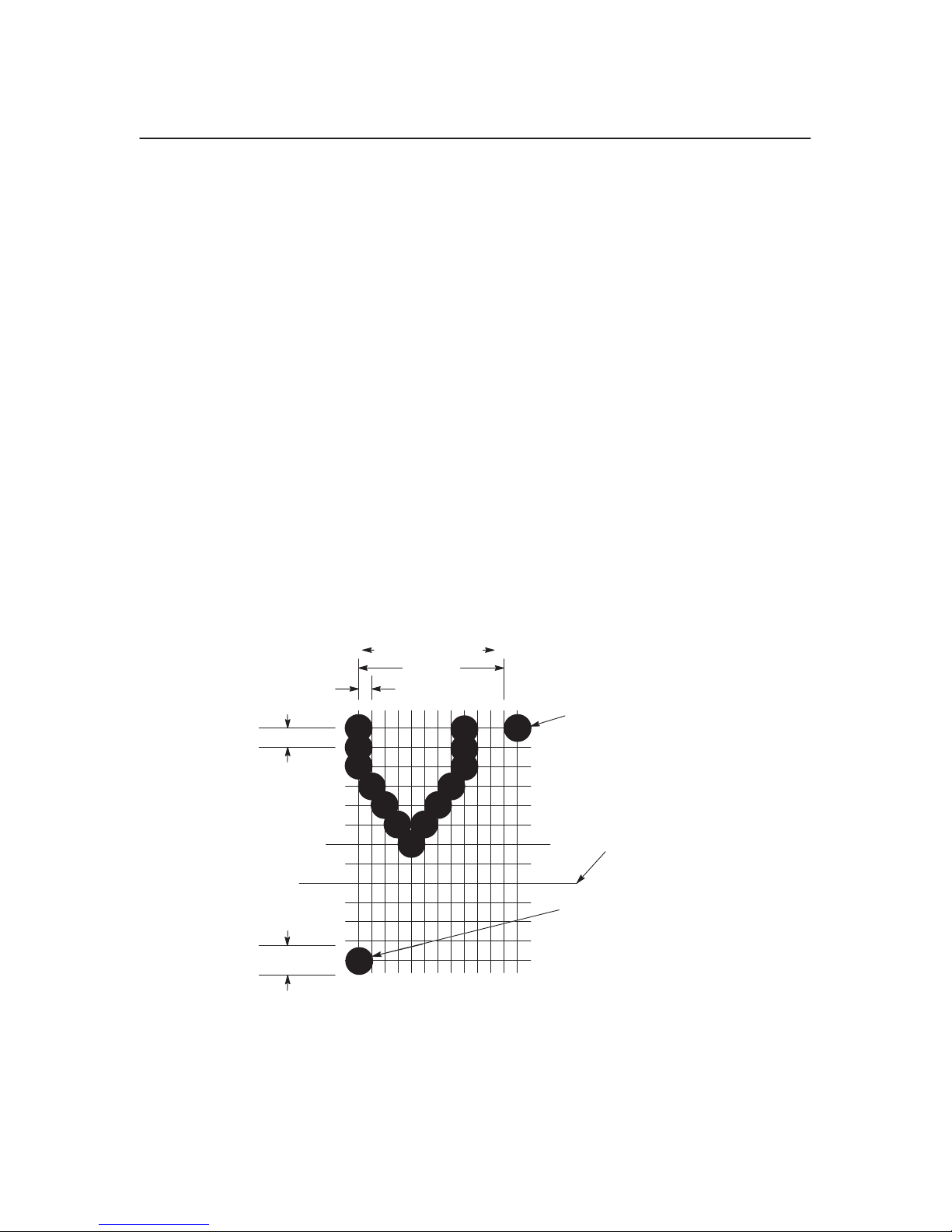

In order to generate characters from dots, the dots must be arranged properly.

The imaginary grid on which the dots are positioned is referred to as the

matrix.

When in the data processing print mode, for spacing of six lines per inch

there are 12 dot rows from the top of one character line to the top of the next

(Figure 2–1 and Figure 2–2). With spacing of eight lines per inch there are

nine dot rows per character line, for nine lines per inch there are eight dot

rows per character line, and for spacing of ten lines per inch there are seven

dot rows per character line.

Elongated characters can be generated by printing each row twice, except for

the first and last (Figure 2–3).

0.01389

0.02

112COLUMN NO.

”

0.10

0.00835

”

”

”

Figure 2–1. Defining the Dot Matrix

FIRST ROW AND

COLUMN OF NEXT

CHARACTER

LOWEST

DESCENDER

LINE

DOT

FIRST ROW AND

COLUMN OF NEXT

CHARACTER LINE

6 LPI)

(AT

Principles of Operation

2–3

Page 22

UPPERCASE

(REFERENCE)

UNDERLINE

Figure 2–2. Typical Characters

LOWERCASE

WITH DESCENDER

PRINTED

WITH

UNDERLINE

WITH UNDERLINES

DOT COLUMN

13579

DOT ROW

1

2

’

2

3

’

3

4

’

4

5

’

5

6

’

6

7

7

’

8

’

8

9

UNDERLINE

WITHOUT

DOT ROW

1

2

’

2

3

’

3

4

’

4

5

’

5

6

’

