Page 1

OWNER’S MANUAL

Model COS18 Cut-Off Saw

Left-Hand model shown,

with 8' and 4' optional r oller tables

WMH TOOL GROUP

Industrial Machinery Division

427 Sanford Road

LaVergne, TN 37086

▪

Ph: 800-248-0144

E-mail : powerm atic@wmhtool gr oup. com M-0460277 10/03 Rev. B

www.wmht oolgroup.com

Fax: 800-274-6840

Copyright © WMH Tool Group

Page 2

This manual has been prepared for the owner and operators of a Powermatic Model COS18

Cut-Off Saw. Its purpose, aside from proper machine operation, is to promote safety through

the use of accepted correct operating and maintenance procedures. Completely read the

safety and maintenance instructions before operating or servicing the machine. To obtain

maximum life and efficiency from your saw, and to aid in using the machine safely, read this

manual thoroughly and follow all instructions carefully.

Warranty & Service

WM H Tool Group warrants every product it sells. I f one of our tools needs service or r epair, one of our

Authorized Repai r Stations loc ated throughout the Uni ted States can give you quic k service.

In most cases, any one of these W M H Tool Group Repair Stations can author ize warranty repair, assist you in

obtaining parts, or perform routine maintenanc e and major repair on your J E T, Performax, Powermatic or

Wilton tools.

For the nam e of an Authorized Repair Station in y our ar ea, call 1-800-274- 6848.

More Information

WM H Tool Group is consistently adding new products to the line. For complete, up-to-date produc t

infor mation, c hec k with your local WMH Tool Group distributor or visit wm htoolgroup.com.

Limited Warranty

WM H Tool Group (including JET, Per formax, Powermatic and Wilton brands) m akes every effort to assure

that its products meet high quality and durability standards and warrants to the ori ginal retail

consumer/purc haser of our products that each product be free from def ec ts in materials and workmanship as

foll ows: 1 YEAR LIMITED WARRANT Y ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE. This

warranty does not apply t o defects due directly or indirec tly to m isuse, abuse, negligence or acc idents, normal

wear-and-tear, repair or alter ations outside our facilities, or to a lack of maintenance.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE, FROM

THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREI N, ANY IMPLIED

WARRANTIES OR MERCHANTI B I LI TY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW

LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY TO YOU. WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO

PERSONS OR PROPERTY, OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL

DAMAGES ARISING FROM THE USE OF O UR P RODUCTS. SOME STATES DO NOT ALLOW THE

EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

To take advantage of thi s warranty, the product or part must be returned for examination, postage prepaid, to

an Authorized Repair Station designated by our office. Proof of purchase date and an expl anation of t he

complaint must accompany the merchandise. If our inspection discl oses a def ec t, W M H Tool Group will

either repair or r eplace the product, or r efund the purchase pric e if we cannot readily and quickly prov ide a

repair or replacement, if you are willing to accept a refund. WMH Tool Group will return repaired product or

replacement at our expense, but if i t is determined there is no def ec t, or that the defect result ed from causes

not within the scope of our warranty, then the user must bear t he c ost of storing and ret ur ning the product.

This warranty gi ves you specific legal r ights; you may also have other ri ghts, whic h vary from state to state.

WM H Tool Group sells through distributors only. WMH Tool Group reserves the right to effect at any tim e,

without pri or notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

2

Page 3

TABLE OF CONTENTS

Safety Rules...............................................................................................................................................4-5

Safety Decals ................................................................................................................................................ 6

Specifications................................................................................................................................................7

Features........................................................................................................................................................8

Receiving......................................................................................................................................................9

Installation & Assembly..................................................................................................................................9

Handwheel............................................................................................................................................. 9

Electrical Connections .........................................................................................................................10

Extension Cords.................................................................................................................................. 10

Dust Collection.................................................................................................................................... 11

Operating Controls...............................................................................................................................11

Installing/Changing Blade ....................................................................................................................11

Air Supply............................................................................................................................................12

Squaring the F ence..............................................................................................................................12

Installing Roller Tables (Optional)........................................................................................................12

8-Foot Table Guide ............................................................................................................ .................. 14

Leveling & Aligning Roller Tables........................................................................................................14

Adjustments................................................................................................................................................. 15

Blade Travel........................................................................................................................................15

Clamp Height Adjustment....................................................................................................................15

Belt Replacement................................................................................................................................16

Operation....................................................................................................................................................16

Maintenance................................................................................................................................................ 16

Optional Accessories...................................................................................................................................17

Parts Lists & Exploded Views:

Table & Motor Assembly................................................................................................................. 18-21

Stand Assembly..............................................................................................................................22-24

Air Control Assembly......................................................................................................................25-27

Safety Guard Assembly..................................................................................................................28-31

4' Roller Table Assembly................................................................................................................32-33

8' Roller Table Assembly................................................................................................................34-35

Pneumatic Diagram........................................................................................................................ 36-37

Electrical Schematic.................................................................................................................................... 38

Prev entiv e M aintenance Checklist...............................................................................................................39

3

Page 4

!

SAFETY RULES

As with all m achines, there i s a certain amount of hazard inv olv ed with the use of thi s c ut-off saw. Use t he

machine with the respect and caution demanded where safety precautions are concerned. When normal

safety precautions are overlooked or ignored, personal injury to the operator can result.

Read, understand and follow the safety and oper ating instruct ions found in this manual. Know the

limitati ons and hazar ds associated with this machine.

Electrical grounding. Make certain that the machine f r ame is elect r ically gr ounded and that a ground lead is

included in the incom ing electrical service. In cases where a cord and plug are used, make certai n that the

grounding plug connects to a suitable ground. Follow the grounding procedure indic ated in the Nati onal

Electrical Code.

Eye safety. Wear an approved safety shield, goggles, or gl asses to protect eyes. (NOTE: Common

eyeglasses are only impact-resistant, they are not safety glasses.)

Personal protection. Before operating the mac hine, remove tie, rings, watch and other jewelry and roll up

sleeves above the elbows. Rem ove all loose outer clot hing and confi ne long hair. Protective type footwear

should be used. Where the noise exceeds the level of exposure allowed in Secti on 1910.95 of the OS HA

Regulations, use hearing protecti ve devices. Do not wear gloves.

Guards. Keep the machine guards in place for every operation for which t hey c an be used. If any guards are

removed for maintenance, DO NOT OPERATE the machine until t he guar ds are reinstalled. The blade guard

is air act uated; it i s al so a clamp for stoc k . Never shut off or disconnect air while oper ator or bystanders are

near guard.

Work area. Keep the floor around the machine clean and free of scr ap material, saw dust, oil and other

liqui ds t o minimize the danger of tripping or slipping. B e sure t he table is fr ee of all scrap, foreign material

and tools befor e st ar ting to cut. M ak e c er tain the work area is well lighted and that a pr oper exhaust system is

used to minimize dust. Powermatic r ec ommends the use of anti-skid floor strips on the floor area where the

operator normally stands and that eac h machine’s work area be mark ed off. P r ovide adequat e work space

around the machine.

Avoid accidental starting: Make certain motor switch is in off position before connecting power to the

machine.

Operator position. Maintain a balanced stanc e and k eep y our body under c ontrol at all tim es.

Housekeeping. Bef or e turning on machine, remove all extra equipment such as keys, wrenches, scrap, and

cleaning rags away from the machine.

Careless acts. Give the work you are doing your undivided att ention. Looking around, carrying on a

conver sation, and “horseplay” ar e c ar eless acts that can result in serious injury.

Disconnect all power so urces (both air and electric) before perf orming any service, maintenance,

adjustment s or when changi ng blades. When the air li ne is disconnected or turned off, the guard will

immediately drop down to the table. Keep hands clear of guard at all times. A machine under repair should be

RED TAGGE D to show it should not be used until the maintenance is complete.

Maintain cutting tools in top condition. Keep blades sharp and clean for safe and best performance. Dull

tools incr ease noi se l evels and can cause ki c k bac ks and glazed surfaces. Check the condition and

adjustment of the tool s before maki ng any cuts.

Hand safety. K eep hands outsi de the machine. Do not clear chips and sawdust with hands; use a brush.

4

Page 5

Job completion. If the operat or leaves the machine area for any reason, the cut- off saw should be turned

"off" and the blade should c ome to a complete stop before his departure. In addi tion, if the operati on is

complete, he should clean the saw and the work area. NEVER clean the saw with power "on" and never use

the hands to clear sawdust and debris; use a brush.

Replacement p art s. Use only Powermatic or fact or y authorized replac ement parts and accessories;

otherwise the warranty and guarant ee is null and void.

Misuse. Do not use t his Powermatic cut-off saw for other than its intended use. If used for other purposes,

Powermati c disclaim s any real or implied warranty and holds itself harmless for any injury or dam age whic h

may result from that use.

If you are not t horoughly familiar with the operation of cut - off saws, obtain advice from your supervisor,

instructor or other qualified person.

Drugs, alcohol, medication. Do not operate this machine while under the influence of drugs, al c ohol, or any

medication.

Health hazards. Some dust created by power sanding, sawing, grindi ng, drilling and other construction

activities contains chemicals known to cause cancer, bir th defects or other r epr oductive harm. Some

examples of these chemicals are:

* Lead from lead-based paint.

