Page 1

Assembly and Maintenance Guide

S3.45

Strength-Training

Fitness Equipment

Page 2

S3.45 Assembly and Maintenance Guide

page 2

IMPORTANT SAFETY INSTRUCTIONS

Important Safety Instructions

Important Safety Instructions

Before beginning any fitness program, you should

obtain a complete physical examination from your

physician.

Il est conseillé de subir un examen médical complet

avant d’entreprendre tout programme d’exercise. Si

vous avez des étourdissements ou des faiblesses,

arrêtez les exercices immédiatement.

When using exercise equipment, you should always

take basic precautions, including the following:

• Read all instructions before using the S3.45

equipment. These instructions are written to

ensure your safety and to protect the unit.

• Do not allow children on or near the equipment.

• Use the equipment only for its intended purpose

as described in this guide. Do not use accessory

attachments that are not recommended by the

manufacturer: such attachments might cause

injuries.

• Wear proper exercise clothing and shoes for your

workout—no loose clothing.

• Use care when getting on or off the unit.

• Do not overexert yourself or work to

exhaustion.

• If you feel any pain or abnormal symptoms,

stop your workout immediately and consult

your physician.

• Never operate the unit when it has been dropped or

damaged. Return the equipment to a service center

for examination and repair.

• Never drop or insert objects into any opening in the

equipment. Keep hands away from moving parts.

• Always check the unit and its cables before each

use. Make sure that all fasteners and cables are

secure and in good working condition.

• Do not use the equipment outdoors.

Personal Safety During Assembly

• It is strongly recommended that a qualified dealer

assemble the equipment.

Assistance is required.

• Read each step in the assembly instructions and

follow the steps in sequence. Do not skip ahead. If

you skip ahead, you may learn later that you have

to disassemble components and that you may

have damaged the equipment.

• Assemble and operate the S3.45 on a solid, level

surface. Locate the unit a few feet from walls or

furniture to provide easy access.

The S3.45 is designed for your enjoyment. By following

these precautions and using common sense, you will

have many safe and pleasurable hours of healthful

exercise with your new equipment.

Obtaining Service

Do not attempt to service the S3.45 yourself

except for the maintenance tasks described

in this guide. This unit does not contain any

user-serviceable parts.

For information about product operation or

service, check out the Precor web site at

www.precor.com or contact an authorized

Precor dealer or a Precor factory-authorized

service company. To locate the dealer or service

person nearest you, call 1-800-347-4404.

If you call or e-mail Customer Support, have

the serial number and part numbers available.

You can find the serial number printed on a

label on the chest press side of the Rear

Upright. For future reference, write the serial

number in the space below.

Serial number: _____________

Page 3

S3.45 Assembly and Maintenance Guide

page 3

Table of Contents

Table of Contents

1

2

3

Important Safety Instructions ....................................................................... 2

Personal Safety During Assembly ........................................................................................... 2

Obtaining Service .................................................................................................................... 2

Before You Begin ........................................................................................... 5

Unpacking the Equipment ....................................................................................................... 5

Optional Equipment ................................................................................................................. 5

Preparations................................................................................................... 6

Required Tools......................................................................................................................... 6

Installation Requirements ........................................................................................................ 6

Assembly Tips ......................................................................................................................... 6

Assembly Instructions .................................................................................. 7

Open Boxes 1 and 2................................................................................................................ 8

1. Attach Main Base.......................................................................................................... 9

2. Attach Top Beam and Top Frame .................................................................................. 10

3. Attach Front Upright ...................................................................................................... 11

4. Attach Cross Brace....................................................................................................... 12

Open Box 3 ............................................................................................................................. 13

5. Attach Seat Upright to Main Base................................................................................. 14

6. Attach Upright Flats ...................................................................................................... 15

7. Attach Roller Pads ........................................................................................................ 16

8. Assemble Preacher Curl Weight Stack ......................................................................... 17

9. Assemble Leg Curl Weight Stack.................................................................................. 18

10. Assemble Chest Press Weight Stack............................................................................ 19

11. Feed Lower Leg Curl Cable .......................................................................................... 20

12. Feed Upper Leg Curl Cable .......................................................................................... 22

13. Assemble Leg Curl Seat ............................................................................................... 24

Page 4

S3.45 Assembly and Maintenance Guide

page 4

Table of Contents

Open Box 4 ............................................................................................................................. 26

14. Attach Chest Press Seat............................................................................................... 27

15. Attach Press Arm Assembly ......................................................................................... 28

16. Attach Handlebars ........................................................................................................ 29

17. Assemble Chest Press Seat ......................................................................................... 30

18. Feed Chest Press Cable............................................................................................... 31

Open Box 5 ............................................................................................................................. 33

19. Attach Foot Support ...................................................................................................... 34

20. Attach Seat Frame ........................................................................................................ 35

21. Attach Row Bar Shelf and Seat Pads ........................................................................... 36

22. Feed Upper Preacher Curl Cable ................................................................................. 37

23. Feed Lower Preacher Curl Cable ................................................................................. 39

24. Attach Lat Bar Holders.................................................................................................. 41

25. Attach Accessories ....................................................................................................... 42

26. Apply Weight Decals ..................................................................................................... 43

Open Box 6 ............................................................................................................................. 44

27. Attach Shrouds ............................................................................................................. 45

Adjustments and Maintenance ..................................................................... 47

1. Cable Adjustments .............................................................................................................47

2. Selector Stem Adjustments ................................................................................................ 48

Forward Angle Adjustment ................................................................................................. 48

Backward Angle Adjustment .............................................................................................. 49

Side-to-Side Vertical Adjustment ........................................................................................ 50

3. Maintenance ...................................................................................................................... 50

Warranty Registration .............................................................................................................. 51

Warranty Card and Specifications .............................................................................. Back cover

4

Page 5

S3.45 Assembly and Maintenance Guide

page 5

1

Before You Begin

Before You Begin

Thank you for purchasing the S3.45. This unit is part

of the Pacific Fitness line of quality strength-training

machines, which let you target specific muscle groups

to achieve better muscle tone and overall body

conditioning. To maximize your use of the equipment,

please study this guide thoroughly.

Unpacking the Equipment

The S3.45 is carefully tested and inspected before

shipment. Pacific Fitness ships the unit in several

pieces that require assembly. Ask for assistance during

the assembly process.

• Review the

Installation Requirements

found on the

next page.

• When instructed to open a box, carefully unpack

the pieces and lay them on the floor near the place

where you plan to use the equipment.

Be careful to open boxes and assemble components in

the sequence presented in this guide.

If any items are missing, contact the dealer from whom

you purchased the unit or call 1-800-347-4404 for the

dealer nearest you.

Optional Equipment

Optional equipment that you can purchase through

your dealer includes the 750-lb Weight Stack and the

Leg Press.

Note: If you have also purchased the Leg Press

Option and are assembling it simultaneously, specific

directions are included to reduce setup time.

Page 6

S3.45 Assembly and Maintenance Guide

page 6

2

Preparations

Preparations

CAUTION: To set up this unit, you will need

assistance. Do not attempt assembly by yourself.

You must review and follow the instructions in this

guide. If you do not assemble and use the S3.45

according to these guidelines, you could void

the Pacific Fitness limited warranty (see back cover).

Required Tools

Tools that you must obtain before assembling the

unit include:

❏ ⁹⁄₁₆-inch socket wrench

❏ ¾-inch socket wrench

❏ ⁹⁄₁₆-inch box-end wrench

❏ ¾-inch box-end wrench

❏ Standard set of metric Allen wrenches

❏ Two adjustable pliers or crescent wrenches

❏ Measuring tape

❏ Wire tie cutter (cuts plastic tie wraps)

❏ Rubber mallet

❏ Step stool

Installation Requirements

Follow these installation requirements when

assembling the unit:

• Fill out and mail the limited warranty card.

The warranty card is found on the back cover of

this guide.

• Set up the S3.45 on a solid, flat surface. A

smooth, flat surface under the unit helps keep it

level. A level unit has fewer malfunctions.

• Provide ample space around the machine.

Open space around the machine allows for

easier access.

• Insert all bolts in the same direction. For

aesthetic purposes, insert all the bolts in the

same direction unless specified (in text or

illustrations) to do otherwise.

• Leave room for adjustments. Tighten fasteners

such as bolts, nuts, and screws so the unit is

stable, but leave room for adjustments. Do not fully

tighten fasteners until instructed in the assembly

steps to do so.

Assembly Tips

• A 6-inch scale is provided at the bottom of every

assembly instruction page. Use this scale to

identify the correct size bolts and spacers. The

head of a bolt is not used in measuring the length

of a bolt.

To find out the length of a particular bolt, measure

its shank (the long, narrow part beneath the head).

Refer to the following diagram:

Bolt head

Bolt threads

Shank

To determine the

length of a bolt,

measure its shank.

• Read all the caution notes on each page before

completing that step.

Note: A few of the bolts used to assemble the

S3.45 are longer than 6 inches. You may want to

use a measuring tape to accurately identify the

correct sizes.

• Some pieces have extra holes that you will not use.

Use only those holes indicated in the instructions

and illustrations.

• While you may be able to assemble the S3.45

using the illustrations only, important safety notes

and other tips are included in the text.

Page 7

S3.45 Assembly and Maintenance Guide

page 7

1 2 3 4 5 6

3

Assembly

Instructions

Assembly Instructions

Assembly of the S3.45 takes professional installers

about 1.5 hours to complete. If this is the first time you

have assembled this type of equipment, plan on

significantly more time.

Professional installers are highly recommended!

However, if you acquire the appropriate tools, obtain

assistance, and follow the assembly steps sequentially,

the process will take time, but is fairly easy.

CAUTION: Obtain assistance! Do not attempt to

assemble the S3.45 by yourself. Review the

Installation Requirements

on page 6 before

proceeding with the following steps.

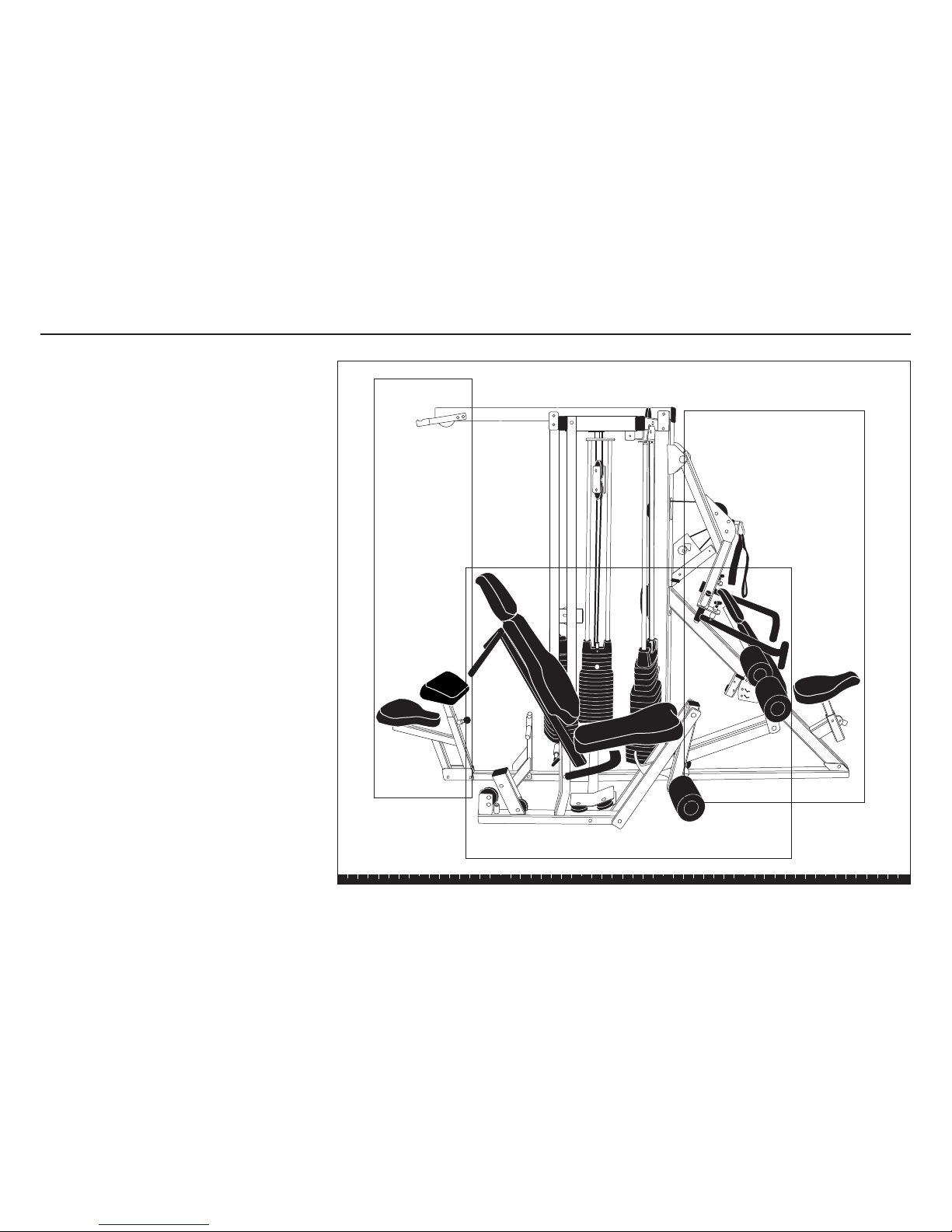

The S3.45 comes in four boxes. (See the diagram at

the right.)

