Page 1

Page 2

Page 3

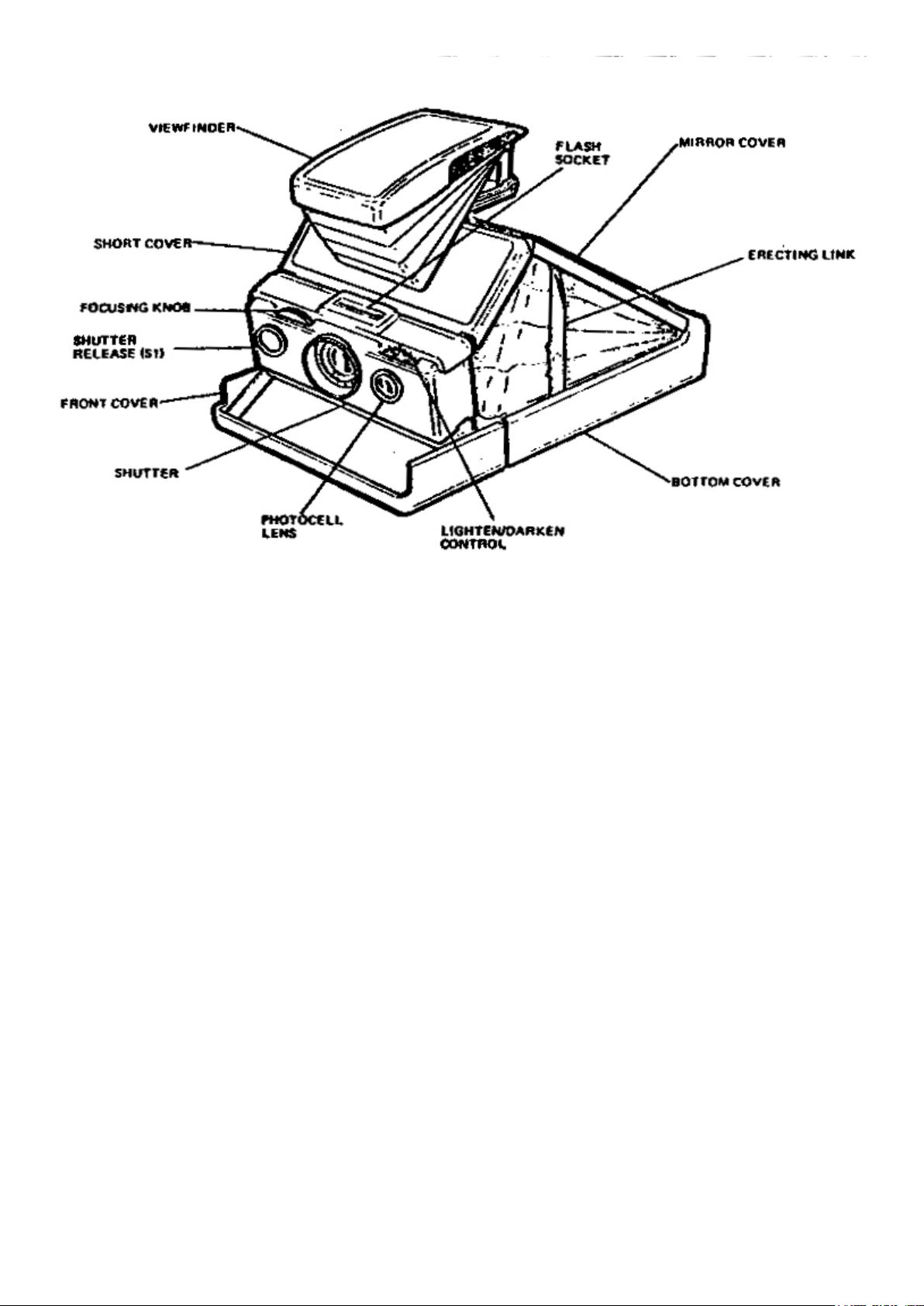

A. GENERAL DESCRIPTION

I - DESCRIPTION

The Polaroid Land SX-70 is a folding, pocket

sized, single-lens reex camera which takes

and immediately delivers full-color pictures

approximately 31/4 inches square (see gures

1-1, 1-2 and 1-3). Operation is automatic; the

user merely inserts the lm, focuses and shoots.

power is provided by a six-volt battery inside the

lm pack; therefore, the batteries are always

fresh as the lm.

The four element lens has a maximum aperture

of f/8, and a focusing rang from 10,4 inches to

innity. The shutter is automatically controlled

by a photocell and electronic timing. Electrical to

mechanical energy conversion is accomplished

by two solenoids and a motor. There are no

separate diaphragm adjustement. The shutter

opening and closing time is controlled by the

exposure measuring system.

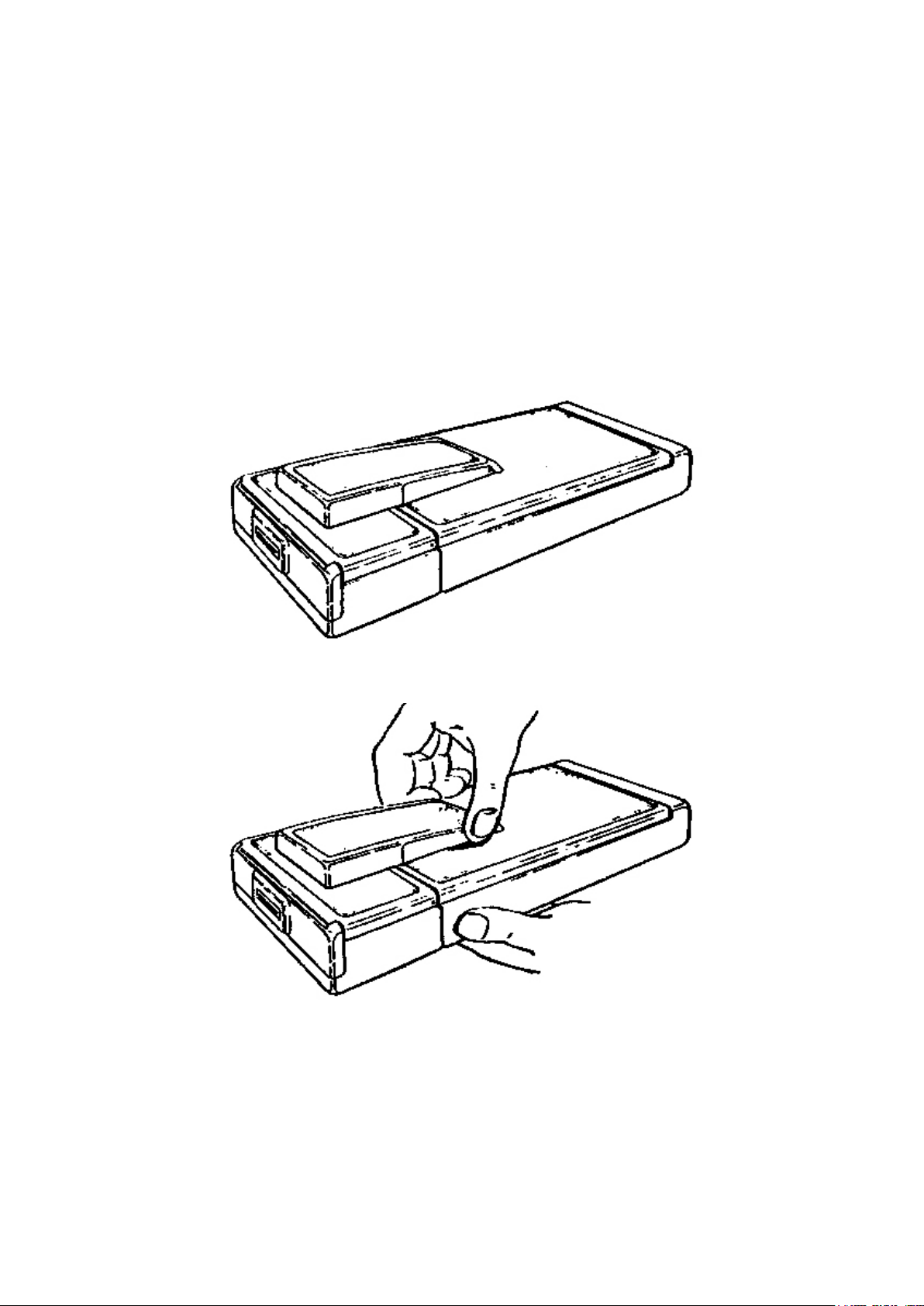

Figure 1-1 SX-70 Camera folded

Figure 1-2 Holding and opening the SX-70

Page 4

Figure 1-3 Opened for picture taking

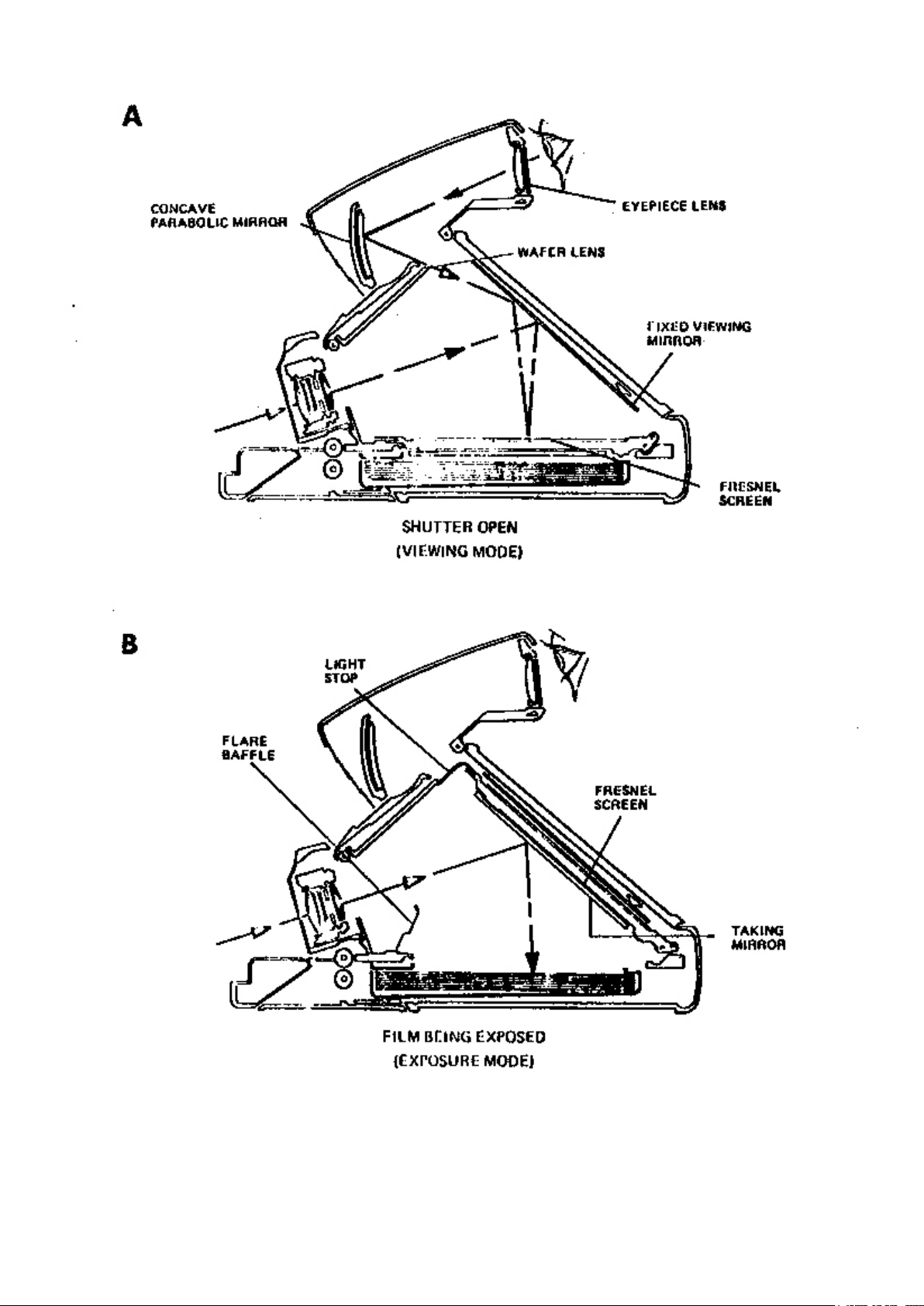

The subject is viewed and focused throught the

taking lens, a mirror, a Fresnel viewing screen

(with spilt-image focusing aid) and a optical

system to focus the image at the viewing eyepiece. As in all single-lens reex cameras, the

shutter must be open to provide an image at

the eye-piece. This requirement is fullled by

the automatic electro-mechanical components

which are described in detail in Section II of this

manual.

When the exposure is made, the image must be

transferred from the viewing system to the surface

of the lm in accurate focus. To accomplish this,

the shutter closes and the viewing screen swings

out of the optical path which is then diverted by

a mirror to the lm surface. These two paths

are described in greater detail elsewhere in this

section.

The exposure is made following the viewing

screen / mirror swing. The screen then returns

to the viewing position and the automatic

mechanism ejects the exposed sheet of lm.

development takes place outside the camera

and can be observed by the operator. As soon as

the print is ejected, the mechanism completes its

cycle to prepare for the next exposure. Following

thenth exposure, the ash circuit is inhibited until

a fresh lm is inserted. Normal operation will

resume when the camera is reloaded.

B. CAMERA OPERATION

The following paragraphs describe the electromechanical events that occur in normal operation.

the purpose of this desciption is to acquaint the

reader with the manner in which the various

functions are accomplished. Detailed analysis

at component / sub assembly level appears in

Section II.

