Page 1

9

Parallel Redundant

Uninterruptible Power

Supply

315

Installation/Operation

Manual

164202013 Rev. D

Page 2

------------------------------------------------------------------------

------------------------------------------------------------------------

----------------------------------

IMPORTANT SAFETY INSTRUCTIONS

Instructions Importantes Concernant La Sécurité

SAVE THESE INSTRUCTIONS

Conserver Ces Instructions

This manual contains important instructions for your Uninterruptible Power

Supply (UPS) system. You should follow these instructions during the

installation and maintenance of the UPS, options, accessories, and batteries.

Cette notice contient des instructions importantes

concernant la sécurité.

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

their own expense.

WARNING:

This is a product for restricted sales distribution to informed partners. Installation

restrictions or additional measures may be needed to prevent disturbances.

ii

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 3

Table of Contents

Introduction 1...................................................

Using This Manual 2............................................

For More Information 3..........................................

Getting Help 3..................................................

Section I Installation 5...........................................

1 Getting Started 7.........................................

Preparing the Site 8.............................................

Environment Considerations 9...................................

Preparing for Wiring the Parallel Redundant System 9...............

Inspecting and Unpacking the Parallel Cabinet 10...................

Unloading the Parallel Cabinet From the Pallet 11....................

Creating an Installation Plan 13....................................

2 Installing the Parallel Redundant System 15.................

3 Parallel Re dundant Modules with Separate Batteries

and Common Batteries 17..............................

Parallel Redundant Modules with Separate Batteries 18...............

Parallel Redundant Modules with Common Battery 20................

Power Wiring Details 22..........................................

Control Wiring Interconnect Details 23..............................

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

iii

Page 4

Section II Operation 25..........................................

4 Getting Started 27.........................................

Parallel Redundant System Description 28..........................

Looking Inside the Parallel Redundant System 30....................

Safety Considerations 31.........................................

Symbols, Controls, and Indicators 32..............................

5 Understanding Parallel Redundant Operation 33.............

Normal, Battery, and Bypass Modes with Parallel Operation 34........

6 Operating Instructions for the Parallel

Redundant System 35..................................

Module Output Breakers (MOBs) 35...............................

How to Open and Close the MOB 35...............................

Starting and Stopping Using Parallel Redundant System 35...........

How to Isolate a Module 36.......................................

Shut Down a Module 36..........................................

Transfer System to Bypass 36.....................................

LOAD OFF 37...................................................

Appendix A A---1.................................................

iv

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 5

List of Figures

Figure 1. Typical Parallel Cabinet 1..................................

Figure 2. Front and Side View of Parallel Cabinet 7....................

Figure 3. Cabinet as Shipped, with Outer Packaging and Pallet 10........

Figure 4. Removing Front and Rear Supports 12.......................

Figure 5. Top, Bottom, and Front View of Parallel Cabinet 15.............

Figure 6. Control and Power Wiring Terminations of UPS Module

and Parallel Cabinet 16....................................

Figure 7. Modules with Separate Batteries 18..........................

Figure8. ModuleswithCommonBattery 20...........................

Figure 9. Grouping for Twisting Requirements 23.......................

Figure 10. Controls and Indicators 29.................................

Figure 11. UPS Outputs and Communications A--- 2......................

Figure 12. Mechanical Details A---3.....................................

Figure 13. Electrical Access Details A--- 4................................

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

v

Page 6

This Page Intentionally Left Blank.

vi

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 7

Introduction

The parallel redundant system allows two UPS modules to operate in parallel and

as backup for each other. When one UPS module is taken out of service for

maintenance or is not operating properly, the redundant UPS module continues to

supply uninterrupted power to the critical load. The parallel redundant system

refers to the parallel cabinet in conjunction with the UPS modules. The parallel

redundant system consists of one parallel cabinet, two identical UPS cabinets, and

up to four battery cabinets per UPS. Each UPS module may have its own battery

cabinet(s), or may share the same battery cabinet(s) with the other UPS module.

NOTE: The installation procedures of this manual only refer to the parallel cabinet

and its connection to the UPS cabinets for parallel redundant operation. The

operation section of this manual refers to the operation for the parallel

cabinet and the UPS system when in parallel. For full installation and

operation of the UPS system and battery installation, refer to the

PowerwareÒ 9315 Installation, PowerwareÒ 9315 Operation,andthe

PowerwareÒ Series 685 and 1085 Auxiliary Battery Cabinets

Installation manuals provided with the UPS system and battery cabinet

accessory.

The parallel cabinet is a free-standing cabinet. Figure 1 shows a typical parallel

cabinet.

Figure 1. Typical Parallel Cabinet

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

1

Page 8

Using This Manual

This manual contains installation and operation procedures for the PowerwareÒ

9315 Parallel Redundant system. In this manual, parallel redundant system refers

to the parallel cabinet, its internal components, and those components of the UPS

modules that assist in parallel redundant operation. The text uses these

conventions:

· Bold type highlights important concepts in discussions, key terms in

procedures, and menu options.

· Italic type highlights notes, references to other system manuals, references to

other sections of this manual, and new terms where they are defined.

· Rectangular boxes containing bold type are warnings or cautions that pertain to

the parallel redundant system or its electrical connections. This important

information indicates possible dangers pertaining to personnel safety,

equipment damage, critical load protection, or operational concerns.

Before installation of the parallel redundant system, read through each installation

procedure provided in Section 1 Installation of this manual. Below is a description

of each chapter in each section as they appear:

Section 1

· Chapter 1 tells you how to prepare the site for the installation of the parallel

cabinet. It discusses equipment environmental requirements, inspecting and

unpacking the parallel cabinet, and pallet removal.

· Chapter 2 describes how to install the parallel cabinet.

· Chapter 3 describes parallel redundant configurations of UPS modules utilizing

separate battery cabinets or sharing a common battery cabinet.

Section 2

· Chapter 4 describes the parallel redundant system and its operation.

· Chapter 5 provides information on understanding parallel operation.

· Chapter 6 contains operation instructions for the parallel redundant system.

· Appendix A contains important information on wiring requirements and

recommendations, and important diagrams of the cabinet’s mechanical details

and electrical access.

Read through each procedure before you begin. Perform only those procedures

that apply to the UPS system you are installing.

2

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 9

For More Information

This manual describes the installation and operation of the parallel redundant

system. For more information on the installation and operation of the UPS system

and its accessories, refer to the following:

164200252 Powerware

9315 30---160 kVA UPS Operation

164201036 Powerware

164201119 Powerware

Each manual describes the UPS cabinet Control Panel and

Monitor Panel, and explains the functions of the UPS; discusses

the standard features o f the UPS and optional accessories;

provides procedures for starting and stopping the UPS, and

information about maintenance and responding to system events.

A l s o d e s c r i b ed a r e t h e R S --- 48 5 a n d R S --- 2 3 2 s e r ia l

communications capabilities of the UPS system; discusses the

two communications ports on the Customer Interface Panel

inside the UPS and how to connect optional remote accessories

to your UPS system; provides information about enabling,

disabling, and customizing building alarms.

164200253 Powerware

164200292 Powerware

164201037 Powerware

164201118 Powerware

Each manual contains the following information: how to prepare

the site and plan for installation, detailed step-by-step

procedures for installing each component of your system, how to

join cabinets in a line-up-and-match system, detailed illustrations

of cabinets and optional accessories, including dimensions and

connection points.

9315 200---300 kVA UPS Operation

9315 400/500 (300--- 500 kVA) UPS Operation

9315 30---80 kVA UPS Installation

9315 100---160 kVA UPS Installation

9315 200---300 kVA UPS Installation

9315 400/500 (300---500 kVA) UPS Installation

Contact the local Powerware Field Service office for information on how to obtain

copies of these manuals.

Getting Help

If you have a question about any of the information in this manual, or if you have a

question this manual does not answer, please call Powerware Corporation Field

Service:

United States 1-800-843-9433

Canada 1-800-461-9166

Outside the U.S. Call your local representative

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

3

Page 10

This Page Intentionally Left Blank.

4

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 11

Section I

Installation

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

5

Page 12

This Page Intentionally Left Blank.

6

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 13

Getting Started

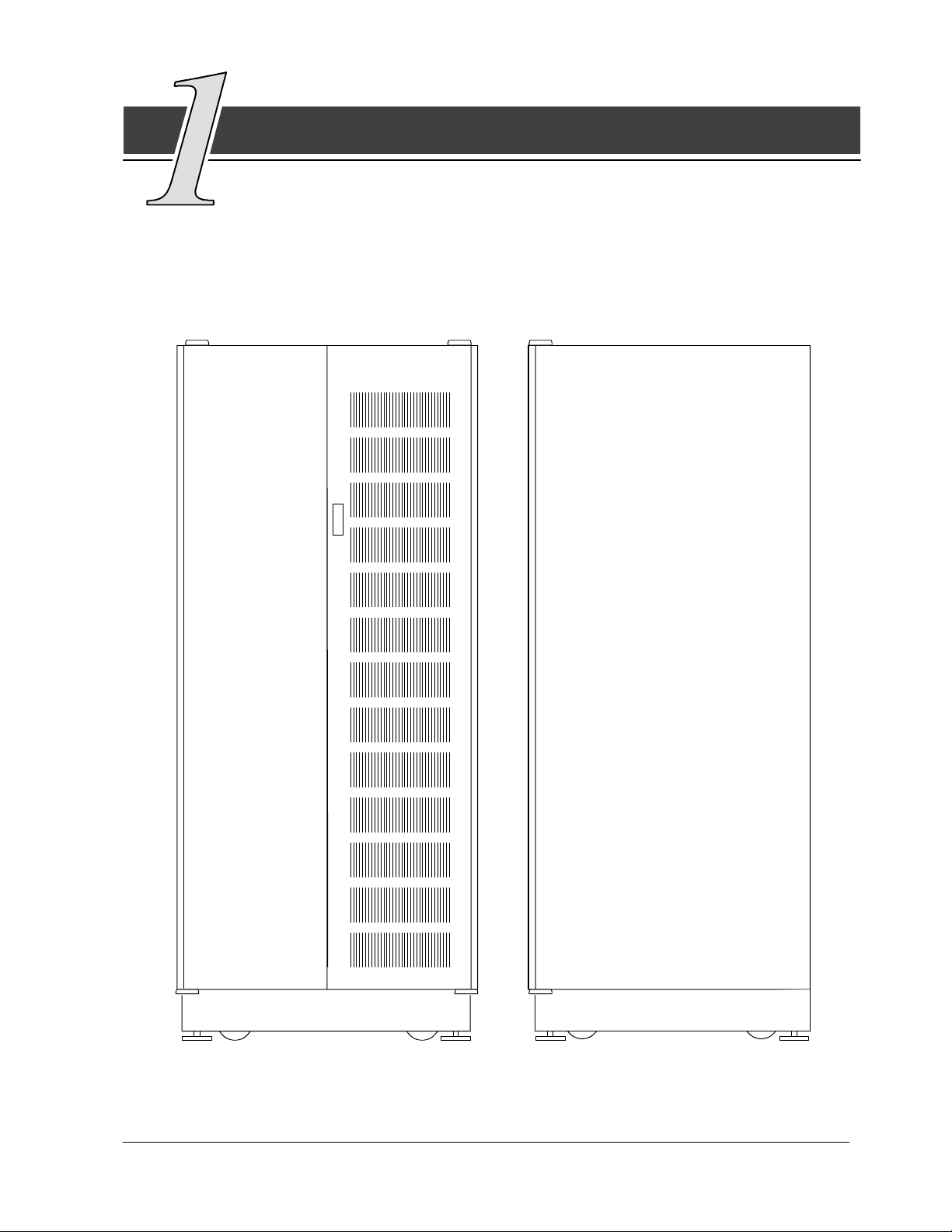

This section describes how to install the parallel cabinet. It contains only

instructions for installing the parallel cabinet as a remote cabinet,

configuration needed for parallel redundant operation, and basic site preparation

procedures. Figure 2 shows the front and side view of the parallel cabinet.

Figure 2. Front and Side View of Parallel Cabinet

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

7

Page 14

The parallel cabinet is shipped on a separate pallet. Use a forklift or pallet jack to

move the packaged cabinet to the installation site, or as close as possible to the

site, before unloading from the pallet.

The basic sequence of the installation steps is:

1. Prepare the site for the cabinet installation.

2. Inspect, unpack, and unload the cabinet.

3. Create an installation plan for wiring the parallel cabinet to the corresponding

UPS modules.

4. Prepare for wiring.

5. Complete the installation checklist from the PowerwareR 9315 Installation manual.

6. Have authorized service personnel perform preliminary checks and startup.

NOTE: Startup and operational checks should be performed only by authorized

service personnel. This service is usually offered as part of the sales

contract for your UPS system.

Preparing the Site

For the parallel redundant system to operate at peak efficiency, the installation site

should meet the environmental parameters outlined in the PowerwareÒ 9315

Operation manual provided with the UPS system. The operating environment must

meet the size and weight requirements supplied in the PowerwareÒ 9315

Installation manual provided with the UPS system. If the parallel redundant system

is to be operated at an altitude higher than 1500 meters (5000 feet), contact the

local sales or service office for important information about high altitude operation.

The basic environmental requirements for operation of the parallel redundant

system are:

Ambient Temperature Range: 0 --- 4 0 ˚C (32---104˚F)

Recommended Operating Range: 20 --- 25˚C (68 --- 77˚F)

Maximum Relative Humidity: 95%

The parallel cabinet uses convection cooling to regulate internal component

temperature. Air inlets are in the front of the cabinet, and outlets are in the top.

Clearance in front of and above each cabinet for proper air circulation is essential.

8

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 15

Environment Considerations

Thelifeoftheparallelredundantsystemwillbeadverselyaffectediftheinstallation

does not meet the following guidelines:

1. The parallel cabinet must be installed on a sealed concrete pad on a sealed

concrete floor.

2. The parallel cabinet must be installed in a dust-free environment.

3. The parallel cabinet must be installed in a humidity-controlled environment.

Preparing for Wiring the Parallel Redundant System

See Tables A---1 through A---4 in Appendix A of this manual for wiring requirements.

The power wiring for this equipment is rated at 75_C. Ifwireisruninanambient

temperature greater than 30_C, higher temperature and/or larger size wire may be

necessary. Wiring for the paralle cabinet should be installed through the 28.6 mm

(1.1 in.) knockout in the bottom of the UPS cabinet. The top entry connection

requires installation of 1/2-in. flexible conduit within the UPS. Bottom entry

connection requires no additional routing of conduit within the UPS. For UPS

external wiring requirements, including minimum AWG size of external wiring, see

the PowerwareÒ 9315 Installation manual provided with the UPS system.

NOTE: Material and labor for external wiring are to be provided by designated

personnel.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

9

Page 16

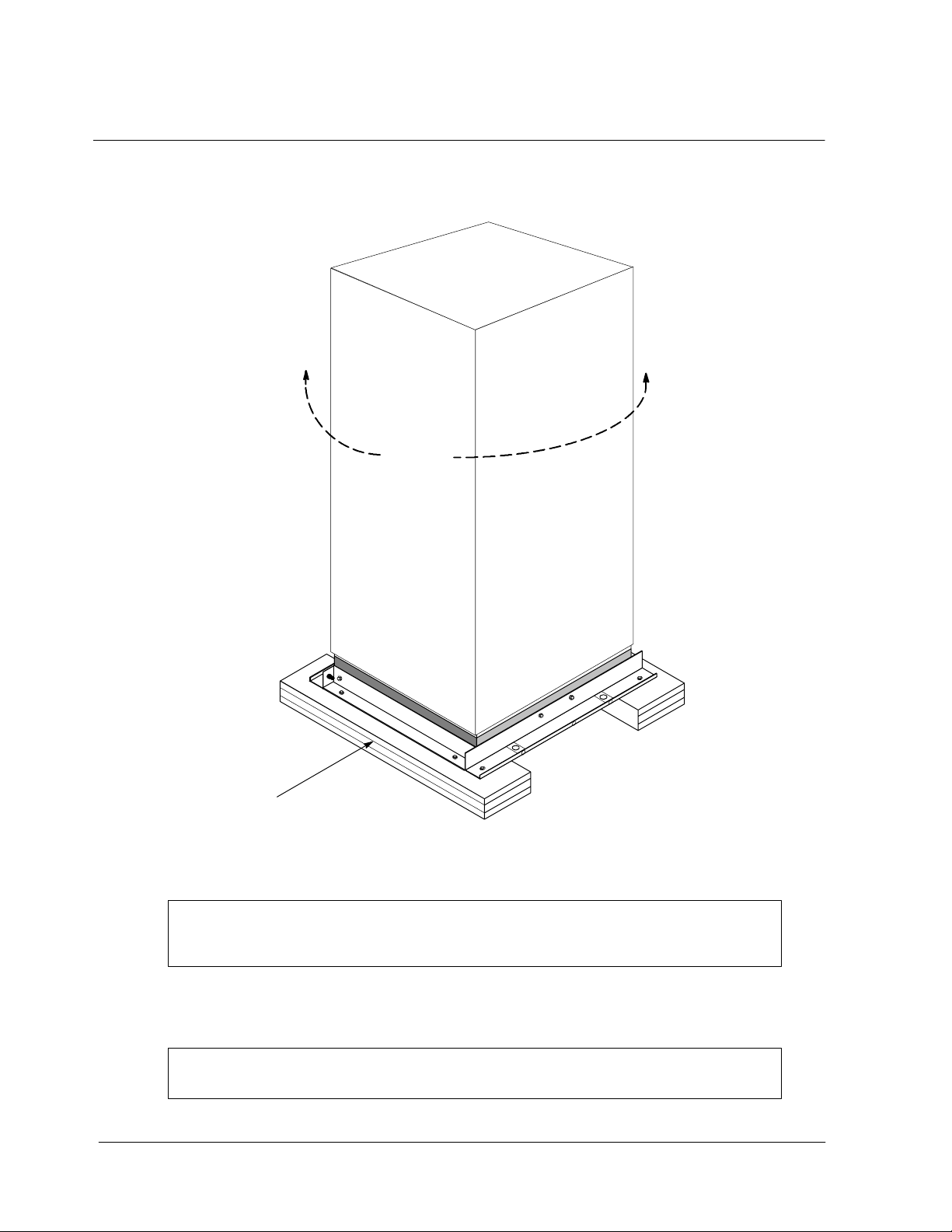

Inspecting and Unpacking the Parallel Cabinet

The first task in preparing for installation of the parallel cabinet is inspecting and

unpacking the cabinet. The cabinet arrives covered with protective packaging

material as shown in Figure 3.

OUTER

PACKA GING

10

FOAM CUSHION

Figure 3. Cabinet as Shipped, with Outer Packaging and Pallet

1. Carefully inspect the outer packaging for evidence of damage during transit.

CAUTION:

Do not install a damaged cabinet. Report any damage to the carrier and

contact the local sales or service office immediately.

2. Use a forklift or other material handling equipment to move the cabinet to a

convenient unpacking area. Insert the forklift jacks between the foam cushions

on the bottom of the unit.

CAUTION:

Do not tilt cabinet more than 10 degrees from vertical.

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 17

3. Set the pallet on a firm, level surface, allowing a minimum clearance of

4.6m (15 ft) on each side for removing the cabinet from the pallet.

4. Cut the steel bands around the cabinet.

5. Remove the protective cardboard covering from the cabinet, cutting where

indicated, using a knife blade no longer than 25 mm (1 in.).

NOTE: Do not discard the packaging material yet. Instructions for unloading the

cabinet from the pallet are printed on the cardboard, and you will need to

refer to them.

6. Remove the plastic bag and foam packing material, and discard or recycle

them in a responsible manner.

Unloading the Parallel Cabinet From the Pallet

The parallel cabinet consists of four supports secured to foam cushions. The foam

cushions act as shock absorbers for the cabinet during shipment.

WARNING:

Cabinet is extremely heavy. If unloading instructions are not closely

followed, the cabinet may tip and cause serious injury.

Turning the jacking bolts unevenly may cause the cabinet to become

unbalanced. To prevent tipping, raise and lower the jacking bolts

evenly. The cabinet should only be raised approximately 3 mm (

above the floor (just enough to remove foam cushions).

1/8 in.)

1. Remove the doors. Remove the retaining screw located inside each door at

the bottom hinge pivot point, then lift the door off. Save the retaining screws

for reinstallation of the doors.

2. Locate the field kit (packed inside of the cabinet or communication panel).

Locate the four ½-in. jacking bolts and install them in the threaded holes in the

front and rear supports. Place a floor protector underneath each jacking bolt,

and screw the bolts down against them. The floor protectors will save the floor

from being marred by the jacking bolts.

3. Loosen, but do not remove the hardware holding the foam cushions to the

front and rear supports (labeled “1” in Figure 4).

4. Turn each jacking bolt consecutively, two full turns, until the foam cushions

clear the floor by approximately 3 mm (

1/8 in.).

5. After the foam cushions clear the floor, remove the hardware loosened in

step 3. Pull the foam cushions out from under the cabinet, and discard or

recycle them in a responsible manner.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

11

Page 18

DOOR

1

FLOOR

PROTECTOR

2

FRONT

SUPPORT

SIDE

SUPPORT

FOAM

CUSHION

2

2

JACKING

BOLT

Figure 4. Removing Front and Rear Supports

2

1

1

WARNING:

Cabinet may fall. Do not loosen hardware attaching the side or front

supports to the cabinet base. Also, do not loosen supports from each

other. The cabinet must be lowered using jacking bolts before supports

can be removed.

6. Carefully and evenly lower the cabinet by turning each jacking bolt

consecutively two full turns (maximum)

the cabinet is no longer supported by the jacking bolts.

until the supports contact the floor, and

7. After the cabinet is resting on the floor, remove the jacking bolts and discard or

recycle them in a responsible manner.

12

8. Removethehardwarelabeled“2”inFigure4,holdingthefront,rearandside

supports to the cabinet base. Discard or recycle the hardware and support

brackets in a responsible manner.

9. Install the doors removed in step 1. The parallel cabinet is now ready to be

rolled to its final location.

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 19

Creating an Installation Plan

Before beginning to install the parallel cabinet, read and understand how this

manual applies to the system being installed. It is important to note that UPS

module installation procedures are contained in the PowerwareÒ 9315 Installation

manual provided with the UPS system. It is recommended to first understand how

to install the UPS modules. The information in Chapter 2 of this manual is a guide

in installation of the parallel cabinet to the UPS modules.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

13

Page 20

This Page Intentionally Left Blank.

14

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 21

Installing the Parallel

Redundant System

Once the parallel cabinet has been moved to its installed location, unpacked, and

inspected, it is ready for installation. This manual discusses the typical

configuration of installing the parallel cabinet in a remote location. The parallel

cabinet arrives as shown in Figure 5.

Cooling Air Inlets

Cooling Grate

Top

(Cooling Air Outlets)

Wire

Entry

Cable Entry, Top View

Bottom Wire Entry

Cable Entry, Floor Plan View

Figure 5. Top, Bottom, and Front View of Parallel Cabinet

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

15

Page 22

Refer to the following while installing the parallel cabinet:

· Dimensions in this manual are in millimeters and inches.

· Do not tilt the cabinet more than 10˚ during installation.

· The conduit landing plates are to be removed to add conduit landing holes as

required. Plate material is 16 gauge steel (0.06 in. thick).

· Terminals E9–E12 and E16 ---E18 are UL and CSA rated at 90˚C. Ahexkeytool

is required to attach wires to the terminals.

· Details about control wiring are provided in Table A---1 of Appendix A and the

Control Wiring Interconnect Details in Chapter 3 of this manual.

Figure 6 shows typical control wiring and power wiring terminations of the UPS

module and parallel cabinet. Refer to the Powerware 9315 Installation manual

provided with the UPS system for location of UPS module cabinet wiring

terminations.

NOTE: Material and labor for external wiring are to be provided by designated

personnel.

MOB#1 TB1

MOB#2

TB1

Output

Neutral

Connection

(E12)

A/C Output

E9, E10,

E11

E10

E10

E11

E9

E9

MOB1

MOB2

LEFT DOOR

TB1

TB3

Terminal Strip

UPS MODULE

TB2

Communication Panel

(100--160kVA UPS Shown)

ÆA ÆCÆBÆA ÆC

E16 E17 E18

Ground

PARALLEL CABINET

ÆB

Figure 6. Typical Control and Power Wiring Terminations of UPS Module

and Parallel Cabinet

E11

E12

Isolated

Ground

(Optional)

16

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 23

Parallel Redundant Modules

with Separate Batteries

and Common Batteries

This chapter describes the internal connections of the parallel cabinet to UPS

modules utilizing separate battery cabinet(s) and a shared battery cabinet(s).

Determine which battery configuration is being utilized before beginning

installation. If battery cabinets and remote disconnects provided by Powerware

Corporation are being installed, refer to the Powerware Series 685 and 1085

Auxiliary Battery Cabinets Installation manual, 164200300, for instructions on

installation. If battery cabinets not provided by Powerware Corporation are being

installed, refer to the battery cabinet manufacturer’s manual for instructions on

battery cabinet installation and maintenance.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

17

Page 24

Parallel Redundant Modules with Separate Batteries

There are two possible configurations for battery connection of the parallel

redundant system. The two UPS modules may share the same battery cabinet(s),

or each module may use a separate battery cabinet(s). Figure 7 shows a diagram

of the parallel redundant system with UPS modules utilizing separate battery

cabinets.

NOTE: Refer to Powerware 9315 Installation manual provided with the UPS system

for battery shunt trip connections.

C C

Battery

Cabinet

UPS

Module 1

TB3 TB3

Battery

Cabinet

UPS

Module 2

BA BA

MOB #1

TB1

MOB1 MOB2

UPS #1

Input

E9---E12

Parallel Cabinet

Critical

Output Bus

E16---E18

UPS #2

Input

E9---E12

Figure 7. Modules with Separate Batteries

MOB #2

TB1

18

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 25

Figure 7 points out the connection areas of the two UPS modules and the parallel

cabinet. The A connection is the power input connections from UPS 1 and UPS 2 to

the parallel cabinet. It is recommended that the UPS modules are labeled in

accordance with Module Output Breaker (MOB) labeling (e.g., the MOB 1 terminals E9

through E11 should be wired with UPS 1 terminals E9 through E11, E12 is the

neutral). The MOBs have already been designated as MOB 1 and MOB 2. See

Table A- -- 2 in Appendix A of this manual for power terminations of the parallel cabinet

and the UPS modules. For power wiring requirements and recommendations, see

Tables A-- -3 and A---4 in Appendix A of this manual. For power wiring connections or

terminal strip locations, refer to Figure 13 in Appendix A of this manual.

The B connection is the control wiring connection between the communication panels

of the UPS modules and the parallel cabinet. In the UPS module, the TB3 terminal

strip is located on the left side of the UPS cabinet and to the left of the TB1 terminal

strip on its communication panel. For control wiring requirements and

recommendations, see Table A -- -1 in Appendix A in this manual. For control wiring

connections and terminal strip locations, refer to Figure 13 in Appendix A of this

manual.

For the UPS Module connections, please refer to the PowerwareÒ 9315 Installation

manual provided with the UPS system for protection and wiring requirements and

recommendations.

For the C connections, make sure the bypass feeds originate from the same power

source. Means for separate isolation (circuit breaker or disconnect) are

recommended. Refer to the PowerwareÒ 9315 Installation manual provided with the

UPS system for bypass power wiring.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

19

Page 26

Parallel Redundant Modules with Common Battery

Figure 8 is a diagram of the parallel redundant system containing UPS modules

sharing a common battery cabinet.

NOTE: UPS modules sharing a battery cabinet(s) must utilize a remote battery

cabinet(s). Refer to the Powerware Series 685 and 1085 Auxiliary Battery

Cabinets Installation manual 164200300, for instructions on installation.

Refer to Powerware 9315 Installation manual provided with the UPS System

for battery breaker shunt trip connections.

C C

TB3

DD

UPS

Module 1

Battery

Cabinet

UPS

Module 2

BA BA

MOB #1

TB1

UPS #1

Input

E9---E12

UPS #2

Input

E9---E12

TB3

MOB #2

TB1

20

MOB1 MOB2

Parallel Cabinet

Critical

Output Bus

E16---E18

Figure 8. Modules with Common Battery

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 27

Figure 8 points out the connection areas of the two UPS modules and the parallel

cabinet. The A connection is the power input connections from UPS 1 and UPS 2 to

the parallel cabinet. It is recommended that the UPS modules are labeled in

accordance with Module Output Breaker (MOB) labeling (e.g., the MOB 1 terminals E9

through E11 should be wired with UPS 1, terminals E9 through E11, E12 is the

neutral). The MOBs have already been designated as MOB 1 and MOB 2. See

Table A- -- 2 in Appendix A of this manual for power terminations of the parallel cabinet

and the UPS modules. For power wiring requirements and recommendations, see

Tables A-- -3 and A---4 in Appendix A of this manual. For power wiring connections or

terminal strip locations, refer to Figure 13 in Appendix A of this manual.

The B connection is the control wiring connection between the communication panels

of the UPS modules and the parallel cabinet. In the UPS module, the TB3 terminal

strip is located on the left side of the UPS cabinet and to the left of the TB1 terminal

strip on its communication panel. For control wiring requirements and

recommendations, see Table A -- -1 in Appendix A in this manual. For control wiring

connections and terminal strip locations, refer to Figure 13 in Appendix A of this

manual.

For the UPS Module connections, please refer to the PowerwareÒ 9315 Installation

manual provided with the UPS system for protection and wiring requirements and

recommendations.

For the C connections, make sure the bypass feeds originate from the same power

source. Means for separate isolation (circuit breaker or disconnect) are

recommended. Refer to the PowerwareÒ 9315 Installation manual provided with the

UPS system for bypass power wiring.

For the D connection, make sure input feeds originate from the same power source.

Means for separate isolation (circuit breaker or disconnect) are recommended. Refer

to the PowerwareÒ 9315 Installation manual provided with the UPS system for input

feeds to the UPS module.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

21

Page 28

Power Wiring Details

Each UPS module must be wired to its corresponding module output breaker in the

cabinet with power cables sufficient for carrying the load. Recommended wiring

size is listed in Tables A---3 and A--- 4 of Appendix A of this manual. Each of the

three phases plus the neutral must be wired. Nonlinear loads can create neutral

currents that are greater than 100%. The neutral bus (terminal strip E12) contains

sufficient cable landing to wire double-size neutrals if needed.

NOTE: Material and labor for external wiring are to be provided by designated

personnel.

22

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 29

Control Wiring Interconnect Details

Each UPS module requires control signal wiring from the module to the parallel

cabinet. The purpose of signaling is to facilitate the closing of the module output

breakers and coordinate transfers to and from bypass. Once this system has been

properly placed into operation, it will operate as a parallel redundant system even if

the control wiring becomes disabled through shorts or opens. Figure 9 shows the

grouping for twisting requirements. Refer to Table A in this chapter for control

wiring recommendations and termination capability.

NOTE: Material and labor for external wiring are to be provided by designated

personnel.

Table A. Control Wiring Requirements and Termination Requirements

Connection

Points in

Parallel

Cabinet

TB1--1

through

TB1--7

Size of

Pressure

Termination

(lb--in)

#18--#8,

(55)

Maximum

Voltage and

Current

24V, 0.25A TB3--1 through

Connection

Points in UPS

TB3--7

Size of

Pressure

Termination

(lb--in)

#22--#12,

(5--7)

Recommended

Wiring Size

#18--#12

Notes for Table A:

1. Install the control wiring in separate conduit from the power wiring. Only

copper wire or tinned copper wire should be used.

2. Control wiring is NEC class 2 (IEC 950 SELV).

3. Class 1 methods are recommended for control wiring.

4. Control wiring should be twisted pairs and twisted triple as shown in Figure 9.

1

2

3

4

5

6

7

Parallel

Cabinet

MOB#1

(#2)

UPS

Module 1

(or 2)

TB3 TB1

1

2

3

4

5

6

7

Indicates grouping for twisting requirements.

Figure 9. Grouping for Twisting Requirements

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

23

Page 30

This Page Intentionally Left Blank.

24

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 31

Section II

Operation

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

25

Page 32

This Page Intentionally Left Blank.

26

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 33

Getting Started

The PowerwareÒ 9315 Uninterruptible Power Supply (UPS) continually

monitors incoming electrical power and removes the surges, spikes, sags, and

other irregularities that are inherent in commercial utility power. With the

PowerwareÒ 9315 Parallel Redundant system, when one UPS module is taken off

line or becomes disabled, the redundant module continues working with the

building’s electrical system to supply clean, consistent power that sensitive

electronic equipment requires for reliable operation.

The parallel redundant system should function automatically and require very little

attention during normal operation. However, once installation has been completed,

read and understand the procedures in this section as they are provided to ensure

trouble-free operation.

Each component of the parallel redundant system is housed in a free-standing

cabinet designed for industrial or computer room applications. The parallel cabinet

has safety shields behind the doors for hazardous voltage protection.

The following descriptions provide a brief overview of the standard parallel

redundant features.

NOTE: Read the Operation section and have thorough knowledge of parallel

redundant operation before attempting to operate. For a more detailed

description of UPS operation, refer to PowerwareÒ 9315 Operation manual

supplied with the UPS system.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

27

Page 34

Parallel Redundant System Description

The parallel redundant system consists of two identical UPS modules, a parallel

cabinet, and one or two battery racks or cabinets.

The parallel cabinet consists of two module output breakers designated MOB 1

and MOB 2. These output breakers receive power input from the AC output of the

UPS modules. If one UPS module becomes disabled, it trips off, leaving the

redundant UPS module to continue to supply power to the critical load. The

primary function of the MOBs is to allow isolation of a module for maintenance or

service. In a parallel redundant system the redundant module becomes the

system’s maintenance bypass source.

There are two lamps located on the inside of the parallel cabinet labeled

OK TO CLOSE. When one of these lamps illuminates, the corresponding MOB

canbeclosed. ItisimportanttonotethatitisonlysafetoclosetheMOBswhen

the OK TO CLOSE indicator lights are illuminated. A LAMP TEST pushbutton is

located inside the parallel cabinet for testing these indicators. The parallel cabinet

also includes associated terminal strips for making the power and control

connections to UPS modules. Figure 10 shows the controls and indicators of the

parallel cabinet.

28

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 35

MODULE

OUTPUT

BREAKER 1

(MOB 1)

MODULE

OUTPUT

BREAKER 2

(MOB 2)

Figure 10. Controls and Indicators

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

29

Page 36

Looking Inside the Parallel Redundant System

The parallel redundant system supports the normal operation of the PowerwareÒ

9315 UPS system by offering parallel redundant capability. The UPS system

continues to maintain power to the critical loads during commercial electrical power

brownout, blackout, overvoltage, undervoltage, and out-of-tolerance frequency

conditions. The parallel redundant system ties two UPS modules together, in

parallel, in order for continuous power to flow even when one module becomes

disabled. Refer to Figure 13 in Appendix A of this manual for the detailed

relationship of the parallel cabinet and the UPS modules.

If utility power is interrupted or falls outside the parameters specified in the

PowerwareÒ 9315 Operation manual, the UPS system uses a backup battery

supply to sustain power to the critical load for a specified period of time or until the

utility power returns. For extended power outages, the backup battery supply

allows you to either transfer to an alternate power system (such as a generator) or

shut down the critical load in an orderly manner. Refer to the PowerwareÒ 9315

Operation manual provided with the UPS system for operation of the UPS.

30

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 37

Safety Considerations

The UPS cabinet and parallel cabinet enclosures are designed for industrial or

computer room applications, and contain safety shields behind the doors.

However, the parallel redundant system is a sophisticated power system and

should be handled with appropriate care, following these guidelines:

· Keep surroundings clean and free from excess moisture.

· Do not operate the parallel redundant system close to gas or electric heat

sources.

· The system is not intended for outdoor use.

· The operating environment should be maintained within the parameters

stated in this manual and the Powerware 9315 Operation manual provided

with the UPS system.

· Keep the cabinet doors closed to ensure proper cooling airflow and to

protect personnel from dangerous voltages inside the unit.

· The parallel redundant system contains its own power source. Lethal

voltages are present even when the UPS is disconnected from utility

power.

WARNING:

Only AUTHORIZED SERVICE PERSONNEL should perform service or

maintenance on the parallel redundant system.

If service or routine maintenance is required:

· Ensure all power is disconnected before performing installation or service.

· Ensure the area around the parallel redundant system is clean and

uncluttered.

· Battery cabinet maintenance or battery replacement should be performed

only by authorized service personnel.

· Observe all DANGER, CAUTION, and WARNING notices affixed to the

inside and outside of the equipment.

· Refer to the more detailed safety precautions described in the Powerware

9315 Operation manual provided with the UPS system.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

31

Page 38

Symbols, Controls, and Indicators

These symbols may appear on the parallel redundant system or on labels inside

the UPS or parallel cabinet. They are accepted by most international safety agents.

Everyone who works with the parallel redundant system should understand the

meaning of these symbols:

ON

The principal power switch is in the “On” position.

OFF

The principal power switch is in the “Off” position.

PHASE

The word “phase.”

CAUTION: REFER TO MANUAL

Stop and refer to the Operator’s Manual for more information.

RISK OF ELECTRIC SHOCK

There is a risk of electric shock present, and you should observe

associated warnings. The equipment contains high voltages.

32

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 39

Understanding Parallel

Redundant Operation

With the parallel redundant system, the UPS system continues to function

automatically to supply AC electrical power to the critical load. There are three

operation modes in this system:

· In Normal mode, the UPS system functions normally as described in the

PowerwareR 9315 Operation manual provided with the UPS system. In the

parallel redundant system, power leaves the UPS module from its AC output

and is routed into the designated MOB in the parallel cabinet. As the system is

in Normal mode, the MOBs are closed and clean power is routed directly to the

AC output of the parallel cabinet and then to supply the critical load.

· In Battery mode, the battery cabinet supplies DC power, which maintains UPS

operation. The battery supports the critical load through the parallel cabinet’s

AC output.

· In Bypass mode, interunit signaling is used by each UPS to determine if its

designated MOB is closed and if the redundant module is on bypass or normal.

This information causes differences to the usual bypass operation of the UPS

system.

The following description provides the operating mode differences between the

parallel redundant and single UPS module systems.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

33

Page 40

Normal, Battery, and Bypass Modes with Parallel Operation

With the parallel redundant system, there are operating mode differences. These

differences primarily deal with the way transfers to and from bypass are handled.

When both UPS modules are in Normal mode, the parallel redundant system

functions normally to supply clean, filtered power to the critical load. The AC

output of the UPS modules feed the clean power to its designated MOB in the

parallel cabinet. In Normal mode, the MOBs are closed and power continues to

the AC output (critical bus) of the parallel cabinet, supporting the critical load.

Whenthereisapoweroutageorsomedisturbanceintheutility,theUPSmodules

automatically switch to Battery mode. In Battery mode, the battery supplies power

to the critical load as in normal UPS system operation. The only difference is that

the critical bus in the parallel cabinet is the AC output. See the PowerwareÒ 9315

Operation manual provided with the UPS system for details on Battery mode of

operation.

When both UPS modules are in Bypass mode, utility power directly supports the

critical load as is normal in UPS system operation.

When one UPS module becomes disabled and the redundant module is in Normal

mode, the disabled module shuts off rather than transfer to Bypass. The redundant

module continues to supply power to the critical load. Bypass is only activated if

the critical bus in the parallel cabinet fails to recover within a quarter cycle of the

initial disturbance.

If a manual transfer to Bypass mode is initiated while the redundant module is in

Normal mode, the module to be transferred to Bypass simply shuts off.

If both UPS modules are in bypass and their mode switches are in the Normal

mode position, activate the key switch on either UPS module and both modules

transfer to Normal.

If one UPS module is in Normal mode and the redundant module is in Bypass

mode, the following sequence will take place:

· The module in Bypass will automatically try to transfer to Normal mode

· If unable to transfer to Normal mode, the redundant module will try to

automatically clear itself from Bypass

· If the redundant module is unable to clear itself from Bypass, the module in

Normal mode will wait ten (10) seconds and then transfer to Bypass.

34

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 41

Operating Instructions for

the Parallel Redundant System

The following procedures are for the operation of UPS modules in parallel. After

installation of the parallel redundant system, the UPS modules run in parallel with

each other.

Module Output Breakers (MOBs)

The parallel cabinet contains two MOBs labeled MOB 1 and MOB 2. The UPS

modules should be labeled in accordance with which MOB it is connected (e.g.,

MOB 1 should be wired to UPS 1).

When both MOB 1 and MOB 2 are closed, each UPS module operates as part of a

parallel system. When one MOB is open, the redundant UPS module continues to

support the critical load. The redundant UPS module acts as a single stand-alone

system.

How to Open and Close the MOB

CAUTION:

Improper operation of these circuit breakers can cause the loss of the critical

bus (output) or damage equipment.

Close the MOB only when its designated OK TO CLOSE lamp is illuminated.

A UPS module’s designated MOB, MOB 1 or MOB 2, may be opened if the MOB

for the redundant module is closed and its OK TO CLOSE lamp is illuminated.

Refer to How to Isolate a Module in this chapter for information on when a module’s

designated MOB can be opened.

Starting and Stopping Using Parallel Redundant System

Start each module as described for normal UPS system startup in the PowerwareÒ

9315 Operation manual provided with the UPS system. If the MOBs have been

opened, they should only be closed when the OK TO CLOSE lamp is illuminated.

The following descriptions give details on starting in modes, turning the module off,

and using the LOAD OFF pushbutton.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

35

Page 42

How to Isolate a Module

The primary function of the MOBs is to allow isolation of a module for maintenance

or service. In parallel operation, each module becomes the other’s maintenance

bypass source.

Do not attempt to isolate a module until it is assured that the redundant module

can support the critical load. The best assurance is if the redundant UPS module’s

designated MOB is closed and the OK TO CLOSE lamp is illuminated.

As an alternative:

1. Make sure the designated MOB for both modules is closed.

2. PlacetheUPSmoduletobeisolatedinBypassmode.

3. Place the redundant module in Bypass mode.

4. Open the designated MOB of the UPS module to be isolated.

When a module’s designated MOB is open, it will work like a standard Reverse

Transfer module as described in the PowerwareÒ 9315 Operation manual provided

with the UPS system. The MOB should only be closed when its OK TO CLOSE

lamp is illuminated.

Shut Down a Module

To turn a module off, place its mode switch to the Bypass position and open its

circuit breaker (CB1).

Transfer System to Bypass

To place the system in Bypass mode:

1. TurnthemodeswitchonbothUPSmodulestotheBypassposition. Thefirst

module will shut off its inverter and the redundant module will transfer to

Bypass.

To place both UPS modules on Bypass:

1. TurnthemodeswitchonbothUPSmodulestotheBypassposition.

2. After the first module shuts off and the redundant module is in Bypass, activate

the start switch on the first module with the mode switch still in the Bypass

position.

To transfer both UPS modules from Bypass mode to Normal mode:

1. Turn the mode switch on both modules to the Normal position.

36

2. Activate the start switch on either UPS module.

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 43

LOAD OFF

The LOAD OFF pushbutton (referred to as the emergency power off) only

interrupts the ability of a single module to deliver power to the critical bus. The

redundant module will continue to support the critical load. Refer to the Powerware

9315 Operation manual for details on the LOAD OFF pushbutton.

NOTE: The LOAD OFF pushbutton will only interrupt the ability for that module to

deliver power to the critical bus. The LOAD OFF pushbutton must be

pressed on both UPS modules in order to cut off power from the critical

load. For a single emergency power off switch, a switch should be

connected to both modules. Each module should be wired from an isolated

contactofthatswitch.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

37

Page 44

This Page Intentionally Left Blank.

38

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 45

Appendix A

The information in Appendix A will help plan for and install the parallel redundant

system. The appendix contains the following figures and tables:

· Figure 11 UPS Outputs and Communications

· Figure 12 Mechanical Details

· Figure 13 Electrical Access Details

· Table A---1 Control Wiring Requirements and Termination Requirements

· Table A---2 UPS Power Cable Terminations and Connection Points

· Table A---3 Tie Cabinet Power Inputs and Termination Requirements

· Table A---4 Power Output Termination Requirements

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

A---1

Page 46

LEFT SIDE PANEL

OUTPUT

NEUTRAL

CONNECTION

(E12)

AC OUTPUT

(E9, E10, E11)

TB3

TERMINAL STRIP

LEFT DOOR

TB1

TB3

COMMUNICATION

TB2

RIGHT SIDE PANEL

SIDE PANEL

MOUNTING SCREWS

LEVELING FEET

PANEL

A --- 2

NOTE: 100---160 KVA UPS Shown with Right Door Open or Removed

Figure 11. UPS Outputs and Communications

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 47

1870.0

(73.6)

853.8

(33.6)

800.0

(31.5)

FRONT VIEW

Dimensions are in millimeters (inches)

Cabinet Weight: 260 kg (570 lb)

Cooling Requirements: Convection

Heat Rejection: Nil

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

PARALLEL TIE CABINET

SIDE VIEW

Figure 12. Mechanical Details

A---3

Page 48

E9

E10

E11

E9

853.8

(33.6)

E10

E11

MOB#1

TB1

MOB#2

TB1

339.85

(13.38)

853.8

(33.6)

Cooling Grate

Top

Wire

Entry

1 15.32

(4.54)

800.0

(31.5)

1870.0

(73.6)

MOB1

MOB2

ÆA ÆCÆBÆA ÆC

E16 E17 E18

Ground

ÆB

E12

Parallel Cabinet

Terminal Locations

Wire Way

Isolated

Ground

(Optional)

122.70

(4.83)

560.63

(22.07)

Parallel Cabinet Cable Entry,

Top Vie w

88.90 (3.50)

Swivel Radius

100.08

(3.94)

606.30

(23.88)

545.42

(21.5)

518.92

(20.43)

Bottom Wire Entry

142.40

(5.61)

50.04

(1.97)

111.76

(4.40)

A --- 4

TB3

TB1

TB2

130.05

(5.12)

914.40 (36.00)

Minimum Clearance

For Subassembly

Removal

Dimensions are in millimeters (inches)

Location of T B3

in UPS Modules

Overall width dimensions include side panels.

Subtract 25 mm (1 in) for each side panel for

line up and match.

Figure 13. Electrical Access Details

Powerware 9315 Parallel Redundant System I & O

369.82

(14.56)

Parallel Cabinet Cable

Entry, Floor Plan View

164202013, Rev. D 041599

Page 49

Table A--1. Control Wiring Requirements and Termination Requirements

Refertot

h

l

icab

leP

931

5

UPSinstallationmanualforthisinformation

Connection

Points in Tie

Cabinet

TB1--1

through

TB1--7

Size of

Pressure

Termination

(lb-in)

#18--#8,

(55)

Maximum

Voltage and

Current

24V, 0.25A TB3--1 through

Connection

Points in UPS

TB3--7

Size of

Pressure

Termination

(lb-in)

#22--#12,

(5--7)

Recommended

Wiring Size

#18--#12

N o t e s f o r Ta bl e A --- 1 :

1. Install the control wiring in separate conduit from the power wiring. Only copper

wire or tinned copper wire should be used.

2. Control wiring is NEC class 2 (IEC 950 SELV).

3. Class 1 methods are recommended for control wiring.

4. Control wiring should be twisted pairs and twisted triple as shown in Figure 9.

Table A--2. UPS Power Cable Terminations and Connection Points

Connection

Point in UPS

Function

Size of

Pressure

Termination

Tightening

Torque

N--M (lb--in)

Int Hex

Size (In.)

Connection Point

in Tie Cabinet

E9 Phase A E9

E10 Phase B

E11 Phase C

Neutral/

E12

Gnd

e app

UPS installation manual for this information

owerware

E10

E11

E12

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

A---5

Page 50

Table A--3. Tie Cabinet Power Inputs and Termination Requirements

UPS

Model

UPS

Output

NP

Voltage

Minimum

Conductor

Size

Breakers

MOB 1

and 2

(Amps)

Terminal

Point in

Tie

Cabinet

40 400 4AWG 80 E9, E10,

E11

50 600 6AWG 60 E9, E10,

E11

50 480 4AWG 80 E9, E10,

E11

50 208 2/0 AWG 175 E9, E10,

E11

65 400 1AWG 125 E9, E10,

E11

80 600 3AWG 100 E9, E10,

E11

80 480 1AWG 125 E9, E10,

E11

80 400 1/0 AWG 150 E9, E10,

E11

80 208 350 kcmil 300 E9, E10,

E11

125 400 4/0 AWG 225 E9, E10,

E11

130 400 250 kcmil 250 E9, E10,

E11

continued

Function

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Size of

Pressure

Termination

(CU wire)

Tightening

Torque

(lb-in)

#14-3/0 #14--#10, (35)

#8--#3, (100)

#2--#3/0, (150)

#14-3/0 #14--#10, (35)

#8--#3, (100)

#2--#3/0, (150)

#14-3/0 #14--#10, (35)

#8--#3, (100)

#2--#3/0, (150)

#8-350 kcmil #8--#4, (150)

#3--#1, (200)

#1/0-350

kcmil, (250)

#8-350 kcmil #8--#4, (150)

#3--#1, (200)

#1/0-350

kcmil, (250)

#8-350 kcmil #8--#4, (150)

#3--#1, (200)

#1/0-350

kcmil, (250)

#8-350 kcmil #8--#4, (150)

#3--#1, (200)

#1/0-350

kcmil, (250)

#8-350 kcmil #8--#4, (150)

#3--#1, (200)

#1/0-350

kcmil, (250)

(2) #2/0-400

kcmil or

(1) #6-600

#2--600 kcmil,

(375)

#8-#3, (275)

kcmil

#8-350 kcmil #8--#4, (150)

#3--#1, (200)

#1/0-350

kcmil, (250)

#8-350 kcmil #8--#4, (150)

#3--#1, (200)

#1/0-350

kcmil, (250)

Internal

Hex Size

(In.)

7/32

7/32

7/32

5/16

5/16

5/16

5/16

5/16

3/8

5/16

5/16

A --- 6

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 51

Table A--3. Tie Cabinet Power Inputs and Termination Requirements (cont.)

Size of

Pressure

Termination

(CU wire)

Tightening

Torque

(lb-in)

UPS

Model

UPS

Output

NP

Voltage

Minimum

Conductor

Size

Breakers

MOB 1

and 2

(Amps)

Terminal

Point in

Tie

Cabinet

Function

Internal

Hex Size

(In.)

150 600 3/0 AWG 200 E9, E10,

E11

150 480 4/0 AWG 225 E9, E10,

E11

150 400 350 kcmil 300 E9, E10,

E11

150 208 (2) 350

kcmil

600 E9, E10,

E11

160 600 3/0 AWG 200 E9, E10,

E11

160 480 250 kcmil 250 E9, E10,

E11

160 400 350 kcmil 300 E9, E10,

E11

160 208 (2) 350

kcmil

225 208 (2) 300

kcmil

600 E9, E10,

E11

800 E9, E10,

E11

225 480 (2) #4/0 350 E9, E10,

E11

300 480 (2) 250

kcmil

450 E9, E10,

E11

continued

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

#8-350 kcmil #8-#4, (150)

#3-#1, (200)

#1/0-350

kcmil, (250)

#8-350 kcmil #8-#4, (150)

#3-#1, (200)

#1/0-350

kcmil, (250)

(2) #2/0-400

kcmil or

(1) #6-600

#2-600 kcmil,

(375)

#8-#3, (275)

kcmil

(2) #2/0-400

kcmil or

(1) #6-600

#2-600 kcmil,

(375)

#8-#3, (275)

kcmil

#8-350 kcmil #8-#4, (150)

#3-#1, (200)

#1/0-350

kcmil, (250)

#8-350 kcmil #8-#4, (150)

#3-#1, (200)

#1/0-350

kcmil, (250)

(2) #2/0-400

kcmil or

(1) #6-600

#2-600 kcmil,

(375)

#8-#3, (275)

kcmil

(2) #2/0-400

kcmil or

(1) #6-600

#2-600 kcmil,

(375)

#8-#3, (275)

kcmil

(3) #3/0-500

kcmil

(2) #2/0-400

kcmil or

(1) #6-600

#3/0-500 kcmil

(375)

#2-600 kcmil,

(375)

#8-#3, (275)

kcmil

(2) #2/0-400

kcmil or

(1) #6-600

#2-600 kcmil,

(375)

#8-#3, (275)

kcmil

5/16

5/16

3/8

3/8

5/16

5/16

3/8

3/8

3/8

3/8

3/8

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

A---7

Page 52

Table A--3. Tie Cabinet Power Inputs and Termination Requirements (cont.)

Size of

Pressure

Termination

(CU wire)

Tightening

Torque

(lb-in)

UPS

Model

UPS

Output

NP

Voltage

Minimum

Conductor

Size

Breakers

MOB 1

and 2

(Amps)

Terminal

Point in

Tie

Cabinet

Function

Internal

Hex Size

(In.)

300 600 (2) 4/0

AWG

400 480 (3) 300

kcmil

500 480 (3) 300

kcmil

All

Models

All

Models

All

Models

(Optional)

— — — E12 Neutral (12) #6--350

— 1/0 AWG — Ground Ground (2) #6--350

— (2) 1/0

AWG

400 E9, E10,

E11

800 E9, E10,

E11

800 E9, E10,

E11

— Isolated

Ground

(Optional)

Phase A,

B, C

Phase A,

B, C

Phase A,

B, C

Isolated

Ground

Table A--4. Power Output Termination Requirements

UPS Model

40 through 300,

except Model

225 at 208 volt

output

Model 225 at

208 volt output

and Models 400

and 500

Minimum

Conductor

Size

Same as

input

Same as

input

Terminal

Point in Tie

Cabinet

E16, E17,

E18

E16, E17,

E18

Size of Pressure

Termination

Function

PhaseA,B,C (2) #6--350 kcmil (275) 3/8

PhaseA,B,C (4) #6--350 kcmil (275) 3/8

(2) #2/0-400

kcmil or

(1) #6-600

kcmil

(3) #3/0-500

kcmil

(3) #3/0-500

kcmil

kcmil

kcmil

(10) #14--1/0

AWG

(CU wire)

#2-600 kcmil,

(375)

#8-#3, (275)

#3/0-500 kcmil

(375)

#3/0-500 kcmil

(375)

(275) 3/8

(275) 3/8

(275) Slotted

Tightening

Torque (lb-in)

10%

3/8

3/8

3/8

Internal

Hex Size

(In.)

A --- 8

N o t e s f o r Ta bl e s A --- 2 , A --- 3 , a nd A --- 4 :

1. Refer to national and local electrical codes for acceptable external wiring practices.

2. Material and labor for external wiring requirements are to be provided by

designated personnel.

3. Power wiring size recommendation is copper wire rated at 75_CforPowerware

9315 models 40 through 300 and 90_C the Powerware 9315 400 and 500. If the

wire is run in ambient temperature higher than 30_C, larger size and/or higher

temperature wire is necessary .

4. The output for the UPS is a separately derived source. Output neutral is bonded to

equipment ground through the main bonding jumper. Refer to NEC Article 250 and

local codes for proper grounding practices.

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Page 53

5. External overcurrent protection is not provided by this product, but is required by

c o d e s . R e f e r t o Ta bl e s A --- 3 a n d A --- 4 f o r p o w e r w i r i n g r e c o mm e n d a t i o n s a n d

requirements for the parallel cabinet. Refer to the PowerwareÒ 9315 Installation

manual provided with the UPS system for UPS module power wiring requirements.

If an output lockable disconnect is required, it is to be supplied by designated

personnel.

6. Nonlinear loads can create neutral currents that are greater than 100%. This

product can accommodate double-size neutral terminations if needed. The neutral

bus (E12) in the parallel cabinet has pressure termination size six (6) times that as

listed for the output (E16---E18).

7. TerminalsE9throughE12andE16throughE18areULandCSAratedat90_C.

A hex key tool is required to attach wires to terminals. Refer to Table A ---3 for

power cable terminations. Figure 13 shows the location of the power cable

terminations inside the UPS and parallel tie cabinets.

8. The ground pressure termination size for all models is: (4) #6--- 350 kcmil. Tighten

with 3/8 in. internal hex tool to 375 lb-in.

Powerware 9315 Parallel Redundant System I & O

164202013 Rev. D 041599

A---9

Page 54

This Page Intentionally Left Blank.

A --- 1 0

Powerware 9315 Parallel Redundant System I & O

164202013, Rev. D 041599

Loading...

Loading...