Page 1

Operating Instructions and Parts Manual

This .pdf document is bookmarked

10-inch Cabinet Saw

Model PM1000

Powermatic

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-1791000

Ph.: 800-274-6848 Revision A4 06/2015

www.powermatic.com Copyright © 2015 Powerm atic

Page 2

1.0 Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. Powermatic woodworking machinery is designed to be used with

Wood. Use of these machines in the processing of metal, plastics, or other materials outside recommended

guidelines may void the warranty. The exceptions are acrylics and other natural items that are made specifically for

wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provid e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Servic e Centers located throughout

the United States. For the name of an Authorized Servi ce Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informatio n

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURI ES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic websit e are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors, Machine Accessories

2 Year – W oodworking Machinery used for industrial or commercial purposes

5 Year – W oodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 4

3.1 Kickback ..................................................................................................................................................... 5

4.0 About this manual .......................................................................................................................................... 6

5.0 Glossary ......................................................................................................................................................... 7

6.0 Specifications ................................................................................................................................................. 8

7.0 Setup and assembly ..................................................................................................................................... 10

7.1 Shipping contents ..................................................................................................................................... 10

7.2 Tools required for assembly ..................................................................................................................... 10

7.3 Unpacking and cleanup ............................................................................................................................ 10

7.4 Installing handwheels and hooks ............................................................................................................. 11

7.5 Installing table extensions ........................................................................................................................ 11

7.6 Leveling table extensions ......................................................................................................................... 11

7.7 Rails and Fence ....................................................................................................................................... 12

7.8 Switch bracket .......................................................................................................................................... 12

7.9 Wood Extension Table ............................................................................................................................. 12

7.10 Motor cover ............................................................................................................................................ 12

7.11 Table insert ............................................................................................................................................. 12

7.12 Installing and removing blade ................................................................................................................. 13

7.13 Riving knife ............................................................................................................................................. 13

7.14 Anti-kickback pawls ................................................................................................................................ 14

7.15 Blade guard ............................................................................................................................................ 14

7.16 Dust chute .............................................................................................................................................. 14

8.0 Electrical connections .................................................................................................................................. 14

8.1 Grounding instructions ................................................................................................... .......................... 14

8.2 Voltage conversion ................................................................................................................................... 15

8.3 Overload reset button ............................................................................................................................... 15

8.4 Extension cords ........................................................................................................................................ 15

8.5 Magnetic switch and safety key ................................................................................................................ 15

9.0 Adjustments ................................................................................................................................................. 16

9.1 Tools required for adjustments ................................................................................................................. 16

9.2 Fence alignment ....................................................................................................................................... 16

9.3 Blade raising/tilt mechanism ..................................................................................................................... 16

9.4 Miter gauge .............................................................................................................................................. 16

9.5 Blade tilt stop adjustment ......................................................................................................................... 17

9.6 Riving knife alignment .............................................................................................................................. 18

9.7 Table to blade alignment .......................................................................................................................... 19

9.8 Belt adjustment ......................................................................................................................................... 19

9.9 Arbor/Arbor Bearing Removal .................................................................................................................. 20

10.0 Operations .................................................................................................................................................. 20

11.0 Safety devices ............................................................................................................................................ 24

12.0 Maintenance ............................................................................................................................................... 26

12.1 Cleaning ................................................................................................................................................. 26

12.2 Lubrication .............................................................................................................................................. 26

12.3 Miscellaneous ......................................................................................................................................... 26

13.0 Optional accessories .................................................................................................................................. 27

14.0 Troubleshooting the PM1000 Cabinet Saw ................................................................................................ 28

15.0 Replacement Parts ..................................................................................................................................... 29

15.1.1 PM1000 Table and Cabinet Assembly – Exploded View .................................................................... 30

15.1.2 PM1000 Table and Cabinet Assembly – Parts List ............................................................................. 31

15.2.1 PM1000 Motor and Trunnion Assembly – Exploded View .................................................................. 33

15.2.2 PM1000 Motor and Trunnion Assembly – Parts List ........................................................................... 34

15.3.1 PM1000 Blade Guard Assembly – Exploded View ............................................................................. 36

15.3.2 PM1000 Blade Guard Assembly – Parts List ...................................................................................... 37

16.0 Electrical Connections for PM1000 ............................................................................................................ 38

3

Page 4

3.0 Safety warnings

1. Read and understand the entire owner’s

manual before attempting assembly or

operation.

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

3. Replace the warning labels if they become

obscured or removed.

4. This table saw is designed and intended for

use by properly trained and experienced

perso nnel on ly. If you are no t fam iliar w ith the

proper and safe operation of a table saw, do

not use until proper training and knowledge

have been obtained.

5. Do not use this table saw for other than its

intended use. If used for other purposes,

Powermatic disclaims any real or implied

warranty and holds itself harmless from any

injury that may result from that use.

6. Always wear approved safety glasses/face

shields while using this table saw. Everyday

eyeglasses only have impact resistant lenses;

they are not safety glasses.

7. Before operating this table saw, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Remove all loose

clothing and confine long hair. Non-slip

footwear or anti-skid floor strips are

recommended. Do not wear gloves.

8. Wear ear protectors (plugs or muffs) during

extended periods of operation.

9. Some dust created by power sanding, saw ing,

grinding, drilling and other construction

activities contain chemicals known to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and

other masonry products.

• Arsenic and chromium from chemically

treated lumber.

Your risk of exposure varies, depending on

how often you do this type of work. To reduce

your exposure to these chemicals, work in a

well-ventilated area and work with approved

safety equipment, such as face or dust masks

that are specifically designed to filter out

microscopic particles.

10. Do not operate this machine while tired or

under the influence of drugs, alcohol or any

medication.

11. Make certain the machine is properly

grounded.

12. Make all machine adjustments or maintenance

with the machine unplugged from the power

source. A machine under repair should be

RED TAGGED to show it must not be used

until maintenance is complete.

13. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and

adjusting wrenches are removed from the

machine before turning it on.

14. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately.

15. Check the alignment of the riving knife, fence

and miter slot to the blade. A caution decal is

installed on each guard to remind the operator

of the dangers of improper machine operation.

16. Check damaged parts. Before further use of

the machine, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

17. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

18. Keep the floor around the machine clean and

free of scrap material, oil and grease.

19. Keep visitors a safe distance from the work

area. Keep children away.

20. Make your workshop child proof w ith padlocks,

master switches or by removing safety keys.

21. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in

serious injury.

22. Maintain a balanced stance at all times so that

you do not fall or lean against the blade or

other moving parts. Do not overreach or use

excessive force to perform any machine

operation.

23. Use the right tool at the correct speed and

feed rate. Do not force a tool or attachment to

do a job for which it was not designed. The

right tool will do the job better and safer.

24. Use recommended accessories; improper

accessories may be hazardous.

Page 5

25. Maintain tools with care. Keep blade sharp and

clean for the best and safest performance.

Follow instructions for lubricating and changing

accessories.

26. Check the saw blade for cracks or missing

teeth. Do not use a cracked or dull blade or

one with missing teeth or improper set. Make

sure the blade is securely locked on the arbor.

27. Keep hands clear of the blade area. Do not

reach past the blade to clear parts or scrap

with the saw blade running. Never saw

freehand. Avoid awkward operations and hand

positions where a sudden slip could cause

your hand to contact the blade.

28. Do not attempt to saw boards with loose knots

or with nails or other foreign material, on its

surface. Do not attempt to saw twisted,

warped, bowed or “in wind” stock unless one

edge has been jointed for guiding purposes

prior to sawing.

29. Do not attempt to saw long or wide boards

unsupported where spring or weight could

cause the board to shift position.

30. Always use the riving knife, blade guard, push

stick and other safety devices for all operations

where they can be used. On operations such

as dadoing or molding where t he blade guard

cannot be used, use feather boards, fixtures

and other safety devices and use extreme

caution. Reinstall the riving knife and blade

guard immediately after completing the

operation that required their removal.

