Page 1

Operating Instructions and Parts Manual

This .pdf document is bookmarked

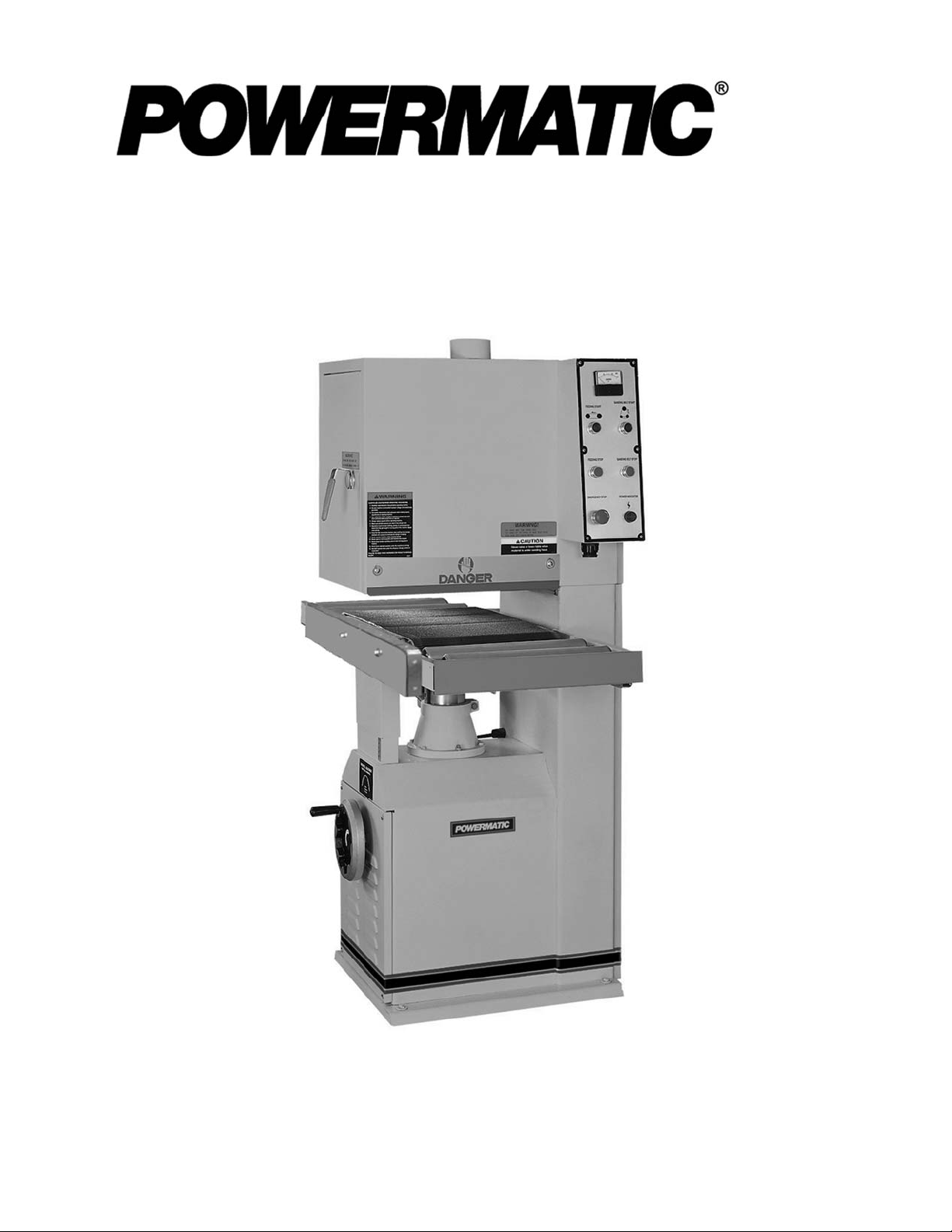

16-inch Open-End Belt Sander

Model 1632

Powermatic

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-0460219

Ph.: 800-274-6848 Revision H1 06/2014

www.powermatic.com Copyright © 2014 Powerm atic

Page 2

1.0 Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. Powermatic woodworking machinery is designed to be used with

Woo d. Use of these machin es in the processing of metal, plastics, or oth er materials may v oid the warrant y. The

exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pro of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informa t io n

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors, Machine Accessories

2 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply

to JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

2.0 Table of contents

SectionPage

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 4

4.0 About this manual .......................................................................................................................................... 5

5.0 Specifications ................................................................................................................................................. 6

6.0 Setup and assembly ....................................................................................................................................... 7

6.1 Shipping contents ....................................................................................................................................... 7

6.2 Installation .................................................................................................................................................. 7

6.3 Assembly .................................................................................................................................................... 7

7.0 Electrical connections .................................................................................................................................... 7

7.1 Voltage conversion ..................................................................................................................................... 7

7.2 Extension cords .......................................................................................................................................... 7

8.0 Adjustments ................................................................................................................................................... 8

8.1 Air control ................................................................................................................................................... 8

8.2 Sanding belt tracking and oscillation .......................................................................................................... 8

8.3 Feed belt tracking and tension ................................................................................................................... 8

8.4 Adjusting table parallel to sanding surface ................................................................................................. 8

8.5 Feed speed adjustment .............................................................................................................................. 9

9.0 Operation ....................................................................................................................................................... 9

9.1 Controls ...................................................................................................................................................... 9

10.0 Maintenance ................................................................................................................................................. 9

11.0 Troubleshooting the 1632 Sander .............................................................................................................. 10

12.0 Replacement Parts ..................................................................................................................................... 10

12.1.1 Air Control Assembly – Exploded View ............................................................................................... 11

12.1.2 Air Control Assembly – Parts List ........................................................................................................ 11

12.2.1 Electrical Control and Upper Adjustment Roller – Exploded View ...................................................... 12

12.2.2 Electrical Control and Upper Adjustment Roller – Parts List ............................................................... 13

12.3.1 Sanding Drum Assembly – Exploded View ......................................................................................... 14

12.3.2 Sanding Drum Assembly – Parts List .................................................................................................. 15

12.4.1 Base and Table Adjustment Assembly – Parts List ............................................................................. 17

12.4.2 Base and Table Adjustment Assembly – Parts List ............................................................................. 18

12.5.1 Conveyor Belt and Table – Exploded View ......................................................................................... 20

12.5.2 Reduction Motor – Exploded View ...................................................................................................... 21

12.5.3 Conveyor Belt and Table; Reduction Motor – Parts List ..................................................................... 22

13.0 Electrical Connections – 1632 Sander ....................................................................................................... 24

13.1 460V – 3 Phase ...................................................................................................................................... 24

13.2 230V – 1 Phase / 3 Phase ...................................................................................................................... 25

3

Page 4

3.0 Safety warnings

As with all machines, there is a certain amount of

hazard involved with the use of this sander. Use

the machine with the respect and caution

demanded where safety precautions are

concerned. When normal safety precautions are

overlooked or ignored, personal injury to the

operator can result.

