Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

3-Roll Powered Stock Feeder

Model PF3-JR

Powermatic

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-1790818

Ph.: 800-274-6848 Revision B3 03/2014

www.powermatic.com Copyright © 2014 Powerm atic

Page 2

Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informa tion

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tat e Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors, Machine Accessories

2 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Warning ................................................................................................................................................... 4

Introduction ............................................................................................................................................. 6

Desc ription ................................................................................................................... ........................... 6

Specifica tions ................................................................................................................ .......................... 6

Features .................................................................................................................................................. 7

Unpac king ............................................................................................................................................... 8

Contents of the Shipping Container ...................................................................................................... 8

Assembly and Installation ........................................................................................................................ 9

Grounding Inst r uc tions ....................................................................................................................... 11

Extension Cords................................................................................................................................. 1 2

Adjustments ................................................................................................................... ....................... 1 2

Basic Feeder/ Stand M ov em ents ......................................................................................................... 12

Edgewise Stock Feeder P osi tion ........................................................................................................ 12

Speed Selecti on ................................................................................................................................. 1 3

Operating Controls ................................................................................................................................ 14

Operation .............................................................................................................................................. 1 4

General Operating Instructions ........................................................................................................... 14

When Used with a Shaper .................................................................................................................. 15

When Used with a Table Saw............................................................................................................. 1 6

When Used with a Jointer .................................................................................................................. 16

Roller Removal/Replacement ............................................................................................................. 16

Maintenance .......................................................................................................................................... 16

Lubrication ......................................................................................................................................... 17

Troubleshooting ..................................................................................................................................... 19

Replacement Parts ................................................................................................................................ 19

Parts List: PF3-JR Stand Assem bly ................................................................................................... 20

Exploded View: PF 3-JR Stand Assembly .......................................................................................... 21

Parts List: PF3-JR Stock Feeder ....................................................................................................... 22

Exploded View: PF 3-JR Stock Feeder ............................................................................................... 23

Electri c al Connec tions for PF3-JR Stock Feeder .................................................................................... 24

Boring Template .................................................................................................................................... 25

3

Page 4

Warning

1. Read and understand the ent ire owners manual bef or e attempti ng assem bly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or remov ed.

4. This stock feeder is designed and intended for use by properl y trained and experienced personnel

only. If you are not familiar with the proper and saf e operation of a stock feeder, do not use until

proper trai ning and k nowledge have been obtai ned.

5. Do not use this stock feeder for other than it s intended use. If used for ot her pur poses, JET discl aims

any real or implied warrant y and holds itself harmless f rom any injury that may result fr om that use.

6. Always wear approved safety glasses/face shields while using this stock feeder. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses.

7. Bef ore operating thi s stock feeder, remove tie, rings, watches and other jewelry, and roll sl eeves up

past the elbows. Rem ove all loose cl othing and confi ne long hair. Non-sl ip foot wear or anti-ski d floor

strips are recommended. Do not wear glov es.

8. Wear ear protector s (plugs or muffs) during extended periods of operati on.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any m edic ation.

11. Make certain t he switc h is i n the OFF position before connect ing the machine to the power supply .

12. Make certain t he machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turni ng it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replac e the guards immediately after m aintenance is complete.

16. Make sure the stock feeder is firmly secured to the auxil iary machine before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Provide f or adequate space surrounding work area and non- glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

20. Keep visit or s a safe di stanc e from the work area. Keep children away.

4

Page 5

21. Make your workshop chil d pr oof with padlocks, master switc hes or by removing starter k ey s.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. M aintain a balanc ed stance at all t imes so that you d o not fall or lean against mov ing parts. Do not

overreach or use exc essive force to perform any mac hine operation.

24. Use the ri ght t ool at the cor rect speed and f eed rate. Do not for ce a t ool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and m or e safely.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain tools wit h c ar e. F ollow instructions for lubr icating and changing accessories.

27. Turn off the stock feeder before cleaning. Use a brush or com pr essed air to remove chips or debris —

do not use your hands.

28. Do not stand on the machine. S eri ous i njur y c oul d oc c ur if the mac hine tips over.

29. Never leave t he m ac hine r unning unattended. Turn the power off and do not l eav e the mac hine until it

comes to a com plete stop.

30. Remove loose it em s and unnecessary work pieces from the ar ea before starting the machine.

31. Check y our stock for l oose knots, nai l s or other aspect s that m ay cr eate a saf ety hazard or affect the

machine’s performance.

