Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Single End Dovetailer

Model DT65

Powermatic

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-1791305

Ph.: 800-274-6848 Revision A4 05/2014

www.powermatic.com Copyright © 2014 Powerm atic

Page 2

Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pro of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informa t io n

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors, Machine Accessories

2 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 4

Introduction ............................................................................................................................................. 6

Desc ription ................................................................................................................... ........................... 6

Specifica tions ................................................................................................................ .......................... 6

Features of the DT65 Dovetai ler .............................................................................................................. 7

Termino lo g y ............................................................................................................................................ 7

Unpac king ............................................................................................................................................... 8

Contents of the Shipping Container ...................................................................................................... 8

Installati on & Assembly ............................................................................................................................ 9

Attaching Dust Hose ............................................................................................................................ 9

Installing Dust Chute .......................................................................................................................... 10

Dust Collection ................................................................................................................................... 10

Grounding Inst r uc tions ....................................................................................................................... 10

230 Volt Operati on ............................................................................................................................. 11

Extension cords ................................................................................................................................. 11

Air Connecti on ................................................................................................................................... 1 1

Adjustments .......................................................................................................................................... 12

Clamping Cylinders ............................................................................................................................ 12

Clamping Pr e ssur e............................................................................................................................. 1 3

Locking Handles ................................................................................................................................ 13

Template Bar ..................................................................................................................................... 13

Indicat ion Template ............................................................................................................................ 14

Fixed Chaser ..................................................................................................................................... 1 4

Horizontal and Vertical Fences ........................................................................................................... 15

Buffer Pads ........................................................................................................................................ 17

Cutter Height ...................................................................................................................................... 17

Mortise Depth .................................................................................................................................... 1 7

Thickness of Tenon Cut ..................................................................................................................... 18

Tightness of Morti se/Tenon Fit ........................................................................................................... 18

Drive Belt Tension .............................................................................................................................. 19

Replacing cutter ................................................................................................................................. 19

Oil Output .......................................................................................................................................... 19

Operation .............................................................................................................................................. 2 0

Preventing Chip Out ........................................................................................................................... 22

Dovetails in Plywood .......................................................................................................................... 22

Maintenance .......................................................................................................................................... 23

Lubrication ......................................................................................................................................... 23

Replacement Parts ................................................................................................................................ 26

Parts List: Base Assembly .................................................................................................................. 26

Base Assembly .................................................................................................................................. 27

Parts List: Hold-Down Assembly ........................................................................................................ 28

Hold-Down Assembly ......................................................................................................................... 29

Parts List: Headstoc k A ssembly ......................................................................................................... 30

Headstock Assembly .......................................................................................................................... 32

Parts List: Cabinet Assembly .............................................................................................................. 33

Electri c al Connec tions ........................................................................................................................... 34

3

Page 4

Warning

1. Read and understand the ent ire owner’s manual before att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This dovetailer i s designed and i ntended f or use by pr operl y tr ained and ex peri enced personnel only .

If you are not familiar with the proper and safe operation of a dovetailer, do not use until proper

training and knowledge have been obtained.

5. Do not use this dovetailer for other than its intended use. If used for other purposes, Powermatic

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Al ways wear approved safety glasses/f ace shields while using thi s dovetailer. Everyday eyeglasses

only have impact resi stant lenses; they are not safet y glasses.

7. Before operating this dovetailer, remove tie, rings, watches and other jewelry, and roll sleeves up past

the elbows. Remove all l oose clothing and confine long hair. Non-slip f ootwear or anti-skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tired or under t he influenc e of drugs, alcohol or any medic ation.

11. Mak e c er tain the switch is in the OFF position before connecting the machine to the power supply.

12. Mak e c er tain the machine is properly grounded.

13. Mak e all machine adjustment s or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning i t on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

17. Pr ov ide for adequate space surrounding work area and non-glare, ov er head lighting.

18. Keep the floor around the machine cl ean and free of scrap material, oil and grease.

19. Keep v isitors a safe distance from the work area. Keep children away.

20. Mak e y our workshop chi ld proof with padlocks, m aster switc hes or by r em ov ing starter keys.

4

Page 5

21. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

22. Maintain a balanced stance at all tim es so that you do not fall or lean against the cutter or other

moving part s. Do not over r eac h or use excessive force to perform any machine oper ation.

23. Use the right tool at the correc t speed and f eed rat e. Do not force a t ool or att achment to do a job for

which it was not designed. T he ri ght tool will do the job better and saf er.

24. Use recommended accessories; improper accessories may be hazardous.

25. Mai ntain tools with care. Keep cutter s sharp and clean for the best and safest perf ormance. Follow

instructions for lubricating and changing accessories.

26. Make sure the work piec e is securely clamped t o the table. Never use your hand to hold the work

piece.

27. T ur n off the machi ne before cleaning. Use a brush or compressed air to remove chips or debri s — do

not use your hands.

28. Do not stand on the machine. Serious injury c ould oc c ur if the mac hine tips over.

29. Never leave the machine runni ng unatt ended. T urn off the electrical power and t he air supply, and do

not leave the machine until cutter comes to a complete stop.

30. Remove loose items and unnecessary work piec es from the area before starting the machine.

Familiariz e you rself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in mi nor i njury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by Powermati c covering the safe operat ion and maintenance pr ocedures for a

Model DT65 Si ngle End Dov etailer. T his manual cont ains instr uctions on i nstallat ion, saf ety precauti ons,

general operating procedures, maintenance instructions and parts breakdown. This machine has been

designed and const ructed to pr ovide years of trouble free oper ation if used in accor dance to i nstructions

set fort h in t his manual . If there are any que sti ons or c om m ents, please co ntac t ei ther your l ocal suppli er

or Powermatic. Powermatic can also be reached at our web site: www.powermatic.com.

Description

The Model DT65 Dov etailer will make cleanly cut half-bl ind dovetails for drawer or box constr uction. A

four-si ded template allows any of four pi tches, from 1” up to 2-1/2”. T he use of different dovetail pitches

will give a unique custom appearance to your work. The cutter is carbide-tipped. The machine has a

magnetic star ter, and is built to last wit h c ast iron and steel construction. The pneum atic clamping system

is quick and easy to use.