1. Read, understand and follow the safety and

operating instructions found in this manual.

Know the limitations and hazards associated

with this machine.

2. Electrical grounding. Make certain that the

machine frame is electrically grounded and

that a ground lead is included in the incoming

electrical service. In cases where a cord and

plug are used, make certain that the grounding

plug connects to a suitable ground. Follow the

grounding procedure indicated in the National

Electrical Code.

3. Power on. Before connecting power to the

sander, make sure the start switch is in the

"OFF" position.

4. Protect yourself. Protect yourself at al l times

when operating the wide belt sander. Avoid

eye injury by wearing approved safety shields,

goggles or glasses at all times (NOTE:

Common eye glasses are only impactresistant, they are not safety glasses). Wear

protective footwear. Steel toed shoes are

recommended because heavy parts can fall off

the conveyor table onto feet.

5. Personal protection. Before operating the

machine, remove tie, rings, watch and other

jewelry and roll up slee ves above the elbows.

Remove all loose outer clothing and confine

long hair. Protective type footwear should be

used. Where the noise exceeds the level of

exposure allowed in Section 1910.95 of the

OSHA Regulations, use hearing protective

devices. Do not wear gloves.

6. Guards. Do not operate the sander with

guards off. Keep the guards in place at all

times when the machine is running. If removed

for maintenance purposes or any other reason,

use extreme caution and replace the guards

upon completion of the task and before using

the machine again. Injury can result from

exposure to the machine's internal moving

parts.

7. Check damaged parts. Before continuing use

of the machine, a guard or other part that is

damaged should be carefully checked to

ensure that it will operate properly and safely

and perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any

other conditions that could affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced before

machine operation continues.

8. Work area. Keep the floor around the

machine clean and free of scrap material, saw

dust, oil and other liquids to minimize the

danger of tripping or slipping. Be sure the

table is free of all scrap, foreign material and

tools before starting to cut. Mak e certain the

work area is well lighted and that a proper

exhaust system is used to minimize dust.

Powermatic recommends the use of anti-skid

floor strips on the floor area where the

operator normally stands and that each

machine’s work area be marked off. Provide

adequate work space around the machine.

9. Operator position. Stand to one side of the

conveyor table and make sure no one else is

standing in line with the table while feeding

into the machine. The wide belt sander

operates at high speed and should a part slip,

it will exit the machine at a high rate of speed

and may res ult in inj uries to anyone sta nding

directly in front of the infeed. (Keep conveyor

belt clean and check pin-roll adjustments.)

Maintain a balanced stance and keep your

body under control at all times. Do not

overreach or use excessive force to perform

any machine operation.

10. Hand safety. Keep hands clear while feeding

parts onto the conveyor table. The part will be

forced down as it begins to feed into the

machine, causing a pinching action between

the part and the table. Use caution! Hands

should be clear of the stock and the table to

avoid pinching. Never reach into a running

machine. Turn off electrical power and stop

machine before attempting to retrieve parts

from within the machine. Contact with internal

moving parts can result in loss or injury to

fingers, hands and arms.

11. Housekeeping. Before turning on machine,

remove all extra equipment such as keys,

wrenches, scrap, and cleaning rags aw ay f rom

the machine

12. Careless acts. Give the work you are doing

your undivided attention. Looking around,

carrying on a conversation, and “horseplay”

are careless acts that can result in serious

injury.

13. Disconnect machine before performing any

service or maintenance or when changing

4

Page 5

blades. A machine under repair should be

RED TAGGED to show it should not be used

until the maintenance is complete.

any real or implied warranty and holds itself

harmless for any injury or damage w hich may

result from that use.

14. Maintain tools in top condition. Keep all

tools sharp and clean for the best and safest

performance, and follow instructions for

lubricating and changing accessories. Never

stand on the machine. Serious injury could

occur if the sander is tipped or if the sanding

belt is accidentally contacted.

15. Job completion. The operator of the sa nder

is responsible for shutting the machine down

when it is not in use. CAUTION: The abrasive

belt will coast to a stop in normal conditions,

and will only break to a stop when the

emergency devices are pressed! IT IS

DANGEROUS TO LEAVE A MACHINE

UNATTENDED. Persons not familiar with the

sander's operation could injure themselves or

others. NEVER clean the sander with power

"ON" and never use the hands to clear

sawdust and debris; use a brush or

compressed air.

16. Replacement parts. Use only Powermatic or

factory authorized replacement parts and

accessories; otherwise the warranty and

guarantee is null and void.

17. Misuse. Do not use this Powermatic openend sander for other than its intended use. If

used for other purposes, Powermatic disclaims

18. If you are not thoroughly familiar with the

operation of wide belt sanders, obtain advice

from your supervisor, instructor or other

qualified person.

19. Drugs, alcohol, medication. Do not operate

this machine while under the influence of

drugs , alcoho l, or any med ication.

20. Health hazards. Some dust created by

power sanding, sawing, grinding, drilling and

othe r c onstruction ac t i vit ies contains chemica ls

known to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paint.

• Crystalline silica from bricks and cement

and other masonry products.

• Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals, work in a well-ventilated area, and

work with approved safety equipment, such as

those dust masks that are specifically

designed to filter out microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

This means that if preca utions are not heeded, it m ay result in minor injury a nd/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly even

death.