Be careful to open boxes and assemble components in

the sequence presented in this guide.

Note: With so many assembled parts, proper

alignment and adjustment is critical. While tightening

the nuts and bolts, be sure to leave room for

adjustments.

Do not fully tighten bolts until

instructed to do so.

Box 3

Leg Curl

Box 5

Preacher Curl

Box 4

Chest Press

Boxes 1 and 2

Main Structure

Page 8

S3.45 Assembly and Maintenance Guide

page 8

1 2 3 4 5 6

Open Boxes 1 and 2

Use tie cutters to open the boxes.

The illustration shows how the S3.45 will look after you

complete this section.

Note: Some items in these boxes may not be needed

until later in the assembly process.

Important: Only use fasteners in bags labeled S3.45.

Discard all fasteners in bags labeled S3.25.

Open Boxes 1 and 2

Page 9

S3.45 Assembly and Maintenance Guide

page 9

1 2 3 4 5 6

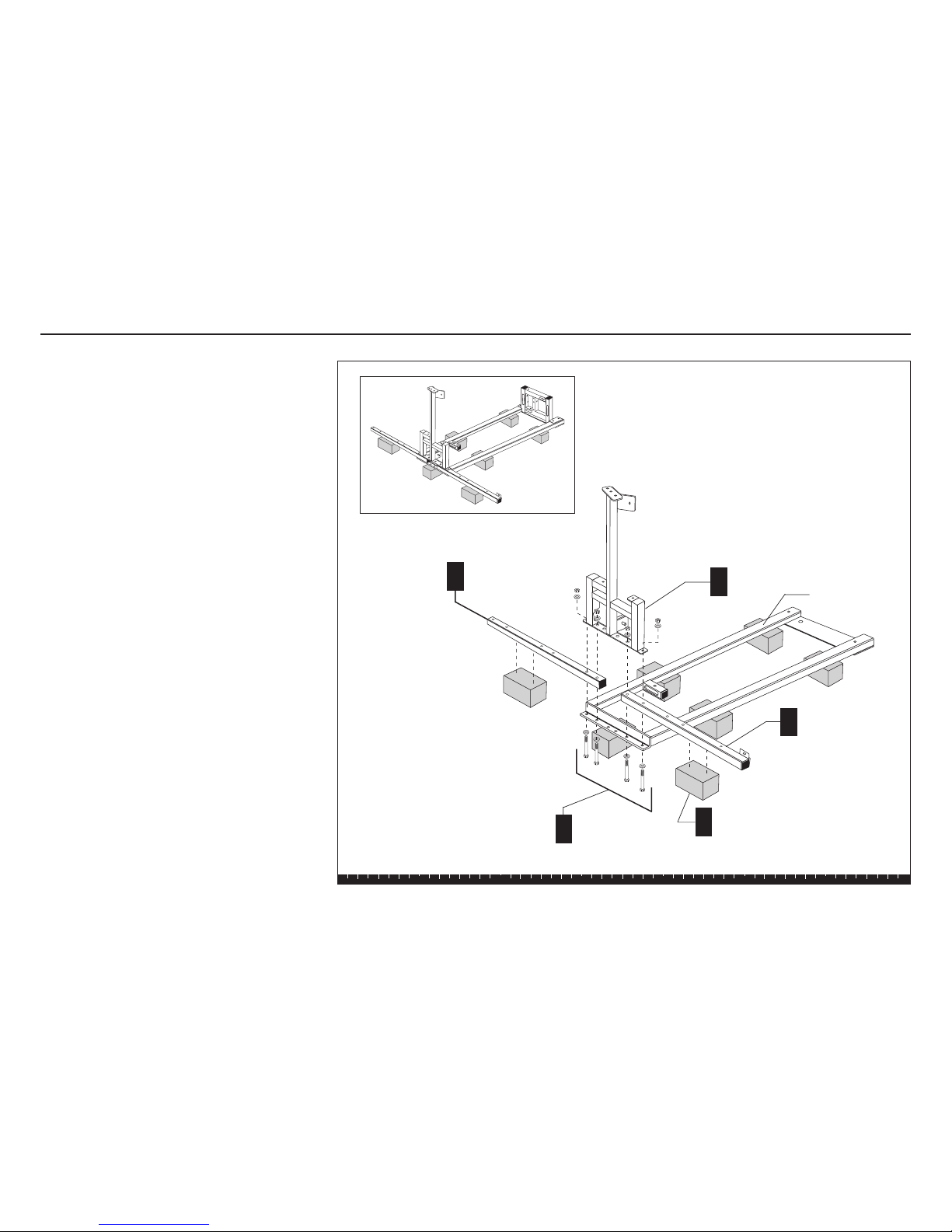

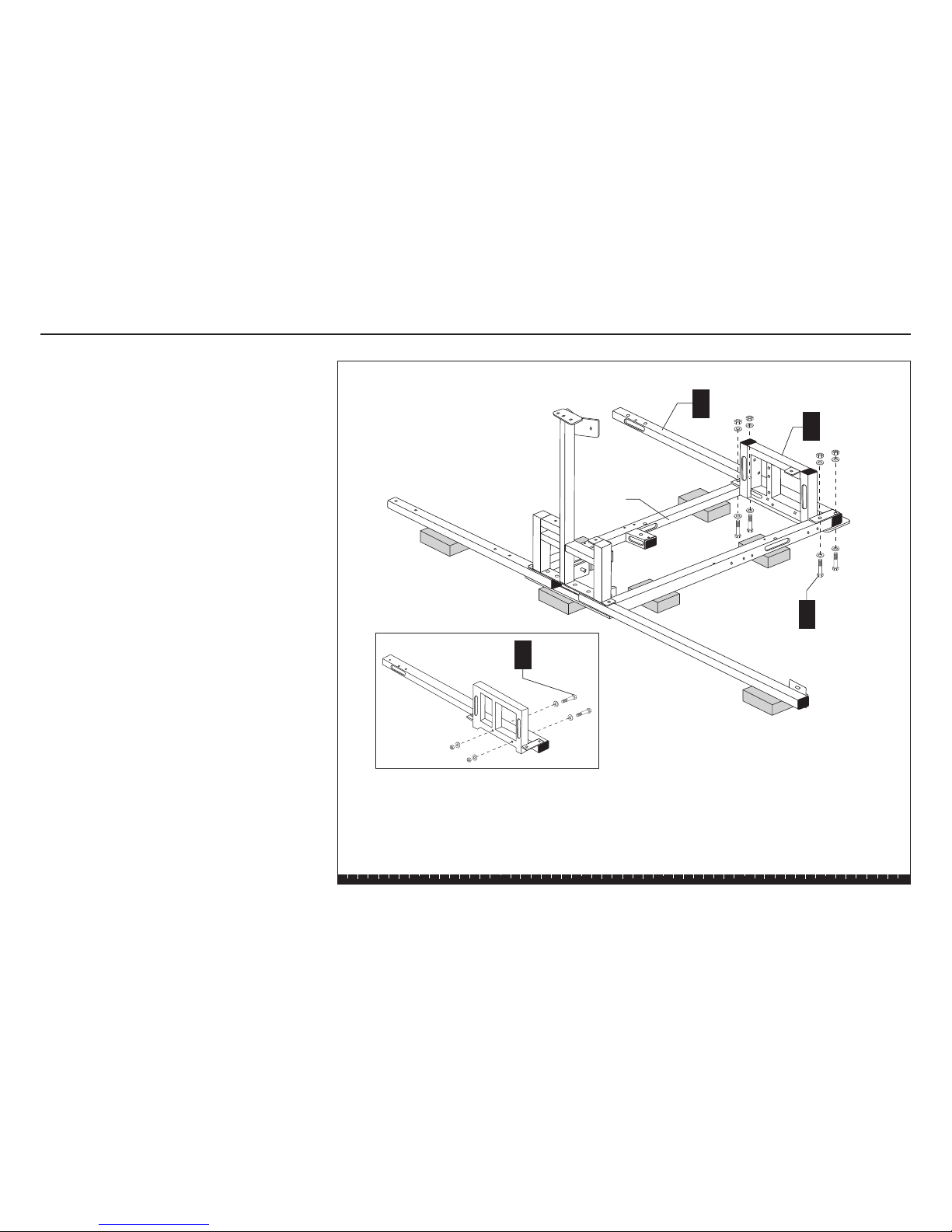

1. Attach Main Base

A. Place the Rear Upright on Weight Boxes with the

flange side down.

B. Place the Chest Press Rear Base on the Rear

Upright. Balance the other end on a Weight Box.

C. Place the Preacher Curl Rear Base on the Rear

Upright. Balance the other end on a Weight Box.

D. Place the Main Base on the Chest Press Rear

Base and Preacher Curl Rear Base.

E. Attach from underneath using

four 3¼-inch bolts

eight washers

four locknuts

F. Finger tighten all bolts, and then wrench tighten.

Step 1. Attach Main Base

4 - 3¼" bolts

8 - washers

4 - locknuts

Weight Box (6)

Rear Upright

Main Base

Chest Press

Rear Base

D

B

A

C

Preacher Curl

Rear Base

E

Page 10

S3.45 Assembly and Maintenance Guide

page 10

1 2 3 4 5 6

2. Attach Top Beam

and Top Frame

A. Place the Top Beam on the Rear Upright with

windows facing down. Ensure the beam extends

out as shown.

B. Place the Top Frame on the Rear Upright and Top

Beam.

C. Attach from underneath using

four 3¼-inch bolts

eight washers

four locknuts

Finger tighten.

D. Attach from the top using

two 5¾-inch bolts

four washers

two locknuts

Finger tighten.

E. Wrench tighten all bolts.

F. With someone helping you, lift the structure into

position. Place the structure where you intend to

keep it permanently.

CAUTION: The frame may be unstable and may

tip. To avoid this possibility, have an assistant

hold the frame until the Seat Upright has been

attached.

