Porsche M 44/01, M 44/02, M 44/05, M 44/04, M 44/06 Workshop Manual

...

Workshop Manuel

Volume I - Engine, 8 valves

DR. ING. h. c. F. PORSCHE Aktiengesellschaft

WORKSHOP MANUAL 944

This Workshop Manual descr

ibes all of the important operations for which special instructions are required to

assure proper completion. This manual is essential for shop foremen and mechanics, who need this

information to keep the vehicles in safe operating condition. The basic safety rules, of course, also apply to

repairs on vehicles without exception.

Only those repair jobs deviating from those of vehicle type 924 are described in the 944 Workshop Manual.

Refer to the 924 Workshop Manual for all other information.

The information is grouped according to repair numbers which are identical to the first two digits of the

warranty job codes.

The repair group index, list of contents and the register tabte are quick guides to find information in the

manual. The layout drawings in this manual are numbered in the order of disassembling and, if necessary,

also have information on assembly or installation and application of special tools.

Descriptions of design and function can be found in the service training course reference material.

This Workshop Manual will be kept up to date with Technical Information Bulletins, which will be made part

of the manual from time to time. We recommend that these bulletins be filed in the standard type folder

provided for this purpose.

Printed in Germany

List of Repair Groups 944

General

Technical Data Page 0.1

Repair Groups

Group

Maintenance, Self-diagnosis 03

Engine

Engine, Crankcase

Engine, Crankshaft, Pistons

Engine, Cylinder Head and Valve Drive

Engine, Lubrication

Engine, Cooling

Fuel Supply

Air Flow Controlled Fuel Injection

Exhaust System/Emission Controls

Starter, Power Supply, Cruise Control

Ignition System

DME Diagnosis

10

13 15 17 19 20

24

26 27

28

Transmission

Clutch, Controls

Torque Converter

Manual Transmission, Controis, Case

Manual Transmission, Gears, Shafts

Autornatic Transmission, Controls, Case

Automatic Transmission, Gears, Valve Body

Differential, Transaxle System

30

32 34 35 37 38

39

Chassis

Front Wheel Suspension

Rear Wheel Suspension, Axle Shaft

Wheels, Tires, Alignment

Antiblock System

Brakes, Mechanical

Brakes, Hydraulics, Regulator, Booster

Steering

40

42

44

45 46 47

48

Body

Body-Front Section

Body-Center Section

Body-Rear Section

Lids

Doors

Hardtop

Bumpers

Glasses, Window Control

Exterior Equipment

Interiør Equipment

Seats

Seat Covers

Airbag Diagnosis

50

51 53 55 57 61 63 64 66 68 72

74

Heating,

Ventilation,

Air Condition

Heater

Ventilation

Air Conditioner

80

85

87

Electrics

Instruments, Fuel Gauge, Alarm System

Radio, Telephone

Windshield Wipers and Washer

Exterior Lights, Lamps, Switches

Interiør Lights

Wiring

90

91 92

94

96

97

Printed in Germany - XXI, 1989

9 4 4

0 Blank Page

944 Table of contents volume I

General

Technical data

Engine, Crankcase

Tolerances and wear limits

Tightening torques for engine

Engine, removing and installing (manual transmission)

Hydraulic engine mounts, removing and installing

Checking hydraulic engine mounts

Installing new hydraulic engine mounts

Engine, Crankcase, Pistons

Checking and adjusting tension of Poly-rib belt for

alternator and compressor

Checking adjustment of compensating shaft

Checking and adjusting tension of the power pump belt

Calibrating Special Tool 9201

Checking and adjusting toothed belt tension - compensating shafts

Checking and adjusting toothed bert tension - compensating shafts (idler pulley with

slot)

Installing toothed belt - compensating shaft

Application - assembly stand VW 540 and engine holders 9127 and 9197

Identification of engine number on crankcase

Identification code, crankcase engine number

Crankcase and crankshaft, disassembling and assembling

Installing cover for the centrifugal compartment

Checking crankshaft bearing play

Identification code - upper and lower crankcase sections and compensating shaft

cover

Sealing crankcase - upper and lower sections

Installing upper and lower crankcase sections

Aligning upper and lower crankcase sections

Installing crankshaft seal (flywheel side)

Flywheel and grooved ball bearing, removing and installing

Refacing the flywheel

Replacing setscrew (reference mark sensor)

Setting crankshaft to TDC, cylinder 1

Crankshaft dimensions - standard and machined

Checking pistons and cylinder bore

Pistons, disassembling and assembling con rods

Installing pistons with con rods

Pistons, from Model 89 onwards

Installing pistons with con rods

Holding the flywheel for assembly work (with engine installed)

Page

0.2

10 - 01

10 - 03

10 - 1

10 - 7

10 - 10

10 - 11

13 - 1

13 - 2

13 - 2a

13 - 2b

13 - 3

13 - 6

13 - 11

13 - 13

13 - 14

13 - 14b

13 - 15

13 - 20 b

13 - 21

13 - 22

13 - 23

13 - 24

13 - 24 a

13 - 25

13 - 26

13 - 26a

13 - 27

13 - 28

13 - 29

13 - 31

13 - 32

13 - 34 a

13 - 34 b

13 - 35

13 - 37

Table of contents

Printed in Germany - XXIV, 1993

1

volume I Table of contents 944

Compensating shaft drive, disassembling and assembling

Installing bearing bridges for compensating shafts

Compensating shaft drive, disassembling and assembling

Compensating shaft drive sprockets, installing (Model 84 onwards)

Machining cylinder bores

Engine, Cylinder head, Valve drive

Camshaft belt tension, checking and adjusting

Installing camshaft belt and adjusting timing

Cylinder head, removing and installing

Tightening specifications for cylinder head

Valve drive, disassembling and assembling

Machining mating face, cylinder head

Replacing valve guides

Valve drive, disassembling and assembling

Machining valve seats, checking valve guides

Valve drive, disassembling and assembling (camshaft housing)

Camshaft drive, disassembling and assembling

Camshaft specifications

Adjusting camshaft belt with mechanical belt tensioner

Engine - Lubrication

Replacing engine oil and oil filter

Parts of the lubrication system, removing and installing

Oil pump, disassembling and assembling

Sleeve for oil-pressure relief valve, removing and installing

Tightening specifications for oil-pump fastening screws.