1. Opening the Camera

When the SX-70 is folded, an interlock switch

(S6) removes all battery power from the camera

mechanism to prevent any drain from the lm

pack encapsulaetd batteries. To prepare the

camera for picture taking, hold the camera in the

left hand, pull straight up on the serrated portion

of the viewnder housing (Figure 1-2). this

action releases latches, which, in turn, allow the

main body of the camera to raise into operating

position.

Page 5

When the camera is fully opened, the interlock

switch (S6), located at the left rear corner of

the mirror cover, is closed and the battery is

connected to the camera electrical circuit.

(Figure 1-4).

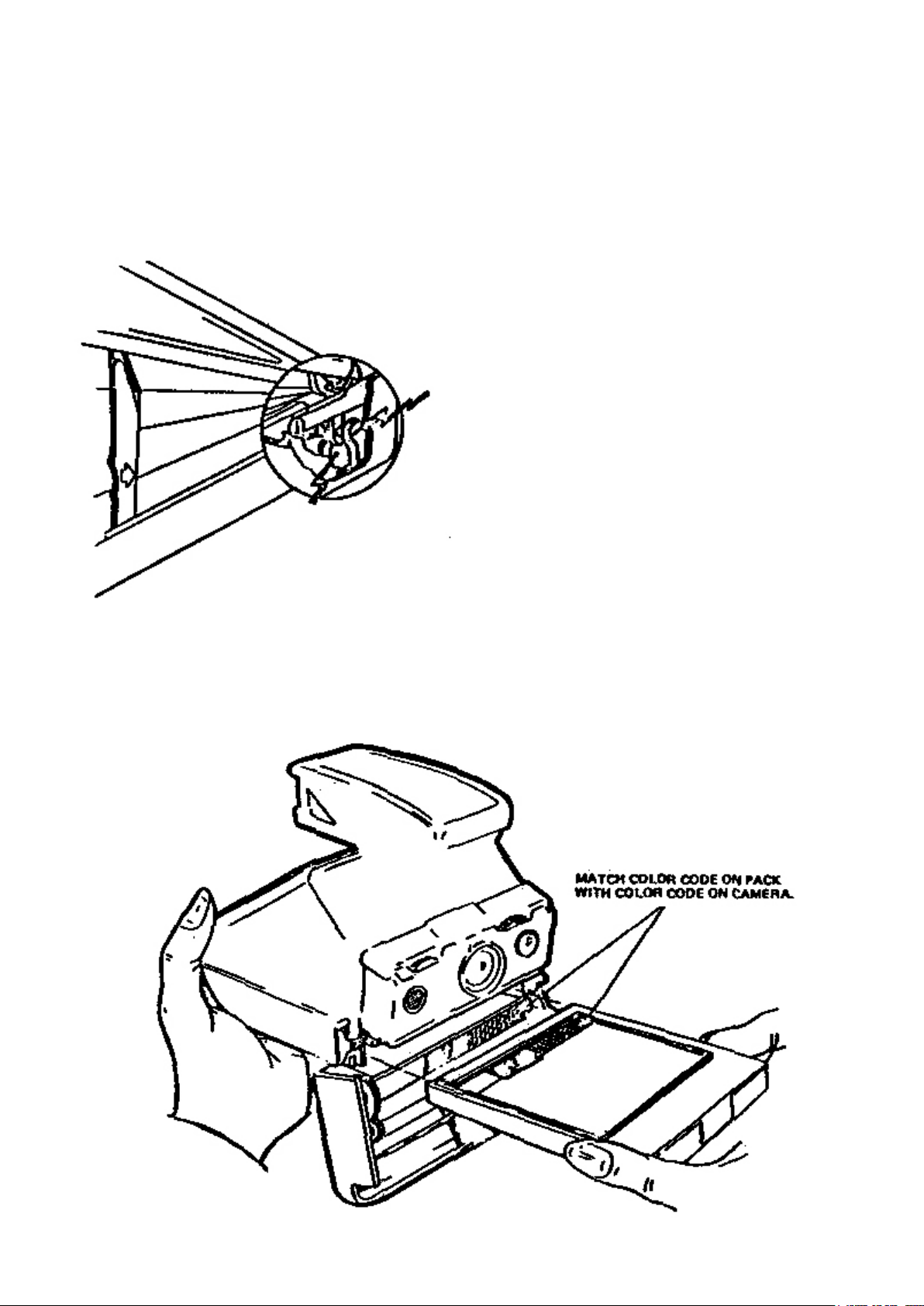

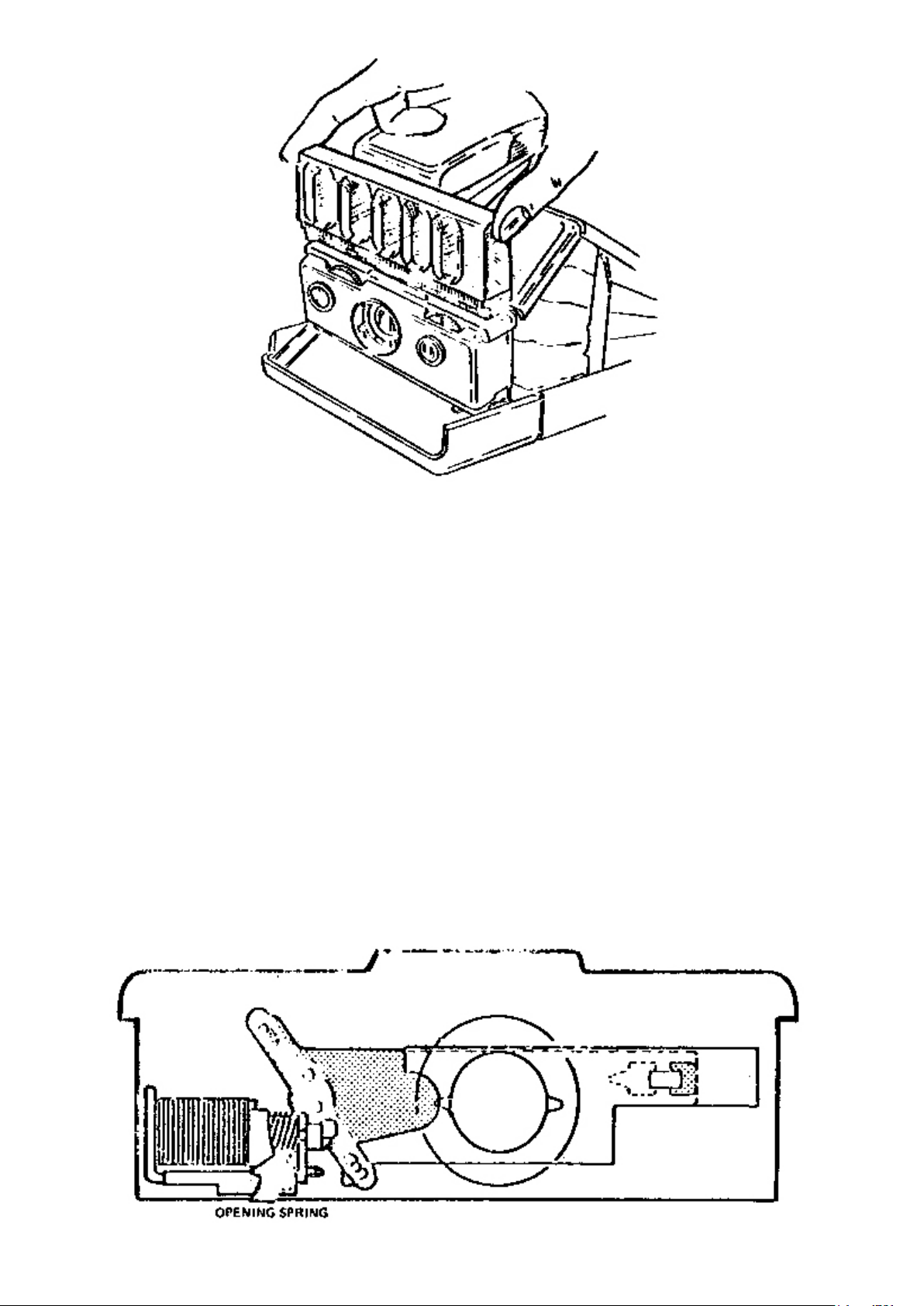

2. Loading the Film pack

The front coverlatchis located on the right side

of the camera just inside the rim of the bottom

cover assembly. Pressing down on this yellow

latch releases the front cover which drops down

to expose the lm chamber. With the cover open,

a lm pack can be inserted or an exhausted pack

can be removed.

A fresh lm pack is loaded into the lm chamber

observing color coding (Figure 1-5). Under

certain circunstances a partially used pack could

be inserted, but this action will cause some

deviation in the normal counting sequence.

The battery is a part of each lm pack, and the

two exposed terminals on the pack engage two

contacts within the lm chamber as the pack is

inserted.

