Page 1

TM

POWERCLASS

OWNER'S MANUAL

CONTENTS

(Click on a topic to view)

Congratulations PC PRO8 Response Graphs

Introduction PC PRO10 Specifications

Sealed Enclosure PC PRO10 Response Graphs

Sealed Enclosure PC PRO12 Specifications

Ported Enclosure PC PRO12 Response Graphs

Ported Enclosure Additional Information

PC PRO8 Specifications Warranty

PC PRO8 / PRO10 / PRO12

Page 2

Congratulations and thank you.....

for choosing

proudly design, engineer and manufacture audio products at our facility in

Phoenix, Arizona. Our award winning engineering team utilizes innovative

technology to consistently deliver Absolutely State of the Art

sound quality, reliability, and value. This

our commitment to offer you unparalleled versatility and quality for years of

dependable service and listening enjoyment.

PrecisionPower

audio epuipment. At

PrecisionPower

PrecisionPower

TM

performance,

product reflects

we

S er vice

Do not attempt to service

Performing exploratory surgery on your audio equipment yourself

will void the warranty. Many parts of your

are custom built to our specifications. Our factory parts are not

made available to anyone else nor are they for sale. Our goal

is to make sure that your

sound as good as the day it was purchased. Contact your

authorized

service through

PrecisionPower

PrecisionPower

PrecisionPower

PrecisionPower

dealer about obtaining any warranty

.(See Warranty inside back cover)

products yourself.

PrecisionPower

product will always

gear

FOR YOUR RECORDS:

Model

Serial Number

Purchase Date

Caution!

The extended use of a high powered audio system may

result in hearing loss or damage. While

systems are capable of

incredible accuracy, they are also designed for you to

enjoy at more reasonable levels all of the sonic subtleties

created by musicians. Please observe all local sound

ordinances.

"Concert Level"

PrecisionPower

volumes with

RETURN TO CONTENTS

Page 3

INTRODUCTION

Y our new

of loudspeakers,

extraordinary design achievements of the

The

PowerClass PR O

PRO8, PRO10

PPI PowerClass PRO

Flat Piston subwoofer is part of an exciting line

and

PRO12

PrecisionPower

, which represent the

Engineering T eam.

Flat Piston subwoofers have been engineered

from the ground up and are constructed at our factory in Phoenix from the

PPI

finest materials available. Like all

“Absolutely State of the Art”

to

PRO8

The

PRO12

subwoofer incorporates a 2” voice coil, while the

incorporate a 3” voice coil. Both the 2" and 3" voice coils are edge

performance and flawless sonic quality.

products, they reflect our commitment

PRO10

and

wound onto Nomex reinforced Kapton formers, and are available in 4Ω and

8Ω versions. The voice coils are cooled and given increased mechanical

damping through the use of a ferrofluid filled magnetic gap. The cooling,

and therefore power handling, is further enhanced by virtue of the inverted

coil geometry , together with a vented pole piece, spiders, and magnet cavity .

The use of an inverted coil geometry results in a substantial reduction of

distortion over conventional loudspeaker systems. Increased linearity over

a large excursion is obtained by using dual matched rear suspension

components together with the finest quality rubber roll surround.

The most unique feature is the use of a flat diaphragm instead of a conical

structure. The diaphragm is constructed from a combination of state of the

art materials which include carbon fiber and Nomex honeycomb. The result

is a diaphragm that is exceptionally stiff and lightweight which does not

exhibit cone flex distortion or the buckling effects inherent in conventional

designs. Additionally,

PrecisionPower’s

exclusive cast basket design is

extremely rigid which ultimately removes any unwanted distortion due to

resonance and flexing.

