Page 1

AddressRight™ Printer

DA700, DA750

Operator Guide

US English Version

Page 2

FCC Notice

This equipment has been tested and found to comply with the limits for Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable pro

tection against interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the user manuals, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at this own

expense. Shielded cables must be used with this unit to insure compliance with Class A limits.

Safety EN60950 (IEC950)

This device passes conformity testing to standards for safety of electrical equipment (IECEE)

CB scheme.

These materials and the related software are the confidential and proprietary property of Pitney Bowes Inc., and may not be lent, sold, hired out, or made available to others in any form,

or be disposed of by way of trade in any form without the express written consent of Pitney

Bowes, Inc.

-

Fourth edition, September, 2004 ©2004 Pitney Bowes Inc. All rights reserved.

This book may not be reproduced, in whole or in part in any fashion, or stored in a retrieval

system of any type, or transmitted by any means, electronically or mechanically, without the

express written consent of Pitney Bowes, Inc.

We have made every reasonable effort to insure the accuracy and usefulness of this manual,

however we cannot assume responsibility for errors or omissions or liability for the misuse or

misapplication of our products.

Envelope Designer™ Plus is a registered trademark and PB Supply Line is a service mark of

Pitney Bowes Inc. Microsoft and Windows are trademarks or registered trademarks of Microsoft Corporation.

Page 3

Table of Contents

Chapter 1, DA700/DA750 Overview

Welcome to the DA700/DA750 ...................................... 1-2

Using This Guide ........................................................... 1-2

System Requirements ................................................... 1-4

Getting Help .................................................................. 1-5

Online Help .............................................................. 1-5

Phone Support ......................................................... 1-5

Before You Call ........................................................ 1-5

The World Wide Web ............................................... 1-6

Printer Options .............................................................. 1-7

Ordering Supplies .......................................................... 1-7

Chapter 2, Getting Started with the DA700/DA750

Unpacking the Printer .................................................... 2-2

Package Contents ................................................... 2-3

Choosing a Location for Your Printer .............................

Important Safety Notes .................................................. 2-4

Assembling the DA700/DA750 ...................................... 2-5

1. Attach the Wire Frame to the Printer ................... 2-6

2. Install the Sliding Fence ...................................... 2-7

3. Position the Output Stacker Tray .........................

4. Connect the Parallel Cable or Serial Cable ......... 2-9

5. Connect the Power Cord ..................................... 2-11

Turning On the DA700/DA750 Printer ........................... 2-11

Install the Ink Jet Cartridges (Color & Black) ................. 2-12

Removing the Ink Jet Cartridges ................................... 2-13

Chapter 3, DA700/DA750 Features and Adjustments

Printer Features ............................................................. 3-2

DA700/DA750 Throughput ...................................... 3-3

Material Thickness ................................................... 3-4

Media Size ............................................................... 3-4

Approved Media Types ............................................ 3-4

Setting Up a Job ............................................................ 3-6

1. Set the Separator Gap ......................................... 3-9

2. Center the Wireframe under the Material ............ 3-12

2-4

2-8

iSV61027 Rev. D

Page 4

Table of Contents

3. Set the Feed Angle .............................................. 3-12

4. Set the Wire Frame Ramp ................................... 3-14

5. Position the Feed Fence ...................................... 3-15

6. Load Material ....................................................... 3-16

7. Adjust the Media Thickness Knob ....................... 3-17

8. Adjust the Exit Rollers .......................................... 3-19

9. Print a Test Piece ................................................. 3-21

Chapter 4, Using the DA700/DA750 With Your

Computer

Printer Driver Software .................................................. 4-2

Selecting Printer Properties ........................................... 4-3

Using the Printer Properties Window ............................ 4-4

Selecting the DA700/DA750

from a Windows Application .........................................

Envelope Designer™ Plus ............................................ 4-15

Chapter 5, Printer Maintenance

Preventive Maintenance ................................................ 5-2

Cleaning ........................................................................5-2

Print Quality Problems ................................................... 5-2

Exit Rollers ....................................................................5-3

Sensor ........................................................................... 5-3

Print Head Shaft ............................................................ 5-3

Floor Assembly and Top Cover ...................................... 5-4

CMYK Printing ............................................................... 5-5

Chapter 6, Troubleshooting

Problems and Solutions ................................................ 6-2

Feed Problems ........................................................ 6-2

Print Quality Problems ............................................. 6-3

Interface Problems .................................................. 6-5

Motor Problems ....................................................... 6-5

Barcode Problems ................................................... 6-6

Other Problems ....................................................... 6-7

4-14

ii SV61027 Rev. D

Page 5

Table of Contents

Appendix A, Control Panel Menus

Using the Control Panel ................................................ A-2

Using the Menus ........................................................... A-3

Using the Main Menu .................................................... A-5

Main Menu Diagram ...................................................... A-6

1.Address Layout ..................................................... A-7

2. Print Quality ......................................................... A-11

3. Font Selection ...................................................... A-13

4. Barcode ............................................................... A-15

5. Address Recovery ...............................................

6. Clear Counter ...................................................... A-18

7. Job Settings ......................................................... A-19

Using the Setup Menu ................................................... A-21

Setup Menu Diagram .................................................... A-22

1. Heavy Media Mode .............................................. A-23

2. Test Print Head .................................................... A-24

3. Purge Print Head ................................................. A-24

4. Lines Per Address ............................................... A-25

5. Communications .................................................. A-26

6. Hex Dump Mode .................................................. A-28

7. Language ............................................................. A-31

8. Envelope Feed Delay .......................................... A-33

9. Auto Envelope Eject ............................................ A-34

10. ROM Revision Number ...................................... A-35

A-17

Appendix B, Specifications

Equipment Specifications ..............................................

Material Specifications .................................................. B-9

Index

Index to the Contents of this Manual ............................. i-1

B-2

iiiSV61027 Rev. D

Page 6

Table of Contents

This page is intentionally blank.

iv SV61027 Rev. D

Page 7

Chapter 1

The DA700/DA750

Color Printer Overview

The Pitney Bowes DA700/DA750 is a

versatile, easy-to-use desktop printer

designed for addressing applications.

This chapter explains what's in this

guide, and tells you how to order supplies and where to get more information

about using your

DA700/DA750.

In this chapter:

Welcome to the DA700/DA750

Color Ink Jet Printer .......................... 1-2

Using This Guide .............................. 1-2

System Requirements ...................... 1-4

Getting Help ..................................... 1-5

Printer Options ................................. 1-7

Ordering Supplies ............................. 1-7

Page 8

1 • DA700/DA750 Printer - Overview

Welcome to

the DA700/

DA750 Color

Ink Jet Printer

Using This

Guide

The Pitney Bowes DA700/DA750 color ink jet printer is a

desktop printer used to print addresses, graphics and other

information, in color, on a wide range of material of various

sizes, construction and composition. With the DA700/DA750

you can define the font, placement, print quality and bar

code characteristics for your addresses.

This Operator Guide shows you how to:

• Set up the DA700/DA750 printer

• Connect it to your computer

• Define your envelope layout

• Print a test mail piece

• Send a mail job to the printer from your computer

application.

Refer to this guide for information about printer setup, operation and troubleshooting. It is divided into the following chapters:

Chapter 1, Introduction

Contains an overview of the DA700/DA750 Operator Guide,

information about ordering supplies and a list of help resources.

Chapter 2, Getting Started

Contains instructions for assembling your printer.

Chapter 3, DA700/DA750 Features and Adjustment

Explains how to set up your printer to run a job.

1-2 SV61027 Rev. D

s

Page 9

DA700/DA750 Printer - Overview • 1

Using This Guide

(continued)

Chapter 4, Using the DA700/DA750 With Your

Computer

Contains instructions for installing the printer driver, selecting the printer from your software program and sending a

mail job from your computer.

Chapter 5, Printer Maintenance

Describes how to keep the printer clean and functioning

properly.

Chapter 6, Troubleshooting

Contains a list of possible problems and their solutions.

Appendix A, Control Panel Menus

Explains the Main Menu and Setup Menu options available

on the DA700/DA750 control panel.

Appendix B, Specifications

Provides hardware and material specifications. Your printer

will run at its best when your material conforms to our specifications.

1-3SV61027 Rev. D

Page 10

1 • DA700/DA750 Printer - Overview

System

Requirements

To operate the DA700/DA750 with your computer, your

system must meet the following requirements:

CPU Pentium II 233 MHZ or greater

64 or more MB RAM recom-

mended

Operating System* Windows 98 (2nd Edition),

Windows ME, Windows ME,

Windows 2000, Windows XP

Parallel Cable A parallel cable is supplied with

your printer. If you choose to

use another cable, make sure it

isn't any longer than 10 feet.

or

Serial Cable To use the serial port, a serial

cable of no more 15 feet in

length is required.

* Subject to change.

1-4 SV61027 Rev. D

Page 11

DA700/DA750 Printer - Overview • 1

System

Requirements

(continued)

Microsoft Windows

Operating System

98 and 98 (2nd ed.) June 30, 2006 July 31, 2006 Windows 2000 Pro or XP Pro

Millennium (Me) June 30, 2006 July 31, 2006 Windows 2000 Pro or XP Pro

NT 4.0 June 30, 2003 July 31, 2004 Windows 2000 Pro or XP Pro

XP Home

2000 Professional Mar 31, 2007 Mar 31, 2007 To be determined

XP Professional

* Source: Microsoft.com (posted 1/12/04)

** Dates subject to change, including any change due to Microsoft’s support cessation dates or if USPS

changes requirements. Should dates change, they will be posted on our web site at www.pb.com/sup

port.

