Primus Washer Service manual

RIGID MOUNTED INDUSTRIAL WASHER

EXTRACTORS

6kg

7kg

10kg

13kg

18kg

22kg

27kg

35kg

INSTALLATION, MAINTENANCE AND USER'S MANUAL

504615 I Publication date: 28 Aug 2009

USER'S MANUAL |

|

1. TABLE OF CONTENTS |

|

1. TABLE OF CONTENTS.................................................................................................. |

1 |

2. WARNINGS AND LABELS............................................................................................. |

2 |

2.1. INSTRUCTIONS FOR MAINTENANCE, ADJUSTMENT AND SAFETY OF PEOPLE.......................... |

3 |

3. SYMBOLS ON THE MACHINE....................................................................................... |

4 |

4. OPERATION INSTRUCTIONS ....................................................................................... |

6 |

4.1. BEFORE WASHING........................................................................................................................... |

6 |

4.2. OPEN THE DOOR.............................................................................................................................. |

6 |

4.3. LOADING THE WASHER................................................................................................................... |

6 |

4.4. CLOSE THE DOOR............................................................................................................................ |

6 |

4.5. PROGRAM SELECTIONS.................................................................................................................. |

6 |

4.6. WASH PROGRAMS OVERVIEW ....................................................................................................... |

7 |

4.7. ADD DETERGENTS........................................................................................................................... |

7 |

4.8. START THE WASHER ....................................................................................................................... |

8 |

4.9. END OF WASH CYCLE...................................................................................................................... |

8 |

4.10. HOW TO OPEN THE DOOR BY FAILURE ....................................................................................... |

9 |

5. FIRST SERVICE AT TECHNICAL PROBLEM ............................................................. |

10 |

504615_I_PUB_DATE_28_AUG_2009.DOC |

USER'S MANUAL |

1 |

2. WARNINGS AND LABELS

TOMINIMIZETHE RISK OFFIRE,INJURY BY ELECTRIC SHOCK OR SERIOUSINJURIESTO PEOPLE

OR PROPERTY DAMAGE, PLEASE READ AND FOLLOW THE FOLLOWING INSTRUCTIONS:

♦This English version is original language version. Without this original version, these instructions are incomplete. ♦Before installation, operation and maintenance of the machine read carefully the complete instructions, i.e. this „Installation, maintenance and user's manual“, „Programming manual“ and „Spare parts manual“. The Programming manual and Spare parts manual are not delivered with a machine by default. You shall

ask the supplier / manufacturer to obtain Programming manual and Spare parts manual.

♦Follow the instruction written in manuals and keep the manuals in a proper place by the machine for later use. ♦The washer extractor is designed for fabrics washing only, other objects can damage the machine and can cause

damage or injuries.

♦The manufacturer is not responsible for the damage to the fabrics that are washed by an inappropriate washing method.

♦Always follow the instructions and/or warnings that are stated on the fabrics, washing products or cleaning products mentioned by the manufacturer.

♦If the machine is used for special applications follow the instructions and warning to avoid person injury. ♦Keep the washer extractor surface and surrounding clean and free of flammable materials.

♦Do not put fabrics in the washer extractor treated with flammable products. Such fabrics must first be washed by hand and air dried.

♦Store laundry aids, dry-cleaning solvents and disinfectants out of the reach of children, preferably in a locked cabinet. ♦Do not tamper the washer-extractor controls and do not bypass the safety instructions and the warnings. ♦Do not remove warning signs placed on the machine. Observe signs and labels to avoid personal injuries. ♦Do not put some part on the soap dispenser lid to held it open by filling or when the machine operates. ♦Do not open the soap dispenser lid after the machine is started. The discharge or splashing of hazardous

liquid can cause serious scalding and burning.

♦The use of hypochlorite will cause corrosion which may cause component failure under certain circumstances. ♦The warranty of the machine cannot be accepted in case corrosion was caused by chlorine and chlorine

compounds impact.

♦Do not operate the washer extractor when parts are broken or missing or when covers are open. The machine shall not be operated until the fixed guards are put correctly in place.

♦The washer extractor is not designed for work which may create an explosive atmosphere inside the machine and will not be used for this purpose.

♦Do not expose the washer extractor to the weather, extreme low or high temperature and humidity.

♦Under certain conditions, hydrogen gas may be created in the hot water system that has not been used for two or more weeks. Hydrogen gas is explosive. If the hot water system has not been used for such period open all hot water taps and let the water run out for few minutes. This will release any accumulated gas. As this gas is flammable, do not smoke or use open flames during this time.

