Pitney Bowes DA80F, DA95F, WF81, WF96 Service Manual

DA80F and DA95F

AddressRight™ Fixed Head Printers

DA80F (WF81)

DA95F (WF96)

Service Manual

FCC Compliance

This equipment had been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy, and if not installed and used in accordance

with the users manuals, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Shielded cables must be used with this unit to insure compliance with Class A limits.

Canadian DOC Compliance

This digital apparatus does not exceed in the Class A limits for radio noise emissions from digital ap-

paratus set out in the Interference-causing Equipment Regulations (Standard ICES-003) of the Canadian Department of Communications.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant les limites applicables aux appareils numeriques de la class A prescrites dans le Reglement sur le brouillage radioelectrique edicte par le ministere des Communications du Canada.

NOTE: This equipment has been tested and found to comply with the U.S. Standard for Safety

UL1950, Third Edition, Safety of Information Technology Equipment including Electrical Business

Equipment and Canadian Standards C22.2 No 950-95, Third Edition, Safety of Information Technology Equipment including Electrical Business Equipment

First Edition, December 2007

SV61962 Rev. A

©2007 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part in any fashion or stored in a

retrieval system of any type or transmitted by any means, electronically or mechanically, without the

express written permission of Pitney Bowes Inc.

We have made every reasonable effort to assure the accuracy and usefulness of this manual, however, we cannot assume responsibility for errors or omissions or liability for the misuse or misapplication of our products.

Table of Contents

Chapter 1 – Introduction

1.1 Purpose of this Manual .............................................................. 1-1

1.2 Related Publications .................................................................. 1-1

1.3 Book Organization ..................................................................... 1-2

1.4 Safety ........................................................................................ 1-2

Chapter 2 – Specifi cations

2.1 Product Description ................................................................... 2-1

2.2 System Requirements ............................................................... 2-1

2.3 Physical Equipment Specifications ............................................ 2-2

2.4 Print Specifications .................................................................... 2-3

2.5 Material Specifications............................................................... 2-7

Chapter 3 - Theory

3.1 Changes From Earlier Models .................................................. 3-1

3.2 Printer Architecture .................................................................... 3-2

3.3 Operating Sequence.................................................................. 3-6

Chapter 4 - Troubleshooting/Diagnostics

4.2 Block Diagrams ........................................................................ 4-2

4.3 Main Controller Board Diagnostics ........................................... 4-4

4.4 Error Codes ............................................................................... 4-9

4.5 Print Samples for Troubleshooting .......................................... 4-12

4.6 Feeding Issues ........................................................................ 4-14

4.7 Printing Issues ......................................................................... 4-19

4.8 Display Issues ......................................................................... 4-23

4.9 Miscellaneous Issues .............................................................. 4-23

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

iii

Table of Contents

Chapter 5 - Removal & Replacement

5.1 List of Procedures...................................................................... 5-1

DA80F (WF81) Parts Removal

5.2 Rear Cover and Keyboard/LCD Display Board ......................... 5-3

5.3 Main Processor Board ............................................................... 5-4

5.4 Encoder Assembly .................................................................... 5-6

5.5 Paper Top Sensor Assembly (Emitter) ...................................... 5-9

5.6 Paper Bottom Sensor Assembly (Receiver) .............................. 5-9

5.7 Feeder Sensor Assembly (Emitter and Receiver) ................... 5-10

5.8 Front Bottom Cover Assembly ..................................................5-11

5.9 Transport Timing Belt .............................................................. 5-12

5.10 Feed Motor Timing Belt ......................................................... 5-13

5.11 Feed Roller Pulley and Feed Roller Assembly ...................... 5-14

5.12 Feed Motor Assembly and Encoder Harness Assembly........ 5-16

5.13 Transport Motor Assembly ..................................................... 5-18

5.14 H-Block Assembly (Media Separators) .................................. 5-20

5.15 Print Head Cables and Print Head Boards ............................ 5-21

5.16 Entry Idler Roller Arm ............................................................ 5-28

5.17A Feed Deck ............................................................................ 5-30

5.17B Front Plate Assembly ........................................................... 5-32

5.18 Transport (Metal Grit) Roller .................................................. 5-34

5.19 Exit (Rubber) Roller ............................................................... 5-35

5.20 Power Supply ........................................................................ 5-36

5.21 Print Head Access Door ........................................................ 5-38

DA95F (WF96) Parts Removal

Standard Feeder (WF9S)

5.22 Rear Cover/Side Guides ....................................................... 5-39

5.23 Lower Sensor Receiver Assembly ......................................... 5-41

5.24 Feeder Top Sensor (Emitter) Assembly ................................. 5-42

5.25 “H Block” Roller (Media Separator) ...................................... 5-43

5.26 Feed Belts and Rollers .......................................................... 5-44

5.27 Motor/Drive Assembly............................................................ 5-46

iv DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

Table of Contents

Chapter 5 - Removal & Replacement (continued)

DA95F (WF96) Parts Removal

Printer Section

5.28 Printer Top Cover ................................................................... 5-48

5.29 Front Cover and Keyboard/LCD Display Board..................... 5-49

5.30 Rear Cover and Processor Board ......................................... 5-51

5.31 Paper Sensor and Sensor Bar............................................... 5-54

5.32 Entry Roller Support Assembly .............................................. 5-55

5.33 Intermediate Idler Rollers Assembly ...................................... 5-56

5.34 Idler Roller Support (“Module A”) Assembly .......................... 5-57

5.35 Idler Roller Support (“Module B”) Assembly .......................... 5-58

5.36 Print Head Cables and Print Head Boards ............................ 5-59

5.37 Belt Drive Assembly............................................................... 5-67

5.38 Media Belts ............................................................................ 5-69

5.39 Encoder Assembly ................................................................. 5-71

5.40 Drive Belt/Motor Assembly .................................................... 5-74

5.41 Power Supply ........................................................................ 5-75

Chapter 6 - Adjustments

6.1 List of Adjustments ................................................................... 6-1

Adjustments for All Models

6.2 LCD Display .............................................................................. 6-2

6.3 Feeder Sensor Test and Calibration ......................................... 6-2

DA80F (WF81) Adjustments

6.4 Leveling the Print Head Assembly to Deck (Belts) .................. 6-3

DA95F (WF96) Adjustments

6.5 Leveling the Print Head Assembly to Deck............................... 6-5

6.6 Adjustable Thickness Knob and Eccentric Sprockets ................ 6-6

Chapter 7 - Maintenance Procedures

7.1 General Maintenance ................................................................ 7-1

7.2 Specific Maintenance ............................................................... 7-2

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

v

Table of Contents

Appendix A – Printer Control Panel Menus and Utilities

A.1 Control Panel Menus for the Printer ..........................................A-1

A.2 LCD Control Panel Menu .........................................................A-3

A.2 LCD Main Menu .......................................................................A-4

A.3 LCD Setup Menu ......................................................................A-9

A.4 LCD Service Menu ................................................................. A-19

A.5 Setting Factory Defaults (from LCD Menu) ............................. A-24

A.6 Updating Firmware .................................................................A-26

Appendix B – Printer Communications

B.1 Communication Scenarios ........................................................B-1

B.2 Troubleshooting Tables .............................................................B-4

B.3 Testing Printer Communications Within a Network ...................B-6

Appendix C – Schematics

Main Processor Board for Both Printers ...........................................C-2

DA80F (WF81) Printer Block Diagram .............................................C-3

DA95F (WF96) Printer Block Diagram .............................................C-4

Appendix D – Print Head Alignment

D.1 Reason for this Appendix ..........................................................D-1

D.2 Print Head Alignment Procedure...............................................D-2

Appendix E – Printing Standards

E.1 USPS® Delivery Point Barcode (DPBC) ...................................E-1

E.2 USPS® PLANET Code Barcode ...............................................E-3

Index ..........................................................................I-1

vi DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

1 • Introduction

1.1 Purpose of

this Manual

1.2 Related

Publications/

Information

This manual contains instructions for troubleshooting and site repair of DA80F

(WF81) and DA95F (WF96) AddressRight™ fixed head printers. It also includes

complete product specifications and a section on theory for training purposes.