31. Be sure the saw blade rotates clockwise when

viewed from the motor side (left side) of the

machine.

32. Turn off the machine before cleaning. Use a

brush or compressed air to remove chips or

debris — do not use your hands.

33. Do not stand on the machine. Serious injury

could occur if the machine tips over.

34. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until it comes to a complete stop.

35. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

3.1 Kickback

The most common accidents among table saw

users, according to statistics, can be linked to

kickback, the high-speed expulsion of material from

the table that can strike the operator. Kickback can

also result in the operator’s hands being pulled into

the blade.

Kickback Prevention

Tips to avoid the most common causes of

kickback:

• Make sure the riving knife is always aligned

with the blade. A workpiece can bind or stop

the flow of the cut if the riving knife is

misaligned, and result in kickback.

• Use a riving knife during every cut. The riving

knife maintains the kerf in the workpiece,

which will reduce the chance of kickback.

• Never attempt freehand cuts. The workpiece

must be fed parallel to the blade, otherwise

kickback will likely occur. Always use the rip

fence or miter gauge to support the workpiece.

• Make sure that rip fence is parallel to blade. If

not, the chances of kickback are very high.

Take the time to check and adjust the rip

fence.

• Feed cuts through to completion. Anytime you

stop feeding a workpiece that is in the middle

of a cut, the chance of binding, resulting in

kickback, is greatly increased.

Protection Tips from Kickback

Kickback can happen even if precautions are taken

to prevent it. Listed below are some tips to protect

you if kickback does occur:

• Stand to the side of the blade when cutting. An

ejected workpiece usually travels directly in

front of the blade.

• Wear safety glasses or a face shield. Your

eyes and face are the most vulnerable part of

your body.

• Never place your hand behind the blade. If

kickback occurs, your hand will be pulled into

the blade.

• Use a push stick to keep your hands farther

away from the moving blade. If a kickback

occurs, the push stick will most likely take the

damage that your hand would have received.

5

Page 6

Familiarize yourself with the following safety notices used in this manual:

This means that if preca utions are not heeded, it m ay result in minor injury a nd/or possible

machine damage.

This means that if prec autions are not heeded, it may result in serious injury or possibly even

death.

4.0 About this manual

This manual is provided by Powermatic covering the safe operation and maintenance procedures for a

Powermatic Model PM1000 Cabinet Saw. This manual co ntains i nstructions on i nstallation, saf ety precautio ns,

general operating procedures, maintenance instructions and parts breakdown. Your machine has been

designed and constructed to provide consistent, long-term operation if used in accordance with the instructions

as set forth in this document.

This manual is not intended to be an exhaust ive guide to table saw operational methods, use of jigs or aftermarket accessories, choice of stock, etc. Additional knowledge can be obtained from e xperienced users or

trade articles. Whatever accepted methods are used, always make personal safety a priority.

If there are questions or comments, please co ntact your local supplier or Powermatic. Powermatic can also be

reached at our web site: www.p owermatic.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attem pting assembly

or operation! Failure to comply may cause serious injury!

6

Page 7

5.0 Glossary

Arbor: Metal shaft that connects the drive

mechanism to the blade.

Bevel Edge Cut: Tilt of the saw arbor and blade

between 0° and 45° to perform an angled cutting

operation.

Blade Guard: Mechanism mounted over the saw

blade to prevent accidental contact with the cutting

edge.

Crosscut: Sawing operation in which the miter

gauge is used to cut across the grain of the

workpiece.

Dado Blade: Blade(s) used for cutting grooves and

rabbets. A stacked dado set can be used f or wider

grooves.

Dado Cut: Flat bottomed groo ve in t he face of the

workpiece made with a dado blade.

Featherboard: Device used to keep a board

against the rip fence or table that allows the

operator to keep hands away from saw blade.

Freehand: Moving the workpiece into the blade

using only the hands, without a fixed positioning

device. (This is a dangerous, unacceptable

procedure – always use appropriate devices to

feed the workpiece through the saw blade during

cutting operations.)

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: An event in which the workpiece is lifted

up and thrown back toward an operator, caused

when a workpiece binds on the saw blade or

between the blade and rip fence (or other fixed

object). To minimize or prevent injury from

kickbacks, see the Operations section.

Miter Gauge: A component that controls the

workpiece movement while performing a crosscut

of various angles.

Non-Through Cut: A sawing operation that

requires the removal of the blade guard and

standard riving knife, resulting in a cut that does

not protrude through the top of the workpiece

(includes Dado and rabbet cuts).

The blade guard and riving knife must be reinstalled after performing a non-through cut to

avoid accidental contact with the saw blade during

operation.

Parallel: Position of the rip fence equal in distance

at every point to the side face of the saw blade.

Perpendicular: 90° (right angle) intersection or

position of the vertical and horizontal planes such

as the position of the saw blade (vertical) to the

table surface (horizontal).

Push Board/Push Stick: An instrument used to

safely push the workpiece through the cutting

operation by keeping the operator’s hands at a

distance.

Rabbet: A cutting operation that creates an

L-shaped channel along the edge of the board.

Rip Cut: A cut made along the grain of the

workpiece.

Riving Knife: A metal plate fixed relative to the

blade, which moves with the blade as cutting depth

is adjusted. Thus, it maintains not only the kerf

opening in the workpiece, but also the knife-toblade distance. A low-profile ri ving k nife sit s low er

than the top edge of the blade, f or making a nonthrough cut.

Splitter (Spreader): A stationary metal plate to

which the blade guard is attached that maintains

the kerf opening in the workpiece during a cutting

operation.

Standard Kerf: 1/8" gap made with a standard

blade.

Straightedge: A tool used to check that a surface

is flat or parallel.

Through Sawing: A saw ing operatio n in whic h the

workpiece thickness is completely sawn through.

Proper blade height usually allows 1/8" of the top

of blade to extend above the wood stock. Keep t he

blade guard down, the anti-kickback pawls down,

and the riving knife in place over the blade.

7

Page 8

6.0 Specifications

Model number ............................................................................................................................................. PM 1000

Stock numbers:

Saw unit only, without Accu-Fence or rail system ..................................................................................... 1791000

Saw with 30” Accu-Fence and rail system ..............................................................................................1791000K

Saw with 50” Accu-Fence and rail system ..............................................................................................1791001K

Mot or an d electricals:

Motor type ............................................................................ totally enclosed fan cooled, induction, capacitor start

Horsepower ............................................................................................................................................ 1-3/4 HP

Phase......................................................................................................................................................... single

Voltage ................................................................................................................................................. 115/230V

Cycle ........................................................................................................................................................... 60H z

Listed FLA (full l oad am ps) ...................................................................................................................... 15/7 .5 A

Motor speed ........................................................................................................................................ 3450 RPM

Starting amps ............................................................................................................................................... 7 4 A

Running amps (no load) ............................................................................................................................... 2.7 A

Start capacitor ......................................................................................................................... 300MFD, 125VAC

Run capacitor ................................................................................................................................ 70μF, 250VAC

Overload reset ......................................................................................................... manual push button on motor

Power transfer ......................................................................................................................................poly v-belt

On/off switch .............................................................................................. magnetic, push button with safety key

Motor speed ........................................................................................................................................ 3450 RPM

Power cord ....................................................................................................................... 14 AWG, 6 ft. (183 cm)

Power plug installed ........................................................................................................................................ yes

Recommended circuit size

Sound emission ........................................................................... 80 dB at 30 " (762 mm) from blade, without load

1

Arbor and blade*:

Blade diameter .................................................................................................................................10" (254mm)

Arbor diameter .............................................................................................................................. 5/8" (15.88mm)

Arbor speed ..................................................................................................................................................4200

Arbor lock ....................................................................................................................................................... yes

Arbor wrench included ..................................................................................................... combination 17 / 27 mm

Maximum depth of cut at 90 degrees ............................................................................................. 3-1/8" (79 mm)

Maximum depth of cut at 45 degrees ............................................................................................. 2-1/8" (54 mm)

Maximum rip to right of blad e ................................................................................................ ................ 30" or 52"

Maximum rip to left of blade .............................................................................................................12" (305 mm)

Dado maximum width ................................................................................................................ 13/1 6 " (2 0.6 mm)

Dado maximum diameter .................................................................................................................. 8" (200 mm)

Blade height per one revolution of handwheel ................................. 19/6 4 " (7.5mm) for 90°; 1/ 1 6 " (1.7 mm) fo r 4 5 °

Blade tilt ...................................................................................................................................... left, 0 to 45 deg.