♦By danger turn off the main switch or other emergency disconnection devices. ♦Check the functioning of the door lock mechanism on regular base.

♦Turn off the main water supply at the end of each operating day.

♦Only qualified service personnel may open the washing washer extractor to carry out servicing. ♦Follow all valid basic safety rules and laws.

♦It is obvious that it is impossible to mention each possible risk in this manual. It is up to the user to proceed as careful as possible.

♦The manufacturer reserves the right to change the manuals without previous notice. ♦If a problem should arise, contact your dealer for assistance.

♦Norm IEC335 is applied for machines with a net usable cage volume between 60 and 150 l. Norm EN60204-1 is used for a net usable cage volume above 150 l.

♦The washer extractor produces equivalent continuous (A-weighted) sound power level which doesn't exceed 70 dB (A).

! WARNING!

IF THE INSTALLED APPLIANCE OPERATE WITH COIN, TOKEN OR SIMILAR OPERATION FOR USE IN SELF-SERVICE SITUATIONS, THEN THE OWNER-INSTALLER MUST PROVIDE A REMOTE-LOCATED EMERGENCY STOP DEVICE. THIS DEVICE MUST BE PLACED IN SUCH A WAY THAT IT IS EASY AND SAFELY ACCESSIBLE FOR THE USERS. THE EMERGENCY STOP DEVICE TAKES CARE THAT AT LEAST THE CONTROL CIRCUIT OF THE APPLIANCE IS INTERRUPTED.

! WARNING!

DO NOT TOUCH THE DOORGLASS UNTIL CYCLE HAS BEEN COMPLETED. DO NOT OPEN DOOR UNTIL CYLINDER REMAINS STOPPED AND WATER HAS BEEN DRAINED FROM CYLINDER.

DO NOT PUT ARTICLES SOILED WITH EXPLOSIF SOLVENTS AND/OR DANGEROUS CHEMICAL PRODUCTS IN THE MACHINE. THIS MACHINE SHOULD NOT BE USED BY CHILDREN.

DO NOT LET CHILDREN PLAY IN, ON, OR AROUND THE MACHINE. BEFORE TURNING THE MACHINE „ON“, MAKE SURE THAT THERE ARE NO PEOPLE OR ANIMALS PRESENT IN OR AROUND THE MACHINE.

2 |

USER'S MANUAL |

504615_I_PUB_DATE_28_AUG_2009.DOC |

WARNING!

Always disconnect the washer from the electrical supply before attempting any service. The washer extractor is out of tension if the main plug is taken out or when the main supply is disconnected. When the main switch is turned off the inlet terminals of the machine main switch are still under current!

CAUTION!

Extreme hot conditions can arise in the surroundings of this air.

Watch out for vapor that escapes from the washer extractor venting!

CAUTION!

Do not cover the washer extractor venting. It serves as a vapor outlet to prevent pressure building in the washer extractor.

! WARNING!

ORIGINAL OR IDENTICAL PARTS MUST BE USED FOR REPLACEMENT IN THIS MACHINE. AFTER SERVICING REPLACE AND SECURE ALL PANELS IN THE ORIGINAL WAY. TAKE THESE MEASURES FOR CONTINUED PROTECTION AGAINST ELECTRICAL SHOCK, INJURY, FIRE AND/OR PROPERTY DAMAGE.

! WARNING!

LOOKING AT THE MACHINE FROM THE FRONT VIEW THE DRUM ROTATION DURING EXTRACTION MUST BE CLOCKWISE.

! WARNING!

SAFETY LABELS APPEAR AT CRUCIAL LOCATIONS ON THE MACHINE. FAILURE TO MAINTAIN LEGIBLE SAFETY LABELS COULD RESULT IN INJURY TO THE OPERATOR OR SERVICE TECHNICIAN.

2.1. INSTRUCTIONS FOR MAINTENANCE, ADJUSTMENT AND SAFETY OF PEOPLE

Some important information for the usage of the machine are not (or only partly) mentioned in this User's Manual. Missing information is possible to find in Installation and maintenance manual, which is delivered with the machine.