Checking oil pressure

Oil check valve in cylinder head, removing and installing

Cleaning the engine oil system

Cleaning the main oil channel in the crankcase

Pressure-reducing valve, removing and installing

Engine - Cooling

Replacing coolant and bleeding cooling system

Checking thermostat, checking system for leaks

Parts of the cooling system, removing and installing

Parts of the cooling system, removing and installing, Mod. 87 onwards

Radiator, removing and installing

Temperature switch, removing and installing - checking temperature switch

Cleaning cooling system after oil and water have been mixed

Page

13 - 39

13 - 44 f

13 - 44 h

13 - 50

13 - 53

15 - 1

15 - 5

15 - 7

15 - 10 a

15 - 11

15 - 16 a

15 - 16 b

15 - 17

15 - 19

15 - 20

15 - 25

15 - 28

15 - 29

17 - 1

17 - 3

17 - 10

17 - 12

17 - 13

17 - 14

17 - 16

17 - 17

17 - 18

17 - 19

19 - 1

19 - 3

19 - 4

19 - 6 a

19 - 7

19 - 9

19 - 11

2 Table of contents

Printed in Germany - XXIV, 1993

944 Table of contents volume I

Temperature switch, removing and installing - checking temperature switch

Cleaning cooling system after oil and water have been mixed

Fuel supply

Replacing fuel filter, checking injection lines for leaks and tightness

Checking delivery rate of fuel pump

Fuel pump, removing and installing

Fuel tank, removing and installing

Line routing, fuel system

Active-carbon tank for pollution-free fuel-tank bleeding (layout)

Fuel expansion tank, removing and installing

Checking fuel expansion tank

Fuel-Ievel sensor, removing and installing

L-Jetronic fuel injection

Replacing air-filter cartridge

Testing and adjusting specifications

Testing and adjusting specifications for Model 85/2 onward and 924 S

Checking fuel pressure

Adjusting idle speed

Adjusting idle speed - USA vehicles

Correcting CO setting at air-flow sensor - USA vehicles

Injection valves, removing and installing

Checking intake system for leaks - troubleshooting

Adjusting idle speed for Model 85/2 onward and 924 S

Adjusting idle speed - USA and vehicles with catalytic convertor

from Model 85/2 onward and 924 S

Testing and adjusting specifications, Model 89 onward

Adjusting idle speed and CO for Model 89 onward

Equipment table for Model 89 onward

Exhaust system

Checking exhaust flanges for tightness

Replacing exhaust pipe or primary muffler/catalytic convertor

Starter, Power supply, Tempostat

Automatic cruise control (Tempostat)

Tempostat control unit, removing and installing

Tempostat operating switch (steering-column switch), removing and installing

Actuator, removing and installing

Tempostat bowden cable, removing and installing

Page

19 - 9

19 - 11

20 - 1

20 - 2

20 - 3

20 - 4

20 - 7

20 - 8

20 - 9

20 - 10

20 - 11

24 - 1

24 - 3

24 - 4

24 - 5

24 - 7

24 - 9

24 - 12

24 - 13

24 - 15

24 - 17

24 - 20

24 - 25

24 - 26

24 - 27

26 - 1

26 - 2

27 - 1

27 - 5

27 - 6

27 - 7

27 - 8

Table of contents

Printed in Germany - XXV, 1992

3

volume I Table of contents 944

Tempostat bowden cable, removing and installing

Clutch switch, removing and installing

Troubleshooting-Tempostat

Checking multiple-pin connector of Tempostat control unit

Checking multiple-pin connector of Tempostat actuator

Automatic cruise control (Tempostat) from Model 85/2 onward

Tempostat control unit, removing and installing steering-column switch

from Model 85/2 onward

Actuator, removing and installing, from Model 85/2 onward

Clutch switch, removing and installing, from Model 85/2 onward

Troubleshooting - Tempostat - from Model 85/2 onward

Connector assignment, Tempostat control unit

Checking the multiple-pin connectors of the Tempostat control unit

from Model 85/2 onward

Alternator, removing and installing

Ignition system

Equipment table

Accident hazards in electronic ignition systems

Ignition-distributor cap, removing and installing

Replacing spark plugs

DEE

Speed and reference-mark sensors, removing and installing

Troubleshooting-DEE

Functional test-Lambda probe

Test - DEE control unit, test - Lambda probe

DEE control unit, removing and installing, from Model 85/2 onward

DEE control unit coding - 924 S from Model 86 onward

DEE control unit coding - 944, from Model 85/2 onward

DEE control unit coding - 944, 2.7 l

DEE control unit coding - 944 turbo, from Mod. 85 onward

DEE control unit coding - 924 S, from Model 88 onward

DEE control unit coding - 944, from Model 88 onward

Equipment table engine type M 44.09 to 12

Page

27 - 8

27 - 9

27 - 10

27 - 11

27 - 12

27 - 13

27 - 17

27 - 19

27 - 20

27 - 21

27 - 22

27 - 23

27 - 25

28 - 1

28 - 3

28 - 5

28 - 7

28 - 10

28 - 14

28 - 16

28 - 37

28 - 38

28 - 39

28 - 41

28 - 42

28 - 42 a

28 - 43

28 - 45

28 - 46

28 - 47

4 Table of contents

Printed in Germany - XXV, 1992

944 G e n e r a l

Printed in Germany 0.1

G e n e r a l 944

TECHNICAL DATA

(adjusting values and wear limits appear in pertinent repair groups)

Note: USA values in brackets.

E n g i n e M 44/01 manuals - M 44/03 automatics

(M 44/02 manuals - M 44/04 automatics)

M 44/05 manuals - M 44/06 automatics

(M 44/07 manuals - M 44/08 automatics)

Number of cylinders

Bore

Stroke

Displacement (actual)

Displacement (tiscal)

Compression ratio

Max. engine power

to 80/1269/EC

Net power, SAE J 1349

At engine speed

Max. torque to 80/1269/EC

Net torque, SAE J 1349

At engine speed

Max. specitic power output

Net power to SAE J 1349

Fuel grade

Engine speed limit

Engine weight (dry)

mm/in.

mm/in.

cm3/in.3

cm3

kW/HP

kW/HP

rpm

Nm/kpm

Nm/ft. Ibs.

rpm

kW I / HP I

kW I / HP I

rpm

kg/Ibs.

