Page 1

Powerware 9390 UPS

®

20–80 kVA

Installation and Operation Manual

Page 2

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that you should follow during installation and maintenance of the UPS and batteries.

Please read all instructions before operating the equipment and save this manual for future reference.

CONSIGNES DE SÉCURITÉ IMPORTANTES

CONSERVER CES INSTRUCTIONS

Ce manuel comporte des instructions importantes que vous êtes invité à suivre lors de toute procédure d'installation et de

maintenance des batteries et de l'onduleur. Veuillez consulter entièrement ces instructions avant de faire fonctionner l'équipement et

conserver ce manuel afin de pouvoir vous y reporter ultérieurement.

Class A EMC Statements

FCC Part 15

NOTE This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

W A R N I N G

This is a product for restricted sales distribution to informed partners. Installation restrictions or additional measures may be needed

to prevent electromagnetic disturbances.

Eaton, Powerware, ABM, LanSafe, Power Xpert, Powerware Hot Sync and X-Slot are registered trademarks and ConnectUPS is a trademark of

Eaton Corporation or its subsidiaries and affiliates. IBM and AS/400 are registered trademarks of International Business Machines Corp. Modbus is

a registered trademark of Schneider Electric. National Electrical Code and NEC are registered trademarks of National Fire Protection Association,

Inc. All other trademarks are property of their respective companies.

ECopyright 2004-2008 Eaton Corporation, Raleigh, NC, USA. All rights reserved. No part of this document may be reproduced in any way without

the express written approval of Eaton Corporation.

Page 3

Special Symbols

The following are examples of symbols used on the UPS or accessories to alert you to important information:

RISK OF ELECTRIC SHOCK - Observe the warning associated with the risk of electric shock symbol.

CAUTION: REFER TO OPERATOR'S MANUAL - Refer to your operator's manual for additional information, such as important

operating and maintenance instructions.

This symbol indicates that you should not discard the UPS or the UPS batteries in the trash. This product contains sealed, lead‐acid

batteries and must be disposed of properly. For more information, contact your local recycling/reuse or hazardous waste center.

This symbol indicates that you should not discard waste electrical or electronic equipment (WEEE) in the trash. For proper disposal,

contact your local recycling/reuse or hazardous waste center.

ON – Indicates that the switch is in the ON position.

OFF – Indicates that the switch is in the OFF position.

PHASE – The word “phase.”

Page 4

This page intentionally left blank.

Page 5

Table of Contents

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 UPS Standard Features 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Control Panel 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Customer Interface 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 X-Slot Communication Bay 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Mini‐CSB (Communication Server Board) 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5 ConnectUPS-X Web/SNMP Card X-Slot Card 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.6 ABM Technology 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.7 Powerware LanSafe Power Management Software 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.8 Installation Features 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Options and Accessories 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Integrated Battery Cabinets 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Integrated Distribution Cabinet 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Integrated Accessory Cabinets (IAC-B, IAC-T, and IAC-D) 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Powerware Hot Sync Parallel System 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Sync Control 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Optional X-Slot Cards 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.7 Remote Monitor Panel 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.8 Relay Interface Module 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.9 Supervisory Contact Module 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Basic System Configurations 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Conventions Used in This Manual 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 For More Information 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Getting Help 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety Warnings 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section I - Installation

3 UPS Installation Plan and Unpacking 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Creating an Installation Plan 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Preparing the Site 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Environmental Considerations 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Preparing for Wiring the UPS System 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Inspecting and Unpacking the UPS Cabinet 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Installing the UPS System 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Preliminary Installation Information 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Unloading the UPS Cabinet from the Pallet and Mechanical Installation 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Battery Cabinet Installation 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Integrated Distribution Cabinet Installation 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Integrated Accessory Cabinet Installation 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 UPS Sidecar Wiring 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Installing UPS External and Battery Power Wiring 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.1 External Wiring Installation Procedure A 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.2 External Wiring Installation Procedure B 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.3 Battery Wiring 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

i

Page 6

TABLE OF CONTENTS

4.8 Installing Interface Connections 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.1 TB1 and TB2 Connections 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.2 TB2 Battery Cabinet Connections 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.3 X-Slot Connections 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.4 Installing Accessories and Parallel System Control Wiring 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Initial Startup 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Completing the Installation Checklist 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

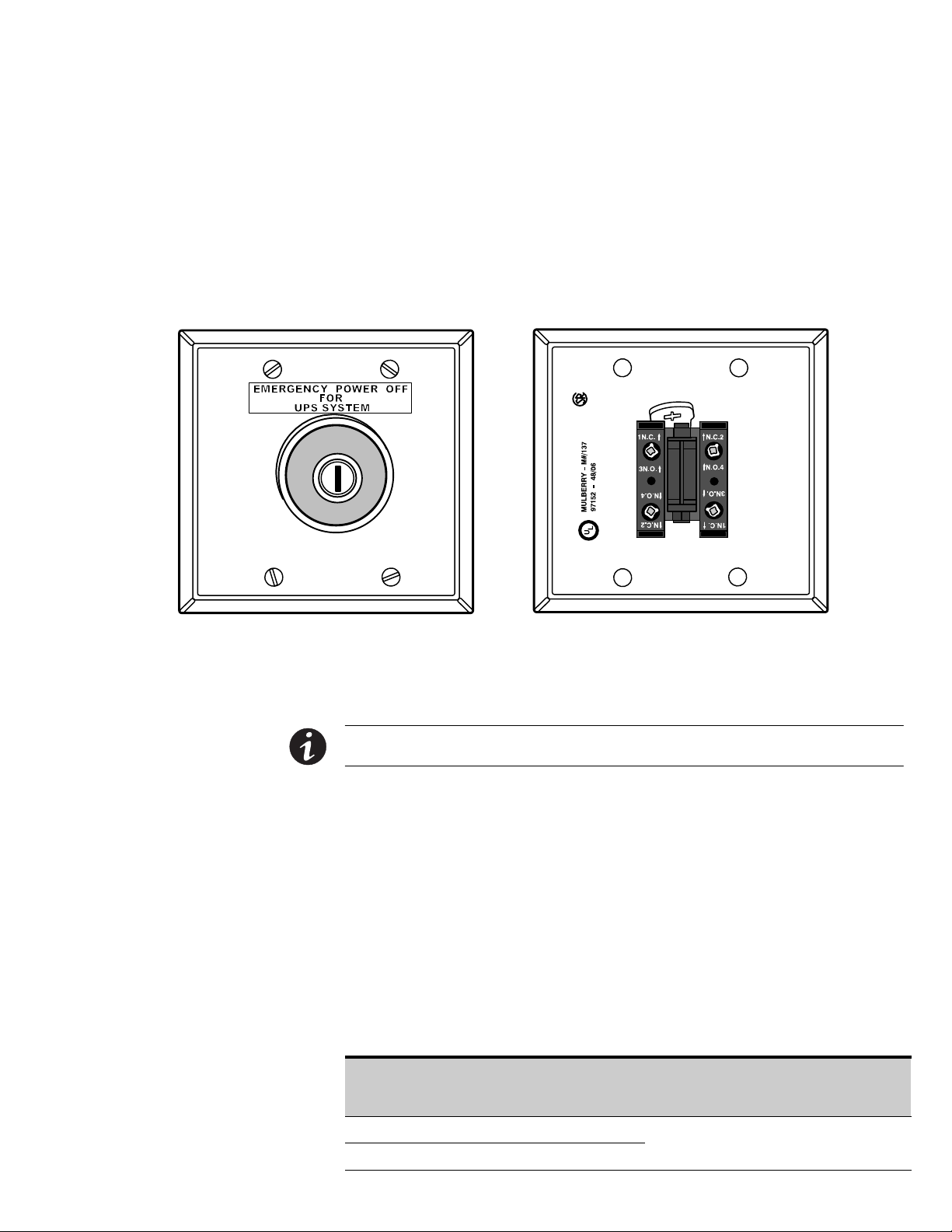

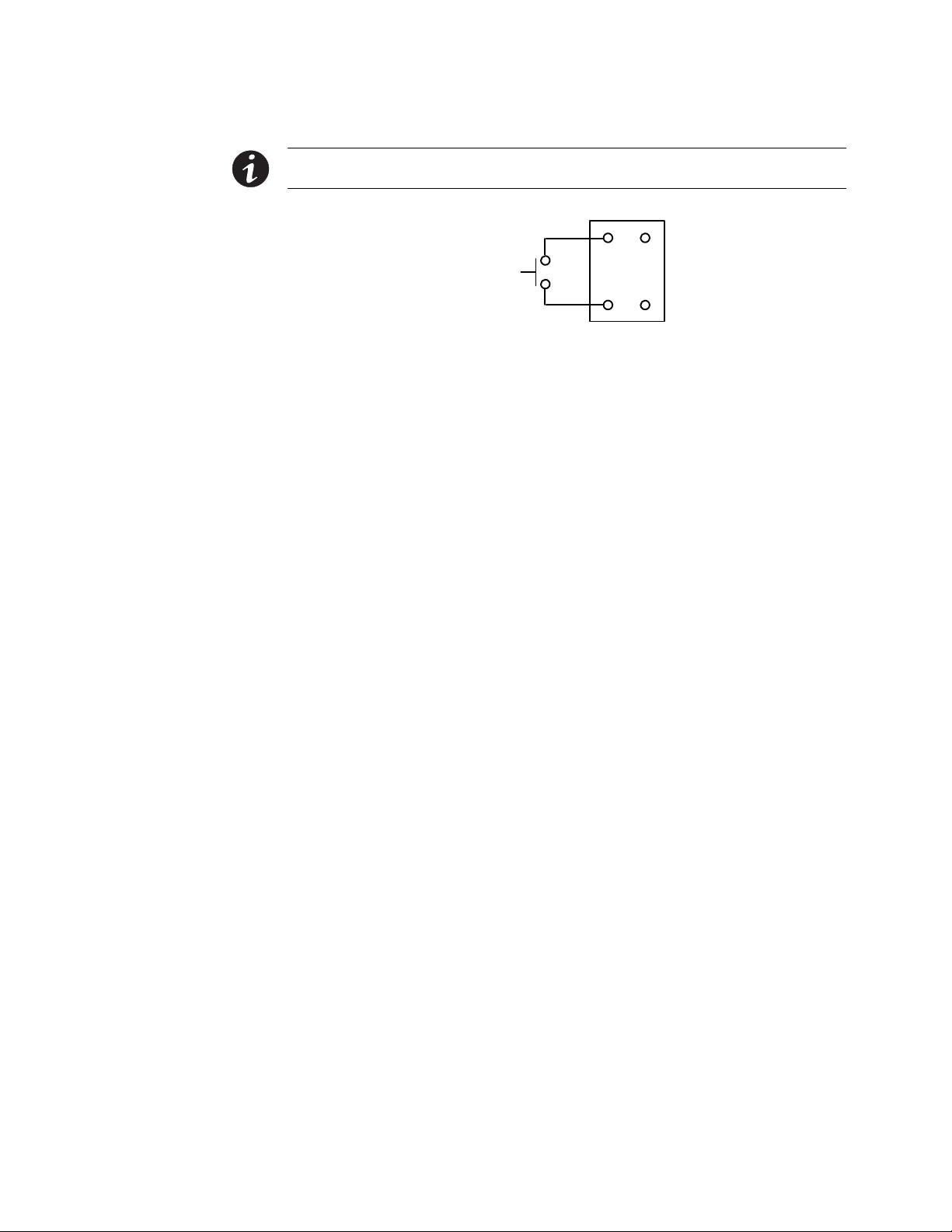

5 Installing a Remote Emergency Power-off Control 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 REPO Installation 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Installing Optional Accessories 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