Included in this manual are a number of sample enclosure drawings. They

are by no means the only enclosures to use, but rather a starting point in the

right direction. To determine the correct enclosure for your needs many

factors need to be addressed (amount of power, vehicle, placement,

crossover, etc.) Therefore, as always,

your subwoofer be installed by an

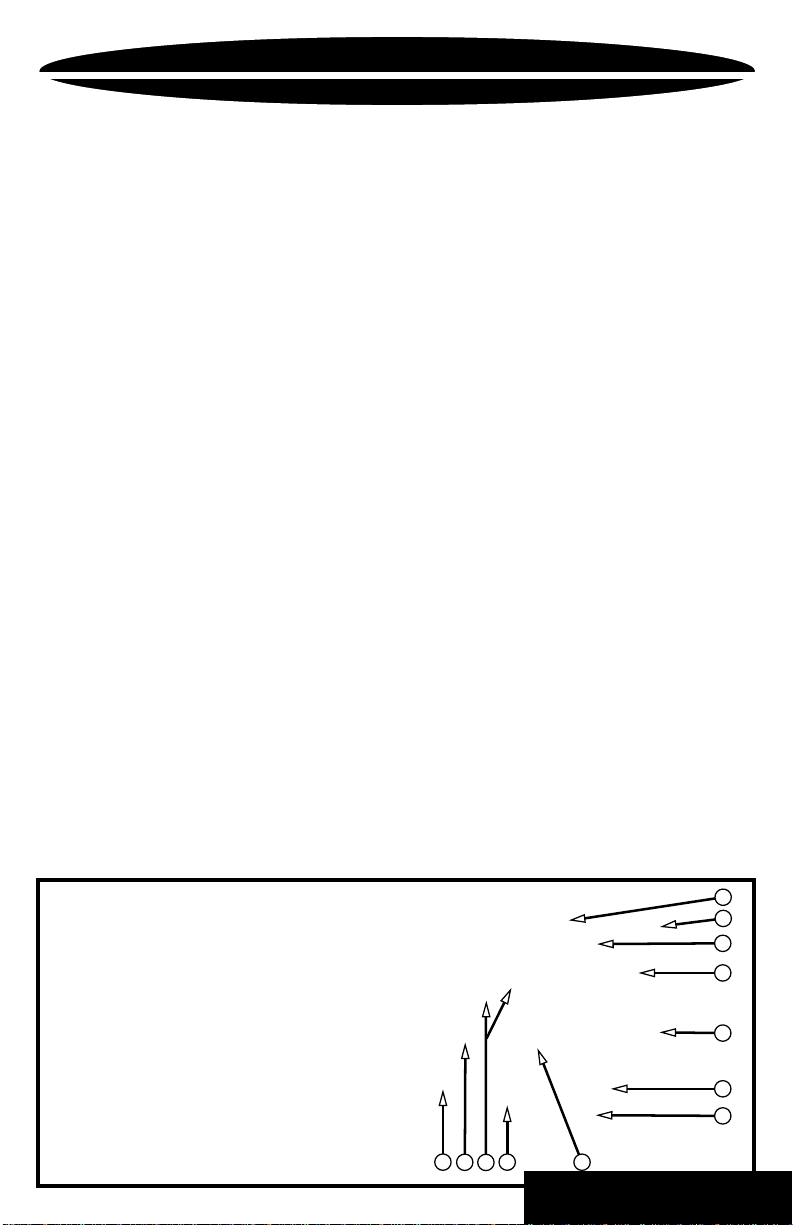

1. Rubber roll surround

2. Aluminum trim ring

3. Carbon fiber/Nomex

honeycomb diaphragm

4. Cast aluminum basket

5. Gold plated, heavy duty

terminal posts

6. Magnet structure

7. Forged steel back plate

8. Magnet cavity vent

9. edge wound voice coil/

Kapton former

10. Dual spiders

11. Vented pole piece

12. Ferrofluid filled magnetic gap

Authorized PrecisionPower Dealer

PrecisionPower

10

9

8

11

recommends that

.