G. Move the Weight Boxes out of the way until step 8.

Step 2. Attach Top Beam and Top Frame

Rear

Upright

Top Beam

A

C

Top Frame

B

4 - 3¼" bolts

8 - washers

4 - locknuts

D

2 - 5¾" bolts

4 - washers

2 - locknuts

Page 11

S3.45 Assembly and Maintenance Guide

page 11

1 2 3 4 5 6

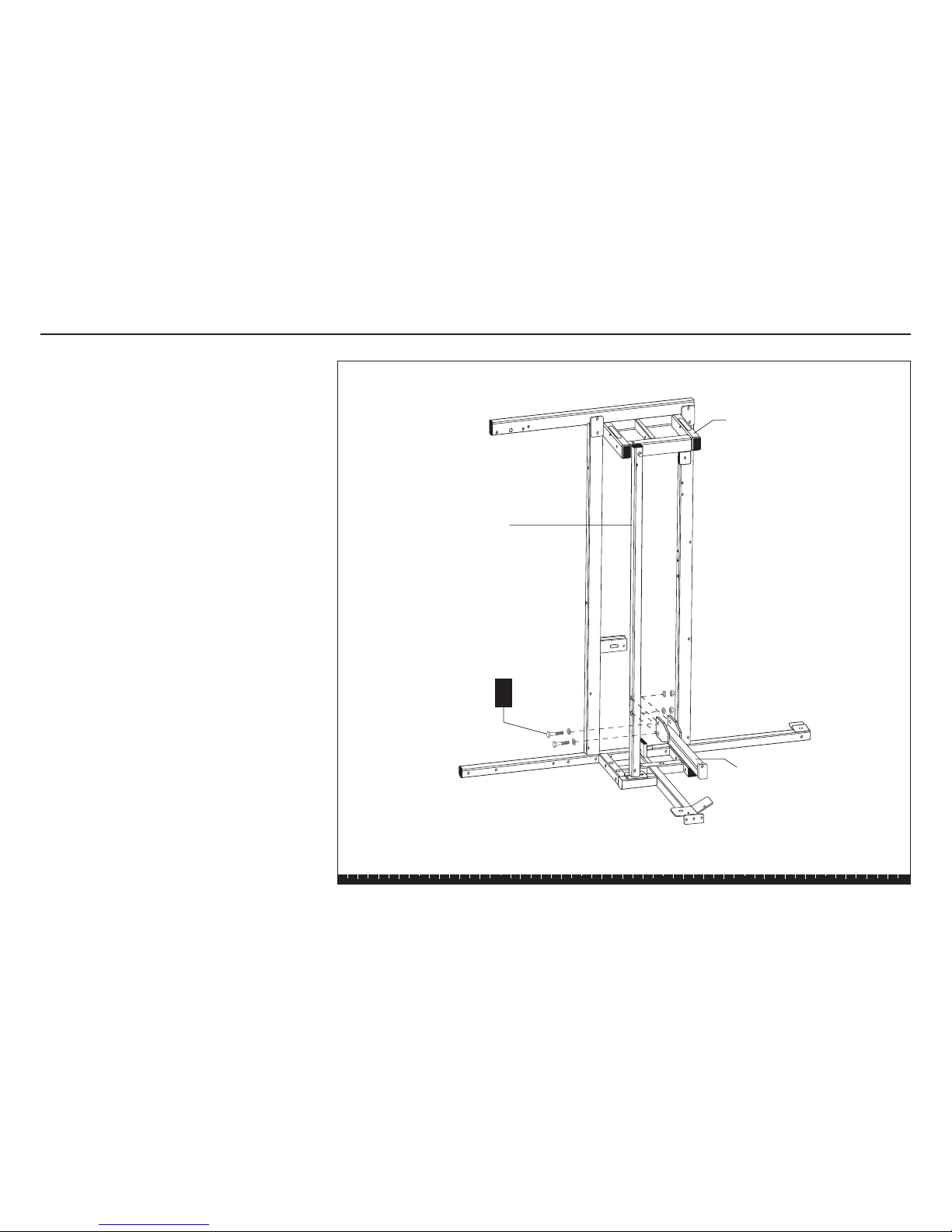

3. Attach Front Upright

A. Attach the Front Upright to the Top Frame from the

front using

one 4¾-inch bolt

two washers

one locknut

Finger tighten.

Note: Placement of the Front Upright must match

the illustration. The Shroud hole must

be offset toward the Preacher Curl Station.

B. Attach the Front Upright to the Main Base using

two ¾-inch bolts

two washers

Finger tighten.

C. Wrench tighten all bolts.

Step 3. Attach Front Upright

Top Frame

Front Upright

Main Base

1 - 4¾" bolt

2 - washers

1 - locknut

B

A

2 - ¾" bolts

2 - washers

Shroud Hole

Preacher Curl

Station will be on

this side.

Page 12

S3.45 Assembly and Maintenance Guide

page 12

1 2 3 4 5 6

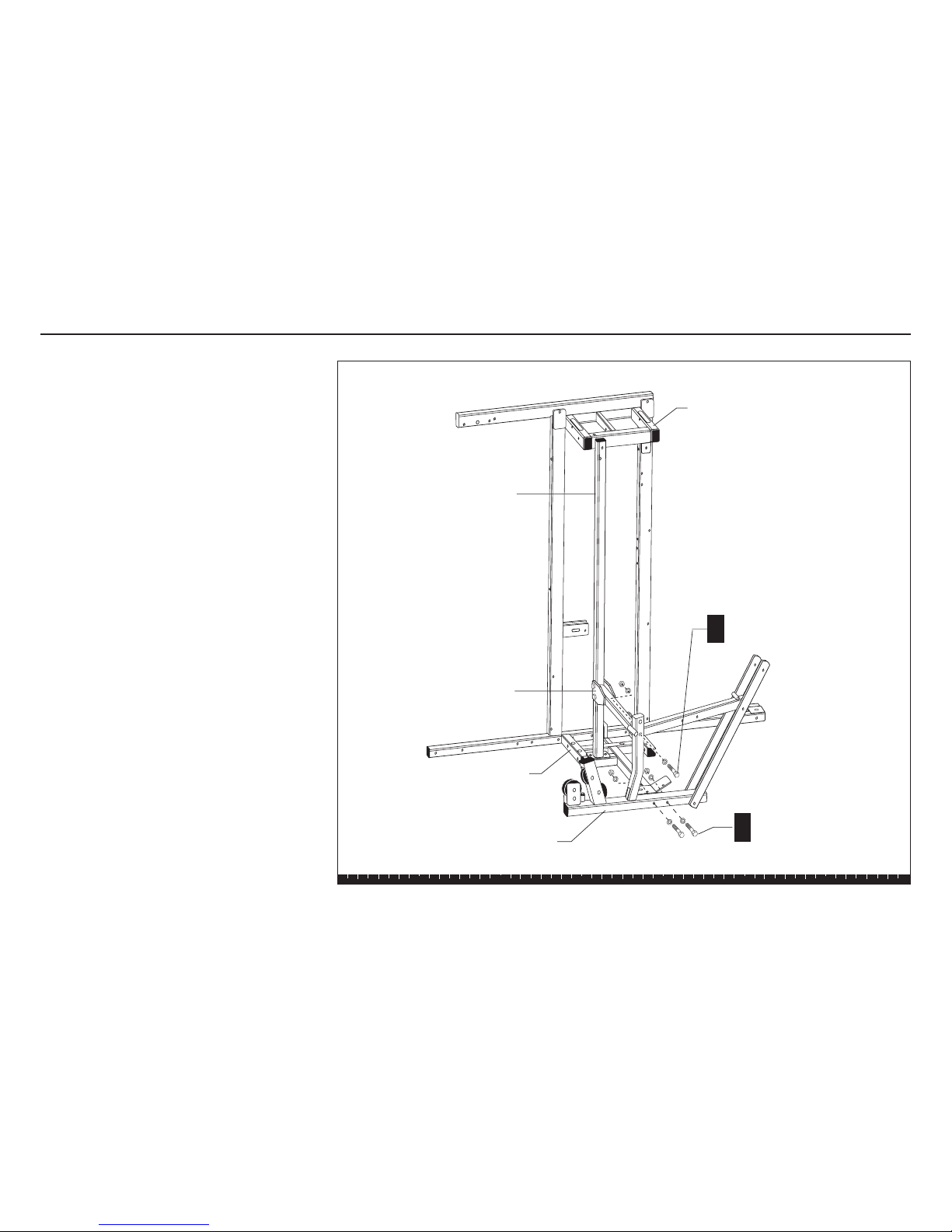

4. Attach Cross Brace

A. Attach the Cross Brace to the Front Upright using

two 3-inch bolts

four washers

two locknuts

B. Finger tighten. Do not wrench tighten until

you attach the Seat Upright in step 5.

Step 4. Attach Cross Brace

Top Frame

Cross Brace

2 - 3" bolts

4 - washers

2 - locknuts

A

Front Upright

Page 13

S3.45 Assembly and Maintenance Guide

page 13

1 2 3 4 5 6

Open Box 3

Use tie cutters to open the box.

The diagram shows how the S3.45 will look after you

complete this section.

Note: Some items in these boxes may not be used

until later in the assembly process.

Open Box 3

Page 14

S3.45 Assembly and Maintenance Guide

page 14

1 2 3 4 5 6

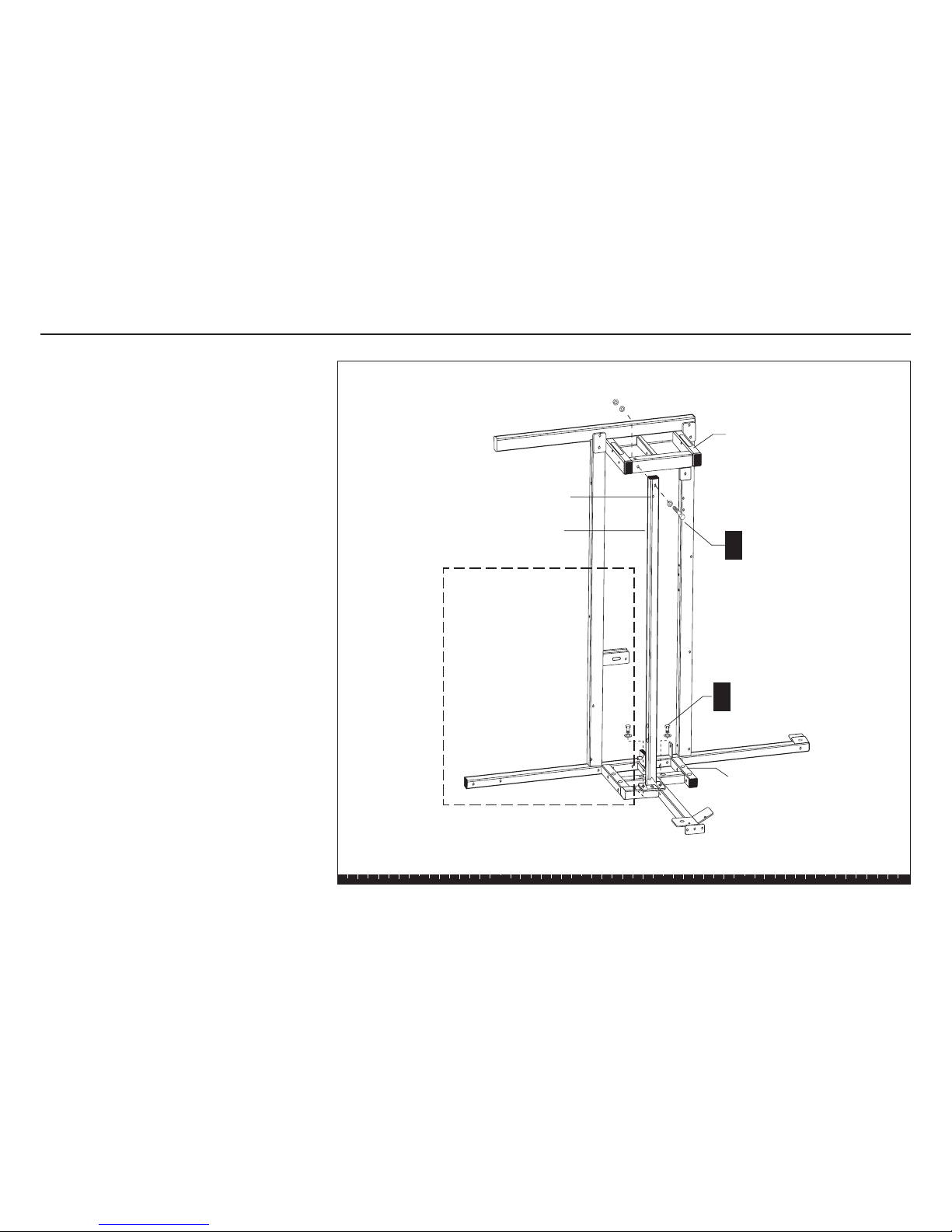

5. Attach Seat Upright to Main

Base

A. Attach the Seat Upright to the Main Base using

two 4-inch bolts

four washers

two locknuts

Finger tighten.

Note: If the holes do not line up easily, tilt the main

structure back while another person puts a weight

stem temporarily below the Main Base. Be sure to

remove the weight stem after you wrench tighten.

B. Attach the Cross Brace to the Seat Upright using

one 3-inch bolt

two washers

one locknut

Finger tighten.

C. Wrench tighten all bolts that connect the Cross

Brace and the Seat Upright to the Main Base.

