Page 1

PLASMA DISPLAY MOUNT MODEL

3130 E. Miraloma Ave. Anaheim, CA 92806 Phone: 800 368-9700 Fax: 800 832-4888

INSTALLATION MANUAL

VISIT US AT WWW.MOUNTS.COM

Page 2

,

Introduction

Plasma display manufacturers are constantly improving their products and introducing new ones. We are committed to keeping up with

them. That’s why we maintain close relationships with all major OEMs – to ensure that we have the latest information on new display

products coming to market. Our mounts are often available before the corresponding displays are even on sale.

Mounts are available in either flat or tilt versions, this versatile mount can be used for just about any application, including walls, stands,

carts

2

ceilings – even inside custom cabinets and other furniture applications.

Contents

NOTE: The following installation procedures indicate a wall structure installation. For installations other than wall mounting refer to installation instructions.

o Safety & precautions

o Mount diagrams

o Parts List

o Optional Adapters

o Installing the mounting bracket

o Installing the mount

o Electrical

o Securing the mount

o Additional security

NOTE: For installations other than wall mounting please refer to page 6. If installing the plasma display to the ceiling or floor stand please refer to its

installation instructions.

o Ceiling structure assembly drawing (pg 6)

Thank you for choosing PREMIER MOUNTS for your installation needs.

If you have any questions please contact PREMIER MOUNTS

Information is shown on the front of this page.

Page 3

p

y

jury

p

Safety & Precautions

WARNING: Safety precaution measures must be practiced at all times during the installation of this product. Use proper safety gear and tools for the

installations

rocedure to prevent personal injury or damage to the plasma displays or plasma mounts.

The wall or ceiling structure must be capable of supporting at least five (5) times the weight of plasma display.

If not, the wall or ceiling must be reinforced. Proper installation procedure by qualified personnel as outlined in the installations instructions

must be adhered to. Failure to do so could result in serious

ersonal injur

The entire installation instructions should be fully read and understood, including all of the safety symbols and safety precautions, before

beginning installation. The installation instructions should be read, understood and followed to prevent personal in

Keep these installation instructions in an easily accessible location for future reference.

or property damage.

Indicates that the power plug is to be disconnected from

the power outlet.

Contact Premier Mounts for any questions

Safety precautions must be taken at all times.

Warning and caution in general

A secured structure wooden stud wall must always support the weight or load of the plasma. Always confirm the center of the wood

stud before beginning the installation.

Do not install in locations where there is vibration, movement or danger of impact. Failure to do so could result in plasma cracking or

falling from the wall causing damage and injury.

Do not install near heater, fireplace, direct sunlight or air conditioning or any other source of direct heat energy. Failure to do so may

result in damage to the plasma television and could cause a risk of fire.

At least two qualified people should always perform the installation work. Injury and damage can result from dropping or mishandling

the plasma television.

Mounting structure recommended wood studs, solid-flat concrete, and reinforced metal studs. If installing the mount on other than

wood studs use (commercially available) suitable hardware.