Getting Help

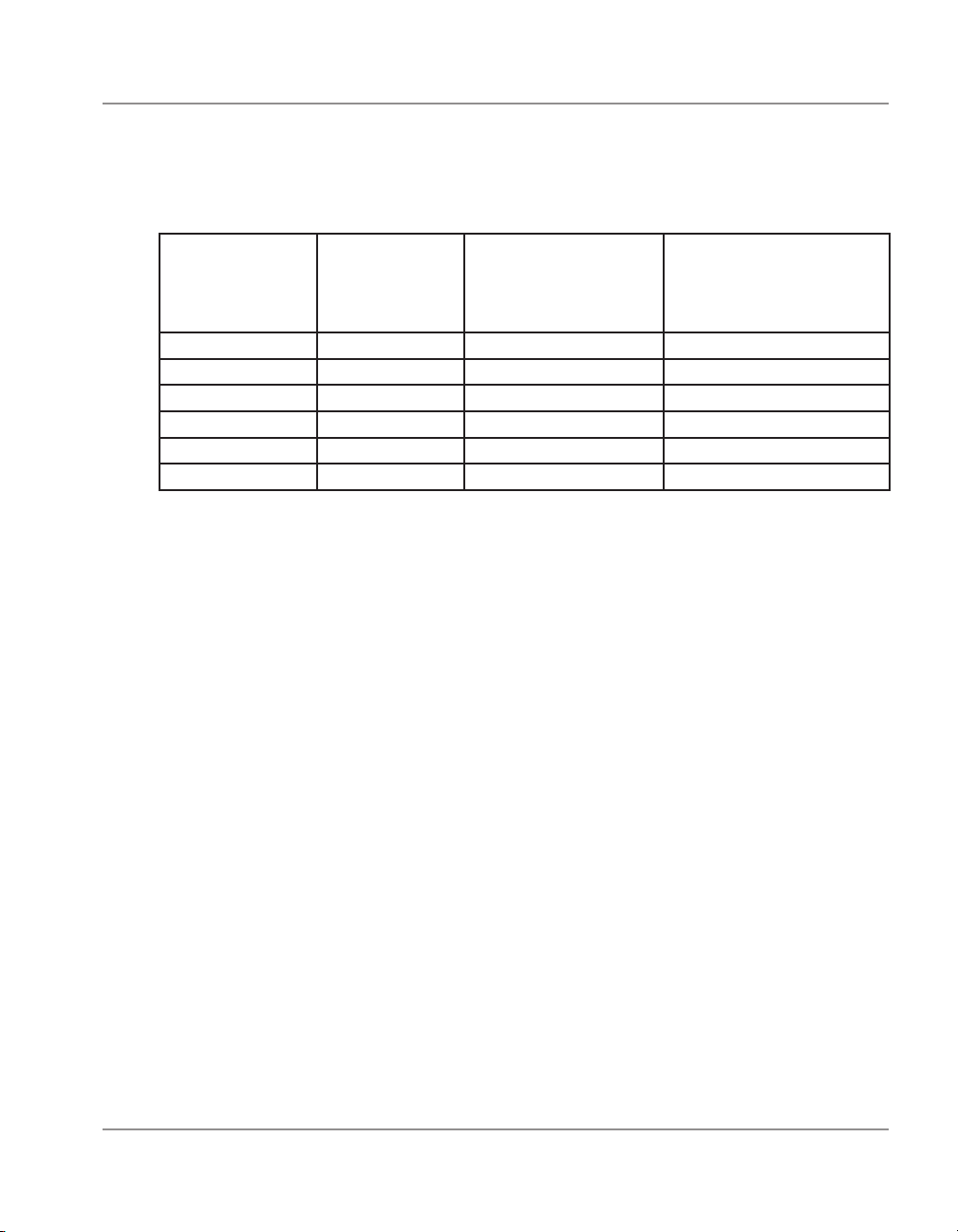

Below is a table of the Microsoft operating systems currently

supported and the dates Pitney Bowes expects to stop pro-

viding support for the drivers that run on those systems.

Last Date Pitney Bowes

supports drivers in-

stalled with MS Windows

Microsoft’s “Not

Supported Date”*

Dec 31, 2006 Dec 31, 2006 To be determined

Dec 31, 2008 Dec 31, 2008 To be determined

OS with AddressRight

and DocuMatch**

Recommended

Replacement

As you use your printer, there may be times when you need

help to solve a specific application problem, or you may want

additional information about printer operation. Pitney Bowes

provides several information resources.

-

Online Help

The DA700/DA750 Print Driver has a built-in help system.

Click on Properties from Windows print dialog box. Right

click on items in question for the "What's This" Help button.

If you're using Pitney Bowes programs such as Envelope

Designer™ or SmartMailer™, press the F1 key while you're

using the program to display information about the open

screen. Select the Help menu to display a list of topics or

search for a term. Refer to the documentation supplied with

these programs for more information.

Phone Support

If you need technical support, call Pitney Bowes Technical

Support at: (800) 522-0020.

1-5SV61027 Rev. D

Page 12

1 • DA700/DA750 Printer - Overview

Getting Help

(continued)

(Phone Support, continued)

Before You Call...

Please see Chapter 6, Troubleshooting, for a description of

common problems and their solutions. If you need to call,

please have the following information at hand:

• Model #: W707/W790

• Serial number: See back of unit.

• Nature of problem: What happens and when

does it happen?

• The steps you've already taken to solve the

problem and the results.

The World Wide Web

We encourage you to visit our web site at: http://www.

pb.com\support\

1-6 SV61027 Rev. D

Page 13

DA700/DA750 Printer - Overview • 1

Printer Options

Ordering

Supplies

You'll find the latest information about our products and ser-

vices as well as answers to frequently asked technical ques-

tions.

Pitney Bowes offers several very useful options for your

DA700/DA750:

• Envelope Designer™ lets you create a professional

looking envelope in a matter of seconds—you don't have

to bother with the print driver or make manual

settings.

• The W853 Ink Dryer helps to eliminate smudging on dif

ficult materials like glossy stock.

• The W760 Power Stacker holds up to 300 #10

envelopes. It helps maintain a neat stack in ZIP Code

order when you run long jobs.

You can order supplies for your DA700/DA750 printer directly through the Pitney Bowes Supply LineSM. To place an

order, call:

(800) 243-7824

or

-

Visit our website at:

The following supplies are available for your DA700/DA750

printer:

• Black Ink Cartridge (order number 660-1)

• Color Ink Cartridge (DA750 Only) (order number 660-5)

• 4Pack of Black Ink Cartridges order number 660-9)

• Fast Drying Black Ink Cartridge (TBD)

www.pb.com\supplies\

1-7SV61027 Rev. D

Page 14

1 • DA700/DA750 Printer - Overview

This page is intentionally blank.

1-8 SV61027 Rev. D

Page 15

Chapter 2

Getting Started with

the DA700/DA750

Printer

This chapter explains how to unpack,

assemble and connect your new

printer.

In this chapter:

Unpacking the Printer ..................2-2

Choosing a Location .................... 2-4

Important Safety Notes ................ 2-4

Assembling the

DA700/DA750 .............................2-5

Attach the Wire Frame ................2-6

Install the Sliding Fence ..............2-7

Position the Output Stacker ......... 2-8

Connect the Parallel or

Serial Cable .................................2-9

Connect the Power Cord ........... 2-11

Turn the Printer On .................... 2-11

Install the Ink Jet Cartridge ....... 2-12

Remove the Ink Jet

Cartridge .................................... 2-13

Page 16

2 • Getting Started with the DA700/DA750 Printer

Unpacking

the Printer

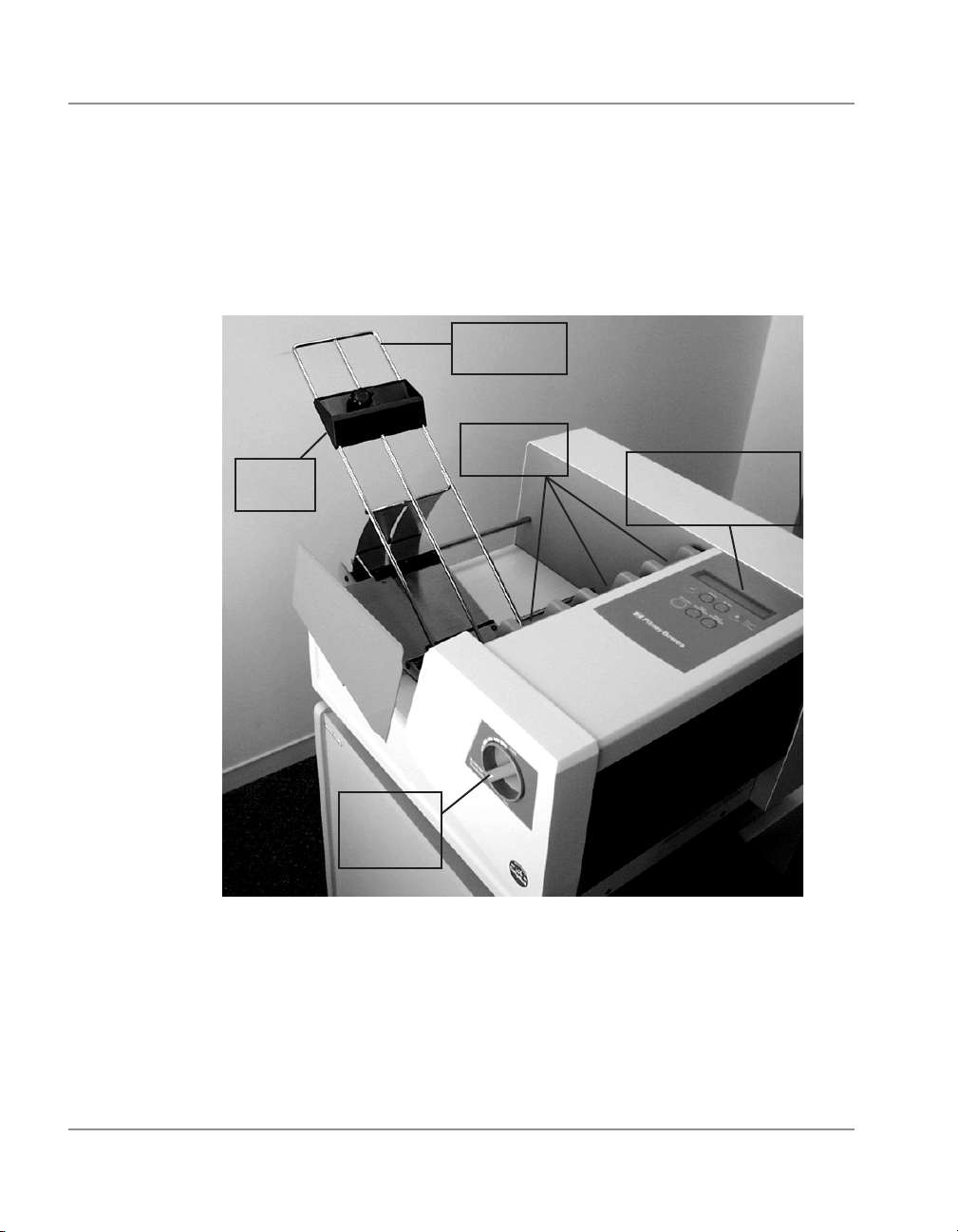

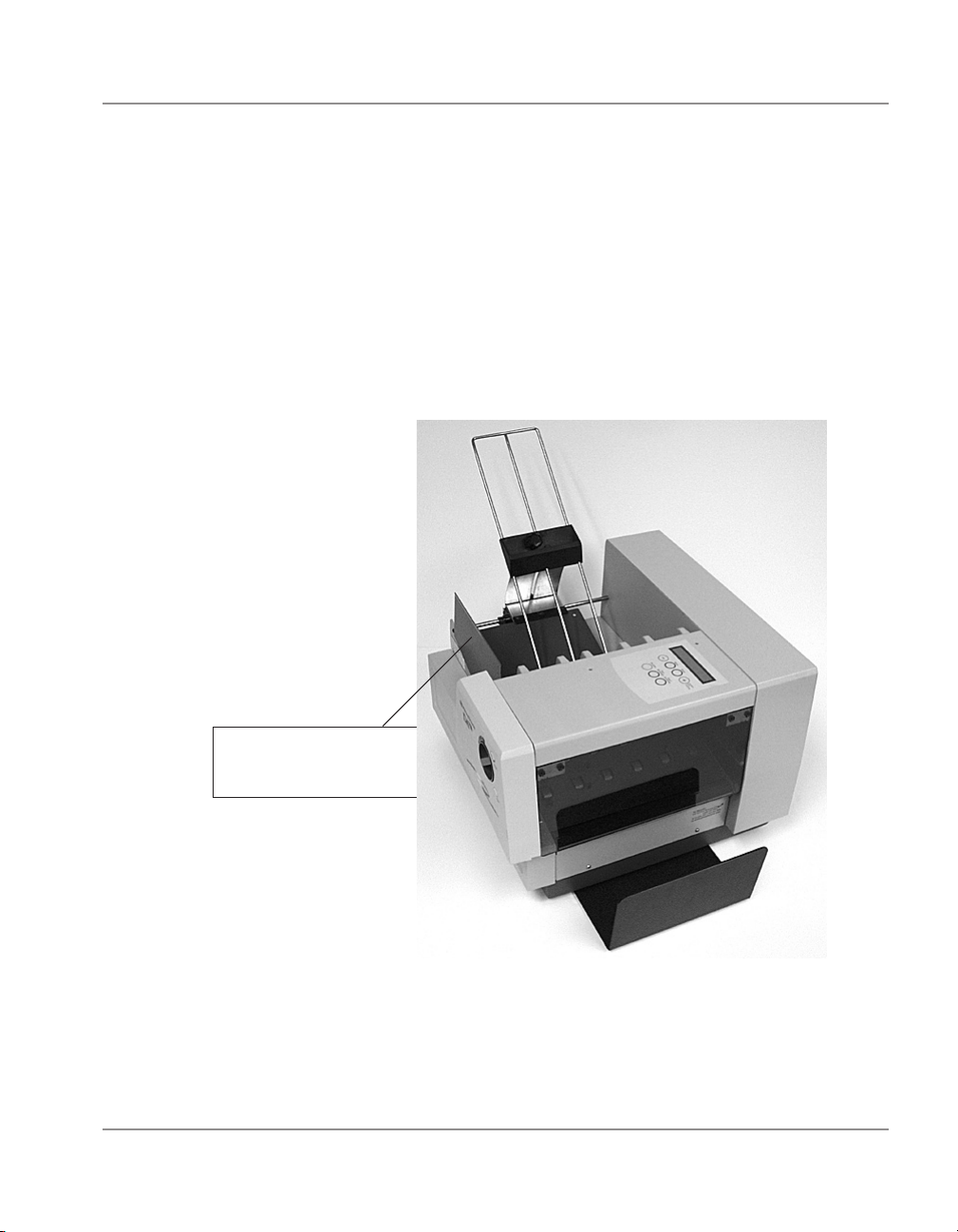

As you remove the DA700/DA750 contents from the box,

note the components of the printer, labeled below.

Wire Frame

Assembly

H-Block

Sliding

Fence

Separators

Control Panel

(LCD Display and

Keypad)

Media

Thickness

Knob

2-2 SV61027 Rev. D

Page 17

Getting Started with the DA700/DA750 Printer • 2

Unpacking

the Printer

(continued)

Package Contents

• DA700/DA750 Printer

• Output Stacker

• Wire Frame with Material Prop, Washer and

Retaining Knob (Input Material Stacker assembled)

• Sliding Fence (long)

• Sliding Fence (short)

• Power Cord

• Parallel Cable

• Printer Operating Guide

• Printer Driver Software

• Ink Jet Cartridge (Black)

(Black & Color for the DA750)

• Operator Training Guide

• POSTNETTM Certificate

• Installation Quality Report

• Print Head Shipment Holder (remove before turning unit

on)

• Quick-Start Instructions

• Shipping Support

(remove before turning unit on)

2-3SV61027 Rev. D

Page 18

2 • Getting Started with the DA700/DA750 Printer

Choosing a

Location for

Your Printer

Important

Safety Notes

Follow these guidelines and safety precautions when selecting a location for your printer:

• Place the printer on a table or other stable, level

surface within the cable’s length (Parallel 10 feet

max.; Serial 15 feet max.) of your computer.

• Allow for adequate space. The DA700/DA750 is 14.7

inches high, 16.2 inches wide and 21.7 inches deep,

without the wire frame input stacker.

• Allow for adequate ventilation around the base and

rear of the printer.

• Protect the printer from heat, dust and moisture.

Avoid placing the printer in direct sunlight.

• To protect against electric shock, plug the machine

into a properly grounded wall outlet.

• DO NOT use an adapter plug. Use of an adapter

could compromise the ground and cause a possible

shock hazard or damage to the equipment in the

event of a short circuit.

• DO NOT remove the ground pin from the line cord.

• Avoid using outlets controlled by wall switches.

Someone could accidently shut your printer off.

• The power cord wall plug is the primary means of

disconnecting the machine from the AC power. The

wall outlet should be near the machine and easily accessible.

• DO NOT route the power cord over sharp edges or

trap it between pieces of furniture.

• Insure that there is no strain on the power cord where

it passes between the equipment, walls or furniture.

• Be certain the area in front of the wall receptacle into

which the machine is plugged is free from obstruction.

2-4 SV61027 Rev. D

Page 19

Getting Started with the DA700/DA750 Printer • 2

Important

Safety Notes

(continued)

Assembling the

DA700/DA750

• DO NOT remove covers. The machine covers serve

to enclose hazardous parts. If the machine has been

dropped or has otherwise had the covers stressed in any

way, report it to your Pitney Bowes Customer Service

Representative.

• To reduce the risk of fire and/or electrical shock, do not

attempt to disassemble this machine. If service is required, contact your Pitney Bowes Customer Service

Representative.

• Keep fingers, loose clothing, jewelry and long hair away

from the moving parts.

• Use only Pitney Bowes approved ink cartridges and

cleaners. Read all instructions before attempting to operate the equipment.

• Follow any specific occupational safety and health stan

dards for your workplace or area.

Once you’ve placed the printer in a suitable location, assemble the printer components in the following order:

NOTE: Do not plug the printer into the power source until

you’ve completed steps 1-4.

-

1. Attach the wire frame input stacker (page 2-6).

2. Install the sliding fence (page 2-7).

3. Position the output stacker (page 2-8).

4. Connect the parallel or serial cable (page 2-9).

5. Attach the power cord and turn the printer ON

(page 2-11).

2-5SV61027 Rev. D

Page 20

2 • Getting Started with the DA700/DA750 Printer

Assembling

the DA700/

DA750

(continued)

Insert the metal sheet into

the height adjustment slot.

Attach the Wire Frame to the Printer.

1. Hook the bottom edge of the wire frame under the de

flector. The wire frame slides between the feed rollers

and the paper deflector. Make sure the front rod is engaged into the key slot bottom.

Slide bottom edge

under here.

-

2. Rotate the wire frame and insert the curved metal sheet

on the bottom of the frame into the height adjustment

slot.