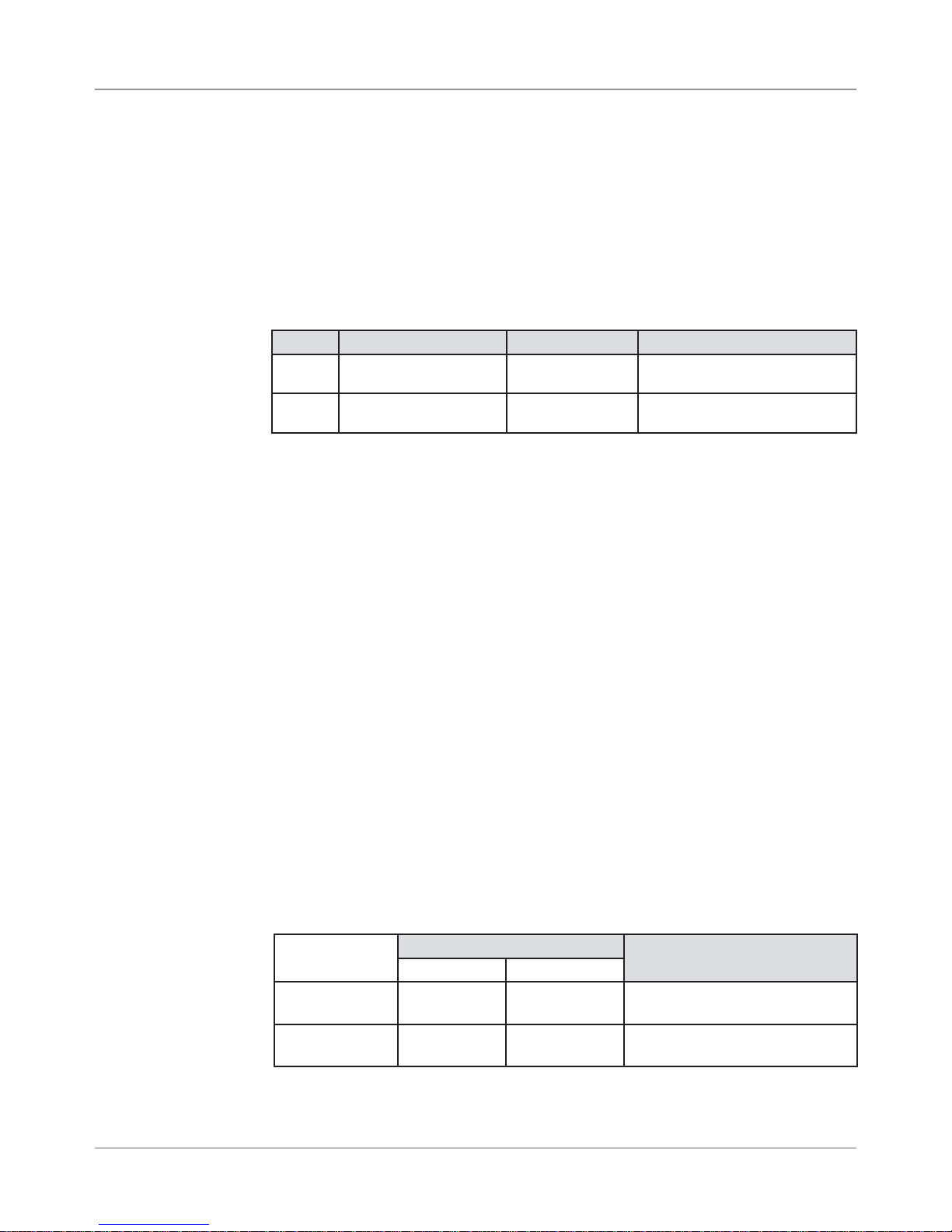

For reference, the table below shows the predecessor fixed head models.

New

Marketing

Model

DA80F WF81 Black and

DA95F WF96 Black and

DA80F Operator Guide SV61722

DA80F Parts List SV62033

DA95F Operator Guide SV61749

New

PCN

Printing

Capability

spot color

spot color

Speed Predecessor

Marketing

Model

Up to 22,000

#10 or DL

envelopes

per hour

Up to 30,000

#10 or DL

envelopes

per hour

DA400 W400

DA950 W803

Predecessor

PCN

DA95F Parts List SV62034

DA80/DA95F Hardware Install (US/Canada only) SV61747

DA80/DA95F Hardware Install (outside of US/Canada) SV61774

AddressRight Printer Drivers and

Envelope Designer™ Plus Software Install SV61108

Customer Tutorial for Setting up a DAxxx Series Printer

Using the AddressRight Printer Control Panel Application SV61986

For other information on the printers, refer to these sources:

• Software Control Panel Application (on the host PC) - see the help sys-

tem on the software.

• FAQs document - see the Customer Service website under the product

page for AddressRight™ printers.

• Training - see Enhanced AddressRight™ Fixed Head Printers Self-Directed Course (GMS-MC-03248) at My Portfolio on the Pitney Bowes intranet.

• Training Job Aids - print the job aids for the software control panel appli-

cation (GMS-MC-03248JA) at My Portfolio on the Pitney Bowes intranet.

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

1-1

1 • Introduction

1.3 Book

Organization

1.4 Safety

Chapter 1: Introductory and safety information

Chapter 2: Product specifications

Chapter 3: Theory of operation

Chapter 4: Troubleshooting and Diagnostics

Chapter 5: Removal and replacement procedures

Chapter 5: Adjustment procedures

Chapter 7: Maintenance procedures

Appendix A: Printer Control Panel Menus

Appendix B: Printer Communications

Appendix C: Schematics/Diagrams

Appendix D: Print Head Alignment

Appendix E: Printing Standards

Warning messages appear throughout this manual to alert you to potentially

hazardous con di tions. Two designations indicate their relative seriousness:

WARNING! Calls attention to improper practices that

could result in a potentially serious, even lethal injury to

you or the customer.

CAUTION! Calls attention to practices that could

cause minor injury to you or a customer or that could

damage equipment or material.

Familiarize yourself with proper procedures and methods before you install,

operate or re pair the equipment to avoid personal injury or damage to the

equipment. If you train service peo ple or equip ment operators, it is important to

explain safety precautions to your students and en cour age safety awareness.

Personal Safety

Follow these precautions for your own safety:

• Treat every circuit like a gun that may be loaded. It may not be “live,” but be

sure. Check with a neon tester or voltmeter, or simply unplug the machine.

• Know how to turn off power in the work area and get help in an emer gen cy.

• Don’t un der es ti mate the danger of shock: 1 mA (1/1000 amp) is un com fort able; 5 mA is dan ger ous —you may jump back and be injured; 12 mA

causes hand muscles to con tract, so you can not free your self; 24 mA has

proven fatal; and 100 mA (1/10 amp) is likely to be fa tal.

1-2 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

Introduction • 1

1.4 Safety

Personal Safety (continued)

• Don’t work on equipment under power unless it’s absolutely necessary.

If you must, use extreme cau tion. Don’t grasp two sides of a live circuit

at the same time—use one hand when reach ing into a cir cuit, touching

a ground ed case or chas sis with that wrist or el bow if pos si ble. This pre vents cur rent from passing through vital organs. Observe this rule when

con nect ing or dis con nect ing plugs or leads, or mak ing any adjustments

on a live cir cuit.

• Use the right tools for the job. A tool which slips can cause a short—or a

shock. Don’t reach into a circuit with metal tools, or while wearing rings or

a watch. Even in low voltage cir cuits, a metal object can short circuit two

terminals. When work ing on live cir cuits, use tools with in su lat ed handles

and try to keep your tool hand grounded.

• Don’t bypass safety devices, particularly fuses. Three-wire outlets (120

Vac) are designed to ground equipment to make it safe. If a hot wire

shorts to a grounded frame, the only result is an open fuse. If a hot wire

shorts to an ungrounded frame, the frame itself be comes hot and po ten tial ly dangerous. A fuse is a weak link in a circuit, de signed to break down

before any thing else does. The maximum safe cur rent in a circuit is de ter mined by the de sign ers. Too large a fuse can pass excessive current,

dam ag ing expensive equipment.

• For electrical fires, use Type C, BC or ABC extinguishers only. Don’t use

soda acid or other liq uid stream extinguishers. They will damage elec tri cal equipment and present a shock hazard to the user.

• Digital equipment can be easily damaged or destroyed by static charges.

Mi cro pro ces sors and other integrated circuits con tain tiny transistors not

much more than a mil lionth of an inch across, which operate at 5 to 12

volts.

• Be extremely careful when lifting heavy equipment. Follow the guidelines

below:

a. Squat to lift and lower. DO NOT bend at the waist.

b. Keep your low back bowed in while bending over.

c. Keep the weight as close to you as possible.

d. Bow your back in and raise up with your head first.

e. If you must turn, turn with your feet, not your body.

f. Never jerk or twist!

g. Put the weight down by keeping your low back bowed in.

h. Keep your feet apart, staggered if possible.

i. Wear shoes with non-slip soles.

j. Get help if you need it.

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

1-3

1 • Introduction

1.4 Safety

Electrostatic Discharge (ESD) Procedures

Follow these guidelines to protect sen si tive equipment from static damage:

• Always use a wrist grounding strap and anti-static mat when working on

equipment sensitive to electrostatic discharge. These items are furnished

in the ESD Field Service Kit, L-8351.

• Ground yourself before reaching into the equip ment, or touch ing any

circuit board or other electrical component. Just touch ing a doorknob or

metal work bench may be enough, but the best guarantee is to turn the

machine off but leave it plugged in, and ground your self on the chassis,

which is grounded through the three-wire power cord.

• Be careful of rugs—even a few steps can recharge you. Re-ground yourself whenever you’ve walked away and re turned to the ma chine. Rugs

are a major source of static build up in the body.

• Take greater precautions as the objects you handle get smaller. A board

in the machine is better protected than one that is not plugged in; a chip

on a board is better protected than one in your hand.

• Stay away from metal conductors. The plastic and resin that chips and

boards are made of are much better insulators than metal. It’s most important to keep your hands away from any metal which contacts the data.

In particular, this means the long connector along the bottom of each

board, and the pins coming out of the chips. These signal and data lines

are directly connected to the fragile inner circuits of the chips. When handling a board, try not to touch the connector; when handling a chip, try

not to touch the pins.

1-4 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

2 • Specifications

2.1 Product

Description

2.2 System

Requirements

The DA80F (WF81) and DA95F (WF96) ink jet printers are fixed head type

desktop models used to print addresses, graphics and other information, in

black ink and spot color on a wide range of material sizes, construction and

composition. The operator can define the font, placement, print quality and bar

code characteristics for the printed addresses.

Customer PCs must meet the following minimum requirements:

• CPU: Pentium III 500MHz. or greater, 500MB RAM or more preferred

• USB Cable/Ethernet Cables cable are supplied with the printer. If the

customer chooses to use another USB cable, it must be no longer than

15 feet (5 meters).

• Windows 2000 SP4, Windows XP Pro SP2, Windows Server 2003 SP1

w/latest Service Pack, and Windows Vista

• Dot Net v2.0

• 5MB Disk space

• Administrative rights to install software

2.3 Physical

Equipment

Specifications

Physical Dimensions

DA80F

17.9" (455mm) high; 18.5" (470mm) wide; 17.7" (450mm) deep

DA95F:

15” (380mm) high; 24” (609.6mm) wide; 27” (685.8mm) deep

Weight

DA80F:

53 lbs. (24 kg), including print cartridges and output stacker.

DA95F:

88 lbs. (39.9 kg), Feeder 28 lbs. (12.7 kg), Printer/Feeder 116 lbs. (52.6 kg)

Electrical

Domestic: 100-240 VAC, 50/60 Hz, 5.0 A

Power Consumption: 575 Watts, 1962 BTU/hr.

Agency Approvals

TUV/UL/cUL/VDE-GS - Refer to the FCC and CE statements at the front of

this manual for more information.

