Page 1

Operator’s Manual

DuraChill™ Air- and Water-Cooled Chillers

5, 7.5 and 10 HP

110-279 26 June 2013

Page 2

Table of Contents

Introduction............................................................................................................................................................ 4

Standard and Optional Features ......................................................................................................................... 4

Standard Features ........................................................................................................................................... 4

Optional Features............................................................................................................................................. 4

General Safety Information.................................................................................................................................. 5

Safety Recommendations.................................................................................................................................... 6

Regulatory Compliance and Testing ................................................................................................................... 7

Unpacking............................................................................................................................................................ 7

Controls and Components...................................................................................................................................8

Control System .................................................................................................................................................... 8

Control Panel ................................................................................................................................................... 8

Power Switch / Disconnect .............................................................................................................................. 8

Temperature Probe .......................................................................................................................................... 8

Flow Sensor ..................................................................................................................................................... 8

Flow Switch ...................................................................................................................................................... 8

Fluid Pressure Sensor ..................................................................................................................................... 8

Refrigerant Pressure Switches ........................................................................................................................ 8

Fan Cycling Switch........................................................................................................................................... 9

Reservoir Float Switch (Optional) .................................................................................................................... 9

Fluid Circulation System ...................................................................................................................................... 9

Evaporator........................................................................................................................................................ 9

Reservoir Tank................................................................................................................................................. 9

Sight Glass or Level Indicator .......................................................................................................................... 9

Pump................................................................................................................................................................ 9

Full Flow Bypass .............................................................................................................................................. 9

Y-Strainer ......................................................................................................................................................... 9

External Bypass / Shutoff Valves..................................................................................................................... 9

Process Side Stream Filter System (Optional) ................................................................................................ 9

Cooling System.................................................................................................................................................... 9

Common Cooling System Components........................................................................................................... 9

Evaporator...................................................................................................................................................... 9

Compressor.................................................................................................................................................... 9

Filter Dryer...................................................................................................................................................... 9

Sight Glass ..................................................................................................................................................... 9

Thermostatic Expansion Valve (TXV) ............................................................................................................ 9

Hot Gas Bypass Solendoid Valve ................................................................................................................ 10

Refrigerant Safety Relief Valve .................................................................................................................... 10

Air-Cooled Chillers (DA Models) .................................................................................................................... 10

Condenser.................................................................................................................................................... 10

Condensing Fan........................................................................................................................................... 10

Water-Cooled Chillers (DW Models).............................................................................................................. 10

Brazed Plate Heat Exchanger / Condenser ................................................................................................. 10

Condensing Water Regulating Valve ........................................................................................................... 10

Receiver ....................................................................................................................................................... 10

Component Identification................................................................................................................................... 11

Front - All Models ........................................................................................................................................... 11

5 HP and 7.5 HP Chillers - Rear .................................................................................................................... 11

10 HP Chillers - Rear ..................................................................................................................................... 12

Installation and Startup ...................................................................................................................................... 13

Site Requirements ............................................................................................................................................. 13

Ambient Temperature and Relative Humidity ................................................................................................ 13

Location.......................................................................................................................................................... 13

Clearance....................................................................................................................................................... 13

Electrical Power ................................................................................................................................................. 14

Signal Inputs/Outputs ........................................................................................................................................ 15

Remote On / Off ............................................................................................................................................. 15

110-279 1

Page 3

Alarm Output .................................................................................................................................................. 15

RS-232/RS-485 Serial Output........................................................................................................................ 15

External Piping................................................................................................................................................... 16

General Considerations ................................................................................................................................. 16

Process Fluid Connections ............................................................................................................................ 16

Facility Water Connections ............................................................................................................................ 16

Reservoir Drain .............................................................................................................................................. 16

Reservoir Vent ............................................................................................................................................... 16

Full Flow Bypass ............................................................................................................................................ 17

Process Coolant ................................................................................................................................................ 18

Suitable Fluids................................................................................................................................................ 18

Startup ............................................................................................................................................................... 19

Facility Water Flow (water-cooled units only) ................................................................................................ 19

Filling the Reservoir ....................................................................................................................................... 19

Starting Process Fluid Flow ........................................................................................................................... 20

Normal Operation................................................................................................................................................ 21

Power On........................................................................................................................................................... 21

Temperature Unit (°C or °F) Selection / Factory Default Reset ........................................................................ 21

Adjusting the Set Point Temperature................................................................................................................. 22

Selecting the Pressure / Flow Rate Display and Units ...................................................................................... 22

Displaying Internal (P1) and External (P2) Probe Temperatures...................................................................... 22

Setting Operational Parameters / Limits............................................................................................................ 22

High Temperature Limit (HL) ......................................................................................................................... 25

Low Temperature Limit (LL)........................................................................................................................... 25

High Ambient Temperature Limit (HA)........................................................................................................... 26

Maximum Fluid Pressure (FP) ....................................................................................................................... 26

Minimum Flow Rate (FL)................................................................................................................................ 26

Lower Band (Lb)............................................................................................................................................. 27

Upper Band (Ub) ............................................................................................................................................ 27

Remote Probe (rP)......................................................................................................................................... 27

Calibration Offset (C1 / C2 / C3) .................................................................................................................... 27

Compressor Delay (Cd) ................................................................................................................................. 28

Flow Rate Calibration (Fc) ............................................................................................................................. 28

Coolant Density (dS)...................................................................................................................................... 28

Specific Heat (Sh) .......................................................................................................................................... 28

Current Control (CC)...................................................................................................................................... 28

Communications Baud Rate (PC).................................................................................................................. 29

Low Ambient Temperature Limit (LA) ............................................................................................................ 29

Password (Pd)................................................................................................................................................ 29

HGB Valve Delay (td)..................................................................................................................................... 29

Fuse Bits (Fb)................................................................................................................................................. 29

Enabling / Disabling the Local Lockout.............................................................................................................. 30

Display, Alarm and Error Messages..................................................................................................................31

Automatic Restart from Alarm Mode ................................................................................................................. 33

Routine Maintenance..........................................................................................................................................34

Recommended Routine Maintenance Schedule ............................................................................................... 34

Reservoir Coolant Level .................................................................................................................................... 34

Coolant Freeze Protection ................................................................................................................................. 34

Inline Strainer..................................................................................................................................................... 34

Air Filters............................................................................................................................................................ 35

Troubleshooting.................................................................................................................................................. 36

Troubleshooting Chart ....................................................................................................................................... 36

Compressor Overload Fault (Ft20).................................................................................................................... 37

Low Pressure Sensor..................................................................................................................................... 37

High Pressure Sensor.................................................................................................................................... 37

Technical Information......................................................................................................................................... 38

110-279 2

Page 4

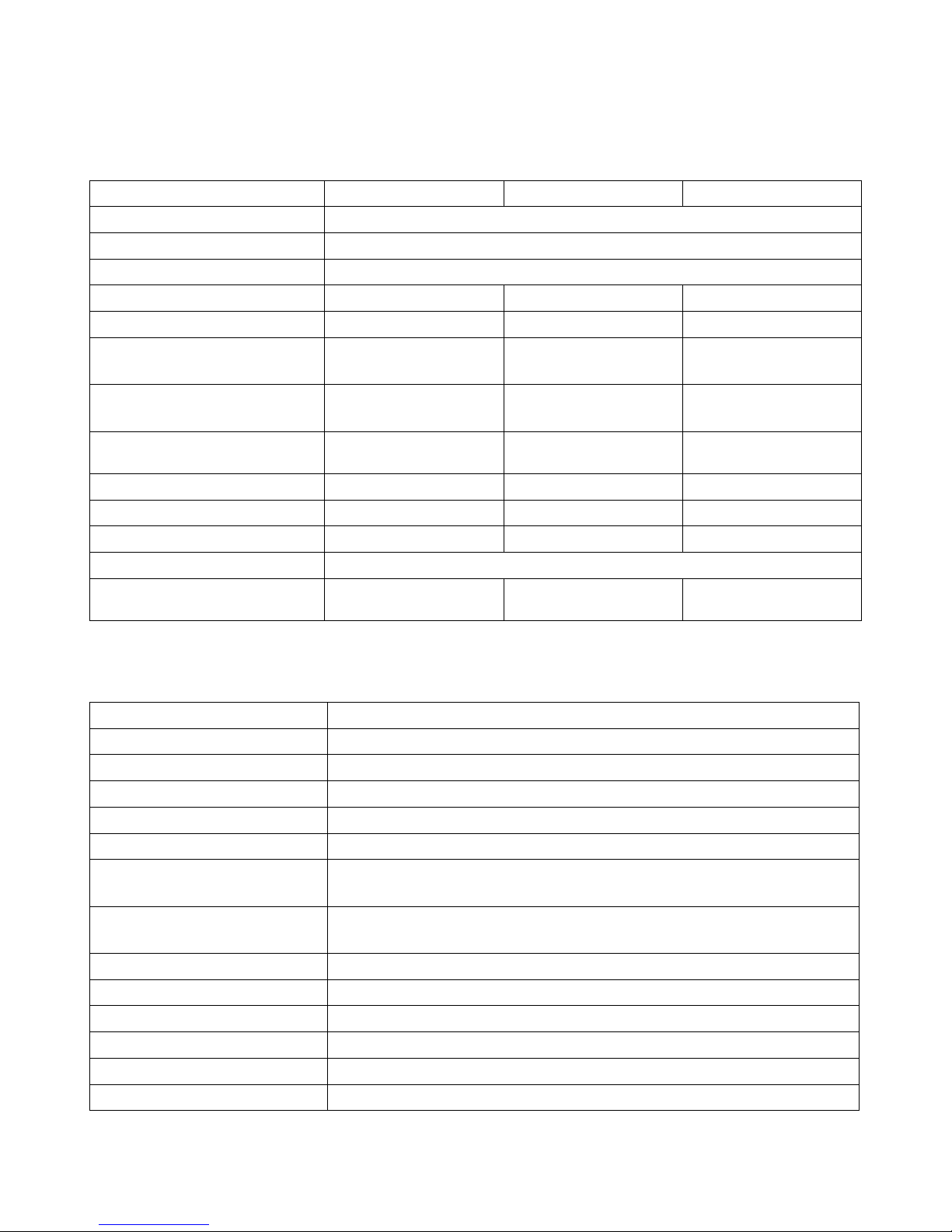

Chiller Specifications ......................................................................................................................................... 38

Air-Cooled Chillers (DA500, DA750, DA1000) .............................................................................................. 38

Water-Cooled Chillers (DW500) .................................................................................................................... 38

Electrical Specifications ..................................................................................................................................... 39

DA500 Chillers ............................................................................................................................................... 39

DW500 Chillers .............................................................................................................................................. 40

DA750 Chillers ............................................................................................................................................... 41

DA1000 Chillers ............................................................................................................................................. 41

Pump Performance............................................................................................................................................ 42

