Page 1

This Manual is Bookmarked

Operating Instructions and Parts Manual

Horizontal Panel Saw

Model HPS67

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60124 Part No. M-0460273

Ph.: 800-274-6848 Revision C1 11/06

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

Warranty and Service

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our Authorized Service

Center located throughout the United States can give you quick service. In most cases, any of these WMH Tool Group

Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance and

major repair on your POWERMATIC

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check with your

local WMH Tool Group distributor, or visit powermatic.com.

WARRANTY

POWERMATIC products carry a limited warranty which varies in duration based upon the product.

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools, abrasives

and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general POWERMATIC warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

The Five Year Warranty does not cover products used for commercial, industrial or educational purposes. Products with a Five

Year Warranty that are used for commercial, industrial or education purposes revert to a One Year Warranty. This warranty does

not cover defects due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair or

alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name of the

location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the merchandise. If our

inspection discloses a defect, we will repair or replace the product, or refund the purchase price, at our option.

We will return the repaired product or replacement at our expense unless it is determined by us that there is no defect, or that the

defect resulted from causes not within the scope of our warranty in which case we will, at your direction, dispose of or return the

product. In the event you choose to have the product returned, you will be responsible for the handling and shipping costs of the

return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE

EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information and are

not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those alterations to parts,

fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

®

tools. For the name of an Authorized Service Center in your area call 1-800-274-6848.

2

Page 3

Table of Contents

Warranty and Service .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning...................................................................................................................................................4

Introduction .............................................................................................................................................6

Specifications..........................................................................................................................................6

Machine Dimensions ...............................................................................................................................7

Unpacking ............................................................................................................................................... 8

Installation and Assembly ........................................................................................................................ 8

Installing Extension Tables...................................................................................................................9

Installing Crosscut Table......................................................................................................................9

Installing Crosscut Fence.....................................................................................................................9

Installing Guide Bar............................................................................................................................ 10

Installing Rip Fence............................................................................................................................ 10

Installing Over Arm.............................................................................................................................10

Installing Blade Guard........................................................................................................................ 10

Installing Miter Fence......................................................................................................................... 11

Electrical Connections........................................................................................................................ 11

Installing/Replacing Main Blade..........................................................................................................11

Installing/Replacing Scoring Blade ..................................................................................................... 12

Riving Knife........................................................................................................................................ 12

Starting the Machine.......................................................................................................................... 13

Dust Collection................................................................................................................................... 13

Adjustments .......................................................................................................................................... 14

Sliding Table Parallel to Blade............................................................................................................ 14

Setting Scoring Blade......................................................................................................................... 14

Setting Blade Guard........................................................................................................................... 14

Sliding Table Lock.............................................................................................................................. 15

Crosscut Fence.................................................................................................................................. 15

Miter Fence........................................................................................................................................17

Rip Fence.......................................................................................................................................... 17

Rip Fence Scale Calibration............................................................................................................... 17

Tensioning the Belt ............................................................................................................................ 18

Precision Tuning Your Panel Saw.......................................................................................................... 18

Free Cut (Blade to Sliding Table) ....................................................................................................... 19

Free Cut (Blade to Rip Fence)............................................................................................................ 20

Square Cut ........................................................................................................................................ 21

Scoring Blade .................................................................................................................................... 21

Operation.............................................................................................................................................. 21

Maintenance.......................................................................................................................................... 22

Optional Accessories ............................................................................................................................. 24

Replacement Parts................................................................................................................................ 24

Parts List: Motor and Arbor Assembly................................................................................................. 25

Motor and Arbor Assembly................................................................................................................. 27

Parts List: Scoring Motor and Arbor Assembly.................................................................................... 28

Parts List: Stand and Table Assembly ................................................................................................ 30

Parts List: Support Arm Assembly ...................................................................................................... 32

Support Arm Assembly....................................................................................................................... 33

Parts List: Cross Cut Fence Assembly................................................................................................34

Cross Cut Fence Assembly................................................................................................................ 35

Parts List: Rip Fence Assembly.......................................................................................................... 36

Rip Fence Assembly .......................................................................................................................... 37

Parts List: Over Arm Guard Assembly................................................................................................ 38

Over Arm Guard Assembly................................................................................................................. 39

Parts List: Sliding Table Assembly......................................................................................................40

Sliding Table Assembly...................................................................................................................... 42

Parts List: Electrical Components – 3 Phase ......................................................................................43

Parts List: Electrical Components – 1 Phase ......................................................................................43

Electrical Connections – 3 Phase........................................................................................................... 44

Electrical Connections – 1 Phase........................................................................................................... 45

3

Page 4

Warning

As with all machines, there is a certain amount of hazard involved with the use of this panel saw. Use the

machine with the respect and caution demanded where safety precautions are concerned. When normal

safety precautions are overlooked or ignored, personal injury to the operator can result.

1. Read and understand the entire owner’s manual before attempting assembly or operation. Know the

limitations and hazards associated with this machine.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This panel saw is designed and intended for use by properly trained and experienced personnel only.

If you are not familiar with the proper and safe operation of a panel saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this panel saw for other than its intended use. If used for other purposes, WMH Tool

Group disclaims any real or implied warranty and holds itself harmless from any injury that may result

from that use.

6. Always wear approved safety glasses/face shields while using this panel saw. Everyday eyeglasses

only have impact resistant lenses; they are not safety glasses.

7. Before operating this panel saw, remove tie, rings, watches and other jewelry, and roll sleeves up

past the elbows. Remove all loose clothing and confine long hair. Protective type footwear should be

used. Anti-skid floor strips are recommended. Do not wear gloves.

8. Where the noise exceeds the level of exposure allowed in Section 1910.95 of the OSHA Regulations,

use hearing protective devices.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before connecting the machine to the power supply.

12. Make certain that the machine frame is electrically grounded and that a ground lead is included in the

incoming electrical service. In cases where a cord and plug are used, make certain that the grounding

plug connects to a suitable ground. Follow the grounding procedure indicated in the National

Electrical Code.

13. Disconnect machine from power source before performing any service or maintenance or when

changing blades. A machine under repair should be RED TAGGED to show it should not be used

until the maintenance is complete.

14. Remove adjusting keys, wrenches, scrap or cleaning rags. Form a habit of checking to see that all

such items are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards before operating the machine.

16. Provide for adequate space surrounding work area and non-glare, overhead lighting.

4

Page 5

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repaired or replaced.

18. Keep the floor around the machine clean and free of scrap material, saw dust, oil and other liquids to

minimize the danger of tripping or slipping. Be sure the table is free of all scrap, foreign material and

tools before starting to cut.

19. Make certain the work area is well lighted and that a proper exhaust system is used to minimize dust.

Anti-skid floor strips are recommended on the floor area where the operator normally stands and

each machine’s work area should be marked off. Provide adequate work space around the machine.

20. Keep visitors a safe distance from the work area. Keep children away.

21. Make your workshop child proof with padlocks, master switches or by removing starter keys.

22. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

23. Maintain a balanced stance and keep your body under control at all times. Do not overreach or use

excessive force to perform any machine operation. Do not stand in line with the saw blade or work

piece and do not allow anyone else to do so.

24. Use the right tool at the correct speed and feed rate. Do not force a tool or attachment to do a job for

which it was not designed. The right tool will do the job better and safer.

25. Maintain tools in top condition. Check the saw blade for cracks or missing teeth. Do not use a cracked

or dull blade or one with missing teeth or improper set. Make sure the blade is securely locked on the

arbor.

26. Turn off the machine before cleaning.

27. Do not stand on the machine. Serious injury could occur if the machine tips over.

28. Never leave the machine running unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

29. Remove loose items and unnecessary work pieces from the area before starting the machine.

30. Keep hands clear of the blade area. Do not reach past the blade to clear parts or scrap with the saw

blade running. Never saw free hand. Avoid awkward operations and hand positions where a sudden

slip could cause your hand to contact the blade.

31. Saw blade rotation: Be sure the main saw blade rotates clockwise when viewed from the front

(operator’s side). The scoring blade should rotate counterclockwise when viewed from front.

32. Do not attempt to saw boards with loose knots or with nails or other foreign material, on its surface.

Do not attempt to saw twisted, warped, bowed or “in wind” stock unless one edge has been jointed for

guiding purposes prior to sawing.

33. If the operator leaves the machine area for any reason, he should turn “off” the power to the saw

motor and wait until the saw blade comes to a complete stop before his departure. In addition, if the

operation is complete, he should clean the saw and the work area. NEVER clean the saw with power

"on" and never use the hands to clear sawdust and debris; use a brush or compressed air.

34. Use only Powermatic or factory authorized replacement parts and accessories; otherwise the

warranty and guarantee is null and void.

5

Page 6

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

Introduction

This manual is provided by WMH Tool Group covering the safe operation and maintenance procedures

for a Powermatic Model HPS67 Horizontal Panel Saw. This manual contains instructions on installation,

safety precautions, general operating procedures, maintenance instructions and parts breakdown. This

machine has been designed and constructed to provide years of trouble free operation if used in

accordance with instructions set forth in this manual. If there are any questions or comments, please

contact either your local supplier or WMH Tool Group. WMH Tool Group can also be reached at our web

site: www.wmhtoolgroup.com.

Specifications

Model number (3 Phase model)...................................................................................................... HPS67

Stock number (3 Phase model).....................................................................................................1791287

Model number (1 Phase model)................................................................................................... HPS67-1

Stock number (1 Phase model).....................................................................................................1791286

Main motor (3 Phase model)................................................................................. TEFC, 5 HP, 3Ph, 230V

Main motor (1 Phase model).................................................................................. TEFC, 3HP, 1Ph, 230V

Blade speed ..............................................................................................................................4500 RPM

Blade size............................................................................................................................. 12” (315 mm)

Arbor size....................................................................................................................................... 30 mm

Dado size (width x bore) ........................................................................................................ 13/16” x 5/8”

Cutting depth.......................................................................................................................... 4” (100 mm)

Scoring motor................................................................................................................................ .3/4 HP

Scoring blade size ..............................................................................................................100 to 120 mm

Scoring blade arbor ........................................................................................................................ 20 mm

Scoring blade speed ..................................................................................................................6500 RPM

Sliding table carriage width ................................................................................................... 13” (330 mm)

Sliding table carriage stroke................................................................................................ 67” (1700 mm)

Rip capacity........................................................................................................................ 50” (1270 mm)

Main and scoring blade tilt ............................................................................................... 90 to 45 degrees

Main table size cast iron .....................................................................................37” x 20” (940 x 508 mm)

Right side extension table...................................................................................31” x 18” (790 x 460 mm)

Rear extension table size....................................................................................30” x 20” (760 x 500 mm)

Working table height............................................................................................................. 34” (860 mm)

Crosscut table size ........................................................................................... 42” x 20” (1060 x 510 mm)

Crosscut fence size with extension ................................................................................... 101” (2565 mm)

Mitre Fence length with flip stop, clamp................................................................................. 31” (790 mm)

Overall size .............................................................................. 122” x 54” x 93” (3100 x 1370 x 2360 mm)

Dust collection ports (two)....................................................................................................... 4” (100 mm)

Gross weight ............................................................................................................... 1,100 lbs. (500 kg.)

