Laboratory Airflow Monitors & Controls

TYPE C STANDARD &

NIGHT SETBACK

LED & DIGITAL - VAV SYSTEMS

Specifications and Owner’s Manual

PLASTEC® VENTILATION, INC.

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

Laboratory Airflow Monitors & Controls

TYPE C STANDARD & NIGHT SETBACK

LED & DIGITAL - VAV SYSTEM

General Description

BENEFITS

• Safety: air flow is maintained at required speed at

all sash heights

• Energy savings: only the lowest required amount of

air is exhausted therefore reducing energy bill

• User comfort: Low air speeds ensure comfortable

noise level

• Ease of installation and maintenance

• Stable and accurate analogical sensor reading

• Attractive design: available in choice of LED or

digital display

RANGE

Versions:

• C LED: Monitors and controls air speed, LED lights

• C DIGITAL: Monitors and controls air speed, digital

read out in meter per second or feet per minute

FEATURES

• Audio and visual alarm

• 0 to 10V or 4-20mA VAV system to link to inverter

• 3 Pushbuttons: Fan On/Off, Light On/Off, Mute

• Automatic pre-purge with inverter

• 30s purge following fan switch off

• Alarm disabled when fan switch off

• Sash High indicator

• Auxiliary contact for fan make up, etc.

OPTIONS

• Surface Box Mounting: Plastic enclosure to mount

the face plate and to avoid profile cutting the

service panel.

• Alarm Relay: A remote alarm can be triggered from

a relay on the controller pcb.

• Battery Back Up: Red LED alarm is still

functional up to 12 hours when unit loses power.

• Custom Resin Stickers: Customizable resin

stickers with logo, address, etc.

INTERNATIONAL STANDARDS

COMPLIANCE

In accordance with:

- European laboratory standard EN 14175-2

- Electromagnetic standards EN

61326 : 1997/A1 : 1998/A2 : 2001/A3 : 2003

(Test report RC-05-42060-1) US FCC Part 15

Class B edition 2005 (Test report RC-05 42060-2-A)

- European RoHS directive governing disposal and

recycling of electronics

- French laboratory standard XPX 15203 of Sept. 1996

- CE

COMPONENTS

• Circuit Board: Panel mounted circuit board to

be installed vertically or horizontally onto fume

cupboard with 2x Ø 2.8 mm / 0.11" screws. IP55

protection ensured by “O” ring seal. Face plate to

be supplied with chemical resistant plastic sticker

(horizontal or vertical) with control/push buttons

on fascia. Surface box mounting optional.

• Numerical and Antistatic Sensor: To be installed

inside fume hood. Sensor measures air speed

variations inside fume hood. Supplied with a

3.5 m / 11.48' (5 m optional) shielded cable with

pin connections onto controller circuit board.

• Power Supply: 115 VAC to 12 VDC power

transformer directly into controller circuit board.

Comes with a wall plug and cord. Adaptor may be

required to fit local power socket.

COLORS

Plastic fascia is available in:

- White (Standard)

PACKING

• Supplied in cardboard box which includes con-

troller circuit board, face plate, sensor and power

transformer. Surface box mounting optional.