Figure 1-4 S6 with contacts closed

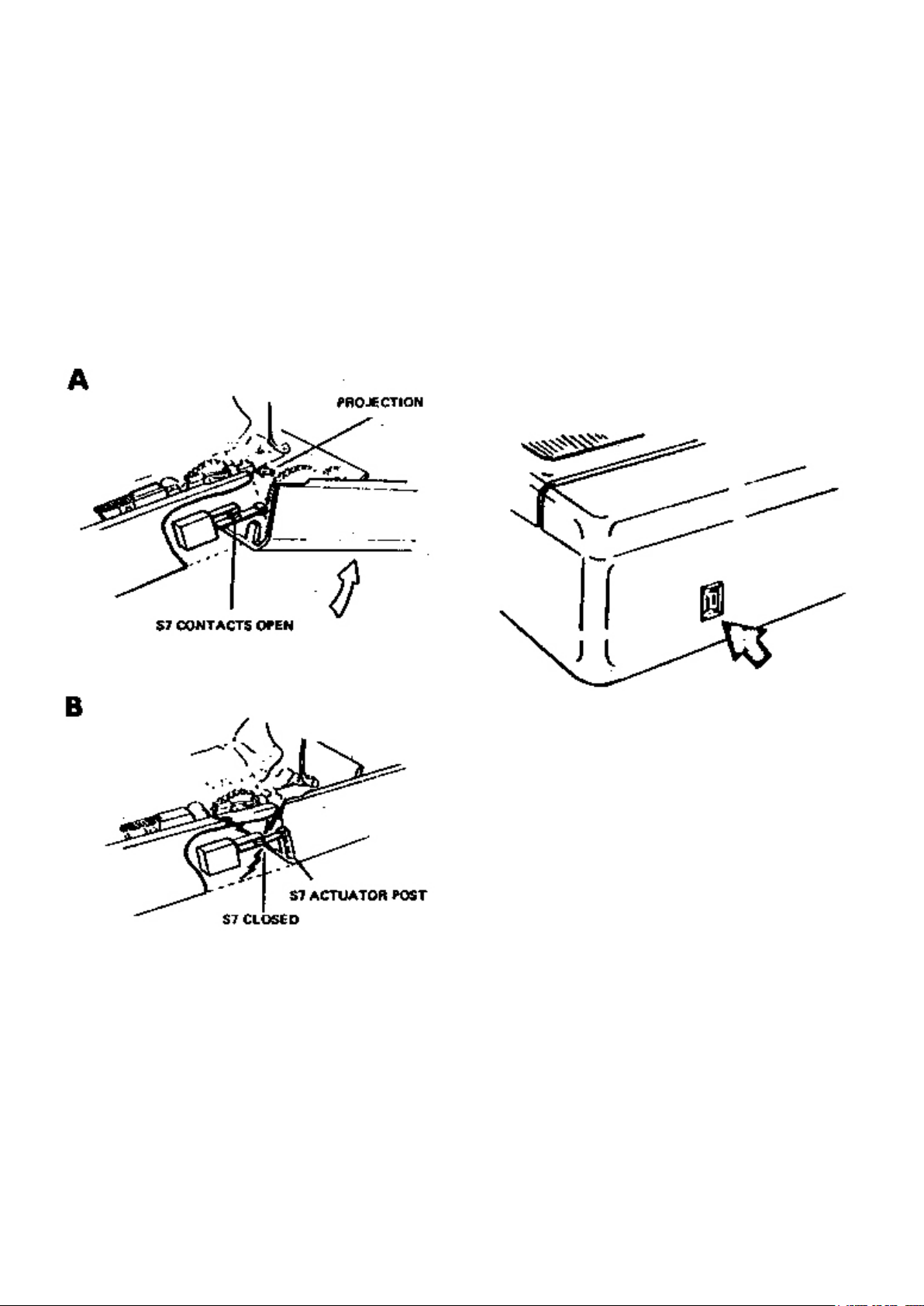

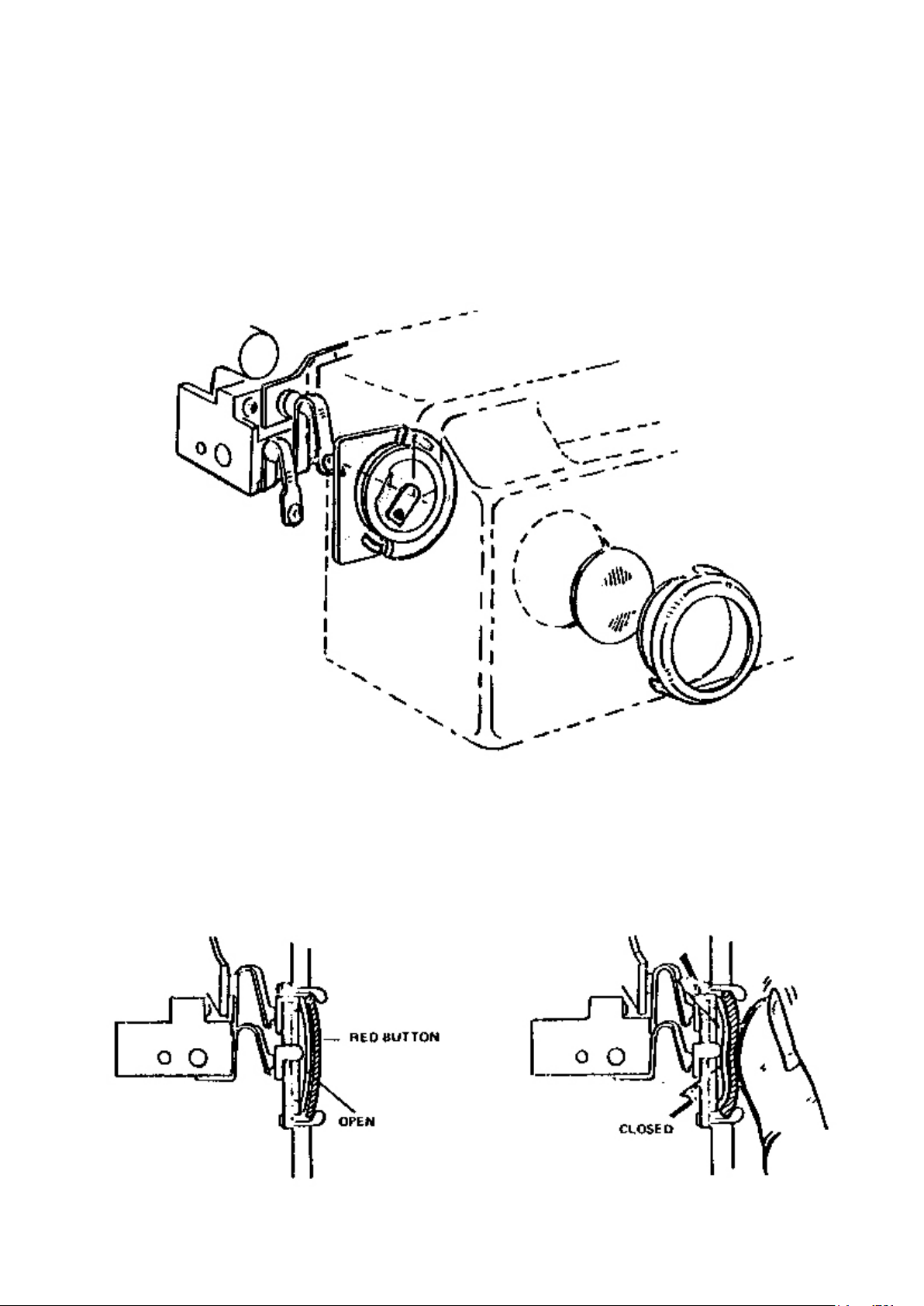

3. Starting the Automatic Mechanism

With the lm pack in place, the front cover can

be closed. It must be fully closed and latched.

Figure 1-5 Inserting lm pack

Page 6

Gears in the front cover must engage the main

gear train of the camera before the gear train

is put into motion. A switch (S7) located in the

forward section of the gear train compartment

initiates the application of power to the gear

train drive motor. Switch (S7) is actuated by two

components

(1) A projection on the front cover latch

(Figure 1-6 A), and

(2) A post on the right rear edge of the front

cover (Figure 1-6 B).

front edge of the front cover. The camera is now

ready to take the rst picture.

4. Setting the exposure counter

When a used lm pack is removed from the lm

chamber, the action automatically resets the

exposure counter at the rear of the camera to the

start position, closing S8. With a new lm pack

installed and the front cover closed and latched (

S7 closed), the motor is powered, and the dark

slide is ejected. The exposure counter turns

to number 10 (Figure 1-7), indicating that 10

pictures remain in the pack.

Figure 1-6 S7 contacts open and closed

Thus, the cover must be fulled closed, the gears

engaged, and the latch fully seated, in order to

actuate the drive motor.

As S7 closes, power is applied to the drive motor

(S8 is also involved and is discussed in a following

paragraph), the gear train is set in motion and

actuates a device called the lm pick. The pick

engages the dark slide, pushes it into the spread

rolls and the dark slide is ejected from the lower

Figure 1-7 Counter

5. Viewing and focusing

Viewing and focusing is accomplished through

a reect system (Figure 1-8 A). In the viewing

mode the image passes through the lens to a

xed mirror which reects it down to the Fresnel

viewing screen. The viewing path from the

viewnder eyepiece lens is from a parabolic

mirror and wafer lens, off the xed mirror to the

Fresnel screen. On most cameras the Fresnel

screen contains a circular split-image aera which

is used to focusing aid. A knurled knob (the

focusing wheel) on the shutter housing is rotated

to adjust the camera focus. The scene is in focus

when a vertical line within the split-image aera

is perfectly straight. On early cameras (without

a split-image feature), the scene is in focus

when the image seen on the Fresnel screen is

sharpest.

6. Viewing and focusing

The exposure is made by pressing the release

button. This completes the electrical circuit to the

Page 7

Figure 1-8 Viewing and shooting

shutter to initiate a series of events. The shutter

blades close to cut off the optical path. The

hinged Fresnel viewing screen is swung upward

and comes to rest in front of the xed viewing

mirror (Figure 1-8 B).

The shutter opens and closes to perform the

exposure function.

A rst-surfaced taking mirror is fastened to

the underside of the Fresnel carrier assembly.

Page 8

The image is reected by the mirror onto the

lm surface. the electronic metering system

determinesthe required exposure, and programs

the shutter opening and duration accordingly.

The incorporation of a mirror in tghe lens-to-lm

path necessitated by the nature of the lm. No

separate negative lm is employed. Instead,

the image appears as a direct positive. Since

the nal product is an opaque print, it is viewed

by reection. As a result, the mirror is needed

to reverse the image so that the nal print will

be properly oriented. This requirement, in

turn, dictates the use of the reectance type

viewing screen rather than a ground-glass type

transmission system.

Note that the lm surface is deplaced from

the Fresnel viewing screen by the thickness

of the viewing screen assembly. The correct

focal distance for both viewing and exposure is

properly maintened, however, since the surfacecoated exposure mirror is deplaced by the same

dimension.

During exposure, the light from the viewing

system must be prevented from striking the

lm. This is accomplished by a rubber light stop

adhered to the hinged Fresnel carrier. When

the Fresnel carrier moves upward, the light stop

blocks off light from the viewnder eyepiece.

As indicated by the foregoing description, the

viewing system is blacked out during the actual

exposure.

As soon as the exposure is complete the

mechanism returns the viewing screen to its

initial position and the picks feeds the exposed

lm to the spreader rolls. The rolls break the pod,

spread the developer, and eject the lm from the

camera.

7. Completing the lm pack

As each exposure is completed, the exposure

counter substracts one digit until the 10 exposures

have be made. The counter then indicates 0...

When this occurs, switch S9 is closed. Closing

this switch inhibits the ash and the exposure

timing. Since the counting cycle is initiated by

the insertion of a lm pack, the pack may not

necessary contain a full supply of lm. If, for

some reason, a partially used pack is removed

and reinserted, the top lm will be the dark

slide. The counter will start at number 10. Since

switches S8 and S9 are physically attached to

the counter, the camera will cycle through 10

exposures even though there be less than 10

sheets of lm in the pack. This deviation must be

recognized whenever a partially exposed pack

is used.

8. Developing the print

As in orther Polaroid pack cameras, the picture

is developed ouside the camera. Unlike previous

Polaroid Land Cameras, however, there is no

negative to pell off and discard.

9. Exposures using ash

The SX-70 accepts a special 10-lamp ash bar

that plugs into a receptacle directly over the

camera lens. There are ve lamps in a rowon

either side of the bar which must be removed,

rotated and reinserted after the fth lamp has

been red (Figure 1-9).

Insering a ash into the ash socket closes

switch S2 in the socket. This action sets up the

shutter electronic circuit to permet ring of the

ash lamp. A follow-focus mechanism, coupled

to the lens focusing system arrests the shutter

blades at an opening related to camera-to-suject

distance.

NOTE : On early camera models, the light

measuring circuit remains active even with the

ash bar inserted into the socket. If the circuit

determines that there sufcient ambient light, an

exposure will be made without the ash. Cameras

with «P» conguration or later shutters, do not

have this light measuring feature in the ash

mode. Regardless of the ambient light level, the

circuits will re the ash when a ash bar is in

the socket (unless of course, the lamps have all

been used).

If the array has been exhausted, the shutter

will complete the exposure cycle without ash.

Maximum exposure duration is 30 seconds.

When the exposure counter reaches 0 (empty)

the camera will not re a ash lamp even though

unused lamps remain in the bar. The previously

discussed deviation associated with the exposure

counter is applicable to the ash functions. If an

unusedlamp is in position and if a partially empty

lm pack has been reinserted, the camera will

continue to re lamps after the last sheet of lm

has been exposed, until the counter reaches 0.

Page 9

Figure 1-9 Inserting the ash bar

10. Closing the camera

When through using camera it be can folded and

latched in its closed conguration by pushing

the erecting link. When the camera is closed,

the interlock switch (S6) is opened so that the

battery is completely disconnect from the camera

circuits. The trim wheel (the lighten / darken

adjustement associated with the photocell)

automatically returns to its normal position each

time the camera is closed.

C. SHUTTER DESCRIPTION

(AMBIENT LIGHT MODE)

The shutter employed in the SX-70 camera is

unique. No direct comparisons should be drawn

between the manner in which it functions and the

function of other Polaroid electronic shutters. No

manually adjustable or xed aperture is employed.

When a picture is taken, two shutter blades, with

specially shaped cutouts, open the lens from a

totally closed position to a suitable aperture. The

two blades then reverse direction and again shut

off the optical path. These same two blades also

contain a similar (although differently shaped)

pair of cutouts that open and close the light path

to the photocell in like manner. In the following

description the functions of photocell cutouts is

deferred until the action of the shutter cutouts is

explained although in operation, the two functions

are interdependent.

When the camera is open for viewing, but before

the release button is pressed, solenoid #1 is

deenergized and the shutter blades are open. A

spring (openong spring) holds the shutter blades

wide open (Figure 1-10). The lens thus provides

maximum viewing / focusing brilliance. Solenoid

/ spring action is discussed in detail in the next

section of this manual.

Figure 1-10 Shutter blades held opened

Page 10

When the release button is pressed, a switch

S1 closes (Figure 1-11 A and B) and applies

operating power to the shutter. As soon as power

is applied to the shutter, solenoid #1 is energized

and rapidly moves the shutter blades to the

closed position.

When the solenoid has reached the end of its

stroke (shutter closed, it no longer requires

maximum current to hold it at that postion.

Switch S4 (located on solenoid #1) closes (CB)

and activates an electronic circuit called the

POWER DOWN CIRCUIT. This reduces power

Figure 1-11 A Location & Arrangement of internal parts

Figure 1-11 B Operation

Page 11

to an adequate level to hold the solenoid after the

high-current circuit has completed the solenoid

operating function and switches on the motor

drive circuit. Thus, the shutter will remain closed,

with minimum battery drain.

Light entering the lens is now cut off and the

reex mirror is swung upward to picture-taking

position. The electronic latch (activated by

opening S5) assures that the sequence will be

completed even if the operator removes his

nger from the exposure button, S1.

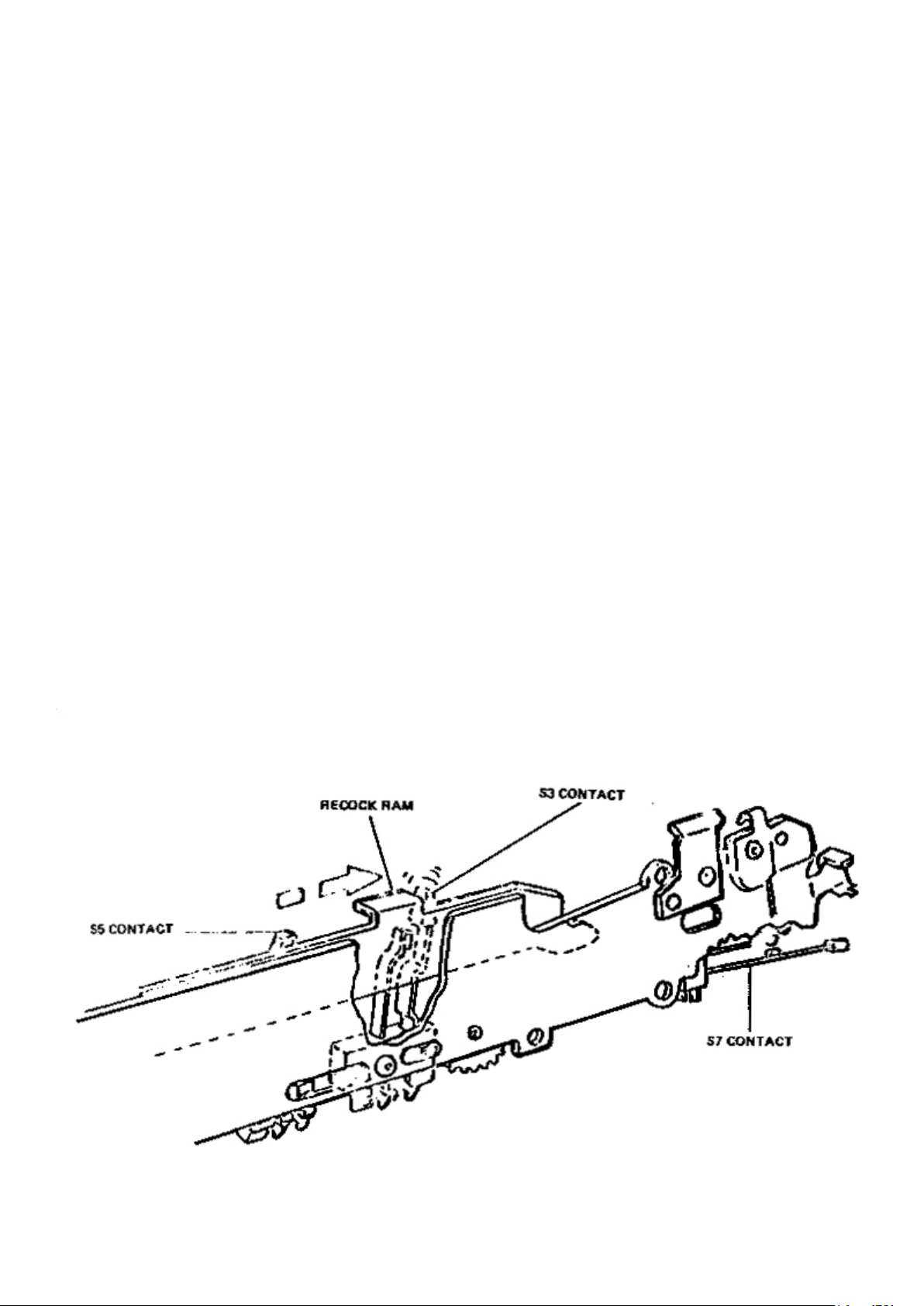

When the mirror swings up, a mecchanically

operated switch (S3) actuates a «Y» delay

circuit (40 milliseconds) (Figure 1-12) so that the

shutter will not function until the mirror bounce

has subsided. At the end of the delay period the

electronic circuitly removes the power from the

soleniod and the opening spring sets the shutter

blades in motion toward the full open position.

