Page 1

Operating and Maintaining the P80 Console

Page 2

Page 3

Operating and Maintaining

the P80 Console

Page 4

Edition Information

OPERATING AND MAINTAINING THE P80 CONSOLE

P/N 301407-141 rev C

Copyright © June 2011 Precor Incorporated. All rights

reserved. Specifications subject to change without notice.

Trademark Note

Precor, AMT, and EFX are registered trademarks and Preva is

a trademark of Precor Incorporated. Other names in this

document may be the trademarks or registered trademarks of

their respective owners.

iPod® is a trademark of Apple Inc., registered in the U.S. and

other countries.

Made for iPod® means that an electronic accessory has been

designed to connect specifically to iPod and has been certified

by the developer to meet Apple performance standards.

Apple is not responsible for the operation of this device or its

compliance with safety and regulatory standards. Please note

that the use of this accessory with iPod may affect wireless

performance.

Made for iPod touch (4th generation), iPod touch (3rd

generation), iPod touch (2nd generation), iPod touch (1st

generation), iPod nano (6th generation), iPod nano (5th

generation), iPod nano (4th generation), iPod nano (3rd

generation), and iPod nano (2nd generation).

Page 5

Manufactured under license from Dolby Laboratories. Dolby

and the double-D symbol are trademarks of Dolby

Laboratories.

Intellectual Property Notice

All rights, title, and interests in and to the software of the

Preva Business Suite, the accompanying printed materials,

any copies of such software, and all data collected via the

Preva Business Suite, are exclusively owned by Precor or its

suppliers, as the case may be.

Precor is widely recognized for its innovative, award-winning

designs of exercise equipment. Precor aggressively seeks U.S.

and foreign patents for both the mechanical construction and

the visual aspects of its product design. Any party

contemplating the use of Precor product designs is hereby

forewarned that Precor considers the unauthorized

appropriation of its proprietary rights to be a very serious

matter. Precor will vigorously pursue all unauthorized

appropriation of its proprietary rights.

Precor Incorporated

20031 142nd Ave NE, P.O. Box 7202

Woodinville, WA 98072-4002

1-800-347-4404

http://www.precor.com

Page 6

Page 7

Important Safety Instructions

This apparatus (hereinafter referred to as the console) is

intended to be shipped with new Precor exercise equipment

(hereinafter referred to as the base unit). It is not packaged

for individual sale.

WARNING

Safety Precautions

Read all instructions in the documentation provided with your

exercise equipment before installation of this device including

all assembly guides, user guides, and owner’s manuals.

Always follow basic safety precautions when using this

equipment to reduce the chance of injury, fire, or damage.

Other sections in this manual provide more details of safety

features. Be sure to read these sections and observe all safety

notices. These precautions include the following:

y Read all instructions in this guide before installing and

using the equipment and follow any labels on the

equipment.

y Make sure all users see a physician for a complete

physical examination before they begin any fitness

program.

To prevent injury, the console must be

attached securely to the base unit following all

assembly and installation instructions shipped

with the base unit. The console is intended to

be connected to AC mains power through the

furnished power supply ONLY. It should be

powered on only when installed as described

in the assembly and installation instructions

shipped with the base unit. The console is

intended for use only with Precor fitness

equipment, not as a standalone device.

Page 8

6 Operating and Maintaining the P80 Console

y Il est conseillé de subir un examen médical complet avant

d’entreprendre tout programme d’exercise. Si vous avez des

étourdissements ou des faiblesses, arrêtez les exercices

immédiatement.

y Do not allow children, or people unfamiliar with the

operation of this equipment, on or near it. Do not leave

children unsupervised around the equipment.

y Make sure all users wear proper exercise clothing and

shoes for their workouts and avoid loose or dangling

clothing. Users should not wear shoes with heels or

leather soles, and they should check the soles of their

shoes to remove any dirt and embedded stones. They

should also tie long hair back.

y Never leave the equipment unattended when it is plugged

in. Unplug the equipment from its power source when it is

not in use, before cleaning it, and before providing

authorized service.

Note: The optional power adapter is considered a power

source for self-powered equipment.

y Use the power adapter provided with the equipment. Plug

the power adapter into an appropriate, grounded power

outlet as marked on the equipment.

y Care should be taken when mounting or dismounting the

equipment.

y Read, understand, and test the emergency stop

procedures before use.

y Keep the power cord or optional power adapter and plug

away from heated surfaces.

y Route power cables so that they are not walked on,

pinched, or damaged by items placed upon or against

them, including the equipment itself.

y Ensure the equipment has adequate ventilation. Do not

place anything on top of or over the equipment. Do not

use on a cushioned surface that could block the

ventilation opening.

y Assemble and operate the equipment on a solid, level

surface.

Page 9

Important Safety Instructions 7

y Proper Location for Equipment

à For all equipment other than treadmills: Locate at

least 40 inches (1 meter) away from walls or

furniture on either side of the equipment, and 40

inches (1 meter) away from objects behind the

equipment.

à For treadmills: Locate at least 40 inches (1 meter)

away from walls or furniture on either side of the

treadmill, and at least 80 inches (2 meters) away

from objects behind the treadmill.

Important: These location standards should also be used

when positioning equipment away from sources of heat, such

as radiators, heat registers, and stoves. Avoid temperature

extremes.

y Keep equipment away from water and moisture. Avoid

dropping anything on or spilling anything inside the

equipment to prevent electric shock or damage to the

electronics.

y When using the treadmill, always attach the safety clip to

your clothing before beginning your workout. Failure to

use the safety clip may pose a greater risk of injury in the

event of a fall.

y Do not operate electrically powered equipment in damp

or wet locations.

y Never operate this equipment if it has a damaged cord or

plug, if it is not working properly, or if it has been dropped,

damaged, or exposed to water. Call for service

immediately if any of these conditions exist.

y Maintain the equipment to keep it in good working

condition, as described in the Maintenance section of the

assembly and maintenance guide. Inspect the equipment

for incorrect, worn, or loose components, and then

correct, replace or tighten prior to use.

y If you plan to move the equipment, obtain help and use

proper lifting techniques.

y Equipment Weight Restrictions: Do not use the treadmill

if you weigh more than 500 pounds (225 kg). If you weigh

more than 350 pounds (160 kg), do not run on the

treadmill. For all other fitness equipment, the weight limit

is 350 pounds (160 kg).

Page 10

8 Operating and Maintaining the P80 Console

y Use the equipment only for its intended purpose as

described in this manual. Do not use accessory

attachments that are not recommended by Precor. Such

attachments may cause injuries.

y Do not operate the equipment where aerosol (spray)

products are being used or where oxygen is being

administered.

y Do not use outdoors.

y Do not attempt to service the equipment yourself, except

to follow the maintenance instructions in this manual.

y Never drop or insert objects into any opening. Keep hands

away from moving parts.

y Do not set anything on the stationary handrails,

handlebars, control console, or covers. Place liquids,

magazines, and books in the appropriate receptacles.

y Do not lean on or pull on the console at any time.

CAUTION: DO NOT remove the cover, or you may risk injury due

to electric shock. Read the assembly and maintenance guide

before operating. There are no user-serviceable parts inside.

Contact Customer Support if the equipment needs servicing. For

use with single phase AC power only.

Hazardous Materials and Proper Disposal

The batteries within self-powered equipment contain

materials that are considered hazardous to the environment.

Federal law requires proper disposal of these batteries.

If you plan to dispose of your equipment, contact Precor

Commercial Products Customer Support for information

regarding battery removal. Refer to Obtaining Service.

Page 11

Important Safety Instructions 9

Product Recycling and Disposal

This equipment must be recycled or disca

applicable local and national regulations.

rded according to

Product labels, in accordance with Europe

an Directive

2002/96/EC concerning waste electrical and electroni

equipment (WEEE), determine the framework for the retu

and recycling of used equipment as applicable throughout the

European Union. The WEEE label indicates that the product is

not to be thrown away, but rather reclaimed upon end of life

per this Directive.

In accordance with

the European WEEE Directive, electrical

and electronic equipment (EEE) is to be collected separately

and to be reused, recycled, or recovered at end of life. Users

of EEE with the WEEE label per Annex IV of the WEEE

Directive must not dispose of end of life EEE as unsorte

municipal waste, but use the collection framework availabl

to customers for the return, recycling, and recovery of WEEE.

Customer participation is important to minimize any potential

effects of EEE on the environment and human health due to

the potential presence of hazardous substances in EEE. For

proper collection and treatment, refer to

Obtaining Service.

Regulatory Notices for the RFID Module

When equipped with a control console as described in t

document, this equipment may include a radio-frequency

identification (RFID) module. The RFID module has been

certified to operate at temperatures between -20°C and 8

(-4°F and 185°F).

c

rn

d

e

his

5°C

Radio Frequency Interference (RFI)

The RFID module conforms to th

standards defining acceptable limits for radio frequen

interference (RFI).

Federal Communications Commission, Part 15

This equipment has been tested and found to comply with th

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a commercial

installation. The equipment generates, uses, and can radi

radio frequency energy and, if not installed and used in

accordance with the owner’s manual instructions, can c

harmful interference to radio communications.

e following national

cy

e

ate

ause

Page 12

10 Operating and Maintaining the P80 Console

Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this

device must accept any interference received, including

interference that may cause undesired operation.

WARNING

Industry Canada

This device complies with RSS-210:2007 of the Spectrum

Management & Telecommunications Radio Standards

Specification. Operation is subject to the following two

conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference

received, including interference that may cause undesired

operation.

This Class A digital apparatus complies with Canadian

ICES-003.

Cet appareil numérique de la classe A est conforme à la norme

NMB-003 du Canada.

ATTENTION: Haute Tension

Débranchez avant de réparer

European Applications

CE compliance is claimed to the following directives:

Per FCC rules, changes or modifications not

expressly approved by the manufacturer could

void the user’s authority to operate the

equipment.

y 1999/5/EC R&TTE Directive

y 2006/95/EC LVD Directive

y 2002/95/EC RoHS Directive

Directive compliance has been verified to the following

standards:

y EN 55022

y EN 300 330-1 V1.5.1

y EN 300 330-2 V1.3.1

y EN 301 489-3 V1.4.1

y EN 301 489-1 V1.8.1

y EN 60950-1

Page 13

Important Safety Instructions 11

Regulatory Notices for Cardiovascular Exercise Equipment

The regulatory information in this section applies to the

Safety Approvals for Cardiovascular Equipment

exercise equipment and its control console.

Precor equipment has been tested and found to comply with

the following applicable safety standards.

Cardiovascular Type Equipment:

y CAN/CSA, IEC, EN 60335-1 (Household and similar

electrical appliances - Safety)

y EN 957 (Stationary training equipment, class S/B

compliant equipment)

PVS and P80 Regulatory Notice

This Precor equipment has been tested and found to comply

with the following applicable safety standards.

y CAN/CSA, UL, IEC, EN 60065 (Audio, video and similar

electronic apparatus - Safety)

Radio Frequency Interference (RFI)

This Precor exercise equipment conforms to the following

national standards defining acceptable limits for radio

frequency interference (RFI).

Federal Communications Commission, Part 15

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a commercial

installation. The equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in

accordance with the owner’s manual instructions, may cause

harmful interference to radio communications.

WARNING

Per FCC rules, changes or modifications not

expressly approved by Precor could void the

user’s authority to operate the equipment.

Page 14

12 Operating and Maintaining the P80 Console

Industry Canada

This Class A digital apparatus complies with Canadian

ICES-003.

