Page 1

FEB

. 1970/1 M

POWERMATIC®

OPERATING

INSTRUCTIONS

AND

PARTS

LIST

Model

100-12"

Planer

•

FOR

SERIAL NUMBERS FROM 6200

UP

•

POWERMATIC

IKJOUDAILLE

McMinnville,

Tennessee

37110

c

Page 2

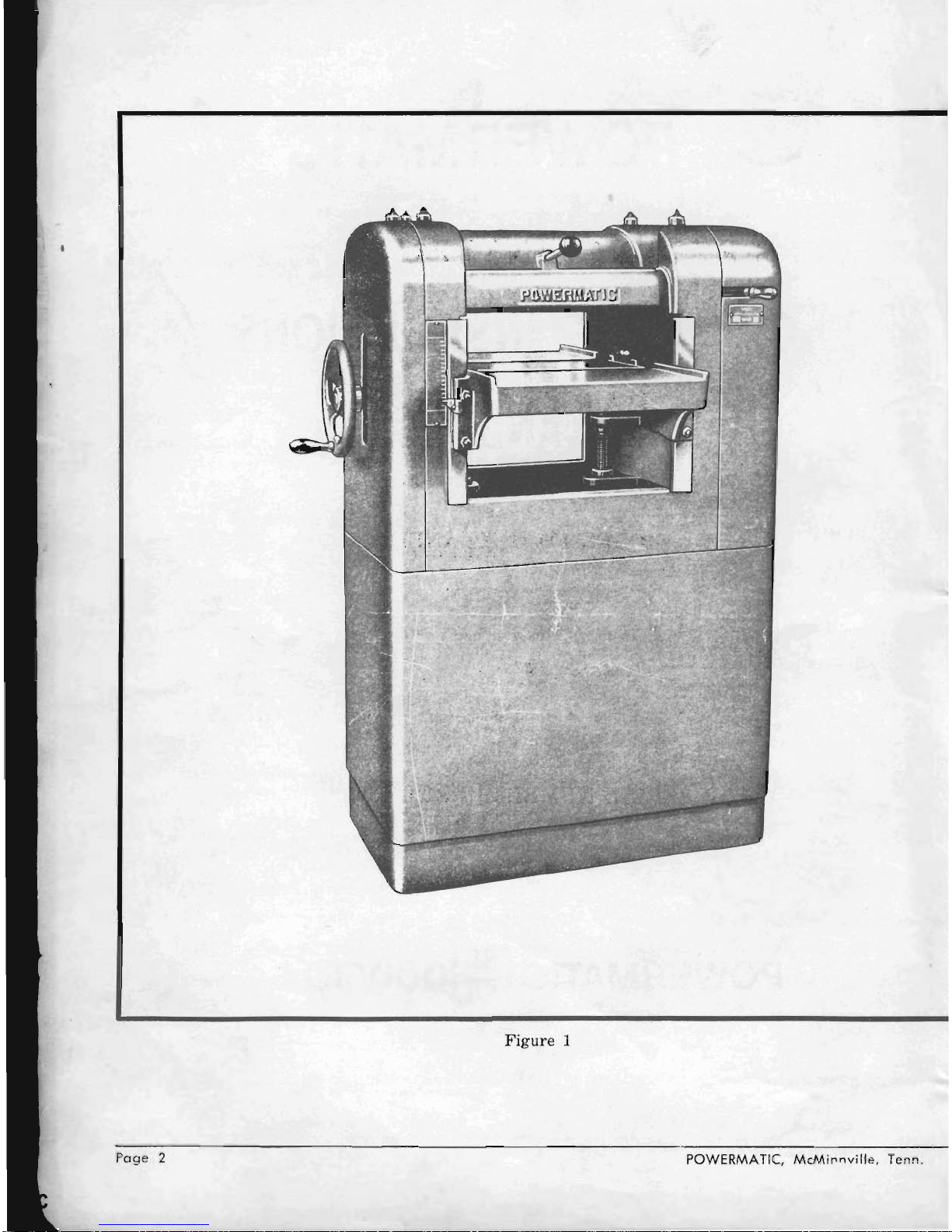

Figure 1

Page 2

POWERMATIC,

McMil'nville, Tenn

.

Page 3

Model

100·12"

Planer

OPERATING INSTRUCTIONS

1.

FRAME

2.

BED

3.

CUTTERHEAD

4.

CHIP BREAKER

5.

FEED ROLLERS

6.

RATE

OF

SPEED

7.

POWER FEED

CONTROL

8.

GUARDS

9.

CAPACITY

MACHINE DESCRIPTION

AND

SPECIFICATIONS

Complete

cast

iron construction

with

detachable motor base.