*blade not included

Materials:

Main table ................................................................................................................... ................ ground cast iron

Extension wings........................................................................................................................... ground cast iron

Trunnion ................................................................................................................................................. cast iron

Enclosed cabinet .......................................................................................................................................... stee l

Table:

Main table dimensions ............................................................................................ 20" L x 27" W (508 x 686 mm)

Table dimensions with wings ................................................................................. 40" L x 27" W (1016 x 686 mm)

Table area in front of blade at maximum height ................................................................................ .10" ( 305 mm)

Table height from floo r, ap proximate .......................................................................................... 34-1/4" (870 mm)

Miter T-slot .................................................................................................... two at 3/4" W x 3/8" D (19 x 10 mm)

Edge bevel ................................................................................................................................................... fron t

Dimensions:

Cabin et footprint ............................................................................................... 23" W x 24-1/2" L (584 x 622 mm)

Overall dimensions of shipping carton (cabinet only) ......... 30-1/2” L x 27-1/2” W x 43-3/4”H (77.5 x 70 x 111.4 cm)

Overall dimensions, fully assembled, accessories mounted:

with 30" rip .............................................................................. 43" W x 61" L x 44" H (1092 x 1549 x 1117 mm)

with 52" rip .............................................................................. 43" W x 83" L x 44" H (1092 x 2108 x 1117 mm)

subject to local/national electrical codes.

1

............................................................................................................................ 20A

8

Page 9

Dust collection:

Dust p o rt outside diame ter ................................................................................................... ............. 4 " (100 mm)

Minimum extraction volume required ......................................................................................... 350 cfm (18 cmm)

Weights:

Saw Only (Net/Shipping) ............................................................................................................... 289 lb (131 kg)

Saw assembled with 30" Rail/Fence .............................................................................................. 330 lb (150 kg)

Saw assembled with 52" Rail/Fence .............................................................................................. 335 lb (152 kg)

L=length; W=width; D=depth; H=height

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Powermatic reserves the right to change specifications at any time and without prior notice,

without incurring obligations.

9

Page 10

7.0 Setup and assembly

7.1 Shipping contents

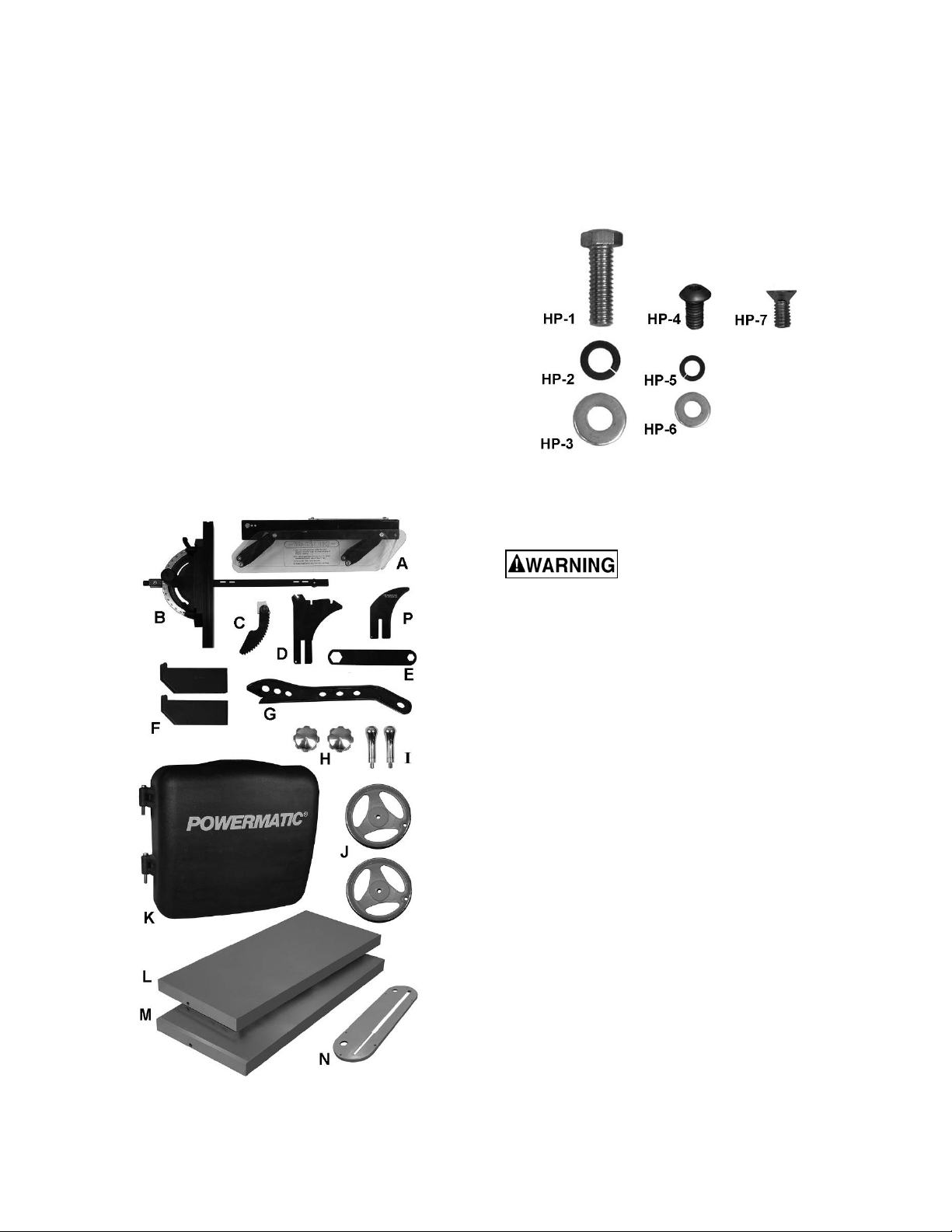

7.1.1 Carton contents (Figure 1)

1 Cabinet saw

1 Guard assembly (A)

1 Miter gauge (B)

1 Anti-kickback pawl assembly (C)

1 Riving knife (D)

1 Arbor wrench (E)

2 Storage hooks (F)

1 Push stick (G)

2 Knobs (H)

2 Handles (I)

2 Handwheels (J)

1 Motor Cover (K)

1 Extension wing – Left (L)

1 Extension wing – Right (M)

1 Insert plate – (N)

1 Low profile riving knife – (P)

1 Hardware package

1 Warranty card

1 Operating Instructions and Parts Manual

7.1.2 Hardware package (Figure 2)

6 Hex cap screws, M10x35 (HP-1)

6 Lock washers, M10 (HP-2)

6 Flat washers, M10 (HP-3)

4 Socket head button screws, M6x16 (HP-4)

4 Lock washers, M6 (HP-5)

4 Flat washers, M6 (HP-6)

3 Socket flat head screws, M6x10 (HP-7)

Figure 2

Note: Fence and rail assemblies, and wood

extension tables and legs, are shipped in separate

cartons.

Figure 1

Read and understand all

assembly instructions before attempting

assembly. The saw must be disconnected

(unplug!) from pow er during assembly. Failure

to comply may cause serious injury.