References to „Installation and Maintenance Manual" according to norm EN ISO 10472-1:

1. |

Description of the safe work system when maintenance is performed |

|

|

/ adjustment / and when eliminating defects. |

- chapter 5 / 5 / 6 |

2. |

Description of qualities for ventilation |

- chapter 4 |

3. |

Procedures on searching for defects / cleaning / maintenance |

- chapter 6 / 5 / 5 |

4. |

Heat risks |

- chapter 3 |

5. |

Safety procedure on manipulation, installation and dismantling |

- chapter 4 |

References to „Installation and Maintenance Manual" according to norm EN ISO 10472-2:

6. |

Maintenance of door blocking |

- chapter 5 |

7. |

Electric risks |

- chapter 2 |

8. |

Heat energy |

- chapter 3 |

9. |

Sight holes |

- chapter 3 |

10. |

Appropriate processes |

- chapter 2 |

11. |

Explosive atmosphere |

- chapter 2 |

12. |

Biological or chemical pollution of water |

- chapter 2 |

13. |

Maximal possible overspeed |

- chapter 3 |

504615_I_PUB_DATE_28_AUG_2009.DOC |

USER'S MANUAL |

3 |

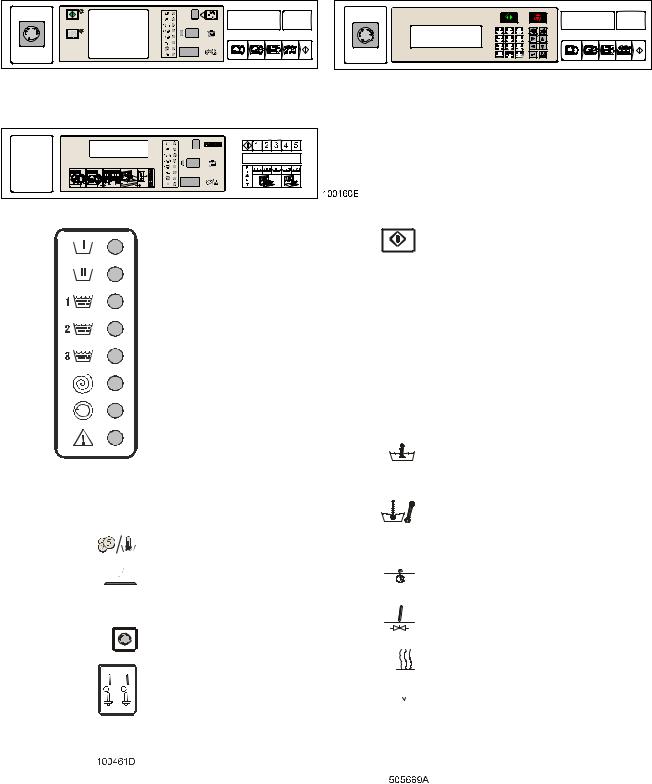

3. SYMBOLS ON THE MACHINE

Caution, dangerous electrical tension, electrical devices

Caution, other danger, read and follow written instructions

Caution - Increased temperature

Do not close or cover

The machine hot air outlet

The machine hot air outlet

In case of emergency press the emergency button to stop the machine

Steam

Warm water inlet (red color of the label)

Soft cold water inlet

(light blue color of the label)

Hard cold water inlet (dark blue of the label)

The holes to be drilled not punched

4 |

USER'S MANUAL |

504615_I_PUB_DATE_28_AUG_2009.DOC |

EASY CONTROL MICROPROCESSOR |

|

|

|

|

|

|

|

GRAPHITRONIC MICROPROCESSOR |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EASY CONTROL MICROPROCESSOR

WITH MECHANICAL BUTTONS

PREWASH

MAIN WASH

RINSE 1

RINSE 2

RINSE 3

EXTRACT

DOOR RELEASE

FAULT

PROGRAM SELECT

PROGRAM SELECT

CYCLE TIME

CYCLE TIME

COIN/TEMPERATURE

FUNCTION BUTTON

FUNCTION BUTTON

START

START

EMERGENCY STOP KNOB

(Only used by not coin washer extractors)

COIN SYSTEM

PROGRAM SELECT

PROGRAM SELECT

START (advancing program)

STOP (interupting program)

STOP (interupting program)

YES SELECTION

YES SELECTION

NO SELECTION

NO SELECTION

INCREASING SEQUENCE TIME

INCREASING SEQUENCE TIME

DECREASING SEQUENCE TIME

DECREASING SEQUENCE TIME

INFO (overview available wash programs and wash sequence functions)

SERVICE (shows actual water temperature and level, number of fullfilled cycles and actual state)

