Page 1

RIGID MOUNTED INDU STRIAL WA SHER

EXTRA CTORS

6kg

7kg

10kg

13kg

18kg

22kg

27kg

35kg

INSTALLATION, MAINTENANCE AND USER'S MANUAL

504615 I

Publication date: 28 Aug 2009

Page 2

Page 3

USER'S MANUAL

1. TABLE OF CONTENTS

1. TABLE OF CONTENTS..................................................................................................1

2. WARNINGS AND LABELS.............................................................................................2

2.1. INSTRUCTIO NS FOR MAI NTENA NCE, A DJ USTMENT AND SAFETY OF PEOPLE..........................3

3. SYMBOLS ON THE MACHINE.......................................................................................4

4. OPERATION INSTRUCTIONS .......................................................................................6

4.1. BEFORE WASHING...........................................................................................................................6

4.2. OPEN TH E D O OR............................................................................................................. .................6

4.3. LOADING THE WASHER...................................................................................................................6

4.4. CLOSE THE DOOR............................................................................................................................6

4.5. PROGRAM SELECTIONS..................................................................................................................6

4.6. WASH PROGR AMS OVERVI E W .......................................................................................................7

4.7. ADD DETERGENTS...........................................................................................................................7

4.8. START THE WASHER.......................................................................................................................8

4.9. END OF WASH CYCLE......................................................................................................................8

4.10. HOW TO OPEN THE DOOR BY FAILURE.......................................................................................9

5. FIRST SERVICE AT TECHNICAL PROBLEM.............................................................10

504615_I_PUB_DATE_28_AUG_2009.DOC USER'S MANUAL 1

Page 4

2. W A RNINGS AND LABELS

TO MINIMIZE THE RISK OF FIRE, INJURY BY ELECTRIC SHOCK OR SERIOUS INJURIES TO PEOPLE

OR PROPERTY DAMAGE, PLEASE READ AND FOLLOW THE FOLLOWING INSTRUCTIONS:

♦ This Eng lish version is original language version. Without this original version, these instructions are incomplete.

♦ Before installation, operation and m aintenance of the machine read carefully the complete instructi ons,

i.e. this „Installation, maintenanc e and user' s manual“, „Programming manual“ and „Spare parts manual“ .

The Programming m anual and S par e par ts manual are not delivered with a machi ne by default. You shall

ask the supplier / manufac turer to obtain Programmi ng m anual and S par e par ts manual.

♦ Follow the instruction written in manuals and keep the manuals in a proper place by the machine for later use.

♦ The washer extractor is des igned for fabrics washing only, other objects can da mage the mach ine and can ca us e

damage or injuries.

♦ The manufact ur er i s not responsible for the damage to the fabrics that ar e washed by an inappr opr iate

washing method.

♦ Always foll ow the instruc tions and/or warnings that ar e stated on t he fabrics, washing products or cleaning

products menti oned by the manufacturer.

♦ If the machine i s used for speci al applications follow the instructions and warning to av oid per son i njury.

♦ Keep the washer ext r actor surf ac e and surr ounding clean and free of fl ammable materials.

♦ Do not put fabrics in the washer extractor treated with flammable products. Such fabrics must first be washed

by hand and air dried.

♦ Store laundry aids, dry-cleaning solvents and disinfectants out of the reach of children, preferably in a locked cabinet.

♦ Do not tamper the washer-ext r ac tor controls and do not bypass the safety instructions and the warnings.

♦ Do not remove warning signs pl ac ed on the machine. Observe signs and label s to av oid personal injuries.

♦ Do not put some part on the soap dispenser lid to held it open by filling or when the machine operates.

♦ Do not open the soap dispenser l id after the machine is started. The discharge or splashing of hazardous

liquid can cause seriou s scalding and burning.

♦ The us e of hyp o c hlorite will c a use corr osion which ma y cause component failure under certain circumstances.

♦ The warranty of t he machine cannot be accepted in case corrosion was caused by chlorine and chlorine

compounds impac t.

♦ Do not operate the washer extractor when parts are broken or missing or when covers are open.

The machine shall not be operated until the fixed guards are put cor r ec tly in place.

♦ The washer extractor is not designed for work which may create an explosive atmosphere inside the machine

and will not be used for this purpose.

♦ Do not expose the washer ext r ac tor to the weather, extreme low or high temperature and humidity.

♦ Under certain conditions, hydrogen gas may be created in the hot water system that has not been used for two

or more weeks. Hydrogen gas is explosive. If the hot water system has not been used for such period open all

hot w ater taps and let the water run o ut for few minutes. This will release a ny accumula ted gas. As this gas is

flammable, do not smoke or use open flam es during this time.

♦ By danger turn off the main switc h or other emergency disconnection dev ices.

♦ Check the functioning of the door lock mechanism on regular base.

♦ Turn off the main water supply at the end of each operating day.

♦ Only qualifi ed service personnel may open the washing washer extractor to carry out servicing.

♦ Follow all vali d basic safety rules and laws.

♦ It is obvious that it is imposs ib le to men tion each possible r isk in this manua l. I t is up to the user to pro cee d

as careful as possibl e.

♦ The manufact ur er reserves the right to change the manuals without pr ev ious notice.

♦ If a problem should ari se, c ontact your dealer for assistance.

♦ Norm IEC335 is applied for machines with a net usable cage volume between 60 and 150 l. Norm EN60204-1

is used for a net usable cage volume above 150 l.

♦ The washer extractor produces equivalent continuous (A-weighted) sound power level which doesn't exceed 70 dB (A).

WARNING!

!

IF THE INSTALLED APPLIANCE OPERATE WITH COIN, TOKEN OR SIMILAR OPERAT ION FOR USE

IN SELF-SERVICE SITUATIONS, THEN THE OWNER-INSTALLER MUST PROVIDE A REMOTE-LOCATED

EMERGENCY STOP DEVICE. THIS DEVICE MUST BE PLACED IN SUCH A WAY THAT IT IS EASY

AND SAFELY ACCESSIBLE FOR THE USERS. THE EMERGENCY STOP DEVICE TAKES CARE

THAT AT LEAST THE CONTROL CIRCUIT OF THE APPLIANCE IS INTERRUPTED.

WARNING!

!

DO NOT TOUCH THE DOORGLASS UNTIL CYCLE HAS BEEN COMPLETED. DO NOT OPEN DOOR

UNTIL CYLINDER REMAINS STOPPED AND WATER HAS BEEN DRAINED FROM CYLINDER.

DO NOT PUT ARTICLES SOILED WITH EXPLOSIF SOLVENTS AND/OR DANGEROUS CHEMICAL

PRODUCTS IN THE MACHINE. THIS MACHINE SHOULD NOT BE USED BY CHILDREN.

DO NOT LET CHILDREN PLAY IN, ON, OR AROUND THE MACHINE. BEFORE TURNING THE MACHINE

„ON“, MAKE SURE THAT THERE ARE NO PEOPLE OR A NIMALS PRESENT IN OR AROUND THE MA CHINE.

2 USER'S MANUAL 504615_I_PUB_DATE_28_AUG_2009.DOC

Page 5

WARNING!

Always dis connect the washer from th e electrical supply before attempting any service. The washer

extractor is out of t ensi on if t he m ain pl ug is tak en out or when the main supply is disconnected.

When the main switch is turned off the inlet terminals of the machine main switch are still under current!

CAUTION!

Extreme hot condit ions can arise in the surroundings of this air.

Watch out for vapor t hat escapes f r om the washer extractor venti ng!

CAUTION!

Do not cover the washer extractor venting. It serv es as a vapor outlet

to prevent pressure building in the washer ext r actor .

!

WARNING!

ORIGINAL OR IDENTICAL PARTS MUST BE USED FOR REPLACEMENT IN THIS MACHINE.

AFTER SERVICING REPLACE AND SECURE ALL PANELS IN THE ORIGINAL WAY. TAKE THESE MEASURES

FOR CON TINUED P RO TECTION A GAIN ST ELEC TRICA L SH OCK, INJ URY, FIRE A ND/OR P ROPER TY DA MAGE .

!

WARNING!

LOOKING AT THE MACHINE FROM THE FRONT VIEW THE DRUM ROTATION DURING EXTRACTION

MUST BE CLOCKWISE.

WARNING!

!

SAFETY LAB ELS AP PEAR A T CRUCIA L LOCATIONS ON THE MA CHIN E. FAILURE TO MAIN TAIN LEGIBLE

SAFETY LABELS COULD RESULT IN INJURY TO THE OPERA TOR OR SERVICE TECHNIC IAN.

2.1. INSTRUCTIONS FOR MAINTENANCE, ADJUSTMENT AND SAFETY

OF PEOPLE

Some important information for the usage of the machine are not ( or only partly) mentioned in this User's

Manual. Missing information is possible to find in Installation and maintenanc e m anual, which is delivered

with the machine.

References to „Installation and Maint enanc e Manual" according to norm EN ISO 10472-1:

1. Description of t he safe work system when maintenance is perf ormed

/ adjustment / and when eliminating defects. - chapter 5 / 5 / 6

2. Description of qualities for ventilation - chapter 4

3. Procedures on searching for defects / cleaning / maintenance - chapter 6 / 5 / 5

4. Heat risks - chapter 3

5. Safety procedur e on m anipulation, install ation and dismantling - chapter 4

References to „Installation and Maintenance Manual" according to norm EN ISO 10472-2:

6. Maintenance of door blocking - chapter 5

7. Electric risks - chapter 2

8. Heat energy - chapter 3

9. Sight holes - chapter 3

10. Appropri ate processes - chapter 2

11. Explosiv e atm osphere - chapter 2

12. Biologi c al or chemical pollution of water - chapter 2

13. Maxim al possible overspeed - chapter 3

504615_I_PUB_DATE_28_AUG_2009.DOC USER'S MANUAL 3

Page 6

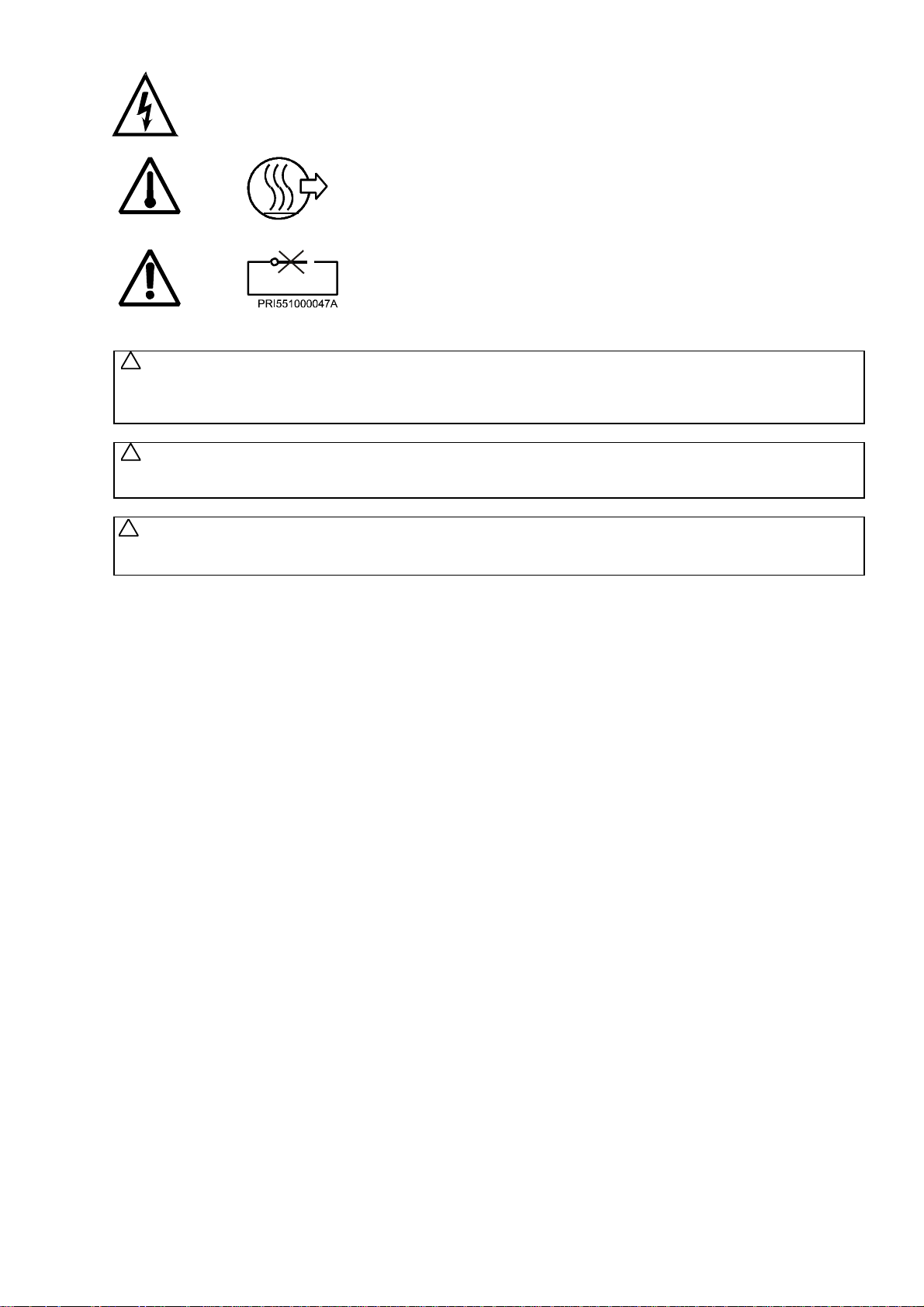

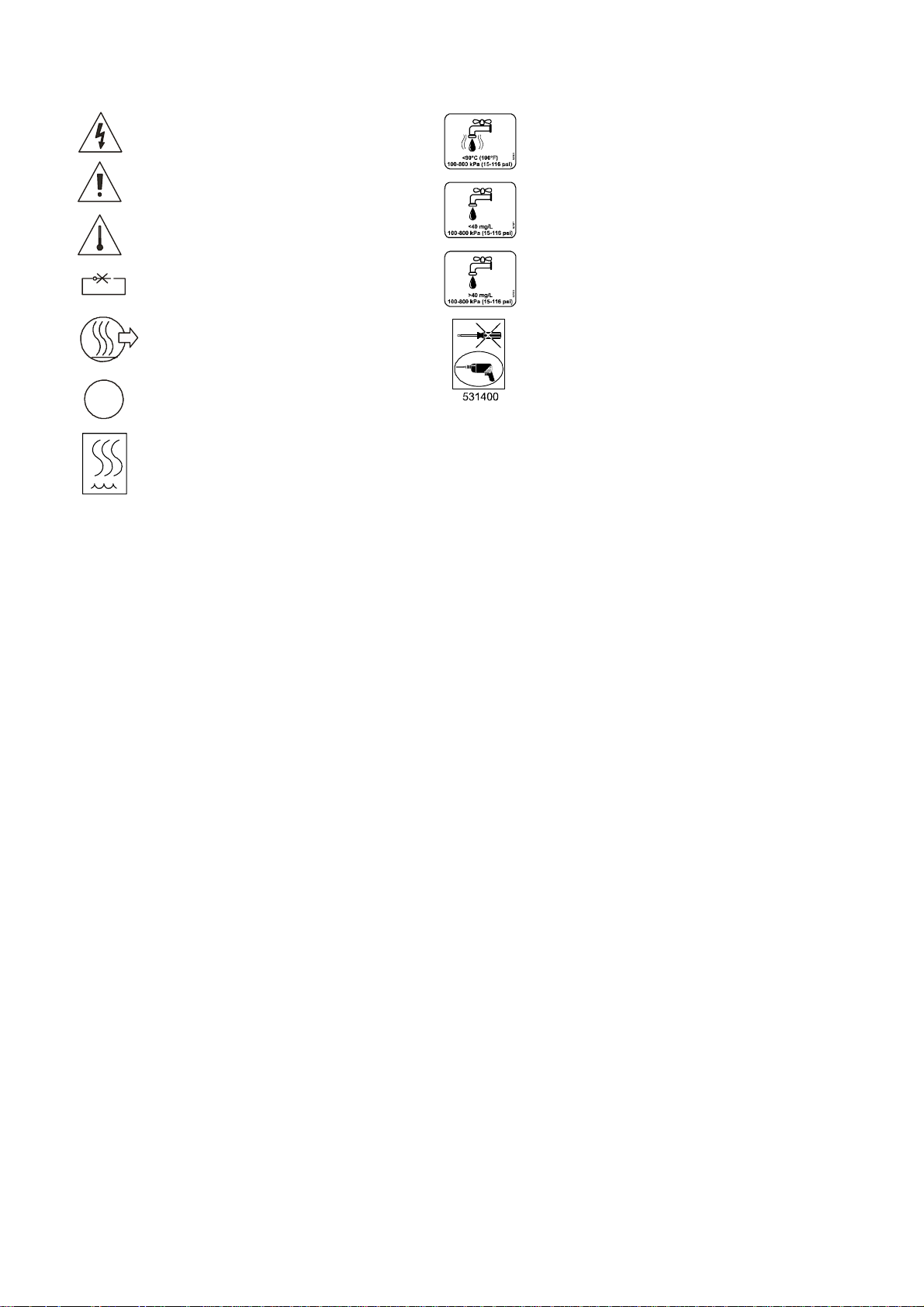

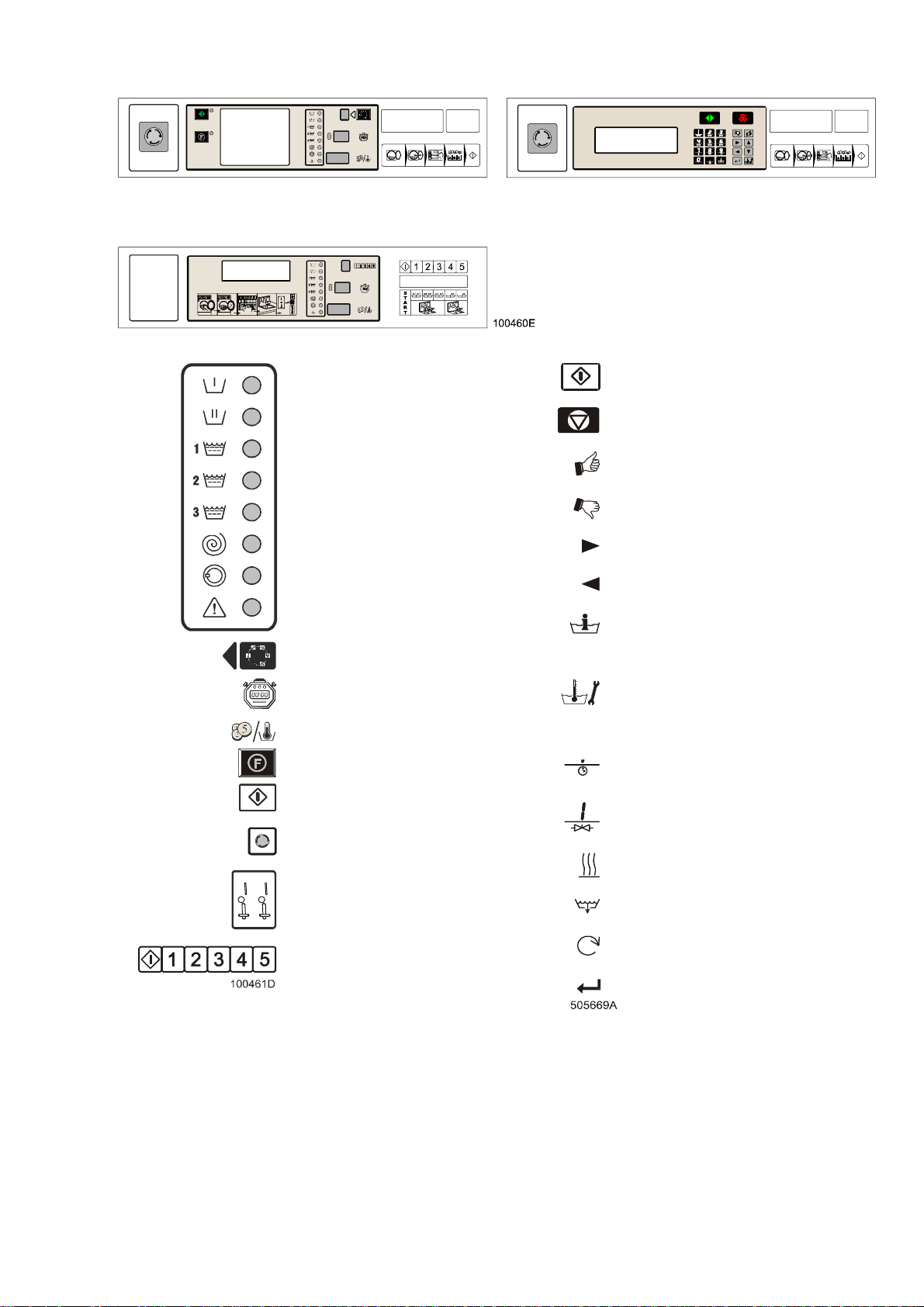

3. SYMBOLS ON THE MACHINE

Caution, dangerous electrical tension,

electric al dev ic es

Caution, other danger , read and follow

written i nstr uc tions

Caution - Increased temperature

Do not close or cover

Warm water inlet

(red color of the l abel)

Soft cold water inlet

(light blue color of t he label)

Hard cold water inlet

(dark blue of the label)

The machine hot air outlet

In case of emergency pr ess the emergency

button to stop t he machine

Steam

The holes to be drilled not punched

4 USER'S MANUAL 504615_I_PUB_DATE_28_AUG_2009.DOC

Page 7

EASY CONTROL MICROPROCESSO R GRAPHITRONIC MICROPROCES SOR

EASY CONTROL MICROPROCESSO R

WITH MECHANICAL BUTTONS

PREWASH

START (advancing program)

MAIN WASH

RINSE 1

RINSE 2

RINSE 3

EXTRACT

DOOR RELEASE

FAULT

PROGRAM SELECT

CYCLE TIME

COIN/TEMPERATURE

FUNCTION BUTTON

START

EMERGENCY STOP KNOB

(O nly us ed by not coin w asher extr acto r s)

COIN SYSTEM

STOP (interupting program)

YES SELECTION

NO SELECTION

INCREASING SEQUENCE TIME

DECREASING SEQUENCE TIME

INFO ( overview available wash programs and

wash sequence functions)

SERVICE (s hows a ctual water temperature

and level, number of fullfilled cycles and

actual state)

ACTIVATES THE TIME DELAY FUNCTION

(delay time will be started by pressing start)

OPENING THE INLET VALVES

ACTIVATE HEATING

OPEN DRAIN VALVE

SPEED ADJUST

PROGRAM SELECT

ENTER – SELECTION OR CONFIRMATION

504615_I_PUB_DATE_28_AUG_2009.DOC USER'S MANUAL 5

Page 8

4. OPERATION INSTRUCTIONS

4.1. BEFORE WASHING

Sort the linen acc or ding on the temperature and the instruc tions of the manufacturer of t he fabrics. Check

if there aren‘t any strange objects between the linen li ke nai ls, screws, needles, etc. in order not t o dam age

the washer-ext r ac tor or the linen. Turn sleeves of shirts, blouses, etc. inside out. To get a better washing

result, you hav e to unf old the fabrics and mix the bigger and smaller pieces of fabrics.

4.2. OPEN THE DOOR

Open the door by pulling on the door handle.

4.3. LOADING THE WASHER

!

CAUTION!