4.0 About this manual

This manual is provided by Powermatic, covering the safe operation and maintenance procedures for a

Powermatic Model 1632 Open-End Sander. This manual contains instructions on installation, safety

precautions, general operating procedures, m aintenance instructio ns and parts breakdown. Your m achine has

been designed and constructed to provide years of trouble-free operation if used in accordance with the

instructions as set forth in this document.

If there are questions or comments, please contact your local supplier or Powermatic. Powermatic can also be

reached at our web site: www.powermati c. com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly or

operation! Failure to comply may cause serious injury!

5

Page 6

5.0 Specifications

Stock number ...................................................... 1791250 ..........................................................1791251

Model number ..................................................... 1632-1 ............................................................... 1632-3

Working width (reversing stock) ........................... 16" (32") ..........................................................16" (32")

Working thickness ............................................... 5" ............................................................................... 5"

Minimum board length ......................................... 13 -3/4" ............................................................... 13-3 /4"

Head configuration .............................................. co mbination ............................................... combinat ion

Feed motor ......................................................... 1/4 HP, 1 PH ............................................. 1/4 HP, 3 Ph

Feed speeds (variable FPM) ................................ 15/3 2.5 ............................................................. 15/32.5

Sanding belt dimensions ...................................... 17" W x 54" L ........................................... 17 " W x 54" L

Sanding belt speed (SF P M ) ................................. 2,200 ................................................................... 2,200

Compressed air requirements at 5 atm (PSI) ....... 4 ................................................................................. 4

Dust collection minimum CFM required ................ 800 ......................................................................... 800

Dust port diameter ............................................... 4" ............................................................................... 4"

Overall dimensions .............................................. 40" L x 29" W x 66" H ................... 40" L x 29" W x 66" H

Main motor (1632-3) ............................................ 5 HP, 1PH, 230V only .............. 7-1/2HP, 3PH, 230/460V

(prewired 230V)

Net weight ........................................................... 996 lbs. ............................................................. 996 lbs.

Shipping weight ................................................... 1,106 lbs. ....................................................... 1,106 lbs.

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Powermatic reserves the right to change specifications at any time and without prior notice,

without incurring obligations.

6

Page 7

6.0 Setup and assembly

Remove the sander from its crate and inspect for

damage to ensure all parts are intact. Any damage

should be reported to your distributor and shipping

agent immediately upon discovery.

Before proceeding with installation, read your

instruction manual thoroughly. Familiarize yourself

with correct set-up, maintenance and safety

procedures.

6.1 Shipping contents

1 WideBeltSander

1 InfeedRollerAssembly

1 OutfeedRollerAssembly

1 SideSupport

1 SandingBelt

1 Toolbox,containingoilgun,doorlatches,and

drawbar(forthegraphitepad)

6.2 Installation

If using a forklift, run the forks between the upper

cabinet and the conveyor belt. Level the machine

and bolt it to the floor with hig h quality anchor bolt s

through the mounting holes located on the four

corners of the base.

2. Remove the wiring cover and attach the

ground wire (A), Figure 1.

3. For 3 Phase: Connect the three power leads

(B) to the wiring board.

For 1 Phase: Connect the two power leads to

the wiring board.

4. This machine should be hard wired into a

dedicated circuit with a properly rated breaker

according to your local code.

5. Replace wiring cover.

6. Turn on the feed belt and verify that the belt

feeds into the machine. It if turns toward the

user, disconnect the machine from the power

source and switch only two of the power leads

(on 3 Phase machine).

Remove the protective coating from the rollers wit h

a soft cloth moistened with a good commercial

solvent. DO NOT USE acetone, gasoline, lacquer

thinner or any type of flammable solvent. Do not

use an abrasive pad.

6.3 Assembly

1. Attach the infeed and outfeed roller

assemblies with sixteen 5/16" x 2" hex head

screws and spring washers.

2. Mount the side support with two hex cap

screws and flat washers.

3. Insert the door latches into the slots on the

cabinet doors.

4. Assemble the sanding belt to the rollers. Make

sure the arrow on the belt matches the rotation

of the rollers.

7.0 Electrical connections

All electrical connections should

be made by a qualified electrician in compliance

with all relevant codes. Failure to comply may

result in serious injury and/or damage to the

machine and property. The machine must be

properly grounded.

1. A cable of the proper gauge should be used to

connect the sander to the power supply.

Figure 1

7.1 Voltage conversion

The 3 Phase machine is pre-wired for 230V

operation. If 460V is needed, see the wiring box

cover on the reduction motor and t he main motor.

BOTH motors must be switched if changing from

230V to 460V. The transformer, behind the control

panel, must also be switched from 230V to 460V.

7.2 Extension cords

Amp Rating Volts Total length of cord in feet

More

Than

00 06 18 16 16 14

06 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

USE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When

using an extension cord, be sure to use one heavy

enough to carry the current your product will draw.

Not

More

Than

Extension Cord Recommendations

120

240

AWG

25

50

Table 1

50

100

100

200

Not

Recommended

150

300

7

Page 8

An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 1

shows correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

8.0 Adjustments

Disconnect sander from power

source before making adjustments.

8.1 Air control

Connect the machine to an air hose. The air

pressure that flows into the f ilter can be adjusted

with the knob (A), Figure 2. Normal working air

pressure should be set at 75 psi, which can be

read on the pressure gauge.

Figure 3

Figure 2

8.2 Sanding belt tracking and

oscillation

The tracking and oscillation of your sander are preadjusted at the factory. However, should

adjustment be required, do the following:

1. Adjust the air valve (A), Figure 3, to control t he

tracking sensitivity.

2. The oscillation speed can be controlled by

adjusting the top air valve (B).

3. Empty the glass container (C) as needed.

NOTE: There is a limit switch at both ends of the

upper roller. If the sanding belt com es in contact

with these limit switches, the brakes will be

activated.

8.3 Feed belt tracking and tension

Tracking and tension for the feed belt is controlled

by two sock et set screw s on ea ch side of the belt

(A) as shown in Figure 4.

Figure 4

8.4 Adjusting table parallel to

sanding surface

The table comes pre-adjusted from the factory.

Check its parallelism by running a 16" wide piece

of plywood through the sander. Use a pair of

calipers to measure the thickness remaining on

both sides.