3. Adjust the angle of the wire frame so it’s positioned at

about a 45 degree angle. Turn the lock knob on the side

of the slide clockwise to hold the wire frame in position.

You can adjust both the height and side-to-side position

of the wire frame to accommodate the size and type of

the material you’re running. We talk about this in the next

chapter.

2-6 SV61027 Rev. D

Page 21

Getting Started with the DA700/DA750 Printer • 2

Assembling the

DA700/DA750

(continued)

Install the Sliding Fence

The DA700/DA750 has two fences—a long one and a short

one. Use the short fence when printing material smaller than

a #10 envelope. Use the long fence for larger material.

1. Slide the square edge of the sliding fence into the slots

on the frame slide as shown below.

Insert Sliding Fence

between Slide Guides

and Feed Carriage.

2. The next chapter explains how to set the fence to the

width of the material you’re running.

2-7SV61027 Rev. D

Page 22

2 • Getting Started with the DA700/DA750 Printer

Assembling

the DA700/

DA750

(continued)

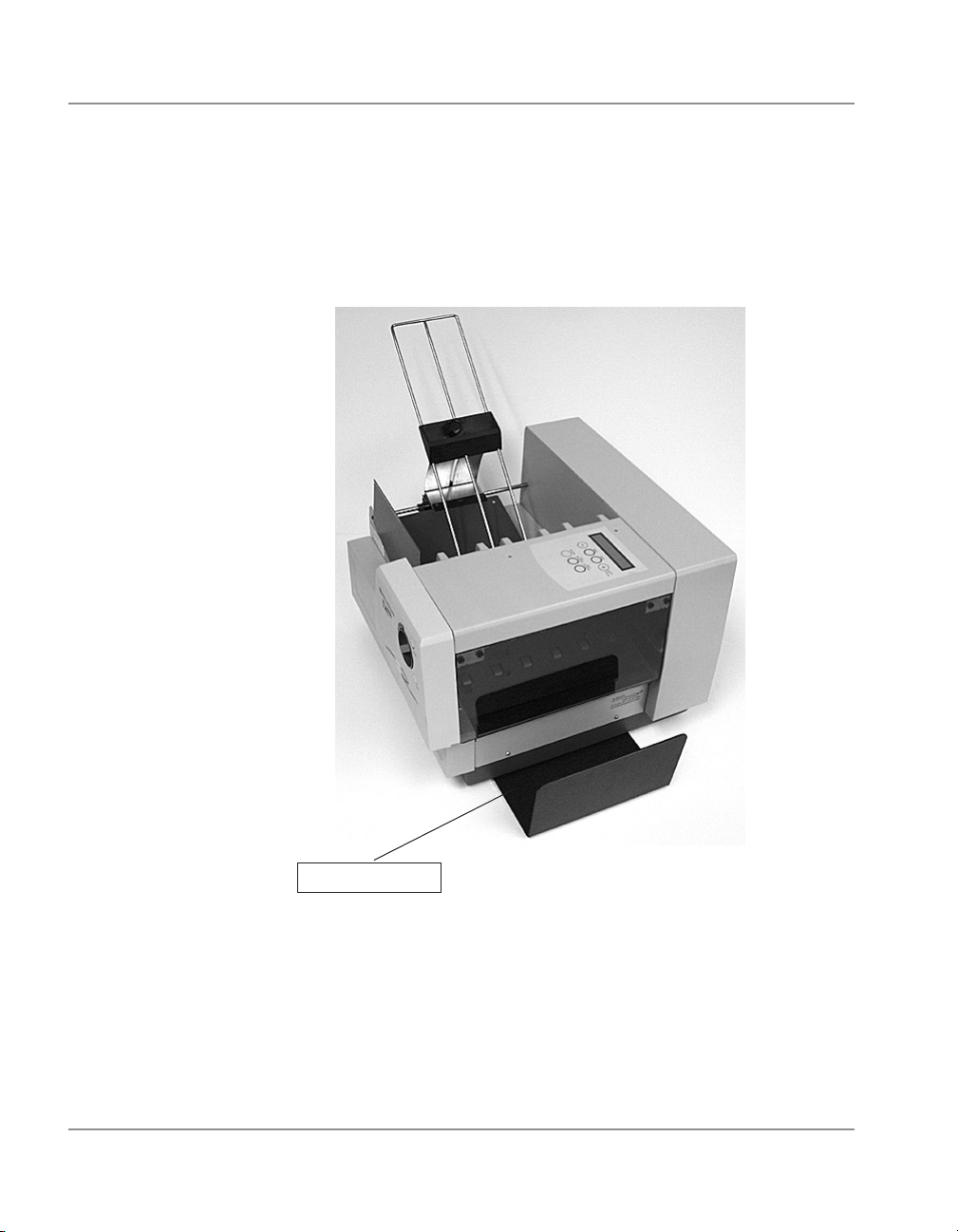

Position the Output Stacker Tray

Printed material is deposited in the output stacker tray. The

tray can stack up to 150 #10 envelopes. Slide it into position

under the back of the printer as shown below.

Stacker Tray

2-8 SV61027 Rev. D

Page 23

Getting Started with the DA700/DA750 Printer • 2

Connecting the

DA700/DA750 to

Your Computer

Connecting the Parallel Cable or Serial Cable

Use the parallel cable supplied to connect the DA700/DA750

to your computer, or use an approved serial cable. Each

end of the parallel cable has a connector. One end is labeled

“Printer” and the other is labeled “Computer.”

1. To connect the Parallel Cable (supplied) to the printer,

align the end of the cable connector labeled “Printer” with

the parallel port located on the right side of the printer’s

interface panel, and push the cable connector into the

port. The interface panel is located at the rear of the

printer. It contains the main power switch, the parallel

cable port, the serial port, the power receptacle and fuse.

Parallel Port

2. Secure the connector by snapping the two wire clips

over the corresponding tabs on the connector.

Serial Port

2-9SV61027 Rev. D

Page 24

2 • Getting Started with the DA700/DA750 Printer

Connecting the

DA700/DA750 to

Your Computer

(continued)

3. Align the end of the cable connector labeled “Computer”

with the printer port on your computer and push the cable connector into the port.

4. To connect a Serial Cable (not supplied) to the printer,

align the 25-pin male connector end of the cable with the

serial port on the left side of the printer’s interface. Attach the cable to the printer and the computer’s hex jack

screws using the thumb screws in the connectors.

5. Initialize the printer’s communications port by sending

data to either the parallel or serial port. To change from

the serial port to the parallel port, or vice versa, the printer must be re-initiailized or manually changed through

the setup menu.

2-10 SV61027 Rev. D

Page 25

Getting Started with the DA700/DA750 Printer • 2

Plugging in the

Power Cord

Connecting the Power Cord

1. Connect the power cord to the printer at the interface

panel, shown below.

Power Switch

2. Plug the power cord into a grounded outlet. Please

review the safety information on pages 2-4 and 2-5.

Power Receptacle

Turning on the

DA700/DA750

Once you’ve connected the cable, press the printer’s power

switch to the “|” (ON) position. The switch is located next to

the power cord receptacle.

When you turn the printer on:

• The LCD menu displays that the printer is initializing and

automatically displays “ON LINE”.

• The print head carriage moves to the right and parks in

the maintenance station.

2-11SV61027 Rev. D

Page 26

2 • Getting Started with the DA700/DA750 Printer

Installing and

Removing

the Ink Jet

Cartridge

Install the Ink Jet Cartridges

The printer uses Ink Jet Cartridges for printing (DA750 uses

color and black; DA700 uses black only). You must install a

black and a color cartridge in the DA750 (a black only for the

DA700) before you can print. To begin:

1. With the printer on, press the ON LINE key until the dis

play reads OFF LINE.

2. Open the back cover of the printer.

3. Press the “Replace Print Cartridge” key on the control

panel to move the carriage to the middle of the printer.

Do not attempt to move the carriage by hand. Doing so

can result in damage to the carriage assembly.

4. Remove the cartridge from its shipping container by peel

ing the top cover off. Be careful not to touch the gold con

tacts.

-

-

-

WARNING! The ink in the cartridge may be

harmful if swallowed. Keep new and used

cartridges out of reach of children. Discard

empty cartridges immediately.

5. Gently remove the tape covering the ink nozzles on the

print cartridge, being careful not to touch the copper

nozzles.

2-12 SV61027 Rev. D

Page 27

Getting Started with the DA700/DA750 Printer • 2

Installing and

Removing the

Ink Jet Cartridge

(continued)

6. Gently insert the cartridge (color to the right, black to the

left-DA750 only) into the carriage at approximately a 20

degree angle with copper strip to the bottom and in first.

Press down on the cartridge until it is seated.

7. Push the cartridge forward (away from you) until it snaps

in place.

IMPORTANT! When installing cartridges in the DA750,

immediately perform the CMYK Printing Alignment pro

cedure. See page 5-5 for instructions.

Removing the Ink Jet Cartridge

When you need to remove or replace the ink jet cartridges,

follow these steps:

1. With the printer on, press the ON LINE key until the dis

play reads OFF LINE.

2. Open the printhead cover of the printer.

2-13SV61027 Rev. D

-

-

Page 28

2 • Getting Started with the DA700/DA750 Printer

Installing and

Removing the

Ink Jet Cartridge

(continued)

3. Press the Replace Print Cartridge key on the control

panel. This moves the carriage to the middle of the printer. Do not move the cartridge by hand.

4. To remove the ink jet cartridge, place your thumb on the

grooved surface and press down slightly then tilt towards

you until it pops loose.

5. Lift the print cartridge out of the cradle.

2-14 SV61027 Rev. D

Page 29

Chapter 3

DA700/DA750 Features

and Adjustments

In this chapter you'll learn about key

features of the DA700/DA750 printer

and how to adjust it to meet the requirements of your print jobs.