* Crystalline silica from bricks and cement and ot her masonry products.

* Arsenic and chromium from chemically-treated l umber.

Your risk from these ex posures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work i n a well-ventilated area, and work with approved safety equipment, such

as those dust masks that are specifically designed to f ilter out microscopic par ticles.

Familiarize yourself with the following safety notices used in this manual:

CAUTION: (This means that if precaut ions are not heeded, it may result i n minor or moderate inj ur y

!

and/or possible machine damage)

WARNING: (Thi s means that if precautions are not heeded, it could result in serious injur y or

!

possibly even death).

5

Page 6

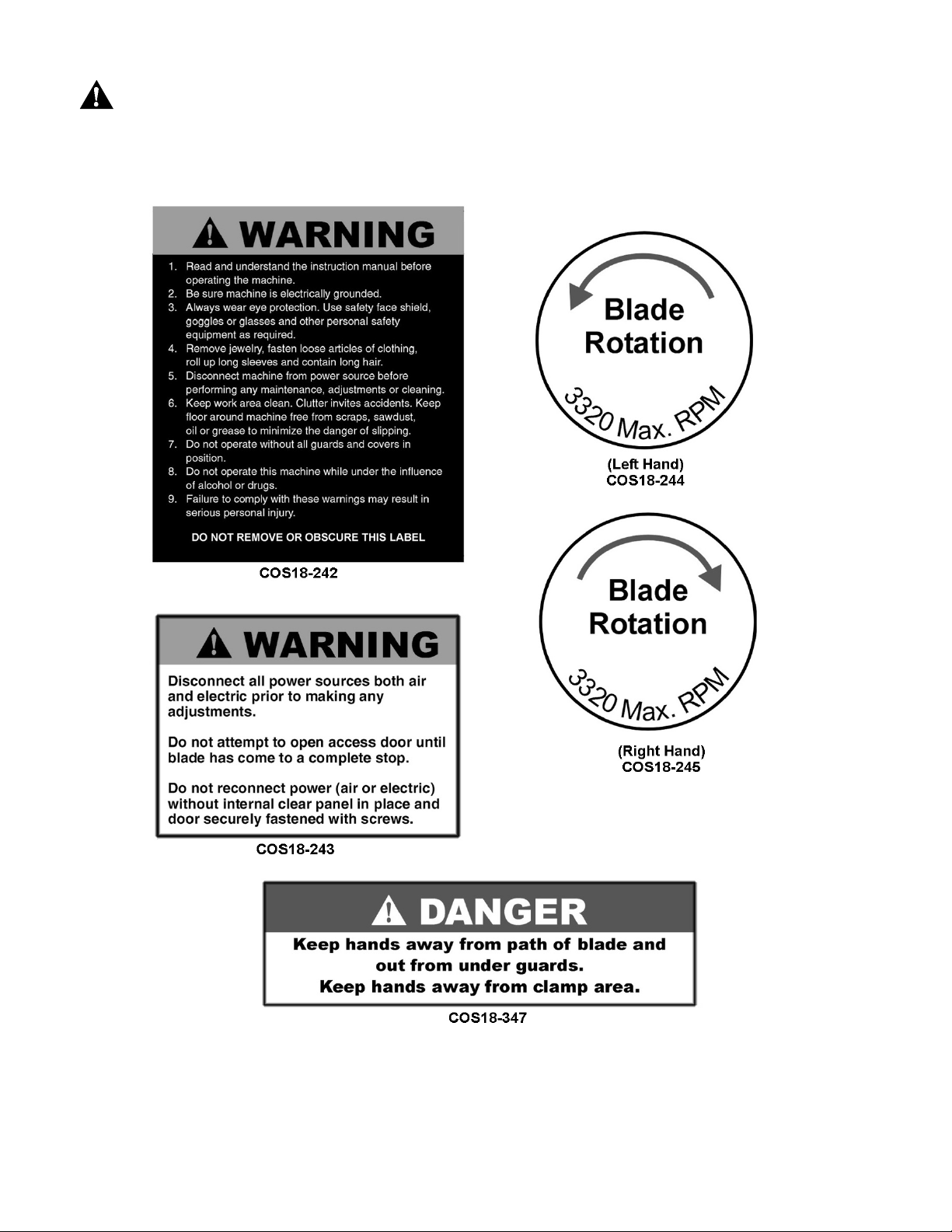

!

SAFETY

Familiarize yourself with the location and content of these decals on your machine.

FIGURE 1

6

Page 7

SPECIFICATIONS: COS18 Cut-Off Saw

Stock num ber (COS18L).....................................................................................................................1791294

Stock number (COS18R)....................................................................................................................1791289

Motor........................................................................................................................... .. 10HP, 3Ph, 230/460V

Blade size......................................................................................................................... 18" diameter / 120T

Arbor size.....................................................................................................................................................1"

Arbor speed.....................................................................................................................................3320 RP M

Cutting capac ity @ maximum height .......................................................................................4-3/8" x 10-1/2"

Cutting capac ity @ m aximum width ...............................................................................................1" x 13-3/8"

Table si ze....................................................................................................................................26-1/2" x 28"

Table hei ght................................................................................................................................................33"

Air supply r equired................................................................................................................. 15 CFM / 70 PSI

Cycles per minute (maximum)..................................................................................................................... 70

Dust port.......................................................................................................................................................4"

Minimum CFM........................................................................................................................................... 600

Gross weight........................................................................................................................................850 lbs.

Net weight ...........................................................................................................................................730 lbs.

NOTE: T he above specificati ons were current at the time this manual was published, but because of our

policy of continuous improvement, Powermatic reserves the right to change specifications without not ice and

without inc ur r ing obligations.

7

Page 8

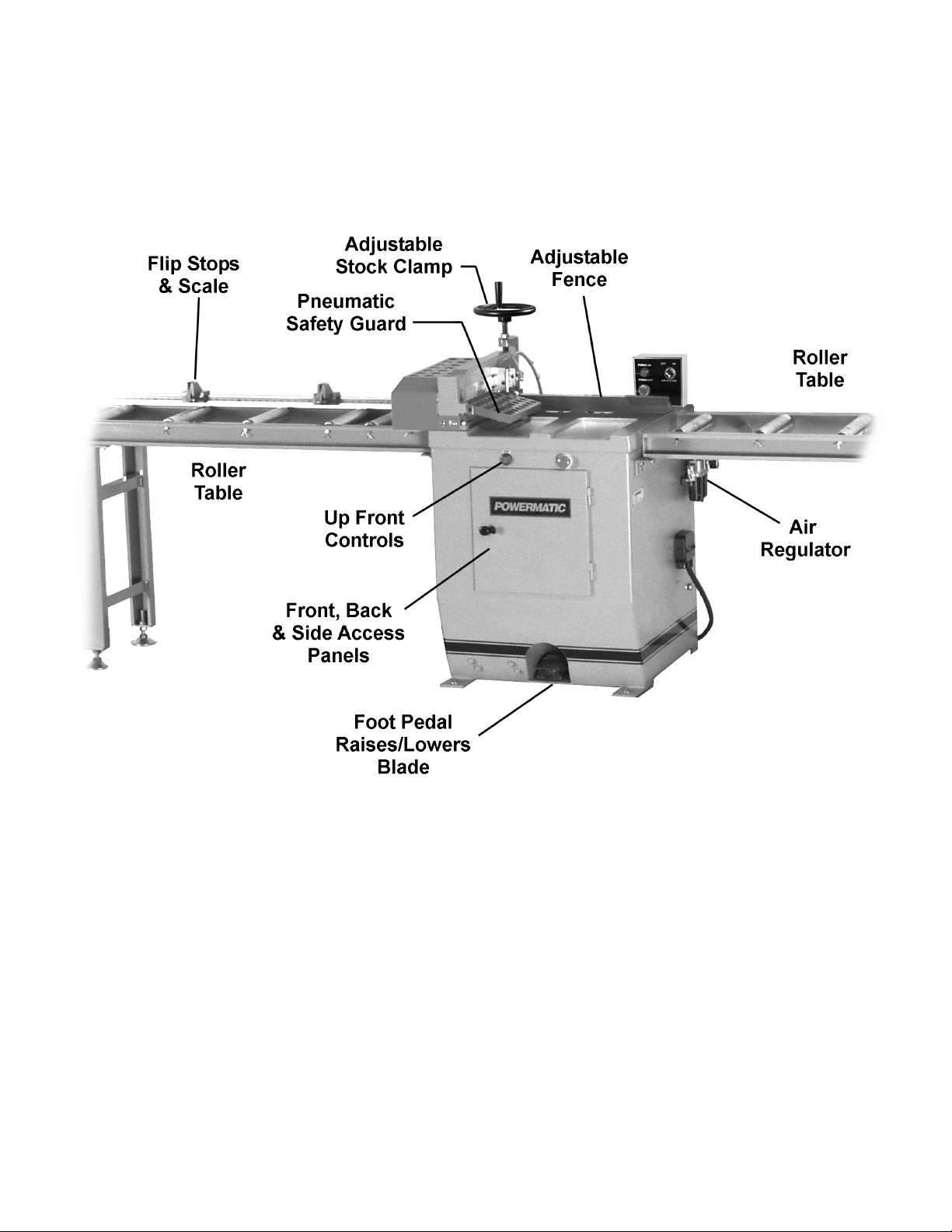

FEATURES: COS18 Cut-Off Saw

FIGURE 2

8

Page 9

RECEIVING

Open shipping crate and check for shipping

damage. Report any damage immediately to

your distri butor and shipping agent . Before using

the cut-off saw, read the instruction manual

thoroughly for assembl y, mai ntenance and safety

instructions.