Cet appareil numérique de la classe A est conforme à la norme

NMB-003 du Canada.

ATTENTION: Haute Tension

Débranchez avant de réparer

European Applications

CE compliance is claimed to the following directives:

y 2004/108/EC EMC Directive

y 2006/95/EC LVD Directive

y 2002/95/EC RoHS Directive

Directive compliance has been verified to the following

standards:

y EN 55022

y EN 55024

y EN 60335-1

y EN 60065 (P80 and PVS)

Page 15

Important Safety Instructions 13

Electrical Recommendations: 120 V and 240 V Treadmills

Note: This is a re

Code) guidelines or local region electric codes must be

followed.

commendation only. NEC (National Electric

You shoul

d have received a power cable that meets your local

electrical code requirements along with the equipment.

Precor treadmills must be connected to a 20 amp individ

ual

branch circuit that can be shared only with one PVS. If you

need additional help with the power connections contact yo

ur

Precor authorized dealer.

Important: An individual br

anch circuit provides a hot conductor

and neutral conductor to a receptacle. The conductors must not be

looped, "daisy-chained", or connected to any other conductors.

The circuit must be grounded according to NEC guidelines or loc

al

region electric codes.

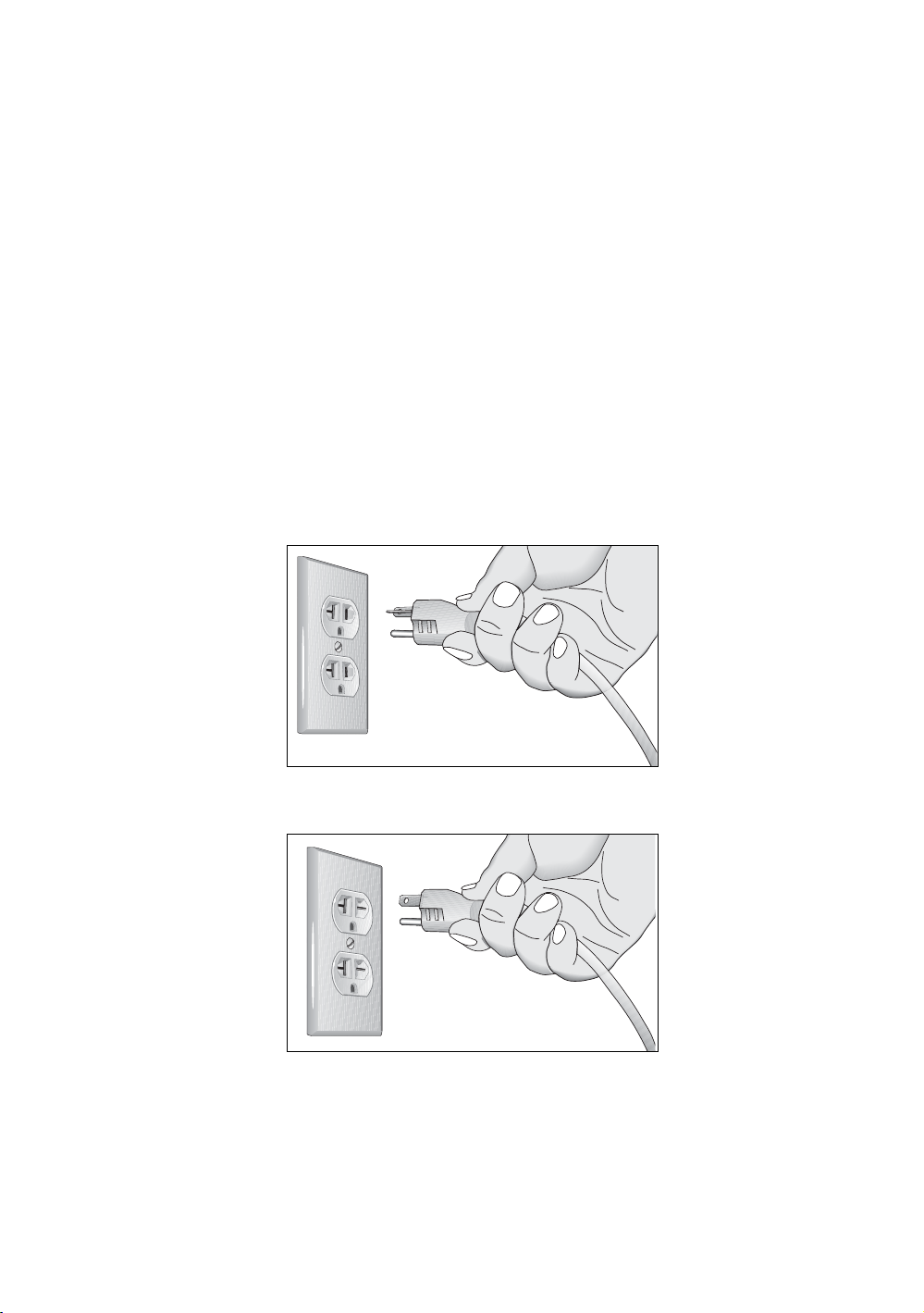

Figure 1: North American 120-volt, 20-amp pow r receptacle e

Figure 2: North American 240-volt, 20-amp power receptacle

Page 16

14 Operating and Maintaining the P80 Console

Electrical Recommendations: All Equipment Excluding Treadmills

Note: This is a recommendation only. NEC (National Electric

Code) guidelines or local region electric codes must be

followed.

For equipment fitted with a P80 console or Personal Viewing

System (PVS) screen a separate power connection is

required. For a 20 amp branch circuit up to 10 screens can be

connected. If the branch circuit has any other devices plugged

into the circuit the number of screens must be reduced by the

wattage of the other devices.

Note: The typical splitter power cords that have IEC-320 C13

and C14 plugs have a recommended maximum capacity of

five screens.

Figure 3: IEC-320 C13 and C14 plugs

Obtaining Service

Do not attempt to service the equipment except for

maintenance tasks. If any items are missing, contact your

dealer. For more information regarding customer support

numbers or a list of Precor authorized service centers, visit

the Precor web site at http://www.precor.com.

For the most current manuals, got to http://www.precor.com.

Page 17

Table of Contents

Important Safety Instructions ................................................... 5

Safety Precautions ................................................................................ 5

Hazardous Materials and Proper Disposal .................................... 8

Product Recycling and Disposal........................................................ 8

Regulatory Notices for the RFID Module ....................................... 9

Regulatory Notices for Cardiovascular

Exercise Equipment ...................................................................... 11

Electrical Recommendations:

120 V and 240 V Treadmills ..................................................... 12

Electrical Recommendations:

All Equipment Excluding Treadmills ....................................... 14

Obtaining Service ................................................................................. 14

Getting Started .........................................................................17

Identifying Parts of the Console ....................................................... 18

Using the Treadmill Safety Clip ....................................................... 18

Treadmill Auto Stop™ (Automatic Stop) Function ................... 20

Configuring the System Settings ............................................. 23

About ..................................................................................................... 24

Equipment Usage ................................................................................ 26

System Settings ................................................................................... 27

Introducing Users to the P80 Console .................................... 35

Using the Touch Heart Rate Feature ............................................. 35

Using a Chest Strap Transmitter .................................................... 37

Using the View Channels and View Buttons ............................... 37

Using the Media Panel....................................................................... 39

Using the Workout Progress Panel ............................................... 40

Beginning Your Workout ......................................................... 43

Starting a QuickStart™ Workout .................................................... 43

Starting a Featured Workout .......................................................... 44

Starting a Preset Workout ............................................................... 44

Ending a Workout ............................................................................... 45

Maintenance ............................................................................ 51

Cleaning the Console and Display .................................................. 51

Page 18

16 Operating and Maintaining the P80 Console

Page 19

Getting Started

Important: Not all settings are currently available in this

release. More features will be available in future software

updates.

The P80 console offers administrators and users the ability to

set default settings that meet their specific needs. To

accomplish this, the console supports settings for different

classes of users depending on their administrative rights.

Chapter 1

y A guest user exercises on a piece of equipment without

signing in or creating a user profile.

y A registered user uses a sign-in password or Preva™

Pass and creates a user profile.

y A registered service technician uses a sign-in password

or Preva™ Pass with extra permissions to administer

console settings.

y An administrator is always registered, uses a sign-in

password or Preva™ Pass, and has full access to the

console settings.

Changes to the Personal Information and Preference settings

are saved to a registered user’s profile. An unregistered user

can change preference settings; however, because they lack a

user profile, those changes are not saved, and apply only to

their current workout.

Page 20

18 Operating and Maintaining the P80 Console

Before beginning any tness program, see your physician for a thorough physical examination. Seek advice from your physician to learn your the target heart rate appropriate fo r your tness level. Do not allow children,

or those

unfamiliar with its the operation on or near of this equipment, on or near it. Read the product owner’s manual or consult a qualied instructor before operating this equipment. Improper use of this equipment can result in serious injury. If you

feel pain, faintness, or dizziness, stop exercising immediately.

