Page 1

DUST COLLECTOR

Model 75

Instruction Manual & Parts List

M-0460200

(800) 248-0144

www.powermatic.com

Page 2

This manual has been prepared for the owner and operators of a Powermatic Model 75 Dust

Collector. Its purpose, aside from machine operation, is to promote safety through the use of

accepted correct operating and maintenance procedures. Completely read the safety and maintenance instructions before operating or servicing the machine. To obtain maximum life and

efficiency from your dust collector and to aid in using the machine safely, read this manual thoroughly and follow all instructions carefully.

Warranty & Service

The WMH Tool Group warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Repair Stations located throughout the United States can give you quick service.

In most cases, any one of these WMH Tool Group Repair Stations can authorize warranty repair, assist you in

obtaining parts, or perform routine maintenance and major repair on your JET, Powermatic, Performax, or

Wilton tools.

For the name of an Authorized Repair Station in your area, please call 1-800-274-6848.

More Information

Remember, the WMH Tool Group is consistently adding new products to the line. For complete, up-to-date

product information, check with your local WMH Tool Group distributor.

WMH Tool Group Warranty

The WMH Tool Group makes every effort to assure that its products meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from defects in

materials and workmanship as follow: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence or accidents, normal wear-and-tear, repair or alterations outside our facilities, or to a lack of maintenance.

THE WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE, FROM

THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN, ANY IMPLIED

WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY

NOT APPLY TO YOU. THE WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES

TO PERSONS OR PROPERTY, OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL

DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage prepaid, to an

Authorized Repair Station designated by our office. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection discloses a defect, we will either repair or replace the

product, or refund the purchase price if we cannot readily and quickly provide a repair or replacement, if you are

willing to accept a refund. We will return repaired product or replacement at WMH's expense, but if it is

determined there is no defect, or that the defect resulted from causes not within the scope of WMH's warranty,

then the user must bear the cost of storing and returning the product. This warranty gives you specific legal

rights; you may also have other rights which vary from state to state.

The WMH Tool Group sells through distributors only. Members of the WMH Tool Group reserve the right to

effect at any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they

may deem necessary for any reason whatsoever.

Page 3

TABLE OF CONTENTS

Safety Rules ...................................................................................................................................... 4-5

Safety Decals ....................................................................................................................................... 6

Specifications........................................................................................................................................ 7

Receiving .............................................................................................................................................. 8

Assembly ......................................................................................................................................... 9-12

Electrical Connection .................................................................................................................... 12

Grounding Instructions .................................................................................................................. 13

Extension Cord ............................................................................................................................. 13

Operation ............................................................................................................................................ 13

Switch .......................................................................................................................................... 13

Motor ............................................................................................................................................ 13

Maintenance ....................................................................................................................................... 13

Dust Bags .................................................................................................................................... 13

Trouble-shooting .................................................................................................................................. 14

Parts List & Exploded View............................................................................................................ 15-17

Optional Accessories .......................................................................................................................... 18

Page 4

!

SAFETY RULES

Read the Manual. Always read the owner's manual carefully before attempting to use the machine. Know the

limitations and hazards associated with its use.

Eyes. Always wear approved safety goggles or glasses that comply with ANSI Z87.1 when operating this machine. NOTE: Common eyeglasses are only impact resistant, they are not safety glasses.

Dress Code. Do not wear loose clothing, neckties, jewelry, or gloves that can get caught in moving parts. Confine

long hair. Keep sleeves above the elbow.

Electrical Grounding. Your machine must be electrically grounded. If a cord and plug are used, make certain the

grounding lug connects to a suitable ground. Follow the grounding procedure indicated by the National Electric

Code.

Guards. Keep machine guards in place at all times when machine is in use. If removed for maintenance purposes, use extreme caution and replace the guards immediately.

Do not overreach. Maintain a balanced stance at all times so that you do not fall or lean against blades or other

moving parts.

Power off. Make sure the machine is either unplugged or electrically disconnected and locked out when performing maintenance or service work.

Housekeeping. Before turning on machine, remove all extra equipment such as keys, wrenches, scrap, stock,

and cleaning rags from the machine. Keep the area around machine clean and free of scrap material and sawdust

to mimimize the danger of slipping.

Power on. On machines equipped with a manual starter make sure the starter is in "STOP" position before

connecting power to machine.

Use the right tool. Don't force a tool or attachment to do a job which it was not designed for.