7.2 Tools required for assembly

Hex keys – 3 and 4mm

Open end wrenches – 14 and 17mm

Cross point screwdriver

Straight edge

Rubber mallet (or hammer with block of wood)

Note: A ratchet wrench/socket set may speed

assembly time. Additional tools may be needed for

assembly of fence and rails – consult Accu-Fence

manual.

7.3 Unpacking and cleanup

Remove all contents from shipping carton. Remove

items from inside cabinet. Do not discard carton or

packing material until saw is assembled and

running satisfactorily.

Compare contents of your container with above

parts lists to make sure all parts are intact. Missing

parts, if any, should be reported to your distributor.

(Check saw first in case parts were preinstalled.)

Read instruction manual thoroughly for assembly,

maintenance and safety instructions.

10

Page 11

1. Remove screws holding saw to pallet, by

unscrewing them from underneath pallet.

2. Carefully slide saw from pallet onto floor.

The cabinet saw should be placed in an area with a

sturdy level floor, good ventilation and sufficient

lighting. Leave enough space around the machine

for mounting extension wings and rail assemblies,

and loading and off-loading stock and general

maintenance work.

Exposed metal surfaces, such as table top and

extension wings, have been given a protective

coating at the factory. This should be removed with

a soft cloth moistened with kero sene or a cleanerdegreaser. Do not use acetone, gasoline, or

lacquer thinner for this purpose. Do not use

solvents on plastic parts, and avoid using an

abrasive pad as it can scratch surfaces.

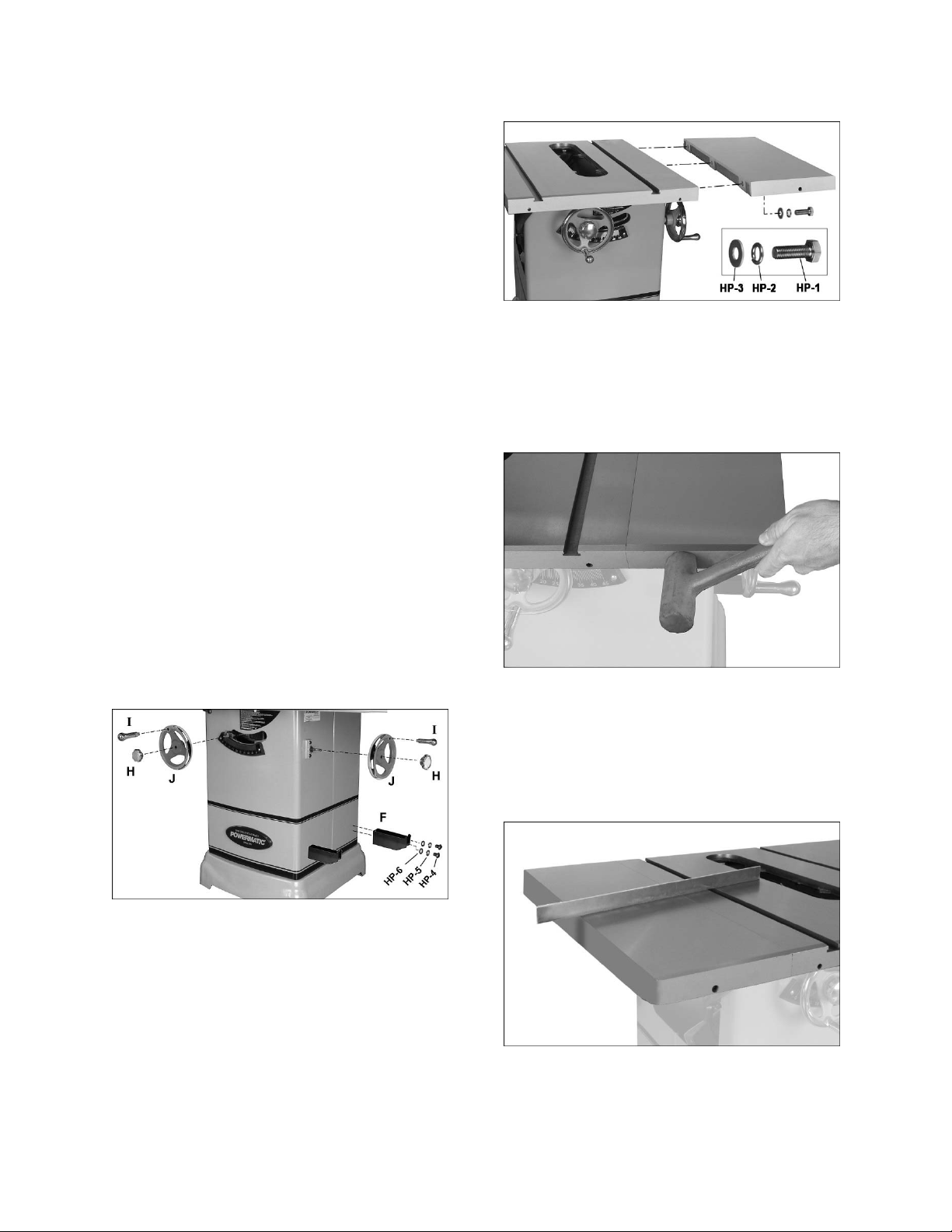

7.4 Installing handwheels and hooks

Refer to Figure 3.

1. Install handwheels (J, Figure 3) onto tilting and

raising shafts, as shown. Fit the slot of

handwheel hub onto roll pin on shaft, then

secure by screwing on a locking knob (H).

2. Install handle (I) onto each handwheel, using

14mm wrench on the flat to tighten it.

3. Install storage hooks (F) with two button head

screws and washers (HP-4/5/6). The hooks

are used to store the Accu-Fence when it is

not in use.

4. Tilt arbor using right handwheel, and remove

Styrofoam packing from around motor.

make snug. Then pivot wing parallel to saw

table to insert remaining two screws.)

Figure 4

2. Repeat for opposite extension wing. Lightly

snug screws.

3. The front edge of extension wings must be

flush with front edge of saw table. If needed,

tap front edge of wing with a rubber mallet to

make flush. See Figure 5.

Figure 5

Figure 3

7.5 Installing table extensions

Refer to Figure 4.

1. Attach an extension wing to saw table (Note:

Extension wings are identical). Use three

screws, lock washers and flat washers (HP1/2/3). Lightly snug screws with 17mm wrench.

(Assembly Tip: If you are doing this without an

assistant, lift extension wing vertically to table

edge. Install center screw and washer, and

7.6 Leveling table extensions

Refer to Figure 6.

Level extension wings to saw table using a straight

edge. A metal straight edge is ideal, though a

carefully jointed board may also be used.

Figure 6

11

Page 12

1. Shift e xtension wing so it is slightly above saw

table surface.

2. Begin by tightening the three screws (17mm

wrench) under the extension wing t hat secure

it to saw table. Tighten these just enough to

hold wing in place but loose enough to change

wing height by tapping on it.

3. Lay straight edge (Figure 6) across saw table

and extension wing, extendi ng it out past edge

of wing as shown.

4. Move straight edge to several places along

wing, as you continue to nudge wing level with

saw table. As each area of wing becomes

flush with table, tighten the screw under that

area. Continue until all three screws are fully

tightened. NOTE: Make sure front edge of

wing remains flush with front edge of saw

table.

5. Repeat above steps for opposite extension

wing.

7.7 Rails and Fence

With extension wings properly aligned, the rails

and Accu-Fence® assembly can now be mounted

to saw. Consult manual no. M-2195075Z, that

accompanies the fence.

NOTE: The switch bracket must be mounted to

front rail before installing guide tube. Follow

instructions in section 7.8, then install guide tube.

7.9 Wood Extension Table

For instructions on mounting the accessory wood

extension table, consult Accu-Fence manual,

document no. M-2195075Z.