Heavy cast iron accurately machined

and

ribbed to

withstand

any

type

of abuse .

Table size 12" x 24".

Fitted

with

two

adjustable

idle rolls.

Three

knife

safety

type. Head diameter 3". Mounted in oversized sealed ball

bear-

ings.

Fitted

with

3 high speed steel knives 12" x %" x

Ifs".

Solid one· piece

cast

iron construction. Exceptionally close fitted to

cutterhead.

Corrugated

infeed roller

and

smooth outfeed roller. 2" diameter.

Adjustable

feed

pressure

on both rollers. Driven by V belts

from

cutterhead

shaft

to oversized

cut

gears.

15

feet

per

minute.

Shift

lever located conveniently to

operator.

Stops feed

instantly

without

stopping

power.

Fully

guarded

over all moving

parts

with

removable guards.

Thickest

...........

. .

Thinnest

......

. .

Widest

.......

.

Shortest

not butted

Maximum

depth

of

cut

Cuts

per

inch

Weight, less

stand

Weight,

with

stand

Floor space required

.....

10.

POWER

REQUIREMENTS

2

HP

for

light and medium

work; 3 HP

for

heavy

duty

planing.

groove drive pulley.

5"

1/16"

12"

7'h"

%"

70

3001bs.

3501bs.

.

.. ..15" x 26"

Furnished

with

2

SAFETY RULES

1.

This machine has been designed

with

as

many

safety

features

as humanly possible, however, always remem·

ber

that a planer

is only as

safe

as

its

operator.

2.

BEFORE

starting

planer be

sure

to check

the

following:

(a)

Table

must

be completely

free

of all

foreign

matter.

(b)

Cutterhead

knives MUST be inspected

before

each operation. Check

for

tightness

in

cutterhead

and

make

certain

knives

are

not

fractured

in

any

place.

Flying

knives

are

DANGEROUS.

(c) Knives

for

sharpness!!

3.

Check

material

thickness

and

depth of

cut

desired. Never overload planer,

or

try

to

cut

beyond its capac-

ity.

4.

As

material

is fed into machine,

stand

to side of

board

(never

directly

behind),

nearest

switch. "Kick-

back," caused by

improper

gripping

of lumber by infeed roll and chipbreaker, can cause serious

injury.

5.

Never

stand

directly behind or walk behind machine when

it

is

running.

Direction of

cutterhead

rotation

usually

throws

chips

or

any

foreign

material

from

rear

of machine.

6.

In case

it

is necessary to stop

material

as

it

is feeding

through

machine, disengage feed clutch and

turn

machine off.

Wait

until

cutterhead

has

completely stopped before lowering table to remove

material.

At·

tempted removal while

cutter

head is

turning

may

cause

"kickback."

7.

Nev

er horse around a

running

planer.

"Play"

should absolutely be forbidden as 9

out

of 10 accidents

are

the results of carelessness and playing

with

machine as though

it

were

a toy.

8.

Always stop machine

for

adjustment

or when leaving immediate

area

. Disconnect power source when

working on or around

any

moving

parts.

9.

Never

feed two boards

through a planer

with

solid in feed rolls,

at

once (side by side

or

stacked).

Kick-

back can result

and

board

fly

from

machine

with

velocity of bullet.

10.

Use only genuine Powermatic

(or

factory

authorized) replacement

parts

and

knives-otherwise

all

war·

ranty

and

guarantees

are

null & void.

11.

Keep all

guards

in

place-and

use them.

12.

Do

not

wear

long

or

loose sleeves

or

neckties when

operating

planer.

13.

Extra

care should be taken when

running

short

pieces,

butt

with

another

piece of

material

of equal

thick·

ness and Rtand

ASIDE.

t Base of machine

Rho

uld be grounded to

water

pipe

or

central

grounding

system.

rO:I::~MATIC

,

McMinnville,

Tenn

.

Page

3

Page 4

Model 100-12"

Planer

OPERATING

INSTRUCTION~

Page

4

GENERAL SET-UP AND ALIGNMENT

1.

RECEIVING

Uncrate

and check

for

shipping damage. Clean all coated and

greased

surfaces. Read

instructions

,thoroughly. Locate all lubrication

points;

adjustments;

methods of drive.

2. MOUNTING

Mount machine securely to solid foundation. Locate in clean,

dry

and

well ventilated building

if

possible. Motor and electrical connections

should be

protected

when

not

in operation

or

if

exposed to

weather

elements.

3.

EXHAUST

SYSTEM

Recommended

as a must

if efficient production operation required. Not

a necessity

where

limited

amount

vf operation beiug performed and

machine can be

kept

clean of shavings.

4.