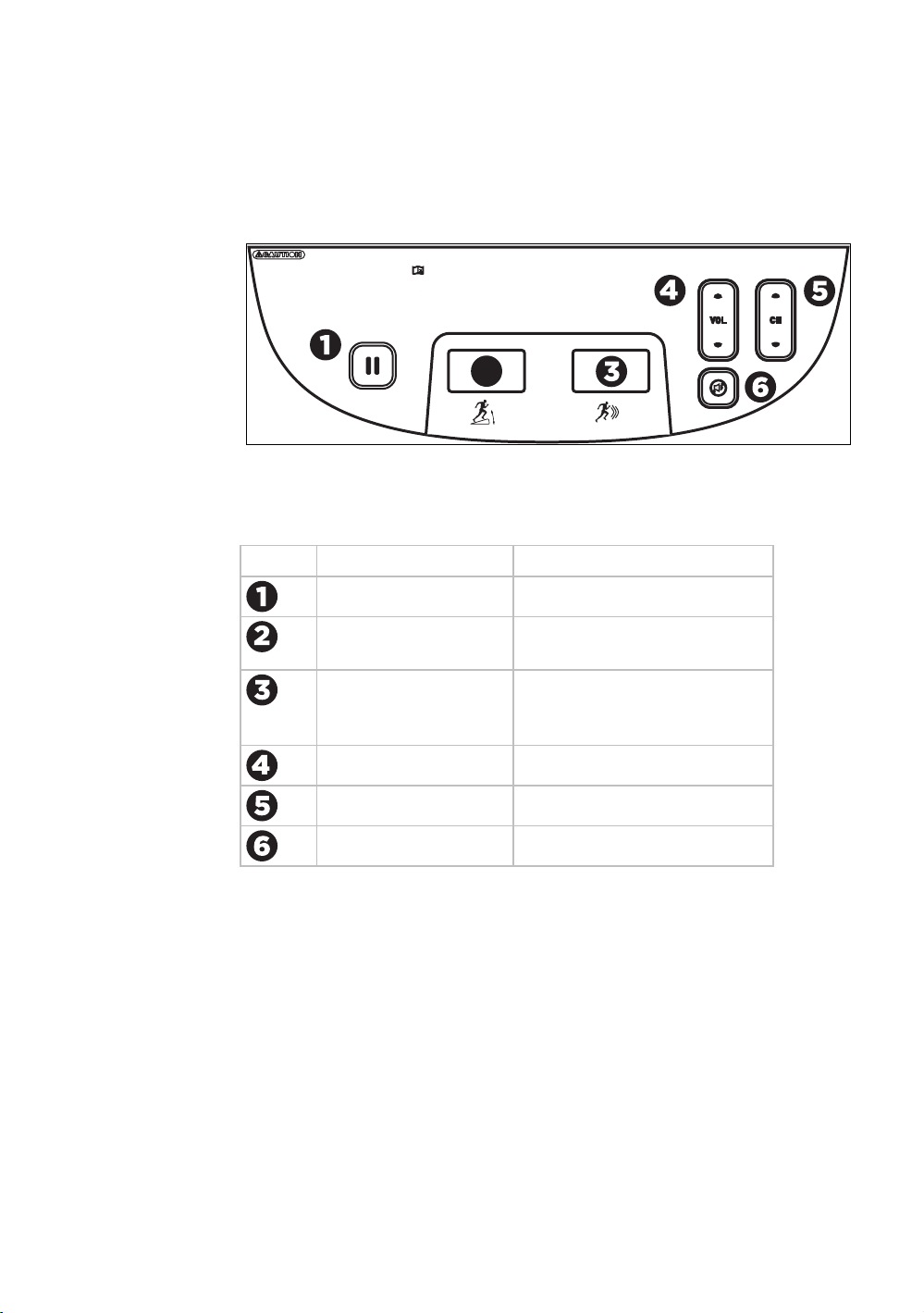

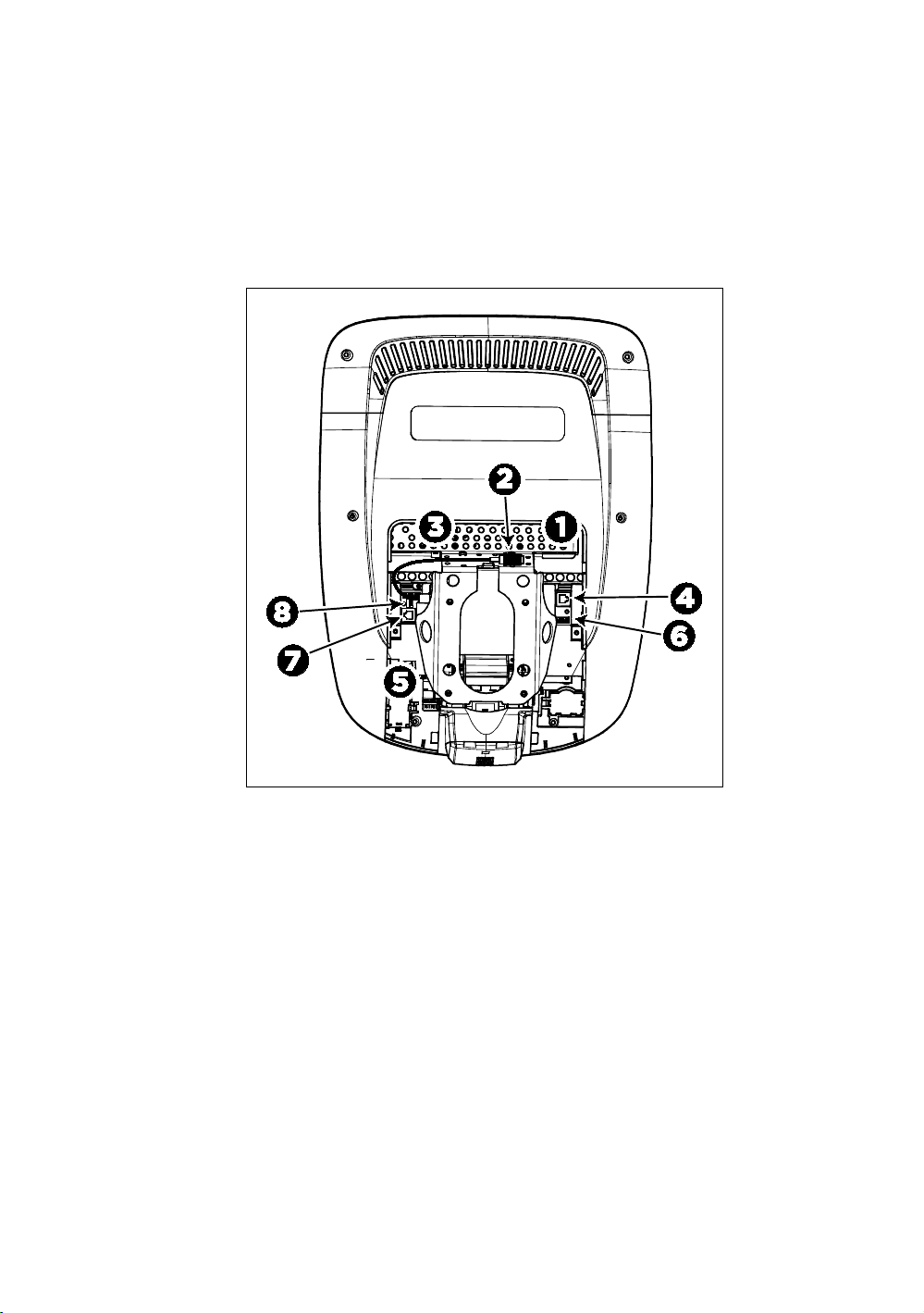

Identifying Parts of the Console

The following diagram provides information about the console

keys. The number and actions of the console keys may differ

slightly depending on the type of equipment.

Before beginning any tness program, see your physician for a thorough physical examination. Seek advice from your physician to learn your the target heart rate appropriate fo r your tness level. Do not allow children,

unfamiliar with its the operation on or near of this equipment, on or near it. Read the product owner’s manual or consult a qualied instructor before operating this equipment. Improper use of this equipment can result in serious injury. If you

feel pain, faintness, or dizziness, stop exercising immediately.