4

100/3.94

78.9/3.11

2479/151.26

2449

10.6 : 1 (9.5: 1)

120/163 (110/150)

116/156 (105/143)

5800 (5500)

205/20.9 (192/19.6)

199/151.3 (186/137)

3000

48/66 (44.4/60.5)

48/63 (42.4/57.7)

96 RON

(91 RON - unleaded fuel only)

6500

166/366

E n g i n e D e s i g n

Type

Crankcase

Crankshaft

Crankshaft bearings

Water-cooled, axial, 4 cylinder, 4 stroke,

in-line, internat combustion engine with

toothed belt driven overhead camshaft

and two compensating shafts

Two-piece, light alloy

Forged steel

Five

0.2 Technical Data V, 1985 Printed in Germany

944 G e n e r a l

Connecting rods

Conrod bearings

Piston pin bearings

Pistons

Piston pins

Piston rings

Cylinders

Cylinder head

Valve seat inserts (shrink-fit)

Valve guides

Valve arrangement

Exhaust valves

Valve springs

Valve timing

Camshaft

Camshaft bearings

Camshaft drive

Valve clearance

Timing with 1 mm lift

and zero valve clearance

Forged steel/cast since February, 1984

Plain

Press-fit brass bushings

Cast fight alloy

Floating installation, secured with circlips

2 compression rings and 1 oil scraper ring

Light alloy

Light alloy

Intake: FCr 330 Exhaust: CoMo 75

Press-fit special brass

1 intake, 1 exhaust, overhead, in-line

With armored seat

2 coil springs per valve

By overhead camshaft and hydraulic cam

followers

Shell hard east

Camshaft runs in camshaft case without bearing shells

Toothed belt with tensioning roller

Automatie hydraulic adjustment

Intake opens 1° after

Intake closes 49° after

Exhaust opens 43° before

Exhaust closes 3° before

TDC

BDC

BDC

TDC

E n g i n e C o o t i n g Closed cooling system, electric fan with

thermo switch, antifreeze for - 25° C

E n g i n e L u b r i c a t i o n

System

Pressure circulation with siekle-type pump,

oil filter and oil/water heat exchanger in

oil full flow and water bypass integrated in

crankcase

Oil pressure at 5,000 rpm

Oil pressure display

Max. oil temperature

Oil consumption ltr./1000 km

Approx. 4 bar at operating temperature

Indicator lamp and pressure gage

140° C

Up to 1.5

Printed in Germany - V, 1985 Technical Data 0.3

G e n e r a l 944

E x h a u s t S y s t e m Manifold, single pipe up to primary

muffler, primary and final mufflers

(manifold, single pipe up to 3-way

catalytic converter, final muffler)

H e a t i n g Warm water heater with heat exchanger

and blower

F u e l S y s t e m

Fuel supply

Fuel grade

Fuel consumption to

80/1268/EC in

Also official specifications

for France and Great Britain

- ECE A 70 -

RON/MON

ltr./100 km

DME (Digital Motor Eletronics

1 electric delivery pump

96/98 (91/82 unleaded)

at 90 km/h

at 120 km/h

city cycle

Manuals

6.4

8.0

11.5

Automatics

6.5

8.1

11.3

E l e c t r i c a l S y s t e m

Interference suppression

Battery voltage

Battery capacity

Battery capacity (M-eq.)

Alternator output

Ignition

Spark plug connectors

Firing order

Ignition timing control

V

Ah

Ah

A/W

ECE - R 10 and 72/245/EC or VDE 0879

12

50 (63)

63

90/1260, 115/1610 since 1985/2 models

Via DME

Without booster gap

1 - 3 - 4 - 2

Via DME

B o d y T y p e Coupe with integral steel body, 2 doors,

bolted front fenders, real window and

spoiler tailgate, concealed headlights;

removable hardtop roof as optional

ekstra equipment

0.4 Technical Data

Printed in Germany

944 G e n e r a l

D i m e n s i o n s (at DIN curb weight)

Length

Length with US bumpers

as optional equipment

Width

Height

Wheelbase (designed)

Front track

Rear track

Ground clearance

(at max. weight)

Bed clearance

Front overhang angle (limited by spoiler)

Rear overhang angle (Limited by exhaust)

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

4200/165.354 (4290/168.898)

4290/168.898

1735/68.307

1275/50.197

2400/94.488

7J x 15/7J x 16

6J x 15/6J x 16

5 1/2J x 15

7J x 15/7J x 16

6J x 15/6J x 16

5 1/2J x 15

1477/58.150

1452/57.165

1440/56.693

1451/57.126

1426/56.142

1414/55.669

125/4.921

120/4.72 since 1985/2 models

53/2.087

14°

15°

W e i g h t s (to DIN 70020)

Curb weight

Curb weight axle force

Front

Rear

Max. total weight

Max. front axle load

Max. rear axle load

Payload

Max. roof load, incl.

roof carrier

Max. trailer load without brakes*

with brakes*

Max. car/trailer weight

Max. drawbar load

kg/Ibs

kg/Ibs

kg/Ibs

kg/Ibs

kg/Ibs

kg/Ibs

kg/Ibs

kg/Ibs

kg/Ibs

kg/Ibs

kg/Ibs

kg/Ibs

1180/2601 (1260/2779)

since 1985/2 models:

1210/2668 (1260/2779)

580/1279(620/1367)

600/1323 (640/1411)

since 1985/2 models:

630/1389 (640/1411)

1500/3307 (1550/3418)

since 1985/2 models:

1530/3373 (1550/3417)

720/1588

880/1940, 900/1984 since 1985/2 models

320/706 (290/639)

35/77 or 75/165 with roof

transporting system

500/1103

1200/2646

2700/5952 since 1985/2 models:

2730/6019 (2750/6063)

50/110

* Gradients up to 16%

Printed in Germany - V, 1985 Technical Data 0.5

G e n e r a l 944

F i l l i n g C a p a c i t i e s

Engine oil (volume depends on

measurement with oil dipstick see Owner's Manual)

Engine oil volume

Engine coolant volume

Transmission with differential

volume

Fuel tank volume

Brake fluid volume

Washing fluid volume for

windshield and headlights

brand name HD oil to API CI.