The optimal washing load is determined by the filling f actor . The proper filling fact or is determined by the type

of linen and other factors. Cotton textiles normally require a filling factor of 1:10-1:13, which is a full drum load.

Put the linen in the dru m de pend ing on the maximu m capacity of the w as her. Do not overload the was her e xtracto r.

Overloading the machine can lead to a bad wash result. Half washing l oads can obstruc t a proper function.

Synthetics and blended fabrics usually require a filling factor of 1:18-1:20, which is half drum load. Loading more

will reduce the wash result and can damage the linen.

4.4. CLOSE THE DOOR

Close the door with t he door handle, making sure the door is properly latched before operating the washer.

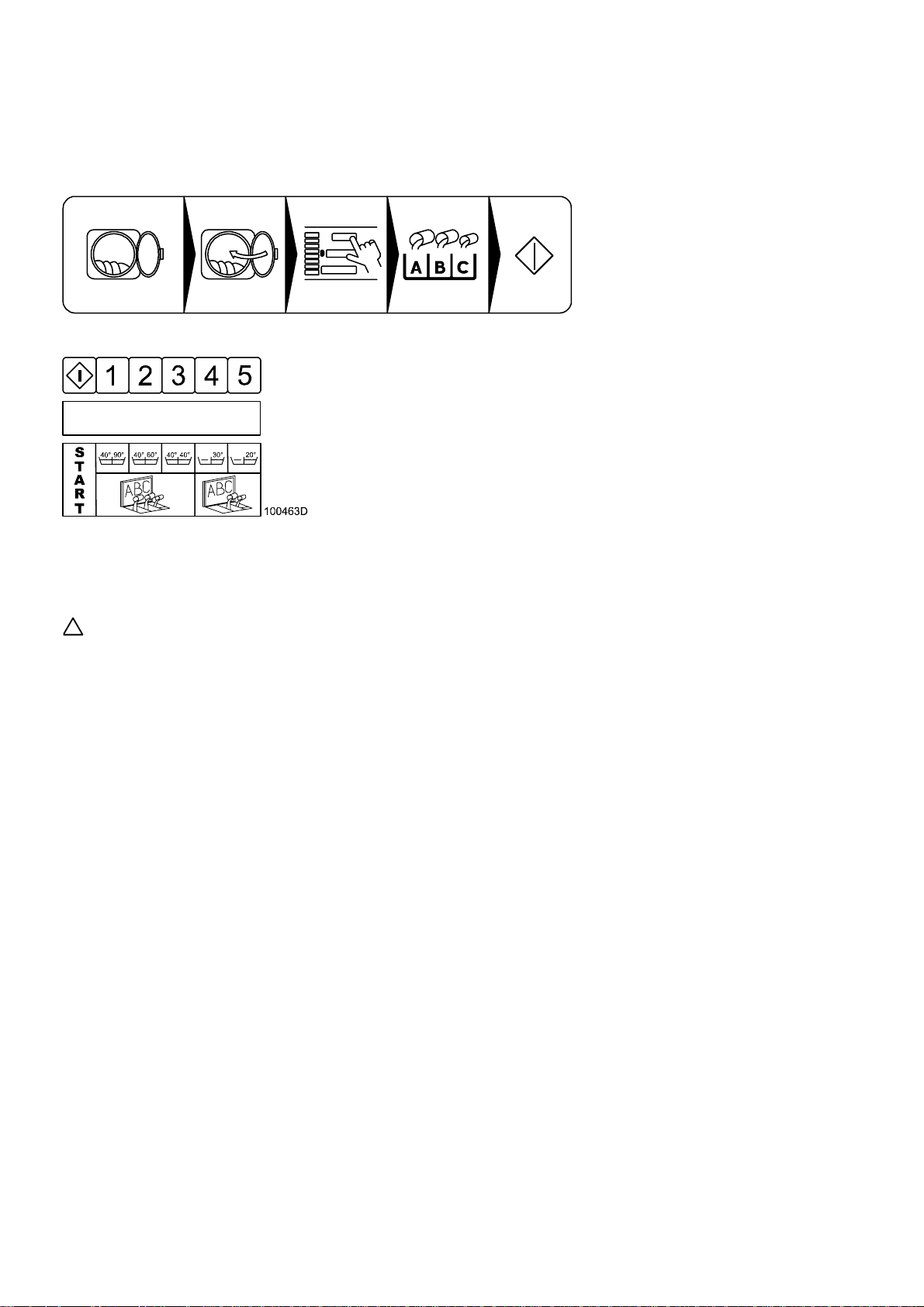

4.5. PROGRAM SELECTIONS

Choose one of the available wash programs, best correspondi ng to the quality of the garments and all owed

wash temperature in the wash load. Insert the wash program number. The different washing programs are indicated

on the operator panel. The selection of the program determines the temperature and the time for washing

and rinsing, the wash action and the spin speed and time.

Note: For locking a program mode, changing factory settings and possibiliti es of pr ogr am c hanges

and setup - see Programming m anual.

6 USER'S MANUAL 504615_I_PUB_DATE_28_AUG_2009.DOC

Page 9

4.6. WASH PROGRAMS OVERVIEW

Wash program 1: Hot wash 90°C

Wash program 2: Warm wash 60°C

Wash program 3: Coloured wash 40°C

Wash program 4: Bright col our ed wash 30°C

Wash program 5: Woollens 15°C

Wash program 6: Hot wash 90°C ECONOMY level

Wash program 7: Warm wash 60°C ECONOMY level

Wash program 8: Coloured wash 40°C ECONOMY level

Wash program 9: Bright col our ed wash 30°C ECONOMY level

EASY CONTROL: Wash program A:

GRAPHITRONIC: Wash program 10:

EASY CONTROL: Wash program B:

GRAPHITRONIC: Wash program 11:

EASY CONTROL: Wash program C:

GRAPHITRONIC: Wash program 12:

EASY CONTROL: Wash program D:

GRAPHITRONIC: Wash program 13:

EASY CONTROL: Wash program E:

GRAPHITRONIC: Wash program 14:

EASY CONTROL: Wash program F:

GRAPHITRONIC: Wash program 15:

Hot wash 90°C SUPER ECONOMY level

Warm wash 60°C SUPER ECONOMY level

Coloured wash 40°C SUPER ECONOMY level

Bright col our ed wash 30°C SUPER ECONOMY level

Extraction low speed

Extraction high speed

4.7. ADD DETERGENTS

Fill the soap dispenser on the top of the washer extractor dependi ng of the chosen program.

Dispenser A: Prewash (add the detergent at t he beginning of the wash cycle)

Dispenser B: Wash (add powder detergent or bleach detergent at the beginning

of the cycle, you may add liquid detergent or liquid bl each during the wash cycle.

If added at the start of the cycle, it will run in the washer prematurely)

101008

Fill the soap dispenser at the front or side of the washer extr actor depending of the chosen program.

Add the detergents before the start of the wash cycle.

R Standard wash programs versu s custom made wash programs.

This explanation is only valid f or standard wash prog rams. For custom made programs, it’s possible that

other dispensers have been selected. (See programming manual)

R Remark

- It is advisable to use onl y deter gents with „foam breaker“ which c an easi ly be found in retail shops.

The dosage of soap to use is generall y menti oned on the packing. An overdose of detergent can lead

to poor wash results and „suds“ ov erflow which can damage the machi ne.

- Take care that the lid of the soap di spenser is closed if the machine star ts.

Dispenser C: Final Rinse (Add f abr ic softener at the beginning of the cycle or before

the final rinse)

Dispenser A: 1 st Wash

Dispenser B: 2 nd Wash

Dispenser D: Last Rinse

:

504615_I_PUB_DATE_28_AUG_2009.DOC USER'S MANUAL 7

Page 10

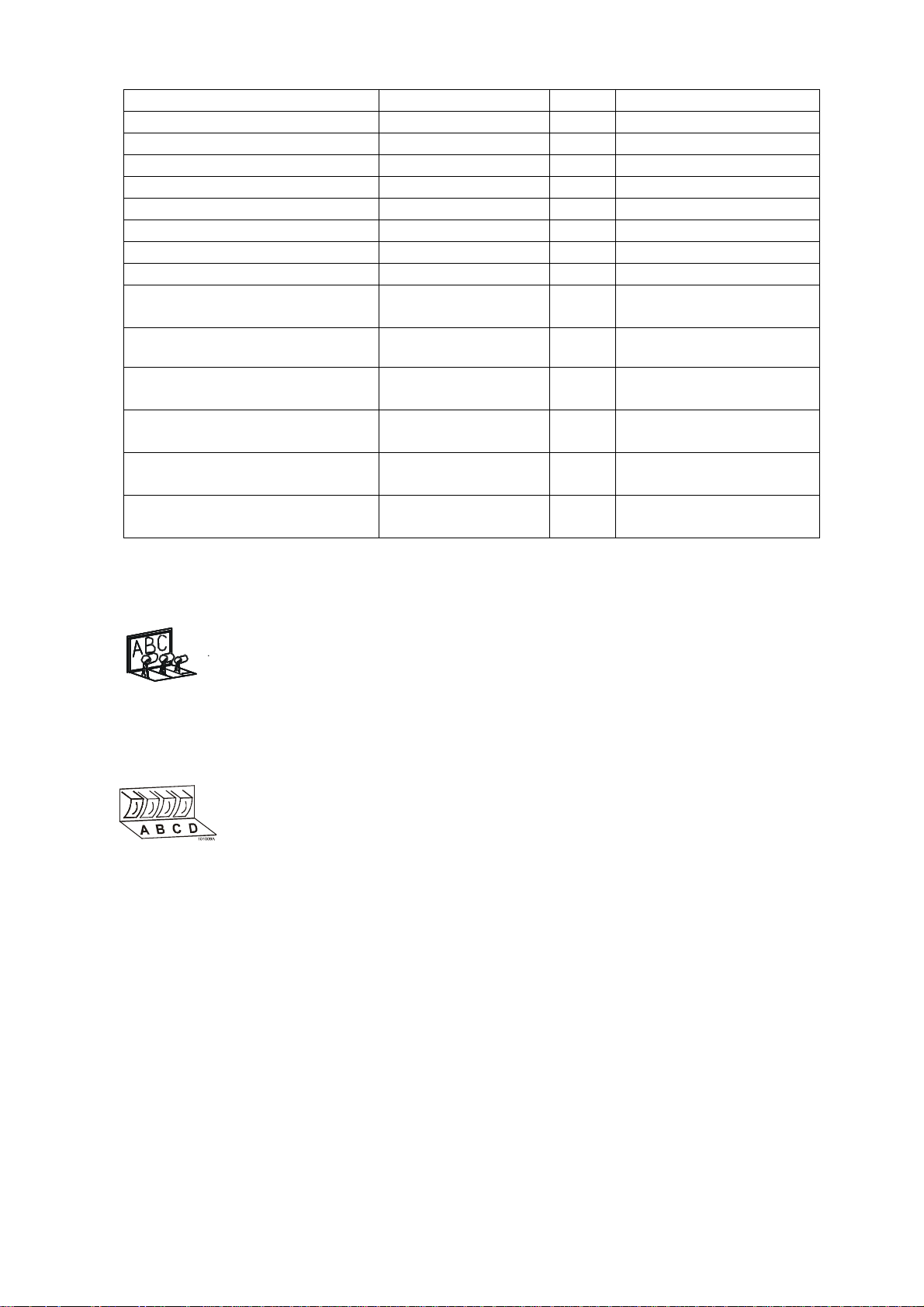

4.8. START THE WASHER

4.8.1. EA SY CO NTRO L MIC ROPRO CESSOR WI TH KEYPAD AND MECHA NICA L BU TTONS

COIN OPERATED MODELS

A. After choosing the pr ogr am with the PROGRAM SELECT button,

throw the right am ount of coins in the slot indicated on the lower

display The displ ay shows the remaining amount that has to be

thrown in. If the di spl ay shows 00, the washer extractor can be

started. The little light by the start button will be flashing.