3

Page 4

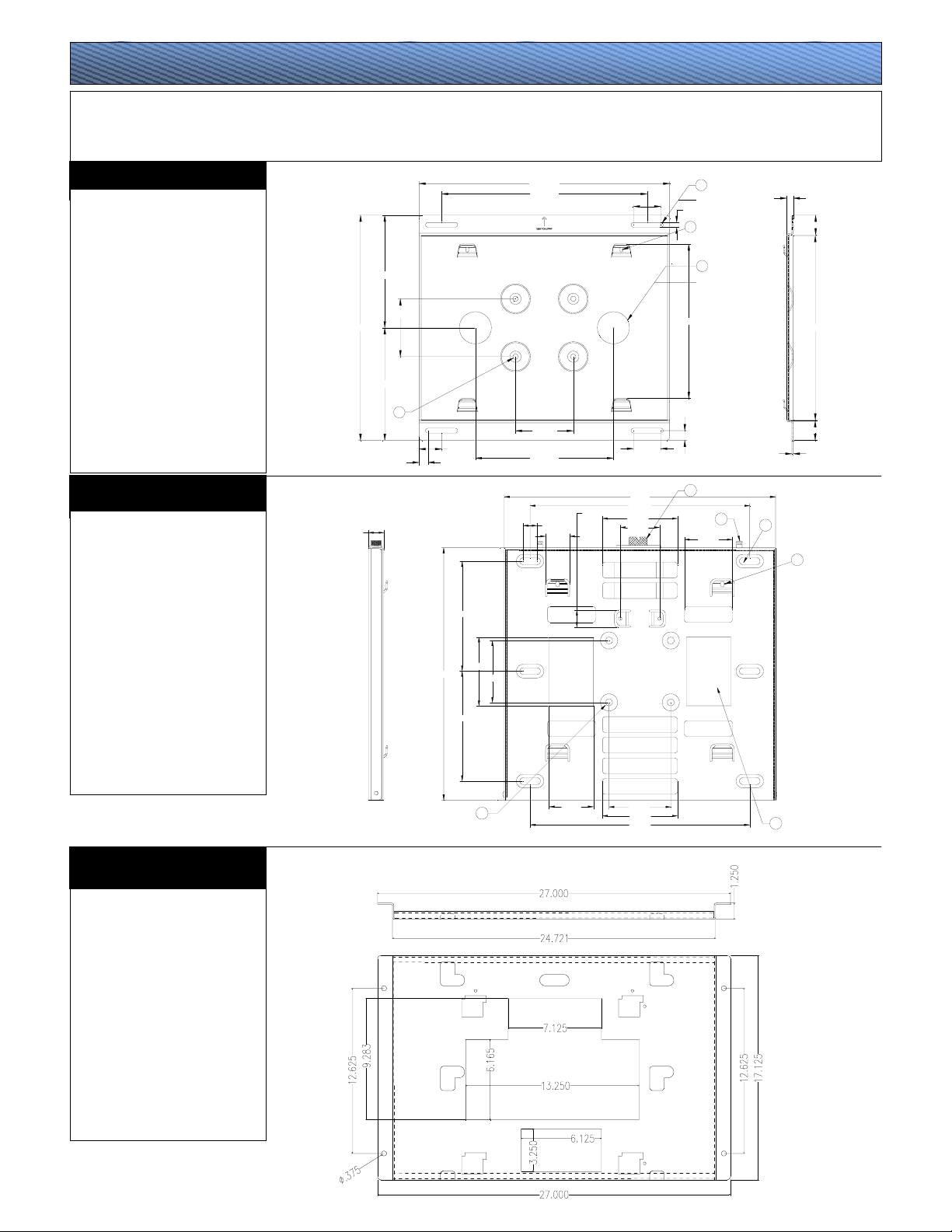

Mount Diagrams

Our PSM flat / tilt mounts are designed for wall or ceiling mounting, or it can mate with any of our popular carts, floor stands or wall arms.

The ultra slim plasma mount stands off the wall just enough for proper, OEM-specified ventilation, yet keeps the plasma close enough for a

clean, seamless look. It allows either vertical (portrait) or horizontal (landscape) display configuration.

UNIVERSAL FLAT MOUNT

PART#:

PDB-UWFB

MATERIAL:

12 (GA) CRS

COLOR:

Black powder coat

A.

Lag bolt access slot.

B.

Mounting points (4.5") used on

installations other than wall mounting.

C.

Access hole for power or cables.

D.

M6 security screw mounting points

used on installations other than flat

wall mounting.

UNIVERSAL TILT MOUNT

PART#:

PSB-TBP

MATERIAL:

12 (GA) P & O

COLOR:

Black powder coat

A.

Lag bolt access slot.

E.

Worm drive

F.

Locking pins

G.

Access hole for power or cables.

H.

Mounting points (4.5") used on

installations other than wall mounting.

8.750

4.500

17.500

8.750

b

1.750

0.688

1.125

8.000

5.000

18.500

4.500

8.000

19.500

16.000

4.500

10.750

1.000

1.750

1.250

2.125

2.125

19.771

16.000

5.460

2.865

0.375

d

12.000

0.750

e

a

Ø0.375 (x4)

c

Ø2.500

F

3.500

0.104

A

b

3.250

4.500

5.460

16.000

c

PSM SERIES MOUNT

PART#:

PDB-442

MATERIAL:

12 (GA) P & O

COLOR:

Black Powder coat

Note: The PDB-Series bracket mates

to the universal PDB-UWFB flat

mount and the universal PSB-TBP tilt

mount.