Check damaged parts. Check for alignment of moving parts, binding of moving parts, breakage of parts, mount-

ing, and any other condition that may affect the machine's operation. A guard or other part that is damaged should

be properly repaired or replaced.

Turn power off. Never leave machine running unattended. Do not leave machine until it comes to a complete

stop.

No horseplay. Give your work your undivided attention. Looking around, carrying on a conversation, and "horseplay" are careless acts that can result in serious injury.

Use recommended accessories; improper accessories may be hazardous.

Collect wood materials only. Metal shavings and dust can set wood dust on fire.

Do not expose the dust collector to moisture or wet surfaces. Use only indoors and on a dry surface to avoid the

risk of electrical shock.

Do not use the dust collector around flammable products. Sparks may ignite the vapors. Do not pick up anything

that is burning or smoking.

Do not operate the dust collector without the hose connected to the suction chute. Hazardous moving parts are

inside and could cause serious injury.

4

Page 5

Do not put any objects into openings. Do not use with any opening blocked; keep free of dust, lint, hair and

anything that may reduce air flow.

Drugs, alcohol, medication. Do not operate machine while under the influence of drugs, alcohol, or any medication.

Health Hazards. Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

* Lead from lead-based paint.

* Crystalline silica from bricks and cement and other masonry products.

* Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area, and work with approved safety equipment, such

as those dust masks that are specifically designed to filter out microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

!

CAUTION: (This means that if precautions are not heeded, it may result in minor or moderate injury

and/or possible machine damage)

!

WARNING: (This means that if precautions are not heeded, it could result in serious injury or

possibly even death).

