Porter-Cable CPF23400S User Manual

Part No. D20692-005

Side Stack

Compressor

Instruction

manual

To learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

The Model and Serial No. plate is located on the

frame. Record these numbers in the spaces below

and retain for future reference.

Model No.

Type

Serial No.

ESPAÑOL: PÁGINA 13

FRANÇAISE: PAGE 27

IMPORTANT

Please make certain that the person who is to use

this equipment carefully reads and understands

these instructions before starting operations.

PROFESSIONAL POWER TOOLS

Copyright © 2000 PORTER-CABLE Corporation

MODEL

CPF23400S

2-ENG

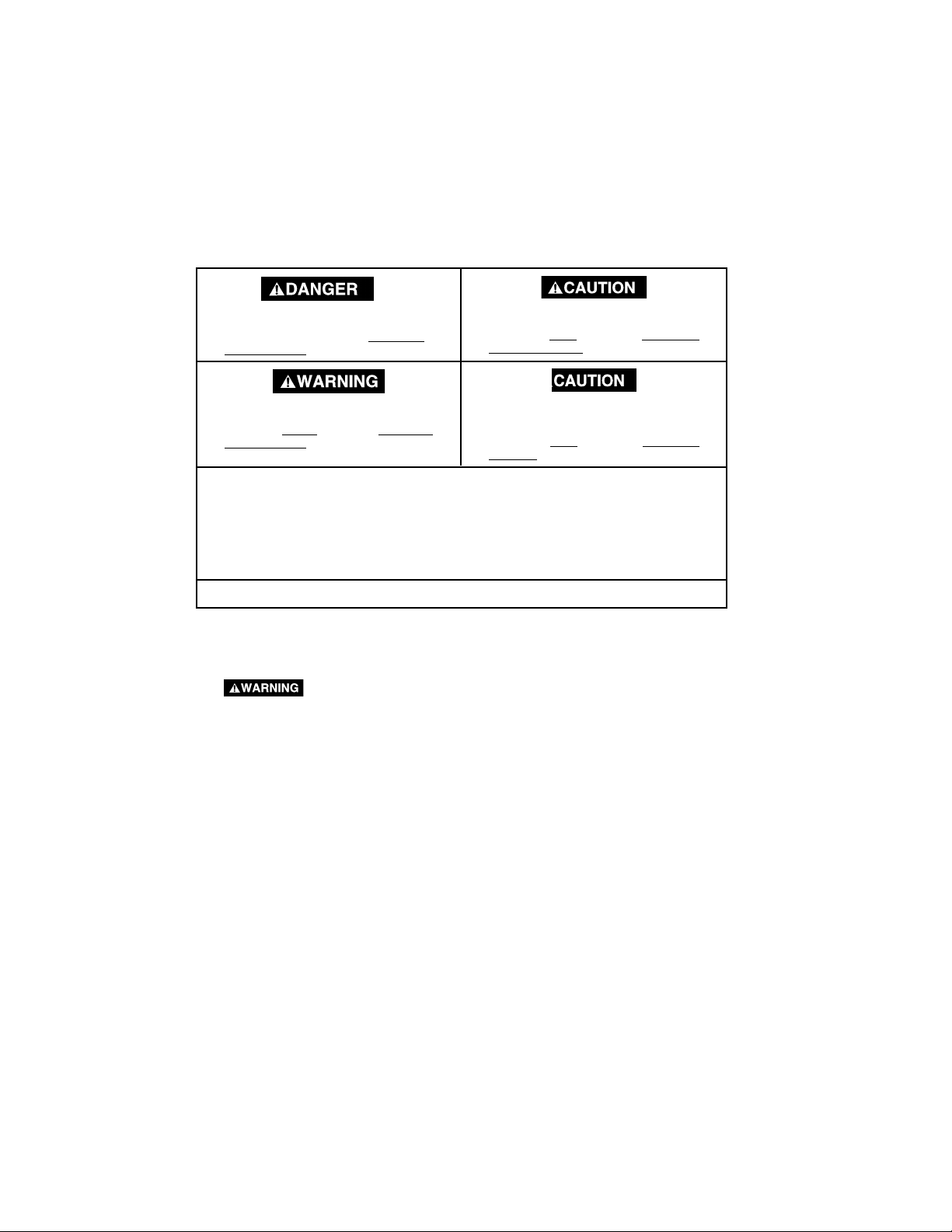

CAUTION indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

This manual contains information that is important for you to know and understand. This infor-

mation relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To

help you recognize this information, we use the symbols below. Please read the manual and

pay attention to these sections.

DANGER indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

CAUTION used without the safety

alert symbol indicates a potentially

hazardous situation which, if not

avoided, may result in property

damage.