Net weight ...................................................................................................................... 902 lbs. (410 kg.)

The above specifications were current at the time this manual was published, but because of our policy of

continuous improvement, WMH Tool Group reserves the right to change specifications at any time and

without prior notice, without incurring obligations.

6

Page 7

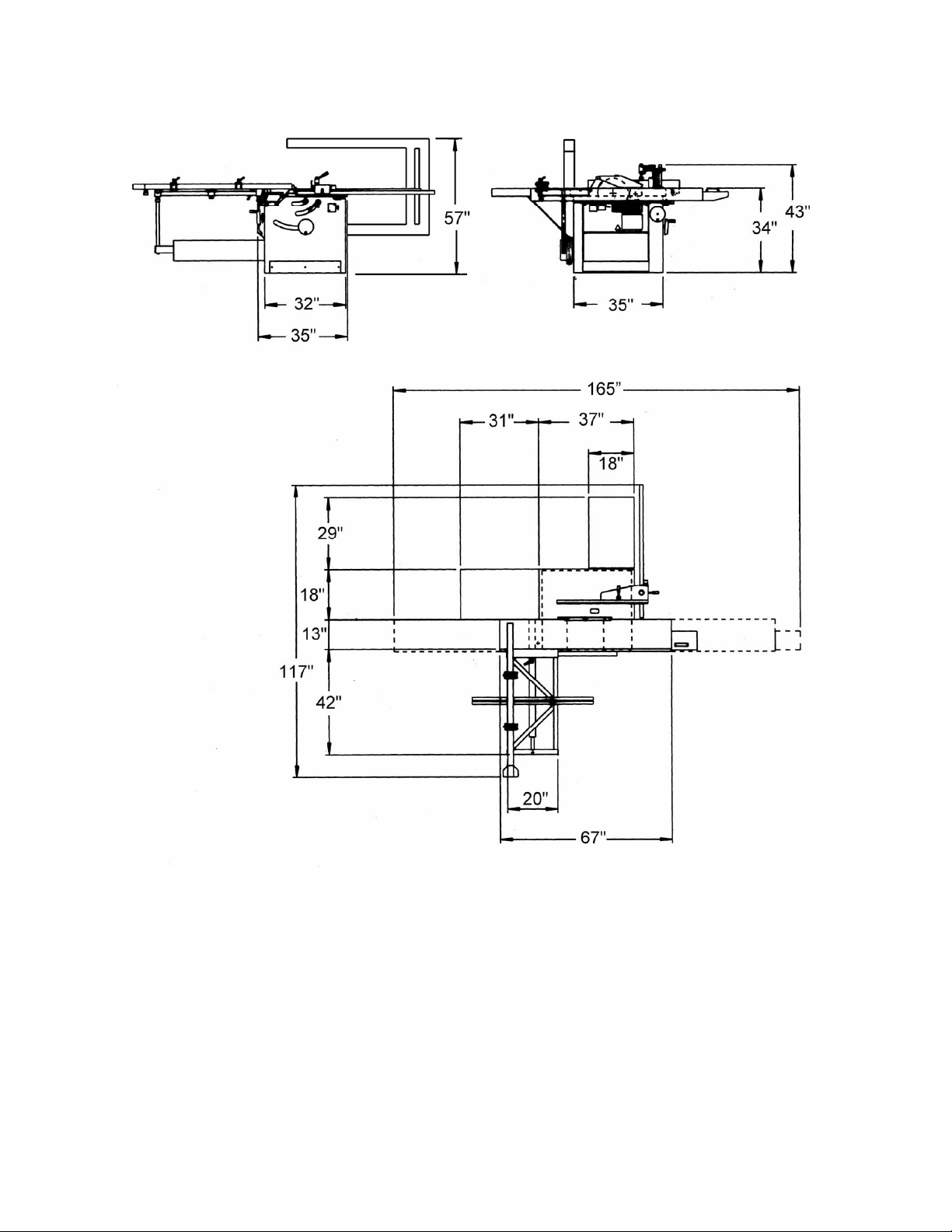

Machine Dimensions

Figure 1

7

Page 8

Unpacking

Remove crate from around machine and check

for shipping damage and ensure all parts are

intact. Report any damage immediately to your

distributor and shipping agent. Read the

instruction manual thoroughly for assembly,

alignment, maintenance and safety instructions.

Contents of crate:

1 panel saw

1 over arm

1 upper guard

2 blade guards

1 steel pin

1 crosscut table

1 mitre fence

1 arbor wrench

1 set hex wrenches

1 open-end wrench

2 extension tables

1 extension table leg

1 hardware bag

1 instruction manual

1 warranty card

Figure 2

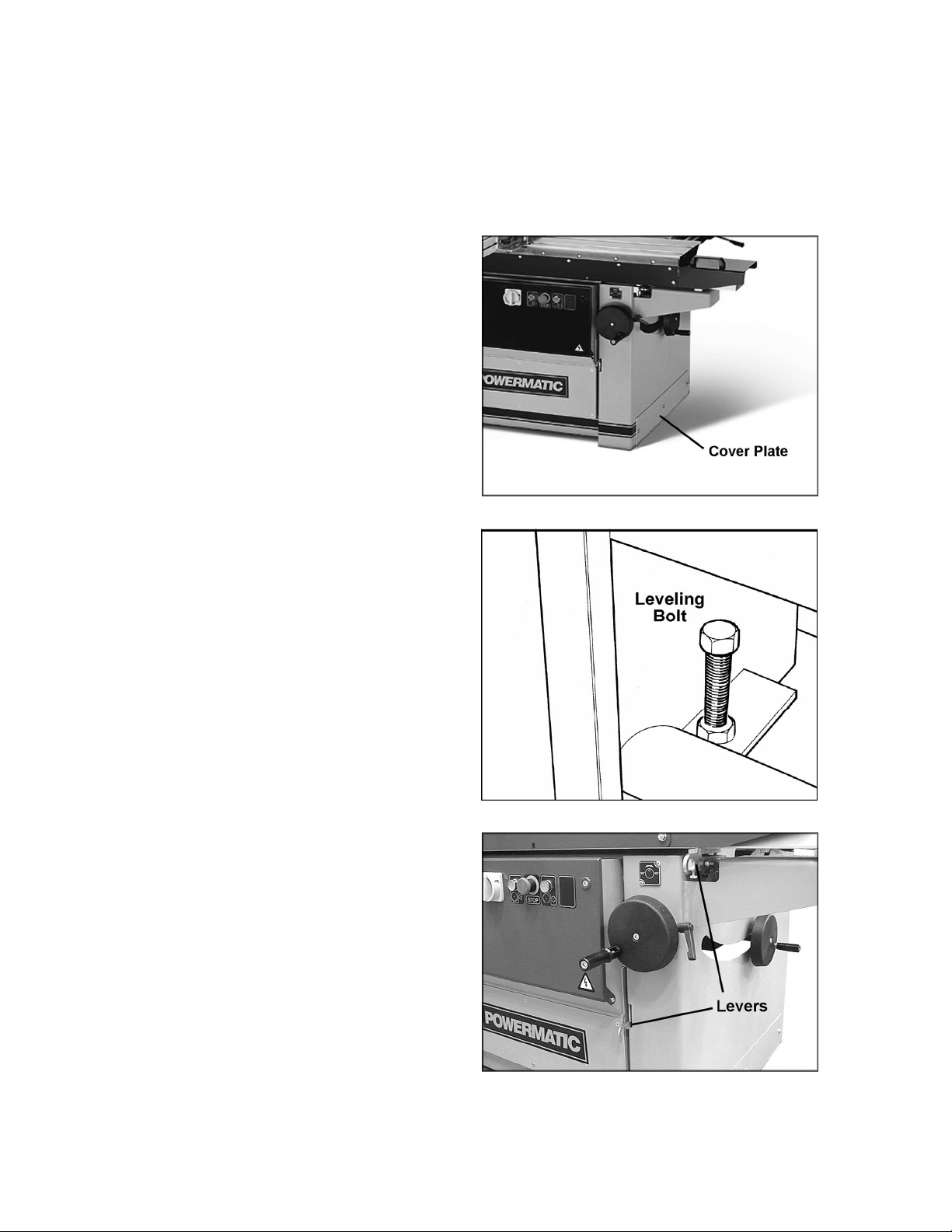

Installation and Assembly

(NOTE: Consult the parts breakdowns at the

back of this manual if further clarification of

assembly process is needed.)

1. Lift the machine off the pallet with crane or

forklift, using a hoist. When the machine is

sitting on the ground, it can be lifted by

removing the side cover plate (Figure 2) and

sliding forks through the two openings.

2. When the machine has been placed in the

intended location, it must be leveled to

ensure the smooth motion of the sliding

table. Use a level on top the table, and

adjust any of the four bolts in the corners of

the base (Figure 3) as necessary.

3. The support arm and sliding table have both

been locked for transportation. Release the

support arm by lifting the lower lever (Figure

4). Release the sliding table by pushing in

the upper lever (Figure 4).

