Page 1

Model

1150=

MAINTENANCE

AND PARTS LIST

15"

(381

mm)

Drill

Press

INSTRUCTIONS

/

Better

McMINNVILLE,

,_.

.~

By

TENNESSEE

.-

..

~

-

Design@

®Iiii®

e15·473

5;;51

'Z-l1~

37110 0

.

.

AC

CC/JO

;

0/'1

III

7

Page 2

FORWORD

SAFETY

This

Model

safety

before

FI

manual

1150

through

operating

RST

has

A

Drill

the use

In order to obtain

ions

in

the operating instructions and maintenance manuals carefully.

The

specifications

Powermatic's

time

without

This

(blades.

of

component

policy

obligation

Powermatlc,

its

authorized

manufactured

of

delivery

date

Powermatfc

period.

This

maintenance

becomes

days

from

warranty

lubricants.

removal.

effective

date

been prepared

Press..

of

the

machine

maximum

put

forth in this manual were in effect at the time

of

continuous

on

for

the

Its

owner

purpose

and those responsible

aside from

proper

accepted practice.. Read the

..

life and efficiency

improvement,

the

part

of

Powermatic.

from

your Powermatic

changes

WARRANTY

a DIvision

by

wilt, at Its

warranty

and

does

shipment

manufacturer's

of

dIstributors

from

of

DeVlfeg-Bullard Inc.,

of

Powennatlc

its authorized distributors

option,

applies

safety set

only

if

delivery

not

etc.);

for

Powermatlc

to

repair

only

forth

the

accompanying

to

the

apply

to

to

el~trtcal

service

local

be free

Morrison

products

of

defects In material and

or

replace

to

products

In the catalogs, manuals,

original

items

and

aulhoflzed

card

purchaser.

that

would

motors

and

reinstallation.

repair

and

or

2000

hours

any

product

which

Is fully

and

normany

components

Claims

station

Road,

the

are

and/or

properly

be

for

of

(or

used

relating

maintenance

safety

to

these specifications

McMinnville,

original

consumed

which

service.

purchasers

workmanship

use,

whichever

component

In

accordance

Instruction

completed

are

to

for

the

maintenance

and

operations

and

operating

Drill

of

publication. However, owing

Tennessee 37110 ("Powermatlc") warrants to

or

warranted

electracal

for

for

a perfod

occurs

part thereof) proving defective

with

sets furnished

and returned to

require

replacement

by

components

instructions

Press

such distributors, all

of

twelve (12)

first.

During

all instructions

by

Powermatlc. This warranty

PowermatIc

their

manufacturer;

must

follow

may

months

said

warranty

as

due

to

be

of

a Powermatic

is

to

thoroughly

all the instruct-

be

made

products

from

during

to operation,

within

ten (10)

normal

or

the

taken

to

promote

at

the

period

said

wear

costs

the

to

any

ORr

LL

Read

1.

limit~tions

belt

ThIS

warranty

(2)

accident,

tampeflng.

bea"ng

repaffs

To

obtaIn

from

whom

product

proof

of

dIrectly

how

and

provided

returned

to

repalrtng

delIvery.

shall

Powermat,c's

THIS IS

BY

LAW.

HEREBY

LOSS,

DAMAGE. OR EXPENSES DIRECTLY

OTHER

VENIENCE.

OTHER

PRESS

understand

guard

is

null

neglect.

alterations

,ts

anginal

required

the

you

was

delIvered

purchase.

If

your

v.here

to

alfow

Without

or

FOB.

POWERMATIC'S

INCLUDING

LIMITED

CAUSE

AND

WARRANTY.

SAFETY

and

damage

or

serial

due

to

natural

fastest

possible

purchased

to

Should

claim

IS

covered

service

WIll

correctIon

I[S

pnor

replac,ng

(return

OR FOA CONSEQUENTIAL

(at

freight

liability

ANY

TO THE

lOSS

OF PRODUCTION). THE

EXPRESS OR

INSTRUCTIONS

and

and

hazards

of

this

machine

void

repairs

number

you,

Cl(cumstances

wrttten

SOLE

WARRANTIES

DURATION

follow

if

the

product

Of'

other

outs,de

plate.

causes

warranty

the

product

(3)

a

description

by

thIs

be·provtded.

by

customer

authortzat.on.

Powermat,c·s

patd

by

under

this

WRIITEN

OF THIS

IMPUED.

the

associated

to

serve

has

circumstances

of

This

or

service

SpecifYing

warranty.

On

customer)

warranty

WARRANTY.

safety

been

P(YNermat'c·s

warranty

acts

of

God.

you

(')

of

the

prohibit

personnel.

option)

FOR

you

your

simple

Powermatic's

products

Powermat,c's

exceed

MERCHANTABILITY

WRITIEN

OR

INDIRECTLY

DAMAGES

WARRANlY

SHALL

and

with

a 1

as a reminder

subjected

beyond

factory

does

not

must

first

the

problem

warranty

Powermatlc

ANY

BE

notIfy

product

for

contacting

Powermat,c

replacement

obligatIon

whIch

the

purchase

AND

WARRANTY.

RELATED

(INCLUDING

CONTAINED

MADE

operating

150

A Drill Press. A

of

basic

to

(1)

misuse.

Powermatic's

nor

authorized

apply

to

in

writing

by

catalog

which

the

dlstflbutor

dIstrIbutor

assumes

under

are

determined

factory.

and

prace

ALL

OTHER

OR FITNESS FOR A PARTICULAR PURPOSE. ARE

POWERMATIC

TO

WlTHOUT

BY OR ON BEHALF OF

instruction

safety

control;

normal

number

you

seek

Will

or

repairs.

no

thlswarranty

on

inspection

paid

WARRANTIES

THE

USE

HEREIN

safety

practice.

abuse

Of

improper

(3)

by

'Near

the

warranty

then

responsibilIty

by

for

LIMITATION.

modifications.

Powermat,c;

and

tear.

authorized

and

serial

contact

provide

installatIons

Powermatic

by

the

product.

SHALL

OFITS

PRODUCTS OR

MAY

NOT

POWERMATIC.

found

rules decal

or

corrosion.

Powermatic

number.

servIce.

the

Pow-ermatlc

you

WIth

for

pr<X1ucts

shall

be

to

Powermatlc.

VVHICH

NOT BE

lOSS

BE

MODIFIED

in

this

service

or

disassembly

to

any

product

abrasion.

distributor

(2)

the

and

(4)

eVIdence

InstructIons

instructions

whIch

exclUSIvely

be

defectIve

In

MAY

BE

llABLE

FROM

OF TIME.

manual..

is

installed

storage;

not

date

the

factory

as

WIll

are

limIted

upon

no

event

IMPLIED

FOR

ANY

ANY

INeON·

AND

NO

Know

or

of

to

be

on

the

the

2.

Grounding

grounding

used,

make

cedu re

indicated

the

drill press: Make certain

lead

is

certain

by

included

that

the

in

the

grounding

National

the

incoming

Electric

that

lug

Code.

the machine frame

electrical

connects

service.

to

a suitable

is

electrically

In

cases

ground.

grounded and

where a cord and

Follow

the

grounding

that

plug

a

are

pro-

Page 3

-------

--

3. Eye Safety: Wear

the

drill

press.

an

approved safety face shield, goggles or glasses to protect eyes

when

operating

4. Personal Protection:

roll up sleeves above the elbow. Remove

type

footwear

should

exposure allowed

5.

Work Area:

Keep

other foreign material, and

sure the table

is

Before operating the machine, remove tie, rings, watch and

all

outer

loose clothing and confine long hair. Protective-

be

worn.

in

Section 1910.95

the floor around the machine clean and free

free of chips, tools and everything

r1@aring

protectors

of

the OSHA regulations. Do Not Wear Gloves.

oil, grease or coolant

shoufd

to

minimize the danger of tripping or slipping.

else

be

used

where

of

tools, tooling, stock scrap and

not

required for the task to be performed.

Powermatic recommends the use of anti·skid floor strips on the floor area where the

ally stands and

lighted and ventilated. Provide for adequate work space around

6.

Guards: Keep

that

each machine's work area be marked off. Make certain the work area

the

machine.

all

machine guards

in

place at

a~1

times when

the

machine

the Machine with the Guard Off.

7.

Do

Not

Overreach: Maintain a balanced stance and keep

8.

Maintain Tools in

Top

Condition: Keep tools sharp and clean for safe and best performance.

tools can increase the feed force required and can result

the

work

to

be pulled free from its holding device. Dull

duce a straight hole.

9.

Use

the Proper Speed and Feed: A table

in

selecting the correct speed and feed rate for a variety of materials.

suit the material supplier for correct speed

is

provided

and feed rate. Adjust speed on variable speed models

only with the power on. On step cone models, make sure power

a complete stop before opening the access

door

to

your

body

in

burning the stock

or

improperly sharpened drills will

in

the operating instruction manual

change speeds.

under control at all times.

For

is

off and

other

jewelry and

noise exceeds the

operator

is

in

use.

Do

Not

or

seizing up, causing

materials

the

not

shown, con·

spindle has come to

level

Be

norm

is

well

Operate

Dull

not

pro·

as

a guide

of

..

10. Never Drill Freehand: Always block

causing

the

work piece, jig,

or

fixture

11. Remove Key Chucks: When a key chuck

lock a tool

chuck and could result

in

the chuck. If

it

is

in

serious injury.

or

clamp

to

rotate

is

not

removed, starting the spindle can cause

the

work piece. A drill

with the spindle and can cause serious injury.

used, remove

12. Hand Safety: Keep hands away from the spindle when

is

chips when the spindle

under power and never use

rake. Chips are razor sharp and can

cause serious

the

injury.

Rotating Under Power.

13. Spindle Rotation:

14. Machine Adjustments: Make all machine

speed model

15. Machine Capacity: Do Not

requiring more than the rated horsepower

life

of

the machine and could cause the breakage

16. Avoid Accidental Starting: Make certain

power to

the

Be

sure

the

rotation

of

the

spindle

is

adjustments

or

feed rate on machine equ ipped with power feed. .

attempt

to

use

the

machine beyond its stated

of

the

motor. This

of

parts which could result

the

motor

switch

machine.

bit

or

tap can seize up

it

immediately

the

machine

after using

is

under

it

to

lock

it

to

be

thrown

off the

power. Never clear

hands to clear chips; use a brush or chip

Do Not Change Tools

correct for

with

is

the

power off

type

use

in

the

"off"

tool being used.

except

capacity

witl

position before connecting

with

the

speed

reduce

in

personal injury.

on

or

for operations

the

Spindle

a variable

productive

or

un-

17. Careless Acts: Give the work you are doing

a conversation, and "horseplay" are careless acts

your

undivided attention. Looking

that

can resu

It

in

serious inju ry.

around,

carrying on

3

Page 4

18.