B. Push the START butt on to start t he washer ex tractor. When you

have select ed a wrong washing progr am, you can change it

during the fi r st 150 seconds of the program by pushing the

SELECT button. When a mor e expensive washing program was

chosen, the value will be shown to add. When you don‘t add more

coins, the chosen program at the start will be executed.

C. During the washing cycle you can follow the actual washing

sequence and the remaining time on the displays.

NON-COIN OPERATED MODELS

A. After choosing the pr ogr am with the PROGRAM SELECT button,

push the START button to start the washer extractor.When you

have select ed a wrong washing progr am, you can change it

during the fi r st washing step by pushing the SELECT button.

B. During the washing cycle you follow the actual washing sequence,

the remaining t ime and if been set the temperature on the displays.

C. If the advance function has been set by the installator, you c an go

on to the next step by pushing t he STA RT but ton.

4.8.2. GRAPHITRONIC MICROPROCESSOR

After selecting the desired wash program number, by press ing the START button the wash cycle w ill be started.

If there is no washing program available for the selected pr ogr am num ber, „INVALID will be displayed“.

Program

Number

Wash/Spin

Sequence

Wa sh Cycle

Name

Wa sh Cycle

Step

Progression

Bar

Units

Door State

Remaining Time

Wa sh Cycle

4.9. END OF WASH CYCLE

4.9.1. EASY CON TROL MI CROP ROCESS OR WI TH KEYPA D A ND M ECHANI CA L BUTTON S

You can see clear ly the end of the wash ing cyc le on th e oper ator panel when the ligh t next to the door symbol

lights up and the tim e displ ay indicates „0“. Open the door with the door handle and take out the fabrics

of the washer extrac tor.

WARNING!

!

IF YOU CAN’T OPEN THE DOOR, FOR EXAMPLE BY A POWER FAILURE, WAIT A CERTAIN TIME

UNTIL THE SECURITY SWITCH IS COOLED DOWN. THIS IS A SAFETY! THE DOOR CAN BE OPENED

AFTER A COUPLE OF MINUTES. MAKE SURE THAT THE DRUM HAS COMPLETELY STOPPED

AND DRAINED BEFORE OPENING THE DOOR.

8 USER'S MANUAL 504615_I_PUB_DATE_28_AUG_2009.DOC

Page 11

When a power failure occ ur s for a short time, the wash program will conti nue when the power comes back

on. When the fail ur e occurs for a longer time and the door is still closed the display and the light next to the

start button starts flashing when power is restored. If the door is still locked the timer will continue the program.

For machines initi alised as coin operated models, the door will be locked immediately . Press the start button

to continue the pr ogr am . If the door was opened, the program will be resetted.

4.9.2. GRAPHITRONIC MICROPROCESSOR

WARNING!

!

IF YOU CAN’T OPEN THE DOOR, FOR EXAMPLE BY A POWER FAILURE, WAIT A CERTAIN TIME

UNTIL THE SECURITY SWITCH IS COOLED DOWN. THIS IS A SAFETY! THE DOOR CAN BE OPENED

AFTER A COUPLE OF MINUTES. MAKE SURE THAT THE DRUM HAS COMPLETELY STOPPED AND

DRAINED BEFORE OPENING THE DOOR. AT THE END OF THE THE WASH CYCLE, WHEN THE

REMA IN IN G PR OGR AM TIME REACHES 0 , P R OGR A M E N D IS D IS PLAYED. WHEN U N LOA D A PP EA R S

ON THE DISPLAY, OPEN THE DOOR BY THE DOOR HANDLE AND TAKE OUT THE GARMENTS

OF THE WASHER EXTRACTOR. (ONLY FOR MACHINES WIT H „GRAPHITRONIC“)

4.10. HOW TO OPEN THE DOOR BY FAILURE

See Installation and maintenance manual.

504615_I_PUB_DATE_28_AUG_2009.DOC USER'S MANUAL 9

Page 12

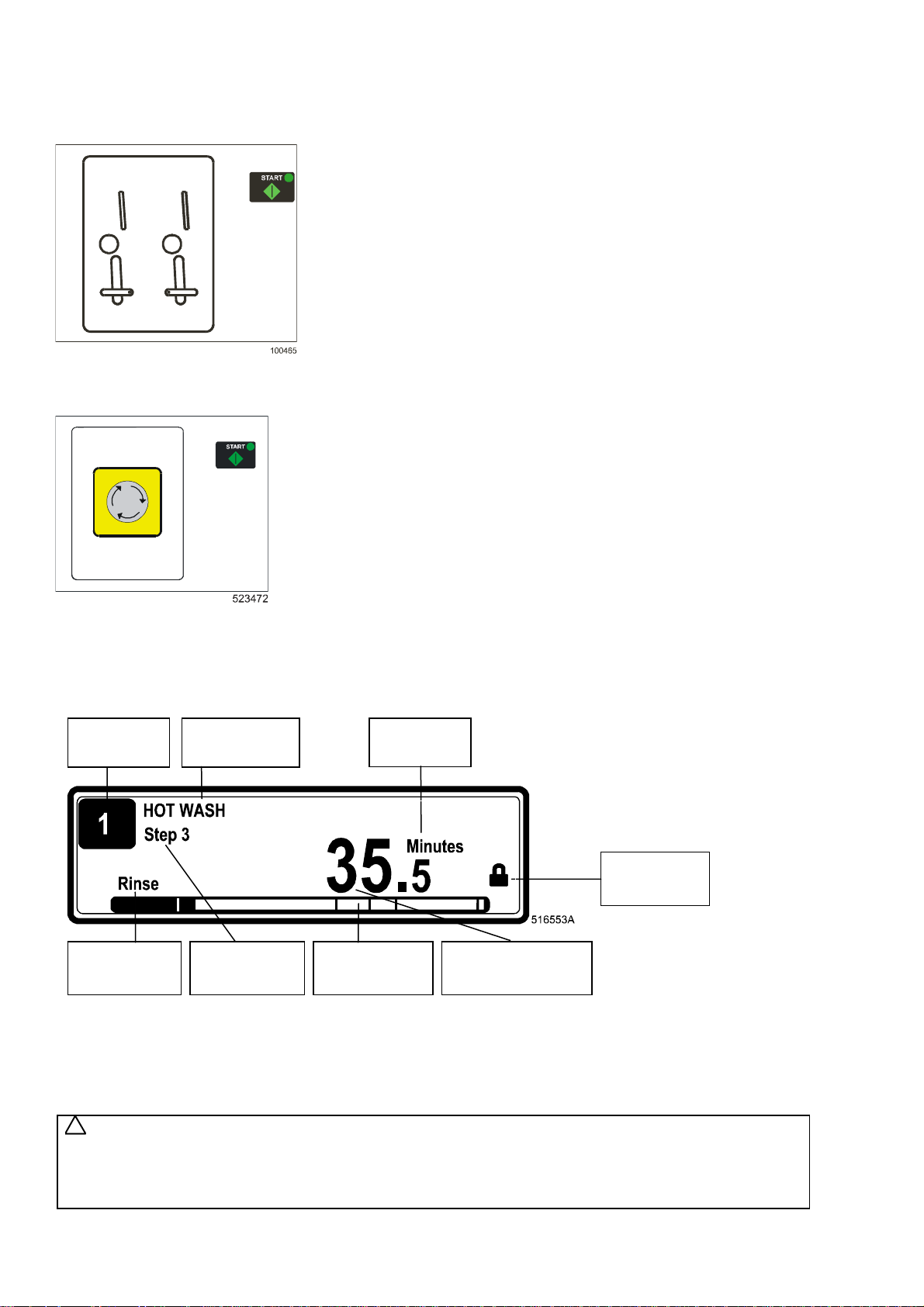

5. FIRST SERVICE AT TECHNICAL PROBLEM

N° Failure message Failure Action Fault occurrence

E1

E2

E3

E4

E5

E6

E7

E8

E9

E10

E11

E12

E13

E14

E15

E21

E22

E24

E25

E26

E27

E28

No Drain Co

No Drain

Tilt Faul t

Imbalance

Tilt High Sp

Door Coil

Door Switch

Door Start

Door Unload

Bimetal/Spring

No Fill

Overfill

No Heating

Heat Time

Too Hot

Overflow

Flush fault

Level Sens

Temp Sensor

Mitsub code

Comm fault

THT time / E.OL

E29 OV3 time /

E.OP

E31

E32

E33

Load Parr

Verify Parr

Stall prev

E35 Wrong Softw

E37 No Drain Sp

E38 No Recycle

Drain failure

Cooldown

Drain failure Full Stop + tumble Draining sequence

Out of balance :

Before spin

Out of balance :

Normal spin

Out of balance : high

spin

Door switch failure Full stop + safety time Whole cycle

Door solenoid switch

failure

Door lock check at

start failure

Door lock switch

closed failure

Bimetal/Spring Continue 2 min 30 sec after start

Fill failure Full stop + reque st for

Overfill fa ilu re Full stop + tumble While filling

Heating failure Full stop + tumble While heating

Heating time failure Full stop + request for

Too Hot Full stop + tumble While heating

Overflo w fa ilure Full stop + tu mble Wash ste p

Flush failure Full stop + tumble Flush step

Defec tive level

sensor

Defec tive

temperature sensor

Undefined frequency

inverter error code

Communication fault

inve rter

THT T ime o u t / E.OL Full s to p + safety time At s p in s e q uence

OV3 Time o u t /

E.OP

Initializ a tio n fa u lt

inve rter

Verificatio n fa u lt

inve rter

Stall prevention

function active

Wrong software

version

Drain failure at the

Spray Sequence

The Tank with

recycle water is

empty

E39 Out of Soap The Soap Supplies

are running Out of

Soap

E40 No Fill Rec Fill failure d u e to an

empty water recycle

Tank

E41 Service Due Service Due

Warning

E42 Connection No Network

Connection

Full Stop + tumble Draining sequence

Cooldown

Full stop + tumble Start sp in

Skip + c o n t in ue After 1 0 x tilt

Full stop + safety time >500 or 750 RPM

Full stop + safety time Whole cycle

Don’t sta rt At start up

Don’t start End cycle

cycle

While filling

Continue

While heating

Continue

Contin ue + Don’t sta rt Before sta rt up

Contin ue + Don’t sta rt Before sta rt up

Full stop + tumble Whole cycle

Full stop + safety time Whole cycle

Full stop + s a fety time At spin s e q uence

Don’t st a rt At initialization

Don’t start At loading parameters

Continue At spin sequence

Don’t sta rt New s o ftwa re version

Full sto p + tu mble Spray Sequence

Warning at the End.

Front soap dispenser

Mach. only

For Info o n ly Wash s tep

Full stop + Request for

Continue

Top soap dispenser

Mach. only

For Info o n ly

Open d oo r = re set

For Info o n ly Data Tra nsfer Networking

Wash step

Wash step

End cycle

10 USER'S MANUAL 504615_I_PUB_DATE_28_AUG_2009.DOC

Page 13

E43 Voltage Par Wrong Voltage

Range Selection

E44 Model type Wrong Inve rte r

Model Type

E45 No Speed

Sensor Signal

No Speed pulses

when drum tur ns.

Make correct selection Configuration menu

Make correct selection Configuration menu

Continue + Warning At spin sequence

(FS120 only)

E46 Brake Closed Brake Stays Closed Full stop + safety time At spin sequence

(FS120 only)

E47 Brake Wear Out Friction blocks

brake are wear-out

Full stop + s a fety time Any time

(FS120 only)

E48 Brake Open Brake Stays Open Continue + Warning At spin sequence

(FS120 only)

E49 UnBalance

Switch At Wash

E50 No Second

Acceleration

Ramp

E51 No Third

Acceleration

Ramp

E52 Board Memory PCB-EEPRROM

E53 Board Data PCB-EE PR OM Data

E57 Lock System Door Lock Switch

E58

E59

E60

E61

E62

E63-

No Free Run

Run Free Run

No reset Drive

Continue spin

Extended speed

Motor Drive

E67

E68

E69

E70

E71

E72

E73

E74

E75

E78

E79

No Sign Spin

RS Unbalance

RS7 Select

RS10 Select

KEB ST LOW

KEB ST HIGH

CFIStuck

KEB code

Lock Active

Lock Start

Air suspension

without compressed

air

Missing wire bridge

inverter / wrong

inverter parameters

Missing wire bridge

inverter / wrong

inverter parameters

CRC failure

out of range failure

stays closed when

the outer door is

open.