Specifications

Model Number ...................................................................................................................................DT65

Stock Number...............................................................................................................................1791305

Minimum work pi ece size (in.) .................................................................................................7-7/8 x 2-3/8

Maximum work piece size (in.) .................................................................................................. 59 x 16-1/2

Minimum dovetail height (in.) .............................................................................................................. 3/16

Maximum dovetai l height (in.) ............................................................................................................... 3/4

Minimum front thickness (in.) .............................................................................................................. 9/32

Maximum front thickness (in.) ............................................................................................................ 2-3/8

Minimum side thickness (in.) ................................................................................................................. 3/8

Maximum side thi ckness (in.) ........................................................................................................... 1-3/16

Number of spindl es .................................................................................................................................. 1

Spindle speed (RPM )...................................................................................................................... 18,500

Center-to-center dovetail spacing (in.) ........................................................................ 1, 1-1/2, 2 and 2-1/2

Table he ig h t from floor (in .) .................................................................................................................... 45

Overall dimensions (L x W x H) (in.) ........................................................................................ 37 x 44 x 63

Motor ........................................................................................................... TEFC, 1HP, 1Ph, 230V, 60Hz

Dust collection ports diameter (in.) .................................................................................. front 2-1/2, rear 4

Dust collection minimum CFM required ................................................................................................ 50 0

Approximate Weight, Shipping/Net (lbs.) ....................................................................................... 510/420

The above specifications were current at the time t his manual was published, but bec ause of our policy of

continuous im provement, Powerm atic reserves the right t o change specific ations at any time and without

prior notic e, wit hout incurring obligations.

6

Page 7

Features of the DT65 Dovetailer

Terminology

Below are the term s used in t his manual to identify types of cuts and measurement s.

7

Page 8

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shi pping material unt il the Dovetail er

is assembled and r unning pr oper ly.

Remove the box from inside the cabinet.

Compare the c ontent s of y our cont ainer wit h t he

following parts list to make sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

1 Dovetail Machine

2 Fixed Chasers (2-1/2” and 3” pitches)

1 Indication Template

1 Set of Open-Ended W r enc hes (8-10, 11-13,

12-14, and 17-19mm)

1 Combination Wrench, 30mm

1 Set of Hex Wrenches (1.5 to 6mm)

1 Dust Chute

2 Sample Dovetailed B oar ds

1 Owner's Manual

1 Warranty Card

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mply may cause serious injury.

8

Page 9

Installation & Assembly

Tools requi red for assemb ly

forklift or hoist with straps/slings

14mm wrench (provided)

[NOTE: A socket set wi th ratchet wrench may

speed assembly ]

4mm hex wrench (provi ded)

knife or wire cutter

flat head screwdriver

1. Remove the four screws and flat washers

holding the machine to the pallet with a

14mm wrench, as shown in Figur e 1.

2. Place lifti ng st r aps thr ough the two eyebolts

at the top of the m achine (Figure 2). Using

a forklift or hoist, lift the machine off the

pallet and into its desired location. The

Dovetail er should be located in a dry area

with sufficient lighting. Leave plenty of

space around the machine for operations

and routine maintenance work.

3. If desired, the Dovetailer can be further

stabilized by securing it to the floor, using

lag screws through the four holes at the

bottom of the cabinet.

4. A group of cords holds the headstock

secure to the machine frame to prevent it

from moving duri ng shipping. These cords

should now be cut and removed (see

Figure 3).

5. Exposed metal areas of the Dovetailer

(such as the table, template bar, cylinder

clamps, rods, etc.) have been factory

coated with a protectant. This should be

removed with a soft cloth dampened with

kerosene or mi neral spirits. Do not use an

abrasive pad. Do not let solvent contact

plastic or rubber parts as it may damage

them.

Figure 1

Figure 2

Figure 3

Attaching Dust Hose

1. Slide the upper end of the hose over the

chute on the dust hood (Fi gur e 4) .

2. Tighten the hose clamp with the attached

screw, using a fl at head screwdriver.

Figure 4

9

Page 10

Installing Dust Chute

Remove the four socket head cap screws at the

rear of the cabinet, using a 4mm hex wrench.

Place the 4” diam eter dust c hute (Fi gure 5) ov er

the hole, and re-insert and tighten the four

socket head cap screws.

Dust Collection

The use of a du st collection system is strongly

recommended f or this machi ne. It will help k eep

your shop clean as well as mi nimize any healt h

risks caused by wood dust. Mak e sure your dust

collector has a capacity of at least 500 cubic feet

per minute (CFM).

Connect the intake hose of your dust c ollector to

the 4” diameter dust chute at the back of the

cabinet (Figure 5) .

NOTE: A variet y of dust coll ection systems are

available from Powermatic. Call customer

service at 1-800-274-6848 or visit our website

for mo re inform ation.

Grounding Instructions

Figure 5

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

This mac hine m ust be grounded. I n the event of

a malfuncti on or break down, groundi ng prov i des

a path of least r esistance f or electri c current to

reduce the ri sk of el ectri c shock .

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conduct or . If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conduc tor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool i s properly grounded. Us e only

three wire extensi on c or ds that have three-prong

grounding plugs and three- pole recept acles that

accept the tool ’s pl ug.

Repair or replace a damaged or worn cord

immediately.

Make sure the voltage of your power supply

matches the specif ications on the m otor plate of

the Dovetailer .