Familiariz e you rself with the following safet y no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by Powermati c covering the safe operat ion and maintenance pr ocedures for a

Model PF3-JR Stock Feeder. This manual contains instructions on installation, safety precautions,

general operating procedures, maintenance instructions and parts breakdown. This machine has been

designed and const ructed to pr ovide years of trouble free oper ation if used in accor dance to i nstructions

set fort h in t his manual . If there are any que sti ons or c om m ents, please co ntac t ei ther your l ocal suppli er

or Powermatic. Powermatic can also be reached at our web site: www.powermatic.com .

Description

The PF3-JR Stoc k Feeder can be mounted to a t able saw, shaper, jointer , etc., and will act as a “thi rd

hand” for t he operat or to smoot hly feed workpi eces thr ough the aux ili ary m achine. The Stock Feeder has

a continuous-duty motor and lubri cated gearbox that transmi t power through rol l er chain and sprock ets to

the feed roll er s, prov i ding superior po si tiv e f eeding f or al l types of m aterial s. T he stand is f ull y adj ustabl e

with univ ersal joints, and heav y locking mechanisms secure the feeder in horizontal, vertical or angled

positions. T he roller system is “mai ntenance-fri endly” allowing y ou to repl ace a single roll er if necessary,

instead of a complete set.

Specifications

Model Number .............................................................................................................................. PF3-JR

Stock Num ber...............................................................................................................................1790818

Approx. Length, with arm fully extended and handl e installed (in.) .................................................... 27- 1/2

Width (in.) ........................................................................................................................................... 11.8

Approx. Hei ght, with handle installed (i n.) ........................................................................................ 23-1/4

Column Diameter (i n.) ........................................................................................................................... 1.6

Rollers ......................................................................................................................... 3 (synthetic rubber)

Roller Size (Diam eter x Length) (in.) ..................................................................................... 3-1/8 x 1-3/16

Motor ............................................................................................... TEFC, 0.25HP, 1Ph only, 115V, 60Hz

Rotation .......................................................................................................................... Forward/Reverse

Number of Speeds ................................................................................................................................... 4

Speed Range (FPM) ................................................................................................................ 13/26/33/62

Distance between Rollers (center to center ) (i n.) ...................................................................... 4.32 to 3.34

Swing (deg.) ........................................................................................................................................ 360

Vertical Movement (in.) ....................................................................................................................... 6.52

Horizontal Movement (in.) ..................................................................................................................... 9.8

Maximum Height of Rollers Parallel to Tabletop (in.) ................................................................................ 6

Approximate Net Weight (lbs.) ............................................................................................................... 71

Approximate Shipping Weight (lbs.) ....................................................................................................... 75

The above specifications were current at the time this manual was published, but because of our policy of

continuous im provement, Powerm atic reserves the right t o change specific ations at any time and without

prior notic e, wit hout incurring obligations.

6

Page 7

Features

7

Page 8

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the Stock

Feeder is assembled and r unning properly.

Compare the c ontent s of y our cont ainer wit h t he

following parts list to make sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Conta iner

1 Stock Feeder

1 Stand Assembly

2 Handles

1 26-Tooth Gear

1 24-Tooth Gear

1 Boring Template

1 Owner's Manual

1 Warranty Card

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mply may cause serious injury.

8

Page 9

Assembly and Installation

Tools needed for assembly:

5mm hex wrench

12mm and 14mm open end wrenches

Remove the clear plastic from around the feeder

and stand.

Exposed metal surfaces have been given a

protectiv e coating at the fact ory. This should be

removed wit h a soft cloth moistened with a good

commercial solvent, such as kerosene or

mineral spirits. Do not use acet one, gasoli ne, or

lacquer thinner for this purpose. Do not get

solvents near pl asti c or rubb er par ts, and d o not

use an abrasive pad because it may scratch

metal surfaces.

The Stock Feeder should be mounted to an

auxiliary machine in a well-lit area. Leave

enough space around the work area for l oading

and off-loadi ng stoc k and gener al maintenance.

The stock feeder and the

auxiliary machine to which you are mounting

it should both be disconnected from power

during insta llation.

1. Determine the mounting location for the

stand. Keep in mind t he overall l engt h of the

horizontal arm on the stand ( 27-1/2” ) so that

there will be enough adjustment when the

Stock Feeder is mounted.

IMPORTANT: Locate the stand so that you

will not drill through any ribs or supports

beneath the tabl e surface.

2. Use the provided boring template to find t he

centerline spacing for the holes in the

feeder’s base. Cl ean the mounting surface,

then remove the backing from the boring

template and stick the template carefully

into place on the mounti ng surface.

NOTE: The sam e template can be found on

page 25.