SE or SF - see Owner's Manual

approx. 6.0 ltr.

approx. 7.8 ltr.

approx. 2.0 ltr. of hypoid gear

lube SAE 80 to MIL-L 2105,

APl Classification GL 4

approx. 66 ltr., of which 9 ltr.

in reserve since 1985/2 models:

approx. 80 ltr., of which 8 ltr.

in reserve

approx. 0.2 ltr.

approx. 6.0 ltr.

P e r f o r m a n c e

Top speed

Acceleration from

0 to 100 km/h*

(0 to 60 mph)*

(1/4 mile)*

Kilometer from

standing start*

km/h / mph

sec

sec

sec

sec

220/137 (210/130)

Manuals

8.4 (9.3)

(8.3)

(16.2)

28.8(30.1)

Automatics

9.6

(9.8)

(17.2)

30.5(31.4)

H i l l C l i m b i n g

In % (slip limit) 1st gear

2nd gear

3rd gear

4th gear

5th gear

Manuals

63

36 (34)

23 (21)

15 (14)

10 (8)

Automatics

55 (38.5)

25 (19)

15 (11)

* DIN curb weight + 1/2 of payload

0.6 Technical Data

Printed in Germany

944 General

Technical Data

Type 944 - Model 88

(Adjusting values and wear limits appear in pertinent repair groups)

Note: USA values in brackets.

Engine

Engine type

Bore

Stroke

Displacement (actual)

Displacement (fiscal)

Compression ratio

Max. engine power

to 80/1269/EC

Net Power, SAE J 1349)

at engine speed

max. torque

to 80/1269/EC

(Net Torque, SAE J 1349)

at engine speed

max. liter output

DIN 70020

(SAE J 1349)

Speed governed by

fuel shutoff at

Engine weight (dry)

mm/in.

mm/in.

cm3/in3.

cm3

KW/PS

KW/HP

1/min

Nm/kpm

Nm/lb ft

1/min

KW/I (PS/I)

KW/I (HP/I)

1/min

kg bs)

M 44/09 (manuals)

M 44/10 (automatics)

100 (3.94)

78,9 (3.11)

2479 (151)

2449

10.2: 1

118 (160)

118 (158)

5900

210 (21.4)

210 (155)

4500

47.6 (64.5)

47.6 (63.7)

6640

169 (373)

Technical Data

Printed in Germany - XXII, 1988

0.6a

G e n e r a l 9 4 4

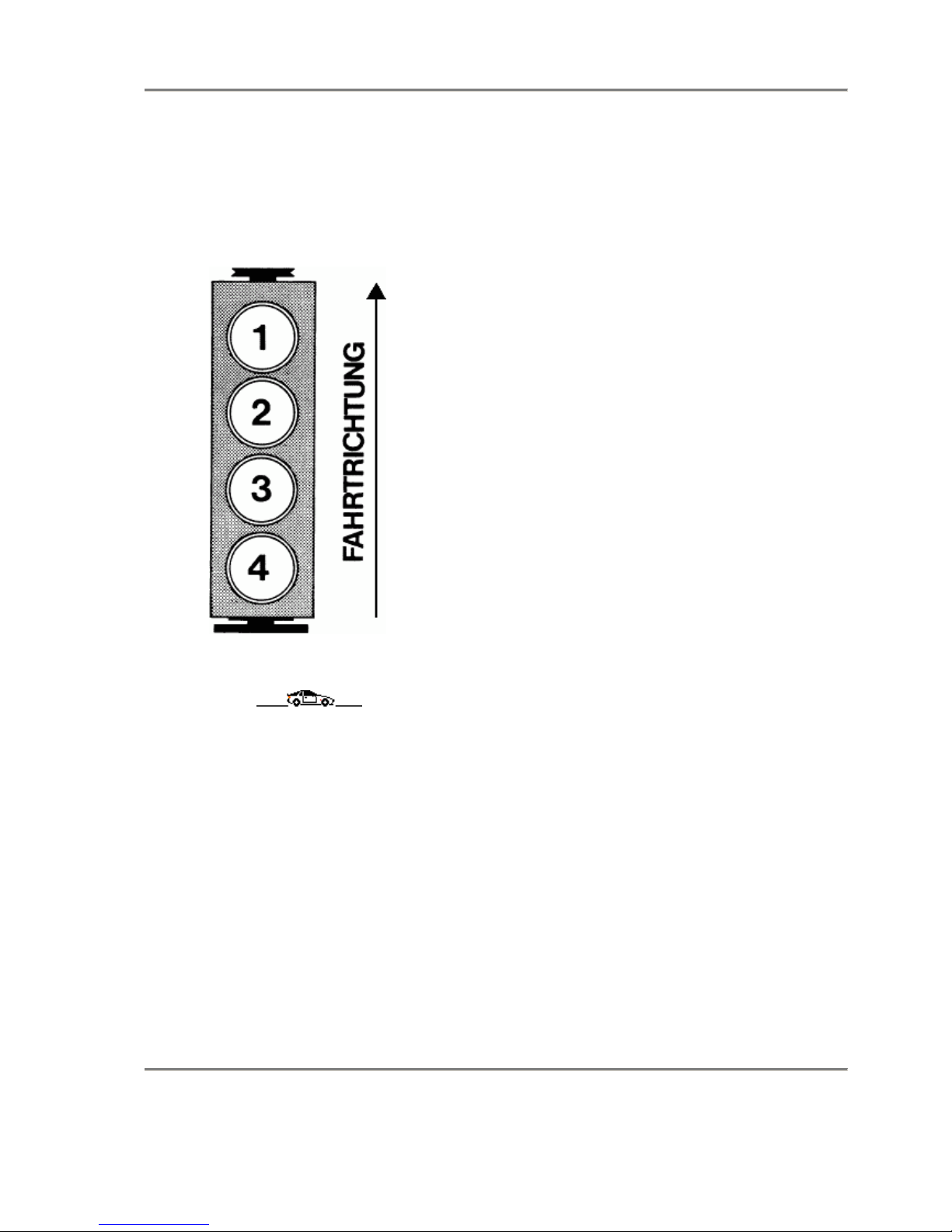

DESIGNATION OF CYLINDERS

0.7 Technical Data Printed in Germany

9 4 4 E n g i n e / C r a n k c a s e

10

TOLERANCES AND WEAR LlMITS

C o o l i n g S y s t e m

New Part Wear Limit

Thermostat

Radiator cap

High pressure valve

Low pressure valve

Opening temperature

Opening pressure

Opening pressure

81 - 85 °C

(178 - 185 °F)

1

+ 0.15

- 0.10

bar

(14,5

+ 2.1

- 1.5

psi)

0.1 bar

(1 .5 psi)

O i l C i r c u i t

Oil consumption

Oil pressure at 80° C (176° F)

oil temperature and at 5000 rpm

Oil dipstiek

Upper mark

Lower mark

ltr./1000 km

(600 mi./US qt)

Pressure

Capacity

Capacity

approx. 4 bar

(58 psi)

5.5 ltr. (5.8 US qt)

4.2 ltr. (4.4 US qt)

approx. 1.5

V a l v e T i m i n g

Camshaft bore

Camshaft

Camshaft

Cam follower bore in camshaft

housing

Cam follower

Camshaft

Inside dia.