At the same instant an electronic switch opens

and starts the integration cycle. The integration

cycle is that period during which the total amount

of light (intensity and duration) reaching the

photocell is transformed electronically to regulate

the lenght of time the ml is exposed. The shape

of the opening in the shutter blades and the

motion of the blades is such that all of the factors

involved are continously variable throughout the

exposure period. this fact, however, is a design

consideration and should not confuse the theory

of the shutter operation from a maintenance

point of view.

When the camera completes all off its automafed

functions and the release button has been

released, all voltage is removed from solenoid #1

and the shutter opens in preparation for the next

exposure.

It should be noted that under extremeley low light

conditions, the shutter will closed completing the

exposure cycle in 14 to 30 seconds whether a

suitable exposure has produced or not.

C. SHUTTER DESCRIPTION

(FLASH MODE)

The special ten-shot ash bar is equiped with

a shorting bar so that when the bar is inserted,

two contacts within the camera is shorted. This

switch is identied as S2. When S2 is closed,

the shutter electronic circuit detects that a ash

bar is in place and ready for ring. In general,

the sequence of the functions remains the same

as for ambient light operation with the following

exceptions :

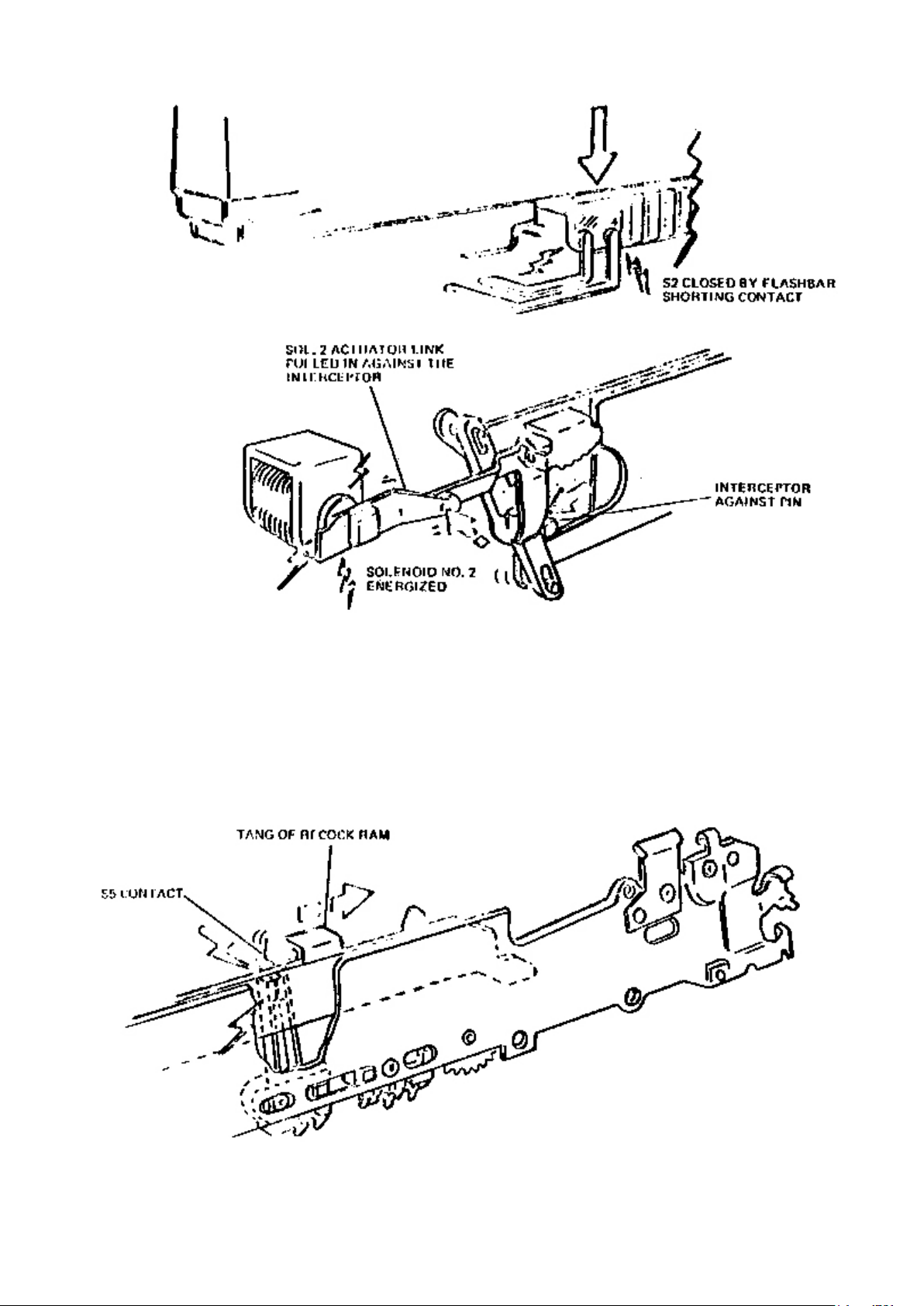

Figure 1-12 S3 Being opened by recock ram

Page 12

mechanical device identied as the interceptor

connected to the lens focusing mecchanism

(Figure 1-13 A). the interceptor is moved as

the lens is focused regardless of whether

ambient-light or ash pictures are being taken.

When ash bar is in place (S2 closed) and the

gear train opens switchs S5 (Fighure 1-14),

solenoid #2 is energized and pulls the interceptor

into position to phycally restrict the shutter blade

travel (Figure 1-13 B). Since the interceptor is

controlled by the focusing mechanism, the

shutter opening is related to camera-to-subject

distance thus compensating for the ashbulb-tosubject distance to give proper ash exposure.

As a solenoid #1 de-energizes switch S4 moves

from the CB position to the CA position. This

switch conects VCC to the FFA.

When the ash delay period reaches completion,

the circuitry removes the holding current from

solenoid #2. Since the solenoid is an electromechanical device, removing power from it

causes a collapsing magnetic eld which induces

a y back voltage. This voltage pulse is fed to

the ash circuitry which then applies the ring

voltage across the ash lamp.

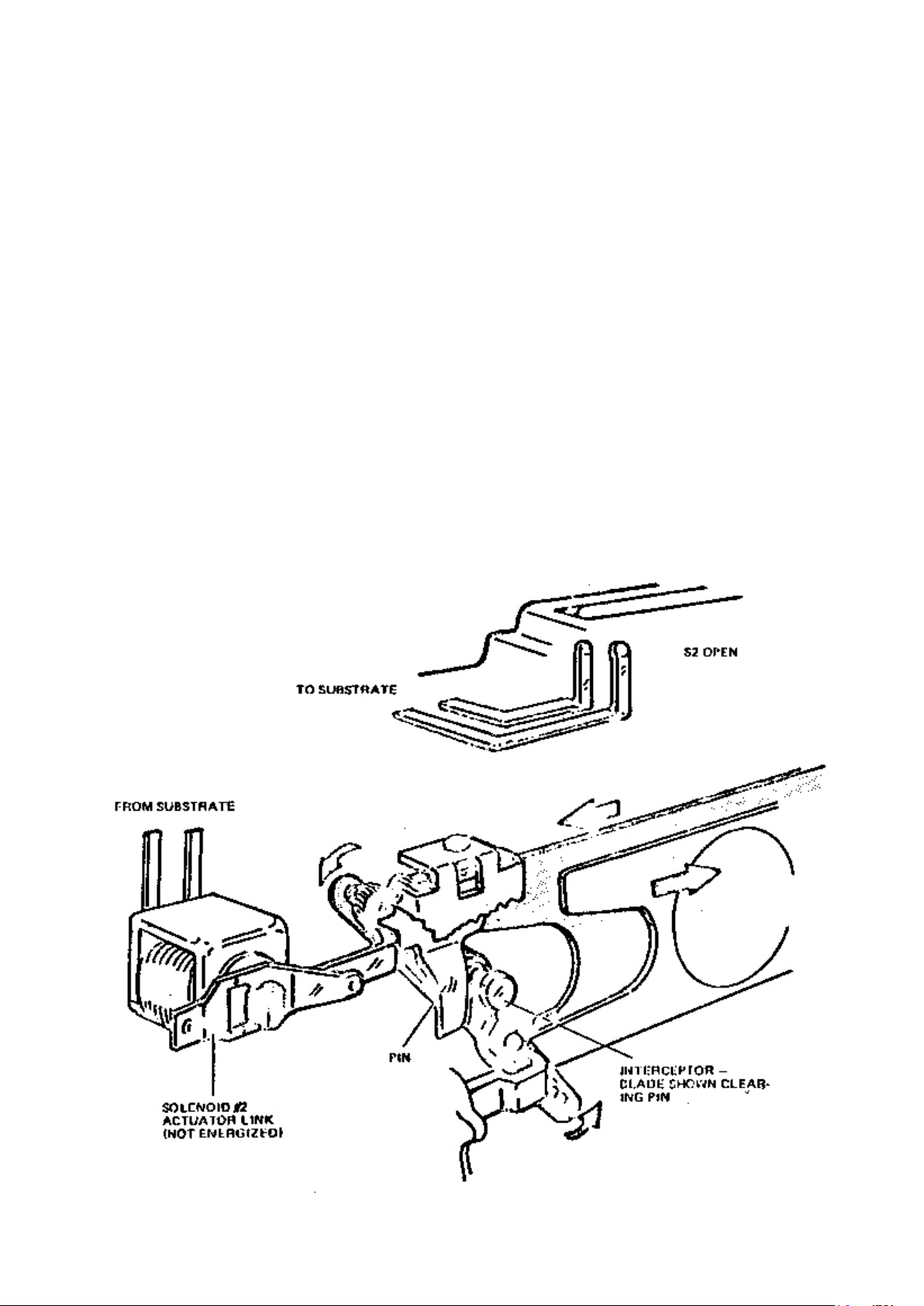

Figure 1-13 A Interceptor link, Solenoid 2, S2 operation - Solenoid de-energized

Page 13

Figure 1-13 B Interceptor link, Solenoid 2, S2 operation - Solenoid energized

Figure 1-14 S5 being opened by the recock ram (Gear train)

Page 14

In cameras with «P» conguration or later shutter

there is no ambient light measurement made. If

a ash bar is in the shutter socket a ash picture

will result regardless of the ambient light level.

On early cameras, an ambient light measurement

is made during the ash delay period. Since the

photocell aperture is a part of the shutter blades,

the amount of reected light reaching the cell will

also be a function of focusing distance. the shutter

electronics delays ring the ash lamp until the

shutter has opened to the aperture established

by the focus wheel. during this delay period, if

the ambient light level is sufciently high to cause

triggering of the integrating circuits, the exposure

will be completed and the shutter closed before

the ring voltage reaches the lamp and the lamp

will not be red.

At the ends of the ash timing interval, the circuit

energizes solenoid #1, the shutter closes, and

the sequence proceeds as in the ambient-light

mode.

If the bulbs in the ash bar are all used when the

operator attemps to make a ash exposure, all of

the previously described circuitly will function up

to the actual ring of the ash lamp. Since there

is no lamp to ignite, no ash ring current will be

drawn.

There will be no output signal from the ash

sequencing circuit, and an ambient light exposure

will be made. On cameras with «P» or later

conguration shutters, the result will be a black

picture unless the ambient light level is high

enough to give an exposure. this is caused by

the fact that «P» and later conguration shutters

have no integrating function as long as a ash

bar is inserted in the socket. Early cameras have

a twenty second time-out period even with a ash

bar inserted in the socket. Therefore, if the ash

bar is exhausted, a properly exposed picture

will result if the ambient light is great enough to

produce one in twenty seconds.

Page 15

A. INTRODUCTION

II - THEORY OF OPERATION

A general description of the camera and the

sequence of its functions is contained in

Section I. In that section, detailed analysis of

individual assemblies and electrical circuits was

minimized so that emphasis could be placed on

the intenelation-ship of various functions. In the

following paragraphs, the individual groups of

components are described in greater detail. The

description are presented in the sequence in the

commponents were mentioned in Section I.

B. POWER SOURCE

Power for the drive motor, the shutter electronics,

and the ash array is supplied by a specially

designed 6 volts battery incorporated in each

10 exposures lm pack. When the pack is

inserted into the camera, two contacts pads

on the bottom surface of the pack engage two

spring-loaded contacts on the inner bottom

surface of the camera bottom plate. From these

two points, it is distributed to its destinations by

the copper foil strips of a ex circuit on the outer

surface of the bottom plate.