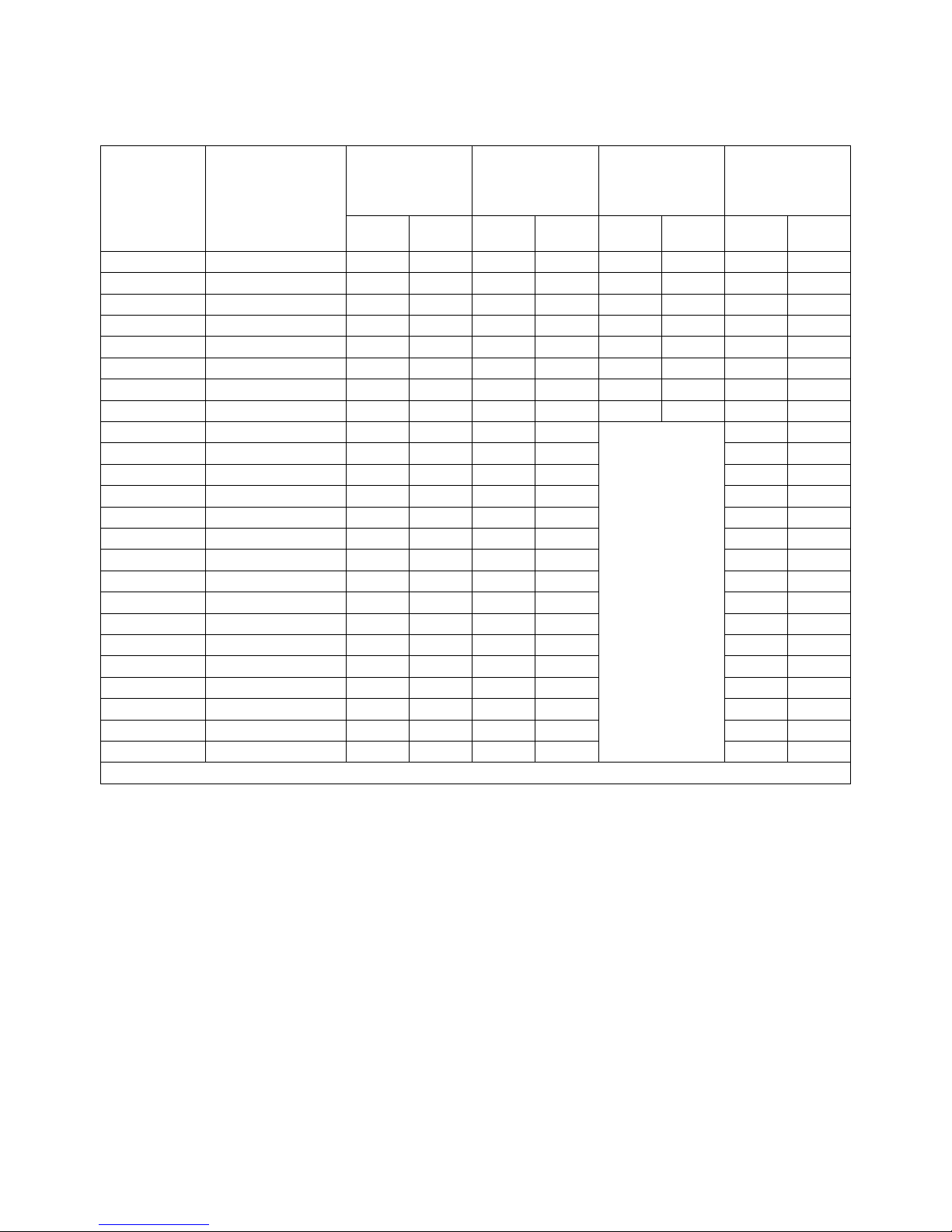

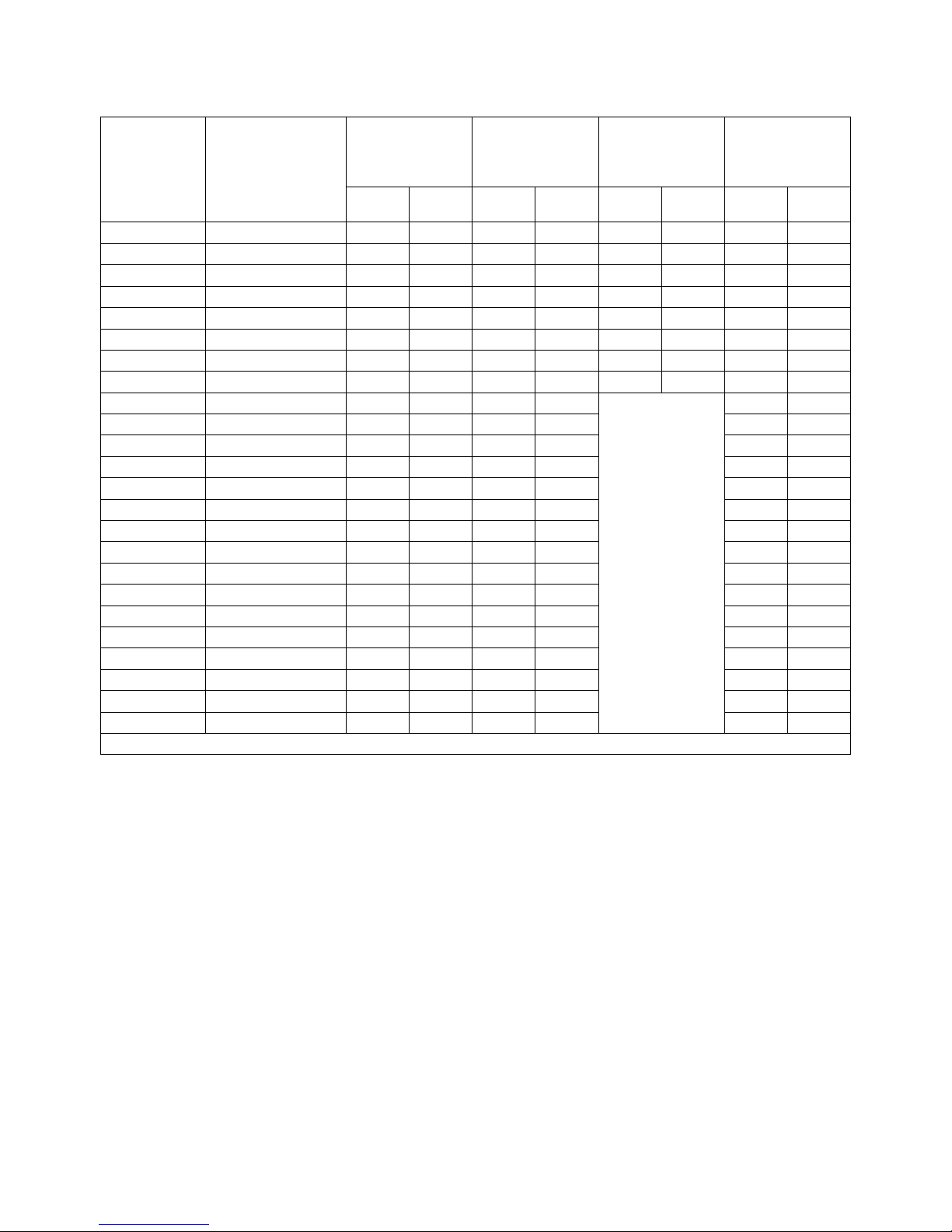

RS-232 Serial Communications (RS-485 Option) ............................................................................................. 43

Equipment Disposal (WEEE Directive) ............................................................................................................. 44

Service and Technical Support.......................................................................................................................... 44

PolyScience Chiller Fluids ................................................................................................................................. 45

Warranty............................................................................................................................................................... 45

Appendix.............................................................................................................................................................. 46

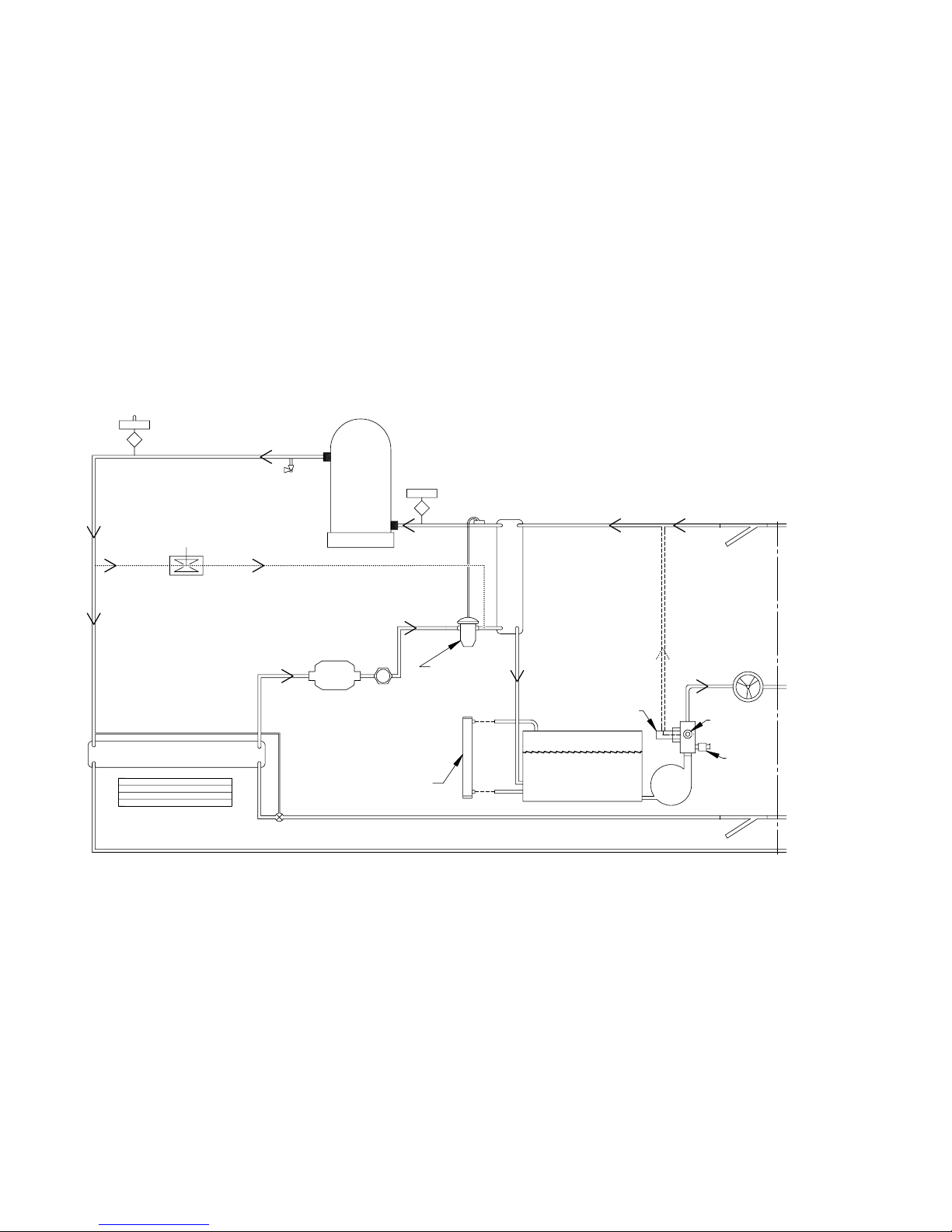

Flow Schematic – Air-Cooled Chillers ............................................................................................................... 46

Flow Schematic - Water-Cooled Chillers........................................................................................................... 47

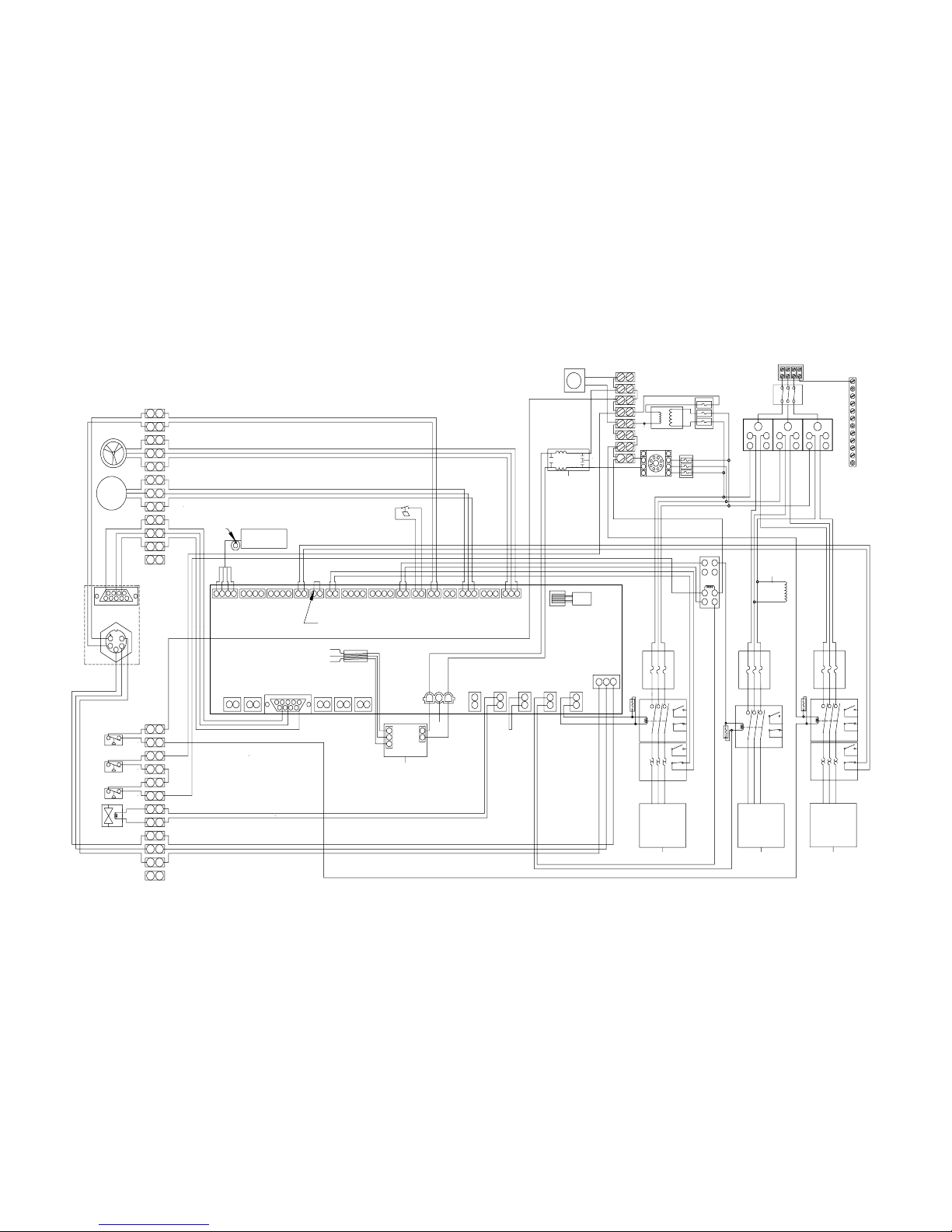

Wiring Diagram - 5 HP and 7.5 HP Air-Cooled Chillers .................................................................................... 48

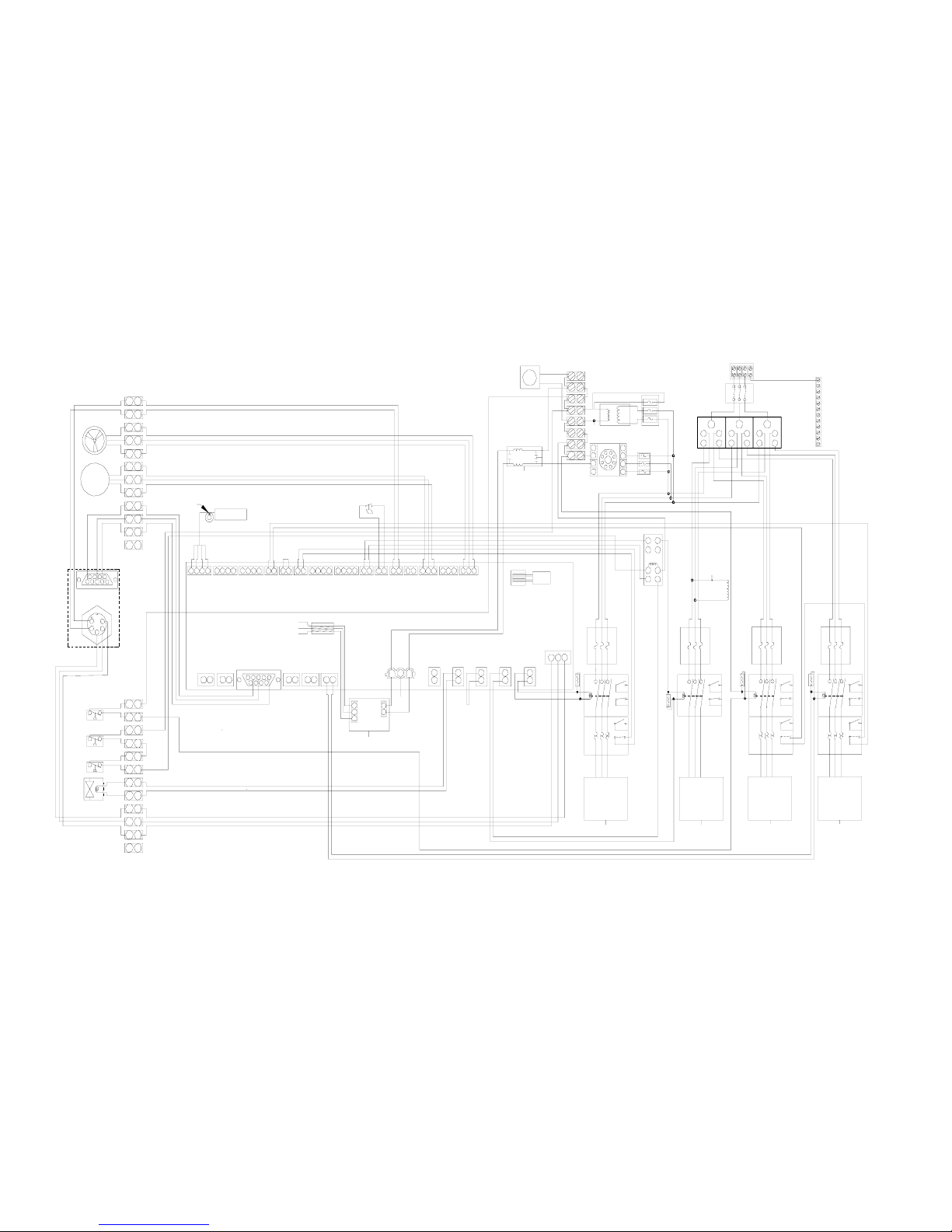

Wiring Diagram - 10 HP Air-Cooled Chillers...................................................................................................... 49

