Plastec Junior Air Control User Manual

Laboratory Airflow Monitor

TYPE JUNIOR

Owner’s Manual and Technical Specifications

PLASTEC® VENTILATION, INC.

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

Laboratory Airflow Monitor

TYPE JUNIOR

General Description

BENEFITS

• Safety: in accordance with latest EU

laboratory standard EN 14175

• Ease of installation and maintenance

• Stable and accurate sensor reading

• Attractive design

FEATURES

• Audio alarm

• 1 Push button: Mute

COLORS

Plastic fascia is available in white standard

color.

INTERNATIONAL STANDARDS

COMPLIANCE

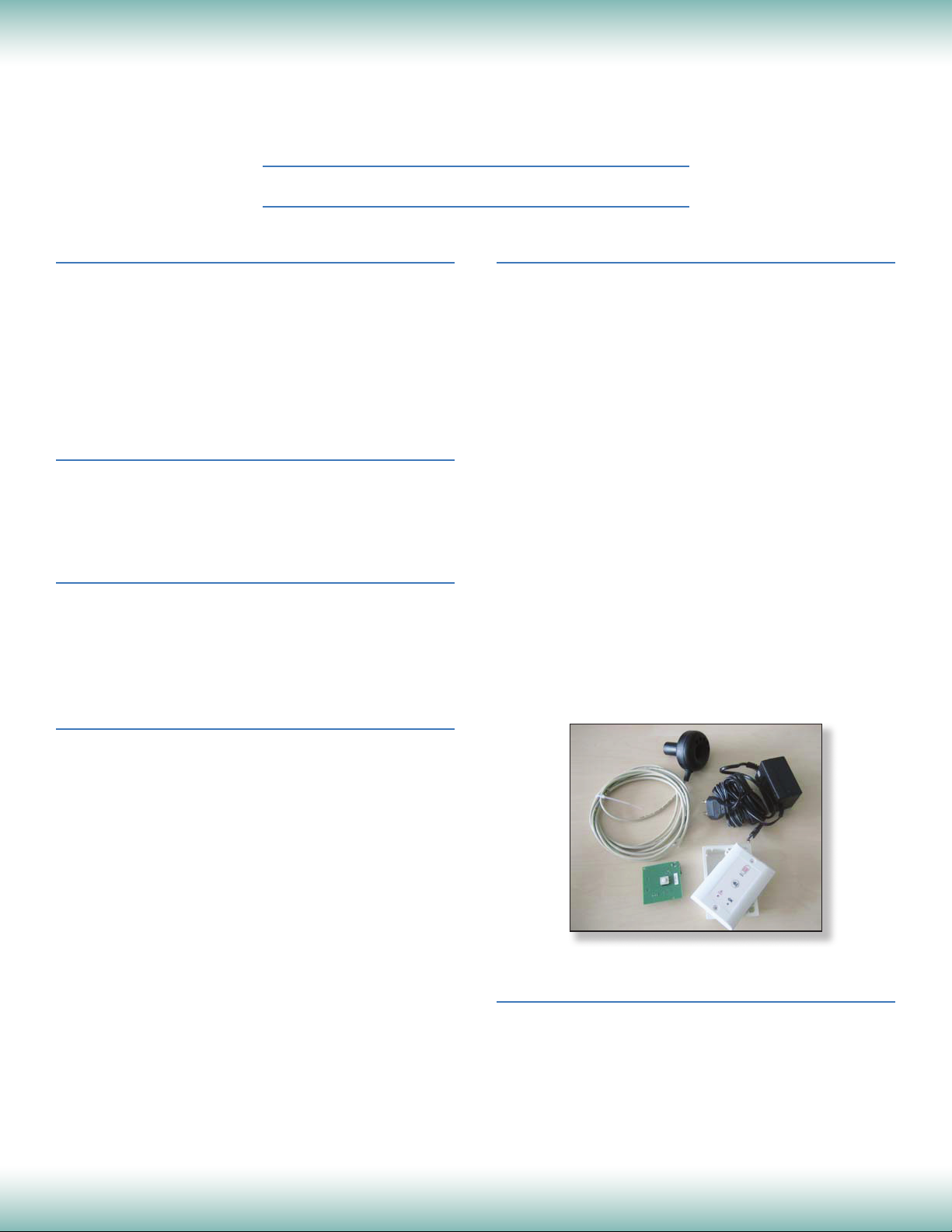

COMPONENTS

• Circuit Board:

Panel mounted circuit board to be installed

vertically onto fume cupboard with 2x Ø

2.8 mm / 0.11" screws. IP55 protection

ensured by “O” ring seal. Face plate to be

supplied with chemical resistant plastic

sticker (vertical) with control/push buttons

on fascia. Surface box mounting included.

• Sensor:

To be installed inside fume hood. Sensor

measures air speed variations inside fume

hood. Supplied with a 3.5 m / 11.48'

shielded cable with pin connections onto

controller circuit board.

• Power Supply:

115 VAC to 12 VDC power transformer

directly into controller circuit board. Comes

with a wall plug and cord. Adaptor may be

required to fit local power socket.