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

2-1

2 • Specifications

2.3 Physical

Equipment

Specifications

Interface

USB, Ethernet

Control Language

PCL5, enhanced

Environmental Limits

Operating Conditions and Longterm Storage

• Temperature: 55 to 95°F (10 to 35°C)

• Humidity: 8 to 80%

• Maximum Wet Bulb Temperature: 80°F (27°C)

Shipment Conditions

• Temperature (Printer): -4 to 140°F (-20° to 60°C)

• Humidity (Supplies): 5 to 85%

• Maximum Wet Bulb Temperature: 85°F (29°C)

Noise Level

DA80F

The sound pressure level at the operator’s position for this equipment as measured in any mode using ANSI and ISO Standards is no more than 75 dB(A).

DA95F

The sound pressure level at the operator’s position for this equipment as measured in any mode using ANSI and ISO Standards is no more than 76 dB(A).

2-2 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

Specifications • 2

2.4 Print

Specifications

Print Modes (Print Resolution)

The printers have four print resolutions; they are Executive (600 DPI), Letter

(300 DPI), Draft (200 DPI), and Super Draft (150 DPI), which represent the

horizontal density. Additionally, there are two Light Mode settings (ON and

OFF), which represent the vertical density. When Light Mode is “ON”, the

vertical density setting is 300 DPI; when Light Mode is “OFF” the vertical density setting is 600 DPI. Refer to the table below for print mode options.

Print Quality With Light Mode set to

"ON"

Executive 600 x 300 DPI 600 x 600 DPI

Letter 300 x 300 DPI 300 x 600 DPI

Draft 200 x 300 DPI 200 x 600 DPI

Super Draft 150 x 300 DPI 150 x 600 DPI

With Light Mode set to

"OFF"

Fonts

Resident Fonts

Arial, Comic Sans MS, Courier New, Georgia, Impact, Kino, MSLogo, Symbol, Tahoma, Times New Roman, Trebuchet MS, Verdana, Webdings, Wingdings, plus there must be included one OCR and one Code 39 font. (All fonts

are scalable from 4 to 108 pt size.)

Resident Font Enhancements

Bold, Underline, Italic

Downloadable Fonts

Supports TrueType and Bitmapped fonts.

Downloadable Graphics

Supports Bitmap and PCL Raster images up to 40 sq in. (258 sq. cm). This

translates to images up to 3" x 13.3" (76mm x 338mm) for the DF95.

User-Definable Parameters

• Font Characteristics

• Address Placement

• Barcode Characteristics

• Print Quality

Barcode Printing Position

The printer can print a barcode in one of three positions:

• Above the address block

• Below the address block

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

2-3

2 • Specifications

2.4 Print

Specifications

✍

TIP: Do not attempt

to print "high density"

barcodes, that is, those

barcodes whose narrow elements are less

than 0.010" (.254mm).

Barcode Printing Types Position

All the printers in the DA Series can print the following barcodes:

1-Dimensional

• USPS Certified POSTNET barcode. All types of barcodes can be printable including FIM, 3 of 9, 4 state barcode (USPS, UK, Canadian, Euro,

Australia, etc.) and others.

• Planet barcode for delivery confirmation services.

• The printer is also capable of printing any barcode rendered by a Windows® True Type font.

2-Dimensional

The printers are capable of printing a USPS Certified IBIP barcode as well as

all types of 2-D barcodes defined for the UK, Canada, Europe, Australia, etc.,

and others to the defined standards. Reference applicable Postal Standards.

NOTE: Do not attempt to print "high density" barcodes. The narrow elements

should not be less than 0.010" (.254mm).

Special Note on FIM Barcode

FIM (Face Identification Marking) barcode was developed by the USPS as

part of their POSTNET barcoding system. It is normally used by high-volume

mailers to put on return envelopes for their customers’ invoices.

When the invoices are mailed back in their return envelope, the USPS sorts

and processes this mail according to what version of FIM barcode is used on

the envelope: FIM A (Postage required, POSTNET bar code included), FIM

C (Postage prepaid, POSTNET bar code included), and FIM D (Postage required, POSTNET bar code not included).

One of the requirements of the FIM barcode is that it needs to be printed on

the edge of the envelope (typically printed in the top right corner). Any attempt to print to the exact edge of the envelope is liable to "miss" the edge

occasionally. Because of these issues, we cannot guarantee full USPS

compliance for printing FIM barcode. As a result, some of our high-volume

customers used pre-printed envelopes containing the FIM barcode that meet

USPS printing specifications.

However, if you want to try printing the FIM using our printers, the Pitney

Bowes Envelope Designer Plus software allows you to place a FIM graphic

on the envelope. You can obtain photo-ready graphics directly from the

USPS (the Envelope Designer software itself can not create the FIM barcode

graphic).

2-4 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

Specifications • 2

2.4 Print

Specifications

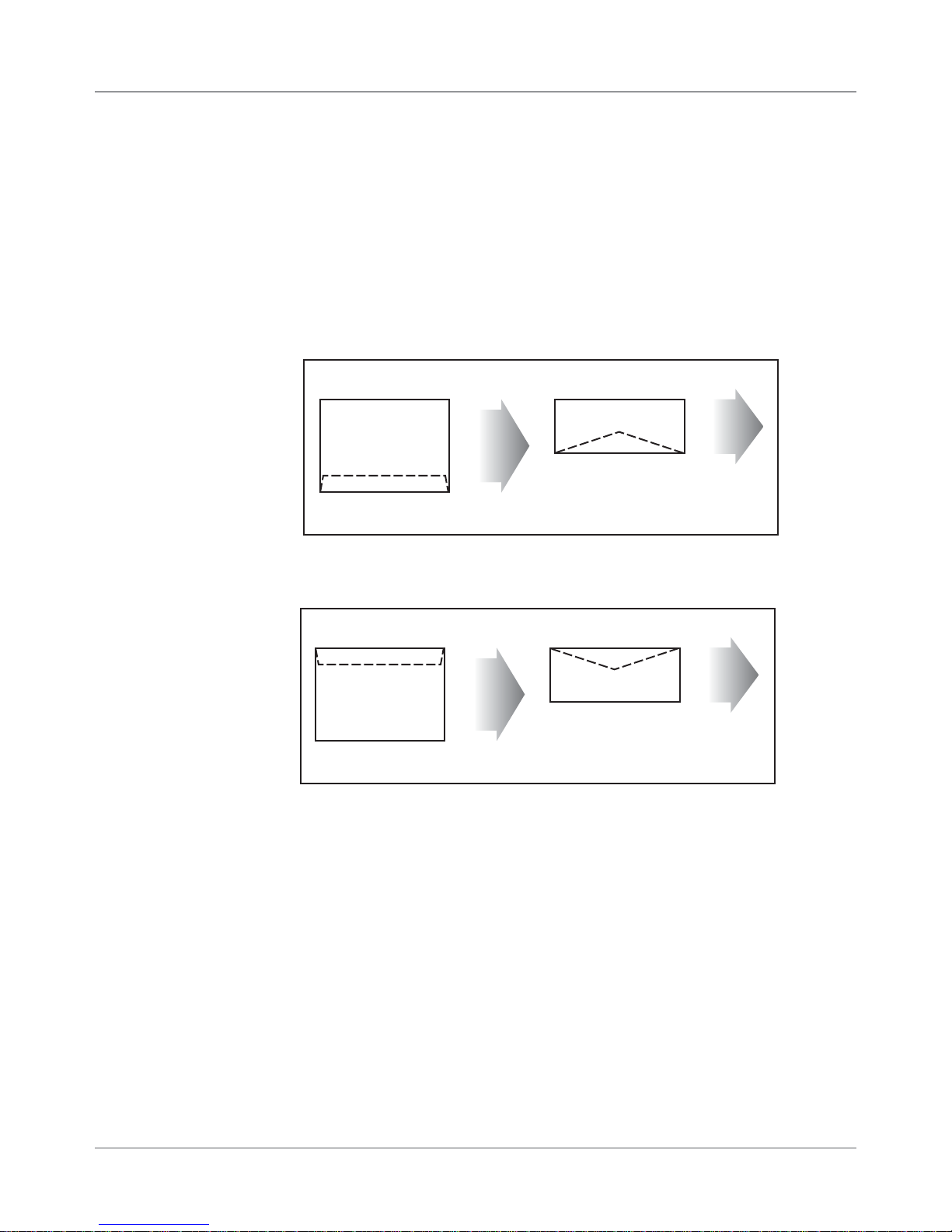

Effective Print Area

The printable width is the width of the piece measured from the right side of

the piece of mail. The printable height is 1.5" (38mm) for the DA80F and 3”

(76mm) fro the DA95F.

NOTES:

• All envelopes should be loaded so the side to be printed faces up, flap

faces down, stacked to feed with the left or right edge first. See example

that follows.

Example of Normal Orientation

This Side Prints

This Side Prints

Flap down, close to operator

Feed Edge

feeds into

printer.

Flap down, close to operator

• If running an inverted job (image prints upside down on media) your envelopes will load like the example below.

Feed Edge

feeds into

printer.

Example of Inverted Orientation

Feed Edge

feeds into

printer.

This Side Prints

Flap down, and away

from operator

Feed Edge

feeds into

printer.

This Side Prints

Flap down, and away

from operator

• All edges are viewed from the front surface of the material.

• Two clear zones, each 0.3" (7.6mm) wide, are required on the piece of

mail to allow clearance for the exit rollers.

• Printing is allowed to the top edge of the media, however print quality will

be degraded.

Print Heads

Able to produce spot color by swapping a black cartridge with a color cartridge on any head.

DA80F: 3 head capacity

DA95F: 6 head capacity

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

2-5

2 • Specifications

2.4 Print

Specifications

Inkjet Cartridges

Cartridges are operator replaceable. The ink supply cartridges for the

DA80F and DA95F are the same ones used on their predecessor models

(see table on page 1-1). The table below lists some common order numbers for replacement cartridges. For a complete list of ink cartridges, go to

http://www.pb.com/supplies. In the Find Your Supplies field on the left pan-

el, select “AddressRight” from the dropdown list provided. Follow the links for

the model of your printer from the web page that displays.