1

2

3

4

5

6

7

12

RETURN TO CONTENTS

Page 4

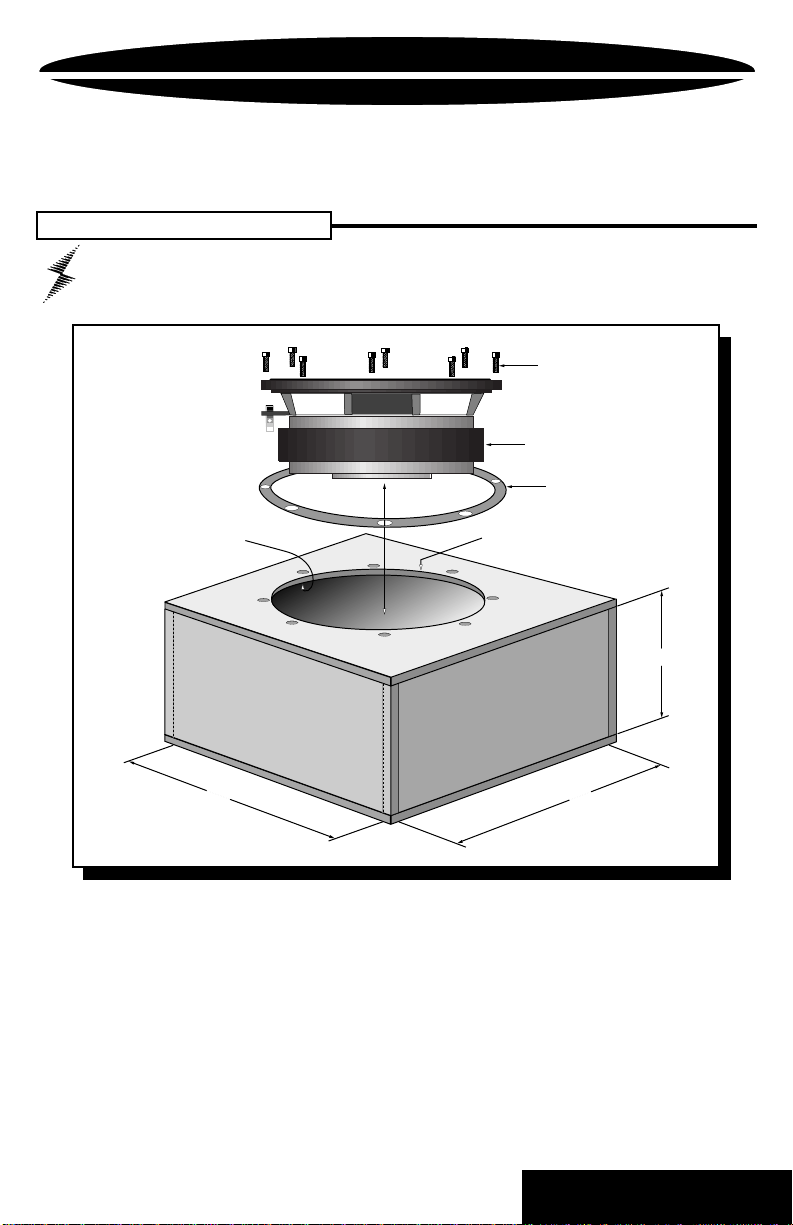

SEALED ENCLOSURE

Building A Sealed Enclosure:

1. Build a sealed box with specified dimensions of L x W x D per

2. Using the supplied template, trace the circle template and

3. Cut the speaker hole from the face of the box with a router.

4. Place the woofer in the opening which you have cut into the

5. Install the 10-24 T-nuts (supplied) into the 7/32” holes

6. Run an appropriate length of wire into the box, leaving enough

7. Vacuum out any shavings and dust that could find it's way into

drawing. (See chart for suggested box sizes) Use 3/4” thick

material (preferably medium density fiber board or equivalent) for

box construction. Be sure to use wood glue and silicone to ensure

your enclosure is sealed properly , as air leaks will af fect the

performance of a subwoofer. (The use of an air stapler will help

to achieve the nicest results for constructing the enclosure.)

mounting hole pattern for your

the appropriate side of the box. (See diagram)

Use a guide or template whenever possible for a clean,

accurate job; use a jig saw only if a router is not available.

Drill out the holes for the T-nuts with a 7/32” drill bit.

box to check the fit. Make sure that the T-nut holes line-up.

from the backside of the face board.

length to comfortably install the wires to the terminals on the

woofer before placing the speaker into its mounting hole. Use

a terminal cup whenever possible.

your woofer from the inside of the box. Fill the box with polyester

fiberfill. Use a ratio of 1/2lb per cubic foot.

PrecisionPower

subwoofer on

8. Apply the included foam gasket to the speaker to ensure a

9. Connect the wires to the woofer observing the proper polarity,

10. Install the woofer into the box using the provided 10-24 bolts.

11. Once the box is completed it is time to connect the speaker

12. Finally, sit back and enjoy to the incredible enhancement

sealed fit. Be sure that the mounting holes line up on the

foam gasket.

positive and negative terminals. Strip away the insulation of

the wire about 1/4" and install the wires into the terminal posts.

wire coming from the subwoofer enclosure to your amplifier.