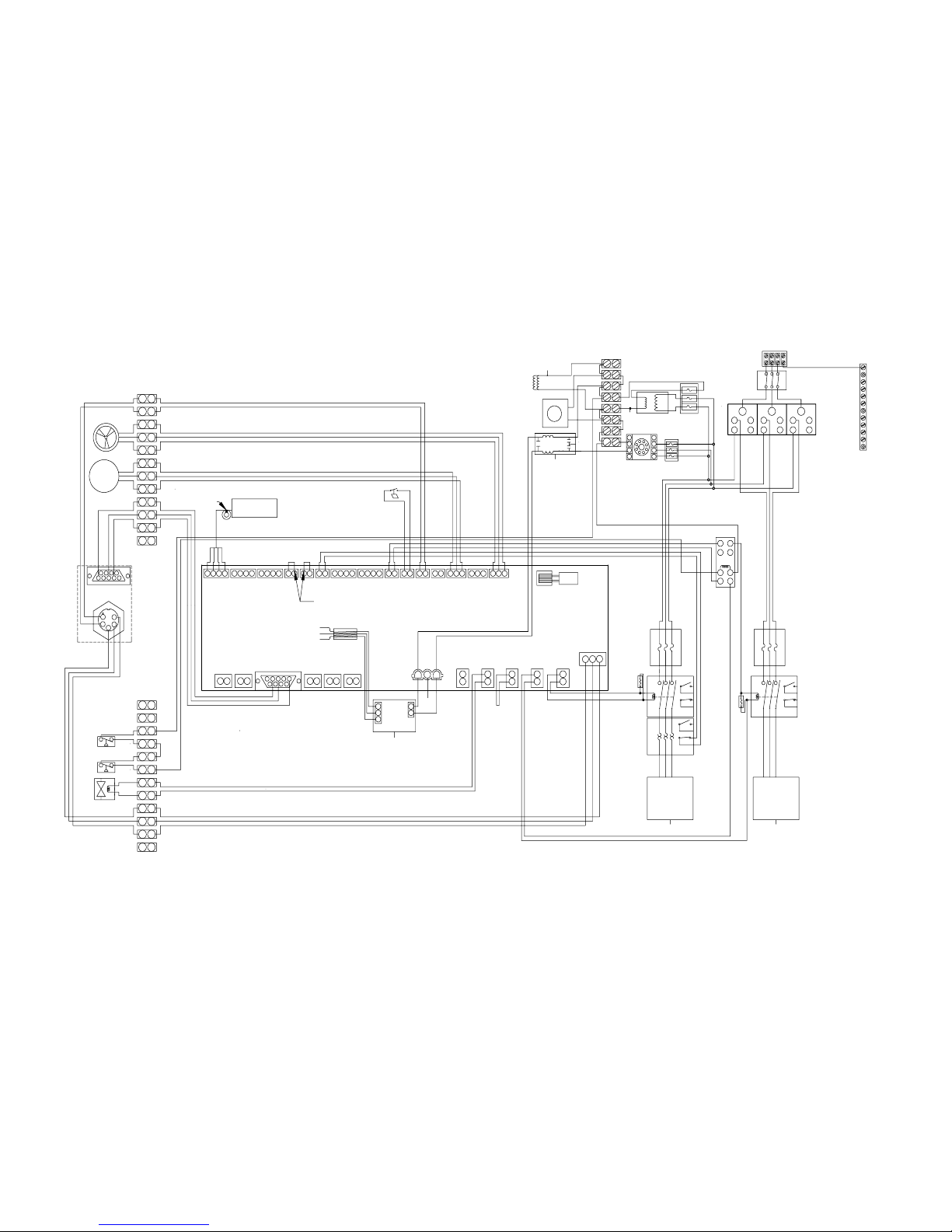

Wiring Diagram - 5 HP Water-Cooled Chillers .................................................................................................. 50

4-20 mA Set Point Control................................................................................................................................. 51

110-279 3

Page 5

Introduction

The PolyScience line of DuraChill Chillers provide cooling power for demanding applications and serve as an

economical alternative to tap water cooling systems. All models feature a microprocessor-based controller,

digital Temperature Display (°C or °F), one-touch set point display, and digital Pressure/Flow Rate Display (PSI,

kPa, GPM, LPM) with push-button selection.

Standard and Optional Features

DuraChill Chillers offer exceptional performance, reliability, and operational simplicity. Available in both air- and

water-cooled models, these robust self-contained Chillers are engineered to provide accurate temperature

control in a broad range of process cooling applications.

These powerful Chillers can be configured with a wide variety of standard and optional features, including:

Standard Features

• Process temperature range: 32° to 86°F (0° to 30°C)

• Ambient temperature range: 60° to 104°F (16° to 40°C)

• Temperature stability: ±2.0°F (±1.1°C)

• High efficiency vertical air exhaust

• Accurate microprocessor control with digital LED readout

• Pump protection by means of a Full Flow Bypass Valve

• Copeland Scroll compressor

• Compressor protection through high and low refrigerant pressure cuto

• RS-232 communications interface

• Reservoir sight glass

• Remote On / Off control (dry con

• Dry contact status alarm output

• Power phase monitor on 3-phase units

• Heavy-duty locking casters for easy maneuverability

• Stainless steel c

®

uts

r- and under-temperature alarms • Process protection provided by ove

tact)

entrifugal pump (1 HP on 5 and 7.5 HP units; 2 HP on 10 HP units)

O t

p ional Features

• Other centrifugal and turbine pump

s

• RS-485 communications interface

• Remote On / Off control

(24 VDC)

• Process shutoff valves

• External bypass valve

• Stainless steel reservoir

• Heaters

• Feet to replace casters

• Reservoir level float switch

• Side stream filter assemblies

• External inlet / outlet filter assemblies

• Deionized compatible process plumbing

Configuration Data Sheet showing how your DuraChill Chiller is equipped is included with the manual if

A

applicable (see inside front cover).

110-279 4

Page 6

General Safety Information

When installed, operated, and maintained according to the directions in this manual and common safety

procedures, your DuraChill Chiller should provide safe and reliable temperature control. Please ensure that all

individuals involved in the installation, operation, or maintenance of this Chiller read this manual thoroughly prior

to working with the unit.

This symbol alerts you to wide range of potential dangers.

This symbol advises you of danger from electricity or electric shock.

This symbol indicates that a hot surface may be present.

This symbol marks information that is particularly important.

/

This symbol indicates alternating current.

This symbol indicates a protective conductor terminal. Only connect the unit to a power socket with earth

(ground) contact (PE – protective earth). The power supply connector plug serves as a safe disconnecting

device from the line and must always be easily accessible.

These symbols on the Power Switch / Disconnect indicate that they place the main power supply ON / OFF.

This symbol on the Power Button indicates that it places the unit in a standby mode. It DOES NOT fully

disconnect the unit from the power supply.

Read all instructions pertaining to safety, set-up, and operation.

Proper operation and maintenance is the user’s responsibility.

110-279 5

Page 7

Safety Recommendations

It is the user’s responsibility to read and understand all instructions and safety precautions included in this

manual prior to installing or operating this equipment. Contact our Customer Service Department with any

questions regarding the operation of this Chiller or the information contained in this manual.

WARNING: All warning labels should be carefully observed. Never remove or obstruct a warning label.

WARNING: Installation, operation, or maintenance of this equipment should be performed in strict

accordance with the instructions outlined in this manual. Failure to follow those instructions may

increase the risk of personal injury, damage the equipment, and/or void the warranty.

WARNING: Be sure to remove power from the equipment, reclaim the refrigeration charge, and relieve

any residual pressure before cutting into the refrigeration system.

WARNING: Do not attempt to operate leaking or damaged equipment.

WARNING: Service should only be performed by fully qualified personnel. Extreme caution is required

as hazards are present when servicing this equipment.

WARNING: Do not attempt to override the power interlock switch or any other safety feature on this

equipment.

WARNING: Disconnect electrical power before moving unit. Keep unit upright when moving. Always

follow your company’s procedures and practices regarding safe lifting and relocation of heavy objects.

WARNING: Make sure the equipment’s main power switch is in the OFF position before connecting or

disconnecting power. Follow all applicable electrical and safety codes and procedures when connecting

power to the unit. Electrical connections should be made by an authorized electrical installer.

WARNING: This equipment must be properly filled with cooling fluid before use and properly drained

before moving or service.

WARNING: Use only fluids that comply with safety, health, and equipment compatibility requirements.

Read the safety data sheet for the fluid being used carefully before use.

CAUTION: Always operate this equipment within the stated design specifications.

110-279 6

Page 8

Regulatory Compliance and Testing

CSA UL (5 HP 60Hz units)

CAN/CSA C22.2 No. 61010-1-04 — Safety Requirements for Electrical Equipment for Measurement, Control

and Laboratory Use, Part I: General Requirements.

CAN/CSA C22.2 No. 61010-010-04 — Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use - Part 2-010: Particular Requirements for Laboratory Equipment for the Heating of

Materials.

UL Std No. 61010-1 (2

nd

edition) — Electrical Equipment for Laboratory Use, Part I: General Requirements.

CE (All 50Hz units)

EC Low Voltage Directive 2006/95/EC

EC Electromagnetic Compatibility Directive 2004/108/EC

IEC 61010-1-2001

IEC 61010-2-10 : 2005

IEC 61326-1:2005

Unpacking

Your Chiller is shipped in a special container. Retain the container and all packing materials until the unit is

completely assembled and working properly. Set up and run the unit immediately to confirm proper operation. If

the unit is damaged or does not operate properly, contact the transportation company, file a damage claim and

contact the company where your unit was purchased immediately.

110-279 7

Page 9

Controls and Components

Your DuraChill Chiller consists of three basic sub-systems:

• Control

• Fluid circulation

• Cooling

This section describes these sub-systems in detail and includes information on the available options. Please

note that your Chiller may or may not be equipped with all the components discussed.

Control System

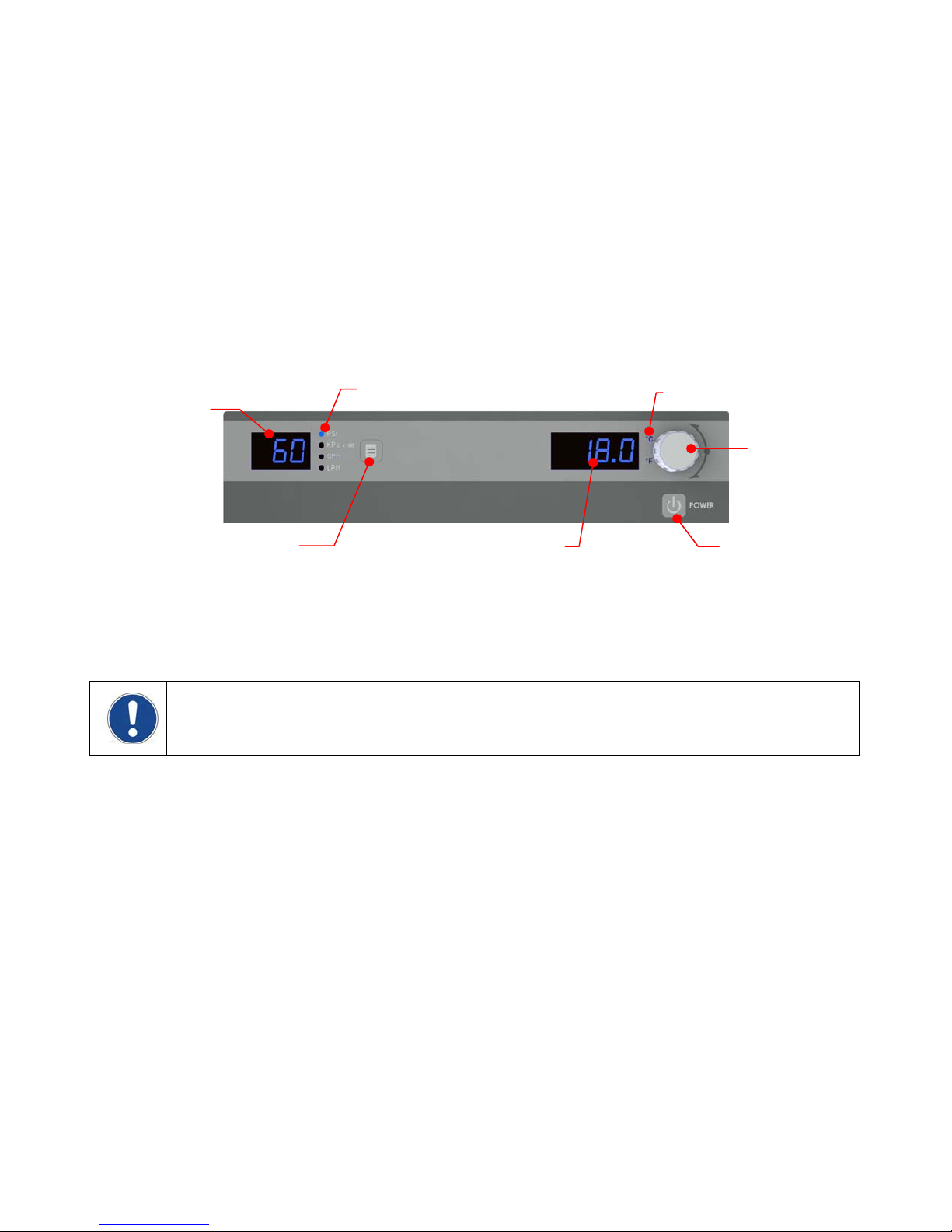

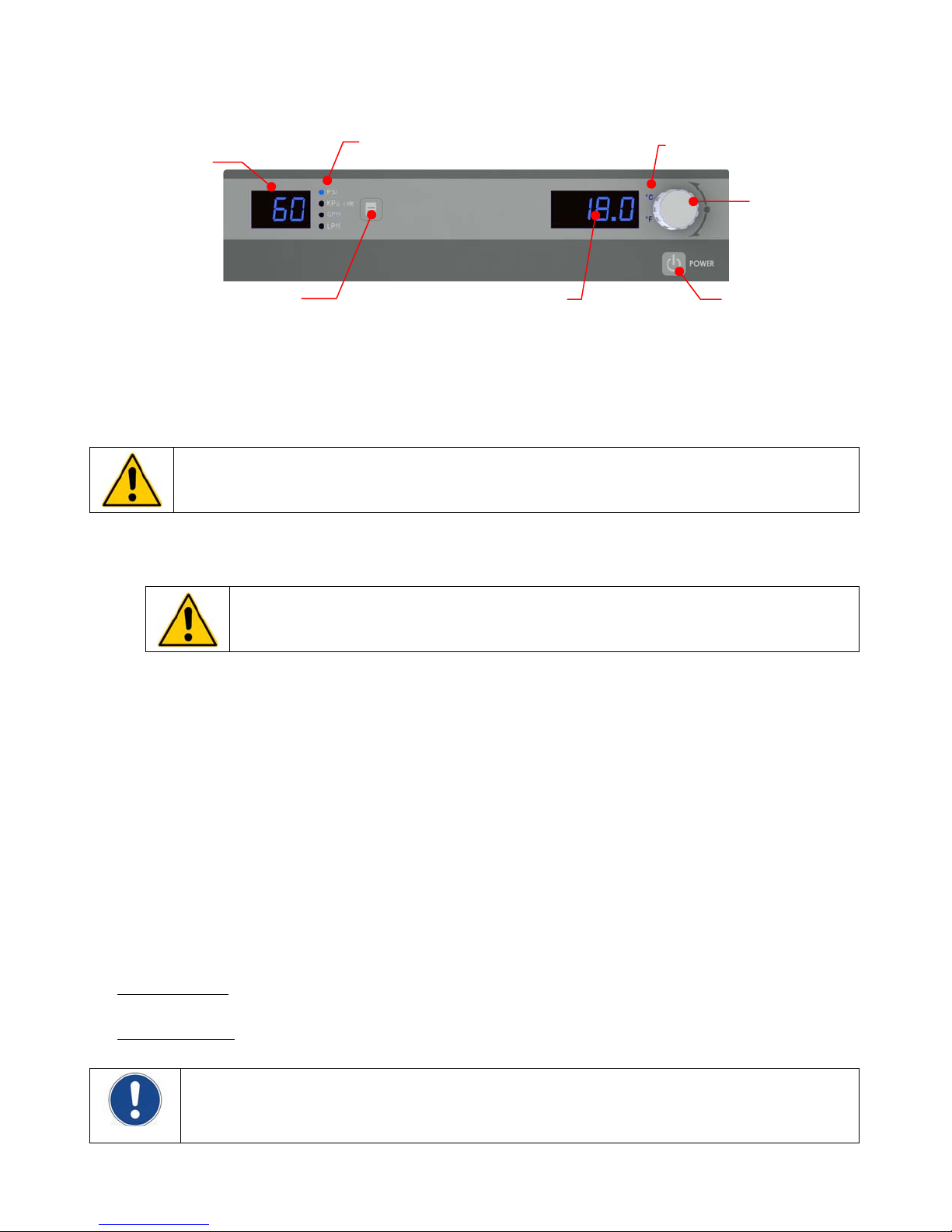

Control Panel — Temperature set point, temperature units, and other operating parameters are set via the

Control Panel. Operating information is displayed on a local digital readout.