INSPECTION

The above machine requires a minimum

amount

of

attention

and serv-

ice. Periodic

or

regular

inspection is recommended

to

insure

that:

machine is in

proper

adjustment;

electrical connections

are

positive;

no

worn

or

loose V belts or bearings

heating

or

loose.

5.

BEFORE

OPERATING

Check

motor

nameplate

data

or

wiring

diagram

of

motor

and

switch

for

proper voltage connection before wiring into line. Run motor without

load to check

the

connections and direction of rotation. Always

refer

to motor nameplate

data

for

rotation

connections.

POWERMATIC,

McMinnville, Tenn.

Page 5

Model 100·12"

Planer

PLANER BED:

PLANER BED IDLER

ROLLERS:

POWER DRIVE

FEED

ROLLS:

CHIPBREAKER:

POWERMATlC,

McMinnville,

Tenn.

OPERATING INSTRUCTIONS

OPERATING ADJUSTMENTS

The

planer

bed

mounts

in

the

main

frame

panels

and

is held

rigid

by

the

shims

and

adjusting

screws (2) located in

front

of

the

machine.

The

bed is

raised

and

lowered

by

the gears

and

thrust

screws

through

the

handwheel

(1).

Keep

shims

adjusted

to

hold

I'

planer

bed rigid

in

ways

but

not

too

tight

to res

trict

freedom

of

raising

and lowering

with

handwheel.

The

planer

bed

must

also

be level

with

cutterhead.

Check

this

by lowering bed to allow

placing a small

jackscrew

type

guage

or

block hptween one

extreme

end

of

cutterhead.

Slide

gauge

to opposite end

of

cutterhead

to

determine

if

same

measurement

exists.

If

bed is

out

of level

adjust

in following

manner.

Loosen

set

screws in

screw

nut

(3) on

high

side

of

bed and

turn

nut

to

left

until

bed

is level and

tighten

set screw

in

nut.

The

adjusting

screws

(4)

for

the

planer

bed

idler

rollers

are

located

directly

under

the

bearings.

Adjust

.006" to .010"

above bed level

for

planing smooth

or

dry

mat

erial, and .015"

to .025"

for

rough

sawed

or

green

mat

erial. Keep rollers

adjusted

to

same

height

at

both

ends.

When

rollers

are

set

too

high

a

snipe

or

bitE'

out

will

appear

on

both

ends of planed

material.

If

set

too low. feedin

l?,

' will be

restricted

thr

ough

material

friction

on

planer

be,t

There

are

two power

driv

en feed rollers. One

corrugated

infeed

(7) and one smooth outfeed.

The

fe ed rollers

are

held

with

a

spring

loaded plung

er

slide

with

tension to regulate

the

pressure.

Pressure

on feerl rollers is

regulated

with spring

cap screw (12).

To increase

pressure, turn

screw to

right,

to decrease,

turn

to

left.

The

feed rollers

are

held up

with

stud

bolts

(3)

and

are

raised

or

lowered by loosening lock

nut

on bolt (13) and

turning

to

the

right

to raise,

or

to

the

left

to lower rollers.

Feed

rollers

should be

set

.030" below

the

arc

of

the

knife

cut

and

the

rollers

should be parallel

with

planer

bed. To

set

feed rolls, lower

planer

bed

about

3"

below

arc

of

cutterhead.

Place

gauge

di-

rectly

under

cutterhead

and

turn

head until one

knife

is down.

Raise

bed

until

gauge

is .001" below knife.

Feed

roller

setting

may

be checked by feeding a

short

board

through

the

machine,

8"

or

10" wide

and

planing

off a

light

cut.

After

the

Qoard

has

been fed

through

the

machine, feed

it

through

the

machine un-

til both feed rollers touch

the

board.

(Stop

with

Clutch.)

There

should be

1/32"

clearance between

the

spring

cap

screw

(12)

and

stud

screw

nut

(13).

If

the

rollers

are

not

properly

adjusted,

they

may

be

adjusted

at

this

time.

The

chipureaker

may ue raised

from

the

cutterhead

with

handle

(18) exposin g

adjustments

(15)

that

adjLst

the

height

of

the

chipbreaker.

Chipbreaker

should be s

et

.030" below

arc

of

cut-

terhead

knife.

Chipbreaker

should rest on

material

while

it

is

being fed

through

the

machine. When

the

material

is fed

through,

chipbreaker

should

raise

approximately

1/32".

Page

5

Page 6

Model 100-12"

Planer

HOLDDOWN

BAR:

FEED

DRIVE

BELTS:

MATERIAL

THICKNESS

GAUGE:

CUTTERHEAD:

KNIFE

CARE:

Page

6

OPERATING INSTRUCTIONS

The holddown

bar

is

adjusted

with

adjusting

nuts

(14) and

should be

adjusted

.003" below

arc

of

cutter

head knife. To ad-

just

hold down

bar,

loosen lock

nut

and

turn

adjusting

screw

(14) to

the

right

to

raise

and

to the

left

to lower .