Contents of crate:

1 Cut-off saw

1 Handwheel

1 Toolbox c ontaining:

1 hex wrench set

1 socket wrench

1 open-end wrench set

1 Manual

1 War ranty card

INSTALLATION & ASSEMBLY

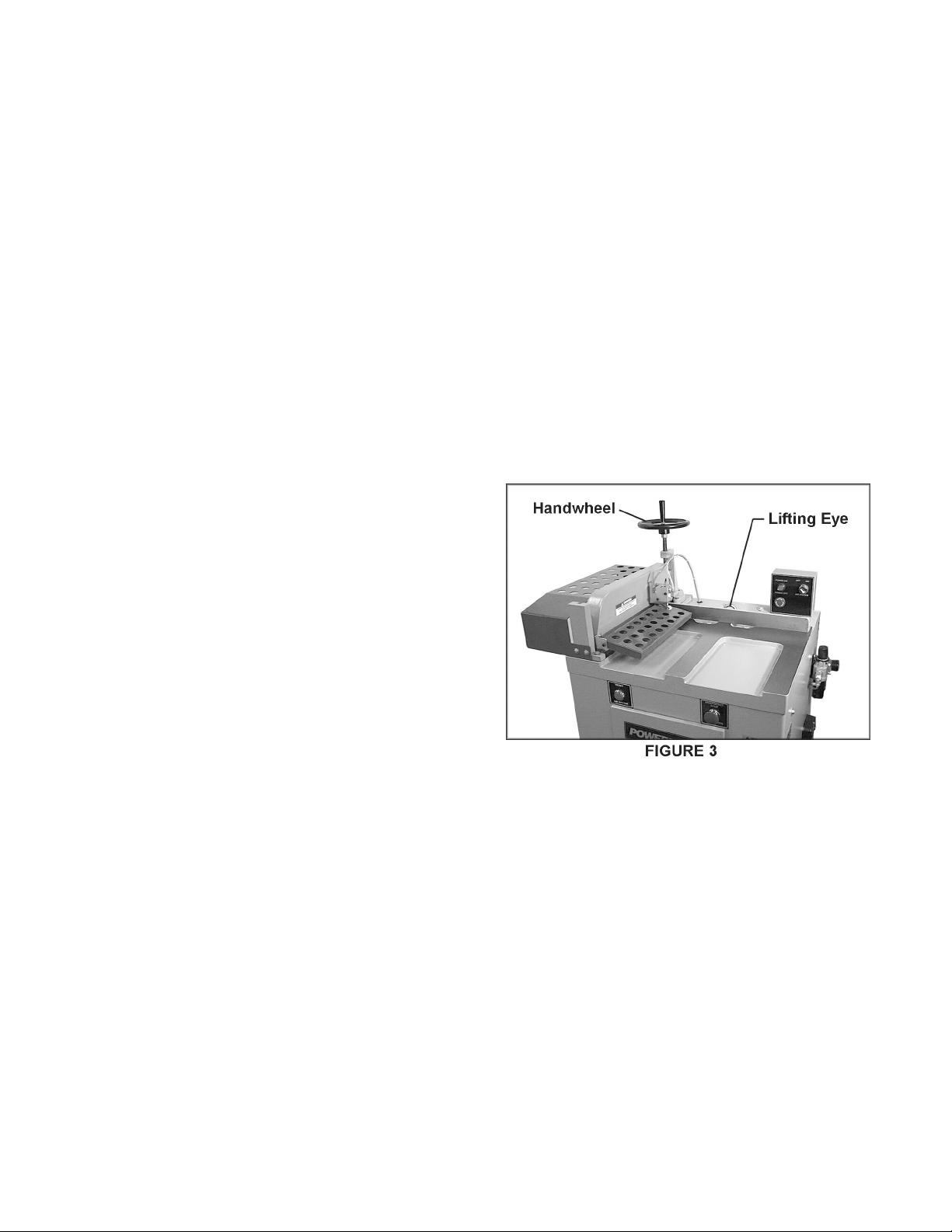

1. Lift the m achi ne with a hoist or fork li ft , using

a sling through the lifting eye on top the

machine, shown in Figure 3. Mak e sur e the

capacity of the lifting unit is sufficient to

safely lift this size machine.

2. The cut-off saw (with any roller table

extensions) should be l ocat ed i n an area that

is well-lit, with enough room around it for

loading and off-loading stock and general

servi cing of the machine.

3. The saw cabinet should be bolt ed to the fl oor

through the holes at the four corners, using

high quali ty lag screws.

Unpainted surf aces, such as the table and f ence,

have been given a protective coating at the

factory. This should be removed with a soft rag

moistened with a good commercial solvent. Do

not use acetone, lac quer thinner, gasoli ne or any

flammable sol vents. Do not use an abrasi ve pad.

HANDWHEEL

Install the handwheel onto the threaded rod as

shown (Fig. 3).

9

Page 10

ELECTRICAL CONNECTIONS

WARNING: Electrical connectio ns must

!

be made by a qualified electrician in

compliance will all relevant cod es. The

machine must be properly grounded to

help prevent electrical shock and

possible death.

A power plug is not provided with the COS18.

You may either connect one, or "hard-wire" the

machine di rectl y to your elect rical panel prov ided

there is a disconnect near the machine.

Consult electrical schematic on page 34 for

further clarification of wiring setup.

This machine must be grounded. Grounding

provi des a path of least resistance t o help divert

current away from the operator in case of

electrical malfunction.

Make sure the voltage of your power supply

matches the specifications on the motor plate of

the machine.

After wiring, disconnect machine from power

source, open the blade access door, rem ove the

internal clear panel, and remove the blade (see

"Installing/Changing Blade"). Re-connect the

power and turn on t he saw motor (see "Oper ating

Controls"). Observe the rotation of the arbor – it

should rotate count erclockwise on the LH model,

clockwise on t he RH m odel . I f i t does not, tur n of f

the machine, disconnect power, and switch any

two of the thr ee electric al leads.

NOTE: A label is affixed to the internal clear

panel to help identify proper rotation.

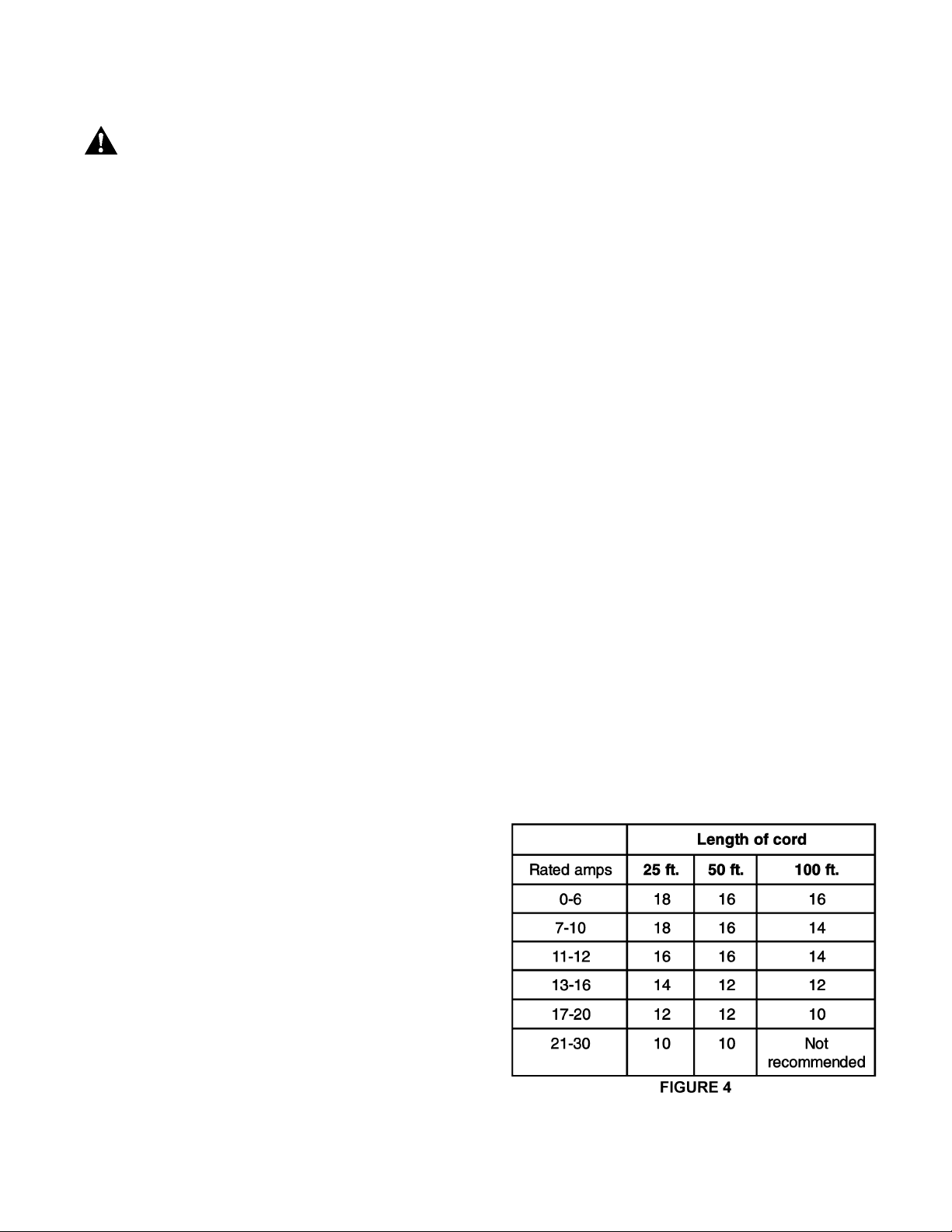

EXTENSION CORDS

If an ex tension cord is necessary, m ake sure the

cord rati ng is suitabl e for the amper age listed on

the machine's motor plate. An undersized cord

will cause a drop in line voltage resulting in loss

of power and overheating.