10

Page 11

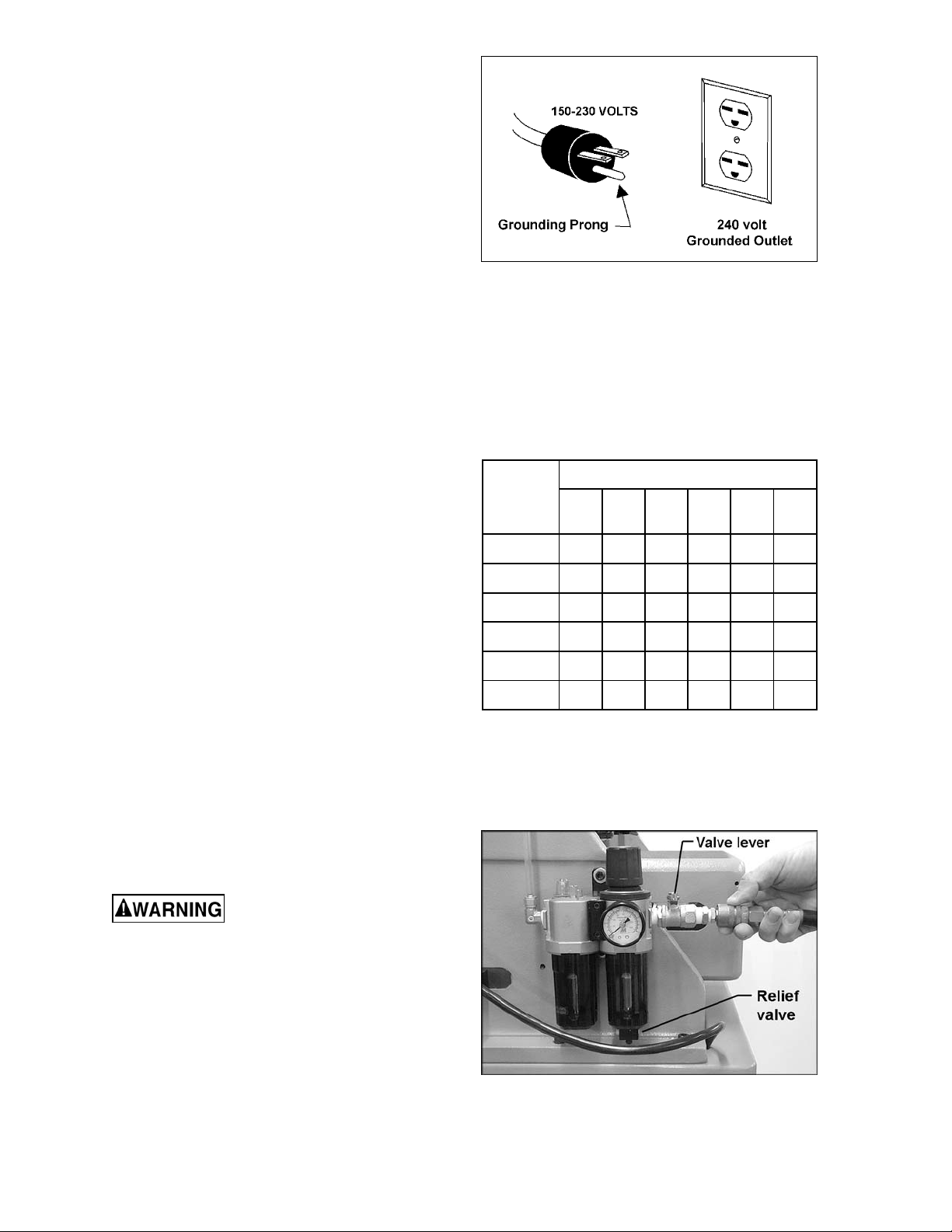

230 Volt Operation

As received from the factory, the DT65

Dovetail er is designed to run on 230 volt power

only. You may either connect a UL/CSA listed

230V plug (similiar to the one shown in Figure 6)

or “hard-wire” the machine directly to a control

panel. If hard-wired to a panel, make sure a

disconnect is available for the operator. The

dovetailer must comply with all local and

national codes after being wired.

1. If it is to be hard- wired, m ak e sure the f uses

have been removed or the breakers have

been tripped in the circuit to which the

dovetailer will be connected. Place a

warning placard on t he fuse holder or circuit

breaker to prevent it being turned on while

the machine is being wired.

2. Refer to “Elec trical Connections” on page 36

for connecting the motor leads.

3. The Dovetail er with a 230 v olt plug should

only be connected to an outlet having the

same confi guration. No adapter is av ailable

or should be used with the 230 v olt plug.

Figure 6

Recommended Gauges (AWG) of Extension Cords

Extension Cord Length *

25

50

75

100

150

200

feet

feet

feet

feet

feet

Amps

feet

Extens ion cords

If an extensi on c or d is necessary, make sure t he

cord rating i s suitable for the am perage listed on

the machine’s motor plate. An undersized cord

will cause a drop in line voltage resulting in loss

of power and overheating.

Use the chart in Fi gure 7 as a general guide in

choosing the c orrect size cord. If in doubt, use

the next heavi er gauge. The smaller the gauge

number, the heavier the cord.

Air Connection

Connect the air supply hose to the coupli ng on

the air uni t (Figure 8). The air i s turned ON by

rotating the valve lever 90 degrees

counterclockwise (until it is parallel with the

hose), and turned OFF by rotating the valve

lever 90 degrees cl oc k wise.

Even after the air has been

turned off to the machine, there may be

residual air inside the lines, and the

clamping cyl ind ers can sti ll p rovid e a hazard

to fingers. After shutting off the air, always

bleed residual air from the system by

pushing the rel ief valve pin at the bottom of

the air cup, shown in Figure 8. Keep the

relief valve open until all air in the system

has been removed.

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on li miting the lin e voltage dr op to 5V at 15 0% of the

rated amp eres.

NR: Not Recommended.

Figure 7

Figure 8

11

Page 12

Adjustments

Disconnect machine from

power source, shut off air supply and bleed

residual air from system, before making

adjustments. Failure to comply may cause

serious injury.

Clamping Cylinders

The workpieces are clamped to the table by

pneumatically operated aluminum cylinders (A,

Figure 9). Each cylinder has its own air on/off

lever. Sim ply turn the lever (B, Figure 9) t o “on”

position to act ivate the cylinder; the c ylinder will

respond immediat ely by clamping the workpiec e

against the table.

Always keep fingers out of

the way of clamping cylinders. Failure to

comply may cause seriou s injury.

Both vertical and horizontal clamping cylinders

can be adjusted t o match the thi ckness of your

workpieces. To change the thick ness capac ity of

the clamping cylinders, proceed as follows:

Figure 9

1. To increase the clamping capacity, loosen

the top two hex nuts (A and B, Figur e 10) on

the stud at the end of the holder bracket,

with a 30mm wrench. Do the same for the

stud at the opposite end of the holder

bracket.

2. Tighten the lower hex nut (C, Figure 10).

You can do thi s without a wrench. This will

raise the holder bracket. Do this

increment ally on both stud s unti l the desir ed

height is reached. When finished, tighten

top hex nuts (A & B, Figure 10) on both

studs with the wrench.

NOTE: Make equal adjustm ent on both stud s at

each end of the holder bracket to ensure the

clamps are parallel to the table. To check this,

measure from the bottom edge of the holder

bracket down to the t able. Measure at each end

of the holder bracket – the measurements

should be equal. Fi gure 10 s hows the h ori zont al

clamping assembly - the procedure is identical

for the vertical cl am ping assembly.

3. To decrease the clam pi ng capacit y, back off

the lower hex nut (C, Figure 10) and t ighten

the top hex nut (B, Figure 10). This will

lower the holder br ac k et.

Figure 10

4. When finished, ti ghten t he l ower hex nut (C)

against the holder bracket, and bring hex

nut (A) down against hex nut ( B).

Figure 11

12

Page 13

The clamping cylinders can also be adjusted

laterally for better support of workpieces with

differing widths. Simply loosen the locking

handle (Figure 11) and slide the clamping

cylinder t o position. Re-tighten locking handle.

Clamping Pressure

The pressure exerted by the cylinder clamps

against the workpi ece c an be a dj usted at t he air

regulator, shown in Fi gure 12. The hardness or

softness of t he wood will determine the amount

of clamping pr essure desired. Enough pressure

should be used to prevent the workpiece from

slipping during operations. Forty (40) psi is

suitable for clamping most wood; going above

that is not recomm ended.

To change the clamping pressure, pull up on the

knob (A, Figure 12) and rotate it; clockwise to

increase pressure, counterclockwise to

decrease pressure. The attached needle

indicator ( B, Figure 12) shows the air pressure.

Lock the setti ng by pushing the knob (A, Figure

12) back down.

