Page 1

Film Data Sheet

T-51HC

4 x 5 Black & White Sheet Film

Description

High-contrast, 4 x 5 positive and negative sheet film for detailed

3URIHVVLRQDO%:6KHHW)LOP

[LQFK

10.2 x 12.7 cm

7\SH

black & white prints.

Key Applications

• Copystand photography

• Fingerprint documentation

• Graphic arts

+&

3RV1HJ

ILOP

Film Speed

ISO 640/DIN 29 (Positive/daylight)

ISO 400/DIN 27 (Positive/tungsten)

ISO 80/DIN 20 (Negative/daylight)

ISO 50/DIN 18 (Negative/tungsten)

Format

4 x 5 in.

(10.2 x 12.7 cm)

Sheet Film

Image Area

31/2 x 41/2 in.

(9 x 11.4 cm)

Finish

Glossy

Exposures per Unit

20 exposures per box

Development Time

30 seconds at 700F

Compatible Hardware

• Any camera or instrument equipped with a Model 545/545i

Film Holder

• MP-4+ camera

Special Treatment

Requires print coating the positive and clearing the negative. To

clear the negative for reuse, immerse it in a sodium sulfite

clearing bath immediately after development. Sodium sulfite

powder is readily available from professional photographic supply

dealers and chemical supply houses.

Mix in the following proportions:

Warm water: 2 liter or 70 fl. oz.

Sodium sulfite Powder: 440 grams or 16 oz. (weight)

(anhydrous/desiccated)

Slowly add the powder to the water; stir continuously until all

powder is dissolved. Allow to cool to approximately 700F(210C)

before using. Store the solution in brown, well-stoppered

bottles or in a tank with a floating lid.

To prevent scratches:

Negative scratch resistance can be improved by treating the

processed negative (after clearing in water and sodium sulfite)

in a solution of Kodak Rapid Fix with Hardener (parts A & B)

for two minutes. This solution should be made up and used in

accordance with Kodak’s recommended mix procedures,

chemical caution statements, wash times and temperatures.

Caution

This film uses a small amount of caustic paste. If any paste appears, avoid contact with skin, eyes and mouth

and keep away from children and animals. If you get some paste on your skin, wipe it off immediately, then

wash with water to avoid an alkali burn. If eye contact occurs, quickly wash the area with plenty of water and

see a doctor. Keep discarded materials away from children, animals, clothing and furniture.

Limited Warranty

See information on the film box.

“Polaroid” is a registered trademark of Polaroid Corporation, Waltham, MA 02451 USA.

All other product names may be the property of their respective owners.

Page 2

Film Data Sheet

Technical Data

T-51HC High Contrast (4x5 sheet)

Instant B&W Peel-Apart Film (HDC)

This information represents the typical performance of Polaroid T-51HC film. Specific film lots may vary .

Recommended

speed (ISO)

Recommended

processing tim e at

o

F/21oC

70

Spectral sen sitivity

Resolution (1000:1)

