Page 1

This Manual is Bookmarked

Operating Instructions and Parts Manual

12” Jointer

Model 1285

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-0460216

Ph.: 800-274-6848 Revision C1 12/05

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

This manual has been prepared for t he owner and operators of a Powermatic Model 1285 Jointer. It s

purpose, aside f rom machine oper ation, is to promot e safety using acc epted operati ng and maint enance

procedures. To obtai n maximum lif e and effici ency from your jointer and t o aid in using i t safely, please

read this manual thoroughly and follow the instruc tions carefully.

Warranty and Service

WMH Tool Gr oup warrants ever y product it sell s. If one of our tools needs s ervice or repai r, one of our

Authorized S ervic e Center located throughout the United States can provide quick servi c e or information.

In most cases, a W MH Tool Group Servi ce Center can assist i n authori zing repai r work, obtai ning part s,

or perform routine or major maintenance repai r on your Powerm atic product.

For the name of an Aut horized Service Cent er in your area, pl ease call 1-800-274-6848, or vi sit our web

site at www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group i s consistently adding new products to the li ne. For complete, up-to-dat e

product information, check with your local WMH Tool Group distributor, or visit our web site at

www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that it s products meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from

defects in mat erials and workmanship as foll ows: 1 YEA R LIMITED WARRANTY ON ALL PRODUCTS

UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or i ndirectly to

misuse, abuse, negl igence or acc idents, norm al wear-and-tear , repair or alterati ons outside our f aciliti es,

or to a lack of maintenanc e.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP

BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Service Center designated by our office. Proof of purchase date and an

explanati on of the complaint m ust accompany the merchandi se. If our inspecti on discloses a defec t, we

will either repair or replace the product at our discret ion, or r efund t he purchase pri ce if we cannot readi l y

and quickly provide a repai r or replac ement. We will return the repai red product or replacem ent at WMH

Tool Group’s ex pense, but if it is determ ined there i s no defect, or that the def ect resulted f rom causes

not within the scope of WMH Tool Group’s warranty, then the user must bear the cost of storing and

returning t he product . This warranty gives you specifi c legal ri ghts; you m ay also have ot her ri ghts, which

vary from state t o state.

WMH Tool Group sells through distribut ors only. Members of the WMH Tool Group reserve the right to

effect at any time, wit hout prior notice, alter ations to parts, fittings and accessory equi pment, which they

may deem necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty and Servic e ..............................................................................................................................2

Warning...................................................................................................................................................4

Introduction..............................................................................................................................................7

Specifications ..........................................................................................................................................7

Unpacking...............................................................................................................................................8

Contents of the Shipping Container......................................................................................................8

Assembly.................................................................................................................................................9

Fence Installation.................................................................................................................................9

Switch Arm.........................................................................................................................................10

Dust Hood..........................................................................................................................................10

Grounding Instructions...........................................................................................................................10

Voltage Conversion............................................................................................................................11

Extensi on cords..................................................................................................................................11

Adjustm ents...........................................................................................................................................12

Drive Belt Tension..............................................................................................................................12

Setting Outfeed Table Height.............................................................................................................. 12

Setting Inf eed Table Height (Depth of Cut) .........................................................................................14

Replacing and Setti ng Knives (Straight Cutterhead) ............................................................................14

Replacing Knife Inserts (Helical Cutter head).......................................................................................16

Fence Adj ustments.............................................................................................................................17

Cutter Gu a rd Ten sion.........................................................................................................................18

Operating Controls.................................................................................................................................18

Operation...............................................................................................................................................18

Hand Placement.................................................................................................................................19

Edge Jointing .....................................................................................................................................19

Surfacing............................................................................................................................................19

Rabbeting ..........................................................................................................................................19

Jointing Warped Surfaces...................................................................................................................20

Jointing Short or Thin Work................................................................................................................20

Direction of Grain ...............................................................................................................................20

Beveling.............................................................................................................................................20

Maintenance.......................................................................................................................................... 21

Lubrication .........................................................................................................................................21

Cutterhead Repair s ............................................................................................................................21

Knife Inserts (Helical Cutterhead) .......................................................................................................22

Whetting Knives (Straight Cutterhead)................................................................................................23

Optional Accessories .............................................................................................................................27

Replacement Parts................................................................................................................................ 27

Parts List: Stand A ssembly.................................................................................................................28

Stand Assembly .................................................................................................................................29

Parts Lis t: Ta b le Assembly.................................................................................................................30

Table Assembly.................................................................................................................................. 31

Parts Li st: Motor Pulley Assembly.......................................................................................................32

Motor Pulley Assembly.......................................................................................................................33

Parts List: Cutterhead Guard Assembly..............................................................................................34

Cutterhead Guard A ssem bly ..............................................................................................................35

Parts List: Str aight Cutterhead Assembly............................................................................................36

Straight Cutterhead Assembly............................................................................................................37

Parts List: Helical Cutterhead Assembly .............................................................................................38

Helical Cutter head A ssem bly..............................................................................................................39

Parts Li st: Fence Assembly................................................................................................................40

Fence Assembly.................................................................................................................................41

Electri c al Connec tions – 1 Phase........................................................................................................... 42

Electri c al Connec tions – 3 Phase........................................................................................................... 43

3

Page 4

Warning

1. Read and understand the entire owners manual before attempting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This joint er is designed and intended f or use by properl y trained and ex perienced personnel onl y. If

you are not familiar with the proper and saf e oper ation of a jointer, do not use until proper trai ning and

knowledge have been obtained.

5. Do not use this j ointer for other than its int ended use. If used f or other purposes, W MH Tool Group

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Always wear approv ed safety glasses/face shi elds while using thi s jointer. Ever yday eyeglasses only

have impact resistant lenses; they are not safet y glasses.

7. Before operating t his jointer, remov e tie, rings, watches and other jewelry, and roll sleeves up past

the elbows. Rem ove all l oose clothing and confine long hair. Non-slip footwear or anti - skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended peri ods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine whil e tired or under the influence of drugs, al c ohol or any m edication.

11. M ak e c er tain the switch is in the OFF position before connecting the machine to the power supply.

12. M ak e c er tain the machine is properly grounded.

13. M ak e all machine adjustments or maintenance with the machine unplugged f r om the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep saf ety guar ds in pl ace at all tim es when the m achine i s in use, the only excepti on bei ng special

operations such as rabbet c uts which require remov al of the cutter guard. If guards are remov ed for

maintenance purposes or special operations, use extreme caution and replace the guards

immediately when finished.

16. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, br eakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged shoul d

be properly repaired or replaced.

17. P r ov ide for adequate space surroundi ng work area and non-glare, ov er head lighting.

18. K eep the floor around the machi ne cl ean and free of scrap material, oil and grease.

4

Page 5

F

F

blahblahblah

19. K eep v isitors a safe distance from the work area. Keep ch il dren away.

20. M ak e y our workshop chi ld proof with padlock s, m aster switc hes or by removing starter key s.

21. Giv e your work undivi ded attention. Looking ar ound, carryi ng on a conversation and “ horse-play” ar e

careless acts that can r esul t in serious injury.

22. Maintain a bal anced stance at all times so that you do not fall or lean against t he knives or other

moving part s. Do not over r eac h or use exc essive force to perform any machine oper ation.

23. Use the ri ght t ool at the corr ect speed and f eed r ate. Do not forc e a tool or att achment to do a job for

which it was not designed. T he ri ght tool will do the job better and safer.

24. Use recom mended accessories; improper accessories m ay be hazardous.

25. Mai ntain tools with care. K eep knives sharp and clea n for the best and saf est performance. Foll ow

instructions for lubricating and changing accessories.

26. Turn off the mac hine before cl eaning. Use a brush or compressed air to remov e c hi ps or debris — do

not use your hands.

27. Do not stand on the machine. Serious i nj ur y c ould oc c ur if the mac hine tips over.

28. Never leave the machine r unning unatt ended. Turn the power off and do not leave t he machine until

the cutterhead c omes to a complete stop.

29. Remove loose items and unnecessary work pieces from the area bef or e starting the machine.

30. Nev er surface stoc k less than 12 inc hes long, or 3 inches wide, or 3 inc hes thick wit hout a hold- down

or push block.