To

adjust

feed belts, loosen

nuts

(20)

on the inside of

planer

frame

and

slide

studs

in slots until belts have

proper

tension.

If

machine does not feed properly remove

guard

and check for

belt slippage.

The infeed

and

outfeed rollers have

grea

se fittings (8) and

(9).

Feed drive sheaves

are

lubricated

at

(16) and

(17).

These

fittings

require

greasing

every ten (10) hours of operation with

No.1

grease,

or

a light weight type.

Planer

bed ways, bed

raising

screws, bed idle roller bearings

should be greased every ten

(10)

hours

of operation

with

SAE

No. 10 oil

or

equivalent.

To set

the

indicator on the

material

thickness scale (6) to indi-

cate

properly

after

changing knives, loosen

the

screw in the

planer

bed which holds

the

brass

pointer

and set to

the

thickness

the

material

measures when planed or fed

through

the

machine.

The hole which mounts the

brass

pointer

is slotted

and

will per-

mit

proper

adjustment.

The

cutter

head is equipped

with

three

knives held in position

with

the

lock shims

and

set screws

(10).

Knives

must

be ad-

justed

to

set

evenly and level in the

cutterhead.

Before remov-

ing knives from cutterhead,

the

knife

gauge

should be adjusted

to

the

height

of

the

knives. so

the

height

of

the

knives will not

be changed relative to the

other

parts

of

the

head when the

knives

are

replaced . The feed rollers,

chipbreaker

and pressure

bar

are

adjusted

to the

arc

of

the

knife

cut.

If

the height of

the

knives

are

raised

or

lowered, the feed rollers, chipbreaker

and

pressure

bar

should be

adjusted

accordingly. Knives should

not

protrude

more

than

.030" beyond

radius

of cutterhead.

When replacing knives

after

sharpening,

place

the

"jack

screw"

studs

in place

making

sure

the

"step"

will

act

as a seat

for

the

knife. Drop knife

and

shim into

cutterhead

slot so

that

the

beveled edge of knife is

just

below

the

surface

of the head.

Tighten

the two outside knife shim screws

just

enough to hold

the

knives snugly in the head., With knife

settin~

gauge in

place over one

extreme

end of

the

head,

turn

the

allen screw in

"jack

screw"

plugs,

raising

knife until knife touches stop on

knife

setting

gauge. Repeat operation on

other

end of

the

cut-

terhead.

Next,

tighten

the

center

knife

locking shim bolt. Set

the

other

knives in

the

cutterhead

before

tightening

remainder

of

the shim bolts.

After

th~

knives have been set, final locking

of knives should be done by

rotating

cutter

head and locking all

shims uniformly.

CAUTION-If

one knife is locked tightly

before

the

others,

it

may

spring

the

cutterhead

and cause vi-

bration

or

uneven knife height.

IMPORTANT:

Knives should be kept

sharp.

The knive s

do

all

of

the

work

and

they

will

not

do

satisfactory

work

if

they

are

DULL. The sets of knives

are

matched and balanced

at

the

factory. When

the

knives

are

sharpened, care should be taken

that

they

are

kept

in balance.

POWERMATIC,

McMinnville,

Tenn.