Figure 12

Locking Handles

All locking handles, such as those shown in

Figure 11, can be rotated out of the way if they

interfere with other machine parts. Simply lift

straight out on the locking handle and rotate it,

then release, maki ng sure it seats properly.

Template Bar

The four-sided template bar, shown in Figure

14, will allow you t o create “half-bli nd” dovetail s,

where the dovetail s are visible on only one side

of the joint. It will create dovetails in one of f our

different “pitches” or centerlines. The available

pitches are 1”, 1-1/2”, 2” and 2-1/2”. To change

the pitch of a dovetail c ut, pr oc eed as follows:

1. First notice how the notches on the

template bar are grouped toward the right

side of the machine. The template bar

should always be oriented in this fashion.

2. Release one end of the spring on the left

side of the head stock (Figure 13) and pul l

the headstock forward until the tracer pin

(Figure 14) i s clear of t he template bar.

3. Loosen and rem ove the loc king handles on

each end of the templ ate bar (Figure 15).

4. Pull out the template bar, flip it to the

desired side, then reinstall it. NOTE: The

pitch dimensi on is inscribed on each si de of

the template bar . The side of the tem plate

bar that you have chosen should face

downward when mounted on the machine.

5. Insert and ti ghten both locking handles.

Figure 13

Figure 14

13

Page 14

6. Push the headstock back and re-connect

the spring (Figur e 13) .

You must now also shift the indication template

(Figure 16). S ee “Indic ation Template”.

Indication Template

Because the tracer pin is not easily observed

while the m achine is in operation, the indicati on

template (A, Figure 16) provides the operator

with a visual record of the progress of the

“hidden” tracer pin. The bracket (B, Figure 16)

slides in and out of the notc hes on the indi c ation

template, echoing the tracer pin as it slides in

and out of the notches on the template bar

below.

The pitch of the indication tem plate must match

the pitch of the template bar. Therefore, when

turning the template bar for a new pitch, you

must also change the i ndic ation template.

1. First notice how the notches on the

indication template are grouped toward the

right side of the machine. The indication

template should always be oriented in this

fashion.

Figure 15

2. Remove the socket head cap screw (C,

Figure 16) at each end of the indication

template, with a 5mm hex wrench.

3. The indication template that came installed

on your machine contains the 1” and 2”

pitch. The ot her indication template has the

1-1/2” and 2-1/2” pitch. Either flip the

indication template, or replace it with the

other one as needed, t o match the pitch of

the template bar.

4. Re-insert and tighten the socket head cap

screws (C, Figure 16) .

Fixed Chaser

The fixed c haser (Figur e 17) provi des a support

on which the workpieces rest. The spacing

between the “f ingers” of the fixed chaser all ows

clearance f or the c utt er .

The DT65 Dovetailer comes standard with three

fixed chasers at 2”, 2-1/ 2” and 3” pi tches. (P itch

is the distance between the centers of the

“fingers”; see Figur e 18) .

NOTE: If you wish to use the 1-1/2” or 2-1/2”

pitch on the t emplate bar, you m ust replace t he

fixed chaser on the machine with one of the

others provided. Figure 18 explains how the

available fixed chasers correspond to the pitch

of the template bar.

Figure 16

Figure 17

14

Page 15

1. To replace the fixed chaser, remove the

three M6 socket head cap screws and flat

washers, using a 5mm hex wrench as

shown in Figure 17. Remove the fixed

chaser.

2. Instal l the new fix ed chaser and make sure

it is level with the main table.

3. Re-insert and tighten the socket head cap

screws against the fl at washers.

After mounting the fixed chaser, make sure it will

correspond to your c hosen pitch on the template

bar. With the machine power off, slide the

headstock across the l ength of the fixed c haser,

allowing the cutter to move in and out of the

spaces. If t here is any interference bet ween the

cutter and one of the “fingers” on the fixed

chaser, then try a different fixed chaser, or

change the pitch of the template bar.

Horizontal and Vertical Fences

The workpieces will lie flush against the f ences

during cutti ng to ensure squarene ss. Two buff er

pads made of polyethylene material are

mounted to the fences – these provide a

“chipbreaker” effect to prevent chip-out on the

left edges of t he workpieces. T hey ar e de signed

so the cutter can bite into them without any

damage to the cutter .

To adjust these fenc es, pr oc eed as follows:

1. Place your F RONT/BACK workpiece on the

horizontal t able and agai nst the fence/buff er

pad. Move t he headstock t o the lef t edge of

the workpiece, then slide it to the right,

allowing the tracer pin to slide just a little

into the templat e recesses, while observing

through the dust hood window t he progress

of the cutter. This will give you an idea

where the cuts will be made and how they

will be spaced across the width of the

workpiece.

Figure 18

2. For broad m ov em ent of the horizontal fence,

loosen both locking handles on the

horizontal fence (A and B, Figure 19) and

slide the horizontal fence into position.

Tighten bot h locking handl es (A & B, F igure

19).

3. There is also a micro adjustment on the

horizontal fence; loosen locking handle (A,

Figure 19), but leave locking handle (B)

tight. Loosen the screw (C, Figur e 19) with a

6mm hex wrench and rotate the knurled

knob (D, Figure 19) as needed for precise

positioning of the horizontal fence.

4. When finished, t ighten screw (C, Fi gure 19)

and locking handl e ( A, Figure 19).

Figure 19

15

Page 16

NOTE: Make sure locking handles (A & B,

Figure 19) will not interfere with the headstock

during operation.

5. Conti nue t o check the spaci ng by slidi ng the

headstock acros s, until the dov etail cuts will

be distribut ed ev enly acr oss the width of t he

workpiece. NOTE: This is an approximate

method of determining by eye where to

place the workpi ece. A scale in inches and

millimeters is mounted to both horizontal

and vertical tables, if you need m or e precise

measurements for the location of the

dovetail cuts.

6. Again, mak e sure t he locking handles on the

horizontal fence (A & B, Figure 19) are

tightened. The position of the horizontal

fence will now be used as the basis for

locating the vertical fence.

7. Loosen the locking handle on the vertical

fence.

8. As noted, the position of the horizontal

fence will affect the position of the vertical

fence. Ther efore, if you are making a drawer

that has a bottom groove, the vertic al fence

should be set so that the bottom groov e in

the drawer piece to be tenoned will go

through the center of a tail. That means the

bottom groove of the mortised piece will go

through the center of a mortise. This will

prevent t he groov e from bei ng vi sible on t he

outside of the assembled drawer. See

Figures 20 and 21.

Important: To make proper dovetail cuts, the

two fences must always be offset from each

other by half the pitch of the template bar. That

is, off set 1/ 2” when using t he one- inc h tem plat e;

3/4” when using the 1-1/2 template; 1” when

using the two-inch template, and 1-1/4” when

using the 2-1/2 inch template. The measuring

scales on the h orizontal and verti cal tables are

marked in 1/16” incr em ents and millimeters.