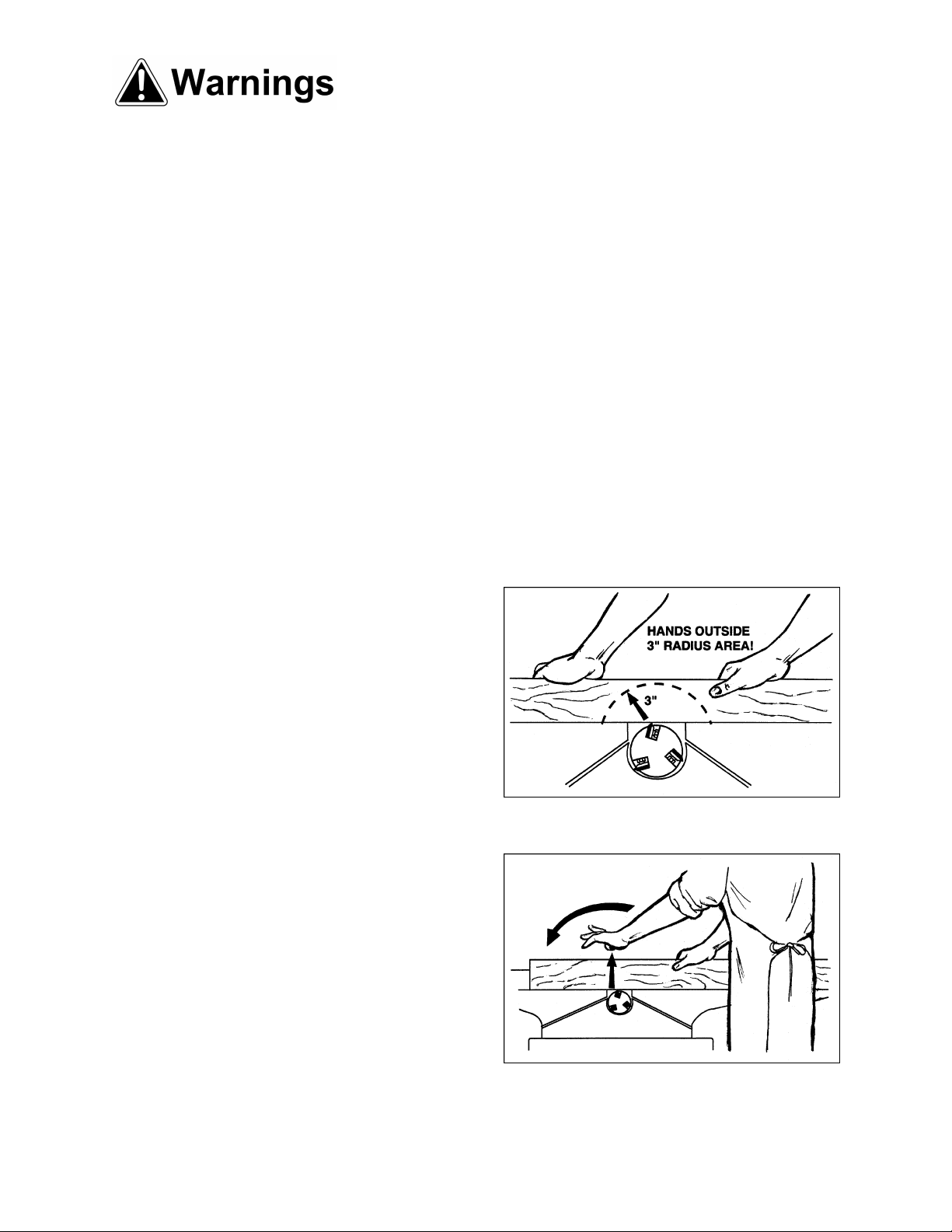

31. When working on the jointer, follow the 3-inch

radius rule. The hands must never be closer than

3 inches to the cutt er head. See Figure A.

32. Use ext ra care in the location of the jointer in the

shop. Position the jointer so that potential kicked

back stock will strike a wall and not endanger

other persons in t he ar ea.

33. Never apply pressure to stock directly over the

cutterhead. This may result in the stock tipping

into the cutterhead along with the operator’s

fingers. Follow the 3-inch rule. Position hands

away from extreme ends of stock, and push

through with a smooth, even motion.

34. “Pull -out ” and the danger of ki ck ed back stock can

occur when the work piece has knots, holes, or

foreign materials such as nails. It can also occur

when the stock is fed against the grain on the

jointer. T he grain shoul d run in the sam e directi on

you are cutting.

35. It is good practice to move the hands in an

alternate motion from back to front as the work

continues through the cut. Nev er pass t he hands

directly over the cutter knife. As one hand

approaches the kniv es, rem ove it from the stoc k in

an arc motion and pl ace it back on the stock in a

position beyond t he cutter knife. See Figure B. At

all times hold the stock firmly.

igure A

igure B

5

Page 6

36. Bef ore attempting to joint or plane, each work piec e must be carefully examined for stock condi tion

and grain ori entation. NOTE: At certain times it may be necessary t o plane against the grai n when

working with a swirl grain wood or burls. W ith this type of work the oper ator must use a lesser dept h

of cut and a slow rate of feed.

Familiariz e y our self with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result i n mi nor i njur y and/or

possible machine damage.

This means that if precautions are not heeded, it may result i n serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

6

Page 7

Introduction

This manual is provided by Powermati c covering the safe operat ion and maintenance pr ocedures for a

Model 1285 Jointer. This manual contains instructions on installation, safety precautions, general

operating proc edures, maintenance i nstructions and part s breakdown. This mac hine has been designed

and constructed to pr ovi de years of troubl e free operation if used in accor dance with instr ucti ons set forth

in this manual . If ther e are any que sti ons or com m ents, please cont act ei t her your loc al suppl ier or W MH

Tool Group. WMH Tool Group can also be reached at our web site: www.wmhtool gr oup.com.

Specifications

Model Number...................................................................................................................................1285

Stock Number (3HP, 1P h, 230V, wit h standar d c utterhead).......................................................... 1791241

Stock Number (3HP, 3P h, 230V/460V*, with standard cutterhead)............................................... 1791249

Stock Number (3HP, 1P h, 230V, with helical cutterhead) ............................................................. 1791307

Stock Number (3HP, 3P h, 230V/460V*, with helical cutterhead)................................................... 1791308

Cutting Capacity (W x D) (in.).................................................................................................. 11-3/4 x 3/4

Cutterhead Speed (RPM)..................................................................................................................5,000

Rabbeting Capaci ty (in.)........................................................................................................................3/4

Table Surface (L x W ) (in.)............................................................................................................. 84 x 12

Outfeed Table Height from Floor (in.)...............................................................................................31-5/8

Fence Size (L x W) (in.)....................................................................................................... 47-1/4 x 5-1/ 4

Fence Tilt (degrees)......................................................................................................90, 45 right, 45 left

Fence Positiv e Stops (deg. ) ....................................................................................................... 45 and 90

Number of Knives – standard cut terhead .................................................................................................3

Number of Inserts – heli c al c utt er head ........................................................................ 44, with 2 rabbeting

Size of knives – standard cut terhead (L x W x T) (in.)........................................................12 x 13/16 x 1/8

Dust Collecti on Minimum CFM Required..............................................................................................800

Approximate Net Weight (lbs.) .............................................................................................................762

Approximate Shipping Weight (lbs.) .....................................................................................................880

*pre-wired 230V

The above specifications were current at the tim e this manual was published, but because of our policy of

continuous im provement, WMH Tool Group reserv es the right to change specif ications at any tim e and

without pri or notic e, without incurring obligations.

7

Page 8

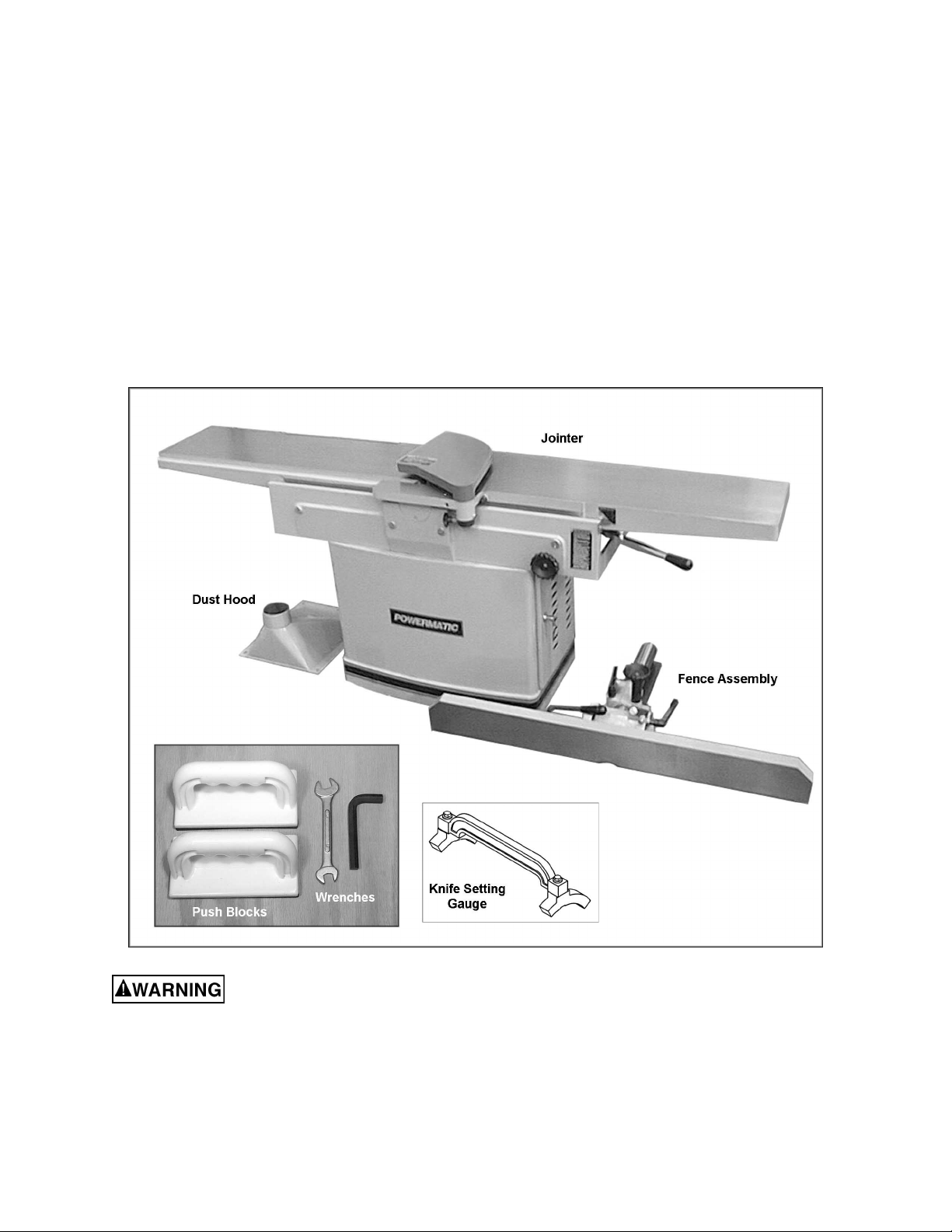

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Compare

the contents of your container with the foll owing

parts list to make sure all parts are intact.

Missing parts, i f any , should be rep orted to y our

distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

NOTE: The wrenches and knife setting gauge

will be found inside the jointer stand.

Contents of the Shipping Container

1 Jointer

1 Fence Assembly

1 Dust Hood

1 Knife Setting Gauge

1 Hex Wrench, 10mm

1 Combination Wrench, 10-12mm

2 Push Blocks

1 Owner's Manual

1 Warranty Card

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mpl y may cause seri ou s injury.