6

7

UNDERLINES

DOT COLUMN

13579

2–4

Figure 2–3. Elongated Characters

Principles of Operation

Page 23

The Hammer Bank

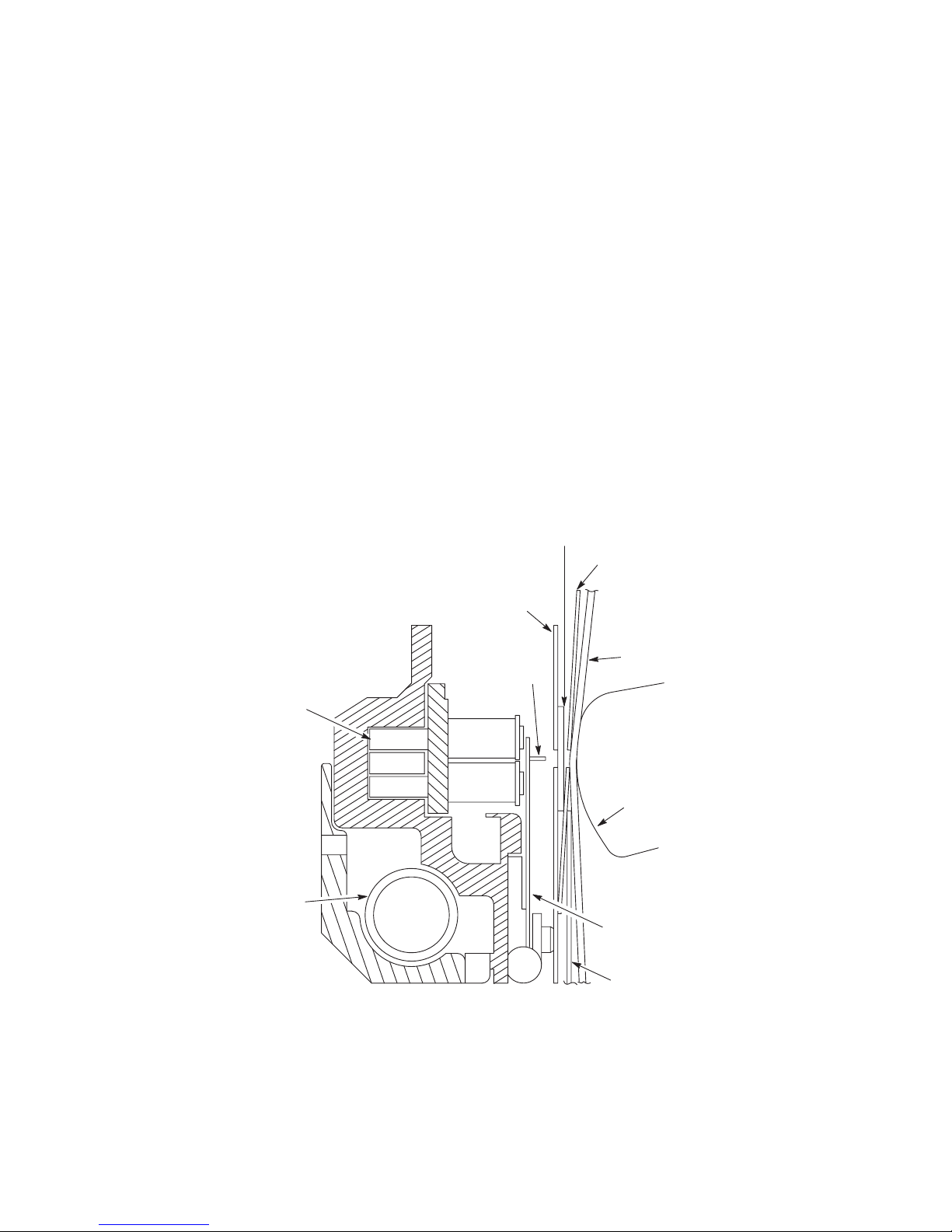

In order to use matrix printing, you must have a method to print the required

dots. The P9012 uses the hammer bank.

The hammer bank contains a number of print hammers mounted on a shuttle

that can move back and forth horizontally. The shuttle prints a full line of

dots during each cycle of back and forth motion.

Each hammer consists of a stiff leaf spring attached at one end to the hammer

bank with a screw (Figure 2–4). The end opposite the screw has a pointed tip

attached. A permanent magnet keeps all the hammers retracted and under

tension. Each hammer has a magnetic coil which when energized counteracts

the permanent magnet, causing the hammer to release and strike the ribbon

and paper, leaving a dot (Figure 2–5). After printing, the rebounding hammer

is recaptured by the permanent magnet.

RIBBON

RIBBON MASK

MAGNET

SHUTTLE SHAFT

HAMMER BANK COVER

PAPER

HAMMER TIP

COIL

COIL

PLATEN

HAMMER SPRING

PAPER IRONER

Figure 2–4. Hammer and Shuttle Arrangement (Typical)