Diameter

End play

Inside dia.

Diameter

Runout

60.5

+ 0.03

- 0

60.5

- 0.04

+ 0.055

0.10 - 0.18

38

+ 0.027

+ 0.007

38

- 0.018

- 0.034

0.02

Printed in Germany - I, 1982 Tolerences and Wear Limits

10 - 01

10

E n g i n e / C r a n k c a s e 9 4 4

TOLERANCES AND WEAR LlMITS

C y l i n d e r H e a d a n d V a l v e s

New Part Wear limit

Mating surface

Valve seat:

Intake

Exhaust

Intake

Exhaust

Outer correction angle

Inner correction angle

Valve guides:

Intake and exhaust

Valve stem:

Intake

Exhaust

Valve guide/valve stem

Intake

Exhaust

Compression

Distortion

Width

Width

Seat angle

Seat angle

Inside dia.

Diameter

Diameter

Clearance

Pressure

1.7

2.0

45°

45°

30°

60°

9 + 0.015

8.97 - 0.012

8.95 - 0.012

0.8

0.8

10 bar (145 psi)

or more

max. 0.08

10 - 02 Tolerences and Wear Limits Printed in Germany

9 4 4 E n g i n e / C r a n k c a s e

10

TOLERANCES AND WEAR LlMITS

P i s t o n s a n d C o n n e c t i n g R o d s

New Part Wear Limit

Cylinder/piston

Piston rings

Clearance

Side clearance

Groove 1

Groove 2

Groove 3

0.008 - 0.032

Mahle KS

0.05 -

0.082

0.04 -

0.072

0.023 -

0.137

0.05 -

0.082

0.05 -

0.082

0.023 -

0.137

approx. 0.080

Piston rings

Connecting rod bushing

Piston pin

Connecting rod bushing/

piston pin

End gap

Diameter

Diameter

Radial play

Groove 1 =

Groove 2 =

Groove 3 =

0.20 - 0.45

0.20 - 0.45

0.38 - 1.40

24

+ 0.018

+ 0.028

24 - 0.004

0.018 - 0.032

C r a n k s h a f t a n d E n g i n e B l o c k

Crankshaft

Connecting rod bearing journal

Connecting rod bearing/

crankshaft

Crankshaft bearing journal

Crankshaft bearing/crankshaft

Cylinder bore

Bore for balance shaft

bearing shells in crankcase

and balance shaft cover

Bore for bushing in bearing

housing

Balance shaft

Runout

Diameter

Radial play

End play

Diameter

Radial play

End play

Out-of-round

Diameter

Diameter

Diameter

0.04 - 0.06

51.971 - 51.990

0.034 - 0.092

0.100 - 0.400

69.971 - 69.990

0.020 - 0.098

0.110 - 0.312

0.010

35.000 - 35.019

34.000 - 34.019

30.975 - 30.991

max. 0.08

0.40

0.020

Printed in Germany - I, 1982 Tolerences and Wear Limits

10 - 02a

10

9 4 4

10 - 02b Blank Page

944 Engine, Crankcase

10

Tightening torques for engine

Location Thread Tightening torque Nm (ftlb)

Crankshaft/

Crankcase

Bolts - upper and lower

crankcase sections (studs)

Rotary body on

compensating shaft

M 12 x 1.5

M 10

M 8

M 6

M 6

30(22)

60° torque angle

20(15)

50(37)

20(15)

10(7.5)

10(7.5) secured

with Loctite

270

1st stage

2nd stage

1st stage

2nd stage

MODEL 82 - 85

Cover for compensating

shaft housing to upper

crankcase section

Hexagon head screw

Stud

M 6

M 8

M 8

8(6)

15(11)

20(15)

15(11)

30(22)

1st stage

2nd stage

1st stage

2nd stage

MODEL 85 ONWARD

Compensating shafts with

separate bearing bridges:

Bearing bridges (nuts) of

compensating shafts to

upper crankcase section

Cover for

compensating-shaft

housing to upper

crankcase section

Hexagon head screw

M 8

M 6

M 8 x 55

15(11)

33(24)

10(7.5)

15(11)

20(15)

1st stage

2nd stage

1st stage

2nd stage

MODEL 87 ONWARD

Hexagon head screw

(bearing bridge) for

compensating-shaft

housing to upper

crankcase section

Bearing housing left and

right to upper crankcase

section

M 8 x 58

M 8

15(11)

33(24)

20(15)

1st stage

2nd stage

Tightening torques for engine

Printed in Germany - XIX, 1989

10 - 03

10

Engine/Crankcase 944

Location Thread Tightening torque Nm (ftlb)

Con rod bolt Verbusrip

nut

Con rod bolt with smooth

contact surface

Water drain plug in upper

crankcase section

Oil pan to crankcase

Oil pan insert to oil pan

Oil drain plug

Engine supports left +

right to crankcase

Flywheel to crankshaft

Sensor holder to

crankcase

Toothed gear to

crankshaft

Sensor to holder

Pulley to toothed gear

Toothed gear to

compensating shaft

Tension pulley to bearing

Housing

Water pump to crankcase

Idler pulley to

water-pump housing

Tensioning pulley to

oil-pump housing

Oil pump to crankcase

Belt tensioner to

Crankcase

M 10 x 1.25

M 10 x 1.25

M 8

M 6

M 5

M 20 x 1.5

M 10

M 10 x 1.25

M 8

M 16 x 1.5

M 6

M 6 x 25

Tensile strength

10.9

M 10

M 10

M 6

M 10

M 10

M 6

M 10

M 8

75(55) + 5(4)