3. Center punch and drill four 8.5 millimeter

diameter holes in the surface, then tap the

holes with M10 x P 1.5 threads. Alter natively,

if you plan to secur e the stand wit h hex nuts

from below the mounting surface, drill

clearance holes of 7/16” diameter without

tapping.

4. Peel off the bori ng template and discard.

5. Loosen the lock handle and remove the

base from the stand assembly, shown in

Figure 1.

Figure 1

9

Page 10

6. Place the base ov er the hole patt ern. Align

the four hol es of the base with the hol es in

the mounting surface. Make sure the lock

handle is positioned in a convenient place

before tightening the base to the m ounting

surface.

7. Insert four M10 screws (not provided)

through the holes of the base and into the

holes on the mounting surface. See Figure

2. Tighten screws securely .

8. The stand assembly can be oriented with

either of the col umns in horiz ontal or verti cal

position. It is recommended, however, that

the longer lead screw be placed in the

horizontal position, as shown in Figure 3;

this will allow maximum adjustment for the

stock feeder across the surface of the

workpiece. Slide the vertical column down

into the base and tighten the lock handle

(Figure 3).

9. Attach a handle (Figure 4) to each elevati ng

handle, by screwing the threads of the

handle into the hole on the elevating handle.

10. The handle (F igure 4) should be a djusted so

that it can move freely. Loosen the hex nut

with a 14mm (9/16”) wrench, and turn the

socket head cap screw with a 5mm hex

wrench until the handl e is just loose enough

to turn freely. Then tighten the hex nut

against the el ev ating handle.

Figure 2

Figure 3

11. Rest the Stock Feeder on the mounting

surface, as shown in Figure 5. Lower the

horizontal arm by rotating the top hand

wheel until t he arm is at a conv eni ent height

for mounti ng the Stock F eeder. (See “Basic

Feeder/Stand Movements” for detailed

explanati on of stand m ov em ents.)

12. Make sure t he hex cap screw (A, F igure 5)

is loosened on the sleeve of the Stock

Feeder. Use a 14mm wrench.

13. Slide the arm cone of the Stock F eeder onto

the horizontal arm as far as it will go, then

tighten the hex c ap screw (A, Figure 5).

Figure 4

Figure 5

10

Page 11

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

This Stock Feeder must be grounded. In the

event of a m alfuncti on or breakdown, grounding

provides a path of least resistance for electric

current to reduce t he risk of electric shock. This

tool is equipped wit h an electric cord having an

equipment-grounding conductor and a

grounding plug similar to the one shown in

Figure 6. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordanc e wit h al l loc al codes and

ordinances.

Do not modify the pl ug provided. If it will not fit

the outlet, hav e the proper outlet install ed by a

qualified elec trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conduct or. If repai r or replac ement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool i s properly grounded. Us e only

three wire extensi on c or ds that have three-prong

grounding plugs and three- pole recept acles that

accept the tool ’s pl ug.

Repair or replace a damaged or worn cord

immediately.

115 Volt Operation

Figure 6

As received fr om the factory, your Stock Feeder

is ready to run at 115 volt operation. It is

intended for use on a circuit that has an outlet

and a plug that looks similar to the one

illustrated in Figure 6.

A temporary adapter, which looks like the

adapter as illustr ated in Figure 7, may be used

to connect t his plug to a two-pole recept acle, as

shown in Figure 7, if a properly grounded outl et

is not available. The temporary adapter should

only be used until a properly grounded outlet

can be installed by a qualified electrician. This

adapter is not applicable in Canada.

Figure 7

11

Page 12

The green colored rigid ear, lug, or tab,

extending fr om the adapter, must be connected

to a permanent ground such as a properly

grounded outlet box, as shown in Figure 7.

Make sure the voltage of your power supply

matches the specif ications on the m otor plate of

the machine.

Extens ion Cords

If an ext ension c ord i s necessary m ak e sure t he

cord rating i s suitable for the am perage listed on

the machine's motor plate. An undersize cord

will cause a drop in line voltage resulting in loss

of power and overheating.

Recommended Gauges (AWG ) of Extension Cords

Extension Cord Length *

25

50

75

100

150

200

feet

feet

feet

feet

feet

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

feet

The chart in Figure 8 shows the correct size

cord to use based on cord length and motor

plate amp rating. If in doubt, use the next

heavier gauge. The smaller the gauge number

the heavier the cor d.

Adjustments

Basic Feeder/Stand Movements

To move the v ertical colum n up or down, l oosen

the lock handle (A, Figure 9) and rotate the

handle (B, Figure 9). When adjustment is

complete, re- tighten lock handle (A, Fi gur e 9).