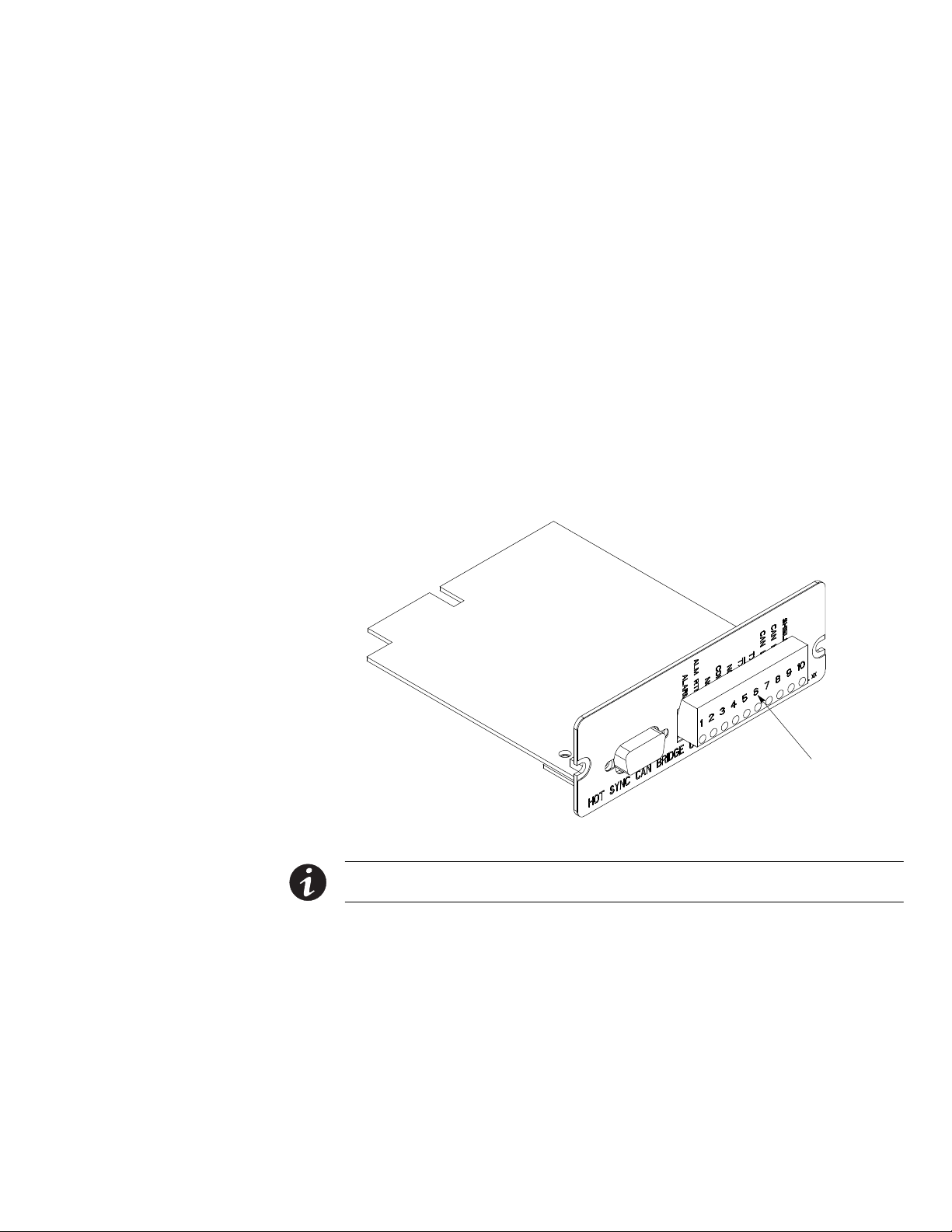

6.1 Installing a Powerware Hot Sync CAN Bridge Card 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Installing Parallel System Control Wiring 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Installing an RMP 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Installing a RIM 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Installing a SCM 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section II - Operation

7 Understanding UPS Operation 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Single Module Reverse Transfer (RT) 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Single Module RT Modes 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