Model Printing Capability Black Cartridge Color Cartridge

DA80F Black and Spot Color

DA95F Black and Spot Color

HP Versatile Black

C8842A

HP Versatile Black

C8842A

HP 45 Spot Color Cartridges

Approved

HP 45 Spot Color Cartridges

Approved

Useful Life

User replaceable black and color ink jet cartridges. A cartridge printing 3 line

addresses with "light" mode off will provide approximately 30,000 pieces in

executive mode, 60,000 letter, 90,000 draft and 120,000 super draft, depending printer settings, materials and image density.

Print Position Accuracy

For a #10 or DL envelope (Acclaim #10 WW Commercial, Regular):

• Horizontal: within +/- 1.5 mm

• Vertical: within +/- 1.5 mm

• Skew: within +/- 1 degree

For other media:

• Horizontal: within +/- 3.0 mm

• Vertical: within +/- 3.0 mm

• Skew: within +/- 2-1/2 degrees

Recommended Usage

The printers have been tested under many different conditions. Use of the

printer should fall within these piece usage recommendations:

Monthly Piece Usage Product Life

Typical Maximum

DA80F 176,000 240,000 5 years or 14,400,000 cycles

(whichever comes first)

DA95F 480,000 1,000,000 5 years or 60,000,000 cycles

(whichever comes first)

NOTE: Usage beyond the maximum monthly pieces is not covered by the

Equipment Maintenance Agreement (EMA).

2-6 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

Specifications • 2

2.4 Print

Specifications

✍

TIP: Any network

the print data has to

flow through to reach

the printer may affect (reduce) printer

throughput.

2.5 Material

Specifications

Throughput

DA80F: 22,000 envelopes hour

DA95F: 30,000 envelope per hour

Based on:

• "Super Draft" mode print quality

• 3-line destination address

• 18 characters per line

• 12-point character size

• Time New Roman font

NOTE: Adding graphics and/or printing at a higher resolution (e.g., Draft, Let-

ter, Executive mode) will decrease throughput.

For envelope addressing purposes, the printer is compatible with any word

processor or database application that can print a mailing label.

The paper types listed below are approved for use with the printer. Please note

that the dimensional limits above apply in all cases, and that all media (enve-

lopes, postcards, flats, etc.) should be without windows.

• White Wove

• Bond paper

• Recycled paper

• Coated paper

• Card stock

• Brown kraft

• Manila

• Perforations

Refer to the table below for media size specifications.

Media Sizes

DA80F DA95F

Min. width 5" (127 mm) 5" (127 mm)

Max. width 14" (355 mm) 14" (355 mm)

Min. height (length) 3.5" (89 mm) 3.5" (89 mm)

Max. height (length) 15.5" (393 mm) 15.5" (393 mm)

Min. thickness 0.003" (0.08 mm) 0.003" (0.08 mm)

Max. thickness 0.25" (6.3 mm) 0.50" (12.7 mm)

Input Feeder Capacity

DA80F/DA95F: 500 #10 or DL Envelopes

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

2-7

2 • Specifications

2.5 Material

Specifications

Approved Media

• Envelopes normally have a flap along the long edge and are processed

by the printer non-flap edge first (see illustration)

Non-flap

Lead Edge

Flap Edge

(flap faces down)

Envelopes may have either a diagonal or straight edge along the enve-

lope flap. Envelopes may have either a diagonal or straight edge along

the envelope flap. Stuffing materials must be machine folded (C, Z, or 1/2

folded) or cut sheets.

• Booklets are defined as media having physical dimensions 6" x 9”

(152mm x 229mm) or larger. Booklets have an opening along their long

edge which is covered by a flap with an adhesive seal.

• Catalog Envelopes have an opening along their short edge which is

closed by a flap with an adhesive seal. A catalog may consist of multiple

pages bound by adhesive or tabs on the feed edge or at 90 degrees with

respect to the feed edge. Material that is too stiff will cause feed problems.

• Postcards have no folds or bends. The printable side may have a higher

surface roughness than the non-printable side.

• Self-mailers may be of “C,” “Z,” or half-folded construction. They may not

exceed the maximum allowable thickness as specified on the previous

page and must be tabbed per postal regulations. Half-folds and tri-folds

must be machine produced.

• A catalog may consist of multiple pages bound by adhesive or tabs on

the feed edge or at 90 degrees with respect to the feed edge.

2

• Sheet stock may consist of 20 to 28 lb. (75 to 105g/m

) bond as well as

60 to 80 lb. (220 to 300g/m2) coated stock. The size and thickness constraints specified above apply.

2-8 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

Specifications • 2

2.5 Material

Specifications

Unapproved Material

• Contaminants – material with visible material loss (loose powder, ink, sur-

face glaze, etc.) when hung free over a clean surface and struck sharply

with a standard wood ruler.

• NCR paper

• Special Materials – materials that are sensitive to heat such as thermal

papers, any pressure-sensitive materials, and materials that are sensitive

to minor magnetic fields.

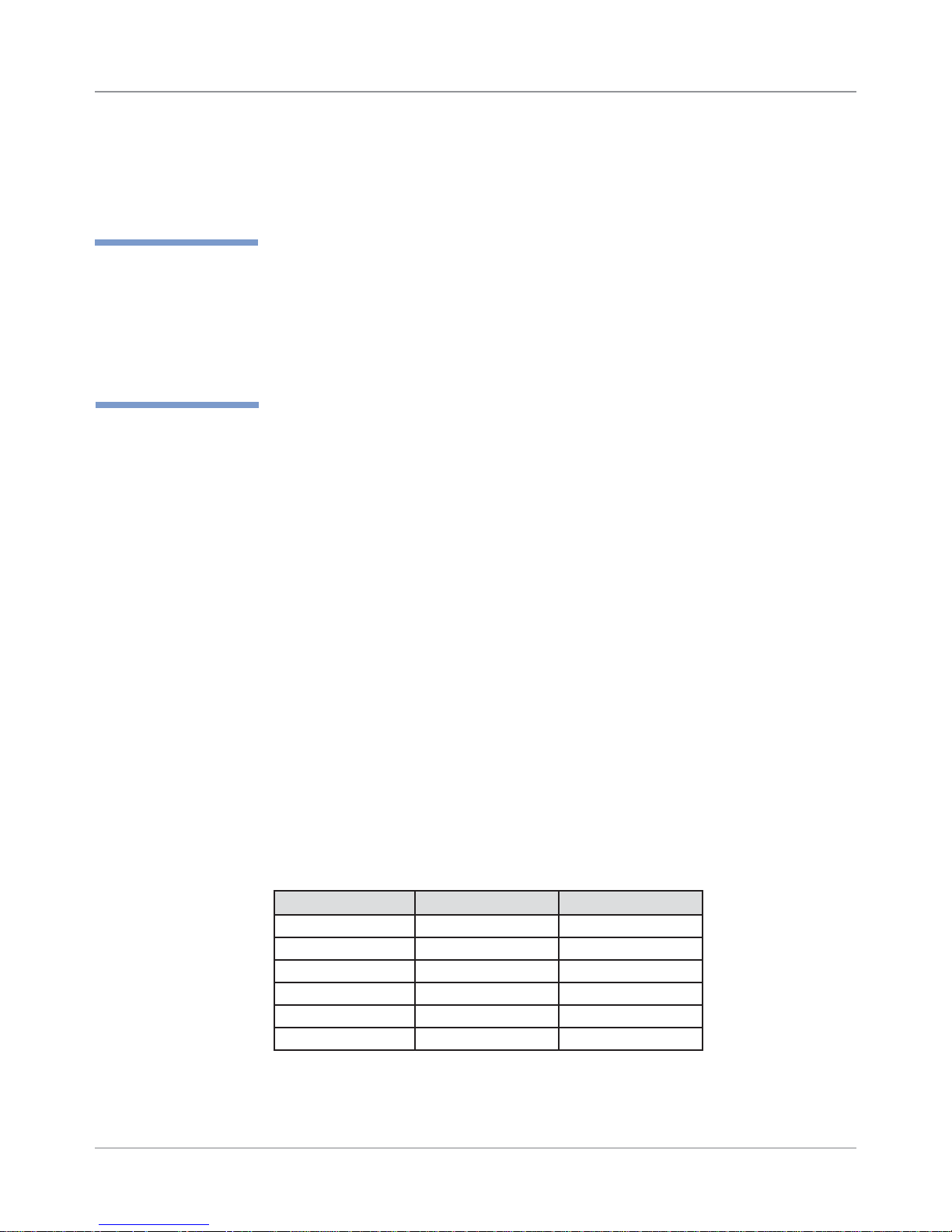

• Excessively Glossy Paper – this is material whose surface frictions falls

outside the guidelines given here (and in chart below).

- Material shall not slide when placed on a 18% slope (10.2 degrees).

- Envelopes shall not slide when placed on a 33% slope (18.2 degrees).

- Material shall slide when placed on a 70% slope (35 degrees).

To test material for proper surface friction (a clipboard is ideal for this test):

1. Secure bottom piece to slope and place ten pieces on top of the bot-

tom piece. Material shall be tested with short edge leading.

2. Raise the clipboard until any portion of the stack begins to slide. The

height to length ratio of the clipboard is the % slope. .

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

2-9

2 • Specifications

2.5 Material

Specifications

✍

*Chou #3 Yoko, Chou

#4 Tate, and Hagaki

sizes cannot be used

with DA80F/DA95F

because they do not

meet the minimum

envelope width of

127mm (5 inches)

when run through the

printer in their usual

orientation.