Figure 20

Figure 21

9. Li ne up the v er tical f ence with t he hori zont al

fence, then offset the vertical fence by

exactly half the pitch of the template bar.

See Figure 22.

10. T his adjustm ent will cause the v ertical work

piece to be sli ghtly offset to t he right of the

horizontal piece (as viewed from front of

machine), thus ensuring the dovetails will

correspond when the two pieces are

assembled.

11. Tighten the locking handle on the vertical

fence.

Figure 22

(view from rear of machine)

16

Page 17

There are a total of four fences on the DT65

Dovetailer – two vertical and two horizontal.

These allow tw o sets of workpiece s to be cut at

the same time. If this is desired, position the

other two fences in the sam e manner as the first

two fences, remembering again to offset the

vertical fence by half t he pitch.

Buffer Pads

The polyethylene buffer pads, shown in Figure

22, have slots through whic h they are secured to

the fences by scre ws. T hese buffer pads can be

re-positi oned if needed.

To adjust a buff er pad, loosen the t wo hex cap

screws (shown in Figure 22) with a 13mm

wrench. Sli de the buffer pad as necessary. Retighten bot h hex cap screws when finished.

Cutter Height

This adjustment will change the hei ght of t he tail

on the tenon (male) cut, and how deep the

mortise (female) cut goes into the thickness of

the workpiece.

1. Disconnect machine from power source.

2. Loosen the spindle lock screw (Figure 23)

by turning it counterclockwise with a 6mm

hex wrench.

3. Turn the spindle height adjustment screw

(Figure 23) with a 5.5mm hex wrench, eit her

clockwise to raise the cutter (increase the

cutter depth), or counterclockwise to lower

the cutter (decr ease the c utter depth).

4. Tighten spindle lock screw by turning it

clockwise.

Figure 23

Mortise Depth

This adjustm ent ensures that t he side pieces of

your drawer will remain flush with the front and

back pieces of the drawer. The correct fit will

have the sides f lush with the fr ont and back of

the drawer, wit hout showing any of the morti se

cut on the inside of the dr awer.

The mortise depth adjustment bolt, shown in

Figure 23, lim its how far for ward the headstock

will go, and thus limits the length of your mortise

cut.

1. Disconnect machine from power source.

2. Loosen the hex nut on the mortise depth

adjustment bolt (Figure 23) by turning the

hex nut counterclockwise with a 17mm

wrench.

17

Page 18

3. To decrease the depth of the mortise

(female) cut, turn the bolt clockwise. To

increase the depth of the mortise cut, turn

the bolt counter cl oc k wise.

4. Re-tighten the hex nut.

Thickness of Tenon Cut

To adjust the t hickness of the t enon (male) cuts,

you will change the depth of the tracer pin (A,

Figure 24).

1. Disconnect machine from power source.

2. Loosen the locki ng handle (B, Figure 24).

3. Insert a 5. 5mm hex wrench into the end of

the adjustment screw (C, Figure 24) and

turn the adjustment screw as needed. To

decrease the thic k nes s of the tenon cut, t ur n

the adjustment screw counterclockwise. To

increase the thi ckness of t he tenon cut, tur n

the adjustment screw cl oc k wise.

4. Tighten loc ki ng handle (B, Figure 24).

Tightness of Mortise/Tenon Fit

A proper dovetail fit should be snug with no

gaps showing, but not ov erly tight as gl ue must

later fill the joints. If the cuts seem correct, but

the joint is simply too tight, or the joint is too

loose, proceed as f ollows.

Figure 24

1. Disconnect machine from power source.

2. Remove the dust hood f rom the front of the

headstock. Release one end of the spring

on the headstock (see Figure 13) and pull

the headstock away f rom the machine until

the cutter becomes more accessible.

3. You will notice the cutter, shown in Figure

25, is slight ly off c enter of the spindle. The

spindle is eccent ric and allows the cutter t o

be turned to a different position on the

spindle.

T he cutter is very sh arp! Use

caution when working with or around it.

4. Loosen both set screws on the spindle

(Figure 25) by turning them counterclockwise with a 4mm hex wrench.

5. A scal e i s locat ed just above the cut ter , wit h

a plus (+) and minus (-) sign. Moving the

cutting edge of the cutter toward the plus (+)

side of the scale wil l i ncrease the si ze of the

mortise cut and decrease the size of the

tenon cut. Moving the cutting edge of the

cutter toward the minus (-) side will

decrease the size of the mortise cut and

increase the size of the tenon cut.

Figure 25

18

Page 19

NOTE: One notch of the scale equals 1mm.

6. With your fi nger s on the shank porti on of the

cutter, carefully rotate the cutter toward the

plus (+) or minus (-) position as needed.

7. When satisfied with the adjustment, tighten

both set screws fi rmly.

8. Re-at tach the spring on the headstock, and

re-install the dust hood.

Drive Belt Tension

The tight ness of the belt that drives the spi ndle

has been adjusted at the factory. Further

adjustment may be nec essary af t er the m achi ne

receives some use, as the belt may stretch

slightly duri ng the “breaking in” process.

Belt tensi on can be adjusted by a socket head

cap screw at t he rear of the headstoc k (Figure

26) which slides the mot or toward or away from

the spindle. To tighten the belt, rotate this cap

screw clockwise with a 6mm hex wrench. To

loosen the belt, rotate the cap screw

counterclockwise. The belt should be just tight

enough to prevent it slipping on the spindle

during operation.

Replacing cutter

Figure 26

T he cutter is very sharp ; use

caution when working with or around cutter.

Disconnect machine from power source!

Failure to compl y may cause seri ou s injury.

1. To replace the cutter, loosen both set

screws (Figur e 25) and carefully pull up on

the cutter until it is free from the spindle.

2. Slide the new cutter down into the spindle,

and align the cutting edge with your

previous setti ng on the spindle scale.

3. Tighten both set screws.

Oil Output

Oil is distributed through the air lines for

constant lubrication of the clamping system. The

oil output can be adjusted by rotating the oil

regulator knob (A, Figure 27). Turn the knob

counterclockwise to increase oil output,

clockwise to decr ease oi l output.

The level of oil should be checked occasional ly

and re-filled as necessary. A minimum level is

marked on the window of the oil cup ( C, Figure

27). Refill by removing the screw (B, Figur e 27)

and pouring oil into the fill hole. When fi nished,

re-install screw (B, Figure 27). Use standard air

tool oil. This is available from your local

distributor, or can be found in most hardware

and tool stores.

Figure 27

19

Page 20

Operation

NOTE: The following are basic dovetailing

procedures as they apply to this machine, and

are not intended to be a full course of instruction

in making dovetails.

Refer back to the terminology on page 7 if

needed.

The Dovetailer can be used to make joints in

drawers, boxes, cabinets, etc. Instruc tions in this

manual are based upon making a drawer

consisting of FRONT and BACK pieces, and two

SIDE pieces. FRONT and BACK pieces are

placed horizontally on top the machine’s table;

SIDE pieces are plac ed v ertic ally.

No matter the project, prevent mistakes by

laying out the pieces beforehand according to

how they will be assembled. Place them with the

inside f acing up, and l abel the m ati ng edges, as

shown in Figure 28.

Before cutting on what is to be the finished

piece, the operator should make test cuts on

scrap wood to make sure all settings and

adjustments are correct.

Figure 28

IMPORTANT: Make sure the workpiece has

been cut square before making dovetails. An

out-of-square workpiece will result in poor

do vetail joints.

1. Check that all the following have been set

correctly ( S ee “Adjustments” above):

• proper pitc h of Template Bar

• proper Indication Template

• Vertical and Horizontal Fence positions

(offset from each other by half the pitch

of the template bar)

• height of Clamping Cylinders for

workpiece thi c k ness

• proper Fixed Chaser, with no cutter

interference

• height of Cutter

2. Mov e the headstock all the way to the right

and out of the way.

3. Connect the air supply and the electrical

power to the machine.

Keep fingers clear of

clamping cylinders.

4. Place the drawer RIGHT SIDE against the

vertical table and on top the fixed chaser.

The RIGHT SIDE should be flush against

the fence, with the bottom groove facing

outward and opposite t he fence (Figure 29).

Figure 29

20

Page 21

5. Activat e the clamping c ylinder in f ront of the

RIGHT SIDE workpiece.

6. Place the drawer BACK on the horizontal

table, and against the horizont al fence. Slide

it flush agai nst the RIGHT SIDE workpiece.

The bottom groove on the BACK should

face downward and oppo sit e the f enc e. See

Figure 30.

7. Activate the clamping cylinder above the

BACK workpiece.

8. The BACK is now butting against the RIGHT

SIDE so they are flush, with the RIGHT

SIDE overlapping the edge of the BACK.

Both workpieces should be firmly and

evenly against the fences.

9. Turn on the machine at the switch, and slide

the headstock to the left edge of the

workpiece. Mov e t he cutter i n sequence, l ef t

to right, allowing the tracer pin to move in

and out of the template slots. See Figur e 31.

You can watch the progress of the cutter

through the window of the dust hood.

NOTE: Do not r ush the cut; allow the cutting

unit to do the work.

Figure 30

10. When finished, slide the headstock out of

the way and unclamp the workpieces by

turning the clamping cylinder levers to “off” .

11. F it the BACK and RIGHT SIDE together and

examine the joint. If the joint is not

satisfactory, make any needed corrections

to your settings as explained under

“Adjustments.” If the joint is satisfactory,

proceed with the next cut as follows.

12. Insert t he LEFT SIDE piece and cl amp it in

vertical position and against the fence.

(NOTE: The bottom groove on the LEFT

SIDE will face outward and toward the

fence.)

13. Turn t he BACK 180 degrees and cl amp it in

the horizontal position against the fence.

(NOTE: The bottom groove on the BACK

workpiece will still be fac e down, but toward

the fence.)

14. Make the cut, then continue the dovet ailing

procedure with the FRONT piece, making

cuts “C” and “D” (Figure 28) until all four

joints of the dr awer have been cut.

Figure 31

TIP: When using drawer side widths that are not

“whole inch” sizes, you may wish to gauge off

the top of the drawer rather than the bottom

when placing workpi eces in the machine. Doi ng

this will improve the look of the drawer by

providing a f ull t enon near the top of the drawer

and the half-tenon will end up at the bottom. See

Figure 32.

Figure 32

21

Page 22

Preventing Chip Out

As noted previously, when the SIDE and

FRONT/BACK pieces are inserted into the

machine, they are offset a bit so they’ll match

correctly when assembled. In other words, the

SIDE will rest slightly to the right of the

FRONT/BACK in the machine. This leaves the

right edge of the SIDE exposed without the

“chipbreaker” effect that the FRONT/BACK

provides for the rest of the SIDE (see Figure

33). Thi s may result in an unsatisfact ory cut at

the edge of the SIDE.

This problem is resolv ed sim ply by t aking a t wo-

inch-plus wide “back-up” board, of the same

thickness as the workpiece, and clamping it

horizontall y next to the FRO NT/BACK piece, so

that it backs up t he exposed edge of the SIDE,

as shown in Figur e 33. You can use this piece

over and over again.

Dovetails in Plywood

Because plywood handles a bit differently than

solid stock, her e ar e some ti ps to follow:

1. When usi ng plywood, the lay ers tend to be

more fr agile. T herefore, t he operat or should

keep the movement of the cutting unit

consistent and proceed relatively slowly.

Figure 33

(view from rear of machine)

2. On t he rounded arcs of the tenon cuts, you

may lose a bit of t he top layer . This is to be

expected wit h plywood, and does not affect

either the look or the strength of the

assembled dovetail joint. Rather, the

strength of the dovetailed corner comes

from the flat side of the tenons.

3. Plywood has a tendency to chip out on

exposed edges. A back-up board may be

necessary (see Figure 33) .

22

Page 23

Maintenance

Keep clean the travel rods upon which the

headstock slides.

Before doing maintenance on

the machine, disco nnect it f rom the electri cal

supply and the air supply, and release any

residual ai r from the lines. Failure to comply

may cause serious injury.

If the power cord is worn, cut, or damaged in

any way, have it repl ac ed immediately.

The horizontal and vertical tables and other

exposed metal parts should be kept clean and

free of rust. A coat of paste wax will help protect

the tables fr om tar nishi ng.

After each day ’s use, brush or blow out dust and

debris from t he cutter, table, motor, etc.

Keep the clamping cylinders clean to prevent

debris adhering to them, which can scar

workpieces.

Lubrication

The linear bushings by which the headstock

travels on the rods are pre-lubricated and

sealed; they do not r equir e additional lubrication.

The spindle bearing should be lubricated as

needed, accordi ng to machine usage. Apply VG120 grease through the grease nipple on the

spindle (#10 i n the exploded v iew on page 32).

Occasionally check the oil level in the oil

regulator cup (see Figure 27). Add more oil as

needed. Use standard air tool oil.

23

Page 24

Troubleshooting the DT65 Dovetailer

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly trips

circuit breaker s or

blo ws fuses.

Machine not plugged in. Verify machine is connected to power

Fuse blown, or cir c uit

breaker tripped.

Cord damaged. Replace cord.

Overload automatic reset

has not reset.

Dovetailer frequently trips.

Building circuit breaker trips

or fuse blows.

Loose electri c al

connections.