To move the horizontal arm forward or back,

loosen the lock handle (C, Figure 9) and rotate

the handle (D, Figure 9). When adjustment is

complete, re- tighten lock handle (C, Figur e 9).

The vertical column and horizontal arm have

stop screws (E, Figure 9) which prevent them

from being moved t oo far.

To rotate the enti re stand assembly, loosen the

lock handle (F, Figur e 9) and pus h the assembly

into desired posi tion. Tighten l ock handle befor e

operating the st oc k feeder.

To rotate the stock feeder alone, loosen lock

handle (G, Fi gure 9) . Tighten l ock handl e before

operating the st oc k feeder.

*based on li miting th e lin e voltag e drop to 5V at 150% of th e

rated amp eres.

NR: Not Recomm ended.

Figure 8

Figure 9

Edgewise Stock Feeder Position

The stock feeder can be turned “edgewise” so

that the f eed is al ong the side of the workpiece.

See Figure 10.

To create thi s positi on:

1. Loosen the screw on the arm cone (A,

Figure 10) with a 14mm wrench, and slide

the Stock Feeder off the horizontal arm.

2. Place the Stock Feeder edgewise with the

rollers toward the bottom, as shown in

Figure 10.

Figure 10

12

Page 13

3. Loosen lock handle (B, Figure 10) and

rotate the swivel cone (C, Figure 10) 180degrees, as shown in Fi gur e 10.

4. Re-tighten l oc k handl e ( B, Figure 10).

5. Loosen lock handle (D, Figure 10) and

rotate the arm cone as needed until it can

slide back onto the horizontal arm. Tighten

locking handl e ( D, Fi gur e 10).

6. Mount the Stock Feeder to the horizontal

arm and tighten t he screw (A, Figure 10).

Speed Selection

The PF3-JR has f our speeds: 13, 26, 33 and 62

feet per mi nute (or 4, 8, 10 and 19 meter s per

minute, respectively). Achieving these four

speeds is dependent upon the choice and

proper positi on of t he gear s.

Unplug the stock f eeder fro m

power source before ch ang ing gears.

To change the positi on of t he gear s:

Figure 11

1. Unscrew the knob (Figure 11) and pull off

the back cov er to expose the gear system,

shown in Figure 12.

2. Remove hex nuts and flat washers (A,

Figure 12) with a 14mm wrench.

3. Figure 13 shows the relationship of gear

position t o c r eate each of the four speeds. A

similiar chart is affixed to the inside of the

back cover on the Stoc k Feeder .

4. Install new gear configuration, making sure

the notch in each gear slides into the

keyway of the shaft. Push the gear as far as

it will go onto the shaft .

5. Install hex nut and flat washer (A, Figure 12)

on each shaft, and tighten.

6. Re-install back cover and tighten knob

(Figure 11).

Figure 12

Figure 13

13

Page 14

Operating Controls

The control switch (Figure 14) turns the motor

on, and also determines its direction – forward

or reverse.

If a jam should occur while

feeding a w orkpiece, DO NOT turn the sto ck

feeder to reverse w hi le th e auxi liary mach in e

is still running in forward direction.

If a workpiece becomes jammed, turn off both

the auxiliary machine and the stock feeder.

Raise the feeder in order t o clear t he workpi ece.

Then reset the feeder height and begin t he feed

over again.

Figure 14

Operation

IMPORTANT: Before attempting operation of

this stock f eeder in c onjunction wit h an auxi liary

machine, you shoul d be thoroughly f amiliar with

the operating and safety instructions that were

included with the auxiliary machine.

Keep hands away from

rollers during operation. Failure to comply

may cause injury.

General Operating Instructions

1. Make sure all l ock handles are tight bef ore

operating the St oc k Feeder.

2. The Stock Feeder should be used in

conjunction with a fence on your auxiliary

machine.

3. The rollers must gri p the offcut, as well as

the part of the workpi ec e still being fed.

4. On some machines, such as a shaper, the

stock feeder can be mounted so that the

rollers exert pressure from the top; or

mounted edgewise so that the rollers exert

pressure from the side, or mounted at an

intermediate angle for beveled workpiec es.

5. The feed rollers have a spring suspension

with approximately 12mm lift, which will

exert the necessary pressure against the

workpiece. This pressure increases

automatic ally with feed r esistance, so that a

workpiece of varying thickness can be fed

through the stock feeder without

adjustments.