8

Page 9

Assembly

Tools need for assembly:

10mm hex wrench (provi ded)

10-12mm combi nation wrench (provided)

forklift or hoist with straps

cross-point screwdriver

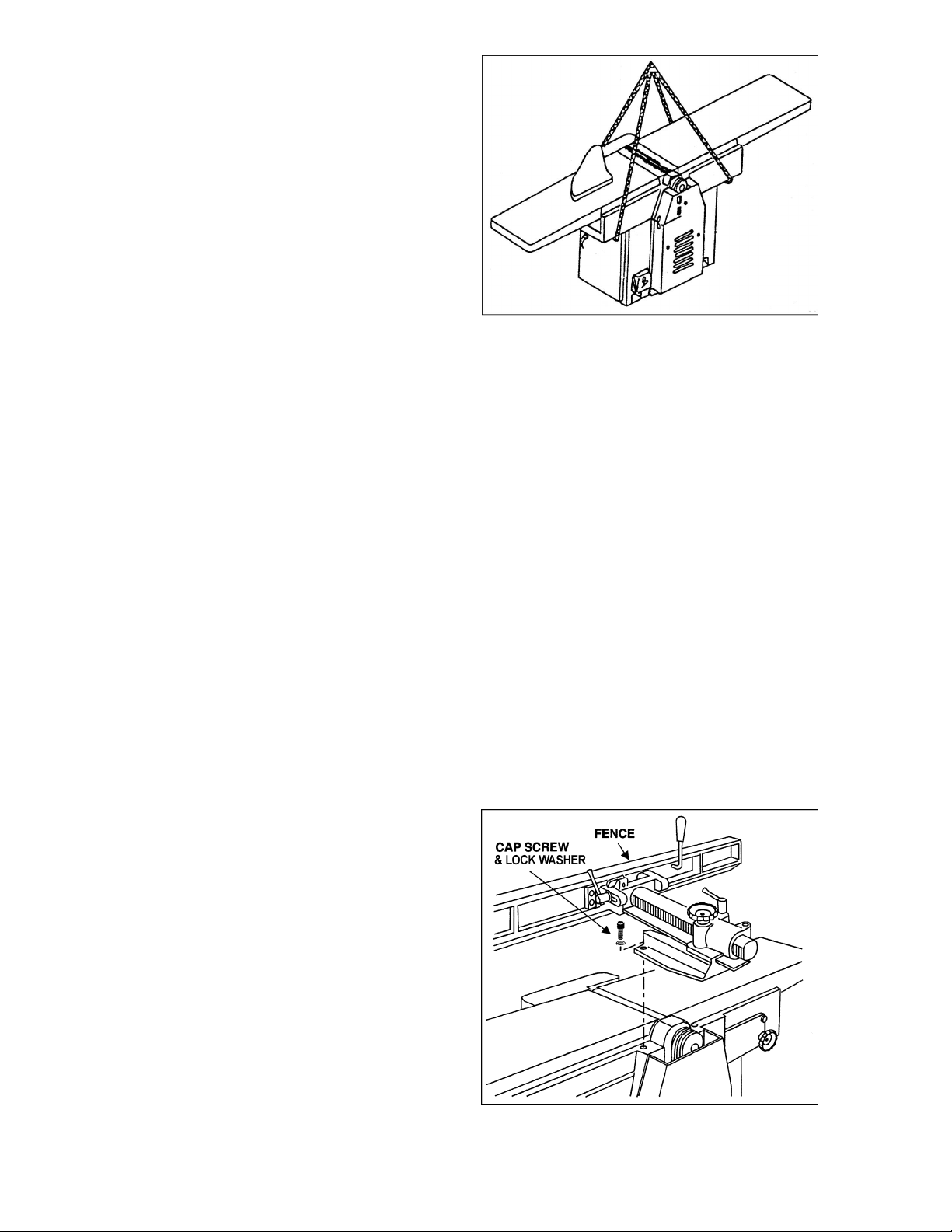

1. Remove top and sides of crat e from around

the machine.

2. Remove the dust hood and the fence

assembly from the skid. Reach into the

stand and remov e the screws securing the

stand to the skid.

3. Raise the jointer off the skid with lifting

straps. The straps should be suitable to lift

762 pounds of weight, and shoul d be plac ed

under the base casti ng as shown in Figure

1. Do not lift the j ointer under t he infeed and

outfeed tabl es.

4. The jointer should be placed on a sturdy,

level floor in a dry area, with sufficient

lighting and v entilation. Leave enough room

around the machine for loading and

offloading stock and routine maintenance

work. The mac hine can be f urther stabi lized

by bolting it to the floor using lag screws

through the holes on the i nsi de of the stand.

5. This machine is equipped with noise-

reducing table lips. The work site should,

however, be one which minimizes

reverberant sound from walls, ceilings and

other equipment.

6. Exposed met al ar eas of the jointer, i ncl uding

the table and fence surfaces, have been

factory coated wit h a prot ectant. This should

be removed wit h a soft clot h dampened wit h

a solvent such as mineral spirits or

kerosene. Do not use ga soline, acetone or

lacquer thinner , and do not use an abrasive

pad. Do not let solvent contact the plastic

parts of the machine, as it may damage

them.

Figure 1

Fence Installation

1. Use an assistant to help place the fence

assembly on top the table, aligning the

holes in the fence assembly with the holes

in the table base, as shown in Fi gur e 2.

2. Use the two socket head cap screws and

two lock washers (Figure 2), and tighten

securely with a 10mm hex wrench.

Figure 2

9

Page 10

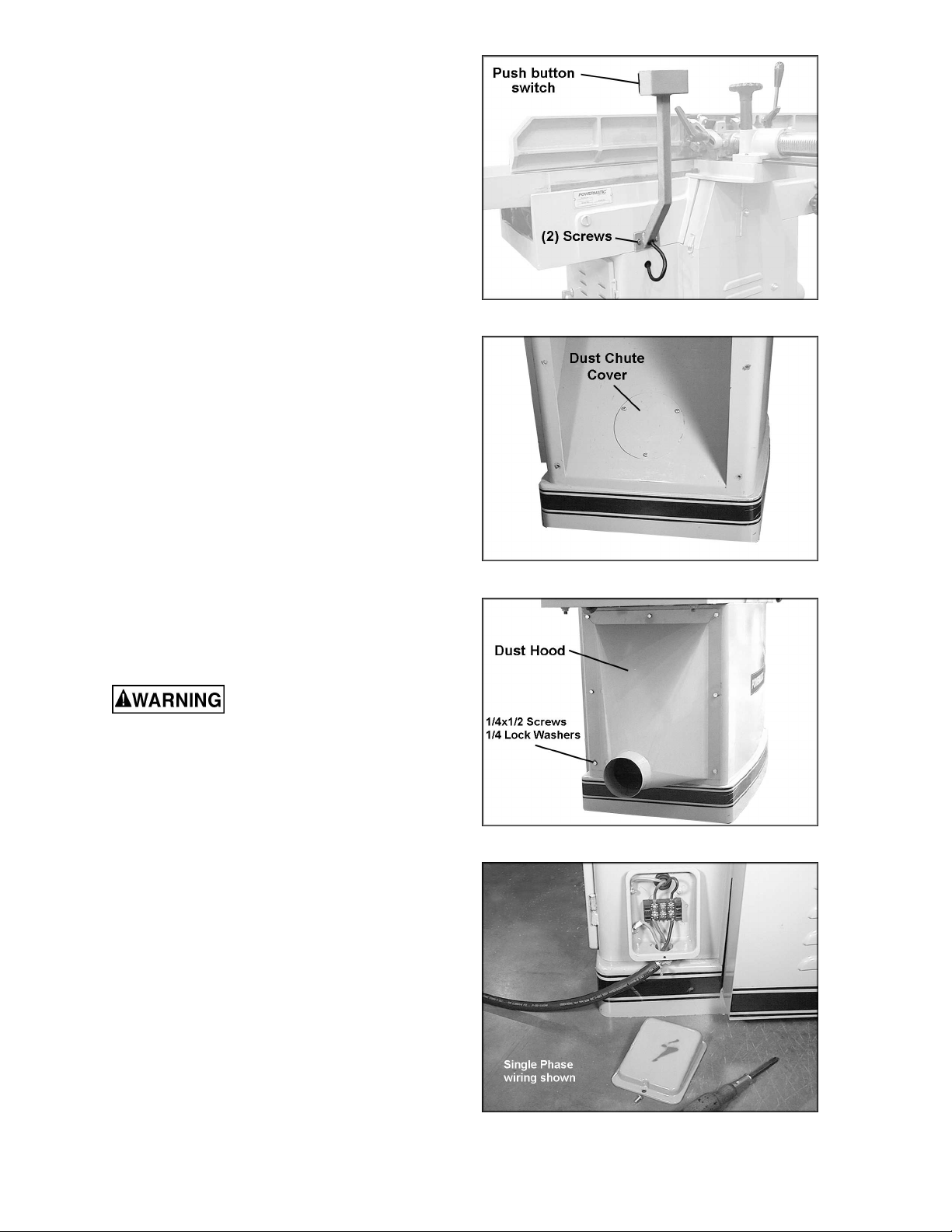

Switch Arm

The arm (Figure 3) on which the push button

switch is l oc ated is shipped in the down posi tion.

The arm should be pivot ed to upright positi on as

shown. Tighten the two screws with a 10mm

wrench.

Dust Hood

Before attaching the dust hood, make sure the

hole in the dust c hute is concealed by the dust

chute cover, as shown in Figure 4.

Mount the dust hood to the jointer stand using

the seven 1/ 4 x 1/2 hex cap screws and seven

1/4 lock washers (Figur e 5) .

It is recom mended that a dust coll ection system

of at least 800 CFM be connect ed to the jointer’s

dust hood, via a 6-inc h diam eter hose.

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

Figure 3

Figure 4

This machine must be grounded. Grounding

provides a path of least resi stance to hel p divert

current away from the operator in case of

electrical malfunction.

Make sure the voltage of your power supply

matches the specif ications on the m otor plate of

the machine.

Open the junction box (Figure 6) and connect

the wires accordi ng t o the di agram on t he inside

of the juncti on box c over. A simi lar diagram can

be found at the back of this manual . The green

wire (ground) m ust be pr operl y gr ounded.

The Model 1285 may be fitted with an

appropriate plug, or be “hard-wired” to an

electric al panel. If hard-wired to a panel, mak e

sure a disconnect is available for the operator.

Figure 5

Figure 6

10

Page 11

If the jointer is to be hard-wired, make sure the

fuses have been r emoved or the breakers hav e

been tripped i n the circuit t o which the saw will

be connected. Place a warning placard on the

fuse holder or ci rcuit breaker to prev ent it being

turned on while the machine is being wired.