Check that you use the proper wire for consistent polarity,

positive and negative. (Refer to amplifier owner’s manual.)

your new

PrecisionPower

subwoofer brings to your audio system.

2

RETURN TO CONTENTS

Page 5

SEALED ENCLOSURE

Sealed speaker diagram

10-24 Allen head bolt

Subwoofer

Foam seal gasket

10-24 T-nut

L

Mounting hole diameter

D

W

Internal dimensions should be calculated to determine the correct box volume.

Be sure to allow for speaker displacement and extra bracing (if used).

3

RETURN TO CONTENTS

Page 6

PORTED ENCLOSURE

Building A Ported Enclosure:

1. Build a sealed box with internal dimensions of LxWxD as specified for

2. Using the supplied template, trace the appropriate circle and mounting

3. Cut the speaker hole out of the box with a router. Use a guide or

4. Locate the port material which you are going to use. Trace the pattern

5. Place the woofer into the hole which you have cut into the box to check

6. Install the 10-24 T-nuts (supplied) into the 7/32” holes from the

7. Run an appropriate length of wire into the box, leaving enough length to

8. Vacuum out any shavings and dust that could find it's way into your

9. Apply the included foam gasket to the speaker to ensure a sealed fit.

10. Connect the wires to the woofer observing the proper polarity,

11. Install the woofer into the box using the provided 10-24 bolts.

12. Once the box is completed it is time to connect the speaker wire coming

13. Finally, sit back and enjoy to the incredible enhancement your new

your woofer. Use 3/4” thick material (preferably medium density fiber

board or equivalent) for box construction. Be sure to use wood glue and

silicone to ensure your enclosure is sealed properly, as air leaks will

affect the performance of a subwoofer. (The use of an air stapler will help

to achieve the nicest results for constructing the enclosure.)

hole pattern for your

mounting the woofer. Be sure to offset the woofer to one side to allow

for the port to fit comfortably.(See Diagram)

template whenever possible for a clean, accurate job; use a jig saw only

if a router is not available. Drill out the mounting holes with a 7/32” drillbit.

of the appropriate hole needed for the port, then cut the hole out. When

installing the port, make sure you have a distance of at least the diameter

of the port from the end of the port to the wall inside the box. To best

seal off any air leaks use silicone around the inside edge. Also, bevel

the inside edge of both ends of the port to cut down on port noise.

the fit. Make sure that the T-nut holes line up.

backside of the mounting board.

comfortably install the wires to the terminals on the woofer before

placing the speaker into its mounting hole. Use a terminal cup whenever

possible.

woofer from the inside of the box. Line the box with a polyester fiberfill

blanket or fiberglass insulation about 1” thick.

Be sure that the mounting holes line up on the gasket.

positive and negative terminals. Strip away the insulation of

the wire about a 1/4" and install the wires into the terminal posts.

from the subwoofer enclosure to your amplifier. Check that you use the

proper wire for consistent polarity, positive and negative.

(Refer to amplifier owner’s manual.)

PrecisionPower

PrecisionPower

subwoofer brings to your audio system.

subwoofer on the proper side for

4

RETURN TO CONTENTS

Page 7

PORTED ENCLOSURE

Ported speaker diagram

10-24 Allen head bolt

Subwoofer

Foam seal gasket

10-24 T-nut

L

Mounting hole diameter

Port

D

W

Internal dimensions should be calculated to determine the correct box

volume. Be sure to allow for speaker displacement, extra bracing (if used),

and port displacement. It may be necessary to angle the port to fit your

design.To calculate volume of the port: Radius2 x 3.14 x Length of port.

5

RETURN TO CONTENTS

Page 8

POWERCLASS PRO8

Subwoofer

PRO8

PRO8

Specifications

Normal Power Handling 200W rms

Voice Coil Diameter 2”

Voice Coil Type / Former edge wound/Kapton

Resonant Frequency 40Hz

Qts-Total Damping .37

Qms- Mechanical Damping 1.5

Qes- Electromagnetic Damping .50

Vas- Equivalent Compliance Volume 14 Liter

DC Resistance of V.C. 4Ω / 8Ω

Sensitivity(SPL at 1W) 85 dB

Linear Excursion ±5.5mm

Peak to Peak Excursion ±13mm

Mms- Total Mass 59.9 grams

Sd- Piston Area 0.0191 sqM

Bl- Magnet Product 11.13 TM

Diaphragm Material carbon fiber/Nomex honeycomb

Basket Material cast aluminum

Net Weight 14.44lb

Dimensions 8.375” dia. X 4.125” H

Mounting Diameter 7.25” dia.