ACTIVATES THE TIME DELAY FUNCTION

(delay time will be started by pressing start)

OPENING THE INLET VALVES

ACTIVATE HEATING

OPEN DRAIN VALVE

OPEN DRAIN VALVE

SPEED ADJUST

SPEED ADJUST

ENTER – SELECTION OR CONFIRMATION

ENTER – SELECTION OR CONFIRMATION

504615_I_PUB_DATE_28_AUG_2009.DOC |

USER'S MANUAL |

5 |

4.OPERATION INSTRUCTIONS

4.1.BEFORE WASHING

Sort the linen according on the temperature and the instructions of the manufacturer of the fabrics. Check if there aren‘t any strange objects between the linen like nails, screws, needles, etc. in order not to damage the washer-extractor or the linen. Turn sleeves of shirts, blouses, etc. inside out. To get a better washing result, you have to unfold the fabrics and mix the bigger and smaller pieces of fabrics.

4.2. OPEN THE DOOR

Open the door by pulling on the door handle.

4.3. LOADING THE WASHER

! CAUTION!

The optimal washing load is determined by the filling factor. The proper filling factor is determined by the type of linen and other factors. Cotton textiles normally require a filling factor of 1:10-1:13, which is a full drum load. Put the linen in the drum depending on the maximum capacity of the washer. Do not overload the washer extractor. Overloading the machine can lead to a bad wash result. Half washing loads can obstruct a proper function. Synthetics and blended fabrics usually require a filling factor of 1:18-1:20, which is half drum load. Loading more will reduce the wash result and can damage the linen.

4.4. CLOSE THE DOOR

Close the door with the door handle, making sure the door is properly latched before operating the washer.

4.5. PROGRAM SELECTIONS

Choose one of the available wash programs, best corresponding to the quality of the garments and allowed wash temperature in the wash load. Insert the wash program number. The different washing programs are indicated on the operator panel. The selection of the program determines the temperature and the time for washing and rinsing, the wash action and the spin speed and time.

Note: For locking a program mode, changing factory settings and possibilities of program changes and setup - see Programming manual.

6 |

USER'S MANUAL |

504615_I_PUB_DATE_28_AUG_2009.DOC |

4.6. WASH PROGRAMS OVERVIEW

Wash program 1: |

Hot wash |

90°C |

|

|

Wash program 2: |

Warm wash |

60°C |

|

|

Wash program 3: |

Coloured wash |

40°C |

|

|

Wash program 4: |

Bright coloured wash |

30°C |

|

|

Wash program 5: |

Woollens |

15°C |

|

|

Wash program 6: |

Hot wash |

90°C |

ECONOMY level |

|

Wash program 7: |

Warm wash |

60°C |

ECONOMY level |

|

Wash program 8: |

Coloured wash |

40°C |

ECONOMY level |

|

Wash program 9: |

Bright coloured wash |

30°C |

ECONOMY level |

|

EASY CONTROL: Wash program A: |

Hot wash |

90°C |

SUPER ECONOMY level |

|

GRAPHITRONIC: Wash program 10: |

||||

|

|

|

||

EASY CONTROL: Wash program B: |

Warm wash |

60°C |

SUPER ECONOMY level |

|

GRAPHITRONIC: Wash program 11: |

||||

|

|

|

||

EASY CONTROL: Wash program C: |

Coloured wash |

40°C |

SUPER ECONOMY level |

|

GRAPHITRONIC: Wash program 12: |

||||

|

|

|

||

EASY CONTROL: Wash program D: |

Bright coloured wash |

30°C |

SUPER ECONOMY level |

|

GRAPHITRONIC: Wash program 13: |

||||

|

|

|

||

EASY CONTROL: Wash program E: |

Extraction |

|

low speed |

|

GRAPHITRONIC: Wash program 14: |

|

|||

|

|

|

||

EASY CONTROL: Wash program F: |

Extraction |

|

high speed |

|

GRAPHITRONIC: Wash program 15: |

|

|||

|

|

|

4.7. ADD DETERGENTS

Fill the soap dispenser on the top of the washer extractor depending of the chosen program.Dispenser A: Prewash (add the detergent at the beginning of the wash cycle)

Dispenser B: Wash (add powder detergent or bleach detergent at the beginning of the cycle, you may add liquid detergent or liquid bleach during the wash cycle. If added at the start of the cycle, it will run in the washer prematurely)

101008 |

Dispenser C: Final Rinse (Add fabric softener at the beginning of the cycle or before |

|

|

|

the final rinse) |

Fill the soap dispenser at the front or side of the washer extractor depending of the chosen program.Dispenser A: 1 st Wash

Dispenser B: 2 nd WashDispenser D: Last Rinse

Add the detergents before the start of the wash cycle.