Principles of Operation

2–5

Page 24

DE–ENERGIZED ENERGIZED

PERMANENT MAGNET

COIL

COIL COIL

NORMAL (RETRACTED) STATE ACTIVATED (RELEASE) STATE

HAMMER

TIP

HAMMER

SPRING

COIL

Figure 2–5. Print Hammer Action

2–6

Principles of Operation

Page 25

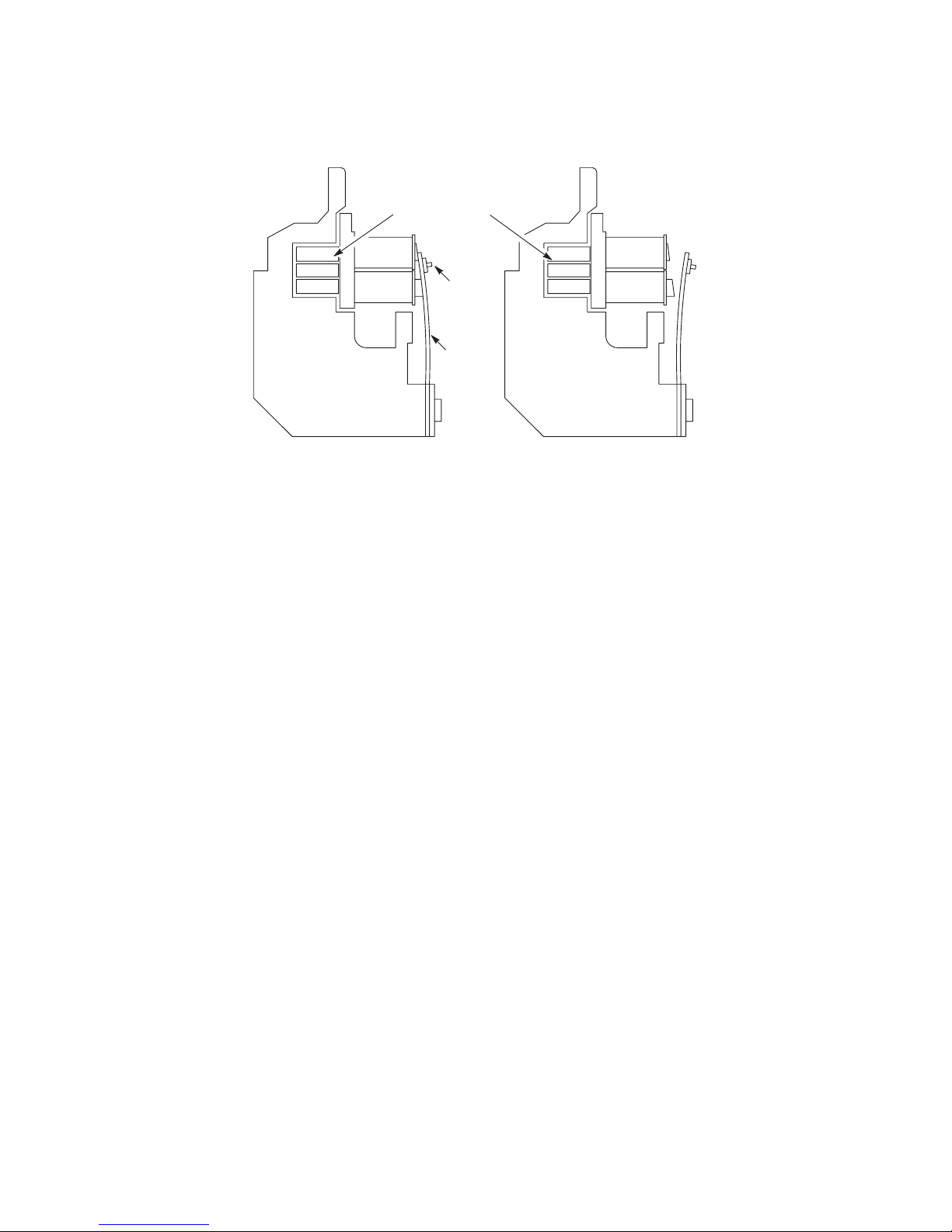

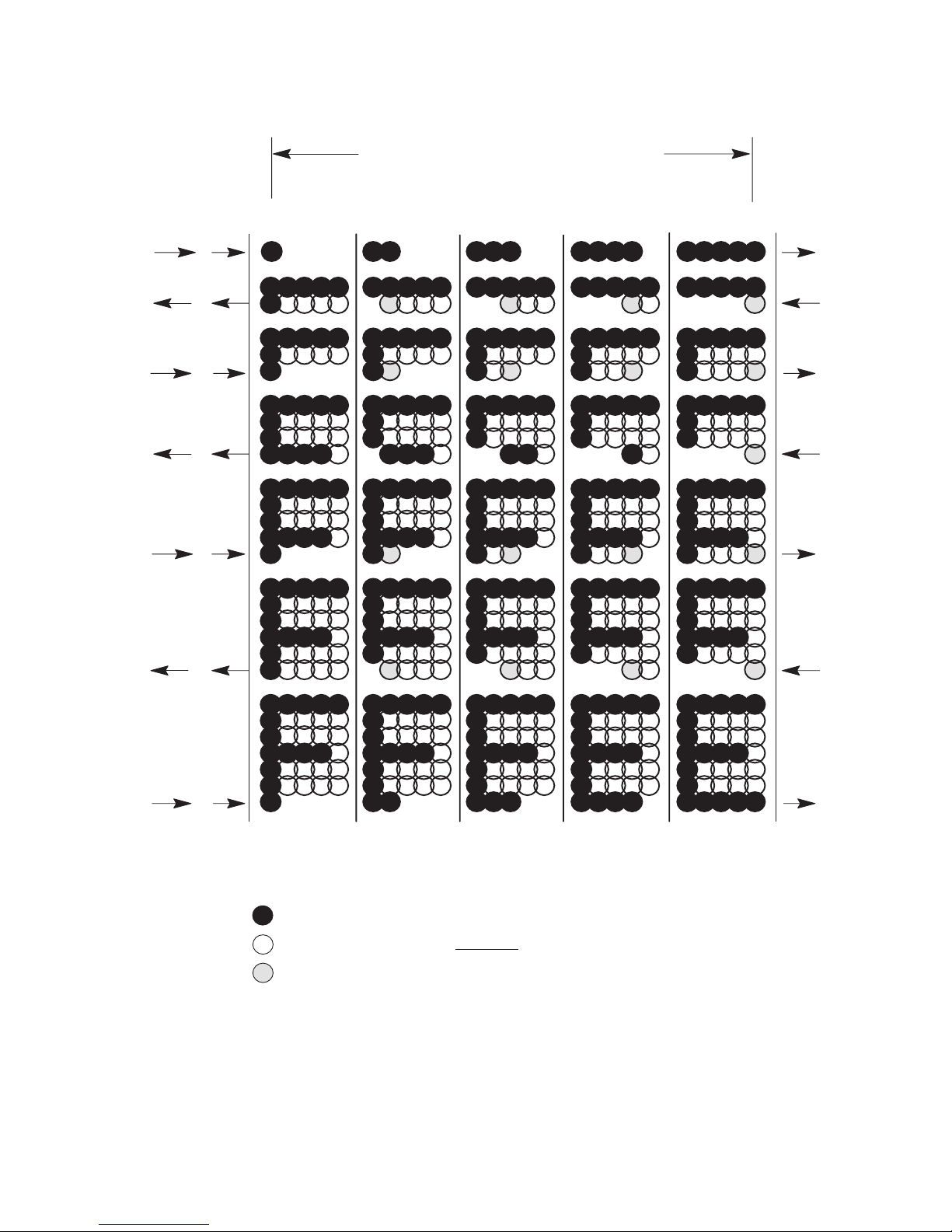

Character Generation

Paper advances one dot row after each shuttle cycle, causing the dot matrix

to be filled as required to generate each character (Figure 2–6 and

Figure 2–7).

DIRECTION OF SHUTTLE MOVEMENT

ONE

CHARACTER

ROW

DOT

ROW START

1

2

3

4

5

6

7

8

*

9

**

10

11

SPACE

12

1

2

1 HAMMER

PRINT SPAN

USED FOR LOWERCASE DESCENDER ONLY

*

USED FOR UNDERLINE AND LOWERCASE DESCENDER

**

NOTE:

The P9012 shuttle sweeps through 1.5 character positions at 10 cpi.

1 HAMMER

PRINT SPAN

PAPER

ADVANCES

PAPER

FEED

PAPER

ADVANCES

Figure 2–6. Standard Character Formation

Principles of Operation

2–7

Page 26

SHUTTLE

SCAN

DOT

* 1 * 1

ROW

SUCCESSIVE HAMMER STROKES PER SCAN

DOT COLUMN

*

1 3

5

* 1

3 5 7 1 3 5 7 9

* * 3

1

2

3

4

5

6

1

1

2

1

2

3

1

2

3

4

1

2

3

4

5

1

2

3

4

5

6

1

2

3

4

5

6

7

7

* EVEN COLUMN DOT CENTERS WITHIN THE PRINTED CHARACTER AREA

AND CHARACTER SPACE HAMMER POSITIONS ARE NOT ILLUSTRATED

IN THIS DIAGRAM.

NOTE: = DOT

= NO DOT WHERE HAMMER HAS BEEN

= HAMMER POSITION

Figure 2–7. Character Formation by One Hammer

2–8

Principles of Operation

Page 27

Printer Functional Elements (Figure 2–8 and Figure 2–9)

The printer is made up of the following functional elements:

• Control Panel

• Data Control Unit (DCU) PCBA

• Mechanism Control Unit (MCU) PCBA

• Mechanism Driver PCBA

• Hammer Driver PCBA(s)

• Hammer Bank and Shuttle Mechanics/Magnetic Pickup (MPU)

• Power Supply PCBA(s)

• Ribbon Deck

• Paper Transport

• Platen Open/Paper Out Switches

Figure 2–8 shows the basic interrelation of these elements and Figure 2–9 is

a simplified block diagram of the printer.

Principles of Operation

2–9

Page 28

TRACTOR

(Paper T

ransport)

PAPER OUT

SWITCH

RIBBON DECK

PLATEN OPEN SWITCH

CONTROL PANEL

SHUTTLE MOTOR

/ MPU

(Shuttle Mechanics)

HAMMER BANK / SHUTTLE

2–10

PCBAs

Figure 2–8. Printer Functional Elements

Principles of Operation

Page 29

SERIAL

HOST I/O

PARALLEL

DATA

CONTROL

STATUS

DATA

CONTROL

STATUS

CONTROL

PANEL

S

T

D

A

A

T

T

U

A

S

S

W

I

T

C

H

FAULT/STATUS

DCU MESSAGE

READY, READ

MESSAGE

BEEPER

DCU MCU

DO–D7

HSC

COM

+5V GND

MOTOR

CONTROL

FAULTS

SENSE

PM1–PM4

FROM P/SFROM MECH DRIVER

+36V GND –12V

MECHANISM

DRIVER

FAULT CIRCUITS

PAPER TRANSPORT

DRIVE

SHUTTLE DRIVE

RIBBON DRIVE

P/S CIRCUITS

+5V

–12V

+12V

GND

TO

DCU

AND

MCU

AC

POWER

120V

240V

50 or 60 Hz

–12V

GND

+12V

+5V

FROM MECH DRIVER

FROM P/S

POWER SUPPLY

+36V

GND

–12V

C

O

M

HAMMER

DRIVERS

HAMMER

+36V

GND

–12V

N

N

H

S

C

H

F

H

U

R

A

C

D

S

U

K

L

T

BANK

TO HAMMER DRIVER

AND MECH DRIVER

D

P

R

O

S

V

I

E

T

I

O

N

PAPER

DRIVE

STEPPER

MOTORDCMOTORDCMOTORS

SHUTTLE

DRIVE

I

S

E

N

S

E

RIBBON

DRIVE

FAULT

(IL/AIR)

BLOWER

ASSEMBLY

D

R

V

E

I

FAN

FAN

FAN

F

A

U

L

T

PLATEN

OPEN/

PAPER

OUT/

PAPER

MOTION

P

B

M

L

D

R

Principles of Operation

Figure 2–9. System Block Diagram

2–11

Page 30

Control Panel (Figure 2–10 and Figure 2–11)

The control panel consists of ten indicators, 16 momentary contact switches,

and an LCD alphanumeric display.