Deceleration end of

spin w h ile brake is

closed.

Run Status inverter

=1 while brake is

closed.

No detection motor

speed signal at

wash

Motor doesn't stop

spinning anymore

Motor sp ins too fa st Full stop + sa fe ty ti me

Reset M oto r Drive fo r

E60, E61 & E62

No detection motor

speed signal at spin

Unbalance input

should not be high on

R machines

RS7 selected in case

of RS10

RS10 selected in

case of RS7

No wire bridge

terminals 16-20

No KEB parameters

loaded in inverter

Inverte r n o t sw itc hed

off at end of cycle.

Undefined frequency

inverter error code

At standby door lock

is locked nevertheless

door is open.

After pressing Start

door lock is locked

nevertheless door is

open.

Full stop + s a fety time Wash action

Continue At spin sequence

Continue At spin sequence

Don't start At Power Up

Don't Start At Power Up

Don’t Start At locking sequence

Full stop + s a fety time At spin s e q uence

Full stop + s a fety time At spin s e q uence

Full stop + s a fety time

Full stop + sa fe ty ti me

Reset Motor Drive Wash Se q uen ce

Full stop + tumble Spin Sequence

Don't Start

Full stop + tumble

Don't Start Start Cycle

Don't Start Start Cycle

Don't Start Start cycle

Full st op + sa fety time Start cycle

For Info only End of cycle

Full stop + tumble Whole cycle

Don't Start At Standby

Don't Start At Start Cycle

(FS120 only)

(FS120 only)

(FS120 only)

(MB70-90-110-140-180

only)

(FS120 only)

(FS120 only)

Wash Sequence

Whole cycle

Whole cycle

Sta r t Spin sequence

Whole cycle

504615_I_PUB_DATE_28_AUG_2009.DOC USER'S MANUAL 11

Page 14

E80

Time Out

Input16

E81

E82

E83

E84

E85

E86

E100

No Reheat Heating F a ilure Full stop + tumble.

No Refill

Cycle Fail No successful wash

No Store PC Communication

RTC Low Batt Real Time Clock, No

No RTC Comm Real Time C lock is

Weigh No

Comm

E101

E102

E103

E104

E105

E300

Weigh Low

Weigh High

Weigh Balance

Weigh Overload

Weigh Airbags No functional air

Mits Err Specific Mitsu b is h i

-

On Hold Signal

Failure S oap

Dispensing System

Refill failure Full stop + request for

cycle termination

failure with P C

Batte ry or b attery low

power

not available

Communication fault

weighing system

Weight machine is too

low

Weight mach ine is

too high

Weight is not

balanced over 4 load

cell's.

Weight on individual

load cell exceeds

max.

pressure system

Inverte r A la rm

Full stop + tumble. Whole cycle

Continue

Info that the wash cycle

has to be repeated .

For Info only. End cycle

For Info only. End cycle

For Info only. End cycle

Full Stop Tumble Before Start (MB16-MB180)

Don't Start Before S ta rt

Don't Start Before S ta rt

Don't Start Before Start

Full Stop Tumble Whole Cycle

Don't Start Before S ta rt

Full stop + safety time Whole cycle

Wash Step

(MB only)

Wash Step

(MB only)

Abnormal Cycle

Termination (MB only)

(MB only)

(MB only)

(MB only)

Whole Cycle (MB16-MB66)

(MB & FS23-55 only)

(MB & FS23-55 only)

(MB & FS23-55 only)

(MB & FS23-55 only)

(MB16-66 & FS23-55 only)

(MB70-180 only)

E353

E400

-

E441

E500

KEB Err Specific KEB

Inverte r A la rm

Full stop + safety time Whole cycle

Memory Err Memory E rro r Full stop + safety time Any time

-

E515

E550 DAQ Version

Err

E551 DAQ Write Err Problem writing

E552 DAQ Full Err DAQ Tra ceability

E553 Store DAQ>PC DAQ Traceab ility

E600

Softw Err Software Error Full stop + s a fety time Any time

Wrong DAQ

Memory ve rs ion

DAQ Me mory

Memory is F u ll

Memory is al most

Full

For Info o n ly Insta lla tio n n ew softw

For Info o n ly Tra ceability function, w h o le

cycle

For Info o n ly Tra ceability function, w h o le

cycle

For Info o n ly Tra ceability function, w h o le

cycle

-

E628

12 USER'S MANUAL 504615_I_PUB_DATE_28_AUG_2009.DOC

Page 15

INSTALLATION AND MAINTENANCE MANUAL

1. CONTENTS

1. CONTENTS.....................................................................................................................1

2. IMPORTANT SAFETY INSTRUCTIONS ........................................................................2

2.1. SYMBOLS ON THE MACHINE...........................................................................................................4

2.2. IMPORTANT INFORMATION BEFORE INSTALLATION....................................................................4

3. TECHNICAL SPECIFICATION .......................................................................................5

3.1. MACHINES 6 kg / 15 lb, 7 kg / 18 l b, 10 kg / 25lb, 13 kg / 30 lb CAPACITY..........................................5

3.2. MACHINES 18 kg / 40 lb, 22 kg / 50 lb, 27 kg / 60 lb, 35 kg / 80 lb.......................................................7

3.3. DIMENSI ONS AND COMPON E T S OF T H E MA C HINE...........................................................................9

4. INSTALLATION OF THE MACHINE.............................................................................11

4.1. HANDLING, TRANSPORT, STORAGE, UNPACKING.......................................................................11

4.2. F O UND A T I ON....................................................................................................................................11

4.3. PREPARING FOUNDATION BASE ......................................................................................................11

4.4. DIMENSIONS FOR FOUNDATION BASE.............................................................................................12

4.5. DIMENSIONS AND POSITIONING OF THE ANCHORING......................................................................13

4.6. D IMENSIONS A N D PO S I TIONIN G RIS E R S..........................................................................................14

4.7. HO W TO IN STA L L A WASHER........................................................................................................15

4.8. CONNECTIONS...............................................................................................................................15

4.9. PUTTING INTO SERVICE................................................................................................................22

5. MAINTENANCE............................................................................................................23

5.1. INTRODUCTION..............................................................................................................................23

5.2. DAILY...............................................................................................................................................23

5.3. EVER Y TH R E E M ONTHS ................................................................................................................23

5.4. EVERY SIX MONTHS ......................................................................................................................23

5.5. STEAM OR WATER FILTER............................................................................................................24

5.6. TIGHTENING OF BOLTS.................................................................................................................24

5.7. DOOR SEAL.....................................................................................................................................25

5.8. ADJUSTMENT GEAR BELTS...........................................................................................................25

5.9. REPLACEMENT WASHER FUSES..................................................................................................26

6. TROUBLE SHOOTING AIDS ........................................................................................27

6.1. EMERGENCY DOOR OPENING......................................................................................................27

6.2. ERROR INDICATION SHOWN ON DISPLAY...................................................................................27

7. LIST OF RECOMMENDED SPARE PARTS.................................................................28

8. PUTTING THE MACHINE OUT OF SERVICE..............................................................29

8.1. DISCONNECTING THE MACHINE...................................................................................................29

8.2. MACHINE DISPOSAL ......................................................................................................................29

504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C INSTALLATIO N A N D MA IN T EN A NCE MANUAL 1

Page 16

2. IMPORTANT SAFETY INSTRUCTIONS

WARNING - SAVE T HESE INSTRUCTIONS FOR LATER USE.

Failure to compl y with the instructions may lead to incorrect use o f the appli ance, and may

result in r is k of fir e , bodily injuries or death and/or dam a ge to t he la undry and/or the appliance.

WARNING - Read the IMPORTANT SAFETY INSTRUCTIONS in this manual carefully before

operating th e appliance. Improper use of the appliance may cause risk of fire, electrical

♦ This English version is the original version of this manual. Without this version, the instructions are incomplete.

♦ Before installation, operation and maintenance of the machine read carefully the complete instructions, i.e.

this „Installation, maintenance and user's manual“, „Programming manual“ and „Spare parts manual“.

The Programming manual and Spare parts manual are not delivered with a machine by default. You shall ask the

supplier / manufacturer to obtain Programming manual and Spare parts manual.

♦ Follow the instruction written in manuals and keep the manuals in a proper place by the machine for later use.

♦ Safety instructions included in manuals for personnel operating the appliance must be printed and posted on a visible

place near the machine in the laundry room.

♦ The washer extractor is designed for fabrics washing only, other objects can damage the washer and can cause

damage or injuries.

♦ The manufacturer is not responsible for the damage to the fabrics that are washed by an inappropriate washing method.

♦ Always follow the instructions and/or warnings that are stated on the fabrics, washing products or cleaning products

mentioned by the manufacturer.

♦ The washer must be set up in accordance with the instructions. All drain, inlet, electrical connections, ventilation,

groundings and other connections must be done in according to the installation manual,

in compliance with the local standards done by qualified technicians with proper authorization.

♦ The valid standards for connecting to the local power network (TT,TN,IT,…) must be followed.

In the standard execution, the appliance may not be suitable for connecting to an IT supply syste m. Contact your

commercial distributor for assistance.

♦ All appliances are produced according the EMC-directive (Electro-Magnetic-Compatibility). They can be used

in restricted surroundings only (comply minimally with class A requir ements). For safety reasons there must

be kept the necessary precaution distances with sensitive electrical or electronic device(s).

♦ Do not change the parameters of the frequency inverter. This can cause serious injury, fire, washer damage, etc.

♦ During transportation and storage never use excessive forces on the packing because components can be

damaged protruding the contour line of the appliance.

♦ Use copper conductors on ly. Th is app liance must be connecte d to a supp ly circuit to which no ligh t ing un its

or general-purpose receptacles are connected.

♦ Any changes concerning the installa tion which are not des cribed in this Installa tion Ma nual must be appro ved

by the supplier or manufacturer. Otherwise, the supplier and manufacturer are not responsible for potential injuries to

operators or for any damages. Interventions in the appliance execution or functions are not allowed, and the

manufacturer refuses any responsibility in such cases.

♦ The washer extractor must be installed on level. If not, the washer may become unbalanced during extraction

and, although fitted with an unbalance safety, the washer may become seriously dam aged what may result

in bo d i ly in jur ie s .

♦ Never put the was her in operation when the transporting braces are not removed. The washer should always be tested

before use.

♦ It is possible that there are residues of products used during the production proces in the new washer. These residues

could cause stains on your laundry. Therefore, you must first run at least 1 hot wash with old rags before using for your

normal laundry.

♦ Keep the appliance top and surface and the area around clean and clear of co mbustible or flammable products.

♦ Do not store flammable materials around the appliances. Define the dangerous areas in the laundry room and obstruct

an admission to them during appliances operating.

♦ Do not wash articles that have been previously cleaned in, wash in soaked in, or spotted with gasoline,

dry-cleaning solvents, or other flammable or explosive substances as they give off vapors that could ignite or explode.

♦ Do not add gasoline, dry-cleaning solvents, or other flammable or explosive substances to the wash water. These

substances give off vapors that could ignite or explode.

♦ Under certain conditions, hydrogen gas may be created in the hot water system that has not been used for two or more

weeks. HYDROGEN GAS IS EXPLOSIVE. If the hot water system has not been used for such period open all hot water

taps and let the water run out for few minutes. This will release any accumulated gas. As this gas is flammable, do not

smoke or use open flames during this time.