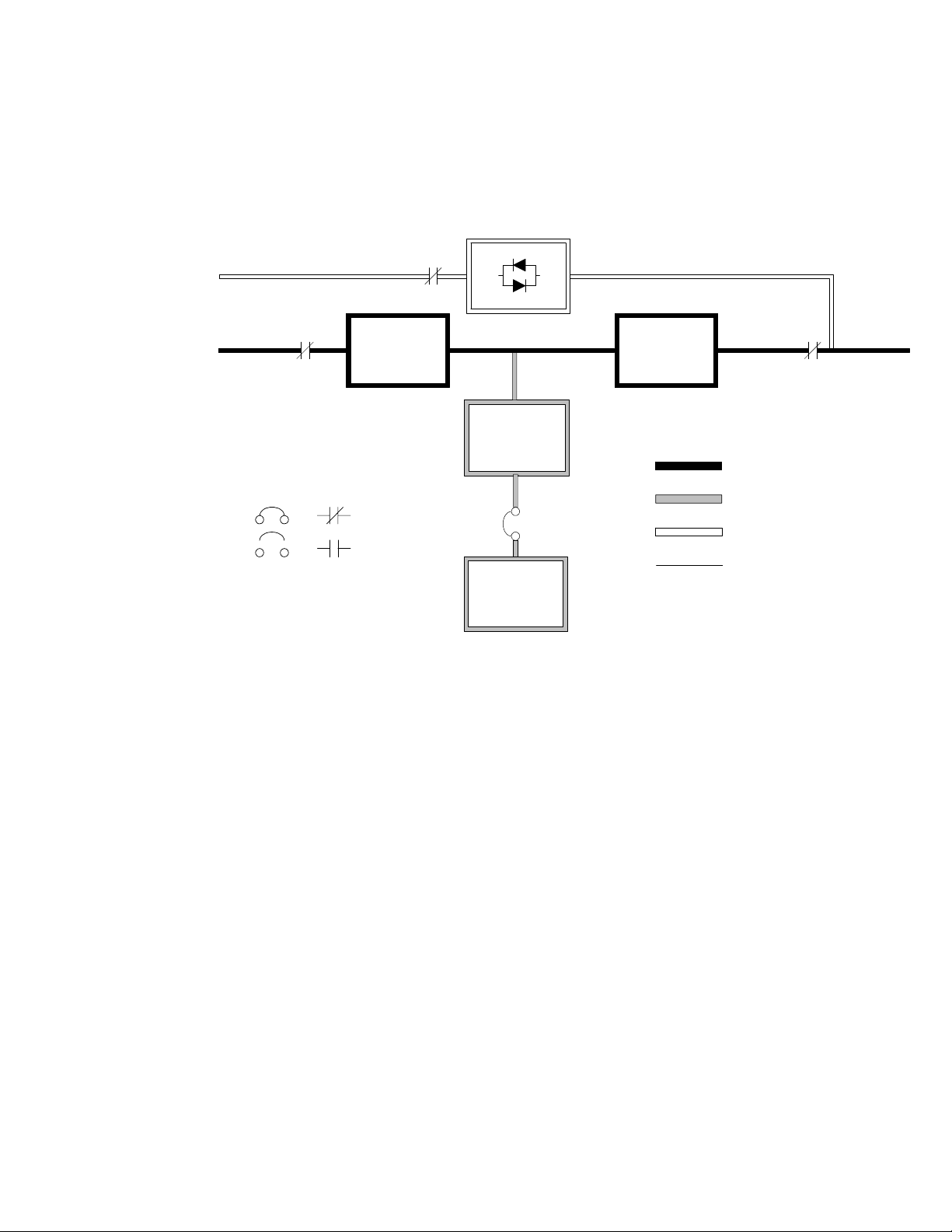

7.1.2 Normal Mode – RT 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

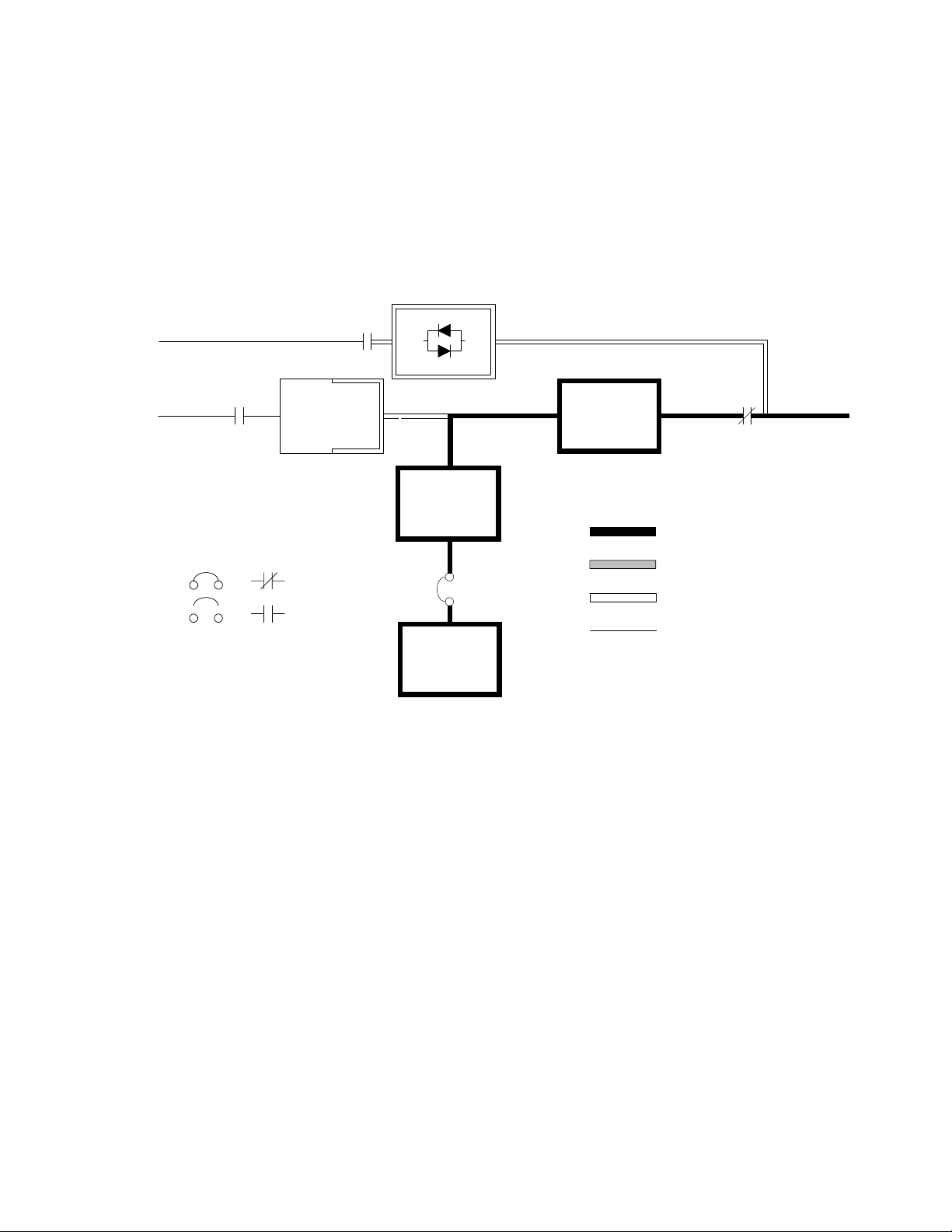

7.1.3 Bypass Mode – RT 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 Battery Mode – RT 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Multiple Module Parallel System 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Multiple Module Parallel System Modes 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

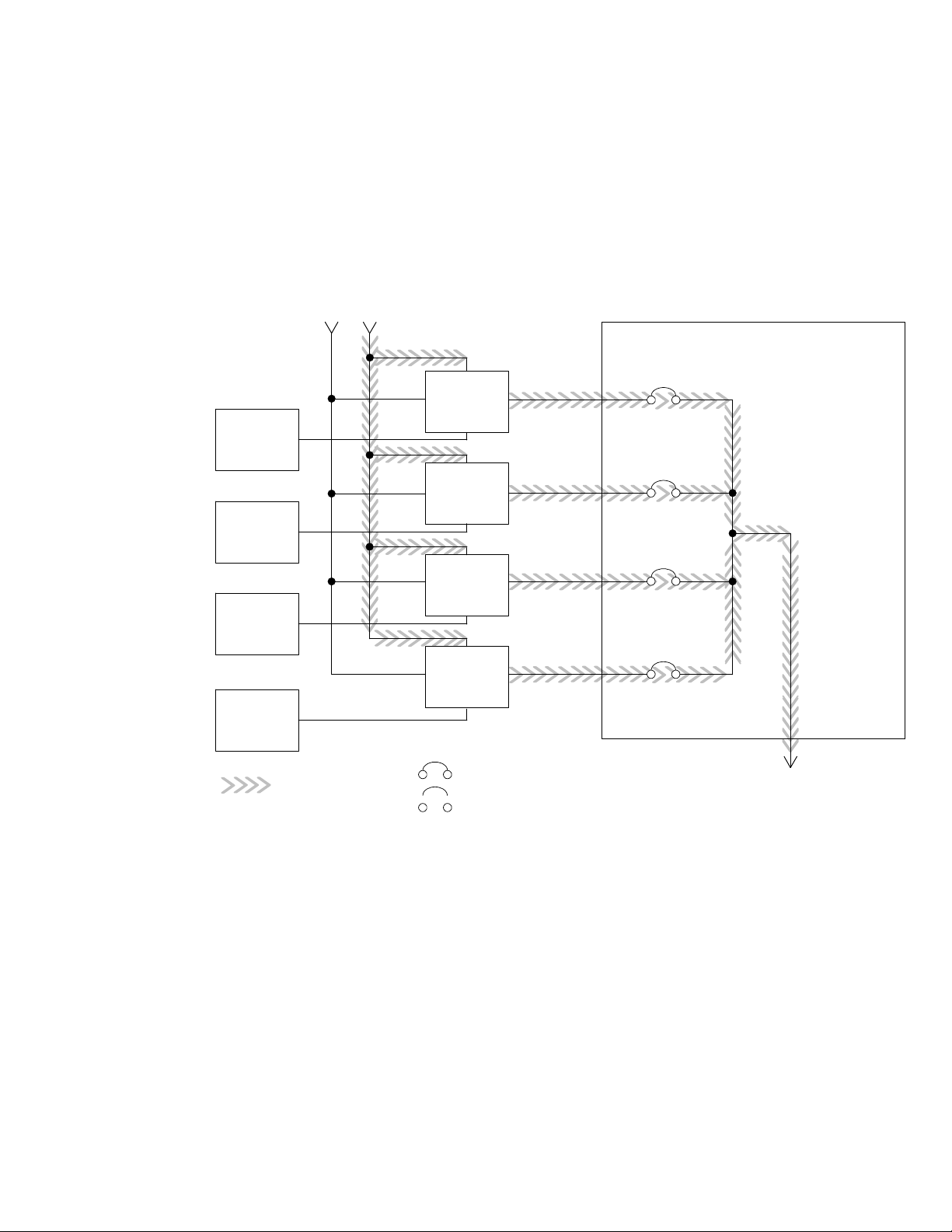

7.2.2 Normal Mode – Parallel 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

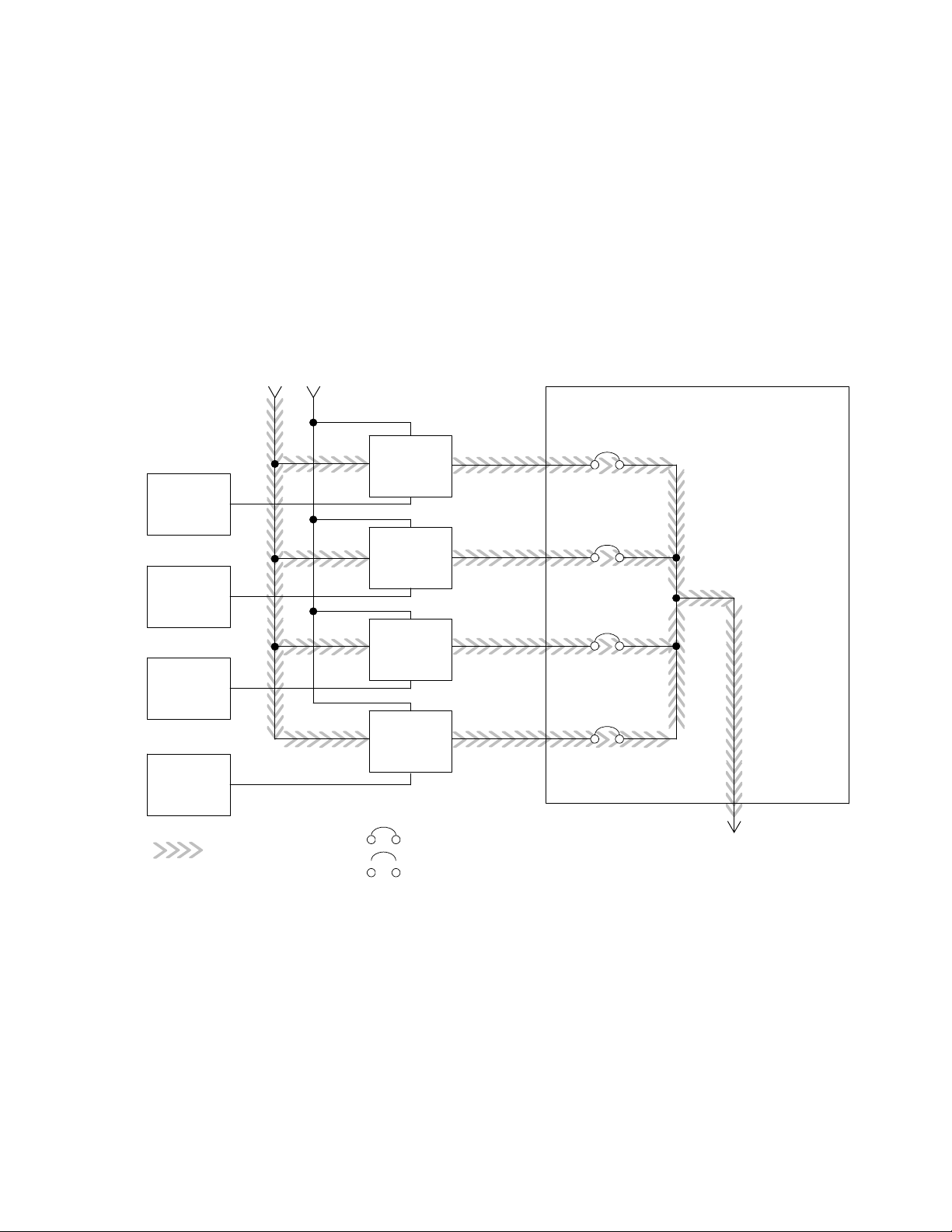

7.2.3 Bypass Mode – Parallel 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4 Battery Mode – Parallel 7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Functional Description 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Input Rectifier 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Inverter 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.3 Battery Charger and ABM 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.4 Bypass 7-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.5 Batteries 7-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Using the Control Panel 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