The control panel processes and sends switch closure information to the

DCU. It receives information on setting up the alphanumeric display as well

as status information. For a detailed discussion of panel operation, refer to

the P9012 User’s Manual.

Status Lamps

Message Display

These

switches are provided only

if the printer is equipped with an

IBM 3287 interface.

These switches are visible only

with the printer cover open.

ON LINE

CLEAR

6/8 LPI

PAPER ADV

HOLD ENABLE

REPRINT PA1

CANCEL

P

A2

ALT

MODE

MENU UP

MENU DOWN

NEXT

PREV

ON LINE

CHECK

8 LPI

VFU LOADED

RUN/STOP

PRINT MODE

ENTER F/L

2–12

Figure 2–10. Control Panel

Principles of Operation

Page 31

CONTROL PANEL ASSEMBLY

SW CLOSURES

STATUS

SWITCH CLOSURES

DATA

CONTROL PANEL PCBAPANEL DCU

CONTROL

Figure 2–11. Control Panel Block Diagram

Principles of Operation

2–13

Page 32

Data Control Unit (DCU) PCBA (Figure 2–12 and Figure 2–13)

The data control unit (DCU) PCBA begins the printing process by receiving

data through the host interface (J1, J2). Three interfaces are available on the

DCU card: the Centronics and Dataproducts parallel interfaces (J2), and an

RS–232 compatible serial interface (J1) running up to l9,200 baud. Protocols

are set up through the control panel.

In the parallel mode the input data is transferred directly via Direct Memory

Access (DMA) into memory. While in the serial mode, the input data is

entered into the input buffer with an interrupt–driven software routine. Once

the data is in the input buffer, as defined by software, the data is then taken

from the ASCII format to the format used in the dot image buffer (DIB).

Software determines the special character attributes and any special handling

of the data in the DIB due to the control characters.

The data is then loaded to the hammer driver card through the hammer load

circuit. The hammer load circuit is activated by the mechanism control unit

(MCU) pulling the NLOAD signal low. This signal interrupts the processor

at the highest level available. In this case the DCU is a slave to the MCU.

Control of the data transferred to the hammer drivers is done in the DCU. A

signal, NHMRBLK (hammer bank), loads all 0’s or non–printables to the

hammer driver card if asserted when the hammer load circuit is activated.

The DCU commands the MCU to drive all of the motors and other

mechanical interfaces. Print densities are transmitted to the MCU from the

DCU for proper MCU control of the mechanics.

2–14

Principles of Operation

Page 33

DCU PCBA

J1

Serial I/O

J2

Parallel I/O

(Slot 3)

J5

TP4 (+12VDC)

TP3 (–12VDC)

TP2 (VCCP5)

TP1 (GND)

Figure 2–12. Data Control Unit (DCU) PCBA

Principles of Operation

J6

2–15

Page 34

CLOCK

GENERATION

8/4/2 MHZ

NRST

2MHZ

RESET

GENERATION

370 ms

4MHZ

CLK

RESET

HALT

8MHZ

NMC

CLK

68000

CPU

ADDR

DATA

(23)

(16)

ADDRESS

DECODE

BUS

ARBITRATION

CONTROL

ADDRESS BUS

DATA BUS

EPROM

160K x 16

INTERFACES

HOST

RS–232

HOST

DATA

PRODUCTS

CEN–

TRONICS

HOST

RXD

DCD

DSR

CTS

TXD

RTS

DTR

REVCHNL

RX CLK

TX CLK

EXT CLK

GND

IDB8–IDB1

8

PI

IDSTB

IDRQ

IRDY

IONL

ICSTB

ICBUSY

IACK

ICPE

+5V

GND

NDAV

DSTBOUT

BAUD RATE

XTAL OSC

CLK INTA INTERRUPT

HOST SERIAL

AND INTERRUPT

CONTROLLER

(RS–232–DVRS/RCVRS)

PARALLEL

I/F

CONTROL

SIGNALS

DATA

LATCHING

CNTL

DTACK

H

O

S

T

D

M

A

INPUTS

68901

N

F

A

U

L

T

ERROR

CNTLS

DECODE

BUFFER

H

O

S

T

D

M

A

A

D

D

R

E

N

S

S

W

S

I

(18)

T

C

H

DMA HNDSHK

DTACK

GENERATOR

4MHZ

I/F

RR

I/O

POLARITY

IDS

PARITY CHECK

CONTROL CODE DETECT

DELETE CODE DETECT

OVERRUN DETECT

AND

RD

WR

INTA

SERIAL

AND

PARALLEL

I/F DMA

CONTROLLER

68B44

NLOAD

2MHZ

DMA

HNDSHK

BUS

ARBITRATION

ADDRESS BUS

DATA BUS

(16)

Figure 2–13. Data Control Unit (DCU) Block Diagram (1 of 2)

2–16

Principles of Operation

Page 35

MISC.

CONTROL

SIGNALS

J1

NLOAD

NVRAM

2K x 8

OE

ADDRESS

OUTPUT

STATUS

REGISTER

N

N

P

B

O

D

R

U

H

C

I

F

O

D

N

C

S

S

T

L

T

R

R

H

W

E

R

A

D

S

E

L

E

C

T

ADDRESS BUS (23)

DATA BUS

(16)

NSWITCH

FRONT

PANEL

I/F

LOGIC

ADDRESSABLE

LATCHES

A0,

– P/S

S/P

SHIFT REGISTER

NPFAULT

REGSEL

NENABLE

NSWITCH

NPCLK

NPLOAD

HAMMER DATA CONTROL

PARALLEL AND SERIAL I/O CONTROL

A1

MCU

I/O

(8)

PDATA

+5V

GND

J11

C

O

N

T

R

O

L

P

A

N

E

L

DOT

PLUCKER

MEMORY

CONTRLR

DRAM

256K X 16

Figure 2–13. Data Control Unit (DCU) Block Diagram (2 of 2)

+5VDC

+12VDC

–12VDC

GND

MCUFLT

MCUREC

NLOAD

COM

HSCK

MCU

HAMMER

DRIVER

MECH

DRIVER

Principles of Operation

2–17

Page 36

Mechanism Control Unit (MCU) PCBA (Figure 2–14 and Figure 2–15)

The mechanism control unit (MCU) PCBA controls the printer mechanism

through signals sent to the hammer driver and mechanism driver PCBAs.

The board is controlled by a microprocessor. It contains three sections of

memory, timers and control ports in order to control hammer firing, shuttle

motion, ribbon movement, and paper feed. It receives instructions and

commands from the DCU and communicates status and fault information

back to the DCU.