Adjust the parallelism using the four hex. screws

(A), under the table base. See Figure 5.

8

Page 9

NOTE: The orange bar on the front of the infeed

roller acts as a safety stop. When the bar is

pressed, the brakes are applied.

1. Connect the air line to the sander.

2. Adjust the pressure gauge to 75 psi.

3. Engage the upper roller by turning the knob

(A), Figure 8, to the upper position.

4. Adjust the platen with the lever (B) and lock it

(C) in the desired position. The platen or main

rubber roller can act as the sanding contact, as

well as a combination of both.

Figure 5

8.5 Feed speed adjustment

The Model 1632 has two speeds that feed the

workpiece at 15 feet per minute (FPM) finished

surface sanding, and 32.5 FPM for faster, lighter

sanding.

To change the feed rate:

1. Disconnect machine from power source.

2. Remove cap screw that holds the sprocket

cover at the right rear of the working table.

3. Loosen the four set screws holding the

sprockets in place.

4. Remove the sprockets and chain together and

position according to the required operation.

See Figure 6.

5. Retighten the four set screws, then replace

cover and cap screw.

9.0 Operation

9.1 Controls

(see Figure 7):

Emergency stop (A) will stop t he feeding belt a nd

sanding belt. The button must be turned clockwise

to reset sanding functions.

Amp Meter (B) displays the amperage.

Feeding Start (C) will start the feeding belt only.

Feeding Stop (D) will stop the feeding belt only.

Sanding Belt Start (E) will start the sanding belt

only.

Sanding Belt Stop (F) will stop the sanding belt

only.

5. Rotate the main handwheel (A), on the lower

cabinet, to raise or lower the table. See Figure

9. Refer to the scale for t he desired setting.

The recommended depth of sanding is .0164"

or two revolutions of the handwheel. The table

can be locked in place by the lever at the base

of the column.

6. Turn on the power to the machine.

7. Start the sanding belt.

8. Start the feeding conveyor.

NOTE: If you are sanding a workpiece greater

than 16 inches, pull out the support extension, and

tighten the wing nuts. After the first pass, the

workpiece can be spun around and fed back

through the machine, for a maximum sanding width

of 32 inches.

10.0 Maintenance

Before performing any

ma inte nanc e o n t he sa nde r, di sco nne ct i t f ro m t he

electrical supply by pulling out the plug or s witching

off the main switch. Failure to comply may cause

serious injury.

The interior of the machine should be thoroughly

cleaned each day after using the sander.

Remove the sanding belt before cleaning and reinstall it when finished.

Keep the sanding belt clean using c leaning sticks

or pads (not provided).

Blow dust off the conveyor belt with compressed

air or use a dust collector vacuum attachment.

The drum bearings should be grea sed (via grease

fittings on each side) after every 150 work hours.

9

Page 10

11.0 Troubleshooting the 1632 Sander

Symptom Possible Cause Correction

Motor will not start Low voltage. Check power line for proper voltage.

Open circuit in motor or loose

connection.

Motor will not start: fuses

or circuit breakers blow.

The sanding belt clogs

quickly.

Edges round when

sanding.

The thickness differs on

left and right sides of

workpiece.

The thickness differs on

front and back sides of

workpiece.

Short circuit in line cord or plug. Inspect cord or plug for damaged insulation

Short circuit in motor or loose

connections.

Incorrect fuses or circuit breakers in

power line.

Sandpaper grit too small. Use larger grit.

Too much material is being sanded off. Reduce sanding depth.

The wood is too dirty or oily. Use dry stock.

Suction is insufficient. Increase suction.

Too much material being removed. Reduce sanding depth.

Conveyor table not parallel to contact

roller or platen.

Worn out felt and graphite on platen

head

Feed speed too fast. Reduce speed.

Too much material is being removed. Reduce sanding depth.

Sandpaper grit too fine. Use coarser grit

Inspect all lead connections on motor for

loose or open connections.

and shorted wires.

Inspect all connections on motor for loose or

shorted terminals or worn insulation.

Install correct fuses or circuit breakers.

Adjust table to parallel.

Replace felt/graphite.

Pressure plate not level Adjust plate to level.

Workpiece slips on

conveyor belt.

Straight notch grooves

on workpiece.

Snake marks on

workpiece.

Belt slips out of track. Tracking air valve is clogged or not

Straight parallel stripes

across the workpiece.

Too much or too little pressure from

pressure plate.

Sanding belt clogged with dust.

Belt worn out. Replace belt.

Dirty pressure roller. Clean pressure roller.

Rubber roller scratched. Replace rubber roller.

Worn out lining and graphite on platen

head.

Sanding belt partially damaged. Repair or replace sanding belt.

Sanding grit loose. Replace sanding belt.

open enough.

Sanding belt joint is too thick. Replace sanding belt

Sanding belt is worn. Replace sanding belt.

Adjust to proper pressure.

Blowoutdustwithhigh‐pressureair.

Replace lining/graphite.

Clean/enlarge valve opening.

12.0 Replacement Parts

Replacement parts are listed on the followi ng pages. To order parts or reach our service departm ent, call 1800-274-6848 Monday through Friday (see our website for business hours, www.powermatic.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to serve you quickly

and accurately.

10

Page 11

12.1.1 Air Control Assembly – Exploded View

12.1.2 Air Control Assembly – Parts List

Index No Part No Description Size Qty

1 ................ 6293482 .................... Filter ......................................................................... ...................................... 1

2 ................ 6293483 .................... Solenoid Valve ......................................................... ...................................... 1

3 ................ 6293484 .................... Brake Cylinder ......................................................... ...................................... 1

4 ................ 6293485 .................... Multi-Hole Connector ............................................... ...................................... 1

5 ................ 6293486 .................... Air Valve .................................................................. . ..................................... 1

6 ................ 6293487 .................... Air Sensor Assembly ............................................... ...................................... 1

7 ................ 6293488 .................... Air Sensor ................................................................ ...................................... 1

8 ................ 6293489 .................... Switching Valve ....................................................... ...................................... 1

9 ................ 6293250 .................... Cylinder.................................................................... . ..................................... 1

10 .............. 6293252 .................... Oscillator Cylinder.................................................... ...................................... 1