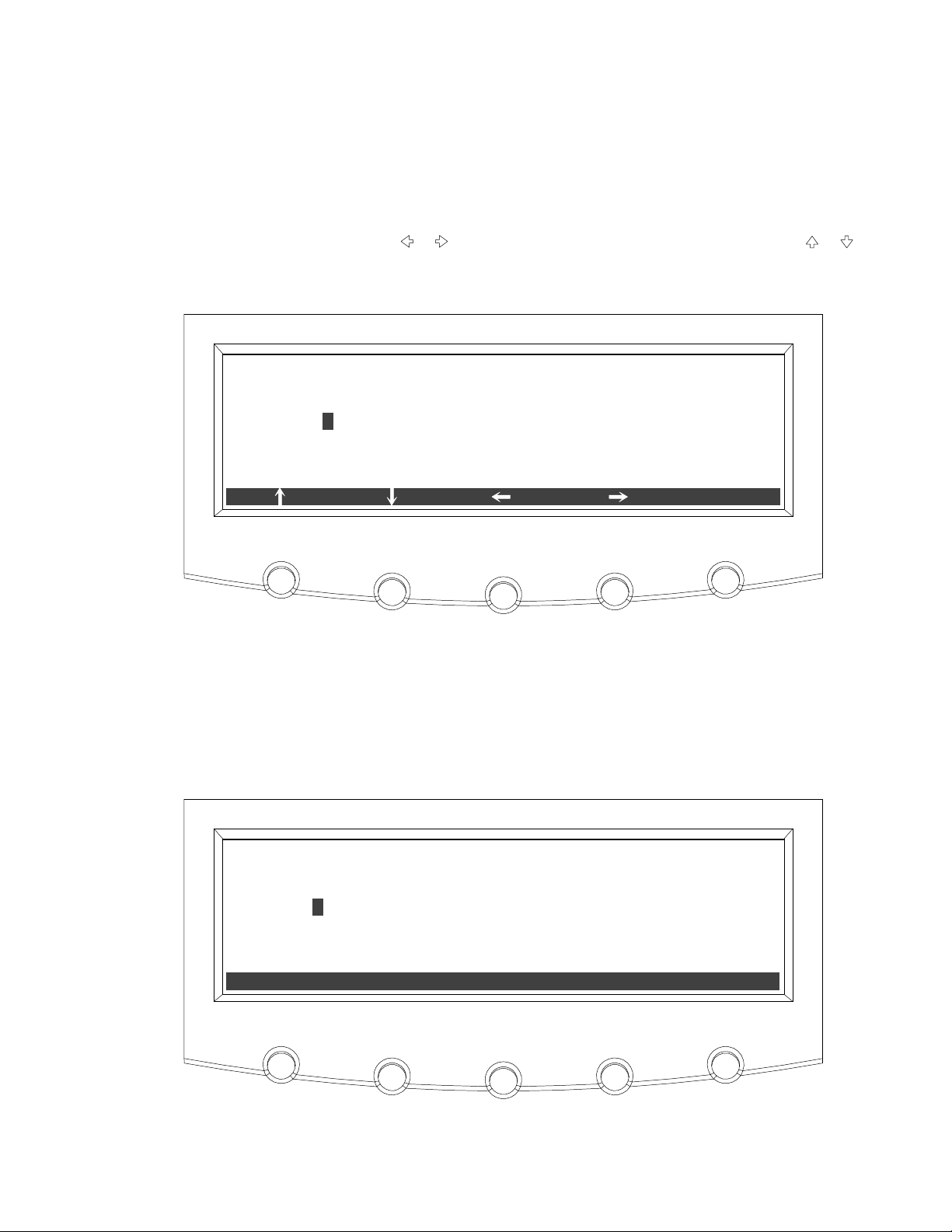

8.1 Using the LCD and Pushbuttons 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Using the Main Menu 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Mimic Screen 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Event Screens 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Unit Meter Screens 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.4 Battery Discharge Log 8-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.5 kW Demand Log 8-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.6 Maximum Current Log 8-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.7 System Meters Screens 8-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.8 System Setup Level 0 Screens 8-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.9 System Setup Level 1 Screens 8-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 7

TABLE OF CONTENTS

8.3 System Controls Screen 8-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Load Off Screen 8-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Reading the Status Indicators 8-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 UPS Operating Instructions 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Single Module Operation 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1 Starting the UPS in Normal Mode 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2 Starting the UPS in Bypass Mode 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3 Starting the Power Module 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.4 Transfer from Normal to Bypass Mode 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.5 Transfer from Bypass to Normal Mode 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.6 Transfer from Normal to Bypass Mode and Shut Down UPS 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.7 UPS and Critical Load Shutdown 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.8 Charger Control 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.9 Using the UPS LOAD OFF Pushbutton 9-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.10 Using the Remote Emergency Power-off Switch 9-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Multiple Module Parallel Operation 9-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Starting the Parallel System in Normal Mode 9-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Starting the Parallel System in Bypass Mode 9-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.3 Transfer Parallel System from Normal to Bypass Mode 9-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.4 Transfer Parallel System from Bypass to Normal Mode 9-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.5 Single UPM Shutdown 9-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.6 Restarting a Single UPM 9-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.7 Parallel System and Critical Load Shutdown 9-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.8 Using the UPS LOAD OFF Pushbutton 9-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.9 Using the Parallel System Remote Emergency Power-off Switch 9-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Using Features and Options 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Building Alarm Monitoring 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 General Purpose Relay Contact 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Optional Remote Monitor Panel 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Relay Interface Module 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 Supervisory Contact Module 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Responding to System Events 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 General 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 System Event Horns 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 System Event Indicators 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 System Event Messages 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Communication 12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 X-Slot Cards 12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 Powerware LanSafe Power Management Software 12-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 Remote Notification 12-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Maintaining the UPS System 13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Important Safety Instructions 13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 Performing Preventive Maintenance 13-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.1 Daily Maintenance 13-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.2 Monthly Maintenance 13-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.3 Annual Maintenance 13-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.4 Battery Maintenance 13-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

iii

Page 8

TABLE OF CONTENTS

13.3 Recycling the Used Battery or UPS 13-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4 Maintenance Training 13-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 Product Specifications 14-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 Model Numbers 14-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 Single Module Specifications 14-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.1 UPS System Input 14-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.2 UPS System Output 14-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.3 Environmental 14-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 Multiple Module Parallel Specifications 14-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.1 UPM Input 14-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.2 UPM Output 14-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.3 Environmental 14-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.4 Battery 14-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.5 Module Tie Cabinet Input 14-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.6 Module Tie Cabinet Output 14-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 Warranty 15-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Factory Warranty 15-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A – Installation Information A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 9

List of Figures

Figure 1‐1. Powerware 9390 UPS (100–160 kVA) Cabinet 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3‐1. Powerware 9390 UPS (100–160 kVA) Cabinet as Shipped on Pallet 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4‐1. Removing Front Shipping Bracket on the Powerware 9390 UPS 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4‐2. Removing Rear Shipping Bracket on the Powerware 9390 UPS 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5‐1. Eaton REPO Switch 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5‐2. REPO Wiring 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6‐1. Powerware Hot Sync CAN Bridge Card 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6‐2. Supervisory Contact Module TB2 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7‐1. Main Elements of the UPS System 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7‐2. Path of Current Through the UPS in Normal Mode – RT 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7‐3. Path of Current Through the UPS in Bypass Mode – RT 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7‐4. Path of Current Through the UPS in Battery Mode – RT 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7‐5. Path of Current through the UPMs in Normal Mode – Parallel 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7‐6. Path of Current through the UPMs in Bypass Mode – Parallel 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7‐7. Path of Current through the UPMs in Battery Mode – Parallel 7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐1. UPS Control Panel 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐2. Parts of the LCD 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐3. Main Menu and Mimic Screen (Normal Mode) 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐4. Active Events Screen 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐5. History Screen 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐6. Unit Output Meter Screen 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐7. Unit Input Meter Screen 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐8. Unit Bypass Meter Screen 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐9. Unit Battery Meter Screen 8-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐10. Unit Output Current (Load) Meter Screen 8-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐11. Battery Discharge Log Summary Screen 8-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐12. Battery Discharge Log Screen 8-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐13. kW Demand Log Summary Screen 8-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐14. kW Demand Log Screen 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐15. Current kW Demand Log Setup Screen 1 8-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐16. Current kW Demand Log Setup Screen 2 8-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐17. Time Interval Monitored Setup Screen 8-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐18. Time Interval Monitored Setup Save Screen 8-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐19. Maximum Level (kW) Setup Screen 8-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐20. Maximum Level (kW) Setup Save Screen 8-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐21. Maximum Current Log Summary Screen 8-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐22. Maximum Current Log Screen (Three-Phase Measurement) 8-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐23. Maximum Current Log Screen (Individual Phase Measurement) 8-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐24. Maximum Current Log Setup Screen 1 8-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐25. Maximum Current Log Setup Screen 2 8-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐26. Time Interval Monitored Setup Screen 8-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐27. Time Interval Monitored Setup Save Screen 8-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐28. Maximum % of Full Load Setup Screen 8-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐29. Maximum % of Full Load Setup Save Screen 8-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐30. Calculation Method Setup Screen 8-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐31. System Meters Screen 8-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐32. Total System Output Meter Screen 8-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

v

Page 10

LIST OF FIGURES

Figure 8‐33. Output Unit X Meter Screen 8-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐34. Input Unit X Meter Screen 8-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐35. Bypass Unit X Meter Screen 8-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐36. Battery Unit X Meter Screen 8-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐37. Output Current (Load) Unit X Meter Screen 8-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐38. System Setup Level 0 Screen 8-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐39. Contrast Adjust Screen 8-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐40. Versions Screen 8-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐41. Unit Type Screen 8-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐42. Enter Password Screen 8-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐43. System Setup Level 1 Screen 8-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐44. Change Password Screen 8-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐45. Change Password Save Screen 8-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐46. Time Format Screen 8-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐47. Set Date and Time MM/DD/YYYY Screen 8-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐48. Set Date and Time DD/MM/YYYY Screen 8-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐49. COM Port Setup Screen 8-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐50. COM Setup Screen 8-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐51. System Controls Screen 1 8-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐52. System Controls Screen 2 8-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8‐53. Load Off Screen 8-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9‐1. REPO Operation 9-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9‐2. REPO Operation 9-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10‐1. Remote Monitor Panel 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10‐2. Relay Interface Module 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10‐3. Supervisory Contact Module 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 12‐1. Optional X-Slot Cards 12-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .

vi

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 11

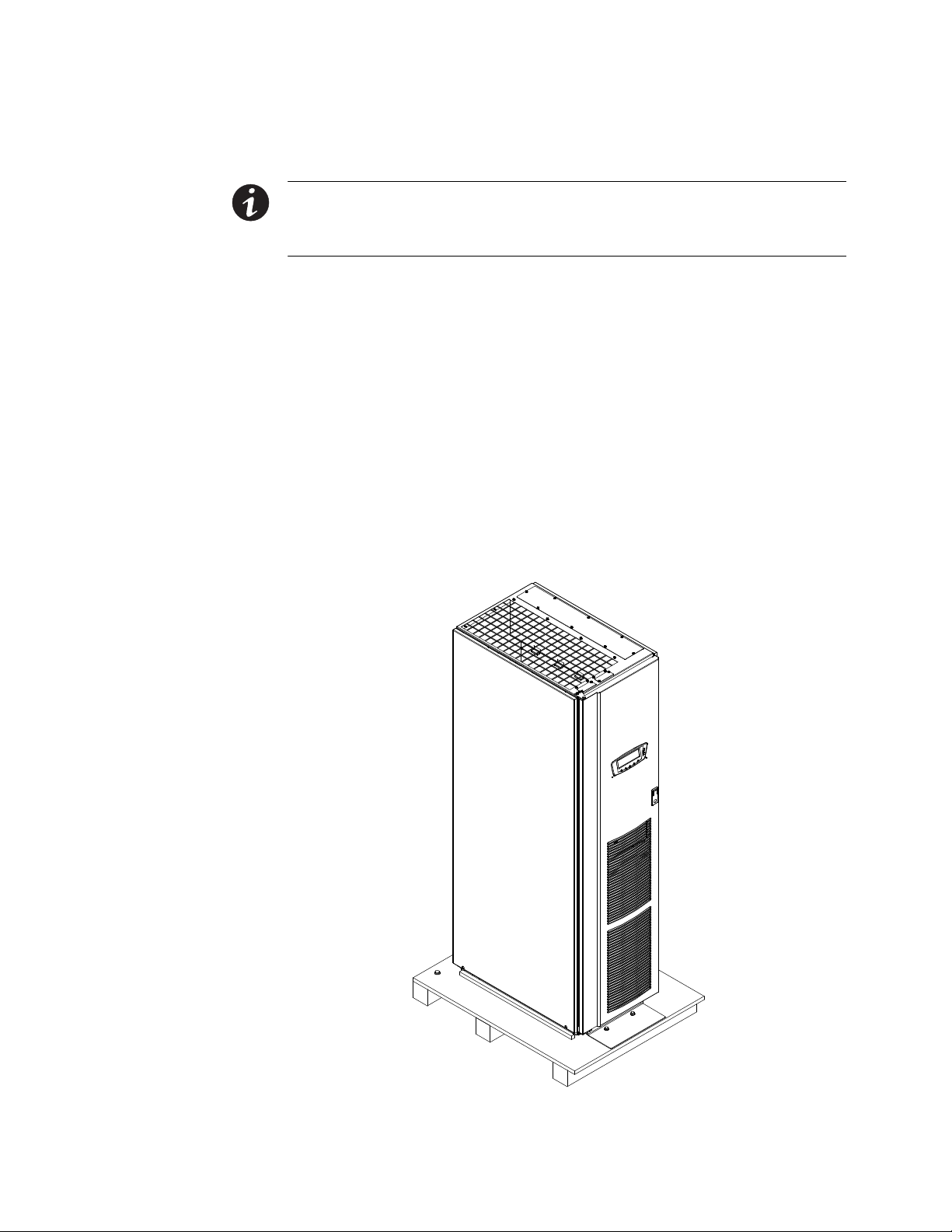

Chapter 1 Introduction

Figure

Eaton's Powerware® 9390 uninterruptible power supply (UPS) is a true online,

continuous-duty, transformerless, double-conversion, solid-state, three-phase system,

providing conditioned and uninterruptible AC power to protect the customer's load

from all nine power failures. The Powerware 9390 UPS is available as a single module

or a multiple module parallel system (see paragraph 1.3).

The Powerware 9390 online power protection system is used to prevent loss of

valuable electronic information, minimize equipment downtime, and minimize the

adverse effect on production equipment due to unexpected power problems.

The Powerware 9390 UPS continually monitors incoming electrical power and

removes the surges, spikes, sags, and other irregularities that are inherent in

commercial utility power. Working with a building's electrical system, the UPS

system supplies clean, consistent power that sensitive electronic equipment requires

for reliable operation. During brownouts, blackouts, and other power interruptions,

batteries provide emergency power to safeguard operation.

The UPS system is housed in a single, free‐standing cabinet with safety shields

behind the door for hazardous voltage protection. The cabinet matches the battery

and distribution cabinets in style and color and can be installed in line-up-and-match or

standalone configurations. Figure 1‐1 shows the Powerware 9390 UPS (20–80 kVA).

Figure 1‐1. Powerware 9390 UPS (20–80 kVA)

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

1-1

Page 12

INTRODUCTION

1.1 UPS Standard Features

The UPS has many standard features that provide cost‐effective and consistently

reliable power protection.

1.1.1 Control Panel

The control panel, located on the UPS front door, contains an LCD and pushbutton

switches to control the operation of the UPS, and to display the status of the UPS

system. See Chapter 8, “Using the Control Panel,” for additional information.

1.1.2 Customer Interface

S Building Alarm Monitoring - The facility's alarm system contacts can be connected to

S Alarm Contact - One alarm contact is provided for connection to equipment at the

six inputs in the UPS. The UPS uses these inputs to monitor the building alarms in

addition to the UPS status. See Chapter 10, “Using Features and Options,” for

additional information.

facility, such as a light, an audible alarm, or a computer terminal. The equipment

connected to this contact alerts you to a UPS alarm. See Chapter 10, “Using

Features and Options,” for additional information.

1.1.3 X-Slot Communication Bay

A pair of two-slot communication bays is standard equipment. Four optional X-Slot

cards can be installed in the UPS module at any time. See Chapter 12,

“Communication,” for additional information.

1.1.4 Mini‐CSB (Communication Server Board)

The mini‐CSB provides increased logging to 512 events, 5 additional programmable

languages, a real‐time clock, 4 additional building alarms, and enhanced alarm contact

programming.

1.1.5 ConnectUPS-X Web/SNMP Card X-Slot Card

A ConnectUPS –X Web/SNMP Card is provided as standard equipment and provides

remote monitoring through a Web browser interface, e‐mail, and a network

management system (NMS) using SNMP. See Chapter 12, “Communication,” for

additional information.

t

1.1.6 ABM Technology

ABM® technology is a three-stage charging system that increases battery service life

by optimizing recharge time, and protects batteries from damage due to high current

charging and inverter ripple currents. Charging at high currents can overheat and

damage batteries.

®

1-2

1.1.7 Powerware LanSafe Power Management Software

Powerware LanSafe® Power Management Software is bundled as part of the

Software Suite CD shipped with the UPS. See Chapter 12, “Communication,” for

additional information.

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 13

1.1.8 Installation Features

Cabinets can be permanently bolted to the floor or left standing on leveling feet.

Power and control wiring can be routed through the top or bottom of the cabinet with

connections made to easily accessible terminals. External sensing and monitoring

control wire must be installed in accordance with Class 1 wiring methods.

Line-up-and-match battery cabinets are wired through the side panels of the units.

Optional X-Slot connectivity cards are quickly installed at the front of the unit and are

hot-pluggable.

1.2 Options and Accessories

Contact your Eaton sales representative for information about the following options:

1.2.1 Integrated Battery Cabinets

Battery backup protection can be enhanced by equipping the UPS system with up to

four Powerware 9390 battery cabinets containing sealed lead‐acid, maintenance‐free

batteries. The battery cabinets are available in small and large sizes, with 192-cell

(208V units only), 216-cell, and 240-cell configurations (380V, 400v, 480v). The

cabinets are designed for line-up-and-match installation, but may be installed separate

from the UPS cabinet.

INTRODUCTION

NOTE NiCad batteries can also be used with the UPS , although firmware and EEP settings would need

modification for proper operation. Please consult your local Eaton Service repreenswtative for additional

information.

1.2.2 Integrated Distribution Cabinet

The Integrated Distribution Cabinet (IDC) provides adaptation and expansion with

distribution panelboards, distribution circuit breakers, a maintenance bypass switch,

and voltage transformation. The IDC is housed in a single, free‐standing cabinet

designed for line-up-and-match installation, but may be installed separate from the

UPS cabinet.

1.2.3 Integrated Accessory Cabinets (IAC-B, IAC-T, and IAC-D)

The following Integrated Accessory Cabinets (IACs) are designed for use with the

Powerware 9390 three-phase UPSs:

S The IAC-B provides maintenance bypass functions.

S The IAC-T provides parallel tie cabinet or parallel tie cabinet with maintenance

bypass functions.

S The IAC-D provides power distribution options for servers, racks, and other

equipment via distribution panelboards, or distributes power to larger loads via

distribution circuit breakers.

The IACs are housed in single, free‐standing cabinets designed for line-up-and-match

installation, but may be installed separate from the UPS cabinet.

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

1-3

Page 14

INTRODUCTION

1.2.4 Powerware Hot Sync Parallel System

A parallel UPS system with two to four uninterruptible power modules (UPMs) can be

installed to provide a parallel capacity and/or redundant system. This load sharing

system provides more capacity than a single UPS, and can provide backup, depending

on the load and configuration. In addition, when one UPM is taken out of service for

maintenance or is not operating properly, a redundant UPM continues to supply

uninterrupted power to the critical load. A Powerware Hot Sync

provides connectivity for system metering and operational mode control. The parallel

system consists of two to four UPMs each with a parallel CAN Bridge Card, and a

module tie cabinet or load distribution panel to act as a tie point. Each UPM requires a

separate battery cabinet.

1.2.5 Sync Control

An optional Sync Control maintains the critical load outputs of two separate single

module Powerware 9390 UPS systems in synchronization. This option facilitates the

uninterrupted transfer of the load from one load bus to another by means of transfer

switches. The Sync Control is housed in a wall‐mounted panel that can be located

between the UPS units for easy wiring.

®

CAN Bridge Card

1.2.6 Optional X-Slot Cards

The optional X-Slot cards support several protocols, such as SNMP, HTTP, AS/400®,

and Modbus®. See Chapter 12, “Communication,” for additional information.

1.2.7 Remote Monitor Panel

An optional Remote Monitor Panel (RMP) contains backlit status indicators and a local

horn, allowing you to monitor the operational status and alarm condition of the UPS

from virtually any location within your facility. This option is described further in

Chapter 10, “Using Features and Options.”

1.2.8 Relay Interface Module

An optional Relay Interface Module (RIM) uses relay contact closures to indicate the

operating status and alarm condition of the UPS. This option is described further in

Chapter 10, “Using Features and Options.”

1.2.9 Supervisory Contact Module

An optional Supervisory Contact Module (SCM) establishes an interface between the

UPS system equipment and the customer's monitor. This option is described further

in Chapter 10, “Using Features and Options.”

1-4

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 15

1.3 Basic System Configurations

The following basic UPS system configurations are possible:

S Single module UPS and one to four battery cabinets

S Single module UPS with UPS Sidecar (maintenance bypass or 1+1 tie

configuration) and one to four battery cabinets

S Single module UPS, one to four battery cabinets, and an optional IDC

S Single module UPS, one to four battery cabinets, and an optional IAC (maintenance

bypass, 1+1 tie, or 1+1 tie with maintenance bypass configuration)

S Single module UPS, one to four battery cabinets, and an optional IAC (distribution

configuration)

S Powerware Hot Sync parallel system with two UPS modules, one to four battery

cabinets for each UPS, and an optional module tie cabinet

- One capacity/one redundant (1+1)

- Two capacity (2+0)

S Powerware Hot Sync parallel system with three UPS modules, one to four battery

cabinets for each UPS, and an optional module tie cabinet

- Two capacity/one redundant (2+1)

- Three capacity (3+0)

S Powerware Hot Sync parallel system with four UPS modules, one to four battery

cabinets for each UPS, and an optional module tie cabinet

- Three capacity/one redundant (3+1)

- Four capacity (4+0)

S Powerware Hot Sync parallel system with two UPS modules, one to four battery

cabinets for each UPS, an optional module tie cabinet, and an optional IDC

- One capacity/one redundant (1+1)

- Two capacity (2+0)

S Powerware Hot Sync parallel system with three UPS modules, one to four battery

cabinets for each UPS, an optional module tie cabinet, and an optional IDC

- Two capacity/one redundant (2+1)

- Three capacity (3+0)

S Powerware Hot Sync parallel system with four UPS modules, one to four battery

cabinets for each UPS, an optional module tie cabinet, and an optional IDC

- Three capacity/one redundant (3+1)

- Four capacity (4+0)

The UPS system configuration can be enhanced by adding optional accessories such

as a Remote Emergency Power-off (REPO) control, RMP, or X-Slot communication

cards.

INTRODUCTION

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

1-5

Page 16

INTRODUCTION

1.4 Conventions Used in This Manual

This manual uses these type conventions:

S Bold type highlights important concepts in discussions, key terms in procedures,

and menu options, or represents a command or option that you type or enter at a

prompt.

S Italic type highlights notes and new terms where they are defined.

S Screen type represents information that appears on the screen or LCD.

Icon Description

[Keys] Brackets are used when referring to a specific key, such as [Enter] or [Ctrl].

In this manual, the term UPS refers only to the UPS cabinet and its internal elements.

The term UPS system refers to the entire power protection system – the UPS

cabinet, the battery cabinet, and options or accessories installed.

Information notes call attention to important features or instructions.

1.5 For More Information

Refer to the Powerware 9390 Integrated Battery Cabinet (Models IBC-S and IBC-L)

Installation Manual for the following additional information:

S Integrated Battery Cabinet (IBC) installation instructions, including site preparation,

planning for installation, wiring, and safety information.

S Detailed illustrations of the cabinet, including dimension and connection point

drawings.

The following ancillary equipment manuals include installation and operation

instructions, including site preparation, planning for installation, and wiring and safety

information, as well as controls, functions of the standard and optional features,

procedures for using with the UPS, and information about maintenance. Detailed

illustrations of the cabinet with dimensional and connection point drawings are

provided.

S Powerware 9390 Integrated Distribution Cabinet (80 kVA) Installation and

Operation Manual

S Powerware 9390 Integrated Accessory Cabinet (IAC-B and IAC-T Configurations)

Installation and Operation Manual

S Powerware 9390 Integrated Accessory Cabinet (IAC-D Configuration) Installation

and Operation Manual

S Powerware 9390 UPS Sidecar Installation and Operation Manual

S Powerware 9390 Sync Control Installation and Operation Manual

1-6

Visit www.powerware.com or contact your Eaton service representative for

information on how to obtain copies of these manuals.

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 17

1.6 Getting Help

INTRODUCTION

If you need help with any of the following:

S Scheduling initial startup

S Regional locations and telephone numbers

S A question about any of the information in this manual

S A question this manual does not answer

Please call the Eaton Help Desk for Powerware products at:

United States:

Canada: 1-800-461-9166 ext 260

All other countries: Call your local service representative

1-800-843-9433 or 1-919-870-3028

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

1-7

Page 18

INTRODUCTION

This page intentionally left blank.

1-8

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 19

Chapter 2 Safety Warnings

Figure

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

S This manual contains important instructions that should be followed during installation and maintenance

of the UPS and batteries. Read all instructions before operating the equipment and save this manual for

future reference.

S The UPS is designed for industrial or computer room applications, and contains safety shields behind the

door and front panels. However, the UPS is a sophisticated power system and should be handled with

appropriate care.

This UPS contains LETHAL VOLTAGES. All repairs and service should be performed by AUTHORIZED

SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS inside the UPS.

S The UPS is powered by its own energy source (batteries). The output terminals may carry live voltage

even when the UPS is disconnected from an AC source.

S To reduce the risk of fire or electric shock, install this UPS in a temperature and humidity controlled,

indoor environment, free of conductive contaminants. Ambient temperature must not exceed 40C

(104F). Do not operate near water or excessive humidity (95% maximum). The system is not intended for

outdoor use.

S Ensure all power is disconnected before performing installation or service.

S All precautions suggested by battery manufacurers concerning working on or around large battery banks

should be adhered to.

S Batteries can present a risk of electrical shock or burn from high short‐circuit current. The following

precautions should be observed: 1) Remove watches, rings, or other metal objects; 2) Use tools with

insulated handles; 3) Do not lay tools or metal parts on top of batteries; 4) Wear rubber gloves and boots.

S In order to change the 9390 UPS batteries from lead acid to Nicad or from NiCad to lead acid, the

internal firmware setup of the UPS must be changed by your Eaton Service representative. Failure to do

so will cause battery pack damage and loss of battery backup capability.

S ELECTRIC ENERGY HAZARD. Do not attempt to alter any UPS or battery wiring or connectors. Attempting

to alter wiring can cause injury.

S Do not open or mutilate batteries. Released electrolyte is harmful to the skin and eyes. It may be toxic.

D A N G E R

W A R N I N G

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

2-1

Page 20

SAFETY WARNINGS

C A U T I O N

S Installation or servicing should be performed by qualified service personnel knowledgeable of UPS and

battery systems, and required precautions. Keep unauthorized personnel away from equipment. Consider

all warnings, cautions, and notes before installing or servicing equipment. DO NOT DISCONNECT the

batteries while the UPS is in Battery mode.

S Replace batteries with the same number and type of batteries as originally installed with the UPS.

S Disconnect the charging source prior to connecting or disconnecting terminals.

S Determine if the battery is inadvertently grounded. If it is, remove the source of the ground. Contacting

any part of a grounded battery can cause a risk of electric shock. An electric shock is less likely if you

disconnect the grounding connection before you work on the batteries.

S Proper disposal of batteries is required. Refer to local codes for disposal requirements.

S Never dispose of batteries in a fire. Batteries may explode when exposed to flame.

S Keep the UPS door closed and front panels installed to ensure proper cooling airflow and to protect

personnel from dangerous voltages inside the unit.

S Do not install or operate the UPS system close to gas or electric heat sources.

S The operating environment should be maintained within the parameters stated in this manual.

S Keep surroundings uncluttered, clean, and free from excess moisture.

S Do not use this equipment for other than intended use.

S The use of accessory equipment not recommended by the manufacturer may cause an unsafe condition.

S Observe all DANGER, CAUTION, and WARNING notices affixed to the inside and outside of the

equipment.

A V E R T I S S E M E N T !

S Les batteries peuvent présenter un risque de décharge électrique ou de brûlure par des courts‐circuits de

haute intensité. Prendre les précautions nécessaires.

S Pour le replacement, utiliser le même nombre et modéle des batteries.

A T T E N T I O N !

S Une mise au rebut réglementaire des batteries est obligatoire. Consulter les règlements en vigueur dans

votre localité.

S Ne jamais jeter les batteries au feu. L'exposition aux flammes risque de les faire exploser.

2-2

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 21

Section I

Installation

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

2-1

Page 22

2-2

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 23

Chapter 3 UPS Installation Plan and Unpacking

Figure

Use the following basic sequence of steps to install the UPS:

1. Create an installation plan for the UPS system (Chapter 3).

2. Prepare your site for the UPS system (Chapter 3).

3. Inspect and unpack the UPS cabinet (Chapter 3).

4. Unload and install the UPS cabinet and wire the system (Chapter 4).

5. Install features, accessories, or options, as applicable (Chapters 5 and 6).

6. Complete the Installation Checklist (Chapter 4).

7. Have authorized service personnel perform preliminary operational checks and

startup.