Figure 3

Figure 4

8

Page 9

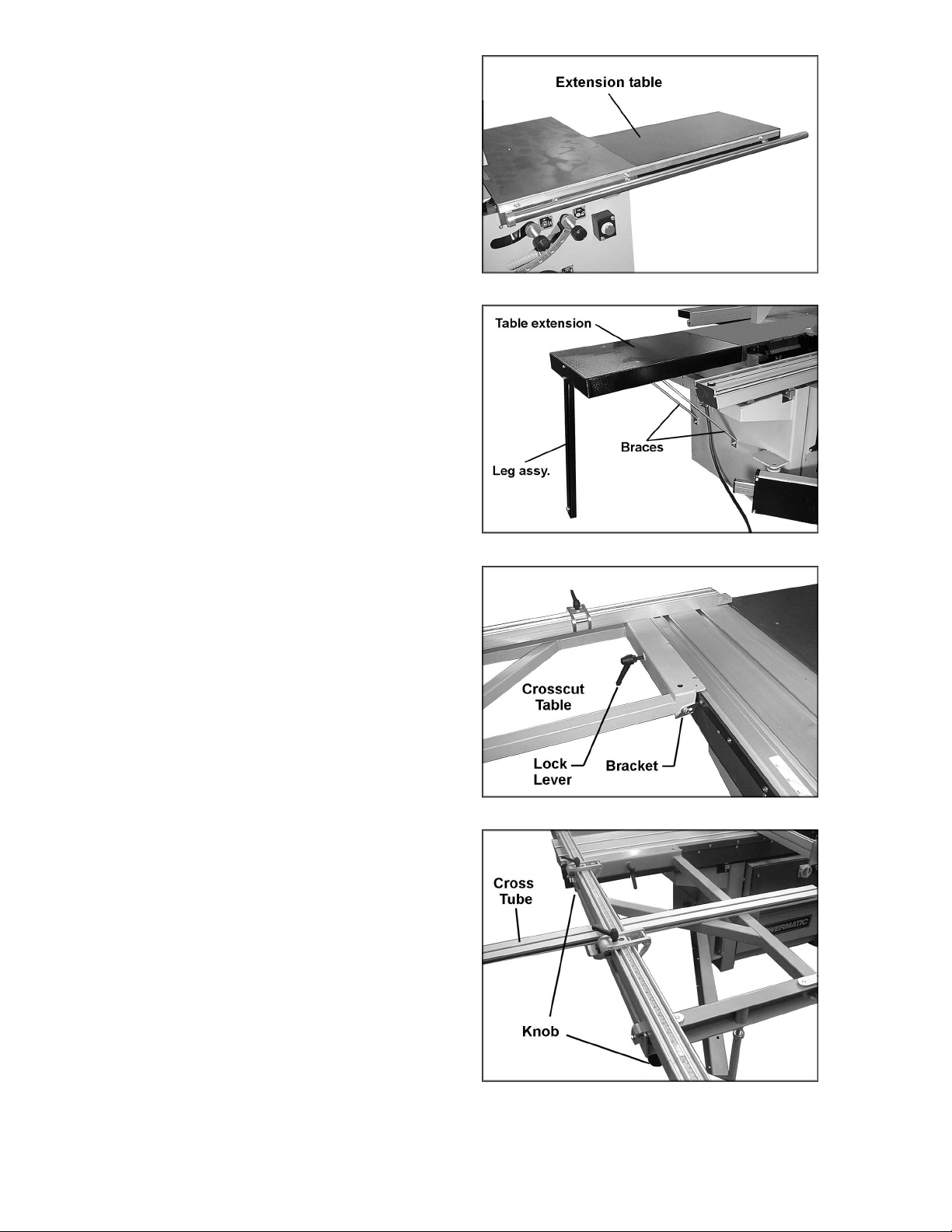

Installing Extension Tables

1. Mount the right extension tables to the edge

of the cast iron table (Figure 5) with two M8

x 25 cap screws and two M8 flat washers.

Do not tighten yet.

2. Level the extension table surface to that of

the cast iron table, then firmly tighten

screws.

3. Mount the left table extension (Figure 6)

with two M8 x 20 cap screws and two M8

flat washers to the cast iron table. Then

mount the top of the two braces (Figure 6)

to the table with two M6 flat screws, flat

washers and nuts. Mount the bottom of the

braces to the stand with two M8 x 20 cap

screws and two M8 lock washers. Do not

tighten yet.

4. Level the extension table surface to the cast

iron table, then firmly tighten all screws.

5. A leg assembly (Figure 6) is provided for the

outer edge of the extension table as shown.

The bottom end of the leg is adjustable for

leveling.

Figure 5

Figure 6

Installing Crosscut Table

1. Slide the crosscut table (Figure 7) onto the

sliding table from the left end. The rod

protruding up from the support arm should

slip into the hole on the bottom of the

crosscut table.

2. Position the two brackets (Figure 7) so that

the crosscut table will easily ride along the

flat bar on the front edge of the sliding table.

3. Tighten the lock lever to secure the table's

position.

Installing Crosscut Fence

1. The crosscut table has four holes allowing

the fence to be placed in two positions: at

the left or right of the crosscut table. Figure

8 shows the fence in the left set of holes.

2. Place the crosscut fence on to the crosscut

table and lock it in position with the knobs.

3. The cross tube is mounted to the crosscut

table as shown, and secured by two knobs

beneath.

Figure 7

Figure 8

9

Page 10

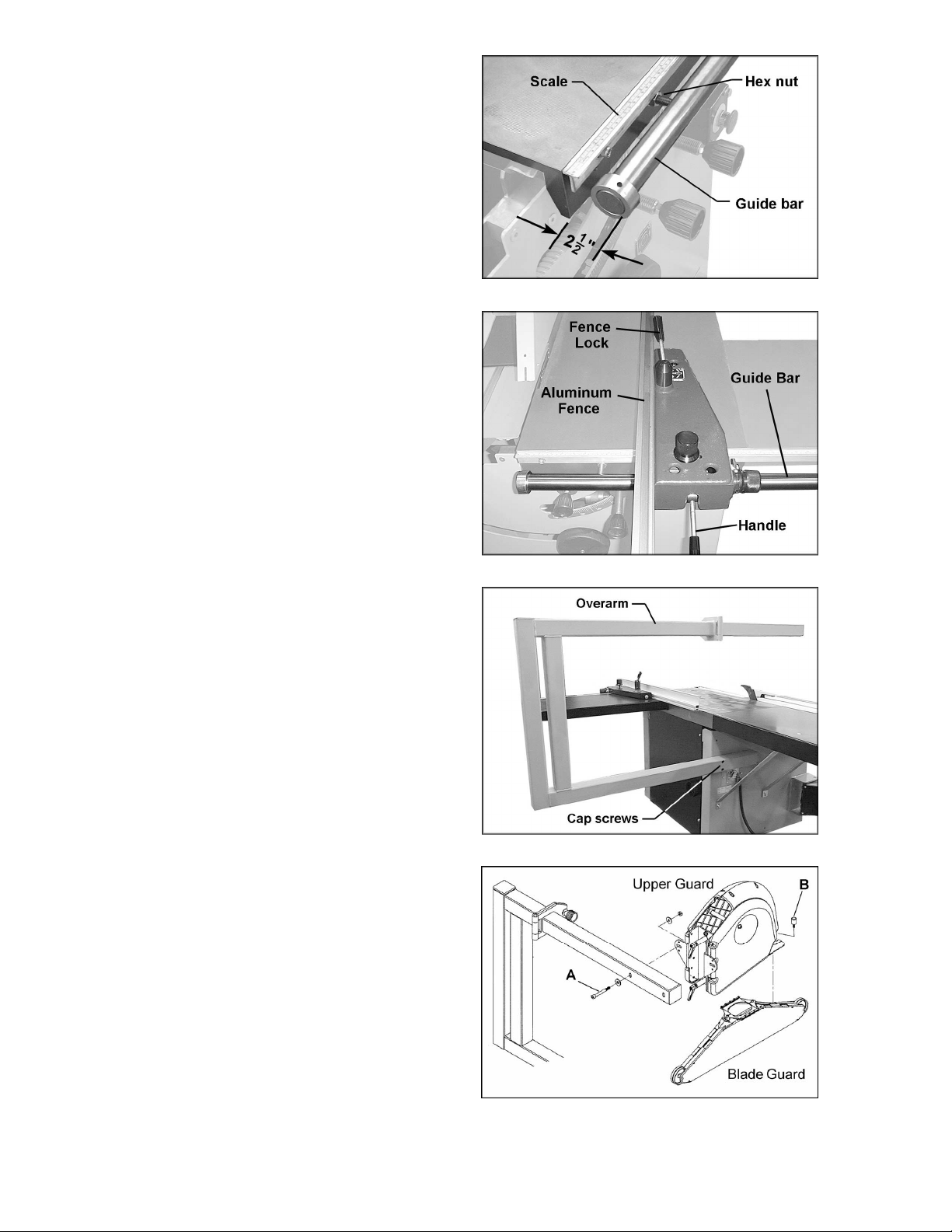

Installing Guide Bar

1. Mount the scale (Figure 9) to the edge of

the cast iron table with three M8 x 30 socket

head screws, M8 flat washers, and spacers.

2. Mount the cylindrical steel guide bar to the

edge of the cast iron table, using the four

M12 hex nuts and flat washers.

3. The outside edge of the bar along its entire

length should be approximately 2-1/2" from

the table, to allow for smooth movement of

the fence.

Installing Rip Fence

The rip fence assembly (Figure 10) has a cast

iron body with a sliding aluminum fence. Mount

the body by sliding it onto the end of the guide

bar while lifting the handle. Loosen the fence

lock and slide the aluminum fence onto the body

as shown.