11 .............. 6293490 .................... Plastic Pipe .............................................................. ...................................... 1

12 .............. 6293491 .................... Plastic Joint.............................................................. PT-1 /8" .......................... 1

13 .............. 6293492 .................... Copper Joint ............................................................ ...................................... 1

14 .............. 6293493 .................... T-Joint ...................................................................... ...................................... 1

15 .............. 6293494 .................... Silencer .................................................................... ...................................... 1

11

Page 12

12.2.1 Electrical Control and Upper Adjustment Roller – Exploded View

12

Page 13

12.2.2 Electrical Control and Upper Adjustment Roller – Parts List

Index No Part No Description Size Qty

1 ................ 6293203 .................... Upper Door (L) ......................................................... ...................................... 1

2 ................ 6293204 .................... Pin for Upper Door ................................................... ...................................... 2

3 ................ 6293205 .................... Upper Cabinet.......................................................... ...................................... 1

4 ................ 6293206 .................... Door Knob................................................................ ...................................... 2

5 ................ 6293207 .................... Door Latch (L) .......................................................... ...................................... 1

6 ................ 6293208 .................... Upper Door (R) ........................................................ ...................................... 1

7 ................ 6293209 .................... Pan Head Screw ...................................................... 1/4" x 1/2"...................... 2

8 ................ 6293210 .................... Flat Washer ............................................................. 1/4" ................................ 2

9 ................ 6293211 .................... Plate......................................................................... ...................................... 1

10 .............. 6293212 .................... Hex Nut .................................................................... 1/2" ................................ 8

11 .............. 6293213 .................... Hex Head Screw ...................................................... 3/8” x 3/4" ...................... 8

12 .............. 6293214 .................... Adjust Stand (L) ....................................................... ...................................... 2

13 .............. 6293215 .................... Adjust Stand (R) ...................................................... ...................................... 2

14 .............. 6293216 .................... Spring ...................................................................... ...................................... 4

15 .............. 6293217 .................... Fixed Roller Stand w/ Adjust Bolt ............................ ...................................... 4

16 .............. 6293218 .................... Flat Washer ............................................................. 3/8” ................................ 8

17 .............. 6293219 .................... Shaft & Rubber Roller .............................................. ...................................... 2

18 .............. 6293311 .................... Door Latch (R) ......................................................... ...................................... 1

19 .............. 6293221 .................... Ball Bearing ............................................................. ...................................... 4

20 .............. 6293222 .................... Set Screw ................................................................ 1/4 "x 3/4"...................... 4

21 .............. 6293223 .................... Ring ......................................................................... ...................................... 4

22 .............. 6293224 .................... Control Plate ............................................................ ...................................... 1

23 .............. 6293225 .................... Gear Washer ........................................................... 3/16” .............................. 6

24 .............. 6293226 .................... Pan Head Screw ...................................................... 3/16” X 3/8” ................... 6

25 .............. 6293227 .................... Amp Meter ............................................................... ...................................... 1

26 .............. 6293228 .................... Feed Start Switch .................................................... ...................................... 1

.................. 6293228 .................... Sanding Belt Start Switch ........................................ ...................................... 1

27 .............. 6293229 .................... Feed Stop Switch..................................................... ...................................... 1

.................. 6293229 .................... Sanding Belt Stop Switch ........................................ ...................................... 1

28 .............. 6293230 .................... Stop Switch .............................................................. ...................................... 1

29 .............. 6293231 .................... Power Indicator Light ............................................... ...................................... 1

30 .............. 6293232 .................... Current Coil.............................................................. ...................................... 1

31 .............. 6293233 .................... Fuse Stand (5 HP) ................................................... ...................................... 1

.................. 6293312 .................... Fus e Stand (7-1/2 HP) ............................................. ...................................... 1

32 .............. 6293234 .................... Terminal Strip (5 HP) ............................................... ...................................... 1

.................. 6293313 .................... Terminal Strip (7-1/2 HP) ......................................... ...................................... 1

33 .............. 1632-233 ................... Relay (5 HP) ............................................................ ...................................... 1

.................. 6293314 .................... Relay (7-1/2 HP) ...................................................... ...................................... 1

34 .............. 6293236 .................... Terminal Strip (5 HP) ............................................... ...................................... 1

.................. 6293315 .................... Terminal Strip (7-1/2 HP) ......................................... ...................................... 1

35 .............. 1632-235 ................... Overload Relay (5 HP)............................................. ...................................... 1

.................. 6293316 .................... Overload Relay (7-1/2 HP) ...................................... ...................................... 1

36 .............. 1632-236 ................... Relay (5 HP) ............................................................ ...................................... 1

.................. 6293317 .................... Relay (7-1/2 HP) ...................................................... ...................................... 1

37 .............. 6293239 .................... Transformer (5 HP) .................................................. ...................................... 1

.................. 6293318 .................... Trans former (7-1/2 HP)............................................ ...................................... 1

13

Page 14

12.3.1 Sanding Drum Assembly – Exploded View

14

Page 15

12.3.2 Sanding Drum Assembly – Parts List

Index No Part No Description Size Qty

1 ................ 6293240 .................... Ring ......................................................................... ...................................... 2

2 ................ 6293241 .................... Ball Bearing ............................................................. ...................................... 2

3 ................ 6293242 .................... Shaft ........................................................................ ...................................... 1

4 ................ 6293243 .................... Upper Roller............................................................. ...................................... 1

5 ................ 6293244 .................... Upper Roller Base (L) .............................................. ...................................... 1

6 ................ 6293245 .................... Column .................................................................... ...................................... 1

7 ................ 6293246 .................... Switch Valve ............................................................ ...................................... 1

8 ................ 6293247 .................... Eccentric Shaft Base ............................................... ...................................... 1

9 ................ 6293248 .................... Eccentric Shaft......................................................... ...................................... 1

10 .............. 6293249 .................... Hex Head Screw ...................................................... 5/16” x 1/2" .................... 2

11 .............. 6293250 .................... Air Cylinder Assembly.............................................. ...................................... 1

12 .............. 6293251 .................... Cover (L) .................................................................. .. .................................... 1

13 .............. 6293252 .................... Air Oscillator Cylinder .............................................. ...................................... 1