Step 5. Attach Seat Upright to Main Base

Top Frame

B

Main Base

1 - 3" bolt

2 - washers

1 - locknut

A

2 - 4" bolts

4 - washers

2 - locknuts

Seat Upright

Front Upright

Cross Brace

Page 15

S3.45 Assembly and Maintenance Guide

page 15

1 2 3 4 5 6

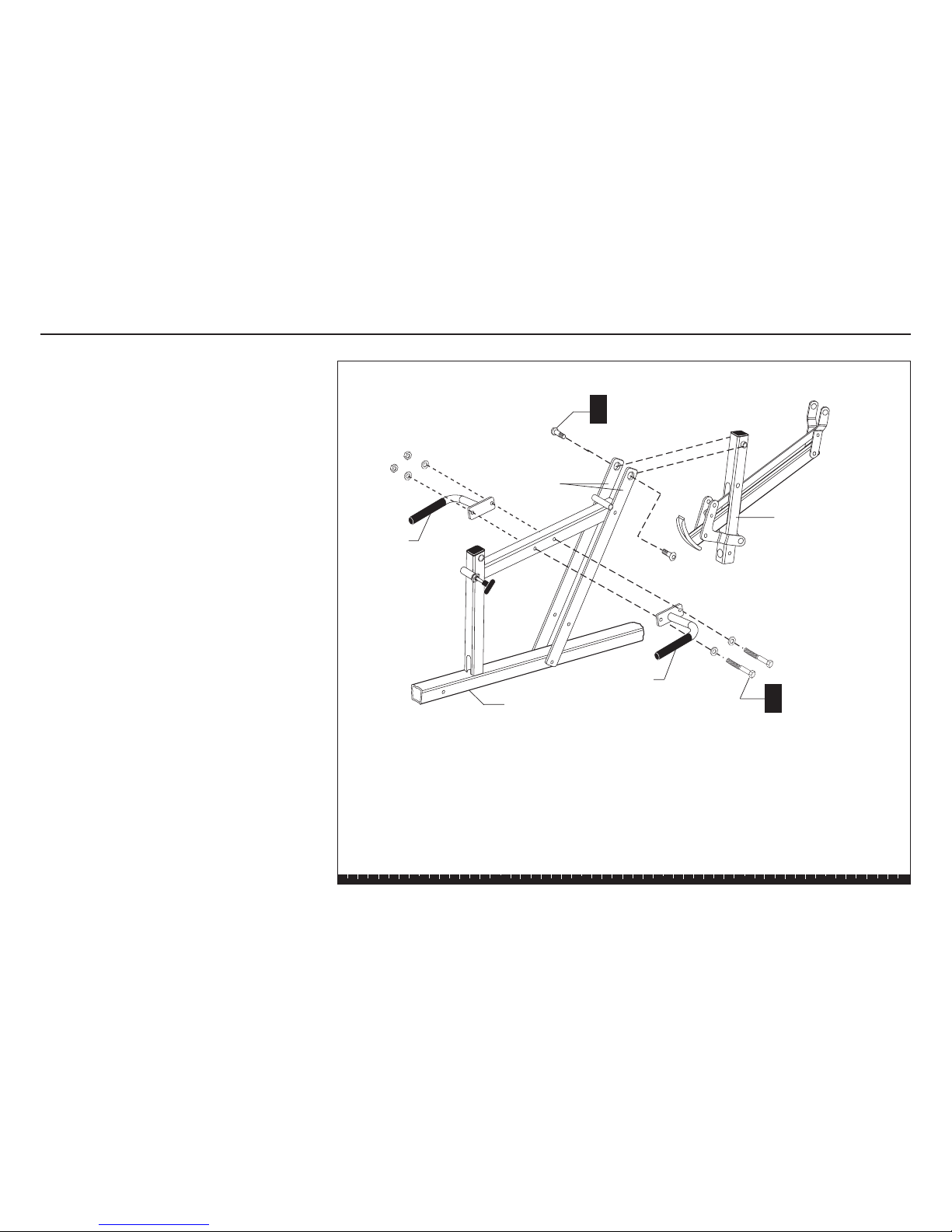

6. Attach Upright Flats

A. Attach the Rotating Arm to the Upright Flats using

two ¾-inch buttonhead bolts

Wrench tighten using the appropriate Allen

wrench.

B. Attach the Handles to the Seat Upright using

two 3¼-inch bolts

four washers

two locknuts

Wrench tighten with a box-end and socket wrench.

Step 6. Attach Upright Flats

A

2 - ¾" buttonhead bolts

B

2 - 3¼" bolts

4 - washers

2 - locknuts

Upright Flats

Handle

Seat Upright

Rotating Arm

Handle

Page 16

S3.45 Assembly and Maintenance Guide

page 16

1 2 3 4 5 6

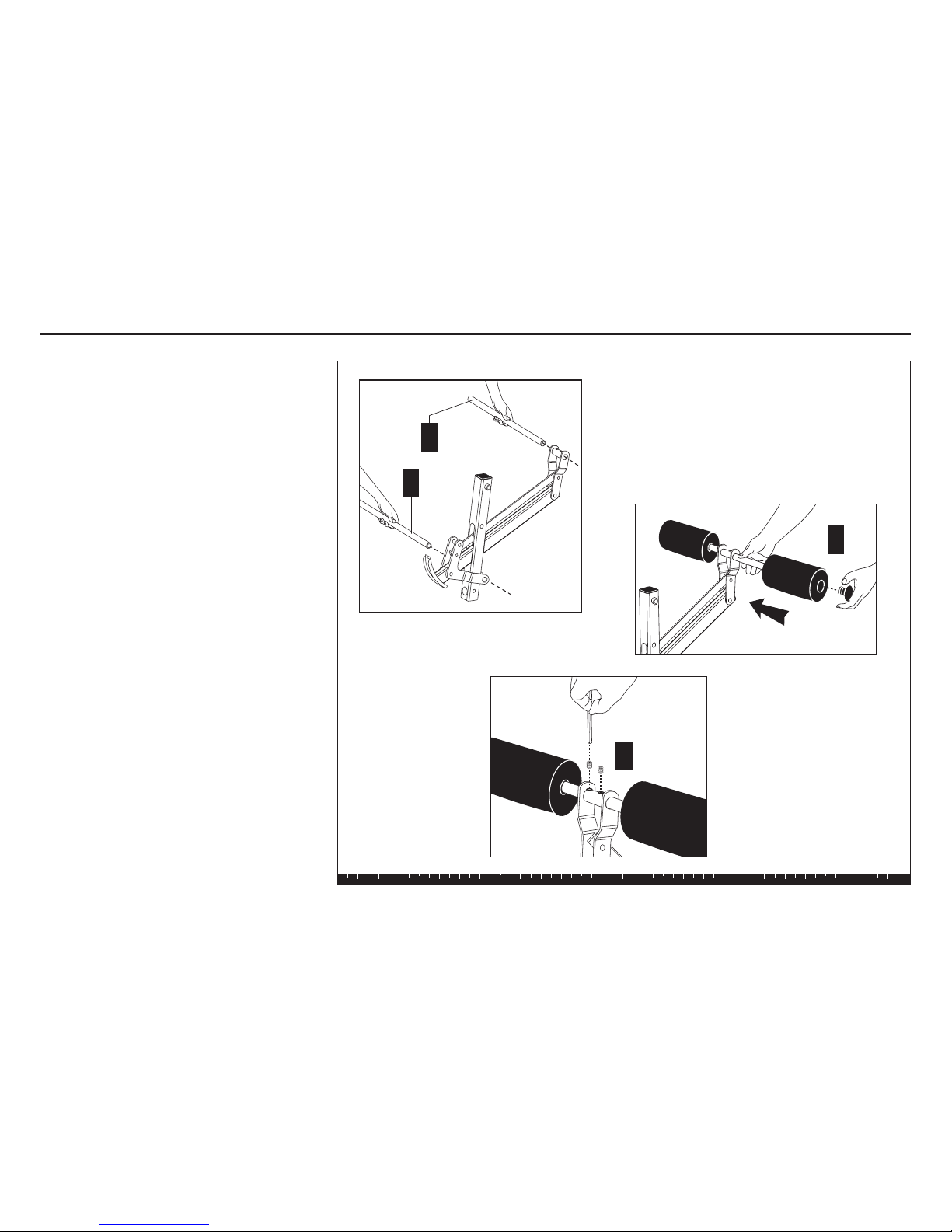

7. Attach Roller Pads

A. Insert the Leg Curl Roller Pad Rod.

B. Slide the Leg Curl Roller Pads on the Rod. Center

the Pads on the Rod. Insert End Caps into the end

of the Rod.

C. Secure the Rod in place from below using two hex

set screws.

D. Repeat steps A through C for the Leg Extension

Roller Rod.

Note: If you are assembling the Leg Press Option and

the S3.45 simultaneously, please go now to Step 2 in

the

S3.45 Leg Press Option Assembly Instructions.

Step 7. Attach Roller Pads

A

B

C

Leg

Extension

Roller

Pad Rod

Leg Curl

Roller

Pad Rod

2 - hex set

screws

D

Page 17

S3.45 Assembly and Maintenance Guide

page 17

1 2 3 4 5 6

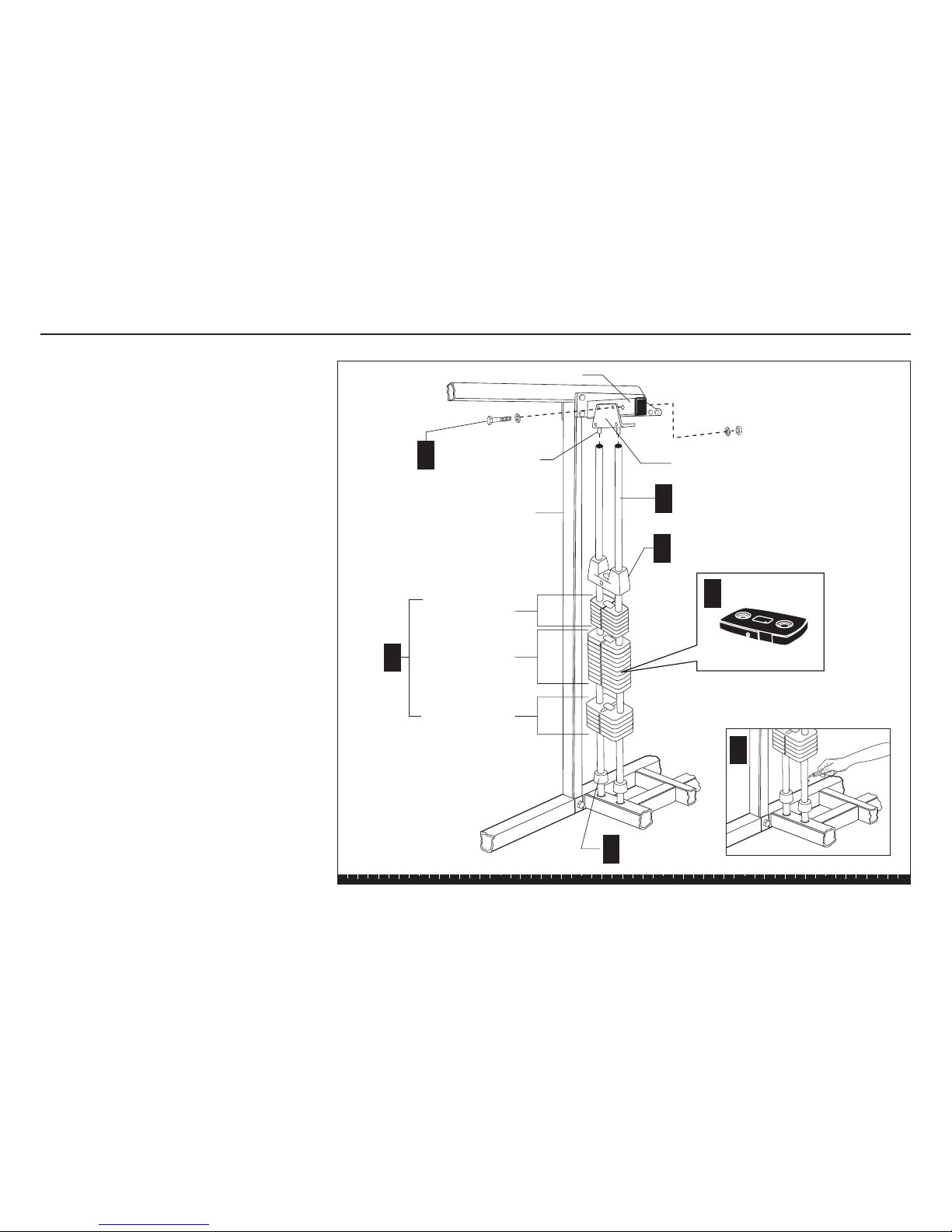

8. Assemble Preacher Curl

Weight Stack

Before assembling the Weight Stacks, be certain the

S3.45 is positioned in its permanent location.