Pressure / Flow

Rate Display

Units / Menu

Select Button

Pressure / Flow Rate Unit

Temperature

Display

Power Switch / Disconnect — The main power switch is located on the front door of the Chiller. This switch

also functions as a power disconnect when access to the unit’s components and terminal blocks is required; the

access door cannot be opened until the Power Switch / Disconnect is placed in the OFF position.

Temperature Unit

Select / Set Knob

Power Button

NOTE: Loss of Power – In the event that power is lost while the Chiller is operating, the unit will

automatically resume operation when the power is restored. If the unit was in Standby mode when power is

lost, it will power up in Standby mode. The above is also true if power is removed via the Power Switch /

Disconnect.

Temperature Probe — An internal RTD is used to measure fluid temperature downstream of the pump. Its

reading is displayed on the Control Panel’s LED temperature display.

Flow Sensor — Monitors process fluid flow. If the flow rate is less than the user-settable alarm value, power to

the pump, compressor, and fan is removed and an alarm message displayed on the Control Panel’s LED

readout.

Flow Switch — Requires a minimum of ~4 gpm (15.1 lpm) to close. If the flow rate is too low, the switch will

open and power to the pump, compressor, and fan removed; an alarm message will also be displayed on the

Control Panel’s LED readout.

Fluid Pressure Sensor — Measures fluid pressure at the pump outlet. If the fluid pressure exceeds the user-

settable alarm value, power to the pump, compressor, and fan is removed and an alarm message displayed on

the Control Panel’s LED readout.

Refrigerant Pressure Switches — When activated, these switches remove power to the pump, compressor,

and fan; an alarm message is also displayed on the Control Panel’s LED readout.

The Low Pressure Switch opens if the refrigerant pressure falls below 10 psi (0.7 bar) and closes if the

pressure is above 30 psi (2.1 bar). The Low Pressure Switch will auto-reset.

The High Pressure Switch opens if the refrigerant pressure exceeds 630 psi (43.4 bar). The High

Pressure Switch must be manually reset (see Troubleshooting, Compressor Overload Fault).

110-279 8

Page 10

Fan Cycling Switch — This switch control fan operation. The fan turns ON when the discharge pressure of the

refrigerant exceeds 400 psi (27.8 bar) and remains running until the pressure falls below 300 psi (20.7 bar).

NOTE: 10 HP Chillers have two fans. One fan turns ON with the compressor and runs continuously as long

as the compressor is ON; operation of the second fan is based on refrigerant pressure as described above.

Reservoir Float Switch (Optional) — Measures liquid level in the Chiller’s reservoir. If the fluid level drops too

low, power to the pump, compressor, and fan is removed and an alarm message displayed on the Control

Panel’s LED readout.

Fluid Circulation System

This sub-system governs fluid flow through the Chiller.

Evaporator — Serves as the heat exchanger between the refrigeration and fluid flow systems. Cools fluid

before it returns to process.

Reservoir Tank — This polyethylene tank is used to maintain stable temperature control and an adequate

reservoir of fluid for the system. It may be equipped with an optional float switch that monitors fluid level and

activates an alarm. A stainless steel reservoir is available as an option.

Sight Glass or Level Indicator — This indicator serves as a convenient means of checking the liquid level

within the Reservoir Tank. The sight glass is located on the rear panel.

Pump — Used to pump fluid from the Reservoir Tank to the process and back to the Chiller. A variety of pumps

are available for operation at different pressures, flow rates, and distances from the Chiller to the process.

Full Flow Bypass — Allows the maximum operating pressure to be regulated and protects the Pump in the

event that process piping becomes restricted or clogged. Diverts flow from the process line back to the

Evaporator and Reservoir.

Y-Strainer — Located on the inlet to the Chiller. Incorporates a cleanable 20 mesh (841 micron) stainless steel

screen to remove large particulate matter from the process fluid.

External Bypass / Shutoff Valves — Allows the unit to be operated independent of the process during the

servicing of process equipment and/or process lines. Can also be used to fine-tune process pressure and flow

rate.

Process Side-Stream Filter System (Optional) — Consists of a 50 micro filter and ball valve connected

between the Chiller inlet and outlet. It is used to filter particulate matter from a portion of the process fluid flow.

Cooling System

NOTE: The Condenser on DuraChill Chillers is either air-cooled or water-cooled.

Common Cooling System Components

The following components are common to both air-cooled (DA models) and water-cooled (DW models)

DuraChill Chillers:

Evaporator — Serves as the heat exchanger between the refrigeration and fluid flow systems. Removes heat

from the process fluid before it is returned to the process equipment.

Compressor — The Chiller incorporates a 5 to 10 HP Copeland Scroll compressor. The Compressor is

protected from overloads through high and low pressure cutouts.

Filter Dryer

— Removes residual particulate matter and moisture from the refrigeration system. The Filter Dryer

must be replaced whenever the sealed refrigeration lines are opened for service.

Sight Glass — Used to observe refrigerant fluid flow to the Evaporator.

Thermostatic Expansion Valve (TXV) — Controls refrigerant superheat at the outlet of the Evaporator to

prevent liquid from returning to the Compressor.

110-279 9

Page 11

Hot Gas Bypass Solenoid Valve — Injects refrigerant vapor into the Evaporator to help maintain a constant

temperature when the temperature of the process fluid falls below the temperature set point. Under low- and noload conditions, temperature continues to fall until it reaches the “Lb” lower band and shuts the Compressor

OFF.

Refrigerant Safety Relief Valve — This is an automatic safety used to vent refrigeration gas if it exceeds 650

psi (44.8 bar).

Air-Cooled Chillers (DA Models)

The following components are specific to air-cooled DuraChill Chillers:

Condenser — The Compressor pumps vapor into the Condenser at high pressure. As the surrounding air is

cooler than the hot vapor, heat energy passes into the air from the condenser coils.

Condensing Fan — a 1 HP fan (two fans on 10 HP units) that draws air over the condenser coils to cool

refrigerant gas. The standard fan cycles ON and OFF based on refrigerant pressure (ON at 400 psi / 27.6 bar;

OFF at 300 psi / 20.7 bar). The second fan on 10 HP units runs whenever the Compressor is ON.

Water-Cooled Chillers (DW Models)

Brazed-Plate Heat Exchanger / Condenser — Serves as the heat exchanger between the refrigeration system

and the facility water supplied by the customer. Removes heat from the refrigerant.

Condensing Water Regulating Valve — This valve regulates the facility water flow to maintain optimal

discharge pressure (approximately 250 psi / 17.2 bar) for the heat exchange in the Condenser. It increases flow

to decrease pressure and decreases flow to increase pressure.

Receiver — The main purpose of the Receiver is to temporarily store refrigerant (in its liquid state) that is not

required when load conditions are low. The Receiver also provides a constant supply of liquid to the

Thermostatic Expansion Valve (TXV).

110-279 10

Page 12

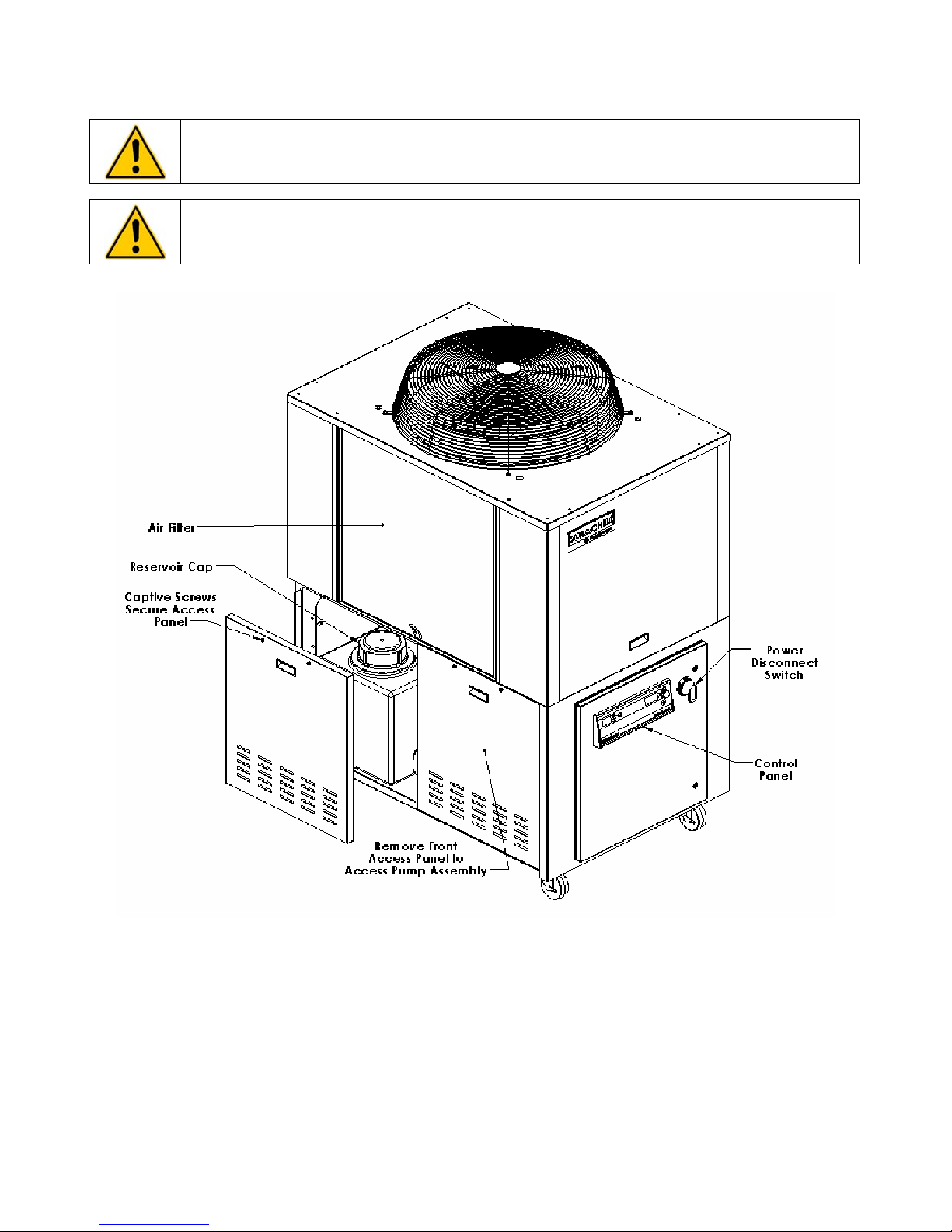

Component Identification

Front – All Models

Control Panel

5 HP and 7.5 HP Chillers – Rear

Power Switch / Disconnect

110-279 11

Page 13

10 HP Chillers – Rear

110-279 12

Page 14

Installation and Startup

WARNING: Be sure all power is OFF before proceeding.

Site Requirements

Ambient Temperature and Relative Humidity

The Chiller is designed for indoor installation in ambient temperatures between 60° and 104°F (16° and 40°C);

relative humidity should not exceed 80% (non-condensing).

Location

The Chiller should be installed on a strong, level surface capable of supporting 1050 lbs. / 476.3 kg (5 and 7.5

HP units) or 1500 lbs. / 680.1 kg (10 HP units).

It should be located as close to possible to the process requiring cooling and installed no closer than 4 feet (1.4

meters) to a heat-generating source, such as heating pipes, boilers, etc. If possible, the Chiller should be

located near a suitable drain to prevent flooding in the event of leaks. Do not place it where corrosive fumes,

excessive moisture, excessive dust, or high room temperatures are present.

For ease of positioning and maneuverability, the Chiller is supplied with casters. The front wheels can be locked

to keep the Chiller in place while in use.

To help prevent voltage drops, position the Chiller as close as possible to the power distribution panel. Avoid

voltage drops by using a properly grounded power source wired to meet electrical data plate requirements. The

use of an extension cord is not recommended.

NOTE: The Chiller may be located at a level below that of the equipment being cooled. As long as the

process remains closed, overflow will not occur when adding cooling fluid to the Chiller reservoir.

Clearance

Adequate clearance should be allowed on the front, sides, and rear of the Chiller for access to connections and

components. The front and rear vents of the Chiller must be a minimum of 24 inches (61 cm) away from walls or

vertical surfaces so air flow is not restricted.