.................. 6293496 .................... Air Valve Assembly (Items 14 thru 17, 74, 75, 79 & 86) ................................. 1

14 .............. 6293253 .................... Front Cover .............................................................. ...................................... 1

15 .............. 6293254 .................... Oscillator Shaft ........................................................ ...................................... 1

16 .............. 6293255 .................... Membrane................................................................ ...................................... 1

17 .............. 6293256 .................... Rear Cover .............................................................. ...................................... 1

18 .............. 6293257 .................... Column .................................................................... ...................................... 1

19 .............. 6293258 .................... Cover (R) ................................................................. ...................................... 1

20 .............. 6293259 .................... Air Sensor ................................................................ ...................................... 1

.................. 6293497 .................... Air Valve Ass e mbly (I tems 21 th ru 26 & 79) ............ ...................................... 1

21 .............. 6293260 .................... Lower Cover ............................................................ ...................................... 1

22 .............. 6293261 .................... Air Sensor Substance .............................................. ...................................... 1

23 .............. 6293262 .................... Piston ....................................................................... ...................................... 1

24 .............. 6293263 .................... Upper Cover ............................................................ ...................................... 1

25 .............. 6293264 .................... Plastic Joint Assembly ............................................. ...................................... 1

26 .............. 6293265 .................... Membrane................................................................ ...................................... 1

27 .............. 6293266 .................... Handle Assembly ..................................................... ...................................... 1

28 .............. 6293267 .................... Set Screw ................................................................ 1/4" x 1/4"...................... 1

29 .............. 6293268 .................... Handle Hub .............................................................. ...................................... 1

30 .............. 6293269 .................... Hex Head Screw ...................................................... 3/8” x 1-1/4”................... 4

31 .............. 6293270 .................... Adjust Bolt................................................................ 3/8” x 1-1/4”................... 2

32 .............. 6293271 .................... Spring ...................................................................... ...................................... 2

33 .............. 6293272 .................... Shaft ........................................................................ ...................................... 1

34 .............. 6293273 .................... Key........................................................................... 5 x 5 x 30mm ................ 2

35 .............. 6293274 .................... Key........................................................................... 8 x 8 x 4 mm ................. 1

36 .............. 6293275 .................... Lock Handle ............................................................. ...................................... 1

37 .............. 6293276 .................... Knob ........................................................................ ...................................... 1

38 .............. 6293277 .................... Hex Head Screw ...................................................... 3/8” x 1-1/2”................... 2

39 .............. 6293278 .................... Pan Head Screw ...................................................... 5/32” x 3/8” .................... 6

40 .............. 6293279 .................... Hex Socket Cap Screw ............................................ 1/4" x 1/2".................... 12

41 .............. 6293280 .................... Bearing Cover .......................................................... ...................................... 2

42 .............. 6293281 .................... Bearing Cover (L) .................................................... ........ .............................. 1

.................. 6293282 .................... Bearing Cover (R) .................................................... ...................................... 1

43 .............. 6293283 .................... Lock Nut (counter-clockwise)................................... ...................................... 2

44 .............. 6293284 .................... Lock Nut (clo ckwise) ................................................ ...................................... 1

45 .............. 6293285 .................... Ball Bearing ............................................................. ...................................... 4

46 .............. 6293286 .................... Round Bearing Frame ............................................. ...................................... 1

47 .............. 6293287 .................... Main Rubber Roller .................................................. ...................................... 1

48 .............. 6293288 .................... Hex Head Screw ...................................................... 5/16” x 1-3/4”................. 2

49 .............. 6293289 .................... Hex Nut .................................................................... 5/16” .............................. 2

50 .............. 6293290 .................... Back Steel Roller ..................................................... ...................................... 1

51 .............. 6293291 .................... Blanket ..................................................................... ...................................... 1

52 .............. 6293292 .................... Pad Slider ................................................................ ...................................... 1

53 .............. 6293293 .................... Hex Head Screw ...................................................... 3/8” x 1” ......................... 2

54 .............. 6293294 .................... Pad .......................................................................... ...................................... 1

55 .............. 6293218 .................... Flat Washer ............................................................. 3/8” ................................ 2

56 .............. 6293295 .................... Pressing Bar ............................................................ ...................................... 2

15

Page 16

Index No Part No Description Size Qty

57 .............. 6293296 .................... Graphite Canvas ...................................................... ...................................... 1

58 .............. 6293297 .................... Pulley (5 HP)............................................................ ...................................... 1

.................. 6293298 .................... Pulley (7-1/2 HP) ..................................................... ...................................... 1

59 .............. 6293299 .................... Flat Washer ............................................................. 5/16” .............................. 1

60 .............. 6293300 .................... Hex Head Screw ...................................................... 5/16” x 1” ....................... 1

61 .............. 6293301 .................... Rectangular Bearing Base ....................................... ...................................... 1

62 .............. 6293302 .................... Cover ....................................................................... ...................................... 1

63 .............. 6293303 .................... Air Sensor Assembly ............................................... ...................................... 1

64 .............. 6293304 .................... Limit Switch.............................................................. ...................................... 2

65 .............. 6293305 .................... Disk .......................................................................... ...................................... 1

66 .............. 6293306 .................... Hex Head Screw ...................................................... 1/4" x 3/8” ...................... 1

67 .............. 6293210 .................... Flat Washer ............................................................. 1/4" ................................ 1

68 .............. 6293330 .................... Pan Head Screw ...................................................... 5/32” x 1/2" .................... 2

69 .............. 6293331 .................... Pan Head Screw ...................................................... 5/32” x 1” ....................... 2

70 .............. 6293332 .................... Hex Head Screw ...................................................... 5/16” x 2” ....................... 4

71 .............. 6293333 .................... Cap Screw ............................................................... M8 x 20 ......................... 4

72 .............. 6293334 .................... Hex Head Screw ...................................................... 1/4" x 2 .......................... 4

73 .............. 6293209 .................... Pan Head Screw ...................................................... 1/4" x 1/2"...................... 6

74 .............. 6293335 .................... Air Valve .................................................................. ...................................... 1

75 .............. 6293336 .................... Block Connector ...................................................... ...................................... 1