The battery has adequate capacity to expose

all 10 lm frames with at least six months of

expected shelf life.

C. LENS

The lens employed is a four element, glass lens

of f/8 aperture with a focal lenght of 115mm. It has

a focusing range of innity down to 10,4 inches.

Focusing is accomplished by movement of the

front element only. Helical threads in the lens

mount provide the linear lens elemet movement.

Operation is by means of a geared focus wheel

at the top of the shutter housing. There is no

manualy adjustable diaphragm associated with

the SX-70 lens.

D. VIEWING AND EXPOSING SYSTEM

When the camera is erected to picture taking

conguration, the subject can be viewed through

the collapsible viewnder. Figures 2-1 and 2-2

show the two optical paths in the camera. Note

the direction of the arrows. Reected light from

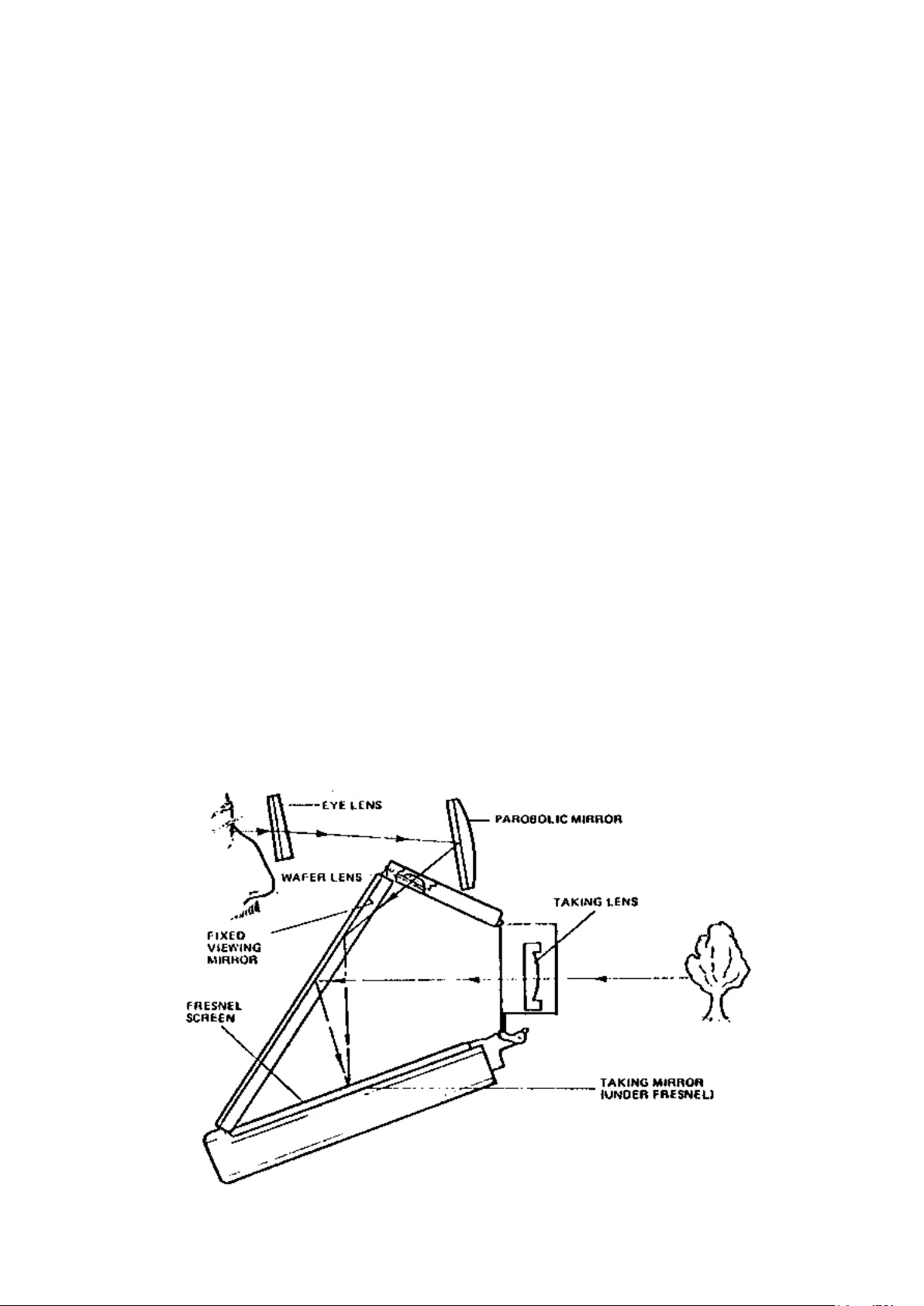

Figure 2-1 Viewnder optics (viewing)

Page 16

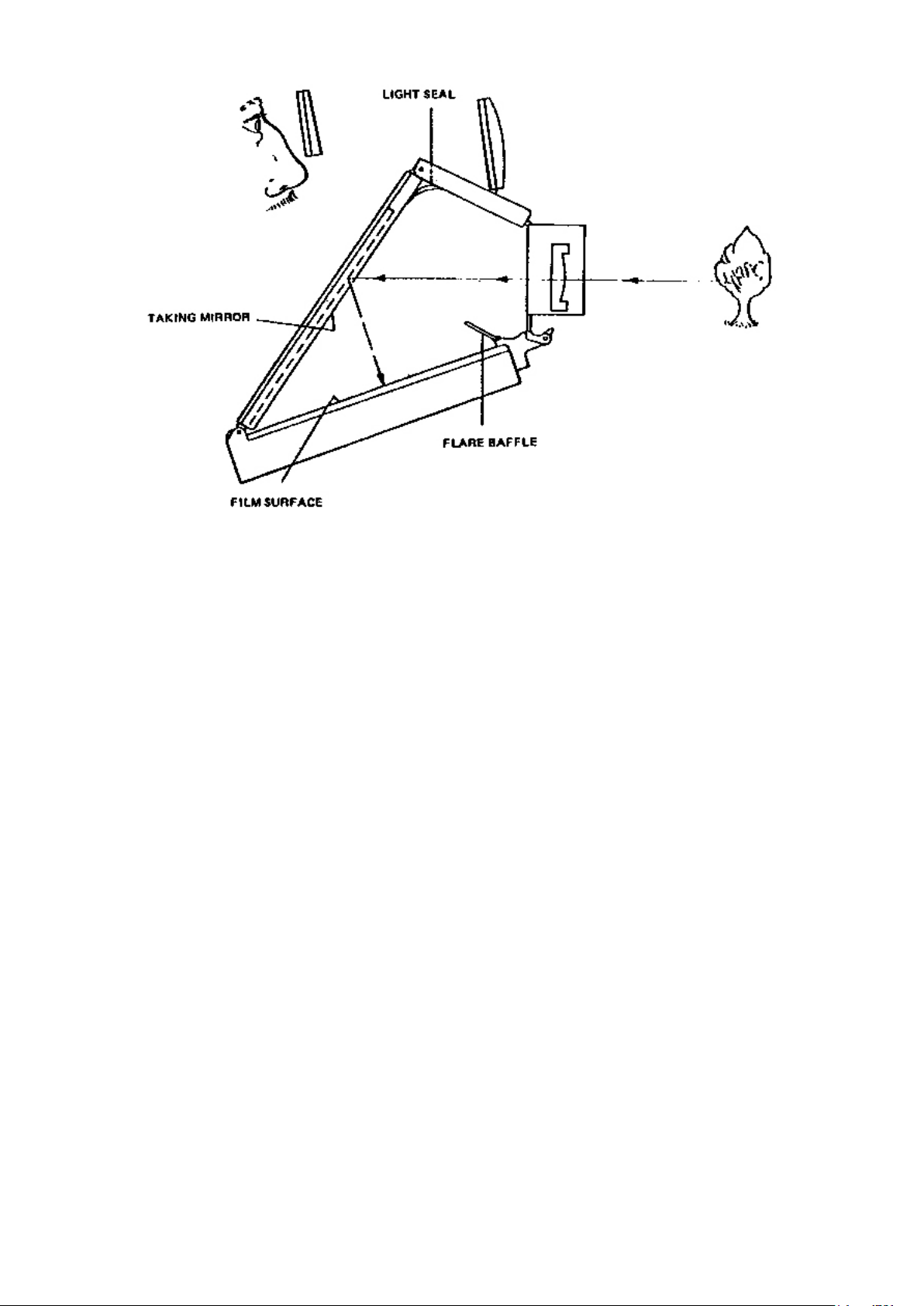

Figure 2-2 Viewnder optics (exposing)

the subject passes through the camera lens and

is reected by the viewing mirror (on the inside

surface of the mirror cover) to the Fresnel viewing

screen.

The entire subject image is now reproduced

on the viewing screen. At this point, viewnder

optics must be employed for focusing. The optics

must transfer the image from the viewing screen

to the eye (done by the parabolic mirror and the

viewing mirror) and must present the image in

a fairly sharp contrast to permit proper focusing

(done by the eye lens and parabolic miror).

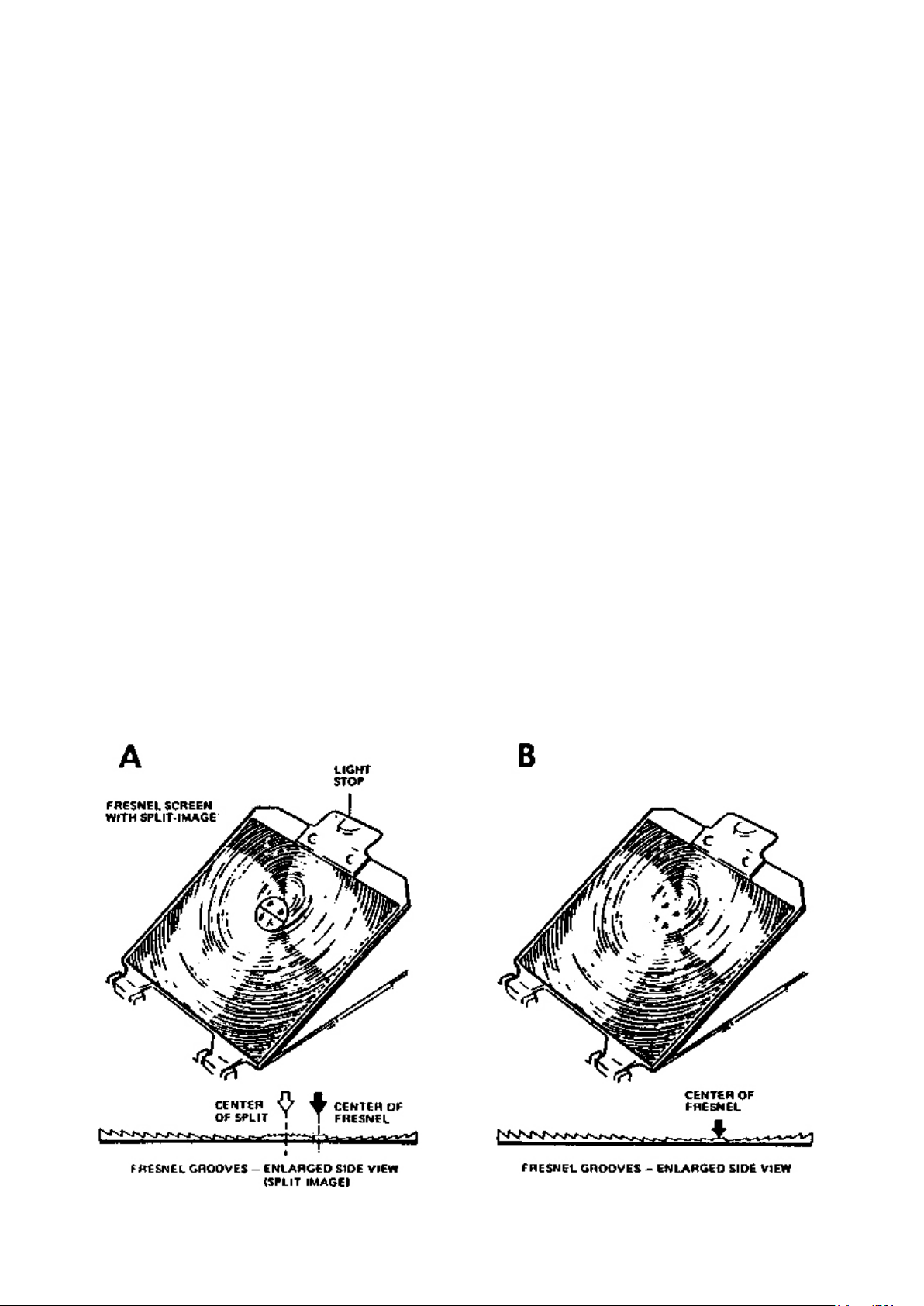

1. Fresnel (Figures 2-3 A and 2-3 B)

The special Fresnel (pronouced Freh-nell)

screen is employed to enhance the viewing

image by increasing the brightness and dention.

If a matte white surface were substituted for the

Fresnel screen, an image would still be visible.

However, the light rays striking nearest the

corners of the screen meet the screen at a more

oblique angle than the rays striking near the

center. At this greater angle, a larger percentage

of the light is dispersed and less light is returned

to the viewer. Thus, on a matte-screen image the

corners would appear darken than the center.

The Fresnel screen is designed to overcome this

problem.

Page 17

The screen itself is a sheet of plastic upon which

are impressed series of concentric rings much like

the grooves pressed into a phonograph record

(Figure 2-3) instead of having a vee shaping;

however, the grooves in the Fresnel screen form

a saw-tooth with a tooth angle increasing slightly

with each successive groove in such a manner as

to complement the decreasing angle of the light

ray. The saw-tooth attens out completely at the

exact optical center of the screen. In the SX-70

camera, the optical center is not the geometrical

center of the screen.

increases the brilliance of the image within teh

viewing aera.