Always follow proper Lock-Out/Tag-Out

procedures when per forming any wiring on thi s

machine.

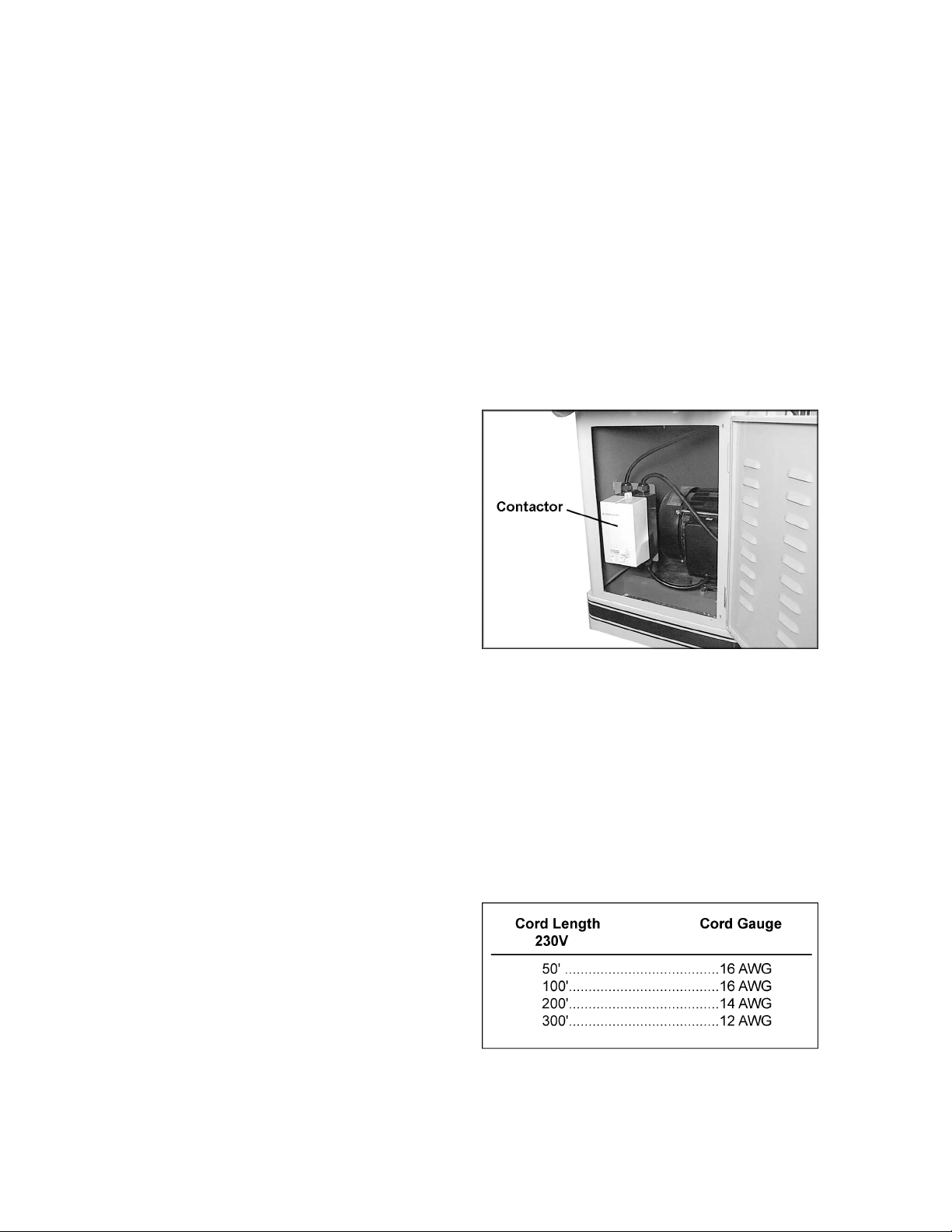

Voltage Conversion

The Model 1285 Jointer is wired for 1-phase,

230 volt only; or 3-phase, 230/460 v olt. The 3phase model i s pre-wired at the f actory for 230

volt. However, if you wish to convert your 3phase joint er from 230 volt t o 460 volt, proceed

as follows:

1. Disconnect machine from power source.

2. Remove cover fr om junction box, and open

the side door on the stand.

3. Change the wires in the junction box by

following the diagram on the inside of the

junction box cover, or the di agram found at

the back of this manual.

4. Replace the 230 volt contactor (see Figure

7) with the 460 volt contactor (stock no.

PJ1285-109). The 460 volt contactor is

available through your authorized

Powermatic distributor, or by calling 1-800274-6848.

5. If you are using a plug on the joi nter’s power

cord, install an appr opr iate 460 volt plug.

6. After wiring f or the new volt age, turn on the

machine and observe the rotation of the

cutterhead; it should be clockwise when

viewed from the front of machine. If it

rotates counterclockwise, disconnect jointer

from power source and switch any two of

the three wires at t he junc tion box.

7. Close junction box and r ec onnec t power.

Extens ion cords

The use of an extension cord is not

recommended, but if one is necessary make

sure the cord rati ng i s suit able f or t he amperage

listed on the machine’s motor plate. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.

Figure 7

Use the chart in Fi gure 8 as a general guide in

choosing the cor rect size cord. If in doubt, use

the next heavi er gauge. The smaller t he gauge

number, the heavier the cord.

Figure 8

11

Page 12

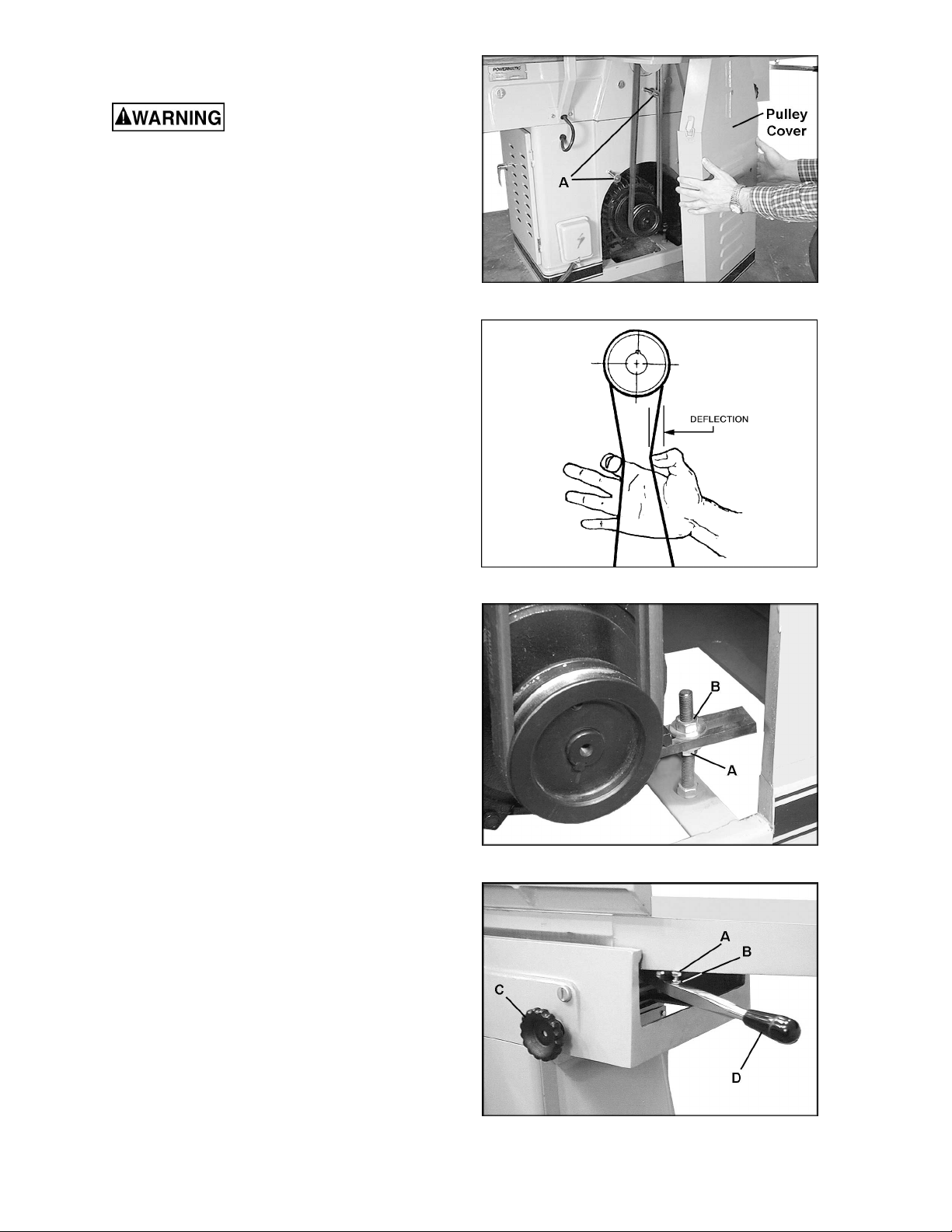

Adjustments

Disconnect jointer from

power supply before makin g ad ju st ments.

Drive Belt Tension

To check the tension of t he drive belts:

1. Rem ove the thr ee cap nuts and fl at washers

on the pulley cover with a 9/ 16 wrench, and

remove the guard to expose the belts and

pulleys. S ee Figure 9.

NOTE: The hex nuts and flat washers on the

threaded rods (A, Figure 9) should be left in

place; they keep t he pulley cover from bending

as it is being ti ghtened back into place with the

cap nuts.

2. There should be a small amount of

deflection in the belt when pressing it

midway between the pul leys with moderate

finger pressure (Figure 10).

3. If the belts need ti ght ening, loosen the l ower

hex nut (A, Figure 11) on the motor base

with a 19mm wrench.

Figure 9

4. Turn the top hex nut (B, Figure 11)

clockwise until proper tension is achiev ed.

5. Retighten lower hex nut (A, Figure 11).

NOTE: The belts should be inspected again

after the first f ew times the machine is used, as

the belts may stretch slightly during the

“breaking-in” process.

Setting Outfeed Table Height

For accurate work in most jointing operations,

the outfeed tabl e must be exactly level with the

knives/insert s at thei r highest poi nt of rev olution.