2–18

Principles of Operation

Page 37

TP3 (PPR BUSY)

TP4 (SDIR)

MCU PCBA

(Slot 4)

P7

TP1 (+5VDC)

TP2 (GND)

Figure 2–14. Mechanism Control Unit (MCU) PCBA

Principles of Operation

P8

2–19

Page 38

CLOCK

GENERATION

6/3 MHZ

RESET

GENERATION

750 ms

COMMAND PORT

4 X 8 MCU/R: DCU/W

4 X 8 DCU/R: MCU/W

H

(4)

A

M

M

E

R

D

R

I

V

(4)

E

R

I/O

(4)

N/A

(4)

CLK

3MHZ

RESET

MCU / DCU

DIP SWITCH

HAMMER

DRIVER

TEST PORT

HAMMER

DRIVER

STATUS PORT

COLOR

CONTROL

PORT

6MHZ

NRST

CLK

Z–80

CPU

BD0–7

BD0–7

D4–7

BD0–3

D0–7

ADDR

DATA

CNTL

(16)

(8)

–7

!/O AND

ADDRESS

DECODE

BUFFERED ADDRESS BUS

EPROM

36K X 8

BUFFERED DATA BUS

B

RD

U

F

CNTLS

DECODE

AND

BUFFER

D

0

Z–80 CTC

8254

TIMER

8254

TIMER

WR

INTA

CS

CS

CS

NUD/HRS

DCMOD

HAM

A0, A1

A0, A1

A0, A1

–7

F

E

R

E

D

D

A

T

A

B

U

S

D

0

B

U

F

F

E

R

E

D

A

D

D

R

E

S

S

B

U

S

MCU REC

D0–7

FIRE 0,1,2

(16)

(8)

DCU

I/F

COM

HSC

Figure 2–15. Mechanism Control Unit (MCU) Block Diagram (1 of 2)

2–20

Principles of Operation

Page 39

BUFFERED ADDRESS BUS

BUFFERED DATA BUS

SRAM

16K X 8

MCU REC

D0–7

DOT

COUNTER

STATUS

REGISTER

D0–3 D4–7

BD0–3

BD0–3

FIRE 0,1,2

PAPER FEED

FIRE

CONTROL

LOGIC

RIBBON

CONTROL

PF1/2

(4)

PF3/4

AIRFLT

IL

NFLT

NPLAO

NPADO

NRIBFLT

PMD

NHCK

NUD/HRS

FAULT

I/F

MECH

DRIVER

I/F

(3)

MECH

DRIVER

I/F

DCU I/F

HAMMER

DRIVER

I/F

HAM

COM

HSC

Figure 2–15. Mechanism Control Unit (MCU) Block Diagram (2 of 2)

Principles of Operation

DCMOD

MECH

DRIVER

I/F

2–21

Page 40

Mechanism Driver PCBA (Figure 2–16 and Figure 2–17)

The mechanism driver PCBA contains those circuits required to drive the

various motors of the printer mechanism. These driver circuits are under

control of the MCU. The mechanism driver PCBA also produces, by use of

switching regulators, the

DCU. These voltages are generated from the +36 V output of the power

supply. A 63 VDC power supply on the board is used in the paper feed motor

circuit and the shuttle motor circuit. Fault detect circuits monitor error

indications and sends a fault message flag to the MCU.

±12 V and +5 VDC required by the MCU and

2–22

Principles of Operation

Page 41

TP8 (PPF RAMP)

TP7 (+5V)

TP6 (+5 R

TP25 (+58V)

TN)

Mech Driver PCBA

TP11 (PF1 CHOP)

TP10 (VREF)

TP9 (PF2 CHOP)

(Slot 5)

Note:

TP23 (SHT PROP)

All voltages shown are in VDC.

TP22 (HES A)

J9

TP24 (SHT INTEG)

TP5 (+12V)

TP4 (+63V)

TP3 (+36V)

TP2 (MPU)

TP1 (PMD)

Principles of Operation

TP21 (HES RET/–12V)

TP13 (–12V)

J10

TP15 (–12V)

Figure 2–16. Mechanism Driver PCBA

2–23

Page 42

+36V

MCU

PCBA

FILE

MPU

+_

12VDC

IN

+5V IN

MASTER

CLEAR

RIB MOV

GUIDES

RIB TEN

PF1/PF2

NRUN1/NRUN2

PMD

NPAPO

NRIBFLT

NPLAO

DCMOD

NUPTOSPD

MPU PULSE

SHAPER

+_

12 VDC

POWER

SUPPLY

+5 VDC

POWER

SUPPLY

POWER UP

RESET

+36V

SWR

SWL

STEPPER MOTOR

+63VDC POWER

RIBBON

DC MOTORS

DRIVER

PAPER FEED

DRIVERS

SUPPLY

FAULT

DETECT

DC MOTOR

DRIVER

–12V +36V

MPU +

MPU –

+36VDC

+36V RTN

+5VDC

BRKRTRP

PMD

AMPLIFIER

DRIVE

SENSE

+58 VDC

REGULATOR

BLOWER

DRIVER

–12V +36V

BREAKER

TRIP

LEFT RIB. MTR

RIGHT RIB. MTR.

PAPER FEED

MOTOR

PAPER

MOTION DETECT

PAPER TRANSPOR T

RIBBON DRIVE

SHUTTLE MECHANICS

DC SHUTTLE

MOTOR

MAGNETIC

SENSOR

BLOWER

AC POWER

CIRCUIT

BREAKER

MECHANISM DRIVER PCBA

Figure 2–17. Mechanism Driver Block Diagram

2–24

GND +36 –12

Principles of Operation

Page 43

Hammer Driver PCBA (Figure 2–18 and Figure 2–19)

Each of the print hammers is controlled by electromagnetic coils, a driver,

and a logic circuit which, among other functions, controls the energizing of

the coils.

The hammer logic circuits perform the following functions:

• Convert serial data bits on the COM line into parallel data bits.

• Control the energizing of hammer coils to print dots in accordance with

the parallel data.

• Provide safety features to prevent coils from energizing under conditions

that could damage coils and hammer drivers.

• Provide an isolated and regulated +5 VDC supply, 5HL, for TTL logic

on the hammer driver PCBA.

Following a SYNC pulse, hammer shift clock (NHSC) pulses load data from

the COM DATA line into the hammer driver shift register. Every bit on the

COM line is clocked into the shift register by the rising edge of NHSC,

containing dot information for the characters to be printed by each hammer.

After the last bit is clocked into the shift register, the next SYNC pulse

causes hammer clock, NHCK, to load the contents of the shift register into

the data latches.

When a dot is to be printed, the data latch for that hammer is set and the

corresponding Darlington driver transistor is forward biased. At the same

time, the overdrive transistor is also forward biased for a period of time

controlled by the upper drive (NUD) signal from the MCU. During the

overdrive period, 48 volts are placed across the coils whose Darlingtons are

energized. After the NUD period is over, a –12V to ground current path

provides the current for the remainder of the hammers on time. This process

energizes the coil, releasing the hammer to print out.

Hammer reset signal, HRS, resets the output enable (OE) of the latch. The

latch output disables all Darlington drivers and deenergizes the coils. The

rebounding hammers are recaptured by the permanent magnet.

Principles of Operation

2–25

Page 44

TP10 (–8V)

TP1 (+5V)

TP7 (–12V)

TP8 (OD)

TP2 (COM1)

Hammer Driver PCBAs (1–3)

Note:

All voltages shown are in VDC.