2

Laboratory Airflow Monitors & Controls

TYPE C STANDARD & NIGHT SETBACK

LED & DIGITAL - VAV SYSTEM

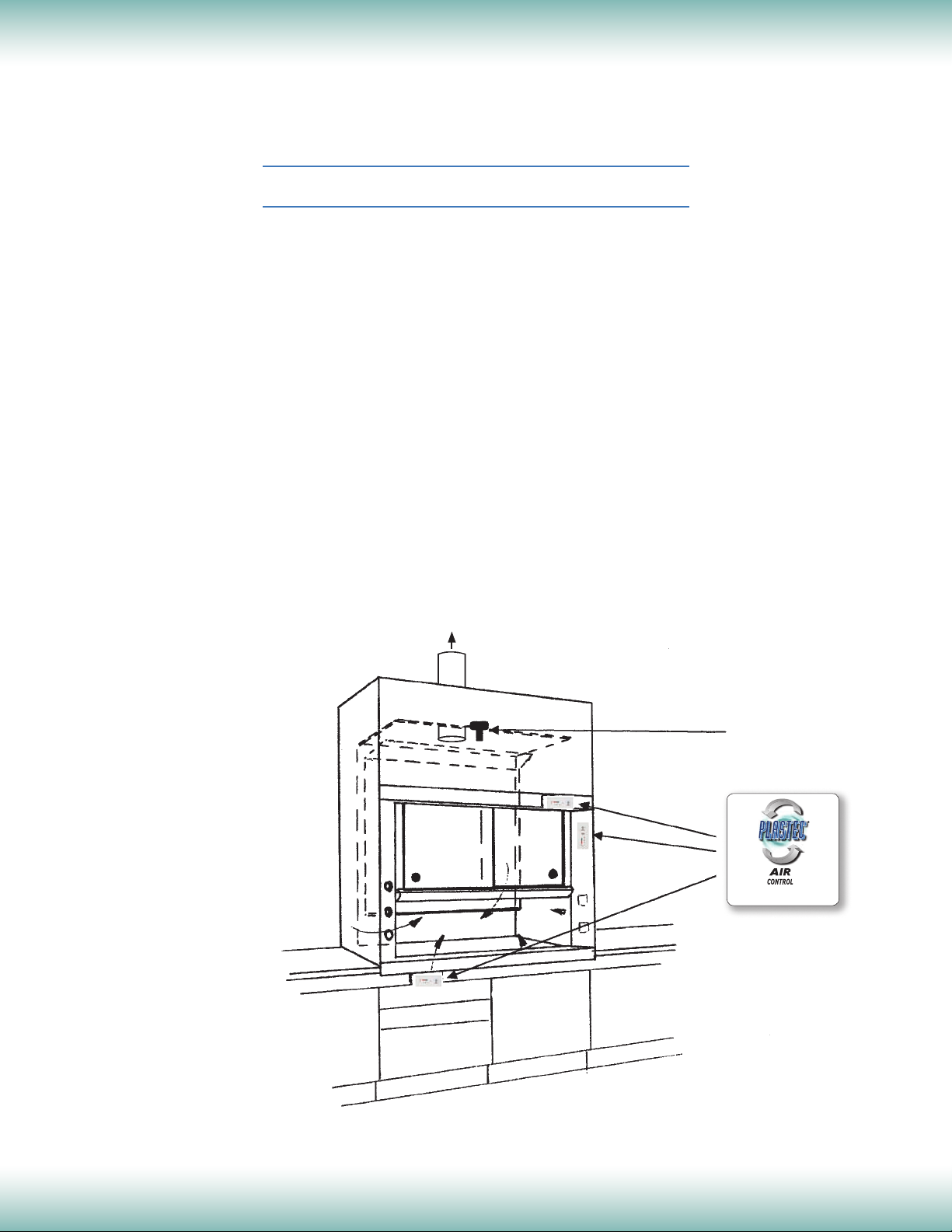

Operating Principle

When the fume extraction fan is running, it causes negative pressure inside

the fume cupboard. If the sash is lowered, the negative pressure become more

intense causing air to be drawn through the sash opening at an increased velocity.

Conversely, if the sash is raised the negative pressure becomes less intense and air

velocity reduces.

If an opening is made in the wall of the fume cupboard, air will enter it at a

velocity determined by the same negative pressure that is drawing air into the

sash opening. By sensing the air velocity through an opening, we can determine

its level at the sash opening.

PLASTEC

or thermal anemometer into a hole in the cupboard and sending the air velocity

measurement obtained to a display on the fascia panel. Based on air velocity

measured, Plastec

or decrease fan speed.

The air velocity level is displayed on the fascia either by LED illumination or

digital read-out. An audible alarm will also sound if the air velocity is too low.