The outfeed table on t he Model 1285 has been

pre-set at the factory to the proper height in

relation to t he cutterhead. Howev er, the level of

the outf eed table should be checked i n case of

slight misadjustment during shipping. Outfeed

table height should also be inspected after resetting or replac ing knives/inserts.

1. The outfeed table has a stop screw (A,

Figure 12) whic h, when contact ing the edge

of the table as shown, will ensure the

outfeed tabl e is at the proper height . Loosen

the handwheel (C, Figure 12) and raise the

outfeed tabl e adjustment arm (D, Figure 12)

until thi s stop screw (A, Fi gure 12) contact s

the edge of the table as shown.

Figure 10

Figure 11

Figure 12

12

Page 13

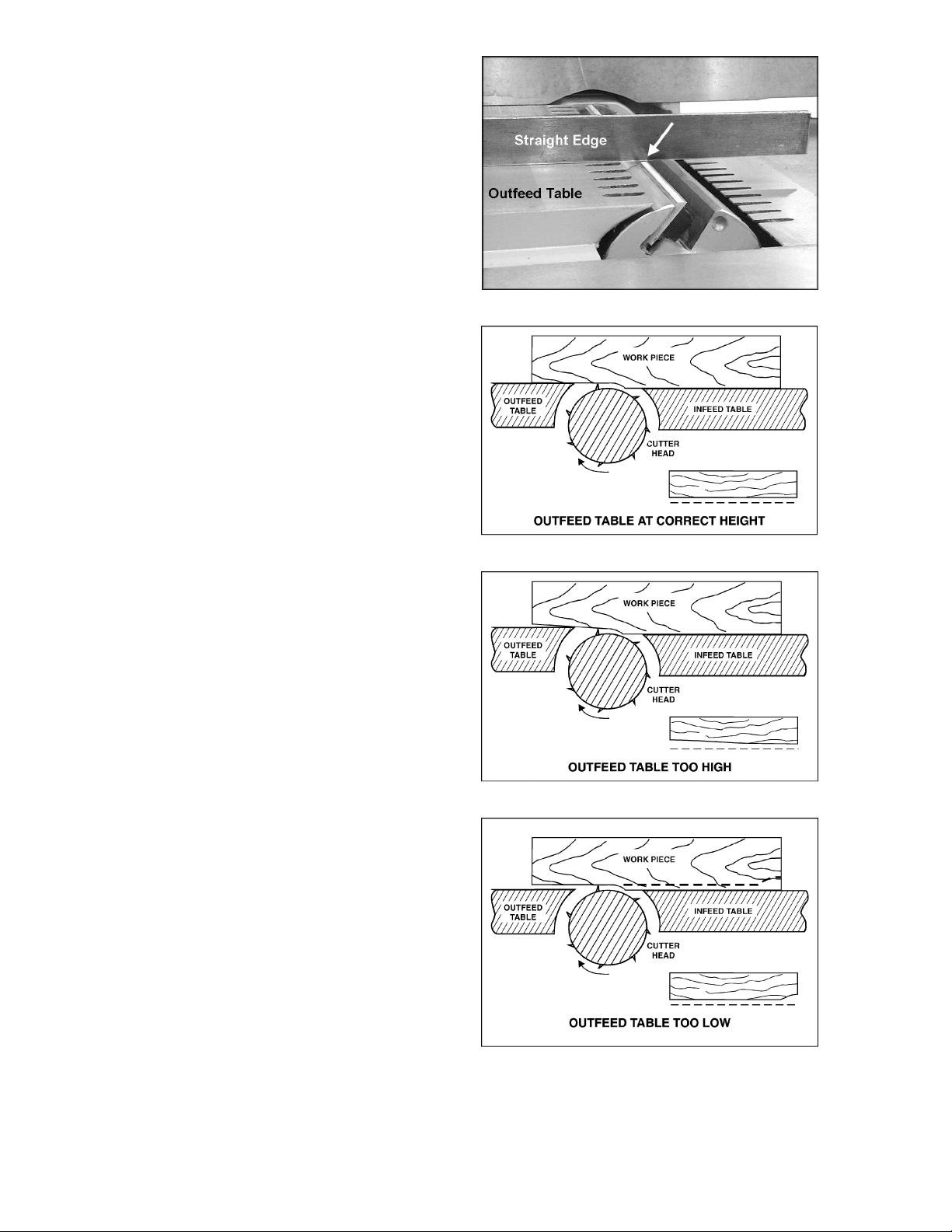

2. Place a straight edge on the outfeed table

and extending over the cutterhead, as

shown in Figure 13.

3. Rock the cut terhead slightly so that a knife

tip contacts the st raight edge. If the knif e tip

just contacts the straight edge without

moving the straight edge, then the outfeed

table is at the pr oper height. If the knife tip

pushes up the straight edge, the outfeed

table is too low. If the knife tip does not

contact the str aight edge, the outfeed tabl e

is too high.

4. To raise the height of the outfeed table,

loosen the hex nut (B, Fi gure 12) and rotate

the stop scre w (A, Figure 12) cl ockwise. To

lower the height of the outfeed table, rotat e

the stop screw (A, Figure 12) counter

clockwise.

5. When the outfeed table is level with the

knives, tighten the hex nut (B, Figure 12)

and firmly tighten the handwheel (C, Figure

12).

After the outfeed table has been set, it should

not be changed except f or speci al operations.

As a final check of the outf eed tabl e adjustment ,

turn on the jointer and run a scrap piece of wood

slowly over the knives for 6 to 8 inches; the

wood should rest firmly on both tables, as

shown in Fi gure 14, with no open space under

the finished cut.

If the outfeed table is too high, the finished

surf ace of the workpiece will be curved (Figure

15).

Figure 13

Figure 14

Figure 15

If the outf eed tabl e i s too l o w, the workpiece wil l

be gouged at the end of the cut (Fi gur e 16) .

Make further changes to the stop screw if

necessary to ensure the outfeed table is level

with the knives/inserts.

Figure 16

13

Page 14

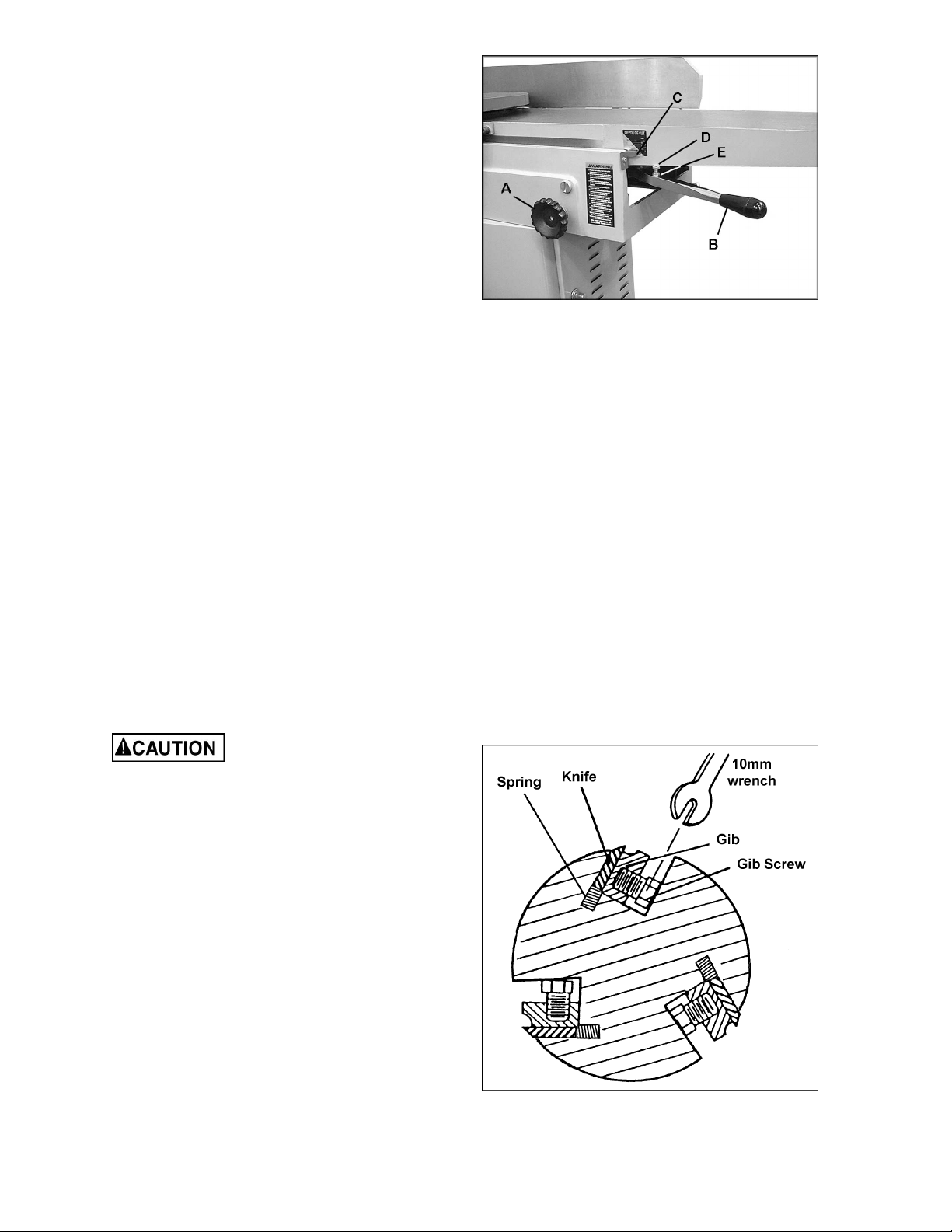

Setting Infeed T able Height (Depth of

Cut)

1. To set t he cutting depth, loosen handwheel

(A, Figure 17) by turning counterclockwise.

2. Move table adjustment arm (B, Figure 17)

up or down to raise or lower infeed table.

The pointer (C, Figur e 17) shows the depth

of cut on the adjoining scale.

3. Tighten handwheel securely (A, Figure 17).

The stop screw (D, Figure 17) on the infeed

table should be set so that when it cont acts the

table, t he infeed table will be ex actly level with

the knives (wit h the scale pointer at zero). The

setting of this stop screw has bee n made at the

factory, but should be checked by the operat or

before using the jointer. It should also be

checked occasionally as the machine receives

use.