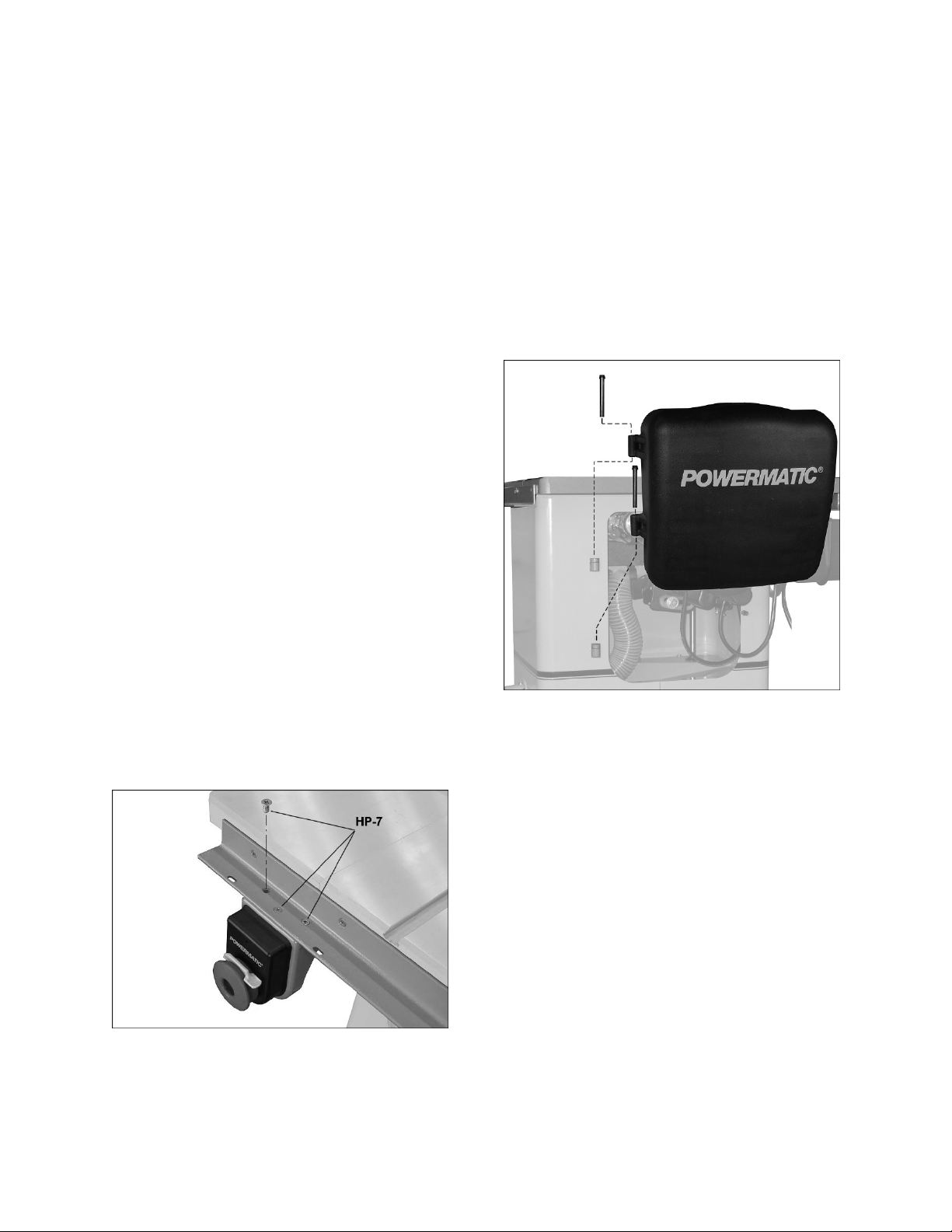

7.10 Motor cover

Refer to Figure 8.

At the motor side, slide hinge pins through motor

cover cylinders and into hinge barrels on saw.

Close m oto r co ver u ntil it cat che s on lat ch p ost o n

saw.

Note: The catch mechanism may require slight

adjustment to ensure proper alignment.

7.8 Switch bracket

Refer to Figure 7.

After front rail has been installed, mount switch

bracket with three flat head screws (HP-7).

Mount guide tube to front rail, referring to

instructions in your Accu-Fence manual.

Figure 7

Figure 8

7.11 Table insert

Refer to Figure 9.

Push insert down into table opening. Verify that

insert lies flush with table surface by resting a

stra ig ht ed ge ac ro ss it at va rio u s p oi nt s. If i nser t is

not f lu s h alo ng its length, turn an y o f six se t sc r e w s

to raise or lower that area of the insert.

12

Page 13

Figure 9

NOTE: If while lowering blade, the points on the

anti-kickback pawls tend to catch in the seam

between table and table insert, slightly raise that

area of table insert above main table surface.

Figure 11 (blade not provided)

7.12 Installing and removing blade

A blade is not provided with the PM1000.

Use care when working with or

around sharp saw blades to prevent injury.

Refer to Figures 10 and 11.

1. Disconnect machine from power source.

2. Remove table insert.

4. Raise blade arbor all the way up, and set

blade tilt to 0°. Tighten handwheel locking

knob.

5. Press arbor lock pin (C) and rotate arbor to

engage pin into slot in the arbor.

Simultaneously remove arbor nut (A); loosen

with arbor wrench if necessary.

6. Remove flange (B).

7. Install blade onto arbor, making sure the teeth

point downward toward front of saw.

8. Install flange (B) and nut (A).

9. Engage arbor lock (C) and tig hten nut (A) w ith

provided arbor wrench.

7.13 Riving knife

Refer to Figure 12.

To install riving knife:

1. Remove table insert.

2. Raise blade arbor all t he way up and set t ilt to

0° position.

3. Pull quick-re lease lever (G, F igure 12) to ope n

position. The clamp plate (F) is spring loaded

and will move away from the bracket (E),

leaving a gap.

Figure 10

Figure 12

4. Slide prongs of riving knife (D) into slot

between bracket (E, Figure 12) and clamp

plate (F), and push riving knife down as far as

it will go.

5. Push lever (G) to closed position.

13

Page 14

6. Riving knife must be parallel to saw blade. See

section 9.6 for inspection and adjustments.

NOTE: A low-profile riving knife is also provided,

for making non-through cuts on the table saw.

7.14 Anti-kickback pawls

Refer to Figure 12.

1. Install insert plate into table.

2. Position anti-kickback pawl assembly (H) as

shown in Figure 12; the angled side of pawl

block faces toward front of saw.

3. Lower pawl assembly onto center notch of

riving knife, with pawls straddling knife. Push

and hold button on pawl block (on opposite

side of that shown in Figure 12), and push

pawl block down until it securely engages in

notch.

4. Allow pawls to drop freely to the table.

7.15 Blade guard

Refer to Figure 12.

1. Push and hold button (J1) at back end of

guard.

2. Push guard (J) down at an angle, as shown,

until pin engages rear slot in riving knife, then

push down front of guard until it seats properly,

and is parallel to table top.

3. Release button (J1). The transparent guard

leaves (K) should drop freely to the table.

4. Lift up on guard assembly to verify proper

seating.

NOTE: The transparent leaves can be kept in

raised position by lifting them up and forward.

8.0 Electrical connections

The PM1000 table saw is rated at 115/230V power,

and is pre-wired for 115 volt. The table saw comes

with a plug designed for use on a circuit with a

grounded outlet that looks like the one pictured i n

A, Figure 13.

Before connecting to power source, be sure switch

is in off position.

It is recommended that the table saw be connected

to a dedicated 20 amp c ircuit with breaker or timedelay fuse marked “D”. Local codes take

precedence over recommendations.

8.1 Grounding instructions

1. All Grounded, Cord-connected Tools:

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce t he risk of electr ic shock.