®

AirControl Type C exploits this by the placing of a numerical sensor,

®

AirControl C will send a signal to an inverter to either increase

SENSOR

Airflow Monitor

www.plastecvent.net

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

3

Controller

Sensor

Laboratory Airflow Monitors & Controls

TYPE C STANDARD

LED & DIGITAL - VAV SYSTEM

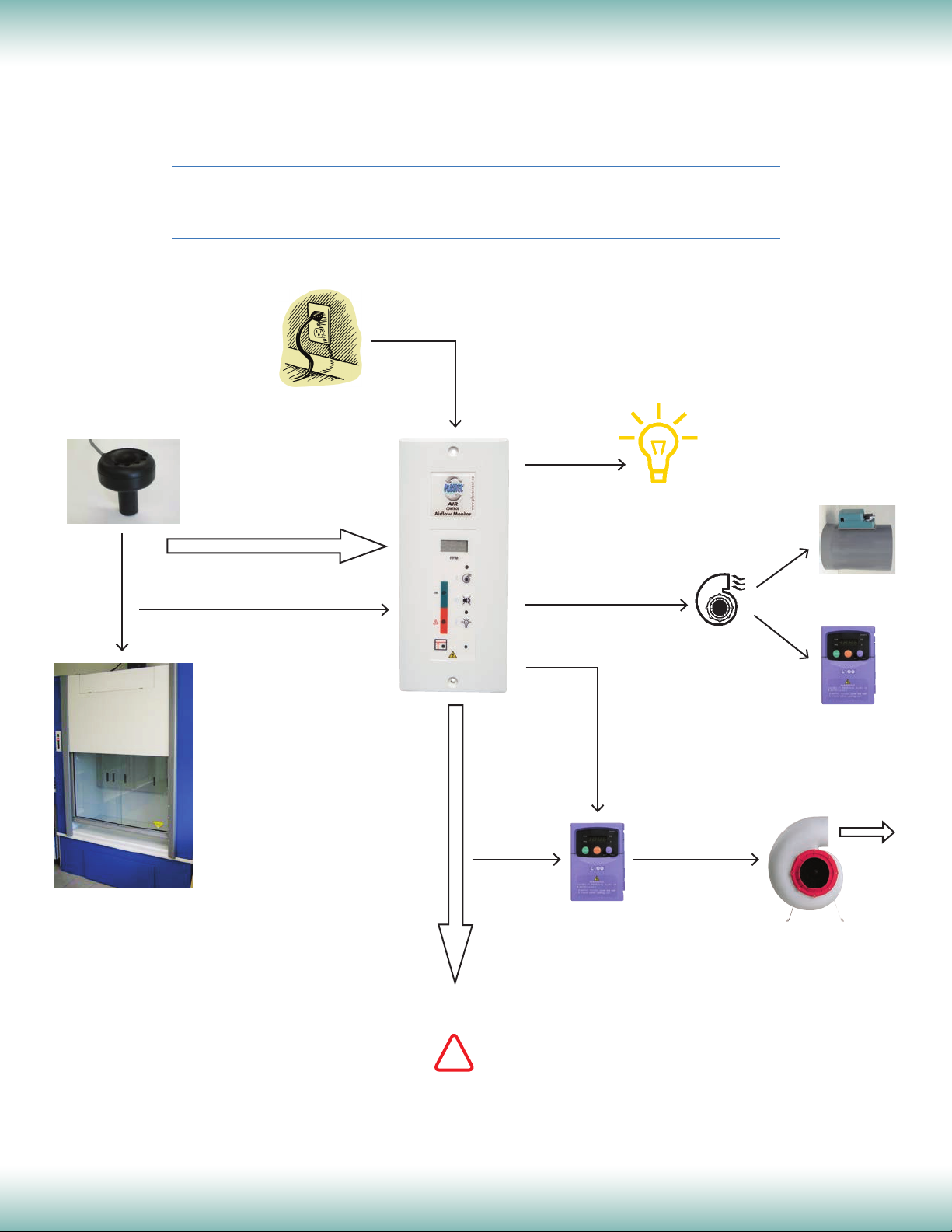

Schematic AirControl C LED & Digital

Inverter System

115 VAC /12 VDC

Power Supply

Hood Light

on/off relay

Sensor

Signal Input

Air Make-up

on/off relay

Sash High Alarm Input

0 to 10V or 4-20mA

OR

Motorized

Damper

Sash movement

=

Pressure decrease

or increase

OUTPUT:

0 to 10V

or

4-20mA

Air speed

monitoring & control

!