Page 7

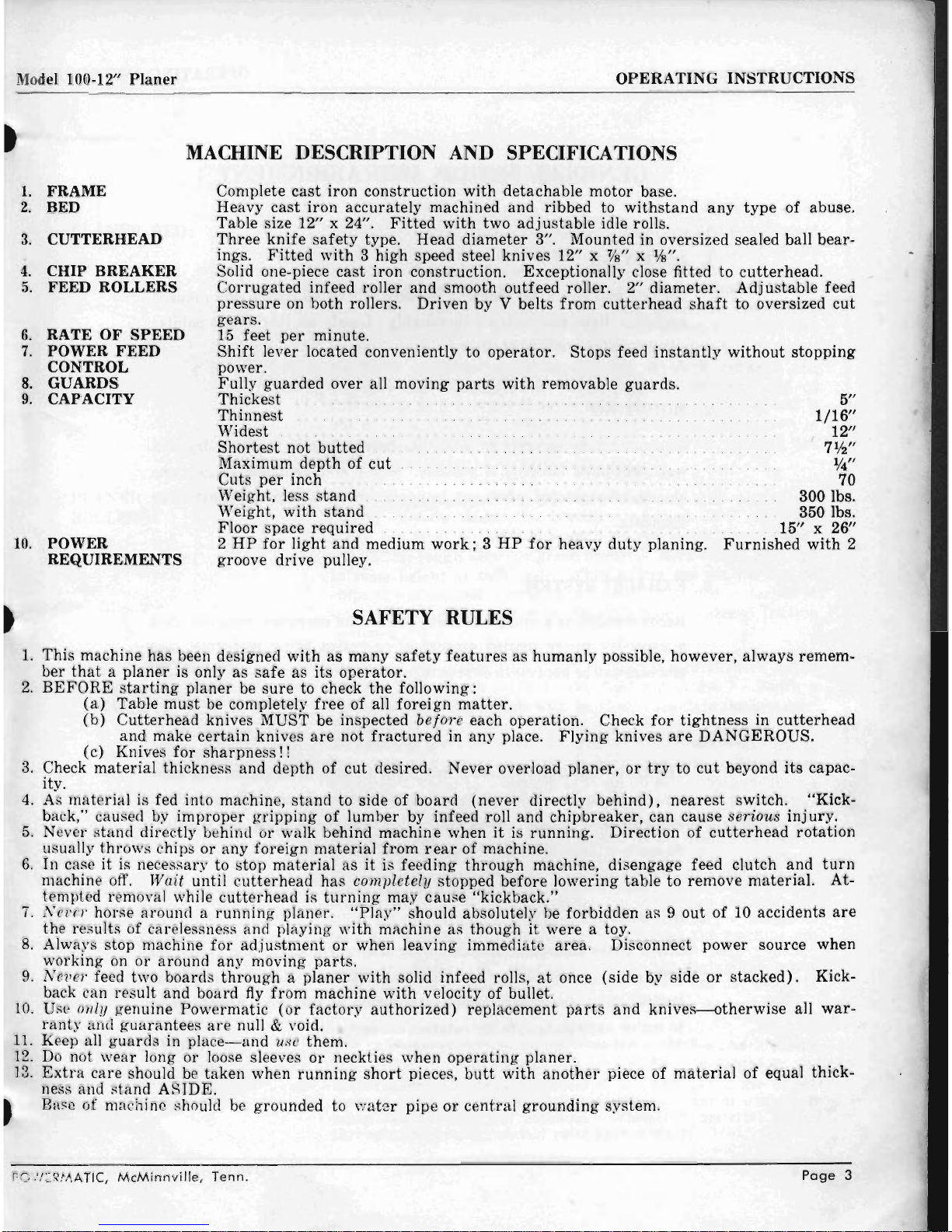

Figure

1

POWERMATIC,

McMinnville,

Tenn.

Page

7

Page 8

Page 8

60067-2

100-17

100 -32

====r-:==t===:::::;2d~

7fi7i,.~

~~

100-30

---

100-08

----'-----I--_

f-...

60035-6

-----.;---

60002-1

----l---

I

---2::

100-16

-11---1-----

60002-3

------

I-

---~

60025-4

------'-----.L-:---~

100.05

-----------1----

-.,

----.

100-102=----------f--

~'·

----.

100-66

----------+--~~--=:

100-55

===========!=====~

100-54

60014-1

---------------=

40136-2

100-54

----------------

100-26

---------------....::

60025-2

---------------

60014-1

60078-7

---------------

100-25

--------------~

100-18

--------------~

40092

100-24

-==============

40111-3

-

40092

100 -73

--------------.

60014-1

100-29

---------

60078-5

---------

100~2

---------.

100 -62

--------

100-

29

-------

100-23

------

60067

-3

-----=:---

60003-1

---

60026-5---

100-12

---

100-20

-----"'

.~

100-21

----.-.:

60014-2

----~~

60002-1

-----

100-18

======

________________

---.J

100-48 =====-------------=====:::..

100-47 1

------

100-35A -

60002-3

-

60002-3

-

100-39

100-80

100-37

POWERMATIC, McMinnville, Tenn.