This tool is equipped with an electric cord having

an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a

qualified electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

cond uctor with insulation having an o uter surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipmentgrounding conductor to a live terminal.

Guard and pawl assemblies

must be securely installed, and leaves must be

in contact with table, before beginning any

through-cutting operation.

The bracket and clamp plate (E/F, Figure 12) are

adjusted at the factory and no furt her adjustment of

the blade guard and riving knife assembly should

be necessary. However, proper alignment is very

important. Before operating table saw, read

section 9.6 ,Riving knife alignment, to verify and

follow adjustment procedure if necessary.

7.16 Dust chute

Use of a dust collection system (not provided) is

strongly recommended during table saw operatio n.

It will help keep the shop clean, as we ll as prevent

potential health issues due to dust inhalation.

Attach dust collection hose to the 4-i nch dust port

at base of saw, and sec ure with a wire hose clamp

(not provided).

Check with a qualified

electrician or service personnel if the

grounding instructions are not completely

understood, or if in doubt as to whether the

tool is properly grounded. Failure to comply

may cause serious or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Repair or replace damaged or worn cord

immediately.

14

Page 15

2. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

less than 150 volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in A, Figure

13. An adapter, shown in B and C, may be used to

connect this plug to a 2-pole receptacle as shown

in B if a properly grounded outlet is not available.

The temporary adapter should be used only unt il a

properly grounded outlet can be installed by a

qualified electrician. This adapter is not permitted

in Canada. The green-colored rigid ear, lug, and

the like, extending from the adapter must be

connected to a permanent ground such as a

properly grounded outlet box.

3. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between 150 - 250 volts, inclusive:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in D, Figure

13. The tool has a grounding plug that looks like

the plug illustrated in D. Make sure the tool is

connected to an outlet having the same

configuration as the plug. No adapter is available

or should be used with this tool. If the tool must be

reconnected for use on a diff erent type of electr ic

circuit, the reconnection should be made by

qualified service personnel; and after reconnection,

the tool should comply with all local codes and

ordinances.

8.3 Overload reset button

If saw becomes overloaded and the motor shuts

off, open motor cover and push reset button (B,

Figure 14) to restart. If overloading happens

frequently, consult the Troubleshooting section in

this manual.

Figure 14

8.4 Extension cords

USE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When

using an extension cord, be sure to use one heavy

enough to carry the current your product will draw.

An undersized cord will caus e a drop in line voltage

resulting in loss of power and overheating. Table 1

shows correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Figure 13

8.2 Voltage conversion

To switch the incoming power leads for 230 volt

operation, follow wiring diagram on ins ide cover of

motor junction box (A, Figure 14). A similar

diagram is found in section 16.0 of this manual. (In

case of discrepancy, diagram in junc tion box takes

precedence.)

The plug on the end of the motor cord must be

replaced with a UL/CSA listed plug rated for 230V.

Ampere

Rating

More

Than

00 06 18 16 16 14

06 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Not

More

Than

Volts

120

240

AWG

Totallengthof

cordinfeet

25

50

100

50

100

200

Not

Recommended

150

300

Table 1

Extension Cord Recommendations

8.5 Magnetic switch and safety key

Refer to Figure 15.

The sta rt swit ch ha s a powe r ind icat or la mp w hic h

is on whenever there is power connected to the

saw, not just when the saw is running. Do not

assume that no light means there is no power to

the machine. If the bulb is bad, there will be no

indication. Always check before use.

15

Page 16

Do not rely t hat no li g ht m eans

no power to the machine. Always check for

power first. Failure to comply may cause

serious injury.

To start saw, pull red button. Push it back in to stop

saw.

The switch has a safety key (Figure 15). Slide key

out and store in a safe place, to prevent

unauthorized starting of saw. Reinstall key to

operate saw.

Figure 15

9.0 Adjustments

9.1 Tools required for adjustments

Hex keys – 3, 4, and 8mm

Wrenches – 11 and 12mm

Straight edge

Com b inat ion squa r e

Figure 16

9.4 Miter gauge

Refer to Figures 17 and 18.

9.4.1 Setting miter angle

The precision miter gauge has a rack and pinion

adjustment for setting the angle. To operate:

1. Slide miter gauge into one of the slots on table

top.

2. Loosen lock handle (A, Figure 17) by turning

counterclockwise.

3. Pull out spring-loaded knob (C) and rotate

knob until body (B) of miter gauge is at desired

angle as indi cated on scale.

4. Tighten lock handle (A).

Disconnect saw from power

source before making adjustments.

9.2 Fence alignment

Before using the Accu-Fence®, verify that it is

properly aligned with the blade. Consult the

manual, no. M-2195075Z, that accompanied the

fence.

9.3 Blade raising/tilt mechanism

Refer to Figure 16:

To raise or lower blade, loosen lock knob (A) a nd

turn handwheel (B) on front of saw until desired

height is reached. Tighten lock knob. The blade

should be adjusted about 1/8" above top surface of

material being cut.

To tilt blade, turn lock knob (C) counter-clockwise

to loosen, turn handwheel (D) until desired a ngle is

obtained, as shown on tilt scale. Retighten lock

knob (C).

Figure 17

9.4.2 Indent settings

There are indents at 0º, 30º a nd 45º right and left

positions. At these settings, release knob (C) to

engage stop rod. Then tighten lock handle (A).

Note: Do not rely solely on the indents for an

accurate setting. After stop rod engages at the 0º,

30º and 45º positions, make a fine adjustment with

the knob (C) if necessary, setting it against the

scale indicator (G).

16

Page 17

9.4.3 Extension plate

The extension plate (D, Figure 17) can be adjusted

by sliding to the right or left or removed entirely.

To adjust, loosen two lock handles (E), slide the

extension plate and retighten lock handles. Make

sure end of extension plate is not in blade path.

NOTE: The lock handles (E) are adjustable. Pull

out on handle, rotate it to different position, then

relea se , m a k ing s ure it se a ts itse lf upo n the pi n.

To remove extension plate, slide it completely off

and remove lock handles (E) and mounting

hardware.

9.4.4 Calibration

1. Place miter gauge into one of the slots on the

table.

2. Set miter gauge at 90º to blade (0º setting on

the scale) by loosening lock handle (A), then

pulling out spring-loaded knob (C) and turning

body (B) until 0º is indicated on scale.

3. Measure accuracy of miter gauge agai nst slot

with a combination square.

If adjustment is needed:

4. Adjust body (B) until it is square (90º) to m iter

slot.

5. Tighten lock handle (A).

screws (4mm hex key) to eliminate any play

between bar and miter slot.

9.5 Blade tilt stop adjustment

The stops for 90°, 45° blade tilt, and elevation

settings have all been factory set, and should

require no immediate adjustment. The settings

should be confirmed by the operator, however, and

especially if cuts become inaccurate. Both tilt stops

are located inside cabinet in front of the motor.

9.5.1 Tilt stop 90°

1. Disconnect machine from power source.

2. Make sure table insert has been leveled with

table surface. See section 7.11.

3. Raise blade all the way, and place a 90°

square on the table and against blade (Figure

19). Make sure that a blade tooth does not

obstruct the actual reading.

6. Verify that scale indicator (G) reads 0º. If

further adjustment is needed:

7. Loosen screw (F) and adj ust indicator (G) until

it reads 0º.

8. Tighten screw (F).

9. If the above procedure does not satisfactorily

align the miter gauge, loosen two screws (J,

Figure 18) beneath mounting block and shift

block as needed. Retighten screws when

finished.

Figure 18

Figure 19

4. Tilt blade with handwheel until square and

blade are flush.

5. If adjustment is required, loosen nut (A1,

Figure 20) on 90° stop screw (A

wrench, and turn screw to proper heig ht. Verify

setting and retighten nut.

6. Check pointer position (Figure 21). If needed,

loosen screw and adjust pointer to zero.