In summary, the Fresnel satises three conditons:

1 - it enhances focusing by distributing light rays

evenly across the entire viewing aera.

2 - it guarantees proper focusing by nature of its

acting as a ground glass - thus insuring that the

subject is in focus when the eye sees the image

in focus on the screen.

3- it acts as a reecting surface to permit the eye

to see the image through the viewnder optics.

The surface of the screen is silvered to provide

optimum reectance. The result is a brilliant

viewing image evenly illuminated from corner to

corner.

For the reader who is familar with the use of a

Fresnel lens used in conjunction with a groundglass focusing screen, or a Fresnel-ground

focusing magnier, it must be noted that these

are transmission devices while the Polaroid

screen is a reecting medium. Otherwise, the

brilliance enhancing properties are the same.

A suitable analogy would be the comparison of

a lenticular projection screen compared with a

matte surface. The ribbed surface of the lenticular

screen narrows the angle of reectance but

As show in Figures 2-3 A and 2-3 B, two types

of fresnel screens are used. Current types

(Figure 2-3 A) have a split-image circle cut into

the center of the screen which makes focusing

easier. Specially oriented prisms within the circle

split the image unless the camera is perfected

focused. Therefore, a straight vertical line in the

image aera would appear to be broken unless

the subject is in focus. To further ease focusing,

the image within the split circle appears brighter

than the rest of the Fresnel image. This is

possible because the split circle is not coated in

the same manner as the rest of the Fresnel. This

latter feature improves the ability of the viewer to

focus the camera in dimly lit aeras.

Figure 2-3 Fresnel screen

Page 18

2. Viewnder

The viewnder optics consist of an eye lens, a

concave mirror and a wafer lens (Figure 2-4). As

in all simple optical system, a certain amount of

distortion is inherent in this design. A small wafer

lens is introduced into the viewnder optical path

to limit to angle of acceptance and, thus, reduce

distortion. The size of the lens opening is large

enough to provide acceptable viewing brilliance

and, at the same time, small enough to be easily

closed when the camera is in the exposure mode.

(On earlier models a rectangular mask called a

stigmatic pupil takes the place of the wafer lens.

mirror, the 6-edges viewing mirror is used in the

optical path twice. First, the light rays entering

the camera from the taking lens are reected

onto the Fresnel screen by the viewing mirror.

Secondly, the operator views the image on the

screen with light reecting off the viewing mirror

(Figure 2-1). (The viewing mirror is located on

the underside of the mirror cover assembly.)

4. Flare bafe

The are bafe (Figure 2-2) is a spring-loaded

plate which springs up when the Fresnel screen

moves into the picture-taking mode. In this state,

light is prevented from passing through the lens

directly onto the lm without rst being reected

off the taking mirror. This prevents «hotspots»

from appearing on the nished picture. When

the Fresnel carrier is in the lowered position, the

are bafe is held down, out of the optical path.

Figure 2-4 Wafer lens assembly

Ignoring the shutter functions momentarily, when

the operators presses the exposure button, the

Fresnel carrier swings away from the lm plane

and comes to rest in front of the viewing mirror.

During the moment of the Fresnel carrier (and

until it returns to its initial viewing position), a

exible light stop closes a path between the

viewnder and the inner camera to prevent light

trough the eye lens from reaching the lm. The

movement of the spring-driven Fresnel carrier is

accomplished by the motor-driven gear train. The

details of the automated action are described

in the discussion of the electro / mechanical

assemblies.

E. CAMERA ELCTRONICS

1. General

The SX-70 is unique, both in its principles of

operation and its functional design. It can be

considered as aan electronically controlled

mechanical device. An electronic control module

(substrate or ECM) contains all of the electronic

components with the exception of the motor

control (MCC) integrated circuit and the ash re

assembly (FFA). Because the ECM is located

inside the shutteur housing, it becomes identied

as part of the shutter (Figure 2-5). It should

be noted that all of the camera automation is

controlled by the integrated circuits in the ECM.

3. Mirrors

Two rst surface mirrors are used in the SX-70

optical system. When a picture is being taken,

the Fresnel carrier is raised. This places the

4-edges taking mirror into the optical path and

light is reected onto the lm plane. (The taking

mirror is mounted on the Fresnel carrier on the

side opposite the Fresnel screen.) The second

Figure 2-5 ECM - Electronic Control Module

Page 19

The entire ECM (rather tna its individual

integrated circuits) is used as a remplacement

item. For that reason, the theory of operation and

analysis techniques presented in this manual

have prepared in such a way that the repairman

can relate a specic camera failure mode to an

ECM function.

2. Switch functions

a- Switch S1 is actuated by either the red shutter

release button or remote control cable release.

It is operated by the photographer and it causes

the camera to run through a complet exposure /

lm delevery cycle.

b- Switch S2 places the circuitry into the ash

mode. Switch S2 si closed when the ash bar

is inserted into the FFA on the top of the shutter

housing. It commands the integrated circuit

in the FFA to select the rst unused ashbulb

and, to re the bulb. It also enables the ECM to

energize solenoid #2 which limits the opening

of the shutter blades so that ash exposure

will be determined by ash-to-subject distance.

When the solenoid #2 is energized it engages a

mechanical coupling between the shutter blades

and the focusing mechanism.

Figure 2-6 SX-70 Switch locations

Page 20

c- Switch S3, normally closed at the begining

of the exposure cycle is opened by the recock

ram located in the gear train assembly. See

Figure 2-7. As the exposure sequence begins,

S3 opens and actuates a delay circuit (Y delay)

in the EMC which retards the start of the actual

exposure approximately 40 milliseconds so

that mirror bounce will have subsided before a

picture is taken. At the end of the delay time, the

shutter starts to open and the electronic timing

function (integration) takes place. If a ash circuit

is inserted into the FFA (S2 closed) an additional

ash delay circuit is avtivated to insure that the

exposure gets full effect of the light derived from

the ash. At the end of the exposure cycle when

the Fresnel carrier moves down into viewing

position, S3 closes as the recock ram moves

away. It is now reset for the next camera cycle.

d- Switch S4 is tripped by an actuator on the

plunger of solenoid #1, the shutter blade actuating

solenoid (Figure 2-8).

NOTE : Whenever the SX-70 shutter is discussed,

it must be noted that, since the camera is a single

lens reex and focusing is accomplished through

the taking lens, the shutter’s normal state si open,

not closed as in other Polaroid cameras.

When the shutter release button is pressed and

the exposure cycle is initiated full battery power

is delivred to solenoid #1, closing the shutter.

Once the solenoid plunger is seated it no longer

requires as much power as was originally

needed to overcome its static inertia. Switch S4,

therefore, closes the S4 CB contacts to the ECM

and the electrical power to the solenoid coil is

reduced to the «power down» value which is

sufcient to continue the exposure cycle yet low

enough to conserve battery drain.

When the switch S4 (CB contacts closed) transfers

to the ECM it sends power to the drive motor and

operates the gear train. When S4 is actuated,

(CB contacts closed) it also disconnects power

from the FFA ash circuitry. This action prevents

Figure 2-7 S3 Being opened by recock ram

Page 21

Figure 2-8 S4 Switch operating congurations

damage to the circuit in the event that ashbulb

becomes short-circuited after it is red.

e- Switch S5 (normally closed at the beginning of

the exposure cycle), like S3, is located in the gear

train and actuated by the recock ram (Figure 2-7).

When the gear train rotates to appropriate point in

its cycle, S5 opens and removes power from the

drive motor, applying dynamic braking voltage to

stop the gear train quickly. The ECM reacts to

this command in such a way that exposure cycle

continues completion even through the operator

has released the exposure button (S1). After the

exposure and when the Fresnel carrier returns to

the viewing position, S5 is closed by the recock

ram and stops the camera cycle.

f- Switch S6 is closed by openong the camera

to the picture taking position. Its disconnects the

negative side of the battery from the commun

return (ground) when the camera is folded to

assure the removal of power from the circuit.

g- Switch S7 is closed when the front cover is

closed. It is wired in series with S6. Like S6, S7

disconnects the negative side of the battery from

the commun return so that the camera cannot

function until the front cover is closed and

latched. It is an interlock during normal picture

taking. With S6 and S8 closed, it initiates the

dark slide function.

Page 22

h- Switch S8 (Figure 2-8 A) is part of the exposure

counter operated by the counter wheel. As S7

closes, power is applied, ejecting the dark slide.

After the dark slide ejection, the counter wheel

turns, opening S8. S8 then remains open until

the lm pack is removed. When the pack is taken

out, S8 closes.

i- Switch S9 is near S8 on the exposure counter

assembly. When the counter reaches the 0

position, switch S9 closes and the ECM inhibits

the falsh-ring function, so that if an unused bulb

is still available it will not be wasted.

j- For an handy summary, see the Switch Function

Table.

3. Function Sequence

The following paragraphs describe the sequence

in which operate during normal operation of the

camera.

a- The operator opens the camera. Switch S6

connects the battery to the camera circuitry.

b- The operator opens the front cover. Switch

S7 opens and removes battery power from the

camera.

c- The operators open a lm pack. (when the

Figure 2-8 A S8 - S9 Exposure counter switches

previously used lm pack was removed, a

SWITCH FUNCTION TABLE

Switch Action Result

1 closes

Initiates exposure cycle and causes circuitry to take and

deliver the pictures.

2 closes Connects circuitry to take ash pictures.

3 opens

CA closes

4

Initiates «Y», 40 milliseconds delay. (Power down

solenoid #2 in the ash mode)

Controls power to solenoid #1 (drop current to holding

level).

CB closes Signals the ECM to start the motor.

5 opens / closes

closes

6

Stops motor both by closing and opening depeending upon

sequence of action and internal circuitry.

● Connects the battery to the electronic circuitry when the

camera is open to use.

opens ● When the camera closed, cuts power from battery.

When S8 is also closed, it provides power to the camera

7 closes

when the front power is latched (for dark slide eject). Also

acts as an interlock during normal picture taking.

8 closes

Enables (with S7 closed) the circuitry to eject dark slide.

Opens again after the dark slide is ejected.

9 closes Prevents ring ash if lm pack counter is on «0».

Page 23

mechanical coupling device set the exposure

counter to the position just before the rst

exposure and closed S8, but since S7 has

removed all battery power no action occurs).

d- The operators closes and latches the front

cover. S7 closes, power is apllied and the camera

eject the dark slide.

NOTE : During this action (and in certain other

operations) other switches actuate and functions

occur but, unless they contribute to the paticular

camera function being described, they are

omitted from the discussion).

The counter indicates exposures #10 (and opens

S8) thereby showing that the camera is ready to

take rst picture.

e- The operators aims, focuses the lens, and

presses the red shutter release button (S1).

The ECM actuates solenoid #1 which closes

the shutter blades. Solenoid #1 transfers the S4

contacts from CA to CB, which in turn, switches

the circuit from full solenoid power to holding

current (power-down). Closing contacts CB of

switch S4 also starts the drive motor. Opening

S4 (CA) removes power from the FFA.

f- As the gear train runs, it mechanically releases

the spring-loaded Fresnel carrier so that it leaves

the lm plane and rises to its exposure position.

This is accomplished by the mirror release cam

of the recock gear. the recock ram falls off the

recock cam, allowing the ram to snap forward.

This allows the drive spring to raise the Fresnel

assembly to the exposure mode. The ram also

moves away from S5 allowing S5 to open. This

action causes the ECM to dynamically brake the

motor which will remain at the rest throughout the

exposure segment of the cycle. The S5 switch

action also programs the ECM to complete the

cycle even though the operator has released the

exposure button after S5 is open.

NOTE : there would appear to be a contradiction

between this step and the step j-10 below wherein

closing of S5 performs the identical function, i.e,

stops the motor and applies braking. S5 is able

to perform in this manner, however, because

the circuit (gate) to which it is connected is in a

different condition during each of the steps.

g- While the Fresnel carrier was moving up prior

to motor shutdown, the recock ram opens switch

S3. When S3 opens, it signals the ECM to initiate

a 40 millisecond delay in the sequence. This

amount of time prevents a picture from being

taken until mirror bounce has subsided.

h- At the end of the 40 millisecond delay period,

the ECM removes power from solenoid #1 and the

shutter opens. Simultaneously, the circuit starts

timing the exposure (integration). The integration

components of the ECm are controlled by the

amount of light received by the photocell. At this

time, the ash delay section of the ECM is made

ready but will not function unless a ashbar has

been plugged in, to close switch S2.

i- When power is removed from solenoid #1 (and

the shutter begins opening), the actuator on the

plunger returns switch S4 to its original condition

(CA closed); When the exposure timing cycle

is complete, power is returned to solenoid #1

and the shutter closes, opening CA, closing CB,

placing solenoid #1 again in the power down

condition and starting the motor to eject the

exposed lm.

NOTE : the lenght of, the timing cycle is

determined in amount of the light reaching the

photocell. If there is insufcient light to correctly

operate the integration circuits, the system will

automaticall terminate the exposure within 14 to

30 seconds.

j- When, in the previous step, the solenoid closes

the shutter blades and drive motor is energized,

the gear train resumes its sequence with the

following results :

1. The lm pick feeds the exposed lm to the

spread rolls.

2. At the end of its travel the pick uis held in its

forward position by the pick latch.

3. Film moves through the spread system.

4. The recock gear cam proceeds to retrun the

recock ran which, through the bell crank, moves

the Fresnel carrier down.

5. The recock ram closes switch S3 to prepare for

another exposure.

6. The light stop opens the optical path to the

viewnder.

7. The lm completes its passage through the

spread rollers. The front cover idler gear meshing

with the gear train powers the top roller which

drives the lm through the exit slot.

8. The Fresnel carrier when fully scated is held by

the recock ram.

9. The pick latch releases the pick and the pick

returns to its starting position.

10. The recock ram closes S5 to cause the ECM to

shut off and dynamically brake the drive motor.