Page 9

I

~

=

===============60067-2

00-(8

=

==-----==

60002-3

=

---------== 60002-3

00-36

:::.:

~~~-=--=--=--=--=--=-========

60014-5

00-35

::-~~~~~~~~~~~~~~~=

IOO-JJ

=

==-----====

00·00

00-06

::==--';11;======60014

-1

~~':111/'---

,18020-1

N

60014-1

---~----------==-

- 00-11

~

00-42

~

~-----===

00-102

~

~~

~=--=======-

00-13

~

:::::=----=====

40112-8

00-43

====--------00-01

00-06

~-----=======-60120

.

-------==

60005-4

'-

00-57

~

=-----~=========-==========-==-=~~~~~~~~~===60003-1

~

~======================

60002-3

00-100

~

-U~~~~~~~~60002-1

L.rL=

00-77

00-107

/J

POWERMATlC,

McMinnville, Tenn.

Page 9

Page 10

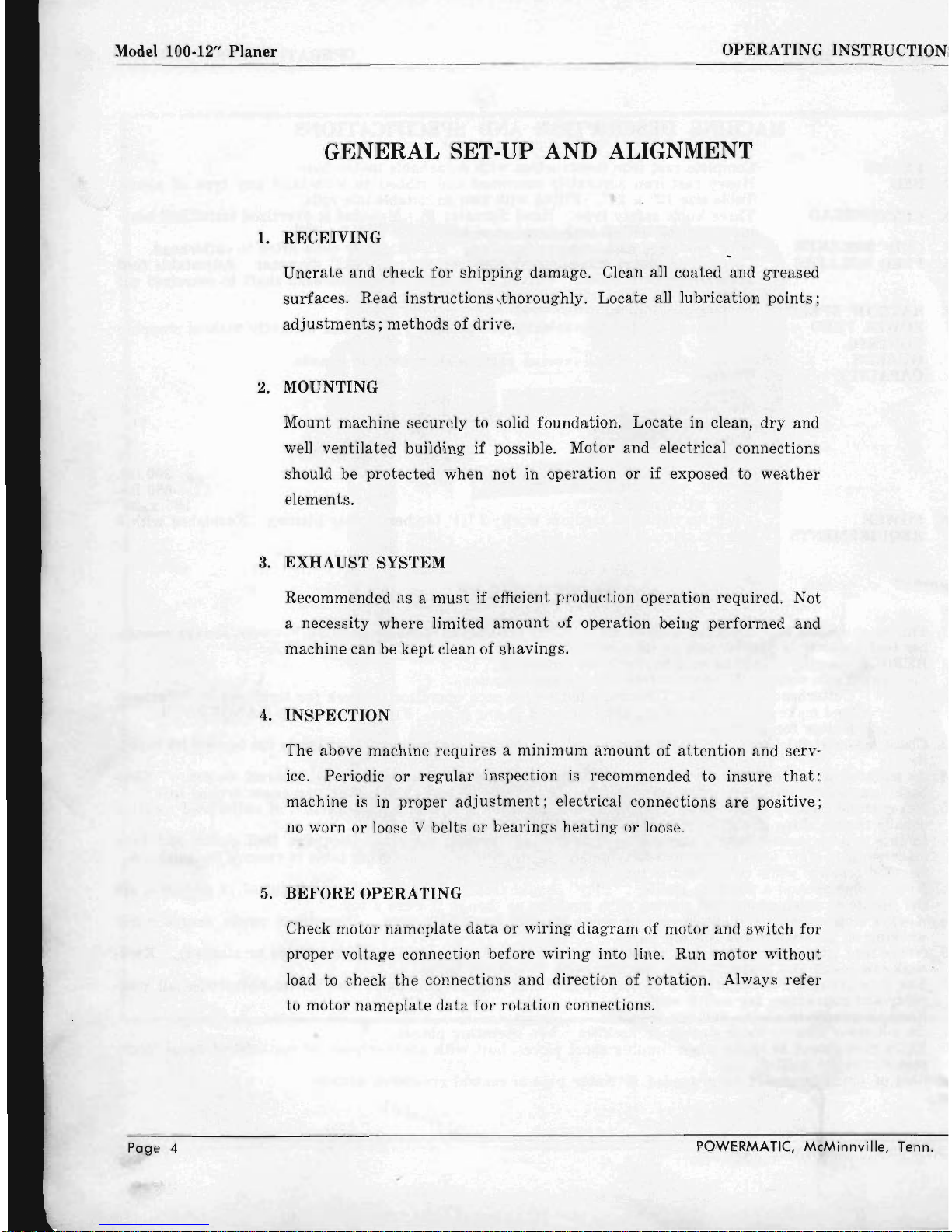

Figure

2

Page

10

POWERMATIC,

McMinnville,

Tenn.

Page 11

®

Figur

e 3

POWERMATlC,

McMinnville,

Tenn.

Page

11

Page 12

PLANER OPERATING HINTS

IF CLIP OR

SNIPE

APPEARS

AT BEGINNING

OF

BOARD

1.

Pressure

bar

may

be

set

too low.

2.

Chipbreaker

may be

set

too high.

3.

Upper

infeed sectional roll

may

be

set

too

high

.

4.

Lower

infeed roll

may

be

set

too high.

5.

Spring

tension

may

be too

light

on

pressure

bar.

6.

Bed

may

be too loose.

IF

CLIP

OR

SNIPE

APPEARS

ON

END

OF LUMBER:

1.

Pressure

bar

may

be

set

too high.

2.

Lower outfeed roll

may

be

set

too high.

3. '

Upper

outfeed roll

may

be

set

too low.

4.

Lumber

may

not

be butted.

5.

Grai.n

may

be

running

against

knives.

IF

KNIVES

TEAR

OUT

LUMBER:

1.

Feed

may

be too

fast.

2.

Moisture

content

may

be too high.

3. Head

may

be

running

too slowly.

4.

Cut

may

be too heavy.

5.

Cutting

angle

may

be too large.

6.

Grain

may

be

running

against

knives.

IF

KNIVES

RAISE

THE

GRAIN:

1. Feed

may

be too

fast.

2.

Cutting

angle

may

be too large.

3.

Head

may

be

running

too slowly.

4.

Moisture

content

of lumber

may

be too high.

5.

Cut

may

be too heavy.

IF CHIP MARKS

APPEAR

ON

LUMBER:

1. Blower

system

may

not

be

strong

enough.

2.

Feed

may

be too

fast.

3. May be loose connection in blower

system-no

suction.

4.

Exhaust

pipe

may

join

at

too

large

an

angle to main blower pipe.

IF

PANELS

ARE

TAPERED

ACROSS

THE

WIDTH:

1.

Planer

bed

out

of level

with

cutterhead.

2.

Knives

not

set

even

with

cutterhead.

IF

UNDESIRED

POUNDED GLOSSY

FINISH

APPEARS:

1.

Knives

may

be dull.

2.

Feed

may

be too slow.

Page

12

POWERMATIC,

McMinnville,

Tenn.

Page 13

Model 100-12"

Planer

OPERATING INSTRUCTIONS

IF

WASHBOARD

FINISH

APPEARS:

1. Knives

may

have

been

driven

back

into

the

head.

2.

Machine

may

be completely

out

of

adjustment.

3.