♦ TEMPERATURE IN WASHING MACHINE TUB: The electronic controller uses the temperature sensor in the tub to control

the temperature of the washing bath. There are a lot of things that have influence on the temperature measurement.

Therefore the temperature control of the washing bath is not very precise.

♦ Always strictly comply with the instructions that are written on the laundry chemicals-, laundry aids-,dry-cleaning

solvents- and disinfectants packaging to avoid personal injury. Keep these agents out of the reach o f c hildren,

preferably in a locked cabinet.

shock or serious body injuries or death as well as serious damage to the appliance.

2 INSTALLA T I ON A ND MAI NTENANCE MANUA L 504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C

Page 17

♦ Do not tamper the washer-extractor controls and do not bypass the safety instructions and the warnings.

♦ Do not use some means on the soap dispenser lid to hold it open by filling or when the machine operates. The discharge

or splashing of hazardous liquid can cause serious scalding and burning.

♦ Do not operate the appliance when parts are broken or missing or when covers are open. The appliance may not be

operated until the fixed guards are put correctly in place.

♦ The appliance must not be stored, installed or exposed to the weather, extreme low or high temperature and humidity

levels. Do no t hos e dow n the wa she r. NEVER a llow the app lian ce to g et we t.

♦ Check the functioning of the door lock mechanism on regular base. NEVER bypass the doorlock mechanism.

♦ Disconnect the power and clos e all water and steam supply before cleaning, se rvicing and at the end of each

operating day.

♦ Out of the venting at the back of the w asher can escape warm vapor or and hot air. Do not co ver the vent but protect it

sufficiently. It serves air gap and as a vapor outlet to prevent pressure building in the washer.

♦ Do not repair or replace any part of the appliance or attempt any servicing unless specifically recommended in

the service manual or published user-repair instructions that you understand and have the skills to c a r r y out.

Only qualified service personnel may open the appliance to carry out servicing.

♦ Information contained in this manual is intended for use by a qualified service technician familiar with proper

and safe procedures to be followed when repairing an electrical appliance. All tests and repairs should be performed by

a qualified service technician equipped with proper tools and measuring devices. All component replacements

should be made by a qualified service technician using only factory approved replacement parts.

♦ Improper assembly or ad jus tmen t may occur if service or repa ir is attemp t ed by persons other then qualified

service technicians or if parts other then app ro ved rep lace ment pa rts a re us ed. I mproper as s embly o r ad justment

can create hazardous conditions.

♦ There can be a risk of injury or electrical shock while perf or ming s ervi c es or repairs . Injur y or elec tric al shoc k

can be serious or even fatal. Consequently, extreme caution should be taken while performing voltage checks

on individual componen ts or a product. PLEASE N O TE: E xcept as ne ces sary to per form a particular in ser vicing

a product, the electrical power supply should ALWAYS be disconnected when servicing a product.

♦ All in dustr ial (OPL - On Premise Laund ry) washe rs are designed for use in Laun dry with p rofessiona lly trained attendan ts.

♦ Before the appliance is removed from service or discarded, remove the door.

♦ Any Water or Steam Leaks Must Be Repaired Immediately. Closed supply immediately.

♦ If any problems or failures should arise, immediately contact your dealer, serviceman or manufacturer.

♦ The manufacturer reserves the right to change the manuals without previous notice.

!

WARNING -- CAUTION

This appliance must be connected to a grounded metal, permanent wiring system, and additionally an

equipment-grounding conductor must be run with the circuit conductors and connected to the equipmentgrounding terminal or lead on the appliance.

!

WARNING -- CAUTION

In order to minimize the risk of fire, electrical shock and injury, THIS WASHER MUST BE PROPERLY GROUNDED

.

Never plug in or direct-wire an appliance unless it is properly grounded in accordance with all local and national

codes .

If more appliances in the same location, mutual grounding must be applied where possible.

!

WARNING -- CAUTION

The washer extractor is intended to be permanently connected, it MUST be secured mounted to a NON-COMBUSTIBLE,

adequate floor structure. A concrete foundation is required. Metal reinforced w o od f loors are NOT al l owed

due to the risk of fire and excessive vibrations.

NEVER install the washer on an upper floor or over a basement without a load sup port designed by a structural

engineer.

!

WARNING -- CAUTION

Looking at the machine f rom the f ron t view th e drum ro t at io n durin g ext ract ion must be clockwise.

WARNING - Although t he appliance may be in the „off“ position, there is still electric al power to the switch

!

supply terminals.

!

WARNING - When power supply has been switched off wait for at least 10 minutes before starting inspection

or servicing the was her . Be fore sta rting inspe c t ion o f fre quen cy in verter, che ck fo r residual voltage across ma in

circuit terminals + and -. This voltage must be below 30 VDC before you can access the inverter for inspection.

!

WARNING - Do not allow children to play on, in or around the applianc e at any tim e. Close supervision

of children is necess ary w hen the app liance is used near children. Never permit ch ildren to opera te the app liance .

!

WARNING - Do not open door until c yli nder r em ains stopped and wat er has been drained completely.

If the door safety loc k does not work, do not use washer until the door lock mechanism is repaired.

504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C INSTALLATIO N A N D MA IN T EN A NCE MANUAL 3

Page 18

CAUTION! - Follow all valid basic safety rules and laws. The instructions in this manual cannot ac c ount

!

for every possibl e danger ous sit uation. They must be generally understood. Caution and c ar e ar e factors

which can not incl uded in the design of the appliance and all persons who install, operate or maintain

the applianc e must be qualif ied and familiar with the operati ng inst r uc tions. It is up to the user to take proper

care when operating the appliance.

!

CAUTION! - Do not remove warning signs placed on the applianc e. Observe signs and labels to avoid

personal inj uri es. S afety labels appear at crucial loc ations on the appliance. F ailure to maintain legible safety

labels coul d result in injury to the operator or service technician.

CAUTION! - If the installed appliance operat e with coi n, token or similar operation f or use in self-service

!

situati ons, then the owner-installer m ust pr ov ide a remote-located emergency stop devi c e. T his device must

be placed in such a way that it is easy and safely accessible for the users. The em er genc y stop dev ice

takes care that at least t he c ontrol circuit of the appliance i s inter rupted.

2.1. SYMBOLS ON THE MACHINE

See - User's manual.

2.2. IMPORTANT INFORMATION BEFORE INSTALLATION

FOR TRANSPORTATION AND STORAGE

IN CASE OF TRANSPORTATION AND STORAGE, WATCH COMPO NE NTS PROTRUDI NG

FROM THE CONTOUR LINE OF MACHINE (DOOR LOCKS ETC.), TO AVOID INJURIES .

– Never push, pull or exert pressure on components protruding fr om the m ac hine c ontour line (controls,

door locks etc.).

– Make sure that these components are secured so as to avoid damages during m ac hine manipulation

and installation.

– In case of the machine transportation by the customer, follow the manufacturer's instructions for transportation,

handling and storage of the product. In case of transportation of machine by the customer the manufacturer

is not responsible f or possible damage of machine in the course of transport ation. In case of storage

the machine in a free area it must be protected against mechanical damage and weather condition factors.

FOR INSTALLATION

ALL CONNECTION, AND IN SPECIAL PROTECT ING EARTH, MUST BE PERFORMED BY QUALIFIED

PERSONNEL WITH A PROPER AUTHORIZATION ACCORDING THE INSTALLATION MANUAL IN COMPLIANCE

WITH LOCAL STANDARDS.

– The washer must not be installed or stored in an area where it will be exposed to water and/ or weather.

Avoid damp conditions where water or moisture could run down the walls and covers of the washer or cover

the floor around t he washer. Do not install the washer above an open gut ter. Close any nearby gutters

so that waste water steam cannot collect near/insi de the washer.

– Any changes in the machine install ations must be approved by dealer or manufac turer. Otherwise the

dealer/manufacturer is not responsibl e for possible injuries or damages. Int erference and changes in the

machine construc tion are not allowed and the manufacturer r efuses any responsibilities in such cases.

– Define dangerous areas in the laundry room and do not allow people to enter if the machine is in operation.

MACH IN E INFORMAT IO N

– This manual comprises inf ormation for the whole series of rigi d - mount m ac hine series with a load of dry

linen 6, 7, 10, 13, 18, 22, 27 and 35 kg (15, 18, 25, 30, 40, 50, 60 and 80 lb) . V erify the machine model

according t o your order and the data plate located on back of washing mac hine, fig.3.3., pos.6 and find

corresponding information in the manual.

– The machines are controlled by e lectron ic pro gra mmer. F ind the programming instructions in the programming

manual.

– Additional heating can be provided by electrical heating elements or by steam from an external steam supply.

– Water inlets can use warm, cold soft and possibly also cold hard water.

– Electrical setup of the m ac hine is indicated on data plate, (see data plate, fig.3.3., pos.6) .

4 INSTALLA T I ON A ND MAI NTENANCE MANUA L 504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C

Page 19

3. TECHNICAL SPECIFICATION

3.1. MAC HI NES 6 kg / 1 5 lb, 7 kg / 18 lb , 1 0 kg / 25 lb , 13 kg / 30 lb CA PAC ITY

DRY LOAD CAPACITY

(1/10)

PACKING DIMENSIONS

width

depth

height

transportation capacity

MACHINE DIMENSIONS

width

depth

height

INNER DRUM DIMENSIONS

diameter

depth

drum capacity

door opening

Netto

Brutto

Permitted dev iations

of feeding voltage

Permitted dev iations

of frequence

Electrical system

of the machine

Minimal power supply

voltage

NOMINAL OUTPUT

OF THE MOTOR A T RPM

INPUT PROTECTION

FOR ONE MACHINE

Electri c al heating

Without electrical heating

Overload pr otection

of the motor

maximum dim ensi ons i ncl uding protruding part s

*

*

6 kg / 15 lb 7 kg / 18 lb 10 kg / 25 lb 13 kg / 30 lb

DIMENSIONS

carton box

700 mm / 27.6“

730 mm / 28.7“

1180 mm / 46.5“

3

0.6m

/ 21.2 ft3

660 mm / 26“

710 mm / 28“

1045 mm / 41.1“

530 mm / 21“

270 mm / 10.6“

3

60 dm

/ 15.8 gal

290 mm / 11.4“

carton box

700 mm / 27.6“

730 mm / 28.7“

1180 mm / 46.5“

3

0.6m

/ 21.2 ft3

660 mm / 26“

710 mm / 28“

1045 mm / 41.1“

530 mm / 21“

330 mm / 13“

73 dm3 / 19.3 gal

290 mm / 11.4“

carton box

700 mm / 27.6 „

880 mm / 34.6“

1280 mm / 50.4“

3

0.79m

1140 mm / 44.9“

/ 27.9 ft3

660 mm / 26“

865 mm / 34“

530 mm / 21“

420 mm / 16.5“

95 dm3 / 25 gal

290 mm / 11.4“

carton box

810 mm / 31.9“

850 mm / 33.5“

1380 mm / 54.3“

3

0.95m

750 mm / 29.5“

820 mm / 32.3“

1225 mm / 48.2“

650 mm / 25.6“

395 mm / 15.6“

131 dm3 / 34.6 gal

410 mm / 16.1“

WEIGHT

140 kg / 309 lb

145 kg / 320 lb

140 kg / 309 lb

145 kg / 320 lb

185 kg / 408 lb

195 kg / 430 lb

195 kg / 430 lb

205 kg / 452 lb

ELETRICAL DATA

-6% to +10%V

±1% Hz

1x220-240V 50/60Hz - not applicable for electri c al heating

1x208-240V 50/60Hz - not applicable for electri c al heating

1x220V 50/60Hz - not appli c able for electrical heating

3x220-240V 50/60Hz

3x208-240V 50/60Hz

3x200V 50/60Hz

3x380-415V+ N 50/60Hz

3x380-480V 50/60Hz

342V / 180V 342V / 180V 345V / 180V 342V / 190V

0.6 kW

6kW / 3x220-240V /

20A

6kW / 3x400V / 16A

9kW / 3x220-240V /

32A

9kW / 3x400V / 20A

9kW / 3x440V / 16A

1x220-240V / 10A

3x220-240V / 10A

3x400V / 10A

3x440V / 10A

6kW / 3x220-240V /

6kW / 3x400V /

9kW / 3x220-240V /

9kW / 3x400V /

9kW / 3x440V /

1x220-240V / 10A

3x220-240V / 10A

electronic protection by the frequency inverter

Tab.3.1.