Motor starter failure.

Motor failure.

Miswiring of the unit.

Replace fuse, or r eset ci r c uit breaker.

If the dovetailer overloads on the circuit breaker

built in to the motor starter, it takes time for the

machine to cool down befor e r estar t. Allow unit to

adequately cool before attempting restart . If

problem persists, c hec k am p setting on the motor

starter insi de the electrical box.

Check the amp setting on the overload relay.

Match the full l oad am ps on the motor as noted on

the motor plat e. If am p setting is correct then there

is probably a loose elec trical lead or a failed

component. See below.

Verify that dovetailer is on a circuit of correct siz e.

If circuit siz e is corr ect, there is probably a loose

electric al lead. Check amp setting on motor starter.

Go through all of the electrical connections on the

dovetailer including motor connections, verifying

the tightness of eac h. Look for any signs of

electric al ar ci ng whic h is a sure i ndicator of loose

connection or ci rcuit ov erl oad.

If you have access to a voltmeter, you can

separate a starter failure from a motor failure by

first, verifying incoming voltage at 220+/-20 and

second, checking the voltage between starter and

motor at 220+/- 20. If incoming voltage is incorrect,

you have a power supply problem. If voltage

between starter and motor is incorrect, you hav e a

starter probl em . If v oltage between starter and

motor is correct , you hav e a motor problem.

If electri c mot or i s suspect, y ou have two options:

Have a qualifi ed elect ri c ian test the motor for

function or rem ov e the motor and take it a qualified

electric motor repai r shop and have it tested.

Check to make certain all electrical connections

are correct and pr operl y tight. The electrical

connections other than the motor are

preassembled and tested at the factory. Theref or e,

the motor connections should be checked as the

highest probability for error. If problem s persist ,

double check t he factory wiring.

On/off switch failure.

If the on/off switch is suspect, you have two

options: Hav e a qualified electrician test the switch

for functi on, or pur c hase a new on/off swit c h and

establish if t hat was the problem on changeout.

24

Page 25

Trouble Probable Cause Remedy

Cutter not cutting

properly.

Dovetailed parts fit

too tightly.

Dovetailed parts fit

too loosely.

Cutter sometimes

slips and misses

revolutions.

Dovetailed parts fit

side to side, but

have depth gaps

between the

mortise and tenon

cuts.

A gap between

mortise and tenon

cuts increases

along the

dovetailed corner.

Cutter in wrong position. Turn cutter t owards the (+) or (-) mark [page 18].

Cutter dull or damaged. Sharpen or replac e c utt er [page 19] .

Cutter not adjusted

properly.

Cutter not adjusted

properly.

Drive belt tension incorrect. Adjust drive belt tension [page 19].

The mortise depth or tenon

thickness is set incorrectly.

Boards not square when

clamped.

Loosen set screws and turn cut ter toward the (+)

mark. Retighten set screws [page 18].

Loosen set screws and turn cutter toward the (-)

mark. Retighten set screws [page 18].

Change depth of morti se cut or thick ness of tenon

cut by using the adjustm ent screw [page 17 & 18].

Make sure the initi al c uts on the board (ripping

and/or crosscutting) have been done squarely, and

that the board is flush agai nst the stop before

clamping.

Side piece edge is

not aligned with

front/bac k piec e

edge.

Workpiec e sli ps

during the cut.

Fences not set correctly. Offset the vertical fence from the horizontal fence

by half the pitc h of the cut [page 16].

Clamping cylinder not

positioned over center of

workpiece.

Clamping cylinder too high

to properly cont ac t

workpiece.

Clamping pr essure too low. Adj ust pr essure at air regulator [page 13] .

Surface area of workpiec e

too small to achiev e

adequate coverage from

clamping cylinder .

Position cl am ping c yli nder to take advantage of its

full surface ar ea [page 13].

Lower clamping cyl inder in relation to thickness of

workpiece [page 12].

Use larger workpiece.

25

Page 26

Replacement Parts

Replacement par ts are li sted on the f ollowing page s. To order parts or reac h our servi ce depar tm ent, call

1-800-274-6848, Monday through Friday (see our website for business hours, www.powermatic.com).

Having the Model Number and Serial Number of your mac hine available when you cal l will allow us to

serve you quickly and accurately.

Parts List: Base Assembly

Index No. Part No. Description Size Qty

1 ............... DT65-101 .................Worktable .............................................................................................. 1

2 ............... DT65-102 .................Base Guide Rod .................................................................................... 1

3 ............... TS-1523041 .............Socket Set Screw ...............................................M6x12 ...................... 13

4 ............... DT65-104 .................Swi tch Bracket....................................................................................... 1

5 ............... TS-1550041 .............Flat Washe r ........................................................M6 .............................. 5

6 ............... TS-1503041 .............Socket Head Cap Screw .....................................M6x16 ........................ 2

7 ............... DT65-107 .................Magnetic Switch .................................................................................... 1

8 ............... TS-1501041 .............Socket Head Cap Screw .....................................M4x12 ........................ 2

9 ............... DT65-109 .................Scale ..................................................................................................... 2

10 ............. DT65-110 .................Fixed Chaser ......................................................2” pitch ....................... 1

................. DT65-110A ..............Fixed Chaser ......................................................2.5” pitch .................... 1

................. DT65-110B ..............Fixed Chaser ......................................................3” pitch ....................... 1

11 ............. TS-1503061 .............Socket Head Cap Screw .....................................M6x25 ........................ 3

12 ............. DT65-112 .................Template ............................................................................................... 1

13 ............. DT45-105 .................Locking Handle ...................................................M6x35 ........................ 2

14 ............. DT65-114 .................Fixing Bar ............................................................................................. 2

15 ............. TS-2361061 .............Lock Washer ......................................................M6 .............................. 4

16 ............. TS-1503081 .............Socket Head Cap Screw .....................................M6x35 ........................ 4

17 ............. DT65-117 .................Indicatio n Template ............................................................................... 1

18 ............. DT65-118 .................Sliding Rod ............................................................................................ 2

19 ............. DT65-119 .................Fence .................................................................................................... 4

20 ............. DT45-120 .................Locking Handle ...................................................M8x25 ........................ 5

21 ............. DT65-121 .................Buffer Pad ............................................................................................. 4

22 ............. TS-1550061 .............Flat Wash er ........................................................M8 .............................. 8

23 ............. TS-1490031 .............Hex Cap Screw ..................................................M 8 x20 ........................ 8

24 ............. DT45-126 .................Adjustment Screw.................................................................................. 1

25 ............. TS-1504061 .............Socket Head Cap Screw .....................................M8x30 ........................ 1

26 ............. DT45-128 .................Knurled Knob......................................................................................... 1

27 ............. DT45-129 .................Adjustment Seat .................................................................................... 1