Retighten screw.

) with a 12mm

2

NOTE: The bar of the miter gauge has two slots

with set screws (H, Figure 17). Adjust these set

Figure 20

17

Page 18

Figure 21

9.5.2 Tilt stop 45°

Repeat steps 1 through 4 above for 45° setting, as

shown in Figure 22. Loosen nut (B

wrench, and turn set screw (B

needed amount. Retighten nut (B1).

Figure 22

2

) with 11mm

1

) wit h a he x ke y t he

9.6 Riving knife alignment

The saw blade and riving knife must be in line. If

adjustment is needed:

3. Pull quick-release lever (A, Figure 24) and

remove riving knife, making note as to which

direction riving knife needs to be moved to

align it with saw blade.

4. Use a 3mm hex key to make adjustments to

four set screws (D, Figure 25) accessible

through openings located in the corners of the

clamp plate (B, Figure 25).

5. Adjust any number of setscrews required to

bring riving knife in al ignment with saw blade.

Then reinsert riving knife, secure by tightening

lever (A) and check the alignment per step 2.

6. Repeat steps 3–5 until alignment is correct.

Figure 23

9.6.1 Lateral alignment

The saw blade and riving knife must be in line as

close as possible with each other (lateral

alignment) for the prevention of kickback. Upon

initial blade guard and riving knife installation no

further adjustment should be necessary. Alignment

should be checked and adjusted, if required, after

each blade change.

Check the alignment as follows:

1. Remove blade guard, pawl assemblies, and

table insert.

2. Place a straightedge (A, Figure 23) on the

table so it rests against blade (B) and riving

knife (C). Rotate blade so that top of blade

tooth touches straightedge.

Figure 24

Figure 25

18

Page 19

9.6.2 Blade proximity alignment

The gap between saw blade and riving knife must

be between 3 and 8mm (Figure 26).

Figure 26

If adjustment is needed, note whether the blade to

knife gap needs to be increased or decreased.

Then adjust as follows:

Refer to Figure 25.

1. Remove blade guard, pawl, table insert and

riving kni fe.

2. Use a 5mm hex key to loosen two socket head

button screws (E, Figure 25).

Note: These screws are accessible through

openings on the clamp plate (B) located

diagonally on either side of the lever (A). T hey

secure the bracket (C) to the riving knife carrier

plate.

Loosening these screws (E) will allow the

bracket (C) to slide back and forth on the

carrier plate.

3. Slide the bracket (C) toward or away from the

saw blade as required.

4. Tighten the socket head button screws (E).

5. R einser t r iving k nif e; t ighte n lock lever (A) a nd

check that saw blade/knife gap is between

3-8mm (Figure 26).

Note: Attempt to make the gaps as even as

possible.

9.7 Table to blade alignment

Refer to Figures 27 and 28.

The table has been squared to the blade by the

manufacturer and no adjustment should be needed

now. If cuts become inaccurate, check table/blade

squareness and correct if necessary. Use the miter

slot to do this:

1. Disconnect saw from power source.

2. Raise blade to maximum height.

3. Mark one tooth (A, Figure 27) with a grease

pencil and position the tooth slightly above top

edge of table at the front.

4. Raise miter gauge slightly out of its slot to

serve as a shoulder. Using a sliding square (B )

against the side of the bar, slide the scale over

until it touches the tip of the blade, and lock

scale in pos ition.

Figure 27

Figure 28

5. Rotate marked tooth (A) so that it is slightly

above table top at the rear and, using the

square as before, verify that distance to blade

is the same. See Figure 28. If the distances

are not the same, make a careful note of the

difference.

6. Loosen table screws (item #66, section

15.1.1), and nudge table according to the

distance you noted.

7. Retighten screws firmly.

8. Verify alignment, angle pointer setting, fence

setting, etc. Make any needed adjustments.

9.8 Belt adjustment

9.8.1 Belt tension

Refer to Figure 29.

Tension of the drive belt should be inspected after

the first few days of operation, as it may stretch

slight l y d uri ng in it ial use; al so in spe ct it pe rio d ical l y

thereafter.

To tighten belt:

1. Disconnect machine from power source.

2. Loosen screw (C, Figure 29) with 8mm hex

key.

19

Page 20

3. Press down on motor while retightening screw

(C).

If belt shows signs of wear, fraying, cracks, etc. it

should be replaced, as follows.

9.8.2 Belt replacement

Refer to Figure 29.

1. Lower trunnion completely.

2. Loosen screw (C) with 17mm wrench.

3. Slightly loosen nut (D) with 1-1/4” (or

adjustable) wrench.

4. Pivot motor upward to release tension on belt.

5. Replace belt.

6. Push down on motor and tighten screw (C) to

tension new belt. Retighten nut (D).

Figure 29

9.9 Arbor/Arbor Bearing Removal

The saw arbor is press fitted in the saw raising arm

housing. If the arbor needs to be removed for

bearing replacement, it should be done by a

qualified service technician. Call your customer

service representative at the phone number o n the

front cover.

Listed below are conditions which can cause

kickbacks:

Confining the cutoff piece when

crosscutti ng or ripping.

Releasing workpiece before completing

operation or not pushing workpi ece all the

way past saw blade.

Not using split ter/riving knife when ripping

or not maintaining alignment of splitter/

riving knife wi t h saw blade.

Using dull saw blade.

Not maintaini ng alignment of rip fence so

that it tends to angle toward rather than

away from saw blade front to back .

Applying feed force when ripping to the

cutoff (free) section of workpiece instead of

the section between saw blade and fence.

Ripping wood that is twisted (not flat), or

does not have a straight edge, or has

twisted grain.

To minimize or prevent injury from kickbacks:

Avoid conditions li sted above.

Wear a safety face shield, goggles, or

saf ety glasses.

Do not use miter gauge and rip fence in

the same operation unless provision is

made by use of a facing board on the

fence, to allow the cutoff section of

workpiece to come free before the actual

cut begins (See Fi gur e 37) .

As the machine receives use, the

operation of the ant i- k ic k bac k pawls should

be checked periodi cally (Figure 30). If the

pawls do not stop the rev erse motion of a

workpiece, resharpen al l the points.

10.0 Operations

Familiarize yourself with the location and operation

of all controls and adjustments and the use of

accessories such as miter gauge and rip fence.

Note : The follow ing figure s may or m ay not show

your exact saw model, but procedures are

identical.

10.1 Kickback prevention

Serious injury can result from kickbacks which

occur when a workpiece binds on the saw blade or

binds between the blade and rip fence or other

fixed object. This binding can cause the workpiece

to lift up and be thrown toward the operator.

Figure 30

Where possibl e, keep your face and body

out of line with potential kickbacks,

including when starting or stopping the

machine.

Dull, badly set, improper, or improperly

filed cutting tools, and cutting tools with

gum or resin adher ing to them can cause

20

Page 21

accidents. Never use a cracked saw blade.

The use of a sharp, well maintained, and

correct cutting tool for the operation will

help avoid injuri es.

Support the work properly and hol d it firml y

against gauge or fence. Use a push stick

or push block when ripping short, narrow

(6" width or l ess), or t hi n work. Use a pu sh

block or miter gauge hold-down when

dadoing or mol ding.

Never use the f enc e as a length stop when

crosscutti ng. Do not hold or touch the free

end or cutoff section of a workpiece. On

through-sawing operations, the cutoff

section must NOT be confined.

Always keep your hands out of li ne of the

saw blade and never reach back of the

cutting blade with either hand to hold the

workpiece.

Bev el ripping cuts should al ways be made

with the fence on the right side of saw

blade so that the bl ade tilts away from t he

fence and minimi zes possibi lit y of the work

binding and the resulting kickback.