14

Page 15

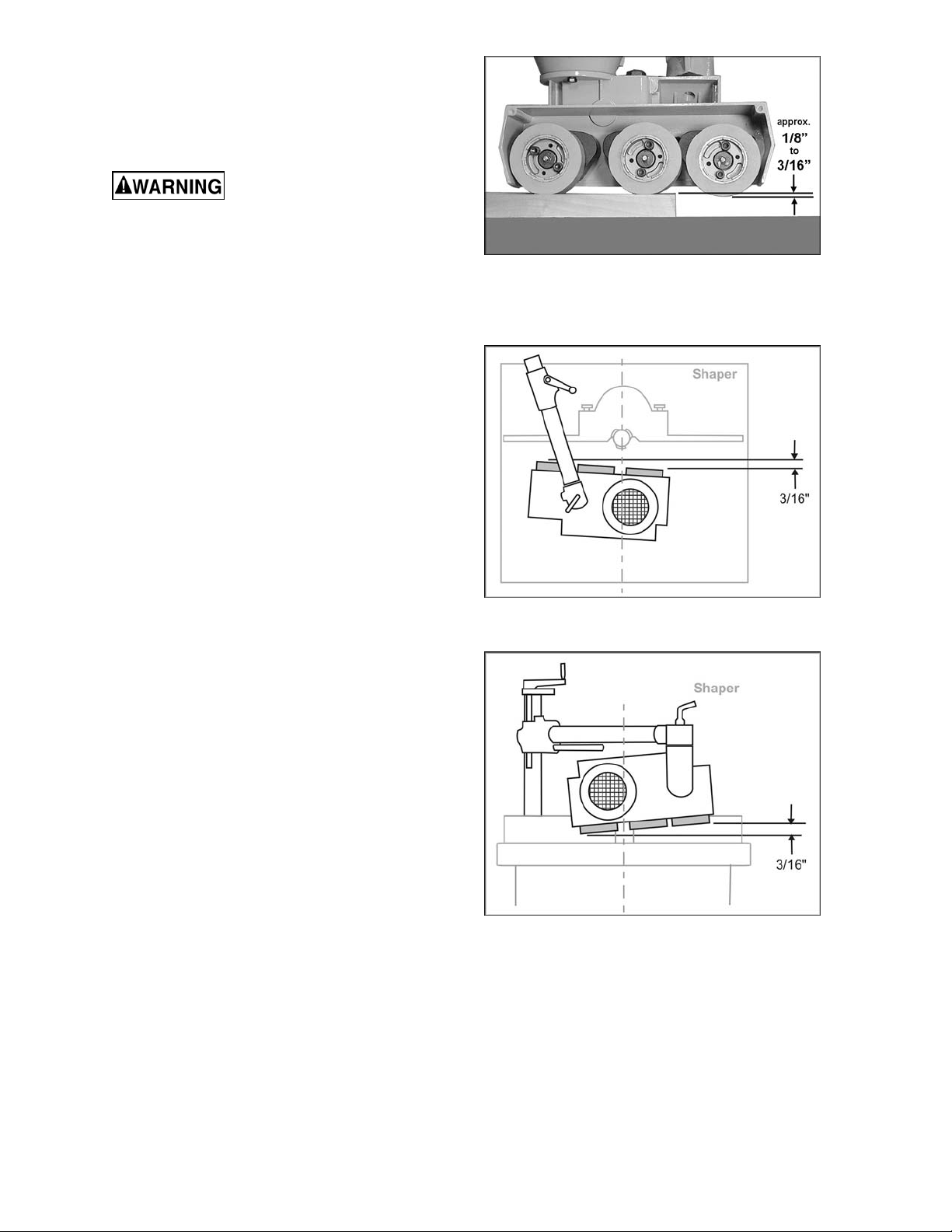

6. When used in normal horizontal position,

the stock feeder should be adjusted for

height so that the distance between the

table and the feed rollers is approximately

1/8” to 3/16” (3 to 5mm) less than the

thickness of the workpi ec e. See Figure 15.

Although the stock feeder

when properly used will greatly reduce the

chance of wo rkpiece kickb ack, t here i s still a

potential for kickback. Never stand directly

in the path of the workpiece as it passes

under the Stock Feed er rollers.

When Used with a Shaper

1. The gap between the fences for the cutter

should be as small as possible.

2. To ensure that the workpiece is held firmly

against the f ence, set the stock f eeder at a

slight angl e toward the f ence i n the dir ecti on

of feed. In other words, the outfeed roller

should be approxim at ely 3/16” (5mm) cl oser

to the fence than the infeed roller. See

Figure 16.

Figure 15

3. When the Stock Feeder is in edgewise

position, it must be inclined slightly t owards

the work table in the direction of feed, to

ensure the workpi ece remains forced down

against the table. In other words, the

outfeed roll er should be a pprox im ately 3/16”

closer to the work table than the infeed

roller. S ee Figure 17.