0.500

1.528

14.324

1.528

d

4

Page 5

(Op

Parts List

PSM-Mount

PSM-313

PSM-375

PSM-401

PSM-402

PSM-410

PSM-421

PSM-423

PSM-424

PSM-425

PSM-426

PSM-427

PSM-428

PSM-432

PSM-460

PSM-478

PSM-499

PSM-500

PSM-501

PSM-502

PSM-532

PSM-540

PSM-542

PSM-550

PSM-570

PSM-610

PSM-615

PSM-783

PSM-442

Standard hardware

QTY SIZE DESCRIPTION

6 (Tilt) – 4 (Flat) 5/16” Dia Lag bolts

1 PSM series mount

1 Flat / Tilt mount

2 M6 x 12 (mm) Phillip security

1 Installations instructions

1

screws

Used for additional security on

tilt mounts, mobile carts, floor

stands and ceiling mounts

Bubble level

PSM-Series Mounting hardware

QTY SIZE DESCRIPTION

6 M5 x 16 Phillip screws

4 M6 x 12 Phillip screws

6 M8 x 20 Phillip screws / Flat washers / Split washers

8 M6 x 12 Phillip screws

6 M5 x 16 Phillip screws / Flat washers / Split washers

6 M5 x 12 Phillip screws

6 M5 x 10 Phillip screws

6 M5 x 12 Phillip screws

8 M4 x 12 Phillip screws

8 M5 x 12 Phillip screws

6 M6 x 16 Phillip screws

8 M8 x 12 Phillip screws

6 M5 x 16 Phillip screws

4 – 4 M5 x 35 – M4 x 12 Phillip screws / Hex bolts

6 M6 x 12 Phillip screws

4 – 2 M5 x 50 / M10 x 25 Hex screws / Hex bolts / Flat washer

8 M5 x 20 Phillip screws / Flat washers / Split washers

6 M8 x 20 Phillip screws

6 M8 x 20 Phillip screws

• • •

6 M8 x 30 Phillip screws

2 M5 x 12 Phillip screws

2 M5 x 12 Phillip screws

6 M8 x 30 Phillip screws

6 M8 x 16 Phillip screws / Flat washers / Split washers

6 M8 x 10 Phillip screws

6 M6 x 12 Phillip screws

4 M8 x 30 Phillip screws / Flat washers / Fender washer / .5” nylon spacers

o Phillips screwdriver

o Drill gun

o Soft material or a blanket

o Pencil

o ¼" drill bit

o Level

o Measuring tape

o Wrench with a 1/2" socket

o Stud finder

o 1/4"-3/8" Toggler bolts: Used for hollow concrete block wall mounting.

o 5/16"-3/8" Wedge anchors: Used in solid brick or minimum-rated (3000psi) solid concrete.

TOOLS & SUPPLY NEEDED

tional) Installation Hardware

5

Page 6

(Optional) ceiling adapters

AST-2446: 1½" (Adjustable height suspension adapter) - Offering height adjustment in 1¼" increments, between 24" and 46"

(12" - 24", if you cut down), this suspension adapter mates with the single display swivel adapter and 1½" (NTP) pipe.

AST-2446/2: 2" (Heavy-duty adjustable height suspension adapter) - Offering height adjustment in 1¼" increments, between 24" and 46"

(12" - 24", if you cut down), this suspension adapter mates with the dual display swivel adapter and 2" (NTP) pipe.

PSD-S: 1½" (Single display swivel adapter) – This adapter could be mated with any two of out ultra slim flat or tilt plasma mounts to allow 360° swivel for a

ceiling installation. It works with 1½" threaded (NTP) pipe or AST-2446.

PSD-D: 2" (Dual display swivel adapter) - This adapter could be mated with any two of out ultra slim flat or tilt plasma mounts to allow 360° swivel for a ceiling

installation of two back to back displays. It works with 2" threaded (NTP) pipe or AST-2446/2.

PSD-PVW1: 1½" (Single display pole adapter) – Attach this adapter directly to any of the flat or tilt plasma mounts, and slide it over a 2" scheduled 40 steel

pipe, then secure at any height with two (2) tension-locked bolts.

PSD-PVW2: 2" (Dual display pole adapter) – Attach any two (2) of the flat or tilt plasma mounts back to back with this adapter, and slide it over a 2" scheduled

40 steel pipe, then secure at any height with two (2) tension-locked bolts.

A Plasma display

B PSM-Mount

C PSM-Hardware

(See chart on pg 5)

D M10 x 12 (mm) Hex

screws, flat washers

(4,4,8 Pack)

E PSB-UWFB Universal flat

mount

F M6 Security screws used

on tilt, ceiling, cart, floor

stand applications.

G PSB-TBP Universal tilt

mount

H AST-2446 adjustable

suspension post for single

display mounting or

AST-2446/2 adjustable

suspension post for dual

display mounting.

I PSD-S Single mounting

adapter

J PSD-D Dual mounting

adapter

K 1½" (NTP) For single

ceiling display installations

or 2" (NTP) For dual

ceiling installations

EXAMPLE PLASMA FOR ILLUSTRATION PURPOSES ONLY

Horizontal to vertical mounting

Horizontal to vertical mounting

Note: The M6 x 12 (mm) Security screws

Note: The M6 x 12 (mm) Security screws

must always be used for extra security.

could be used for additional safety.

Ceiling installation

assembly

6

Page 7

play

play

p

play

Installing the mounting bracket

WARNING : Proper installation procedure by qualified personnel as outlined in the installation instructions must be adhered to. Failure to do so could

result in serious personal injury and possible damage to the plasma display.

Step 1

CAUTION: The plasma displays are fragile and heavy. At least two (2) qualified personnel are strongly recommended for the installation of this product.

Invert the plasma display and set it on a soft, flat surface to prevent any damage to the plasma display. See fig 1.

EXAMPLE PLASMA FOR ILLUSTRATION PURPOSES ONLY

Top of the plasma

dis

Inverted plasma

dis

Soft and flat surface

blankets, foam, cloth

etc.

Bottom of the

lasma display

Step 2

CAUTION

Locate the mounting points found on the back of the plasma chassis, align the mounting holes from the mounting bracket to the holes on the chassis. Arrow found

on the PSM mount must always be pointing to the top of the plasma display before securing it to the chassis. Secure the mounting bracket to the plasma display by

using the hardware specified on the parts list. CAUTION

WARNING: Do not use the drill gun to secure the screws to the plasma display. A Phillips head screwdriver is preferred.

: The plasma displays are fragile and heavy. At least two (2) qualified personnel are strongly recommended for the installation of this product.

: Do not over tighten the mounting hardware. See fig 2.

PSM-series

mount

Mounting hardware

(see chart on pg 5)

Inverted plasma

dis

7

Page 8

A

V

g

Installing the mounts

Step 3

Securing the flat mount

: The plasma displays are fragile and heavy. At least two (2) qualified personnel are strongly recommended for the installation of this product.

CAUTION

All plasma models vary depending on the manufacturer and some are centered and others are not. Please verify that your plasma mounting points from the back of the chassis are

centered before installing the universal back plate.

Select the area where the plasma will be installed and make sure it can support the weight standards (see warning on page 3). Locate the 16" wood stud centers behind the wall using

a (commercially available) stud finder and mark the center of the studs when found. Set the mounting bracket to the wall and mark the desired height by marking the center of the

universal flat mount.

Note: Same installation process applies to the PSM-Tilt series. See fig 3.

Note: Pre drill before the securing the

5/16" la

bolts.

Caution: Do not over tighten the 5/16" lag bolts

Wall structure

Desired height

marking

Universal flat

mount

16"

Stud centers

marking

djusting the

mount

CENTER

Wood studs behind

the wall structure

floor floor

OF

IEWING

HEIGHT

8

Page 9

y

Securing the flat mount or tilt mount

To determine the desired viewing height, use the center slot opening in the wall mount as a center reference for the plasma television when mounted. Once the height is determined,

use the bubble level to insure that the bracket is level. Next, using a pencil, mark the four (4) lag bolt slot openings on the mounting bracket. Before continuing, confirm the marks are

located on the center of the studs.