A. Place two Guide Rods (from Box 1) into the large

holes on the Preacher Curl side of the Main Base.

The Guide Rods will be unstable until you

complete step 5.

B. Place one Weight Cushion (from Box 1) on each

Guide Rod and allow it to slide down to the top of

the Main Base.

C. Apply one tube of lubricant to each Guide Rod.

Avoid getting lubricant on your clothing or on other

parts of the machine.

D. Add the five 15-lb weights, the ten 10-lb weights,

and the five 5-lb weights. Note the tab location for

weight stickers (you will attach the stickers later).

Hold your finger over the plastic bushing in each

weight to prevent the bushing from popping out.

CAUTION: The weights are heavy! Handle

the weights carefully so as not to drop them

or injure yourself. Pick up and place one weight

at a time on the Guide Rods. Have someone

hold the Guide Rods in place while you slide

the weights on the stack.

E. Place the Cap Plate on the Guide Rods with

the hole facing toward you. Allow it to slide onto

the Weight Stack.

F. Inser t the retainer pins of the Side Bracket into the

Guide Rods. Attach the Side Bracket to the Top

Frame using

one 2¾-inch bolt

two washers

one locknut

Wrench tighten.

Step 8. Assemble Preacher Curl Weight Stack

Top Frame

1 - 2¾" bolt

2 - washers

1 - locknut

Guide Rods (2)

Rear Upright

Weight

Cushions (2)

D

B

A

F

E

Cap Plate

5 - 5-lb Weights

10 - 10-lb Weights

5 - 15-lb Weights

D

Side Bracket

Retainer

Pins

C

Page 18

S3.45 Assembly and Maintenance Guide

page 18

1 2 3 4 5 6

9. Assemble Leg Curl

Weight Stack

A. Place two Guide Rods into the large holes on the

Leg Curl side of the Main Base.

B. Place one Weight Cushion on each Guide Rod and

allow it to slide down to the top of the Main Base.

C. Apply one tube of lubricant to each Guide Rod.

Avoid getting lubricant on your clothing or on other

parts of the machine.

D. Add the five 15-lb weights, the ten 10-lb weights,

and the five 5-lb weights. Note the tab location for

weight stickers (you will attach the stickers later).

Hold your finger over the plastic bushing in each

weight to prevent the bushing from popping out.

CAUTION: The weights are heavy! Handle

them carefully so as not to drop them or injure

yourself. Pick up and place one weight at a time

onto the Guide Rods. Have someone hold the

Guide Rods in place while you slide the

weights on the stack.

E. Place the Cap Plate on the Guide Rods with

the hole facing toward you. Allow it to slide onto

the Weight Stack.

F. Inser t the retainer pins of the Center Bracket into

the Guide Rods, making sure the longest end of

the bracket points in the direction of the Chest

Press. Attach the Center Bracket to the Top Frame

using

two 3-inch bolts

four washers

two locknuts

Wrench tighten.

Step 9. Assemble Leg Curl Weight Stack

Guide Rods (2)

Weight

Cushions (2)

D

B

A

E

Cap Plate

Main Base

5 - 5-lb Weights

10 - 10-lb Weights

5 - 15-lb Weights

D

Rear Upright

2 - 3" bolts

4 - washers

2 - locknuts

Top Frame

F

Retainer Pins

Center Bracket

F

Front

Page 19

S3.45 Assembly and Maintenance Guide

page 19

1 2 3 4 5 6

10. Assemble Chest Press

Weight Stack

A. Place two Guide Rods into the large holes on the

Chest Press side of the Main Base. Use care not to

get lubricant from the Rods on your clothing or on

other parts of the machine.

B. Place one Weight Cushion on each Guide Rod and

allow it to slide down to the top of the Main Base.

C. Apply one tube of lubricant to each Guide Rod.

Avoid getting lubricant on your clothing or on other

parts of the machine.

D. Add the five 15-lb weights, the ten 10-lb weights,

and the five 5-lb weights. Note the tab location for

weight stickers (you will attach the stickers later).

Hold your finger over the plastic bushing in each

weight to prevent the bushing from popping out.

CAUTION: The weights are heavy! Handle

the weights carefully so as not to drop them or

injure yourself. Pick up and place one weight at

a time onto the Guide Rods. Have someone

hold the Guide Rods in place while you slide

the weights on the stack.

E. Place the Cap Plate on the Guide Rods with

the hole facing toward you. Allow it to slide onto

the Weight Stack.

F. Inser t the retainer pins of the Side Bracket into the

Guide Rods. Attach the Side Bracket to the Top

Frame using

one 2¾-inch bolt

two washers

one locknut

Wrench tighten.

Step 10. Assemble Chest Press Weight Stack

Guide Rods (2)

Weight

Cushions (2)

D

B

A

E

Cap Plate

Main Base

5 - 5-lb Weights

10 - 10-lb Weights

5 - 15-lb Weights

D

Rear Upright

1 - 2¾" bolt

2 - washers

1 - locknut

Top Frame

F

Retainer Pins

Side Bracket

Front

Page 20

S3.45 Assembly and Maintenance Guide

page 20

1 2 3 4 5 6

11. Feed Lower Leg Curl Cable

A. Feed the barrel end of Cable 43622-103 under one

3½-inch pulley. Note the location of the Spring Clip

in the illustration. Attach the pulley using

two 2-inch bolts

four washers

two locknuts

B. Feed the Cable over one 3½-inch pulley and under

another 3½-inch pulley. Attach the pulleys

using

two 2¾-inch bolts

four step spacers

two locknuts

C. Place the Cable between the Retainer Pin and the

hole on the Angle Pulley Bracket (bottom).

Sandwich one 4½-inch pulley between the top and

bottom Angle Pulley Brackets using

one 2-inch bolt

two washers

one locknut

Finger tighten.

D. Feed the Cable between the retainer pin and

hole in the Angle Pulley Bracket (Bottom) so that

the barrel end of the Cable is toward the Rotating

Arm. Attach the 4½-inch pulley to

the top and bottom Angle Brackets using

one cable retainer

one 2¼-inch bolt

two washers

one locknut

Finger tighten.

Step 11. Feed Lower Leg Curl Cable

C

Angle Pulley

Bracket (top)

Cable Retainer

D

1 - 4½" pulley

1 - 2" bolt

2 - washers

1 - locknut

1 - 4½" pulley

1 - cable retainer

1 - 2¼" bolt

2 - washers

1 - locknut

Step 12

A

D

C

G

B

E

A

1 - 3½" pulley

2 - 2" bolts

4 - washers

2 - locknuts

B

2 - 3½" pulleys

2 - 2¾" bolts

4 - step spacers

2 - locknuts

Upright Flats

Rotating Arm

End Pulley Bracket

Angle Pulley

Bracket (bottom)

Retainer Pin

Page 21

S3.45 Assembly and Maintenance Guide

page 21

1 2 3 4 5 6

E. Feed the barrel end of the Cable between the two

Upright Flats. Attach the barrel end of the Cable to

the Rotating Arm using

one 2¾-inch bolt

two step spacers

one locknut

F. Pull all excess Cable between the Guide Rods

toward the back of the Rear Base. Position

the Cable above the retainer pin, around the back.

Ensure the Cable is straight and free of tangles.

G. Attach two 4½-inch pulleys using

one 3¾-inch bolt

two washers

one locknut

Ensure the Cable is below the pulley and above

the retainer pins. Finger tighten.

H. Wrench tighten all bolts from this step.

Step 11. Feed Lower Leg Curl Cable, Continued

G

2 - 4½" pulleys

1 - 3¾" bolt

2 - washers

1 - locknut

F

E

1 - 2¾" bolt

2 - step spacers

1 - locknut

Rotating Arm

Rear Base

Retainer Pin

Barrel End of Cable

Page 22

S3.45 Assembly and Maintenance Guide

page 22

1 2 3 4 5 6

12. Feed Upper Leg Curl Cable

A. Insert the Selector Stem (from Box 2) into the Leg

Curl Weight Stack with the threaded hole at the

top. Hold the Selector Stem with several holes

above the Cap Plate. Insert the Weight Pin into the

Weight Stack to suspend the Selector Stem.

B. Place the loop end of the Weight Pin Lanyard into

the U end of Cable 40535-102. Place the U end of

the Cable on the top of the Selector Stem.

C. Align the holes in the top of the Selector Stem, U,

and Cap Plate. Attach using

one 1½-inch socket cap bolt

Wrench tighten. Remove the Weight Pin and lower

the Cap Plate.

D. Draw the threaded end of the Cable up and

through the center hole on the Center Bracket.

Place the Cable between the cable retainer and

one 4½-inch pulley. Attach the pulley and the

Cable Retainer to the Top Frame using

one 2¾-inch bolt

two washers

one locknut

Finger tighten.

E. Unscrew the locknut and washer from the threaded

end of the Cable and attach the threaded end of

the Cable to the Top Frame.

Tighten the locknut so that at least two threads

stick out past the top of the nut. The cable will be

loose. It will be adjusted later.

Step 12. Feed Upper Leg Curl Cable

E

D

Guide Rods

Cap Plate

Selector Stem

Weight Pin

Cable Retainer

Top Frame

1 - 4½" pulley

1 - 2¾" bolt

2 - washers

1 - locknut

1 - locknut

1 - washer

B

C

1 - 1½" socket

cap bolt

Step 11

E

D

F

H

A

Center Bracket

Threaded end of

Cable

Page 23

S3.45 Assembly and Maintenance Guide

page 23

1 2 3 4 5 6

F. Attach two Floating Pulley Plates to one

4½-inch pulley using

one 2-inch bolt

two washers

one locknut

Finger tighten.

G. Loop the Cable from the Top Frame around the

pulley.

H. Loop the Cable from the Main Base around one

4½-inch pulley and attach it to the remaining holes

in the Floating Pulley Plates using

one 2-inch bolt

two washers

one locknut

I. Wrench tighten all bolts from this step.

J. Ensure the Weight Pin is in place. Hold the

threaded end of the Cable in place with pliers, and

tighten the locknut until there is no slack in the

Cable. If the weights lift, you have over-tightened.

Step 12. Feed Upper Leg Curl Cable, Continued

F

H

1 - 4½" pulley

1 - 2" bolt

2 - washers

1 - locknut

1 - 4½" pulley

1 - 2" bolt

2 - washers

1 - locknut

J

G

Cable from the Top

Frame

Page 24

S3.45 Assembly and Maintenance Guide

page 24

1 2 3 4 5 6

13. Assemble Leg Curl Seat

A. Attach the Backpad Support Tubes to the Seat

Upright using

one 5½-inch bolt

two ½-inch washers

one ½-inch locknut

Note: The tube with the Selector Pivot Flat is

nearest the Weight Stack. Also note that the hole

in the other support tube is positioned closest to

the Backpad Pop Pin, as shown. Wrench tighten,

and then loosen until the support tube can fall

freely without wobbling.

CAUTION: Keep your hands clear to avoid

injury when the support tube falls.

B. Align the Selector Pivot Flat with the Backpad

Pop Pin.

C. Attach the Seat Pad to the Seat Upright using

one 7-inch bolt

one ½-inch locknut

Finger tighten.

Step 13. Assemble Leg Curl Seat

A

C

A

Seat Upright

1 - 7" bolt

1 - ½" locknut

Seat Pad

1 - 5½" bolt

2 - ½" washers

1 - ½" locknut

Backpad Support

Tubes

Seat Upright

Selector

Pivot Flat

Backpad

Pop Pin

B

Page 25

S3.45 Assembly and Maintenance Guide

page 25

1 2 3 4 5 6

D. Attach the lower section of the Backpad to the

lower hole of the right Backpad Support Tube using

two 3-inch bolt

two washers

Finger tighten.

E. Attach the Leg Curl Handle to the holes at the top of

the Backpad Support Tubes using

two 1-inch bolts

two washers

F. Attach the Backpad Support Tubes to the top of the

Backpad using

two 3-inch bolts

two washers

G. Attach the top portion of the Leg Curl Handle to the

holes at the top and bottom of the Headrest using

two 1¼-inch bolts

two washers

Note: Handles point down when fastened.