0.6 kW

20A

16A

32A

20A

16A

3x400V / 10A

3x440V / 10A

0.6 kW

6kW / 3x220-240V /

20A

6kW / 3x400V/16A

9kW / 3x220-240V /

32A

9kW / 3x400V/20A

9kW / 3x440V/16A

12kW / 3x220-240V /

40A

12kW / 3x400V /

25A

12kW / 3x440V /

25A

1x220-240V / 10A

3x220-240V / 10A

3x400V / 10A

3x440V / 10A

0,75 kW

6kW/3x220-240V/

20A

6kW/3x400V/16A

9kW/3x220-240V/

32A

9kW/3x400V/20A

9kW/3x440V/20A

12kW/3x220-240V/

40A

12kW/3x400V/25A

12kW/3x440V/25A

1x220-240V / 10A

3x220-240V / 10A

3x400V / 10A

3x440V / 10A

/ 33.6 ft3

504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C INSTALLATIO N A N D MA IN T EN A NCE MANUAL 5

Page 20

DRY LOAD CAPACITY

(1/10)

6 kg / 15 lb 7 kg / 18 lb 10 kg / 25 lb 13 kg / 30 lb

WASHING FUNCTION

RPM OF THE DRUM:

washing

extracting

G - factor of spinning

48 rpm

580 rpm

100

CONNECTIONS

WATER CONNECTION

Water pressure

0.1 - 0.8 MPa / 1 - 8 bar / 14.5 -116 PSI

Recommended water

pressure

Water inlet

0.3 - 0.5 MPa / 3 - 5 bar / 43 - 73 PSI

BSP 3/4“

Maximal water

temperature

90°C / 194°F

DRAIN CONNECTION

Dimension

Capacity

Ø 76 mm / 3“

3.5 l / s

MACHINE VENTING

Venting connection

Ø 75 mm / 3“

of outer drum

STEAM C ONNECTION

Steam connection

Steam pressure low

Steam pressure high

Connections to external

liquid soap supply

1 - 3 bar / 14.5 - 44 PSI

3 - 8 bar / 44 - 116 PSI

standard 6 pcs,

(see electrical scheme)

G1/2“

Soap hoppers 3

CONSUMPTION

STEAM

Average steam

consumption (depends

on selected programme)

Maximum steam

consumption

6 kg. cycle

13.2 lb. cycle

0.01 kg.s

0.02 lb.sec

-1

/

-1

-1

/ 36 kg.h-1

-1

/ 79 lb.h-1

15.4 lb. cycle

0.01 kg.s

0.02 lb.sec

7 kg. cycle

-1

/ 36 kg .h-1

-1

/ 79 lb.h-1

-1

/

-1

WORKING CONDITIONS

Ambient temper ature

Relative humidity

Height abov e sea level

Storage temper ature

+ 5°C (41°F) to + 35°C (95°F)

30% to 90% without condensation

up 1000 m / 3280 ft

0°C (32°F) to +55°C (131°F)

ANCHORING

Bolt

FLOOR DATA

Max. static floor load

Max. dynamic floor load

Frequency of dy nami c

load

1.7 kN / 370 lb

3.6 kN / 801 lb

9.67 Hz

1.7 kN / 370 lb

3.6 kN / 801 lb

6 pcs M16 x 160

9.67 Hz

NOISE

Sound level

Leq (dB(A))

Tab.3.1. conti nuation

< 70 dB(A)

10 kg. cycle

22 lb. cycle

0.011 kg.s

-1

0.024 lb .sec

2.1 kN / 474 lb

4.5 kN / 1020 lb

9.67 Hz

-1

/

-1

/ 40 kg .h-1

-1

/ 88 lb.h-1

45 rpm

525 rpm

13 kg. cycle

-1

28.7 lb. cycle

-1

0.016kg.s

0.031lb.sec

/ 57.6kg.h-1

-1

/ 111 .6lb.h

2.6 kN / 577 lb

6.5 kN / 1450 lb

8.75 Hz

/

-1

-1

6 INSTALLA T I ON A ND MAI NTENANCE MANUA L 504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C

Page 21

3.2. MACHINES 18 kg / 40 lb, 22 kg / 50 lb, 27 kg / 60 lb, 35 kg / 80 lb CAPACITY

DRY LOAD CAPACITY

(1/10)

18 kg / 40 lb 22 kg / 50 lb 27 kg / 60 lb 35 kg / 80 lb

DIMENSIONS

PACKING DIMENSIONS

width

depth

height

transportation capacity

MACHINE DIMENSIONS

width

depth

height

INNER DRUM DIMENSIONS

diameter

depth

drum capacity

door opening

Netto

Brutto

*

carton box

935 mm / 36.8“

955 mm / 37.6“

1530 mm / 60.2“

1.37 m3 / 48.4 ft3

855 mm / 33.7“

900 mm / 35.43“

1315 mm / 51.8“

700 mm / 27.6“

470 mm / 18.5“

3

181 dm

410 mm / 16.1“

280 kg / 617 lb

290 kg / 639 lb

/ 47.8 gal

ELETRICAL DATA

Permitted dev iations

of feeding voltage

Permitted dev iations

of frequence

Electrical system

of the machine

Minimal power supply

voltage

NOMINAL OUTPUT

OF THE M OTOR A T RPM

INPUT PROTECTION

FOR ONE MACHINE

Electri c al heating

Without electrical heating

Overload pr otection

of the motor

maximum dim ensi ons i ncl uding protruding part s

342V / 190V 342V / 190V 342V / 190V 342V / 190V

1.5 kW

1x220-240V 50/60Hz - not applicable for electri c al heating

12kW / 3x220-240V / 50A

12kW / 3x 400V+N / 32A

12kW / 3x400V / 25A

12kW / 3x440V / 25A

18kW / 3x220-240V / 63A

18kW / 3x 400V+N / 40A

18kW / 3x400V / 32A

18kW / 3x440V / 32A

1/3x220-240V / 16A

3x400V+N / 16A

3x400V / 10A

3x440V / 10A

electronic protection by the frequency inverter

*

carton box

935 mm / 36.8“

1050 mm / 41.3“

1530 mm / 60.2“

1.5 m3 / 53 ft3

855 mm / 33.7“

1000 mm / 39.37“

1315 mm / 51.8“

700 mm / 27.6“

565 mm / 22.4“

217 dm3 / 57.3 gal

410 mm / 16.1“

WEIGHT

280 kg / 617 lb

300 kg / 661 lb

-6% to +10%V

±1% Hz

3x220-240V 50/60Hz

3x380-415V+ N 50/60Hz

3x380-480V 50/60Hz

1.5 kW

Tab.3.2.

wooden crate

950 mm / 37.4“

1220 mm / 48“

1570 mm / 61.8“

1.82 m3 / 64.3 ft3

870 mm / 34.3“

1140 mm / 44.9“

1380 mm / 54.3“

750 mm / 29.5“

610 mm / 24“

269 dm3 / 71 gal

504 mm / 19.8“

410 kg / 904 lb

470 kg / 1036 lb

2.2 kW

18kW / 3x220-240V / 63A

18kW / 3x 400V+N / 40A

18kW / 3x400V / 40A

18kW / 3x440V / 32A

24kW / 3x220-240V / 80A

24kW / 3x 400V+N / 50A

24kW / 3x400V / 50A

24kW / 3x440V / 50A

1/3x220-240V / 20A

wooden crate

1150 mm / 45.3“

1200 mm / 47.2“

1630 mm / 64.2“

2.25 m3 / 79.4 ft3

1100 mm / 43.7“

1140 mm / 44.9“

1460 mm / 57.5“

914 mm / 36“

505 mm / 19.9“

355 dm3 / 93.7 gal

504 mm / 19.8“

710 kg / 1565 lb

740 kg / 1631 lb

3 kW

3x400V+N / 20A

3x400V / 16A

3x440V / 16A

504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C INSTALLATIO N A N D MA IN T EN A NCE MANUAL 7

Page 22

DRY LOAD CAPACITY

(1/10)

18 kg / 40 lb 22 kg / 50 lb 27 kg / 60 lb 35 kg / 80 lb

WASHING FUNCTION

RPM OF THE DRUM:

washing

extracting

G - factor of spinning 100 90 100 133

44 rpm

505 rpm

44 rpm

480 rpm

42 rpm

490 rpm

38 rpm

510 rpm

CONNECTIONS

WATER CONNECTION

Water pressure

0.1 - 0.8 MPa / 1 - 8 bar / 14.5 -116 PSI

Recommended water

pressure

0.3 - 0.5 MPa / 3 - 5 bar / 43 - 73 PSI

Water inlet

Maximal water

temperature

DRAIN CONNECTION

Dimension

Capacity

Ø 76 mm / 3“

3.5 l / s

MACHINE VENTING

Venting connection

of outer drum

STEAM CONNECTION

Steam connection

Steam pressure low

Steam pressure high

Connections to external

liquid soap supply

1 - 3 bar / 14.5 - 44 PSI

3 - 8 bar / 44 - 116 PSI

G1/2“

standard 6 pcs,

(see electrical scheme)

Soap hoppers 3

BSP 3/4“

90°C / 194°F

2 x Ø 76 mm / 2x3“

2 x 3.5 l / s

Ø 75 mm / 3“

G3/4“

1 - 3 bar / 14.5 - 44 PSI

3 - 8 bar / 44 - 116 PSI

CONSUMPTION

STEAM

Average steam

consumption (depends

on selected programme)

Maximum steam

consumption

18 kg. cycle

40 lb. cycle

0.021 kg.s

0.038 lb.sec

-1

/

-1

-1

/ 76 kg.h-1

-1

/ 137 lb.h-1

22 kg. cycle

49 lb. cycle

0.025 kg.s

0.055 lb.sec

-1

-1

/ 90 k g.h

-1

/ 199 lb.h-1

/

-1

27 kg. cycle

60 lb. cycle

-1

/

-1

35 kg. cycle

-1

0.032 kg.s

0.071 lb.sec

-1

/ 115 kg.h-1

-1

/ 256 lb.h-1

0.039 kg .s

0.086 lb.sec

77 lb. cycle

-1

/ 140 kg.h-1

-1

WORKING CONDITIONS

Ambient temper ature

Relative humidity

Height above sea level

Storage temper ature

+ 5°C (41°F) to + 35°C (95°F)

30% to 90% without condensation

up 1000 m / 3280 ft

0°C (32°F) to +55°C (131°F)

ANCHORING

Bolt

FLOOR DATA

Max. static floor load

Max. dynamic floor load

Frequency of dy nami c

load

3.1 kN / 675 lb

8.9 kN / 1994 lb

8.42 Hz

6 pcs M16 x 160 6 pcs M20 x 320

3.2 kN / 698 lb

9.6 kN / 2165 lb

8 Hz

4.5 kN / 985 lb

13.3 kN / 2996 lb

8.17 Hz

7.2 kN / 1598 lb

21.6 kN / 4863 lb

8.5 Hz

NOISE

Sound level

Leq (dB(A))

Tab.3.2. conti nuation

< 70 dB(A)

-1

/

-1

/ 309 lb.h-1

8 INSTALLA T I ON A ND MAI NTENANCE MANUA L 504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C

Page 23

3.3. DIMENSIONS AND COMPONETS OF THE MACHINE

18/22/27 kg - 40/ 50/60 lb

only for

27 kg / 60 lb

6/7/10/13 kg - 15/18/25/30 lb 35 kg / 80 lb

Fig.3.3.