Contrast

Print: 640/29

Neg.: 80/20

Print: 20 - 30 line pairs/mm

Neg.: 100 - 120 line pairs/mm

o @

o @

55000K

30 se conds

Panchromatic

Print: High

Neg.: Medium

55000K

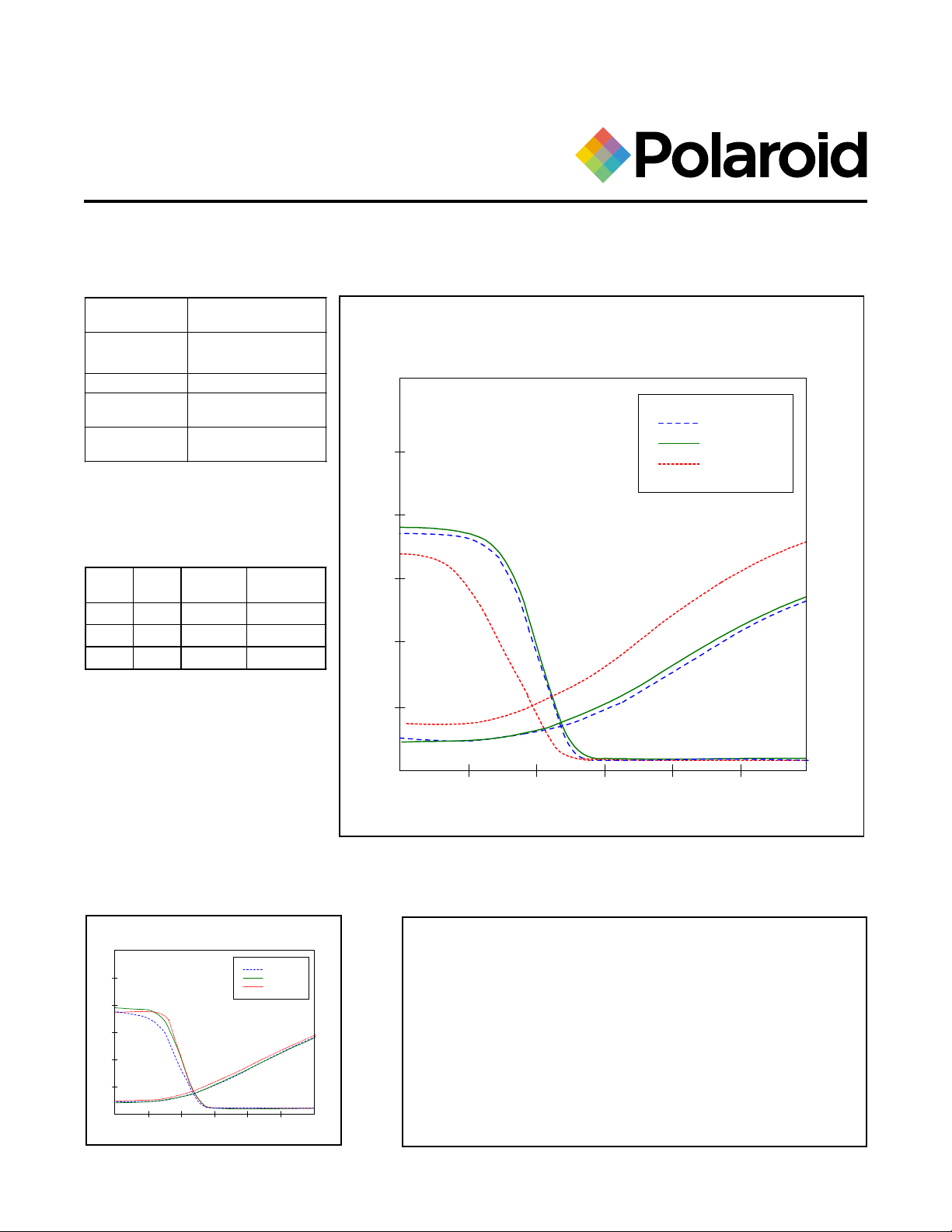

Processing time and temperature

For best results process at temperatures

above 60oF(16oC).

o

F

70-95 21-35 30 None

65 18 35 None

55 13 50 None

Time in

o

C

seconds

Exposure

Adjustment

Effect of over/under development

Beyond compensating for the effects of

high and low temperatures, this film can

be over or under developed for positive

contrast modulation. Over development

produces higher contrast and lower

densities in the positive. Under

development results in lower contrast.

Neither over nor under development has

any significant effect on the negative

contrast. Under development can result in

an increase in negative D-Min.

Characteristic H&D curve for

normal, hot and cold development

3.0

55oF/13oC

2.5

2.0

1.5

Sample Density

1.0

0.5

0.0

-3.0 -2.5 -2.0 -1.5 -1.0 -0.5 0.0

Relative Log Exposure

70

85oF/29oC

o

F/21oC

Characteristic H&D curve for normal,

3.0

2.5

2.0

1.5

Sample Density

1.0

0.5

0.0

under and over development

Positive

-3.0

-2.5 -2.0 -1.5 -1.0 -0.5 0.0

Relative Log Exposure

25 seconds

30 seconds

120 seconds

Negative

D-Max: The density value for the film’s darkest black.

D-Min: The lowest density value that a film exhibits. In prints, the

whiteness of the brightest highlight, relative to the unprocessed print.

Slope: The positive ratio of the log E increments of the straight line region

of the curve, as determined by the 1/4-3/4 increment method. The slope of

an H&D curve indicates the overall contrast of a film: low contrast slopes

less than 1.10; medium contrast slopes from 1.10 to 1.70; high contrast

slopes greater than 1.70.

Reciprocity: The ability of the film to respond in a constant manner to a

constant exposure (light intensity x time). Reciprocity failure occurs during

very long or very short exposures, requiring the photographer to increase

exposure.

Page 3

Film Data Sheet

Technical Data

T-51HC High Contrast (4x5 sheet)

Instant B&W Peel-Apart Film (HDC)

Reciprocity law failure

A wide range of shutter speeds can be used without loss of film speed.

For longer exposure times, some exposure compensation is suggested.

0.5

0.0

-0.5

-1.0

-1.5

-2.0

-2.5

-3.0

Speed Change (f-stops)

-3.5

0.001 0.01 0.1 1 10 100

Reciprocity: The ability of the film to respond in a constant manner to

a constant exposure (light intensity x time). Reciprocity failure occurs

during very long or very short exposures, requiring the photographer to

increase exposure.

Reciprocity Law Failure

Exposure Time (seconds)

Processing the reusable negative

In order to remove the reagent layer and the antihalation dyes, the processed negative needs to be

washed in an 18% sodium sulfite solution. The salts

within the solution minimize swelling in the

negative’s gelatin layer that would be caused by

washing in water only. Swelling can cause

reticulation which would remain after the negative

dries.

To prevent scratches:

Negative scratch resistance can be improved by

treating the processed negative (after clearing in

water and sodium sulfite) in a solution of Kodak

Rapid Fix with Hardener (parts A & B) for two

minutes. This solution should be made up and

used in accordance with Kodak’s recommended

mix procedures, chemical caution statements,

wash times and temperatures.

Ingredients

Warm Water

Sodium sulfite

Metric

2.0 liters

440 grams

U.S.

70 fl. oz.

16 oz. (avdp)

(anhydrous)

1000

Spectral Sensitivity

100

10

1

Spectral Sensitivity

0

350 400 450 500 550 600 650 700 750

Wavelength (nm)

Modulation Transfer Function

100

80

60

40

% Modulation

20

0

0.1 0.25 1 2.5 4

Spatial Frequency (cycles/mm)

Loading...

Loading...