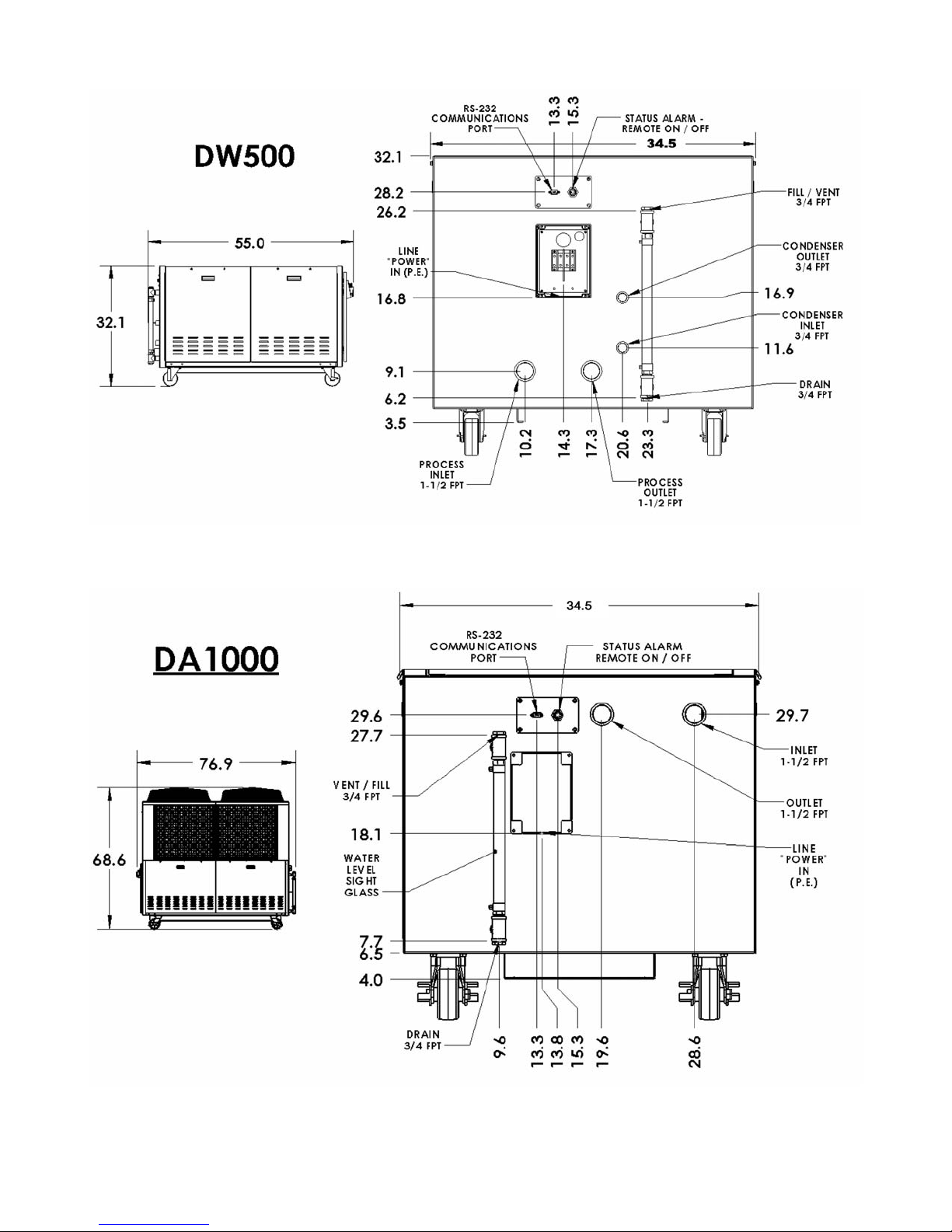

Overall Dimensions

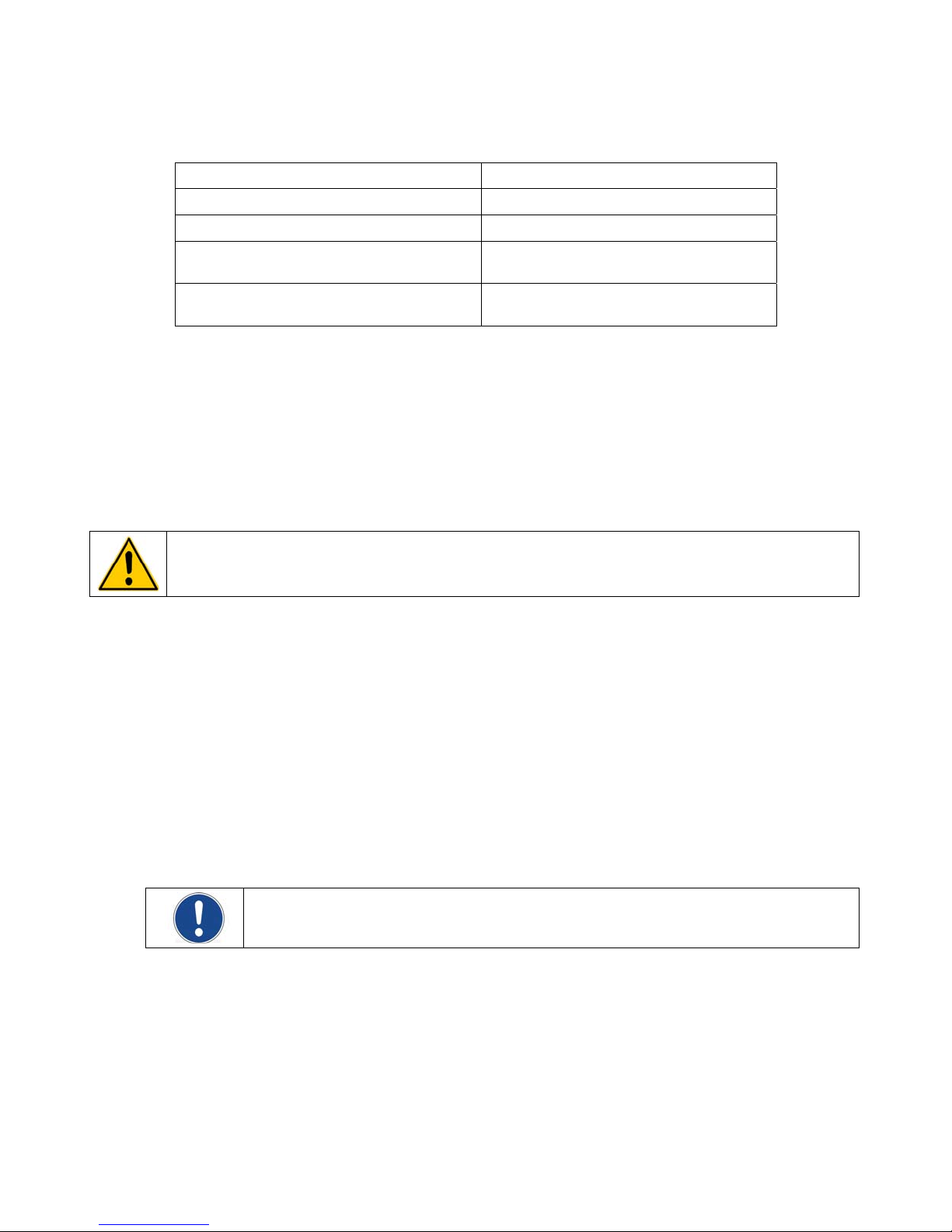

Model Length Width Height

DA500 56 in. (142.2 cm) 34.5 in. (88 cm) 67 in. (170.2 cm)

DW500 56 in. (142.2 cm) 34.5 in. (88 cm) 32.1 in. (81.6 cm)

DA750 56 in. (142.2 cm) 34.5 in. (88 cm) 67 in. (170.2 cm)

DA1000 77 in. (195.6 cm) 34.5 in. (88 cm) 68.2 in. (173.2 cm)

110-279 13

Page 15

Electrical Power

WARNING: Make sure the main power switch is in the OFF position before connecting or disconnecting

electrical power from the unit. Follow all applicable electrical and safety codes and procedures when

connecting power to the unit. Electrical connections should be made by an authorized electrical installer.

WARNING:

Make certain that the electrical supply is the same voltage and frequency as your unit (see identification

label).

Make sure electrical connections comply with all applicable electrical codes.

Ground the Chiller in accordance with NEC Article 250.

Operating voltage must be within 10% of the data plate rating.

Phase imbalance must be below 5%.

WARNING: DO NOT apply power to the Chiller until the unit is ready for Startup

CAUTION: DO NOT apply power to the Chiller until the Reservoir has been filled. When Controller power

is turned ON, the pump automatically begins pumping. If the Reservoir has not been filled, the pump could

be damaged.

The Chiller is equipped with a phase monitor that prevents startup if phase sequence is incorrect. It will also turn

the Chiller OFF in the event of a loss of one phase and/or prevent Chiller operation if there is a voltage

mismatch between any two phases greater than 8%. Be sure to connect electrical lines in proper sequence, i.e.:

L1, L2, and L3.

There is a junction box on the rear of the unit to which you can connect the electrical power supply conduit. Be

sure to provide suitable conduit strain relief and grounding.

WARNING: DO NOT remove the ground wire while diagnosing any power supply problems.

110-279 14

Page 16

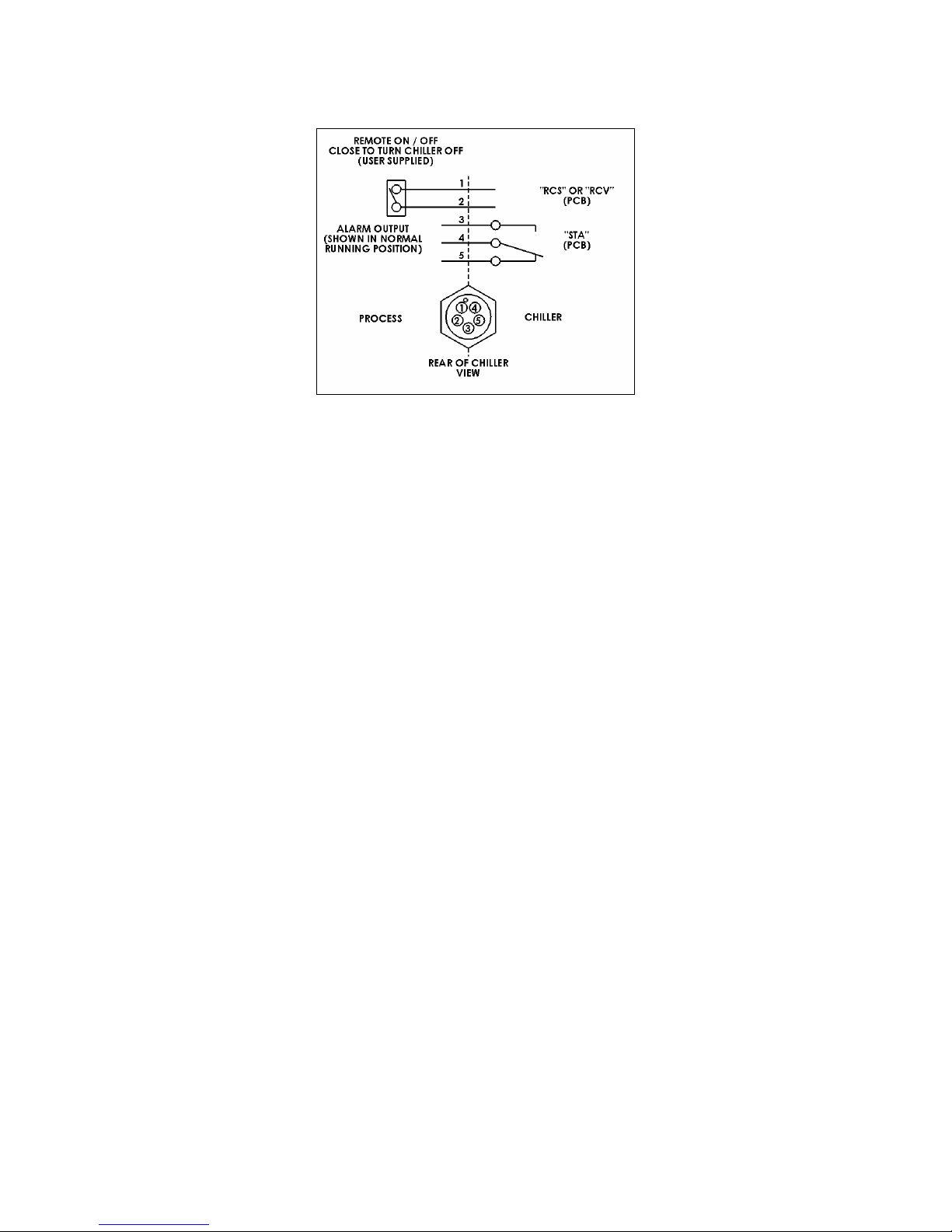

Signal Inputs/Outputs

Remote On / Off and Alarm Output

Remote On / Off

This allows the operator to turn the Chiller ON and OFF using a remote dry contact. The Chiller is ON when the

contact is open; it is OFF when the contact is closed. A 10-ft (3 m) cord with 5-pin mating plug is provided.

Alarm Output

This allows the operator to connect a remote alarm device to the Chiller. The alarm output consists of normally

open (NO) and normally closed (NC) contacts which are switched whenever an alarm, fault, or error condition is

detected or when the Chiller is OFF. A 10-ft (3 m) cord with 5-pin mating plug is provided.

RS-232 Serial Communication (RS-485 Option)

This allows the operator to remotely control the Chiller and/or output temperature readings to an external

recorder or other auxiliary device. A 9-pin D-connector is provided on the rear of the instrument enclosure for

this connection.

The maximum communications distance for Chillers equipped with RS-232 is 50 feet (15 meters); the maximum

distance for units equipped with the RS-485 option is 4000 feet (1200 meters).

See the Technical Information section for serial communications protocol and commands.

110-279 15

Page 17

External Piping

WARNING: All facility water connections must be made by a licensed plumber.

General Considerations

To maintain a safe workplace and avoid leaks, special care should be taken when choosing hoses and

connectors for the Chiller. It is the user’s responsibility to ensure that the tubing and fittings connected to the

Chiller are compatible with the fluid, temperature, and pressure being used.

• Pressure Ratings – Hoses should be able to withstand a minimum pressure of 250 psi (17.2 bar).

• Flexible Tubing – Avoid tubing that will expand and increase fluid volume when operating at the desired

pressure.

• Take care when selecting hoses and connections for the Chiller. All external piping, tubing, or hoses should

be run full size to limit the potential for external pressure drops. The use of quick-connect fittings is not

recommended, as they can cause substantial pressure drops.

• Where applicable, always use a back-up wrench when making piping connections to the Chiller.

• Hose Diameter – The fittings on the Chiller’s process fluid lines are female 1.5 in NPT. The facility water

fluid inlets and outlets on water-cooled models are female 0.75 inch NPT.

• Facility Water (water-cooled models only) – Should be clean and well maintained. Ideally, the facility water

should be tested monthly to ensure a pH level between 7.2 and 7.8. Add algaecide if algae growth is

present.

Process Fluid Connections

The Chiller has two internally threaded (1.5 inch ID NPT) fittings on the rear of the instrument housing for the

process water connections.

Connect the Chiller’s inlet and outlet to the external apparatus with hoses or pipes. The direction of the flow

through the system can be controlled by the way the connections are made. Fluid is drawn into the Chiller

through the “Inlet” connection; fluid is pumped out of the Chiller through the “Outlet” connection.

Facility Water Connections

WARNING: The incoming cooling water pressure should be 20 psi / 1.4 bar minimum and 40 psi / 2.8 bar

maximum.

Water-cooled Chillers have two internally threaded (0.75 inch ID NPT) on the rear of the instrument housing for

the facility water connections. The cooling water supply should be connected to the facility water inlet on the

Chiller. The facility water outlet on the Chiller should be connected to the appropriate return or drain, as

required.

The cooling water supply may be from city tap water or a cooling tower. The incoming water pressure should be

between 20 and 40 psi / 1.4 and 2.8 bar.

Reservoir Drain

A 0.75 inch NPT connection is provided at the bottom of the reservoir Sight Glass / Level Indicator for the

reservoir’s gravity drain. It should be piped to a drain or receptacle positioned below the bottom of the reservoir.

If a receptacle is used, be sure it is of sufficient volume to hold all the coolant in the reservoir, process, and

process lines.