The chart i n Figure 4 shows the correct si ze cord

to use based on cord lengt h and nameplate am p

rating. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the

cord.

10

Page 11

DUST COLLECTION

Powermatic recommends the use of a dust

collection system with this cut-off saw. The

collector should have sufficient capacity (600

CFM) for this size machine.

Mount the dust collector via a 4" hose to the

outlet on t he blade access door.

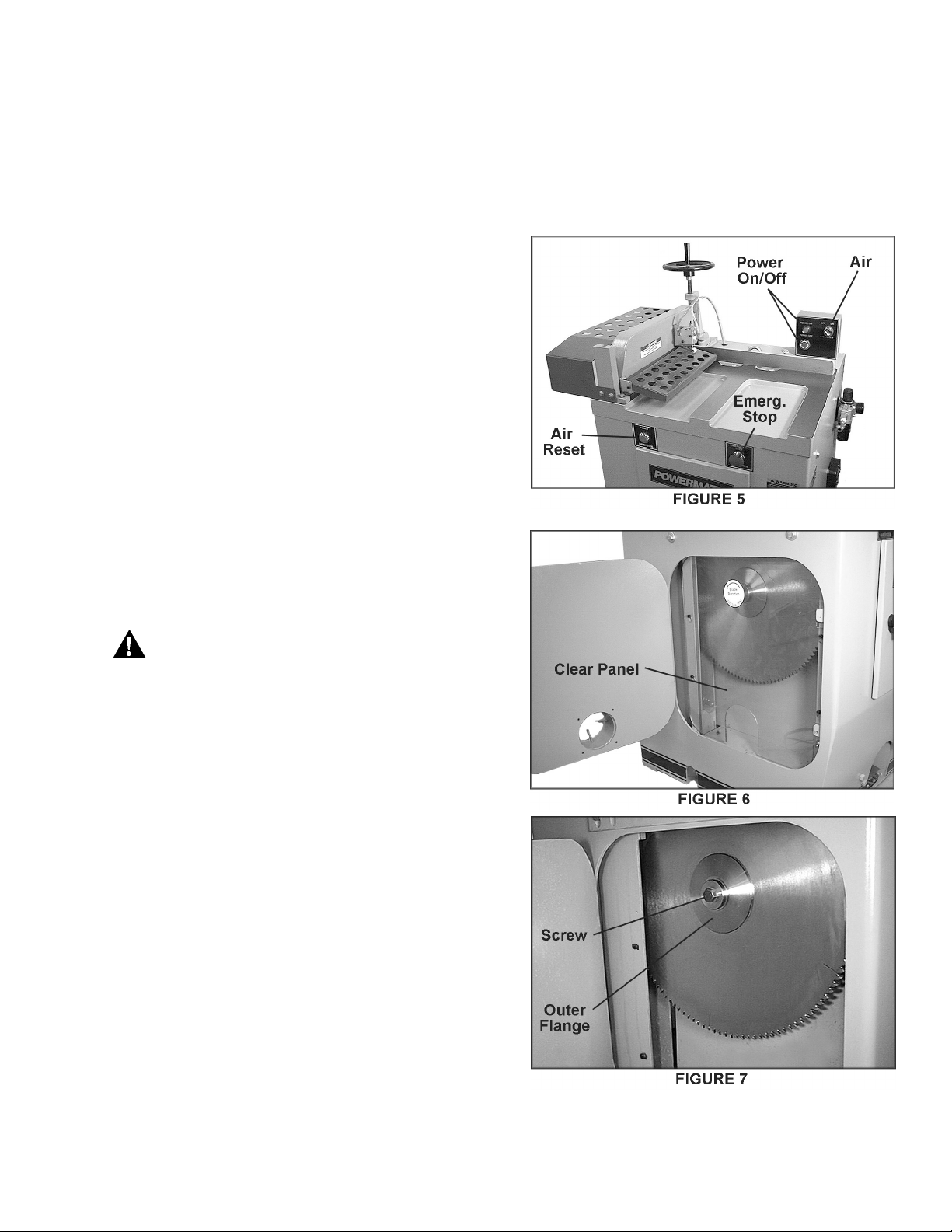

OPERATING CONTROLS

Control buttons are in two locations on the saw,

and are shown in Figure 5. A main start and stop

button i s located at t he back of the tabl e top. An

emergency stop but ton is also f ound on the front.

The air -cont rol switch, i n both l oc ati ons, start s the

flow of air to the cy linder.

INSTALLING / CHANGING BLADE

1. Disconnect machine from power source.

WARNING: Never attemp t t o open bl ade

!

access door until blade has come to a

complete stop.

2. Open the saw blade access door by

loosening the screws.

3. Remov e the clear panel guarding the blade

(Fig. 6) by loosening the screws and lifting

up on the panel.

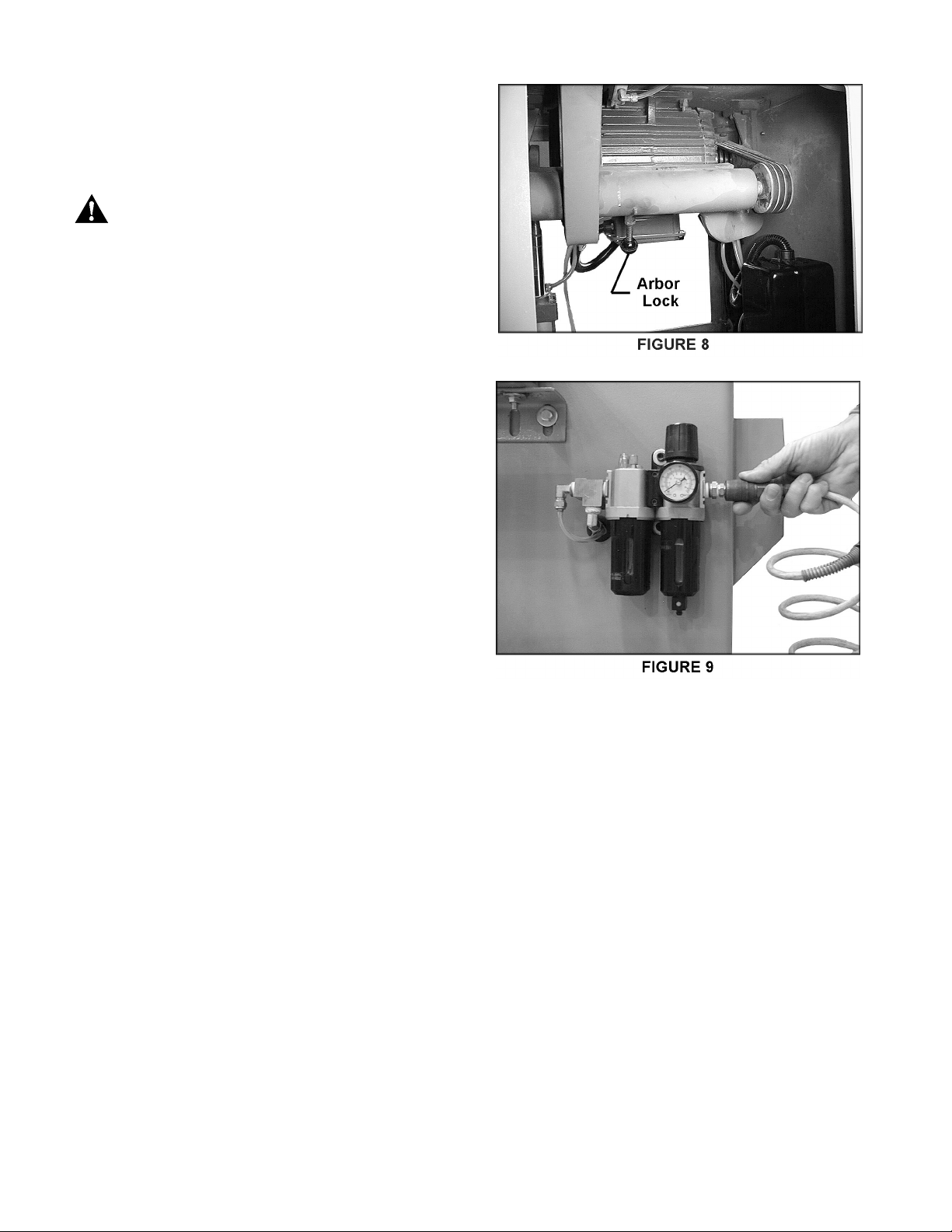

4. Lock the arbor by pulling the lever ( Fig. 8).

4. Loosen hex screw (Fig. 7) on the arbor.

(counterclockwise to loosen on the LH

model; clockwise on RH model). Remove

hex screw and outer flange from the arbor.

5. Mount the blade on the arbor as shown,

making sure the teeth are pointed in the

proper direction – the teeth at top of blade

should point toward rear of machine.

6. Re-install outer flange and screw, and

tighten securely.

11

Page 12

7. Re-install clear panel and c lose blade access

door, fasteni ng it securely. NO TE: A sensor

switch on the door will automatically shut

down the saw if the door i s opened whi le the

blade is moving.

WARNING: Do not reconnect power, air

!

or electric, without internal clear panel in

place and door securely fastened with

screws.

AIR SUPPLY

The correc t ai r pr essure for t he COS18 saw is 70

PSI. At tach the hose from your air source to the

machine' s air val ve as shown in Figure 9.

SQUARING THE FENCE

The best way to square the fence is to make

sample c uts. Using a square, check the end of a

board af ter it has been chopped. If the cut is not

square, proceed as follows:

1. Loosen one of the bolts on the fence and

lightly tap the fence with a block or mallet .

2. Retighten the bolt, and make another cut.

Repeat as necessary until fence is square.

INSTALLING ROLLER TABLES

(OPTIONAL)

Four-f oot and 8-f oot roll er tables are av ail able as

accessories to your cut- off saw. The roller tables

can be used as infeed or outfeed tables and

mounted to either side of the saw. The terms

"Right Hand" and "Left Hand" Model are

determined by the location of the blade in

reference to the main table. (The cover of this

manual shows a lef t-hand model. )

12

Page 13

To mount roller tables to saw:

1. Mount an angle bracket to the pre-drilled

holes in the side of the saw cabinet with four

M8 x 20 hex cap screws and four M8 flat

washers (Fig. 10). Do not fully tighten yet.

2. Place the roller table upside down on a flat

surface and attach the leg assemblies with

four M8 x 25 hex cap screws, eight M8 flat

washers, and four M8 hex nuts per leg

assembly (Fig. 11).

3. Screw an adjustable foot pad into each leg

as shown in Figure 12.

4. Flip the roller table ri ght-side up and mount it

to the angl e brack et on t he cabi net as shown

in Figur e 10. Use two M8 x 25 screws, four

M8 f lat washers and two M8 hex nuts. Do not

fully tighten y et.

13

Page 14

8-FOOT TABLE GUIDE

1. The 8-foot table comes with a guide and

scale. The guide should be mounted to the

edge of the table with six M8 x 27 square

head bolts, six M8 flat washers and six M8

hex nuts (Fig. 13).

2. Attach the three stops to the 8-foot table

guide (Fig. 13). These stops can be slid to

any point along the guide and secured by

tightening the lock l evers.

LEVELING & ALIGNING ROLLER TABLES

Each roller table must now be leveled with the

main saw table and aligned with t he fence. (The

fence m ust be square with blade – see "Squaring

the Fence", page 11.)

WARNING: Disconnect saw from both

!

air and elect ric power sou rces.

1. Select a piece of scrap board with a good

straight edge, 4 to 6 feet i n length.

2. Raise the blade guard and keep it raised.

Place t he board, straight edge down, on the

saw table surface and allow it to extend to

the second or third roller of the roller table

(Fig. 14).

3. Level the roller table by loosening the hex

nut on the f oot pad and screw the f oot pad in

or out. (see Fig. 12).

4. When roller table and main table are lev el,

tighten t he nuts on the foot pads.

14

Page 15

5. Now pl ace the board f lush against the f ence

and against the rail of the roller table(s). If

necessary, shif t a roller tabl e horizontally to

bring it in line wit h the fence.

6. When final adjustments have been made

and re-checked on the roller tables, tighten

all screws/nuts connecti ng t he rol ler tabl es to

the angle brackets.

CAUTION: Never adjust the outfeed

!

table level higher than the level of the

machine tab le surface.

ADJUSTMENTS

WARNING: Disconnect all power

!

sources, both air and electric, prior to

making adjustments.

BLADE TRAVEL

To adjust the speed by which t he saw blade (and

the cl amp) trav el up and down, open the cabi net

door and locate the upper and lower pressure

regulating valves which are attached to the air

cylinder (Fig. 15). Turni ng these will regul ate the

trav el speed of t he blade and clamp. The c lamp

will lower during the blade's upstroke, and rise

during the bl ade's downstroke.

The top valve (shown in Fig. 15) adjusts the

speed of the blade's downstroke (and the speed

of the cl amp as it rises back up). Turn the knob

counterclockwise to increase the speed, c lockwise

to decrease. W hen the speed is satisfact ory, lock

the setting by tightening t he knurled nut.

Repeat for the lower valve, which adjusts the

speed of the blade' s upstroke (and t he loweri ng of

the clamp).

CLAMP HEIGHT ADJUSTMENT

The distance between the stock clamp and the

workpiece can be adjusted by turning the

handwheel (Fig. 16). Line up the red indicator

plate with t he measurement on the scale. Ideall y,

there should be a space of 1/8" between the

clamp and the workpi ece. Aft er setting the c lamp

height, move the hex nut downward and tighten

against the casting as shown – this will prevent

your setting being altered by machine vibrations.

IMPORTA NT: The cl amp height adjustment m ust

be made each time the workpiec e si z e c hanges.

15

Page 16

BELT REPLACEMENT

1. Release tension on the v-belt and remove

old belt.

2. Make sure the new belt is properly situated

into the v-grooves of the pul ley.

3. Tension new belt.

OPERATION

WARNING: Do not place your hands

!

close to the guard/clamp at any time

during operations. All guards must be

install ed before using the machine.

1. St ar t the motor and the air supply.

2. Adjust height of clamp so it clears the

workpiece by about 1/ 8" .

3. Set the appr opri ate stop( s) on the rol l er tabl e

and load the stock on to the machine from

the infeed side.

4. When the stock is situated, press the foot

pedal to m ak e the cut.

WARNING: If the motor is shut off, but

!

the air is still on, the clamp will still be in

raised position. Turning off the air will

cause the clamp to lower suddenly. Keep

hands clear! Re-starting the air will cause

the clamp to rise suddenly.

MAINTENANCE

Frequently drain any water out of the pneumatic

valve.

The exposed met al areas on the table and f ence

should be kept clean and free f rom rust. A pply a

coat of paste wax as needed. Another option is to

briskly rub talcum powder into the surf ace with a

clean blackboard eraser.

Bearings should be greased thr ough the f itt ing on

the center of the arbor housing (F ig. 18).

16

Page 17

OPTIONAL ACCESSORIES - COS18 Cut-Off Saw

Part No. Descriptio n

6827037 ............. 8' Roller Table

6827038 ............. 4' RollerTable

6080157 ............. Blade, 18" 120T, 1" B or e

6080158 ............. Premium Blade, 18", 120T, 1" B or e

17

Page 18

PARTS LIST: Table & Motor Assembly (COS18 Cut-Off Saw)

Index Part

No. No. Descrip t ion Size Q t y.

1 ......... COS18-101L...........Casting Table (Left Hand)........................... .......................................... 1

1 ......... COS18-101R..........Casti ng Table (Right Hand) ........................ ..........................................1

2 ......... TS-1505051............Socket Head Cap Screw.............................M10x35.............................. 4

3 ......... TS-2361101............Lock W asher..............................................M10…………………………..4

4 ......... COS18-104 ............Bracket....................................................... ..........................................2

Φ

5 ......... COS18-105 ............Pin .............................................................

6 ......... BB-6204ZZ.............Ball Bearing................................................6204ZZ……….…………… . 2

7 ......... COS18-107............Spindle.......................................................……………………………… 2

8 ......... COS18-108L...........Spindle Frame (Left Hand) ......................... .......................................... 1

8 ......... COS18-108R..........Spindle Frame (Right Hand)....................... .......................................... 1

9 ......... TS-1523031............Socket Set Screw.......................................M6x10................................ 2

10 ....... TS-2211451............Hex Cap Screw..........................................M12x45.............................. 2

11 ....... TS-2360121............Fl at Washer................................................M12 ................................... 2

........... COS18-109L...........Spindle Assembly (Left Hand) (Items 12 thru 17 & 19 thr u 28)............... 1

........... COS18-109R..........Spindle Assembly (Right Hand) (Items12 thru 17 & 19 thr u 28) ............. 1

12 ....... COS18-112 ............Main Shaft Housing.................................... .......................................... 1

13 ....... COS18-113L...........Main Shaft.................................................. ..........................................1

13 ....... COS18-113R..........Main Shaft.................................................. ..........................................1

14 ....... BB-6206Z...............Ball Bearing................................................6206Z ................................ 2

15 ....... COS18-115L...........Spacer (Left Hand)..................................... .......................................... 1

15 ....... COS18-115R..........Spacer (Right Hand)................................... .......................................... 1

16 ....... COS18-116L...........Spacer (Left Hand)..................................... .......................................... 1

16 ....... COS18-116R..........Spacer (Right Hand)................................... .......................................... 1

17 ....... COS18-117 ............Spindle Collar............................................. .......................................... 1

18 ....... 6080157 .................Saw Blade..................................................