RStandard wash programs versus custom made wash programs.

This explanation is only valid for standard wash programs. For custom made programs, it’s possible that other dispensers have been selected. (See programming manual)

RRemark:

-It is advisable to use only detergents with „foam breaker“ which can easily be found in retail shops. The dosage of soap to use is generally mentioned on the packing. An overdose of detergent can lead to poor wash results and „suds“ overflow which can damage the machine.

-Take care that the lid of the soap dispenser is closed if the machine starts.

504615_I_PUB_DATE_28_AUG_2009.DOC |

USER'S MANUAL |

7 |

4.8.START THE WASHER

4.8.1.EASY CONTROL MICROPROCESSOR WITH KEYPAD AND MECHANICAL BUTTONS

COIN OPERATED MODELS

A. After choosing the program with the PROGRAM SELECT button, throw the right amount of coins in the slot indicated on the lower

display The display shows the remaining amount that has to be thrown in. If the display shows 00, the washer extractor can be started. The little light by the start button will be flashing.

B. Push the START button to start the washer extractor. When you

have selected a wrong washing program, you can change it during the first 150 seconds of the program by pushing the

SELECT button. When a more expensive washing program was chosen, the value will be shown to add. When you don‘t add more

coins, the chosen program at the start will be executed.

C. During the washing cycle you can follow the actual washing sequence and the remaining time on the displays.

NON-COIN OPERATED MODELS

A. After choosing the program with the PROGRAM SELECT button, push the START button to start the washer extractor.When you have selected a wrong washing program, you can change it during the first washing step by pushing the SELECT button.

B. During the washing cycle you follow the actual washing sequence, the remaining time and if been set the temperature on the displays.

C. If the advance function has been set by the installator, you can go on to the next step by pushing the START button.

4.8.2. GRAPHITRONIC MICROPROCESSOR

After selecting the desired wash program number, by pressing the START button the wash cycle will be started. If there is no washing program available for the selected program number, „INVALID will be displayed“.

Program |

|

Wash Cycle |

|

Units |

||

Number |

|

Name |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Door State

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wash/Spin |

|

Wash Cycle |

|

Progression |

|

Remaining Time |

||||||

Sequence |

|

Step |

|

Bar |

|

Wash Cycle |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

4.9. END OF WASH CYCLE

4.9.1. EASY CONTROL MICROPROCESSOR WITH KEYPAD AND MECHANICAL BUTTONS

You can see clearly the end of the washing cycle on the operator panel when the light next to the door symbol lights up and the time display indicates „0“. Open the door with the door handle and take out the fabrics

of the washer extractor.

!WARNING!

IF YOU CAN’T OPEN THE DOOR, FOR EXAMPLE BY A POWER FAILURE, WAIT A CERTAIN TIME UNTIL THE SECURITY SWITCH IS COOLED DOWN. THIS IS A SAFETY! THE DOOR CAN BE OPENED AFTER A COUPLE OF MINUTES. MAKE SURE THAT THE DRUM HAS COMPLETELY STOPPED AND DRAINED BEFORE OPENING THE DOOR.

8 |

USER'S MANUAL |

504615_I_PUB_DATE_28_AUG_2009.DOC |

When a power failure occurs for a short time, the wash program will continue when the power comes back on. When the failure occurs for a longer time and the door is still closed the display and the light next to the start button starts flashing when power is restored. If the door is still locked the timer will continue the program.

For machines initialised as coin operated models, the door will be locked immediately. Press the start button to continue the program. If the door was opened, the program will be resetted.

4.9.2. GRAPHITRONIC MICROPROCESSOR

!WARNING!