5

Page 6

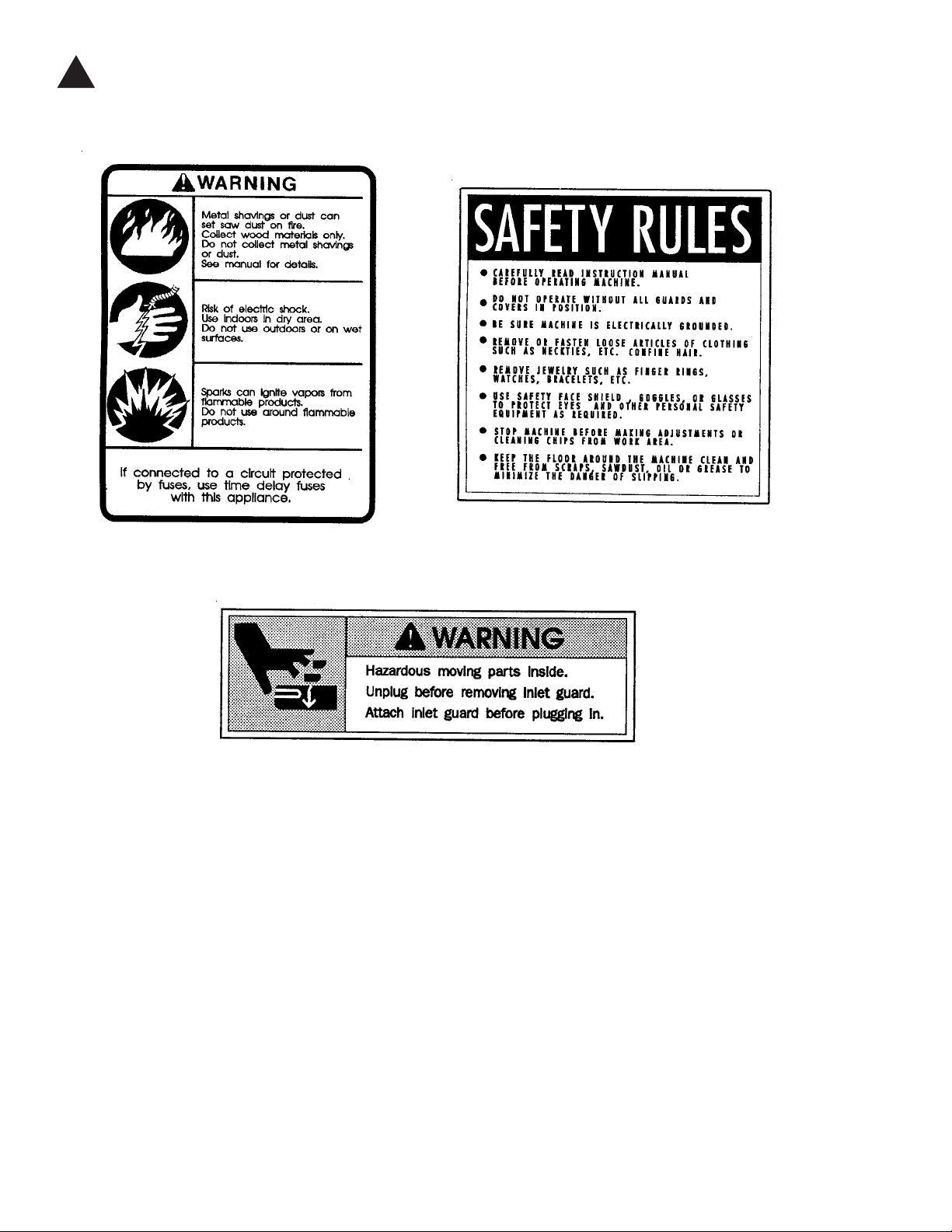

!

SAFETY

Familiarize yourself with the location of these safety decals on your dust collector.

6

Page 7

SPECIFICATIONS: Model 75 Dust Collector

Motor .................................................................................................. 3 HP, 1 Ph, 230V

.................................................................. 3 HP, 3 Ph, 230/460V (prewired 230V)

CFM ........................................................................................................................ 1900

Capacity ........................................................................................................... 10 cu. ft.

Upper dust bag ....................................................................................................... cloth

Lower dust bag ....................................................................................................... cloth

Switch ......................................................................................... industrial push button

Height ........................................................................................................................ 90"

Inlet sizes............................................................................. one-8", one-6", or three-4"

Casters........................................................................................................... four swivel

Weight (gross) ..............................................................................................154.32 lbs.

NOTE: The above specifications were current at the time this manual was published, but because of our policy

of continuous improvement, Powermatic reserves the right to change specifications without notice and without

incurring obligations.

7

Page 8

FIGURE 1

RECEIVING

Remove all contents from the shipping carton and

check each item against the packing list. Report any

missing or damaged parts immediately to your shipping agent and distributor.

Read the instruction manual thoroughly for assembly,

alignment, maintenance and safety instructions.

Contents of carton (Figure 1):

A - 1 impeller housing with motor

B - 1 base K - 2 rubber gaskets

C - 2 support brackets L - 4 casters

D - 2 housings M - 2 hanger brackets

E - 1 adapter (4") N - 4 retainer straps

F - 1 adapter (6") O - 1 hardware bag*

G - 4 cloth bags P - 4 support legs

H - 1 support plate R - 2 extension plates

I - 2 upper hangers 1 manual

J - 2 lower hangers 1 warranty card

Hex Nut

M8 x 1.25

Qty. 42

Hex Head Screw

M8 x 1.25 x 20

Qty. 48

Flat Washer

M8

Qty. 76

FIGURE 2

Lock Washer

M8

Qty. 16

* Contents of hardware bag are drawn full scale in

Figure 2.

8

Page 9

ASSEMBLY

Tools needed

13mm wrench

pliers

1. Turn the base on edge and attach the four caster

assemblies to the threaded holes in the corners of the

base. The loose nut and washer on the caster should

be removed and reversed (washer on top of nut) as

shown in Figure 3. Place a wrench on the bottom nut

and turn clockwise to screw the caster assembly firmly

into the base.

FIGURE 3

2. Mount the two extension plates to the ends of

the base, each with four screws, four flat washers,

four lock washers, and four hex nuts. See Figure 4.

3. Mount the support plate to the underside of the

base, as shown in Figure 5. Use four screws, eight

flat washers and four nuts.

!

FIGURE 4

FIGURE 5

9

Page 10

4. Turn the base upright on to its casters. Attach

the two support brackets to the threaded holes in the

center of the base, as shown in Figure 6. Use four

screws with four flat washers. NOTE: Be careful not

to strip the screws.

5. With the aid of an assistant, lift the impeller housing with motor on to the support brackets, dropping

the four bolts mounted to the impeller housing into the

four holes in the support brackets. See Figure 7.

Secure with four nuts, four lock washers, and four flat

washers.

NOTE: Minor adjustments can be made by slightly

loosening the screws at the bottom of the support

brackets and moving the brackets accordingly. Be sure

to re-tighten the screws after adjusting.