4. When the Stock Feeder is in the edgewise

position, or angled for a beveled workpiece,

the axis of the cutter should be between the

outfeed roller and the center roller. See

Figure 17. The center roller should NOT be

directed toward the opening between the

fences, but should act directly against the

fence.

5. When mounting the Stock Feeder in

edgewise posi tion, keep in mi nd the spring

tension of t he roller s. The distance bet ween

the shaper fence and t he f eed roller s should

be approximately 1/8” to 3/16” (3 to 5mm)

less than the thickness of the workpiece

(refer to Figure 15) .

6. Shaping hardwood with the Stock Feeder

may increase the fricti on between workpiece

and table. Keep t he work tabl e rust-free and

smooth, by using paste wax or other

necessary means.

Figure 16

(Stock Feeder in horizontal position)

Figure 17

(Stock Feeder in edgewise position)

15

Page 16

When Used with a Table Saw

1. Position the Stock Feeder so that the axis of

the saw blade lines up between the center

roller and infeed roller. See Fi gure 18. This

will allow the Stock Feeder to grip t he offcut

of the workpiece as it leaves the blade.

2. Rotate the Stock Feeder so that the

direction of feed is angled sli ghtly toward the

fence by approx im ately 3/16” (5mm) ; that i s,

the outfeed roll er shoul d be sli ghtly cl oser to

the fence t han the infeed roll er. See Figure

18.

When Used with a Jointer

1. Mount the stock f eeder on a jointer so that

all rollers are over the outfeed table, as

shown in Figure 19.

2. The infeed roller should be approximately

3/16” away from the lip of t he outfeed table

at the cutter ar ea. See Figure 19.

3. Rotate the Stock Feeder so that the

direction of feed is angled sli ghtly toward the

fence by approx im ately 3/16” (5mm) ; that i s,

the outfeed roll er shoul d be sli ghtly cl oser to

the fence t han the infeed roll er. See Figure

19.

Figure 18

Figure 19

Roller Removal/Replacement

If more space is needed between rollers, for

example when f eeding a curved workpi ece, the

center roller can be removed from the Stock

Feeder. To remove the roller, loosen and

remove the t wo socket head ca p scre ws (Fi gure

20) with a 5mm hex wrench and pull the roller

off the shaft.

Maintenance

Before performing any

maintenance on the Stock Feeder,

disconnect its plug from the electrical

supply. Also disconnect the auxiliary

machine from the el ect rical supply. Failure t o

comply may cause seriou s injury.

If the power cord is worn, cut, or damaged in

any way, have it repl ac ed immediately.

The rubber rollers should be kept clean of

grease, sawdust and other debris. Use a soft

cloth with soap and water to wipe down the

rollers. DO NOT use a solvent on the rubber

rollers.

Figure 20

16

Page 17

The mating parts of the arm cone and swivel

cone should be kept clean. See Figure 21.

When disassembli ng any of the cones from t he

stock feeder, wipe off both mating parts with a

clean rag before re-assembling. NOTE: These

cones are subject t o high tor ques and it m ay be

necessary to periodically re-tighten the lock

handles until the cone surfaces become

securely seated.

Lubrication

Gearbox

The Stock Feeder i s shipped with oi l install ed in

the gearbox. Occasionally check the oil level

and add oil if nec essary. The oil level shoul d be

approxim ately 1-1/ 2” deep; that is, about 1” from

the rim of the hole. Completely drain and refill

the oil every 1,000 working hours, or every 6

months, wit h a good quality gear oil.

Figure 21

To change the oil:

1. Loosen t he screw (A, Fi gure 5) which holds

the feeder body t o the horiz ontal arm.

2. Carefully remove the feeder body from the

horizontal arm.

3. Unscrew and rem ov e the oil cap (i dentified

in Figure 22) and turn the feeder body

upside down to completely drain the oil.

(NOTE: Always dispose of used oil

properly.)

4. Turn feeder body right side up, and pour

new oil into the fill hole, until it is about 1”

from the rim.

5. Re-install the oil cap (Figure 22).

Rollers

Each of the three rollers has a grease fitting

(Figure 23) located in the hub center. Use a

grease gun to insert a good quality, all-purpose

grease into these fittings every 200 working

hours, or every 30 days.

Figure 22

Figure 23

17

Page 18

Chains

Lubricate t he drive chai ns (Figure 24) with good

quality all-purpose grease every 3 months, or

more frequently if needed.