TP3 (–HCK)

TP6 (+36V)

TP4 (NHSCB)

TP5 (–HRS)

TP9 (COMOUT)

2–26

Figure 2–18. Hammer Driver PCBA

Principles of Operation

Page 45

TEST

TIMING

+12V R

+5V

HMC

TN

–12V

+36V

MONITOR #1

HAMMER

DRIVER (H/D)

REGULATOR

Q

Q

FAULT

+5V

HAMMER

OUTPUT

DISABLE

CIRCUITS

5HL

SD

OD

OE

tt

tt

DARLINGTON DRIVERS (33)

tt

+36V

–12V

FAULT

MONITOR #2

NHCK

HRS

NUD

COM IN

NHSC

OPTO–

ISOLATORS

HCK

HRS

OD

COM IN

NHSC

D

CK

DATA

LA

TCHES (33)

SHIFT REGISTER (33)

CK

Q

OPTO–

ISOLATOR

Figure 2–19. Hammer Driver Block Diagram

COM OUT

Principles of Operation

2–27

Page 46

Hammer Bank and Shuttle Mechanics/MPU (Figure 2–20)

Hammer Bank Assembly/Shuttle

Operation of the hammer bank and shuttle is described on page 2–5.

Magnetic Pickup Unit (MPU)

Printing is synchronized with shuttle movement by the magnetic pickup

(MPU) signal. The magnetic pickup, located next to the flywheel timing disk,

is so oriented that timing signals relate precisely to the shuttle position.

Variations in magnetic reluctance are sensed by the magnetic pickup from

apertures on the timing disk as it rotates, generating SYNC pulses. Two

aperture locations at opposite ends of the disk are of double width (material

between two adjacent apertures is removed). These double width apertures

separate the 284 single width apertures into two groups and generate a

RESYNC signal coincident with the shuttle starting to move from left to

right.

Full rotation of the disk provides eight printing periods and four back and

forth shuttle cycles. Each printing period is followed by a turnaround period

when the shuttle movement is reversed, paper is advanced 0.0139 inches, and

no printing occurs.

The SYNC pulses are distributed to timers on the MCU.

The SYNC signal performs the following functions:

• Signals the MCU to load the hammer driver shift register for the next

hammer firing.

• Activates all hammers armed with a logic “1” during the previous load of

the hammer driver shift register by generating the NHCK signal.

• Initiates two time out periods which control the upper drive (NUD) and

the hammer reset signal (HRS). These signals activate and reset hammer

driver circuits previously activated by SYNC.

In the generation of SYNC and RESYNC signals, the roughly sinusoidal

output of the magnetic pickup is amplified and converted to a TTL

compatible square pulse by a circuit on the mechanism driver PCBA. The

2–28

Principles of Operation

Page 47

resulting MPU signal is synchronized with the timers (CLK) and applied to

print synchronizing logic on the MCU PCBA.

Typical signal levels received from the magnetic pickup are:

SYNC: 2.5 to 5.5 Vpp

RESYNC: 4 Vpp minimum

SHUTTLE MOTOR

(Shuttle Mechanics)

HAMMER BANK/SHUTTLE ASSEMBLY

Figure 2–20. Printer Functional Elements

MPU

Principles of Operation

2–29

Page 48

Power Supply (Figure 2–21)

The power supply PCBA is a switching power supply. Its regulated outputs

are –12 and +36 VDC. These voltages are supplied to the hammer driver and

mechanism driver PCBAs.

The printer contains three identical power supply PCBAs. Loading of the

PCBAs is such that some operation of the printer may be possible with an

inoperable power supply.

The required AC input line voltage for operation of the power supply is as

follows:

90 to 128 VAC, 49–51 and 59–61 Hz

190 to 256 VAC, 49–51 Hz

If the AC input voltage is removed from the power supply, during either

normal operation or an overload condition, the power supply will recover so

that power may be reapplied in less than 2.5 seconds. If an overload occurs,

the power supply will return to the normal operation less than 8 seconds after

the fault is cleared.

The performance characteristics of the power supply are as follows:

–12 VDC supply, –12.8 V output voltage, ±10%

+36 VDC supply, +36 V output voltage, ±10%

Note that the 12V load includes 60,000 mfd of filter capacitors and is

considered a part of the power supply output filter.

NOTE: As shown in Figure 2–21, the power supply contains a jumper that

must be configured for the type of P9012 printer in use. For printers

that contain an Autotap board, place the jumper in the “SHORT”

position. For printers that do not contain an Autotap board, place the

jumper in the “OPEN” position.

2–30

Principles of Operation

Page 49

Power Supply PCBAs (1–3)

SHORT

OPEN

Principles of Operation

Figure 2–21. Power Supply PCBA

2–31

Page 50

Ribbon Deck (Figure 2–22 through Figure 2–24)

The ribbon deck assembly contains two dc servomotors that move the ribbon

continuously while there is shuttle action. One motor acts as the driver,

drawing the ribbon against opposing torque exerted by the other motor.

When a length of metal tape at either ribbon end is detected by the ribbon

guide at either side of the shuttle, the two motors exchange roles and ribbon

travel is reversed. This system maintains a relatively constant ribbon speed

and tension.

The ribbon moves only while the shuttle is in motion. When the printer is on

and no faults have occurred, the ribbons will be tensioned by the application

of NRIBEN from the MCU PCBA. When NRIBMOV is applied, the ribbon

will move. NRIBMOV is applied when DCMOD comes on starting the

shuttle.

The NRIBMOV and NRIBEN signals enable gates which control power to

the ribbon drive motors.

When an end of ribbon sensor is activated, the corresponding latch turns on

the related FET.

NRIBENMOV

NRIBEN

RIGHT

DETECTOR

LEFT

DETECTOR

When the right end of the ribbon is detected, the latch is set to the opposite

state and the motors reverse roles.

When the shuttle motor is not running, that is, DCMOD not modulating and

NRIBMOV is high, both FETs are held off and the motors act in opposition,

as the voltage provides feedback to resist ribbon movement, provided

NRIBEN is not deactivated by a printer fault.

+36V

RIBBON

DIRECTION

CONTROL

+5V

RIBBON

DC MOTOR

DRIVERS

M

M

Figure 2–22. Ribbon Deck Block Diagram

2–32

Principles of Operation

Page 51

+5V

Figure 2–23. Ribbon Deck

+27V

+17.8V

K1

M1

R

F1

M2

+1V

TO +5V

R

+5V++

K2

––

F2

+36V

NSD

RH

END OF

RIBBON

DETECTORS

LATCH

LH

Figure 2–24. Ribbon Control PCBA Simplified Schematic

Principles of Operation

+5V

R

IN1

+3.7V +5V

Q1 Q2

R

S1

(LOW)

(HIGH)

R

C

(VOLTAGES ARE AS INDICATED

WHEN RIBBON IS RUNNING FROM

R

R

RIGHT

IN2

S2

TO LEFT)

2–33

Page 52

Paper Feed Control Circuits (Figure 2–25 and Figure 2–26)

The paper feed motor contains two pairs of coils, driven in sequence. As the

electromagnetic detent locking the rotor is released, the rotor is advanced one

increment, and the detent is set again. One pair of coils is driven by the

push–pull signal, PFM1/PFM2, and the other pair by PFM3/PFM4.

The drive signals are controlled by the four phase paper feed signals, PF1,

PF2, NRUN1, and NRUN2 generated in paper feed logic. Each pair of

PF1/PF2/NRUN1/NRUN2 pulses increments the motor one step to advance

paper 1/288 inch.