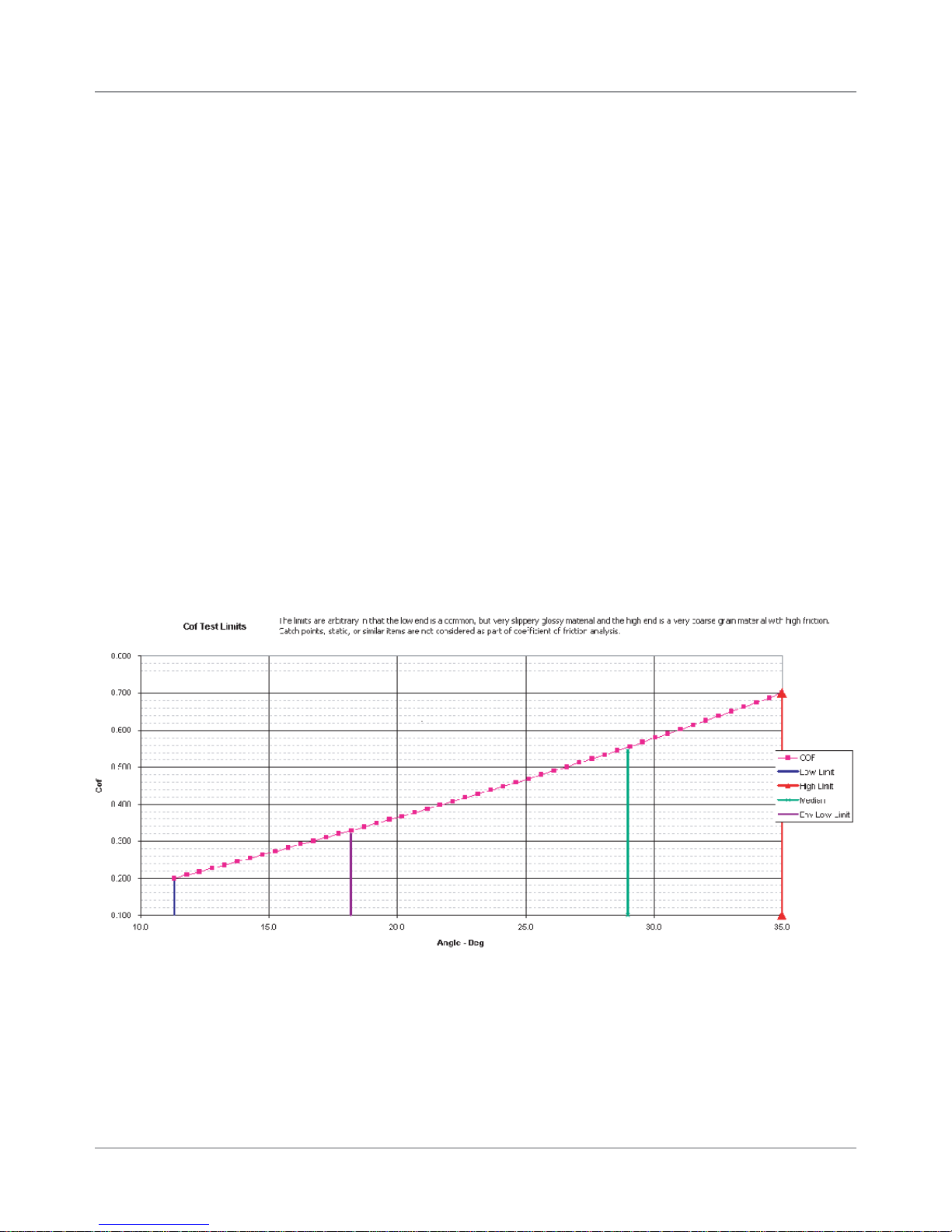

Common Envelope/Paper Sizes

Paper Name Displayed in List Size (Width) Size (Height)

US/Canada Envelope/Paper Sizes

ENV_9 Envelope #9 8⅞"3⅞"

ENV_10 Envelope #10 9½" 4⅛"

ENV_11 Envelope #11 10⅜" 4½"

ENV_12 Envelope #12 11" 4¾"

PPR_Booklet_9_12 Booklet 9 x 12 12" 9"

ENV_MONARCH Envelope Monarch 7½" 3⅞"

PPR_Card_4_6 Card 6 x 4 6" 4"

PPR_Card_5_7 Card 7 x 5 7" 5"

LETTER Letter 8½" 11"

LEGAL Legal 8½" 14"

EXECUTIVE Executive 7¼" 10½ in

European Envelope/Paper Sizes

ENV_B4 Envelope B4 353mm 250mm

ENV_B5 Envelope B5 250mm 176mm

ENV_B6 Envelope B6 176mm 125mm

ENV_C4 Envelope C4 324mm 229mm

ENV_C5 Envelope C5 229mm 162mm

ENV_C6 Envelope C6 162mm 114mm

ENV_C65 Envelope C65 229mm 114mm

PG_ENV_C76 Envelope C76 162mm 81mm

PG_ENV_C7 Envelope C7 114mm 81mm

ENV_DL Envelope DL 220mm 110mm

ENV_DLX Envelope DLX 235mm 120mm

ENV_DLE Envelope DLE 225mm 114mm

A4 A4 210mm 297mm

A5 A5 148mm 210mm

Asian Envelope/Paper Sizes

Envelope 12JE 140mm 265mm

Envelope 9JE 190mm 265mm

Envelope 6JE 215mm 305mm

Envelope ZL [China] 230mm 120mm

Chou #3 Yoko* 120mm 235mm

Chou #4 Tate* 90mm 205mm

Hagaki* 100mm 148mm

Postcard #3 165mm 102mm

Postcard #4 183mm 100mm

Maximum Paper Size 14" (356mm) 15.5" (394mm)

2-10 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

3 • Theory

3.1 Changes

From Earlier

Models

The DA80F (three print heads) and DA95F (six print heads) are fixed head,

ink jet desktop printers. The DA80F (WF81) and DA95F (WF96) printers are

based on the previous Pitney Bowes fixed head printers (DA400 and DA950,

respectively). For those familiar with the older models, the changes implemented include:

• Updated Main Board, as well as LCD/Keyboard Board/Print Head Driver

Board. Same Main Board used in both DA80F/DA95F models. Now

100% RoHS compliant.

• Elimination of Centronics (parallel) connector; replaced by Ethernet connector (USB port kept)

• Improved paper sensor calibration now accessible via LCD Service menu

• New options on the LCD control panel menus for greater flexibility and

control

• Introduction of a Pitney Bowes “software control panel” (running under

Windows on a separate PC) which mimics the features of the printer’s LCD

control panel while also adding more diagnostic and administrative features

• Control panel menu supports bulk cartridge ink management (“low ink“

warning now works when using these types of cartridges)

• Removed large transformer and replaced with heavier duty power supply

(allows a graceful shutdown of the printer and for the software parameters

to be saved). Same supply as used in DA5xx/DA7xx shuttle-head printers.

• Print heads now raise up straight (instead of to the side) which allows

easier access to wipe and clean the print heads

• One printer software for all functionality (uses PB monolithic driver)

• Support for 18 languages in the Operator Guide, soft control panel, and

drivers

DA95F-Specific Improvements

• Removed feeder board (used in predecessor DA950 model)

• New exit sensor and new feeder deck extension

• New “feet” on bottom of feeder allows better alignment of feeder

• Two new idler roller assemblies provide better control of the media

through the print path resulting in better print quality and more accurate

placement of printed items

DA80F-Specific Improvements

• New feeder clutch added

• Added auto-tensioner on drive belts.

• Media thickness range increased from 1/8” to ¼”

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

3-1

3 • Theory

3.2 Printer

Architecture

The printer system is made up of several sub-systems (see also Figure 3-1):

• Universal Power Supply - The universal power supply has auto sensing/

switching for input voltage and intelligent shutdown capability. It ensures

proper parking of the cartridges in the maintenance station and proper

shutdown of the software. (It is the same supply used in the midrange

DM series mailing machines.)

• System Controller - The system controller is comprised of the overall op-

erating system in the firmware that controls the behavior of the system

and coordinates activities between the other sections.

• User Interface - The user interface is the LCD display, the buttons, and

the software to drive it within the firmware.

• Feeder and Transport Motion Control - The feeder and transport motion

control is responsible for feeding and positioning the envelope beneath

the printer for printing. All material motion is controlled by the transport

motor and firmware.

• Head Management - The head management controls the proper operation

of the print cartridges.

• Communications - The communications hardware and firmware are re-

sponsible for the interface to the host PC through which print streams are

received and passed to the system controller for parsing and rendering.