Lead Screw s

Occasionall y apply a light coat of gr ease to the

lead screw of the vertical column, and to the

lead screw of the hori z ontal arm. See Figure 25.

Figure 24

Figure 25

18

Page 19

Troubleshooting

Trouble Probable Cause Remedy

Not connected t o power source. Check plug connection.

Fuse blown, or cir c uit break er tr ipped. Replace fuse, or reset ci r c uit break er.

Feeder will not start .

Cord damaged. Replace cord.

Starting capac itor bad. Replace starting capacitor.

Wrong gears instal led for the desired

Feed speed is not

suffic ien t; m a ch in e

has low power.

Workpiece jams while

feeding it beneat h

rollers.

Workpiece slips while

passing under rollers.

Rollers slip on

workpiece.

feed rate.

Extension cord too light or too long.

Low current fr om el ectri c al suppl y . Contact a qualified electrician.

Rollers too low. Raise feeder.

Rollers too high, no traction. Lower feeder.

Grease or debris on roll er s. Clean rollers.

Replacement Parts

Install corr ec t gears i n pr oper

positions. [ page 13]

Replace with adequat e si z e and

length cord. [ page 12]

Replacement par ts are li sted on the f ollowing page s. To order parts or reac h our servi ce depar tm ent, call

1-800-274-6848, Monday through Friday (see our website for business hours, www.powermatic.com).

Having the Model Number and Serial Number of your mac hine available when you cal l will allow us to

serve you quickly and accurately.

19

Page 20

Parts List: PF3-JR Stand Assembly

Index No. Part No . Description Size Qty

1 ............... PF3JR-101 ..............Base ...................................................................................................... 1

2 ............... TS-1550061 .............Flat Wash er ........................................................M8 .............................. 1

3 ............... PF3JR-103 ..............Lock Handle .......................................................................................... 1

4 ............... TS-1540061 .............Hex Nut ..............................................................M8 .............................. 1

5 ............... PF3JR-105 ..............Elevating Bracket................................................................................... 1

6 ............... TS-1550061 .............Flat Wash er ........................................................M8 .............................. 2

7 ............... PF3JR-107 ..............Lock Handle .......................................................................................... 2

8 ............... TS-1540061 .............Hex Nut ..............................................................M8 .............................. 4

9 ............... PF3JR-109 ..............Mod. Screw ........................................................................................... 2

10 ............. TS-2361081 .............Lock Washer ......................................................M8 .............................. 2

11 ............. PF3JR-111 ..............Arm Cone .............................................................................................. 1

12 ............. TS-2310162 .............Hex Nut ..............................................................M16x1.5P ................... 1

13 ............. PF3JR-113 ..............Lock Handle .......................................................................................... 1

14 ............. TS-1550071 .............Flat Washer ........................................................M10 ............................ 1

15 ............. TS-1491081 .............Hex Cap Screw ..................................................M 1 0 x50 ...................... 1

16 ............. PF3JR-116 ..............Handle................................................................................................... 2

17 ............. PF3JR-117 ..............Vertical Column ..................................................................................... 1

18 ............. PF3JR-118 ..............Horizontal Arm ....................................................................................... 1

19 ............. PF3JR-119 ..............Elevating Screw ..................................................................................... 1

20 ............. PF3JR-120 ..............Horizontal Screw ................................................................................... 1

21 ............. PF3JR-121 ..............Column Cap .......................................................................................... 1

22 ............. TS-1524031 .............Socket Set Screw ...............................................M8x12 ........................ 3

23 ............. PF3JR-123A ............Elevating Handle ................................................................................... 2

24 ............. PF3JR-124 ..............Pin......................................................................4x30 m m .................... 2

25 ............. PF3JR-125 ..............Swivel Cone .......................................................................................... 1

26 ............. TS-2310162 .............Hex Nut ..............................................................M16x1.5P ................... 1

27 ............. PF3JR-127 ..............Lock Handle .......................................................................................... 1

20

Page 21

Exploded View: PF3-JR Stand Assembly

21

Page 22

Parts List: PF3-JR Stock Feeder

Index No. Part No . Description Size Qty

1 ............... PF3JR-201 ..............Oil Cap .................................................................................................. 1

2 ............... PF3JR-202 ..............“O” Ring ................................................................................................ 1

3 ............... PF3JR-203 ..............Sprocket Case ....................................................................................... 3

4 ............... PF3JR-204 ..............S pring.................................................................................................... 3

5 ............... PF3JR-205 ..............Case Cover ........................................................................................... 3

6 ............... PF3JR-206 ..............Roller Supporter .................................................................................... 3

7 ............... PF3JR-207 ..............Sprocket ................................................................................................ 3