Use the same procedure as for the outfeed

table, placing the straightedge across outfeed

table, cutterhead and infeed table. Loosen the

hex nut (E, Figure 17) and adjust t he stop screw

(D, Figure 17) as necessary. When finished,

retighten hex nut (E, Figure 17).

If the infeed t abl e is lev el wit h the kniv es but the

scale pointer (C, Figure 17) appears to be off,

loosen the scale poi nter with a screwdriv er and

adjust it as needed unti l it reads zero. Ret ighten

the screw.

Replacing and Setting Knives (Straight Cutterhead)

Figure 17

Jointer knives are very

sharp. Use care and proceed slowly when

working with or around the cu t t erhead .

After a period of use, dull knives should be

reground or repl aced. Remove the pul ley cover

at the rear of the machine – this will allow you to

rotate the cutt erhead by using the belts.

To remove a knife:

1. Disconnect machine from power source.

2. Back the f ence away f rom the cutt erhead as

far as it will go. Lower infeed and outfeed

tables.

3. Tur n the six gib screws (Figure 18) into t he

gib with a 10mm wrench. A s the pressure of

the gib is released, the two springs in the

cutterhead slot wil l c ause the k nife to rise.

4. Carefully remove the knife from the

cutterhead.

Figure 18

14

Page 15

5. It is recommended when replacing knives

that you clean the knife slots in the

cutterhead. Rem ove the gib along with the

gib screws, and remove the two springs.

Clean the cutterhead slot of any debris or

dust that might prevent the knife from

seating properly. Also clean the gib, gib

screws, and spring s. Closely i nspect the gi b

screws – if the threads appear worn or

stripped, or if the heads are becoming

rounded, replac e the screws.

6. Re-insert the springs and the gib.

7. Place t he new or resharpened k nif e into t he

slot as shown in Fi gure 18, maki ng sure the

direction of the knife is correct.

8. Place the knife setting gauge (provided)

upon the cutterhead and centered over a

knife, as shown in Figure 19. Make sure the

feet of the knife setting gauge rest solidly

upon the cutterhead and that its handle is

parallel t o the c utt erhead. T he gauge i s now

holding the knife at proper depth.

9. While keeping the knife setting gauge in

place, tighten t he six gib screws just enough

to hold the knife in position. Start with the

center screws first, and work your way

toward the end screws.

10. Repeat steps 3 through 9 f or the other two

knives in the cutterhead. Make the gib

screws just ti ght enough to hold the kniv es

in position.

With all three jointer knives in the cutterhead,

the knives should now be tightened

incrementally to prevent any buckling or

distortion of the cutterhead. Proceed as foll ows:

11. Rotate the c ut terhead to each knife in turn,

tightening the gib screws a little more

(center screws first, then toward the end

screws). Do this at least twice; on the final

rotation, fi rmly tighten all gib screws.

After replaci ng and checking

knives, check again carefully. Make certain

the direction of knives is correct, and all

eighteen gib screws are tightened securely.

Loose gib screws can result in knives being

thrown from the cutterhead, causing severe

damage to the machi ne and po ssible serio us

or fatal injury to the operator or bystanders.

Figure 19

15

Page 16

Replacing Knife Inserts (Helical Cutterhead)

Jointer kni fe inserts are very

sharp. Use care and proceed slowly when

working with or around the cu t t erhead .

The helical cutterhead is a solid steel design

that holds 44 two-sided knife inserts, and two

rabbet knif e inserts on the outboard end of the

cutterhead. Replacing knife inserts is a simple

process, and they will seat themselves properly

without having to be set with a knife gauge.

After a period of use, dul l knife inserts should be

flipped over to present a new edge. If both

edges are worn, knife inserts should be

replaced.

1. Loosen the gib screw (A, Figure 20).

2. Rem ove the knife insert ( B, Figure 20) with

the gib (C, Figure 20) f r om its slot .

3. Make sure t he slot (D, Fi gure 20) is free of

dust and debris that would prevent the gib

and insert from seating properly. Wipe out

the slot and clean wit h solvent if needed.

4. Flip the knife insert 180 degree s and place it

onto the two pins of t he gib. Make sure the

knife edge faces the proper direction (see

Figure 21).

5. Re-install the gib into the slot.

6. Firmly tighten the gib screw (A, Figure 20).

NOTE: To ensure optimal cutting, all knife

inserts in the c utt erhead should be f lipped at the

same time. Of course, if an insert is nicked or

damaged, it can be flipped or replaced

individually as needed.

After install ing a knife insert, be sure to ti ghten

the gib screw befor e m oving on to t he next knife

insert.

Figure 20

Figure 21

Make certain the direction of

knife inserts is correct, and all gib screws

are tightened securely. Loose gib screws

can result in kn ife insert s being thrown fro m

the cutterhead, causing severe damage to

the machine and possible serious or fatal

injury to t he ope r a tor or by s t a n de r s .

16

Page 17

Fence Adjustments

The fence (A, Figure 22) tilts backward and

forward to 45 degrees. I t has a 90-degree stop

(B, Figure 22) and a 45-degree stop (C, Figure

22).

To tilt fence forw ard:

1. Loosen the lock handl e (D, Figure 22) and

tilt the fence forward using the handle (E,

Figure 22). NOTE: Lift up slightly on the

fence while tilting it, to prevent scratching

the table surface.

2. Retighten lock handle (D, Figure 22).

To tilt fence backw ard:

1. Loosen the lock handl e (D, Figure 22) and

pivot the stop bl oc k (F , Fi gure 22) out of the

way.

2. Tilt the fence using the handle (E, Figure

22). NOTE: Lift up slightly on the fence

while tilti ng it to prevent scratching the t able

surface.

3. Retighten lock handle (D, Figure 22).

To move fence forward or backward:

1. Loosen lock handle (G, Figure 22) and

rotate handwheel (H, Figure 22);

counterclockwise for forward fence

movement, clockwise for backward fence

movement.

2. When desi red position is reached, securel y

tighten lock handle (G, Figure 22).

To check and adjust the 90-d egree stop :

1. Loosen lock handle (D, Figure 23) and tilt

fence until the stop screw (B, Figure 23)

contacts the stop block (F, Figure 23).

Figure 22

2. Place a square or machini st’s protractor (not

provided) on t he table and flush against t he

fence surface. S ee Figure 23.

3. If adjustment is necessary, loosen the hex

nut on the stop screw (B, Figure 23) and

turn the stop screw as needed until the

fence is flush with your square.

4. Retighten the hex nut .

Figure 23

17

Page 18

To check and adjust the 45-d egree stop :

1. Loosen lock handle (D, Figure 22) and tilt

fence until it contacts the 45-degr ee stop (C,

Figure 22).

2. Place a machinist’s protractor or similar

device set at 45 degrees on the table and

against the fence.

3. If adjustment is necessary, loosen the hex

nut on the stop screw (C, Figure 22) and

turn the stop screw until the fence is flush

with the protr actor .

4. Retighten the hex nut .

Cutte r Guard Tension

The tension of the guard (Figure 24) must

always be suffic ient during jointer operations to

cause the guard to conceal the unused part of

the cutterhead, and to s wing back t o cont act t he

fence after the workpiece has cleared the

cutterhead. To adjust the guard tension:

1. Loosen the knob shown in Figure 24 and

push the knob to the ri ght to incr ease guard

tension; or to the left to decrease guard

tension.

2. Tighten the knob in that position.

Operating Controls

The push button on/off switch is conveniently

positioned above the table (Figure 25). Do not

remove the clear plastic cover, as this keeps

wood dust out of the switch.

Operation

NOTE: If y ou are inexperienced at jointing, use

scrap pieces of lumber to c hec k set tings and get

the feel of operati ons before attem pting regular

work.

Always use the guard

whenever possible and keep hands away

from cutterhead. Failure to comply may

cause serious injury.

Ideally, the fence should be moved forward

(toward the f r ont of the m achine) to ex pose only

the amount of cutterhead needed for the

workpiece.

Figure 24

Figure 25

TIP: If workpieces of the same size are

constantly bei ng run on the joi nter, the operator

may wish to occasionally adjust the fence

forward or backward to prevent wear on only

one area of the knives.

18

Page 19

Hand Placement

At the start of the cut, the left hand holds the

workpiece firmly against the infeed table and

fence, while the right hand pushes the

workpiece toward the knives. After the cut is

under way, the j ointed surf ace of the workpi ece

rests firmly on the outfeed table. The left hand

should press down on this part, at the same time

maintaining flat contact of the workpiec e with the

fence. The right hand pushes the workpiece

forward and before the right hand reaches the

cutterhead, the right hand shoul d be moved to

the workpiece on the outfeed table. The

workpiece is then pushed on through to

complete the cut. Follow the 3-inch rule (see

page 5). Never pass hands directly over the

cutterhead.

Edge Jointing

This is the most common operation for the

jointer. S et the fence to the 90-degree stop and

thus square with the t able. Depth of cut should

be the minimum required to obtain a straight

edge. Do not m ake cuts deeper than 1/8” in a

single pass. Hol d the be st f ace of t he workpiec e

firmly against the fence throughout the feed.

See Figure 26.

Surfacing

Figure 26

Jointing the fac e of stock, or surfacing is shown

in Figure 27. Adjust the infeed tabl e for depth of

cut. Cuts of approximately 1/16” at a time are

recommended, as this allows better control over

the material being surfaced. More passes can

then be made to reach the desir ed depth.

Always use a hold-down or

push block when surfacing short stock or

stock less than 3 inches thick. Figure 26

shows push blocks being used fo r surfacing.

Rabbeting

A rabbet is a groove cut along the edge of a

workpiece. See Figure 28. The width and

thickness of the workpiece used will be

dependent upon the de sired width and l ength of

the rabbet. However , never rabbet a workpiece

less than 12 inches long.

A rabbet cut requires

removal of the cutterhead guard. Use

extreme caution and keep hands clear of

cutterhead. Always replace guard

immediately after rabbeting operation is

completed.

Figure 27

Figure 28

19

Page 20

Use push blocks to rabbet cut whenever

possible. The rabbeting capacity is 3/4”.

1. Disconnect machine from power source.

2. Set fence for desir ed width of rabbet.

3. Check width of the r abbet by m easuring the

distance from the end of a knife in the

cutterhead to the fence.