Reservoir Fill / Vent

A 0.75 inch female NPT connection is provided at the top of the Reservoir Sight Glass / Level Indicator.

If desired, you may add coolant to the Chiller through this connection to maintain an adequate fluid level. It is

recommended that you fill the Reservoir initially via the fill port at the top of the Reservoir.

110-279 16

Page 18

If the Chiller is equipped with the heater option, a Reservoir vent should be installed. This vent relieves pressure

within the Reservoir as coolant heats and expands.

It may be also necessary to vent and/or add a venting pipe to the Chiller to prevent siphoning and/or overflow

due to the amount of fluid external to the Chiller’s reservoir and/or location of the process being cooled.

NOTE: If the amount of fluid present in the process piping when the Chiller is turned OFF exceeds the

capacity of the Reservoir, it may be necessary to install a normally closed (NO) solenoid valve on the

Chiller’s fluid inlet and a check valve on the Chiller’s fluid outlet to prevent backflow into the unit.

Full Flow Bypass

This allows the operator to adjust the maximum operating pressure to the process. For low pressure pumps, the

pressure range is 7 to 35 psi (0.5 to 2.4 bar). For high pressure pumps, the pressure range is 30 to 100 psi (2.1

to 6.9 bar). The Full Flow Bypass is located on the left front side of the Chiller housing just above the pump.

NOTE: The Full Flow Bypass also protects the pump when running continuously under dead head conditions

caused by a blockage in the process or process lines.

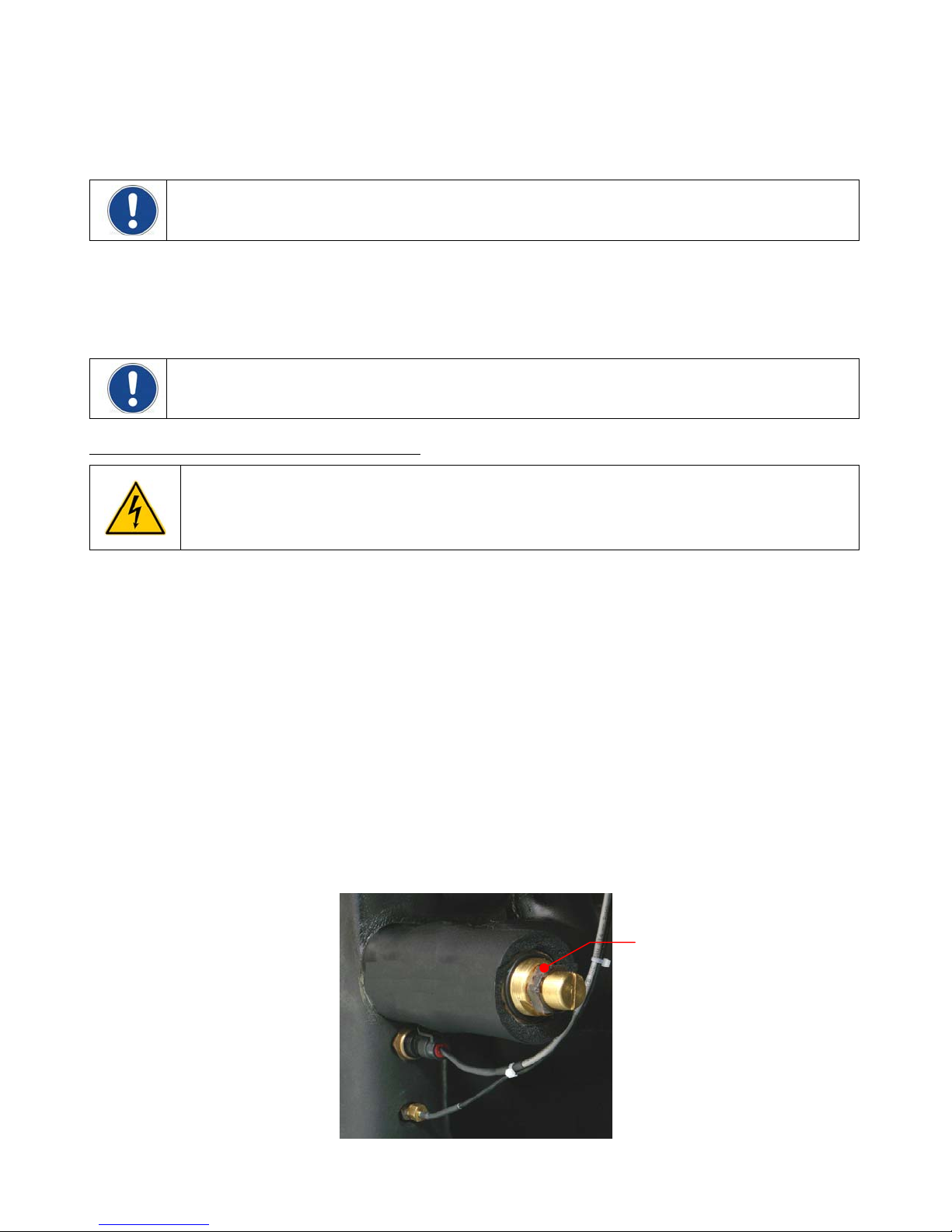

Adjusting the Full Flow Bypass Pressure Setting

WARNING: Hazardous voltages are present.

The pressure setting on the Full Flow Bypass is adjusted as follows:

1. Set the minimum allowable flow rate to 0 (see Normal Operation, Setting Operational Parameters /

Limits, Minimum Flow Rate).

2. Completely block the flow from the Chiller’s fluid outlet. This should cause the pressure to rise.

3. Set the Pressure / Flow Rate Display to read in either PSI or kPa (see Normal Operation, Selecting the

Pressure / Flow Rate Display and Units).

4. Remove the insulation covering the pressure regulating valve cap and then remove the cap. There may

be some coolant in the cap; this is normal.

5. Loosen the locknut and then using a flat blade screwdriver, adjust the pressure until the reading on the

Pressure / Flow Rate Display matches the desired maximum operating pressure. A clockwise rotation

increases pressure; a counter-clockwise rotation decreases pressure.

6. Set the minimum allowable flow rate to the desired value.

7. Tighten the locknut and replace the cap and insulation.

8. Set the Pressure / Flow Rate Display to the preferred reading (GPM, LPM, PSI, kPa).

Locknut

110-279 17

Full Flow Bypass Valve

Page 19

Process Coolant

Suitable Fluids

WARNING: Use only fluids that comply with safety, health, and equipment compatibility requirements. Read

the safety data sheet for the fluid being used carefully before use.

CAUTION: Do not fill the Reservoir with deionized water unless the Chiller is equipped with the DI water

compatible plumbing option.

The Chiller is designed to accommodate a variety of coolant fluids (water, glycol mixtures, etc). For most

applications above 60°F (16°C), distilled water is satisfactory. For operation below 60°F (16°C), the Chiller must

be protected with an antifreeze solution. Laboratory grade ethylene glycol or propylene glycol and water in a

50/50 mixture is satisfactory from 5° to 60°F (-15° to +16°C). Select a fluid that is compatible with the Chiller’s

wetted parts (brass, bronze, stainless steel, EPDM rubber, nylon, PVC).

CAUTION: Coolant freeze protection must be 25°F (14°C) below the lowest possible temperature. The

lowest possible temperature is equal to the process temperature minus the Lower Band ‘Lb’ setting (see

Normal Operation, Setting Operational Parameters / Limits, Lower Band).

WARNING: Do not use caustic, corrosive, or flammable fluids.

CAUTION: Operation below 15°C (59°F) requires antifreeze in the circulation fluid. DO NOT use

automotive antifreeze as the additives may be harmful to the Chiller’s wetted parts.

DO NOT USE the following fluids:

• Automotive antifreeze with additives**

• Hard tap water**

• Deionized water with a specific resistance > 1 meg ohm (except units with the DI water compatible

plumbing

• Any flammable fluids

• Concentrations of acids or bases

• Solutions with halides: chlorides, fluorides, bromides, iodides or sulfur

• Bleach (Sodium Hypochlorite)

• Solutions wi

th chromates or chromium salts

• Glycerin

• Syltherm fluids

** At temperatures above 40°C, additive

allowed to build up, the heater may over

additives can hasten deposit build up.

s or mineral deposits can adhere to the heater. If deposits are

heat and fail. Higher temperatures and higher concentrations of

An algaecide may be added to the coolant fluid to prevent algae growth (see PolyScience Chiller Fluids).

110-279 18

Page 20

Startup

CAUTION: The first time the Chiller is operated it should run for 12 hours in the Standby mode to allow the

compressor crankcase heater to boil off any refrigerant absorbed in the compressor oil.

CAUTION: DO NOT turn Controller power ON until the Reservoir has been filled. When Controller power is

turned ON, the pump automatically begins pumping. If the Reservoir has not been filled, the pump may be

damaged.

Facility Water Flow (water-cooled units only)

1. Open the valves to the facility water supply and return.

2. Check for leaks.

Filling the Reservoir

1. Remove the rear left panel of the Chiller housing. It is held in place with two captive screws.

2. Remove the reservoir cap located on the top of the Reservoir and, using a funnel, add fluid until it is

approximately 2 inches (5.1 cm) below top of reservoir.

3. Once the fluid level is about 2 inches (5.1 cm) below the top of the reservoir, remove the funnel but do not

replace the cap at this time.

110-279 19

Page 21

Starting Process Fluid Flow

1. Place the Power Switch / Disconnect in the ON position. The Control Panel displays will respond by

showing five decimal points (.....). This indicates that the Chiller is in the Standby mode and is ready for

power up. If this is the first time the Chiller is being operated, allow it to run in the Standby mode for 12

hours (see Caution note above).

2. Press the Power Button on the Control Panel. The system startup sequence will begin and proceed as

follows:

• The pump will turn on and fluid will begin circulating through the system.

CAUTION: On initial startup or after long periods of inactivity, run the Chiller for 10 seconds, turn

power OFF, and restart five times to remove any air in the process lines.

• The set point temperature will appear briefly on the Temperature Display; after a few seconds, it will be

replaced by the actual fluid temperature. The right decimal point will flash while the set point is being

displayed.

• The system will go through a short initialization sequence.

• Once initialization has been completed, the compressor will begin operating. When the pressure in the

discharge line reaches 400 psi (27.6 bar), the fan will turn ON. Water-cooled units: The coolant water

regulating valve opens/closes to maintain the pressure in the discharge line at approximately 250 psi

(17.2 bar).

• The Controller will display the actual process fluid temperature and the appropriate ‘degrees’ LED will

be lit (C or F).

3. Check for leaks.

4. With the pump running, the reservoir’s fluid level will drop as the process and/or process cooling lines fill

with fluid. Slowly add fluid to the reservoir until the liquid level remains stable. This means that the system

is filled and any entrained air has been purged.

5. Replace the reservoir cap.

110-279 20

Page 22

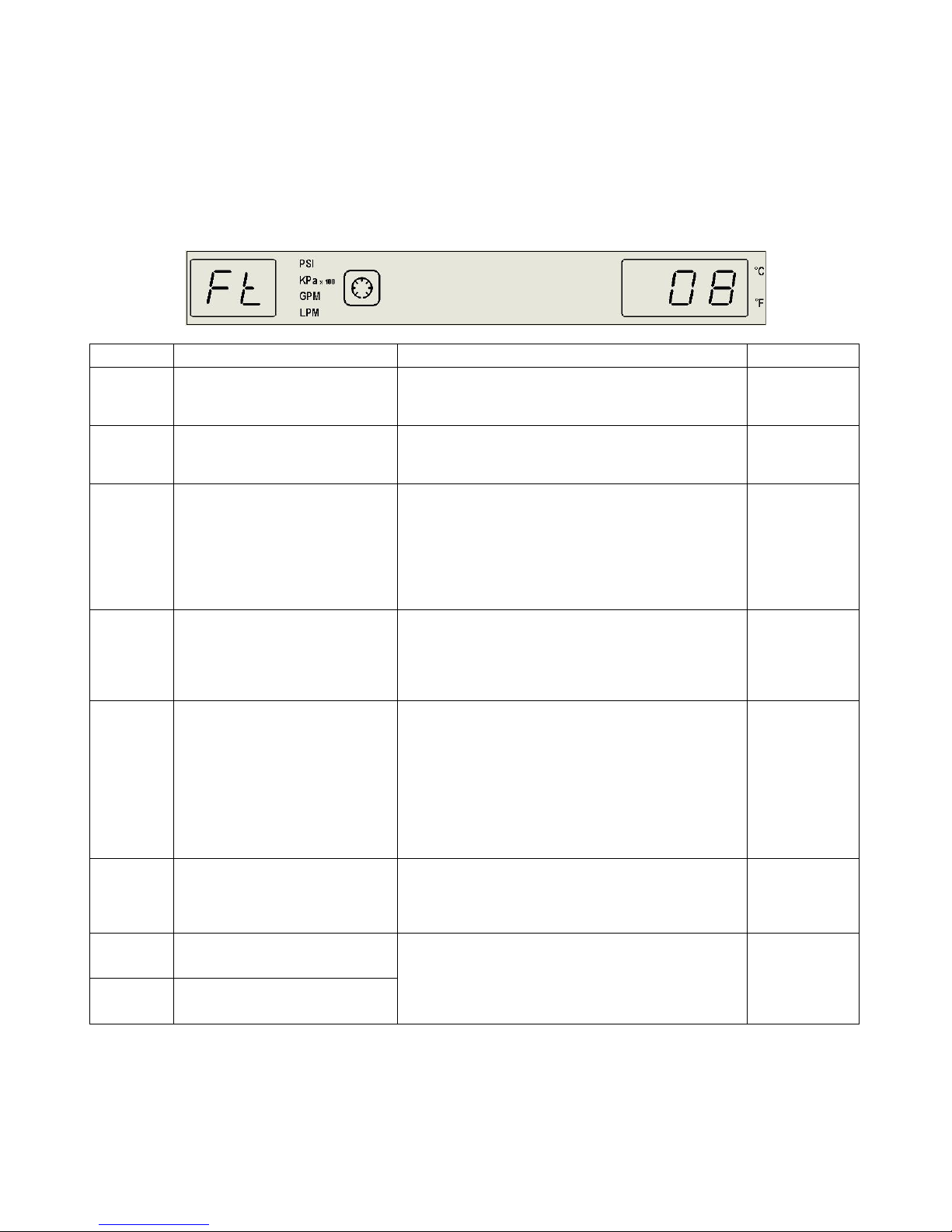

Normal Operation

Pressure / Flow Rate Unit

Pressure / Flow

Rate Display

Temperature Unit

Select / Set Knob

Units / Menu

Select Button

Temperature

Display

Power Button

P ower On

When the Power Switch / Disconnect is placed in the ON position, the Controller goes into a “Standby” mode.

Five decimal points (…..) will appear on the Controller’s displays.

CAUTION: DO NOT turn Controller power ON until the Reservoir has been filled. When Controller power is

turned ON, the pump automatically begins pumping. If Reservoir has not been filled, the pump may be

damaged.

Press the Controller’s Power Button. The system startup sequence will begin and proceed as follows:

• The pump will turn on and fluid will begin circulating through the system.