57(42) + 5(4)

20(15)

hand tight

4(3)

10(7.5)

1st stage

2nd stage

3rd stage

6(4.5) secured with Loctite 270

50(37)

48(35)

90(66)

20(15)

210(155)

8(6)

13(9.5)

45(33)

45(33)

8(6) secured with Loctite 270

45(33)

45(33)

8(6)

45(33)

20(15)

10 - 04 Tightening torques for engine

Printed in Germany - XIX, 1989

944 Engine/Crankcase

10

Location Thread Tightening torque Nm (ftlb)

Tensioning pulley to belt

Tensioner

Fastening - belt cover

Console for generator to

Crankcase

Remote thermometer

Sensor

Temperature sensor

(NTC II)

Oil pressure sensor

Housing insert in

oil-pump housing

Cooler

housing/thermostat

housing to crankcase

Sealing plug to

oil/water-cooler housing

Coolant bleeder screw

Pressure-relief valve

Oil filter

Oil separator to crankcase

Cylinder head

Cylinder head fastening

to upper crankcase

Section

Intake tube to cylinder

head

Inlet connectors - heating

to cylinder head

Connector for water pipe

Camshaft housing to

cylinder head

Aluminium sealing plugs

to camshaft housing

Camshaft bearing to

camshaft housing

M 10

M 6

M 10

M 10 x 1

M 12 x 1.5

M 18 x 1.5

M 6

M 8

M 18 x 1.5

M 8 x 1

M 20 x 1.5

M 8

M 8

M 8

M 8

M 8

M 18 x 1.5

M 6

45(33)

8(6)

45(33)

35(26)

15(11)

35(26)

8(6) mating surface sealed

with Loctite 574

20(15)

35(26)

12(9) + 3(2)

45(33)

20(15)

20(15)

Refer to Page 15 - 10 a

20(15)

20(15)

20(15)

20(15)

40(29.5)

8(6)

Tightening torques for engine

Printed in Germany - XIX, 1989

10 - 05

10

Engine/Crankcase 944

Location Thread Tightening torque Nm (ftlb)

Camshaft pulley to

camshaft Allen screw

Screw with internall

serrations

Console to camshaft

bearing

Connector to driver

Distributor rotor to

connector

Transport strap to

Cylinder head

Spark plugs

Fuel system

Fastening - diaphragm

damper and pressure

regulator to fuel

collection pipe

Cap nut to fuel collection

pipe

Exhaust system

Sealing nut to catalytic

convertor

All other screws and nuts:

M 10

M 10

M 6

M 5

M 4

M 6

M 14 x 1.25

M 16 x 1.5

M 12 x 1.5

M 14x 1.5

M 6

M 8

M 10

45(33)

65(48) - 70(52)

8(6)

5(4) secured with Loctite 221

4(3) selt-locking

8(6)

25(18) - 30(22)

30(22)

12(9)

30(22)

8(6) + 2(1.5)

20(15) + 2(1.5)

40(29) + 5(4)

10 - 06 Tightening torques for engine

Printed in Germany - XIX, 1989

9 4 4 E n g i n e / C r a n k c a s e

10

TOOLS

No. Description Special Tool Remarks

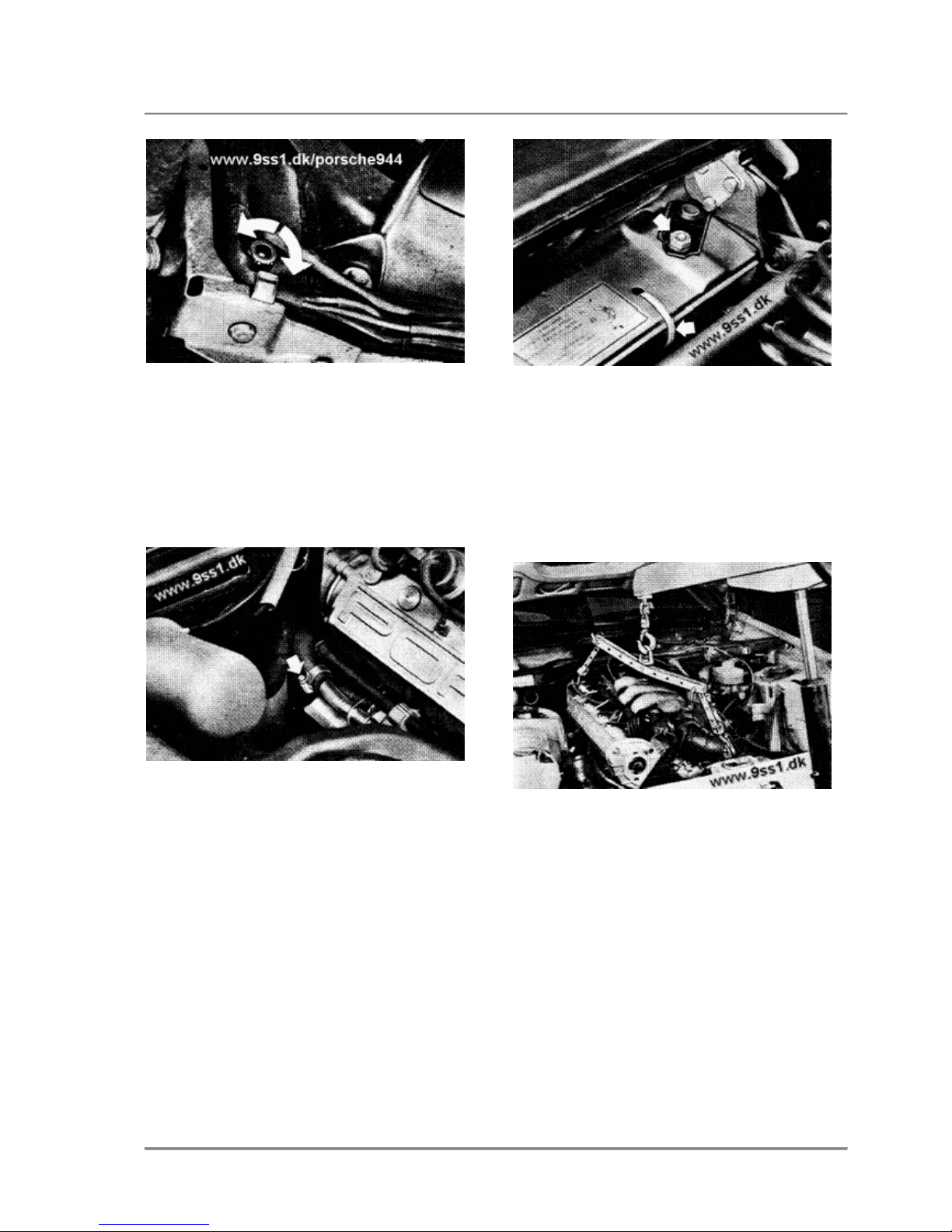

1 Chain sling US 1105

Printed in Germany Removing and Installing Engine

10 - 1

10

E n g i n e / C r a n k c a s e 9 4 4

REMOVING AND INSTALLlNG ENGINE

( M a n u a l T r a n s m i s s i o n )