IF YOU CAN’T OPEN THE DOOR, FOR EXAMPLE BY A POWER FAILURE, WAIT A CERTAIN TIME UNTIL THE SECURITY SWITCH IS COOLED DOWN. THIS IS A SAFETY! THE DOOR CAN BE OPENED AFTER A COUPLE OF MINUTES. MAKE SURE THAT THE DRUM HAS COMPLETELY STOPPED AND DRAINED BEFORE OPENING THE DOOR. AT THE END OF THE THE WASH CYCLE, WHEN THE REMAINING PROGRAM TIME REACHES 0, PROGRAM END IS DISPLAYED. WHEN UNLOAD APPEARS ON THE DISPLAY, OPEN THE DOOR BY THE DOOR HANDLE AND TAKE OUT THE GARMENTS

OF THE WASHER EXTRACTOR. (ONLY FOR MACHINES WITH „GRAPHITRONIC“)

4.10. HOW TO OPEN THE DOOR BY FAILURE

See Installation and maintenance manual.

504615_I_PUB_DATE_28_AUG_2009.DOC |

USER'S MANUAL |

9 |

5. FIRST SERVICE AT TECHNICAL PROBLEM

N° |

Failure message |

Failure |

Action |

Fault occurrence |

E1 |

No Drain Co |

Drain failure |

Full Stop + tumble |

Draining sequence |

|

|

Cooldown |

|

Cooldown |

E2 |

No Drain |

Drain failure |

Full Stop + tumble |

Draining sequence |

E3 |

Tilt Fault |

Out of balance : |

Full stop + tumble |

Start spin |

|

|

Before spin |

|

|

E4 |

Imbalance |

Out of balance : |

Skip + continue |

After 10 x tilt |

|

|

Normal spin |

|

|

E5 |

Tilt High Sp |

Out of balance : high |

Full stop + safety time |

>500 or 750 RPM |

|

|

spin |

|

|

E6 |

Door Coil |

Door switch failure |

Full stop + safety time |

Whole cycle |

E7 |

Door Switch |

Door solenoid switch |

Full stop + safety time |

Whole cycle |

|

|

failure |

|

|

E8 |

Door Start |

Door lock check at |

Don’t start |

At start up |

|

|

start failure |

|

|

E9 |

Door Unload |

Door lock switch |

Don’t start |

End cycle |

|

|

closed failure |

|

|

E10 |

Bimetal/Spring |

Bimetal/Spring |

Continue |

2 min 30 sec after start |

|

|

|

|

cycle |

E11 |

No Fill |

Fill failure |

Full stop + request for |

While filling |

|

|

|

Continue |

|

E12 |

Overfill |

Overfill failure |

Full stop + tumble |

While filling |

E13 |

No Heating |

Heating failure |

Full stop + tumble |

While heating |

E14 |

Heat Time |

Heating time failure |

Full stop + request for |

While heating |

|

|

|

Continue |

|

E15 |

Too Hot |

Too Hot |

Full stop + tumble |

While heating |

E21 |

Overflow |

Overflow failure |

Full stop + tumble |

Wash step |

E22 |

Flush fault |

Flush failure |

Full stop + tumble |

Flush step |

E24 |

Level Sens |

Defective level |

Continue + Don’t start |

Before start up |

|

|

sensor |

|

|

E25 |

Temp Sensor |

Defective |

Continue + Don’t start |

Before start up |

|

|

temperature sensor |

|

|

E26 |

Mitsub code |

Undefined frequency |

Full stop + tumble |

Whole cycle |

|

|

inverter error code |

|

|

E27 |

Comm fault |

Communication fault |

Full stop + safety time |

Whole cycle |

|

|

inverter |

|

|

E28 |

THT time / E.OL |

THT Time out / E.OL |

Full stop + safety time |

At spin sequence |

E29 |

OV3 time / |

OV3 Time out / |

Full stop + safety time |

At spin sequence |

|

E.OP |

E.OP |

|

|

E31 |

Load Parr |

Initialization fault |

Don’t start |

At initialization |

|

|

inverter |

|

|

E32 |

Verify Parr |

Verification fault |

Don’t start |

At loading parameters |

|

|

inverter |

|

|

E33 |

Stall prev |

Stall prevention |

Continue |

At spin sequence |

|

|

function active |

|

|

E35 |

Wrong Softw |

Wrong software |

Don’t start |

New software version |

|

|

version |

|

|

E37 |

No Drain Sp |

Drain failure at the |

Full stop + tumble |

Spray Sequence |

|

|

Spray Sequence |

|

|

E38 |

No Recycle |

The Tank with |

Warning at the End. |

Wash step |

|

|

recycle water is |