In this chapter:

Printer Features ........................... 3-2

DA700/DA750 Throughput ..........

Setting Up a Job ..........................3-6

Set the Separator Gap ................3-9

Center the Wire Frame .............. 3-11

Set the Feed Angle ....................

Set the Wire Frame Ramp ......... 3-14

Position the Feed Fence ...........3-15

Load Material ............................. 3-16

Adjust Media

Thickness Knob .........................3-17

Adjust Exit Rollers .....................3-19

Print a Test Piece .......................

3-3

3-12

3-21

Page 30

3 • DA700/DA750 Features and Adjustments

Printer

Features

The DA700/DA750 has the following features:

Speed (Throughput): Refer to chart on next page.

Print Qualities: Draft, Letter, Executive

Internal Fonts: 13 (14 including Barcode)

Optional Font Card

Font Point Size: 4 to 30

Material Thickness: 0.003" to .250"

Speed

Printer speed refers to the number of pieces of mail that

can be processed in an hour. Printer speed depends on the

number of characters per line, the number of lines, character

size, font, interface, barcode, material size and graphics.

Print Qualities

The printer has three selectable print qualities: Draft (fastest speed), Letter (medium speed) and Executive (slowest

speed).

Internal Fonts

A font is a set of characters (letters, numbers and symbols)

that use the same typeface. The DA700/DA750 has thirteen

(plus barcode) different typefaces: Courier, Sans Serif, Ro

man, Baxter, Ding bat, Hancock, Marina, Quincy, Silicon,

Springer, Stencil, and Windmill. You can select these fonts

from the printer control panel menus. If you set up a print job

from your computer, you can use any font that is available

from your software application.

3-2 SV61027 Rev. D

-

Page 31

DA700/DA750 Features and Adjustments • 3

DA700/DA750 Throughput

Throughput specifications for the printer have the following parameters in common: 18

average characters per line; 10 pt character size; Roman font; normal print width; bold off;

parallel interface; each line terminated with CR LF; each address terminated with FF. (All

speeds rated in pieces/hour.)

Printing Black (DA700) / Black with Color Cartridge Removed (DA750)

#10 Envelopes: 600 x 200 dpi 14,000 letters per hour (lph)

600 x 300 dpi 13,000 lph

600 x 600 dpi 11,000 lph

Printing Black, Color Cartridge Installed (DA750 only)

#10 Envelopes: 600 x 200 dpi 11,000 letters per hour (lph)

600 x 300 dpi 10,000 lph

600 x 600 dpi 9,000 lph

Printing Color with Color Cartridge Installed (DA750 only)

Minimum throughputs for destination address (three lines without barcode) in printing with

color cartridge using the H.P. 51641A Head:

#10 Envelopes: 300 x 150 dpi 5,000 letters per hour (lph)

300 x 200 dpi 4,600 lph

300 x 300 dpi 3,000 lph

3-3SV61027 Rev. D

Page 32

3 • DA700/DA750 Features and Adjustments

Printer

Features

(continued)

Font Size

Font size refers to the size of each typeface, and is measured in points. The DA700/DA750 uses from 4 to 30 point

size for internal or downloaded fonts.

Material Thickness

Thickness refers to the size of the material that is processed

through the printer. The DA700/DA750 can handle material

from .003" up to .250" thick.

Media Size

The DA700/DA750 can print on the following range of material sizes.

Width Height Thickness

Maximum 15.5" 15" 25"

(399.4 mm) (381 mm) (6.35 mm

Minimum 3 " 5" .003"

(76 mm) (127 mm) (.0762 mm)

For envelope addressing purposes, the DA700/DA750 is

compatible with any word processor or database application

that can print a mailing label.

Approved Media Types

The printer can be used with the following types of material:

• Envelopes • Postcards

• Booklets • Self Mailers

• Catalog Envelopes • Paper

All envelopes must be without windows, empty and unsealed. Any folded material needs to be tabbed on the lead

ing edge.

Refer to Appendix B, Specifications, for detailed specifications for the DA700/DA750, including specific requirements

for using each type of material.

3-4 SV61027 Rev. D

-

Page 33

DA700/DA750 Features and Adjustments • 3

Printer

Features

(continued)

Other printer features include:

• Ink Jet technology with shuttling head.

• Interface to a standard IBM® compatible

computer.

• Prints USPS POSTNET certified bar code.

• LCD menu display available in seven languages.

• Memory capable of storing up to eight jobs.

• Printing virtually anywhere on an envelope.

• Graphic printing capability.

3-5SV61027 Rev. D

Page 34

3 • DA700/DA750 Features and Adjustments

Setting Up A Job

Setting up a print job means adjusting the printer to accommodate the width, height, thickness and weight of your material. The setup adjustments and the quality of your material

determine how reliably your printer feeds the material.

A good setup minimizes misfeeds and jams. And, your

printer will perform at its best when you run material that

falls within our published specifications. See Appendix B for

complete material specifications.

The figure below calls out key machine adjustments. Each

of these is briefly described starting on the next page. In the

pages that follow, we explain each adjustment in detail.

3

2

1

7

10

9

4

5

3-6 SV61027 Rev. D

6

8

Page 35

DA700/DA750 Features and Adjustments • 3

Setting Up A Job

(continued)

1. H-Block Separators

Adjust to the thickness of your material. The gap between

the H-Block separator fingers and the feed rollers should

be just enough to allow a single piece to feed through the

printer.

2. Interface Panel (Not Shown)

Located on the lower part of the rear cover, the panel has

the ON/OFF switch, parallel cable connector and power

cord receptacle.

3. Wire Frame

Supports the material stack. Adjust the feed angle to ac

commodate the weight of the material you're running.

Adjust its side-to-side position so it's centered under the

stack.

4. Material Prop and Lock Knob

The prop adds a gentle slope to the stack to help feeding.

Adjust so the top of the prop is even with the top of the

stack. Secure the prop with the lock knob.

-

5. Wire Frame Slide and Wire Frame Slide Lock Lever

(Not Shown)

Slides the wire frame side to side. Lock in position with the

lock lever.

6. Feed Fence (Not Shown)

Helps confine the stack. Adjust to the width of your material

plus 1/16" clearance.

3-7SV61027 Rev. D

Page 36

3 • DA700/DA750 Features and Adjustments

Setting Up A Job

(continued)

7. Control Panel

Use the control panel buttons to access printer menus, define print options, run the print job, position the print carriage

and turn the printer on and off line. See Appendix A,

Printer Menus, for detailed instructions.

If you have the DA700/DA750 print driver loaded on your

computer, you can easily perform these functions from within

your software application.

8. Stacker Tray

Printed material is deposited in the stacker (catch) tray. The

tray holds about 5" of material.

9. Exit Rollers (Not Shown)

Guide the printed material as it exits the printer. Adjust so

that each roller overlaps the edge of the material by at least

1/4".

10. Print Area Door Assembly

Open to gain access to the print cartridge and exit rollers.

3-8 SV61027 Rev. D

Page 37

DA700/DA750 Features and Adjustments • 3

Setting Up A Job

(continued)

1. Set the

Whenever you switch from one material type to another, you

need to set the gap between the separators and the feed

roller before printing begins.

NOTE: There are three positions of the "H" Blocks.

• Lever fully down - adjusted to media thickness (ready

to operate).

• Lever midpoint - not adjusted to any media (free

floating on media, not set up to operate).

• Lever fully up - locked in the up position, not adjusted

to any media thickness.

Separator Gap

H-Blocks

Setting the Proper Feed Gap

1. Loosen the lock knobs to unlock all three H-Blocks.

2. Lift the H-Blocks to their highest position and lock in

place.

3. Place a sample piece of material between the sepa

rator fingers (the lower section of the H-Blocks) and

the feed roller.

-

3-9SV61027 Rev. D

Page 38

3 • DA700/DA750 Features and Adjustments

Setting

Up A Job

(continued)

4. Lower only the H-Blocks that come in direct

contact with the material and let them touch the

material.

5. Lock each separator in place. When lowering the HBlocks, check that the material is between the separator tabs and the feed roller.

Setup Example Using #10 Envelopes:

1. When you set the feed gap for a #10 envelope, note

that the width of the envelope will fall completely under the inside and middle H-Blocks, but only half way

under the outer H-Block. Follow steps 2 through 4 to

fix this.

2. Remove the sliding fence.

3. Place a second envelope next to the first, under the

outer H-Block. Place the second envelope flap down

with the short edge under the outer H-Block.

4. Lock the separator in place.

NOTE: If the separator gap is not set properly, the

printer will misfeed.

• If the gap is too big, the printer will feed doubles

(two or more pieces at the same time).

• If the gap is too small, material will jam at the

feed roller entrance.

3-10 SV61027 Rev. D

Page 39

DA700/DA750 Features and Adjustments • 3

Setting Up A Job

(continued)

2. Center the Wire Frame under the Material

This adjustment helps eliminate skewing.

1. Unlock the feed carriage assembly by pushing the

locking lever down.

2. Adjust the feed carriage by aligning with the center of

the media.

3. Lock the feed carriage again by pulling the lever

up.

Locking lever

pushed down

3-11SV61027 Rev. D

Page 40

3 • DA700/DA750 Features and Adjustments

Setting

Up A Job

(continued)

3. Set the Feed Angle

The height of the wireframe input stacker depends on the

type of material you're running:

• Heavy material—adjust to a low angle

• Standard material—adjust to the center (45 degree

angle)

• Light material—adjust to a high angle

To make the adjustment:

1. Unlock the knob on the wireframe slide by turning

counter clockwise.