28 ............. DT45-142 .................Buffer Pad ............................................................................................. 2

29 ............. TS-1550041 .............Flat Wash er ........................................................M6 .............................. 2

30 ............. TS-1503051 .............Socket Head Cap Screw .....................................M6x20 ........................ 2

31 ............. TS-2361081 .............Lock Washer ......................................................M8 .............................. 1

32 ............. TS-1503031 .............Socket Head Cap Screw .....................................M6x12 ........................ 2

26

Page 27

Base Assembly

27

Page 28

Parts List: Hold-Down Assembly

Index No. Part No. Description Size Qty

1 ............... DT65-301 .................Cylinder Assembly (Index #2 thru #16) .... ............................................. 4

2 ............... DT65-302 .................Cylinder Body .......................................... ............................................. 4

3 ............... DT65-303 .................Piston ...................................................... ............................................. 4

4 ............... DT65-304 .................Wearing ................................................... ............................................. 4

5 ............... DT65-305 .................Piston Backing......................................... ............................................. 4

6 ............... DT65-306 .................Piston Rod............................................... ............................................. 4

7 ............... TS-2361121 .............Lock Was h e r ........................................... M12 ....................................... 4

8 ............... TS-1540081 .............Hex Nut ................................................... M12 ....................................... 4

9 ............... DT65-309 .................Locking Piece .......................................... ............................................. 4

10 ............. DT65-310 .................O-Ring..................................................... ............................................. 4

11 ............. DT65-311 .................O-Ring..................................................... ............................................. 4

12 ............. DT65-312 .................End Cover ............................................... ............................................. 4

13 ............. DT65-313 .................Clamping Disc ......................................... ............................................. 4

14 ............. TS-1550061 .............Flat Wash er ............................................. M8 ......................................... 4

15 ............. TS-1490021 .............Hex Cap Screw ....................................... M8x16 ................................... 4

16 ............. DT65-316 .................Male Elbow Connector ............................. ............................................. 9

17 ............. DT65-317 .................Holder Bracket......................................... ............................................. 1

18 ............. DT65-318 .................Special Washer ....................................... ............................................. 4

19 ............. DT65-319 .................Locking Handle ........................................ M10x35 ................................. 4

20 ............. DT65-320 .................Stud ........................................................ ............................................. 4

21 ............. TS-

22 ............. TS-1550111 .............Flat Wash er ............................................. M20 ....................................... 8

23 ............. DT65-323 .................Holder Bracket......................................... ............................................. 1

24 ............. DT65-324 .................Fixing Bra ck e t .......................................... ............................................. 4

25 ............. TS-1502031 .............Socket Head Cap Screw .......................... M5x12 ................................... 8

26 ............. DT65-326 .................Control Valve ........................................... ............................................. 4

27 ............. DT65-327 .................Handle..................................................... ............................................. 4

28 ............. TS-1522011 .............Socket Set Screw .................................... M5x6 ..................................... 4

29 ............. TS-1502101 .............Socket Head Cap Screw .......................... M5x45 ................................... 8

30 ............. DT65-330 .................Male Connector ....................................... PT-1/8”-∅6 ............................ 8

31 ............. DT65-331 .................T- Connector ........................................... PT-1/8”-∅6 ............................ 3

32 ............. DT65-332 .................Air Supply Unit......................................... ............................................. 1

33 ............. DT65-333 .................Air Control

34 ............. DT65-334 .................Adapter ................................................... 3/8”X1/4" ...............................

35 ............. DT65-335 .................Male Coupling ......................................... PT-1/4” .................................. 1

36 ............. DT65-336 .................Male Elbow Connector ............................. PT-3/8”-∅6 ............................ 1

37 ............. TS-1550041 .............Flat Wash er ............................................. M6 ......................................... 2

38 ............. TS-1503041 .............Socket Head Cap Screw .......................... M6x16 ................................... 2

................. JPU0406Z ................Air Hose, Black (not shown) ..................... Ø6mm x ø4mm.............. 5m roll

................. JPU0406W ..............Air Hose, Clear (not shown) ..................... Ø6mm x ø4 mm .............. 2m roll

2310201 .............Hex Nut ................................................... M20 ..................................... 16

Valve ..................................... PT-1/8” .................................. 1

1

28

Page 29

Hold-Down Assembly

29

Page 30

Parts List: Headstock Assembly

Index No. Part No. Description Size Qty

1 ............... DT45-201 .................Spindle Assembly (Index #2 thru #10) .................................................... 1

2 ............... DT45-202 .................Spindle Bea rin g Hou sing ....................................................................... 1

3 ............... DT45-203 .................Ball Bearing (special) ..........................................6005 TB.P 63 .............. 2

4 ............... DT45-204 .................Fixing Nut .............................................................................................. 1

5 ............... DT45-205 .................Eccentric Spindle ................................................................................... 1

6 ............... TS-1524021 .............Socket Set Screw ...............................................M8x10 ........................ 2

7 ............... DT45-207 .................Spacer................................................................................................... 1

8 ............... DT45-208 .................Disc Spring ............................................................................................ 4

9 ............... DT45-209 .................Fixing Nut .............................................................................................. 1

10 ............. DT45-210 .................Grease Nipple ....................................................................................... 1

11 ............. DT65-211 .................Spindle Sl id e Seat ................................................................................. 1

12 ............. DT45-212 .................Gear Shaft ............................................................................................. 1

13 ............. TS-1550061 .............Flat Wash er ........................................................M8 .............................. 1

14 ............. TS-1490031 .............Hex Cap Screw ..................................................M 8 x20 ........................ 1

15 ............. DT45-215 .................Clamping P ie ce ..................................................................................... 1

16 ............. DT45-216 .................Bushing ................................................................................................. 1

17 ............. TS-1504121 .............Socket Head Cap Screw .....................................M8x60 ........................ 1

18 ............. DT65-218 .................Panel ..................................................................................................... 1

19 ............. DT45-219 .................Plug ....................................................................................................... 1

20 ............. TS-1550071 .............Flat Washer ........................................................M10 ............................ 1

21 ............. TS-1540071 .............Hex Nut ..............................................................M10 ............................ 1

22 ............. DT65-222 .................Hex Head Bolt ....................................................M10x150 .................... 1

23 ............. DT65-223 .................Indication Bracket .................................................................................. 1

24 ............. TS-1550031 .............Flat Wash er ........................................................M5 .............................. 6

25 ............. TS-1502041 .............Socket Head Cap Screw .....................................M5x16 ........................ 2

26 ............. DT65-226 .................Adjustment Piece................................................................................... 1

27 ............. TS-1501031 .............Socket Head Cap Screw .....................................M4x10 ........................ 2

28 ............. DT45-247 .................Tracer Pin.............................................................................................. 1

29 ............. DT45-248 .................Adjustment Screw.................................................................................. 1