Front soap dispenser |

|

|

|

empty |

Mach. only |

|

E39 |

Out of Soap |

The Soap Supplies |

For Info only |

Wash step |

|

|

are running Out of |

|

|

|

|

Soap |

|

|

E40 |

No Fill Rec |

Fill failure due to an |

Full stop + Request for |

Wash step |

|

|

empty water recycle |

Continue |

|

|

|

Tank |

Top soap dispenser |

|

|

|

|

Mach. only |

|

E41 |

Service Due |

Service Due |

For Info only |

End cycle |

|

|

Warning |

Open door = reset |

|

E42 |

Connection |

No Network |

For Info only |

Data Transfer Networking |

|

|

Connection |

|

|

10 |

USER'S MANUAL |

504615_I_PUB_DATE_28_AUG_2009.DOC |

E43 |

Voltage Par |

Wrong Voltage |

Make correct selection |

Configuration menu |

|

|

Range Selection |

|

|

E44 |

Model type |

Wrong Inverter |

Make correct selection |

Configuration menu |

|

|

Model Type |

|

|

E45 |

No Speed |

No Speed pulses |

Continue + Warning |

At spin sequence |

|

Sensor Signal |

when drum turns. |

|

(FS120 only) |

E46 |

Brake Closed |

Brake Stays Closed |

Full stop + safety time |

At spin sequence |

|

|

|

|

(FS120 only) |

E47 |

Brake Wear Out |

Friction blocks |

Full stop + safety time |

Any time |

|

|

brake are wear-out |

|

(FS120 only) |

E48 |

Brake Open |

Brake Stays Open |

Continue + Warning |

At spin sequence |

|

|

|

|

(FS120 only) |

E49 |

UnBalance |

Air suspension |

Full stop + safety time |

Wash action |

|

Switch At Wash |

without compressed |

|

(FS120 only) |

|

|

air |

|

|

E50 |

No Second |

Missing wire bridge |

Continue |

At spin sequence |

|

Acceleration |

inverter / wrong |

|

(FS120 only) |

|

Ramp |

inverter parameters |

|

|

E51 |

No Third |

Missing wire bridge |

Continue |

At spin sequence |

|

Acceleration |

inverter / wrong |

|

(FS120 only) |

|

Ramp |

inverter parameters |

|

|

E52 |

Board Memory |

PCB-EEPRROM |

Don't start |

At Power Up |

|

|

CRC failure |

|

|

E53 |

Board Data |

PCB-EEPROM Data |

Don't Start |

At Power Up |

|

|

out of range failure |

|

|

E57 |

Lock System |

Door Lock Switch |

Don’t Start |

At locking sequence |

|

|

stays closed when |

|

(MB70-90-110-140-180 |

|

|

the outer door is |

|

only) |

|

|

open. |

|

|

E58 |

No Free Run |

Deceleration end of |

Full stop + safety time |

At spin sequence |

|

|

spin while brake is |

|

(FS120 only) |

|

|

closed. |

|

|

E59 |

Run Free Run |

Run Status inverter |

Full stop + safety time |

At spin sequence |

|

|

=1 while brake is |

|

(FS120 only) |

|

|

closed. |

|

|

E60 |

No reset Drive |

No detection motor |

Full stop + safety time |

Wash Sequence |

|

|

speed signal at |

|

|

|

|

wash |

|

|

E61 |

Continue spin |

Motor doesn't stop |

Full stop + safety time |

Whole cycle |

|

|

spinning anymore |

|

|

E62 |

Extended speed |

Motor spins too fast |

Full stop + safety time |

Whole cycle |

E63- |

Motor Drive |

Reset Motor Drive for |

Reset Motor Drive |

Wash Sequence |

E67 |

|

E60, E61 & E62 |

|

|

E68 |

No Sign Spin |

No detection motor |

Full stop + tumble |

Spin Sequence |

|

|

speed signal at spin |

|

|

E69 |

RS Unbalance |

Unbalance input |

Don't Start |

Start Spin sequence |

|

|

should not be high on |

Full stop + tumble |

Whole cycle |

|

|

R machines |

|

|

E70 |

RS7 Select |

RS7 selected in case |

Don't Start |

Start Cycle |

|

|

of RS10 |

|

|

E71 |

RS10 Select |

RS10 selected in |

Don't Start |

Start Cycle |

|

|

case of RS7 |

|

|

E72 |

KEB ST LOW |

No wire bridge |

Don't Start |

Start cycle |

|

|