2. Move the wireframe up or down as required by

sliding the retaining knob.

Lock

Scale

3. Turn the lock knob clockwise to secure the

wireframe.

NOTE: Center line of the knob aligns with

relative number of the scale. Refer to the

scale on following page.

3-12 SV61027 Rev. D

Page 41

DA700/DA750 Features and Adjustments • 3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Setting Up A Job

(continued)

The center of the knob aligns with number 1 for a typical 3" x 5" post card.

The center of the knob aligns with number 3 for a typical # 10 envelope.

The center of the knob aligns with number 12 for typical 8 1/2" x 11" copy paper.

Note: The above settings are

suggested settings. You can adjust

the wire frame accordingly (up or

down) until the desired feed

throughput is achieved.

3-13SV61027 Rev. D

Page 42

3 • DA700/DA750 Features and Adjustments

Setting Up A Job

(continued)

4. Set the Wire Frame Ramp

Slide Ramp

Upward—Slide the

ramp to the top of

the Wire Frame.

Slide Ramp

Down—With the

Feed Gap properly

set for one piece of

media, slide the ramp

down.

Adjust Ramp to Edge

of Media —Add a stack

of media and adjust the

ramp downward until

the first piece of media

is resting half way down

the angle of the ramp

surface as pictured below (one piece of media

is shown for simplicity).

NOTE: This picture is

shown without the Sliding Fence, for ease of

illustration.

3-14 SV61027 Rev. D

Page 43

DA700/DA750 Features and Adjustments • 3

Setting Up A Job

(continued)

5. Position the Feed Fence

Your printer comes with two feed fences—a long one and a

short one. Use the long fence for #10 envelopes and larger

materials. Use the short fence for materials smaller than a

#10 envelope.

It is important that the sliding fence not be adjusted tight

against the media.

To position the fence:

1. Place a sample piece or trial stack of material in the

input area.

2. Slide the fence until it almost touches the stack of

material.

3. Check that there's about 1/16" clearance (the thickness of a dime) between the fence and the stack.

NOTE: Proper clearance is important. If you push the

fence tight up against the stack, it could retard feeding

and cause jams. If the clearance is too great, pieces

could skew as they feed into the printer.

Adjust Sliding Fence

to media width.

3-15SV61027 Rev. D

Page 44

3 • DA700/DA750 Features and Adjustments

Setting Up A Job

(continued)

6. Load Material

Once your printer is set up, you can load material and make

a test print.

To avoid misfeeds, follow these instructions:

1. Make sure the input area is free of dust and other

matter.

2. Take a manageable amount of material and while

holding it as shown, fan all sides of the material to

separate each piece. This step helps keep misfeeds

to a minimum.

3. Tamp the material on a flat surface, making sure

that the stack is square.

4. Shingle the stack as you load it into the input area.

Load envelopes so the side to be printed aces up.

Flaps should be down and oriented away from the

feed roller (flaps trailing). Position the right edge of

the envelopes flush against the rear wall.

Begin with just a few envelopes to start the stack and

get the proper contour, then add several more pieces.

Then add the remainder of the stack.

5. Adjust the position of the media thickness knob as

described on the next page.

3-16 SV61027 Rev. D

Page 45

DA700/DA750 Features and Adjustments • 3

Setting Up A Job

(continued)

7. Adjust the Media Thickness Knob

The media thickness knob sets the distance between the

printhead and the material. Use it to compensate for differ

ent material thicknesses and to increase clarity of the printing.

1. Estimate the thickness of the material to be run

NOTE: All material in a run must be the same thickness.

For envelopes with 0 - 2 inserts, start with the media thick ness knob set as shown below. For 1/4" thick material,

start with setting all the way at the Thick side. For 1/8",

start 1/2 way.

2. While running test samples, turn the knob

counter-clockwise to close the gap until the desired

quality of printing is obtained.

NOTE: Adjusting the media thickness knob too far

counter clockwise may cause smearing or jamming.

3-17SV61027 Rev. D

Page 46

3 • DA700/DA750 Features and Adjustments

Setting

Up A Job

(continued)

A Note about Print Quality

The DA700/DA750 is designed to feed and print on a range

of materials with various finishes and coatings. However

the sharpness of the print may vary with different materials,

depending on how absorbent the surface is, as well as other

qualities.

You'll get best results using white wove bonded stock. Print

ing is less sharp on Tyvek, recycled and glossy material. It is

also possible that ink may not dry thoroughly on certain very

glossy materials.

Always test high gloss materials for their drying qualities before you buy them in quantity and attempt to run a print job.

A dryer may be needed for high gloss material.

-

3-18 SV61027 Rev. D

Page 47

DA700/DA750 Features and Adjustments • 3

Setting

Up A Job

(continued)

8. Adjust the Exit Rollers

Adjust the exit rollers so they overlap the left and right edges

of the material by 1/4". Rotate the release lever to vertical

then slide the rollers from side to side to make the adjustment and press the lever down to lock. Must be down and

latched to operate.

Exit Roller

Release Lever

IMPORTANT: Make sure the rollers do not touch any

printed area of the material. If this happens, the rollers

will act like a printing press and imprint a faint impression

at incremental distances on the material. If this happens,

move the roller or rollers toward the nearest clear zone,

that is, an area free of printing.

Exit Slide Rollers (in

jam-clearing position)

3-19SV61027 Rev. D

Page 48

3 • DA700/DA750 Features and Adjustments

Setting Up A Job

(continued)

Output Stack Height

The output stacker holds up to five inches of material

before it becomes necessary to remove the stack

from the bin. The optional W760 stacker increases

capacity to 300 #10 envelopes.

NOTE: As the stack approaches the 5" limit, there is a potential for stacking misfeed (pieces not neatly stacked one on

top of the other). This can cause envelopes to stack out of

ZIP Code sequence.

3-20 SV61027 Rev. D

Page 49

DA700/DA750 Features and Adjustments • 3

Setting Up A Job

(continued)

9. Print a Test Piece

1. Make sure material is loaded properly. (Or you can

use a single test piece if you'd like to check that your

setup adjustments are okay.)

2. Turn the printer ON. The ON/OFF switch is located

on the interface panel at the rear of the machine.

Display

On Line

3. Press the ON LINE button on the printer control

panel until the LCD display reads OFF LINE.

4. Press the Test Envelope button. A single envelope

will feed and a sample address should print.

5. Check the print quality. If it's not what you want,

adjust the media thickness knob (page 3-14) as

required and run another test piece.

When you're satisfied with your setup adjustments, you're

ready to run the job. The next chapter explains how to use

the printer with your computer.

Test Envelope

3-21SV61027 Rev. D

Page 50

3 • DA700/DA750 Features and Adjustments

This page is intentionally blank.

3-22 SV61027 Rev. D

Page 51

Chapter 4

Using the

DA700/DA750

With Your Computer

This chapter has instructions for installing the DA700/DA750 printer driver and

using the printer with your computer. It

also briefly explains Envelope Designer™

Plus, the Pitney Bowes envelope design

software that comes with the printer.

In this chapter:

Printer Driver Software ................ 4-2

Selecting Printer Properties ......... 4-3

Using the Printer Properties

Windows ......................................4-4

Selecting the DA700/DA750

from a Windows Application ......

Envelope DesignerTM Plus ......... 4-15

4-14

NOTE: The DA750 is shown in this chapter;

the DA700 is similar. The screen captures

used to illustrate setup options were taken

from the Windows™ 2000 operating system.

Page 52

4 • Using the DA700/DA750 with Your Computer

Printer Driver

Software

Before you can use your printer with your computer, you

must install the DA700/DA750 printer driver. The driver gives

your computer information about the printer you're using,

and tells the printer about the settings you want to use in

your print job.

If you have not previously installed the printer driver on your

computer, refer to the installation instructions furnished with

it.

The printer drivers are contained on the Envelope Designer

Plus CD that comes with your printer. Select "printer drivers"

from the initial screen and follow the on-screen prompts.

The product code is on the label sheet contained in the pack.

4-2 SV61027 Rev. D

Page 53

Using the DA700/DA750 with Your Computer • 4

Selecting

Printer

Properties

This section describes printer properties and how to select

available options. To access the main properties window, follow these steps:

1. Click the "Start" button in the task bar, then select "Set

tings."

2. Click "Printers." The Printer window displays.

3. Right click the Pitney Bowes icon, then left click the

Properties option.

The Properties window opens and displays seven tabs,

each of which allows access to different printer options. Note

that the General tab window displays when the Properties

window opens.

-

To access another option, left click on the appropriate tab.

A window for the selected option displays.

4-3SV61027 Rev. D

Page 54

4 • Using the DA700/DA750 with Your Computer

Selecting Printer

Properties

(continued)

Using the Printer

Properties

Window

NOTE: An explanation of items in each window is also

available by doing the following:

• Right click an item to display the "What's This"

button.

• Right or left click this button to display information

about the selected item.

Use of the window for each tabbed item follows, starting with

the General tab window.

If the General tab window is not currently active, left click the

General tab.

Use the Location area to specify where the printer resides.

You can use alphanumeric characters to designate the site.

For example, if your printer is in building 27 in area C, you

could specify 27/C as the Location entry.

4-4 SV61027 Rev. D

Page 55

Using the DA700/DA750 with Your Computer • 4

Using the Printer

Properties

Window

(continued)

Use the Comment area to make a statement about the

printer. For example, you might want to indicate what the

printer should be used for and when it is available.

If this printer is shared, the comment entered in this area

displays on the computers sharing this printer.

NOTE: The DA700/DA750 printer driver does not support sharing.

Click "Printing Properties" to change the printer's default

settings. Default options include document orientation and

paper source. Click "Advanced" in the Printing Preferences

window to access other settings such as print quality and

paper size.