Power

Universal Power

Supply

Communications

USB Ethernet

Busy/Error

System

Controller

Head

Management

Display

Te xt

User Interface

Motion Control

Operator

Input

Feeder

and

Transport

LED

3-2 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

Figure 3-1 Printer System Functional Architecture

Theory • 3

3.2 Printer

Architecture

✍

TIP: Module A =

Print Heads 1, 2, 3

Module B =

Print Heads 4, 5, 6

Throughput

Cycle Time

Values

Material #10 Envelope

Model

22828

0.158

60.000

50.000

40.000

30.000

20.000

10.000

0.000

-10.000

0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 0.7000

WF81

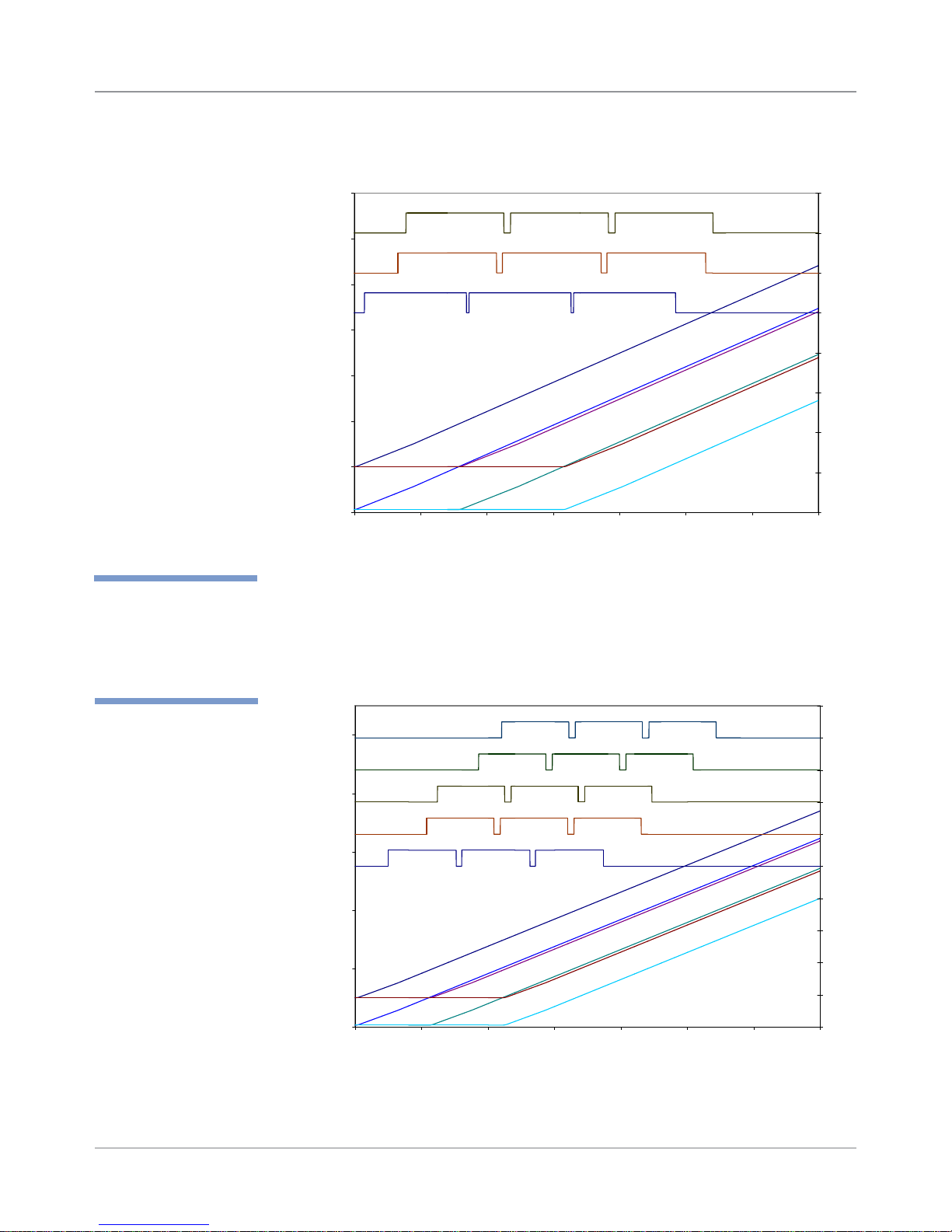

Figure 3-2 DA80F (WF81) Printer Timing Diagram

Throughput 32230

Cycle Time 0.112

90.000

70.000

Print Sensor

50.000

Values

30.000

pcs/hr

sec

Module A Printing

Feeder Sensor

pcs/hr

sec

Exit Sensor

Module A Printing

Module B Printing

Print Sensor

Timing Diagram

Piece 1 Piece 3Piece 2

Time

Timing Diagram

Feeder Sensor

Piece 1 Piece 3

Piece 2

1.5

1

0.5

0

-0.5

-1

-1.5

-2

-2.5

2.5

2

1.5

1

0.5

0

-0.5

-1

10.000

-10.000

Material #10 Envelope

Model WF96

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

-1.5

-2

-2.5

0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 0.7000

Time

Figure 3-3 DA95F (WF96) Printer Timing Diagram

3-3

3 • Theory

3.2 Printer

Architecture

On Line

_

Menu Enter

+

Test Env.

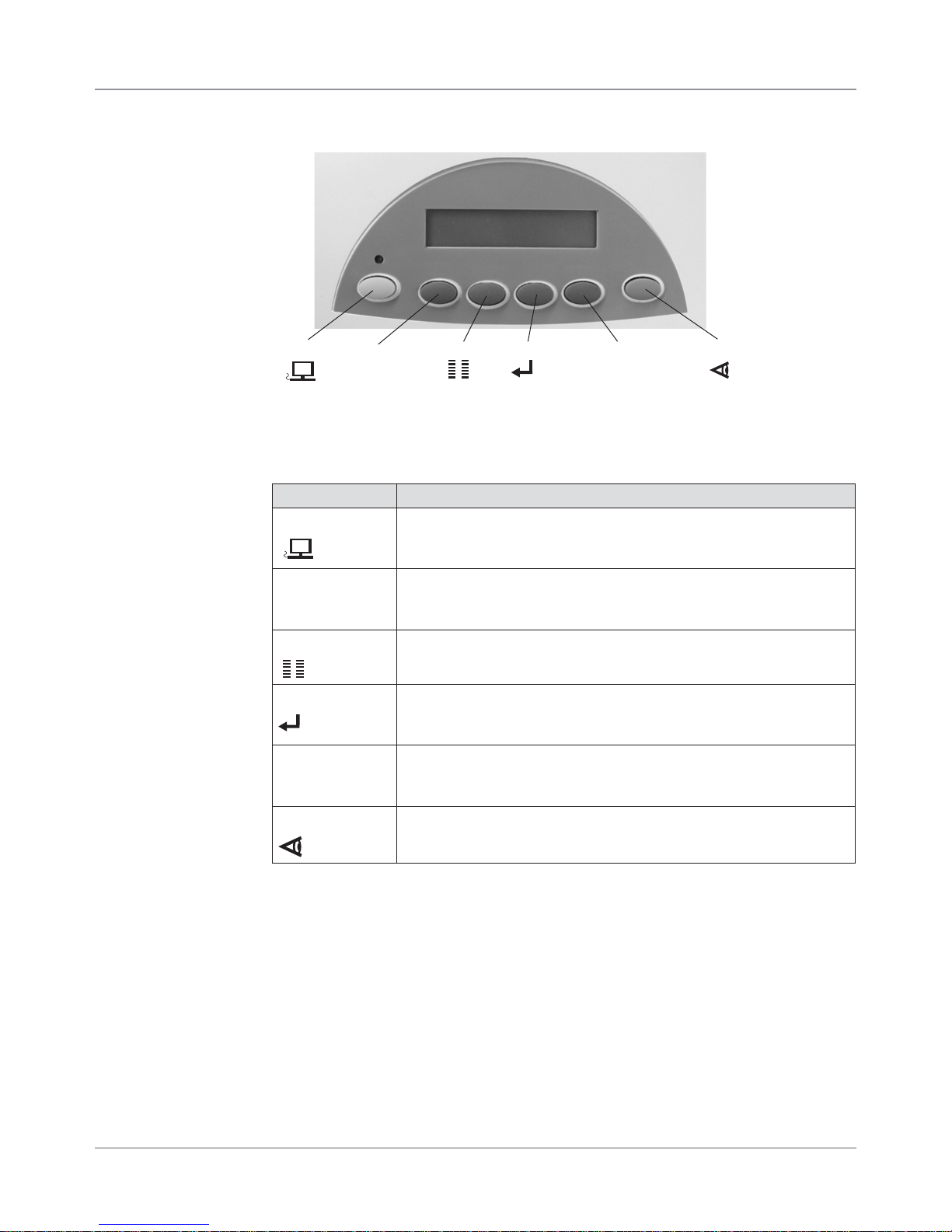

Figure 3-4 User Interface ( Control Panel) on Printer

The buttons on the control panel perform the following functions:

Button Description

ON LINE

_

(minus)

Menu

Enter

(plus)

+

Test Env

• Toggles (switches) between ON LINE (communicates with host

PC) and OFF LINE (no communications with host PC).

• Exits the menu system.

• Decrements a value.

• Moves backwards through a choice list.

• Negative response to query.

• Enters the menu system when OFF LINE.

• Exits a submenu.

• Selects and/or saves the displayed value.

• Causes system to perform described action.

• Advances to next screen.

• Increments a value.

• Moves forward through a choice list.

• Affirmative response to a query.

• Prints a test piece when OFF LINE.

• Prints a report for specific menu items.

NOTE: See Appendix A, Printer Control Panel Menus for a full explanation of

all the menu options.

3-4 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

Theory • 3

3.3 Operating

Sequence

When the printer is either, “off line” (led is unlit) and the [test] button is depressed, or the printer is “on line” (led is lit) and a valid address is received

from the computer, the belt drive motor will be energized. A belt, driven by

the motor, drives the belt drive roller assembly which in turn drives the media

belts.

The printer motor will be energized. The printer belt connects the printer motor to the transport roller and exit roller. The processor board will compare

the speed of the encoder on the transport roller to calculate the desired

speed.

The feed motor will be energized, and the feed rollers and feed belt will rotate, pushing the bottom piece of media between the rollers and the “h” block

media separators. The frictional design of the “h” block media separator is to

restrict all but the bottom piece of media.

The feed roller moves the piece of media between the entry idler rollers and

the transport rollers. The speed differential between the transport rollers and

the feed rollers will create a gap between the moving pieces. The feeder

photo sensor assembly is energized as the piece of media is pushed out.

The transport roller continues to push the leading edge of the media into the

path of the printer sensor. When the leading edge of the media is detected

by the printer sensor assembly, two things occur:

• Position counting begins so that printing will occur at the preprogrammed

position on the media. This pre-programmed position is set in the address layout or is controlled by the software driver.

• The media is captured between the exit roller and the exit idler roller

where it is ejected from the printer. In the DA95F, an exit sensor captures

the piece exit data.

This process is repeated until all the records in the file are printed.

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

3-5

3 • Theory

3-6 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

4 • Troubleshooting/Diagnostics

4.1

Troubleshooting

Overview

✍

TIP: See Appendix B

- Printer Communications, for troubleshoot-

ing problems relating to

networking and printer

communications.