WARNING indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Call our Toll Free Number 1-888-559-8550, to obtain the location of the nearest Autho-

rized Service Center for ordering repair parts and for warranty repairs.

When ordering repair parts from your local Authorized Service Center, always give the

following information:

• Model number of your compressor

• Part number and description of the item you wish to purchase

Retain Original Sales Receipt as Proof of Purchase for Warranty Repair Work.

SAFETY GUIDELINES - DEFINITIONS

IMPORTANT SAFETY INSTRUCTIONS

When using electric tools, basic safety precautions

should always be followed to reduce the risk of fire, electric shock

and personal injury, including the following:

READ AND FOLLOW ALL INSTRUCTIONS.

This tool was designed for certain applications. Porter-Cable strongly recommends

that this tool NOT be modified and/or used for any application other than for which

it was designed. If you have any questions relative to its application DO NOT use

the tool until you have written Porter-Cable and we have advised you.

Technical Service Manager

Porter-Cable Corporation

4825 Highway 45 North

P.O. Box 2468

Jackson, TN 38302-2468

3-ENG

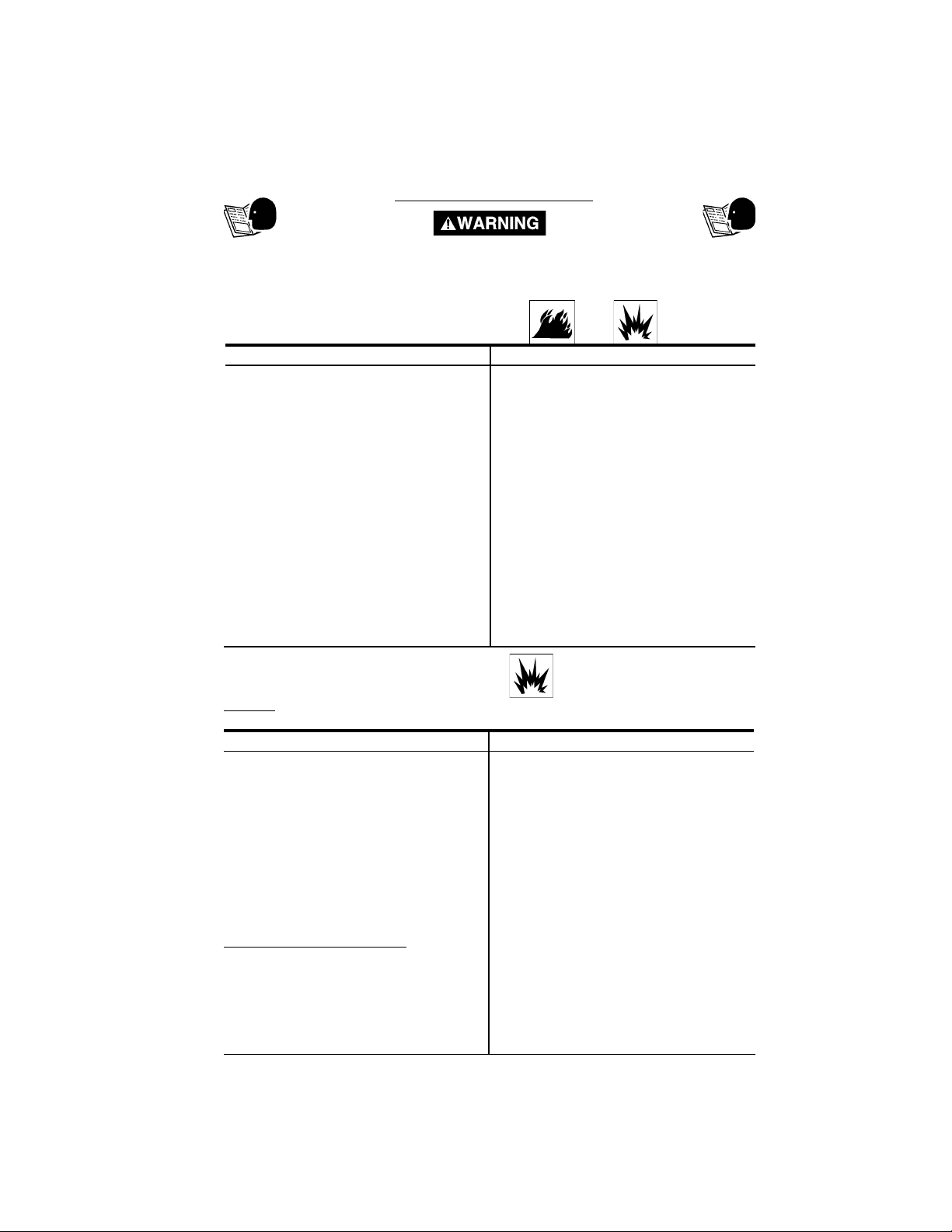

RISK OF BURSTING

IT IS NORMAL FOR ELECTRICAL CONTACTS

WITHIN THE MOTOR AND PRESSURE SWITCH TO

SPARK.