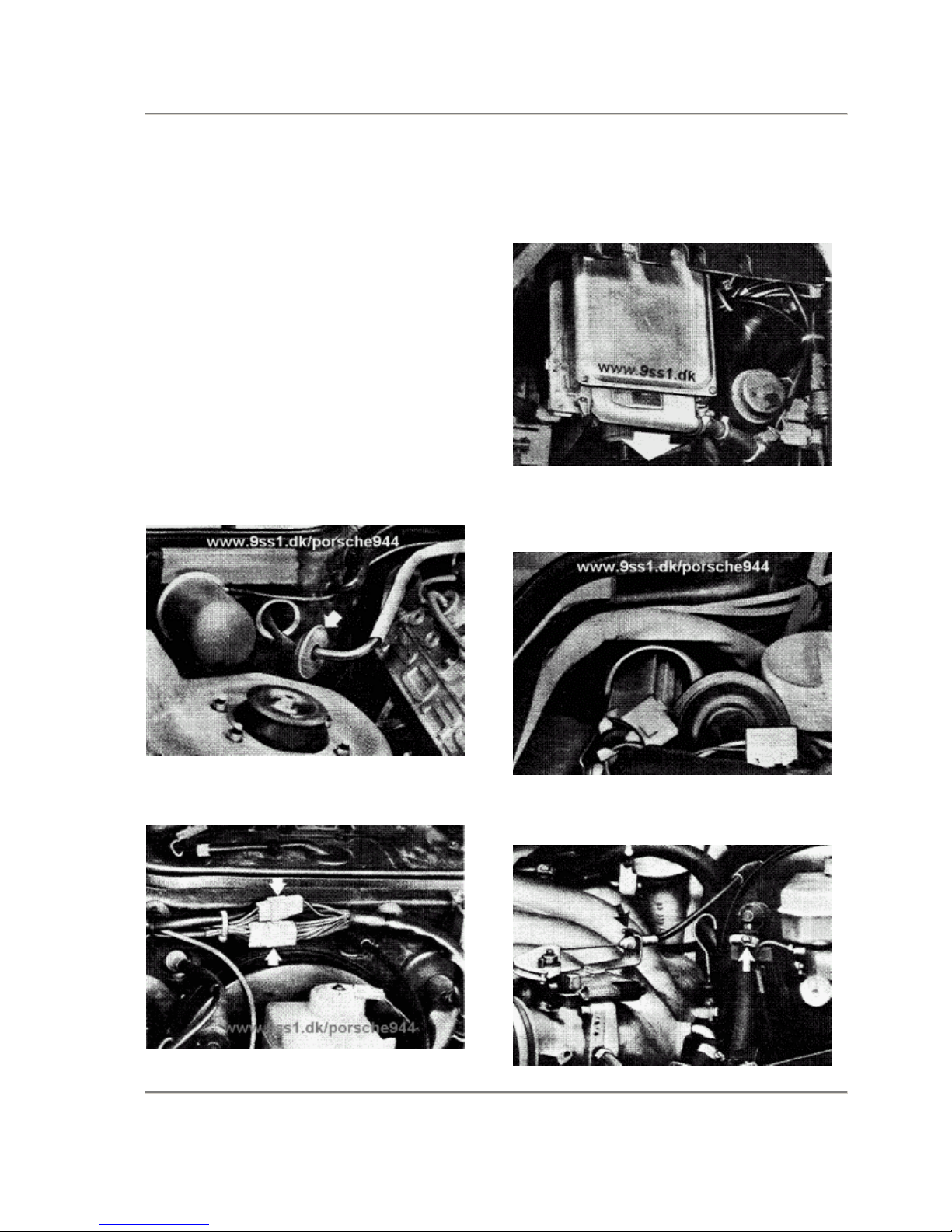

E n g i n e r e m o v e d f r o m u n d e r n e a t

h .

Clutch bell housing remains on engine.

R e m o v i n g

1. Set up hoist and lift car on the pick-up points.

2. Use fender covers.

3. Remove front wheels.

4. Disconnect battery ground cable.

5. Disconnect battery positive cable and push

through splash wall with the rubber grommet.

6. Disconnect two plugs for engine wire harness.

Remove wire clamps.

7. Pull off wire plugs on control unit (in area of

steering column).

8. Push wires and plugs through splash wall.

Detach bracket with sensor wire on intake pipe

to make engine removal easier.

9. Disconnect throttle operating cable. Disconnect

and pull off vacuum hose on brake booster.

10 - 2 Removing and Installing Engine Printed in Germany

9 4 4 E n g i n e / C r a n k c a s e

10

10. Disconnect air cleaner with air flow sensor on

body and on coolant hose, and lay aside.

11. Remove distributor cap, distributor rotor and

dust cap (to avoid damage).

12. Disconnect ground wire on splash wall.

13. Pinch fuel return line with a standard hose

clamp. Unscrew fuel feed line while

counterholding.

14. Unscrew fuel return line.

15. Attach Special Tool VW 10-222 on front

transport bracket of engine hold hold engine

tight in installed position.

16.

Open heater regu!ating valve. Remove cap on

coolant expansion tank.