Job

Completion:

turned

is

and never clean chips

off

complete, he should clean the machine and

and

the

If

the

spindle

with

operator

come

the hands;

leaves

the

machine area

to a complete

use

a brush

for

any reason,

stop

before he departs. In addition,

work

area.

Never clean the machine

or

chip rake.

the

drill press should

if

the

with

be

operation

power on

19. Disconnect Machine: Before

20.

Replacement

otherwise,

21. IVlisuse:

Parts: Use

the

drill

Do

Not

poses, Powermatic disclaims any real

that

may

result

power

in

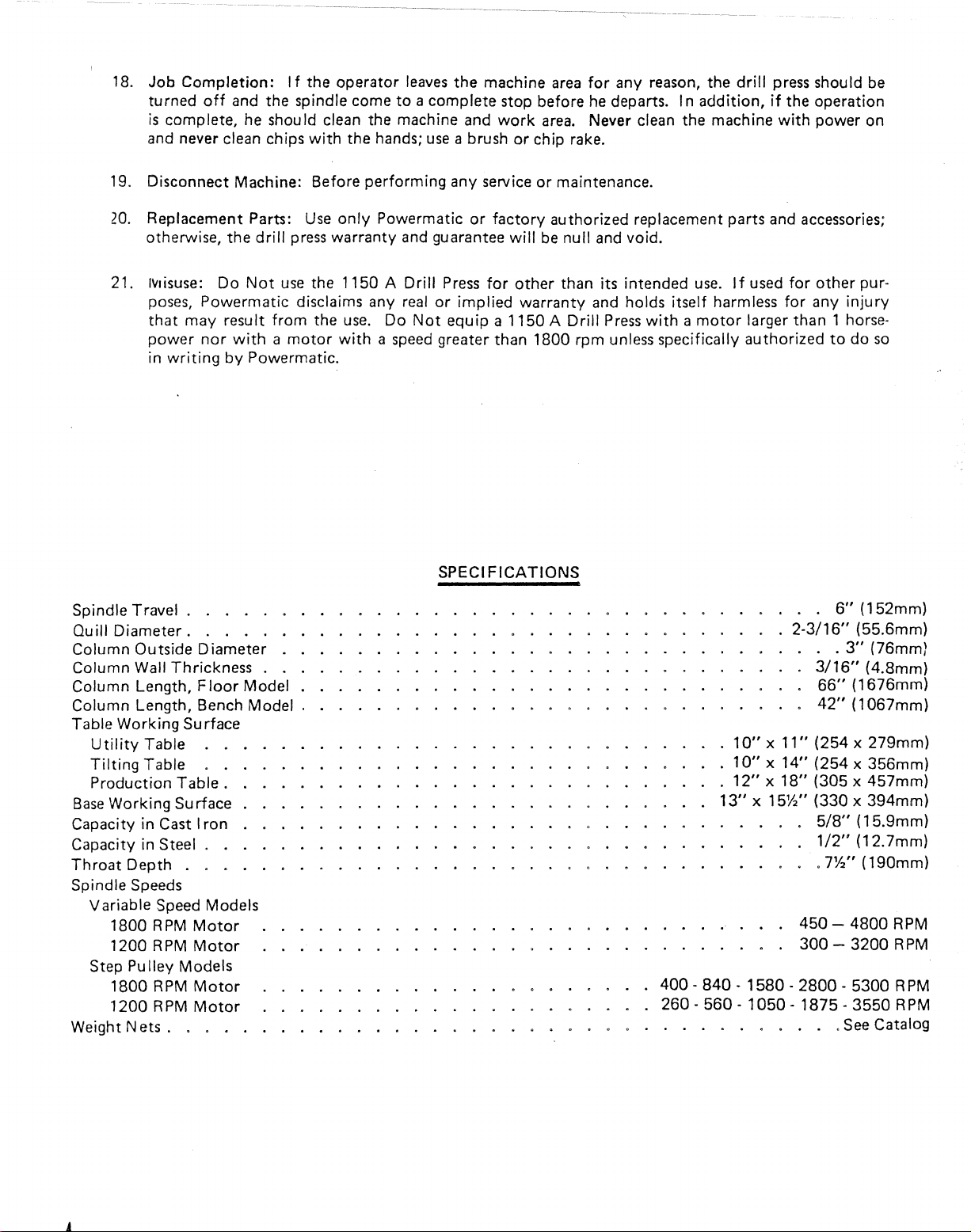

Spindle

Quill

Column Outside

Column Wall

Column

Column Length, Bench

Travel.

Diameter.

Length,

Table Working

Utility

Tilting

Production

Table

Table

Base Working

Capacity

Capacity

Throat

Spindle

Variable

Step

Weight

in

in

Depth

Speeds

1800 R

1200 RPM

Pu

tley Models

1800

RPM

1200

RPM

Nets.

nor

writing

. . .

. . . .

Diameter

Thrickness

Floor

Surface

Table.

Surface

Cast I

ron

Steel "

. " " .

Speed Models

PM

Motor

Motor

Motor

Motor

" " .

from

with

a

by

Powermatic.

..

.

Model .

Model.

. . . .

.

. .

. . . .

performing

only

press

warranty

use

the

1150 A Drill

the

use.

motor

with

. .

..

. . . . . . . .

any service

Powermatic

or

factory

or

maintenance.

authorized

and guarantee will be null and void.

Press

for

other

than its

or

Do

Not

a speed

implied

equip a 1150 A

greater

SPECI

warranty

Drill

than

1800

FICATIONS

and holds itself harmless

Press

rpm unless specifically

replacement

intended

with a motor

use.

parts

and accessories;

If used

for

other

for

any

larger than 1 horse-

authorized

" .

.. . 6"

·

2-3/16"

. .

· .

3/16"

66"

42"

. .

10"

x

11"

(254 x

.. . 10"

.

x

12" x 18"

13"

x

15Y2"

14"

(254

(305 x 457mm)• e • • •

(330 x 394mm)

· .

5/8"

1/2"

g

450-4800

300 -3200

. . 400 - 840

260 -560 -1050 -1875 -3550

c • • • • " • " " " • •

..

1580 -2800 - 5300 R

pur-

injury

to

do

so

(152mm)

(55.6mrn)

3"

(76mrn}

(4.8mrn)

(1676mrn)

(1

067mrn)

279mm)

x 356mm)

(15.9mm)

(12.7mm)

7Y2"

(190mm)

See Catalog

RPM

RPM

PM

RPM&

Page 5

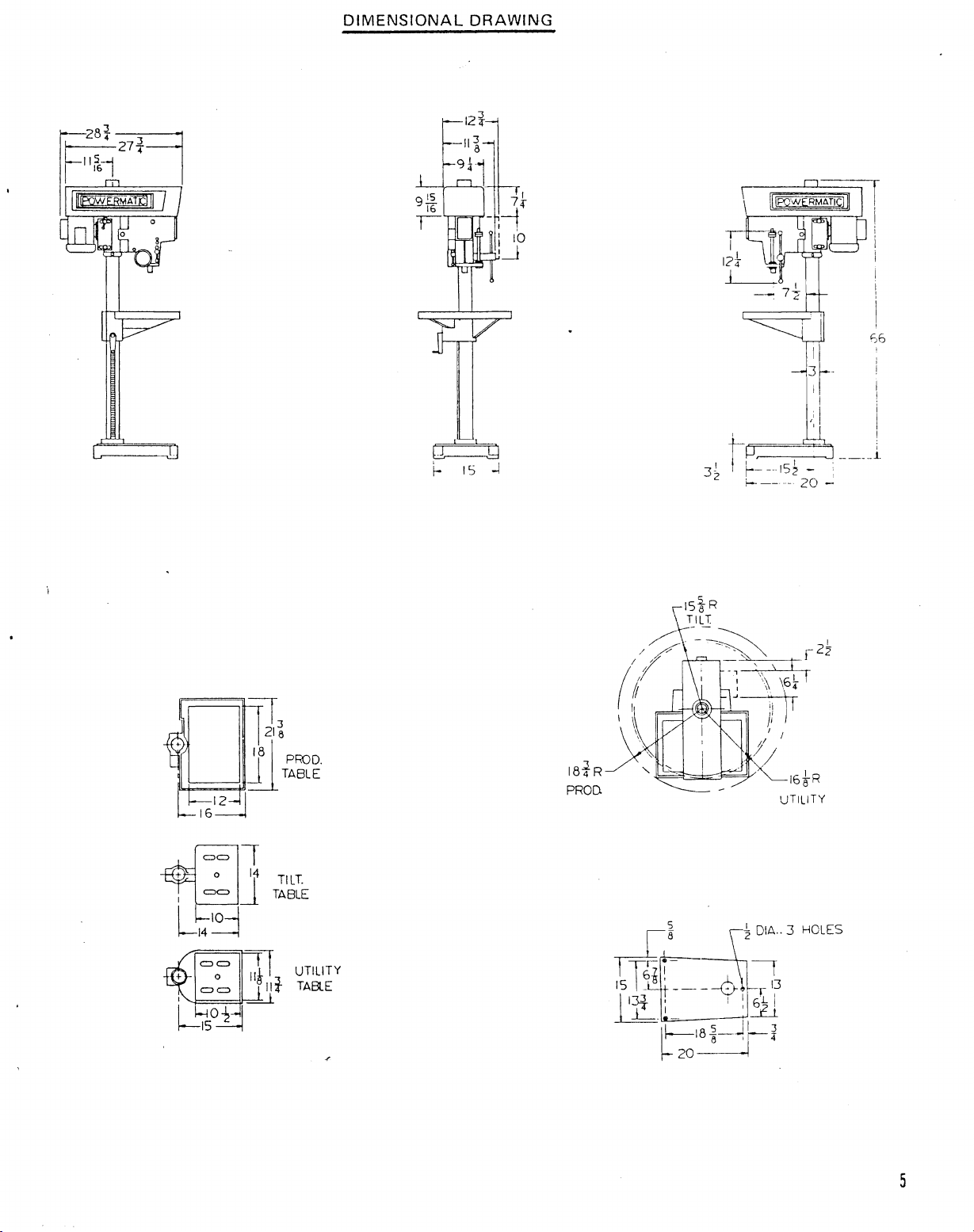

DIMENSIONAL

DRAWING

7'

-

-(

, I

I

10

:~

I'

i

! I

--11~

r-

I I

,

f--

--

;-.-_...

~~

J

15 ~ - •

_.