Sealed Enclosure

Basic working dimensions for the

Outer Diameter 8 3/8”

Mounting Hole Diameter 7 1/4”

Mounting Depth (from bottom of top ring) 4 1/4”

Speaker Displacement .07 cubic foot

PRO8

Inside Volume / Internal Box Dimensions

.33 cubic foot LxWxD 12” x 9” x 6 13/32”

.50 cubic foot LxWxD 14” x 10” x 7 9/32”

.75 cubic foot LxWxD 12” x 10” x 12 1/32”

PRO8

Ported Enclosure

Due to the very small box size and the very large port necessary to

appropriately tune the enclosure, we do not recommend a ported enclosure

for the

PRO8

6

RETURN TO CONTENTS

Page 9

POWERCLASS PRO8

Subwoofer

PRO8

IMPEDANCE CURVE

OHMS

PC PRO8 INPUT IMPEDANCE: MAGNITUDE

*

100.0

30.0

Sealed

10.0

3.0

1.0

10 1000

20

30

PRO8

Sealed RESPONSE CURVE

15

12

9

6

3

0dB

-3

-6

-9

-12

-15

-18

-21

-24

-27

-30

PRO8

Ported RESPONSE CURVE

10

50 70 100

.75 cubic foot

.50 cubic foot

.33 cubic foot

50 70 100

30

20

Frequency Hz

200 300 500

*

200 300 500

Hz

*

700 1K

700

2K

Due to the very small box size and the very large

port necessary to appropriately tune the

enclosure, we do not recommend a ported

enclosure for the

*ACTUAL IN-CAR RESPONSE CURVE WILL VARY BASED ON CAR TYPE, WOOFER LOADING, AND ENCLOSURE DESIGN.

PRO8

7

RETURN TO CONTENTS

Page 10

POWERCLASS PRO10

Subwoofer

PRO10

PRO10

Specifications

Normal Power Handling 300W rms

Voice Coil Diameter 3”

Voice Coil Type / Former edge wound/Kapton

Resonant Frequency 37Hz

Qts-Total Damping 0.36

Qms- Mechanical Damping 2.22

Qes- Electromagnetic Damping 0.42

Vas- Equivalent Compliance Volume 34.1 Liter

DC Resistance of V.C. 4Ω / 8Ω

Sensitivity(SPL at 1W) 88.1 dB

Linear Excursion ±5.5mm

Peak to Peak Excursion ±13mm

Mms- Total Mass 75.13 grams

Sd- Piston Area 0.0315 sqM

Bl- Magnet Product 12.92 TM

Diaphragm Material carbon fiber/Nomex honeycomb

Basket Material cast aluminum

Net Weight 23.66lb

Dimensions 10.4” dia. X 4.75” H

Mounting Diameter 9.25” dia.

Sealed Enclosure

Basic working dimensions for the

Outer Diameter 10 7/16”

Mounting Hole Diameter 9 1/4”

Mounting Depth (from bottom of top ring) 4 1/4”

Speaker Displacement .092 cubic foot

PRO10

Inside Volume / Internal Box Dimensions

0.5 cubic foot LxWxD 16 5/16” x 10 1/16” x 6 1/4”

.75 cubic foot LxWxD 18 5/16” x 11 5/16” x 7”

1.0 cubic foot LxWxD 20” x 12 3/8” x 7 5/8”

PRO10

Ported Enclosure

Basic working dimensions for the

Outer Diameter 10 7/16”

Mounting Hole Diameter 9 1/4”

Mounting Depth (from bottom of top ring) 4 1/4”

Speaker Displacement .092 cubic foot

Inside Volume 1.0 cubic foot

Internal Box Dimensions (LxWxD)

Port Length 10 1/16”

Port Diameter 3” ID

Port Displacement .04 cubic foot

PRO10

20 1/4” x 12 1/2” x 7 3/4”

8

RETURN TO CONTENTS

Page 11

POWERCLASS PRO10

Subwoofer

PRO10

PRO10

IMPEDANCE CURVE

*

Sealed RESPONSE CURVE

*

PRO10

Ported RESPONSE CURVE

*ACTUAL IN-CAR RESPONSE CURVE WILL VARY BASED ON CAR TYPE, WOOFER LOADING, AND ENCLOSURE DESIGN.