terminals 16-20 |

|

|

E73 |

KEB ST HIGH |

No KEB parameters |

Full stop + safety time |

Start cycle |

|

|

loaded in inverter |

|

|

E74 |

CFIStuck |

Inverter not switched |

For Info only |

End of cycle |

|

|

off at end of cycle. |

|

|

E75 |

KEB code |

Undefined frequency |

Full stop + tumble |

Whole cycle |

|

|

inverter error code |

|

|

E78 |

Lock Active |

At standby door lock |

Don't Start |

At Standby |

|

|

is locked nevertheless |

|

|

|

|

door is open. |

|

|

E79 |

Lock Start |

After pressing Start |

Don't Start |

At Start Cycle |

|

|

door lock is locked |

|

|

|

|

nevertheless door is |

|

|

|

|

open. |

|

|

504615_I_PUB_DATE_28_AUG_2009.DOC |

USER'S MANUAL |

11 |

E80 |

Time Out |

On Hold Signal |

Full stop + tumble. |

Whole cycle |

|

Input16 |

Failure Soap |

|

|

|

|

Dispensing System |

|

|

E81 |

No Reheat |

Heating Failure |

Full stop + tumble. |

Wash Step |

|

|

|

|

(MB only) |

E82 |

No Refill |

Refill failure |

Full stop + request for |

Wash Step |

|

|

|

Continue |

(MB only) |

E83 |

Cycle Fail |

No successful wash |

Info that the wash cycle |

Abnormal Cycle |

|

|

cycle termination |

has to be repeated. |

Termination (MB only) |

E84 |

No Store PC |

Communication |

For Info only. |

End cycle |

|

|

failure with PC |

|

(MB only) |

E85 |

RTC Low Batt |

Real Time Clock, No |

For Info only. |

End cycle |

|

|

Battery or battery low |

|

(MB only) |

|

|

power |

|

|

E86 |

No RTC Comm |

Real Time Clock is |

For Info only. |

End cycle |

|

|

not available |

|

(MB only) |

|

|

|

|

|

E100 |

Weigh No |

Communication fault |

Full Stop Tumble |

Before Start (MB16-MB180) |

|

Comm |

weighing system |

|

Whole Cycle (MB16-MB66) |

|

|

|

|

(MB & FS23-55 only) |

E101 |

Weigh Low |

Weight machine is too |

Don't Start |

Before Start |

|

|

low |

|

(MB & FS23-55 only) |

E102 |

Weigh High |

Weight machine is |

Don't Start |

Before Start |

|

|

too high |

|

(MB & FS23-55 only) |

E103 |

Weigh Balance |

Weight is not |

Don't Start |

Before Start |

|

|

balanced over 4 load |

|

(MB & FS23-55 only) |

|

|

cell's. |

|

|

E104 |

Weigh Overload |

Weight on individual |

Full Stop Tumble |

Whole Cycle |

|

|

load cell exceeds |

|

(MB16-66 & FS23-55 only) |

|

|

max. |

|

|

E105 |

Weigh Airbags |

No functional air |

Don't Start |

Before Start |

|

|

pressure system |

|

(MB70-180 only) |

|

|

|

|

|

E300 |

Mits Err |

Specific Mitsubishi |

Full stop + safety time |

Whole cycle |

- |

|

Inverter Alarm |

|

|

E353 |

|

|

|

|

E400 |

KEB Err |

Specific KEB |

Full stop + safety time |

Whole cycle |

- |

|

Inverter Alarm |

|

|

E441 |

|

|

|

|

|

|

|

|

|

E500 |

Memory Err |

Memory Error |

Full stop + safety time |

Any time |

- |

|

|

|

|

E515 |

|

|

|

|

|

|

|

|

|

E550 |

DAQ Version |

Wrong DAQ |

For Info only |

Installation new softw |

|

Err |

Memory version |

|

|

E551 |

DAQ Write Err |

Problem writing |

For Info only |

Traceability function, whole |

|

|

DAQ Memory |

|

cycle |

E552 |

DAQ Full Err |

DAQ Traceability |

For Info only |

Traceability function, whole |

|

|

Memory is Full |

|

cycle |

E553 |

Store DAQ>PC |

DAQ Traceability |

For Info only |

Traceability function, whole |

|

|

Memory is almost |

|

cycle |

|

|

Full |

|

|

|

|

|

|

|

E600 |

Softw Err |

Software Error |

Full stop + safety time |

Any time |

- |

|

|

|

|

E628 |

|

|

|

|

12 |

USER'S MANUAL |

504615_I_PUB_DATE_28_AUG_2009.DOC |

Loading...

Loading...