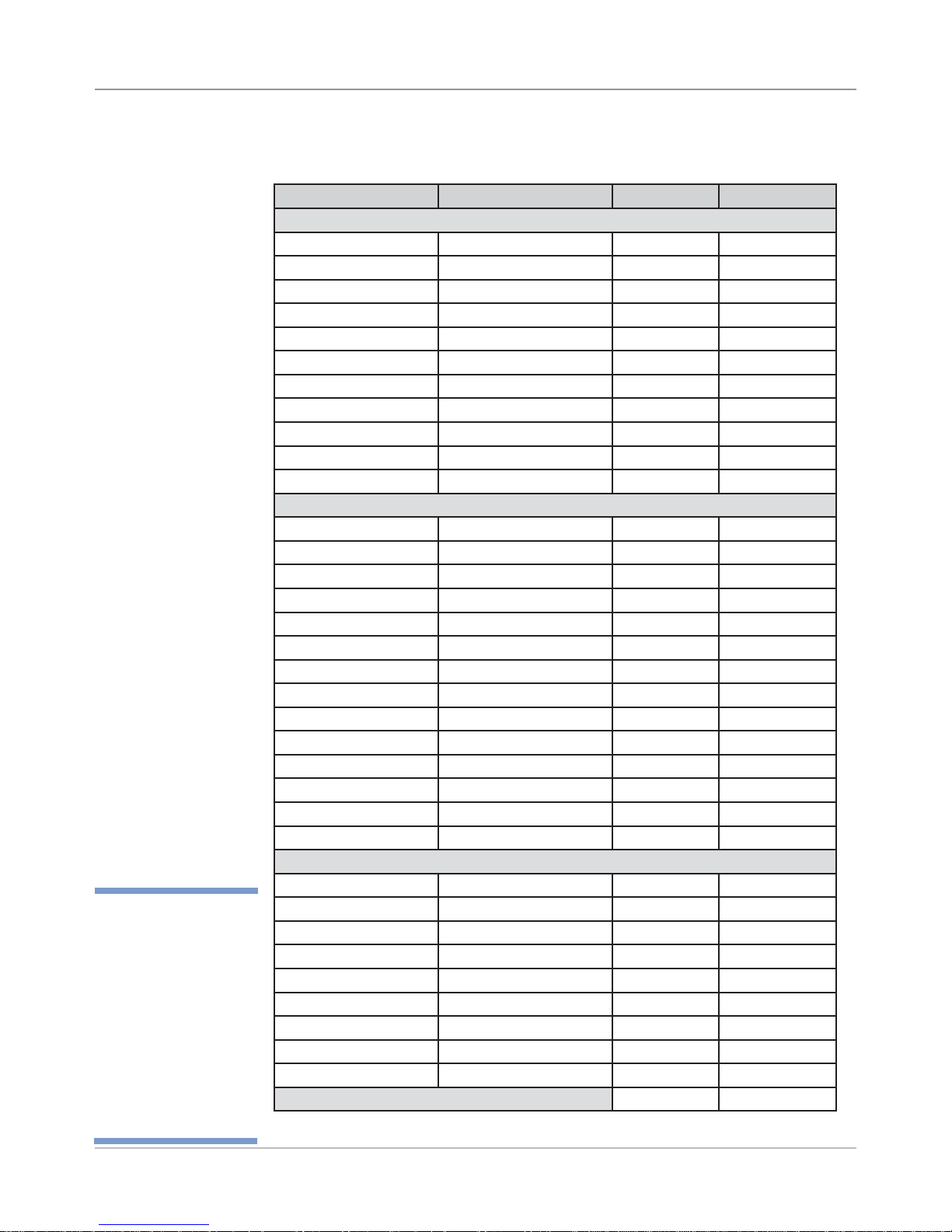

This chapter discusses printer troubleshooting in the following sections:

4.2 Block Diagrams ........................................................................ 4-2

4.3 Main Controller Board Diagnostics ........................................... 4-4

4.4 Error Codes ............................................................................... 4-9

4.5 Print Samples for Troubleshooting .......................................... 4-12

4.6 Feeding Issues ........................................................................ 4-14

4.7 Printing Issues ......................................................................... 4-19

4.8 Display Issues ......................................................................... 4-23

4.9 Miscellaneous Issues .............................................................. 4-23

When You Start Y our Troubleshooting

When any paper handling/printing errors begin to occur frequently, perform

the following standard printer setup procedures in the order given. There is

a high likelihood that performing these procedures will correct the error. If

these procedures do not correct the problem, then refer to the troubleshoot-

ing tables starting on page 4-14 for further actions, including part removal/

replacement.

Standard Printer Setup Procedures

(see DA80F or DA95F Operator Guides for specific instructions)

1. Verify that the output stack is not backing up into paper path

2. Recheck standard feeder setup procedures:

a. Adjust the “H” blocks

b. Adjust input ramp

c. Adjust feed guide

d. Verify stack weight limits

e. Adjust side guides

f. Check feed roller/belt surface for glazing

3. Check the thickness adjustment on the print heads

4. Check all adjustable nips for position and tension

5. Clean the paper path

6. Sensors:

a. Clean Sensors

b. Calibrate Sensors

c. Check Sensor Operation

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

4-1

4 • Troubleshooting/Diagnostics

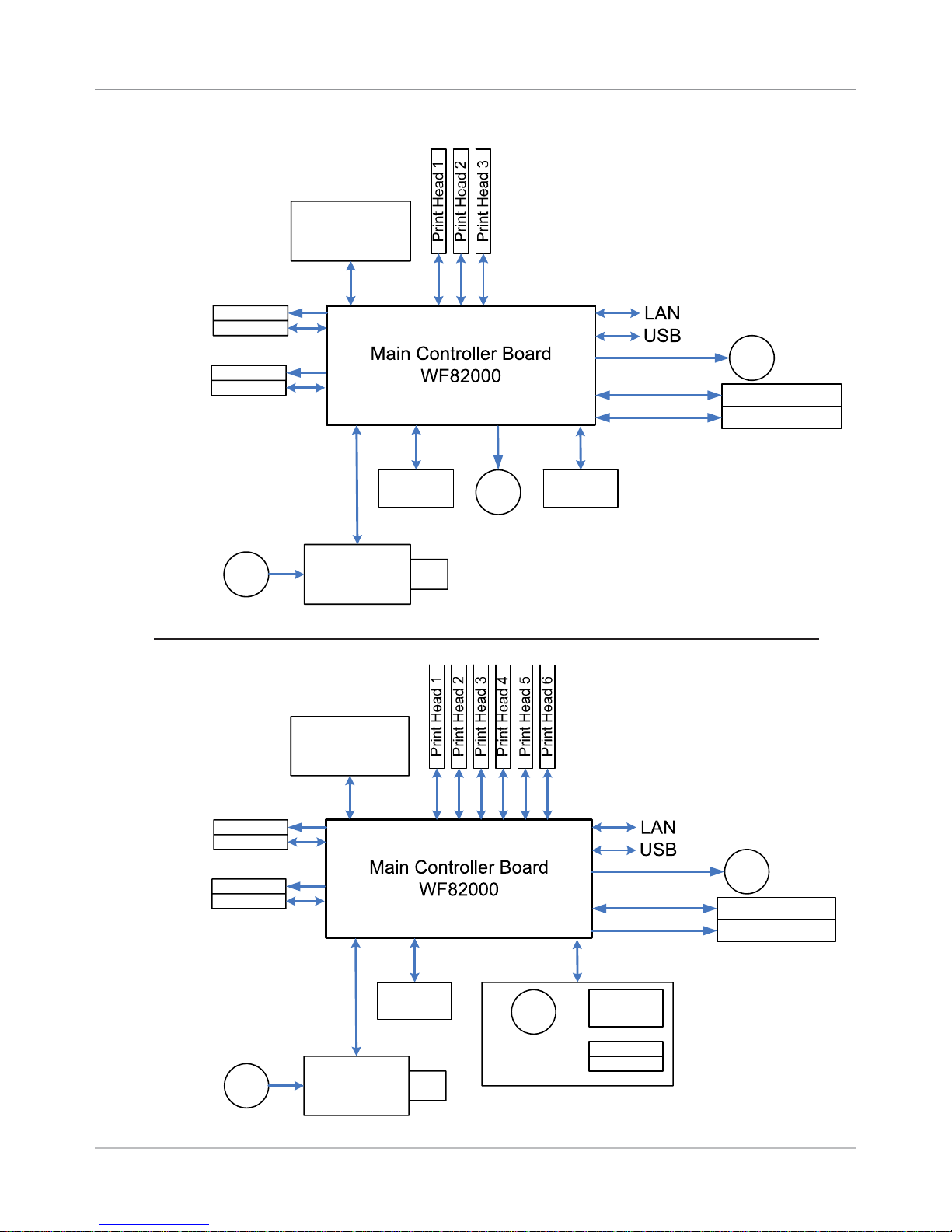

4.2 Block

Diagrams

Control Panel &

Display Board

WS82002

Paper Sensor

Emitter

Receiver

Feeder Sensor

Emitter

Receiver

Universal

AC Fan

Power Input

Power Supply

WS80001

Shaft

Encoder

M

Feeder Motor

Figure 4-1 DA80F (WF81)

Printer Block Diagram

Transport Motor

M

PB Stacker

Bryce Stacker

Feeder

Encoder

Control Panel &

Display Board

WS82002

Paper Sensor

Emitter

Receiver

Exit Sensor

Emitter

Receiver

Universal

AC Fan

Power Input

Power Supply

WS80001

Shaft

Encoder

M

Feeder Motor

External Feeder

Figure 4-2 DA95F (WF96)

Printer Block Diagram

Transport Motor

M

PB Stacker

Hi Speed Feeder

Feeder

Encoder

Emitter

Receiver

Feeder Sensor

4-2 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

3RZHU

6ZLWFK

,(&

FRQQHFWRU

8VHU,QWHUIDFH

/&'%XWWRQV

IURP.0DFKLQH

)(0$%DFNOLJKW/&'

)HHGHU

0RWRU

'&%UXVK

:6

9'&

([LW6HQVRU .

:65HFHLYHU237(.23

+%ULGJH

'ULYHU

6,

&38 6+

5HQHVDV6+

+'%3$'9

99

6'5$0

07/&0

0%0LFURQ

9

)/$6+

()-&

0%,QWHO

9

0LG-HW

3RZHU

VXSSO\

)XVH

;LOLQ[)3*$

6SDUWDQ(6HULHV

;&6()7*&

999

..6<67(0

%/2&.',$*5$0

..