If air speed is low

Fan on/off

relay

Frequency Inverter

230V – 1Ph input

Make-up

Fan

Frequency

Inverter

230V – 3Ph

Plastec® Extraction

Fan: Speed increase

or decrease

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

4

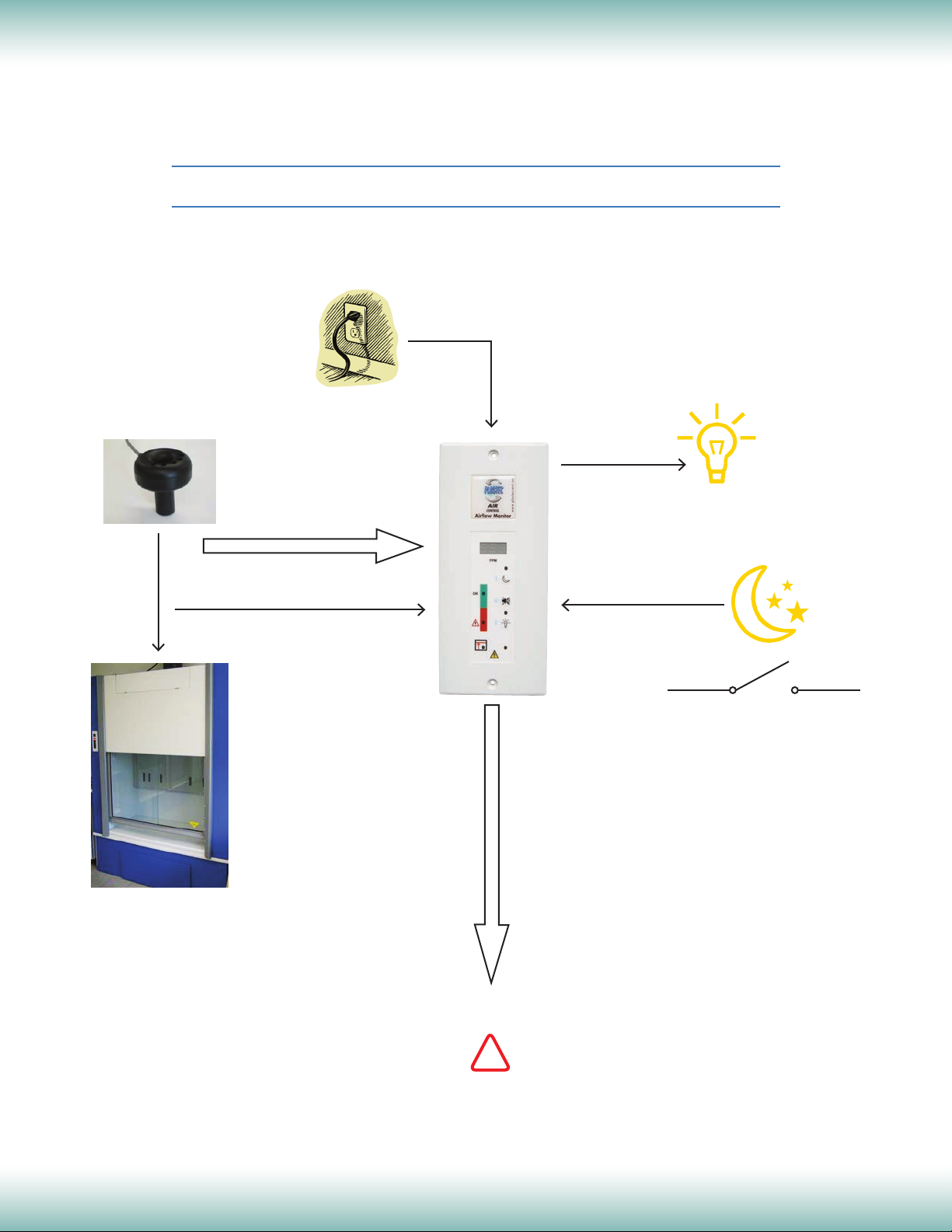

Laboratory Airflow Monitors & Controls

TYPE C NIGHT SETBACK

LED & DIGITAL - VAV SYSTEM

Schematic AirControl C Night Setback

115 VAC /12 VDC

Power Supply

Controller

Sensor

Sensor

Signal Input

Hood Light

on/off contact

Sash movement

=

Pressure decrease

or increase

Sash High Alarm Input

Night Setback relay

OUTPUT

Air speed

monitoring & control

!