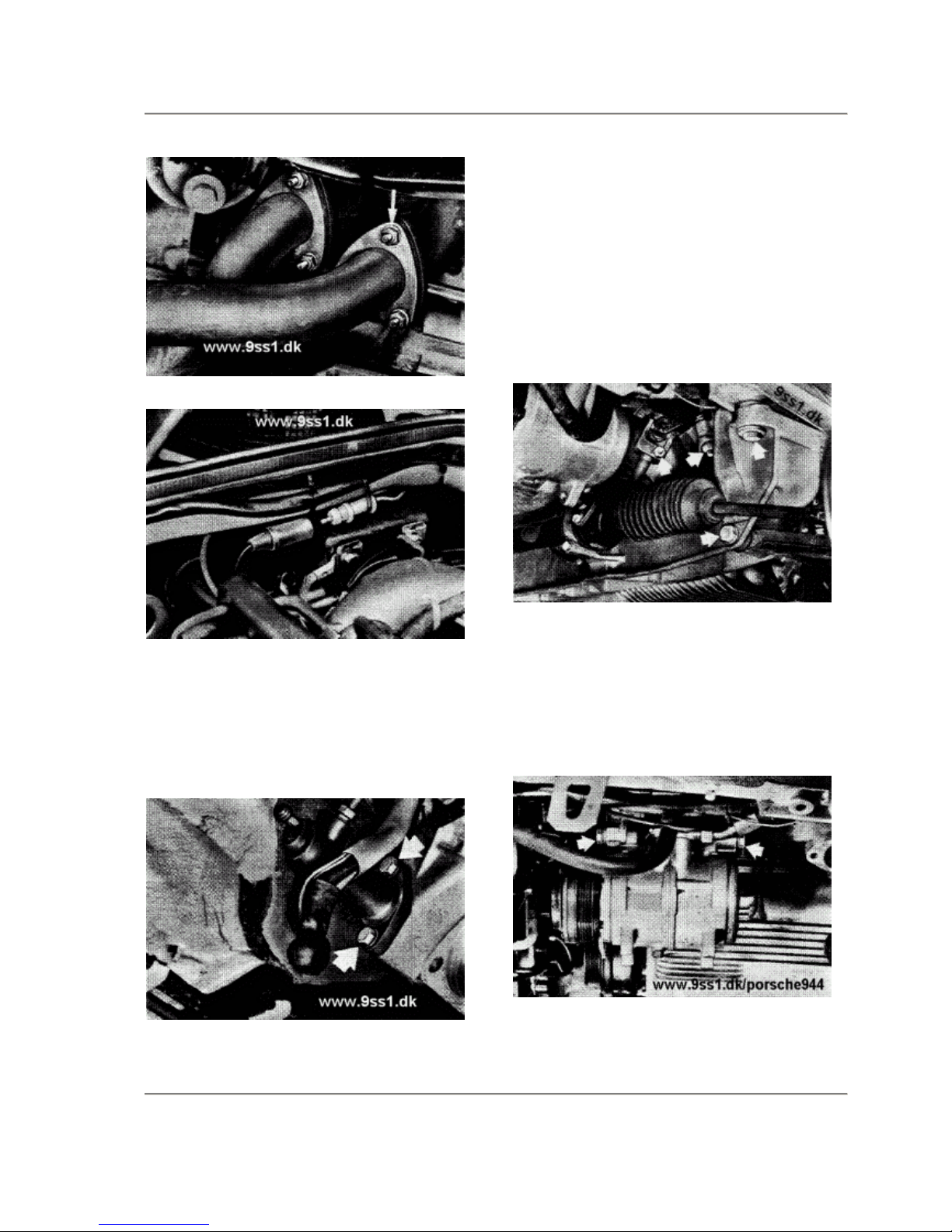

17. Remove splash shield.

18. Remove exhaust assembly, by unscrewing

flange, exhaust manifold/exhaust pipe

connections and suspension points.

USA cars:

Also disconnect oxygen sensor plug and wire

in metal lug on firewall.

Printed in Germany - III, 1983 Removing and Installing Engine 10 - 3

10

E n g i n e / C r a n k c a s e 9 4 4

19. Disconnect electric wires for starter.

Unscrew and remove starter.

20. Unscrew clutch line clamp on engine.

21. Unscrew clutch slave cylinder on clutch

housing (line remains connected).

22. Unscrew stabilizer on body and control arms,

and remove.

23.

Unscrew shield for right engine mount on front

axle cross member.

24. Unscrew universal joint on steering gear, tie

rods on steering arms, upper hydraulic engine

mount on engine braces, left and right control

arms on front axle cross member, and remove

front axle cross member with steering from

underneath.

25. Cars with Air Conditioner:

Unscrew poly-rib belt tensioner and take off

belt.

26. Unscrew compressor on console (don't

disconnect refrigerant hoses). Suspend

compressor from the spring strut with a pjece

of wire.

27. Drain coolant through drain plug bore in

radiator or the coolant hose and catch coolant.

10 - 4 Removing and Installing Engine Printed in Germany

9 4 4 E n g i n e / C r a n k c a s e

10

28. Remove coolant hose on bottom of radiator.

29. Remove upper central tube mounting bolts.

30. Lower car.

31. Remove coolant hose on heater valve.

32. Remove coolant return hose for heater.

33. Remove coolant feed hoses on expansion

tank.

34. Remove A/C fast idle hose.

35. Remove charcoal venting hose.

36. Remove vacuum line to vent valve and

vacuum

line to thermo valve at back of engine.

37. Remove upper radiator hose.

38. Remove radiator vent hose.

39. Remove wiring to temperature switch and both

cooling fans.

40.

Remove top radiator brackets and lift out

radiator with cooling fans.

41. Attach Special Tool US 1105 on engine

(shorter end towards rear of engine).

42. Lift engine slightly and remove VW 10-222.

43. Remove lower central tube mounting bolts.

44. Lower engine. pull forward and remove from

underneath.

Printed in Germany Removing and Installing Engine

10 - 5

10

E n g i n e / C r a n k c a s e 9 4 4

I n s t a l l i n g

Note the following for installation.

1. First insert transaxle/clutch housing mounting

bolts, but do not tighten.

N o t e

Only tighten mounting bolts to final torque after

Hydraulic engine mount and front axle cross member

have been mounted.

Torque for mounting bolts: 42 Nm (30 ft lb).

Front wheel alignment need not be checked after

removal and installation of engine.

2. Make sure radiator fits correctly in rubber mounts.

3. Secure coolant hose (between radiator and

expansion tank) on lock carrier with two straps.

4. Tighten bolts and nuts to specified torque.

5. Fill and bleed cooling system (see page 19-1).

10 - 6 Removing and Installing Engine Printed in Germany

Loading...

Loading...