20

-

t-o:=

]~ !

r

I

i

I

So

I

I

1-

~_-,"*J

~~~¥

12~1

16~

c)c)

+ 0

I

=J

I l

10-1

~14

----1

II

21~

8

PhDD.

TABLE

11

I

14

TILT.

TABLE

18~R

PROD.

UTILITY

TABlE

5

Page 6

MACHINE

INSTALLATION

RECEIVING:

ADJUSTMENTS

AND

MAINTENANCE

Remove

immediately.

and spindle

drill

press

from

shipping container and check

Attach

with

accessories shipped

a good commercial solvent. Read

maintenance and safety instructions.

I

NST

ALLATI

Mount

and table

head

available

1.

Place a·brock

2.

Loosen head

3.

Turn

4.

Lock

through

5. If the above procedure

lift

6.

After

the head.

ON:

machine on a solid

of

the machine have been lowered on

to

raise

the

head, proceed

of

wood

locking

handle

head again

counter

handles,

- clockwise (toward the

with

4.

head and one

head

is

This

to

at

proper

will

prevent head

handle loosening and

foundation

as

between spindle nose and

bumping

Jacking handles, raise table

is

too

slow,

height - - secure

with

drill

and

lag

follows:

them lightly

use a minimum

locking

tightly,

from

falling

press,

instruction

to

the

floor

the

top

operator).

to a position

the head locks

then

if

loosened

for

damage.

then

clean

Report

protective

manual

through

column

of

table.

to

make certain

Head

of

three men

make sure the safety

for

holes

for

convenience in packaging. If a crane

they

will

move

just

under

to

..

swing drilling operations.

any damage

coating

thoroughly

provided

release.

upward

spindle nose and repeat steps 2

move

head

collar

in

6""

to

to

your

from

table,

for

assembly alignment,

base

of

drill

its

proper

is

locked

height;

in

distributor

column,

press. The

is

two

place

under

base

not

to

Visually

7.

MULTIPLE

In the

assemble the

supports and

more than one piece.

guarantee alignment

precision level and level using the

in

MOTOR

Step Pulley

case

legs.

If

your

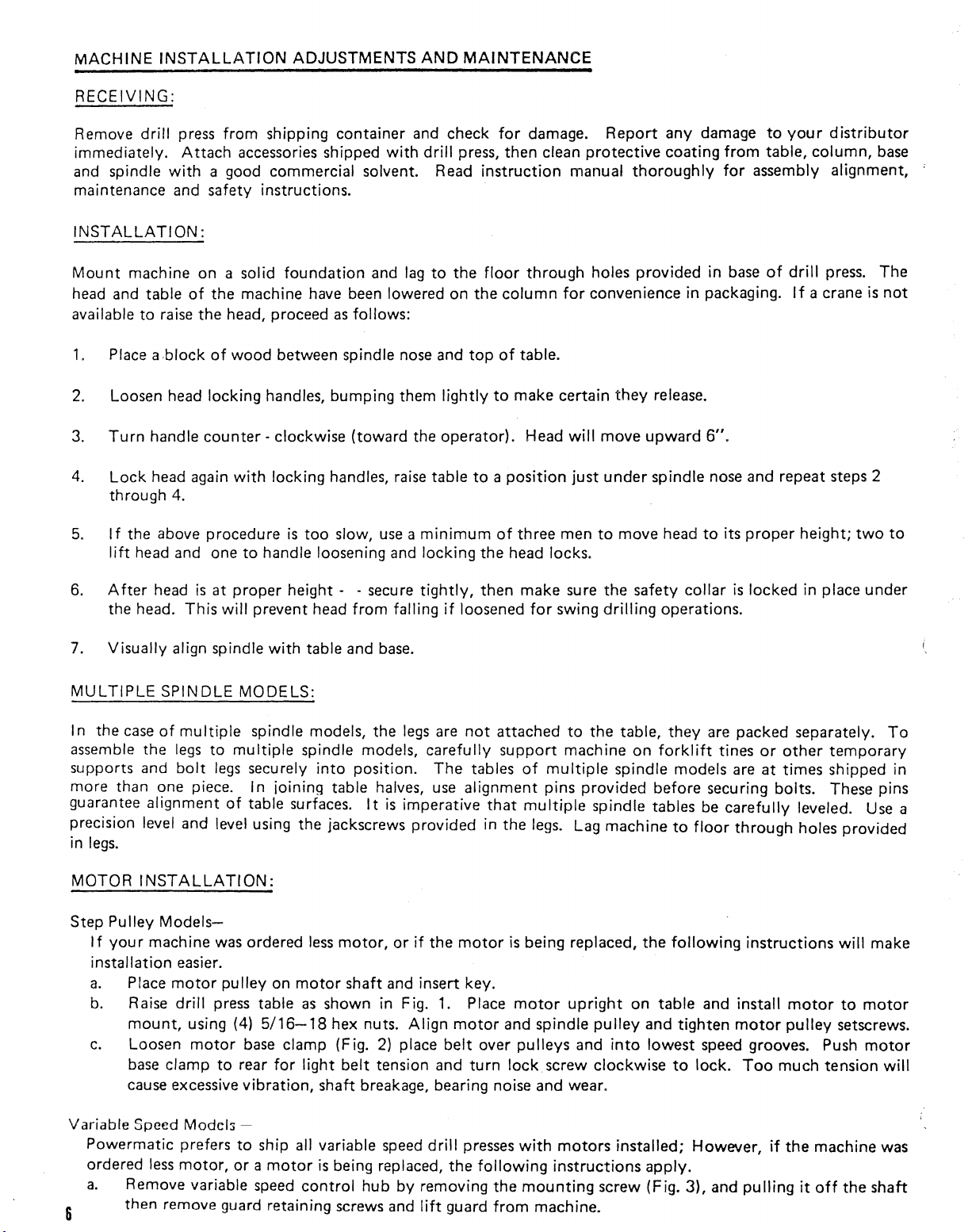

installation

a.

b.

c.

align spindle

SPINDLE

of

multiple

legs

bolt

INSTALLATION:

Models-

machine was ordered

easier.

Place

motor

Raise

drill

mount,

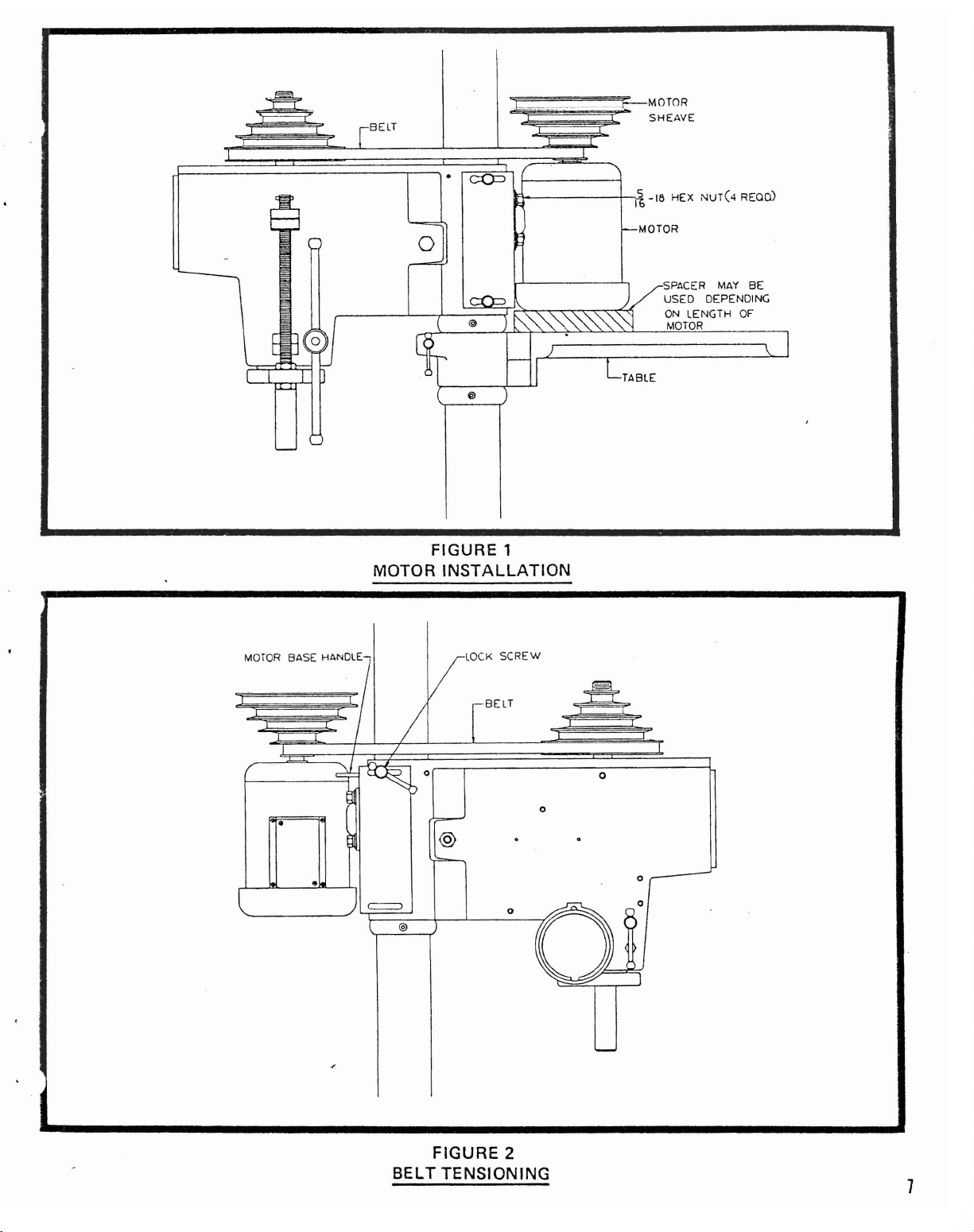

Loosen

base

cause excessive

using (4)

motor

clamp

MODELS:

to

multiple

legs

securely

In

of

table surfaces.

pulley

press table

base

to

rear

vibration,

with

table and

spindle models, the

spindle models,

ioining

less

on

motor

as

5/16-18

clamp (Fig.

for

light

base.

legs

are

not

attached

carefully

into

position.

table halves,

It

jackscrews

motor,

shaft and insert

shown in Fig.

hex nuts.

2)

belt

tension and

shaft breakage, bearing noise and wear.

The

use

is

imperative

provided

or

if

the

Align

place

1.

belt

support

tables

alignment

that

in

the

motor

key.

Place

motor

and spindle

over

turn

is

motor

pulleys

lock, screw

to

the

machine

of

multiple

pins

provided

mu~tiple

legs.

Lag machine

being replaced,

upright

and

table,

spindle models are

spindle tables be

pulley

into

clockwise

they

are packed separately.

on

forklift

before securing bolts. These pins

to

floor

the

following

on

table

and install

and

tighten

lowest

speed grooves. Push

to

lock.

tines

or

at

carefully

through

instructions

motor

Too

other

temporary

times

shipped in

leveled. Use a

holes provided

will make

motor

pulley

much

to

setscrews.

tension

To

motor

motor

will

Variable

Powermatic

ordered

a.

6

Speed

Remove variable

then

less

remove

Models

prefers

motor,

or a motor

guard

-

to

ship all variable speed

is

being replaced,

speed

control

retaining

hub

screws

by

and

drill

presses

the

following

removing

lift

guard

with

the

mounting

from

motors

instructions

machine.

installed; However,

apply.

screw (Fig. 3), and

if

pulling

the

machine was

it

off

the

shaft

Page 7

BELT

..

)_._~~~_~

&-----f--,~

~

F"--M0 TOR

SHEAVE

-18

HEX

NUT(4

REao)

MOWR

sa

MOTOR

H~DC7

-;

FIGURE

INSTALLATION

VLOCK

/

[BELT

1

SCREW

SPACER

USED

ON

LENGTH

MOTOR

MAY

BE

DEPENDING

OF

C

'----------'

..

..

)c:=

(' @

BELT

o

FIGURE

2

TENSIONING

o

o

o

-

7

Page 8

---""_.-...

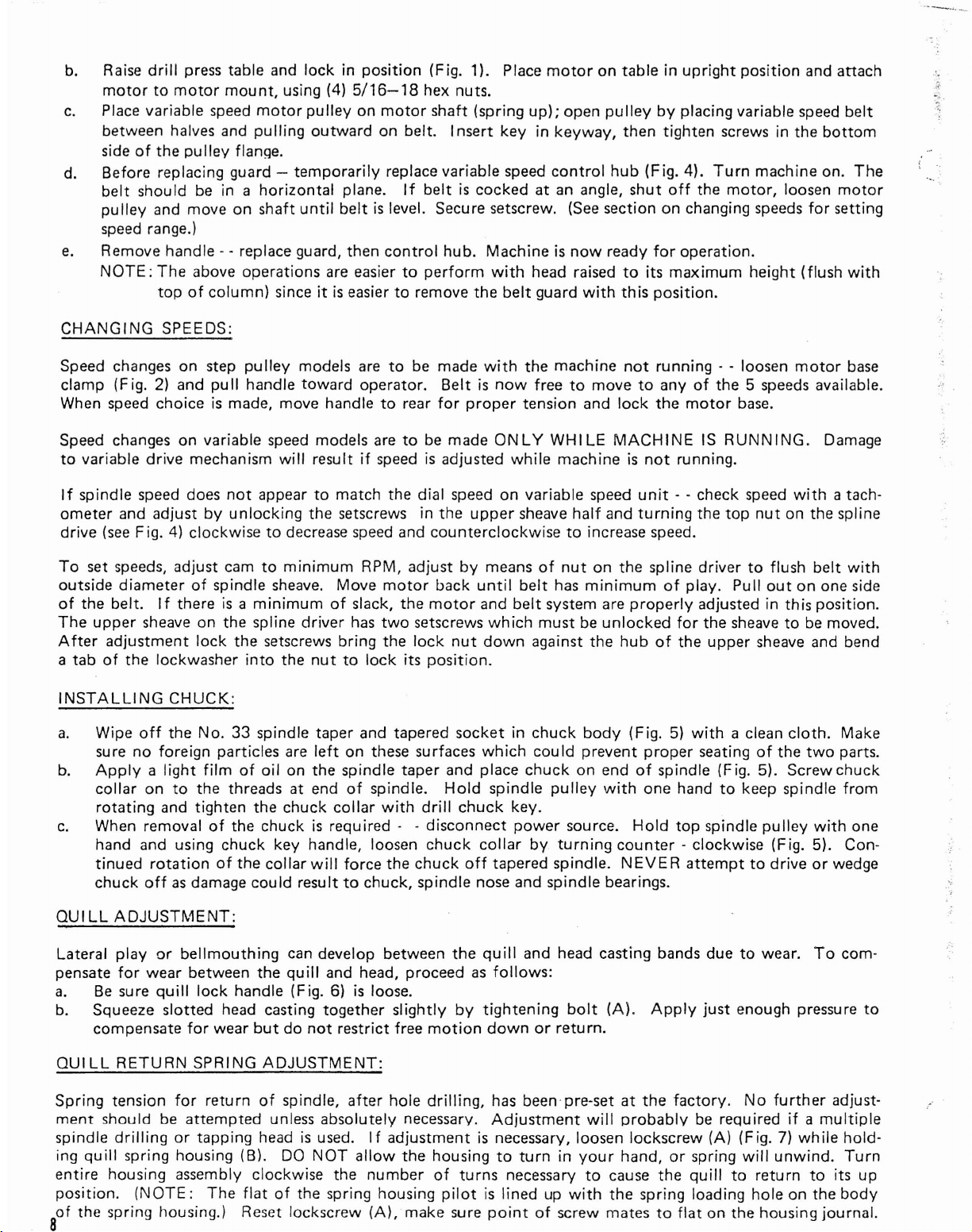

b. Raise

c.

d. Before replacing guard -

drill

press table and

motor

to

motor

mount,

Place variable speed

between halves and

side

of

the pu lIey flange.

belt

shouId

pulley

be

and move

in a

on

lock

using (4)

motor

pulling

pulley

outward

temporarily

horizontal

shaft

until

in

position

5/16-18

on

motor

on belt. Insert

plane. If

belt

is

speed range.)

e.

Remove handle - - replace guard, then

NOTE:

CHANGING

Speed changes

clamp

When speed choice

(F

The

top

SPEEDS:

ig.

2)

above operations are easier

of

column)

on

step

and pu

is

made, move handle

pulley

II

handle

since

it

is

models are

toward

control

easier

operator.

to

Speed changes on variable speed models are

to

variable

If

spindle speed does

ometer

drive

drive

and adjust

(see

Fig.

mechanism

by

4)

clockwise

will

not

appear

unlocking

to

decrease speed and

result

the

if

speed

to

match the dial speed

setscrews in

(Fig. 1). Place

hex nuts.

shaft (spring

key

up);

in

replace variable speed

belt

is

cocked

at

level. Secure setscrew.

hub.

Machine

to

to

remove

to

be made

rear

to

perform

Belt

for

be made

is

adjusted

the

with

the

belt

with

is

now

proper

ONLY