If airflow is low

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

5

Laboratory Airflow Monitors & Controls

TYPE C STANDARD

LED & DIGITAL - VAV SYSTEM

Specifications

AirControl C LED

Part Number 819703 819704

1 green LED for normal air speed 1 green LED for normal air speed

Display – Visual 1 red LED flashing for alarm "HI" for high air speed displayed

No digital display 1 red LED flashing for alarm

3 digit display with velocity reading

Units

Display Range N/A 0 - 2.00 m/s / 0 - 400 FPM

Alarm Setpoint

Alarm Delay Selectable: 15s or 30s Selectable: 15s or 30s

Analog Output 0 - 10V or 4 - 20mA 0 - 10V or 4 - 20mA

Standard: below 0.39m/s / 78 FPM Standard: below 0.39m/s / 78 FPM

N/A meter per second (m/s) / FPM

AirControl C Digital

Alarm Indication

Alarm Mute

Light On/Off

Fan On/Off

Alarm Relay

Battery Back Up

Sash High Input

sash position switch has been tripped sash position switch has been tripped

Mounting Flush or surface box (option) Flush or surface box (option)

Calibration

Power Requirement 12VDC (power supply included) 12VDC (power supply included)

Orientation Vertical/Horizontal Vertical

Front fascia: 210L x 90W x 10D mm Front fascia: 210L x 90W x 10D mm

Monitor Dimensions (metric)

Front fascia: 8.27"L x 3.54"W x 0.39"D Front fascia: 8.27"L x 3.54"W x 0.39"D

Monitor Dimensions (U.S.)

Surface box: 8.07"L x 3.35"W x 0.55"D Surface box: 8.07"L x 3.35"W x 0.55"D

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

1 red LED flashing & audible buzzer 1 red LED flashing & audible buzzer

Yes, optional Yes, optional

Yes, optional Yes, optional

Audible and orange flashing LED indicate Audible and orange flashing LED indicate

Factory pre-calibrated @ 0.5m/s / 100 FPM

Recalibration possible Recalibration possible

Surface box: 205L x 85W x 14D mm Surface box: 205L x 85W x 14D mm

Factory pre-calibrated @ 0.5m/s / 100 FPM

5

6

Laboratory Airflow Monitors & Controls

TYPE C NIGHT SETBACK

LED & DIGITAL - VAV SYSTEM

Specifications

AirControl C LED

Part Number 819703 819704

1 green LED for normal air speed 1 green LED for normal air speed

Display – Visual 1 red LED flashing for alarm 1 red LED flashing for alarm

No digital display 3 digit display with velocity reading

Units

Display Range N/A 0 - 2.00 m/s / 0 - 400 FPM

Alarm Setpoint

Alarm Delay Selectable: 15s or 30s Selectable: 15s or 30s

Analog Output 0-10V 0-10V

Alarm Indication

Standard: below 0.39m/s / 78 FPM Standard: below 0.39m/s / 78 FPM

1 red LED flashing & audible buzzer 1 red LED flashing & audible buzzer

N/A meter per second (m/s) / FPM

AirControl C Digital

Alarm Mute

Light On/Off

Night Setback On/Off

Alarm Relay

Battery Back Up

Sash High Input

sash position switch has been tripped sash position switch has been tripped

Mounting Flush or surface box (option) Flush or surface box (option)

Calibration

Power Requirement 12 VDC (power supply included) 12 VDC (power supply included)

Orientation Vertical/Horizontal Vertical

Front fascia: 210L x 90W x 10D mm Front fascia: 210L x 90W x 10D mm

Monitor Dimensions (metric)

Front fascia: 8.27"L x 3.54"W x 0.39"D Front fascia: 8.27"L x 3.54"W x 0.39"D

Monitor Dimensions (U.S.)