Planer

bed loose

and

rocking

in

ways.

IF

REVOLUTION MARKS SHOW

UP:

1. Knives

may

be

ground

poorly.

2.

Knives

not

set

properly

or

evenly.

IF

LINES

APPEAR

AT RIGHT ANGLES

TO

THE

KNIFE

MARKS:

1. Knives

may

have checkered

and

nicked up

by

overgrinding

and

taking

temper

out

of

steel.

2.

Chips

may

have

wedged

between

rolls

and

tables.

3.

Pressure

bar

may

be

dragging.

IF

STOCK TWISTS IN MACHINE:

1.

Pressure

bar

may

be cocked.

2.

Upper

outfeed

roll

may

be cocked.

3.

Upper

outfeed

roll

may

have

uneven

spring

tension

on

it.

4.

Lower rolls

may

be cocked.

IF

STOCK STICKS OR HESITATES IN MACHINE:

1.

Pressure

bar

may

be

set

too low.

2.

Lower rolls

may

be

set

too low.

3.

Upper

rolls

may

not

be

set

low enough.

4.

Cut

may

be too heavy.

5. Coaxer

board

may

help

lumber

through

machine.

6.

Feed

belts

may

be slipping.

IF

MACHINE IS NOISY AND VIBRATES AND POUNDS:

1. Knives

may

be too dull.

2.

Machine

may

not

be leveled

up

correctly.

3. Machine

may

not

be on solid foundation.

4.

Pressure

bar

may

be

set

too low.

IF

MOTORS KICK OUT:

1. Knives

may

be dull,

thus

overloading

motors.

2.

Pressure

bar

may

be'

set

too low,

putting

drag

on

motors.

3.

Motors

may

be

drawing

high

current

because

other

machinery

in

the

plant

in use

has

pulled down

the

voltage.

4.

Machine

may

be

out

of

adjustment.

5. Lower rolls

may

be

set

too low.

POWERMATIC,

McMinnville,

Tenn.

Page

13

Page 14

Model 100-12"

Planer

OPERATING INSTRUCTIONS

Part

No.

100-1

100-2

100-3

100-4

100-5

100

-6

100-8

100-9

100-10

100-11

100-12

100-13

100-16

100-17

100-18

100-20

100-21

100-22

100-23

100-24

100-25

100-26

100-29

100-30

100-32

100-33

100-35

100-35A

100-36

100-37

100-39

100-42

100-43

100-44

100-46

100-47

100-48

100-50

100-51

100-52

100-53

100-54

100-55

100-57

100-58

100-59

100-60

100-62

100-66

PARTS LIST FOR MODEL

100-12"

PLANER

STATE PLANER SERIAL

NUMBERS

\VH

EN

ORDERING

PARTS

Description

Cutterhead

Roller,

Outfeed

Roller,

Infeed

Chipbreaker

Bearing

Housing,

R

Bearing

Housing

, l

Table

Belt

Guard

Stud,

Cutterhead

Guard

Pulley, 2

AK

27

Pin

____________

_

Bearing,

Fafnir,

206Kll

_________

_

Shim,

Table

Adj

Feed

Drive

Guard

Assy

Stud

Feed

Drive

Guard

Mtg

_

lever,

Clutch

Brkt, Clutch

lever

Mtg

Sheave,

Clutch

Collar

& Clutch

Pinion, Clutch

lever

____________

_

Shaft,

Clutch Pinion _

__

______

__

Brkt, Clutch Mtg

_________________

_

Gear,

Feed

Roller Drive

Bearing

Housing

Table

Roller

Stud,

Feed

Roller

Bearing

_

Spring, Outfeed

Press