H. Wrench tighten all bolts from this step.

I. Attach the Calf Raise Block to the Leg Curl Seat

Upright using

one 4¼-inch bolt

two washers

one locknut

Step 13. Assemble Leg Curl Seat, Continued

D

G

2 - 1¼" bolts

2 - washers

2 - 3" bolt

2 - washers

Leg Curl

Handle

Backpad

I

Calf Raise Block

1 - 4¼" bolt

2 - washers

1 - locknut

Backpad Support

Tubes

Leg Curl Seat Upright

Headrest

E

2 - 1" bolts

2 - washers

F

2 - 3" bolts

2 - washers

Page 26

S3.45 Assembly and Maintenance Guide

page 26

1 2 3 4 5 6

Open Box 4

Use tie cutters to open the box.

The diagram shows how the S3.45 will look after you

complete this section.

Note: Some items in these boxes may not be needed

until later in the assembly process.

Open Box 4

Page 27

S3.45 Assembly and Maintenance Guide

page 27

1 2 3 4 5 6

14. Attach Chest Press Seat

A. Attach the Chest Press Upright to the Chest Press

Seat using

four ¾-inch bolts

four washers

Finger tighten.

B. Attach the lower hole at top of the Chest Press

Upright to the Rear Upright using

one 3½-inch bolt

one washer

Finger tighten.

C. Attach the middle hole at the top of the Chest

Press Upright to the Rear Upright using

one 3½-inch bolt

one washer

D. Attach the Chest Press Seat to the Chest Press

Rear Base using

one 3-inch bolt

two washers

one locknut

Finger tighten.

E. Wrench tighten all bolts.

F. Attach the Prestretch Tube and Pulley Plate to the

Rear Upright using

two 3½-inch bolts

two washers

Wrench tighten.

Step 14. Attach Chest Press Seat

F

B

D

2 - 3½" bolts

2 - washers

Pulley

Plate

1 - 3½" bolt

1 - washer

C

1 - 3½" bolt

1 - washer

Rear Upright

Chest Press

Rear Base

A

4 - ¾" bolts

4 - washers

1 - 3" bolt

2 - washers

1 - locknut

Chest Press

Upright

Chest Press

Seat

Prestretch

Tube

View from behind.

Page 28

S3.45 Assembly and Maintenance Guide

page 28

1 2 3 4 5 6

15. Attach Press Arm Assembly

CAUTION: This step requires two people. Do not

pinch yourself between the Press Arm and the

Prestretch Tube.

A. Attach the Press Arm Assembly to the Rear Upright

using

two 4-inch bolts

four washers

two locknuts

B. Check the alignment of the Press Arm

Assembly and Prestretch Tube. Wrench tighten.

C. Use the supplied allen wrench and tighten the set

screws.

Step 15. Attach Press Arm Assembly

A

2 - 4" bolts

4 - washers

2 - locknuts

Prestretch

Tube

Rear

Upright

Press Arm

Assembly

View from behind.

C

2 - set screws

Page 29

S3.45 Assembly and Maintenance Guide

page 29

1 2 3 4 5 6

16. Attach Handlebars

A. Slide each Handlebar (one at a time) onto the Pivot

Shaft and attach it using

one ½-inch washer

one ½-inch hat washer

one locknut

Note: Tighten the locknut until the Handlebars

don't move. Then, loosen the locknut about onehalf turn until the arms pivot freely. Note that a few

threads should show beneath the Pivot Shafts, if

you have tightened it properly.

B. Secure the plastic caps over the locknuts.

A rubber mallet may be useful to lightly tap the

caps into place.

Step 16. Attach Handlebars

Press Arm

Assembly

1 - plastic cap

Handlebars

Pivot Shaft

1 - ½" washer

1 - ½" hat washer

1 - ½" locknut

A

B

Page 30

S3.45 Assembly and Maintenance Guide

page 30

1 2 3 4 5 6

17. Assemble Chest Press Seat

A. Place the Backpad and Headrest on the floor. Place

the Long Support Tube and Short Support Tube on

the Backpad. Attach at the top using

two 1¼-inch bolts

two washers

B. Attach at the bottom using

three 3-inch bolts

three washers

C. Attach the Backpad and Headrest assembly to the

Chest Press Upright using

one ½-inch x 5¼-inch bolt

two washers

one locknut

Finger tighten.

Note: The Stop Pad on the seat assembly should be

between the Pop Pin and the Support Stop on the

Chest Press Upright.

D. Wrench tighten, still allowing movement.

CAUTION: If you move the Handlebars out of

the way for this step, be careful that they don’t

hit you.

E. Attach the Seat Pad to the Seat Stem using

two 1¼-inch bolts

two washers

Wrench tighten.

Step 17. Assemble Chest Press Seat

1

2

3

4

1

2

3

4

Long Support

Tube

Seat Pad

Backpad

1 - ½" x 5¼" bolt

2 - washers

1 - locknut

C

Seat Stem

Short

Support

Tube

2 - 1¼" bolts

2 - washers

E

Long Support Tube

Short

Support

Tube

3 - 3" bolts

3 - washers

B

2 - 1¼" bolts

2 - washers

A

Short Support

Tube

Long

Support

Tube

Backpad

Stop Pad

Pop Pin

Chest Press

Upright

Headrest

Headrest

The Backpad and Headrest are not

shown in this illustration.

Page 31

S3.45 Assembly and Maintenance Guide

page 31

18. Feed Chest Press Cable

A. Insert the Selector Stem into the Chest Press

Weight Stack with the threaded hole at the top. Hold

the Selector Stem with several holes above the Cap

Plate. Insert the Weight Pin to suspend the Selector

Stem. Place the loop end of the Weight Pin Lanyard

into the U end of Cable 43623-103. Align the U end

of the Cable, the top of the Selector Stem, and the

Cap Plate. Attach using

one 1½-inch socket cap bolt

Wrench tighten. Remove the Weight Pin and lower

the Cap Plate.

B. While standing on a step ladder, loop the middle

section of the Cable through the window in the Top

Frame and over one 6-inch pulley. Lower the pulley

and Cable into the window and attach using

one 2¾-inch bolt

two ½-inch step spacers

one locknut

Finger tighten.

Note: If you have the Leg Press option, see the

Leg Press assembly instructions for an alternate

Cable and pulley installation step.

C. Place the Cable between the cable retainer and

one 4½-inch pulley. Attach to the Pulley Plate using

one 2½-inch bolt

two washers

one ½-inch barrel spacer

one locknut

Wrench tighten.

D. Remove the Spring Clip from the other end of the

Cable. Feed the Cable through the window in the

Rear Upright and attach one 4½-inch pulley using

one 2¾-inch bolt

two ½-inch step spacers

one locknut

Step 18. Feed Chest Press Cable

Ensure the Cable passes between the pulley and

retainer pin. Wrench tighten.

E. Place the Cable over one 4½-inch pulley and

attach to the upper hole in the Press Arm Flats

using

one 2-inch bolt

two washers

one locknut

Finger tighten.

F. Ensure the Cable wraps around the pulley and

then feed the Cable back through the Press

Arm Flats. Wrap the Cable over and around one

4½-inch pulley and attach it to the Prestretch Tube

using

one 2-inch bolt

two washers

one cam washer

one locknut

Finger tighten.

G. Wrap the Cable over one 3½-inch pulley and

attach it to the bottom hole on the Press Arm Flats

using

one 2-inch bolt

two washers

one locknut

H. In the middle hole on the Press Arm Flats, make a

retainer pin using

one 2-inch bolt

two washers

one 1-inch long barrel spacer

one locknut

Finger tighten.

I. Wrench tighten steps E through H. Do not

overtighten.

J. Reattach the Spring Clip to the Cable.

K. Remove excess slack by adjusting the cam washer

attached to the Prestretch Tube. Wrench tighten.

A

B

C

D

E

F

H

Each step is shown in more detail on the following page.

This completes box 4. You may move the box out of

the way.

Page 32

S3.45 Assembly and Maintenance Guide

page 32

Step 18. Feed Chest Press Cable, Continued

1 - 6" pulley

1 - 2¾" bolt

2 - ½" step spacers

1 - locknut

B

C

1 - 4½" pulley

1 - 2½" bolt

2 - washers

1 - ½ barrel spacer

1 - locknut

1 - cable retainer

D

1 - 4½" pulley

1 - 2¾" bolt

2 - ½" step spacers

1 - locknut

E

1 - 4½" pulley

1 - 2" bolt

2 - washers

1 - locknut

H

1 - 2" bolt

2 - washers

1 - long barrel

spacer

1 - locknut

G

1 - 3½" pulley

1 - 2" bolt

2 - washers

1 - locknut

F

1 - 4½" pulley

1 - 2" bolt

2 - washers

1 - cam washer

1 - locknut

Pulley plate

Guide Rods

Weight Pin

Selector Stem

Cap Plate

A

1 - 1½" socket

cap bolt

Barrel Spacer

Press Arm Flats

Prestretch

Tube

Page 33

S3.45 Assembly and Maintenance Guide

page 33

1 2 3 4 5 6

Open Box 5

Use tie cutters to open the box.

The diagram shows how the S3.45 will look after you

complete this section.

Note: Some items in these boxes may not be used

until later in the assembly process.

Open Box 5

Page 34

S3.45 Assembly and Maintenance Guide

page 34

1 2 3 4 5 6

19. Attach Foot Support

A. Attach the Foot Support to the Preacher Curl Rear

Base using

two 3¼-inch bolts

four washers

two locknuts

Wrench tighten.

Step 19. Attach Foot Support

2 - 3¼" bolts

4 - washers

2 - locknuts

A

Foot Support

Page 35

S3.45 Assembly and Maintenance Guide

page 35

1 2 3 4 5 6

20. Attach Seat Frame

A. Attach the Seat Frame to the Preacher Curl Rear

Base using

two 3¼-inch bolts

four washers

two locknuts

Wrench tighten.

Step 20. Attach Seat Frame

Seat Frame

2 - 3¼" bolts

4 - washers

2 - locknuts

B

Page 36

S3.45 Assembly and Maintenance Guide

page 36

1 2 3 4 5 6

21. Attach Row Bar Shelf and

Seat Pads

A. Attach the Row Bar Shelf to the Rear Upright above

the pulley window using

one 3¾-inch bolt

two washers

one locknut

Finger tighten.

B. Insert the Arm Stem into the Seat Frame with the

seven-hole side facing the Rear Upright.

C. Attach the Arm Pad, thick portion up, to the Arm

Stem using

two 1¼-inch bolts

two washers

Finger tighten.

D. Attach the Seat Pad to the Seat Frame using

two 3-inch bolts

two washers

Finger tighten.

E. Wrench tighten.

Step 21. Attach Row Bar Shelf and Seat Pads

Seat Pad

Arm Pad

Row Bar

Shelf

Arm Stem

Rear Upright

Seat Frame

2 - 1¼" bolts

2 - washers

C

1 - 3¾" bolt

2 - washers

1 - locknut

A

2 - 3" bolts

2 - washers

D

B

Page 37

S3.45 Assembly and Maintenance Guide

page 37

1 2 3 4 5 6

22. Feed Upper Preacher Curl

Cable

A. While standing on a step ladder, feed the U end of

Cable 43621-103 through the window in the Top

Beam and out the window at the other end. Note the

location of the Spring Clip on the Cable.

B. Wrap the Cable over one 4½-inch pulley. Attach it to

the Top Beam using

one 2¾-inch bolt

two ½-inch step spacers

one locknut

Wrench tighten.

C. Attach the cable retaining bolt to the Top Beam

using

one 2¾-inch bolt

two washers

one locknut

D. At the inner window in the Top Beam, wrap the

Cable over one 3½-inch pulley and attach it using

one 2¾-inch bolt

two ½-inch step spacers

one locknut

Wrench tighten.

E. Loop the Cable through the window in the Top

Frame and over one 6-inch pulley. Lower the pulley

and Cable into the window and attach it using

one 2¾-inch bolt

two ½-inch step spacers

one locknut

Wrench tighten.

Note: Some extra cable must be hanging between

steps D and E for use in step G.