on

upper

head raised

guard

the

free

tension and

while

variable speed

sheave

counterclockwise

motor

open

on

pulley

keyway,

control

an

angle,

(See

section on changing speeds

is

now

ready

with

machine

to

move

WHILE

machine

half

and

to

increase speed.

table in

by

then

tighten

hub

(Fig. 4).

shut

off

for

to

its

maximum

this

position.

not

running·

to

any

lock

the

MACHINE

is

not

unit

- - check speed

turning

upright

position

and attach

placing variable speed

screws in the

Turn

machine

the

motor,

bottom

on.

loosen

for

operation.

of

the

motor

IS

height

. loosen

5 speeds available.

base.

RUNNING.

(flush

motor

running.

with

the

top

nut

on the spline

belt

The

motor

setting

with

base

Damage

a tach-

~-

To

set speeds, adjust cam

outside

of

The

A

fter

a tab

INSTALLI

a.

b.

c.

diameter

the belt.

upper

If

sheave on the spline

adjustment

of

the

lockwasher

NG

Wipe

off

sure

no

foreign particles are

Apply a light

collar

rotating

on

and

When removal

there

CHUCK:

the

to

hand and using

tinued

chuck

LL

QUI

Lateral

pensate

a.

Be

b.

Squeeze

rotation

off

as

ADJUSTMENT:

play

or

bellmouthing

for

wear between the qu

sure

quill

slotted

compensate

of

spindle sheave.

is a minimum

lock

the

into

No.

33

spindle taper and tapered

film

of

the

threads at end

tighten

of

the

the

chuck

of

the

damage

lock

could

handle (Fig. 6)

head casting

for

wear

but

to

minimum

driver

setscrews

the

nut

oil

on

the

chuck

chuck

is

RPM, adjust

Move

motor

of

slack,

has

two

bring

the

to

lock

left

on these surfaces

spindle

of

spindle.

collar

with

required - -

key handle, loosen

collar

will

force

result

to

chuck, spindle nose and spindle bearings.

can develop between

ill

and head, proceed

is

loose.

together

do

not

restrict

the

setscrews

lock

its

taper

drill

the

chuck

slightly

free

by

means

back

until

motor

and

which

nut

down

position.

socket

which

and place

Hold

spindle

chuck

disconnect

chuck

motion

collar

off

tapered spindle.

the

quill

as

follows:

by

tightening

down

of

nut

on

the

belt

belt

system are

must

against

in

chuck

cou Id

chuck

has

minimum

be

body

prevent

on end

pulley

properly

unlocked

the

hub

(Fig. 5)

with

spline

proper

of

one hand

of

play. Pull

for

of

the

with

spindle

driver

adjusted in

seating

key.

power

by

source.

turning

Hold

counter

NEVER

top

- clockwise (Fig. 5). Conattempt

and head casting bands due

bolt

(A).

Apply

or

return.

to

flush

out

the

sheave

upper

sheave and bend

a clean

of

the

(F

ig.

5). Screw

to

keep spindle

spindle

just

pulley

to

drive

to

wear.

enough pressure

belt

on

one side

this

position.

to

be moved.

cloth.

two

with

or

wedge

To

with

Make

parts.

chuck

from

one

com·

to

QUI

LL

Spring

ment

tension

should be

spindle

ing

quill

entire

housing assembly clockwise the

position.

RETURN

drilling

spring housing (B), DO

(NOTE:

SPRING

for

return

attempted

or

tapping head

The

ADJUSTMENT:

of

spindle,

after

unless absolutely necessary.

is

used.

NOT

flat

of

the spring housing

aof the spring housing.) Reset lockscrew

hole

If

adjustment

allow

number

(A),

drilling,

the

housing

of

turns

pilot

make sure

has been pre-set

Adjustment

is

necessary, loosen

to

turn

in

your

necessary

is

lined

up

with

point

of

screw mates

will

to

at

the

factory.

probably

lockscrew

hand,

cause

the

or

the

spring loading

to

No

be

required

(A) (Fig. 7)

spring

quill

flat

will

to

on the housing

further

if a multiple

unwind.

return

hole

on

while

to

the

journal.

adjust-

holdTurn

its

up

body

Page 9

VIS

FIGURE 3

GUARD

REMOVAL

FIGURE 4

VIS SPEED ADJUSTMENT

v.S._,

:~"-lTRO~

"'!UB

I

SPINDLE

SPINDLE

THREADS--~~:Jt-

CHUCK

FIGURE 5

KEY CHUCK

...

TiGHTEN

lOOSEN

KEY

INSTALLATION

~

CHUCK

CHUCK

COllAR

QUILL

LOCK

HANDLE

QUILL

0

r-==

............,,:

R

~

FIT

@

[j]

t--

(A)

FIGURE 6

UP

ADJUSTMENT

!.

p

@

L.-

'-'-

r!

0

-

~

h

u......u

9

Page 10

"'-

..

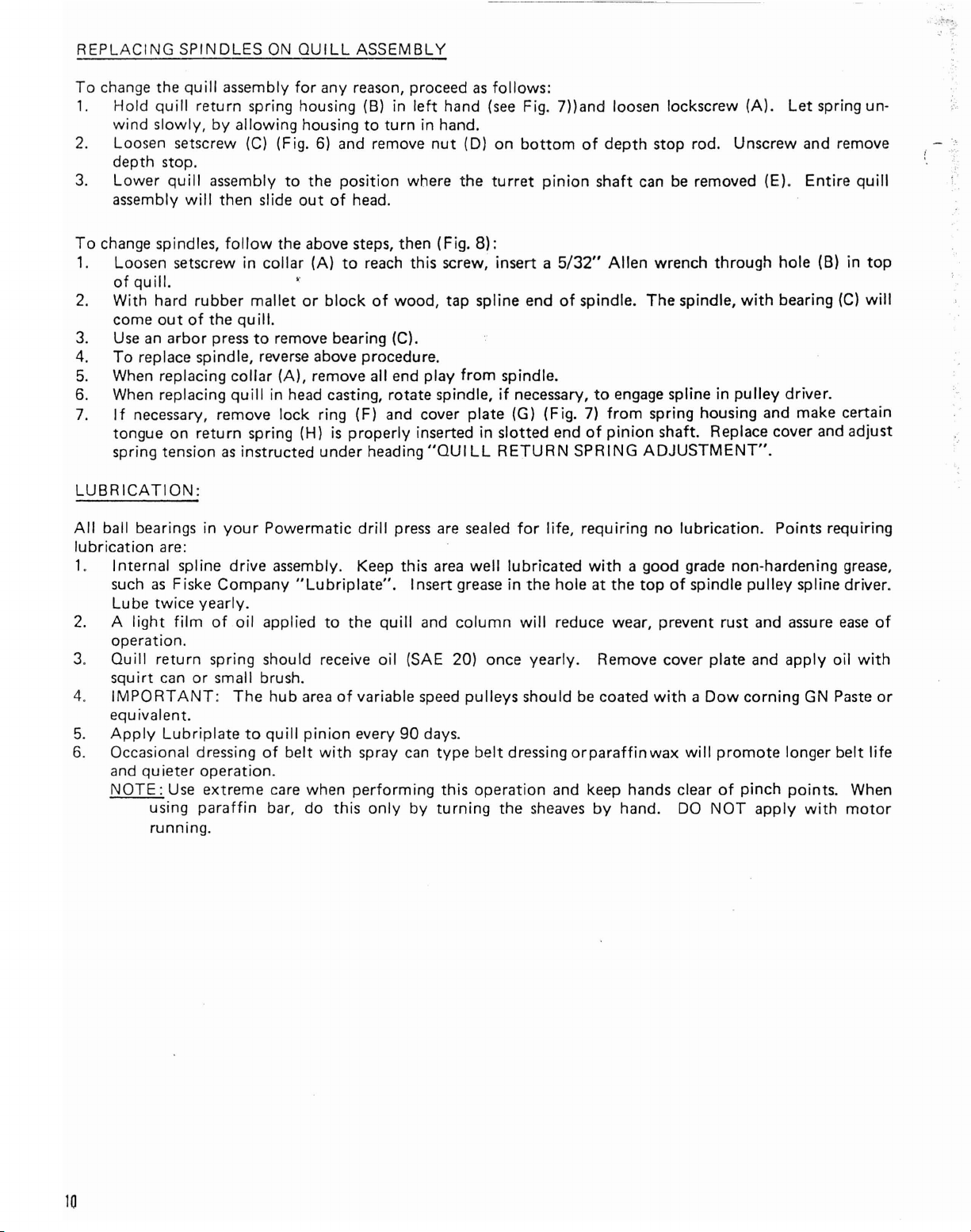

REPLACING

To

change the

1.

Hold

wind

2.

Loosen setscrew (C) (Fig.

SPINDLES

quill

quill

return

slowly,

by

depth stop.

3.

Lower

assembly

To

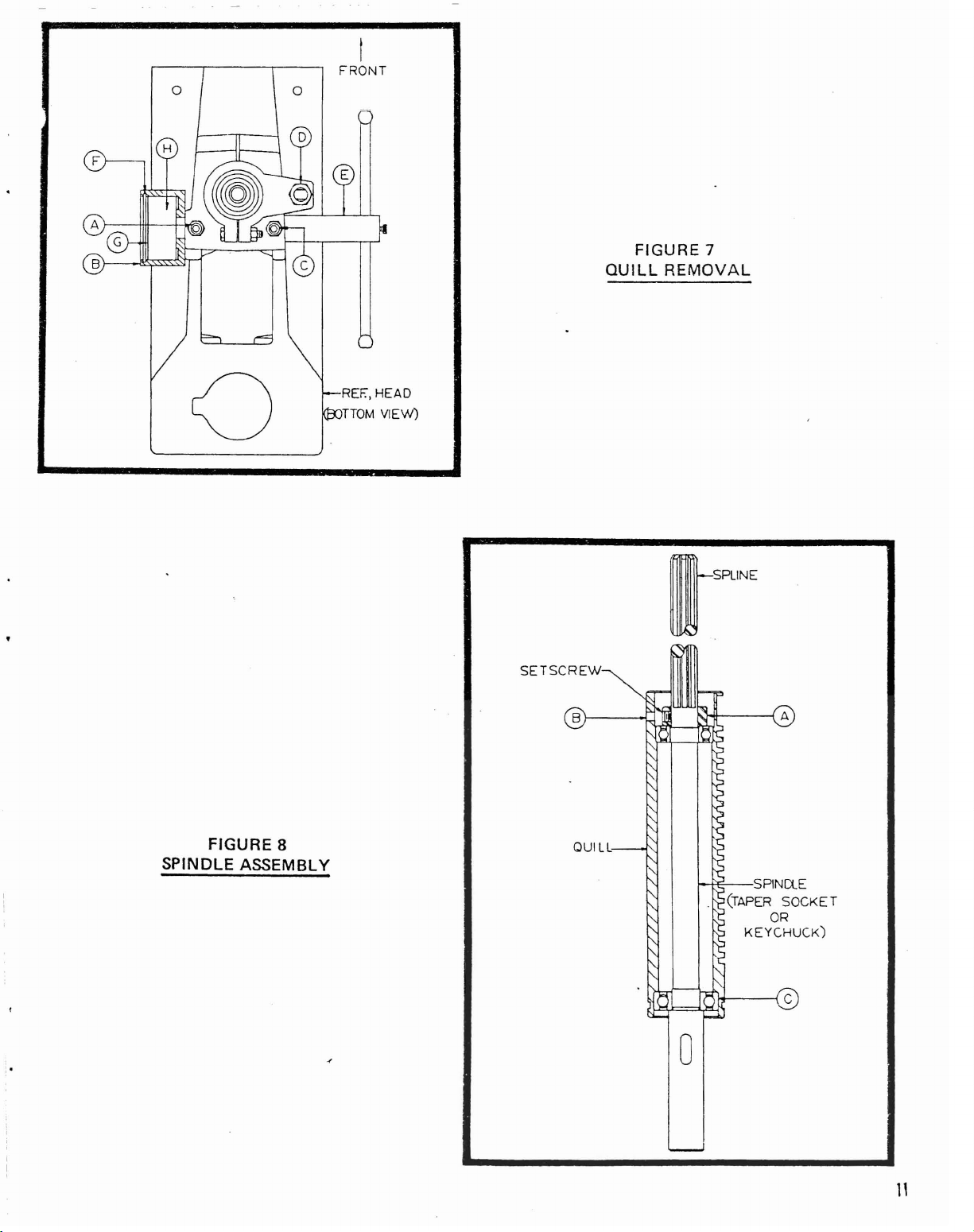

change spindles,

1.

Loosen setscrew in

of

2.

With

come

3.

Use

4.

To

5.

When replacing

6.

When replacing

7.

If

tongue on

spring tension

quill

assembly

will

then slide

quill.

hard

rubber

out

of

the

an

arbor

press

replace spindle, reverse above procedure.

necessary, remove

return

as

LUBRICATION:

ON

assembly

QUILL

for

ASSEMBLY

any reason, proceed

spring housing (B) in

allowing

follow

mallet

housing

to

the

out

to

6)

and remove

position

of

head.

turn

the above steps, then (Fig.

collar

or

(A)

block

to

reach this screw, insert a 5/32"

of

quill.

to

remove bearing (C).

collar

(A),

remove all end play

quill

in head casting, rotate spindle,

lock

ring (F) and cover plate (G) (Fig.

spring (H)

instructed

is

properly

under

heading

left

in hand.

nut

where

wood,

inserted in

"QUI

as

follows:

hand

(see

Fig. 7))and loosen lockscrew

(OJ

on

bottom

the

turret

8):

tap spline end

from

spindle.

if

necessary,

slotted

LL

RETURN

pinion

of

end

SPRING

of

depth

shaft

can

Allen

spindle.