*

9

RETURN TO CONTENTS

Page 12

POWERCLASS PRO12

Subwoofer

PRO12

PRO12

Specifications

Normal Power Handling 300W rms

Voice Coil Diameter 3”

Voice Coil Type / Former edge wound/Kapton

Resonant Frequency 43Hz

Qts-Total Damping 0.52

Qms- Mechanical Damping 2.51

Qes- Electromagnetic Damping 0.66

Vas- Equivalent Compliance Volume 43.97 Liter

DC Resistance of V.C. 4Ω / 8Ω

Sensitivity(SPL at 1W) 89.31 dB

Linear Excursion ±5.5mm

Peak to Peak Excursion ±13mm

Mms- Total Mass 114.7 grams

Sd- Piston Area 0.0512 sqM

Bl- Magnet Product 13.74 TM

Diaphragm Material carbon fiber/Nomex honeycomb

Basket Material cast aluminum

Net Weight 24.18lb

Dimensions 12.27” dia. X 4.75” H

Mounting Diameter 11.125” dia.

Sealed Enclosure

Basic working dimensions for the

Outer Diameter 12 9/32”

Mounting Hole Diameter 11 1/8”

Mounting Depth(from bottom of top ring) 4 1/4”

Speaker Displacement .098 cubic feet

PRO12

Inside Volume / Internal Box Dimensions

1.0 cubic foot LxWxD 20” x 12 3/8” x 7 5/8”

1.25 cubic feet LxWxD 21 7/16” x 13 1/4” x 8 3/16”

1.50 cubic feet LxWxD 22 11/16” x 14” x 8 11/16”

PRO12

Ported Enclosure

Basic working dimensions for the

Outer Diameter 12 9/32”

Mounting Hole Diameter 11 1/8”

Mounting Depth(from bottom of top ring) 4 1/4”

Speaker Displacement .098 cubic feet

Inside Volume 1.50 cubic feet

Internal Box Dimensions (LxWxD)

Port Length 11 1/16”

Port Diameter 4” ID

Port Displacement .08 cubic foot

PRO12

23 1/16” x 14 1/4” x 8 13/16”

10

RETURN TO CONTENTS

Page 13

POWERCLASS PRO12

Subwoofer

PRO12

PRO12

IMPEDANCE CURVE

*

Sealed RESPONSE CURVE

*

PRO12

11

*

RETURN TO CONTENTS

Ported RESPONSE CURVE

*ACTUAL IN-CAR RESPONSE CURVE WILL VARY BASED ON CAR TYPE, WOOFER LOADING, AND ENCLOSURE DESIGN.

Page 14

Additional information

The

PowerClass PRO8

enclosures from .33 cubic foot to over .75 cubic foot.

subwoofer will give you excellent results in sealed

PowerClass PRO10

The

subwoofer will give you excellent results in

enclosures from .5 cubic foot to over 1 cubic foot, ported or sealed.

The

PowerClass PRO12

subwoofer will give you excellent results in

enclosures from 1 cubic foot to over 1.5 cubic feet, ported or sealed.

If a ported enclosure is utilized, the port should be tuned from 32-40 Hz.

Use as large a port diameter as possible to eliminate port “whistle”. Be

sure to refer to diagrams and charts for specifications for your new

subwoofer.

Our dealers are trained to achieve the highest level of performance from

our products. If you are installing your new subwoofers on your own and

need assistance, please call your local

PrecisionPower

Technical Service Department at

1-800-62-POWER

Thanks again for choosing

PrecisionPower

PrecisionPower

.

dealer or

.

Ferrosound means more stable sound quality and performance, smoother frequency response,

reduced distortion, increased power handling, greater efficiency and voice coil centering.