8 ............... PF3JR-208 ..............Snap Ring ..........................................................Ø 22 mm .................... 3

9 ............... TS-1551041 .............Lock Was h e r ......................................................M6 .............................. 6

10 ............. TS-1503061 .............Socket Head Cap Screw .....................................M6x25 ........................ 6

12 ............. PF3JR-212 ..............Chain (18S) ........................................................18S ............................ 3

13 ............. PF3JR-213 ..............Tube ...................................................................................................... 3

14 ............. PF3JR-214 ..............Snap Ring ..........................................................Ø 26 mm .................... 3

15 ............. PF3JR-215 ..............Sprocket Shaft Assembly ...................................................................... 2

16 ............. PF3JR-216 ..............Snap Ring ..........................................................Ø 15 mm .................... 2

17 ............. PF3JR-217 ..............Sprocket Shaft Assembly ....................................................................... 1

18 ............. TS-1550071 .............Flat Washer ........................................................M10 ............................ 1

19 ............. TS-1540071 .............Hex Nut ..............................................................M10 ............................ 1

20 ............. PF3JR-220 ..............Grease Fitting ........................................................................................ 3

21 ............. PF3JR-221 ..............Shaft ..................................................................................................... 3

22 ............. TS-2361081 .............Lock Washer ......................................................M8 .............................. 3

23 ............. TS-1540061 .............Hex Nut ..............................................................M8 .............................. 3

24 ............. PF3JR-224 ..............Frame .................................................................................................... 1

25 ............. PF3JR-225 ..............Bushing ................................................................................................. 1

26 ............. PF3JR-226 ..............Sprocket ................................................................................................ 2

27 ............. PF3JR-227 ..............Sprocket ................................................................................................ 2

28 ............. PF3JR-228

29 ............. PF3JR-229 ..............Chain (30S) ........................................................30S ............................ 1

30 ............. PF3JR-230 ..............Chain (22S) ........................................................22S ............................ 1

31 ............. PF3JR-231 ..............Worm Gea r Shaft................................................................................... 1

32 ............. TS-1550071 .............Flat Washer ........................................................M10 ............................ 1

33 ............. TS-1540071 .............Hex Nut ..............................................................M10 ............................ 1

34 ............. PF3JR-234 ..............Oil Seal ................................................................................................ 1

35 ............. PF3JR-235 ..............Bushing ................................................................................................. 1

36 ............. PF3JR-236 ..............Worm Gea r Cover ................................................................................. 1

37 ............. PF3JR-237 ..............Oil Seal ................................................................................................. 1

38 ............. TS-1502031 .............Socket Head Cap Screw .....................................M5x12 ........................ 4

39 ............. PF3JR-239 ..............Gear (16T)..........................................................16T............................. 1

40 ............. PF3JR-240 ..............Gear (34T)..........................................................34T............................. 1

41 ............. PF3JR-241 ..............Gear (26T)..........................................................26T............................. 1

42 ............. PF3JR-242 ..............Gear (24T)..........................................................24T............................. 1

43 ............. PF3JR-243 ..............“O” Ring ................................................................................................ 1

44 ............. PF3JR-244 ..............Motor ..................................................................1/4HP, 1Ph, 115V ....... 1

................. PF3JR-244C ............Capacit or ( Not shown) ........................................250V 20uf ................... 1

45 ............. PF3JR-245 ..............Switch Box ............................................................................................ 1

46 ............. PF3JR-246 ..............Switch ................................................................................................... 1

47 ............. PF3JR-247 ..............Knob ..................................................................................................... 1

48 ............. PF3JR-248 ..............Back Cover ............................................................................................ 1

49 ............. PF3JR-249 ..............Roller (30 x 80 Dia) .............................................30x80 dia. mm ............ 3

50 ............. TS-1482041 .............Hex Cap Screw ..................................................M 6 x20 ........................ 2

51 ............. TS-1550041 .............Flat Washer ........................................................M6 .............................. 2

52 ............. PF3JR-252 ..............Powermatic Nameplate (not shown)....................1”x4” ........................... 1

53 ............. PF3JR-253 ..............Warning Label – Main Switch (not shown) ............................................. 1

..............Bushing ................................................................................................. 1

22

Page 23

Exploded View: PF3-JR Stock Feeder

23

Page 24

Electrical Connections for PF3-JR Stock Feeder

24

Page 25

Boring Template

SCALE 1:1

Cut out and tape int o plac e on mounting surface.

25

Page 26

NOTES

26

Page 27

27

Page 28

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.powermatic.com

28

Loading...

Loading...