2

Figure 4: P80 console keys

Table 1. Key descriptions for the P80 console

Number Key Name Detail

Pause Stop the equipment

or those

Incline/CrossRamp®

Indicator

Intensity Indicator Also called Speed or Resistance

Appears on treadmill and

elliptical

indicator depending on

equipment type

Volume Up/Down Increase or decrease volume

Channel Up/Down Change TV channel

Mute Turn the volume on or off

Page 21

Getting Started 19

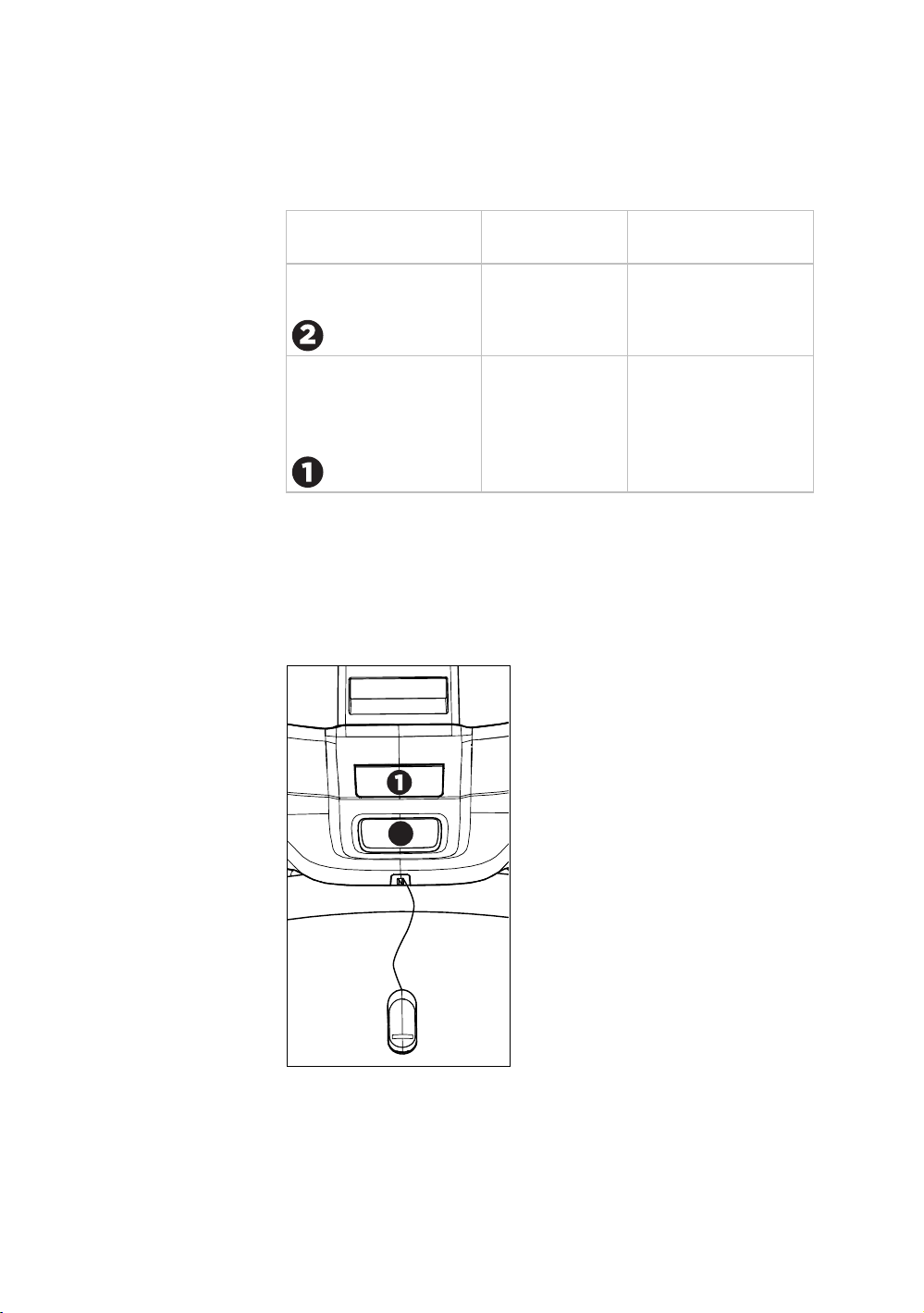

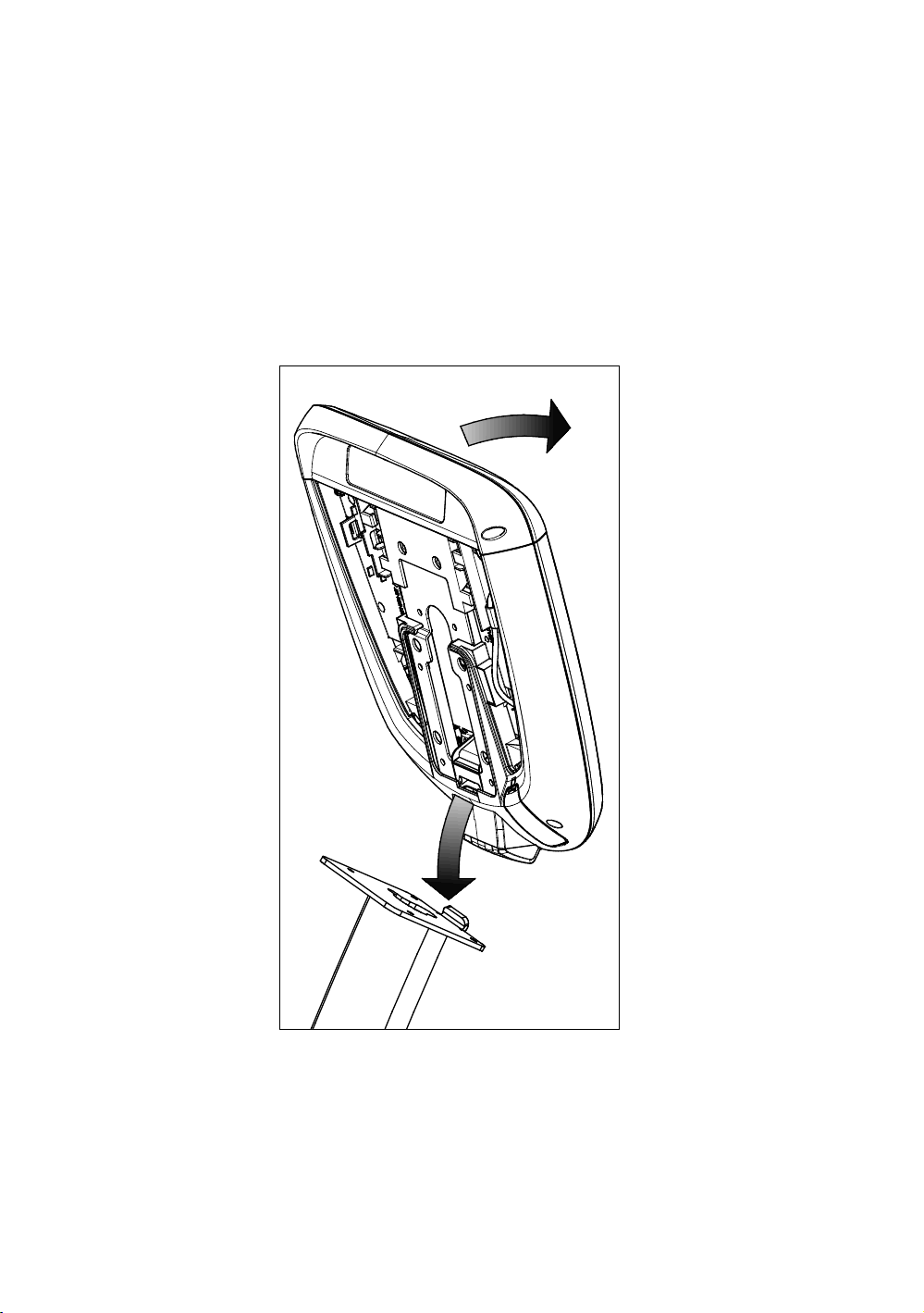

Using the Treadmill Safety Clip

The treadmill is equipped with two diffe

which behave as follows:

If the user … Then the treadmill And the console …

belt …

Presses down on the

red STOP button

Slows to a stop Shows that the

rent stop functions,

t is exercise workou

paused

Pulls on the lanyard

attached to the safety

clip and trips the restar

switch

Slows to a stop Shows the words

t

PUSH TO RESET

SWITCH and an a

pointing to the Restart

switch

The restart switch is located just below the console and

immediately behind the red STOP button, as shown in th

e

following illustration. When it is tripped, the bar pops up,

displaying the words PUSH TO RESET SWITCH on its fron

side. The treadmill does not operate while these words are

visible.

2

rrow

t

Figure 5: Restart switch

Instruct users on how important it is to use the safety clip

y while exercising on the treadmill, and demonstrate how the

should attach it to their clothing near the waistline.

Page 22

20 Operating and Maintaining the P80 Console

If the restart switch trips during exercise, perform the

following steps:

1. Reattach the safety clip if necessary.

2. Press the restart switch down until it clicks, returning it to

its normal position.

Note: If the restart switch trips, all information about the

current workout is deleted.

3. Start the workout from the beginning, reducing the time

as needed to account for the amount of exercise that has

been completed.

Figure 6: Attaching the safety clip

Page 23

Getting Started 21

Treadmill Auto Stop™ (Automatic Stop) Function

portant: The default setting for this feature is ON. An

Im

administrator can turn off this feature in the System Settin

however, Precor recommends it remain ON.

gs;

The Auto Stop™ (Automatic Stop) feature

bring the treadmill to a gradual stop when it is not in use. T

might occur if a user steps off the treadmill before the end of

a workout and leaves the treadmill running.

Sixty seconds after a treadmill workout start

equipment begins Auto Stop monitoring. If a user is detected,

then no message appears, and the selected workout

continues.

If no user is d

console displays the message NO USER DETECTED,

STOPPING IN 10 SECONDS as notification of the pen

stop. During the display of this message, a ten second

countdown begins. If a user does not override the coun

the belt comes to a gradual stop after the countdown is

complete.

Note: User

detected within the speed and position limits of the featu

Users weighing 50 pounds (22.7 kg) to 89 pounds (40.5 kg)

may not be detected depending on their speed and location.

Always be aware of and follow the console’s instructions for

proper operation.

etected after an additional 30 seconds, the

s weighing more than 90 pounds (41 kg) are

is designed to

his

s or resumes, the

ding

tdown,

re.

Page 24

22 Operating and Maintaining the P80 Console

Page 25

Chapter 2

Configuring the System Settings

Use the System mode to configure settings in ways that

benefit your users and your facility. The System menu is

visible only to administrators and registered service

technicians. Changes made to these settings are saved to the

fitness equipment.

Important: A special code is required to access these settings. Do

not share this code with anyone except those authorized to

change system settings.

The System menu contains the following settings:

y About

y Equipment Usage

y System Settings

Page 26

24 Operating and Maintaining the P80 Console

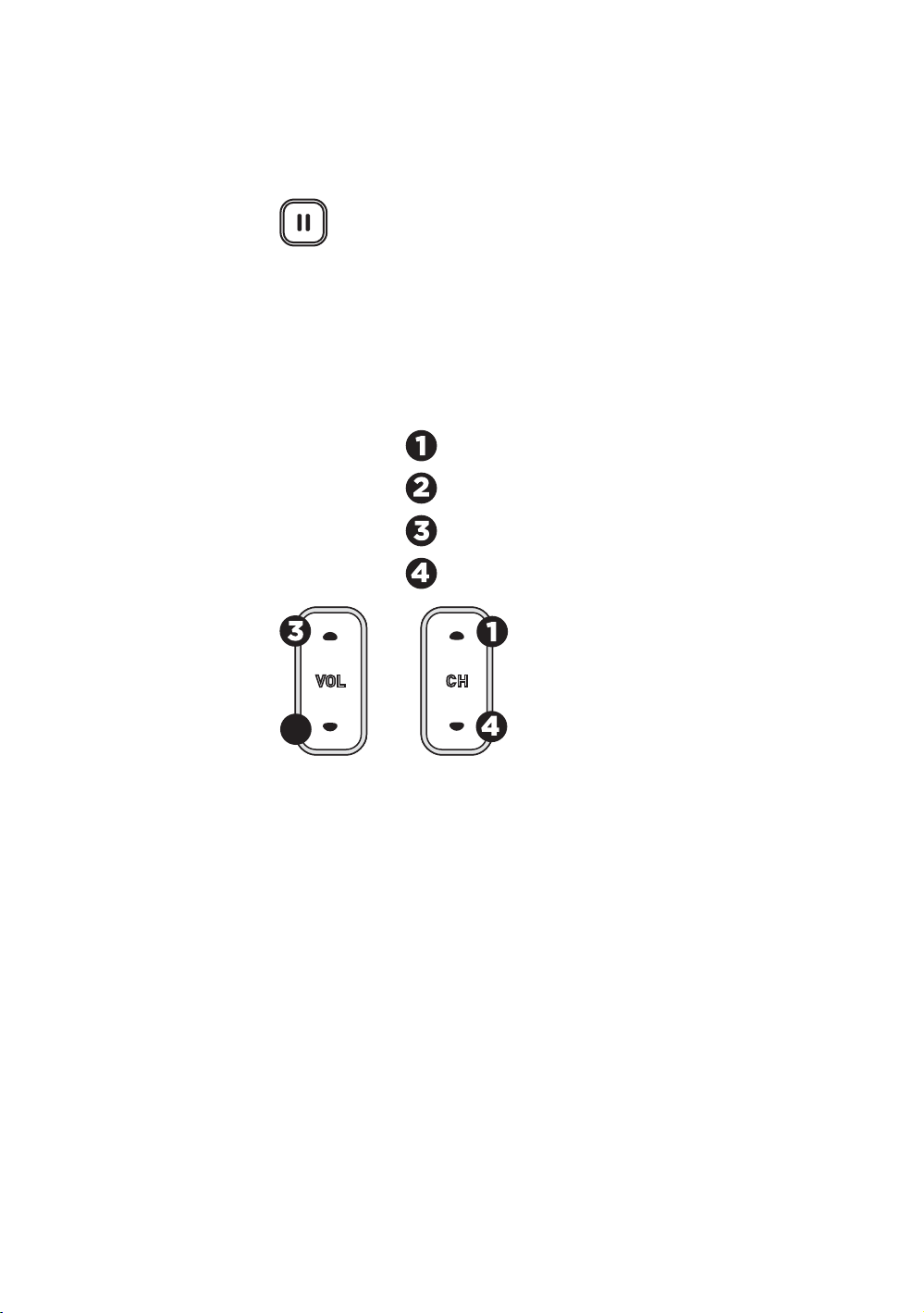

To view the System menu:

1. On the Welcome screen, press and hold Pause.

Figure 7: Pause key

2. While holding Pause, press each of the following keys

once in the order presented. Referring to the diagram

below, press:

1 2 3 4

Channel Up

Volume Down

Volume Up

Channel Down

2

Figure 8: Settings security code

3. Release Pause.

4. Using the number pad on the screen, touch the following

numbers to enter the password:

5 6 5 1 5 6 5

5. Touch OK.

Page 27

Configuring the System Settings 25

About

System information settings provide basic information

including equipment models and serial numbers. Most o

these settings are for informational purposes only and can

be modified.

To view the System Info settings menu:

1. Use the administrator code and passw

ord to view the

equipment settings.

2. Touch About.

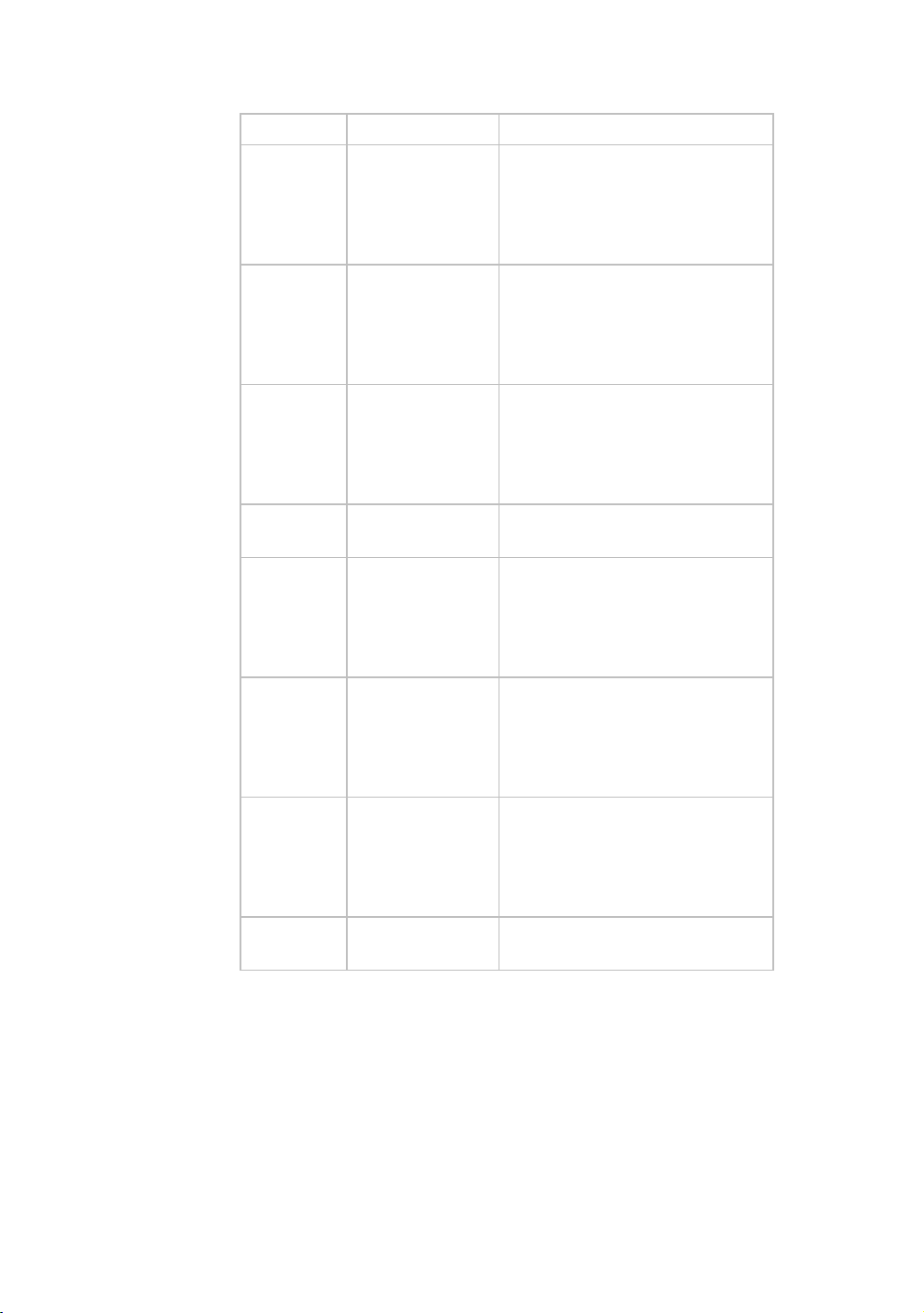

Table 2. About settings

Setting Access Detail

Event Log ech: s a list of the most recent

Event Count Admin/Tech: vents recorded by

Console Tech: console’s memory.

Serial

Number

Lower Serial Admin/Tech: Stored in the console’s memory.

Number View

Location Admin/Tech: Entered on console at time of

Release

Bundle

Version

ETag Check Only Precor

Interval

Admin/T

View

View

Admin/

View

View

Modify

Admin/T

View

service

technicians

modify this

setting.

ech: Shows current version and a list of

Provide

hardware and software events,

and equipment status. If no

events have occurred since t

last time the event log was

cleared, the event log screen

be empty.

Number of e

equipment.

Stored in the

registration.

past software updates.

Automatically updates a

each software upgrade.

Stored in the console’s m

can

f

not

he

will

s part of

emory.

Page 28

26 Operating and Maintaining the P80 Console

Setting Access Detail

Heartbeat

Interval

Minimum

Heartbeat

Interval

Maximum

Heartbeat

Interval

Mfe MAC

Address

Network

Time Server

1

Network

Time Server

2

Network

Time Server

3

Machine

Type

Only Precor

service

technicians can

modify this

setting.

Only Precor

service

technicians can

modify this

setting.

Only Precor

service

technicians can

modify this

setting.

Admin/Tech:

View

Only Precor

service

technicians can

modify this

setting.

Only Precor

service

technicians can

modify this

setting.

Only Precor

service

technicians can

modify this

setting.

Admin/Tech:

View

Determines how often the

console communicates with the

server.

Minimum number of times that

the console communicates with

the server in a given time period.

Maximum number of times that

the console communicates with

the server in a given time period.

Stored in the console’s memory.

Type of equipment.

Equipment Usage

The Equipment Usage settings provide information on

individual usage as well as cumulative equipment usage. This

information and these settings are accessible only to

administrators and registered service technicians.

Page 29

Configuring the System Settings 27

To view the Usage settings:

1. Use the administrator code and password to view the

equipment settings.

2. Touch Equipment Usage.

Table 3. Equipment Usage settings

Setting Access Detail

Cumulative

Workout

Seconds

Cumulative

Workout

Distance

Cumulative

Workout

Sessions

Last Workout

Start Date Time

Last Workout

End Date Time

Admin/Tech:

View

Admin/Tech:

View

Admin/Tech:

View

Admin/Tech:

View

Admin/Tech:

View

Total number of seconds.

Seconds are counted when the

workout clock starts.

• Treadmills will report miles of

use.

• AMTs will report a

"horizontal distance" as

miles.

• Ellipticals will convert total

strides to miles.

• Bikes will convert total

revolutions to miles

Total number of sessions. A

session is counted if the

summary screen displays.

The date of the start of the last

workout.

The date of the end of the last

workout.

System Settings

Use the System Settings to test your equipment and set

parameters that benefit your users and your facility. The

System Settings menu is visible only to administrators and

registered service technicians.

The System Settings menu contains the following sections:

y Connectivity

y Display

y TV Settings

y Workout Limits

y Manage Settings

Page 30

28 Operating and Maintaining the P80 Console

Connectivity

Configuring your audio, video, and network infrastructure

requires expertise. Precor strongly recommends that you

work with a qualified contractor to set up this infrastructure.

This setting provides the following information:

y Network Type

y Configuration

y Status

y IP Address

y Preva Server

To view connectivity information:

1. Use the administrator code and password to view the

equipment settings.

2. Touch System Settings, then touch Connectivity.

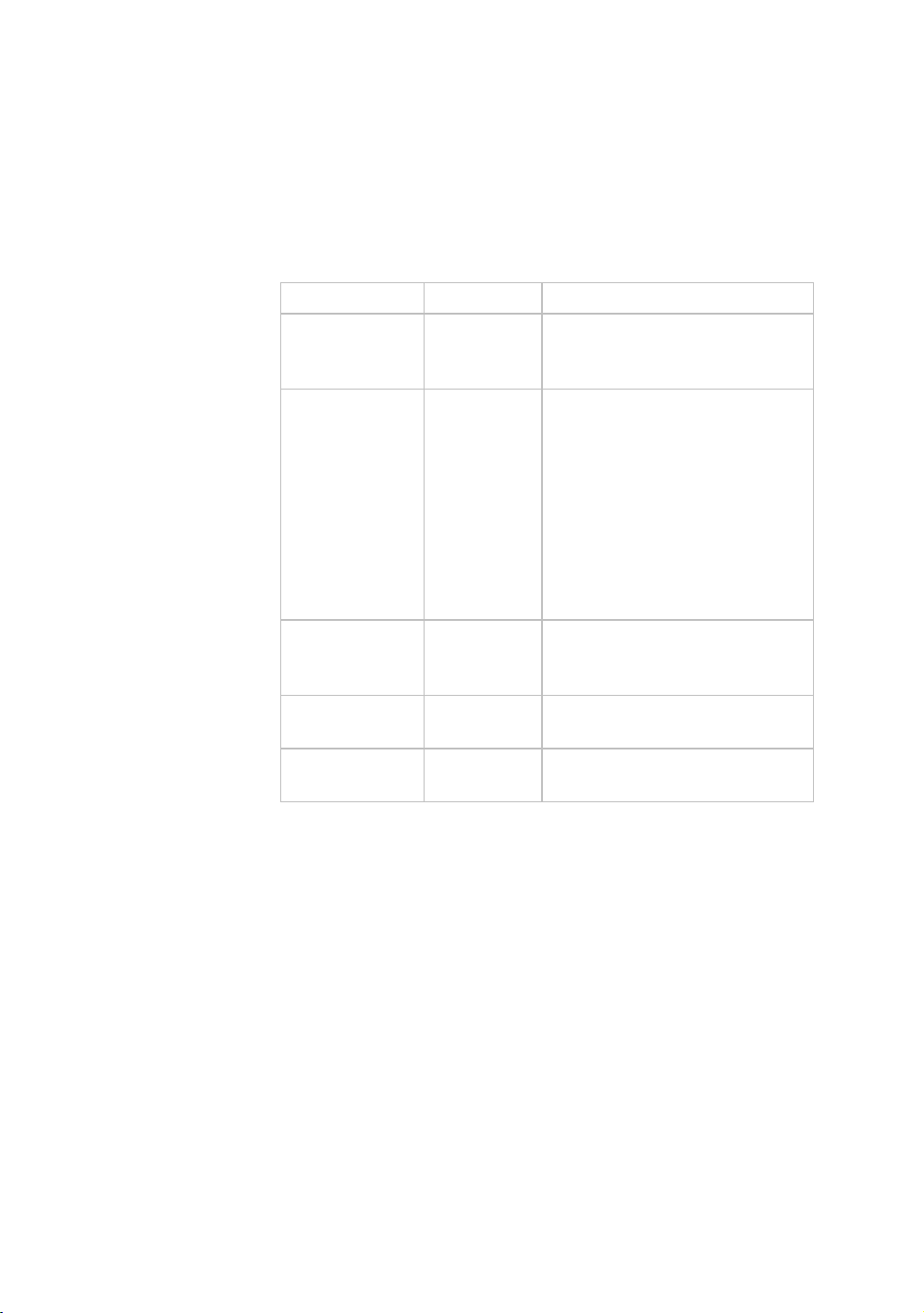

Table 4. Connectivity settings

Settings Default Detail

Network Type Wired

Configuration Automatic Automatic or Manual

Press Network Settings to

view the

• IP Address

• Netmask

• Gateway

• DNS Primary

• DNS Secondary

Status

IP Address

Preva Server

Connected or Not Connected

Location-specific

URL region-specific

Page 31

Configuring the System Settings 29

Display

These settings are configurable per console, but can also be

configured using Preva™ Business Suite. The equipment mus

be inactive before you can change the display settings. Fitness

equipment is defined as inactive if all of the following

conditions are true:

t

y No registered us

y The frame parts of the equipment ar

ers have logged in.

e not moving.

y The touch screen has detected no input.

y No buttons have been pressed.

To view the Display settings:

1. Use the administrator code

equipment settings.

2. Touch System Settin

Table 5. Display settings

Setting Setting Default

Options Value

Measurement rd dard

Units

Standby Mode inutes

Delay

Time Zone

Closed Captioning ON ON / OFF

US Standa

Metric

• 5 M

• 15 Minutes

• 30 Minutes

• 60 Minutes

GMT —12

through

GMT + 12

and password to view the

gs, then touch Display.

US Stan

15 Minutes

GMT-06 Pacific Time

(US & Canada)

Page 32

30 Operating and Maintaining the P80 Console

TV Settings

Settings help you set up television channels for your users.

TV

The TV Settings are:

y Channel Guide

y Region

y Default Ch

y Skip Unnamed Ch

To view TV Setting information:

1. Use the administrator code an

equipment settings.

2. Touch System Settin

3. Touch Display, then touc

annel

annels

d password to view the

gs.

h Channel Guide.

Channel Guide

You can set up the c

ways:

hannels in either or both of the following

y Sca

n for available channels.

y Add channels manually.

The following procedures dis

guide and how to configure audio and video playback.

To scan for available channels:

1. Touch System Settings.

2. On the System Settings m

TV Settings.

3. Touch Channe

The console scans available channels, and all avai

channels display on the screen.

To add a channel in the Channel Guide:

1. On the Channel Guide screen, touch Add Channel

2. On the Add Channel screen, select the number of th

channel.

3. Type the

box.

4. Touc

h OK as needed to return to the desired screen.

l Guide, then touch Scan Channel.

name of the new channel in the Channel Name

cuss how to set up the channel

enu, touch Display, then touch

lable

.

e new

Page 33

Configuring the System Settings 31

To delete a channel from the Channel Guide:

1. On the Channel Guide screen, touch the listing for the

channel you want to delete.

2. Touch the Delete button that appears next to the listing.

3. When asked “Are you sure?", verify that you want to

proceed, then touch Yes.

Table 6. TV Settings

Settings Default Detail

Channel

Guide

Region United

Default

Channel

Skip Unnamed

Channels

States

Scan channels

Select the appropriate region for your

location

Set a default channel for the equipment.

This is the channel that will display when

the TV is turned on.

ON/OFF

Workout Limits

Important: Not all settings are currently available in this

release. More features will be available in future software

updates.

The Workout Limit settings give you control over how the

equipment is used. Use these settings to create reasonable

limitations for equipment usage including speed, incline,

resistance, and duration.

In general, fitness equipment use is based on its popularity

with users, and its availability during a site’s busiest times of

day. Settings to enforce time limits will help locations restrict

user usage during the busiest hours to provide more access to

equipment for more users.

Page 34

32 Operating and Maintaining the P80 Console

Workout Limit settings are not associated with or saved as

part of a user profile and users do not have access to them.

Both administrators and service technicians have view and

modify access rights.

To modify the Workout Limits settings:

1. Use the administrator code and password to view the

equipment settings.

2. Touch System Settings, then touch Workout Limits.

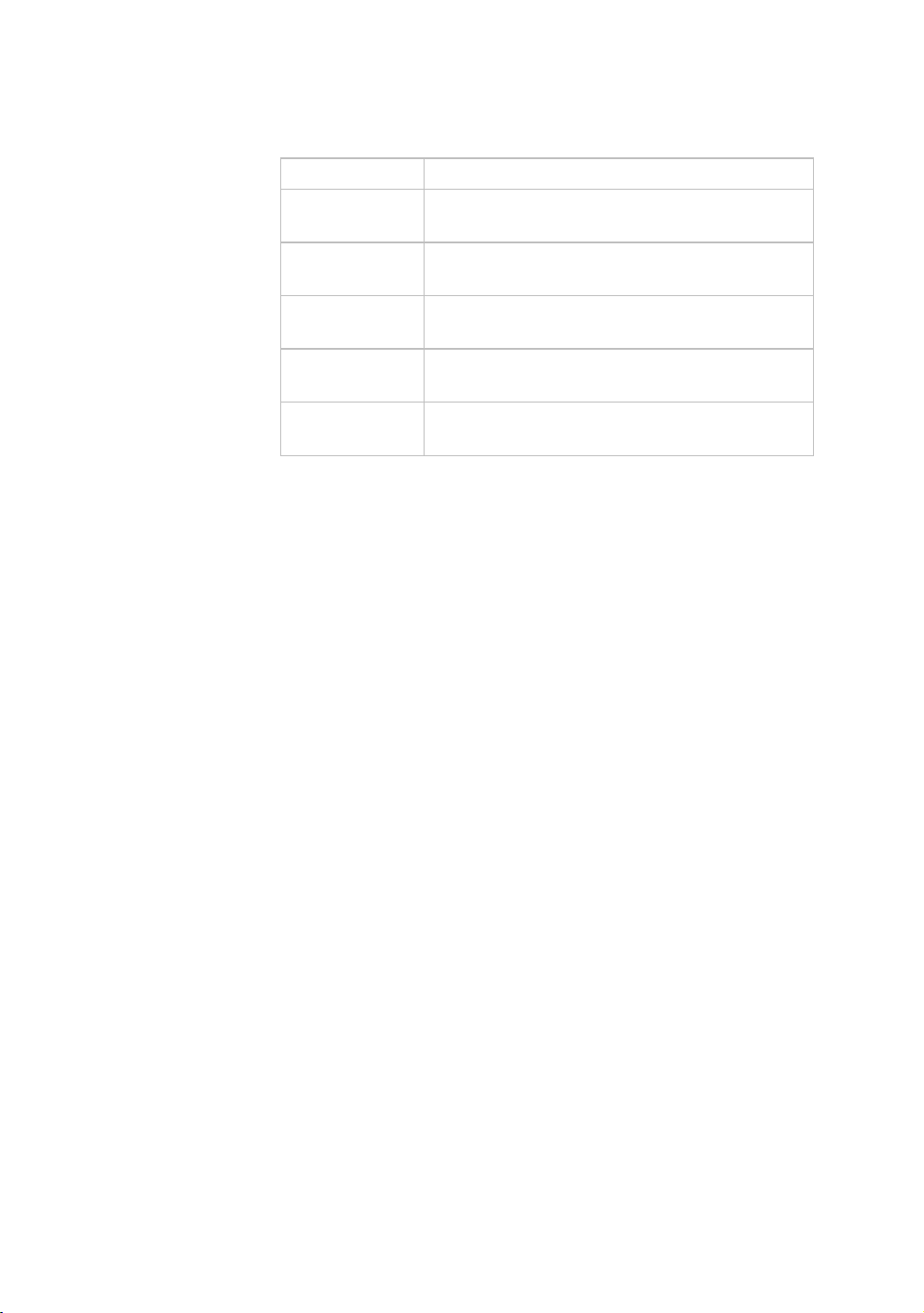

Table 7. Workout Limits settings

Setting Name Setting Options Default Value

Maximum Workout

Duration

Maximum Pause • 1 second

Summary Time Out • No Time Out

Resistance Range • Low

Speed Limit

(Treadmill)

Incline Limit

(Treadmill)

Autostop • ON

Use on-screen keypad to

60 minutes

enter the maximum workout

duration allowed on this

fitness equipment

30 seconds

• 5 seconds

• 15 seconds

• 30 seconds

• 60 seconds

• 120 seconds

• 300 seconds

60 seconds

• 30 seconds

• 60 seconds

• 120 seconds

Medium

• Medium

• High

1-16 mph 16 mph

0.5-15

15

(Incline range is -3 to 15)

ON

• OFF

Page 35

Configuring the System Settings 33

Manage Settings

Use this setting to save your equipment settings to a USB

flash drive, or to import new features from a USB flash drive.

To manage settings:

1. Use the administrator code and password to view the

equipment settings.

2. Touch System Settings, then touch Manage Settings.

3. Press Save to USB or Import from USB depending on

what you want to do.

Page 36

Page 37

Chapter 3

Introducing Users to the P80 Console

Important: Not all settings are currently available in this

release. More features will be available in future software

updates.

The P80 console offers clear visuals and a touch-screen

layout that encourages program exploration. Multiple preset

workouts are designed to help individual users meet their

fitness goals, and the console keys and durable motion

controls are responsive and easy to use.

Important: Please review the following sections in this guide with

your users before allowing them to use the fitness equipment:

y Important Safety Instructions

y Using the Safety Clip (for treadmill only)

y Educating Users

Using the Touch Heart Rate Feature

Note: Touch heart rate performance may vary based on a

user’s physiology, fitness level, age, and other factors. You

may experience an erratic readout if your hands are dry, dirty,

or oily, or if the skin on your palms is especially thick. Wearing

hand lotion can also cause an erratic readout. In addition,

make sure that the sensors are clean to ensure proper contact

can be maintained.

Page 38

36 Operating and Maintaining the P80 Console

To use the touch heart rate feature, place the palm of your

hands directly on the metal heart rate sensors on the

equipment’s handlebars. To ensure a more accurate heart

rate readout, make sure you follow these tips:

y Both hands must grip the sensors for your heart rate to

register.

y It takes a number of consecutive heart beats (15-20

seconds) for your heart rate to register.

y When gripping the sensors, do not grip tightly. Keep a

loose, cupping hold. Holding the grips tightly can affect

the reading.

y As you work out, your perspiration will help transmit your

heart rate signal. If you have difficulty using the handheld

grips to determine your heart rate, try the sensors again

later in the workout to see if you can obtain a heart rate

signal.

y If the touch heart rate feature does not work for you,

Precor recommends that you use a chest transmitter

strap.

Heart Rate Target Zones

200

190

180

170

160

150

140

130

120

Your Heart Rate

110

100

90

80

70

20 25 30 35 40 45 50 55 60 65 70 75

Recommended Cardiovascular Zone

Recommended Weight Loss Zone

Your Age

High

Peak

Cardio

Fat Burn

Warmup

Figure 9: Heart rate target zones

CAUTION: Your heart rate should never exceed 85% of your

maximum aerobic heart rate. Your maximum heart rate is equal to

220 minus your age.

Page 39

Introducing Users to the P80 Console 37

Using a Chest Strap Transmitter

WARNING

Signals used by the Chest Strap Transmitter

(or heart rate strap) may interfere with

pacemakers or other implanted devices.

Consult your physician and the manufacturers

of your Chest Strap Transmitter and implanted

device before using a Chest Strap Transmitter.

Wearing a chest strap transmitter during your workout

provides steady heart rate information. For the equipment to

detect your heart rate, you must grip the touch heart rate

sensors or wear a chest strap transmitter while exercising. In

the presence of both touch and wireless data, the touch data

takes precedence and will display.

Note: To receive an accurate reading, the strap needs to be in

direct contact with the skin on the lower sternum (just below

the bust line for women).

To use a chest strap transmitter:

1. Carefully dampen the back of the strap with tap water.

Important: Do not use deionized water. It does not have the

proper minerals and salts to conduct electrical impulses.

2. Adjust the strap and fasten it around your chest. The

strap should feel snug, not restrictive.

3. Make sure that the chest strap is right-side-up, lies

horizontally across, and is centered in the middle of your

chest.

4. Test the chest strap placement by checking the heart rate

function on the equipment. If a heart rate is registering,

your chest strap placement is correct. If the equipment

does not register a heart rate, readjust the strap and

recheck the heart rate function.

Page 40

38 Operating and Maintaining the P80 Console

Using the View Channels and View Buttons

There are three primary screen views that make certain

information visible during your workout. You can change

look and information provided on the screen by at anytime

using the Views button.

the

y Workout View – Show

bar. This view allows you to focus fully on your workout.

y Status View – Shows only the status bar and icon bar,

leaving the center of the console for media viewing.

y Media View – Shows only media and the Views and

Channel buttons. This view allows you to fully focus on

media.

Note: T

he name of the Channels button changes

depending on the media you are using. For examp

are watching a workout guide, the name of the button will

be Videos.

Changing Screen Views

The Views icon

screen when the Personal Progress panel is visible.

Figure 10: View

s panels, icon bar, and the status

le, if you

appears at the bottom right of the workout

s icon

To get to this panel:

y Press Quick Star

y Press Workouts, ch

t.

oose a preset workout, and then press

GO.

y Select t

he Featured Workout on the Welcome screen by

pressing GO.

To change views:

1. The default vie

w is the Workout View. Slide the panels

side to side on the screen to see the media panel.

2. Press Views two times to see the Status view.

3. Press Views a third time to make the Status Bar

leaving only the Media view.

disappear

Page 41

Introducing Users to the P80 Console 39

Using the Media Panel

Use the Media panel to select a media source.

To choose a media source:

1. On a Workout Progress panel, touch the Media icon, or

slide the right edge of the next panel across the screen.

Figure 11: Media icon

2. The Media panel describes the current media selection.

Navigate this panel using the buttons to the right of the

box.