In accordance with:

- European laborator standard EN 14175-2

- Electromagnetic standards EN

61326 : 1997/A1 : 1998/A2 : 2001/A3 : 2003

(Test report RC-05-42060-1) US FCC Part 15

Class B edition 2005 (Test report RC-05 42060-2-A)

- European RoHS directive governing disposal

and recycling of electronics

- French laboratory standard XPX 15203 of

Sept. 1996

- CE

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

PACKING

• Supplied in cardboard box which includes

controller circuit board, face plate, sensor

and power transformer.

2

Laboratory Airflow Monitor

TYPE JUNIOR

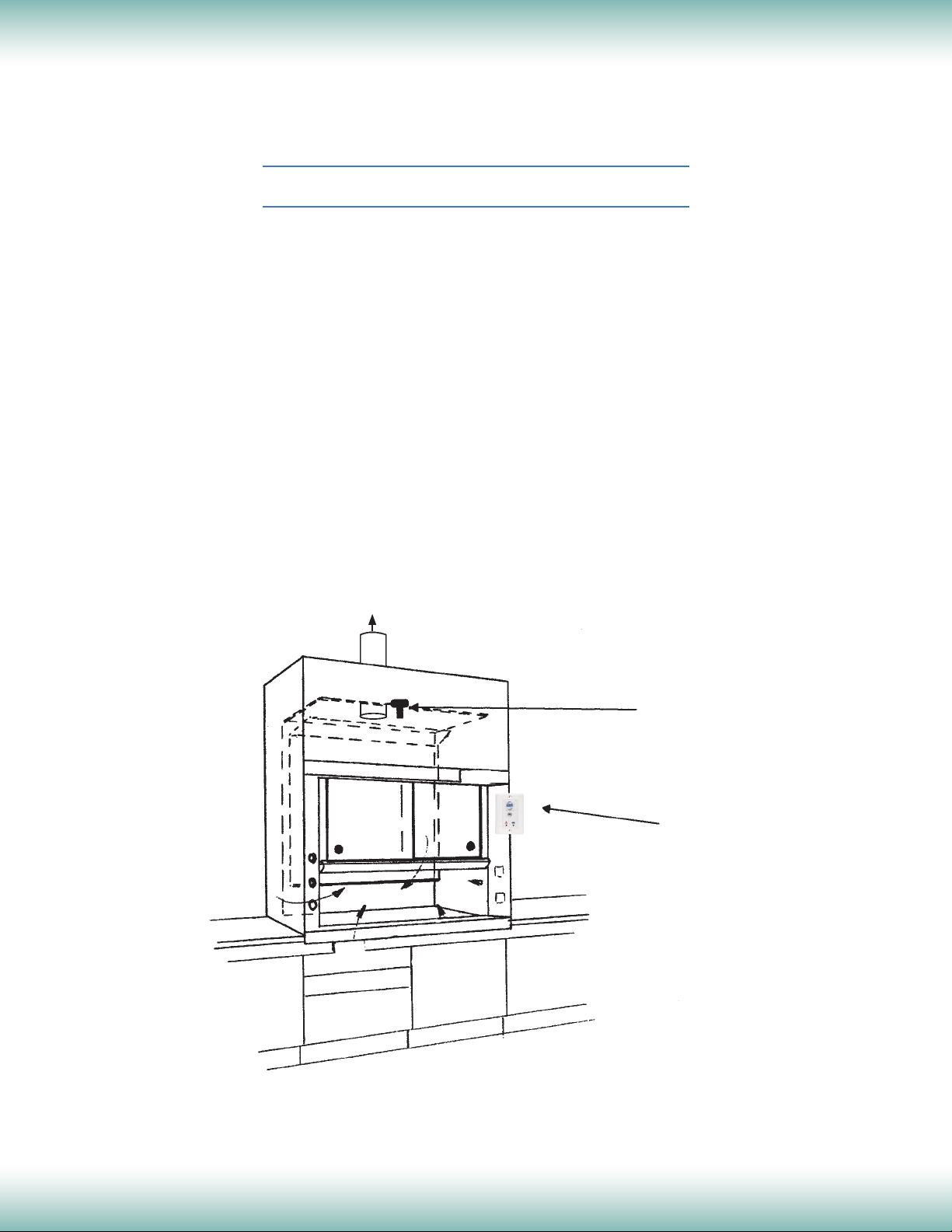

Operating Principle

When the fume extraction fan is running, it causes negative pressure inside

the fume cupboard. If the sash is lowered, the negative pressure becomes

more intense causing air to be drawn through the sash opening at an increased

velocity. Conversely, if the sash is raised, the negative pressure becomes less

intense and air velocity reduces.

If an opening is made in the wall of the fume cupboard, air will enter it at a

velocity determined by the same negative pressure that is drawing air into the

sash opening. By sensing the air velocity through an opening, we can determine

its level at the sash opening.

PLASTEC® AirControl exploits this by the placing of a numerical sensor, or

thermal anemometer, into a hole in the cupboard and sending the air velocity

measurement obtained to a display on the fascia panel.

The air velocity level is displayed on the fascia by LED illumination. An audible

alarm will also sound if the air velocity is too low.

SENSOR

PLASTEC

JUNIOR

AIRCONTROL

®

2216 60th Drive East • Bradenton, Florida 34203

(941) 751-7596 • Fax (941) 751-7598 • www.plastecvent.net

3

Loading...

Loading...