4-5SV61027 Rev. D

Page 56

4 • Using the DA700/DA750 with Your Computer

Using the

Printer

Properties

Window

(continued)

To display the Sharing window, left click the Sharing tab in

the Properties window.

To configure the printer for private use, choose the "Not

Shared" option. Only the user logged onto the computer will

be able to use this printer.

The window shown here is a standard Windows driver

dialog. It was not developed nor is it supported by Pitney

Bowes.

DO NOT change the settings in this tab; Pitney Bowes does

not support networking of its Envelope printers.

4-6 SV61027 Rev. D

Page 57

Using the DA700/DA750 with Your Computer • 4

Using the

Printer

Properties

Window

(continued)

To display the Port window, left click the Port tab in the

Properties window.

The displayed list shows the available ports, the associated

port monitor, and the printers that use the ports.

To add another port to the display list, click "Add Port." Fol

low the subsequent prompts to identify and name the new

port(s).

To delete a port, select the desired port and then click "De

lete Port."

To set the transmission retry value, click "Configure Port",

enter the desired number of seconds, then click "OK."

-

-

4-7SV61027 Rev. D

Page 58

4 • Using the DA700/DA750 with Your Computer

Using the

Printer

Properties

Window

(continued)

To display the Advanced window, left click the Advanced tab

in the Properties window.

To make the printer available 24/7, select the "Always available" option.

To configure the printer for limited availability, select the

"Available from" option, then enter the desired time frame.

NOTE: If a document is sent to the printer when it is unavailable, the document will be held (spooled) until the printer is

available.

Use the Priority area of this window to rank the status of the

document to be printed. Settings range from 1 to 99, with 1

indicating the highest priority.

4-8 SV61027 Rev. D

Page 59

Using the DA700/DA750 with Your Computer • 4

Using the

Printer

Properties

Window

(continued)

The name of the installed driver displays in the "Driver" area.

This usually matches the name of the print device, however,

for the DA700/DA750, you will see "Pitney Bowes W700/

W790" instead.

To install a new driver, click "New Driver" to launch the Add

Printer Driver Wizard. Follow the prompts to select and install the desired printer driver.

Spooling and Printing Options

Spooling is the process of storing the document on the hard

disk and then sending it to the printer. Right click each option and read the 'What's This?" topic for more information.

Choose the spooling options that best suit your needs:

• To have the document printing in the background, select

the "Spool print documents so program finishes printing

faster" option.

• To ensure that the whole document is ready at the same

time for printing, select the "Start printing after last page

is spooled" option.

• To start printing as soon as the first page of a document

is received by the printer, select the "Start printing immediately" option.

To send the document directly to the printer and by pass

spooling, select the "Print directly to the printer" option.

To direct the printer to check that its setup matches the document setup, select the "Hold mismatched documents."

4-9SV61027 Rev. D

Page 60

4 • Using the DA700/DA750 with Your Computer

Using the

Printer

Properties

Window

(continued)

When the option, "Print spooled documents first", is selected,

the printer operates at maximum efficiency by printing documents that have completed spooling regardless of their designated priority.

To direct the printer to keep printed documents in the queue,

select the "Keep printed documents" option.

To make the printer's advanced features available, select the

"Enable advanced printing features" option.

To change the default document properties:

1. Click "Printing Defaults."

2. Select the default options for document orientation and

paper source.

3. Click "Advanced" to access other settings such as, print

quality and paper size.

4. Click "OK" to return to the Printer Properties window.

To change the default print processor and/or data type:

1. Click "Print Processor...".

2. Select from the options available.

3. Click "OK" to return to the Printer Properties window.

4-10 SV61027 Rev. D

Page 61

Using the DA700/DA750 with Your Computer • 4

Using the

Printer

Properties

Window

(continued)

To display the Color Management window, left click the

Color Management tab in the Properties window.

To allow the system to select the best colors from the available profile, choose the "Automatic" option: this is the manufacturer-recommended choice.

If you want to choose the desired colors, select the "Manual"

option.

Use the color profile portion of this window to:

• Add or remove color profiles associated with this

printer.

• Change the default color profile.

4-11SV61027 Rev. D

Page 62

4 • Using the DA700/DA750 with Your Computer

Using the

Printer

Properties

Window

(continued)

To display the Security window, left click the Security tab

in the Properties window.

Pitney Bowes does not support Networking. Therefore,

adding or removing permissions should not be used.

4-12 SV61027 Rev. D

Page 63

Using the DA700/DA750 with Your Computer • 4

Using the

Printer

Properties

Window

(continued)

To display the Device Settings window, left click the Device

Settings tab in the Properties window.

Pitney Bowes recommends that you leave the manufacturerset default as it is in this window and refer to your envelope

printing application to change envelope sizes.

4-13SV61027 Rev. D

Page 64

4 • Using the DA700/DA750 with Your Computer

Selecting the

DA700/DA750

Printer from

a Windows

Application

The following steps explain how to select the DA700/DA750

printer from a Windows software application. The steps are

similar for most applications. You can also refer to your application's documentation for specific instructions on installing

selecting printers.

1. Start the software application that you use when printing

envelopes with the DA700/DA750 printer and open the

file you want to use.

2. From the File menu, select Print. The Print dialog box ap

pears.

3. Click on the arrow in the Printer Name box. When you

click on the arrow, a drop-down list box appears contain

ing the names of the available printers.

The illustration below shows a typical print dialog box

with the DA750 selected.

-

-

4. Click OK to send the job to the printer.

4-14 SV61027 Rev. D

Page 65

Using the DA700/DA750 with Your Computer • 4

Selecting the

DA700/DA750

Printer from

a Windows

Application

(continued)

Envelope

Designer™

Plus

Once you've made this selection, your print job will automatically go to the DA700/DA750 printer when you select File/

Print provided the DA700/DA750 is selected as the default

printer). Remember to change the printer selection back to

your regular printer for your other printing jobs.

The Pitney Bowes Envelope Designer™ Plus is an easyto-use program that helps you create professional-looking

envelope layouts quickly. With Envelope Designer Plus

you can create and position a mailing address, return address, single-line message, barcode and graphics. Envelope Designer Plus has an extensive online help system

and a Wizard that guides you through the entire design

process.

Envelope Designer™ Plus virtually eliminates the need for

setting up your envelope manually, using either the print

driver options or the printer's control panel menu options.

NOTE: Settings created in Envelope Designer™ Plus will

override the settings entered in Setup on the control panel

of the DA700/DA750.

To access Envelope Designer™ Plus:

1. Click "Start" in the task bar.

2. Select Programs.

3. Select Pitney Bowes Printing, then left click Envelope

Designer™ Plus. The program displays a sample en

velope for you to customize.

-

4-15SV61027 Rev. D

Page 66

4 • Using the DA700/DA750 with Your Computer

This page is intentionally blank.

4-16 SV61027 Rev. D

Page 67

Chapter 5

Printer

Maintenance

This chapter describes the maintenance

procedures you should perform on a

regular basis to keep your printer running trouble-free.

In this chapter:

Preventive Maintenance ..............5-2

Cleaning ......................................5-2

Print Quality Problems ................. 5-2

Exit Rollers ..................................5-3

Sensor ......................................... 5-3

Print Head Shaft .......................... 5-3

Floor Assembly and Top

Cover ...........................................5-4

CMYK Printing Alignment

(DA750 Only) .............................. 5-5

Page 68

5 • Printer Maintenance

Preventive

Maintenance

Cleaning

The Pitney Bowes DA700/DA750 Ink Jet Printer is designed

for trouble-free service with a minimal amount of care. You

should schedule regular cleaning of the Feed Rollers, Exit

Rollers and Lower Guide.

Caution

Clean print head, cartridge, ink surfaces and covers with

plain water only. (Water works best!)

Clean all rubber rollers with the Pitney Bowes Multi-Purpose

Cleaning Kit Number 902-0.

Use of any other cleaning solvents will void all warranties.

Keep petroleum based cleaning solvents away from rubber or plastic parts. Anything but the recommended Pitney

Bowes Cleaning Kit solvent could cause premature breakdown of the rubber compound.

Print Quality

Problems

5-2 SV61027 Rev. D

The print head performs a self cleaning cycle periodically. If

print quality is unacceptable, try the following:

• Adjust the

print quality improves. If the printhead is too high above

the envelope, fuzzy printing results. If the knob is adjusted too low, envelopes jam or print smears.

• From the Setup Menu, select 3.

purging process clears any clogged ink on the print nozzle. Often this returns the print quality to a normal level.

See Appendix A, Control Panel Menus, for information

on using this feature.•

media thickness knob (page 3-18) to see if

Purge Printhead. The

Page 69

Printer Maintenance • 5

Print Quality

Problems

(continued)

Exit Rollers

Sensor

Print Head Shaft

• Clean the print head cartridge: dampen a soft cotton

cloth with water and wipe the nozzles clean (wipe in the

proper directions).

• Install a new ink cartridge (page 2-12).

If the right and left exit rollers are misaligned, that is, contact

printed surfaces, they can become contaminated with ink.

Use water to dampen a soft cloth and remove the ink from

the rollers.

A film and/or dust can build up on the sensors and cause

misfeeds of the material. Lift the transport door and use

compressed air to blow dust from the sensors. Cans of

compressed air are available from many computer supply

houses.

Periodically wipe the print head shaft clean with a dry, soft,

lint free, cotton cloth. DO NOT OIL! Refer to illustration on

the next page.

5-3SV61027 Rev. D

Page 70

5 • Printer Maintenance

Print Head Shaft

(continued)

Floor Assembly

and Top Cover

Print Head Shaft

Sensor

Periodically wipe the cover and floor assembly (feed deck)

with a soft cotton cloth, dampened with water only.