0DLQ%RDUG

7UDQVSRUW

0RWRU

'&%UXVK

:6

9'&

+%ULGJH

'ULYHU

6,

5HJXODWLRQIRU

999

999

9

86%)XQFWLRQ

3KLOLSV

,63$

(WKHUQHW

606&

/$1&

IRUWHVWRQO\

5(6(7

&LUFXLWU\

56

'ULYHU

</HH

(QFRGHUDWVKDIW+3

+('6$&35.

+('0%&35.

9$

9$

',3

6ZLWFK

-

ELW

'$7$

ELW

'$7$

)5$0

0+]

-7$*

-7$*

0+]0+]

ELW'DWDELW'DWD

&RQILJ3LQIRU..

WKUX3DSHUVHQVRUUHFHLYHU

5HG/('

*UHHQ/('

-

--

-.

/$1

86%

)$1

'(

-

-5$7\SH%

-5$0DJQHWLFV/('

([LW6HQVRU .

:6(PLWWHU237(.23%

&RQILJ3LQIRU6:9HUFRQWURO

,54

,5/

(QFRGHUDWPRWRU

+3+('6)

&35

)HHGHU6HQVRU .

:6(PLWWHU237(.23%

)HHGHU6HQVRU .

:65HFHLYHU237(.23

3DSHU6HQVRU ..

:65HFHLYHU237(.23

3DSHU6HQVRU..

:6(PLWWHU237(.23%

-

- - - -

3+ 3+ 3+ 3+ 3+ 3+

)HHGHU

'ULYHU

.

6WDFNHU

'ULYHU

.

+L6SHHG

)HHGHU

'ULYHU

.

)HHGHU

0RWRU

(QFRGHU

6HQVRU

3%6WDFNHU,)

-

%U\FH

6WDFNHU,)

,&WR'$

0$;

5HFHLYHU

&LUFXLWU\

3LQ3LQ

-.

-.

-.

- -

-

-

-

-

:).

:).

-

-

-

.RQO\

.RQO\

.RQO\

3RZHU6XSSO\

$VVHPEO\

-

-

-

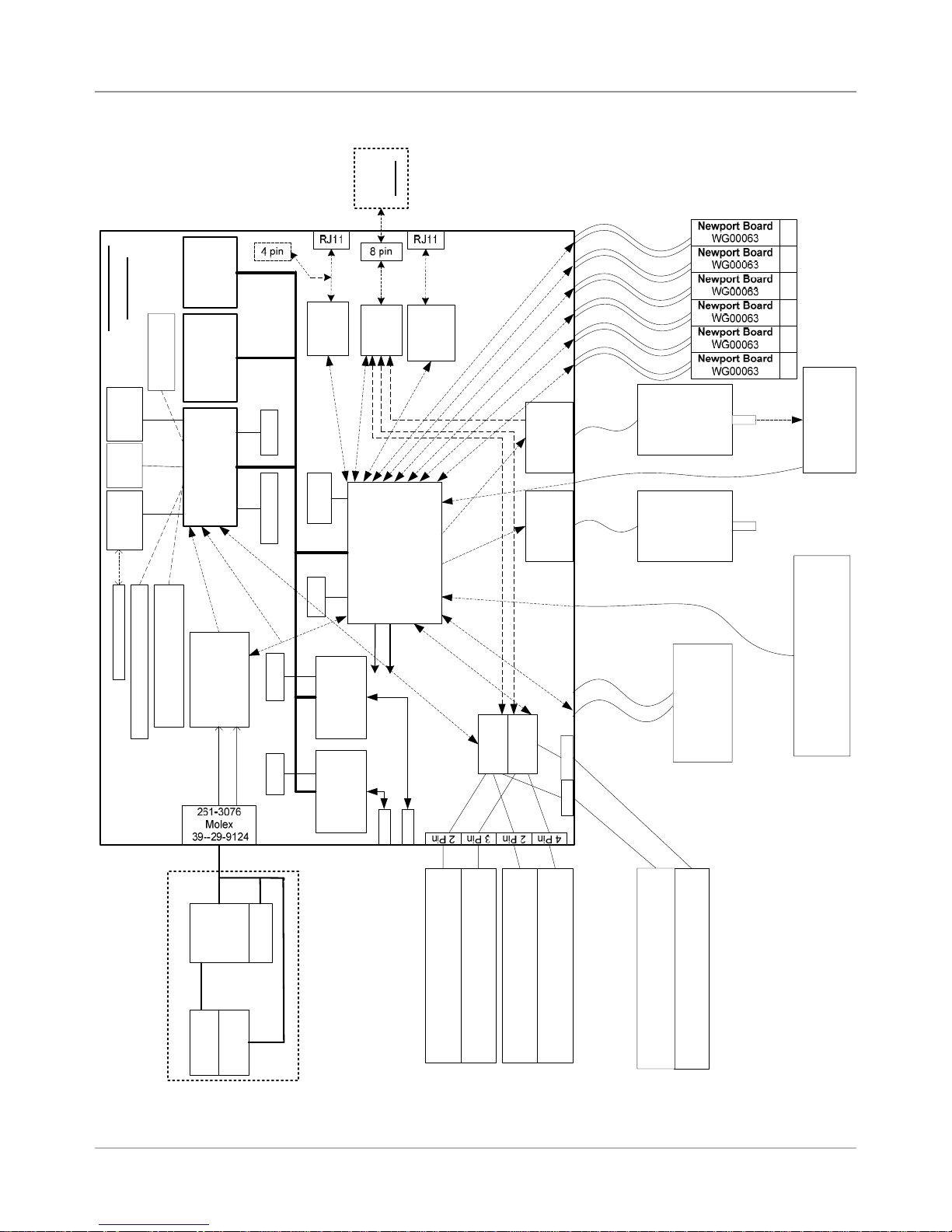

4.2 Block

Diagrams

Troubleshooting/Diagnostics • 4

Figure 4-3 DA80F (WF81)/DA95F (WF96) Printer Detailed Block Diagram

DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

4-3

4 • Troubleshooting/Diagnostics

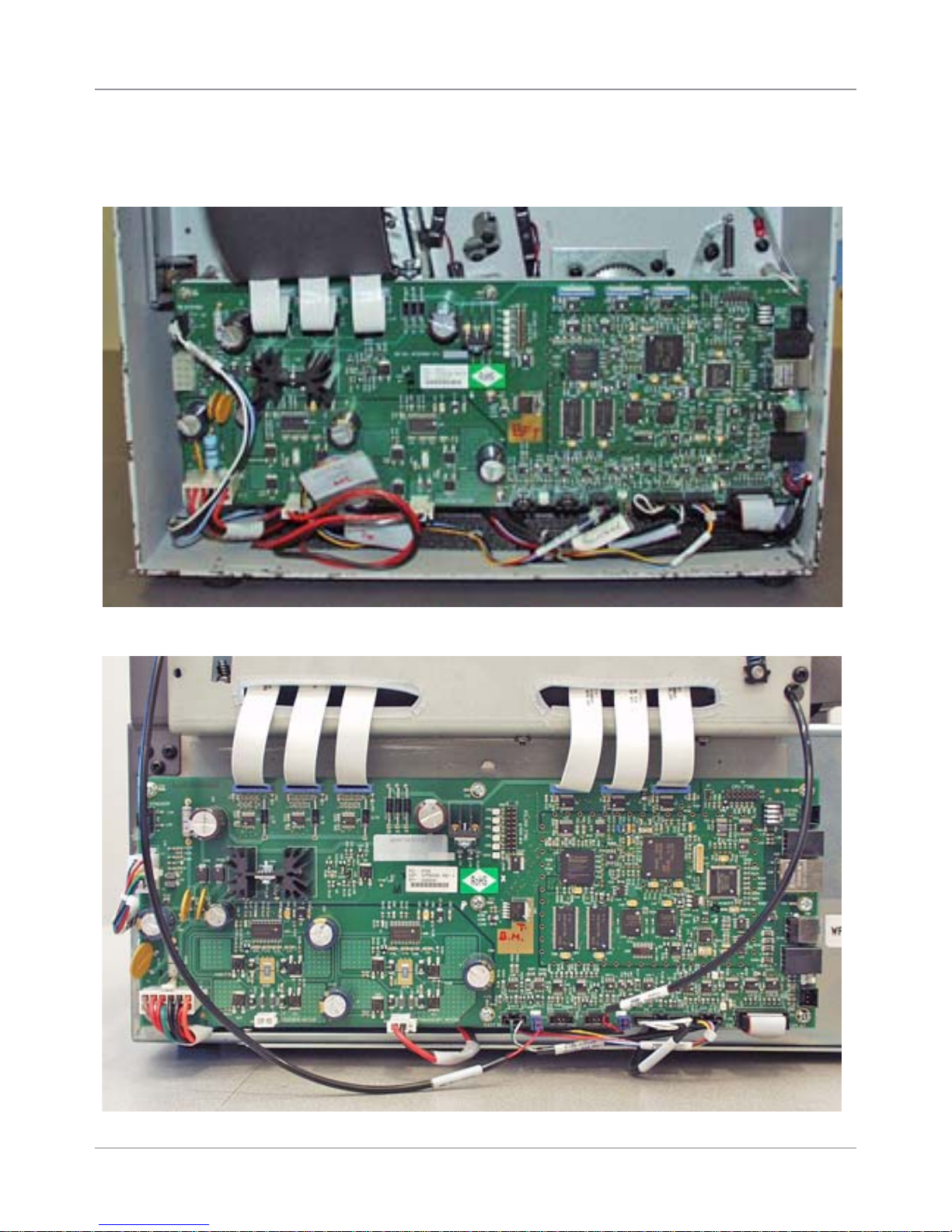

4.3 Main Controller

Board Diagnostics

Figure 4-3 Main Controller Board Mounted in DA80F (WF81) Printer

Figure 4-4 Main Controller Board Mounted in DA95F (WF96) Printer

4-4 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

Loading...

Loading...