19 ....... COS18-119 ............Spindle Collar............................................. .......................................... 1

20 ....... COS18-120L...........Socket Head Cap Screw.............................M12x30 (L.H.).................... 1

20 ....... TS-1506031............Socket Head Cap Screw.............................M12x30 (R.H.)................... 1

21 ....... COS18-121 ............Key.............................................................7x7x50............................... 1

22 ....... COS18-122 ............Pulley......................................................... .......................................... 1

23 ....... COS18-123 ............Adapter ...................................................... .......................................... 1

24 ....... TS-1503061 ...........Socket Head Cap Sc r ew.............................M6x25................................ 3

25 ....... COS18-125 ............Special Pin................................................. .......................................... 1

26 ....... COS18-126 ............Locker........................................................ .......................................... 1

27 ....... COS18-127 ............Spring........................................................ ..........................................1

28 ....... COS18-128 ............Knob..........................................................W3/8”x30...........................1

29 ....... TS-1492031............Hex Cap Screw..........................................M12x35.............................. 2

30 ....... COS18-130L...........Bracket (Left Hand).................................... .......................................... 1

30 ....... COS18-130R..........Bracket (Right Hand).................................. ..........................................1

31 ....... TS-1503091............Socket Head Cap Screw.............................M6x40................................ 2

32 ....... TS-1550041 ...........Flat Washer................................................M6 .....................................6

33 ....... COS18-133 ............Fix Plate..................................................... ..........................................1

34 ....... TS-1540041............Hex Nut......................................................M6x1P............................... 6

35 ....... COS18-135 ............Limited Switch Seat.................................... .......................................... 1

36 ....... TS-1503041............Socket Head Cap Screw.............................M6x16................................ 2

39 ....... COS18-139 ............Limit Switch................................................ .......................................... 1

40 ....... COS18-140 ............Tube Fitt ings (L type) .................................1/8"x

41 ....... COS18-141 ............Silencer......................................................1/8".................................... 1

42 ....... TS-2284252............Pan Head Machine Scr ew ..........................M4x25................................ 3

6x30................................ 2

Φ

18”x25.4x120T................1

Φ

6..............................2

18

Page 19

PARTS LIST: Table & Motor Assembly (COS18 Cut-Off Saw) continued

Index Part

No. No. Descrip t ion Size Q t y.

43........ TS-1540021 ...........Hex Nut ..................................................... M4x0.7P.............................3

44........ TS-1491101 ...........Hex Cap Screw.......................................... M10x60 ..............................4

45........ TS-1550071 ...........Flat Washer............................................... M10....................................4

46........ COS18-146L..........Motor, 10HP, 3PH, 230/460V, 60Hz (LH)... ...........................................1

46........ COS18-146R .........Motor, 10HP, 3PH, 230/460V, 60Hz, (RH) ...........................................1

47........ TS-1540071 ...........Hex Nut ..................................................... M10x1.5P...........................8

48........ COS18-148 ............Key............................................................ 10x8x75 .............................1

49........ TS-1523031 ...........Socket Set Screw....................................... M6x10................................1

50........ COS18-150 ............Pulley ........................................................ ...........................................1

51........ COS18-151 ............Special Flat Washer................................... ...........................................1

52........ COS18-152L..........Socket Head Cap Screw............................ M10x30 (L.H)......................1

52........ TS-1505041 ...........Socket Head Cap Screw............................ M10x30 (R.H).....................1

53........ COS18-153 ............Socket Head Cap Screw............................ M6x16................................2

55........ COS18-155 ............Fix Plate .................................................... ...........................................1

56........ COS18-156 ............V-Belt ........................................................ 3V-1310.............................. 3

57........ TS-1506051 ...........Socket Head Cap Screw............................ M12x40 ..............................4

58........ TS-2361121 ...........Lock Washer.............................................. M12....................................4

19

Page 20

Table & Motor Assembly – Left Hand (COS18 Cut-Off Saw)

20

Page 21

Table & Motor Assembly – Right Hand (COS18 Cut-Off Saw)

21

Page 22

PARTS LIST: Stand Assembly (COS18 Cut-Off Saw)

Index Part

No. No. Descrip t ion Size Q t y.

1 ......... COS18-201L...........Stand (Left Hand)....................................... .......................................1

1 ......... COS18-201R..........Stand (Right Hand)..................................... .......................................1

2 ......... TS-1481041............Hex Cap Screw..........................................M5x16 ........................... 12

3 ......... TS-1550031............Flat Washer................................................M5 ..................................2

4 ......... COS18-204 ............Pedal S witch ..............................................230-8A............................1

φ

5 ........ COS18-205 ............Tube Fitt ings (I type) ..................................1/4"x

6 ......... COS18-206 ............Silencer......................................................1/4”.................................2

7 ......... COS18-207 ............Rubber Sleeve ........................................... .......................................1

8 ......... COS18-208L...........Front Door (Left Hand) ............................... .......................................1

8 ......... COS18-208R..........Front Door (Right Hand)............................. .......................................1

9 ......... COS18-209 ............Lock........................................................... .......................................1

10 ....... COS18-210 ............Key............................................................. .......................................1

11 ....... COS18-211 ............Emergency Button...................................... .......................................1

12 ....... COS18-212 ............Quick Fittings.............................................1/4”.................................1

13 ....... COS18-140 ............Tube Fitt ings (L type) .................................1/8"x

14 ....... COS18-214 ............Air Pressure Start Button............................ .......................................1

15 ....... COS18-215 ............Tube Fitt ings (T type) .................................1/8"x

16 ....... TS-1502021............Socket Head Cap Screw.............................M5x10……………………18

17 ....... COS18-217 ............Plate........................................................... .......................................1

18 ....... TS-2310051............Hex Nut......................................................M5x0.8P ………………….2

19 ....... COS18-219 ............Safety Cover, P.V.C................................... .......................................1

21 ....... COS18-221L...........Side Door (Left Hand)................................. .......................................1

21 ....... COS18-221R..........Side Door (Right Hand).............................. .......................................1

22 ....... TS-1502061............Socket Head Cap Screw.............................M5x25.............................2

23 ....... COS18-223 ............Exhaust Hood............................................. .......................................1

25 ....... COS18-225 ............Cover......................................................... .......................................1

28 ....... COS18-228L...........Air Filter (Oil Type) (Left Hand) ..................MACP300-10A................1

28 ....... COS18-228R..........Air Filter (Oil Type) (Right Hand)................MACP300-10A................1

29 ....... COS18-229 ............Ball valve...................................................1/4”.................................1

30 ....... COS18-230 ............Pressure Gauge ......................................... .......................................1

31 ....... TS-1550041............Fl at Washer................................................M6 ..................................2

32 ....... TS-1503041............Socket Head Cap Screw.............................M6x16.............................2

33 ....... COS18-233 ............Connection Bloc k .......................................3/8” .................................1

34 ....... COS18-234 ............Tube Fitt ings (L type) .................................3/8”x

35 ....... COS18-235 ............Tube Fitt ings (L type) .................................3/8”x

36 ....... COS18-236 ............Connection Board....................................... ...........……………………1

37 ....... TS-1532052............Pan Head Machine Scr ew ..........................M4x15.............................2

38 ....... COS18-238 ............Connection Box.......................................... .......................................1

40 ....... TS-1502101............Socket Head Cap Screw.............................M5x45.............................2

41 ....... COS18-241 ............Rubber Sleeve ........................................... .......................................2

42 ....... 3312341 .................Powermatic Logo Label.............................. .......................................1

43 ....... COS18-242 ............Warning Label............................................ .......................................1

44 ....... COS18-243 ............Warning Label............................................ .......................................1

45 ....... COS18-244 ............Rotation Blade L.H. Label........................... .......................................1

46 ....... COS18-245 ............Rotation Blade R.H. Label.......................... .......................................1

6...........................2

φ

6...........................2

φ

6...........................2

φ

10.........................1

φ

6...........................1

22

Page 23

Stand Assembly – Left Hand (COS18 Cut-Off Saw)

23

Page 24

Stand Assembly – Right Hand (COS18 Cut-Off Saw)

24

Page 25

PARTS LIST: Air Control Assembly (COS18 Cut-Off Saw)

Index Part

No. No. Description S ize Qty.