NOTE: Abuse and/or Installation Error:

to, burnt voice coils (blackened, no continuity, melted adhesives, coil separated from

the former, etc.), punctured or damaged surrounds, broken speaker terminals, non-

PrecisionPower

damaged back plates. Speakers submitted with any of the above will be considered out

of warranty.

modifications, bent, chipped, or broken frames, ripped spiders, or

The Solution Is Loud And Clear™

PrecisionPower

12

defines abuse as, but not limited

RETURN TO CONTENTS

Page 15

WARRANTY

Three-Year Limited U.S.A. Warranty

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

workmanship under normal use and service for a period of three (3) years from the date of

original purchase when the unit is installed by an Authorized Dealer. Non-Authorized Dealer

installed products carry a one (1) year parts and ninety (90) days labor limited warranty. The

extent and conditions of Limited Warranty are as follows:

1. Authorized Dealer Installed Products:

to the original purchaser, any unit which

and under warranty, provided the defect occurs within three (3) years from the date of original

purchase when the unit is installed by an Authorized Dealer and the product is returned immediately to

2. Non-Authorized Dealer Installed Products:

charge, to the original purchaser, any unit which

defective and under warranty, provided the defect occurs within ninety (90) days from the date of

purchase and the product is returned immediately to

ninety (90) days for Non-Authorized Dealer Installed Products will be for parts only and will

extend for one (1) year from the date of purchase. This warranty is not transferable.

3. The date of purchase and proof of Authorized Dealer Installation of a PrecisionPower product

must be established by an original sales receipt which must accompany the article being returned for warranty work.

4. This warranty shall NOT apply to any

tory serial number removed or defaced. All products received (by

ranty or out of warranty repair, with their original serial numbers removed or defaced, will NOT be

repaired and will be returned to sender, freight collect. Refer to original packaging for the serial

number of your component speakers.

5. The provisions of this warranty shall not apply to any

purpose for which it is not designed, which has been repaired or altered in any way , or which has

been connected, installed, or adjusted other than in accordance with the instructions furnished in

PrecisionPower’ s

subject to misuse, neglect, or accident.

6. PrecisionPower does not authorize any other persons to assume any other liability in connection with its products. THIS WARRANTY IS THE ONLY EXPRESS WARRANTY MADE BY

PRECISIONPOWER APPLICABLE T O ITS PRODUCTS. ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE APPLICABLE TO

PRECISIONPOWER PRODUCTS IS LIMITED IN DURATION TO THE DURATION OF THIS

LIMITED WARRANTY. PRECISIONPOWER SHALL NOT BE LIABLE FOR THE INCIDENTAL,

CONSEQUENTIAL, OR COMMERCIAL DAMAGES RESUL TING FROM THE BREACH OF THIS

WRITTEN WARRANTY. Some states or provinces do not allow the exclusion or limitation of

incidental or consequential damages or limitations on how long an implied warranty lasts; so the

above limitations or exclusions may not apply to you.

7. Y our product will be serviced on an in-warranty basis within the warranty period for the correction of warranted defects. If improper operation of your

contact your Authorized Dealer for assistance with the return and factory repair of your

PrecisionPower

product. If an Authorized Dealer is not available, return the unit including your name, telephone

number, return address, a copy of your sales receipt, and a description of the problem to:

TO RETURN PRECISIONPOWER PRODUCTS OUT OF W ARRANTY : Return the unit, postage

prepaid, in the original protective carton. Please include a description of the problem and, if

desired, a request for an estimate of repair costs. Unless a request for an estimate is included,

the unit will be repaired as necessary. Please contact

800-62-POWER for questions concerning out of warranty repair charges. Repaired unit will be

returned with an itemized statement, C.O.D.

PrecisionPower

PrecisionPower

owner’s manual. Nor shall this warranty apply to any part which has been

warrants its products to be free from defects in materials and

PrecisionPower

PrecisionPower’ s

. This warranty is not transferable.

PrecisionPower

PrecisionPower

PrecisionPower,Inc.

Service Department

4829 S. 38th Street

Phoenix, AZ 85040-2964

will either repair or replace at no charge,

examination discloses to be defective

PrecisionPower’s

PrecisionPower

will either repair or replace at no

examination discloses to be

. Warranty claims beyond

product found to have the original fac-

PrecisionPower

PrecisionPower

PrecisionPower

PrecisionPower

product should occur,

Customer Service at 1-

product used for a

RETURN TO CONTENTS

) for in war-

Loading...

Loading...