Table 8. Media buttons

Button Action

Previous

Channel

TV Channels Displays the channel list.

Workout

Guides

iPod® Changes the source to iPod and updates the

Off Turns off all media.

Returns you to the previous media source or TV

channel.

Displays a list of tutorial videos.

Media panel.

Page 42

40 Operating and Maintaining the P80 Console

Connecting and Using Your iPod®

You can listen to your favorite moti

your iPod directly from the console.

To connect your iPod:

1. Insert the iPod into

the connector at the top of the console

and place your iPod securely in the pocket provided.

The media panel displays the words Now Playing iPo

along with the name of the song currently playing.

2.

Plug your headphones into the console.

Note: Be sure that the headphones are p

console and not the iPod. If they are plugged into the iPo

you will not be able to adjust the volume using the

console keys.

3. h the pause button.

To pause, touc

Figure 12: Track buttons

vational music and control

lugged into the

d

d,

4. To hear a different song, touch the track buttons.

Page 43

Introducing Users to the P80 Console 41

Using the Workout Progress Panel

Use the Workout Progress panel to customize

This is the first panel that displays once you select a workout

or press GO. If you are on the Media panel, there are two

ways to return to the Workout Progress panel.

To return to the Workout Progress panel:

1. On the Media panel, touch the Workout

right edge of the next panel across the screen.

2. The Workout Progress panel describes the curr

selection. There are buttons to the right of the box.

Figure 13: Workout Progress icon

your workout.

icon, or slide the

ent media

Table 9. Workout Progress buttons

Button Action

Workouts a list of goals and preset workouts Displays

available on that equipment.

Duration t. Set the length of your workou

Personal Info Enter your age and weight.

Target Choose Distance or Calories as a target for your

workout session.

Maximum distanc

Maximum calories: 5000 calor

e: 50 miles.

ies.

Page 44

Page 45

Chapter 4

Beginning Your Workout

CAUTION: If you are using a treadmill, be sure to attach the

security clip to your clothing before starting your workout.

Important: Not all settings are currently available in this

release. More features will be available in future software

updates.

The P80 console offers many different workout options. The

following section explains the type of workouts available and

how to get started using them.

Starting a QuickStart™ Workout

The QuickStart workout lets you begin your workout in the

Manual mode. Default calculations, such as calories burned,

are based on a 150 pound (68 kg), 35-year old individual. You

can complete a workout using the default values, or

personalize the settings.

To begin exercising immediately:

1. Touch Quick Start.

The words Enjoy Your Workout (or Starting Treadmill

when using the treadmill) appear on the screen and the

Manual workout begins.

Note: For treadmills, the equipment begins a

three-second count down 3, 2, 1, before the belt starts

moving.

2. At any time during a workout, you can press Pause. When

you press it, the workout pauses and you can choose to

Resume or Finish your workout.

If you choose to finish a workout, the Workout Summary

screen displays your workout status for that session.

Page 46

44 Operating and Maintaining the P80 Console

Starting a Featured Workout

The Featured Workout appears in a panel on the Welcome

Screen. Use Featured Workouts to explore the fitness benefits

of preset programs and to add variety to your workout.

To begin a Featured Workout, touch Go on the Featured

Workout panel.

Starting a Preset Workout

Preset workouts are a great way to tailor your workouts to

your fitness goals, stay challenged, and add variety to your

sessions.

Preset workouts use age and weight to calculate calories and

heart rate targets. You can enter this information at the start

of the workout. If no information is entered, the workout uses

the equipment default settings to calculate workout values.

To begin a preset workout:

1. On the Welcome screen, touch Workouts.

A Workouts screen appears.

2. Each goal heading on the screen can be expanded to view

the workouts available in that goal group. To view

available workouts for a particular goal, touch a workout

heading for that goal.

3. To start a specific workout, touch the workout name, then

touch GO.

The words Enjoy Your Workout appear on the screen and

the Manual workout begins.

Note: For treadmills, the equipment begins a

three-second count down 3, 2, 1, before the belt starts

moving.

4. Anytime during a workout, you can press Pause. When

pressed, the workout pauses and you can choose to

Resume or Finish your workout. To continue your

workout, touch Resume.

If you choose to finish a workout, the Workout Summary

screen displays your workout status for that session.

Page 47

Beginning Your Workout 45

Table 10. Preset workout descriptions

Goal Workout Details

Lose Weight Choose from several courses designed to

encourage weight loss.

Be Fit Maintain your fitness level so you can stay active

and fit.

Get Toned Tone your legs. Pick a focus of calf, thigh, or

gluteal region.

Push

Performance

Test Your

Fitness

Choose a high-intensity interval or work on

distance training.

Test your fitness level based on your age and

weight.

Ending a Workout

To end your workout, press Pause, and then touch Finish. A

summary screen for your current workout appears. The

measurements include:

y Distance

y Calories

y Duration

y Average movement rate/min (or the appropriate measure

based on equipment type)

y Average Heart Rate

Personal Information and Progress Settings

Before you begin the fitness tests or the heart rate program,

you are prompted to enter personal information in the

Workout Progress panel. This information may include age,

weight, or a length of time for that workout session. The

equipment uses this information to accurately compute your

energy expenditure during that workout if you are tracking

status such as calories or watts.

To enter your personal settings:

1. Begin exercising by touching Quick Start™ or selecting

Workout.

A Workout Progress panel appears on the screen.

2. In the panel, touch Duration to enter how much time you

want to exercise.

Page 48

46 Operating and Maintaining the P80 Console

3. In the panel, touch Personal Info to enter your age and

weight.

Important: Not all settings are currently available in this

release. More features will be available in future software

updates.

Table 11. Examples of Personal Information settings

Setting Setting

Options

Age • Over 85

• 75 - 84

• 65 - 74

• 55 - 64

• 45 - 54

• 36 - 44

• 35

• 25 - 34

• 18 - 24

• Under 18

Weight • Over 310

• 290 - 309

• 270 - 289

• 250 - 269

• 230 - 249

• 210 - 229

• 190 - 209

• 171 - 189

• 170

• 150 - 169

• 130 - 149

• 110 - 129

• Under 110

Default

Access Detail

Value

35 Admin/Tech:

None

170 Admin/Tech:

None

Enter age as

a value or a

range.

Enter weight

as a value or

a range.

Page 49

Beginning Your Workout 47

Adjusting the Workout Intensity

To adjust the equipment incline, speed, and/or resistance,

use the motion controls located just below the console keys.

Figure 14: Motion controls

Adjust the motion controls, upward or downward, to change

the incline, speed, or resistance.

Figure 15: Adjust motion controls up or down

Many preset workouts will adjust these settings automatically

to meet the workout intensity. At any time during a workout,

you can adjust control settings and override the default

workout settings.

Page 50

48 Operating and Maintaining the P80 Console

Viewing Your Workout Status While Exercising

The Status Bar contains status measurements a

across the top of the viewing screen. Information displayed in

the Status Bar helps you measure how your body is

responding to the exercise session. The default statu

measurements displayed are:

nd is visible

s

y Total Distance

y Calories Burned

y Time Remaining

y Average Speed (d

RPM depending on equipment type)

isplayed as strides per minute, pace, or

y Heart Rate

You can modify h

Bar. For example, you can view the length of your exercise

session as time elapsed, or as time remaining.

There are two ways to modify the display:

ow a measurement appears in the Status

y Change the default value setting.

y Change the view on the Status Bar

.

To modify the status measurement using the Status Bar:

1. On the Status Bar, touch the corner arrow on the status

category to pull down the menu.

2. On the drop-down menu, touch a

measurement to display in the Status Bar.

The alternate measure moves to the top of

and replaces the default measurement. The menu closes.

3.

Touch the arrow again to retract the menu.

4. Repeat with any status category to customiz

workout status view.

Note: Administrators an

can override status settings.

d registered service technicians

n alternate display

the Status Bar

e your

Page 51

Beginning Your Workout 49

Scoring Your Fitness Workout

This information helps yo

Your Fitness workout.

u interpret your score for the Test

The score for this test is

oxygen (O

) consumption, in ml per minute, modified for the

2

determined by this formula: Rate of

user’s maximum heart rate (220 - age), divided by the user’s

weight in kilograms.

Table 12. Fitness score reference tables

Low Fitness Level

Age Low Fitness Male Low Fitness Female

28 - 39 < 35 < 28

40 - 49 < 35 < 26

50 - 59 < 29 < 24

60 and over < 24 < 22

Medium Fitness Level

ness Medium Fitness Female Age Medium Fit

Male

28 - 39 28 - 33 35 - 42

40 - 49 32 - 39 26 - 31

50 - 59 29 - 36 24 - 29

60 and over 24 - 31 22 - 26

High Fitness Level

Age High Fitness Male High Fitness Female

28 - 39 > 42 > 33

40 - 49 > 39 > 31

50 - 59 > 36 > 28

60 and over > 31 > 26

Page 52

Page 53

Maintenance

To keep the equipment functioning properly, perform the

minor maintenance tasks in this section at the intervals

suggested. Failure to maintain the equipment as described in

this section could void the Precor Limited Warranty.

Chapter 5

DANGER

To reduce the risk of electrical shock, always

disconnect the equipment from its power source

before cleaning it or performing any maintenance

tasks. If the equipment uses an optional power

adapter, disconnect the adapter.

Cleaning the Console and Display

The console and screen require little maintenance once

installed. Precor recommends that you clean the console and

screen before and after each exercise session.

To remove dust and dirt from the console:

y Wipe all exposed surfaces with a soft cloth that you have

moistened with a solution of 30 parts of water to 1 part of

Simple Green® (for more information, visit

www.simplegreen.com).

To clean the screen:

y The manufacturer recommends diluting one part 91%

isopropyl alcohol solution in one part water, or using the

91% isopropyl alcohol solution in its original strength. Be

sure to follow the solvent manufacturer’s precautions and

directions when using any solvent.

CAUTION: Potentially hazardous situations associated with the

use of isopropyl alcohol may result in minor or moderate injury

and property damage. To avoid these situations, follow all

instructions and recommendations in the manufacturer’s Material

Safety Data Sheet and product label.

Page 54

52 Operating and Maintaining the P80 Console

Important: Do not use any acidic cleaners. Doing so will weaken

the paint or powder coatings and void the Precor Limited

Warranty. Never pour water or spray liquids directly on the

console or console’s screen.

y It is important to avoid using any corrosive chemicals on the

console or screen.

y Always dampen the cloth and then clean the screen. Be sure

to spray the cleaning liquid onto the cloth, not the screen, so

that drips do not seep into the console.

y Apply the cleaner with a soft, lint-free cloth. Avoid using gritty

cloths.

Page 55

Page 56

Precor Incorporated

20031 142nd Avenue NE

P.O. Box 7202

Woodinville, WA USA 98072-4002

P80 OM 301407-141 rev C, en

27 June 2011

Page 57

Assembling and Maintaining

AMT

®

800-Series

Adaptive Motion Trainers

®

Page 58

Page 59

Page 60

Edition Information

ASSEMBLING AND MAINTAINING AMT 800-SERIES

ADAPTIVE MOTION TRAINERS

P/N 300710-341 rev G

Copyright © July 2011 Precor Incorporated. All rights

reserved. Specifications subject to change without notice.

Trademark Note

Precor, AMT, and EFX are registered trademarks and Preva is

a trademark of Precor Incorporated. Other names in this

document may be the trademarks or registered trademarks of

their respective owners.

Intellectual Property Notice

All rights, title, and interests in and to the software of the

Preva Business Suite, the accompanying printed materials,

any copies of such software, and all data collected via the

Preva Business Suite, are exclusively owned by Precor or its

suppliers, as the case may be.

Precor is widely recognized for its innovative, award-winning

designs of exercise equipment. Precor aggressively seeks U.S.

and foreign patents for both the mechanical construction and

the visual aspects of its product design. Any party

contemplating the use of Precor product designs is hereby

forewarned that Precor considers the unauthorized

appropriation of its proprietary rights to be a very serious

matter. Precor will vigorously pursue all unauthorized

appropriation of its proprietary rights.

Precor Incorporated

20031 142nd Ave NE, P.O. Box 7202

Woodinville, WA 98072-4002

1-800-347-4404

http://www.precor.com

Page 61

WARNING

Important Safety Instructions

Read all instructions in the documentation provided with your

exercise equipment, including all assembly guides, user

guides, and owner’s manuals, before installation of this

device.

The display apparatus (hereinafter referred to as the console)

is intended to be shipped with new Precor exercise equipment

(hereinafter referred to as the base unit). It is not packaged for

individual sale.

To prevent injury, the console must be

attached securely to the base unit following all

assembly and installation instructions shipped

with the base unit. The console is intended to

be connected to AC mains power through the

furnished power supply ONLY. It should be

powered on only when installed as described

in the assembly and installation instructions

shipped with the base unit. The console is

intended for use only with Precor fitness

equipment, not as a standalone device.

Safety Precautions

Always follow basic safety precautions when using this

equipment to reduce the chance of injury, fire, or damage.

Other sections in this manual provide more details of safety

features. Be sure to read these sections and observe all safety

notices. These precautions include the following:

Read all instructions in this guide before installing and

using the equipment and follow any labels on the

equipment.

Make sure all users see a physician for a complete

physical examination before they begin any fitness

program.

Il est conseillé de subir un examen médical complet avant

d’entreprendre tout programme d’exercise. Si vous avez des

étourdissements ou des faiblesses, arrêtez les exercices

immédiatement.

Page 62

4 Assembling and Maintaining AMT 800-Series Adaptive Motion Trainers

Do not allow children, or people unfamiliar with the

operation of this equipment, on or near it. Do not leave

children unsupervised around the equipment.

Make sure all users wear proper exercise clothing and

shoes for their workouts and avoid loose or dangling

clothing. Users should not wear shoes with heels or

leather soles, and they should check the soles of their

shoes to remove any dirt and embedded stones. They

should also tie long hair back.

Never leave the equipment unattended when it is plugged

in. Unplug the equipment from its power source when it is

not in use, before cleaning it, and before providing

authorized service.

Note: The optional power adapter is considered a power

source for self-powered equipment.

Use the power adapter provided with the equipment. Plug

the power adapter into an appropriate, grounded power

outlet as marked on the equipment.

Care should be taken when mounting or dismounting the

equipment.

Read, understand, and test the emergency stop

procedures before use.

Keep the power cord or optional power adapter and plug

away from heated surfaces.

Route power cables so that they are not walked on,

pinched, or damaged by items placed upon or against

them, including the equipment itself.

Ensure the equipment has adequate ventilation. Do not

place anything on top of or over the equipment. Do not

use on a cushioned surface that could block the

ventilation opening.

Assemble and operate the equipment on a solid, level

surface.

Page 63

Important Safety Instructions 5

Proper Location for Equipment

For all equipment other than treadmills: Locate at

least 40 inches (1 meter) away from walls or

furniture on either side of the equipment, and 40

inches (1 meter) away from objects behind the

equipment.

For treadmills: Locate at least 40 inches (1 meter)

away from walls or furniture on either side of the

treadmill, and at least 80 inches (2 meters) away

from objects behind the treadmill.

Important: These location standards should also be used

when positioning equipment away from sources of heat, such

as radiators, heat registers, and stoves. Avoid temperature

extremes.

Keep equipment away from water and moisture. Avoid

dropping anything on or spilling anything inside the

equipment to prevent electric shock or damage to the

electronics.

When using the treadmill, always attach the safety clip to

your clothing before beginning your workout. Failure to

use the safety clip may pose a greater risk of injury in the

event of a fall.

Do not operate electrically powered equipment in damp

or wet locations.

Never operate this equipment if it has a damaged cord or

plug, if it is not working properly, or if it has been dropped,

damaged, or exposed to water. Call for service

immediately if any of these conditions exist.

Maintain the equipment to keep it in good working

condition, as described in the Maintenance section of the

assembly and maintenance guide. Inspect the equipment

for incorrect, worn, or loose components, and then

correct, replace or tighten prior to use.

If you plan to move the equipment, obtain help and use

proper lifting techniques.

Equipment Weight Restrictions: Do not use the treadmill

if you weigh more than 500 pounds (225 kg). If you weigh

more than 350 pounds (160 kg), do not run on the

treadmill. For all other fitness equipment, the weight limit

is 350 pounds (160 kg).

Use the equipment only for its intended purpose as

described in this manual. Do not use accessory

attachments that are not recommended by Precor. Such

attachments may cause injuries.

Page 64

6 Assembling and Maintaining AMT 800-Series Adaptive Motion Trainers

Do not operate the equipment where aerosol (spray)

products are being used or where oxygen is being

administered.

Do not use outdoors.

Do not attempt to service the equipment yourself, except

to follow the maintenance instructions in this manual.

Never drop or insert objects into any opening. Keep hands

away from moving parts.

Do not set anything on the stationary handrails,

handlebars, control console, or covers. Place liquids,

magazines, and books in the appropriate receptacles.

Do not lean on or pull on the console at any time.

CAUTION: DO NOT remove the cover, or you may risk injury due

to electric shock. Read the assembly and maintenance guide

before operating. There are no user-serviceable parts inside.

Contact Customer Support if the equipment needs servicing. For

use with single phase AC power only.

Educating Users

Take time to educate users about the Important Safety

Instructions found in both the User Reference Manual and

Product Owner’s Manual. Explain to your club or facility

patrons that they should observe the following precautions:

Hold onto a stationary handrail or handlebar while

assuming the starting position on the equipment.

Face the console at all times.

Hold on to a stationary handrail or handlebar with one

hand whenever you operate the console keys with the

other hand.

Hazardous Materials and Proper Disposal

The batteries within self-powered equipment contain

materials that are considered hazardous to the environment.

Federal law requires proper disposal of these batteries.

If you plan to dispose of your equipment, contact Precor

Commercial Products Customer Support for information

regarding battery removal. Refer to Obtaining Service.

Page 65

Important Safety Instructions 7

Product Recycling and Disposal

This equipment must be recycled or discarded according to

applicable local and national regulations.

Product labels, in accordance with European Directive

2002/96/EC concerning waste electrical and electronic

equipment (WEEE), determine the framework for the return

and recycling of used equipment as applicable throughout the

European Union. The WEEE label indicates that the product is

not to be thrown away, but rather reclaimed upon end of life

per this Directive.

In accordance with the European WEEE Directive, electrical

and electronic equipment (EEE) is to be collected separately

and to be reused, recycled, or recovered at end of life. Users

of EEE with the WEEE label per Annex IV of the WEEE

Directive must not dispose of end of life EEE as unsorted

municipal waste, but use the collection framework available

to customers for the return, recycling, and recovery of WEEE.

Customer participation is important to minimize any potential

effects of EEE on the environment and human health due to

the potential presence of hazardous substances in EEE. For

proper collection and treatment, refer to Obtaining Service.

Regulatory Notices for the RFID Module

When equipped with a control console as described in this

document, this equipment may include a radio-frequency

identification (RFID) module. The RFID module has been

certified to operate at temperatures between -20°C and 85°C

Radio Frequency Interference (RFI)

(-4°F and 185°F).

The RFID module conforms to the following national

standards defining acceptable limits for radio frequency

interference (RFI).

Page 66

8 Assembling and Maintaining AMT 800-Series Adaptive Motion Trainers

WARNING

Federal Communications Commission, Part 15

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a commercial

installation. The equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in

accordance with the owner’s manual instructions, can cause

harmful interference to radio communications.

Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this

device must accept any interference received, including

interference that may cause undesired operation.

Per FCC rules, changes or modifications not

expressly approved by the manufacturer

could void the user’s authority to operate the

equipment.

Industry Canada

This device complies with RSS-210:2007 of the Spectrum

Management & Telecommunications Radio Standards

Specification. Operation is subject to the following two

conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference

received, including interference that may cause undesired

operation.

This Class A digital apparatus complies with Canadian

ICES-003.

Cet appareil numérique de la classe A est conforme à la norme

NMB-003 du Canada.

ATTENTION: Haute Tension

Débranchez avant de réparer

Page 67

Important Safety Instructions 9

European Applications

CE compliance is claimed to the following directives:

1999/5/EC R&TTE Directive

2006/95/EC LVD Directive

2002/95/EC RoHS Directive

Directive compliance has been verified to the following

standards:

EN 55022

EN 300 330-1 V1.5.1

EN 300 330-2 V1.3.1

EN 301 489-3 V1.4.1

EN 301 489-1 V1.8.1

EN 60950-1

Regulatory Notices for Cardiovascular Exercise Equipment

The regulatory information in this section applies to the

exercise equipment and its control console.

Safety Approvals for Cardiovascular Equipment

Precor equipment has been tested and found to comply with

the following applicable safety standards.

Cardiovascular Type Equipment:

CAN/CSA, IEC, EN 60335-1 (Household and similar

electrical appliances - Safety)

EN 957 (Stationary training equipment, class S/B

compliant equipment)

PVS and P80 Regulatory Notice

This Precor equipment has been tested and found to comply

with the following applicable safety standards.

CAN/CSA, UL, IEC, EN 60065 (Audio, video and similar

electronic apparatus - Safety)

Page 68

10 Assembling and Maintaining AMT 800-Series Adaptive Motion Trainers

Radio Frequency Interference (RFI)

This Precor exercise equipment conforms to the following

national standards defining acceptable limits for radio

frequency interference (RFI).

Federal Communications Commission, Part 15

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a commercial

installation. The equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in

accordance with the owner’s manual instructions, may cause

harmful interference to radio communications.

WARNING

Per FCC rules, changes or modifications not

expressly approved by Precor could void the

user’s authority to operate the equipment.

Industry Canada

This Class A digital apparatus complies with Canadian

ICES-003.

Cet appareil numérique de la classe A est conforme à la norme

NMB-003 du Canada.

ATTENTION: Haute Tension

Débranchez avant de réparer

European Applications

CE compliance is claimed to the following directives:

2004/108/EC EMC Directive

2006/95/EC LVD Directive

2002/95/EC RoHS Directive

Directive compliance has been verified to the following

standards:

EN 55022

EN 55024

EN 60335-1

EN 60065 (P80 and PVS)

Page 69

Important Safety Instructions 11

Electrical Recommendations: All Equipment Excluding Treadmills

Note: This is a recommendation only. NEC (National Electric

Code) guidelines or local region electric codes must be

followed.

For equipment fitted with a P80 console or Personal Viewing

System (PVS) screen a separate power connection is

required. For a 20 amp branch circuit up to 10 screens can be

connected. If the branch circuit has any other devices plugged

into the circuit the number of screens must be reduced by the

wattage of the other devices.

Note: The typical splitter power cords that have IEC-320 C13

and C14 plugs have a recommended maximum capacity of

five screens.

Figure 1: IEC-320 C13 and C14 plugs

Obtaining Service