FIGURE 6

6. Mount the two side housings onto the impeller

housing, making sure they are oriented properly, as

shown in Figure 8. Place a rubber gasket over the

opening of the housing, inserting the small knobs on

the gasket into the corner holes of the housing opening.

Attach the housings, each with eight screws, sixteen

flat washers, and eight nuts. Tighten all screws and

nuts.

FIGURE 7

FIGURE 8

10

Page 11

7. Attach two of the support legs to the front of the

machine. See Figure 9. The bottom of the support

leg is slotted and mounts to the pre-tapped holes in

the base with two screws and two flat washers. Do

not tighten yet.

The top of the support leg mounts to the housing with

two screws, four flat washers, and two nuts.

Use the slots at the bottom of the support leg for adjustment if needed, then tighten all screws and nuts.

8. Attach the two rear support legs as follows:

The bottom of the support leg is slotted and mounts to

the pre-tapped holes in the base with two screws and

two flat washers. Do not tighten yet.

The top of the support leg mounts to the holes in the

housing, with a hanger bracket placed in between, as

shown in Figure 10.

FIGURE 9

Make any necessary adjustments using the slots at

the bottom of the support leg, then tighten all screws

and nuts.

9. Screw the lower hanger onto the threads of the

upper hanger, as shown in Figure 11. A flat has been

placed on the lower hanger for use of a wrench to help

in the attachment.

10. Place the two hanger assemblies into the hanger

brackets on the back of the housings, as shown in

Figure 12. The "hooks" should face to the front.

FIGURE 10

FIGURE 11

FIGURE 12

11

Page 12

11. Install the lower dust bag as follows:

Insert a retainer strap through the loops in the bag as

shown in Figure 13.

CAUTION: Retainer straps are rolled up

!

under tension. Hold strap with hand and

allow to unroll gradually.

Place the bag over the lip of the housing and secure

by fastening the retainer strap. Repeat for other lower

bag.

12. In the same fashion, install the upper bag with a

retainer strap over the top lip of the housing. (NOTE:

the upper bag has the Powermatic name on it). See

Figure 14. Place the top loop of the bag over the "hook"

on the hanger as shown. Repeat for other bag.

FIGURE 13

All bags should be securely fastened to the housings

with no air leaks.

13. Two adaptors are provided with the dust collector. Place one upon the inlet as shown in Figure 15. A

hole is provided on the inlet for a screw to secure a

hose or an adaptor to the machine.

ELECTRICAL CONNECTION

The dust collector is equipped with a 3 horsepower,

single phase, 230 volt, or three phase, 230/460 volt

motor. The unit is factory wired for 230 volts and

equipped with a 20 amp cord and plug set. The 230

volt plug requires a receptacle as illustrated in Figure

16.

The three phase motor may be reconnected for 460

volts by changing the connections as illustrated in the

diagram motor wiring box. The three phase power

cord is not equipped with a plug.

FIGURE 14

FIGURE 15

FIGURE 16

12

Page 13

GROUNDING INSTRUCTIONS

OPERATION

WARNING: The dust collector must be

!

grounded to protect the operator from

electric shock. Not all outlets are

properly grounded. Have your outlets

checked by a qualified electrician.

All grounded, cord connected tools:

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current

in order to reduce the risk of electric shock.

This machine is equipped with an electric cord having

an equipment-grounding conductor and a grounding

plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances. Do not

modify the plug provided if it will not fit the outlet; have

the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment grounding conductor to a live terminal.

Check with a qualified electrician or service personnel

if the grounding instructions are not completely understood, or if in doubt as to whether the machine is properly grounded.

SWITCH

The switch box attached to the impeller housing is an

industrial type switch with standard "start" and "stop"

push buttons.

MOTOR

Motors used in a woodworking environment are constantly exposed to sawdust and wood chips. The

operator should make frequent inspections of the motor and remove, or vacuum, any accumulation of foreign material in order to maintain normal motor ventilation.

Remove dust from the motor with a low pressure air

hose.

CAUTION: The operator should follow all

!

safety procedures regarding dust

particles and always wear safety goggles

and a filter mask during any cleaning

operation.

MAINTENANCE

CAUTION: Never perform maintenance

!

on this machine before pushing "stop"

and removing plug from power source.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tools' plug. Repair or replace any damaged or

worn cord immediately.

As the three phase 230/460 volt motor does not have

a plug, please carefully follow the rotation direction of

the impeller when connecting to the power source.

EXTENSION CORD

Use only a 3-wire extension cord with a 3-prong

grounding plug and a 3-pole receptacle as shown in

Figure 16. Replace a damaged or worn cord immediately. The use of an extension cord, if required, results in a certain loss of power. The recommended

wire gage is no. 10.

DUST BAGS

Each operator has his own particular application of

woodworking machinery. As such, a maintenance

schedule for the dust collector must be performed on

a regular and timely basis. To remove dust and chips:

1. Disconnect machine from its power source.

2. Shake the upper dust bag and allow the fine dust

to settle down into the lower bag.

3. Release the clamp around upper bag, remove the

upper bag and deposit all remaining dust into a fireproof metal container.

4. Release clamp around lower bag, remove the

lower bag and deposit chips and dust into a fire-proof

metal container.

5. Reconnect both sets of dust bags making sure

the clamps firmly secure the bags to the housings.

13

Page 14

Trouble-Shooting for Model 75 Dust Collector

PROBLEM POSSIBLE CAUSE SOLUTION

Motor will not run.

Excessive sawdust

in air.

Excessive

impeller noise.

Excessive noise.

Motor fails to develop

full power.

1. Defective cord, plug, switch,

and/or motor.

2. Blown fuse or circuit breaker

tripped.

1. Loose clamps; dust bag and/or

chip collection bag not secure.

1. Picked up large chips and debris.

2. Loose impeller.

3. Rubbing impeller.

1. Motor.

2. Overloaded circuit.

3. Undersize extension cord or extension cord too long.

1. Consult service. Any attempt to repair

this motor may create a hazard unless

repair is done by a qualified service

technician.

2. Check for blown fuses and replace with

fuse of proper capacity or re-set circuit

breaker.

1. Tighten clamps.

1. Stop the machine to allow material to

fall to the bottom of inlet pipe. Remove

debris.

2. Unplug unit prior to disassembly due to

hazardous moving parts inside. Use a

piece of wood to free impeller. Attach to

inlet guard before plugging in.

3. Consult service to repair loose or rubbing impeller. A repair to the housing

may create a hazard unless it is done

by a qualified service technician.

1. Have motor checked by a qualified service technician.

2. Do not overload circuit when using dust

collection system with other appliances.

3. Increase the wire sizes on extension

cord, reduce length of extension cord or

use larger wire sizes. Request a power

check from the power company.

Motor starts slowly or

fails to come up to full

speed.

Motor overheats.

Motor stalls.

Frequent opening of

fuses or circuit

breakers.

14

1. Low voltage.

2. Windings burned out or open.

3. Starting switch will not operate.

(Switch contacts not working

properly.)

1. Motor overloaded.

2. Improper cooling. (Air circulation

restricted through motor due to

sawdust accumulation inside of

motor.

1. Low voltage does not permit motor to reach operating speed.

2. Fuses or circuit breakers lack

sufficient capacity.

1. Motor overloaded.

2. Fuses or circuit breakers lack

sufficient capacity.

1. Request voltage check from power company.

2. Have motor repaired or replaced by a

qualified service technician.

3. Replace capacitor by a qualified service

technician.

1 & 2. Clean out sawdust and provide nor-

mal air circulation through motor.

1. Request voltage check from power company.

2. Install proper size fuses or circuit breakers.

1 & 2. Install proper size fuses or circuit

breakers.

Page 15

Parts List: Model 75 Dust Collector

No. Part No. Description Quantity

1 6286605 Impeller Housing ....................................................................................................1

2 6286606 Housing .................................................................................................................2

3 6286607 Impeller ................................................................................................................. 1

4 6286608 Gasket .................................................................................................................. 1

5 6286609 Inlet Cover ............................................................................................................. 1

6 6286610 Adapter, 8" - (3)4" .................................................................................................. 1

7 6286611 Adapter Cap .......................................................................................................... 2

8 6286600 Upper Bag .............................................................................................................2

9 6286619 Upper Hanger ........................................................................................................ 2

10 6286620 Lower Hanger ........................................................................................................ 2

11 6286621 Hanger Bracket .....................................................................................................2

12 6286622 Handle ...................................................................................................................4

13 6286623 Support Block ....................................................................................................... 4

14 6286624 Support Leg ...........................................................................................................4

15 6286625 Support Bracket ....................................................................................................2

16 6286626 Retainer Strap ....................................................................................................... 4

17 6286601 Lower Bag .............................................................................................................2

18 6286627 Base ..................................................................................................................... 1