IF ELECTRICAL SPARKS FROM COMPRESSOR

COME INTO CONTACT WITH FLAMMABLE

VAPORS, THEY MAY IGNITE, CAUSING FIRE OR

EXPLOSION.

RESTRICTING ANY OF THE COMPRESSOR

VENTILATION OPENINGS WILL CAUSE SERIOUS

OVERHEATING AND COULD CAUSE FIRE.

UNATTENDED OPERATION OF THIS PRODUCT

COULD RESULT IN PERSONAL INJURY OR

PROPERTY DAMAGE.

ALWAYS OPERATE THE COMPRESSOR IN A WELL

VENTILATED AREA FREE OF COMBUSTIBLE

MATERIALS, GASOLINE OR SOLVENT VAPORS.

IF SPRAYING FLAMMABLE MATERIALS, LOCATE

COMPRESSOR AT LEAST 20 FEET AWAY FROM

SPRAY AREA. AN ADDITIONAL LENGTH OF HOSE

MAY BE REQUIRED.

STORE FLAMMABLE MATERIALS IN A SECURE

LOCATION AWAY FROM COMPRESSOR.

NEVER PLACE OBJECTS AGAINST OR ON TOP

OF COMPRESSOR. OPERATE COMPRESSOR IN

AN OPEN AREA AT LEAST 12 INCHES AWAY FROM

ANY WALL OR OBSTRUCTION THAT WOULD

RESTRICT THE FLOW OF FRESH AIR TO THE

VENTILATION OPENINGS.

OPERATE COMPRESSOR IN A CLEAN, DRY, WELL

VENTILATED AREA. DO NOT OPERATE UNIT

INDOORS OR IN ANY CONFINED AREA.

ALWAYS REMAIN IN ATTENDANCE WITH THE

PRODUCT WHEN IT IS OPERATING.

SAVE THESE INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS INJURY

AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING

INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

RISK OF EXPLOSION OR FIRE

AIR TANK: THE FOLLOWING CONDITIONS COULD LEAD TO A WEAKENING OF THE TANK, AND RESULT

IN A VIOLENT TANK EXPLOSION AND COULD CAUSE PROPERTY DAMAGE OR SERIOUS INJURY.

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

DRAIN TANK DAILY OR AFTER EACH USE. I F TANK

DEVELOPS A LEAK, REPLACE IT IMMEDIATELY

WITH A NEW TANK OR REPLACE THE ENTIRE

COMPRESSOR.

NEVER DRILL INTO, WELD, OR MAKE ANY

MODIFICATIONS TO THE TANK OR ITS

ATTACHMENTS.

THE TANK IS DESIGNED TO WITHSTAND SPECIFIC

OPERATING PRESSURES. NEVER MAKE

ADJUSTMENTS OR PARTS SUBSTITUTIONS TO

ALTER THE FACTORY SET OPERATING

PRESSURES.

FOR ESSENTIAL CONTROL OF AIR PRESSURE,

YOU MUST INSTALL A PRESSURE REGULATOR

AND PRESSURE GAUGE TO THE AIR OUTLET OF

YOUR COMPRESSOR. FOLLOW THE EQUIPMENT

MANUFACTURERS RECOMMENDATION AND

NEVER EXCEED THE MAXIMUM ALLOWABLE

PRESSURE RATING OF ATTACHMENTS. NEVER

USE COMPRESSOR TO INFLATE SMALL LOW-

PRESSURE OBJECTS SUCH AS CHILDREN’S

TOYS, FOOTBALLS, BASKETBALLS. ETC.

1. FAILURE TO PROPERLY DRAIN CON-

DENSED WATER FROM THE TANK,

CAUSING RUST AND THINNING OF THE

STEEL TANK.

2. MODIFICATIONS OR ATTEMPTED REPAIRS

TO THE TANK.

3. UNAUTHORIZED MODIFICATIONS TO THE

UNLOADER VALVE, SAFETY VALVE, OR

ANY OTHER COMPONENTS WHICH

CONTROL TANK PRESSURE.

4. EXCESSIVE VIBRATION CAN WEAKEN THE

AIR TANK AND CAUSE RUPTURE OR

EXPLOSION.