Stud, 12102

__

Spring,

Infeed

Press

Stud, 12101

Nut,

Feed

Roll

Spring

_____________

_

Stud,

Pressure

Bar

Bushing

Pressure

Bar

Shaft

__ _ ________________

_

Gear

____________________

_

Gear

____ . _________

_

Bearing

, Thrust, Nice

605

__ . __

_

Screw

(lH)

_____ _____ _ ________

_ _

_____

_

Nut

____

_

*Belt, Clutch ,

Browning

33A

__

_

*Belt,

Cutterhead, Browning

36A

_

*Belt,

Compound

Drive,

Brwng

28A

Hange~

Compound

Sheave

Sheave

,

Compound

Shaft, Threaded

Pressure

Bar

Shim, Cutte

rhead Knife

Jacksc

rew

Peanut

Brace

Front

Pane

l

Spacer

, Clutch

Space

r,

Comp

Feed

Roller

No

.

Required

1

1

1

2

2

2

1

2

2

2

2

1

2

2

1

2

2

4

2

2

2

2

3

Part

No.

100-72

100-73

100-77

100-83

100-86

100-89

100-92

100-102

100-106

100-107

100-108

18020-1

40092

40111-3

40111 -7

40112-8

40136-2

60002-1

60002

-3

60002-6

60003-1

60005-4

60008-3

60014-1

60014-2

60014-5

60025-2

60025-4

60025

-1

(\

60026-1

60026

-5

60026-6

60026-7

60035

-3

60035-6

60062

60067-2

60067

-3

6

0078-

5

60078-7

60120

60025

-4

100-80

1200-623

Description

Shaft

Compound

Sheave

Grease,

Alemite,

Va

Pipe

Stand

Assembly

Main

Frame

___

_

Cutterhead

Knife

Knob

Handwheel

Bearing

Housing

_____________ _ __ _ ______

_

Slotted

Head

SS,

5/16

- 18 x 1

Screw

__

Nut

Handwheel

Collar

Key, 3/

16 x 3/16

x

Key, 3/ 16 x

3/16

x 1Y2

Key,

\~

x

\4

x 1 %

Pulley, AS-

26

Nut

, Hex, 5 / 16 - 18

Nut, Hex,

% -

16

____

_

Nut, Hex, Y2 - 13

____________________

_

lock

Washer,

5/16

_____________

_

Socket

Cap

Screw,

5/16

- 18 x Y2 _

Split Pin,

\4

x 1

\4

Socket

Set

Screw,

5/16

- 18 x %

___

_

Socket

Set

Screw,

5/16

- 18 x

Yl

Socket Set

Screw,

5/ 16 - 18 x 1

Hex

Head

Cap

Screw,

3/

S

- 16 x 1

Hex

Heod

Cap

Screw,

% - 16 x ]34

l:Iex

Head

Cap

Screw,

% - 16 x 1

\4

Washer

Flat, %

Washer

Flat, 5/

16

Washer

Flat, Y2

___________________________

_

Washer

Flat, %

____________

_

Square

Head

Set

Screw, 5/16-

18 x

Yl

_____

_

Square

Head,

Set

Screw,

5/16

-

18

x 1 Y2

__

____

__

Rivet ,

\4

x 3

Hex

Head

Cap

Screw,

5/16-

18x

Yl

Hex

Head

Cap

Screw,

5n 6 18 x

11

1"

Bushi

ng,

Oi lite

Bushing, Oilite

Grease,

Alemi

te

_____________

______ _

Hex

Head

Cap

Screw

, % -

16

x 134

Spring

Handle

'No

t Picture d

No.

Required

1

3

2

2

1

2

1

6

10

1

2

~

4

14

2

4

2

4

1

5

18

4

4

2

4

4

4

2

-P-a-g-e--14--------------------------

--

---

-----

---------------------P~O~\-

V~[~R

~M~,A~T~.;~(-,~i.~A

~~-:-~~~in-n-v~ii~:e-,~ienn.

Page 15

Page 16

Loading...

Loading...