5-4 SV61027 Rev. D

Page 71

Printer Maintenance • 5

CMYK Printing

Alignment

(DA750 ONLY)

Your DA750 printer allows black (K) to print with color (CMY)

at the same time. This is known as CMYK printing. To ensure

proper printing, the black (K) and color cartridges (CMY)

must be correctly aligned. Perform the alignment procedure

below whenever you replace any of your cartridges.

1. Turn ON the DA750. When the startup completes, the

following screen displays.

2. Press plus (+) Replace Print Cartridge.

3. Replace the ink print cartridge if you haven't already

done so. The following prompt displays. Press any key to

continue.

4. When the "Reset color (or black) Ink..." prompt displays,

press plus (+) to reset the ink if you've just installed a

new cartridge; otherwise press minus (-) if you need only

to perform the alignment procedure.

5-5SV61027 Rev. D

Page 72

5 • Printer Maintenance

CMYK Printing

Alignment

(DA750 ONLY)

5. When the "ALIGN INK CARTRIDGES" prompt displays,

press (+ ):

6. When the prompt for horizontal color alignment displays,

insert an envelope into the printer and press ENTER.

7. The following prompt displays and the sample shown on

the next page prints on the envelope.

5-6 SV61027 Rev. D

Page 73

CMYK Printing

Alignment

(DA750 ONLY)

Printer Maintenance • 5

8. Press the (+) or (-) buttons to scroll through the selections (1-15) and choose the number that represents the

best horizontal alignment of the upper and lower lines

(for the color and black cartridges, respectively).

9. Insert an envelope into the printer and press ENTER.

The horizontal adjustment prompt displays and the

sample shown on the next page prints on the envelope.

5-7SV61027 Rev. D

Page 74

5 • Printer Maintenance

CMYK Printing

Alignment

(DA750 ONLY)

NOTE: The number you selected is highlighted

(underlined) and all lines on the envelope should now be

aligned.

10. Press MENU to return to the alignment choice window

11. Press (+) or (-) to move to the vertical alignment screens.

12. Insert an envelope into the printer and press ENTER.

The vertical adjustment prompt displays and the sample

shown on the next page prints on the envelope.

5-8 SV61027 Rev. D

Page 75

CMYK Printing

Alignment

(DA750 ONLY)

Printer Maintenance • 5

13. Press (+) or (-) to scroll through the selections (1-15)

and choose the number that represents the best vertical

alignment of the upper and lower lines (for the color and

black cartridges, respectively).

14. Insert an envelope into the printer and press ENTER.

The vertical adjustment prompt displays and the sample

shown on the next page prints on the envelope.

NOTE: The number you selected will be highlighted and

all lines on the envelope should now be aligned.

5-9SV61027 Rev. D

Page 76

5 • Printer Maintenance

CMYK Printing

Alignment

(DA750 ONLY)

15. Press MENU twice to return to the normal ON LINE

screen.

5-10 SV61027 Rev. D

Page 77

Chapter 6

Troubleshooting

This chapter lists common printer

problems and offers suggestions on

how to fix them.

In this chapter:

Problems and Solutions ..............6-2

Feed Problems ............................ 6-2

Print Quality Problems ................. 6-3

Interface Problems ......................6-5

Motor Problems ........................... 6-5

Barcode ....................................... 6-6

Other Problems ...........................6-7

6-1

Page 78

6 • Troubleshooting

Problems and

Solutions

Feed Problems

Before calling our Technical Operations Center or your Pit

ney Bowes Customer Service Representative, look for your

problem below. If you can solve the problem yourself, you

will be able to resume printing sooner. Also review the FAQs

on our web site.

Problem Intermittent Feed

Reason: Feed Ramp not used.

Solution: The feed ramp adds a gentle slope to the

stack and helps feeding. If you’re using the

prop, check the H-Block gap for proper separation. Also make sure the wire frame is centered

under the material. See Chapter 3.

Reason: Dirty feed rollers.

Solution: Clean the feed roller with the Pitney Bowes Mul

tipurpose Cleaning Kit (Number 902-0).

DO NOT use any other solvents or detergents.

They could damage the feed rollers.

-

-

Reason: Paper dust present (yellow or white residue),

blocking feed sensor.

Solution: Clean sensor with compressed air (see page

5-3).

Reason: Too much material in feeder (too heavy). Weight

of stack must be 20 lbs. or less.

Solution: Remove some material from stack.

6-2 SV61027 Rev. D

Page 79

Troubleshooting • 6

Print Quality

Problems

Problem Multifeed (Feeds Doubles) or Skewing

Reason: Separators (H-blocks) not set correctly. Also

feed fence set incorrectly.

Solution: Adjust H-blocks to thickness of material. See

page 3-10. Check feed fence position. See page

3-16.

Reason: Envelope thickness knob set too thick.

Solution: Reduce setting.

Problem No Print

Reason: Ink cartridge problem.

Solution: Purge ink cartridge (see page A-24).

Clean cartridge jets with soft cotton

cloth and water (in line with color as

shown).

Change to a new cartridge.

Problem Gray or Light Print - Black Ink Off Color or

Low Intensity - Color Ink (DA750 only)

Reason: Ink supply is low, or media thickness knob is set

too high.

Solution: Check adjustment of the media thickness knob

(page 3-18). If this fails to correct the problem,

replace ink cartridge (pages 2-12, 2-13).

6-3SV61027 Rev. D

Page 80

6 • Troubleshooting

Print Quality

Problems

(continued)

Problem Address Printing is not Sharp

Reason: Incorrect media thickness knob setting. Also,

unsuitable material.

Solution: Check whether envelope thickness knob is ad

justed too high (page 3-18).

Print quality is less sharp when using Tyvek,

recycled or glossy media.

Problem Address Smudging

Reason: Incorrect media thickness knob setting. Also,

ink may not dry on very high gloss material.

Solution: Check whether media thickness knob is adjust

ed too low (page 3-18).

Try using less glossy material.

Check exit rollers.

-

-

Problem Unwanted Bolding

Reason: Escape sequence turning on bold or bold selec

tion in printer’s menu options is set to bold.

Solution: Turn off bolding in software and/or turn bold

selection in printer menu OFF. See Appendix A

for instructions. If problem still exists, call Pitney

Bowes for service.

6-4 SV61027 Rev. D

-

Page 81

Troubleshooting • 6

Print Quality

Problems

(continued)

Interface

Problems

Problem Addresses “Walking”

Reason: Incorrect Address Setup.

Solution: Count carriage returns and line feeds and

adjust Lines Per Address to the same number.

Reason: Address Termination should be Form Feed.

Solution: Set Address Setup for 8 lines.

Check Line Termination: Typical, CR=CR;

LF=LF. Other choices, (CR=CR+LF;LF=LF),

(CR=CR;LF=CR+LF), (CR=CR+LF;LF=CR+LF)

Problem No Communications; Printer Does Not

Respond

Reason: Incorrect print driver, bad parallel or serial ca

ble, bad printer controller board.

Solution: Use DA700/DA750 print driver; replace parallel

or serial cable. Make sure cable connections

are tight. If the problem still persists, call Pitney

Bowes for service.

Clear memory (see page A-17).

Cycle power.

-

Motor Problems

Problem Motor Turning but No Feed Roller Movement

Reason: Mechanical problem.

Solution: Call Pitney Bowes for Service.

6-5SV61027 Rev. D

Page 82

6 • Troubleshooting

Barcode

Problems

Problem Barcode (Lower Right) is not Printing

Reason: Barcode not enabled

Solution: Turn barcode ON using Envelope Designer™

Plus, or the DA700/DA750 print driver or the

printer’s control panel menus.

Reason: Missing ZIP Code.

Solution: Insert ZIP Code.

Reason: Invalid ZIP Code format.

Solution: Check ZIP Code for invalid character.

Example: Zero (0) can only be the number, not

the letter (O). Verify that there is a dash inserted

between the 5 + 4 ZIP Code Per DMM specifications.

Reason: Address too low.

Solution: Verify the bottom of the last line of the address

field is not less than 5/8” from bottom edge of

the media.

6-6 SV61027 Rev. D

Page 83

Troubleshooting • 6

Barcode

Problems

(continued)

Other

Problems

Problem Address Too High

Reason: Address field is within 1/10” of the top edge of

the media, or material may be jamming.

Solution: Move address field down to DMM specifica

tions, or correct the jamming.

Problem Barcode Fails MERLIN Standards at USPS

Reason: Mail does not meet barcode, address place-

ment, or other acceptance tests of MERLIN

(Mail Evaluation Readability Look-up Instrument) at USPS.

Solution: For more info on MERLIN, go to PB.com. Select

Support, click on Search the Support Knowledge base, then search the database for MERLIN.

Problem Paper Out or Paper Jam

-

Reason: Input area is empty.

Solution: Refill the input area.

Reason: H-Block separators not adjusted correctly.

Solution: Adjust the H-Blocks to the thickness of the ma-

terial you’re running. See page 3-7.

Reason: Paper jam obstructing paper path.

Solution: Clear obstructed path.

Reason: Dirty paper feed sensor.

Solution: Clean sensor with compressed air. See page

5-3.

6-7SV61027 Rev. D

Page 84

6 • Troubleshooting

Other Problems

(continued)

Problem Shuttle Jam

Reason: Envelope thickness knob is set too low for mate

rial.

Solution: Open the print area door assembly of the print-

er, and adjust the media thickness knob. See

page 3-18.

Reason: Lower rail shaft dirty.

Solution: Wipe lower rail shaft clean. DO NOT OIL!

Problem Memory Card Error