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

Audible and orange flashing LED indicate Audible and orange flashing LED indicate

Factory pre-calibrated @ 0.5m/s / 100 FPM

Surface box: 205L x 85W x 14D mm Surface box: 205L x 85W x 14D mm

Surface box: 8.07"L x 3.35"W x 0.55"D Surface box: 8.07"L x 3.35"W x 0.55"D

Yes, optional Yes, optional

Yes, optional Yes, optional

Factory pre-calibrated @ 0.5m/s / 100 FPM

Recalibration possible Recalibration possible

5

7

Laboratory Airflow Monitors & Controls

TYPE C STANDARD & NIGHT SETBACK

LED & DIGITAL - VAV SYSTEM

Specifications

MONITOR & MOUNTING BOX

Mounting Box

35 mm / 1.38"

24 mm / 0.94"

90 mm / 3.54"

210 mm / 8.27"

Face Plate

Ø 2.8 mm / 0.11"

PANEL CUTOUT DIMENSION

17 mm / 0.67"

7.5 mm / 0.30"

NOTE: All dimensions in mm / inches

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

SENSOR

65 mm / 2.56"

28 mm / 1.10"

Cable L = 3.5m /

137.76” (11.48')

40 mm / 1.57"

Ø 22 mm / 0.87"

8

Laboratory Airflow Monitors & Controls

Front plate/fascia

Customizable

Resin Sticker

TYPE C STANDARD

LED & DIGITAL - VAV SYSTEM

Overall View

Chemical and pressure

resistant sticker

Digital display.

Not applicable on

LED version

“HI” displayed:

Airow too high

One green LED lit up:

Airow OK

Flashing red LED for

alarm: air speed too low

Sash high LED. Starts

ashing when sash

position switch has

been tripped

LED fan on/off indicator

If fan on, LED orange

Fan on/off push button

Alarm Mute push button

LED light on/off indicator

If light on, LED orange

Light on/off push button

Calibration LED. Should

be off when calibration is

completed

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

9

7

Laboratory Airflow Monitors & Controls

TYPE C NIGHT SETBACK

Front plate/fascia

Customizable

Resin Sticker

LED & DIGITAL - VAV SYSTEM

Overall View

Chemical and pressure

resistant sticker

Digital display

in m/s or fpm

“HI” displayed:

Airow too high

One green LED lit up:

Airow OK

Flashing red LED for

alarm: air speed too low

Sash high LED. Starts

ashing when sash

position switch has

been tripped

Night Setback on/off

indicator. If LED lit up,

night setback is on.

Alarm cannot sound

Alarm Mute on/off

push button

LED light on/off indicator

If light on, LED orange

Light on/off push button

Calibration LED. Should

be off when calibration is

completed

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

10

Laboratory Airflow Monitors & Controls

TYPE C STANDARD & NIGHT SETBACK

LED & DIGITAL - VAV SYSTEM

Contacts & Features

Contact Light On/Off Control

220v 3A

VENT1: Fume fan to

Alarm Relay

220v 3A

(optional)

inverter ‘run’ relay

VENT2: Make-up fan

220v 3A

Power Supply:

115 VAC /12 VDC input

Resistance to be cut

for night setback use

Sash High Contact

0-10V signal to link to

inverter control

Reset

Sensor Connection

Settings:

1. On: Alarm always active

Off: Alarm disabled when fan is off

2. Alarm delay setting:

On: 30 seconds

Off: 15 seconds

Auxiliary contact or

Night setback contact

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

Battery back up

Rechargeable (optional)

ON

OFF

11

5

Laboratory Airflow Monitors & Controls

TYPE C STANDARD & NIGHT SETBACK

LED & DIGITAL - VAV SYSTEM

Installation, Calibration & Alarm Test

INSTALLATION

1) Drill a Ø 23mm / 0.91" hole either in the top or side of the fume cupboard to allow sensor

positioning. Make sure sensor is not in a turbulent zone where the pressure can fluctuate but

where it can monitor stable changes in pressure. Attention should be paid to dead zones near

the top of the fume cupboard.

2) Proceed with wiring as seen on page “Contacts & Features”.

3) Position and secure monitor to service panel of the fume cupboard with the two self-tapping

screws supplied. Do not forget to position “O” ring seal into the moulded groove in the back of

the face plate.