1..........COS18-301 .................Toggle Joint .......................................... ........................................... 1

2..........COS18-302 .................Shaft..................................................... ...........................................2

3..........COS18-303.................Cotter Pin.............................................. SSP-12...............................6

4..........TS-1540071 ................Hex Nut................................................. M10x1.5P...........................5

5..........COS18-305 .................Shock Absorber..................................... Tokico3243.........................1

6..........TS-1506131 ................Socket Head Cap Screw........................M12x80..............................1

7..........COS18-307 .................Ring...................................................... M12 ....................................2

8..........COS18-308 .................Nylon Ring............................................ M12....................................2

10........ TS-155108 ..................Lock Washer......................................... M12 ....................................1

11........ TS-1540081 ................Hex Nut................................................. M12x1.75P......................... 5

12........ COS18-312 .................Valve .................................................... ...........................................2

13........ TS-2284352 ................Pan Head Machine Screw ..................... M4x35................................4

14........ TS-1540021 ................Hex Nut................................................. M4x0.7P .............................4

φ

15........ COS18-140 .................Tube Fittings (L type) ............................ 1/8"x

16........ COS18-316 .................Plug ...................................................... 1/4"x10...............................1

17........ COS18-317 .................Tube Fittings (L type) ............................ 1/4”x

18........ COS18-141 .................Silencer................................................. 1/8”.....................................4

19........ COS18-319 .................Tube Fittings (T type) ............................ 1/4”x

20........ COS18-320 .................Tube Fittings (I type) ............................. 1/4”x

22........ COS18-322 .................Connector Bl oc k.................................... 1/8”.....................................2

23........ COS18-323 .................Nipple ................................................... 1/8”x1/8”............................. 2

24........ COS18-215 .................Tube Fittings (T type) ............................ 1/8"x

25........ COS18-325 ................Tube Fittings (L type) ............................ 1/4”x

26........ COS18-326 .................Switch Control Box................................ MS-P35..............................1

27........ TS-1533032 ................Pan Head Machine Screw ..................... M5x10................................4

28........ COS18-328 .................Toggle Joint .......................................... ........................................... 1

29........ TS-2310162 ................Hex Nut................................................. M16x1.5P...........................1

30........ COS18-330 .................Cylinder................................................. CB-50*230..........................1

31........ COS18-331 .................Jointer................................................... 1/4"x3/8".............................2

32........ COS18-332 .................Air Regulator......................................... 3/8” .....................................2

34........ COS18-234 .................Tube Fittings (L type) ............................ 3/8”x

35........ COS18-335L...............Swaying Arm (Left Hand)...................... ...........................................1

35........ COS18-335R ..............Swaying Arm (Right Hand).................... ...........................................1

36........ COS18-336 .................Special Pin............................................ ...........................................1

37........ COS18-337 .................Shaft..................................................... ...........................................1

38........ TS-2360121 ................Flat Washer .......................................... M12.................................... 4

39........ TS-0720111 ................Lock Washer ......................................... 1/2”.....................................3

40........ COS18-340L...............Bracket (Lef t Hand)............................... ...........................................2

40........ COS18-340R ..............Bracket (Right Hand)............................. ...........................................2

42........ TS-1491031 ................Hex Cap Screw..................................... M10x25..............................4

43........ TS-1551071 ................Lock Washer ......................................... M10....................................8

45........ COS18-345L...............Clamp Arm (Left Hand)......................... ...........................................1

45........ COS18-345R ..............Clamp Arm (Right Hand)....................... ...........................................1

46........ COS18-346 .................Limit Switch........................................... ...........................................1

47........ COS18-347 .................Danger Label......................................... ...........................................1

6...............................5

φ

6...............................1

φ

6...............................1

φ

10.............................2

φ

6...............................1

φ

10.............................1

φ

10.............................2

25

Page 26

Air Control Assembly – Left Hand (COS18 Cut-Off Saw)

26

Page 27

Air Control Assembly – Right Hand (COS18 Cut-Off Saw)

27

Page 28

PARTS LIST: Safety Guard Assembly (COS18 Cut-Off Saw)

Index Part

No. No. Descrip t ion Size Q t y.

1 ......... COS18-401 ................ Special Fixed Pin, guider....................... .......................................... 1

2 ......... TS-0561051................ Hex Nut.................................................1/2”-13...............................1

3 ......... COS18-403 ................ Rubber Cushion..................................... .......................................... 1

4 ......... COS18-404 ................ Knob...................................................... .......................................... 1

5 ......... COS18-405 ................ Handwheel............................................. .......................................... 1

6 ......... TS-1524021................ Socket Set Screw..................................M8x10................................ 1

7 ......... TS-0561081 ...............Hex Nut.................................................3/4”-10............................... 1

8 ......... TS-1491061................ Hex Cap Screw......................................M10x40.............................. 3

9 ......... TS-2361101................ Lock Washer .........................................M10 ................................... 3

10 ....... COS18-410 ................Depth scale............................................ .......................................... 1

11 ....... COS18-411 ................Support Seat.......................................... ..........................................1

12 ....... COS18-412 ................Donut, Red sign..................................... .......................................... 1

13 ....... COS18-413 ................Stopper.................................................. .......................................... 1

Φ

14 ....... COS18-414 ................Pin .........................................................

15 ....... COS18-415 ................Ring....................................................... .......................................... 1

16 ....... COS18-416 ................Lead Screw............................................ ..........................................1

17 ....... TS-1492041................ Hex Cap Screw......................................M12x40.............................. 2

18 ....... TS-2360121................ Flat Washer...........................................M12 ................................... 2

19 ....... COS18-419 ................Fence.................................................... .......................................... 1

20 ....... COS18-420 ................Control Box............................................ .......................................... 1

21 ....... TS-1482011................ Hex Cap Screw......................................M6x10................................ 2

22 ....... TS-1550041................ Flat Washer...........................................M6 ..................................... 9

23 ....... TS-1533042 ...............Pan Head Machine Screw......................M5x12................................ 4

24 ....... COS18-424 ...............Power On Button................................... .......................................... 1

25 ....... COS18-425 ...............Power Off Button................................... .......................................... 1

26 ....... COS18-140 ...............Tube Fit tings (L type).............................1/8"x

27 ....... COS18-427 ...............On/Off Air Control Swi tch ......................VM104............................... 1

28 ....... COS18-215 ...............Tube Fit tings (T type).............................1/8"x

29 ....... COS18-429 ...............Guider Seat ........................................... .......................................... 1

30 ....... TS-1482031 ...............Hex Cap Screw......................................M6x16................................ 3

32 ....... TS-1490051 ...............Hex Cap Screw......................................M8x30................................ 2

33 ....... TS-2361081 ...............Lock Washer .........................................M8..................................... 2

34 ....... COS18-434 ...............Limit Switch........................................... .......................................... 1

35 ....... COS18-317 ...............Tube Fit tings (L type).............................1/4”x

36 ....... COS18-436 ...............Silencer.................................................1/4” .................................... 1

37 ....... TS-2235991................ Socket Head Cap S c r ew........................M5x100.............................. 1

38 ....... COS18-438L...............Bracket (Left Hand)................................ .......................................... 1

38 ....... COS18-438R..............Bracket (Ri ght Hand) ............................. .......................................... 1

39 ....... COS18-439 ...............Spring Housing...................................... .......................................... 1

40 ....... COS18-440 ...............Spring.................................................... .......................................... 1

41 ....... TS-1540031 ...............Hex Nut.................................................M5x0.8P ............................ 2

42 ....... TS-1501091 ...............Socket Head Cap Screw........................M4x35................................ 2

43 ....... TS-1550021................ Flat Washer...........................................M4 ..................................... 2

44 ....... TS-1540021................ Hex Nut.................................................M4x0.7P ............................2

45 ....... TS-1481021................ Hex Cap Screw......................................M5x10................................ 6

46 ....... TS-1550031................ Flat Washer...........................................M5 ..................................... 2

47 ....... TS-1503041................ Socket Head Cap S c r ew........................M6x16................................ 2

48 ....... COS18-448 ................Bracket.................................................. .......................................... 1

49 ....... COS18-449 ................Bracket.................................................. .......................................... 1

52 ....... COS18-452 ................Special Rubber Head Screw..................W1/4"x25........................... 2

28

6x40................................ 1

φ

6.............................. 1

φ

6.............................. 1

φ

6.............................. 2

Page 29

PARTS LIST: Safety Guard Assembly (COS18 Cut-Off Saw) continued

Index Part

No. No. Descrip t ion Size Q t y.

53........ TS-1540041 ................Hex Nut................................................. M6x1P................................4

54........ COS18-454L...............Pneumatic Guard (Left Hand)................ ...........................................1

54........ COS18-454R ..............Pneumatic Guar d ( Right Hand) ............. ...........................................1

55........ COS18-455L...............Safety Cover (Left Hand) ...................... ...........................................1

55........ COS18-455R ..............Safety Cover (Right Hand).................... ...........................................1

58........ COS18-207 .................Rubber Sleeve...................................... ...........................................1

29

Page 30

Safety Guard Assembly – Left Hand (COS18 Cut-Off Saw)

30

Page 31

Safety Guard Assembly – Right Hand (COS18 Cut-Off Saw)

31

Page 32

PARTS LIST: 4' Roller Table Assembly (COS18 Cut-Off Saw) #6827038

Optional Accessory

Index Part

No. No. Description S ize Qty.

1 ......... COS18-501 ..............Roller Table............................................4’........................................1

2 ......... COS18-502 ..............Roller...................................................... ..........................................5

3 ......... COS18-503 ..............Split Pin .................................................. ........................................ 10

4 ......... TS-1490021 ..............Hex Cap Screw.......................................M8x16................................ 8

5 ......... TS-1550051...............Flat Washer............................................M8 .....................................8

6 ......... COS18-506 ..............Bracket.................................................... ..........................................1

9 ......... TS-1540061 ..............Hex Nut...................................................M8x1.25P .......................... 6

10 ....... COS18-510 ..............Leg.......................................................... .......................................... 1

14 ....... TS-0561071 ..............Hex Nut...................................................5/8”-11............................... 2

15 ....... COS18-515 ..............Adjusting Foot.........................................5/8"....................................2

32

Page 33

4' Roller Table Assembly (COS18 Cut-Off Saw) #6827038 Optional Accessory

33

Page 34

PARTS LIST: 8' Roller Table Assembly (COS18 Cut-Off Saw) #6827037

Optional Accessory

Index Part

No. No. Description S ize Qty.