76 .............. 6293337 .................... Knob ........................................................................ ...................................... 1

77 .............. 6293338 .................... Cylinder Disk............................................................ ...................................... 1

78 .............. 6293339 .................... Eccentric Roller........................................................ ...................................... 2

79 .............. 6293340 .................... Pan Head Screw ...................................................... 3/16” x 5/8” .................... 8

80 .............. 6293341 .................... Gear Washer ........................................................... 5/16” .............................. 4

81 .............. 6293342 .................... Gear Washer ........................................................... 3/8” ................................ 4

82 .............. 6293343 .................... Flat Washer ............................................................. 5/32” .............................. 1

83 .............. 6293344 .................... Spring Washer ......................................................... 3/8” ................................ 2

84 .............. 6293345 .................... Hex Nut .................................................................... ...................................... 1

85 .............. 6293346 .................... Hex Head Screw ...................................................... 1/4" x 1/2"...................... 1

86 .............. 6293347 .................... Spring Pin ................................................................ 3” x 16” .......................... 1

87 .............. 6293348 .................... Gear Washer ........................................................... 1/4" ................................ 4

88 .............. 6293349 .................... Gear Washer ........................................................... M8 ................................. 4

89 .............. 6293350 .................... Spring Washer ......................................................... 1/4" ................................ 1

90 .............. 6293501 .................... Upper Roller Base (R) ............................................. ...................................... 1

16

Page 17

12.4.1 Base and Table Adjustment Assembly – Parts List

17

Page 18

12.4.2 Base and Table Adjustment Assembly – Parts List

Index No Part No Description Size Qty

1 ................ 6293415 .................... Door ......................................................................... ...................................... 1

2 ................ 6293416 .................... Crosspiece ............................................................... ...................................... 1

3 ................ 6293417 .................... Door Knob................................................................ ...................................... 1

4 ................ 6293418 .................... Cover ....................................................................... ...................................... 1

5 ................ 6293419 .................... Hex Head Screw ...................................................... 1/4" x 1” ......................... 4

6 ................ 6293420 .................... Base......................................................................... ...................................... 1

7 ................ 6293421 .................... Cover ....................................................................... ...................................... 1

8 ................ 6293422 .................... Hex Head Screw ...................................................... 3/16” x 3/8” .................... 4

9 ................ 6293423 .................... Flat Washer ............................................................. 3/16” .............................. 4

10 .............. 1632-410 ................... Motor (s/n 05061632360 and higher) ......................... 5 HP, 1 PH .................... 1

.................. 6293425 .................... Motor........................................................................ 7-1/2 HP, 3 PH .............. 1

11 .............. 6293293 .................... Hex Head Screw ...................................................... 3/8” x 1” ......................... 4

12 .............. 6293426 .................... Lock Washer ............................................................ 3/8” ................................ 4

13 .............. 6293427 .................... Brake Base .............................................................. ..... ................................. 1

14 .............. 6293428 .................... Brake Pole ............................................................... .... .................................. 1

15 .............. 6293429 .................... Brake Spring ............................................................ ...................................... 2

16 .............. 6293430 .................... Brake ....................................................................... ...................................... 2

17 .............. 6293431 .................... Bolt........................................................................... 5/1”6 x 1-1/2”................. 1

18 .............. 6293432 .................... Bolt........................................................................... 1/2" ................................ 1

19 .............. 6293433 .................... Socket Head Screw ................................................. 5/16” x 1/2" .................... 6

20 .............. 6293434 .................... Bolt........................................................................... 3/8” x 1-1/2”................... 1

21 .............. 1632-421 ................... Pulley (5 HP)............................................................ ...................................... 1

.................. 6293436 .................... Pulley (7-1/2 HP) ..................................................... ...................................... 1

22 .............. 6293210 .................... Flat Washer ............................................................. 1/4" ................................ 1

23 .............. 6293437 .................... Hex Head Screw ...................................................... 1/4" x 1” ......................... 1

24 .............. 1632-424 ................... Motor Plate (5 HP) (s/n 05061632360 and higher) .... ...................................... 1

.................. 6293439 .................... Motor Plate (7-1/2 HP) ............................................. ...................................... 1

25 .............. 6293212 .................... Hex Nut .................................................................... 1/2" ................................ 1

26 .............. 6293440 .................... Base......................................................................... . ..................................... 1

27 .............. 6293441 .................... Set Screw ................................................................ 5/16” x 1” ....................... 4

28 .............. 6293442 .................... Hex Socket Cap Screw ............................................ 5/16” x 1-1/2”................. 4

29 .............. 6293299 .................... Flat Washer ............................................................. 5/16” .............................. 1

30 .............. 1632-430 ................... Belt (s/n 05061632360 and higher) ............................ A-84 .............................. 2

31 .............. 6293444 .................... Flat Head Screw ...................................................... 1/4" x 1/2"...................... 2

32 .............. 6293445 .................... Key........................................................................... 19 x 3/8 x 270 ............... 1

33 .............. 6293446 .................... Base Lifting Pipe ...................................................... ...................................... 1

34 .............. 6293447 .................... Cap Screw ............................................................... 3/4" ................................ 1

35 .............. 6293249 .................... Hex Head Screw ...................................................... 5/16” X 1/2" ................... 4

36 .............. 6293341 .................... Gear Washer ........................................................... 5/16” .............................. 4

37 .............. 6293448 .................... Spring Pin ................................................................ 5 x 25mm ...................... 1

38 .............. 6293449 .................... Lock Handle ............................................................. ...................................... 1

39 .............. 6293450 .................... Hex Nut .................................................................... 1/4" ................................ 2

40 .............. 6293451 .................... Bolt........................................................................... 1/4" x 290mm ................ 1

41 .............. 6293452 .................... Lock Washer ............................................................ 1/4" ................................ 1

42 .............. 6293453 .................... Gear ......................................................................... ...................................... 1

43 .............. 6293454 .................... Ring ......................................................................... ...................................... 1

44 .............. 6293455 .................... Ball Bearing ............................................................. ...................................... 2

45 .............. 6293456 .................... Bolt........................................................................... 3/8” X 4” ........................ 2

46 .............. 6293457 .................... Hex Nut .................................................................... 3/8” ................................ 6