Step 22. Feed Upper Preacher Curl Cable

1 - 4½" pulley

1 - 2¾" bolt

2 - ½" step spacers

1 - locknut

B

Top Beam

1 - 3½" pulley

1 - 2¾" bolt

2 - ½" step spacers

1 - locknut

D

1 - 2¾" bolt

2 - ½" step spacers

1 - locknut

1 - 6" pulley

E

Top Frame

Step 23

G

B

D

E

F

View from behind.

View from behind.

A

1 - 2¾" bolt

2 - washers

1 - locknut

C

Page 38

S3.45 Assembly and Maintenance Guide

page 38

1 2 3 4 5 6

F. Ensure the U end of the Cable feeds between the

Guide Rods. Insert the Selector Stem into the

Preacher Curl Weight Stack with the threaded hole

at the top. Hold the Selector Stem with several

holes above the Cap Plate.

G. Insert the Weight Pin to suspend the Selector

Stem.

H. Place the loop end of the Weight Pin Lanyard into

the U end of the Cable.

I. Align the U end of the Cable, Selector Stem, and

Cap Plate. Attach using

one 1½-inch socket cap bolt

Wrench tighten. Remove the Weight Pin and lower

the Cap Plate.

J. Place one 4½-inch pulley into the previously

created cable loop from step E. Sandwich the

pulley between two Floating Pulley Plates. Attach

using

one 2-inch bolt

two washers

one locknut

Finger tighten.

Step 22. Feed Upper Preacher Curl Cable, Continued

1 - 1½" socket cap bolt

I

1 - 4½" pulley

1 - 2" bolt

2 - washers

1 - locknut

J

Pulley Plates

Guide Rods

Cap Plate

Selector Stem

Weight Pin

H

G

F

Page 39

S3.45 Assembly and Maintenance Guide

page 39

1 2 3 4 5 6

23. Feed Lower Preacher Curl

Cable

A. Wrap the center of Cable 43620-103 around one 4½-

inch pulley and attach it in the remaining hole of the

two Floating Pulley Plates using

one 2-inch bolt

two washers

one locknut

Wrench tighten bolts in the Pulley Plates.

B. Ensure the Cables are not crossed. Take the end of

the Cable closest to the Preacher Curl and feed it

through the upper window in the Rear Upright. Feed

it under one 4½-inch pulley and attach using

one 2¾-inch bolt

two ½-inch step spacers

one locknut

Ensure the Cable passes between the pulley and

retainer pin. Wrench tighten.

C. Feed the other Cable end (the end closest to the

Chest Press) through the Rear Upright extension

window. Attach one 4½-inch pulley in the window

using

one 2¾-inch bolt

two 1³⁄₈-inch step spacers

one locknut

Finger tighten.

Step 23. Feed Lower Preacher Curl Cable

1 - 4½" pulley

1 - 2" bolt

2 - washers

1 - locknut

A

1 - 4½" pulley

1 - 2¾" bolt

2 - ½" step washers

1 - locknut

B

1 - 4½" pulley

1 - 2¾" bolt

2 - 1³⁄₈" step spacers

1 - locknut

C

Step 22

A

B

Rear Upright

Rear Upright

C

D

View from behind.

View from behind.

Page 40

S3.45 Assembly and Maintenance Guide

page 40

1 2 3 4 5 6

D. Lift up the Selector Stem and insert the Weight Pin

to create slack in the Cable. Feed the Cable

through the remaining window in the Rear Upright.

Attach one 4½-inch pulley using

one 2¾-inch bolt

two ½-inch step spacers

one locknut

Ensure the Cable passes between the pulley and

the retainer pin.

E. Wrench tighten bolts from steps B and D.

F. Push the pulley from step C toward the Chest

Press Station until you feel the Weight Stack begin

to lift. Wrench tighten the pulley in that position.

Note: If you are assembling the Leg Press Option and

the S3.45 simultaneously, go to Step 5 in the

S3.45

Leg Press Option Assembly Instructions

now.

Step 23. Feed Lower Preacher Curl Cable, Continued

1 - 4½" pulley

1 - 2¾" bolt

2 - ½" step spacers

1 - locknut

D

F

Rear Upright

Rear Upright

Page 41

S3.45 Assembly and Maintenance Guide

page 41

1 2 3 4 5 6

24. Attach Lat Bar Holders

A. Attach the Lat Bar Holders to the Top Beam using

two 3¼-inch bolts

four washers

two locknuts

B. Wrench tighten.

Step 24. Attach Lat Bar Holders

2 - 3¼" bolts

4 - washers

2 - locknuts

A

Top Beam

Lat Bar Holders

Page 42

S3.45 Assembly and Maintenance Guide

page 42

1 2 3 4 5 6

25. Attach Accessories

A. Attach the Lat Bar to the Spring Clip at the end of

the Top Beam.

B. Attach the Row (V) Handle to the Spring Clip at the

upper window of the Rear Upright and place it in

the holder above it.

C. Attach the 18-inch Straight Bar and chain to the

Spring Clip at the lower pulley window of the Rear

Upright and place it in the holder below it.

D. Attach the Ab Crunch Strap to the Spring Clip on

the Press Arm.

E. Attach the Ankle Strap to the Spring Clip on the

Leg Station.

Step 25. Attach Accessories

A

Lat Bar

B

Row (V)

Handle

C

18-inch

Straight Bar

D

Ab Crunch Strap

E

Ankle Strap

Page 43

S3.45 Assembly and Maintenance Guide

page 43

1 2 3 4 5 6

26. Apply Weight Decals

A. Remove the backing for the decals labeled

“1–5.” Press the decals to the front surface of the

top five weight plates in the tab location as

indicated. Remove the front decal protector.

B. Remove the backing for the decals labeled

“6–15.” Press the decals to the front surface of the

middle ten weight plates in the tab location as

indicated. Remove the front decal protector.

C. Remove the backing for the decals labeled

“16–20.” Press the decals to the front surface of

the bottom five weight plates in the tab location as

indicated. Remove the front decal protector.

D. Repeat steps A through C for all three Weight

Stacks.

Step 26. Apply Weight Decals

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Page 44

S3.45 Assembly and Maintenance Guide

page 44

1 2 3 4 5 6

Open Box 6

Use tie cutters to open the box.

The illustration shows how the S3.45 will look after you

complete this section.

Open Box 6

Page 45

S3.45 Assembly and Maintenance Guide

page 45

1 2 3 4 5 6

27. Attach Shrouds

Important: Before attaching the Shrouds, make any

necessary adjustments. Refer to "Adjustments and

Maintenance" on page 47.

A. Slide the Left-Hand Leg Curl Shroud between the

Front Upright and the Main Base, starting from the

bottom and rotating the top into position. Attach the

Shroud to the Front Upright and Main Base using

two 2¾-inch buttonhead bolts

Finger tighten.

B. Attach Right-Hand Leg Curl Shroud to the Front

Upright and Main Base using

two ¾-inch buttonhead bolts

Finger tighten.

Note: The Leg Curl Shrouds are larger than the

Preacher Curl or Chest Press Shrouds.

C. Attach both Shrouds to the Side Bracket and Main

Base using

four 3¾-inch buttonhead bolts

four 3-inch barrel spacers

Finger tighten.

Step 27. Attach Shrouds

A

A

C

C

B

C

B

A

C

1 - 3¾" buttonhead bolt

1 - 3" barrel spacer

1 - 3¾" buttonhead bolt

1 - 3" barrel spacer

1 - 3¾" buttonhead

bolt

1 - 3" barrel spacer

1 - 3¾" buttonhead bolt

1 - 3" barrel spacer

1 - ¾" buttonhead bolt

1 - 2¾" buttonhead bolt

1 - 2¾" buttonhead bolt

1 - ¾" buttonhead

bolt

Page 46

S3.45 Assembly and Maintenance Guide

page 46

1 2 3 4 5 6

D. Attach the Side Shrouds to the Side Bracket and

Main Base using

four 3¾-inch buttonhead bolts

four barrel spacers

Note: This is done for two Shrouds.

E. Attach the Leg Press Shroud to the Rear Upright

and Side Shroud using

eight ¼-inch by 2½-inch buttonhead bolts.

F. Wrench tighten all bolts, for steps A through E.

This completes the assembly of your Precor S3.45.

Side Shroud

Side Shroud

Leg Press Shroud

View from behind.

E

E

E

E

E

E

E

E

E

8 - ¼" x 2½"

buttonhead bolts

D

D

D

1 - 3¾" buttonhead

bolt

1 - 3" barrel spacer

1 - 3¾" buttonhead

bolt

1 - 3" barrel spacer

1 - 3¾" buttonhead

bolt

1 - 3" barrel spacer

D

1 - 3¾" buttonhead

bolt

1 - 3" barrel spacer

Step 27. Attach Shrouds, Continued

Page 47

S3.45 Assembly and Maintenance Guide

page 47

1 2 3 4 5 6

4

Adjustments and

Maintenance

After the S3.45 is completely assembled, you must

check the Cables for proper tension. Obvious signs

that Cable problems exist include:

✔ The Cap Plate does not rest squarely on the top

weight of the Weight Stack.

✔ The Cable rubs the inside edges of the pulleys.

✔ Excess slack exists in the Cable.

CAUTION: Take the time to perform the following

steps. If the Cables do not have the proper tension,

you could void the Precor Limited Warranty.

1. Cable Adjustments

A. Place the Weight Pin in the Top Cap to ensure the

least Cable resistance.

B. To remove slack from the Cable, pull up on the

Chest Press Handlebars and adjust the cam

washer.

C. Lower the Chest Press Handlebars.

D. Check the weights. Move the Weight Pin to each

weight plate and Selector Stem location.

Adjustments and Maintenance

C

Chest Press Arms

B

Cam Washer

Top Cap

Weight

Weight

Pin

A

Top Weight

D

Weight

Pin

Page 48

S3.45 Assembly and Maintenance Guide

page 48

1 2 3 4 5 6

2. Selector Stem Adjustments

To prevent the Selector Stem from contacting the inside

of the Weight Stack when the machine is in use, you

need to check the vertical angle of the Selector Stem

(steps A and B). If the stem slides smoothly without

contacting the inside of the weight plates, assembly of

the unit is complete.

Caution: Performing the following tasks requires

two people.

A. Remove the Weight Pin from the Weight Stack.

B. Perform an exercise using each part of the S3.45.

When the base of the Selector Stem is clear of

the Weight Stack, observe the position of the

Selector Stem.

The following sections describe how to adjust the

Selector Stem when contact does occur.

The Selector Stem can be adjusted forward or

backward, depending on the area of contact.

Forward Angle Adjustment

When the Selector Stem angles forward (toward the

seat) and contacts the inside of the Weight Stack

during use, adjust it by taking these steps:

Caution: This adjustment requires two people.

A. Completely disassemble the Cap Plate,

Selector Stem, and Cable Clamp.

B. Thread Allen head set screw into the hole closest

to the top of the U end of the cable and turn

clockwise until the end of the screw is flush with

the inside surface of the clamp.

C. Turn the set screw clockwise another one-half turn

(see diagram).

Step 2. Selector Stem Adjustments

Forward Angle

Selector Stem

Cap Plate

1 ½" Socket

Cap Bolt

U Bracket

Allen head

Set screw

Inside

surface

Set screw

▲

A

B

B

Forward Angle Adjustment

Page 49

S3.45 Assembly and Maintenance Guide

page 49

1 2 3 4 5 6

D. Reassemble the Cap Plate, Selector Stem, and

Cable Clamp.

E. Test the movement of the Selector Stem inside the

Weight Stack.

F. If the Selector Stem continues to contact the

plates, repeat steps A through E until the Selector

Stem slides through the Weight Stack without

contacting the plates.

Backward Angle Adjustment

When the Selector Stem angles backward (away from

the seat) and contacts the inside of the Weight Stack

during use, adjust it by taking these steps:

Caution: This adjustment requires two people.

A. Completely disassemble the Cap Plate, Selector

Stem, and Cable Clamp.

B. Thread Allen head set screw into the hole closest

to the top of the U end of the Cable and turn

clockwise until the end of the screw is flush with

the inside surface of the clamp.

C. Turn the set screw clockwise another one-half turn

(see diagram).

D. Reassemble the Cap Plate, Selector Stem, and

Cable Clamp.

E. Test the movement of the Selector Stem inside the

Weight Stack.

F. If the Selector Stem continues to contact the

plates, repeat steps A through E until the Selector

Stem slides through the Weight Stack without

contacting the plates.