to

7)

of

The

engage spline in

from

spring housing and make certain

pinion

ADJUSTMENT".

(A).

Let

spring un-

stop rod. Unscrew and remove

be

removed (E).

wrench

spindle,

through

with

pulley

Entire

hole (B) in

bearing

(C)

driver.

quill

top

will

shaft. Replace cover and adjust

;

"

All

ball bearings in

lubrication

1.

such

2.

A

are:

Internal spline

as

Fiske

Lube

twice

light

operation.

3.

Quill

return

squirt

4.

IMPORTANT:

can

equivalent.

5.

Apply

6.

Occasional dressing

Lubriplate

and qu ieter

NOTE:

Use

using

running.

your

Powermatic

drive

assembly. Keep this area

Company

yearly.

film

of

oil

applied

spring should receive

or

small brush.

The

hub

to

quill

of

belt

operation.

extreme

paraffin

care when

bar, do

drill

"Lubriplate".

to

the

quill

oil

area

of

variable

pinion

with

every

spray

performing

this

only

press

are

sealed

Insert grease in

and

column

well

for

life, requiring

lubricated

the

hole at

will

reduce wear, prevent rust and assure

no

lubrication.

with

a good grade non-hardening

the

top

of

spindle

(SAE 20) once yearly. Remove cover plate and

speed

90

can

by

days.

type

this

turning

pulleys

belt

operation

should be coated

dressing

orparaffinwax

and keep hands clear

the

sheaves

by

hand. DO

with a Dow

will

promote

of

NOT

corning

pinch

Points requiring

pulley

spline driver.

apply

GN Paste

longer

points. When

apply

with

grease,

ease

oil

with

belt

motor

of

or

life

10

Page 11

o

o

o

I

FRONT

REF.,

HEAD

nOM

VIEW)

FIGURE 7

QUILL

REMOVAL

FIGURE 8

SPINDLE ASSEMBLY

SETSCREW

o-SRINE

1--+1E'---S

PIN

(TAPER

OR

KEYCHU(K)

Ct.

E

SOCKET

o

Page 12

~RTISE

ATTACHMENT

INSTALLATION

IMPORTANT NOTE: Mortise attachments cannot be installed'on Morse

To

mount

bolt

locknut

Insert proper size hollow chisel (with discharge hole

between shoulder on

head

mortise attachment, remove quill

at rear

bott

(B).

(D).

of

quill. Replace

top

Insert

drill bit into chisel allowing shank

yoke

of

chisel and

yoke

(Fig.

9)

by removing locknut (8) and loosening yoke clamp

with chisel housing (C). Insert depth stop rod into housing and replace

to

left if possible) into chisel housing. Insert a dime

bottom

of chisel housing. Lock chisel

to

extend as far as possible into chuck jaws. Apply

Taper

in

Spindle Models

..

place temporarily with square

pressure against bit end with a wood block and while holding, pressure tighten chuck jaws securely. Remove

dime and move chisel up against chisel housing.

as

tables

pictured

in

Fig. 9.

The

mortise attachment

lockscrew

is

now ready

(0)

tightly. Affix fence assembly

to

use. Use

short

pecking strokes on

to

tilting

all

Set

mortise operations.

If

chisel end begins

Pressures exerted during mortise operation will sometimes force drill

clearance gap. A loud squeal

to

turn

blue, check chisel for sharpness and clearance between end

bit

deeper into chuck jaws, reducing

is

usually an indication

of

insufficient clearance.

of

drill

bit

and chisel.

12

GUARO ASSY.

(2250091)

GUARQ ASSY.

(2250092)

MORTISE

(nOOR

MTGJ

(WITH

eAsE)

FIGURE 9

ATTACHMENT

rOOT

ASSY

(2192003)

INSTALLATION

rEED

Page 13

TROUBLE

SHOOTING

HINTS

TROUBLE

Exce~~ivg

I

Motor

Noisy Operation

Drill

Up

ori

II

Excessive

or

Work

Loose

Vibration

Stalls

or

Tool

or

Burns"

Leads 0

Drill

Wobble

or Fixtu

or

Spins.

Heats

ff

Work

Runout

re

Comes

'I.

2.

3.

4.

1.

-,

2.

3. V/S

4.

5. Bad

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

1.

2.

3.

4.

1.

2.

3.

1.

PROBABLE

I

mproper

Uneven

Motor

belt

or

belt

spindle

CAUSE

tension.

wear (hard spots).

pulley

out-of-

-l-""'"

REMEDY

Adjust

1.

Replace belt.

2.

Balance

3.

belt

or

tension.

replace

balance.

Replace

Bad

motor.

Over feeding.

Dull

drilL

belt

Motor

riding on

not

building

inner

up

cone.

to

running

speed.

motor.

Excessive

Improper quill

Noisy

Noisy

Excessive speed. 1. Reduce speed.

Chips

Dull

Feed rate

Rotation

Failure

coolant

No

Cutting

Quill

Bearing play.

Bent

Bearing

Drill

chucks.

Failure

work

vibration.

spline.

motor.

not

clearing.

tool.

too

of

drill

to

use

(on steel).

drill

spot.

lips on

loose in head.

drilt.

play.

not

seated

to

clamp

holding

adjustment.

slow.

incorrect.

cutting

drill

device

oil

off

properly

workpiece

to

or

center.

in

or

table.

4.

Reduce feed rate.

1.

Sharpen

2.

3. Re-adjust V/S belt.

4.

Replace

fuses in all three

.

motors

5. Replace

Check remedy

1.

vibration.

Adjust

2.

quill

Lubricate

3.

Check

4.

motor

Use

2.

3. Sharpen

Increase feed enough

4.

Reverse

5.

wiring

J

Use

6.

Center

1.

Regrind

2.

Tighten

3.

Check bearings and reseat

4.

necessary.

Replace

1.

straighten.

Replace

2.

Loosen, reseat and

3.

Clamp

1.

device

motor.

drill

or

repair

and replace

motor.

quill

(refer

adjustment).

spline.

motor

fan.

pecking

cutting

operation

tool

motor

diagram).

oil

punch

drill.

quill

drill.

or

reseat bearings.

workpiece

to

table

"

,--

problem

and keep sharp.

motor.

regs

on three phase

if

under

to

bearings

or

replace.

rotation

or

coolant

or

center

(refer

to

Do

not

tighten

or

su

rface.

pulley.

Check

necessary.

excessive

paragraph on

or

for

to

clear

to

clear chips.

(refer

on steel.

drill

quill

or

attempt

chuck.

work

holding