When paper is to be advanced either to the next character line, to the top of

form, to a selected vertical tab or by being put under EVFU control, the

corresponding profile of paper movement velocity is selected by the MCU to

obtain precise paper control. Paper is accelerated at a variable rate to

optimize both speed and precision and decelerated at a variable rate that

prevents overshoot. To achieve this modulated paper movement, paper feed

logic generates PF1, PF2, NRUN1, and NRUN2 regulated by the velocity

profile software.

NRUN1/PF1

NRUN2/PF2

NRUN1/PF1 and NRUN2/PF2 each drive identical independent control

circuits. Either circuit operates when the paper feed pulse passes through

gates and drives a push–pull current amplifier circuit that provides drive

current to one pair of motor coils.

CURRENT

DRIVER

CURRENT

DRIVER

PFM1

PFM2

TO PAPER

FEED MOTOR

PFM3

PFM4

Figure 2–25. Paper Feed Control Circuits Block Diagram

2–34

Principles of Operation

Page 53

TRACTORS

(PAPER TRANSPOR T)

PAPER FEED MOTOR

Principles of Operation

Figure 2–26. Paper Feed Components

2–35

Page 54

Platen Open/Paper Out Switches (Figure 2–27)

These switches signal the mechanism driver that the printer is out of paper or

the platen has been left open. When either signal is detected, paper transport

is disabled and the ribbon loses tension. The signal faults are reported to the

control panel from the MCU to the DCU.

2–36

PLATEN OPEN SWITCH

PAPER OUT SWITCH

Figure 2–27. Platen Open/Paper Out Switches

Principles of Operation

Page 55

Safety Circuits (Figure 2–28)

Excessive current and overheating can damage coils and hammer drivers in

either of the following situations:

• Current turned on when not needed to release hammer springs.

• Current left on after hammer spring release.

Three safety circuits on the hammer driver board prevent excessive current

by disabling the latch output drivers under control of the OE signal. For each

of the following three conditions, OE is held low:

• +5VHL supply out of tolerance — when the +5VHL voltage output

exceeds Zener diode avalanche levels, OE is held low.

• –12V, +36V supply ground missing — if the –12V, +36V return is not

connected to the hammer driver board, the OE line is held low.

• +5V, –12V voltages levels are out of tolerance.

Two other circuits monitor the leakage currents of both the overdrive

transistor and the lower hammer driver transistors and if the currents are too

large, the fault circuit signals the MCU which in turn turns off the printer via

BRKRTRIP.

A fourth safety circuit halts hammer firing in the event of a hammer master

clear, HMC, or the loss of the hammer reset pulse, HRS. When HMC is low,

the output of the one millisecond one–shot, U16, is normally kept high while

being triggered by HRS pulses. Whenever HRS pulses stop or HMC goes

high, the one–shot resets within one millisecond and hammer firing stops.

NORMALLY HIGH

GOES LOW FOR HMC

OR LOSS OF HRS PULSES

+5VHL

HRS

HMC

3

4

1

2

4

U16

3

1 MILLISECOND

2

ONE – SHOT

1

Q

Q

8

SD

HRS

OE

Figure 2–28. Safety Circuits

Principles of Operation

2–37

Page 56

Normal Operation (Figure 2–29)

Character Printing

During one cycle of normal operation, the printer is set up and put online by

the operator, using the control panel. Host computer data is then read into the

data input buffer. ASCII data from the input buffer is compared to tables

stored in memory to determine the matrix locations to be printed for each

character and build the dot image buffer. Information from the dot image

buffer is synchronized with printer requirements using the magnetic pickup

signal then shifted out to hammer drivers. The selected hammers are fired.

When all dots in a row are printed, the paper is shifted one dot row and the

next dot row of data from the dot image buffer is synchronized then shifted

out to the hammer driver. Shifting of paper is delayed to allow double

printing when adjacent dot printing is required.

Self–Test

During self–test, internally generated data is used to build the dot image

buffer. Operation then proceeds as in normal printing.

2–38

Principles of Operation

Page 57

FRONT PANEL

PRINTER SETUP

PRINTER ENABLE

HOST

CONNECTION

INPUT DATA

THROUGH DMA CONTROLLER

SELF–TEST

SELECT FROM

FRONT

P

68B44

(DCU)

ANEL

(DCU)

SOFTWARE

INPUT DATA

BUFFER

(IN DYNAMIC RAM)

ASCII DATA (DCU)

BUILD DOT IMAGE BUFFER (DIB)

FROM LOOK UP

PUT INTO DYNAMIC RAM (DCU)

SYNCHRONIZE THE TIMING TO

THE CODE WHEEL (MPU)

SOFTWARE (MCU)

DEMAND HAMMER LOAD (MCU)

DATA SHIFTED OUT

TABLES IN FONT

TO HAMMER DRIVER (DCU)

(DCU)

CONTROLLED BY SOFTWARE

EXECUTED BY HARDWARE

CONTROLLED BY SOFTWARE

EXECUTED BY HARDWARE

Principles of Operation

FIRE HAMMERS

ON NEXT MPU

ALL DOTS IN ROW PRINTED ?NY MOVE

(MCU)

SOFTWARE TIMERS

SOFTWARE DECISION

Figure 2–29. Operation Flow Diagram

PAPER

(MCU/MECH

DRIVER)

2–39

Page 58

2–40

Principles of Operation

Page 59

3

Chapter Contents

Scheduled Maintenance

Preventive Maintenance Checks and Services (PMCS) 3–2. . . . . . .

Inspecting the Printer 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Printer 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scheduled Maintenance

3–1

Page 60

Preventive Maintenance Checks and Services (PMCS)

Perform Preventive Maintenance Checks and Services (PMCS) every three

months or after every 250 hours of operation, whichever comes first.

Do these checks more often if the printer is used for heavy–duty, continuous

printing or if it is located in a dusty area.

PMCS are listed in Table 3–1.

WARNING

Disconnect the AC power cord before performing PMCS. Failure to do

so could result in injury to you or damage to the equipment.

Table 3–1. Preventive Maintenance Checks and Services

Interval Assembly Procedure Page

Every 3 months or 250 hours

of operation, whichever

occurs first.

Printer

Printer

Shuttle Belt

Paper Feed Belt

Inspect the printer.

Clean the printer.

Check tension.

Check tension.

3–3

3–4

5–24

5–26

3–2

Scheduled Maintenance

Page 61

Inspecting the Printer

Visually inspect the printer using Table 3–2 as a guide. Correct any condition

found during inspection that could affect printer performance or reliability.

Item(s) to Inspect Procedure

Table 3–2. Physical Inspection

Cabinet, base, frame

Attaching hardware Inspect fasteners for thread damage, rust, or corrosion.

Nameplates Inspect for legibility and damage.

Printer cover, cabinet door(s),

damper/struts

Hinges Inspect for damage and loose or missing hardware.

Electrical connectors Inspect for damage and bent or broken pins.

Controls and indicators

Windows Inspect for breaks, cracks, or discoloration.

Ribbon cables

Circuit boards Inspect for breaks, warpage, and evidence of overheated

Check for damage, cracks, breaks, dents, gouges, scratches,

warpage, rust, corrosion, and proper finish.

Inspect for damage and loose or missing hardware. Check that the

door(s) open/close without binding and stay closed. Check that

the printer cover opens/closes smoothly and damper/struts hold

cover open.