Step 2. Selector Stem Adjustments, Continued

Backward Angle

Selector Stem

▲

Cap Plate

1 ½" Socket

Cap Bolt

Allen head

set screw

Set screw

U Bracket

Inside

surface

B

B

A

Backward Angle Adjustment

Page 50

S3.45 Assembly and Maintenance Guide

page 50

1 2 3 4 5 6

Step 3. Maintenance

A

B

Pull the Selector Stem and

Top Cap Weight up to

expose at least 5 holes.

Hold the stem in place by inserting

the Weight Pin (through a weight)

near the base of the Selector Stem.

C

Loosen the socket cap bolt and align the

Selector Stem.

D

Once the Selector Stem is centered, retighten the

socket cap bolt securely.

Side-to-Side Vertical Adjustment

If the Selector Stem contacts the inside of the Weight

Stack during use or the Weight Pin becomes difficult to

insert in the Weight Stack, the Selector Stem may be

out of alignment vertically side to side. Adjust the

Selector Stem by taking these steps:

Caution: Performing these steps requires two

people.

A. Pull the Selector Stem and Top Cap up to expose

at least five Selector Stem holes.

B. Insert the Weight Pin near the base of the Selector

Stem to hold it in place.

C. To center the Selector Stem, loosen the socket cap

bolt that attaches the Top Cap to the U bracket.

D. Once the Selector Stem is centered, retighten the

socket cap bolt securely.

E. Lower the Selector Stem into the Weight Stack.

Test the movement of the Selector Stem inside the

Weight Stack.

F. Make certain that the Weight Pin can be inserted

into every hole in the Weight Stack. If the Selector

Stem continues to contact the plates, repeat steps

A through E until the Selector Stem slides through

the Weight Stack without contacting the plates.

After completing the adjustments, fill out the warranty

card and mail it in.

3. Maintenance

Lubricate the Guide Rods every six months.

Thank you for choosing Precor!

Page 51

page 51

RET.

To allow us to serve you better, please take a few moments to

complete and return your warranty registration.

YOU MAY ALSO REGISTER ONLINE AT

www.precor.com/warranty

If you have questions or need additional information, contact your

local dealer or call Precor Customer Support at 800-347-4404.

Thank You and Welcome to Precor

Precor Incorporated

20031 142nd Avenue NE

PO Box 7202

Woodinville, WA 98072-4002

PLACE

STAMP

HERE

Page 52

page 52

TELL US ABOUT YOUR NEW PRECOR PRODUCT

Purchased

from:

The serial number is located on the shipping box and on the product.

Product

Serial

Number:

Please indicate the type of product purchased:

❑ Elliptical Fitness CrossTrainer (EFX

®

)

❑ Treadmill

❑ Strength Training System

TELL US ABOUT YOU

Date of

Purchase:

❑ Mr.

❑ Mrs.

❑ Ms.

First Name

Apt./Suite:

TELL US ABOUT YOUR PURCHASE

Please detach and mail in the warranty registration within ten days of purchase.

❑ StretchTrainer

TM

❑ Cycle

❑ Stair Climber

Middle Initial Last Name

Street Address

Zip CodeCity State

Gender: Marital status: Age: Annual household income: What are your fitness goals?

❑ Male ❑ Married ❑ Under 18 ❑ Under $50,000 ❑ Weight loss/management

❑ Female ❑ Divorced ❑ 18-24 ❑ $51,000-75,000 ❑ Muscle tone enhancement

❑ Widowed ❑ 25-34 ❑ $76,000-100,000 ❑ Cardiovascular improvement

❑ Never been married ❑ 35-44 ❑ $101,000-150,000 ❑ Overall health

❑ 45-54 ❑ $151,000+ ❑ Increase energy and flexibility

❑ 55-64 ❑ Stress reduction

❑ 65+ ❑ Rehabilitation

❑ Other

Purchase (check all that apply): How did you FIRST become aware of Precor

❑ First Precor product products (choose only one):

❑ Replaces a Precor product of the same type ❑ A gift

❑ Replaces same type of product – different brand ❑ Friend/relative

❑ Addition to equipment currently owned ❑ Physician

❑ Fitness club

❑ Internet

What factors MOST influenced your decision to ❑ News report or product review

purchase your Precor product (choose up to three): ❑ Magazine advertisement or article

❑ Precor reputation ❑ Print advertisement

❑ Prior use of Precor product(s) ❑ In-store display or demonstration

❑ Design/appearance ❑ Other

❑ Value for the price

❑ Special product features

❑ Rebate or sale price

❑ Quality/durability

❑ Warranty

❑ Physician recommendation

Month

Day

Year

Your Email Address

Area Code

Telephone

Dealer Name

Effective 01 July 2004

P/N 45623-102

Page 53

Effective 01 January 2003

P/N 36287-110

Precor Residential Equipment Limited Warranty

PLEASE READ THESE WARRANTY TERMS AND CONDITIONS CAREFULLY BEFORE USING

YOUR PRECOR INCORPORATED PRODUCT. BY USING THE EQUIPMENT, YOU ARE

CONSENTING TO BE BOUND BY THE FOLLOWING WARRANTY TERMS AND CONDITIONS.

Limited Warranty.

Precor Incorporated warrants all new Precor products to be free from defects in materials and

manufacture for the warranty period set forth below. The warranty period commences on the

invoice date of original purchase. This warranty applies only against defects discovered within

the warranty period and extends only to the original purchaser of the product. Parts repaired or

replaced under the terms of this warranty will be warranted for the remainder of the original

warranty period only. To make claim under warranty, the buyer must notify Precor or their

authorized Precor dealer within 30 days after the date of discovery of any nonconformity and

make the affected product available for inspection by Precor or its service representative.

Precor’s obligations under this warranty are limited and set forth below.

Warranty Periods and Coverage

All residential products and commercial products used in the home are warranted for the

following periods:

• Lifetime frame and welds

• 10 years parts and wear items

• 1 year labor

• Coverage for options and accessories defined below.

Options / Accessories

Many options or accessories have components that are connected internally or mounted inside the

electronic console. The following guidelines determine the warranty for these components. If the

internal components are installed by the factory or by an authorized dealer as part of the original

sale and delivery, they have a warranty that is identical to the warranty of the equipment in which

they are connected or mounted. If the internal components are not installed by the factory or by an

authorized dealer as part of the original sale and delivery, they have a 90-day parts and labor

limited warranty. All components that are not internally connected have 90-day parts only limited

warranty. Satisfactory proof of purchase is required in all cases.

Conditions and Restrictions

This warranty is valid only in accordance with the conditions set forth below:

1. The warranty applies to the Precor product only while:

a. It remains in the possession of the original purchaser and proof of purchase is

demonstrated

b. It has not been subjected to accident, misuse, abuse, improper service, or non-Precor

modifications

c. Claims are made within the warranty period

2. This warranty does not cover damage or equipment failure caused by electrical wiring not in

compliance with electrical codes or Precor owner’s manual specifications, or failure to provide

reasonable and necessary maintenance as outlined in the owner’s manual.

3. Warranty of all Precor products applies to residential use only and is void when products are

used in a nonresidential environment or installed in a country other than where sold.

4. Except in Canada, Precor does not pay labor outside the United States.

5. Warranties outside the United States and Canada may vary. Please contact your local Dealer

for details.

This limited warranty shall not apply to:

1. Software version upgrades

2. Cosmetic items, including, but not limited to the following: grips, seats, and labels.

3. Repairs performed on Precor equipment missing a serial number or with a serial tag that has

been altered or defaced.

4. Ser vice calls to correct installation of the equipment or instruct owners on how to use the

equipment.

5. Pickup, delivery, or freight charges involved with repairs.

6. Any labor costs incurred beyond the applicable labor warranty period.

Disclaimer and Release

The warranties provided herein are the exclusive warranties given by Precor and supersede any prior,

contrary or additional representations, whether oral or written. ANY IMPLIED WARRANTIES, INCLUDING THE

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE THAT APPLY TO ANY PARTS DESCRIBED ABOVE

ARE LIMITED IN DURATION TO THE PERIODS OF EXPRESS WARRANTIES GIVEN ABOVE FOR THOSE SAME PARTS. PRECOR

HEREBY DISCLAIMS AND EXCLUDES THOSE WARRANTIES THEREAFTER.

Some states do not allow limitation on how

long an implied warranty lasts, so the above limitation may not apply to you. PRECOR ALSO HEREBY DISCLAIMS

AND EXCLUDES ALL OTHER OBLIGATIONS OR LIABILITIES, EXPRESS OR IMPLIED, ARISING BY LAW OR OTHERWISE, WITH

RESPECT TO ANY NONCONFORMANCE OR DEFECT IN ANY PRODUCT, INCLUDING BUT NOT LIMITED TO: (A) ANY OBLIGATION,

LIABILITY, RIGHT, CLAIM OR REMEDY IN TORT, WHETHER OR NOT ARISING FROM THE NEGLIGENCE OF PRECOR OR ITS

SUPPLIERS (WHETHER ACTIVE, PASSIVE OR IMPUTED); AND (B) ANY OBLIGATION, LIABILITY, RIGHT, CLAIM, OR REMEDY FOR

LOSS OF OR DAMAGE TO ANY EQUIPMENT.

This disclaimer and release shall apply even if the express warranty set

forth above fails of its essential purpose.

Exclusive Remedies

For any product described above that fails to conform to its warranty, Precor will provide, at their option, one of

the following: (1) repair; (2) replacement; or (3) refund of the purchase price. Precor Limited Warranty service

may be obtained by contacting the authorized dealer from whom you purchased the item. Precor

compensates Servicers for warranty trips within their normal service area to repair equipment at the owner’s

location. You may be charged a trip charge outside the service area. THESE SHALL BE THE SOLE AND EXCLUSIVE

REMEDIES OF THE BUYER FOR ANY BREACH OF WARRANTY.

Exclusion of Consequential and Incidental Damages

PRECOR AND/OR ITS SUPPLIERS SHALL HAVE NO OBLIGATION OR LIABILITY, WHETHER ARISING IN CONTRACT

(INCLUDING WARRANTY), TORT (INCLUDING ACTIVE, PASSIVE, OR IMPUTED NEGLIGENCE AND STRICT LIABILITY), OR

OTHERWISE, FOR DAMAGE TO THE EQUIPMENT, PROPERTY DAMAGE, LOSS OF USE, REVENUE OR PROFIT, COST OF

CAPITAL, COST OF SUBSTITUTE EQUIPMENT, ADDITIONAL COST INCURRED BY BUYER (BY WAY OF CORRECTION OR

OTHERWISE) OR ANY OTHER INCIDENTAL, SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, WHETHER

RESULTING FROM NONDELIVERY OR FROM THE USE, MISUSE OR INABILITY TO USE THE PRODUCT.

This exclusion

applies even if the above warranty fails of its essential purpose and regardless of whether such damages

are sought for breach of warranty, breach of contract, negligence, or strict liability in tort or under any other

legal theory. Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation might not apply.

This warranty gives you specific legal rights, and you may also have other rights, which vary state

to state.

Complete this portion and keep for your records.

Purchased From: ____________________________ Example: Dealer or store name.

Phone Number: _____________________________ Example: Dealer or store telephone number.

Product/model: _____________________________ Example: M9.31

Serial number: ______________________________ The serial number is found on the shipping container

Page 54

S3.45 Specifications

Length: 117 inches (297 cm)

Height: 83 inches (211 cm)

Width: 78 inches (198 cm) Leg press option adds 14 inches (36 cm)

Shipping weight: 589 lb (268 kg)

Precor and Pacific Fitness are registered trademarks of Precor Incorporated.

Specifications subject to change without notice.

Copyright 2006 Precor Incorporated.

Precor web site: www.precor.com

Precor Incorporated

20031 142nd Avenue NE

P.O. Box 7202

Woodinville, WA USA 98072-4002

NOTICE:

Precor is widely recognized for its innovative, award winning designs of exercise equipment. Precor aggressively seeks U.S. and foreign patents for

both the mechanical construction and the visual aspects of its product design. Any party contemplating the use of Precor’s product designs is hereby

forewarned that Precor considers the unauthorized appropriation of its proprietary rights to be a very serious matter. Precor will vigorously pursue all

unauthorized appropriation of its proprietary rights.

S3.45 Literature Kit # 47990-104

Owner's Manual # 47991-104

Warranty Registration # 45623-102

Warranty Card # 36287-110

Effective date: 01 May, 2006

Loading...

Loading...