--,

loose

ch

ips.

to

motor

workpiece.

adjustment).

replace

if

to

f

I

13

Page 14

:I:

m:I:

»m

0»

»0

en»

sm

~~

-<r-

IOJ

coS:

-<

"

...l

--

C/) .....

-OC/)

:0."

-:0

2-

G)Z

-iC)

m-<

-am

:t>"

cnJ:

:DC")

Oc

nO

-i

m

"'"

'\

12-/\

SET

LIEU

IN

(49)COMPRISE

USED

IS

9COJIS. RAPID

~6)THRU

NO.

STOP AND

ASSY.

ITEMS

I.

NOTES'

(12)

ITEM

OF

USED

COMPRISE

IS

(54)

ANLJ

THRU

9100016, TURRE T

ASSY.

(~U)

NO.

ITEMS

HANDLE

ASSY.

2.

(6\("/)

0)

(f

ANf)

LIEU or ITEMS

IN

(8)

-0

---0)

,..}

'~

~

®~

~--=--@>

-G7

I

-

.@

_-@

I

I

,--@

~-@

't"

.

"

~,

~

~.

~.

,,~

r,.

.-

~"',

~//

ij,

G)

~

~

@-

'-

"-

~-

~L'~«~

~8)

--.,----,

r;0

.........

.~

":

..

;;._~_

I ®

~O

~O;-~_

~

Qyr-----

I

I

I .

I@__ _

t

I

i

I

j®--.-

'''

~

m"

~

,

/

..

eJ

5~

@-

-~

~o~---

I

'''1

"-,

._.

1

,

--~~ct=::Ji\

-

"Jk~

__

I@

if£)

,

----@

----

..

0

-

®

:

~-J

~~

'.

'

~

..".-

~

I, I

ONLY

SOCKET

ASSY.

(2640018)

TAPER

QUILL

ASSY.ONLY-·

(2640017)

~EYCHU(K

QUilL

Page 15

NO.

PART

NO.

HEAD

ASSEMBl

DESCRIPTION

Y

CTY.

".------------------------,

NO.

PART

HEAD

NO.

ASSEMBLY

DESCRIPTION

QTY.

f

,

':l1440Q3

1

6670006

3144006

2

3

6060014

4

3737021

6804003

5

2240071

3406045

6

7 6714019

I 8

9

10

6430024

3586025

3268053

2670014

11

3526093

12 3526094

13

6626035

14

3670102

3528005

15

2695009

16 3268002

17

3695010

18 3406016

2640017

2640018

19 6715016

20 3096244

21

6060165

3640016

22

23

6060009

24

2749037

3749105

25

6118005

26

27

2440013

3277028

28

3448014

29

30

6861513

31

3526039

32

3661016

33

3104010

34

6715116

35

6813026

36

3298288

37

6716040

38

6518001

39

6718038

40

6804004

41

6715039

42

6515001

43

6714090

44

3936013

45

3528005

9100015

46

6515006

47

6715010

48

3055104

3689070

49

9100016

2268006

3406206

50

3670025

51

52 6715013

DRIVE

SPLINE

5)

RETAINING

INTERNAL

BEARING

BEARING

"0"

RING

PINION

GEAR

THRU

10)

HANDLE

SOC

SHEAR·LOC

QUILL

HANDLE

DEPTH

THRU

GRADUATED

PLAIN

SPRING

DEPTH

LOCK

LOCK

THRU

HANDLE

LOCK

HANDLE

KEYCHUCK

19

TAPER

19

CUP

COLLAR

BEARING

SLIDING

BEARING

SPINDLE

CHUCK

TAPER

TAPER

JACOBS

HEAD

MENT)

DRILL

HEAD

FLAT

NUT,

RETAINING

SPRING

HALF

-18

SPRING

SINGLE

HEX

HEX

HALF

-13

"0"

HEX

HEX

HALF

-20x

QUILL

LOCK

RAPID

49)

HEX

FLAT

STOP

LOCK

TURRET

THRU

HANDLE

PHENOLIC

TURRET

KNURLED

HD

OPERATING

ADJ

15)

DEPTH

ADJUST

NUT

seR

18)

seR

THRU

SOCKET

THRU

PT

SOC

ONL

SOCKET

SOCKET

SLEEVE

PRESS

SLEEVE

WASHER

1/2-13

DOG

x 1/2

HD

NUT,

DOG

x 1-1/4

RING

HD

NUT

DOG

1/2

YOKE

NUT

SET

(IN

LIEU

NUT,

PT

BLOCK

SCREW

54)

KNOB

CAP

PIN,

KNOB

24)

23, &

QUILL

ASSY,

CHUCK,

COVER

SPRING

seR

SCR,

SOC

HANDLE

ROD

5/16-18x3/8

ASSY,

RING

DRIVE

SPACER

ASSY,

seR

KNOB

ROD

ASSY,

DEPTH

STOP

3/16

ROD

ASSY.

QUILLASSY,

QUILL

25)

SET

SCR,

(1

Y)

SPINDLE

ON LY)

1/2"

LOCK

HEAD

LOCK

1/2"

RING

PT

SOC

HOUSING

3/8-16 x 2·1/2

1/2-13

PT

SOC

5/16-18

5/16-18

PT

SOC

STOP,

OF

STANDARD)

5/16-18

SET

(IN

LIEU

ASSY

(ITEMS

KNOB

CUP

PT

(lTEM5 1

(SHAFT)

(ITEMS

6

~.'4-20

x

5/8

PINION

(ITEMS

STOP

NUT

NUT

)(

5/8

(ITEMS

16

(ITEMS

ASSY,

5/16-18

SPRING

SET

SET

w/33

ASSY,

SCR,

SCR,

KEY·

(1

SPRING

MT

(WELD·

5/16

1/2

x 1-3/4 1

SET

SCR,

1/4

(ITEMS

46

THRU

SCR,

5/16-18

~

ASSY,

(ITEMS

OF

STANDARD)

50 &

51)

SOC

SET

SCR,

T~-cfRU

11

(ITEMS

x 5/16

x

1/2

50

1

- •

54 6420001 WOODRUF F

KE

Y

"1

2

1

2

1

1

2

1

1

1

1

1

1

1

1

1

i

1

1

1

2

1

1

1

1

1

1

1

1

I

1

1

1

1

1

1

1

I

1

1

1

2

2

1

1

1

1

1

1

1

1

1

3

1

!

1

1

15

Page 16

VARIABLE

SPEED

@

I

ASSEMBLY

'/F:'

'C,

~

'&

I

,"CO'"

t~

~'~

I I i

® ®

I I I I

®®

@

®

I

\

Page 17

VARIABLE

SPEED

ASSEMBL

Y

VARIABLE

SPEED

ASSEMBL

Y

--

NO.

PART

2404005

2298033

2305002

1

6626056

3406045

2

3268056

3

3301042 SPEED

4

6716123

5

3703013

6

32982"36

7

6516001

8

6716117

9

I

10

i

6715032

11

3673032

12

6095043

I 6515007

13

14

3936014

15

2076004

16 6670002

17

6813089

2719065

18 3096144

19

6623013

6060123

20

21

2719069

3719177

22

6765003

23

24 6864006

6549006

25

6714154

26

6861101

27

28 3062109

29 6077158

3387028

30

31

2042163

2250140

6714083

32

33

6458002

34

2250131

6710003

35

36 6860800

6510009

37

2388061

38

3119003

39

3119005

3330284

40

3312228

41

6747000

42

43

6861201

44

6715035

45

3277028

6716031

46

47

6861300

48 2719066

49

6515001

50

6861200

51

6861201

6470600

::>2

6470607

6470608

NO.

VIS

31

HOUSING

17)

SPEED

1

THRU

SPA

HANDLE

HANDLE

BUT

CAM

CAM

HEX

SLOTTED

3/8-16

HEX

VIS

BUSHING, .3125/.3115 10 x .4375/.4365

00

HEX

VIS

VIS

RETAINING

I

BELLVILLE

VIS

18

BEARING

DOWEL

FAFNIR

VIS

FIXED

CUP

(ONE

LOCK

LOCK

HEX

FLAT

ANGLE

VIS

FLAT

MOTOR

VIS

DESCRIPTION

KIT

ASSY,

)

ASSY,

HANDLE & HUB

4)

ING

PIN,

KNOB

HANDLE

HD

SCR,

SHAFT

HOUSING

NUT

3/8-16

HD

x

1-1/2

HD

SCA

ROLLER

x

3/8

JAM

NUT,

YOKE

CAM

ASSY

DRtVEN

THRU

25)

COLLAR

PIN

BEARING

SLIDING

FLANGE

PT SOC

NOT

SHOWN)

WASHER,

NUT,

HD

seR,

WASHER,

BRACKET

BELT

KEY,

MOUNT

GUARD

(ITEMS 1 THRU

(ITEMS 1 THRU

5/32 x 3/4

HUB

3/8-16

x 1 1

SET

CONE

5/16-18

5/16-18

RING

SPRING

SHEAVE

5/16

SHEAVE

SET

N-06

1/4-20