Inspect for damage.

Inspect for broken wire or strands, damaged insulation, pinched

wiring, and possible shorting conditions.

components. Some printer disassembly is required. See Chapter 6,

Replacement Procedures.

Fans and motors

Flywheel cam, Shuttle and

Counterweight cam followers

Scheduled Maintenance

Inspect for obvious damage. Some printer disassembly is

required. See Chapter 6, Replacement Procedures.

After checking belt tension, inspect the cam and follower surfaces

for excessive wear or damage. If required, replace the parts as

described in Chapter 6, Replacement Procedures.

3–3

Page 62

Cleaning the Printer

Do not use abrasive cleaners, particularly on the window. Do not drip

water into the printer; damage to equipment will result. When using

spray solutions, do not spray directly onto the printer; spray the cloth.

Exterior of Cabinet

1. Wipe the cabinet with clean, lint–free cloth dampened (not wet) with

water and mild detergent or window cleaning solution.

2. Dry the cabinet with a clean, lint–free cloth.

3. Vacuum the ventilation slots at the sides of the cabinet.

Interior of Cabinet (Figure 3–1)

CAUTION

1. Set the AC power switch on the rear of the printer to the O (OFF)

position.

2. Disconnect the the AC power cord from the rear of the printer and open

the top cover.

3. Move the forms thickness adjustment lever (1) to the fully–open

position.

4. Remove paper from the printer.

5. Squeeze the lock tabs (2) and lift the ribbon spools (3) from the ribbon

hubs (4).

6. Using a soft–bristled brush, wipe off paper dust and ribbon lint. Vacuum

up the residue. Pay particular attention to the tractors (5), hammer bank

(6), and base casting (7).

7. Wipe the splined shaft (8) with a soft cloth.

8. Using a cloth dampened with alcohol, clean the ribbon guides (9).

3–4

Scheduled Maintenance

Page 63

1. Forms

2. Lock T

3.

4.

5. Tractor (2)

6.

7.

8.

9.

10.

11.

12.Platen

Thickness Adjustment Lever

ab (2)

Ribbon Spool (2)

Ribbon Hub (2)

Hammer Bank

Base Casting

Splined Shaft

Ribbon Guide

Paper Motion Detector

Ribbon Path

3

5

11

6 (under cover)

12

10

1

2

4

8

9

7

Figure 3–1. Cleaning Interior of Cabinet

Scheduled Maintenance

3–5

Page 64

9. Open the left tractor (5) and clean the paper motion detector (10) with a

soft brush.

10. Clean the ribbon path (11) with a soft brush.

11. Inspect the platen (12). If necessary, wipe with a cloth dampened with

alcohol to remove ink or dirt.

12. Vacuum dust or residue that has accumulated inside the lower cabinet.

13. Wipe the lower cabinet interior with a clean, lint–free cloth dampened

with water and mild detergent or window cleaning solution.

Hammer Bank Assembly (Figure 3–2)

1. Remove the power cord from the rear of the printer and open the top

cover.

2. Raise the forms thickness adjustment lever (1) to fully open. Remove

any paper present.

3. Squeeze the lock tabs (2) and remove the ribbon spools (3) from the

ribbon hubs (4). Slide the right tractor (5) fully to the right.

4. Remove the ribbon deck (6) as described on page 6–8 of Chapter 6,

Replacement Procedures. This will provide access to the hammer

bank (7).

5. Push the top edge of the ribbon mask (8) on the hammer bank cover

assembly (9) toward the platen (10) and hold.

CAUTION

Exercise care when handling the ribbon mask; damage can affect print

quality.

6. Use a stiff, nonmetallic bristle brush to remove ribbon lint and paper dust

from the hammer springs (11) and tips (12) and from the ribbon mask,

especially in the ribbon path. Vacuum loosened particles. Remove

stubborn accumulations using a cloth or Kimwipe moistened (not wet)

with isopropyl alcohol.

7. Return the ribbon mask to the operating position.

3–6

Scheduled Maintenance

Page 65

5

1

3

2

10

4

1. Forms

2. Lock T

3.

4.

5.

6. Ribbon Deck

7.

8.

9. Hammer Bank Cover

10.Platen

11.

12.

Thickness Adjustment Lever

ab (2)

Ribbon Spool (2)

Ribbon Hub (2)

Right T

ractor (6)

Hammer Bank

Ribbon Mask

Hammer Springs

Hammer T

ips

6

8

9

11

12

7

Figure 3–2. Cleaning Hammer Bank Assembly

Scheduled Maintenance

3–7

Page 66

8. Install the ribbon deck as described on page 6–8 of Chapter 6,

Replacement Procedures.

9. Install the ribbon spools on the ribbon hubs. Replace paper.

10. Close the cover and return the printer to normal operation.

3–8

Scheduled Maintenance

Page 67

4

Chapter Contents

Troubleshooting

Introduction 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Messages 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symptoms Not Indicated by Fault Messages 4–11. . . . . . . . . . . . . . .

Diagnostic Self–Tests 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Self–Tests 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hex Code Printout 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

4–1

Page 68

Introduction

This chapter contains procedures for troubleshooting printer malfunctions.

You must operate the printer to check printer performance after correcting

problems, so have the User’s Manual at the printer site. Although diagnostic

self–test procedures are covered in this chapter, basic printer operation is not

covered.

Fault Messages

If a fault condition occurs in the printer, the CHECK light illuminates, the

status lamps blink alternately, and the first line of the message display

indicates “FAULT CONDITION.” If configured, an alarm sounds when the

Fault Condition occurs. The second line of the display indicates the specific

fault.

NOTE: The alarm can be turned off before the fault is cleared by pressing

the CLEAR switch.

There are two types of displayed faults:

• Operator correctable

• Field–service required, indicated by an asterisk (*) next to the fault

message

When troubleshooting a fault message, always perform the following

procedure first:

1. Press the CLEAR switch. If the printer displays “OFFLINE READY”

after a few seconds, the message was a false indication. Return the

printer to normal service.

2. If the fault message reappears after pressing CLEAR, turn printer power

off, wait five seconds, and turn power on. If the message reappears, find

the applicable message on one of the following pages, and perform the

checks and corrective actions listed.

4–2

Troubleshooting

Page 69

Test the printer after each corrective action. Stop maintenance when the

symptom disappears. Always press the CLEAR switch after correcting a

fault indicated by a fault message.

Operator Correctable Faults

Printer problems that the operator can correct are self–explanatory and

appear on the second line of the display:

CHANGE RIBBON PLATEN OPEN

COOLING RIBBON

PAPER JAM SHUTTLE STALL

PAPER OUT STACKER

After correcting an operator correctable fault, press the CLEAR switch

before placing the printer on line. If any other fault messages appear without

an asterisk (*), press the CLEAR switch to continue. However, if this

problem persists, contact the customer service representative (CSR) to

correct the problem.

IMPORTANT

IMPORTANT

If NVM INITIALIZED PRESS CLEAR appears on the display every

time the printer power is cycled, non–volatile memory must be replaced.

Non–volatile memory can be temporarily bypassed by pressing the

CLEAR switch. However, no configuration data will be saved, and the

factory default is loaded. Contact the customer service representative to

correct the fault.

Troubleshooting

4–3

Page 70

Field Service Required

Printer problems requiring the attention of the customer service

representative also appear on the second line of the display and are indicated

by an asterisk (*) next to the message: