Page 1

This .pdf document is bookmarked

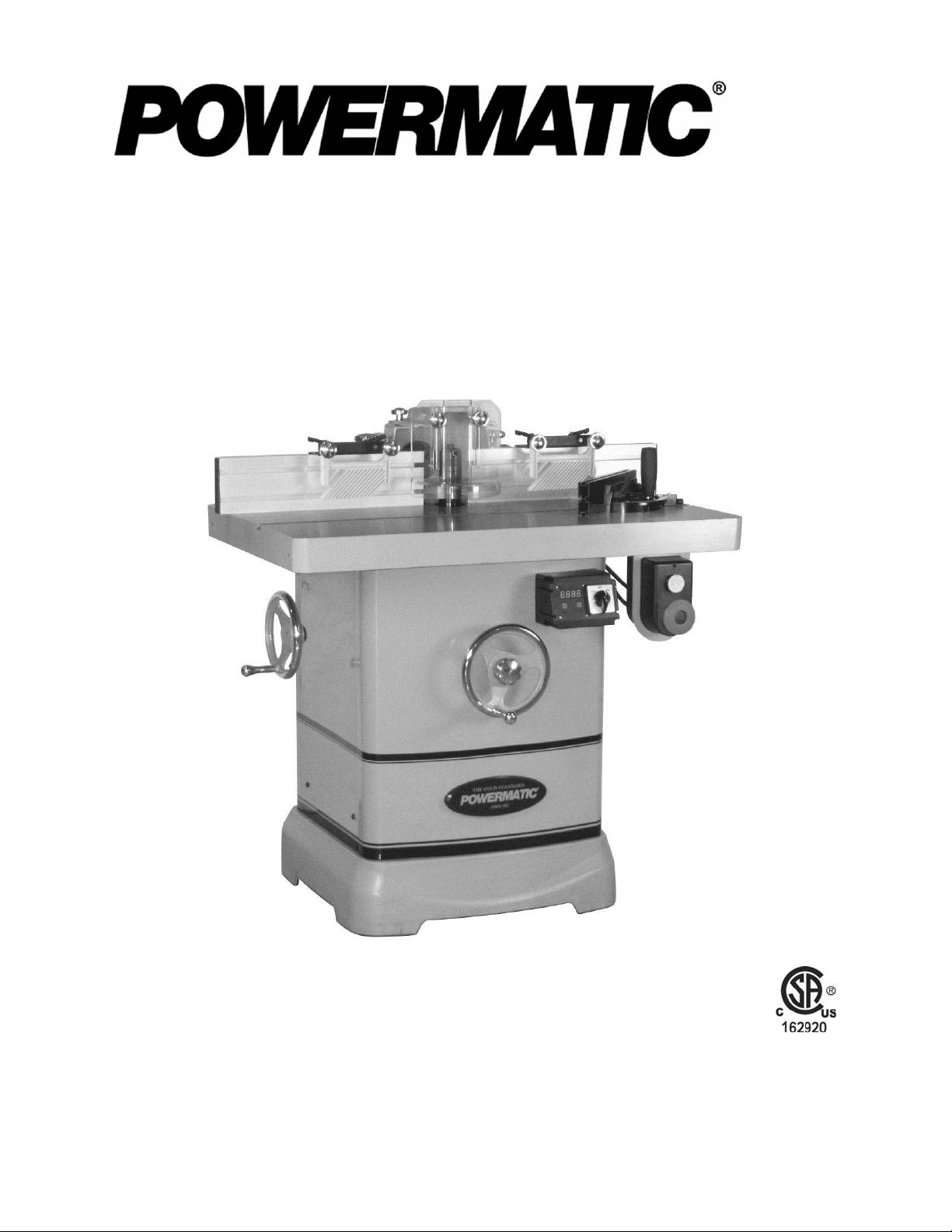

Operating Instructions and Parts Manual

Model PM2700 Shaper

Model: 270 0

Powermatic

427 New Sanford Road

LaVergne, TN 37086 Part No. M-1280100C

Ph.: 800-274-6848 Revision G1 02/2014

www.powermatic.com Copyright © 2014 Powerm atic

Page 2

Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informa tion

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Warning ................................................................................................................................................... 6

Introduction ............................................................................................................................................. 7

Specifica tions ................................................................................................................ .......................... 7

Unpac king ............................................................................................................................................... 8

Shipping Contents ................................................................................................................................ 8

Installing .................................................................................................................................................. 8

Assembly ................................................................................................................................................ 9

Mounting the Fenc e ............................................................................................................................. 9

Electri c al Connec tions ............................................................................................................................. 9

General Information ............................................................................................................................. 9

Extension Cords................................................................................................................................. 10

Adjustments ................................................................................................................... ....................... 1 1

Fence Assembly Movement ............................................................................................................... 11

Coplanar Alignment............................................................................................................................ 12

Ram Dial Calibration .......................................................................................................................... 13

Spindle G ib Adjust men t ...................................................................................................................... 14

Featherboard Hold-downs .................................................................................................................. 14

Spindle Asse mbly In stallatio n ............................................................................................................. 15

Spindle Asse mbly Remova l ................................................................................................................ 15

Shaper Cutter Installation ................................................................................................................... 16

Router Collet (O ptional) Installati on .................................................................................................... 16

Changing Cutter S peed ...................................................................................................................... 17

Drive Belt Tension .............................................................................................................................. 17

Precision Miter Gauge ........................................................................................................................ 18

Handwheel Adjustments ..................................................................................................................... 11

Belt Replacement ............................................................................................................................... 17

Operating Controls ................................................................................................................................ 19

Start/Stop ........................................................................................................................................... 19

Safety Ke y .................................................................................................................... ..................... 1 9

Digital Readout .................................................................................................................................. 19

Operations............................................................................................................................................. 2 0

Special Cuts .......................................................................................................................................... 29

Troubleshooting for PM2700 Shaper...................................................................................................... 32

Optional Accessories ............................................................................................................................. 3 3

Parts ..................................................................................................................................................... 34

Ordering Replacement Parts .............................................................................................................. 34

Table – Parts List ............................................................................................................................... 34

Table – Assembly Drawing ................................................................................................................. 35

Fence – Parts List .............................................................................................................................. 36

Fence – Assembly Drawing ................................................................................................................ 37

Frame and Motor – Parts List ............................................................................................................. 38

Elevator – Parts List ........................................................................................................................... 40

Elevator – Assembly Drawing ............................................................................................................. 41

Caster Assembly – Parts List ............................................................................................................. 42

Caster Assembly Drawing .................................................................................................................. 43

Spindle Assembly – Parts List ............................................................................................................ 44

Spindle Assembly Drawing- ................................................................................................................ 45

Cabinet and Base – Part s Li st ............................................................................................................ 46

Cabinet and Base .............................................................................................................................. 48

Wiring Diagrams .................................................................................................................................... 49

3HP/5HP, 230V, 1Phase .................................................................................................................... 49

5HP, 230V, 3Phase............................................................................................................................ 50

5HP, 460V, 3Phase............................................................................................................................ 51

3

Page 4

Warnings

1. Read and understand the ent ire owner's manual bef or e att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This shaper is designed and int ended for use by proper ly t rained and experi enced personnel onl y. If

you are not f amiliar wit h the proper and safe operati on of a shaper, do not use unt il proper training

and knowledge have been obtained.

5. Do not use this shaper for other than its intended use. If used for other purposes, Powermatic

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Always wear appr oved safety glasses/face shi elds while u si ng this shaper. Everyday ey eglasses only

have impact resistant lenses; they are not safety glasses.

7. Before operati ng this shaper, rem ove tie, rings, watches and other j ewelry, and r oll sleeves up past

the elbows. Remove all loose clothing and c onfine long hair. Non-sli p footwear or anti-skid fl oor st r ips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during ext ended peri ods of oper ation.

9. Some dust created by power sanding, shaping, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machi ne while tired or under the influence of drugs, alcohol or any medication.

11. M ak e c er tain the machine is properl y grounded.

12. M ak e all machine adjustments or maintenance with the m ac hine unplugged from the power source. A

machine under repair should be RED TAGGED to show it must not be used until maintenance is

complete.

13. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

14. Keep safety guards in place at all times when the machi ne is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

15. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

16. P r ov ide for adequate space surroundi ng work ar ea and non-glare, ov er head lighting.

17. K eep the floor around the machi ne cl ean and free of scrap material, oil and grease.

18. K eep v isitors a safe distance fr om the work area. K eep chi ldren away.

4

Page 5

19. M ak e y our workshop child proof wit h padloc k s, m aster swit c hes or by r em ov ing safety keys.

20. K eep v isitors a safe distance fr om the work area. K eep chi ldren away.

21. M ak e y our workshop child proof wit h padloc k s, m aster swit c hes or by r em ov ing safety keys.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. Maintain a balanced stance at all times so that you do not fall or lean against the blade or other

moving part s. Do not over r eac h or use excessive force to perform any mac hine oper ation.

24. Use the ri ght t ool at the cor rect speed and feed r ate. Do not for ce a tool or attachment to do a job for

which it was not designed. T he ri ght tool will do the job better and safer.

25. Use recom mended accessories; improper accessories may be hazardous.

26. Maintai n tools with care. Keep cutter sharp and clean f or the best and safest perform ance. Follow

instructions for lubricating and changing accessories.

27. Check t he cutter f or crack s or missing teet h. Do not use a cracked c utter or one wi th missing teeth or

improper set. Make sure the c utt er i s securel y locked on the arbor.

28. Keep hands clear of the cutter area. Do not reach past the cutter to clear parts or scrap with the

shaper running. Avoi d awkward operations an d hand posi ti ons where a sudden sli p coul d cause your

hand to contact the c utt er .

29. Do not attem pt to shape boards with loose knots or with nails or other foreign mat eri al, on its surfac e.

Do not attempt to shape twisted, warped, bo wed or “i n wind” stoc k unl ess one edge ha s been joi nt ed

for guiding purpose s prior to shaping.

30. Do not at tempt to shape long or wide board s unsupported where spring or weight coul d cause the

board to shift posit ion.

31. A lways use safety devices for al l oper ations where they can be used.

32. B e sure t o c hec k the direction of spindl e rotation before use.

33. Turn off the mac hine before cl eaning. Use a brush or compressed air to rem ov e c hips or debris — do

not use your hands.

34. Do not stand on the machine. Seri ous i njury could occur if the machine tips over.

35. Never leave the mac hine r unning unattended. Turn the power off and do not leav e the machine until it

comes to a complete stop.

36. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiariz e you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precauti ons are not heeded, it may result in serious injury or possibly

even death.

5

Page 6

Warning

Short stock – Never shape stock less than 12

inches in length without special fixtures. Where

practic al, shape longer stoc k and c ut to size.

12 inch rule – When shaping, never allow your

hands to come closer than 12 inches to the

cutters.

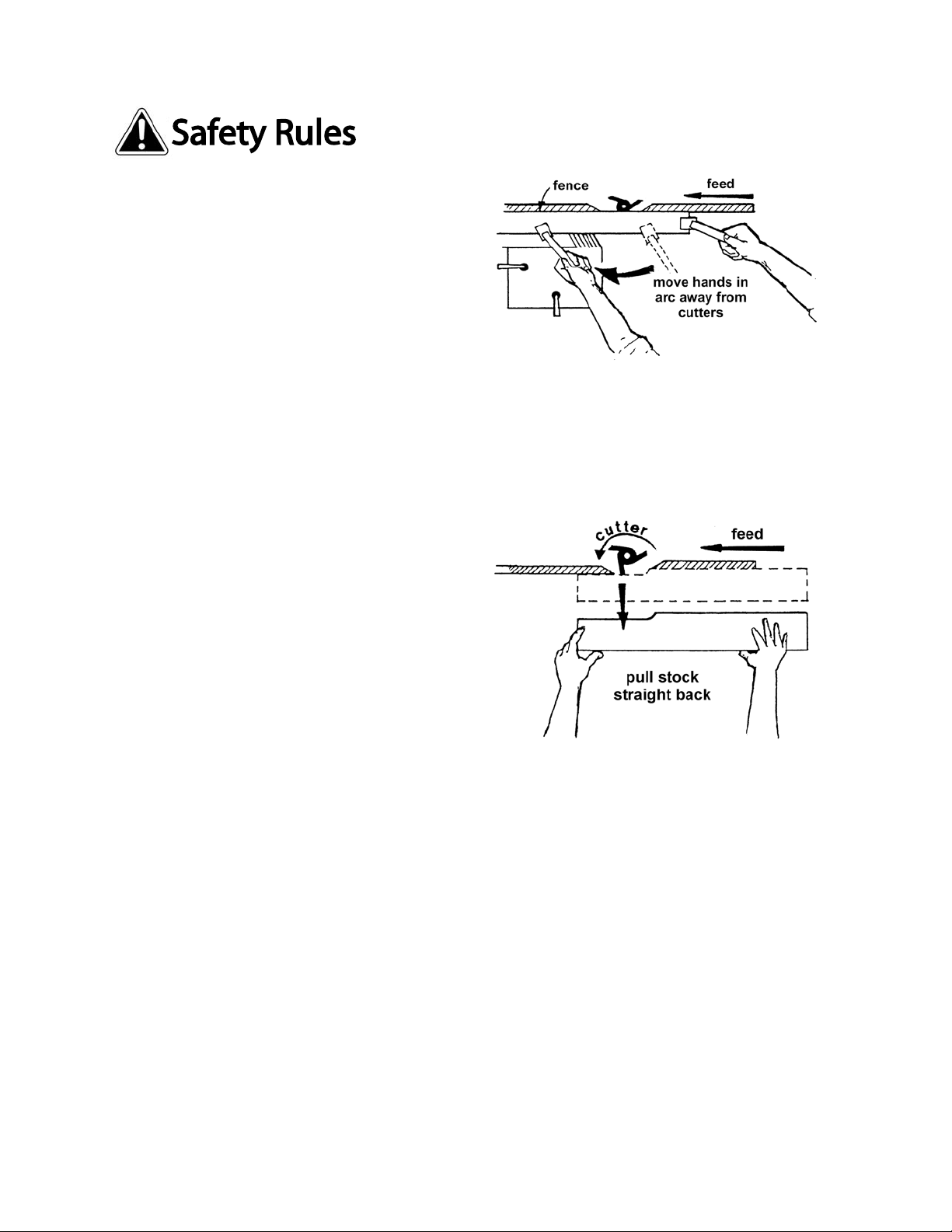

Hand safety – Never pass the hands directly

over, or in front of, the c utters (Figure A). As one

hand approaches the 12 i nch radius point , remove

it (or the push stick) in an arc motion and

reposition hands 12 i nc hes beyond t he c utters.

Blind cut – W hen blind cutting, t he workpiece is

positioned on t op of the template. This keeps the

cutter(s) cutting only the underside of the

workpiece and prov ides a "distanc e" guard f or the

operator.

Cutter Clearance – W ith the power disconnect ed,

always rotate the spindle by hand with any new

set-up to ensure pr oper c learance wit h the cutters.

At the same tim e, check to be sure the c utt erhead

is turning in the cor r ect dir ec tion.

Stock feed – Feed stock opposi te to the di recti on

of the cut ter rot ation (Figur e B). Nev er back stock

out of the cutter once the cut has been started.

Instead, pull the stock straight out away from

cutter and begin the cut again.

Guide pin – Whenever possibl e, use a guide pin

when performing pattern shaping and collar

shaping operations.

Tool maintenance – Cl ean and sharp tools giv e

safer and better performance. Dull tools can

cause kickbacks and excessive chatter. Before

making a cut, always check the condition and

adjustment of the tools. Never use a tool that is

not balanced and rated for the selected RPM.

Spindle speed – Do not o perate tools at speeds

higher than rated by the manufacturer.

Cutter selection – Use only those cutters

designed to be used on the m achine, and mount

only safety type c utt er s on the spi ndle.

Stock condition – The danger of kicked-back

stock can occur when the stock ha s knots, hole s,

or foreign objec ts such as nails. Warped or in-wind

stock should f ir st be joi nt ed on one surf ac e bef ore

attempting to use it on the shaper.

Figure A

Figure B

6

Page 7

Introduction

This manual is provided by Powermati c covering the safe operat ion and maintenance pr ocedures for a

Powermati c Model PM 2700 Shaper. This m anual contains i nstruct i ons on instal lati on, saf ety pr ecautions,

general operating procedures, maintenance instructions and parts breakd own. This machine has been

designed and constructed to provide years of trouble free operation if used in accordance with

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local supplier or Powermatic. Powermati c can also be reached at our web site: www.powermati c .com.

Specifications

Model Number .............................................................................................................................. PM2700

Motor (TEFC Capaci tor Start Induction) Stock Number

3HP, 1 Phase, 230V, 60Hz, 14A .............................................................................................. 1280100C

5HP, 1 Phase, 230V, 60Hz, 22A .............................................................................................. 1280101C

5HP, 3 Phase, 230V/460V-prewir ed 230V (for 460V see Note below), 60Hz, 13/6.5A .............. 1280102C

Table Size (L x W) ....................................................................................................................... 40" x 30"

Table He ight from F loo r .................................................................................................................. 35-1 /2”

Spindle Size (Standard) .................................................................................. 3/4", 1-1/4" Interchangeable

Router Bit Coll et Si z e (Optional) .................................................................................................. 1/4", 1/2"

Spindle Capacity Under Nut:

3/4” Spindle (provided).............................................................................................................. 3-27/64"

1-1/4” Spindle (provi ded) ............................................................................................................ 5-5/32”

1” Spindle (optional accessory) ................................................................................................. 4-59/64”

Spindle Travel ........................................................................................................................................ 4"

Spindle Speeds (RPM) .......................................................................................... 7500, 10000, reversible

Table Opening Diameter .................................................................................................................... 7.33"

Insert Openi ng Diam eters .............................................................................................. 2.55", 4.16", 5.75"

Fence Size (x 2) .................................................................................................... 4-7/8" (H) x 18-3/4" (W)

Dust Collecti on Minimum CFM Required .............................................................................................. 600

Dust Port Diameter ................................................................................................................................. 4”

Overall Dimensions .......................................................................................... 40" (L) x 37" (W) x 45" (H)

Weight ..................................................................................................... 690 lbs (Shipping), 664 lbs (Net)

Note: For 460V operat ion, magnetic switch (Part No. PM2700-114C) m us t be purchased separately and

installed. A qualified elec trician is recommended.

The above specifications were current at the tim e this manual was published, but because of our policy of

continuous im provement, Powerm atic reserves the right t o change specific ations at any time and without

prior notic e, wit hout incurring obligati ons.

Read and understand the entire contents of this manual before attempting

assembly or operat io n! Failure to comply may cause serious inju ry.

7

Page 8

Unpacking

Remove box and wood crating completely from

around shaper. Chec k for shippi ng damage. Report

any damage immediately to your distributor and

shipping agent. Do not discard any shipping

material until the Shaper is assembled and r unning

properly.

Compare the contents of your container with the

parts lists on thi s page to make sure all parts are

intact. Mi ssing parts, if any, should be reported to

your distributor. Read the instruction manual

thoroughly for assembly, maintenance and safety

instructions.

Shipping Contents

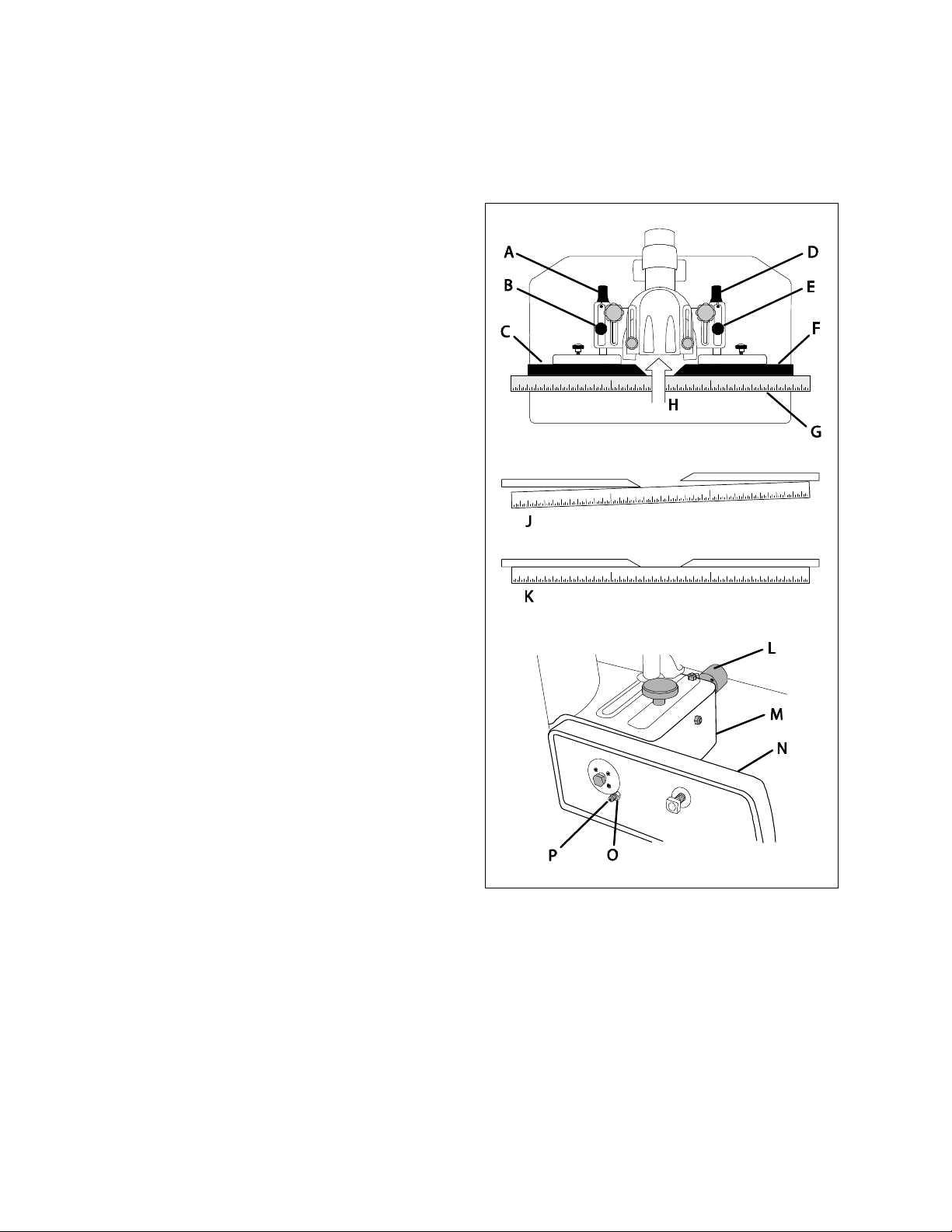

Referring to F igur e 1:

Main Shaper Container

1 Fence Assembly (A)

1 Cabinet and Base (B)

Hardware and included tools consist of the

following items:

2 Lock Handle (C)

2 M13 Flat Washer (D)

1 Miter Gauge Assembly ( E)

1 Draw Bar (F)

1 1-1/4" Spi ndle (G)

1 3/4" Spindle ( H)

2 Spindle Nut (I)

3 Insert Rings – 2.55”, 4.16”, 5.75” (J)

4 M10 Socket Head Cap Screw (K)

4 M10 Lock Washer (L)

1 Starting Pin ( M)

1 8 mm Hex Wrench (N)

1 Crosspoint/Flathead Screwdriver (O)

1 Wrench (P)

Main Shaper Container

Installing

1. Unbolt the shaper f r om the skid.

2. Carefully slide the shaper f rom the pallet onto

the floor.

Make sure that the casters do

not get damaged when removing from the skid.

The Shaper should be placed in an area with a

sturdy level floor, good ventilation and sufficient

lighting. Leav e enough space around the m achine

for mounti ng extension wings and r ail assemblies,

and loading and off-loading stock and general

maintenance work.

Hardware

Figure 1

8

Page 9

Cleaning

Exposed met al surfaces, such as the t able top and

extension wings, have been given a protective

coating at t he f actory. This should be rem ov ed wit h

a soft cloth moistened with kerosene. Do not use

acetone, gasoline, or lacquer thinner for this

purpose. Do not u se solvents on pl astic parts, and

do not use an abrasive pad because it may scratc h

the surfaces.

Assembly

Mounting the Fence

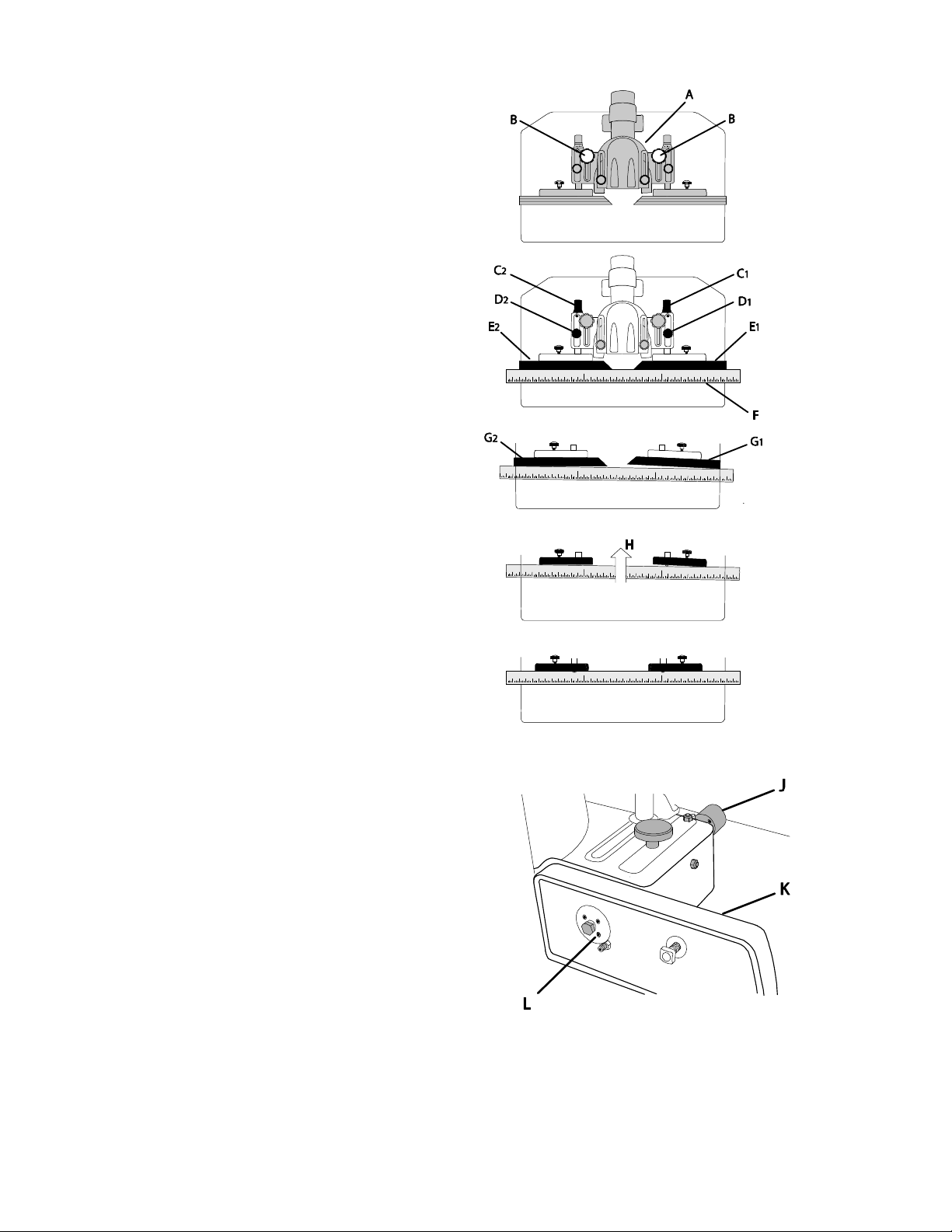

Referring to Fi gur e 2:

1. Place the fence assembly (A) on the table (B),

lining up the four mounting holes (C) on the

bracket with the t hreaded holes (D) on the rear

of the table above the dust port (E).

2. Hand fasten with four each M10 hex socket

cap screws (F) and M10 lock washers (G). Do

not tighten at this time.

3. Place two M13 flat washers (H) on two lock

handles (J). Insert the lock handles through

slots (K) on each side of the base. Partially

thread the lock handles (J) into two mounting

holes (L) on the table. Do not tighten at this

time.

4. Turn the adj ust knob on the br acket to po siti on

the fence all the way to the rear .

5. Tighten the lock handles (J) sufficiently to

prevent the fence from movement.

Electrical Connections

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. This machine must be

properly grounded to help prevent electrical

shock and possible fat al injury.

General Information

A power plug is not provided with the Model

PM2700. You may either connect the proper

UL/CSA listed plug or “hardwire” the machine

directly to your electrical panel provided there i s a

disconnect near the machine for the operator.

Consult electrical drawings at the back of this

manual for further clarification of wiri ng setup.

Figure 2

9

Page 10

This machine must be grounded. Grounding

provides a path of least resistance to help divert

current away f rom the operator in case of electrical

malfunction.

Make sure the voltage of your power supply

matches the specif ications on the motor plate of t he

machine.

The PM2700 Shaper should be connected to a

dedicated ci rcuit, and prot ected by a circ uit break er

or time delay fuse, with minimum amp ratings as

shown in Table 1. Local codes take precedence

over recommend ation s.

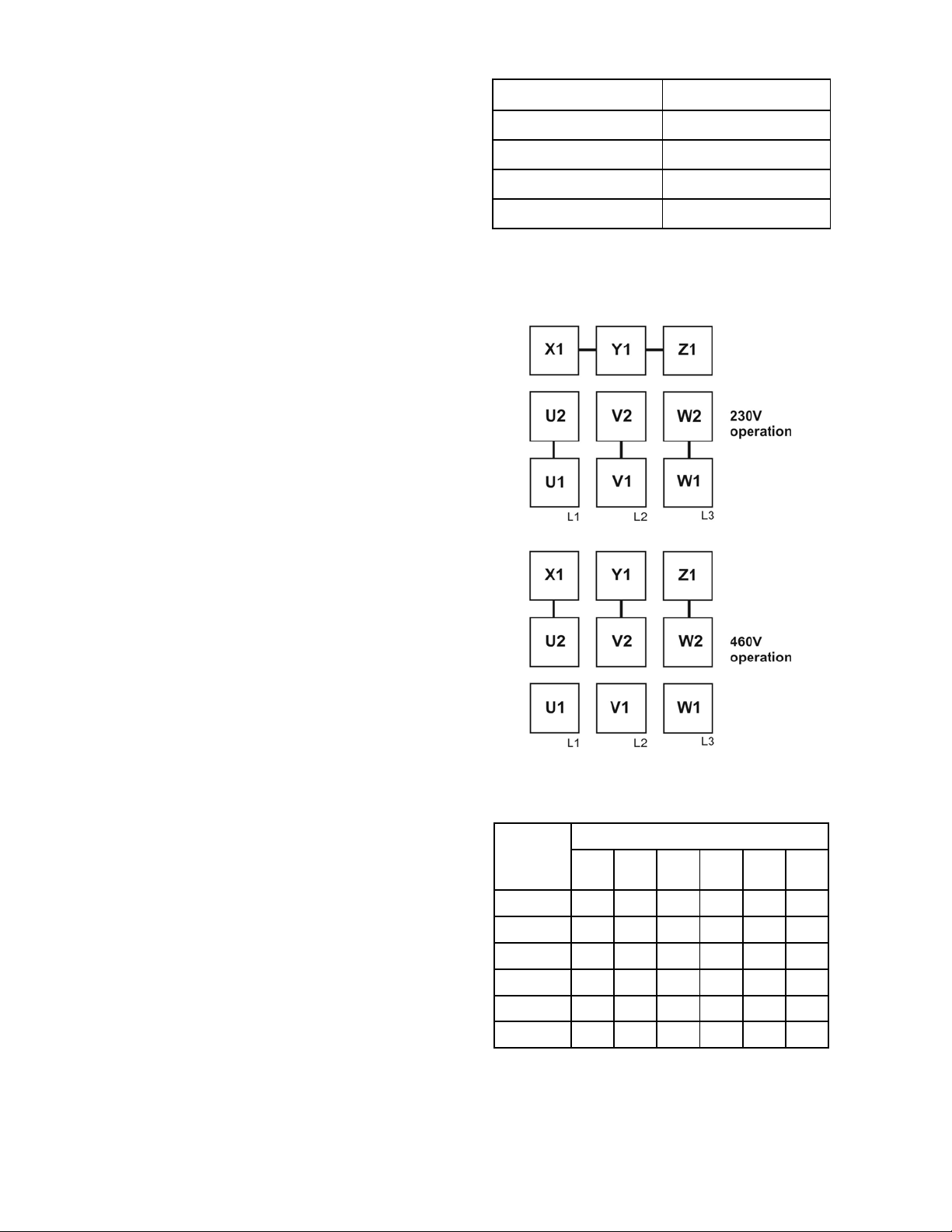

Voltage Conversion (3 Phase Shaper only)

On the 3 phase model, to convert from 230V to

460V, replace the 230V switch with the 460V

switch (not inc luded, order par t no. PM 2700-114C),

and re-wire the incoming leads to the motor as

shown on the diagram inside t he c over of the m otor

junction box. A similar diagram is also i ncluded in

the back of this manual. (Figure 3 shows a

summary of the lead changes for 230V to 460V

conversion.) Note: In case of discrepancies, the

diagram in the motor junction box should take

precedence.

Model Recommended circuit*

1280100C (3 HP 1 PH 23 0V) 30 Amp

1280101C (5HP 1PH 230V) 40 Amp

1280102C (5 HP 3 PH 23 0V) 30 Amp

1280102C (5 HP 3 PH 46 0V) 15 Amp

*subject to local codes

Table 1

Extens ion Cords

The use of ext ension cords is discouraged. Try to

position equipment within reach of the power

source. If an extension cord becomes necessary,

make sure the cord rating is suitable for the

amperage list ed on the machine's m otor plate. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.

The chart i n Table 2 shows the correct size cord to

use based on cord length and motor plate amp

rating. If in doubt, use the nex t heavier gauge. The

smaller the gauge number, the heavier the cord.

Figure 3

Extension Cord Length *

25

50

75

100

150

feet

feet

feet

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on limiting the line voltage drop to 5V at 150% of the

rated amp eres.

NR: Not Re commended.

feet

feet

200

feet

Table 2

10

Page 11

Adjustments

When changing tools, making

adjustments, or doing clean-up and

maintenance, always turn the machine off and

unplug the machine from its power source.

Fence Assembly Movement

Referring to Fi gur e 4:

The adjustm ent contr ols of the f ence assembl y are

as follows:

A – Fence Assembly Lock Knob – to secure fenc e

assembly to table

B – Fence Adjustment Knob – mov es fenc e

assembly forward or back

C – Lock Knob – to secure the infeed and outfeed

fences

D – Infeed/Outf eed Ram Adjust – fine adjustment

for infeed or outfeed fence

E – Lock Knob – loosening permits side to side

adjustment of infeed or outfeed fence

F – Lock Knob – loosening permi ts vertical

adjustment of guar d ( H)

G – Lock Knob – loosening permi ts

backward/for ward adj ustment of guard (H)

Handwheel Adjustments

Referring to Fi gur e 5:

The front handwheel (B) controls the spindle

height.

The side handwheel (C) controls the casters. The

Model PM2700 has a retr ac table caster system that

can be extended to permit t he shaper to be rolled

from one location to another.

Spindle he ig ht

1. Loosen the lock knob (B) on the spindl e height

adjust handwheel (A).

2. Turn the handwheel (A) cloc kwise to raise and

countercl oc k wise to lower the spi ndle.

3. Tighten the lock knob (B).

Caster system adju stment

Retractabl e casters can be ex tended per mi tti ng the

shaper to be moved as follows:

1. Turn the handwheel (C) clockwise to extend

the casters, rai si ng the shaper.

Note: Because of the weight of the machine,

both hands may be needed to turn the

handwheel. Raise the shaper just enough to

permit moving t o another location.

When the shaper has been reposit ioned:

2. Retract the casters by turning the hand-

wheel (C) count er cl oc k wise.

Figure 4

Figure 5

11

Page 12

Coplanar Alignment

Follow steps 1–5 to determine if alignment is

necessary. Steps 6–9 will guide you through the

alignment if required.

Verifying that fences are coplanar

1. Remove the guard and spindle attachment.

2. Adjust the fence assembly (A) so it is

positioned approx imately at midpoint and l ock

(B).

3. Place a straightedge (F) on the table pressed

against the infeed (E

4. Unlock the fence lock knobs (D

5. With the ram adjust dials (C

position of either fence as required to bring

both fences in-line (coplanar alignment) using

the straight edge as the point of reference.

No adjustment is requi red if both fences are flush

with the straightedge as shown in Figure 7. Procede to Ram Dial Calibration ( step 00) .

Adjustment is required if the fences appear

skewed (Figure 8). Continue with Coplan ar Adjust-

ment (f ollowing steps).

Coplanar Adjustment

Determine whic h fence i s skewed (in t his ex ample:

, Fig. 8), which will requi re adjustment while the

G

1

remaining fence (G

point.

6. Remove both fences and place the straightedge against the infeed and outfeed fence

castings (Fi gur e 9) .

7. Lock the reference fence (D

skewed fence (D

Read step 8 completely before attempting.

) and outfeed fences (E2).

1

, D2).

1

, C2) adjust the

1

) will serve as the reference

2

) and unlock the

2

).

1

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

8. Maintain steady pressure of the straightedge

against the fence castings (H, Fig. 9). At the

same time, attempt to bring both fences into

alignment as shown in Figure 10. This is

accomplished by al ternately making incremental adjustments to four setscrews (L, Fig. 11)

on the front f ace of the casting (K, Fig. 11) wit h

a 2mm hex wrench, followed by repositioning

the casting with the micro adjust dial (J, Fig.

11) as required.

Important: It is recommended that the

adjustment setscrews (K, Fi g. 11) be rotat ed in

1/16th increments or less at a time.

Alignment is complete when the skewed and

reference fence castings are coplanar (in-line) as

shown in Figure 10.

9. Replace both fences and secure.

Figure 11

12

Page 13

Ram Dial Calibration

The guard and spindle shoul d be r em ov ed.

Referring to Fi gur e 12:

1. Loosen the infeed fence lock knob (E), then

turn the infeed ram dial (D) countercl ockwise to

bring the inf eed fence ( F) bac k al l t he way unti l

the limiter setscrew (P) touches the head

casting (M). Then retighten the lock knob (E).

2. If necessary, loosen two setscrews on the

infeed ram dial (D) with a 2mm hex wrench and

align the zero on the dial with the indicator

mark. Then tighten the setscrews.

3. Next, loosen the outfeed fence lock knob (B)

and turn the outfeed ram dial (A) counterclockwise to bri ng t he outfeed fenc e (C) all the

way back.

4. Place a straightedge (G) on the table against

both fences.

If both fences are flush with the straightedge (K)

and the outfeed ram dial (A) indicates zero, no

further action is necessary.

If alignment is necessary ( J ) :

5. Slide the outfeed fence (C) a side to reveal the

limiting setscr ew (P) on the fence casting (N).

6. Loosen the hex locking nut (O) with a 10mm

wrench and back out the limiting setscrew (P)

with a 3mm hex wrench to permit a sufficient

backward and f or ward adjustment r ange for the

outfeed fence (C).

7. Slide the outfeed fence (C) back onto the

casting and secure.

8. Loosen the out feed fence lock knob (B).

9. While maintaining pressure (H) on the

straightedge (G) against the fences (C, F),

adjust the outfeed ram dial (A) until bot h fences

are in-li ne (K).

After proper alignm ent is made:

10. Slide the outfeed fence (C) aside again.

11. Turn the limiting setscrew (P ) in (t urn cw) until

it comes in contact with the head casting (M)

12. Tighten the hex locking nut (O) with a 10mm

wrench w hile maintain ing the sets crew posit ion

with the 3mm hex wrench.

13. Replace the outf eed fence and secure.

14. Loosen the t wo set-screws (2mm hex wrench)

on the outfeed ram dial (A) and align t he zero

on the dial with the indicator mark. Then tighten

the setscrews.

Infeed side fence casting

-- Outfeed side is mirror image

Figure 12

13

Page 14

Spindle Gib Adjustment

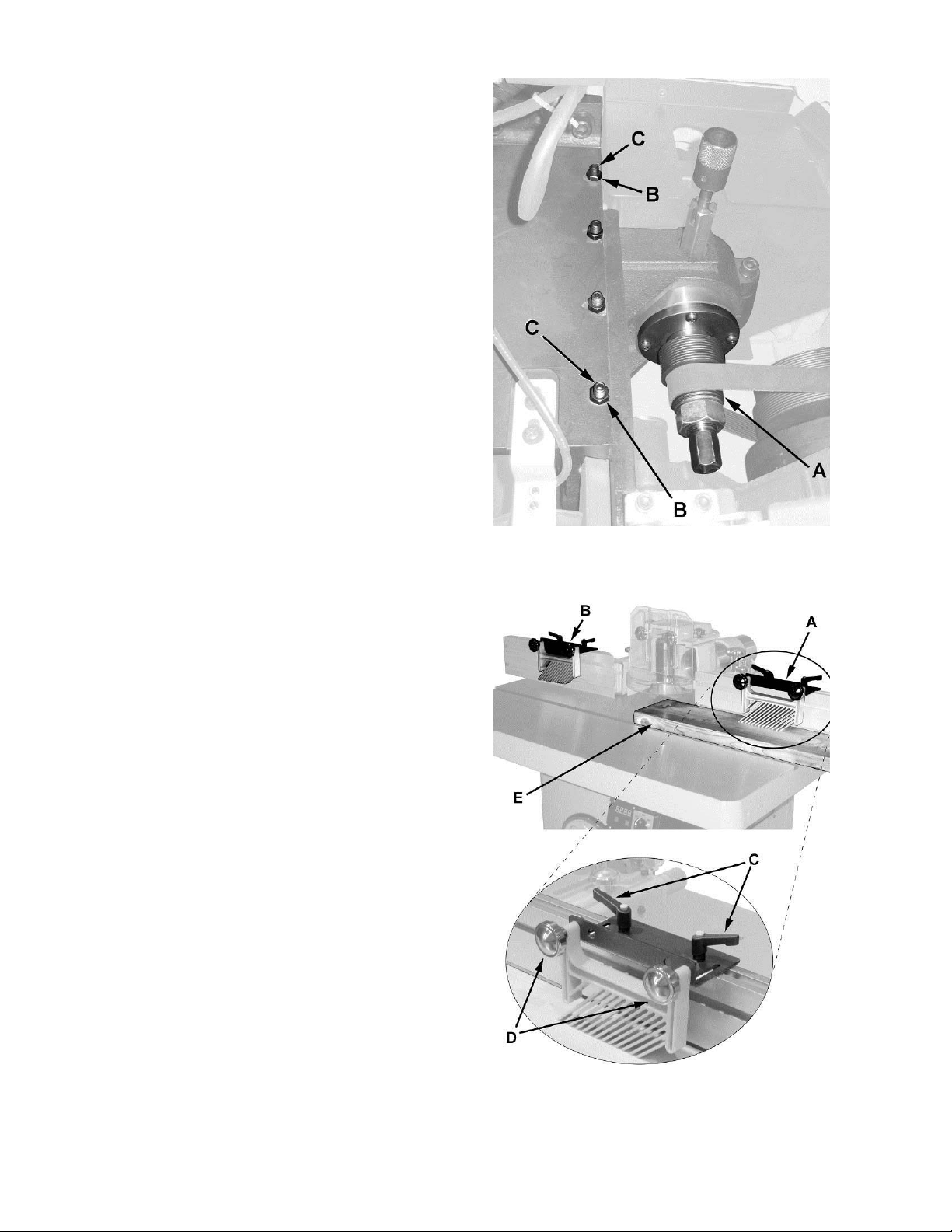

Referring to Fi gur e 13:

The spindle housin g gib on your m ac hine i s f actory

adjusted and initially should not require readjustment. After a period of use the gib may wear and

become loose, introducing play and potentially

causing the spindle (A) to vibrate. This requires

adjustment.

To adjust (refer to Figure 13):

1. With a 12m m wrench, l oosen four jam nut s (B)

that secure the gib sets crew s (C).

2. With a 4mm hex wrench, tighten each setscrew

1/8 or less turn starting with the lowest one,

followed by the uppermost one, then the two

middle setscr ews.

If this is not enough t o remove the table play,

repeat this step unt il the play is removed.

Note: If the gi bs are too tight the front handwheel

(A, Fig. 3) that controls the spindle height will be

difficult to turn.

3. When adjustment is complete, hold the set-

screws (C) in position with the 4mm hex

wrench to mai ntain the setting while tighteni ng

the jam nuts (B) with the 12mm wrench.

Featherboard Hold-downs

Referring to Fi gur e 14:

The PM2700 Shaper comes equipped with two

featherboard hold-downs (A, B) mounted on the

infeed and outf eed fenc es.

1. Loosen lock handles (C) and lock knobs (D).

2. Slide the hold-down guides to the desired

position along the fence and tighten the lock

handles (C).

3. Place the workpiece (E) on the table against

the fence and under t he hold- down guide (A).

4. Adjust the featherboard stay to put moderate

pressure on the workpiece, then tighten the

lock knob (D).

Figure 13

Figure 14

14

Page 15

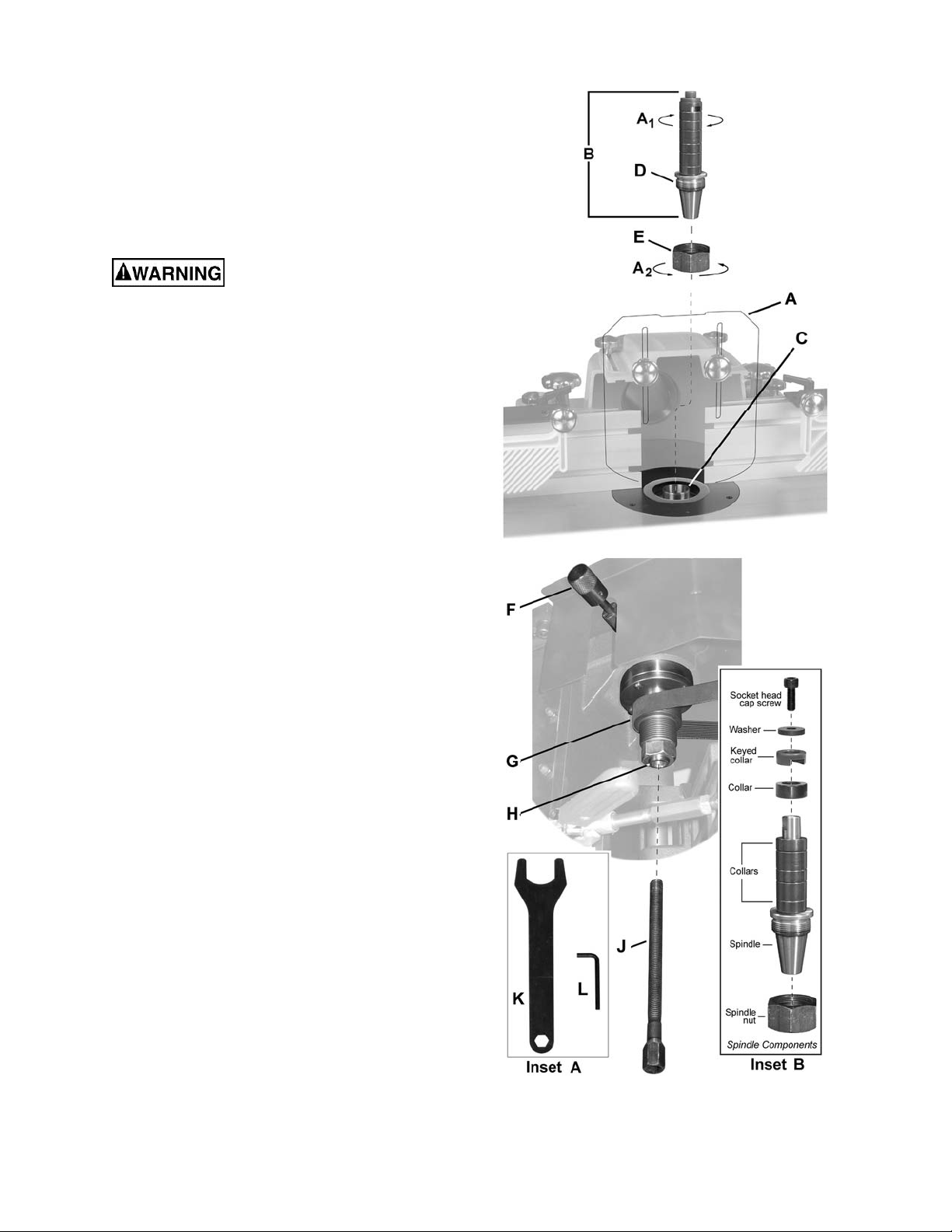

Spindle Assembly Installation

Refer to Figur e 15. The fence guard (A) has bee n

removed for clarity.

The spindle assembly (B) is mounted t o the arbor

(C) and secured with a draw bar (J) and nut (E).

Use the following procedure to install the spindle

assembly. Reverse the order to remove the

spindle.

When changing tools, making

adjustments, or doing clean-up and maintenance, always t urn the machine off and unplug

the machine from its power source.

1. Raise the arbor (C) all the way using the

handwheel located on the front of the cabinet.

Locking the Arbor

2. Locate the spindle lock (F) acc essible through

the door on the right side of the cabi net. Pull

out and rotate 90º right or left, resetting the

knob into the indent.

Turn the arbor ( C) by hand until it locks, then

verify that it will not rotate.

Installing the Spindle Assem bly

3. Thread the nut (E) onto the threaded end of t he

spindle (D) in t he direction indi cated by arrows

, A2). Tighten securely by hand.

(A

1

4. Thread the spindle assembly (B) and nut (E)

onto the arbor (C) and hand tighten only.

5. Insert the draw bar ( J) through the opening in

the shaft (H) just below the drive belt (G ). Turn

clockwise, fastening and securing it to the

spindle. Tighten the draw bar (J) with the

provided wrench (K).

6. Tighten the nut (E) with the wrench (K).

Shaper Cutter installation is described in the

following section. Note that at this time the

spindle holder i s still locked.

Spindle Assembly Removal

Referring to Fi gur e 15:

The spindle hol der must be locked as descri bed in

Spindle Assembly Installation, step 2.

1. Remove the dr aw bar (J).

2. Loosen the nut (E) then, using the wrench (K)

continue to turn until the spindle attachment

breaks free of the ar bor .

Figure 15

15

Page 16

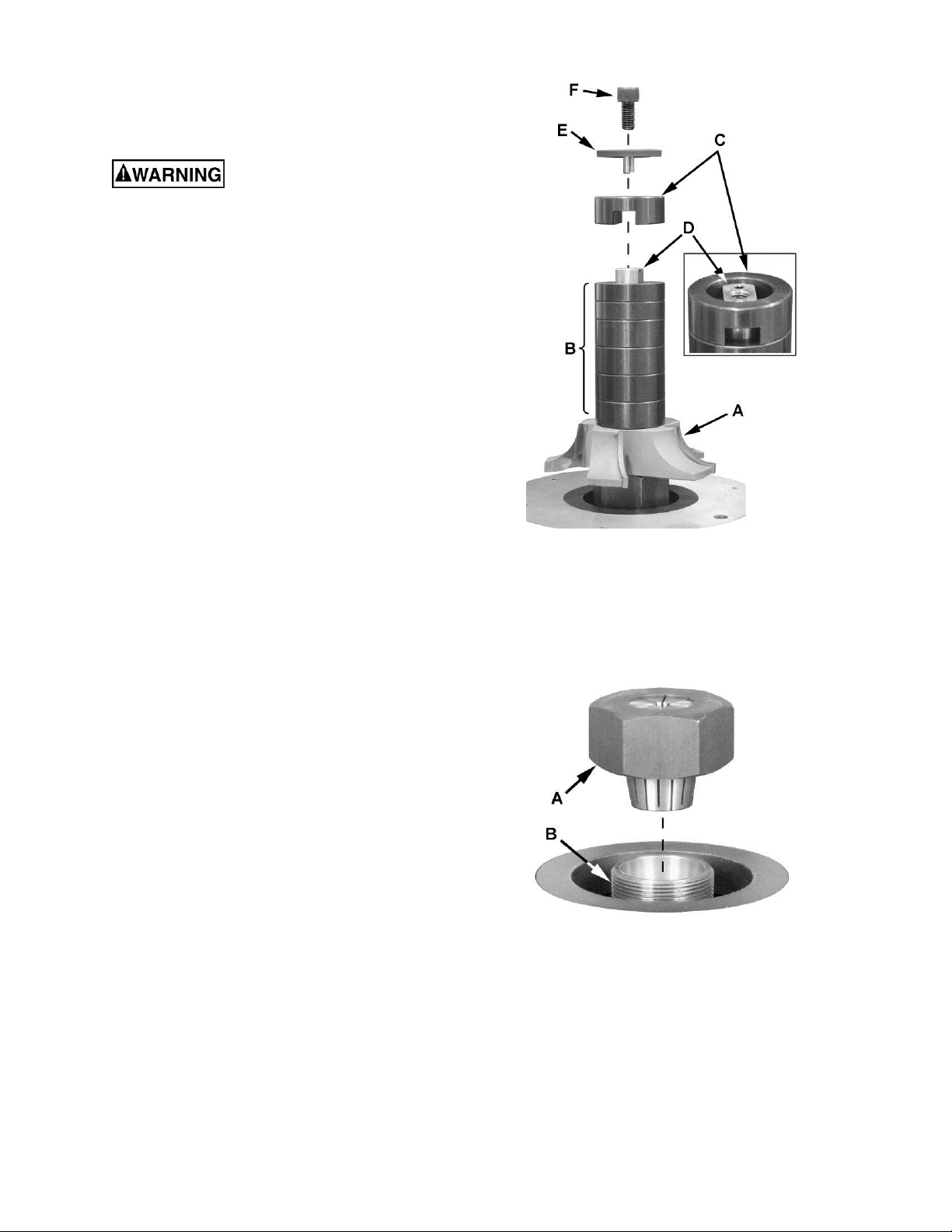

Shaper Cutter Installation

Note: Spindle installation is described in the

previous section.

When changing tools, making

adjustments, or doing clean-up and maintenance, always t urn the machine off and unplug

the machine from its power source.

Locking the Spindle

1. Locate the spindle lock (F, Fig. 15) accessible

through the door on the right side of the

cabinet. Pull out and rotate 90º right or left,

resetting the knob into the indent.

Attempt to turn the spindle (B, Fig. 15) by hand

to verify that it is l oc k ed and will not rotate.

Installing the Shaper Cut ter

Referring to Fi gur e 16:

1. Place the shaper cutter (A) ( not incl uded) ont o

the spindle, ori ented in the proper direction.

2. Place the spacers (B) and keyed collar (C) onto

the spindle.

Note: Spacers come in several widths and the

stacked select i on (B) must be such that the t op

of the keyed collar (C) sits slightly above the

top of the spindle (D ) . This will ensure suffici ent

pressure to properly secure the shaper cutter

(A) when install ation is complete.

3. Install the pronged w as her ( E ) and s oc k et head

cap screw ( F). Tighten screw with t he 8mm hex

wrench provided.

Unlocking the Spindle

4. Pull out the spindle lock (F , Fig. 15) acc essible

through the door on the right side of the

cabinet. Rotate 90º right or left, resetting the

knob into the indent.

Using gloves to prevent injury from the

shaper cutter , turn the spindle (B) by hand to

verify that it turns freely.

Router Collet (Optional) Installation

1. Locate the spindle lock (F, Fig. 15) accessible

through the door on the right side of the

cabinet. Pull out and rotate 90º right or left,

resetting the knob into the indent.

Attempt to turn the spindle (B, Fig. 15) by hand

to verify that it is l oc k ed and will not rotate.

2. Place the router collet (A, Fig. 17) onto the

spindle (B, Fig. 17) and secure with the

wrench (K, Fig. 15) provided.

Figure 16

Figure 17

3. Unlock t he spindle by pulli ng out the lock knob

(F, Fig. 15) accessibl e through t he door on t he

right side of the cabi net. Rotate 90º right or left,

resetting the knob into the indent.

Turn the router collet (A, Fig. 17) by hand to

verify that it turns freely.

16

Page 17

Changing Cutter Speed

Referring to Fi gur e 18:

The Model PM2700 Shaper is equipped with

pulleys that all ow you to change the spindl e speed.

The belt (B) placed on t he upper pull eys (as shown

in Figure 16) provides 7,500 RPM spindle speed.

Placing the belt on the lower pulleys provides

10,000 RPM spindl e speed.

To change speed (ref er to Fi gur e 16):

1. Disconnect the machine from the power

source.

2. Open the door of the cabinet.

3. Remove the belt tension by moving the belt

tension handle (A) to the unlock ( left) position.

This allows the motor (E) to swivel on its

mounting hinge.

4. Move the drive belt (B) to the other set of

grooves (C).

5. Lock the belt tension handle (A), securing the

motor (E) and placing tension on the drive

belt (C).

Drive Belt Tension

Referring to Fi gur e 18:

The drive belt should have sufficient tension to

prevent sli ppage when the machine i s in operation.

If the tension on t he belt needs adjustment:

1. Disconnect the machine from the power

source.

2. Open the door of the cabinet.

3. With a 17mm wrench, loosen the lock nut (G)

on the belt tension assembl y (refer to inset for

loosening dir ec tion).

4. Adjust the hex bushing (F) with a 17mm

wrench (refer t o inset for adj ustment direction)

for proper tension on the belt (B). The tension

handle (A) must be in the lock ed posi tion (ri ght)

while performi ng this step.

Note: Two 17mm wrenches are required for the

next step.

5. Maintain the position of the hex bushing (F)

with one wrench while tightening the lock

nut (G) with the ot her .

Figure 18

Belt Replacement

Referring to Fi gur e 18:

Replace the drive belt (B) as follows:

1. Disconnect the machine from the power

source.

2. Open the door of the cabinet.

3. Remove the belt tension by moving the belt

tension handle (A ) to the unlock (left ) position.

This allows the motor (E) to swivel on its

mounting hinge.

4. Work the drive belt down all the way past the

pulleys.

5. Continue slidi ng the belt down on t he left side

until it is free from the spindle (C), t hen remove

the belt over the top of t he motor pulley (D).

6. Install the new belt by f ollowing these steps in

reverse.

17

Page 18

Precision Miter Gauge

Setting the miter gauge angle

Referring to Fi gur e 19:

The precision miter gauge has a rack and pinion

adjustment f or setting the angle. To operate:

1. Slide the miter gauge i nto one of the slot s on

the table top.

2. Loosen lock handle (A).

To adjust the body (B) of the miter gauge to the

desired angle:

3. Pull the spring-loaded knob (C) out and turn

until the body ( B) of the miter gauge i s at the

desired angle as indicated on the scale.

4. Tighten the lock handle (A).

Indent settings

There are indent s at the 0º, 30º and 45º right and

left positions. At these settings, release the

knob ( C) to engage the stop rod. Then tighten the

lock handle (A).

Note: Do not rely solely on the indents for an

accurate setti ng. After the stop r od engages at the

0º, 30º and 45º po sitions, make a fi ne adjustment

with the knob (C), if necessary, setting it against

the scale indic ator.

Extension plate

The extension plat e (D) can be adj usted by slidi ng

to the right or left or r em ov ed entirely.

To adjust – loosen two lock handles (E), position

the extension plate and tighten the lock handles.

Figure 19

To remove – slide the extension plate completely

off and rem ove the l ock handles (E) and m ounting

hardware.

Calibratin g the mi t er gauge

1. Place the m iter gauge in one of the slots (H) on

the table top.

2. Set the miter gauge to 90º (0º setting on the

scale) by loosening the lock handle (A), then

pulling the spring-loaded knob (C) out and

turning the body (B) unti l 0º i s indicat ed on th e

scale (F).

3. Measure t he accurac y of the gauge agai nst the

slot with a combination square.

If adjustm ent is necessary:

4. Adjust the body (B) until it is perfectly square

(90º) to the miter slot (H).

5. Tighten the lock handle (A).

Verify that the scale indicator (G ) reads 0º. If further

adjustment is necessary:

6. Loosen the screw (F) and adjust the

indicator (G) until it reads 0º

7. Tighten the screw (F).

The mit er gauge should fit snugly within t he miter

slot while still sliding easily. The bar of the miter

gauge has t wo slot s, each wit h a set scre w. Rot ate

one or both of these set screws with a hex wrench

as needed to eliminat e any play between the miter

gauge bar and miter slot .

18

Page 19

Operating Controls

Start/Stop

Power Indicator Light – The start switch has a

power indicator lamp which is on whenever

there is power connected to the shaper, not

just when the shaper i s running. Do not assume

that no light means there is no power to the

machine. If the bulb is bad, there will be no

indication. Always check before use.

magnetic, t he lock can be removed to make the

machine inoper able and can be hidden f or safe

storage by attaching it underneath the rail or

another magnetic surface.

When using the shaper, place the key on the

switch cov er lining up the arrow on the key with

the REMOVE arrow on the cover. Then rotate

the key so the arrow lines up with the LOCK

arrow. This will prevent the safety key from

coming loose f rom vibration when the machine

is in use.

Do not rely that no light

means no power to the machine. Always

check for po wer first. F ailure to co mply may

cause serious inj ury!

Referring to Fi gur e 20:

Start – Press the green start switch (see Note).

When power is connected to the machine, the

green light is always on regardless of whether

the shaper is running or not.

Note: In addition, the switch on the digital

readout must be set t o forward (or rev erse) and

the cabinet door must be closed.

Stop – Press the red switch to stop.

Reset – In the event that the shaper stops

without pre ssing the stop but ton, a s the r esul t of

a tripped fuse or ci rcuit br eak er , etc.:

1. Press red button to reset

2. Press the green button to restart the

machine.

Digital Readout

The digital readout (Figure 21) is used for

making incremental spindle height adjustments

where applicable, if multiple shaping/cutting

passes are to be performed on a given workpiece.

Set the digital r eadout as follows:

1. Set the desired spindle height for the

workpiece to be cut .

2. Supply power to the machine so the digital

display is lit.

3. Select inch or mm by momentarily

depressing the button on the right.

4. Press the 0" SET button for approximately

two seconds.

The digit al display resets to zero, which is your

reference point. When the spindle is raised or

lowered (fr ont handwheel), the change is relative

to this reference.

Figure 20

Safety Key

The start/stop switch on the Model PM2700

comes equipped with a magnetic safety key.

When in place on t he switch as shown in Figur e

20 the magnetic safety key trips a relay which

will allow the machine to start and stop when the

respective switches are pressed. Being

If this feature is used, the display should be

reset to zero for each new cutt ing operation.

Figure 21

19

Page 20

Operations

Overview

Before applyi ng power to the machine, Check t he

motor and switch wiring diagrams for proper

voltage connections. Check that all mounting

screws and bolts are tight.

Turn on the motor mom entarily to check for proper

rotation. The spindle should rotate counterclockwise when looki ng down on the spindle. Correc t as

required.

Run the machine for a short period of time to

ensure that the movi ng parts are working properly

with no excessiv e vibration. If a probl em develops,

correct it before turning t he shaper over for general

use.

Safety Devices

Safety devic es such as guards, fixtures, t emplates

hold-downs, push sticks (Figure 22), feather

boards and power feeders should be used

whenever possibl e. Figure 22 shows a push sti ck

which can be easily m ade from scrap wood.

Note: For the sake of clarit y, the shaper guard ha s

been omitted from most illustrations. All shaper

operations m ust be done with the proper guar d in

place and any other device which insures the

safety of the oper ator.

Deep cuts require excessive

horsepower and pushing force to control the

cut.

Deep cuts can also cause the wood to splinter or

split and may lead to lost c ontrol or personal i njury.

Preband shaper the stock whenever possible to

1/16 inch of finished size. When an edge finish is

unsatisfact ory, take two or more cuts with t he final

cut no more than 1/16 inch deep.

In the case of shaping acro ss the gr ain, t he trail ing

board edge will often splinter. To correct this, the

best solution i s to make the board 1/4 inch ov ersiz e

in width, shape the board, and sim ply trim off the

excess.

Cutter Rotation

Counterclockw ise Setup – With the cutter install ed

as shown in Figure 23, feed the workpiece from

right to left.

Grain Direction Considerations

Plan to shape the workpi ece in the same direct ion

as the grain when possible. Some open grain

woods (such as redwood, fi r and oak) will leave a

rough, or sli ghtly spl intered edge when c ut against

the grain.

Figure 22

Figure 23

Clockwise Setup – With the cutter installed as

shown in Fi gure 24, feed t he workpiece f rom left to

right.

Figure 24

20

Page 21

Using the Fence

Using the fence is the saf est and most satisfact ory

method of shaping, and should always be used

when the work permits. Almost all straight work

can be used with the fence.

For average work, where a porti on of the original

edge of the work is not to be touched by the cutter,

both the front and rear fences are set in a str aight

line as shown in Figur e 25.

When the shaping operation removes the entire

edge of the work, e.g. in jointing or making a full

bead, the shaped edge will not be supported by

the outfeed fence when both fences are in line,

Figure 26. In this case, the stock should be

advanced to the position shown in Figure 26 and

stopped. Turn off the machine and move the

outfeed fence forward to contact the workpiece,

Figure 27. Remove the workpiec e, start t he mot or,

and then continue the oper ation.

Always remove workpiece

before starting the machine! This will prevent

kickback and potential serious injury.

Figure 25

Figure 26

Figure 27

21

Page 22

"Z" Dimension

Before making a template (or using the edge of the

workpiece) for shaper cutting, the "Z" dimension

must be established in order to determine the

shape and size of the finished stock. The "Z"

dimension is t he diff erence between the i nnerm ost

part of the c utter edge and the outsi de diameter of

the ball beari ng follower (collar). See Figure 28.

Note: The "Z" dim ension can be either positive or

negative.

The "Z" dim ension is positiv e if the cutt er is larger

than the coll ar bearing.

The "Z" dimension is negative if the cutter is

smaller than the c ollar bear ing.

Depth of Cut

The depth of cut is the distance from the outside

circumference edge of the collar (which the work

rides against) t o the outside edge of the cutter. The

depth of cut is determined by the position of the

fence rel ative to the cutt erhead and/or by the u se

of shaper coll ar s (see Figure 29).

Straight Edge Shaping

Straight edge shaping is always performed with the

workpiece again st the fence. Use only push sti cks

and hold downs to keep the workpi ec e on posi tion.

Do not use a miter gauge to

feed material along the fence face. The workpiece can bind and cause kickback. Failure to

comply may cause seriou s injury!

To set up:

1. Disconnect or unplug the machine from its

power source.

2. Check to see t hat the f ence f aces are paral lel,

properly in line or offset if necessary, and

securely tightened.

3. Rotate the cutt er s and i nspect for clearance.

4. Lock the spindl e.

5. Install all nec essary guards.

6. Reconnect power to the mac hine.

7. Take a tri al cut on a piece of scrap the same

thickness as workpiece.

Note: Only a short cut i s necessary t o determ ine if

the profile, depth, and height of cut is correct.

Figure 28

Figure 29

22

Page 23

Edge Shaping

When edge shaping, never attempt t o hand guide

any stock less than 12 inches long, or narrower

than 3 inches wit hout t he use of a special gui de as

shown in Figure 30.

When edge shaping, the work-

piece must b e at least 12 inch es long unless a

special guide is used.

1. Use the hol d-ins and hold-do wns as shown in

Figure 30 to firmly hold the workpiece down

and against the f ence. If workpiece i s too wide

for the hold-ins to be used, clamp a scrap

board to the table to substitute for the hold-i ns.

2. Check the rotation of the cutter. Be sure to

feed workpiec e against rotation of the cutter.

Figure 30

3. Feed the workpiece slowly and steadily with

firm, even pressure to m ak e a smooth cut.

Important: The rate of feed depends on de pth of

cut and experi enc e of operator.

End Shaping

When end shaping narrow stock, it is important

that at least one half of the workpiece end be in

contact with either the in-feed or out-feed fence.

Use a guide similar to t he one shown in Figure 31

which tightly clamps the scrap piece to the workpiece and provides the necessary width.

End shaping a narrow workpiece without a special guide could result in

the workpiece rocking into the cutterhead,

causing personal injury.

Shaping All Sides

Because cross grain shaping is more likely to

create chi pping out and splinters on some woods,

it is good practice to first shape the cross-grain

sides. Any chippi ng that does occur is taken care

of by the with-grain cuts, as shown in Figure 32.

On-Edge Shaping

If the shaper fence does not firmly support wide

stock, use the T-slots in the fence to attach a

special rigid high fence as shown in Figure 33.

Figure 31

Figure 32

Note: Be sure the scre w holes are counter sunk in

the special fence to avoid interference with the

workpiece.

Figure 33

23

Page 24

Straight Line Bevel Shaping

To shape a beveled straight edge, use a beveledge shaping jig in combination with the regular

fence as shown in Figur e 34.

Figure 34

To perform a bevel-edge cut, the in-f eed edge of

the jig is placed against the infeed fence and

clamped to the table as shown in Figure 35. The

outfeed fence is moved forward as necessary to

compensate for the cut.

Contour Edge Shaping With Collar Bearing

To shape contoured edge s, the operator m ust first

remove the fenc e assembly .

In order to control the workpiece and limit the

depth-of- cut, the operator m ust use an anti-f riction

collar with the cutt er ( s) as shown in Figure 36.

Figure 36

The collar may be positioned above or below the

cutter(s), and its function is to ride against the

workpiece or tem plate. A t the same tim e, the coll ar

will establish the depth-of-cut as shown in

Figure 37. Whenever possible, al ways use the ring

guard or safety collar.

Figure 35

Never attempt to bevel cut free

hand. Always use a bevel-edg e f ixture.

Note: Since the collar requires at least 1/8" of

surface edge to r ide against, t he entire edge cannot

be shaped as sho wn in Figure 38. The added u se

of a pattern, however, permits the shaping of the

entire contour edge.

Figure 37

Figure 38

24

Page 25

If the workpiece is to be shaped all around the

perimeter , hold it firmly and pu sh the work strai ght

into the cut ter until the depth of cut is established

by the collar as shown in Figure 39. Continue to

feed the work so that the point of contact on the

edge is always 90 degrees to t he collar (or dir ectly

in line with the c utter edge) and held firml y against

it.

When the workpiece is not contoured all around,

start the cut as shown in Figure 45. With this

operation, t he workpiece i s positioned agai nst the

starter pin and the end swung into place to start

the cut. When the cut has begun and the

workpiece f irmly agai nst t he col l ar, swing the stoc k

away from the pin and proceed wit h c ut.

Freehand shaping is extremely

dangerous. The operator must be aware at all

times of the proximity of his hands to the

cutter. Han ds must never come closer th an 12

inches to the cu t t er wi t hou t t he proper guard or

similar safet y devi ce over the cutterhead.

Shaping With Collars

When shaping with coll ars and starting pin, always

adhere to the following rules for good work and

safe operation:

Figure 39

Figure 40

The collar m ust have suffici ent beari ng surface, as

shown in Figure 40. Also, the stock must be f airly

heavy in proporti on to the cut being made. Under

no circumstances should a short, light workpiece

be shaped against the collars, as in Figure 41.

Note: The edge of t he work to be shaped must be

smooth. Any irregul arit y on the surface which ri des

against the coll ar will be duplicated on t he molded

surface.

Collars must be smooth and free from pitch and

other substances.

Position of Collars

Collars may be used above, below or between

cutterheads.

1. When the collar is used below the cutter, as

shown in Figure 42, the progress of the cut c an

be seen throughout the operation. However,

any accident al lif ting of the work will gouge the

wood and ruin the workpi ec e.

2. When the collar is used above the cutter, as

shown in Figure 43, the cut cannot be seen.

But this method offers an advantage i n that the

cut is not affected by slight variations in the

thickness of the stock. Also, accidental lifting of

the workpiece will not gouge the workpiece;

simply repeat the operation to correct the

mistake.

Figure 41

Figure 42

Figure 43

25

Page 26

3. Using the collar between the two cutters has

the adv antages and disadvantages of the first

two procedure s, and is frequentl y used where

both edges of the work are to be molded,

Figure 44.

Note: It is adv isable to place t he cutter as low as

possible on the spi ndle to reduce spindle deflecti on

and ensure the best possible finish. Also make

sure that t he contacting surf aces of the cutter are

smooth, clean and without dents.

Starting Pin

Use of the starting pin should

only be attempted by advanced users. If you

have never used this method, it is

recommended you get training from a qualified

person. Fail ure to co mply may resul t in serious

injury.

The starti ng pin is used to support the work when

starting t he c ut.

1. The work should be placed in the position 1,

(Figure 45), usi ng the starting pin as a support

2. Swing the work into t he cutter as shown in t he

position 2. The work is no w supported by t he

starting pin and the collar.

3. After the cut has been started, the work is

swung free of the starting pin and only rides

against the collar (Figure 46). Always feed

against the cut terhead rotation.

Figure 44

Figure 45

Figure 46

26

Page 27

Arcs and Circles

Large circular and arc-shaped stock can be

shaped as descri bed in Contour Edge Sh aping on

page 24. However, sm aller sized stock requires the

use of special shaping jigs similar to t hose shown

in Figure 47.

With the ent ire fence assem bly remov ed, carefully

position the jig for desired depth-of-cut and

securely clamp to the table.

It is important with the arc and circle shapes that

the workpiece, prior to being shaped, must be

roughly cut to the desired size and curve of the

finished piece. Make sure that the jig curve

matches exactl y the workpiece curv e. At all times

keep the workpiece firmly in contact with the jig

while the cutter is cut ting the stock.

Never perform this type

operation without a ring guard, safety collar or

similar safet y devi ce over the cutterhead.

Enclosed Edge Shaping

An enclosed workpiece edge is shaped in the

same manner as an outside contoured edge

except that a starting pin is not required as shown

in Figure 48.

Note: If the whole edge is to be shaped, the

operator must use a patter n.

Figure 47

Position the workpi ece on the table before starti ng

the motor. The operator must do the entire shaping

cut by pushing (feeding) the workpiece into the

cutter(s).

Enclosed edge shaping is

extremely dangerous. The operator must be

aware at all times of the di rect io n of feed. Never

perform this type operation without a ring

guard, safety collar or similar safety device

over the cutterh ead.

With a firm grip, ease the edge into the cutter(s)

until stopped by t he c ollar as shown in Fi gur e 48.

Continue to push straight in while feeding and

turning the workpiece at the sam e time until t he c ut

is finished. T urn off the motor and do not remove

workpiece until the cutters have completely

stopped.

Never perform enclosed edge

shaping if there is less than two inches of

workpiece material all around the opening.

Never perform enclosed edge shaping if the

workpiece op ening is smaller, in an y direction,

than twice the diameter o f th e cut t er( s) .

Figure 48

27

Page 28

Templates

The template must be thick enough to provide a

solid bearing edge against a collar. When

constructi ng a templat e similar to the one shown in

Figure 49, keep in mind that it serves only as a

guide for the cutter.

If the workpiece requires all-around shaping, the

template c an be constructed f rom sev eral sect ions

pieced together as shown in Figure 50.

Securing the Template

There are various methods used to secure the

template to the workpiece. The experienced

operator will choose the most appropriate

according t o the shape, size, and type c onstruct i on

of the template. For example, if the workpiece is

large enough to extend beyond the front of the

table and sti ll l eave r oom for the desir ed cut , it can

be securely held to the tem plate with "C" clamps

as shown in Figure 51.

Figure 49

Figure 50

In many situations the workpiece is positioned

against the template using dowels as anchor

points and handles (wood blocks) to assist the

operator in guidi ng the work-piece through the cut

as shown in Figure 52.

Figure 51

Figure 52

28

Page 29

Special Cuts

The illustrat ions in this section show the prof ile, or

section, views made by the cutter(s). The most

effici ent cutters are carbide ti pped to ensure clean

and long-term cutting. Small cutters may be solid

carbide, and some use inserts. Since there are

such a wide variety of choices, the operator is

limited only by his experience and imaginati on.

Stacked Cutters

A variety of inter esting and timesavi ng cuts can be

made in a single setup by stacking the cutters.

When the operator stacks the cutters, extra care

should be taken to see that all par ts are clean, free

of nicks and flaws, and perfectly balanced in the

stacked positi on.

Sash and Door Shaping

Shaping a door requires two operations.

Figure 53 shows the sash cut for the first

operation.

Figure 54 shows the stock flipped over and the

sash cutter used with a 1/4 inch groove cutter to

complete the cut.

Figure 55 shows the f i rst shaping cut wit h the sash

cutter for t he matc hing door stile sash.

Figure 56 shows the same cut with the stock

flipped ov er.

Figure 57 shows the f irst shaping c ut for a window

sash stile ut ilizing a sash cutter, col lar, and a 1/2

inch groove cutt er .

Figure 53

Figure 54

Figure 55

Figure 56

Figure 57

29

Page 30

Figure 58 shows BOT H cut s required for a window

sash rail end. The f irst operat ion at t op is a rabbet

cut made with a groove cutter. The second

operation is performed with a stub spindle and

buttonhead screw.

Butt Joints

All butt-type joints require both work-pieces to be

perfectly square and straight-edged.

Glue Butt Joint

To perform a glue butt joint, both fences are kept

inline and adj ust ed for a depth of cut (Figure 59).

The cuts on both work-pieces are part-edge cuts

which do not reduce the stock width during the

cutting procedure. When shaping the two

workpieces, one i s f ed t op-side up; the ot her is fed

bottom-side up.

Tongued Joint

Similar to the glue joint, both fences are kept in-line

for the tongued joint and adjusted for a 1/4 inch

depth of-c ut with no reducti on in stock widt h. With

this joint, however, both work-pi eces are fed with

the same side up as shown in Figure 60.

Drop Leaf Joint

When shaping a drop-leaf joint as shown in

Figure 61, the leaf workpiece is shaped with a

Drop-Leaf Bead cutter; the table workpiece is

shaped with a Drop-Leaf Cove cutter.

With this type joint, the whole edge of both

workpieces is shaped, same-side up, and

allowance m ade for a 1/16 i nch reducti on in widt h.

Adjust the in-feed fence to reduce the workpiece

width by 1/16 i nc h, and adjust the out-feed fence to

compensate for stock removed.

Taper Cuts

Taper cuts can be made by offsetting the fences

for the amount of taper desired, or with a layout

line on the stock which can be paralleled to the

infeed fence as shown in Figure 62.

Figure 58

Figure 59

Figure 60

Figure 61

Start the cut by holding the stock against the

infeed fence and swinging it into contact with the

outfeed f ence just past the cut terhead. As the cut

is started, t ransfer pressure to hol d the workpiece

against the outfeed fence, and continue feeding

the workpiece through. After the first cut, the

fences will have to be readjusted in order for the

second cut (parall el cut) and the final depth-of-cut

to remain true with the taper.

Figure 62

Do not use the standard fence

for short work (12 inches or less in length on

the side t o be cut). Instead, use a miter gau ge

or special fixture to avoid l osing control o f the

workpiece.

30

Page 31

Tenoning

The tenoning f ixture ill ustrated in Fi gure 63 shows

a miter gauge equipped with a hold-down for

shaping the ends of narr ow work-piec es.

The miter gauge can also be adapted to cut square

and centered tenons at t he ends of legs for tables,

chairs, etc. S ec ur e the leg t o jig and posi tion for cut

as shown in Figure 64.

Make all first cuts with the same jig setting and

spindle height. When the first series of cuts have

been made, reposition leg on the jig for each

succeeding cut.

Note: If the leg is taper ed, use a wedge to place

the side fac ing the cutt er into a 90 degree vertical

position as shown in Figur e 65.

Figure 63

Figure 64

Figure 65

31

Page 32

Troubleshooting for PM2700 Shaper

Trouble Possible Cause Remedy

Shaper will not star t.

Overload kicks out

frequently.

Cuts are

unsatisfactory.

1. Cord unplugged f rom the power

source.

2. Fuse blown or circuited breaker

tripped.

3. Cord damaged.

4. Reversing switch is in the Off

position.

5. Overload tripped.

6. Cabinet door is open.

1. Extension cord or wiri ng

inadequate size.

2. Feeding stock too fast.

3. Cutter needs cleaning or replacing.

See also Unsatisfactory Cuts

below.

1. Dull cutter.

2. Cutterhead rot ating in wrong

direction.

3. Feeding work in wrong di r ec tion.

4. Gum or pitch on cutter.

5. Gum or pitch on table causi ng

erratic feed.

1. Plug in power cord.

2. Replace fuse or reset circuit

breaker.

3. Replace cord.

4. Turn switch to f orward of r ev erse.

5. Reset overl oad by depressi ng r ed

stop button.

6. Close cabinet door .

1. Replace cord or wiri ng with proper

gauge wire.

2. Reduce feed stock r ate.

3. Clean or replace cutter.

1. Replace cutter.

2. Check for proper r otati on at startup.

3. Feed work against the cutter

rotation.

4. Remove cutter and clean with

solvent.

5. Clean table with solvent.

Cutter does not com e

up to full speed.

Machine vibrates.

Edge splits off on

cross grain cut.

1. Shop wire gauge is too small.

2. Extension cord or wiri ng

inadequate size.

3. Power source is not adequate.

4. Motor not wired for c or r ect v ol tage.

5. Spindle is locked with madrel lever.

1. Stand on uneven surf ac e.

2. Cutterhead damaged.

3. Defective V-belt.

4. V-belt incorrectly tensioned.

5. Bent pulley.

6. Motor mounted improperly.

1. Characteri stic of this type of cut. 1. Make cross grain cuts fir st, then

1. Replace wiri ng with proper gauge

wire.

2. Replace wit adequat e si z e c or d.

3. Contact your elec tric utility.

4. Refer to motor name plac e and

wiring diagram for correct wiring.

5. Unlock spindle – see label next to

lover on base.

1. Stand must rest solidly on level

surface. Fasten to floor if

necessary.

2. Replace cutterhead.

3. Replace V-belt.

4. Apply proper tension.

5. Replace pulley.

6. Motor must be properly m ounted

with snug nuts and bolts.

finish cut wit h the grain. Use scrap

block to support end of c ut.

32

Page 33

Trouble Possible Cause Remedy

Raised areas on

shaped edge.

Work pulled from

hand.

Depth of cut not

uniform.

Work burns.

Cut height not

uniform.

Cuts not smooth.

1. Variation of pressure holding work

against cutt er .

1. Feeding in wrong direc tion. 1. Always feed work against the

1. Fence misalignment.

2. Side pressure not uniform.

1. Cutting too deep on one pass.

2. Forcing work.

1. Variation in pr essure holding work

to table.

1. Wrong R.P.M.

2. Feed too fast.

3. Working against the grain.

4. Cutting too deep on one pass.