Drill 1/4" pilot holes on the four (4) markings on the wall. Raise the universal flat or universal tilt bracket and have someone hold it in place (arrow side away from the wall and

pointing up). Put the lag bolt through the flat washers. Screw the lag bolt through the upper left slot opening into the 1/4" pilot hole. Confirm that the wall mount is still leveled and then

screw a lag bolt to the upper right side slot opening into the 1/4" pilot hole. Then install the remaining two lag bolts tightly into the wall studs in the lower left and right slot openings on

the wall mount.

Lateral movement of approximatel

1½" for final positioning is now possible. Make any positioning changes then secure the lag bolts. See fig 4.

Flat washers

Lag bolts

Universal flat

mount

Drill gun with a

1/4" drill bit

Marking on wall

Access holes

Wall structure

Wood studs behind

the wall structure

floor

floor

Electrical

Step 4

All electrical wiring components should be installed at this time to ensure that the plasma display has enough power sources.

9

Page 10

Securing the mount

A

p

Step 5

Warning: The plasma display is heavy and 2 people are needed to lift and install it. Failure to do so could result in serious personal injury.

Before placing the plasma on the wall recheck all hardware for proper tightness and security. Before installing, become familiar with the way the plasma mount attaches to the wall

mount. Align the four (4) tab openings to the four (4) receiving tabs on the flat back plate. When all four (4) the tabs are aligned slide the plasma down, right and down again to lock the

mounts together. Make sure all (4) tab openings are interlocked with the receiving tabs before letting go of the plasma. See fig 5.

Caution: The plasma display is heavy and 2 people are needed to lift and

install it. Failure to do so could result in serious personal injury.

PSM-series

mount

Tab openings

Universal flat

mount

Locked tab

Securing tabs

lign the tabs and

push the plasma

as shown on

arrows to lock in

Caution: All four (4) receiving tab openings from the

mounting bracket must be locked to the tabs found on

the flat back plate before letting go of the plasma

display. See the diagram on the left to see the

interlocked tab.

Plasma display

lace

Plasma display

Wall structure

Wall structure

Additional security (Does not apply to flat wall mounting)

Step 6

For additional security gradually tilt the bracket forward using a Phillips screwdriver. Secure the two (2) M6 x 12 (mm) Phillips screws (screws) see fig 6. Do not over tighten the screws.

Position the bracket to the desired angle.

10

Page 11

HARDWARE NOTICE

PANASONIC MODELS

PACK 2

USED ON THE FOLLOWING

MODELS

42" TH42PWD4UY, TH42PWD4EX,

PT42P1, 42PD2, TH42PWD3U,

TH42PHD5U, PT42PD4, PT42PHD4P,

TH42PWD5UY, TH42PW5UZ,

TH42PWD6UY

50" TH50PHD3U, PT50PD3P,

TH50PHD3E, TH50PHW3, TH50PD4,

TH50PHD5UY, 50PHW5UZ

PACK 28

USED ON THE FOLLOWING

MODELS

42" TH42PA20UP

If you have any questions contact

Page 12

NEW HARDWARE APPLIES TO

PLASMA MODELS:

Fujitsu 50" & 61"

5001, 5002, PDS6101, PDS6001,

PDS6002,P50XCA11UH

P50XCA10WH, P50XCA10HA

P50XCA10UH,P50XCA11WH

P50XCA11AH, P50XCA12WH

P50XCA12EH, P50XCA12AH

P50XCA12UH

Panasonic 42", 50"

TC42P1, PT42PD3P, PT42PD1P,

TC42P1F, PT37P1, TH42PWD3,

TH37PWD4UZ, TH42PWD4UY,

TH42PWD4EX, PT42P1, 42PD2,

TH42PWD3U, TH50PHD3U,

PT50PD3P, TH50PHD3E, TH50PHW3

Runco 42"

PL42cx,

Toshiba 42", 50"

50HP81, PD42W, PD42W1

ViewSonic 42"

VPW420,

Dwin 50"

HD50

JVC 50"

GDV500PZU

N E W H A R D W A R E

NOTICE APPLIES TO PCM (REV 8)

CTM (REV 8) / PSM / PRM MOUNTS.

Nylon sleeves

½" Nylon spacers

ASSEMBLED

CAUTION!

The nylon sleeves and ½” nylon spacers must ALWAYS be used in order to install plasma bracket on to the

plasma. Failure to do so will result in damaging the plasma internally. This application is required by the plasma

manufacture.

Loading...

Loading...