Page 24

k- If the operator has removed pressure from

S1

Closes

Y DELAY FLASH DELAY

Sol. #1

Power

Down/

SA BC

Closes

S3

Opens

Sol. #2

Power

Down

At Hight Light

Levels Early

Cameras will

take Ambient

Exposure

(does not apply to

"P" configuration (T1)

and

Stop

Ambient

Exposure

Blades

Close

S4 CA

Opens

Film

Ejected

Cycle

Complete/

S5

Closes

S5

Opens

Sol. #2

Power Up

Sol. #15

Power Up /

FT

Blades Open to Correct

Aperture S4 AC Close

to Power FFA

Sol. #1

Power Up

Activated

Flash delay

FD

Sol. #2

Power Off

FF

End

Flash

Delay

Down

S4 BC

Closes

S3

Close

Flash

Time

Out

FTO

Flash

Fires

FLASH TIMING SEQUENCE CHART

exposure button all power will be removed and

the shutter blades will open to permit viewing.

If the button has not been released, the shutter

blades will remain closed until the operator

removes his nger from the button.

l- When a ash bar is placed in its socket, it closes

switch S2. This switch connects the ECM in the

ash mode. All of the mechanical sequences will

remain as just described. The ECM however, will

now provide power to solenoid #2 when switch

S5 (in the gear train) opens, and will maintain it

in a power down condition when S3 opens.

m- Within the shutter assembly a cam follower

is driven by a cam on the focus wheel and

arranged so that it will mechanically stop the

travel of the shutter blades relative to the focus

distance. When solenoid #2 is not energized, a

spring on the cam follower prevents engagement

of the cam follower and the shutter mechanism

functions in the ambient exposure mode. When

the ECM is programmed for ash, solenoid #2 is

energized and the shutter openeing is controlled

by focusing distance.

n- When making a ash exposure and the shutter

blades start to open, the interceptor will be set to

a position determined by the focusing mechanism

but out of the path of the interceptor pin. When

solenoid #2 is energized, it pulls the interceptor

into the pins path of the blades and stops them

at the aperture for ash exposure at the set

distance (Figure 1-13). The interceptor latches

in this position. At this time, the ECM removes

the power from solenoid #2. The solenoid, like

any inductive device, produces a yback voltage

when its magnetic eld collapses. This yback

voltage is used to trigger the ECM which, in

turn, applies power to the FFA to ignite the next

unused ashbulb.

o- The shutter performs an additional function

in the ash mode. One of its circuits examines

the #1 ashbulb contacts and by virtue of the

resistance determines whethever or not the bulb

has been red. If the #1 lamp is exhausted, the

circuit scans the #2, etc. When an unused lamp

is located, the ring circuit remains connected to

the lamp until is used.

NOTE : It is important to be aware that in early

cameras the timing (integration) circuits of the

substrate continue to function even though the

insertion of a ash array has placed the substrate

in the ash mode. Thus, if the ambient light level

is high, the picture may be made by ambient light

without ring the ash. Also, if all the ash lamps

are expended and a picture is taken, an ambient

light exposure will result. The photographer will

recognize this situtation by the absence of a ash.

However, he may still get an acceptable picture.

the aperture in this case will be determined by

the ash to subject distance.

Page 25

F. SHUTTER MECHANICAL DETAILS

(Figure 2-9)

The following paragraphs describe the manner in

which the mechanical components of the shutter

respond to either manual or electrical direction.

1. When the operator prepares to take a picture,

he rst must aim and focus the camera. As he

rotates the focus wheel to bring the split Fresnel

image into focus, a cam molded into the rear

surface of the focus wheel moves the component

identied as the cam follower assembly. The

trim link coupled to the trim assembly is pinned

to the cam follower in such a way that follower

movement is also directly inuenced by the

setting of the trim wheel. (The trim wheel is the

lighten / darken control on the photocell.)

Figure 2-9 Shutter, exploded view

Page 26

2. When an ambeint light exposure is being

made, all of the action just described takes place

but does not affect the shutter action. However,

when a ash array is inserted switch S2 in the

ash socket programs the electronics to energize

solenoid #2. The impact of this action on the

movement of the shutter blades is described in

paragraph F.4. but rst the shutter blade actuation

must be described as follow :

3. When the ECM circuit powers solenoid #1,

the solenoid plunger is pulled into its seat,

overcomming the opening spring force. The

plunger pulls the walking beam, rotating it about

60 degrees.

Each of the shutter blades has a pin which

engages a slot in the walking beam. As the

walking beam rotates, it transmits its rotary motion

to the shutter pins and drives the rear blade to

the right (facing the front of the shutter) and the

front blade to the left thus closing the light path

of the picture taking lens and the light path of the

photocell lens. When the shutter is totally closed

and the gear train has reached the point in the

sequence at which the Fresnel carrier snaps up,

the exposure sequence starts. The blades will

proceed toward the fully open position and retrun

to a closed position in the time interval dictated

by the photocell and integrating circuit. The

blades may not reach the fully open condition if

the illumination level is high, or they may fully

open for a period of time if the light level is low.

If a ash array is mounted, the blades may not

be permittedto open completely because of the

follow focus mechanism described in part in the

foregoing paragraph. The following paragraph

explains the interaction of the follow focus

components and the shutter blades.

4. Installing a ash bar in the camera ash socket

switches the ECM to the ash mode. As previously

explained, at a point in picture taking sequence

(ash mode), solenoid #2 is energized. Fastened

to the plunger is pull down bar. when the plunger

pulls this bar down, it moves the interceptor into

the position where it will intercept a pin (the stop

pin) on the walking beam (Figure 2-9 A). Now

when the shutter blades move towards the open

position, they will be interrupted by the mechanism

just described which means the maximum size

of the blade opening (aperture) is determined by

the focus setting of the camera. As the camera

(and thus the ash lamp) is moved closer to the

subject, the maximum aperture is reduced so

that a correct exposure will result. The reverse

(greater distance/greater aperture) is also true.

Figure 2-9 A Solenoid S2 operation

5. The shape of the pin on the walking beam si

such that once contacted by the cam interceptor it

remains latched in that position until solenoid #1

actuated during the next phase of the shutter

cycle. When the plunger on solenoid #1 pulls

in, the follow focus pin disengages from the

interceptor and the solenoid #2 plunger returns

to it original position under the force of the

interceptor hinge spring.

6. Since the photocell components are contained

within the shutter housing, they are included in

this discussion. A lens is employed to focus the

reected light from the subject on the photocell.

A second pair of openings in the shutter blades

control the amount of light received by the cell

as previously described. A variable neutrality

density wedge system is employed to provide

lighten / darken adjustements. (Trim assembly).

The operation of this control differs slightly from

those used on other Polaroid cameras. When

the camera is folded, a cam on the shield of

the front cover strikes a release lever on the

lighten / darken assembly and returns the trim

adjusting wheel to its center (normal) position.

The trim wheel is automatically centered when

the camera is closed.

7. To compensate for any variations in individual

photocell characteristics, a neutral density lter

is selected and installed in front of the photocell

lens during assembly. A calibration must be

performed and a lter of correct density installed

any time the ECM requires replacement.

Page 27

G. FILM PROCESSING COMPONENTS

The basic theory of the lm processing method

remains unchanged from previous Polaroid

system. That is , the developping chemistry is

encapsuled in a pod on each sheet of lm and,

as the sheet is passed between rollers, the

pod is burst and the chemical spread evenly

between the negative and the mylar protective

cover. Except for this characteristics, no direct

similarities exist. The SX-70 camera employs a

unique process which totally eliminates the «throw

array» negative. The print is drawn through the

spread rolls by the motor drive system so that

no action need be taken by the operator. See

Figure2-10. Development takes place outside

of the camera and unaffected by ambient light

conditions. Since the end result is determined

when the picture emerges from the camera, no

time measurement si necessary. (Additional lm

information is available on page 60 and 61 of

«The world of SX-70»)

spring action, raises the Fresnel carrier. When

the recock rammoves, it opens S5 and then S3

at certain Fresnel carrier angles. Opening S5

stops the motor after it has made only a brief jog.

Opening S3 starts the «Y» delay : 40 milliseconds

delay which allows the Fresnel carrier to come

to rest after its travel. (This eliminates bouncing

caused by the sudden stop of the carrier on the

mirror cover.)

At the end of the «Y» delay, power is removed

from solenoid #1, allowing the spring to open the

shutter for exposure, and moving S4 from CB to

CA position. When the proper exposure level is

reached, the photocell trips the Schmitt Trigger

(S/T) in the ECM which sends full power to

solenoid #1. This closes the blades and tranfers

S4 from CA to CB. As before, closing CB cuts

solenoid #1’s power from full to low, sufcient to

hold the blades closed; closing CB also signals

the electronics to start the motor.

Figure 2-10 Spread roller system

H. SEQUENCE OF OPERATIONS

The operator pushes S1, applying full power to

solenoid #1, which closes the shutter blades,

and pushed solenoid #1 against S4, changing it

from CA to CB. Closing CB cuts solenoid #1’s

power from high to low; low is enough to hold the

blades closed. Closing CB also signals the ECM

to start the motor. The motor starts the gear train

moving. The movement of a cam on cam on the

gear train releases the recock ram and, through

The motor starts the gear train again, and this

time the cams cause a series of actions at

different position of gear train movement :

- it starts the pick which pulls the lm into the

rollers (one of which is attached to gear train it

is this powered roller rotation that pulls the lm

through and out of the camera);

- it stops the pick;

- it pulls down the Fresnel carrier, which in turn,

moves the counter to the next number;

- it moves the recock ram, closing S3 (resetting it

for the next cycle);

- it retruns the pick;

- it seats the Fresnel carrier so it is ready for the

next cycle;

- it moves the recock ram, closing S5, which

stops the motor;

- and it stops the spred action.

When S5 closes, it cuts power to the solenoid #1;

the spring opens the shutter blades, and S4 is

pushed from CB to CA. (The blades open only

if the operator releases the red button.) The

system is ready for a new exposure cycle.

Springs are used in three of the operations

discussed above : holds the shutter blades open,

lps the Fresnel carrier up, and holds the pick at

the rest position.

As indicated, inserting a lm pack causes

automatic action. This could, of course, be a

Page 28

partial pack : the top of the sheet of lm would

be ejected as a dark slide and the counter would

registrer «10». After the last actual sheet is

used, the camera would still function until «0»

is reached. If a ash bar were attached, and an

unused bulb was available after the last lm sheet

was used, attempting to make another exposure

would re the ash.

The difference in the ash mode are :

inserting a ash bar closes S2, which activates

solenoid #2 to move the interceptor into position.

This controls the shutter blades according to

focusing : the closer the subject the more light

from the ash will bounce back. Therefore, the

smaller the permitted aperture.

At the end of the «Y» delay, a ash delay circuit

is activated, and when S4 switches from CB to

CA, Ca sends power to the ash circuit. During

the xed ash delay, the photocell and S/T are

operative , so that if enough light energy is

collected before the end of the ash delay, the

blades will be closed as in ambient picture.

However, on newer cameras («P» conguration

shutters), the ash will re whether or not

sufcient ambient light si available.

At the end of the ash delay (the blades at

this point are open to the aperture dictated by

focusing) power is removed from solenoid #2

and the discharge (yback voltage) triggers the

ash circuit, ring the ash and starting the ash

time out interval (the xed exposure time). If, on

early cameras, an ambient exposure has been

made, S/T-2 in the ECM receives the signal and

no ash or ash time out occurs.

At the end of the ash time out, the circuitry

energizes solenoid #1 which closes the blades.

if no ash has occured, caused by all the bulbs

having been used, no signal will be sent to

solenoid #1, and on early cameras an ambient

exposure will be made. If the S/T has not collected

sufcient light energy at the end of a xed period

(20 seconds), the blades will automatically close.

On newer cameras, the exposure time remains

short and a black picture will result.

Page 29

CLOSED BY OPERTOR

S4 SWITCHES AC to BC

S4 SWITCHES AC to BC

CLOSES

CLOSES

S1

S4 BC

S4 BC

S4 AC

End "Y"

S5

S3

S3

S5

ST 2

S1 T - 0

S2 → Closed if flash array inserted

Solenoid #2 power up (S2 closed)

●

S9 opens when previous pack removed

●

S6 closed during the erecting mode

●

S8 closed until film cover ejected

●

Gears between front cover and gear train

mesh as cover closes (3

rd

& 4th idler)

●

S7 closes during front cover closure

resulting in dark slide ejection after a

new pack inserted

●

S8 opens (counter set to 10)

S4 BC

S4 BC

S4 AC

End "Y"

S5

S3

S3

S5

FT

FF

S4 SWITCHES BC to AC

S4 AC/BC open

OPENS

POWER RELEASED FROM SOLENOID #1

EXPOSURE COMMAND SIGNAL COMPLETE

Shutter starts to close

Cam moves from 20° position

Solenoid #1 power down

Shutter close

Electronic Latch off

Motor stops

(if S1 closed, Solenoid #1 remaing in power down)

Shutter opened (provided S1 is open)

Counter set to next position

Mirror carrier starts to drive counter

Shutter close

Shutter starts to open

Starts integration ambient

Motor starts

Fresnel starts down

Integration

20 to 35 ms

Shutter at full open (f/8 16)

Mirror continue to rise

Mirror at rest

Y delay activated

Solenoid #1 power up

Solenoid #1 power up

Shutter starts to close

Motor braked

Cam stopped at 20°

Electronic latch ON

(S1 may be opened)

Cam rotates

Mirror released

OPENS 26° 34°

AMBIENT

EXPOSURE / PROCESS

OPERATION SEQUENCE

FLASH

Solenoid #2 power down

Flash delay FD circuit actived

Switches power to falsh circuit (S2 closed)

Removes power from flash circuit

20° - pick starts

45° - spread starts

50° - pick stops and latches

130° - mirror starts to recock

260° - spread stops

325° - mirror is recocked, pick returns

345°

Solenoid #2 back onf (power off) triggers FF circuit

at the end of flash delay (FD); ST 2 shorted out; time

out interval FT initiated.