ATTACHMENTS & ACCESSORIES:

EXCEEDING THE PRESSURE RATING OF AIR

TOOLS, SPRAY GUNS, AIR OPERATED

ACCESSORIES, TIRES AND OTHER INFLATABLES

CAN CAUSE THEM TO EXPLODE OR FLY APART,

AND COULD RESULT IN SERIOUS INJURY.

WHAT CAN HAPPEN

HOW TO PREVENT IT

4-ENG

RISK FROM FLYING OBJECTS

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

THE COMPRESSED AIR STREAM CAN CAUSE

SOFT TISSUE DAMAGE TO EXPOSED SKIN AND

CAN PROPEL DIRT, CHIPS, LOOSE PARTICLES

AND SMALL OBJECTS AT HIGH SPEED,

RESULTING IN PROPERTY DAMAGE OR PERSONAL

INJURY.

ALWAYS WEAR ANSI Z87.1 APPROVED SAFETY

GLASSES WITH SIDE SHIELDS WHEN USING THE

COMPRESSOR.

NEVER POINT ANY NOZZLE OR SPRAYER TOWARD

ANY PART OF THE BODY OR AT OTHER PEOPLE

OR ANIMALS.

ALWAYS TURN THE COMPRESSOR OFF AND

BLEED PRESSURE FROM THE AIR HOSE AND

TANK BEFORE ATTEMPTING MAINTENANCE,

ATTACHING TOOLS OR ACCESSORIES.

WHAT CAN HAPPEN

HOW TO PREVENT IT

THE COMPRESSED AIR FROM YOUR

COMPRESSOR IS NOT SAFE FOR BREATHING!

THE AIR STREAM MAY CONTAIN CARBON

MONOXIDE, TOXIC VAPORS OR SOLID PARTICLES

FROM THE TANK.

SPRAYED MATERIALS SUCH AS PAINT, PAINT

SOLVENTS, PAINT REMOVER, INSECTICIDES,

WEED KILLERS, CONTAIN HARMFUL VAPORS AND

POISONS.

ALWAYS OPERATE AIR COMPRESSOR OUTSIDE

IN A CLEAN, WELL VENTILATED AREA. AVOID

ENCLOSED AREAS SUCH AS GARAGES,

BASEMENTS, STORAGE SHEDS, WHICH LACK A

STEADY EXCHANGE OF AIR. KEEP CHILDREN,

PETS AND OTHERS AWAY FROM AREA OF

OPERATION.

NEVER INHALE AIR FROM THE COMPRESSOR

EITHER DIRECTLY OR FROM A BREATHING DEVICE

CONNECTED TO THE COMPRESSOR.

WORK IN AN AREA WITH GOOD CROSS-

VENTILATION. READ AND FOLLOW THE SAFETY

INSTRUCTIONS PROVIDED ON THE LABEL OR

SAFETY DATA SHEETS FOR THE MATERIAL YOU

ARE SPRAYING. USE A NIOSH/MSHA APPROVED

RESPIRATOR DESIGNED FOR USE WITH YOUR

SPECIFIC APPLICATION.

RISK TO BREATHING

WHAT CAN HAPPEN

HOW TO PREVENT IT

YOUR AIR COMPRESSOR IS POWERED BY

ELECTRICITY. LIKE ANY OTHER ELECTRICALLY

POWERED DEVICE, IF IT IS NOT USED PROPERLY

IT MAY CAUSE ELECTRIC SHOCK.

REPAIRS ATTEMPTED BY UNQUALIFIED

PERSONNEL CAN RESULT IN SERIOUS INJURY OR

DEATH BY ELECTROCUTION.

ELECTRICAL GROUNDING: FAILURE TO PROVIDE

ADEQUATE GROUNDING TO THIS PRODUCT

COULD RESULT IN SERIOUS INJURY OR DEATH

FROM ELECTROCUTION. SEE GROUNDING

INSTRUCTIONS.

NEVER OPERATE THE COMPRESSOR OUTDOORS

WHEN IT IS RAINING OR IN WET CONDITIONS.

NEVER OPERATE COMPRESSOR WITH COVER

COMPONENTS REMOVED OR DAMAGED.

ANY ELECTRICAL WIRING OR REPAIRS

REQUIRED ON THIS PRODUCT SHOULD BE

PERFORMED BY AUTHORIZED SERVICE

CENTER PERSONNEL IN ACCORDANCE WITH

NATIONAL AND LOCAL ELECTRICAL CODES.

MAKE CERTAIN THAT THE ELECTRICAL CIRCUIT

TO WHICH THE COMPRESSOR IS CONNECTED

PROVIDES PROPER ELECTRICAL GROUNDING,

CORRECT VOLTAGE AND ADEQUATE FUSE

PROTECTION.

RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN

HOW TO PREVENT IT

Loading...

Loading...