4. Reconnect power. Lower the infeed table

1/32” at a time and make successive cuts

until the desired depth of rabbet has been

obtained. See F igure 28. NOTE : It is easier

and safer to take a seri es of shall ow cuts.

Jointing Warped Surfaces

If the wood to be jointed is di shed or warped,

take light cuts until the surface is flat. Avoid

forcing such material down against the tabl e;

excessive pressure will spring it while passing

the knives, and it will spring back and remain

curved after the cut is completed.

Jointing Short or Thin Work

When jointing short or thin pi eces, use a push

block to elimi nate all danger to t he hands. Two

push blocks are shipped with your jointer, and

additional ones (stock no. 6285917) can be

purchased fr om your distri butor or by calling 1800-274-6848. You can also make your own

easily from scrap material. Three types of

commonly used push block s are represented in

Figure 29.

Direction of Grain

Avoid feeding work into the jointer against the

grain. This will result in chipped and splintered

edges. See Figure 30. Feed with the grain to

obtain a smooth surfac e, as shown in Figure 31.

Beveling

To cut a bevel, lock the fence at the required

angle and run t he workpiece across the kniv es

while keeping it firmly against the fence and

tables. Several passes may be necessary to

achieve the desi r ed r esul t.

Figure 29

Figure 30

While the fence can be tilt ed in or out for bevel

cutting, it is recommended for safety reasons

that the f ence be ti lted i n toward the operat or, i f

possible, making a cradled cut.

Figure 30

20

Page 21

Maintenance

Disconnect machine from

power source before performing any

maintenance. Failure to comply may cause

serious injury.

Check all screws and f astener s occasionally and

keep them tightened secur ely.

Inspect cords; a cord t hat is frayed or dam aged

in any way should be replac ed immediately.

The table and fence surfaces must be kept

clean and free of rust for best results. Some

users prefer a paste wax c oating. Another opti on

is talcum powder applied with a blackboard

eraser rubbed in vigorously once a week; this

will fill casting pores and form a moisture barrier.

This method provides a table top that is slick

and allows rust ri ngs to be easil y wiped from the

surface. Important also is the fact that talcum

powder will not stain wood or mar finishes as

wax pickup does.

Lubrication

The cutterhead runs in two single-row sealed

and shielded ball bearings, which are prelubricated for life - no maintenance is necessary.

Occasionally apply a good grade of light grease

to areas of the joint er where fricti on may occur,

such as when the tables are raised or lowered.

Cutterhead Repairs

The entire cutterhead assembly may be

removed for bearing replacement or other

cutterhead maintenance procedures. The

procedure is identical for both helical and

straight cutt er heads.

To remove the cutterhead:

1. Disconnect machine from power source.

2. Remove rabbeti ng ledge and fence.

3. Lower infeed and outfeed tables until they

are clear of the cutterhead.

4. Remove belts.

5. Remove the two hex cap screws and lock

washers that hold t he cutterhead to the bed

– these are accessed fr om the underside of

the bearing block s as shown in Figure 32.

Before removing cutterhead,

wrap it with several cloths to prevent

perso nal inju r y .

Figure 32

21

Page 22

6. Slide the cutt er head out the rabbeting side.

7. Loosen hex cap screw (A, Figure 33) and

remove pulley (B, Figure 33) and key (C,

Figure 33).

8. Loosen screws (D, Figure 33) on both sides

and remove bearing cap plates (E, Figure

33).

NOTE: Figure 33 shows the pulley end of

the cutterhead. The procedure is sim ilar for

breaking down the opposite end of the

cutterhead - refer to assembl y drawing on

page 39 for the specifi c parts.

IMPORTANT: If the bearings (G, Figure 33)

need replacement, it is strongly recommended

this be done by qualif ied service personnel . The

bearings are press f itted and must be removed

with an arbor press.

9. To re-install the cutterhead, reverse the

above procedure. NOTE: Before reinstalling, make sure the machine’s curved

seats of the base casting are free of dirt,

dust or grease, whi c h will help ensure a ti ght

fit.

Knife Inserts (Helical Cutterhead)

When knife insert s become dull enough so that

it is noticeable when cutting, they should be

turned over or replaced entirely. A sharp knife

works easier and results in longer blade life. The

penalty pai d for a dull k nife is less blade l if e and

greater wear and tear on all parts of the

machine.

An advantage of the helical style cutterhead is

that if knif e inserts develop nicks, these insert s

can be individually flipped or replaced without

the need to disturb the other inserts. See

“Replacing Knife Inserts (Helical Cutterhead)”

for this procedure.

If the jointer is used oft en, keeping a spare set

of knife inserts on hand is recom mended. Knife

inserts (stock no. 6400013) may be ordered

from your authorized Powermatic distributor or

by calling 1-800-274- 6848.

Gum and pitch which c ollect on the knif e inserts

cause excessiv e friction as the work cont inues,

resulting in overheating of the inserts, less

efficient cutting, and consequent loss of blade

life. Use "Gum and Pitch Remover" or oven

cleaner, to carefully wipe off the knife inserts.

Figure 33

Jointer kni fe inserts are very

sharp. Use care and proceed slowly when

working with or around the cu t t erhead .

22

Page 23

Whetting Knives (Straight Cutterhead)

When knives become dull enough so that it is

noticeable when cutting, they should be

resharpened or repl aced. A sharp knif e will work

easier and last longer. The penalty paid for a

dull knif e is less blade life and greater wear and

tear on all parts of t he machine.

Jointer knives are very

sharp. Use care and proceed slowly when

working with or around the cu t t erhead .

1. Disconnect machine from power source.

2. Rem ove the pulley cover so you can r otate

the cutterhead by means of t he belts.

3. Use a fine carborundum stone. Cover it

partly wit h paper, as shown in Fi gure 34, to

avoid marking the table.

4. Lay t he stone on the i nf eed table. Adjust the

infeed table and t urn the cutter head until t he

stone lies f lat on the bev el of the knife and

flat on the infeed table.

Figure 34

5. Hold the c utterhead from turning, and whet

the beveled edge of the knife, stroking

lengthwise by sliding the stone back and

forth across the tabl e. Do the same amount

of whetting on each of the thr ee k niv es.

6. When finished, reset the knives parallel to

the outfeed table. See “Setting Knives

(Straight Cutterhead)”.

If knives cannot be properly retouched as

described above, they must be ground and resurfaced to a new bevel edge. Check in the

phone directory under “Sharpening Service” or

“Tool Grinding or Sharpening.” It may be less

expensive to purchase a new set of knives. If

the joint er is used often, keeping a spare set of

knives on hand is recomm ended.

Knives (stock no. 6292535) may be ordered

from your authorized Powermatic distributor or

by calling 1-800-274- 6848.

Gum and Pitch which collect on the knives

cause excessiv e friction as the work cont inues,

resulting in overheating of the knives, less

efficient cutting, and consequent loss of blade

life. Use "Gum and Pitch Remover" or oven

cleaner, to carefully wipe off the knives.

23

Page 24

Troubleshooting – Operating Problems

Trouble Probable Cause Remedy

Finished stock i s

concave on back

end.

Finished stock i s

concave on front end.

Finished stock i s

concave in the

middle.

Ends of finished

stock are cut more

than the middle.

Knife is higher than outfeed table.

Outfeed table is higher than knife.

Both tables have t oo much end f all . Raise both table ends using the

Table ends are rai sed hi gher than t he

middle.

Raise outfeed table until it aligns with

tip of knife. (see page 13)

Lower outfeed table until it aligns with

tip of knife. (see page 13)

adjustment screws below the t ables

(see Figure 35).

Figure 35

Lower both table ends using the

adjustment screws under the tables

(see Figure 35).

Chip out.

Fuzzy grain.

Cutterhead slows

while operating.

“Chatter” marks on

workpiece.

Cutting against the grain. Cut with the grain whenev er possible.

Dull knives/i nsert s. Sharpen or replac e k niv es/inserts.

Feeding workpiec e too fast. Use slower rate of feed.

Cutting too deepl y. Make shallower cuts.

Knots, imperfections in wood.

Wood has high moistur e c ontent. Allow wood to dry or use diff er ent stock.

Dull knives/i nsert s. Sharpen or replac e k niv es/inserts.

Feeding workpiec e too quickly, or

applying too much pressure to

workpiece.

Knife/inserts incorrectly set.

Feeding workpiec e too fast.

Inspect wood closely for imperfections;

use different stock if necessary.

Feed more slowly, or appl y l ess

pressure to workpiece.

Set knives properl y usi ng pr ov ided k nife

setting gauge (straight cutterhead onl y

– see page 15). Check that insert sl ots

are clean and free of dust or debri s

(helical cutterhead only).

Feed workpiece slowly and

consistently.

24

Page 25

Trouble Probable Cause Remedy

Uneven knife marks

on workpiece.

Knives/inserts are knicked, or out of

alignment.

Replace knicked k nives/inserts; align

knives properl y with knife-setting gauge

(straight c utt er head only).

Troubleshooting – Mec hanical and Elect rical Problems

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly t rips

circuit breaker or

blo ws fu ses.

No incoming power.

Overload aut omatic reset has not

reset.

Jointer frequently trips.

Building circuit breaker trips or fuse

blows.

Motor starter failure.

Verify unit is connected to power, and

on-switch i s pushed in com pletely.

When jointer overloads on the circuit

breaker built into the motor starter, it

takes time for the machine to cool

down before restar t. Allow unit to

adequately cool bef ore attempting

restart. If pr oblem persists, check

amp setting on the mot or start er

inside the electrical enclosure.

One cause of overl oading trips which

are not electric al in nature is too

heavy a cut. The solution is to take a

lighter cut. If too deep a c ut is not t he

problem, then chec k the amp setting

on the overload rel ay . Match the full

load amps on the motor as noted on

the mo tor plate. If amp se tting is

correct then ther e is probably a loose

electric al lead. Check amp setting on

motor starter.

Verify that jointer is on a circuit of

correct size. If circuit size is correct,

there is probabl y a loose el ectr ic al

lead. Check amp setting on motor

starter.

If you have access to a voltmeter, you

can separate a starter f ailure from a

motor fai lu re by fi r st, verify ing

incoming voltage at 220+/-20 and

second, checking the voltage

between starter and motor at 220+/-

20. If incoming voltage is incorrect,

you have a power supply problem. If

voltage between start er and m otor is

incorrect, y ou hav e a starter pr oblem.