10.2 Rip sawing

Ripping is feeding the workpiece with the grai n into

the saw blade using the fence or other positioning

device as a guide to ensure desired width of cut

(Figure 31).

is properly aligned. When wood is cut along the

grain, the kerf tends to close and bind on the blade

and kickbacks can occur.

Note: A warning decal is affixed to the guard to

remind the operator of some basic safety

procedures.

The rip fence (A , Figure 32) should be set for the

width of the cut by using the scale on the front rail,

or by measuring the distance between blade (A)

and fence (B). Stand out of line with saw blade and

workpiece to avoid sawdust and splinters coming

off the blade or a potential kickback.

If the work piece does not have a straight edge,

nail an auxiliary straight edged board on it to

provide one against the fence. To cut proper ly, the

board must make good contact with the table. Do

not attempt to cut warped boards.

Figure 32

Before starting a ripping cut,

verify that fence is clamped securely and

aligned properly.

Nev er rip freehand or use miter gauge in

combination with the fence.

Nev er ri p workpieces shorter than the saw

blade diamet er.

Never reach behind the blade with either

hand to hold down or remove the cutoff

piece with the saw blade rotat ing.

Figure 31

In ripping, use one hand to hold the board down

against the fence or fixture, and the other to push it

into the blade between blade and fence. If

workpiece is narrower than 6" or shorter than 12",

use a push stick or push block to push it through

between fence and blade (Figure 33). Never push

in a location such that the pushing hand is in line

with the blade. Move the hand serv ing as a holddown a safe distance from blade as cut nears

completion.

For very narrow ripping where a push stick ca nnot

be used, use a push block or auxiliary fence.

Always push the workpiece completely past the

blade at the end of a cut to minimize the possibility

of a kickback.

Always use blade guard, splitter/riving knife and

anti-kickback pawls. Make sure splitter/riving knife

21

Page 22

Figure 33

use the same side of the board against the fence

for both cuts.

Figure 35

10.4 Crosscutting

Crosscutting is where the workpiece is fed cross

grain into the saw blade using the miter gauge to

support and position the workpiece (Figure 36).

Figure 34

When ripping long boards, use a support at front of

table (C, Figure 34), such as a roller stand, and a

support or "tailman" at the rear (D).

Never use the rip fence beyond the point where the

carriage is flush with the end of the rails.

Have the blade extend about 1/8" above the top of

the workpiece. Exposing the blade above this po int

can be hazardous.

10.3 Resawing

Resawing is a ripping operation in which thick

boards are cut into thinner ones. Note: A band saw

is the ideal tool for resawing.

If the table saw is used for

resawing, take precautions such as using an

auxiliary fence, resaw barrier or similar devices

to stabilize the workpiece and provide operator

safety.

Narrow boards up to 3" can be resawn in one pass.

Wider boards up to 6" must be resawn in two

passes.

In resawing wider boards, adjust the blade height

so as to overlap the two cuts by 1/2" as shown in

Figure 35. Too deep a first cut can result in binding

and possible kickbacks on the second cut. Always

Figure 36

Crosscutting should never be done freehand nor

should the fence be used as an end stop unless an

auxiliary block (E, Figure 37) is clamped to the

front of the blade area such that the cutoff piece

comes free of the block before cutting begins.

Figure 37

22

Page 23

Length stops should not be used on the free end of

the workpiece in the cutoff area.

Do not crosscut workpieces shorter than 6". Before

starting a cut, be sure the miter gauge is securely

clamped at the desired angle. Hold the workpiece

firmly against the table and back against the miter

gauge. Always use t he saw guard a nd riving knif e

and make sure the riving knife is properly aligned.

For 90 degree crosscutting, most operators prefer

to use the left-hand miter gauge slot. When using it

in this position, hold the workpiece against the

gauge with the left hand and use the right hand to

advance the workpiece. When using the right hand

slot for miter and compound crosscutting so that

the blade tilts away from the gauge, the hand

positions are reversed.

When using the miter gauge, the workpiece must

be held firmly and advanced smoothly at a slow

rate. If the workpiece is not held firmly, it can

vibrate causing it to bind on the blade and dull the

saw teeth.

Never use a zero-clearance

insert with saw blade in tilted position.

Figure 39

Mitering – Crosscuts made at an angle to the edge

of the workpiece are cal led miters (Figure 40). Set

the miter gauge at the required angle, and make

the cut the same as a normal crosscut except the

workpiece must be held extra firmly to prevent

creeping.

Figure 38

To augment the effectiveness of the miter gauge in

crosscutting, some users mount an auxiliary

wooden extension face (F, Figure 38) with a gl uedon strip of sandpaper (G) to the miter gauge.

Provide auxiliary support for any workpiece

extending beyond the table top with a tendency to

sag and lift up off the table.

Have the blade extend about 1/8" above the top of

the workpiece. Exposing the blade above this po int

can be hazardous.

10.5 Bevel and miter operations

Bevel cut – A bevel cut is a special type of

operation where the saw blade is tilted at a n angle

less than 90 degrees to the table top (Figure 39).

Operations are performed in the same manner as

ripping or crosscutting, except the fence or miter

gauge should be used on the right-hand side of the

blade to provide added safety in avoiding a binding

action between blade and table top. When beveling

with the miter gauge, the workpiece must be held

firmly to prevent creeping.

Figure 40

Note: When making compound miters (with blade

tilted) use the miter gauge in the right ha nd s lot to

provide more hand clearance and safety.

Have the blade extend only 1/8" above the top of

the workpiece. Exposing the blade above this po int

can be hazardous.

10.6 Dado cutting

Dadoing is cutting a wide groove into a workpiece

or cutting a rabbet alo ng the edge of a workpiece.

A dado insert (optional accessory, not provided)

shown in Figure 41, is necessary for this type of

operation.

Do not use the standard table

insert for dadoing operations.

23

Page 24

Figure 41

The process of cutting 1/8" to 13/16" grooves in

workpieces is accomplished by the use of a

stacked dado blade set or an adjustable type blade

mounted on the saw arbor. By using various

combinations of stacked dado blades, or properly

setting the dial on an adjustable blade, an accurate

width dado can be made. This is very useful for

shelving, making joints, tenoning, etc.

The guard, riving knife, and anti-kickback pawls

supplied with the saw should be used for all cutting

operations where they can be used. When

performing operations where the guard cannot be

used, as in some dadoing operations, alternative

safety precautions should be taken. These incl ude

push sticks, feather boards, filler pieces, fixtures,

jigs and any other appropr iate device that can be

utilized to keep operators’ hands away from the

blade. Upon completion of t he operation req uiring

removal of the guard, the entire guard assembly

must be placed back on the machine in its proper

working order.

Never use a dado head in a

tilted position. Never operate the saw without

the blade guard, riving knife and anti-kickback

pawls for operations where they can be used.

Figure 42

Filler piece

A filler p iece (Figure 43) is necessary for narrow

ripping and permits the blade guard to remain on

the machine. It also provides space for the safe

use of a push stick.

11.0 Safety devices

Feather board

Feather boards can be purchased at most tool

stores, or made by the operator to suit particular

applications. The feather board (Figure 42) should

be made of straight grain hardwood appro ximately

1" thick and 4" to 8" wide depending on the size of

the machine. The length is developed in

accordance with intended use.

Feather boards can be faste ned to the table or rip

fence by use of C-clamps. Alternatively, drilled and

tapped holes in the table top a llow the use of w ing

nuts and washers as a method of clamping. If this

method of fastening is used, provide slots in the

feather board for adjustment. (The illustration

shows a method of attaching and use of the

feather board as a vertical comb. The horizontal

application is essentially the sam e except that the

attachment is to the table top.)

Figure 43 – Filler Piece

24

Page 25

Push stick and push block

The use of a push block or push stick provide s an

added level of safety for the operator. A p ush stick

is included with your table saw, but you may wish

to make others personalized for different cutting

procedures. The templates in Figures 44 and 45

offer construction details.