Figure 9

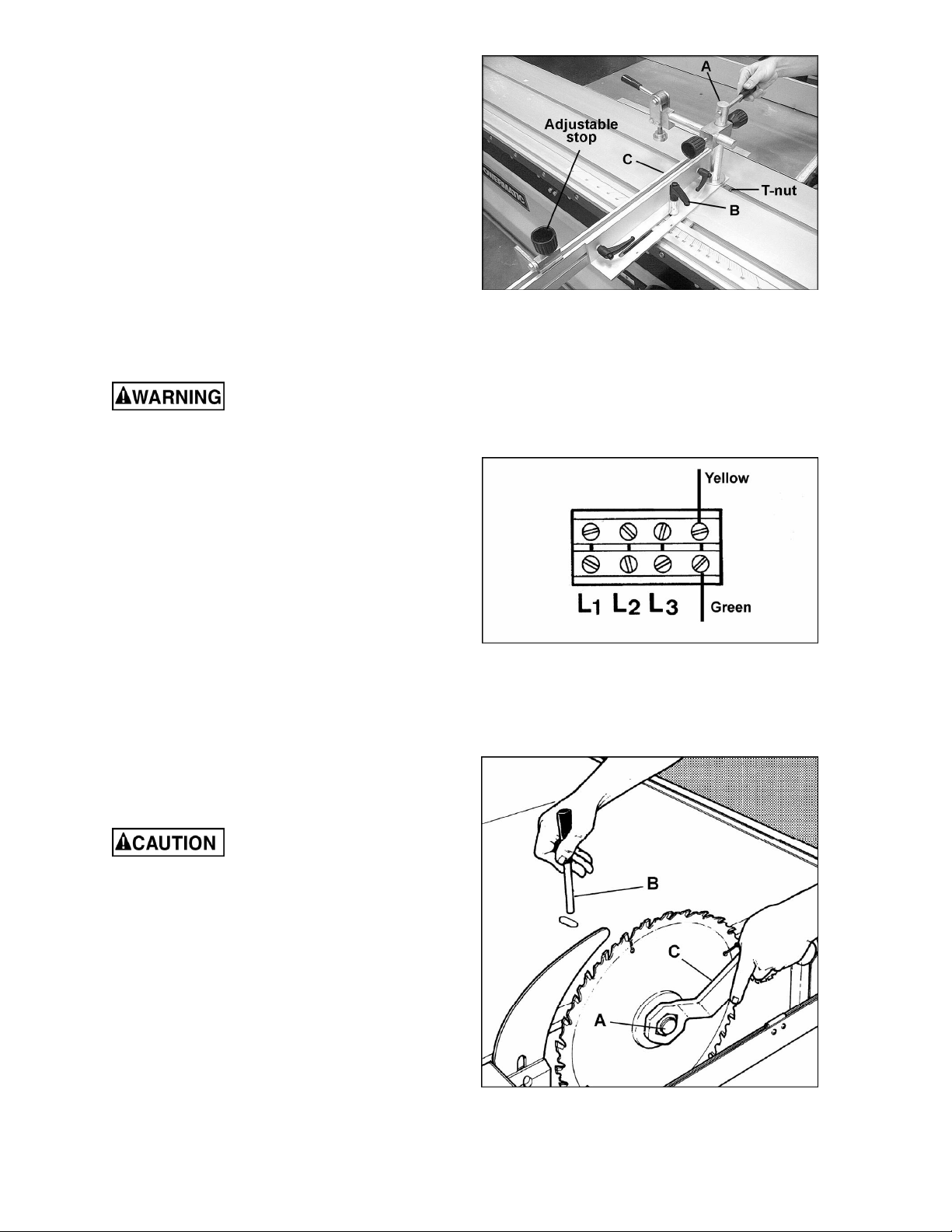

Installing Over Arm

Mount the over arm (Figure 11) with the four

M10 x 30 socket head cap screws, four M10 flat

washers and four M10 hex nuts to the holes on

the side of the frame. Tighten the screws and

nuts securely to the side of the frame.

Installing Blade Guard

Mount the upper guard assembly (Figure 12) to

the over arm with two M10x80 socket head cap

screws, two M10 flat washers, and an M10 hex

nut (A, Figure 12).

Install the blade guard using the bolt (B, Figure

12).

Figure 10

Figure 11

Figure 12

10

Page 11

Installing Miter Fence

Mount the miter fence assembly as shown in

Figure 13. Tighten the rod (A, Figure 13) with

the provided pin into the stationary T-nut.

NOTE: Do not move the stationary T-nut; it has

been calibrated with the angle scale.

Screw the large lock lever (B, Figure 13) down

into the other T-nut.

Loosen the small lock levers and slide the

aluminum fence (C, Figure 13) on to the

assembly as shown. The adjustable stop can be

mounted to the fence if desired for making

multiple cuts of the same length.

Figure 13

Electrical Connections

Electrical connections must

be performed by a qualified electrican. The

machine must be properly grounded to help

prevent electrical shock and possible death.

Check that the voltage of the machine

corresponds with the voltage of your power

supply.

Remove the electrical box cover and introduce

the cable. Connect the three wires to the

terminals L1, L2, L3 (Figure 14).

The green ground wire must be connected to

the yellow wire terminal.

Turn on the main saw motor [see "Starting the

Machine"] and check that the blade arbor

rotates clockwise (as viewed from front of

machine). If it does not, turn motor off,

disconnect from power source, and exchange

wires L1 and L2.

Figure 14

Installing/Replacing Main Blade

Use care when working

around sharp blades. Use only carbide

tipped saw blades, not High Speed Steel

blades.

1. Disconnect machine from power source.

2. Push sliding table all the way to the left, and

open blade cover.

3. Raise main saw blade to its highest position

and place spanner (C, Figure 15) over the

arbor nut (A, Figure 15).

4. Insert the locking pin (B, Figure 15) into the

hole on the saw table and turn the arbor

with the spanner until the locking pin

engages the hole in the saw arbor pulley.

Figure 15

11

Page 12

5. Unlock the nut (NOTE: Left hand threads –

loosen by turning clockwise).

6. Make sure the set screws in the adaptor are

set flush on the blade side. (They should

protrude to the rear to engage the arbor for

positive drive). See Figure 16. Clean the

mating surfaces, install new blade, and

tighten arbor nut securely.

7. Remove locking pin (B, Figure 15) and close

blade cover.

SAFETY TIP: Tape a red rag on the locking pin

and drape it over the blade while pin is inserted.

This will remind you to remove the pin before

starting the saw!

Installing/Replacing Scoring Blade

1. Disconnect machine from power source.

2. Push sliding table all the way to the left and

open blade cover.

3. Tilt scoring blade all the way, and place

spanner (A, Figure 17) on the flat of the

arbor.

4. Loosen the bolt with the hex wrench (B,

Figure 17). (NOTE: Right hand threads-turn

counterclockwise to loosen).

5. Mount scoring blade and re-tighten bolt.

Close blade cover.

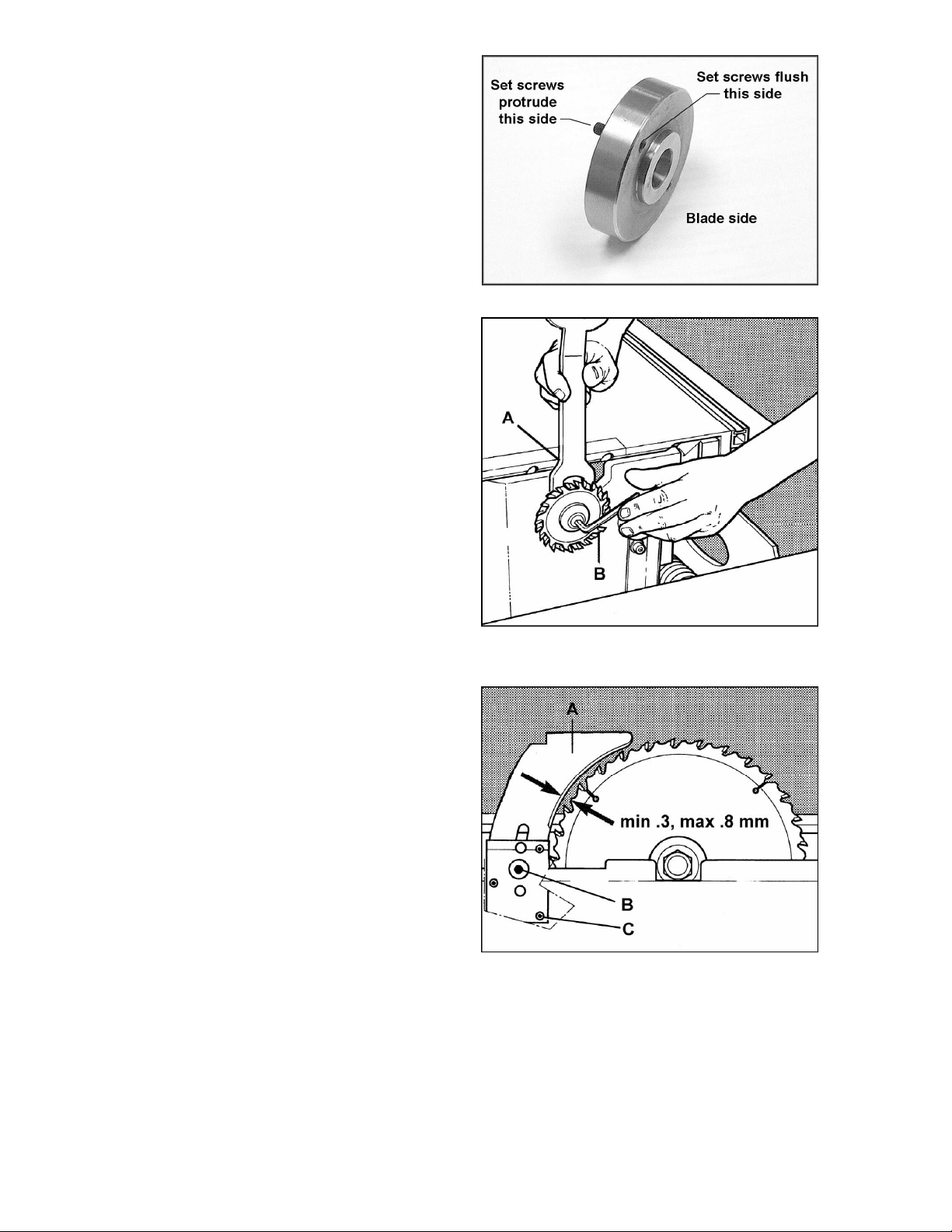

Riving Knife

The machine is equipped with a riving knife (A,

Figure 18) for use with saw blades up to 315mm

in diameter.

Figure 16

Figure 17

The purpose of the riving knife (or "splitter") is to

prevent the kerf from closing as it leaves the

cutting teeth, and thereby reduce the chance of

the kerf coming in contact with the up-running

teeth of the blade and causing binding or a

dangerous kickback. When the forward edge of

the workpiece reaches the riving knife, the knife

also helps guide the rest of the cut and will

prevent the up-running teeth from scoring the

workpiece.

The riving knife must be adjusted so that over its

entire length the gap between saw blade and

riving knife does not exceed 3 to 8mm.

The riving knife can be adjusted in both vertical

and horizontal directions. The highest point of

the riving knife should never exceed 3mm above

the highest placed saw blade tooth.

Use the central bolt (B, Figure 18) and the three

adjustment screws (C, Figure 18). After

adjustment, always lock the central bolt (B,

Figure 18).

Figure 18

12

Page 13

Do not remove the riving

knife for saw operations.

For slotting or grooving, the riving knife has to

be adjusted in such a way that the upper part of

the riving knife is never set lower than the

highest sawtooth in use.

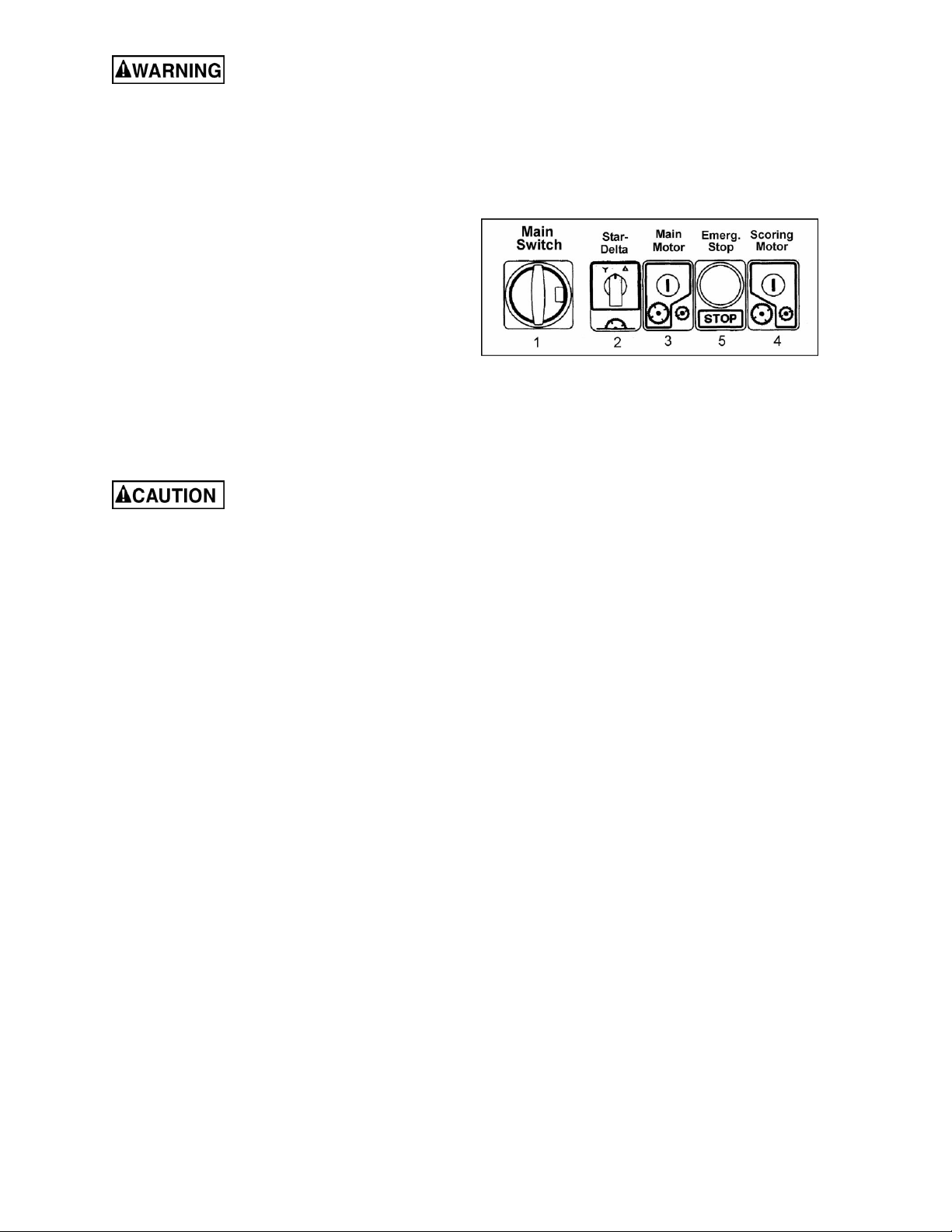

Starting the Machine

NOTE: The machine will not start if the blade

cover or the rear door is open.

When starting in Star-Delta mode, proceed as

follows (Figure 19):

1 – Turn Main Switch to position "I".

2 – Turn Star-Delta switch into star position "Y".

3 – Push Main Motor start button.

2 – After five seconds, put Star-Delta switch into

delta position "∆".

This five second delay is

necessary for the motor to gain full speed

before switching to delta. If you forget to

switch to delta, the motor will operate at full

speed but without power, and the motor may

become damaged.

4 – Push Scoring Motor start button (main motor

must be running).

5 – Emergency stop button halts both main and

scoring motors.

The main motor is equipped with an automatic

brake which stops the motor within 10 seconds

after the machine is shut off.

Fuses are located inside the electrical control

panel. The machine must be disconnected from

power supply when opening this panel.

This machine has overload protection on both

main and scoring motors. Should the motor be

shut off by one of these protectors, wait a few

minutes until the overload has cooled down

before restarting.

Figure 19

Dust Collection

It is strongly recommended that a dust collection

system be connected to the HPS67. The dust

collector should have sufficient capacity for this

size machine. Both the outlet on the blade guard

and on the machine base should be connected

to the dust collection system.

13

Page 14

Adjustments

Sliding Table Parallel to Blade

The position of the sliding table relative to the

machine is factory set, but should be checked

periodically as the saw receives use. To ensure

a clean cut, the sliding table must be set parallel

to the saw blade. If adjustment is ever needed,

proceed as follows:

1. The bolts (B, Figure 20) are used to adjust

the height of the sliding table. They are preset at the factory.

2. Use bolts (A, Figure 20) to correct

parallelism between sliding table and saw

blade.

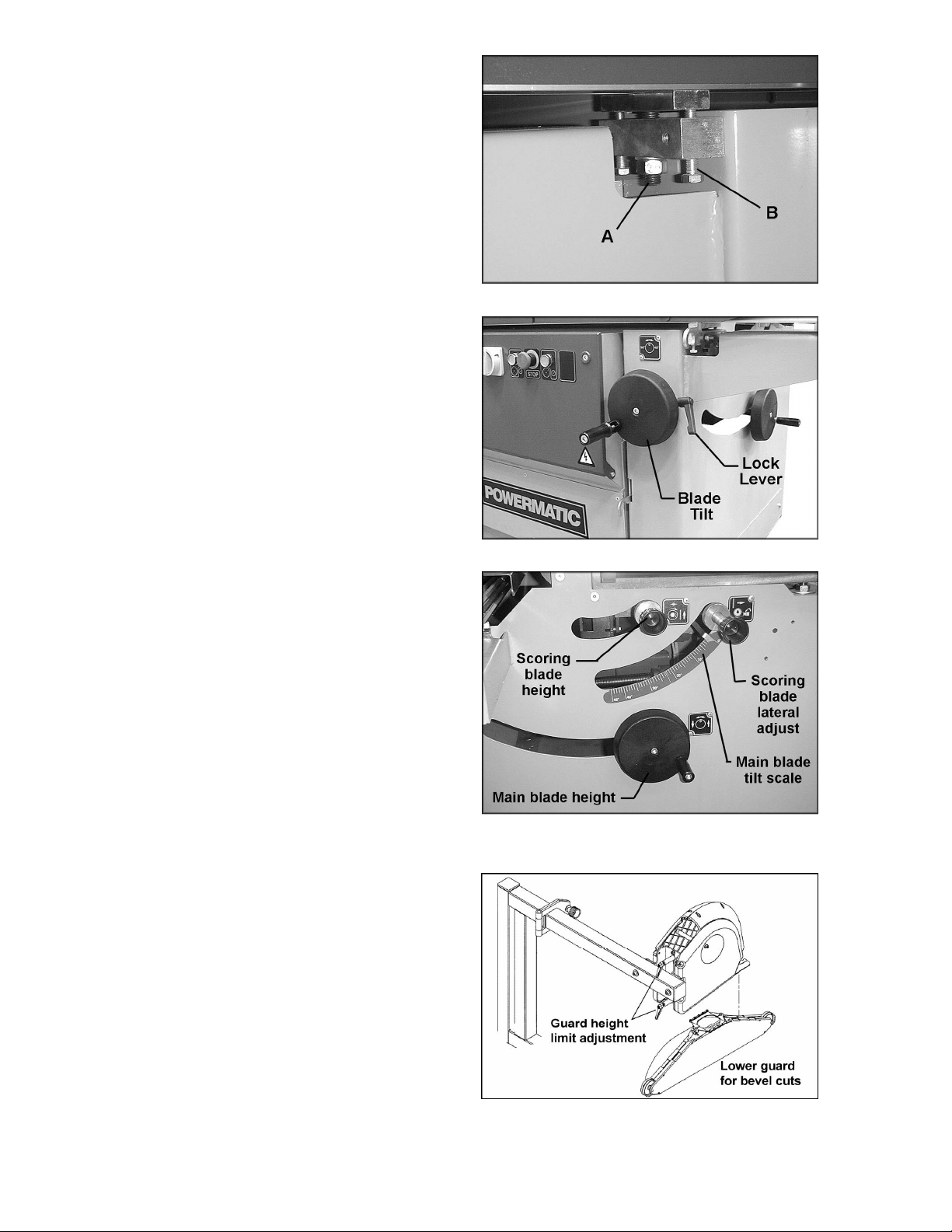

Setting Main Blade (Figures 21 and 22)

Adjust the height of the saw blade with the

handwheel on the side of the machine. One turn

of the handwheel raises or lowers the blade by

2.5mm.

The blade is tilted by using the front handwheel.

The blade can be tilted at any angle between 90

and 45 degrees. After setting, lock the blade in

this position with the lock lever. The blade angle

can be read on the tilt scale.

NOTE: The 90 and 45 degree stops are pre-set

at the factory and should require no adjustment.

After setting the main blade at the desired

cutting angle, the cutting depth of the scoring

blade must be re-set.

Setting Scoring Blade

Figure 20

Figure 21

Turn the scoring blade height knob (Figure 22).

One turn raises or lowers the scoring blade by 3

mm.

Each time the main saw blade is resharpened or

replaced, the scoring blade must be adjusted

laterally to match the main blade teeth. This

must be done to ensure a clean cut free of

splintering. Lateral movement is obtained by

turning the lateral adjustment knob (Figure 22),

then locking it at the desired setting.

Setting Blade Guard

The two handles (Figure 23) are for setting the

guard height limits. Loosen a handle and slide

the bracket as needed. Both handles on the

guard should be tightened securely before

operating the panel saw.

When the arbor is tilted for a bevel cut, mount

the alternate lower guard with the convex back

(Figure 23).

Figure 22

Figure 23

14

Page 15

When bevel cutting, make

sure the appropriate blade guard has been

mounted before operating the saw.

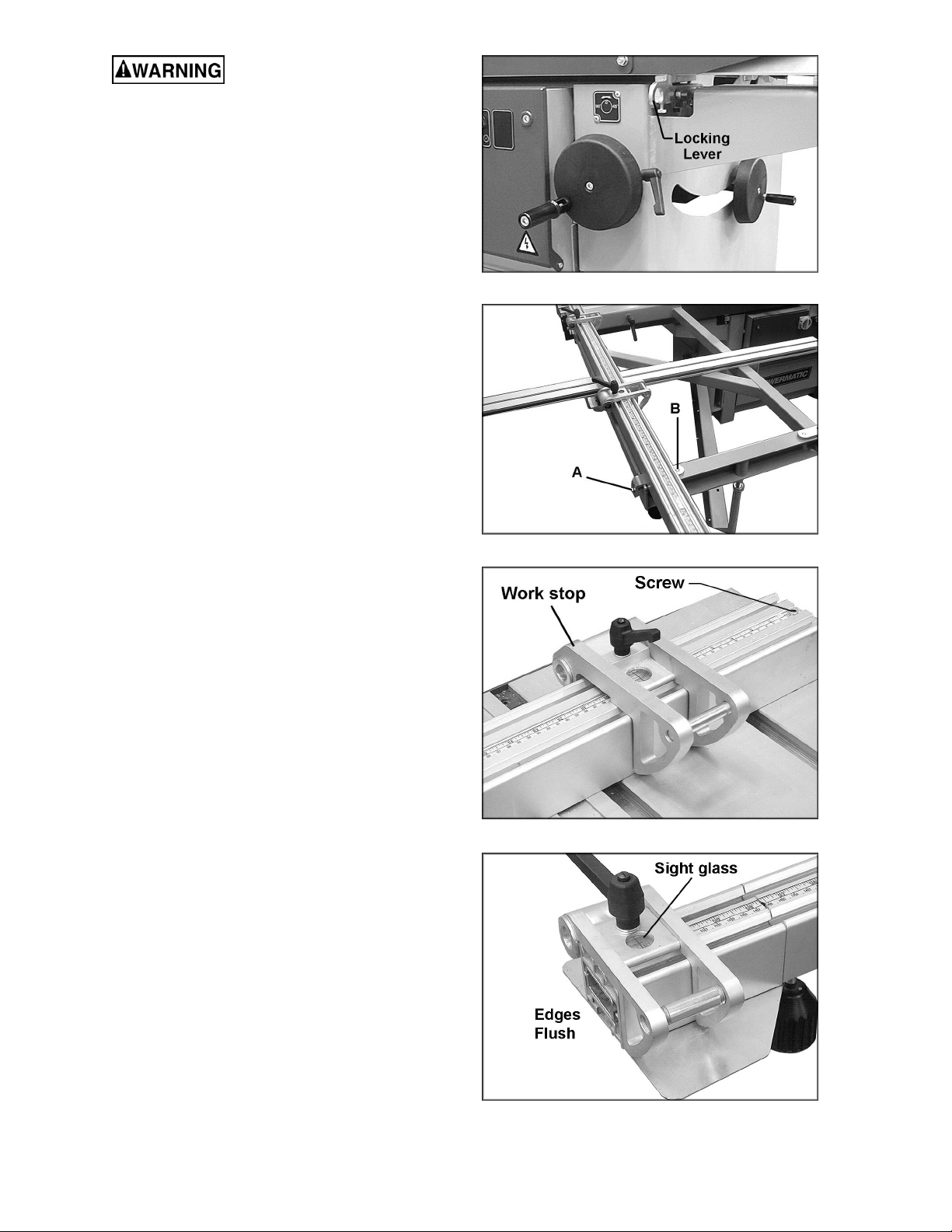

Sliding Table Lock

When loading panels and when cutting using the

rip fence, the sliding table should be locked.

To lock the sliding table, pull lever (Figure 24)

into one of the slots in the sliding table.

Over a long period of time, if many short

movements of the sliding table are made (e.g.

crosscutting solid wood) then it is possible that

the ball carrier between the upper and lower part

of the sliding table will move. This means it will

no longer be correctly positioned to allow the

sliding table to slide through its full course. The

operator will feel resistance in the sliding table

motion and the full stroke will not be achieved.

This effect can be corrected simply by pushing

the table with a few short, light pushes against

the buffer stop at the end, until the position of

the ball carrier is adjusted and the table can be

moved again along its full stroke.

Figure 24

Crosscut Fence

The 90-degree angle of the fence is factory set.

However, should adjustment ever be needed,

proceed as follows:

1. Loosen the two bolts (A, Figure 25).

2. Turn bolt (B, Figure 25) to open or close the

angle of the fence in relation to the saw

blade.

3. Re-tighten bolts (A, Figure 25).

Before using the first time, and each time a new

blade is installed, the scales must be calibrated.

Proceed as follows:

1. Put the stop (Figure 26) at a certain

measure and cut off a sample.

2. Measure the exact length of the sample.

Loosen the screw (Figure 26) which holds

the scale and move the scale until the

measurement corresponds to the length of

the previously cut sample. The main part of

the fence is now calibrated to the saw blade.

3. The scale on the telescopic extension of the

fence should now be checked and adjusted.

Move the other stop to the outermost edge

of the extension fence until the edge of the

stop is flush with the edge of the fence

(Figure 27). Lock the stop in position by

tightening the handle.

NOTE: DO NOT loosen the stop until the

adjustment procedure has been completed.

Figure 25

Figure 26

Figure 27

15

Page 16

4. Record the measurement in the sight glass.

5. Add 2” to this measurement and slide out

the extension until the new measurement is

read at the end of the fixed fence (Figure

28). NOTE: Be careful to set this correctly,

because the scale on the sliding fence

reads opposite the scale on the fixed fence.

6. Lock the extension fence to this new

measurement by tightening the knob

underneath.

7. With a 3mm hex wrench, loosen the set

screws underneath the short movable fence

extrusion (Figure 29), and slide the

extrusion to 2” of the fixed fence (Figure 30).

Tighten the set screws.

8. When using the telescopic extension, make

sure the stop is positioned flush with the end

of the movable extrusion.

9. The best way to check if all scales

correspond is to make several test cuts on

the different scales.

Figure 28

Wood Cap

After a period of use, if the wood protection cap

at the end of the crosscut fence is cut away, a

new one must be made. See Figure 31 for the

correct dimensions.

Figure 29

Figure 30

Figure 31

16

Page 17

Miter Fence

The flat T-nut which holds the vertical rod of the

clamp is factory set and must remain in its

position to make the angle scale correspond.

1. To set the required angle, loosen the rod (A,

Figure 32) with the provided pin as shown.

Loosen the large lever (B, Figure 32).

2. To slide the fence (C, Figure 32) toward or

away from the saw blade, unlock the two

smaller levers.

3. Reading the angle is done at the edge of the

aluminum bracket. An adjustable stop can

be mounted to the miter fence as shown in

Figure 32, for making multiple cuts of the

same length.

Rip Fence

1. To move the rip fence, shown in Figure 33,

turn the micro-adjust gear counterclockwise,

and lift the handle. The fence should slide

freely on the guide bar.

2. To lock the fence in position, push the

handle down and tighten the micro-adjust

gear by turning it clockwise.

3. Micro-adjustment is achieved by locking the

micro-adjust gear, by holding the handle in

the upright position, and by turning the

micro-adjust knob.

Figure 32

Figure 33

4. After adjustment, push handle down to lock

the fence in place.

NOTE: When cutting small workpieces with the

saw blade tilted at 45 degrees, the aluminum rip

fence should be used in the low position:

1. Loosen the aluminum fence lock, slide the

fence off and slide it back on in the low

position, as shown in Figure 34.

2. Tighten the aluminum fence lock.

When cutting solid wood using the rip fence, to

avoid the wood getting stuck between the fence

and riving knife (which can result in a dangerous

kickback) reposition the aluminum fence so that

its end protrudes just past the end of the riving

knife.

Rip Fence Scale Calibration

Each time a new blade is mounted, the rip fence

scale has to be calibrated to the new blade.

Figure 34

With the fence at a convenient spot, cut a

sample and measure its exact width.

17

Page 18

Loosen the three screws on the scale (Figure

35) and nudge the scale until it matches the cut

measurement. Make another cut to confirm the

measurement.

To avoid the fence contacting the rotating saw

blade, the stop ring must be adjusted.

Slide the fence to about 10mm from the saw

blade.

Slide the stop ring across the round guide bar

until it comes up against the casting of the

fence. Tighten the set screw on the stop ring.

Tensioning the Belt

To tension the belt on the main motor:

1. Remove the access door and loosen the

four bolts (Figure 36) which hold the motor.

2. Tension the belt by pushing the motor to the

right, and tighten the four bolts.

Make sure the belt is not

over-tensioned as this may lead to damage

to the saw arbor and belt.

Figure 35

To tension the belt on the scoring motor:

1. Loosen the two nuts (Figure 37) which hold

the scoring motor.

2. While pushing the motor down, tighten the

two nuts.

When replacing belts on the main or scoring

motor, make sure the belt is well positioned into

the v-groove of the pulley.

Precision Tuning Your Panel Saw

Your HPS67 is a precision machine designed to

give accurate performance over many years.

But like all fine equipment, it can only meet the

tight tolerances required if it is tuned correctly.

Your machine has been so designed that all the

major parameters which influence the quality of

cut can be adjusted by non-technical staff.

These tuning procedures should be carried out

in the proper order, as later adjustments depend

upon the earlier being correct.

The four steps of the procedure are:

1. Free Cut from blade to sliding table

2. Free Cut from blade to rip fence

3. Square Cut

4. Scoring Saw

Figure 36

Figure 37

18

Page 19

Free Cut (Blade to Sliding Table)

The sliding table does not run exactly parallel to

the saw blade. It runs away from the back teeth

by a fraction of a millimeter. This is called "free

cut."

A very slight amount of free cut is desirable to

avoid the problems of back cutting due to saw

blade flutter. All saw blades vibrate to some

extent. They flutter less at the front, where the

cutting teeth are held stable by the material,

than at the back.

If the table were set absolutely parallel to the

saw blade, the back teeth could contact the

material and spoil the clean cut achieved by the

front teeth. As the back teeth are ascending,

they could cause chip out on the top surface of

laminated boards.

The free cut required is less than .05 mm over

one meter of travel.

A dial indicator is not required. You can use your

ears to compare the noise of the front teeth with

that of the back teeth. To do this will require a

workpiece shorter than the distance between

front and back teeth. The saw blade should be

raised to its maximum height to achieve the

most contrast.

1. Lay the workpiece against the crosscut

fence and make a cut.

2. Hold the workpiece firmly after the front

teeth have cut and push it on past the back

teeth. As you pass the back teeth you

should feel rather than hear a slight tingling

or whisper. If there is no sound from the

back teeth, you probably have too much

("positive") free cut. If the noise from the

back teeth is similar to that of the front teeth,

there is too little ("negative") free cut and the

table is running in towards the back of the

blade.

3. Having passed the back teeth, stop level

with the riving knife and cut backwards. The

back teeth will make a noise as they are

now cutting the material.

The workpiece must be held

down firmly when making this backward cut.

4. As you continue past the front teeth, the

noise from the front teeth should be equal to

or slightly less than the noise from the back

teeth. Slight back cutting on the backstroke

equals slight free cut on the forward stroke.

5. If the front teeth make more noise than the

back, the free cut is positive; if they make no

noise, the free cut is negative. If the noise

relationship front teeth to back teeth on the

forward stroke is the same as the noise

relationship back teeth to front teeth on the

back stroke (on a scale of 100, 100/30 in

each case), the sliding table is running

exactly parallel to the blade (zero free cut).

To correct the free cut, one end of the sliding

table must be moved outward or inward. It

doesn't matter whether you move the left or the

right end. The only consideration is that there is

enough clearance between the sliding table and

the fixed cast iron table at the end you are

moving.

1. At the end you have decided to move,

loosen the hex nut (A, Figure 38) holding the

sliding table to the frame.

Figure 38

2. Loosen the other two hex nuts in the middle

of the sliding table so that the table will pivot

at the remaining fixed end.

3. Move the table end in or out as needed then

retighten the table mounting nuts.

4. Check again to confirm the free cut is

satisfactory. Repeat the process if needed.

NOTE: The sliding table should be

approximately 0.3 mm higher than the fixed cast

iron table (thickness of a piece of paper). This is

pre-set at the factory, but if adjustment should

ever be needed, use the four height adjustment

bolts (Figure 38) on each end of the table.

Trouble-shooting Free Cut

(Blade to Sliding Table):

Symptoms of positive free cut:

Back cutting on rip fence side. Workpiece on

cast iron table pulled into back of sawblade.

Chip out on top.

Machine cutting out of square. Workpiece

moves slightly on sliding table due to pressure of

saw blade, without operator noticing.

19

Page 20

Scoring saw correctly aligned for sliding table is

out of alignment on rip fence side and viceversa.

Chip out on the bottom as alignment of scoring

saw with main blade inconsistent due to

movement of workpiece.

Symptoms of negative free cut:

Back cutting on sliding table side. Workpiece

runs into back of saw blade. Chip out on top.

Machine cutting out of square. Workpiece

moves slightly on sliding table due to pressure of

saw blade, without operator noticing.

Chip out on the bottom as alignment of scoring

saw with main blade inconsistent due to

movement of workpiece.

NOTE: The above test depends upon the riving

knife being properly in line with the blade.

Free Cut (Blade to Rip Fence)

If the free cut on the rip fence side is negative,

the symptoms are fairly obvious. The workpiece

gets stuck between the back teeth and the fence

and, in the worst case gets kicked back.

into the saw blade for half the direction

which the back teeth just cut. The width here

will correspond to the distance between the

front teeth and the fence.

Between the teeth marks from the back teeth

and front teeth there will be a small ridge. The

height of this ridge is the free cut over the length

of the saw blade. This ridge should hardly be

visible, but just possible to feel.

To correct the free cut:

Loosen the nuts on the outside (third) bolt

holding the guide bar on which the rip fence

slides. See Figure 39.

If the free cut is positive, other problems arise

which are not so easily recognized, as for

example, an incorrect rip fence setting. The

following procedure will help you compare the

distance between front teeth and rip fence with

the distance between back teeth and rip fence:

1. Lower scoring blade all the way down, and

out of the way.

2. Raise main blade to its highest position.

3. Take a workpiece of convenient size (e.g.

12" x 18") and edge one long side using the

sliding table.

4. Set the rip fence slightly narrower than the

workpiece, and cut the opposite long side of

the workpiece using the fence.

5. Stop the workpiece when the trailing edge is

level with the riving knife (i.e. has passed

the back teeth.)

6. Using the rip fence micro adjustment, move

the rip fence 1/4 turn inward, and pull

workpiece backward almost to sawblade

middle. The back teeth will then cut, and

where they have cut, the workpiece width

will correspond to the distance between the

back teeth and the rip fence.

7. Remove workpiece in normal cutting

direction.

8. Flip the workpiece over so that the trailing

edge becomes the leading edge and feed

Figure 39

Move the bar, and therefore the fence, in or out

by pivoting it upon the second bolt.

When corrected, tighten outside (third) bolt.

Trouble-shooting Free Cut

(Blade to Rip Fence)

Symptoms of negative free cut:

Workpiece gets jammed between fence and

back of saw blade, danger of kickback.

Backcutting, top chip out to the right of blade.

Symptoms of positive free cut:

Backcutting to the left of saw blade. Workpiece

on left is pulled into back teeth. Chip out on top.

Scoring saw, while correctly aligned on sliding

table side, is out of alignment for ripping.

When the rip fence section is in a pulled back

position, the actual width cut is less than that

shown on the scale.

NOTE: The above check depends on the riving

knife being in line with the blade, not bent,

narrower than the tooth kerf and wider than the

body of the blade.

20

Page 21

Square Cut

1. Take a panel approximately 40" and cut five

times round, always turning the cut edge up

against the crosscut fence (counterclockwise with crosscut fence in normal

position). The fifth cut cuts the same edge

as the first.

2. The last offcut strip (whose left side was the

last cut and whose right side was the first

cut) must be the same width at both ends if

every corner was precisely 90 degrees. Any

error in the squareness has been multiplied

four times.

3. Break the strip and lay the ends side by side

and check the difference. (Break the strip in

such a way that you know afterward which

was front and which was back; e.g. front bit

short, back bit long).

Unlike other methods of checking for

squareness, this system tells you which way to

move the fence should adjustment be

necessary. It depends upon the shape of the

fifth offcut strip:

If front thick, back thin – move fence counterclockwise.

If front thin, back thick – move fence clockwise.

1. The crosscut fence position is adjusted at

the outer attachment point only. Loosen the

clamping device on the bottom of the

crosscut fence.

2. Loosen the adjust the cross cut fence

bracket on the top surface of the table.

3. Re-tighten the cross cut fence clamp device.

4. Perform another test to check the setting.

NOTE: An incorrect free cut on the sliding table

can affect the squaring; see "Free Cut (Blade to

Rip Fence)"

Thus, the scorer and the main blade are slightly

out of alignment with regard to the tilt axis.

As the blades are tilted to 45 degrees, this

misalignment in the horizontal plane also

becomes a misalignment in the vertical plane.

The scorer must, therefore, be "raised" (moved

to the left) or "lowered" (moved to the right)

depending on whether the free cut on the sliding

table, or the rip fence, needs to be compensated

for.

The free cut can influence the scoring cut; it is

essential to carry out the first two free-cut tests

mentioned above before adjusting the scoring

blade.

Operation

The panel saw is designed for the following work

and is equipped with safety devices for these

particular procedures. It is not designed to work

materials such as ferrous or non-ferrous metals.

Available procedures:

• Ripping with the parallel saw fence with or

without the saw blade tilted and the fence

upright or in the low position.

• Right-angled or mitre cuts with the 90

degree fence mounted to the sliding table

with tilted or vertical saw blade.

• Crosscutting workpieces using the

adjustable stop on the 90 degree fence.

• Cutting panels or solid wood on the sliding

table.

The machine has overload protection on both

main and scoring motors. Should the motor be

shut off by one of these protectors, it is

necessary to wait a few minutes until the

overload has cooled down before restarting.

Scoring Blade

The scoring blade should penetrate the material

about 2mm.

Problems with the alignment of the scoring blade

can normally be traced back to too much free

cut. For this reason, the free cut must be

checked for correctness before the scoring saw

is adjusted.

For example, when the main blade is tilted to 45

degrees, the scoring blade may need to be

readjusted sideways.

The tilt axis is independent of the free cut on the

sliding table rip fence. The scorer alignment at

90 degrees takes the free cut into account.

21

Page 22

Maintenance

NOTE: All bearings in the machine are selfsealed and require no lubrication.

The sliding table should be cleaned once a

week, and all sawdust and chips removed.

From both sides of the sliding table, blow out

the dust which has accumulated between the

two sections and on the ball carrier. This can be

done more efficiently when the upper part of the

sliding table is slid to the rear. Then repeat the

process when the upper part is slid to the front

end.

Remove any resin deposits on sliding table and

other surfaces.

After blowing out the dust, spray a thin oil onto

the steel rods (Figure 40) on both the upper and

lower part of the sliding table. Never use a thick

oil or grease!

Lubricate all moving parts with a light coating of

oil.

Blow sawdust out of the cooling fan and motor.

Figure 40

22

Page 23

Troubleshooting

Trouble Probable Cause Remedy

Access door open. Close door completely.

Machine will not start

when start button is

pushed.