3/16 x 1/4 x 3·5/16

ASSY

ASSY

x 1

SHEAVE

SCR,

5/16-24 x 1/2

W-06

x

1/4

BASE

(ITEMS

37)

BUT

HD

SCA

1/4-20

RUBBER

GUARD

TRUSS

FLAT

SPEED

ViS

42)

IDENTiFICATION

NOJ

IDENTIFICATION

MATIC)

SAFETY

SERIAL

DRIVE

SHOWN)

FLAT

HEX

HEAD

HEX

LOCK

MOTOR

HEX

LOCK

FLAT

ELEC

RPM

ELEC

RPM

ELEC

RPM,

MOLDING

ASSY

HD

SCA,

WASHER,

NUT

PLATE

KIT,

DECAL

PLATE

SCA,

WASHER

HD

CAP

HD

SCR

WASHER

SHEAVE

NUT,

5/16-18

WASHER

WASHER,

MOTOR,

115/230V

MOTOR,

20QV

56FR

MOTOR, 3/4

230/460V,

NO.4

SCR

x

(WELDMENT)

10-24

NO.

10

(ITEMS

DECAL

DECAL

(NOT

(NOT

SHOWN)

x 3/16

5/16

5/16-18

3/8-16

x 1 2

3/8

ASSY

5/16

5/16

3/4

HP,

56

FR

3/4

HP, 3 PH,

TEFC

HP,

56

FR,

ASSY,

(ITEMS

PT

seR,

x 1

(ITEMS

3/8

ASSY

32

THRU

1/2

x

1/2

38

THRU

(MODEL

(POWER-

SHOWN)

(NOT

x

3/4

1 PH,

1200

TEFC

1200

3 PH, 1200

TEFC

QTY.

1

2

2

1

1

1

2

2

1

1

1

1

1

1

2

1

1

2

1

1

1

2

1

1

2

2

I 2

1

1

1

2

2Ft.

1

2

2

2

1

2

1

1

2

4

4

1

2

1

4

4

4

NO.

PART

6470700

6470702

6470707

6470712

6470602

NO.

DESCRIPTION

ELEC

MOTOR,

RPM,

115/230V,

ELEC MOTOR,

RPM

575V

ElEC

RPM

ElEC

56

MOTOR,

230/460V 56 FR

MOTOR,

RPM, 200V, 56

ELEC MOTOR,

RPM,

230/460V,

REVERSING

3/4

HP, 1 PH.

56

FA,

3/4

FR

3/4

TEFC

HP, 3 PH,

TEFC

HP, 3 PH,

TE

3/4

HP,

FR,

3/4

3 PH, 1800

TEFC

HP, 3 PH, 1200

56

FR,

Fe

ODP,

1800

1800

lBOO

HIGH

I

I

I

I

I

QTY.

I

I

I

17

Page 18

STEPCONE A

\

SSEMBLY

I

e

18

Page 19

'\1.

}/

J~

........,.,...-,..

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

PART

NO.

2381004

6077018

3062109

6861101

6714154

6330002

2042164

6715014

3718031

3387028

2250141

6710034

6122038

·6510001

3755258

2250133

2250132

6458002

6714083

6710003

6860800

6510009

2268025

3268002

3448032

3406016

6515001

6715143

2717003

3718032

6715014

"2388062

3119004

3119005

3330284

3312228

6747000

6861201

6336010

6715035

6861201

3277028

6861201

6861200

6515001

6470600

6470607

6470608

6470700

6470702

6470707

6470712

64-70602

STEPCONE

STEPCONE

1

THRU

VEE

ANGLE

FLAT

HEX

VINYL

STEPCONE

CUP

STEPCONE

FLAT KEY

STEPCONE

10THAU

RD

WECKESSER

HEX

SPRING

DOOR

GUARD

RUBBER

BUT

TRUSS

FLAT

SPEED

STEPCONE

ASSY

LOCKSCREW

STEPCON E

HANDLE

HEX

FLAT

STEPCONE

(ITEMS

STEPCONE

CUP PT SOC

STEPCON E

THAU

IDENTIFICATION

IDENTIFICATION

SAFETY

SERIAL

DRIVE

SHOWN)

FLAT

RUBBER

HEX

FLAT

HEAD

FLATE

LOCK

HEX

ELEC

115/230V

ELEC

RPM,

ELEC

RPM

ELEC

RPM

ELEC

RPM

ELEC

RPM,

ELEC

RPM

ELEC

RPM,

REVERSING

9)

BELT

BRACKET

WASHER,

HO

SCA

GRIP,

P.T

SOC

HO SCA,

NUT

GUARD

ASSY

MOLDING

HO

SCA

HD

WASHER

NUT

(ITEMS

NUT

PT

SET

26

32)

DECAL

PLATE

SCR,

WASHER

GROMMET

HD

SCA

WASHER

WASHER

WASHER

NUT

MOTOR,

MOTOR,

200V,

MOTOR,

230/460V

MOTOR,

115/230V

MOTOR,

575V

MOTOR,

230/460V

MOTOR,

200V

MOTOR,

230/460V,

ASSEMBLY

DESCRIPTIONS

SHEAVE

MOTOR

seT

SHEAVE

3/16 x 1/4

GUARD

20)

10-24 x 1/2

10-24

seR

BASE

MOTOR

LOCKSCREW

5/16-18

MOTOR

& 27)

SHEAVE

SET

PLATE

No.4

5/16-18

56

56

56

56

KIT,

1/4

1/4-20 x 3/8

.090

x 1 x 3

BASE

seR,

5/16-18 x 1/2

x 3

ASSY

CLAMP

1/4-20 x 1/2

3/16-H-FR

ASSY

(WELDMENT)

(WELDMENT)

10-24 x 1/2

No.10

LOCK

21

THAU

HANDLE

MOUNTLOCK

seR

5/16-18

SHEAVE

SCR

5/16-18 x 1/2

KIT,

DECAL

DECAL

(NOT

SHOWN)

(NOT

SHOWN)

x

3/16

5/16

5/16-18 x 3/4

5/16

5/16

5/16

*HP, 1

Fr.

3/4

FR.,

3/4

3/4

3/4

FR

3/4

3/4

FR

3/4

TEFC

HP, 3 PH,

FEFC

HP, 3 PH,

56FR.

HP, 1 PH,

56

FR.

HP, 3 PH,

TEFC

HP, 3 PH,

56

FR

HP, 3 PH,

TEFC

HP, 3

56

FA,

PH,

(ITEMS

ASSY

..

5/16

(ITEMS

HANDLE

25)

KNOB

x 1-1/4

(ITEMS

(NOT

1200

1200

1200

TEFC

1800

TEFC

1800

1800

TEFC

1800

PH,

1200

OOP,

HIGH

ASSY

28

RPM

~r

..."'"

p~

QTY.

,

2

2

2

1

1

1

1

,

4

2

4

1

1

1

2Ft.

2

2

2

2

1

1

1

1

1

1

1

1

2

1

1

2

1

2

2

2

1

4

4

4

I

19

Page 20

PRODUCTION

@

@

TABLE

&-~~~S·--E-

-

ASSEMBLY

9-----

~

D'

_

@~

--

.-.

4.

@J

O'~t

I

,~

~

@

...

I

_.

1

---

20

~._-

Page 21

PRODUCTION

NO.

PART

NO.

•

1

,~

,

t

i

:.~

2797033

2797.132

2268013

6624006

1

2 3268201

3

3268005

4

6670008

6626038

5

6626040

6

3701001

7

3838009

8

2729004

9

6064001

10

11

3237332

6716099

12

13

3237333

14 3743011 SPACER 2

3710007

15

16

6638004

3797303

17

2695019

3268002

18

19

3695014

3406016

20

2645003

6626033

21

3650005

22

6715118

23

TA66[; &

OEseR

PRODUCTION

1

THRU

PRODUCTION

(ITEMS 1 THRU

TABLE

ASSY

FLAT

NYLON

TABLE

RETAINING

SHOWN)

SPRING

SPRING

ELEVATING

BEVEL

HEAD

THRUST

WORM

HALF

x

SPUR

GEAR

PIPE

PRODUCTION

PRODUCTION

ASSY

HANDLE

LOCK

KNOB

TABLE

21

RACK

3/16

TABLE

24"

HALF

30)

RAISING

(ITMES 1 THRU

HD

PIN.

MACHINE

ELEVATING

RING

PIN,

1/4

PIN.

1/4 x 1·1/4

HANDLE

WASHER

RAISING

BEARING

GEAR

DOG PT SOC SET SCR.

5/8

GEAR

SHAFT

PLUG

1/2-14

(ITEMS

SCR

RAISING

THRU

27)

MOUNTING

x 2

ELEVATING

LONG

DOG PT SOC SET SCR.

BASE

IPTION

TABLE

TABLE

17)

PINION

3"

LONG

HANDLE

(ONE

xl

SLEEVE

TABLE

TABLE

18

THRU

RACK

SPRING

ASSEMBLY

ASSY.

(ITEMS

SUB

ASSY.

HANDLE

3)

HANDLE

NOT

SHAFT

ASSY 1

3/8-16

LOCK

SCR

20)

ASSY,

(ITEMS

PIN

GEAR

RACK

5/16

OTY.

1

1

1

3

1

.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

-18x3/4

24

6515001

25

3078026

6054002

26

27

3096042

3598023

28