NOTE Startup and operational checks must be performed by an authorized Eaton Customer Service

Engineer, or the warranty terms specified on page 15-1 become void. This service is offered as part of the

sales contract for the UPS. Contact your Eaton service representative in advance (usually a two-week notice is

required) to reserve a preferred startup date.

3.1 Creating an Installation Plan

Before installing the UPS system, read and understand how this manual applies to the

system being installed. Use the procedures and illustrations in the following chapters

to create a logical plan for installing the system.

3.2 Preparing the Site

For the UPS system to operate at peak efficiency, the installation site should meet

the environmental parameters outlined in this manual. If the UPS is to be operated at

an altitude higher than 1500m (5000 ft), contact your Eaton service representative for

important information about high altitude operation. The operating environment must

meet the weight, clearance, and environmental requirements specified in Drawing

164201603-2 on page A-3 and size requirements specified on Drawing 164201603-9

starting on page A-57.

The UPS cabinets use forced air cooling to regulate internal component temperature.

Air inlets are in the front of the cabinet and outlets are in the top. You must allow

clearance in front of and above each cabinet for proper air circulation. See Table

Table B on page A-4 .

3.2.1 Environmental Considerations

The life of the UPS system is adversely affected if the installation does not meet the

following guidelines:

S The system must be installed on a level floor suitable for computer or electronic

equipment.

S The system must be installed in a temperature and humidity controlled indoor area

free of conductive contaminants.

Failure to follow guidelines may void your warranty.

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

3-1

Page 24

UPS INSTALLATION PLAN AND UNPACKING

3.2.2 Preparing for Wiring the UPS System

NOTE If installing, as part of the UPS system, a maintenance bypass without a rectifier input breaker, a

minimum of two separate feeds with upstream feeder breakers, or one feed with two upstream feeder

breakers, must be provided: one for the UPS and one for the maintenance bypass input. DO NOT use one feed

or a single feeder breaker to supply both the UPS and the maintenance bypass.

For external wiring requirements, including the minimum AWG size of external wiring,

see Table G through Table I starting on page A-13. The power wiring connections for

this equipment are rated at 90°C. If wire is run in an ambient temperature greater

than 30°C, higher temperature wire and/or larger size wire may be necessary.

Control wiring for Emergency Power-off (EPO) and optional accessories (such as

building alarms and monitoring interface) should be connected at the customer

interface terminal blocks located inside the UPS.

LAN and telephone drops, for use with X-Slot connectivity cards, must be supplied by

facility planners or the customer.

3.3 Inspecting and Unpacking the UPS Cabinet

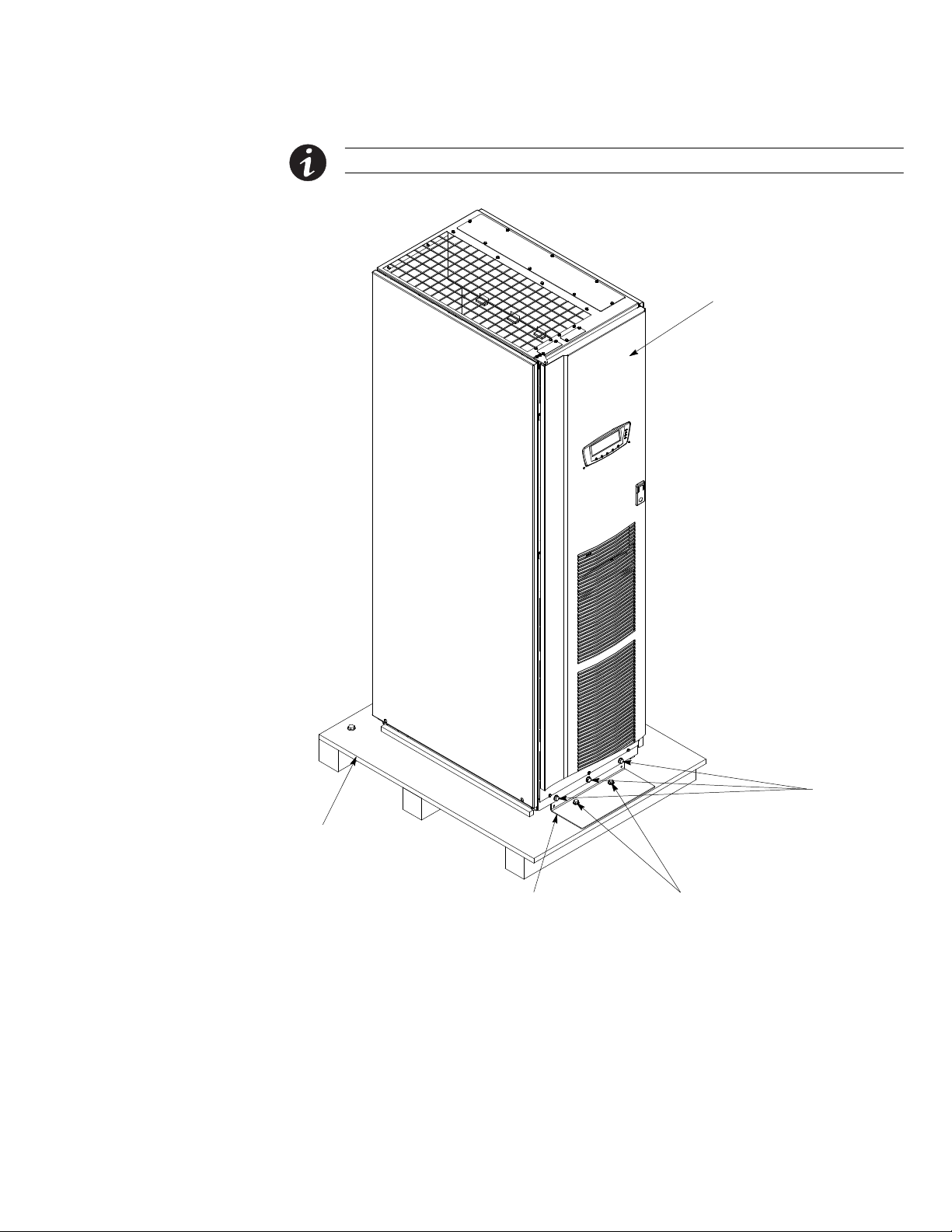

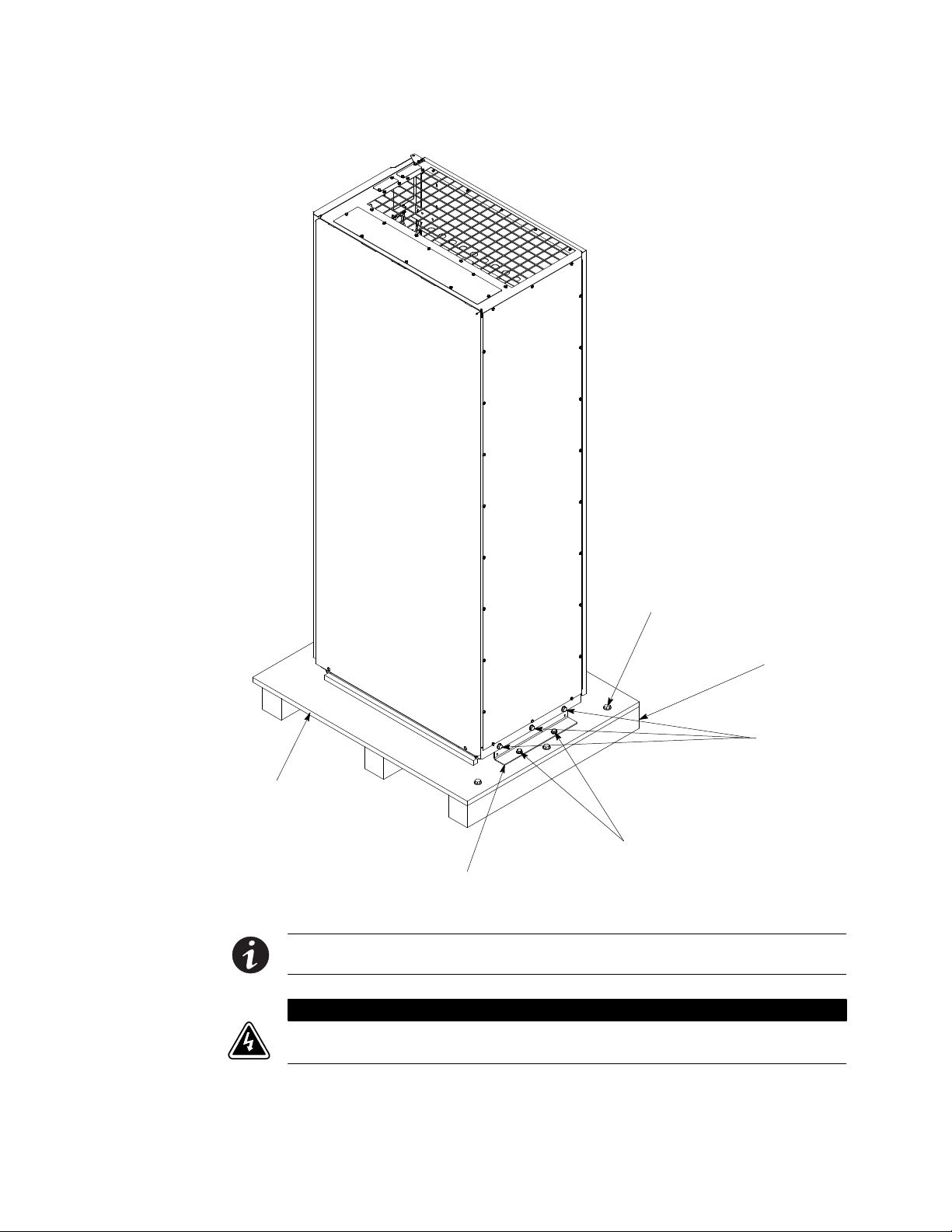

The cabinet is shipped bolted to a wooden pallet and protected with outer protective

packaging material (see Figure 3‐1).