CAUTION: On initial startup or after long periods of inactivity, run the Chiller for 10 seconds, turn

power OFF, and restart five times to remove any air in the process lines.

• The set point temperature will appear briefly on the Temperature Display; after a few seconds, it will be

replaced by the actual fluid temperature. The right decimal point will flash while the set point is being

displayed.

• The system will go through a short initialization sequence.

• Once initialization has been completed, the compressor will begin operating. When the pressure in the

discharge line reaches 400 psi (27.6 bar), the fan will turn ON. Water-cooled units: The coolant water

regulating valve opens/closes to maintain the pressure in the discharge line at approximately 250 psi

(17.2 bar).

• The Controller will display the actual process fluid temperature and the appropriate ‘degrees’ LED will

be lit (C or F).

Temperature Unit (°C or °F) Selection / Factory Default Reset

The LEDs adjacent to the Temperature Display indicate the unit (°C or °F) used for Temperature Displays.

To change from °C to °F or vice versa, proceed as follows:

To change to °F

Units/Menu Select Button while returning the Power Switch / Disconnect to the ON position.

To change to °C

Power Button on the front panel while returning the Power Switch / Disconnect to the ON position.

— Place the Power Switch / Disconnect in the OFF position. Press and hold the

— Place the Power Switch / Disconnect in the OFF position. Press and hold the

IMPORTANT: Temperature set point and many other user-settable operating parameters return to the

original factory defaults when the temperature unit is changed. It is recommended that you record all usersettings before changing the temperature unit or performing a factory default reset so that these operating

parameters can be restored easily to the desired values.

110-279 21

Page 23

A djusting the Set Point Temperature

Press the Select/Set Knob on the front panel. The current set point temperature will be displayed and the

decimal point at the bottom right of the display will flash, indicating the temperature can be changed.

Rotate the Select/Set Knob until the desired set point temperature is displayed. The setting is accepted after the

Select/Set Knob is pressed a second time or automatically after a few seconds of inactivity.

Selecting the Pressure / Flow Rate Display and Units

The Chiller can be set up to display either fluid pressure (in PSI or kPa) or flow rate in GPM or LPM. Pressing

the Units/Menu Select Button briefly toggles through the available selections.

NOTE: The metric pressure reading displayed must be multiplied by 100 for the actual kPa value

NOTE: If there is no flow sensor fitted, the display will show “- -“ when GPM or LPM is selected.

NOTE: The flow rate readout is intended as a reference only. If accurate flow readings are required, an

external flow meter is recommended.

Displaying Internal (P1) and External (P2) Probe Temperatures

The Units/Menu Select Button may also be used to quickly check the internal (P1) and external (P2) probe

temperatures by pressing it once (for P1) or twice (for P2) after the LPM LED is lit. The probe ID will appear on

the Pressure/Flow Rate Display and the probe temperature will appear on the Temperature Display. If an

optional external probe is not installed, the P2 ID will appear but the Temperature Display will show all dashes.

Setting Operational Parameters / Limits

The Chiller’s various operational parameters, such as temperature, flow rate, and pressure alarm values, are all

user-adjustable. They are accessed by pressing and holding the Units/Menu Button until HL appears on the

Pressure/Flow Rate Display. Pressing and releasing the Units/Menu Button once HL appears allows you to

scroll through the various parameters; rotating the Select/Set Knob allows you to change the displayed setting.

You can accept the displayed value by either pressing the Select/Set Knob or allowing the display to timeout.

Operational parameter limit alarms will shut down the compressor, fan, pump and heaters. Some temperature

values are only displayed and settable in ºC. A few parameters require a special keystroke sequence to access

and change values.

NOTE: Some parameters listed may not be included in your version of software.

NOTE: The Ranges and Default Settings shown are for standard models. Ranges and Default Settings for

your unit may differ depending on the options selected.

110-279 22

Page 24

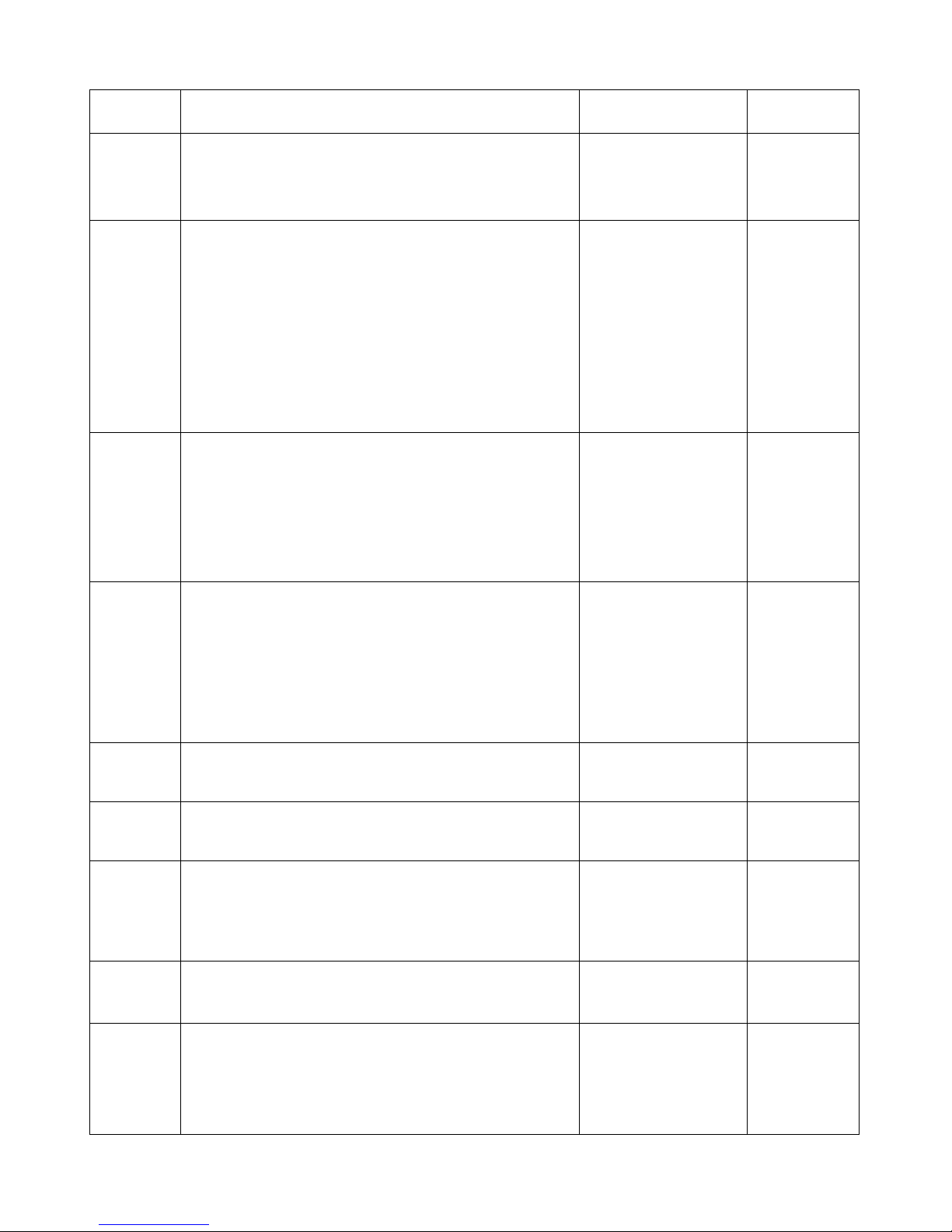

Menu Item Description Choices / Ranges Default Setting

HL High Temperature Limit — Limits the maximum allowable

set point temperature. Audio and visual alarm indicators are

activated when the measured fluid temperature reaches the

HL temperature setting.

NOTE: EHL will appear on the display if the High Limit value

is set below the current set point.

LL Low Temperature Limit — Limits the minimum allowable

set point temperature. Audio and visual alarm indicators are

activated when the measured fluid temperature reaches the

LL temperature setting.

NOTE: ELL will appear on the display if the Low Limit value

is set above the current set point.

HA High Ambient Temperature Limit — Maximum ambient

temperature limit. Displayed and settable only in ºC. Should

the ambient temperature rise above the HA value, the audio

and visual alarms will activate and the compressor, heater,

fan, and pump will turn OFF.

NOTE: The rated cooling capacity on air-cooled chillers is

dependent on an ambient temperature below 104°F (40°C);

performance will decrease as ambient temperature rises.

CAUTION: Continuous operation at ambient temperatures

above 104°F (40ºC) is not recommended for any air-cooled

or water-cooled chiller.

5° to 131°F

(-15° to +55°C)

-4° to 80°F

(-20° to +27°C)

30° to 75ºC

Always displayed

and set in °C

95°F (35°C)

39°F (4°C)

45 ºC

FP Maximum Fluid Pressure — Maximum allowable fluid

pressure; settable in either PSI or kPa. Should the fluid

pressure rise above the maximum fluid pressure value, the

audio and visual alarms will activate and the compressor,

heater, fan, and pump will turn OFF.

NOTE: The Chiller also incorporates a built-in pressure

regulated bypass valve. It will maintain a maximum outlet

pressure by diverting flow of the process fluid to the

reservoir. The bypass valve may be adjusted by the

customer.

CAUTION: Maximum operating pressure for the Chiller is

100 PSI (6.9 bar). Different pumps have different maximum

operating pressures.

FL Minimum Flow Rate — Minimum allowable flow rate;

settable in either GPM or LPM. Should the fluid flow rate

drop below the minimum value, the audio and visual alarms

will activate, and the compressor, heater, fan, and pump will

turn OFF.

Lb Lower Band — This sets how many degrees the process

temperature can fall below set point before the compressor

will turn OFF. It is displayed and settable in °C only.

10 to 100 PSI

0.68 to 6.8 (x100) kPa

Reference:

0.68 = 68 kPa

6.8 = 680 kPa

10 psi = 68.9 kPa

100 psi = 689 kPa

0 to 50 GPM

0 to 190 LPM

1.0° to 5.0°C

Always displayed

and set in °C

100 PSI

6.8 x 100 kPa

(680 kPa)

0 GPM

0 LPM

2.0°C

110-279 23

Page 25

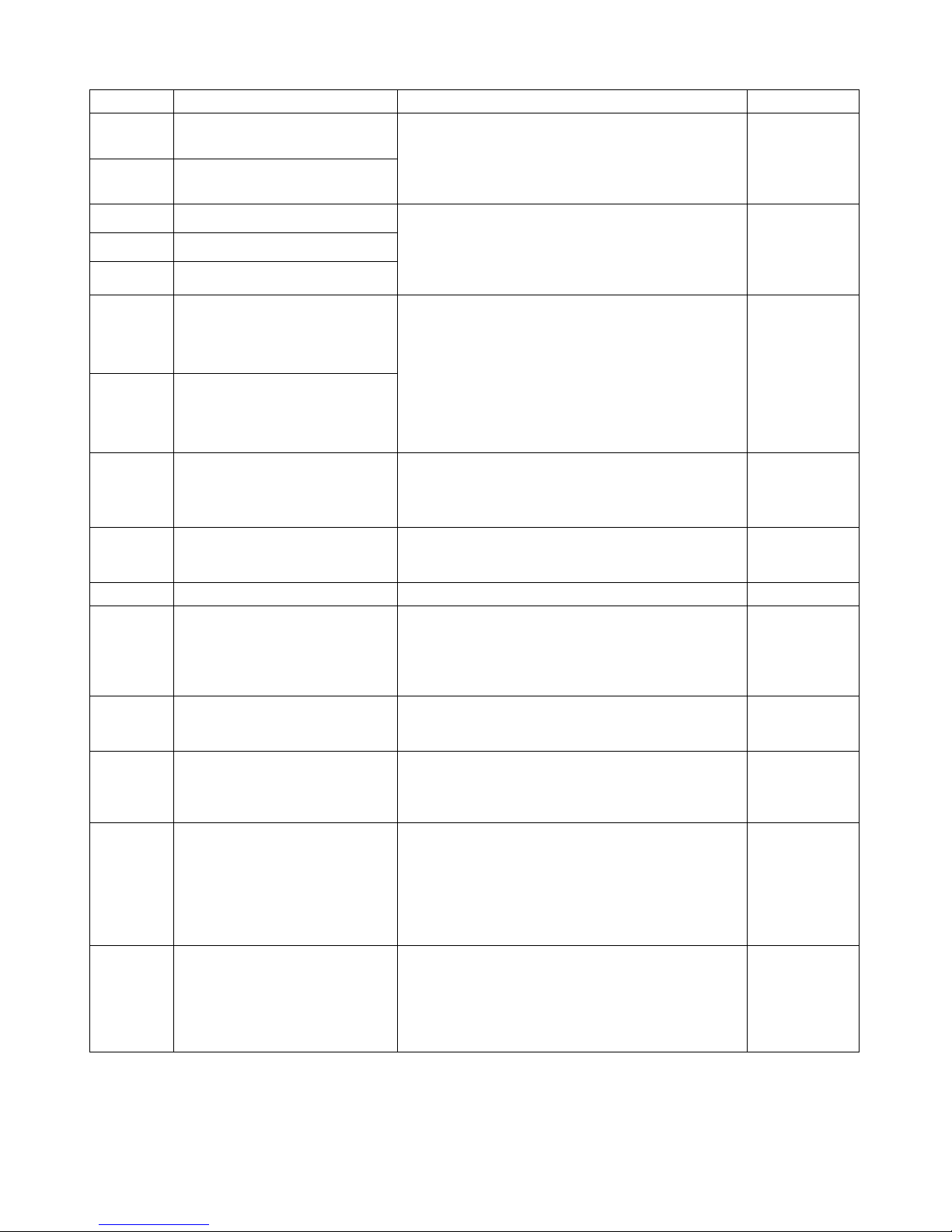

Menu Item Description Choices / Ranges Default Setting

Ub Upper Band — This sets how many degrees the process

temperature can rise above set point before the compressor

will turn ON. It is displayed and settable in °C only.

C1

C2

C3

Calibration Offset — Allows the Chiller’s displayed and

control or externally sensed temperature to match an

independent traceable standard. The Calibration Offset is

displayed and settable in °C only.

C1 — Internal calibration offset

C2 — External calibration offset

C3 — External calibration offset

NOTE: A special keystroke sequence is required to adjust the

Calibration Offset. See Calibration Offset.

Cd Compressor Delay — Allows the operator to set the minimum

amount of time allowed from when the Compressor turns OFF

to when it turns back ON again.

NOTE: When the Compressor turns OFF because it has

reached the Lb value, it will remain OFF until both the Ub (°C)

value has been reached and the Cd (delay time) value has

expired.

Fc Flow Rate Calibration — Allows adjustment of the displayed

flow rate to match that of a known standard.

NOTE: During Flow Rate Calibration, the left hand LCD

displays the desired flow rate in GPM. The right hand LCD

displays the Gain value.

NOTE: A special keystroke sequence is required to adjust the

Flow Rate Calibration. See Flow Rate Calibration.