If voltage bet ween start er and m otor

is correct, you hav e a motor pr oblem .

Motor overheat ed.

Clean motor of dust or debri s to allow

proper air circulation. Allow motor to

cool down before r estar ting.

25

Page 26

Trouble Probable Cause Remedy

Motor failure.

Miswiring of the unit.

On/off switch failure.

If electri c mot or i s suspect, you have

two options: Have a qualified

electrician test the motor for function

or remove the motor and take it t o a

qualified elec tric motor repair shop

and have it tested.

Double check to confirm all electrical

connections are cor r ec t and properly

tight. The elect ri c al c onnec tions other

than the motor are pre- assembled

and tested at the factory. Therefore,

the motor connections should be

double checked as the highest

probability for error. If problems

persist, double c hec k the factory

wiring.

If the on/off switch is suspect, you

have two options: Hav e a qualified

electrician test the switch for function,

or purchase a new on/off switc h and

establish if that was the pr oblem on

changeout.

26

Page 27

Optional Accessori es

6292535 12” Jointer Knives (set of 3)

6400013 Carbide Insert Knives for Heli c al Head (set of 10)

PJ1696-011 Rabbet Inserts for Helic al Head (set of 2)

PJ1285-109 Contactor, 3P h, 460V

6285917 Push Block

Replacement Parts

Replacement part s are li sted on the f ollowing page s. To order par ts or reac h our servi ce depar tment, call

1-800-274-6848 between 7:00 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve you quic kly and

accurately.

27

Page 28

Parts List: Stand Assembly

Index No. Part No. Description Size Qty

1...............PJ1285-101............. Stand........................................................... .........................................1

2...............TS-0680041............ Flat Washer.................................................3/8”...................................4

3...............TS-0720091............ Lock Wash e r ................................................3/8”...................................4

4...............TS-0060051............ Hex Cap Screw............................................3/8”-16x1”.........................4

5...............6292491.................. Cover, Dust Chute....................................... .........................................1

6...............TS-081C022............ Machine Screw, Pan Head, Phillips..............#10-24x3/8”....................... 5

7...............6292493.................. Motor Assembly, Motor With Pulley..............3HP, 3Ph..........................1

................. 6295366.................. Motor Assembly, Motor With Pulley..............3HP, 1Ph..........................1

8...............6292494.................. Plate, Switch................................................ .........................................1

9...............6295112.................. Contactor.....................................................1Ph ...................................1

................. 6292495.................. Contactor.....................................................3Ph, 230V.........................1

................. PJ1285-109............. Contactor.....................................................3Ph, 460V.........................1

10.............PJ1285-110............. Clamp..........................................................3Ph...................................3

................. PJ1285-110A .......... Clamp..........................................................1Ph...................................3

11.............6292497.................. Box, Junction............................................... .........................................1

12.............6292498.................. Strip, Ter m ina l............................................. .........................................1

13.............TS-081C062............ Machine Screw, Pan Head, Phillips .............#10-24x1” .........................2

14.............TS-0720051............ Lock Wash e r................................................#10...................................2

15.............PJ1696-211............. Switch.......................................................... .........................................1

16.............PJ1285-116............. Hood, Dust .................................................. .........................................1

17.............TS-0720071............ Lock Wash e r................................................1/4”...................................9

18.............TS-0050011............ Hex Cap Screw............................................1/4”-20x1/2”......................7

19.............6292507.................. Cover, Pulley............................................... .........................................1

20.............6292508.................. Bolt.............................................................. .........................................3

22.............TS-0561031............ Hex Nut.......................................................3/8”-16..............................6

23.............TS-059303.............. Cap Nut.......................................................3/8”-16..............................3

24.............6292510.................. Door, Access............................................... .........................................1

25.............6292511.................. Hand Assembly ........................................... .........................................1

26.............PJ1285-126............. Washer........................................................3/8”x3/4 OD......................1

27.............PJ1696-210............. Switch Arm .................................................. .........................................1

28.............TS-1533052............ Machine Screw, Pan Head, Phillips..............M5x16...............................2

29.............PJ1285-129............. Switch Cord................................................. .........................................1

30.............PJ1285-130............. Motor Cord ..................................................1Ph...................................1

................. PJ1285-130A .......... Motor Cord..................................................3Ph...................................1

31.............PJ1285-131............. Power Cord .................................................1Ph...................................1

................. PJ1285-131A .......... Power Cord .................................................3Ph...................................1

32.............3312341.................. Powermatic Logo......................................... .........................................1

28

Page 29

Stand Assembly

29

Page 30

Parts List: Table Assembly

Index No. Part No. Description Size Qty

1...............6292525.................. Base............................................................ .........................................1

2...............6292526.................. Bar, Tabl e Raising Link................................ .........................................2

3...............6292527.................. Bracket........................................................ .........................................2

4...............TS-0680041............ Lock Wash e r ................................................3/8”...................................8

5...............TS-0209051............ Socket Head Cap Screw..............................3/8”-16x1”.........................4

6...............6292530.................. Bushing....................................................... .........................................8

7...............6292531.................. Support........................................................ .........................................8

8...............6292532.................. Bushing....................................................... .........................................8

9...............6292533.................. Axis, Pivot.................................................... .........................................4

10.............6292534.................. Screw.......................................................... .........................................2

11.............TS-0680061............ Flat Washer.................................................1/2”...................................2

12.............6292536.................. Handwheel .................................................. .........................................2

13.............6292537.................. Handle......................................................... .........................................2

14.............TS-0209061............ Socket Head Cap Screw ..............................3/8”-16x1-1/4”...................4

15.............TS-1490041............ Hex Cap Screw............................................M8x25...............................2

16.............TS-1540061............ Hex Nut.......................................................M8 ....................................4

17.............6292540.................. Knob............................................................ .........................................2

18.............6292541.................. Axis, Pivot.................................................... .........................................8

19.............TS-0208071............ Socket Head Cap Screw ..............................5/16”-18x1-1/4”.................8

20.............6292543.................. Bar,Table Raising Link................................. .........................................2

21.............6292544.................. Axis, Pivot.................................................... .........................................4

22.............6292545.................. Screw.......................................................... .........................................8

23.............TS-0561031............ Hex Nut.......................................................3/8”-16............................24

24.............6292547.................. Tube............................................................ .........................................2

25.............6292548.................. Spring.......................................................... .........................................4

26.............PJ1696-509............. Spring Holding Bolt...................................... .........................................4

27.............6292550.................. Straight Cutterhead Assembly...................... .........................................1

................. PJ1285-600............. Helical Cutterhead Assembly ....................... .........................................1

28.............TS-1491041............ Hex Cap Screw............................................M10x30.............................2

29.............6292551.................. Infeed Table ................................................ .........................................1

30.............6292552.................. Lip, Table ..................................................... .........................................1

31.............TS-1505061............ Socket Head Cap Screw ..............................M10x40.............................8

32.............6292554.................. Deflector, Dust ............................................. .........................................1

33.............TS-081C062............ Machine Screw, Pan Head, Phillips .............#10-24x1” .........................5

34.............TS-0680011............ Flat Washer.................................................3/16”.................................5

35.............TS-0560071............ Hex Nut.......................................................#10-24 ..............................5

36.............6292558.................. Outfeed Table.............................................. .........................................1

37.............6292559.................. Lip,Table...................................................... .........................................1

38.............6292560.................. Guard Assembly.......................................... .........................................1

39.............TS-2361101............ Lock Wash e r................................................M10..................................2

40.............PJ1285-240............. Pointer......................................................... .........................................1

41.............PJ1285-241............. Scale........................................................... .........................................1

42.............TS-0680011............ Flat Washer.................................................3/16”.................................1

43.............TS-081C022............ Machine Screw, Pan Head, Phillips..............#10-24x3/8”.......................1

44.............TS-0680041............ Flat Washer.................................................3/8”.................................24

45.............TS-0271051............ Socket Set Screw ........................................3/8”-16x1/2”......................4

46.............TS-0271031............ Socket Set Screw ........................................3/8”-16x3/8”......................4

47.............TS-0561011............ Hex Nut.......................................................1/4”-20..............................4

48.............6285917.................. Push Block .................................................. .........................................2

49.............PJ1285-249............. Set Screw....................................................M8x35...............................2

30

Page 31

Table Assembly

31

Page 32

Parts List: Motor Pulley Assembly

Index No. Part No. Description Size Qty

1...............6292512.................. Motor...........................................................3HP 3Ph...........................1

................. 6292512-MF............ Motor Fan (not shown) ................................ .........................................1

................. 6292512-MFC......... Motor Fan Cover (not shown) ...................... .........................................1

................. 6292563.................. Motor...........................................................3HP 1Ph...........................1

................. 6292563-MF............ Motor Fan (not shown) ................................ .........................................1

................. 6292563-MFC......... Motor Fan Cover (not shown) ...................... .........................................1

................. 6292563-CS............ Centrifugal Switch (not shown) .................... .........................................1

................. 6292563-SC............ Starting Capac itor (not shown) ....................400MFD, 250VAC.............1

................. 6292563-RC............ Running Capacitor (not shown) ...................50uf, 350VAC ...................1

2...............6292513.................. Pulley..........................................................3Ph...................................1

................. 6294246.................. Pulley..........................................................1Ph...................................1

3...............TS-1525011............ Socket Screw Screw....................................M10x10.............................1

4...............6292515.................. Bracket, Motor............................................. .........................................1

5...............TS-0680041............ Flat Washer.................................................3/8”...................................3

6...............TS-0720091............ Lock Wash e r ................................................3/8”...................................6

7...............TS-0060081............ Hex Cap Screw............................................3/8”-16x1-3/4”...................3

8...............TS-0561031............ Hex Nut.......................................................3/8”-16..............................3

9...............6292520.................. Plate............................................................ .........................................1

10.............6292521.................. Rod ............................................................. .........................................1

11.............TS-2360121............ Flat Washer.................................................M12..................................2

12.............TS-1540081............ Hex Nut.......................................................M12 ..................................8

13.............TS-1525021............ Socket Set Screw ........................................M10x12.............................1

14.............6295367.................. Belt, 1PH.....................................................A-53..................................2