Excessive vibration.

Cuts out-of-square

when crosscutting.

Motor stalls or

workpiece binds or

burns.

No power; possible shortage. Check power source.

Star-delta switch in wrong position. Switch must be on “Y” position.

Main switch off. Put main switch on “1”.

Tilt or raising lock knobs not tight. Tighten knobs.

Blade out of balance. Have it balanced or replaced.

Worn or damaged belt. Replace belt.

Bad motor. Replace motor.

Fence misaligned. Reset fence angle.

Table not aligned with blade arbor. Realign table.

Excessive feed. Reduce feed.

Dull or incorrect blade. Replace blade.

Bad motor. Replace motor.

Fence misaligned. Realign fence.

Lock knob not released. Loosen lock knob.

Tilt or saw raising

handwheels difficult

to turn.

After starting, arbor

won’t turn and motor

makes straining

noises.

Motor overheats.

Thermal overload.

Motor starts slowly or

fails to come up to full

speed.

Worm and worm gear segment caked

with sawdust and pitch.

Worm and worm gear segment out of

alignment.

Pin not removed from arbor hole after

changing blade.

Motor overloaded.

Improper cooling of motor.

Overload not set on automatic reset,

or overload is faulty.

Low voltage.

Start switch malfunction. Replace switch.

Clean and re-grease.

Realign worm and worm gear

segment.

Remove pin.

Correct overload condition such as

reducing feed rate.

Clean sawdust from fan and duct

areas of motor.

Contact service technician.

Request voltage check from power

company and correct low voltage

condition.

Bad motor. Replace motor.

23

Page 24

Trouble Probable Cause Remedy

Reduction of speed

during cutting.

Motor fails to develop

full power.

Belt tension incorrect. Properly tension belt.

Motor overload due to incorrect feed

rate.

Dull blade(s). Resharpen or replace.

Power line overloaded. Correct overload condition.

Undersize wires in supply system. Increase supply wire size.

Low voltage.

Bad motor. Replace motor.

Optional Accessories

6080152 Saw Blade, 120mm/24T, 20mm Bore

6080153 Saw Blade, 12”/72T, 30mm Bore

HPS67-159 Dado Bushing 1”

Reduce feed rate.

Request voltage check from power

company and correct condition.

Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call

1-800-274-6848 between 7:30 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve you quickly and

accurately.

24

Page 25

Parts List: Motor and Arbor Assembly

Index No. Part No. Description Size Qty

1............... HPS67-101..............Collar .................................................................................................... 1

2............... HPS67-102..............Arbor Shaft............................................................................................ 1

3............... HPS67-103..............Shaft ..................................................................................................... 1

4............... HPS67-104..............Bushing................................................................................................. 1

5............... HPS67-105..............Retainer Ring ........................................................................................ 1

6............... HPS67-106..............Bracket.................................................................................................. 1

7............... HPS67-107..............Retainer Block....................................................................................... 1

8............... HPS67-108..............Spacer...................................................................................................1

9............... HPS67-109..............Sleeve................................................................................................... 1

10............. HPS67-110 ..............Motor Base............................................................................................ 1

11............. HPS67-111 ..............Flange Washer ...................................................................................... 1

12............. HPS67-112 ..............V-Belt .................................................................................................... 2

13............. HPS67-113 ..............Arbor Pulley........................................................................................... 1

14............. HPS67-114 ..............Shaft ..................................................................................................... 1

15............. HPS67-115 ..............Hose Clamp .......................................................................................... 3

16............. HPS67-116 ..............Riving Knife Holder Plate....................................................................... 1

17............. HPS67-117 ..............Spacer...................................................................................................1

18............. HPS67-118 ..............Strap Bracket.........................................................................................1

19............. HPS67-119 ..............Flange Nut Height Adjustment ............................................................... 2

20............. HPS67-120 ..............Spacer...................................................................................................2

21............. HPS67-121 ..............spacer ................................................................................................... 1

22............. HPS67-122 ..............Nut Inclination........................................................................................ 2

23............. HPS67-123 ..............Motor Pulley.......................................................................................... 1

24............. HPS67-124 ..............Bracket.................................................................................................. 1

25............. HPS67-125 ..............Bracket.................................................................................................. 1

26............. HPS67-126 ..............Riving Knife .......................................................250/300 ...................... 1

27............. HPS67-127 ..............Bracket.................................................................................................. 1

31............. ----------------..............Saw Blade (not included) ....................................................................... 1

32............. HPS67-132 ..............Spring....................................................................................................1

33............. HPS67-133 ..............Handwheel ............................................................................................ 1

34............. HPS67-134 ..............Pin......................................................................Φ 4 x 24mm................ 1

35............. HPS67-135 ..............Handwheel Mouting Handle ................................................................... 1

36............. HPS67-136 ..............Handwheel ............................................................................................ 2

37............. HPS67-137 ..............Collar ....................................................................................................1

38............. HPS67-138 ..............Stud ...................................................................M8 x 60 ...................... 1

39............. HPS67-139 ..............Bushing................................................................................................. 2

40............. HPS67-140 ..............Spindle.................................................................................................. 1

41............. HPS67-141 ..............Plate...................................................................................................... 1

42............. HPS67-142 ..............Mount Bracket ....................................................................................... 1

43............. HPS67-143 ..............Spindle Bracket ..................................................................................... 1

44............. HPS67-144 ..............Spindle.................................................................................................. 1

45............. HPS67-145 ..............Cover Tube ........................................................................................... 1

46............. HPS67-146 ..............Plate...................................................................................................... 2

47............. HPS67-147 ..............Plate...................................................................................................... 1

48............. HPS67-148 ..............Handle................................................................................................... 1

49............. HPS67-149 ..............Strap Bracket.........................................................................................1

50............. HPS67-150 ..............Tube...................................................................................................... 1

51............. HPS67-151 ..............Sleeve................................................................................................... 1

52............. BB-6003ZZ ..............Ball Bearing........................................................................................... 2

53............. HPS67-153 ..............Stud ...................................................................M12 x 50 .................... 2

54............. HPS67-154 ..............Motor..................................................................5HP, 3Ph, 230V.......... 1

................. HPS67-154A............Motor..................................................................3HP, 1PH, 230V ......... 1

55............. HPS67-155 ..............Bolt Handwheel ..................................................................................... 1

56............. HPS67-156 ..............Bracket.................................................................................................. 1

57............. TS-1504051.............Socket Head Cap Screw.....................................M8 x 25 ...................... 1

58............. TS-1504041.............Socket Head Cap Screw.....................................M8 x 20 ...................... 5

60............. TS-1541031.............Nylon Lock Hex Nut............................................M8.............................. 2

25

Page 26

61............. TS-1490031.............Hex Head Cap Screw .........................................M8 x 20 ...................... 1

62............. TS-1540061.............Full Hex Nut .......................................................M8.............................. 6

63............. TS-2238751.............Socket Head Cap Screw.....................................M8 x 75 ...................... 1

64............. TS-1504131.............Socket Head Cap Screw.....................................M8 x 70 ...................... 2

65............. TS-2239101.............Socket Head Cap Screw.....................................M10 x 8 ...................... 1

66............. TS-1505011.............Socket Head Cap Screw.....................................M10 x 16 .................... 2

67............. HPS67-157 ..............Flange Washer ...................................................................................... 1

68............. TS-2360101.............Flat Washer........................................................M12............................ 2

69............. TS-2342121.............Full Nylon Inset Lock Nut....................................M12............................ 2

70............. TS-1490041.............Hex Cap Screw ..................................................M8 x 25 ...................... 4

71............. TS-2312241.............Hex Jam Nut ......................................................M24............................ 4

72............. TS-1504011.............Socket Head Cap Screw.....................................M8 x 10 ...................... 1

73............. TS-1516031.............Flat Head Socket Cap Screw..............................M10 x 30 .................... 1

74............. TS-1506051.............Socket Head Cap Screw.....................................M12 x 40 .................... 1

75............. TS-1524011.............Socket Set Screw...............................................M8 x 8........................ 4

76............. TS-1490061.............Hex Head Cap Screw .........................................M8 x 35 ...................... 1

77............. TS-2361081.............Lock Washer ......................................................M8.............................. 1

78............. TS-1524041.............Socket Set Screw...............................................M8 x 16...................... 2

79............. TS-1490081.............Hex Head Cap Screw .........................................M8 x 45 ...................... 3

80............. TS-1514051.............Flat Head Socket Cap Screw..............................M6 x 30 ...................... 1

81............. TS-1541021.............Nylon Lock Hex Nut............................................M6.............................. 1

82............. TS-1550041.............Flat Washer........................................................M6.............................. 1

83............. HPS67-158 ..............Dado Bushing.....................................................30mm......................... 1

84............. TS-1522061.............Socket Set Screw...............................................M5 x 20...................... 2

26

Page 27

Motor and Arbor Assembly

27

Page 28

Parts List: Scoring Motor and Arbor Assembly

Index No. Part No. Description Size Qty

1............... HPS67-201..............Collar .................................................................................................... 1

2............... ---------------...............Scoring Blade (not included) .................................................................. 1

3............... HPS67-203..............Arbor Shaft............................................................................................ 1

4............... HPS67-204..............Bushing................................................................................................. 1

5............... HPS67-205..............Sleeve................................................................................................... 1

6............... HPS67-206..............V-Belt .................................................................................................... 1

7............... HPS67-207..............Arbor Pulley........................................................................................... 1

8............... HPS67-208..............Tilt Bracket ............................................................................................ 2

11............. HPS67-211 ..............Micro Switch.......................................................................................... 1

14............. HPS67-214 ..............Handle Knob ......................................................................................... 1

15............. HPS67-215 ..............Bushing................................................................................................. 1

17............. HPS67-217 ..............Bracket.................................................................................................. 1

18............. HPS67-218 ..............Adjustment Screw.................................................................................. 1

19............. HPS67-219 ..............Block ..................................................................................................... 1

20............. HPS67-220 ..............Arbor Housing ....................................................................................... 1

21............. HPS67-221 ..............Shaft ..................................................................................................... 1

22............. HPS67-222 ..............Shaft Guide ........................................................................................... 1

23............. HPS67-223 ..............Shaft Bracket......................................................................................... 1

24............. HPS67-224 ..............Guide Bracket........................................................................................1