6718055

29

30

6716114

31

3042121 1

32

6718056

3098209

33

34

3598023

"

35

6718055

3096008

36

37

9100014

HEX

NUT.

THRUST

STEEL

THRUST

BRASSPROTECTORSETSCR

PLUG.

CUP PT SOC

HD

WINYLOK

DRILL

CUPPT SOC

DRILL

BRASSPROTECTORSETSCRPLUG

BEARING

BALL

BEARING

7/16 x 3/16

HEX

SCR.

PRESS

PRESS

5/16-18

COLLAR

3/8"

DIA.

COLLAR

SET

SCR.

3/8-16 x 2·3/4

INSERT

8ASE

SET

SCR.

COLUMN

CAP 1

1/2-13

x 1/2 1

1/2-13 x 3/4

7/16x3/16

CUP PT SOC

SAFETY

FINISHED

SET

COLLAR

BASE IN

SCR

LIEU

1/2-13 x 1/2

OF

CAST

2

30

1

1

2

1

1

2

2

1

1

'11

Page 22

@

@

c

.:>i"l

NDL

E

TABLE

AND

LEG ASSEMBLY

I

1

g

,

,

l

,

:

~

I

..

I

-,

"

Page 23

".

•

,

..

~

,

~

~

I

MULT SPINDLE

PART

NO.

3063075

1

6517001

2

3098208

3

6717020

4

6717018

5

6

3797016

7

3797017

3797039

8

9

379706B

10

3797038

11

3797067

12

3797037

13

3797066

14

2797122

15

2797124

16

2797014

17

2797125

18

2797015

19

2797126

20

2423007

21

2423008

NO.

COLUMN

1

SPINDLE

2

SPINDLE

3SPINDLE

4

SPINDLE

SPINDLE

5

SPINDLE

6

8

SPINDLE

HEX

1

SPINDLE

2

SPINDLE

3

SPINDLE

4

SPINDLE

SPINDLE

5

6

SPINDLE

8

SPINDLE

BENCH

1

SPINDLE

SPINDLE

2

3

SPINDLE

4

SPINDLE

SPINDLE

5

SPINDLE

6

8

SPINDLE

HEX

1

SPINDLE

2

SPINDLE

3

SPINDLE

4

SPINDLE

SPINDLE

5

SPINDLE

6

8

SPINDLE

HEX

1

SPINDLE

2

SPINDLE

3

SPINDLE

4

SPINDLE

5

SPINDLE

6

SPINDLE

8

SPINDLE

ONE

ONE

TWO

TWO

THREE

THREE

FOUR

FOUR

FIVE

T·SLOTS

FIVE

T-SLOTS

SIX

T·SLOTS

SIX

T-SLOTS

EIGHT

T·SLOTS

EIGHT

T·SLOTS

TABLE

1

SPINDLE

SPINDLE

2

3

SPINDLE

SPINDLE

4

5

SPINDLE

6

SPINDLE

8

SPINDLE

TAB

5

SPINDLE

6

SPINDLE

8

SPINDLE

I

TABLE & LEG

DESCR

MOUNTING

NUT.

7/16-14

MODEL

HD

HD

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

SPINDLE

END

LE

MI

CAP

CAP

DO

COLUMN

SCR,

SCR,

TABLE

TABLE

TABLE

TABLE

TABLE

TABLE

TABLE

TABLE

TABLE

TABLE

LEG

LE

TABLE

TABLE

TABLE

TABLE

ASSY

LEG

ASSY

IPTlON

BRACKET

7/16-14 x 2-1/2

7/16-14 x 1-1/2

W/O

T-SLOTS

WI

T-SLOTS

W/O

T-SLOTS

WI

T-SLOTS

W/O

T-SLOTS

WI

T-SLOTS

WIO

T-SLOTS

WI

T-SLOTS

ASSY

W/O

ASSY

WI

ASSY

W/O

ASSYWI

ASSY

W/O

ASSY

Wi

~

ASSY

OTY.

1

2

3

4

5

6

8

1

2

3

4

5

6

8

1

2

3

4

5

6

8

1

2

3

4

5

6

8

4

8

12

16

20

24

32

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

1

1

2

NO.

22

23

24

MU LT

PART

6717015

3694005

.

6638004

NO.

SP

IN DLET

HEX

1

SPINDLE

2SPINDLE

SPINDLE

3

SPINDLE

4

5SPINDLE

6

SPINDLE

8

SPINDLE

TABLE

SPINDLE

1

SPINDLE

2

3

SPINDLE

4

SPINDLE

5SPINDLE

SPINDLE

6

SPINDLE

8

sa

1

SPINDLE

2

SPINDLE

SPINDLE

3

SPINDLE

4

5

SPINDLE

6

SPINDLE

8SPINDLE

HD

HD

CAP

LEG

PIPE

A BLE &

DESCRITPION

seR,

7/16-14 x 1-1/4

LEVELING

PLUG,

1/2-14

LEG

SCR

ASS Y

! orr

8

8

8

8

12

1:2

16

4

4

4

4

6

6

8

1

1

1

1

1

1

1

23

Page 24

24

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PART

2797120

2440014

3406016

3448033

3268002

6861501

3448014

2440013

3797052

2797008

3096008

3598023

6718055

3098209

3042121

6718056

9100014

NO.

I

,

I

DESCRIPTION

UTILITY

THRU

UTILITY

(ITEMS 1 THRU

HANDLE

TABLE

LOCK

FLAT

HEAD

HEAD

MENT)

UTILITY

TILTING

SAFETY

BRASS

TABLE

7)

TABLE

KNOB

LOCK

HANDLE

WASHER,

SLEEVE

SLEEVE

TABLE

TABLE

COLLAR

PROTECTOR

7/16 x 3/16

CUP

PT

SOC

PRESS

PRESS

SOC

BASE

SET

SET

DRILL

DRILL

CUP

PT

FINISHED

ASSY,

LOCK

3)

1/2

LOCK

LOCK

ASSY

SET

seR,

COLUMN

BASE

seR

IN

LIEU

(ITEMS

1

ASSY,

ASSY,

(WELD·

SCR

PLUG

1/2-13 x 1/2

1/2-13 x 3/4

OF

CAST

QTY.

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

Page 25

ELECTRICAL

MANUAL

SCHEMATIC

·.~i

.r,:';;

:~

:Il

.

"";~

"

'~

:.:.:

,4'

.

.;,

-1

:J

.:-!

'.

'6

~

~~

~'i

":'".."

.,

::~

''''

.~

,t

\

l

>

.\

g;

:\\

Ii

.,

"j

~f

~

:

..

OJ

3~

II

V

l2

l3

230

.;';

60",

.-

1I

230V

l2

---=-=-<>-If-_-jl~

3¢

l3

60",

,

230V

1I

----<::>--_---j~

l2

30

l3

60",

HI

TI

2PB

START

51

'7

0

0

0

-'-

o :

-L-

0

=

10L

1M

=

H4

10l

I TI

IT2

IT)

MOTOR

ITI

I

rTOR

STARTER

STARTER

MOTOR

MOTOR

MOTOR

MAGNETIC

MAGNETIC

WITH

VOLTAGE

CONTRa..

LON

REF.

~~y)

TI

1M

iWlTH

~MR

MTR. I

REF.

SI

REF.

MI

1)bl:1b~

OTY.

I SWITCH ,FURNAS,

1

I

POWERMATIC

OTY.

(J0)

I

(10)

POIN£RMATIC NO.

OTY.

(J¢)

I

10) 6816105

POWERMATIC

6821014

6831068

6831069

6831070

6816119

6816138

6816122

6816126

6470600

6470607

6470608

6470700

6470702

6470707

6470712

6816111

6821014

NO

682i13S

6821134

NO

TRANSFORMER

SWITCH,

SWITCH

STARTER

STARTER

ISWITCH, FURNAS,

"

"

STARTER ,MAG. W/XMR, 1~ ,24V,

MOTOR,ELEC,1f-P.

"

"

"

..

.

.

"

. .

"

"

"

"

"

.. ..

.

.

"

MFG.

FURNAS

FURNAS

MFG. DESCRIPTION

MAGNETIC,

MAGNETIC

MFG. DESCRIPTiON

MCMENTARY

IIS/230-24V,

237460-24

230460-IISV,

10,IISV,

"

3l2l

"

30,IISV,

"

I""

1200 RPM,

30,

1200

..

30,

1200

10.

1800

"

30

,1800

"

30,1800

"

"

3l2l

, 1800

DESCRIPTION

12

BA34P

12

BA24P

F\.JR'.lAS

,14BF328C

,FURNAS,

~o.£NTARY

V,

.24

RPM,

RPM,

RPM,

RPM,

RPM, 2JO/460

RPM,

I4CFI2

PB,

A..ISHl3IJT1(;N,B2813IB

SO

VA

75

VA

SO

VA

FURNAS 14CFI07013

..

14CFi0700

.,

V,

14BFJ2BJ7180

o.

148F328A71BA

"'¥Z

JOV,

200

V

230/460

IISP-JO

V,

575

V

200

V

BA7

8281318

56

V,

"

"

, "

V, "

.

.

I

I

I

71

FR

"

TRANsrnR~IFR

I-'RI\I.\RY

.'10

NOTE: