Page 1

20" DRILL PRESS

Model 1200HD

Instruction Manual & Parts List

M-0460237

(800) 248-0144

www.wmhtoolgroup.com

Page 2

This manual has been prepared for the owner and operators of a Powermatic Model 1200HD

Drill Press. Its purpose, aside from machine operation, is to promote safety through the use of

accepted correct operating and maintenance procedures. Completely read the safety and maintenance instructions before operating or servicing the machine. To obtain maximum life and

efficiency from your drill press and to aid in using the machine safely, read this manual thoroughly and follow all instructions carefully.

Warranty & Service

WMH T ool Group warrant s every product it sells. If one of our tools needs service or repair, one of our Authorized Repair S tations located throughout the United States can give you quick service.

In most cases, any one of these WMH Tool Group Repair St ations can authorize warranty repair , assist you in

obtaining parts, or perform routine maintenance and major rep air on your JET , Powermatic, Performax, or

Wilton tools.

For the name of an Authorized Repair S tation in your area, call 1-800-274-6848.

More Information

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information,

check with your local WMH T ool Group distributor or visit wmhtoolgroup.com.

Limited Warranty

WMH Tool Group makes every effort to assure that its products meet high quality and durability standards and

warrants to the original retail consumer/purchaser of our products that each product be free from defects in

materials and workmanship as follows: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS

SPECIFIED OTHERWISE. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence or accidents, normal wear-and-tear, rep air or alterations outside our facilities, or to a lack of maintenance.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE, FROM THE

DA TE THE PRODUCT WAS PURCHASED A T RET AIL. EXCEPT AS ST A TED HEREIN, ANY IMPLIED

WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED. SOME ST A TES DO NOT ALLOW

LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMIT A TION MA Y NOT

APPL Y TO YOU. WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENT AL, CONTINGENT , SPECIAL, OR CONSEQUENTIAL DAMAGES

ARISING FROM THE USE OF OUR PRODUCTS. SOME ST A TES DO NOT ALLOW THE EXCLUSION OR

LIMIT ATION OF INCIDENT AL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMIT A TION OR EXCLUSION MA Y NOT APPL Y T O YOU.

T o take advant age of this warranty , the product or part must be returned for examination, postage prep aid, to an

Authorized Repair S tation designated by our office. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection discloses a defect, WMH Tool Group will either repair or

replace the product, or refund the purchase price if we cannot readily and quickly provide a repair or replacement, if you are willing to accept a refund. WMH Tool Group will return repaired product or replacement at our

expense, but if it is determined there is no defect, or that the defect resulted from causes not within the scope

of our warranty , then the user must bear the cost of storing and returning the product. This warranty gives you

specific legal rights, you may also have other rights which vary from state to state.

WMH Tool Group sells through distributors only . WMH Tool Group reserves the right to effect at any time,

without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever .

Page 3

TABLE OF CONTENTS

Safety

Instructions ................................................................................................................................4-5

Decals .......................................................................................................................................... 6

Specifications........................................................................................................................................6

Dimensional Drawings........................................................................................................................... 7

Installation, Maintenance & Adjustments

Receiving......................................................................................................................................8

Installation .................................................................................................................................... 8

Spindle Table Models ...................................................................................................................8

Quill Adjustment ........................................................................................................................... 8

Quill Return Spring Adjustment ....................................................................................................8

Replacing Spindles on Quill Assembly..........................................................................................9

Lubrications .................................................................................................................................. 9

Drill Press Operations......................................................................................................................... 10

Controls ...................................................................................................................................... 10

Operating Tips.........................................................................................................................10-1 1

Inverter Drive System ................................................................................................................. 11

Power Connection - Electronic Variable Speed.......................................................................... 11

Foot Switch Operation (Optional)................................................................................................11

Parts Lists & Exploded Views:

Production & Tilting Table with Table Raising Rack ............................................................... 12-13

Electronic Variable Speed Assembly ..................................................................................... 14-16

S pindle Table, Legs & Column Mounting Bracket Assembly.......................................................17

Head Raising Assembly ........................................................................................................18-19

Head Assembly ..................................................................................................................... 20-21

Electrical Schematics

1200HD ...................................................................................................................................... 22

1200HD when used with Reversing Foot Switch ........................................................................ 23

Trouble-shooting T ip s......................................................................................................................... 24

Table 1A: Drilling Feeds - Speed - Horsepower Required.................................................................. 25

TABLE 1B: Drilling Feeds - Speed - Horsepower Required ............................................................... 26

TABLE 2: Reaming Speeds - High Speed Steel Tools - Materials - RPM .......................................... 27

TABLE 3: T apping and Threading Formula for Calculating Horsepower Requirements ..................... 28

Page 4

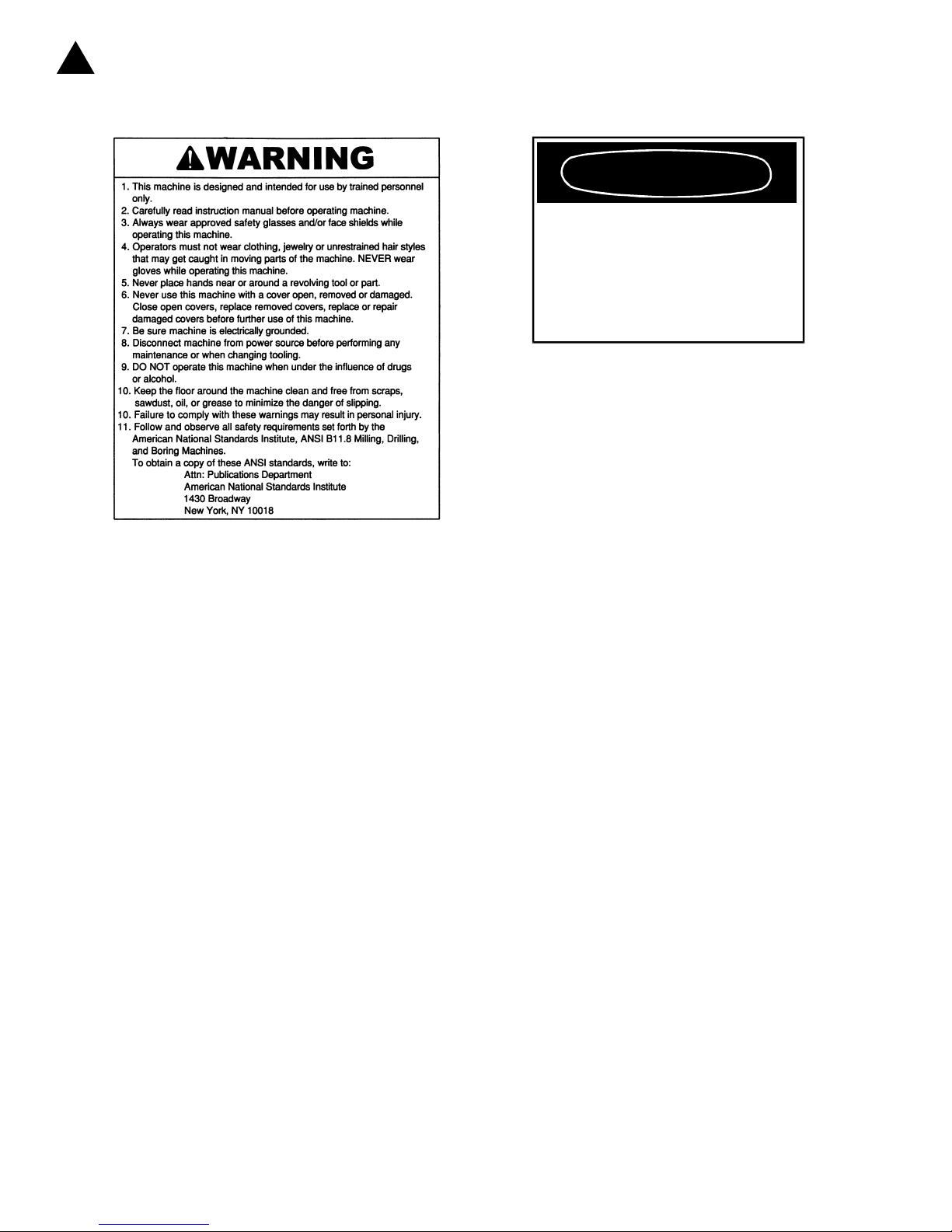

!

SAFETY INSTRUCTIONS

Read, understand and follow the safety and operating instructions found in this manual. Know the limita-

tions and hazards associated with a 1200HD Drill Press. A safety rules decal is installed on the belt guard of

this machine to serve as a reminder of basic safety practice.

Electrical Grounding. Make certain that the machine frame is electrically grounded and that a grounding

lead is included in the incoming electrical service. In cases where a cord and plug are used, make certain that

the grounding lug connects to a suitable ground. Follow the grounding procedure indicated by the National

Electric Code.

Eye Safety . Wear an approved safety face shield, goggles or glasses to protect eyes when operating the drill

press.

Personal Protection. Before operating the machine, remove tie, rings, watch and other jewelry and roll up

sleeves above the elbow. Remove all outer loose clothing and confine long hair . Protective type footwear

should be worn. Hearing protectors should be used where noise exceeds the level of exposure allowed in

Section 1910.95 of the OSHA regulations. Do not wear gloves.

Work Area. Keep the floor around the machine clean and free of tools, tooling, stock scrap and other foreign

material, and oil, grease or coolant to minimize the danger of tripping or slipping. Be sure the table is free of

chips, tools and everything else not required for the task to be performed. Powermatic recommends the use

of anti-skid floor strips on the floor area where the operator normally stands and that each machine's work

area be marked off. Make certain the work area is well lighted and ventilated. Provide for adequate work

space around the machine.

Guards. Keep all machine guards in place at all times when the machine is in use. Do not operate the

machine with the guard off.

Do Not Overreach. Maintain a balanced stance and keep your body under control at all times.

Maintain Tools in Top Condition. Keep tools sharp and clean for safe and best performance. Dull tools can

increase the feed force required and can result in burning the stock or seizing up,causing the work to be

pulled free from its holding device. Dull or improperly sharpened drills will not produce a straight hole.

Use the Proper Speed and Feed. A table is provided in the instruction manual as a guide in selecting the

correct speed and feed rate for a variety of materials. For materials not shown, consult the material supplier for

correct speed and feed rate. Adjust speed on variable speed models only with the power on. On step cone

models, make sure power is off and the spindle has come to a complete stop before opening the access door

to change speeds.

Never Drill Freehand. Always block or clamp the work piece. A drill bit or tap can seize up causing the work

piece, jig, or fixture to rotate with the spindle and can cause serious injury .

Remove Key Chucks. When a key chuck is used, remove it immediately after using it to lock or unlock a

tool in the chuck. If it is not removed, starting the spindle can cause it to be thrown off the chuck and could

result in serious injury .

Hand Safety . Keep hands away from the spindle when the machine is under power. Never clear chips when

the spindle is under power and never use the hands to clear chips; use a brush or chip rake. Chips are razor

sharp and can cause serious injury . Do Not Change Tools with the Spindle Rotating Under Power.

Spindle Rotation. Be sure the rotation of the spindle is correct for the tool being used.

Machine Adjustments. Make all machine adjustment s with power off except speed on a variable speed

model or feed rate on machine equipped with power feed.

4

Page 5

Machine Capacity. Do not attempt to use the machine beyond its stated capacity or for operations requiring

more than the rated horsepower of the motor. This type use will reduce the productive life of the machine and

could cause the breakage of parts which could result in personal injury.

Avoid Accident al St arting. Make certain the motor switch is in the "off" position before connecting power to

the machine.

Careless Acts. Give the work you are doing your undivided attention. Looking around,carrying on a conversation, and "horseplay" are careless acts that can result in serious injury .

Job Completion. If the operator leaves the machine area for any reason, the drill press should be turned off

and the spindle come to a complete stop before he departs. In addition, if the operation is complete, he

should clean the machine and work area. Never clean the machine with power on and never clean chips with

the hands; use a brush or chip rake.

Disconnect Machine before performing any service or maintenance and when changing tools.

Replacement Parts. Use only Powermatic or factory authorized replacement parts and accessories; other-

wise, the drill press warranty and guarantee will be null and void.

Misuse. Do not use the 1200HD Drill Press for other than its intended use. If used for other purposes,

Powermatic disclaims any real or implied warranty and holds itself harmless for any injury that may result

from the use. Do not equip a 1200HD Drill Press with a motor larger than 2 horsepower nor with a motor with

a speed greater than 1800 rpm unless specifically authorized to do so in writing by Powermatic.

If you are not thoroughly familiar with the operation of drill presses, obtain advice from your supervisor ,

instructor or other qualified person.

Drugs, alcohol, medication. Do not operate this machine while under the influence of drugs, alcohol, or any

medication.

Health hazards. Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

* Lead from lead-based paint.

* Crystalline silica from bricks and cement and other masonry products.

* Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area, and work with approved safety equipment, such

as those dust masks that are specifically designed to filter out microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

!

CAUTION: (This means that if precautions are not heeded, it may result in minor or moderate injury

and/or possible machine damage)

!

WARNING: (This means that if precautions are not heeded, it could result in serious injury or

possibly even death).

5

Page 6

C

F

!

SAFETY

Familiarize yourself with the location of these safety decals on your drill press.

DANGER

HEAD WILL FALL IF UNCLAMPED

WITH THE SAFETY COLLAR LOOSE.

MAKE SURE SAFETY COLLAR IS

LOCKED TO COLUMN BEFORE

UNCLAMPING HEAD WITH COLUMN

LAMP SCREWS. SEE INSTRUCTIONS

OR PROPER SPIN DLE HEAD RAISING

AND LOWERING.

3408259

3408211

SPECIFICATIONS (Model 1200HD Drill Press)

Spindle Travel.........................................................................................................................................6"

Quill Diameter................................................................................................................................... 2-3/4"

Column Diameter .............................................................................................................................4-1/2"

Column Wall Thickness ....................................................................................................................... 1/2"

Column Length ..................................................................................................................................... 66"

Table Working Surface

Production Table............................................................................................................ 15-1/2" x 18"

Base Working Surface...................................................................................................13-1/2" x 18"

Drilling Capacity (Cast Iron) ..............................................................................................................1-1/2"

Tapping Capacity (Cast Iron) .................................................................................................................. 1"

Drilling Capacity (Steel) .................................................................................................................... 1-1/4"

Tapping Capacity (Steel)......................................................................................................................3/4"

Throat Depth ............................................................................................. Drills to center of 20" diameter

Spindle Speeds:

Electronic V ariable S peed Model

Low Range ......................................................................................................................50-500 rpm

High Range .................................................................................................................200-1820 rpm

Height (overall) .....................................................................................................................................75"

Front to Rear ..................................................................................................................................33-1/2"

Weight .........................................................................................................................................606 lbs

Motor (horsepower) ............................................................................................................................ 2 hp

6

Page 7

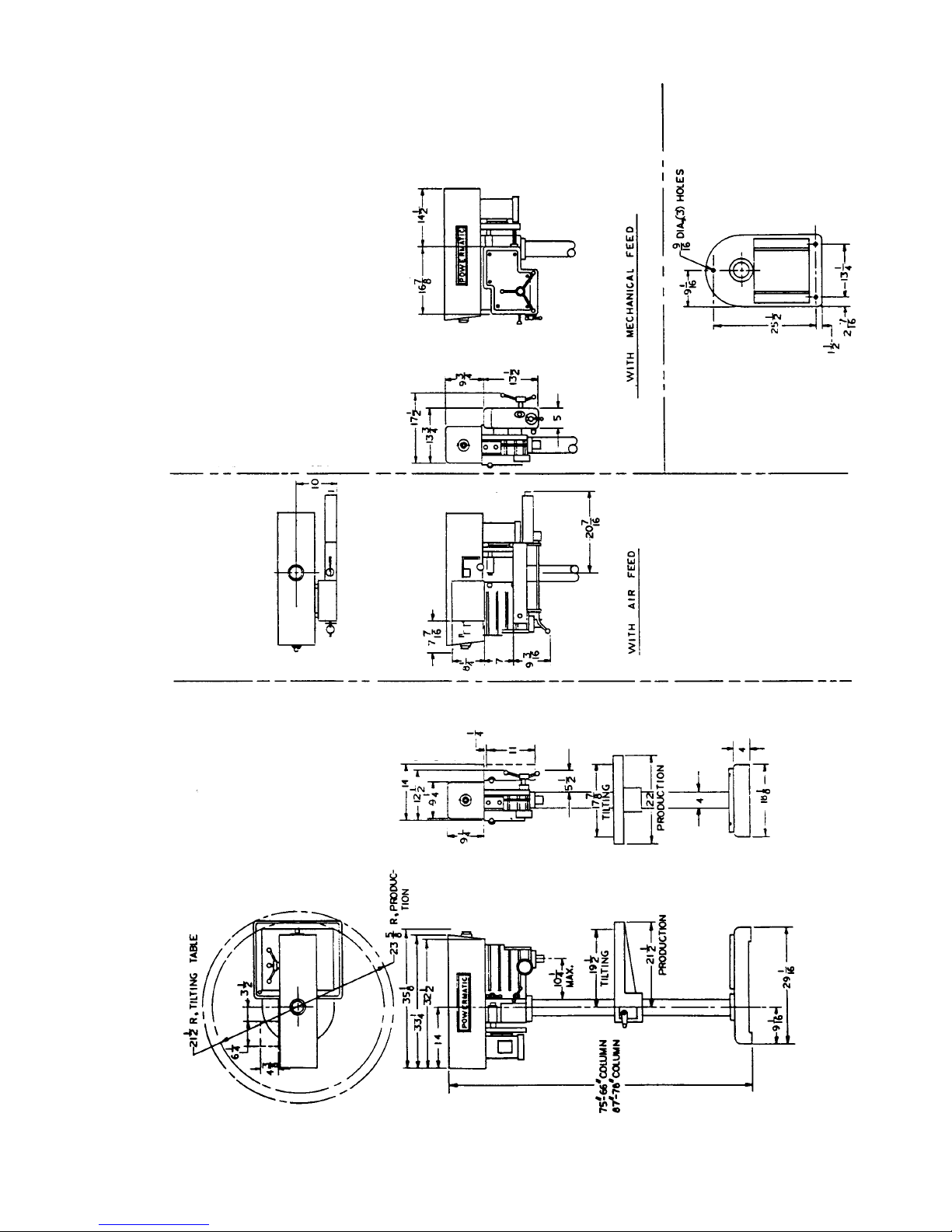

DIMENSIONAL DRAWINGS (Model 1200HD Drill Press)

FIGURE 1

7

Page 8

INSTALLATION, MAINTENANCE AND ADJUSTMENTS

RECEIVING

Remove drill press from shipping container and

check for damage. Report any damage to the

carrier and to your distributor immediately . Attach

accessories shipped with drill press, then clean

protective coating from table, column, base and

spindle with a good commercial solvent. Read

instruction manual thoroughly for assembly alignment, maintenance and safety instructions.

INSTALLATION

Mount machine on a solid foundation and lag to the

floor through holes provided in base of drill press.

The head and table of the machine have been

lowered on the column for convenience in packaging.

1. Using a crane and sling with blocks to prevent

damage to the guard; place a sling under the

head near the column on the spindle side.

2. Loosen the two binders clamping the head to

the column and raise the head to the desired

height. Move the safety collar to a position

under the head by loosening the two set

screws, sliding the collar up, and relocking

setscrews.

3. Remove the sling and clamp the head in

position.

4. Using the crane and sling, unlock the table

binder and raise the table height enough to

install the table raising rack.

5. Install the rack by placing it in the notched

area in the lower collar and driving the roll pin

through the hole in the rack and through both

ears on the collar .

6. Position the rack to engage the table raising

gearing and lower the table until the rack

engages the rack pinion.

7. Lower the crane to put slack in the sling,

engage the table raising lever and lower the

table on to the rack. Visually align the table

with the base, lock the table binder and

remove the sling.

SPINDLE TABLE MODELS

In the case of spindle table models, the legs are not

attached to the table, they are packed sep arately.

To assemble the legs to the spindle table, carefully

support machine on forklift tines or other temporary

supports and bolt legs securely into position. It is

imperative that a spindle table be carefully leveled.

Use a precision level, and adjust the level using the

jackscrews provided in the legs. Lag machine to

floor through holes provided in leveling screws (3/8"

dia. lag screws).

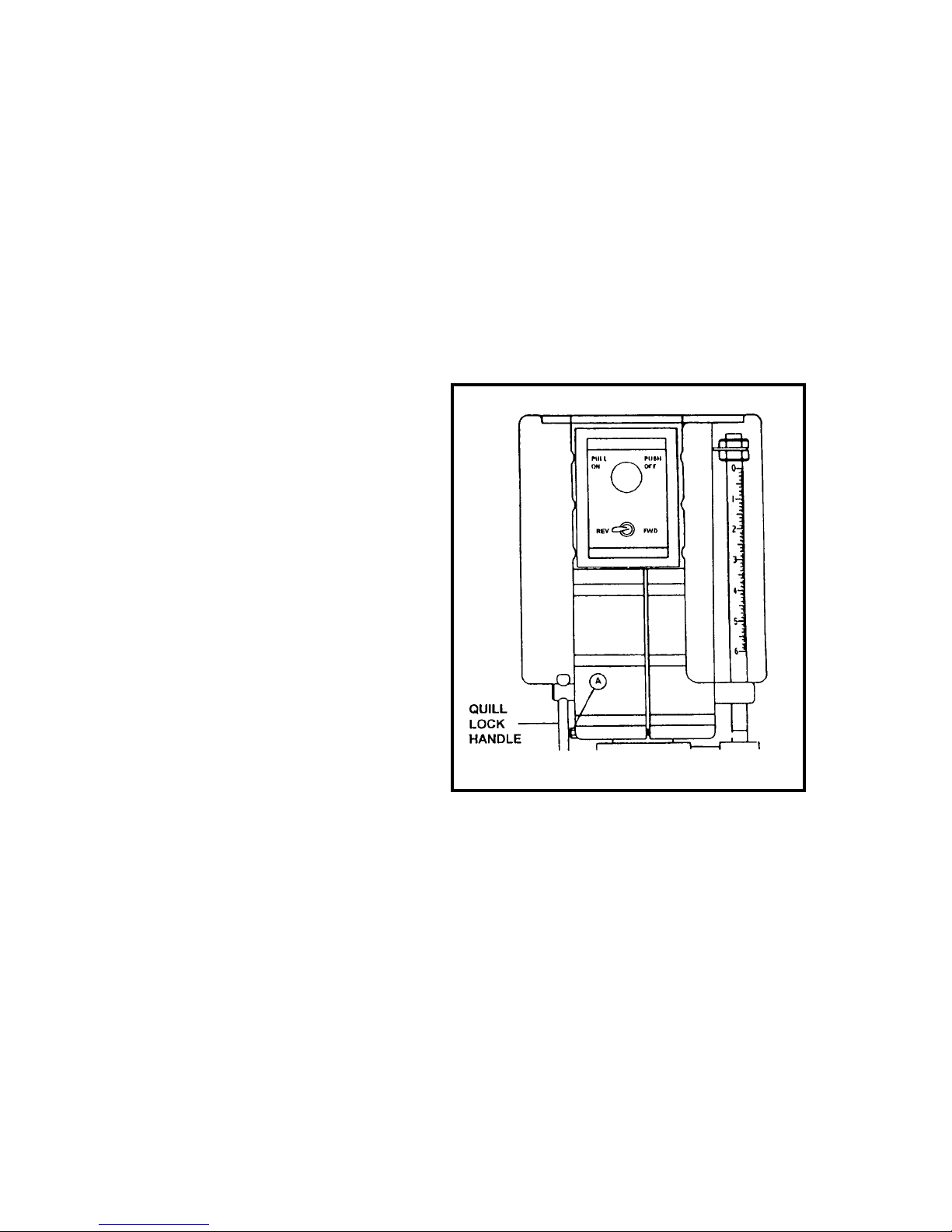

QUILL ADJUSTMENT

Lateral play or bellmouthing can develop between

the quill and head casting bands due to wear. To

compensate for wear between the quill and head,

proceed as follows:

1. Be sure quill lock handle (Figure 2) is loose.

2. Squeeze slotted head casting together slightly

by tightening bolt (A). Apply just enough

pressure to compensate for wear but do not

restrict free motion down or return.

FIGURE 2

Quill Fit Up Adjustment

QUILL RETURN SPRING ADJUSTMENT

Spring tension for return of spindle, after hole

drilling, has been pre-set at the factory. No further

adjustment should be attempted unless absolutely

necessary. Adjustment will probably be required if a

multiple spindle drilling or tapping head is used. If

adjustment is necessary, loosen lock screw (A)

(Figure 3) while holding quill spring housing (B). Do

not allow the housing to turn in your hand or spring

will unwind. Turn entire housing assembly clockwise the number of turns necessary to cause the

quill to return to its up position. (NOTE: The flat of

the spring housing pilot is lined up with the spring

loading hole on the body of the spring housing.)

8

Page 9

Reset lockscrew (A), make sure point of screw mates

to flat on the housing journal.

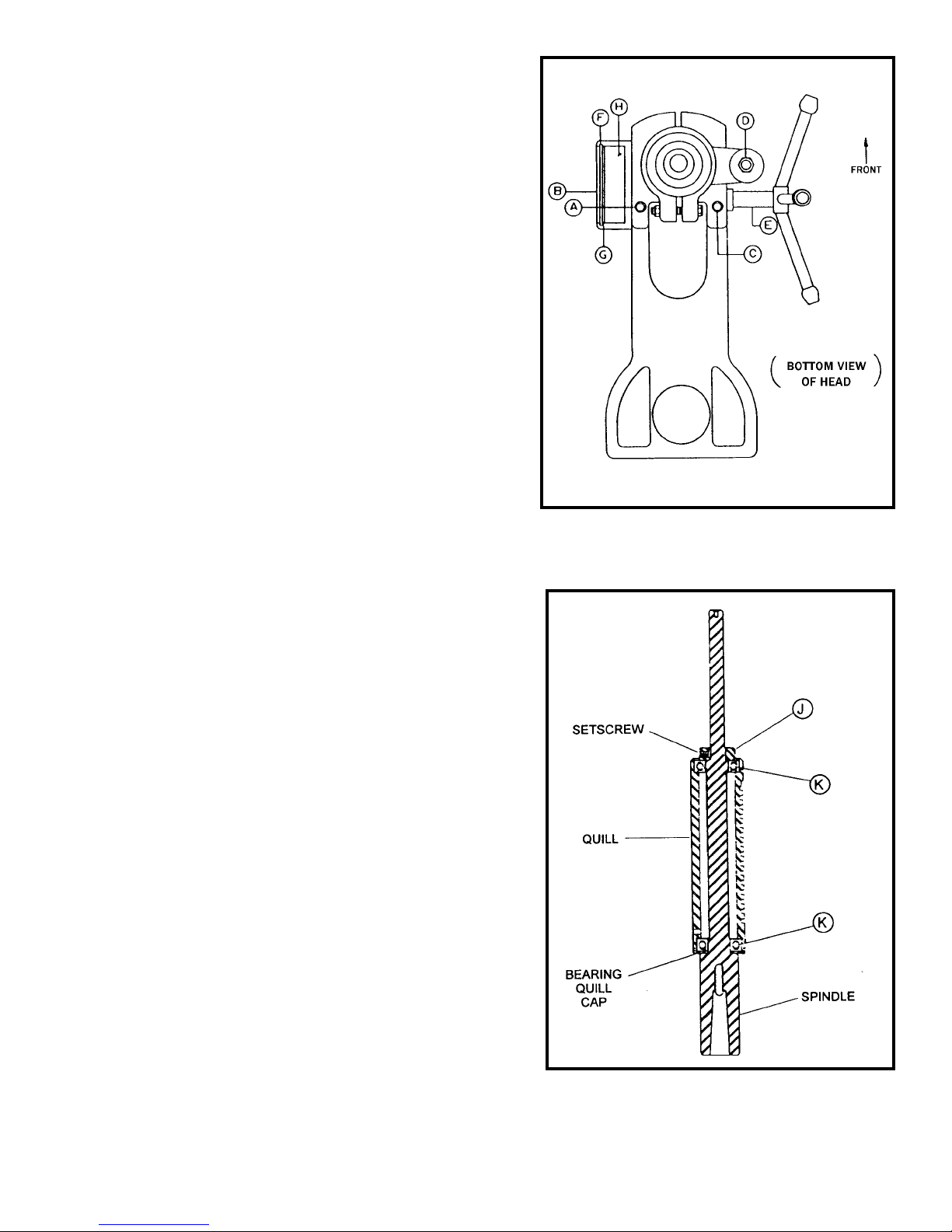

REPLACING SPINDLES ON QUILL

ASSEMBLY

To change the quill assembly for any reason, proceed

as follows:

1. Hold quill return spring housing (B) in left hand

(Figure 3) and loosen lockscrew (A). Let spring

unwind slowly , by allowing cam to turn in hand.

2. Loosen setscrew (C) and remove nut (D) on

bottom of depth stop rod. Unscrew and remove

depth stop.

3. Hold quill assembly and remove the turret pinion

shaft (E). Entire quill assembly will slide out of

head.

To change spindles, follow the above steps, then

(Figure 4):

1. Loosen setscrew in collar (J). To reach this

screw , insert a 5/32" hex head wrench.

2. With a hard rubber mallet or block of wood, tap

spline end of spindle. The spindle, with bearing

(K), will come out of quill.

3. Use an arbor press to remove bearing (K).

4. To replace spindle, reverse above procedure.

5. When replacing collar (J), remove all end play

from spindle.

6. When replacing quill in head casting, rotate

spindle, if necessary , to engage spline in pulley

driver.

7. Remove lock ring (F) and cover plate (G)

(Figure 3) from spring housing and make

certain tongue on return spring is properly

inserted in slotted end of pinion shaft. Replace

cover and adjust spring tension as instructed

under heading "QUILL RETURN SPRING

ADJUSTMENT."

FIGURE 3

Quill Removal

LUBRICATIONS

All ball bearings in your Powermatic drill press are

sealed for life, requiring no lubrication. Points requiring lubrication are:

1. Internal spline drive assembly . Keep this area

well lubricated with a good grade non-hardening

grease, such as Fiske Company "Lubriplate."

Insert grease in the hole at the top of spindle

pulley spline driver. Lube twice yearly.

2. A light film of oil applied to the quill and column

will reduce wear, prevent rust and assure ease

of operation.

3. Quill return spring should receive oil (SAE 20)

once yearly . Remove cover plate and apply

oil with squirt can or small brush.

FIGURE 4

Spindle Assembly

9

Page 10

4. IMPORTANT: The hub area of variable speed

pulleys should be oiled with a light lubricant

such as SAE 10W or automatic transmission

oil every 90 days.

5. Apply Lubriplate to quill pinion every 90 days.

6. Occasional dressing of belt with spray can

type belt dressing or parafin wax will promote

longer belt life and quieter operation.

NOTE: Use extreme care when performing

this operation and keep hands clear of pinch

points. When using parafin bar , do this only

by turning the sheaves by hand. DO NOT

apply with motor running.

7. When equipped with mechanical power feed

unit, periodically coat the gears with a good

open gear lubricant.

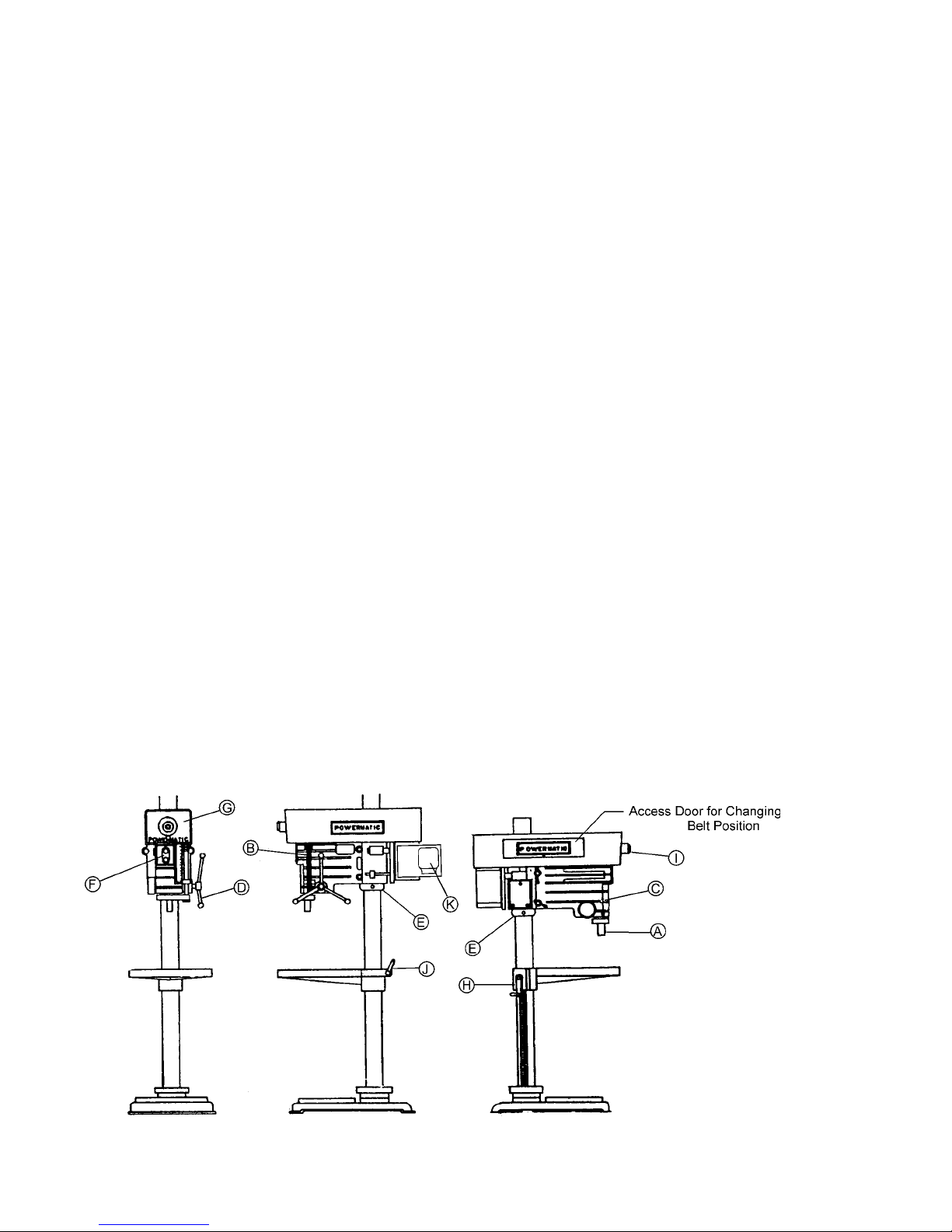

DRILL PRESS OPERATIONS

Familiarize yourself with all operating controls

before attempting use of this machine.

CONTROLS (see Figure 5)

1. The spindle (A) in this machine has a No. 3

Morse Taper.

2. A depth stop rod (B) is provided to control hole

depth and to prevent drilling through material into

table surfaces.

3. A quill lock (C) is located on the left side of the

head and is used to hold quill at any position.

4. The turret handle (D) is used to lower the

spindle and quill a total depth of 6"

5. A safety collar (E) is provided to prevent head

from falling when locks are released.

6. Starting switch (F) is mounted on the front of

drill press head within easy reach of the operator.

7. A speed selection chart (G) is located on the

front of the head. This chart is to provide assistance in determining proper drill speed.

8. On all 1200HD models, a knob (I) is used to

change speed.

9. On production table models, binder (J) locks

the table to the column and handle (H) is used to

raise and lower the table.

10. The model 1200HD is provided with an ACinverter (K) which is pre-programmed from the

factory and requires no changing or adjustment.

OPERATING TIPS

1. Determine drill size, inspect for sharpness,

insert and lock securely in chuck or Morse taper .

2. Arrange at this point to protect table surface

from drill breakthrough. A piece of scrap material

under the workpiece will prevent marring table

surface and eliminate splintering at breakthrough

point. Lock table securely to prevent movement.

3. Prevent the work from being torn from

operator's hand, by always securing the workpiece,

jig, fixture, or holding device to table by clamping or

blocking on the table. DO NOT use the column as a

stop. Clamp all light workpieces, jigs, fixtures, or

holding devices to the table to prevent them from

being picked up as the quill returns.

4. Select the proper RPM for the tool being used,

the material being machined, the operations to be

performed, and other conditions as indicated. (See

Tables 1A, 1B, 2, and 3 on pages 25 thru 28 for

recommendations.) If drill press is the step pulley

type, raise door and set drive belt in proper ration

position. If the machine is a variable speed model,

turn machine on the turn control cam to proper

speed. (NEVER attempt speed adjustment of

variable speed machines unless machine is running.) Turn machine off.

10

FIGURE 5

Page 11

5. Set depth stop for desired hole depth. Fine

adjustment is made by turning the fine adjustment

collar directly under pointer on depth rod. Use

upper jam nut to lock stop setting position.

6. Start coolant, if coolant is being used.

7. Turn spindle on and begin drilling operation.

As the breakthrough point is reached, always slow

feed rate down slightly to assist in elimination of

burring underside of workpiece and to help prevent

a sudden break through which can cause the drill to

grab and pull the workpiece free of its clamping

device.

8. Perform all operations with a minimum

extension of the quill. Adjust table or head position

rather than using excessive quill travel.

9. On tilting table models be sure to block the

part or holding fixture from sliding off the table

when it is used tilted at an angle. In addition, be

sure the table is clamped.

INVERTER DRIVE SYSTEM

The 1200HD Drill Press utilizes the latest technology in A.C. inverter drives to provide the infinitely

variable spindle speeds. The inverter controls the

speed of the motor by varying the frequency of the

voltage supplied to the motor . The inverter provides

an acceleration ramp that eliminates the shock of

normal across-the-line starting. Also a braking

feature eliminates long coasting periods when the

drill press is turned off.

the ON position when the power is connected, the

inverter will trip out. If this happens, disconnect

power, turn switch OFF, wait thirty seconds and

then reconnect power.

NOTE: If there is a power outage while operating

the 1200HD Drill Press, turn the switch to the OFF

position, disconnect power source, wait thirty

seconds then reconnect power source and resume

normal operation.

FOOT SWITCH OPERATION

(OPTIONAL)

The optional foot switch (Figure 6) is used only for

reversing the spindle in tapping operations.

Before using the foot switch, place the control

switch in the FWD position. When performing a

tapping operation and the tap needs to be reversed

or retracted out of a hole, press the foot switch and

hold it down. The spindle will ramp down and

immediately reverse direction. Once the tap has

completely exited or retracted from the hole,

release the foot switch and the spindle will ramp

down and immediately return to forward rotation.

The 2 HP Baldor motor is wound with "Inverter

Spike Resistant" magnet wire to give extended

motor life when used with inverter drives. The

motor is also specially balanced to reduce noise

and minimize vibration.

The A.C. Inverter does not require any programming; it is pre-programmed from the factory . The

buttons on the face of the inverter should NEVER

be pushed at anytime. Use ONLY the controls on

the front of the head assembly .

POWER CONNECTION - ELECTRONIC

V ARIABLE SPEED

The 1200HD Drill Press will operate on single or

three phase 230V or 460V , depending on inverter,

without any adjustments or programming. For

single phase power connect hot leads to R and S,

and for three phase power connect hot leads to R,

S and T as shown in the wiring diagram on page 22.

Remember to always connect the ground lead.

Before connecting to the power source make sure

the ON/OFF switch is in the OFF position and turn

the speed dial counterclockwise. If the switch is in

FIGURE 6

11

Page 12

PARTS LIST: Production & Tilting Table with Table Raising Rack (1200HD)

No. Part No. Description Quantity

2298013 Elevating Gear Box Housing Assembly (Items 1 thru 15) ........................................1

1 6624006 Groove Pin, 1/4 x 2-3/4 Lg.........................................................................................

2 3268201 Nylon Handle ........................................................................................................... 1

3 6715132 Round Head Screw, 5/16-18 x 1/2 ...........................................................................3

4 6861201 Flat Washer, 5/16.....................................................................................................3

5 3268005 Elevating Handle, D-21............................................................................................1

6 3741211 Flat Shaft Spacer, 1/2 ..............................................................................................1

7 6064001 Thrust Bearing, Nice 605 .........................................................................................1

8 6626040 Spring Pin, 1/4 x 1-1/4 .............................................................................................1

9 3237013 Pinion Gear..............................................................................................................1

10 3237002 Worm Gear..............................................................................................................1

1 1 3237001 Spur Gear ................................................................................................................1

12 6714004 Socket Set Screw, 1/4-20 x 1/4 ................................................................................2

13 3388015 Square Key, 3/16 x 3/16 x 2-1/4 ...............................................................................1

14 3701004 Gear Shaft ...............................................................................................................1

15 3298017 Gear Box Housing ...................................................................................................1

2797026 Production Table Assembly (Items 16 thru 19).........................................................1

16 3797030 Production Table ......................................................................................................1

17 3728010 Table Locking Sleeve...............................................................................................1

18 3773012 Table Locking Stud ..................................................................................................1

19 3528001 Table Stud Lock Nut.................................................................................................1

2645002 Table Raising Rack Assembly (Items 20 thru 26)..................................................... 1

20 3096040 Bearing Elevating Rack Collar .................................................................................1

21 6715118 Half Dog Point Socket Set Screw, 5/16-18 x 3/4 ......................................................2

22 6515001 Hex Nut, 5/16-18......................................................................................................2

23 3046003 Thrust Collar Bearing...............................................................................................1

24 6054002 Steel Ball Bearing, 3/8 ...........................................................................................41

25 6626033 Spring Pin, 3/16 x 2.................................................................................................. 1

26 3650005 Gear Rack, 24 .........................................................................................................1

27 6718056 Cup Point Socket Set Screw, 1/2-13 x 3/4 ...............................................................2

28 3598023 Protector Plug, 7/16 x 3/16 ......................................................................................4

29 6718055 Cup Point Socket Set Screw, 1/2-13 x 1/2 ...............................................................4

30 3042037 Drill Press Base .......................................................................................................1

31 6517006 Hex Jam Nut, 7/16-14..............................................................................................2

32 3838008 Table Locking Bevel Washer....................................................................................1

33 3268008 Table Locking Handle ..............................................................................................1

34 6638004 Pipe Plug, 1/2-14 ..................................................................................................... 1

35 3096039 Column Collar..........................................................................................................1

36 3098004 Floor Model Column ................................................................................................1

37 3104014 Head & Table Cover.................................................................................................1

38 6716038 Hex Head Cap Screw, 3/8-16 x 1/2 ..........................................................................3

39 6716042 Hex Head Cap Screw, 3/8-16 x 3.............................................................................3

40 2797028 Tilting T able Assembly (not shown).......................................................................... 1

12

Page 13

Production & Tilting Table with TABLE RAISING RACK

13

Page 14

PARTS LIST: Electronic Variable Speed Assembly (1200HD)

No. Part No. Description Quantity

2387006 Step Cone Sheave Kit Assembly (Items 1 thru 52).......................................................1

2144004 Drive Spline Sheave Assembly (Items 1 thru 6) ............................................................1

1 6060054 Ball Bearing, NTN ........................................................................................................ 2

3 6807136 Sheave - HTD Spindle .................................................................................................. 1

4 6715013 Socket Set Screw, 5/16-18 x 3/8 ................................................................................. 2

5 3388102 Square Key, 3/8 x 1-3/4 ............................................................................................... 1

6 3749133 Spline Drive Shaft.........................................................................................................1

2298005 Countershaft Housing Assembly (Items 7 thru 14)........................................................ 1

7 3298032 V/S Shaft Housing .......................................................................................................1

8 6060010 Ball Bearing, Fafnir 205PP...........................................................................................2

9 3706005 V/S Drive Shaft ............................................................................................................ 1

10 3388019 Square Key 3/16 x 3/16 x 3-11/16................................................................................1

1 1 6670005 Retaining Ring, Truarc No. 5100-100............................................................................1

12 6811326 Steel Arbor Spacer, 1 x 1-1/2 x .062............................................................................. 1

13 6807137 Sheave - HTD Countershaft ..........................................................................................1

14 6714004 Socket Set Screw, 1/4-20 x 1/4 ................................................................................... 1

2042021 Step Cone Tilting Motor Base (Items 15 thru 27)..........................................................1

15 6716114 Hex Head Cap Screw, 3/8-16 x 2-3/4 ...........................................................................1

16 6813068 Spring, 9/16 x 2 ...........................................................................................................1

17 6861301 Flat Washer, 3/8.......................................................................................................... 1

18 6715016 Cup Point Socket Set Screw, 5/16-18 x 5/16 ...............................................................5

19 3670031 Motor Base Handle Rod............................................................................................... 1

20 3268007 Tilting Handle...............................................................................................................1

21 3076011 Motor Base Handle Cam..............................................................................................1

22 3042057 Step Cone Motor Base.................................................................................................1

23 6516002 Hex Lock Nut, 3/8-16...................................................................................................1

24 3711004 Tilting Motor Base Shaft ..............................................................................................1

25 6622002 Cotter Pin, 1/8 x 1 ....................................................................................................... 1

26 3042056 Motor Mounting Base ..................................................................................................1

27 3670032 Tilting Motor Base Rod ................................................................................................2

2250061 Step Cone Belt Guard Assembly (Items 28 thru 31) ..................................................... 1

28 2136034 Step Cone Door Guard Assembly (W eldment) .............................................................1

29 6710034 Round Head Screw, #10-24 x 1/2.................................................................................4

30 6510001 Hex Nut, No. 10-24 ......................................................................................................4

31 2250165 Guard Assembly ..........................................................................................................1

32 6760046 Round Head Screw, #10-32 x 3/8.................................................................................1

33 6430017 Knob............................................................................................................................ 1

34 6458002 Rubber Molding ...........................................................................................................1

35 6514014 Self Retaining Nut........................................................................................................1

36 6714127 Hex Head Cap Screw, 1/4-20 x 1/2 ..............................................................................1

37 3063246 Upper Spindle Bearing Bracket ....................................................................................1

38 3595271 Safety Plate................................................................................................................. 1

39 6714154 Round Head Screw, 1/4-20 x 1/4..................................................................................2

40 6861200 Lock Washer, 5/16 ......................................................................................................2

41 6715032 Hex Head Screw, 5/16-18 x 1 ......................................................................................2

42 3767211 Guard Mounting Strap.................................................................................................. 2

43 6715033 Hex Head Cap Screw, 5/16-18 x 1/2 ............................................................................ 4

44 6861401 Flat Washer , 7/16........................................................................................................2

45 6717017 Hex Head Cap Screw, 7/16-14 x 1 ............................................................................... 2

46 6077230 Belt, HTD 720-8M-3 ................................................................................................... 10

47 6077229 V-Motor Belt, 3VX450 ..................................................................................................1

49 6714004 Socket Set Screw, 1/4-20 x 1/4 ................................................................................... 1

50 6716009 Cup Point Socket Set Screw, 3/8-16 x 1/2...................................................................2

51 3719191 Step Cone Sheave .......................................................................................................1

14

Page 15

PARTS LIST: Electronic Variable Speed Assembly (1200HD)

No. Part No. Description Quantity

52 6715016 Cup Point Socket Set Screw, 5/16-18 x 5/16 ...............................................................1

54 3312343 Powermatic Logo Label (one not shown)......................................................................2

55 3408259 Warning Label (not shown) ..........................................................................................1

56 3330368 Instruction Plate 1200HD .............................................................................................1

58 3719190 Step Cone Sheave .......................................................................................................1

59 6715016 Cup Point Socket Set Screw, 5/16-18 x 5/16 ...............................................................1

60 6715180 Hex Washer Head Cap Screw , 5/16-18 x 5/8 ...............................................................4

61 6471603 Electric Motor, 2 HP, 3 Ph, 1800 RPM, 230/460V , 145T, TEFC....................................1

62 6399016 Inverter, 230V............................................................................................................... 1

63 6399014 Inverter, 460V............................................................................................................... 1

64 3064737 Inverter Mounting Bracket ............................................................................................ 1

65 6716038 Screw, 3/8 ...................................................................................................................2

66 6760092 Screw, #10-32 x 1/2..................................................................................................... 6

67 6083021 Contact Block.............................................................................................................. 1

68 6821492 Fwd/Rev Switch ...........................................................................................................1

69 6643000 Control Pot .................................................................................................................. 1

70 3578353 Control Panel...............................................................................................................1

71 6821491 Push/Pull Switch .........................................................................................................1

72 6860800 Washer........................................................................................................................1

73 6601000 "O" Ring ...................................................................................................................... 2

74 6430054 Control Panel Knob...................................................................................................... 1

75 6095272 Strain Relief Connector Bushing...................................................................................1

76 6095271 Strain Relief Bushing ...................................................................................................1

77 6860802 Lock Washer, #10 .......................................................................................................2

78 4709259 Rubber Bumper ...........................................................................................................2

79 6861100 Lock Washer, 1/4 ........................................................................................................2

80 6122038 Clamp.......................................................................................................................... 2

81 3755258 Spring .......................................................................................................................... 1

82 3595381 Plate (Stiffening) ..........................................................................................................2

84 3408211 Danger Label (not shown) ............................................................................................1

85 6706035 Round Head Machine Screw, #6-32 x 1/4 .................................................................... 2

86 6295733 Brake Resistor (230V) .................................................................................................1

87 6661023 Brake Resistor (460V) .................................................................................................1

88 6860802 Lock Washer #10 ........................................................................................................ 6

15

Page 16

Electronic Variable Speed Assembly (1200HD)

16

Page 17

PARTS LIST: Spindle Table, Legs & Column Mounting Bracket Assy.

(1200HD)

No. Part No. Description Quantity

1 3098005 Bench Model Column for Spindle Table ...................................................................1

2 6718009 Hex Head Cap Screw, for Spindle Table ..................................................................4

3 6718025 Hex Head Cap Screw, 1/2-13 x 2-1/2 for Spindle Table ...........................................2

4 3064078 Column Mounting Bracket for Spindle Table ............................................................1

5 3797015 1 Spindle Table with T-Slots.....................................................................................1

6 6638004 Pipe Plug, 1/2-14 NPT .............................................................................................1

7 6718015 Hex Head Cap Screw, 1/2-13 x 1 for Spindle Table .................................................4

8 2423003 Table End Leg Assembly (Weldment) for Spindle Table ..........................................2

9 3694006 Table Leveling Hex Head Bolt for Spindle T able.......................................................4

17

Page 18

PARTS LIST: Head Raising Assembly (1200HD)

No. Part No. Description Quantity

2298016 Head Raising Mechanism (Items 1 thru 15) 1 Spindle Table....................................1

1 3237002 Gear ........................................................................................................................1

2 3237001 Gear ........................................................................................................................1

3 6714004 Socket Set Screw, 1/4-20 x 1/4 ................................................................................2

4 3388015 Square Key, 3/16 x 3/16 x 2-1/4 ...............................................................................1

5 3701004 Gear Shaft ...............................................................................................................1

6 6861201 Flat Washer, 5/16.....................................................................................................3

7 6715132 Round Head Screw, 5/16-18 x 1/2 ...........................................................................3

8 3237013 Pinion Gear..............................................................................................................1

9 6626040 Spring Pin, 1/4-1-1/4................................................................................................1

10 6064001 Thrust Bearing, Nice 605 .........................................................................................1

11 6861602 Flat Shaft Spacer, 1/2 ..............................................................................................1

12 3268005 Elevating Handle, D-21............................................................................................1

13 3268201 Nylon Machine Handle.............................................................................................1

14 6624006 Groove Pin, 1/4 x 2-3/4............................................................................................ 1

15 3298018 Elevating Gear Box Housing....................................................................................1

2645001 Head Raising Rack Assembly (Items 16 thru 22) 1 Spindle Table ...........................1

16 3650004 Gear Rack, 13-1/4 ...................................................................................................1

17 3096040 Elevating Rack Bearing Collar .................................................................................1

18 6626033 Spring Pin, 3/16 x 2.................................................................................................. 1

19 6515001 Hex Nut, 5/16-18......................................................................................................2

20 6715118 Half Dog Point Socket Set Screw, 5/16-18 x 3/4 ......................................................2

21 6054002 Steel Bearing Ball, 3/8............................................................................................ 41

22 3046003 Thrust Bearing Collar ................................................................................................1

23 3098005 Bench Model Column, 1 S pindle ...............................................................................1

24 3096039 Column Collar, 1 S pindle...........................................................................................1

25 3598023 Protector Plug, 7/16 x 3/16, 1 Spindle ...................................................................... 4

26 6718055 Cup Point Socket Set Screw , 1/2-13 x 1/2, 1 Spindle ...............................................4

29 6716042 Hex Head Cap Screw , 3/8-16 x 3, 1 Spindle .............................................................3

18

Page 19

Head Raising Assembly (1200HD)

19

Page 20

PARTS LIST: Head Assembly (1200HD)

No. Part No. Description Quantity

2268006 Turret Handle Assembly (Items 1 and 2)..................................................................1

1 3406206 Phenolic Knob..........................................................................................................3

2 3670025 Knob Handle............................................................................................................3

2277016 Head Assembly (Items 3 thru 39) ............................................................................1

2686003 Pinion Hub Assembly (Items 3 thru 6)......................................................................1

3 3301003 T urret Hub ...............................................................................................................1

4 6715016 Cup Point Socket Screw, 5/16-18 x 5/16 ..................................................................1

5 3388004 Key, 3/16 x 3/16 x 1 .................................................................................................1

6 3586026 Quill Operating Pinion..............................................................................................1

2670026 Depth Adjustment Rod Assembly (Items 7 thru 1 1, 40 & 41) ................................... 1

7 3526094 Depth Adjustment Lock Nut-Plain............................................................................1

8 3526093 Graduated Depth Adjustment Nut............................................................................1

9 6626035 Spring Pin, 3/16 x 5/8...............................................................................................1

10 3670102 Depth Adjustment Rod.............................................................................................1

1 1 3528005 Hex Nut.................................................................................................................... 2

2640019 No. 3 Mounting Quill Assembly (Items 12 thru 17)...................................................1

12 3078006 Quill Bearing Cap.....................................................................................................1

13 6060014 Ball Bearing, SKF No. 6206 2RS ............................................................................. 2

14 3640017 Sliding Quill..............................................................................................................1

15 3096214 Spindle Collar ..........................................................................................................1

16 6715015 Socket Set Cup Point Screw, 5/16-18 x 1/4 .............................................................1

17 3749110 No. 3 Mounting Spindle............................................................................................1

2695009 Quill Locking Screw Assembly (Items 18 thru 20)....................................................1

18 3268002 Handle .....................................................................................................................1

19 3695010 Quill Lock Screw......................................................................................................1

20 3406016 Knob ........................................................................................................................1

2695015 Head Locking Screw Assembly (Items 21 thru 23) ..................................................1

21 3406016 Knob ........................................................................................................................1

22 3695002 Head Locking Screw................................................................................................1

23 3268002 Handle .....................................................................................................................1

24 3448014 Plain Head Locking Sleeve ......................................................................................2

25 6670071 Retaining Ring, RS-275 ............................................................................................2

26 3104010 S pring Cover .............................................................................................................1

27 6813026 Clock Spring.............................................................................................................1

28 3298280 Spring Housing .........................................................................................................1

29 6716114 Hex Head Screw , 3/8-16 x 2-3/4 ............................................................................... 1

30 6714199 Round Head Screw, 1/4-20 x 1-1/4 ...........................................................................1

31 3092012 Switch Wire Clamp...................................................................................................1

32 3448015 Threaded Head Locking Sleeve.................................................................................2

33 3277013 Head ........................................................................................................................1

34 6718038 Half Dog Point Socket Set Screw, 1/2-13 x 1-1/4......................................................2

35 6518008 Hex Nut, 1/2-13 ........................................................................................................ 2

36 6804005 "O" Ring Seal, Rubber..............................................................................................1

37 6515001 Hex Nut, 5/16-18 ......................................................................................................1

38 6715044 Hex Head Screw , 5/16-18 x 2 ................................................................................... 1

39 3936021 Quill Y oke................................................................................................................. 1

40 3119012 Inches Scale Decal ..................................................................................................1

41 3119013 Metric Scale Decal ................................................................................................... 1

42 3104014 Head & T able Cover , 1 S pindle .................................................................................. 1

43 6716038 Hex Head Cap Screw, 3/8-16 x 1/2, 1 S pindle ..........................................................3

20

Page 21

Head Assembly (1200HD)

21

Page 22

ELECTRICAL SCHEMATIC 1200HD

22

Page 23

ELECTRICAL SCHEMATIC 1200HD (when used with Reversing Foot Switch)

23

Page 24

Trouble-Shooting for Model 1200HD Drill Press

PROBLEM POSSIBLE CAUSE SOLUTION

Excessive vibration. 1. Improper belt tension. 1. Adjust belt tension.

2. Uneven belt wear (hard spots). 2. Replace belt.

3. Motor or spindle pulley out-of-balance. 3. Balance or repair problem pulley

4. Bad motor. 4. Replace motor .

Motor stalls 1. Over feeding. 1. Reduce feed rate.

2. Dull drill. 2. Sharpen drill and keep sharp.

3. V/S belt riding on inner cone. 3. Re-adjust V/S belt.

4. Motor not building up to running speed. 4. Replace or repair motor . Check fuses

in all three legs on three phase motor

and replace if necessary.

5. Bad motor. 5. Replace motor .

Noisy operation. 1. Excessive vibration. 1. Check remedy under excessive

vibration.

2. Improper quill adjustment. 2. Adjust quill (refer to paragraph on quill

adjustment).

3. Noisy spline. 3. Lubricate spline.

4. Noisy motor . 4. Check motor bearings or for loose

motor fan.

Drill or tool heats up or 1. Excessive speed. 1. Reduce speed.

burns work. 2. Chips not clearing. 2. Use pecking operation to clear chips.

3. Dull tool. 3. Sharpen tool or replace.

4. Feed rate too slow . 4. Increase feed enough to clear chips.

5. Rotation of drill incorrect. 5. Reverse motor rotation (refer to motor

wiring diagram).

6. Failure to use cutting oil or coolant 6. Use cutting oil or coolant on steel.

(on steel).

Drill leads off. 1. No drill spot. 1. Center punch or center drill work-

piece.

2. Cutting lips on drill off center . 2. Regrind drill.

3. Quill loose in head. 3. Tighten quill (refer to quill adjustment).

4. Bearing play. 4. Check bearings and reseat or replace

if necessary .

Excessive drill runout or 1. Bent drill. 1. Replace drill. Do not attempt to

wobble. straighten.

2. Bearing play. 2. Replace or reseat bearings.

3. Drill not seated properly in chuck. 3. Loosen, reseat and tighten chuck.

Work or Fixture comes 1. Failure to clamp workpiece or work 1. Clamp workpiece or work holding

holding device to table. device to table surface.

24

Page 25

TABLE 1A: DRILLING FEEDS - SPEED - HORSEPOWER REQUIRED

CAST IRON

FT. PER MIN. 250 FT. 150 FT. 300 FT. 80 FT. 100 FT. 80 FT. 80 FT. 40 FT.

INCHES INCHES RPM RPM RPM RPM RPM RPM RPM RPM

1/16 0.003 15279 9167 18320 4889 6111 4889 4889 2445

3/32 0.0035 10186 6111 12212 3262 4077 3262 3262 1628

1/8 0.004 7639 4583 9160 2445 3056 2445 2445 1222

5/32 0.0045 6111 3667 7328 1956 2445 1956 1956 976

3/16 0.005 5093 3056 6106 1630 2037 1630 1630 815

7/32 0.0055 4365 2619 5234 1398 1747 1398 1398 698

1/4 0.006 3820 2292 4575 1222 1528 1222 1222 611

9/32 0.0065 3395 2037 4071 1087 1359 1087 1087 542

5/16 0.007 3056 1833 3660 978 1222 978 978 489

11/32 0.0075 2778 1667 3330 889 1111 889 889 444

3/8 0.008 2546 1528 3050 815 1019 815 815 407

13/32 0.0085 2350 1410 2818 752 940 752 752 376

7/16 0.009 2183 1310 2614 698 873 698 698 349

15/32 0.0095 2037 1222 2442 652 815 652 652 326

1/2 0.01 1910 1146 2287 611 764 611 611 306

17/32 0.0102 1798 1079 2157 575 719 575 575 288

9/16 0.0105 1698 1019 2035 543 679 543 543 271

19/32 0.0107 1608 965 1930 515 643 515 515 257

5/8 0.011 1528 917 1830 489 611 489 489 244

21/32 0.0112 1456 873 1746 466 582 466 466 233

11/16 0.0115 1389 833 1665 444 556 444 444 222

23/32 0.0117 1329 797 1594 425 532 425 425 213

3/4 0.012 1273 764 1525 407 509 407 407 204

25/32 0.0122 1222 733 1467 391 489 391 391 196

13/16 0.0125 1175 705 1409 376 470 376 376 188

7/8 0.013 1091 655 1307 349 436 349 349 175

15/16 0.0135 1019 611 1221 326 407 326 326 163

1 0.014 955 573 1143 306 382 306 306 153

SIZE OF

DRILL

FEED PER

REVOLU-

TION

BRONZE

BRASS

COPPER

ALUMINUM

MALLE-

ABLETION

MACHINE

SURFACE

SCALE

SURFACE

DEEP

HOLES

STEEL

CASTING

25

Page 26

TABLE 1B: DRILLING FEEDS - SPEED - HORSEPOWER REQUIRED

STEEL CAST IRON STEEL

SIZE OF

DRILL

INCHES INCHES RPM RPM RPM RPM RPM HP HP HP HP

1/16 0.003 2445 3056 3667 4278 4889 0.07 0.0043 0.18 0.0076

3/32 0.0035 1628 2039 2446 2852 3262 0.11 0.0044 0.27 0.0079

1/8 0.004 1222 1528 1833 2139 2445 0.14 0.0045 0.36 0.0081

5/32 0.0045 976 1223 1467 1711 1956 0.18 0.0046 0.45 0.0084

3/16 0.005 815 1019 1222 1426 1630 0.22 0.0047 0.54 0.0087

7/32 0.0055 698 874 1048 1222 1398 0.25 0.0049 0.63 0.0089

1/4 0.006 611 764 917 1070 1222 0.29 0.005 0.72 0.0092

9/32 0.0065 542 680 815 950 1087 0.33 0.0051 0.81 0.0095

5/16 0.007 489 611 733 856 978 0.37 0.0053 0.89 0.0097

11/32 0.0075 444 555 667 778 889 0.4 0.0054 0.98 0.01

3/8 0.008 407 509 611 713 815 0.44 0.0055 1.07 0.0102

13/32 0.0085 376 470 564 658 752 0.47 0.0056 1.16 0.0104

7/16 0.009 349 437 524 611 698 0.5 0.0057 1.25 0.0106

15/32 0.0095 326 408 489 570 652 0.54 0.0058 1.34 0.0107

1/2 0.01 306 382 458 535 611 0.57 0.0059 1.43 0.0109

17/32 0.0102 288 360 431 503 575 0.6 0.006 1.51 0.0111

9/16 0.0105 271 340 407 475 543 0.64 0.0061 1.6 0.0112

19/32 0.0107 257 322 382 450 515 0.68 0.0062 1.69 0.0114

5/8 0.011 244 306 367 428 489 0.72 0.00624 1.78 0.0115

21/32 0.0112 233 291 349 407 466 0.75 0.0063 1.87 0.0117

11/16 0.0115 222 278 333 389 444 0.79 0.0064 1.96 0.0118

23/32 0.0117 213 266 319 372 425 0.83 0.0065 2.05 0.012

3/4 0.012 204 255 306 357 407 0.87 0.0066 2.14 0.0121

25/32 0.0122 196 245 293 342 391 0.9 0.00665 2.22 0.0122

13/16 0.0125 188 235 282 329 376 0.94 0.0067 2.31 0.0123

7/8 0.013 175 218 262 306 349 1.01 0.0068 2.49 0.0126

15/16 0.0135 163 204 244 285 326 1.09 0.0069 2.67 0.0128

FEED PER

REVOLU-

TION

FT. PER MIN. 40 FT. 50 FT. 60 FT. 70 FT. 80 FT.

1 0.014 153 191 229 267 306 1.16 0.007 2.85 0.013

VERY

HARD

BRINELL

402-444

HARD

BRINELL

302-387

MEDIUM

BRINELL

202-293

SOFT

BRINELL

101-196

DEAD

SOFT

BRINELL

UNDER 100

CUTTING

HP

FEED

HP

CUTTING

HP

FEED

HP

26

Page 27

TABLE 2: REAMING SPEEDS - HIGH SPEED STEEL TOOLS

MATERIALS - RPM

STEEL

BRASS

1/8 0.004 1222 1528 1833 2139 2445 0.14 0.0045 0.36 0.0081

1/4 0.006 611 764 917 1070 1222 0.29 0.005 0.72 0.0092

3/8 0.008 407 509 611 713 815 0.44 0.0055 1.07 0.0102

1/2 0.01 306 382 458 535 611 0.57 0.0059 1.43 0.0109

5/8 0.011 244 306 367 428 489 0.72 0.00624 1.78 0.0115

3/4 0.012 204 255 306 357 407 0.87 0.0066 2.14 0.0121

7/8 0.013 175 218 262 306 349 1.01 0.0068 2.49 0.0126

1 0.014 153 191 229 267 306 1.16 0.007 2.85 0.013

NOTE: For Carbide Reamers Use 3 Times Charts Speeds

325 100 50 50 40 30 45 55 65 110

NOTE: For Carbide Spotfacers Use 4 Times Chart Values

BRONZE

Counterboring & Spotfacing - High Speed Steel Tools - Surface Ft./Min.

MALLE-

ABLE

IRON

CAST

IRON

CLASS 30

STEEL

CASTING

VERY

HARD

BRINELL

400-425

HARD

BRINELL

300-375

MEDIUM

BRINELL

225-300

SOFT

BRINELL

100-200

DEAD

SOFT

BRINELL

UNDER 100

27

Page 28

TABLE 3: TAPPING AND THREADING FORMULA FOR CALCULATING

HORSEPOWER REQUIREMENTS

PPV = Power Pitch V alue

SFM = Surface Feet Per Minute

M = Material Factor

TD = Tool Dullness Factor

HP = Horsepower

RPM = Revolutions Per Minute

TAPPING AND THREADING FACTORS CHART

Threads per inch Power Pitch Value* PPV

32 0.002

27 0.0034

24 0.004

20 0.006

18 0.007

16 0.009

14 0.011

13 0.012

12 0.014

11-1/2 0.015

11 0.016

10 0.02

9 0.025

8 0.03

7 0.035

6 0.04

Multiply PPV by 2.2 for Double or Taper Pipe Threads

TD - Use (1.5 Factor) for Tool Dullness

HP = PPV x SFM x M x TD

28

MATERIAL AND SPEED FACTORS CHART

MATERIAL FACTOR - M SPEED - S.F.M.

Aluminum 0.5 100

Bakelite 0.6 75

Brass 0.6 90

Bronze 0.6 50

Bronze Mang. 1 40

Copper 0.5 80

Alum. Die Cast 0.6 80

Fiber 0.5 75

Zinc Die Cast 0.6 80

Cast Iron 0.6 70

Mall eable Iron 0.6 45

Magnesium 0.5 100

St eel Cast 1.4 35

St eel Fr. Mach. 1 50

St eel Chromium 1.7 30

St eel Alloy 1.7 25

St eel Stainless 1.7 20

REVOLUTIONS PER MINUTE CALCULATION

R.P.M. = 3.82 X S.F.M. + Dia.

Page 29

29

Page 30

30

Page 31

T o order parts or reach our service dep artment, please call our toll-free number between 8:00 a.m. and 4:30 p.m.

(CST), Monday through Friday . Having the Model Number and Serial Number of your machine available when

you call will allow us to serve you quickly and accurately . Locating the stock number of the part(s) required from

your parts manual will also expedite your order .

Phone No.: (800) 248-0144

Fax No. (800) 274-6840

If you are calling from Canada, please call 800-238-4746

E-mail: powermatic@wmhtoolgroup.com

Website: www .wmhtoolgroup.com

31

Page 32

10/03

WMH T ool Group

427 Sanford Road

LaVergne, TN 37086

Phone: (800) 248-0144

Fax: (800) 274-6840

E-mail: powermatic@wmhtoolgroup.com

Website: www.wmhtoolgroup.com

C

POWERMA TIC ALL RIGHTS RESERVED

Loading...

Loading...