47 .............. 6293218 .................... Flat Washer ............................................................. 3/8” ................................ 4

48 .............. 6293458 .................... Hex Head Screw ...................................................... 3/8” X 1-3/4” .................. 4

49 .............. 6293459 .................... Ring ......................................................................... ...................................... 1

50 .............. 6293460 .................... Gear Box.................................................................. ...................................... 1

51 .............. 6293461 .................... Ball Bearing ............................................................. ...................................... 2

52 .............. 6293462 .................... Worm Gear .............................................................. ...... ................................ 1

53 .............. 6293218 .................... Flat Washer ............................................................. 3/8” ................................ 4

54 .............. 6293463 .................... Shaft ........................................................................ ...................................... 1

55 .............. 6293267 .................... Set Screw ................................................................ 1/4" x 1/4"...................... 2

56 .............. 6293464 .................... Set Screw ................................................................ 1/4" x 1” ......................... 1

18

Page 19

Index No Part No Description Size Qty

57 .............. 6293450 .................... Hex Nut .................................................................... 1/4" ................................ 1

58 .............. 6293465 .................... Wheel....................................................................... 8" ................................... 1

59 .............. 6293466 .................... Handle ..................................................................... ...................................... 1

60 .............. 6293209 .................... Pan Head Screw ...................................................... 1/4" x 1/2"...................... 2

61 .............. 6293467 .................... Lower Guard ............................................................ ...................................... 1

62 .............. 6293468 .................... Upper Guard ............................................................ ...................................... 1

63 .............. 6293277 .................... Hex Head Screw ...................................................... 3/8” x 1-1/2”................... 8

64 .............. 6293342 .................... Gear Washer ........................................................... 3/8” ................................ 8

65 .............. 6293469 .................... Air Cylinder Assembly.............................................. ...................................... 1

66 .............. 6293300 .................... Hex Head Screw ...................................................... 5/16” x 1” ....................... 2

67 .............. 6293289 .................... Hex Nut, 5/16" ......................................................... ...................................... 2

68 .............. 6293470 .................... Key (7-1/2 HP) ......................................................... 10 x 8 x 60mm .............. 1

.................. 6293471 .................... Key (5 HP) ............................................................... ...................................... 1

69 .............. 6293472 .................... Cover ....................................................................... ...................................... 1

70 .............. 6293210 .................... Flat Washer ............................................................. 1/4" ................................ 2

71 .............. 6293457 .................... Hex Nut .................................................................... 3/8” ................................ 1

72 .............. 6293473 .................... Solenoid Valve ......................................................... ...................................... 1

73 .............. 6293331 .................... Pan Head Screw ...................................................... 5/32” x 1” ....................... 2

74 .............. 6293474 .................... Filter ......................................................................... ...................................... 1

75 .............. 6293475 .................... Pan Head Screw ...................................................... 5/32” x 1-3/8”................. 1

76 .............. 6293476 .................... Hookup Box ............................................................. ...................................... 1

77 .............. 6293477 .................... Screw ....................................................................... 3/16” X 1-3/8” ................ 2

78 .............. 6293478 .................... Flat Washer ............................................................. 3/16” .............................. 2

79 .............. 6293479 .................... Hex Nut .................................................................... 3/16” .............................. 2

80 .............. 6293210 .................... Flat Washer ............................................................. 1/4" ................................ 4

81 .............. 6293480 .................... Screw Lead .............................................................. 3/4" ................................ 1

82 .............. 6293481 .................... Lifting Pipe ............................................................... ...................................... 1

19

Page 20

12.5.1 Conveyor Belt and Table – Exploded View

20

Page 21

12.5.2 Reduction Motor – Exploded View

21

Page 22

12.5.3 Conveyor Belt and Table; Reduction Motor – Parts List

Index No Part No Description Size Qty

1 ................ 6293351 .................... Hex Socket Cap Screw ............................................ 1/4" x 1/4"...................... 6

2 ................ 6293352 .................... Bearing Cover .......................................................... ...................................... 2

3 ................ 6293353 .................... Ball Bearing ............................................................. ...................................... 2

4 ................ 6293354 .................... Back Convey or Roller Base (L) ............................... ...................................... 1

5 ................ 6293355 .................... Roller ....................................................................... ...................................... 1

6 ................ 6293356 .................... Key........................................................................... 6 x 6 x 20mm ............... 1

7 ................ 6293357 .................... Back Conveyor Roller & Motor Base ....................... ...................................... 1

8 ................ 6293358 .................... Key........................................................................... 5 x 5 x 25mm ................ 1

9 ................ 6293267 .................... Set Screw ................................................................ 1/4" x 1/4"...................... 4

10 .............. 6293359 .................... Chain ....................................................................... ...................................... 1

11 .............. 6293360 .................... Sprocket................................................................... ... ................................... 1

12 .............. 6293332 .................... Hex Head Screw ...................................................... 5/16” x 2” ....................... 5

13 .............. 6293361 .................... Cover ....................................................................... ...................................... 1

14 .............. 6293362 .................... Hex Socket Cap Screw ............................................ 1/4" X 2” ........................ 1

15 .............. 6293495 .................... Reduction Motor Assembly, 1 PH (Items 16 thru 38) ..................................... 1

.................. 6293498 .................... Reduction Motor Ass e mbly, 3 PH (Items 16 thru 38) ..................................... 1

16 .............. 6293363 .................... Body......................................................................... . ..................................... 1

17 .............. 6293364 .................... Gear B ..................................................................... 40T ................................ 1

18 .............. 6293365 .................... Gear A ..................................................................... 19T ................................ 1

19 .............. 6293366 .................... Ball Bearing ............................................................. ...................................... 4

20 .............. 6293367 .................... Gear B ..................................................................... 47T ................................ 1

21 .............. 6293368 .................... Gear C ..................................................................... 14T ................................ 1

22 .............. 6293369 .................... Output Shaft............................................................. ...................................... 1

23 .............. 6293370 .................... Key........................................................................... 5 x 5 x 10mm ................ 1

24 .............. 6293371 .................... Gear D ..................................................................... 46T ................................ 1

25 .............. 6293372 .................... Washer .................................................................... ...................................... 1