504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C INSTALLATIO N A N D MA IN T EN A NCE MANUAL 9

Page 24

1. Control panel

2. Door handle

3. Service panel

4. Tub ventilation

5. Liquid soap hose connecti ons

6. Name plate

7. Steam connection

8. Drain connection

9. Earthing connection

10. Hot water connecti on

Machine

capacity

A

B

C

D

E

F

G

H

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

Y

Z

6 kg

15 lb

660 mm

26“

1045 mm

41.1“

420 mm

16.5“

710 mm

28“

620 mm

24.4“

100 mm

3,9“

86 mm

3.4“

90 mm

3.5“

190 mm

7.5“

75 mm

3“

- - - - - - -

270 mm

10.6“

60 mm

2.4“

- - - - - - -

970 mm

38.2“

133 mm

5.2“

875 mm

34.4“

55 mm

2.2“

395 mm

15.6“

92 mm

3.6“

330 mm

13“

- - - - - - -

415 mm

16.3“

350 mm

13,8“

7 kg

18 lb

660 mm

26“

1045 mm

41.1“

420 mm

16.5“

710 mm

28“

620 mm

24.4“

100 mm

3,9“

86 mm

3.4“

90 mm

3.5“

190 mm

7.5“

75 mm

3“

270 mm

10.6

60 mm

2.4“

970 mm

38.2“

133 mm

5.2“

875mm

34.4

55 mm

2.2“

395 mm

15.6“

92 mm

3.6“

330 mm

13“

415 mm

16.3“

350 mm

13,8“

10 kg

25 lb

660 mm

26“

1140 mm

44.9“

460 mm

18.1“

865 mm

34“

780 mm

30.7“

100 mm

3,9“

86 mm

3.4“

90 mm

3.5“

190 mm

7.5“

75 mm

3“

270 mm

10.6

60 mm

2.4“

1062 mm

41.8“

133 mm

5.2“

962 mm

37.9“

55 mm

2.2“

395 mm

15.6

92 mm

3.6“

330 mm

13“

415 mm

16.3“

390 mm

15,4“

13 kg

30 lb

750 mm

29.5“

1225 mm

48.2“

420 mm

16.5“

820 mm

32.3“

740 mm

29.1“

100 mm

3,9“

86 mm

3.4“

90 mm

3.5“

190 mm

7.5“

75 mm

3“

270 mm

10.6

60 mm

2.4“

1145 mm

45.1“

182 mm

7.2“

1025 mm

40.4“

53 mm

2.1“

333 mm

13.1“

86 mm

3.4“

375 mm

14.8“

530 mm

20.8“

355 mm

13,98“

Tab.3.3.

11. Cold soft water connect ion

12. Cold hard water connection

13. Fuses

14. M a in switch

15. Switch: elect ri c al heating / steam heating

16. Electrical connection of machine

17. Plastic box for el ectri c al c onnec tion to liquid

soap pumps

18. Soap hoppers

18 kg

40 lb

855 mm

33.7“

1315 mm

51.8“

515 mm

20.3“

900 mm

35.43“

810 mm

31.9“

125 mm

4.9“

90 mm

3.5“

100 mm

3.9“

190 mm

7.5“

75 mm

3“

305 mm

12“

75 mm

3“

1215 mm

47,8"

205 mm

8.1“

1110 mm

43.7"

100 mm

3.9"

435 mm

17.1"

135 mm

5.3“

427,5 mm

16.8“

530 mm

20.8“

450 mm

17,7“

22 kg

50 lb

855 mm

33.7“

1315 mm

51.8“

515 mm

20.3“

1000 mm

39.37“

905 mm

35.6“

125 mm

4.9“

90 mm

3.5“

100 mm

3.9“

190 mm

7.5“

75 mm

3“

305 mm

12“

75 mm

3“

1215 mm

47,8"

205 mm

8.1“

1110 mm

43.7"

100 mm

3.9"

435 mm

17.1"

135 mm

5.3“

427,5 mm

16.8“

530 mm

20.8“

450 mm

17,7“

27 kg

60 lb

870 mm

34.3“

1380 mm

54.3“

455 mm

17,9“

1140 mm

44.9“

1043 mm

41.1“

160 mm

6.3“

85 mm

3.3“

90 mm

3.5“

190 mm

7.5“

70 mm

2.8“

260 mm

10.2“

170 mm

6.7“

1245 mm

49“

120 mm

4.7“

1135 mm

44.7"

135 mm

5.3"

470 mm

18.5"

90 mm

3.5“

435 mm

17.1“

630 mm

24.8“

380 mm

14,96“

35 kg

80 lb

1100 mm

43.3“

1460 mm

57.5“

510 mm

20.1“

1140 mm

44.9“

1041 mm

41“

125 mm

4.9“

85 mm

3.3“

100 mm

3.9“

195 mm

7.7“

124 mm

4.9“

360 mm

14.2“

305 mm

12“

355 mm

14“

84 mm

3.3“

1320 mm

51,9"

250 mm

9.8“

1220 mm

48.3"

100 mm

3.9"

972 mm

38.3"

90 mm

3.5“

400 mm

15.7"

300 mm

11.8“

630 mm

24.8“

430 mm

16,9“

10 INSTALLA T I ON A ND MAI NTENANCE MANUA L 504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C

Page 25

4. INSTALLATION OF THE MACHINE

4.1. HANDLING, TRANSPORT, STORAGE, UNPACKING

For safety reasons, be sure that the persons that transport , handles and store the machines are i nformed

about the machines specif ications and information’s. Read and respect also the „IM PORTANT SAFETY

INSTRUCTIONS“.

The machines with capacity 6-22 kg / 15-50 lbs is delivered to the customer in a cardboard packing and crating

packing. Under the outside packing is the machine additionally protected by pol y ethylene foil.

Do not store or install the machine where it can be exposed to envi r onm ental conditions (rain, wind)

or extreme humidity.

The machines are fixed to the wooden palette by four bolt s M12x60.

Before moving the machine into its final location, follow the following precautions:

– Check all passages and spaces where the mac hine has to be tr ansport ed through, they must have

sufficient dim ensi ons to m eet the height and width of the machine including the package.

– Lift the machine up by lift truck or hand-operated pallet truck usi ng a transport skid to which the machine

has been attached.

Just before y ou install the machine in its final position, remove the packing, release four bolts of the pallet

and lift up the machi ne and r em ov e the wooden pallet.

It is possible to handle the machine by the fork lift or the manual truck if the forks supporting the sides of the frame.

If not, it can damage t he component s l oc ated in its lower part.

After unpacking , chec k if the machine has not been dam aged and if a ll the accessor ies are inc luded ac cor d ing

to your order. Verify the information of your machine at the name plate located on the machine rear and note

corresponding information in the information sheet at the back side of the manual.

The accessories and the m anual are placed inside the drum.

When moving the un-pac k ed m ac hine:

– Never p ush, pull or press the components pro t rud in g f rom the contour line of machine (front part ,

filling door, cont rol elements, belt cover, water inlet and outlet pipes etc.).

– Make sure that the filling door are secured t o av oid its opening during the handling.

4.2. FO UN DATIO N

GENERAL

For safety reasons, be sure that the persons that install ar e informed about the machines specifications

and informati on’s. Read and r espect also the „IMPORTANT SAFETY INSTRUCTIO NS “.

The washer is a rigid-m ount model, it MUST be securely fixed mounted to a foundation to work properly

and in a safe way.

Note: It is strongl y recomm ended that the 35 kg / 80 lb and 27 kg / 60 lb machines be mounted onto a not

elevated concrete base only. We also recommend it for the 18 kg / 40 lb, 22 kg / 50 lb.

CAUTION: - Putting machines on an elevation or riser creates a higher distance to reach the soap dispenser.

- Never put a riser on raised foundation.

- The washer needs to i nstalled always level or very sligh tly t ipped with front higher,

for sure not opposite. Therefore the foundation surface has to be made with these conditions.

NEVER install the washer on an upper floor or over a basement without a load support designed by a structural

engineer. It is required the installation be on a concr ete foundation. Metal-rei nforced wood floors and all not

concrete foundations are NOT allowed due to a potential for excessive vibrations and fire.

Improper installation will void the warranty. Manufacturer is not responsible for damage or injury

caused by improper installation.

4.3. PREPARING FOUNDATION BASE

Check the thickness of the existing floor and verify the quality of the concrete. The foundation MUST be always

been engineered to be able to co mp ly with the s tatic and dyna mic floor data. If necessar y con ta ct you r building

engineer.

Use 1360 kg / 3000 lb test concret e for the floor and foundation. For max. str ength, allow concrete to cur e

for min. of 72 hours in dry weather.

Layout and mark the area of the enti r e washer base tak e into account and respect the dist anc es to si des,

ceiling and r ear, see tab.4.4. Add also minimum 10 cm / 4“ on all sides of the entire washer base

for the foundat ion re-enforcement if it concerns a raised foundation, riser founda tion or a floor re-enfo rcement.

504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C INSTALLATIO N A ND MAI NTENANCE MANUAL 11

Page 26

Break up the floor to a depth mention in the tab.4.4., accordance the machine model, inclu ding the min 10 cm / 4“

around all si des. If a higher capacity model stands on the right or left hands side, select the depth of the higher

capacity mode l for the co nce rne d mode l. Under cu t the s ides of the ho le to create an invert „mushroom“ effec t.

It is essential t o hav e a real good connection between the new foundati on and the existing floor, theref or e it

is necessary to place rebar that are well (chemical) anchored in the existing floor or other types of reinforcement

rods throughout the floor. Wet the hole well and brush the bottom and all sides with cement grout before pouring

in the new concrete. T his i s required for a solid foundation and joint.

If a raised foundation is used for some models, never make it higher then 30,5 cm / 12“. The overall dimensions

must also be equal with the total washer footprint plus the requi r ed 10 cm / 4“ on all sides.

4.4. D I MEN SION S F O R FO UN DA TI O N BASE

Fig.4.4.

12 INSTALLA T I ON A ND MAI NTENANCE MANUA L 504615 _I _P UB_DAT E_ 28 _A U G_2009.D O C

Page 27

Machine

capacity

A

B

C

D

E

F

G

H

I min.

J min.

K

L

M

N

O

P

Q min.

R max.

S min.

7 kg

18 lbs

530 mm

20.9 “

65 mm

2.6 “

100 mm

4 “

20 mm

0.79 “

48 mm

1.9 “

275 mm

10.83 “

90 mm

3.5 “

169 mm

6.7 “

600 mm

23.6 “

700 mm

27.6“

560 mm

22.1“

38 mm

1.5“

605 mm

23.82 “

300 mm

11.8“

120 mm

4.7“

40 mm

1.5“

7 mm

0.276“

300 mm

11.81“

M16

5/8“

10 kg

25 lbs

530 mm

20.9 “

65 mm

2.6 “

100 mm

4 “

20 mm

0.79 “

48 mm

1.9 “

365 mm

14.37 “

295 mm

11.6 “

34 mm

1.3 “

600 mm

23.6 “

700 mm

27.6 “

725 mm

28.54 “

38 mm

1.5“

605 mm

23.82 “

300 mm

11.8“

120 mm

4.7“

40 mm

1.5“

7 mm

0.276“

300 mm

11.81“

M16

5/8“

13 kg

30 lbs

594 mm

23.39“

78 mm

3.07“

100 mm

4 “

20 mm

0.79 “

43 mm

1.7 “

400 mm

15.75“

232 mm

9.13“

40 mm

1.6“

600 mm

23.6 “

700 mm

27.6 “

690 mm

27.2“

25 mm

1.0“

744 mm

29.3“

400 mm

15.7“

120 mm

4.7“

40 mm

1.5“

7 mm

0.276“

240 mm