1 ......... COS18-601 ..................Guide Rail............................................8’........................................1

2 ......... COS18-602 ..................Scale....................................................2400mm.............................1

3 ......... COS18-603 ..................Pan Head Machine Screw....................M5x5..................................2

4 ......... TS-1550031..................Flat W asher.........................................M5 .....................................2

5 ......... COS18-605 ..................Guide Body.......................................... ..........................................3

6 ......... COS18-606 ..................Square Head Bol t.................................M8x 40…………………….....6

7 ......... COS18-607 ..................Lock Handle......................................... .......................................... 6

8 ......…TS-1550051..................Flat Washer .........................................M8 ................................... 24

9 ......... COS18-609 ..................Guide Stopper...................................... ..........................................3

Φ

10 ....... COS18-610 ..................Spring Pin............................................

11 ....... COS18-611 ..................Squar e Head B olt.................................M8x27................................6

13 ....... TS-1540061..................Hex Nut................................................M8x1.25P ........................ 19

14 ....... TS-1490041..................Hex Cap Screw....................................M8x25................................3

16 ....... COS18-616 .................Roller Table .........................................8’........................................1

17 ....... COS18-502 .................Roller................................................... ........................................ 11

18 ....... COS18-503 .................Split Pin ............................................... ........................................ 22

19 ....... TS-1490021..................Hex Cap Screw....................................M8x16..............................12

21 ....... COS18-506 ..................Bracket ................................................ .......................................... 1

25 ....... COS18-510 .................Leg....................................................... .......................................... 2

29 ....... TS-0561071 .................Hex Nut................................................5/8”-11............................... 4

30 ....... COS18-515 ..................Adjusting Foot......................................5/8"....................................4

3x30................................3

34

Page 35

8' Roller Table Assembly (COS18 Cut-Off Saw) #6827037 Optional Accessory

35

Page 36

PARTS LIST: Pneumatic Diagram (COS18 Cut-Off Saw)

Index Part

No. No. Description S ize

1 ......... COS18-211 ................ Emergency Button.................................

φ

2 ......... COS18-140 ................ Tube Fitt ings (L type).............................1/8"x

3 ......... COS18-215 ................ Tube Fitt ings (T type).............................1/8"x

4 ......... COS18-214 ................ Air Pressure Start Button .......................

5 ......... COS18-215 ................ Tube Fitt ings (T type).............................1/8"x

6 ......... COS18-140 ................ Tube Fitt ings (L type).............................1/8"x

7 ......... COS18-140 ................ Tube Fitt ings (L type).............................1/8"x

8 ......... COS18-140 ................ Tube Fitt ings (L type).............................1/8"x

9 ......... COS18-322 ................ Jointer Block..........................................1/8”

10 ....... COS18-323 ................Jointer...................................................1/8”x1/8”

11 ....... COS18-322 ................Jointer Block..........................................1/8”

12 ....... COS18-215 ................Tube Fit tings (T type).............................1/8"x

13 ....... COS18-323 ................Jointer...................................................1/8”x1/8”

14 ....... COS18-320 ................Tube Fit tings (I type)..............................1/4”x

15 ....... COS18-320 ................Tube Fit tings (I type)..............................1/4”x

16 ....... COS18-312 ................Connector..............................................

17 ....... COS18-140 ................Tube Fit tings (L type).............................1/8"x

18 ....... COS18-141 ................Silencer.................................................1/8”

19 ....... COS18-325 ...............Tube Fit tings (L type).............................1/4”x

20 ....... COS18-141 ................Silencer.................................................1/8”

21 ....... COS18-312 ................Connector..............................................

22 ....... COS18-317 ................Tube Fit tings (L type).............................1/4”x

23 ....... COS18-140 ................Tube Fit tings (L type).............................1/8"x

24 ....... COS18-141 ................Silencer.................................................1/8”

25 ....... COS18-319 ................Tube Fit tings (T type).............................1/4”x

26 ....... COS18-141 ................Silencer.................................................1/8”

27 ....... COS18-140 ................Tube Fit tings (L type).............................1/8"x

28 ....... COS18-204 ................Pedal Switc h..........................................230-8A

29 ....... COS18-206 ................Silencer.................................................1/4”

30 ....... COS18-205 ................Tube Fit tings (I type)..............................1/4"x

31 ....... COS18-205 ................Tube Fit tings (I type)..............................1/4"x

32 ....... COS18-330 ................Cylinder.................................................CB-50*230

33 ....... COS18-332 ................Air Regulator .........................................3/8”

34 ....... COS18-234 ................Tube Fit tings (L type).............................3/8”x

35 ....... COS18-331 ................Jointer...................................................1/4"x3/8"

36 ....... COS18-332 ................Air Regulator .........................................3/8”

37 ....... COS18-234 ................Tube Fit tings (L type).............................3/8”x

38 ....... COS18-331 ................Jointer...................................................1/4"x3/8"

39 ....... COS18-317 ...............Tube Fit tings (L type).............................1/4”x

40 ....... COS18-436 ...............Silencer.................................................1/4”

41 ....... COS18-434 ...............Limit Switch...........................................

42 ....... COS18-317 ...............Tube Fit tings (L type).............................1/4”x

43 ....... COS18-140 ...............Tube Fit tings (L type).............................1/8"x

44 ....... COS18-427 ...............On/Off Air Control Swi tch ......................

45 ....... COS18-215 ...............Tube Fit tings (T type).............................1/8"x

46 ....... COS18-228(R/L)......... Air Filter (Oil Type)................................MACP300-10A

47 ....... COS18-212 ................Quick Fittings.........................................1/4”

48 ....... COS18-229 ................Ball valve ..............................................1/4”

49 ....... COS18-233 ................Connection Block...................................3/8”

36

6

φ

6

φ

6

φ

6

φ

6

φ

6

φ

6

φ

10

φ

10

φ

6

φ

10

φ

6

φ

6

φ

6

φ

6

φ

6

φ

6

φ

10

φ

10

φ

6

φ

6

φ

6

φ

6

Page 37

PARTS LIST: Pneumatic Diagram (COS18 Cut-Off Saw) continued

Index Part

No. No. Description S ize

φ

φ

Φ

Φ

6

10

6

6

50........ COS18-235 .................Tube Fittings (L type) ............................ 3/8”x

51........ COS18-234 .................Tube Fittings (L type) ............................ 3/8”x

52........ COS18-141 .................Silencer................................................. 1/8"

53........ COS18-140 .................Tube Fittings (L type) ............................ 1/8"x

54........ COS18-140 .................Tube Fittings (L type) ............................ 1/8"x

55........ COS18-139 .................Limit Switch...........................................

37

Page 38

ELECTRICAL SCHEMATIC (COS18 Cut-Off Saw)

38

Page 39

Preventive Maintenance

Checklist for Model COS18 Cut-Off Saw

[ ] W or k ar ea around machine marked off clearly.

[ ] Non-skid f loor strips in area where operat or nor mally stands.

[ ] Inspect enti r e machine for loose bolts, nuts, screws. Tighten and replace as necessary.

[ ] Clean tabl e ar ea, removing sawdust and chips with a soft br istle brush. Remove gum and pitch

with ov en cleaner.

[ ] Lubricate appr opr iate places with a good grade non- har dening grease.

[ ] Clean tabl e and fence surface. If rusted, use paste mixtur e of household ammonia, a good commercial

detergent and 000 steel wool . Wash surf ac e down with hot , soapy water, rinse and dry thoroughly.

Coat surface with talcum powder, r ubbing briskly into surface with a c lean blackboard eraser.

[ ] Check blade condition; should be sharp and free of ni c ks or grooves.

[ ] Check belt c ondition. Replace as needed. Dress with belt dressing. Check belt tension.

[ ] Check mot or for loose wiri ng and sawdust congestion, pulleys tight and in line.

[ ] Check bearings. Replace any bad or suspect bearings immediat ely.

[ ] Fence properl y aligned and square.

[ ] Foot pedal has proper adjustment.

[ ] Check elect r ical controls function and pneumatic guard operation.

[ ] Check ali gnment of r oller tabl es wit h main tabl e.

To order parts or reac h our service department, please call our toll-fr ee number between 8:00 a.m . and 4:30

p.m. ( C S T), Monday through F r iday. Having the Model Number and Serial Number of y our machine available

when you call will allow us to serve you quickly and accuratel y . Locating the stock number of t he par t(s)

required from your parts manual will also expedite your order.

Phone No.: (800) 248- 0144

Fax No. (800) 274-6840

If you ar e c alling from Canada, please call 800-238-4746

E-mai l: powermatic@wmhtoolgr oup.com

Website : www.powermatic.com

39

Page 40

40

WM H Tool Group

427 Sanford Road

LaVergne, TN 37086

Phone:(800) 248-0144

Fax: ( 800) 274-6840

E-mai l: powermatic@wmhtoolgr oup.com

Website : www.wmhtoolgroup.com

Loading...

Loading...