Note 1. No flash fire signal if:

a- S9 closed (empty pack)

b- new pack inserted with array already

inserted (S8 function)

Note 2.

A 25 to 34 exposure results if the array

does not fire

200 ms max.60 ms

12 ms max

51± 6.5ms

Flash delay

Y Delay

40 ± 5ms

20 to 35 ms

FLASH

25 to 34 ms

Page 30

III - TROUBLESHOOTING

A. INTRODUCTION B. INITIAL TESTS

The Sx-70 camera is an electronically controlled

device, the electronics being in the integrated

circuits (IC) mounted in the Electronic Control

Modul (ECM) and Flash Fire Assembly (FFA)

in the shutter housing and in the Motor Control

Circuit (MCC) in the camera back. Because

the IC’s are non-reparaible items, there is no

requirement to trace faults whithin the integrated

circuits. It is mandatory, however, to be able to

identify the command inputs (switches open or

closed, etc.) and the resulting output signals.

The SX-70comprehensive Tester provides the

readouts necessary to conrm an exposure

malfunction; but thorough understanding of the

theory of operation is required if meaningful use

of the tester is expected. If a particular camera

function fails, it is necessary to recognize how

the failure is related to the operating sequence

of events and thus reduce testing procedures to

those related to the aera malfunction.

Do not make any arbitrary assumptions. An

assembly or component should be thoroughly

tested to determine whether or not it is performing

its function correctly. Complete the tests in the

chart below.

Because of the camera’s total automation, it

is unlikely that much useful guidance can be

obtained from customer complaints except

in cases of visible mechanical damage. For

this reason, a well dened series of checks,

observations, and tests must be followed. This

section of the manual denes these procedures.

The primary purpose of any fault analysis program

is to reduce the investigation time to a minimum.

Thus, it is not only important to establish a

xed routine, but it is mandatory to acquire the

maximum amount of information from each step

of the checkout procedure. Use the charts at the

end of this section to guide through each step

of inspection, dynamic testing and post-repairs

tests.

Analysis of the SX-70 camera is a key part of

the complete repair task. If the analysis is done

correctly, it will eliminate excessive repair time

and high parts replacement cost. For instance,

initial evaluation may show the entire shutter

to be at fault; however, continuing analysis

determines that the problem is in solenoid #2,

which, when replaced reduces the materiel cost

considerably (from over 20 $ to under 2 $). The

repair person must always consider the labor vs.

material trade-off when making a repair.

Page 31

SX-70 CMAERA REPAIR INSPECTION PROCEDURE

A. FUNCTIONAL TEST

1. Perform light leak test.

2. Check focus and trim wheel torque.

3. Check trim wheel reset ±2 teeth and front

cover to shutter gap.

4. Cycle camera 3 times at 5.0 and 6.4 volts

with power pack.

5. Focus camera at 8’ - performe aperture test

(see specication sheet).

6. Ambient mode tracking at 3 lights levels

(note current drain) (see specication sheet).

7. Collimate at innity.

8. Flash mode tracking at 10.4’’ (see

specication sheet).

9. Check ash system

a. Flash sequence (with camera tester)

check counter rotation

b. Flash on zero.

10. Inner frame bow ( +.004 to +.011)

B. OPERATIONAL SEQUENCE

1. Check camera latching.

2. Erecting link (grinding).

3. Positive lock.

4. Check front movement and latch.

a. Check trim reset cam (correct cam and

condition).

b. Light shield (condition and movement).

c. Light piping seal.

d. Idler gear stacking.

e. Outpout gear slippage.

5. Check ash on dark slide power pack and

ash simulator.

6. Take ash pix at 10.4’’, check premature

dark slide.

7. Check for dirty rollers and lm catcher

spring.

C. FINAL VISUAL

1. Check optical path.

2. Fresnel cosmetics (per standards chart).

Split image.

3. Wafer and 3° eye lens.

4. Entrance and exit pupil position.

D. SHUTTER COSMETICS

1. Chrome

2. Lens conditions

3. S1 button and photocell conditon - trim

wheel decal.

4. S1 remote and ash socket condition.

5. Shutter mounting screws (missing or

loose).

E. CAMERA BACK

1. Shade blade condition (scratched distorted).

2. Shade blade movement (gap between

blades).

3. Concave mirror condition (color code

refurbished only).

4. Repair techs scribe (data and repair center

code).

5. Gear train cover.

6. Bottom cover window and condition.

7. Cable cover - cable camp - cable restrainer

(conditon-position).

8. Cable spring hook on.

9. Boot retainer tabs in place.

10. Cracked / broken hinges

11. Shutter hinge bracket pivots and gap

(.0125 max).

12. Leather and chrome cosmetics.

13. Set lens at innity.

F. PICTURE EVALUATION

1. Bafe in pix aera.

2. Cracked / dirty taking mirror.

3. Incomplete coverage (front cover related).

4. Color code and FTC label (refurbished

camera only).

Page 32

Figure 3-1 Film pack simulator and power suplly

C. TEST EQUIPMENT OPERATION

Checkout the SX-70 camera requires the use of

several pieces of test equipment. The purpose of

this section is to instruct you in the proper use of

this equipment.

1. Power supply and pack simulator (Figure 3-1)

In use the system subsitutes for the lm pack,

giving a steady, reliable source of power.

a. Plug the pack simulator into the power supply

being careful to observe polarity (ground is

negative).

b. Set the power supply switch to VOLTS and

turn the supply ON.

c. Adjust the output to the desired volatge (5.8v

normal).

NOTE : Except on Lafayette-made units, the

power supply mete is not adequate to set the

voltage. Use an external meter (VOM or VTVM)

to make this setting.

Figure 3-2 SX-70 Collimator

Page 33

Figure 3-3 Location of new collimator target

a. Collimation of the Split Image Viewing

System.

NOTE : If the collimator is not available, set the

focus wheel to innity and look at a scene at least

200 feet away. Observe that the focus is sharp

within a tolerance of -1 tooth to +2 teeth beyond

the innity setting of the focus wheel.

NOTE : If an early vintage collimator is being

used, a new adhesive backed label must be

added to the target in the position show in Figure

3-3.

(1) Remove the camera front cover and load

the camera onto the horn of the collimator

#321564 (Figure 3-2). (The collimator uses

a rear illuminated target so no additional

equipment is needed).

(2) Turn on the collimator light

d. Set the power supply to the AMPS position.

b. Remove front cover from camera.

c. Insert the pack simulator into the camera

as you would a lm pack (with the contact

down). Close the camera S7 switch using the

actuator.

2. Collimator (Figure 3-2)

When performing several of the Comprehensive

Tester checks, a requirement of the test is that

the camera lens be correctly collimated. For this

reason and because the lens can be checked

simply and rapidly, the collimation checks should

be done before Comprehensive Tester checks.

Collimation for the SX-70 camera is done on the

special collimator as indicated below.

(3) View the added target with the focu wheel

set to innity.

(4) Compare the observed conditions with the

examples shown in Figure 3-4. As indicated

(best case), the upper part of the vertical line

should be aligned with the bottom part of the

line or it may be displaced to the right. (If

displaced to the right - acceptable -, it should

still be touching the lower part of the line.

(5) If the upper part of the line is displaced to

the right so far that it does not touch the lower

part of the line or if it is displaced to the left (out

of tolerance), the tolerance levels are exceeded

and the camera must be rejected. Corrective

procedures are outlined in Section IV.

b. Collimation of Non-Split Image Viewing

System

(1) Turn on the collimator light source.

Figure 3-2 Typical collimation conditions

Page 34

(2) Open the camera front cover slide the

camera onto the horn of the collimator. Make

sure that the camera is all the way on the horn

so that the camera is captured by the spring

latches.

(3) Swing the collimator innity lens to its

vertical position. (Be sure the 8’ lens is not in

the viewing path.)

(4) Look into the camera viewnder while

turning the focus wheel counterclockwise until

the image appears sharp. Look at the collimator

center target (top group of lines) and note the

number .63. This number and the lines should

have maximum clarity as the focusing wheel

reaches innity.

(5) if the wheel stops before the focus is

sharp, make the following adjustment before

continuing with the collimation procedure.

Spring Loaded Idler Gears

(a) With the camera still on the colimator, slip

special tool #11939 over the lens and push it

in, toward the back of the camera. This will

disengage the idler gear from the focus wheel,

allowing the lens to be turned without affecting

the focus wheel.

(b) With the focus wheel still set it its innity

position, look through the camera while turing

the lens. (This is done by maintaining pressure

on the tool.) While turning it, you will be able

to see the target through the opening in the

tool.

(c) When the image is sharpest, release the

special tool to reengage the refocused lens to

the focus wheel. (Continue setp 6.)

Non Spring Loaded Idler Gears

(a) Remove the camerar from the collimator

(b) Loosen the adjusting screw at the bottom

of the shutter housing so the idler gear no

longer engages the focus wheel and lens

barrel (Figure 3-5).

Figure 3-5 Disengaging the idler gear

(6) Verify the innity setting. Do this by

observing the vertical line target through the

collimator innity lens and the camera optics.

The line should be straight within the tolerance

in Figure 3-4.

(7) Swing the collimator innity lens back down

to its horizontal position, out of the viewing path

of the camera. Turn the camera focus wheel to

the 10.4’ setting.

(c) Return the camera to the collimator and

adjust the innity focus by rotating the lens

barrel while maintaining the innity position

on the focus wheel.

(d) When the focus is sharpest, remove the

camera from the collimator and tighten the

adjustement screw. Returns the camera to the

collimator and continue with step 6.

Page 35

(8) Look through the camera and observe the

vertical line target. Compare the observed

image with Figure 3-4 to determine if the

camera is within specications.

NOTE : There is no separate close-focus

adjustement on the camera. if the focus

wheel has reached its stop before maximum

resolution is achieved, return to the innity

check. If there is any tolerance at that setting,

readjsut the innity setting as close as possilbe

to the focus wheel stopping point and recheck

the close focus. If it is still impossible to obtain

a sharp image, the lens is defective and the

shutter must be replaced.

NOTE : The foregoing tests assume that when

the camera is operated, the viewing mirror

(Fresnel carrier) reaches the correct attitude

during the exposure cycle. If the lens has been

correctly collimated, the only check possible of

actual picture denition is to expose lm.

interrelated units : the Comparalumen calibrated

ligh source, the electronics module, and the

mounting horn or holding xture. The purpose

of both tester models is to check the dynamic

operating functions of the camera ( A detailed

description of the later tester is available in a

technical manual titled «Model B camea tester».

This section will deal only with the operating

instructions for the tester.)

MODEL A CAMERA TESTER

a. Set-up

Before testing the camera, perform the following

set-up procedure.

(1) Calibrate the tester daily. Record the

calibration reading in a log. (If the test equipment

is suspected of poor performance, calibrate

more frequently and repair if necessary.)

(2) Remove the front cover from the camera

(3) Set the L/D control to the mid-range position

usiong the trim reset cam and focus the camera

at innity.

3. Comprehensive Testers (Figure 3-6 and 3-7)

There are two models of Comprehansive Testers

available for semi-automatic testing of the SX70 camera. The earlier model, Comprehensive

Tester Model A, consists of three interrelated

units : the lightbox, the electronics module, and

the power supply (Figure 3-6). Comprehensive

Tester Model B (Figure 3-7) also consists of three

(4) using the S7 actuator, close teh s7 switch.

(5) Allow the tester to warm up for a period of

30 minutes.

Figure 3-6 Comprehensive tester

Page 36

Figure 3-7 Model B Camera tester

b. Ambient mode exposure test

(1) Place the S2 switch int he OPEN position.

Set the voltage to 5.8 volts

(2) Set the light level selector to the desired 100

light level

(3) Slide the camera over the horn on the tester.

The camera should go through the dark slide

(S8) cycle. If not, remove the camera from the

horn, determine the cause of failure, and correct

the dark slide operation. If the camera cycles

correctly, push the simulator ash plug all the

way down into the ash socket.

(4) Read the current meter - it should read «0»

after the dark slide cycle.

(5) Press the exposure button and hold it

down while observing the exposure meter. The

readings must compare to the specications

shown in the Standards paragraph at the end

of this section. (When the exposure is released,

the meters will automatically reset.)

(6) Observe teh BATTERY DRAIN meter. The

reading should be according to specications.

This test applies only to the rst exposure of

series.

(7) Release the exposure button actuator. All of

the meters will reset automatically.

(8) Repeat steps 5 through 7 twice ( a total of

three times). The exposure readings observeted

must be within specications.

(9) Move the light level selector to 6.25. Repeat

steps 5 through 7. The reading must agree with

specications.

(10) Move the light level selector to 800. Repeat

steps 5 through 7. All readings must agree with

specications.

(11) Recycle the camera by removing it from the

horn and then reinstalling it on the horn. This is

necessary for the next portion of the testing.

c. Flash Circuit and S9 Mode Test

(1) Set 5.0 volts on the tester voltmeter. Set

light level at 6.25 and close S2.

(2) Press the exposure button. The numbere

one READY lamp will go off and the number the

number one FLASH indicator lamp will light.

(3) Press and release the exposure button four

more times. The READY lamps should go off

and the FLASH indicator lamps should light in

numerical sequence each time hte exposure

button is pressed.

(4) Press and release the RESET button on the

ash simulator assembly.

(5) Press and release the exposure button ve

Page 37

more times. The READY and FLASH indicator

lamps should sequence as in step 3.

camera using a square of cardboard or other

material.

(6) On the ash simulator assembly, press and

release the RESET button.

(7) Press the exposure button actuator. The

number one READY indicator lamp should

remain lighted and the number one FLASH

indicator should not light. (Checks S9.)