CONTROLLER SET UP PROCEDURE

All monitors unless indicated otherwise are factory pre-calibrated at 0.5 m/s or 100 FPM. If you need a

different sensor calibration and/or displayed speed reading:

1) Make sure that controller is properly linked to inverter and that the ventilation is working. You

need an anemometer to do this set up.

2) Push

or

LED is on and the red LED is flashing indicating controller is in manual set up mode.

3) Raise the fume cupboard to its test height e.g. 500mm/19.69".

4) Push

is reading required air speed. Every button press increases or decreases the speed of 0.5V

producing one beep.

The maximum value is 10V, the minimum is 0.3V.

For model without digital display (819703), please go directly to step 6.

5) For digital display model (819704), press “Reset” button at the back of the controller to change

the required speed display from 0.3 m/s/59 FPM to 0.7 m/s /138 FPM, using

value will be memorized as the set point.

6) Wait for 15 seconds or so for air speed to stabilize.

7) To return to “AUTO” mode, push

the green LED is illuminated: new calibration (above or equal at 0.2 m/s) is accepted.

for more than 5 seconds, then release and push simultaneously

for Night Setback

or

to increase or to decrease

within the following 5 seconds. Buzzer sounds twice, the green

the fan speed via the inverter until the anemometer

again until the buzzer beeps 3 times (about 3 seconds) and

for Standard

and

. The

This is automatically done after 7 minutes in manual mode.

The buzzer beeps 10 times in case of incorrect calibration.

All updated information is stored in an internal memory which saves and holds the data even in case of power cut.

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

12

5

Laboratory Airflow Monitors & Controls

TYPE C STANDARD & NIGHT SETBACK

LED & DIGITAL - VAV SYSTEM

Installation, Calibration & Alarm Test

VELOCITY TYPE

To change Digital readout from/to m/s to FPM:

Press simultaneously the following buttons:

until buzzer sounds (about 5 seconds).

DISPLAY MESSAGES

The display will show “HI” for an airflow superior to 1 m/s / 96 FPM and “LO” for an airflow inferior to

0.20 m/s / 40 FPM.

In case of faulty, improper or absent sensor, the display will show “PB”.

FACTORY DATA RESET

Press “Reset” (at the back of the controller) for 15 seconds. Buzzer sounds 5 times.

When using this feature, you restore factory default settings: set point and display at 0.5 m/s / 100

FPM, 7V output to the inverter and all relays and LEDs deactivated.

This operation should be imperatively done in “Auto” mode.

TEST MODE

Test mode is to confirm that all functions are operational. To access test mode, follow this procedure:

1) Press simultaneously following buttons:

* Buzzer sounds twice

2) Press the 3 buttons alternately.

* Buzzer sounds 10 times if malfunction

In case of faulty sensor, the display will show “PB”.

* Buzzer sounds 3 times indicating normal operating mode

for 2 seconds for Night Setback

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

for 2 seconds for Standard or

13

5

Laboratory Airflow Monitors & Controls

TYPE C STANDARD & NIGHT SETBACK

LED & DIGITAL - VAV SYSTEM

Maintenance, Troubleshooting & Warranty

MAINTENANCE

Front plate and stickers of airflow monitor may be cleaned with mild soap and water on a damp

cloth to remove finger marks, oils and residue. Do not use abrasives. Do not allow liquids to enter

the plastic casing. Dry the monitor thoroughly after cleaning.

TROUBLESHOOTING

PROBLEM CHECK

No indicators Power supply may not be plugged into AC supply.

Improper alarm setpoint Airflow sensor is factory precalibrated at 0.5 m/s or 100 FPM.

Alarm setpoint may not be accurate if sensor is not properly

located. Sensor needs to be recalibrated if setpoint is different than

0.5 m/s or 100 FPM. Follow Sensor Recalibration Procedure on

page 6.

Alarm is too sensitive, Change alarm delay setting to 15s or 30s if already set to 0. See

buzzer rings often for contact & features section.

short periods of time

WARRANTY

PLASTEC® Ventilation, Inc. warrants its equipment, products and parts, to be free from defects in

workmanship and material under normal use and service for one year after delivery to the first

user. Product must be returned to point of purchase, with dated bill of sale, within one year of

purchase. If factory return is required, please contact distributor first.

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

14

5

Loading...

Loading...