1.0° to 5.0°C

2.0°C

Always displayed

and set in °C

±2.9°C

0.0°C

Always displayed

and set in °C

10 to 300 seconds 20 seconds

Varies

Record current

Gain value for

reference

dS Coolant Density — This value is set at the factory and

should not be changed.

Sh Specific Heat — This value is set at the factory and should

not be changed.

CC Current Control (optional) – Allows setting of the set point

temperature via a 4-20 mA analog signal.

YES = Enables current control

NO = Disables current control

PC Communications Baud Rate — Selects the baud rate for

serial (RS-232/RS-485) communication.

LA Low Ambient Temperature Limit —Minimum ambient

temperature limit. Displayed and settable only in ºC. Should

the ambient temperature fall below the LA value, the audio

and visual alarms will activate and the compressor, heater,

fan, and pump will turn OFF.

110-279 24

0.1 to 9.00 8.35

0.1 to 1.00 1.00

Yes or No No

24 (2400), 48 (4800),

96 (9600) or 192 (19200)

1 to 7°C

Always displayed

and set in °C

lb/gal

BTU/lb °F

9600

2°C

Page 26

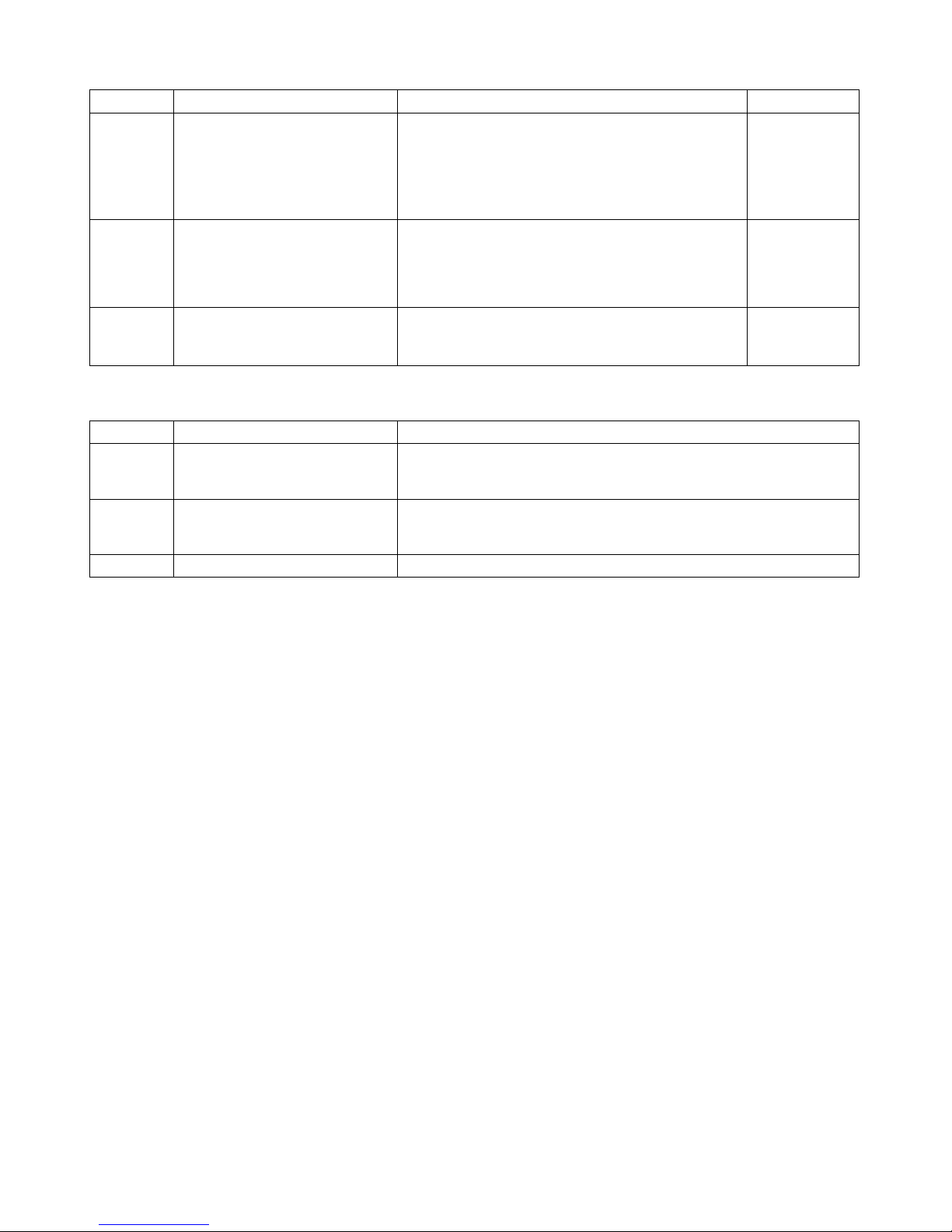

Menu Item Description Choices / Ranges Default Setting

Pd Password — For factory use only.

td HGB Valve Delay — For factory use only.

Fb

Fuse Bits — The current Fuse Bits (Fb) setting appears after the td setting and can be viewed, but not

changed. To change Fuse Bits (Fb) operational parameters, electrical power must be turned OFF and a

special key stroke combination entered. See Fuse Bits (Fb) for detailed instructions.

Input Logic State h00 h01 h02 h04 h05 h06

Remote

On / Off

dry contact

Remote

24 VDC

On / Off

Water Level

Float Switch

Closed OFF ON OFF ON

Open ON OFF

24 VDC OFF ON OFF ON

0 VDC ON

Open OK OK OK Low Low Low

N/A

0 to 999 0

0 to 999 2

N/A

ON OFF

OFF ON

N/A

N/A

OFF

Closed Low Low Low OK OK OK

You can adjust the following settings for your particular application or simply accept the default values.

High Temperature Limit (HL)

This menu item serves two functions. First, it establishes the maximum allowable set point temperature and thus

helps prevent an operator from inadvertently selecting a temperature set point above a pre-established value.

Secondly, it serves as a high temperature alarm, automatically activating both audio and visual alarm indicators

if the measured fluid temperature reaches the HL setting. This also causes the compressor, heater, fan, and

pump to turn OFF.

To change the high limit value, rotate the Select/Set Knob until the desired value is displayed.

HL

95

Low Temperature Limit (LL)

This menu item also serves a dual function. First, it establishes the minimum allowable set point temperature

and thus helps prevent an operator from inadvertently selecting a temperature set point below a pre-established

value. Secondly, it serves as a low temperature alarm, automatically activating both audio and visual alarm

indicators if the measured fluid temperature drops to the LL setting. This also causes the compressor, heater,

fan, and pump to turn OFF.

To change the low limit value, rotate the Select/Set Knob until the desired value is displayed.

LL

110-279 25

39

Page 27

High Ambient Temperature Limit (HA)

NOTE: This value is always set in °C.

This menu item protects the Chiller from overheating due to a high ambient temperature. Should the ambient

temperature rise above the limit value, the audio and visual alarms will activate and the compressor, heater, fan,

and pump will turn OFF.

To change the high ambient temperature value, rotate the Select/Set Knob until the desired value is displayed

on the Temperature Readout.

HA

45

Maximum Fluid Pressure (FP)

This is the maximum allowable fluid pressure and can be set in either PSI or kPa (the LED adjacent to the

display indicates the active unit of measure). Should the fluid pressure rise above the maximum fluid pressure

value, the audio and visual alarms will activate and the compressor, heater, fan, and pump will turn OFF.

To change the fluid pressure limit value, rotate the Select/Set Knob until the desired value is displayed on the

Temperature Readout.

NOTE: When FP first appears, the PSI LED will be lit. To view the FP value in kPa, press the Units/Menu

Button again. FP will remain on the display and the kPa LED will light up.

PSI

FP

FP

NOTE: The Chiller incorporates a built-in safety that automatically maintains fluid pressure below a valve-

regulated pressure value. It maintains this maximum outlet pressure by diverting the flow of process fluid to

the Reservoir (i.e., begin internally recirculating the fluid). A maximum pressure value is set at the factory,

but is user-adjustable. See “Installation and Startup, External Piping, Full Flow Bypass” for information on

changing the maximum outlet pressure value.

kPa x 100

100

6.8

Minimum Flow Rate (FL)

This is the minimum allowable flow rate and can be set in either GPM or LPM (the LED adjacent to the display

indicates the active unit of measure). Should the fluid flow rate drop below the minimum value, the audio and

visual alarms will activate, and the compressor, heater, fan, and pump will turn OFF.

To change the minimum flow rate value, rotate the Select/Set Knob until the desired flow rate value is displayed

on the Temperature Readout.

With FL set to “0”, the flow alarm is disabled, and the Chiller will continue to operate with the output flow

blocked.

NOTE: When FL first appears, the GPM LED will be lit, indicating the FL value is GPM. To view the FL

value in LPM, press the Units/Menu Button again. FL will remain on the display and the LPM LED will light

up.

FL

110-279 26

GPM

●

1.5

Page 28

LPM

●

FL

06

Lower Band (Lb)

NOTE: This value is always displayed/set in °C.

This menu item allows you to set how many degrees the process temperature can fall below set point before the

Compressor will turn OFF.

To change the lower band value, rotate the Select/Set Knob until the desired value is displayed.

Lb

2.0

Upper Band (Ub)

NOTE: This value is always displayed/set in °C.

This menu item allows you to set how many degrees the process temperature can rise above set point before

the Compressor will turn ON.

To change the upper band value, rotate the Select/Set Knob until the desired value is displayed.

Ub

2.0

Calibration Offset (C1 / C2 / C3)

IMPORTANT: To prevent the operator from accidentally changing the calibration offset, a special

keystroke sequence is required to access this function.

This menu item allows you to adjust the Chiller’s internal and/or external temperature reading to match that of a

traceable standard. It allows you to offset the displayed temperature value by as much as ±2.9°C.

NOTE: Calibration offset values are always set and displayed in °C.

1. Press and hold the Units/Menu Button until HL appears on the display.

2. Press and release the Units/Menu Button until the operating parameter preceding the calibration value you

wish to change appears on the display.

For C1 (Internal Calibration Offset), the preceding operating parameter is Ub

For C2 (External Calibration Offset), the preceding operating parameter is C1

For C3 (External Calibration Offset), the preceding operating parameter is C2

3. Press and hold

the Units/Menu Button.

4. While holding the Units/Menu Button, press and release the Select/Set Knob.

5. When CAL will appears on the Temperature Display, release the Unit/Menu Button. The current calibration

offset value will appear on the Temperature Display and alternate with the fluid temperature reading

(enabling you to simultaneously adjust the offset and see the effect on the temperature).

6. Rotate the Select/Set Knob until the desired calibration offset is displayed. Press the Select/Set Knob

or simply allow the display to time out to accept the displayed value.

110-279 27

Page 29

C1

Compressor Delay (Cd)

This menu item allows you to adjust the minimum amount of time (in seconds) the Compressor should be OFF

before it cycles back ON.

To change the compressor delay, rotate the Select/Set Knob until the desired value is displayed.

Cd

Flow Rate Calibration (Fc)

NOTE: Your Chiller’s flow rate is calibrated at the factory at the nominal flow value for the installed pump.

Further adjustment is not necessary.

0.0

20

This menu item allows you to adjust the flow rate display to match that of a known standard.

1. Press and hold

2. Press and release the Units/Menu Button until Cd appears on the display.

3. Press and hold

4. While holding the Units/Menu Button, press and release the Select/Set Knob.

5. When CAL appears on the Temperature Readout, release the Units/Menu Button.

6. Rotate the Select/Set Knob until the desired offset is displayed. Press the Select/Set Knob or simply allow

the display to time out to accept the displayed value.

the Units/Menu Button until HL appears on the display.

the Units/Menu Button.

Fc

0.0

Coolant Density (dS)

This menu item is for factory use only and should not be changed.

Specific Heat (Sh)

This menu item is for factory use only and should not be changed.

dS

Sh

8.35

1.00

Current Control (CC)

This optional menu item allows you to adjust the temperature set point using a 4-20 mA analog signal. To

change the displayed setting, rotate the Select/Set Knob until the desired selection is displayed (YES = enabled;

NO = disabled).

CC

110-279 28

NO

Page 30

Communications

This menu item allows you to establish the baud rate for serial communication. Allowable settings are 0 (no

serial communication), 24 (2400 baud), 48 (4800 baud), 96 (9600 baud), 192 (19200 baud).

To change the displayed setting, rotate the Select/Set Knob until the desired baud rate is displayed.

Press the Select/Set Knob or allow the display to time out to accept the displayed value.

Low Ambient Temperature Limit (LA)

Baud Rate (PC)

PC

NOTE: This value is always set in °C.

96

This menu item sets the lowest allowable ambient temperature at which the Chiller should operate. Should the

ambient temperature fall below the limit value, the audio and visual alarms will activate and the compressor,

heater, fan, and pump will turn OFF.

To change the low ambient temperature value, rotate the Select/Set Knob until the desired value is displayed on

the Temperature Readout.

LA

Password (Pd)

This menu item is for factory use only and is not operator adjustable.

Pd

HGB Valve Delay (td)

This menu item is for factory use only and is not operator adjustable.

Fuse Bits (Fb)

This menu item allows you to select the logic settings for remote control and the water level float switch. To set

fuse bits, proceed as follows:

1. Place the Power Switch / Disconnect in the OFF position.

2. Press and hold the Select/Set Knob and Power Button simultaneously.

3. While holding the Select/Set Knob and Power Button, place the Power Switch / Disconnect in the ON

position.

4. Fb will appear on the Pressure/Flow Rate Display; h followed by two digits will appear on the Temperature

Display.

5. Rotate the Select/Set Knob to the desired setting (h00, h01, h02, h04, h05, or h06).

6. Press and release the Select/Set Knob or simply allow the display to time out to accept the displayed

setting.

td

Fb

2

0

2

h00

110-279 29

Page 31

Enabling / Disabling the Local Lockout

This feature is used to prevent unauthorized or accidental changes to set point and other operational values.

When enabled, the values for set point and operational parameters can be displayed, but not changed:

To enable the local lockout, press and hold the Select/Set Knob until LLO is displayed (approximately 5

seconds). Once enabled, LLO will appear momentarily when the Select/Set Knob is pressed to display the set

point.

To disable the local lockout, press and hold the Select/Set Knob until CAn appears momentarily as local lockout

status changes from enabled (LLO) to disabled (approximately 5 seconds).

IMPORTANT: The Local Lockout feature does not prevent set point changes entered via the RS-232

interface.

110-279 30

Page 32

Display, Alarm and Error Messages

When an alarm or error condition is detected, Ft appears on the Pressure/Flow Rate Display and a

corresponding code flashes on the Temperature Display. Operational limit parameter alarms will shut down the

compressor, fan, pump, and heaters. Alphabetical codes will also appear on the Temperature Display. An audio

alarm will also sound.

After taking corrective action, restart the Chiller to clear the fault or error.

Code Description Action Required Default

Alarm – Process fluid temperature has dropped

02

03

04

05

07

08

09

10

Low limit temperature alarm

High limit temperature alarm

Over-temperature alarm

(select models only)

Low liquid level alarm

(units with Liquid Level Float

Switch option only)

Low flow alarm

High pressure alarm

Internal software fault

Triac fault