3-2

Figure 3‐1. Powerware 9390 UPS (20–80 kVA) as Shipped on Pallet

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 25

UPS INSTALLATION PLAN AND UNPACKING

W A R N I N G

The UPS cabinet is heavy (see Table A on page A-3). If unpacking instructions are not closely followed, the

cabinet may tip and cause serious injury.

C A U T I O N

S Do not install a damaged cabinet. Report any damage to the carrier and contact your Eaton service

representative immediately.

S Do not tilt the UPS cabinet more than 10° from vertical or the cabinet may tip over.

To unpack the cabinet:

1. Carefully inspect the outer packaging for evidence of damage during transit.

2. Use a forklift or pallet jack to move the packaged cabinet to the installation site,

or as close as possible, before unpacking. Insert the forklift or pallet jack forks

between the pallet supports on the bottom of the unit.

NOTE Verify that the forklift or pallet jack is rated to handle the weight of the cabinet (see Table A on

page A-3 for cabinet weight).

3. Set the pallet on a firm, level surface, allowing a minimum clearance of 3m (10 ft)

on each side for removing the cabinet from the pallet.

NOTE The UPS cabinet is shipped with a debris shield covering the ventilation grill on top of the unit. Do

not remove the debris shield until installation is complete.

4. Remove the protective covering from the cabinet.

5. Remove the packing material, and discard or recycle in a responsible manner.

6. Inspect the contents for any evidence of physical damage, and compare each

item with the Bill of Lading. If damage has occurred or shortages are evident,

contact your Eaton service representative immediately to determine the extent of

the damage and its impact upon further installation.

NOTE While waiting for installation, protect the unpacked cabinet from moisture, dust, and other harmful

contaminants. Failure to store and protect the UPS properly may void your warranty.

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

3-3

Page 26

UPS INSTALLATION PLAN AND UNPACKING

This page intentionally left blank.

3-4

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 27

Chapter 4 Installing the UPS System

Figure

4.1 Preliminary Installation Information

W A R N I N G

Installation should be performed only by qualified personnel.

Refer to the following while installing the UPS system:

S Appendix A contains installation drawings and additional installation notes.

S Dimensions are in millimeters and inches.

S Do not tilt the cabinets more than "10° during installation.

S Remove the conduit landing plates to add conduit landing holes as required. Plate

material is 16 gauge steel (1.5 mm/0.06” thick).

S The cabinets must be installed on a level floor suitable for computer or electronic

equipment.

S If perforated floor tiles are required for ventilation, place them in front of the UPS.

See Table A on page A-3 for equipment weight and point loading.

S Details about control wiring are provided in each procedure for connecting options

and features. Drawing 164201603-8 and Table W through Table AC starting on

page A-42 identify the control wiring terminations.

To install a UPS cabinet, perform the procedures in the following paragraphs.

NOTE When a line-up-and-match UPS system is ordered together with battery cabinets, the first battery

cabinet is supplied with two cosmetic covers. The UPS cabinet, additional battery cabinets, and other ancillary

cabinets are supplied without cosmetic covers.

NOTE When a UPS system is ordered together with battery cabinets for standalone installation, the first

battery cabinet is supplied with two cosmetic covers. Additional battery cabinets are supplied without

cosmetic covers. Cosmetic covers must be ordered for the UPS cabinet and/or other ancillary cabinets.

4.2 Unloading the Powerware 9390 UPS Cabinet from the Pallet

The UPS cabinet is bolted to a wooden pallet supported by wood skids. To remove

the pallet:

1. If not already moved, use a forklift or pallet jack to move the cabinet to the

installation area, or as close as possible, before unloading from the pallet. Insert

the forklift jacks between the skids on the bottom of the unit.

W A R N I N G

The UPS cabinet is heavy. See Table A on page A-3 for weight of cabinets. If unloading instructions are not

closely followed, the cabinet may cause serious injury.

C A U T I O N

Do not tilt cabinets more than 10° from vertical.

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

4-1

Page 28

INSTALLING THE UPS SYSTEM

NOTE Verify that the forklift or pallet jack is rated to handle the weight of the cabinet (see Table A on

page A-3 for cabinet weight).

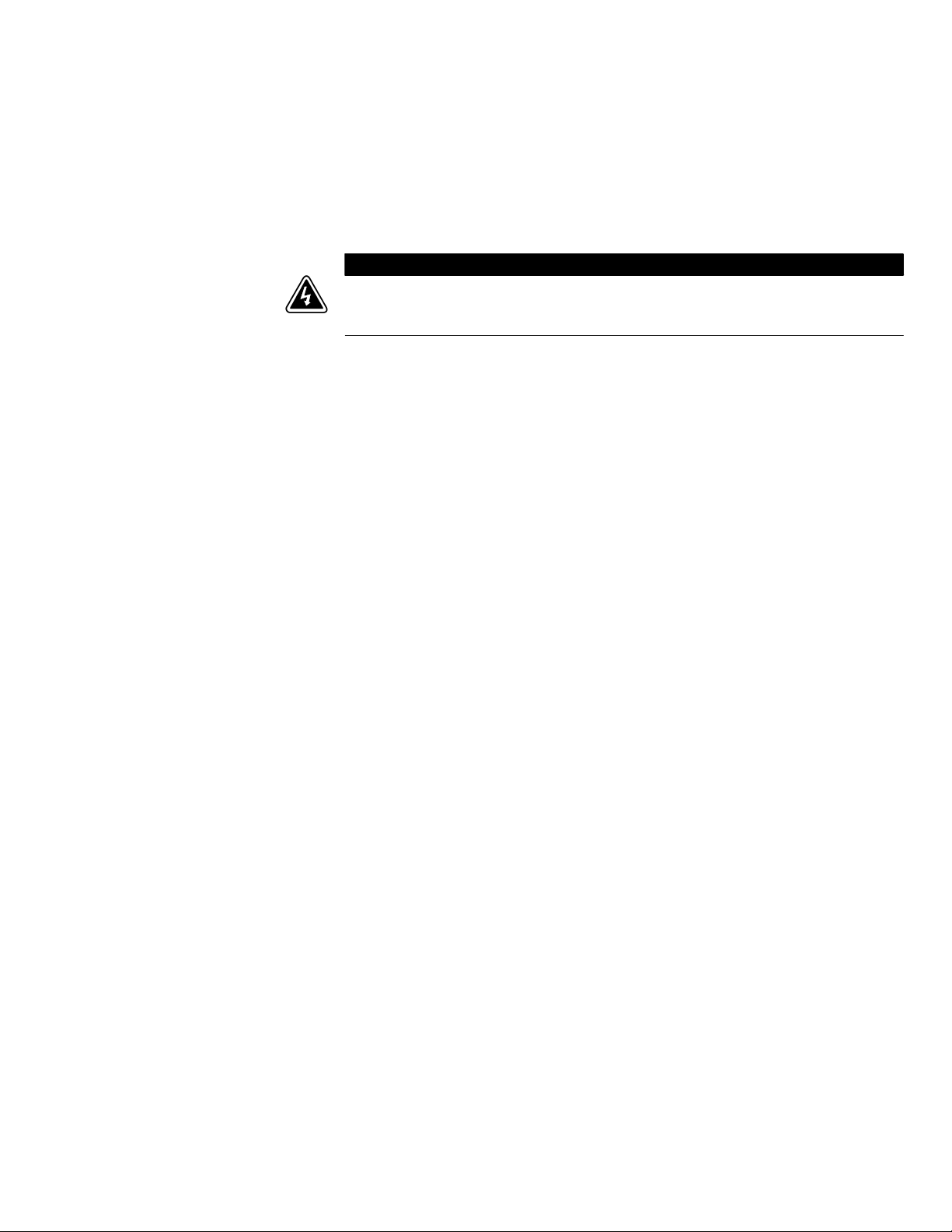

2. Unfasten the front door latch and swing the door open (see Figure 4‐1).

3. Remove the door. Remove the retaining screw located inside the door at the

bottom hinge pivot point, then lift the door off. Retain the hardware for later use.

4. If the leveling feet are not fully retracted, turn the leveling feet until they are

retracted.

5. Remove three bolts securing the rear shipping bracket to the cabinet and two

bolts securing the bracket to the pallet (see Figure 4‐2 on page 4-4). Remove

the rear shipping bracket. If installing the cabinet permanently, retain the

shipping bracket and securing hardware for later use.

6. Remove three bolts securing the front anti‐tip/shipping bracket to the cabinet and

two bolts securing the bracket to the pallet (see Figure 4‐1). Remove the front

anti-tip/shipping bracket. Retain the front anti-tip/shipping bracket and securing

hardware for later use. Do not discard the front anti-tip/shipping bracket. This

bracket is required for installation.

7. Remove three bolts securing the removable skid and remove the skid (see

Figure 4‐2 on page 4-4).

4-2

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 29

INSTALLING THE UPS SYSTEM

NOTE Do not discard the front anti‐tip/shipping bracket. This bracket is required for installation.

Front View

Vented Front Door

Pallet

Front Anti‐tip/Shipping Bracket

(note wide base)

Shipping Bracket Bolts

Figure 4‐1. Removing the Front Shipping Bracket on the Powerware 9390 UPS

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Shipping Bracket

Bolts

4-3

Page 30

INSTALLING THE UPS SYSTEM

Rear View

Skid Bolts (3 places)

Pallet

Shipping Bracket Bolts

Rear Shipping Bracket

Figure 4‐2. Removing the Rear Shipping Bracket on the Powerware 9390 UPS

NOTE In the following step the pallet tilts and acts as a ramp once the cabinet is rolled beyond the center

of the pallet. Be sure to restrain the cabinet as it continues to roll down the pallet/ramp.

W A R N I N G

Do not stand directly behind the pallet while unloading the cabinet. If unloading instructions are not closely

followed, the cabinet may cause serious injury.

Removable Skid

Shipping Bracket

Bolts

4-4

8. Slowly roll the cabinet toward the rear of the pallet. Once the pallet tilts, continue

rolling the cabinet down the pallet until the cabinet is clear of the pallet.

9. Roll the cabinet to the final installation location.

EATON Powerware® 9390 UPS (20–80 kVA) Installation and Operation Manual S 164201603 Rev 2 www.powerware.com

Page 31

INSTALLING THE UPS SYSTEM