19 6286628 Extension Plate ..................................................................................................... 2

20 6286629 Support Plate ........................................................................................................1

21 6286656 Pivoting Caster ......................................................................................................4

22 6286603 Motor, 3 HP, 1 Ph, 230V ........................................................................................1

6286604 Motor, 3 HP, 3 Ph, 230/460V ................................................................................. 1

23 6286631 Power Cord ........................................................................................................... 1

24 6286632 Power Cord Holder ................................................................................................ 1

25 6286633 Motor Shaft Key ....................................................................................................1

26 6286634 Motor Gasket ........................................................................................................1

27 6286635 Control .................................................................................................................. 1

28 6286636 Control Box ...........................................................................................................1

29 6286637 Strain Relief ........................................................................................................... 2

30 6286638 Rubber Gasket ...................................................................................................... 2

31 6286639 Round Head Screw, M6 x 1 x 12 ........................................................................... 8

32 6286660 Hex Head Screw, M8 x 1.25 x 20 ........................................................................ 48

34 6286642 Socket Head Screw, M8 x 1.25 x 12 ..................................................................... 8

35 6286667 Self Tapping Screw, M3.5 x 16 ............................................................................... 2

36 6286644 Round Head Screw, M5 x 0.8 x 12 ........................................................................ 3

37 6286645 Nut, 5/8 x 18 UNF .................................................................................................1

38 6286445 Nut, M8 x 1.25 .................................................................................................... 42

39 6286647 Nut, M10 x 1.5 ...................................................................................................... 4

40 6293809 Nut, 3/8-16 UNC ....................................................................................................4

41 6286662 Flat Washer, M16 ..................................................................................................1

42 6286663 Flat Washer, M10 ..................................................................................................4

43 6286664 Flat Washer, M8 .................................................................................................. 76

44 6286665 Lock Washer, M8 ................................................................................................ 16

45 6286666 Lock Washer, M10 ................................................................................................ 4

46 TS-1550021 Flat Washer, M4 ....................................................................................................2

47 6286654 Plate "Better by Design" ........................................................................................ 1

48 6286655 Motor Plate ........................................................................................................... 1

49 3330283 Safety Rules Decal ................................................................................................1

50 6286657 Caution Decal ........................................................................................................1

51 6286658 Warning Label .......................................................................................................1

52 3312334 Serial Plate ........................................................................................................... 1

53 6286618 Adapter Attachment Kit, 8" - 6" (Items 54 thru 59) ................................................. 1

15

Page 16

Parts List: Model 75 Dust Collector

No. Part No. Description Quantity

54 6286612 Hose, 20' x 4" ........................................................................................................ 1

55 6286615 Clamp, 4" ..............................................................................................................1

56 6286614 Adapter, 4" - 4 .......................................................................................................1

57 6286613 Stainless Clamp, 4" ...............................................................................................2

58 6286616 Plastic Tube, 3'L x 4" ............................................................................................ 1

59 6286617 Vacuum Head........................................................................................................ 1

60 6286630 Hardware ............................................................................................................... 1

61 M-0460200 Manual .................................................................................................................. 1

16

Page 17

Model 75 Dust Collector

17

Page 18

Optional Accessories

6050011 Collector (lower) bags, clear plastic (50 each)

6286600 Filter (upper) bag, cloth (1 each)

6286601 Collector (lower) bag, clear plastic (1 each)

6286602 Vacuum attachment (20' hose with 12" vacuum head)

6286618 Adaptor for 8" to 6"

6292835 Collector (lower) bag, cloth (1 each)

18

Page 19

To order parts or reach our service department, please call our toll-free number between 8:00 a.m. and 4:30 p.m.

(CST), Monday through Friday. Having the Model Number and Serial Number of your machine available when you

call will allow us to serve you quickly and accurately. Locating the stock number of the part(s) required from your

parts manual will also expedite your order.

Phone No.: (800) 248-0144

Fax No. (800) 274-6840

If you are calling from Canada, please call 800-238-4746

E-mail: powermatic@wmhtoolgroup.com

Website: www.powermatic.com

19

Page 20

10/2001

WMH Tool Group

427 Sanford Road

LaVergne, TN 37086

Phone: (800) 248-0144

Fax: (800) 274-6840

E-mail: powermatic@wmhtoolgroup.com

Website: www.powermatic.com

C

POWERMATIC ALL RIGHTS RESERVED

Loading...

Loading...